Patents

Literature

112results about How to "Will not stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

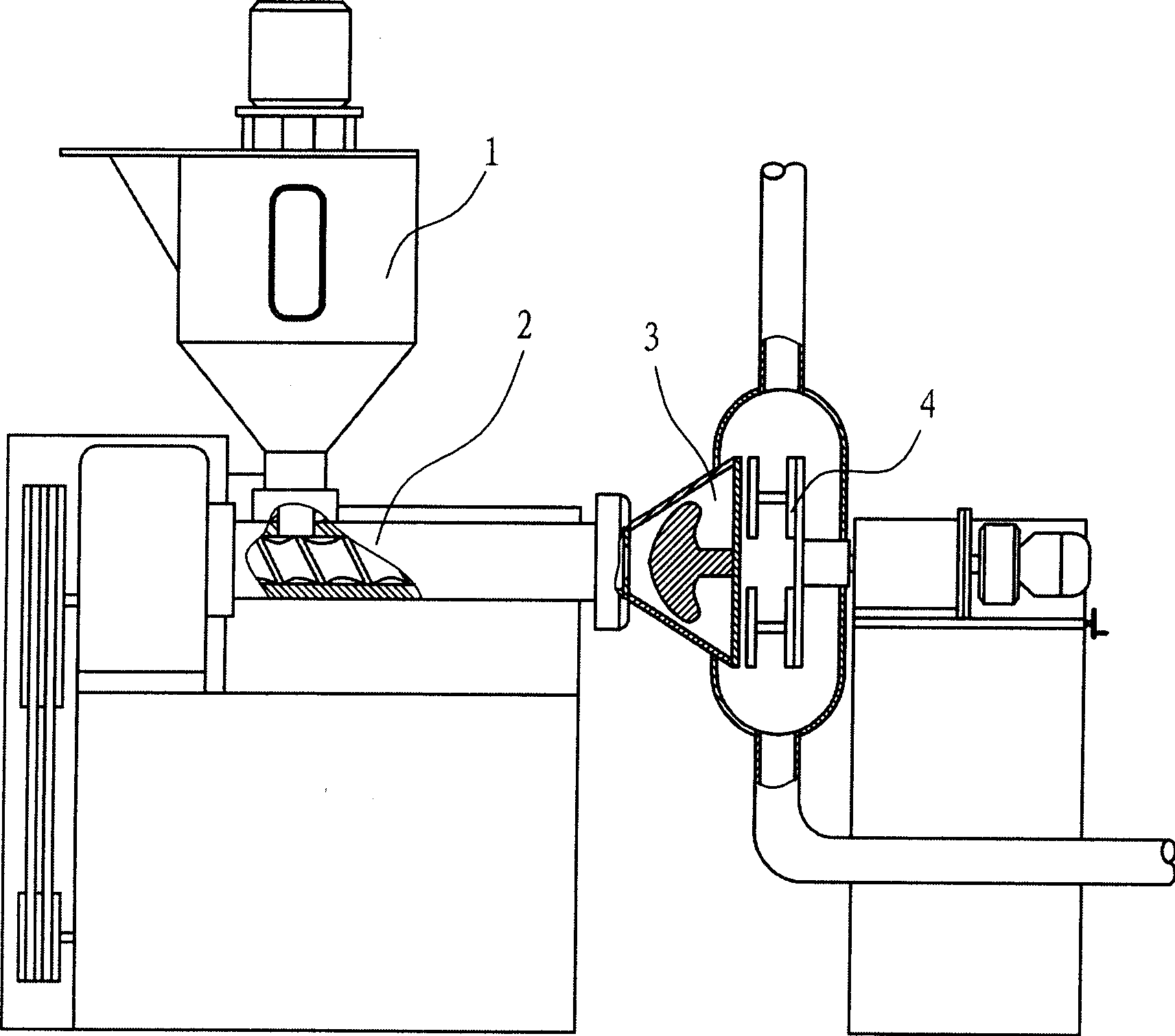

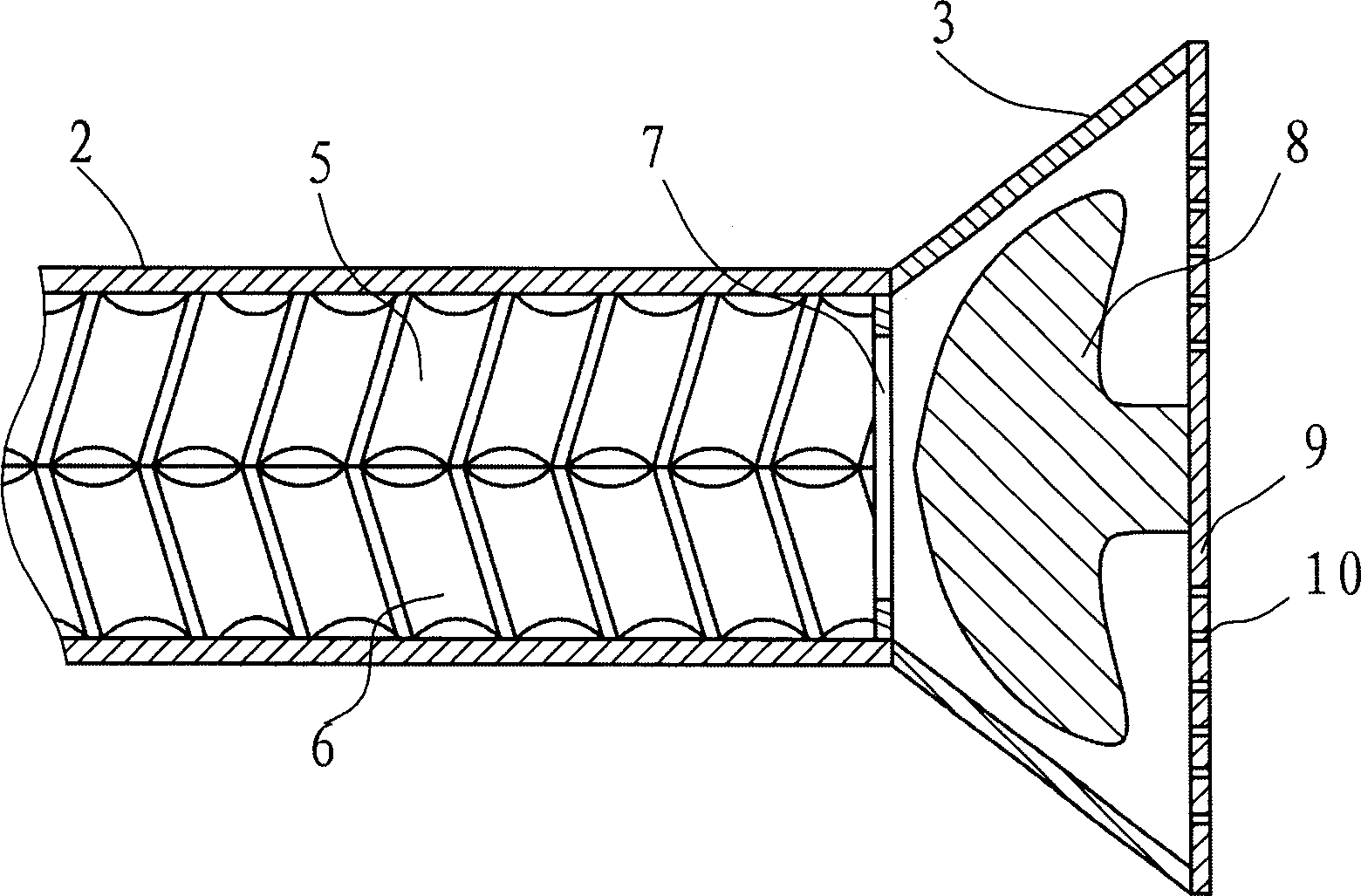

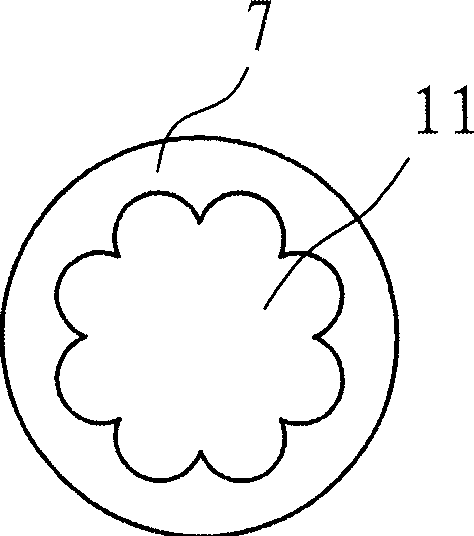

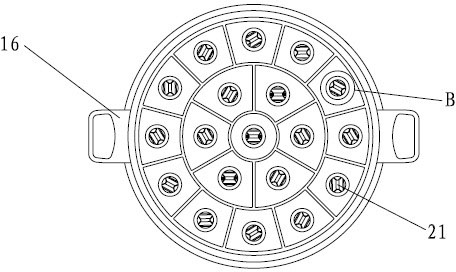

Granulate device for tiny pills in Chinese herbal medicine

InactiveCN1444917AThe effect of decompression and diversion is obviousQuality assurancePharmaceutical product form changeGranulation by pressingMixing chamberMedicine

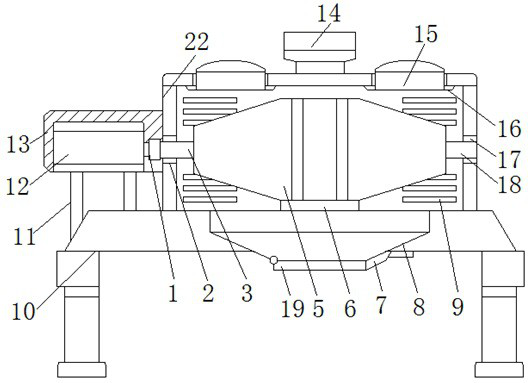

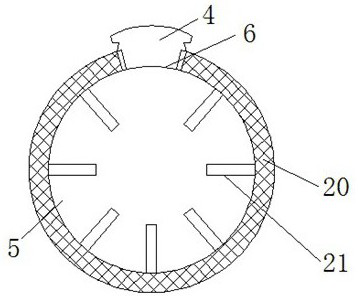

A pelletizer for preparing Chinese-medicinal micropills is composed of is composed of mixing chamber, screw conveyer, flow-splitting chamber containing a splitting cone, flow-splitting plate between flow-splitting chamber and outlet, and a perforated discharge template at the end of flow-splitting chamber.

Owner:高庆凌 +1

Process for preparing rare earth modified carbon nanotube/polyimide composite materials

The invention relates to a method for preparation of rare earth-modified carbon nano-tube / polyimide composite, which consists of performing mat-forming treatment of modifying property to carbon nano-tube adopting rare earth modifier first, then laying the disposed carbon nano-tube into the ball grinder to mill, afterwards, mechanically blending the carbon nano-tube and the polyimide powder and controlling the percentage by weight of the carbon nano-tube to occupy 1-10 % of the mixed powder, then laying the mixed powder into the stainless steel die for press forming, finally preparing the composite by high-sintering. Thereinto, the rare earth modifier consists of rare-earth compound, alcohol, ethylene diamine tetraacetic acid, ammonii chloridum, aqua fortis and aquacare. The invention is of simple technique and low cost, is non-contamination, and the prepared composite possess good dynamic property and frictional behavior.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of oxide ceramic coating layer on surface of silicon carbide fiber

InactiveCN104213099AGood lookingUniform and dense coatingChemical vapor deposition coatingOxide ceramicCarbide silicon

The invention discloses a preparation method of an oxide ceramic coating layer on a surface of a silicon carbide fiber. The preparation method comprises the following steps: (1) the silicon carbide fiber is removed glue for cleaning; (2) the silicon carbide fiber is put in an ALD reaction chamber to repeatedly vacuumize and replace nitrogen for three times; (3) a reaction precursor is selected according to the type of a deposited oxide coating layer; and the parameters of a deposition process are set; (4) precursor steam is guided in the ALD reaction chamber under the carrying of nitrogen or argon; (5) the reaction chamber is blown by the nitrogen or argon; (6) oxygen source steam is guided in the ALD reaction chamber under the carrying of the nitrogen or argon; (7) the reaction chamber is blown by the nitrogen or argon; (8) the steps (4)-(7) are repeated until the needed thickness of the coating layer is deposited; and (9) the coating layer is put in a high-temperature tube furnace, and is thermally treated under the nitrogen protection. The preparation method can be used for preparing the uniform and compact oxide ceramic coating layer with few impurities and precisely controlled thickness on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

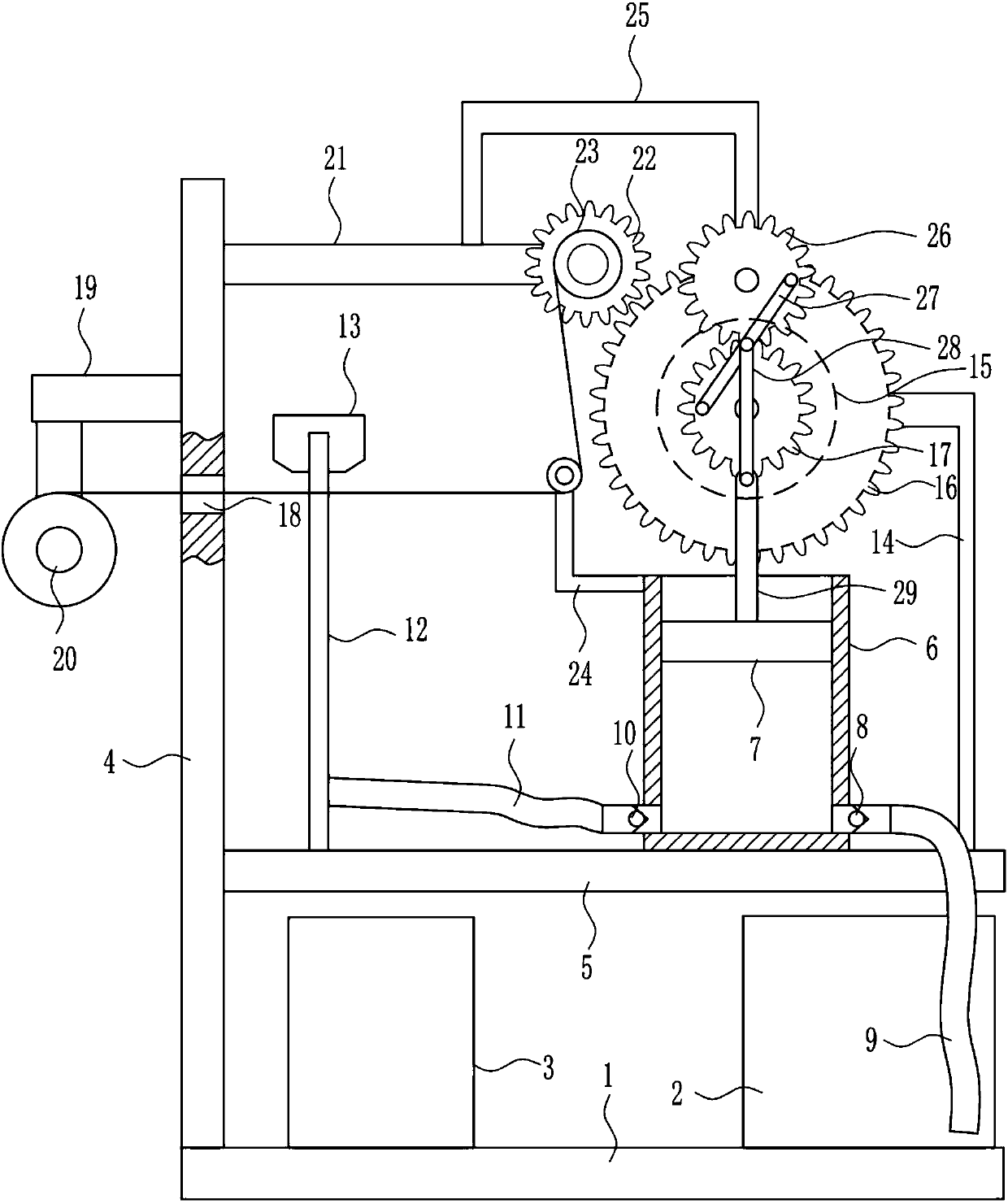

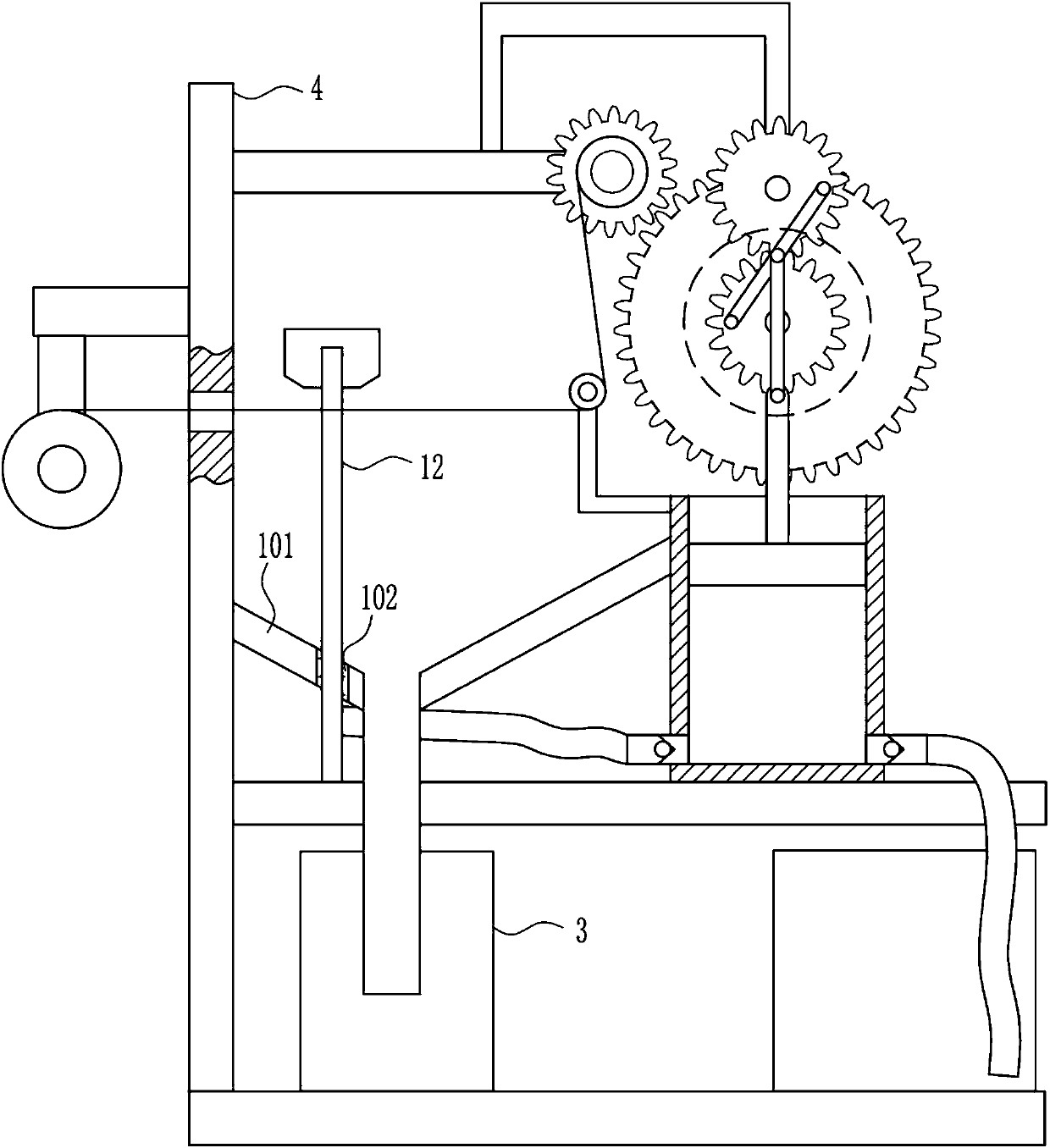

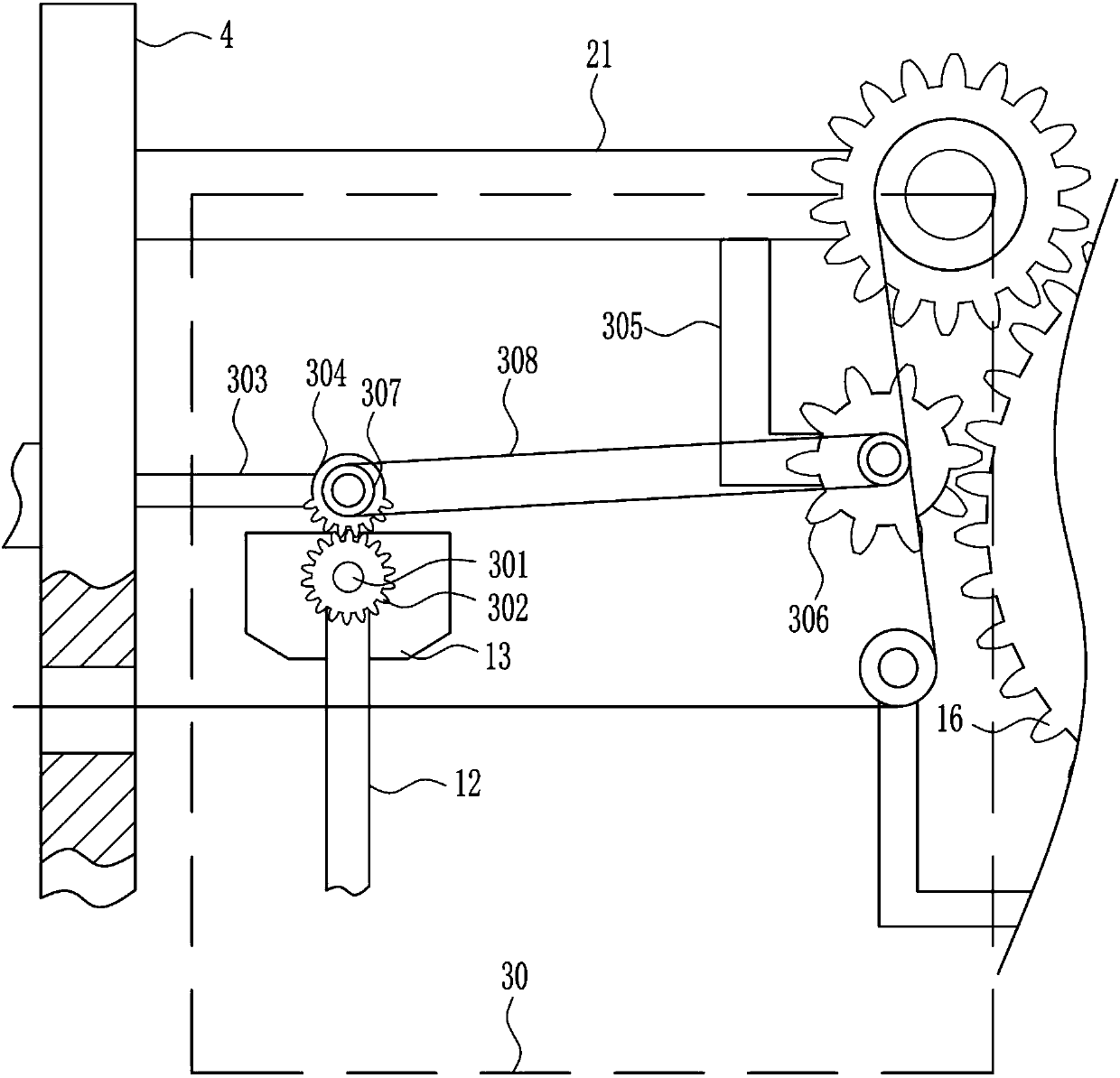

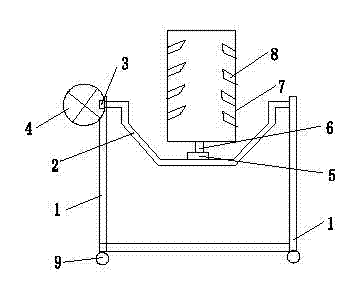

Dyeing and drying equipment of colored yarns for spinning

ActiveCN107780081AWill not stickTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnSpray nozzle

The invention relates to spinning equipment and in particular relates to dyeing and drying equipment of colored yarns for spinning. Aiming at solving the technical problems, the invention provides thedyeing and drying equipment of the colored yarns for spinning, which has the advantages that dyestuff can be completely attached on the colored yarns and the colored yarns can be dried by blowing intime after dyeing and are not stuck together. In order to solve the technical problems, the invention provides the dyeing and drying equipment of the colored yarns for spinning; the dyeing and dryingequipment comprises a bottom plate, a dyeing box, a collection box, a supporting plate and the like; the dyeing box is arranged at the right side on the bottom plate; the collection box is arranged atthe left side on the bottom plate; the supporting plate is mounted at the left side on the bottom plate through a welding manner; a fixed plate is mounted below the right side of the supporting platethrough the welding manner. By adopting the dyeing and drying equipment of the colored yarns for spinning, provided by the invention, the effects that the dyestuff can be completely attached on the colored yarns and the colored yarns can be dried by blowing in time after dyeing and are not stuck together are realized; an electric wheel drives a spraying nozzle to spray out the dyestuff and the spraying nozzle is driven to rotate so that the dyestuff can be completely attached to the colored yarns.

Owner:浙江森创服装股份有限公司

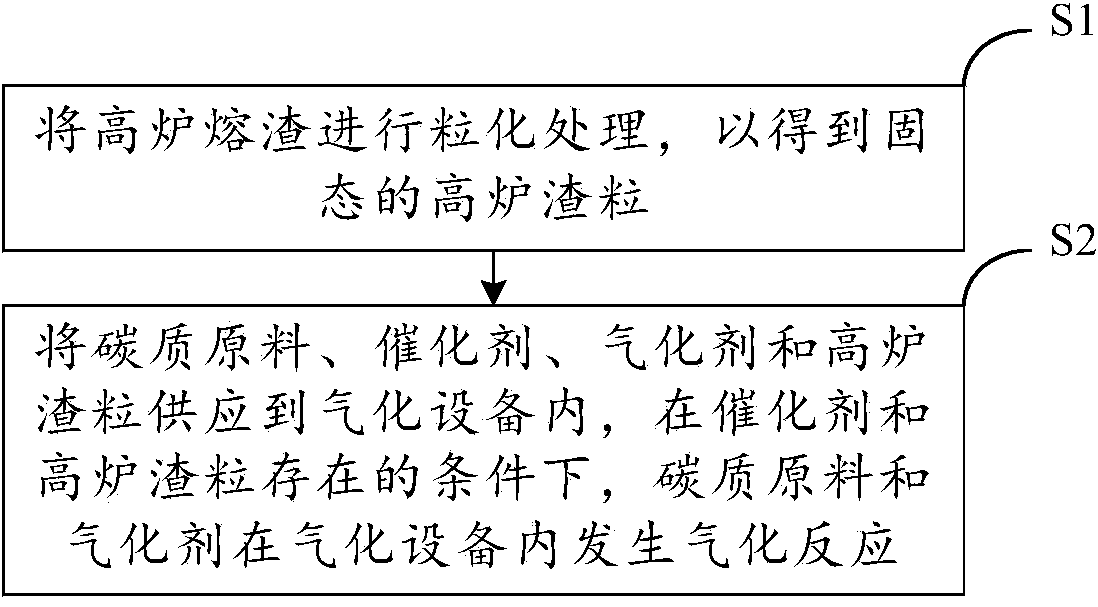

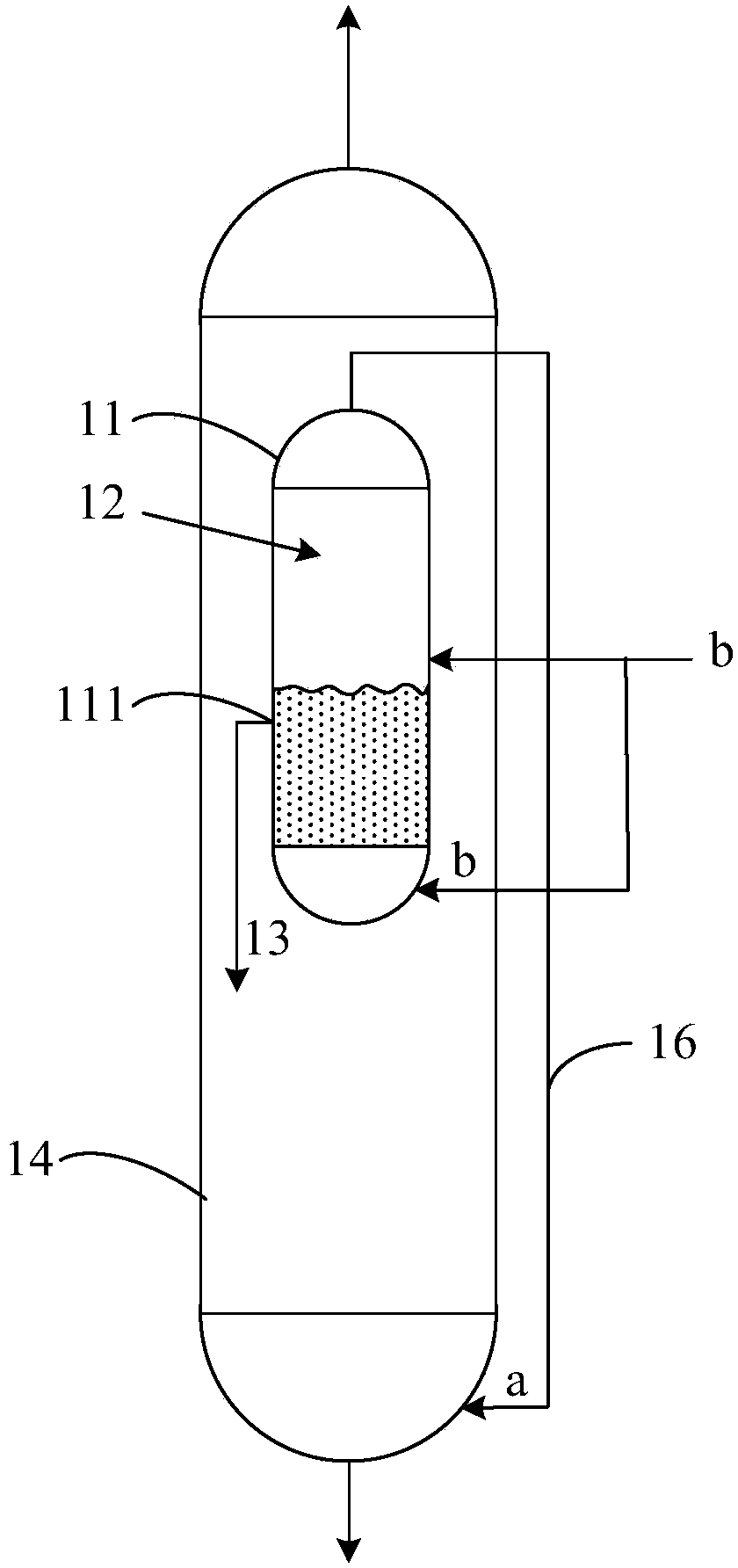

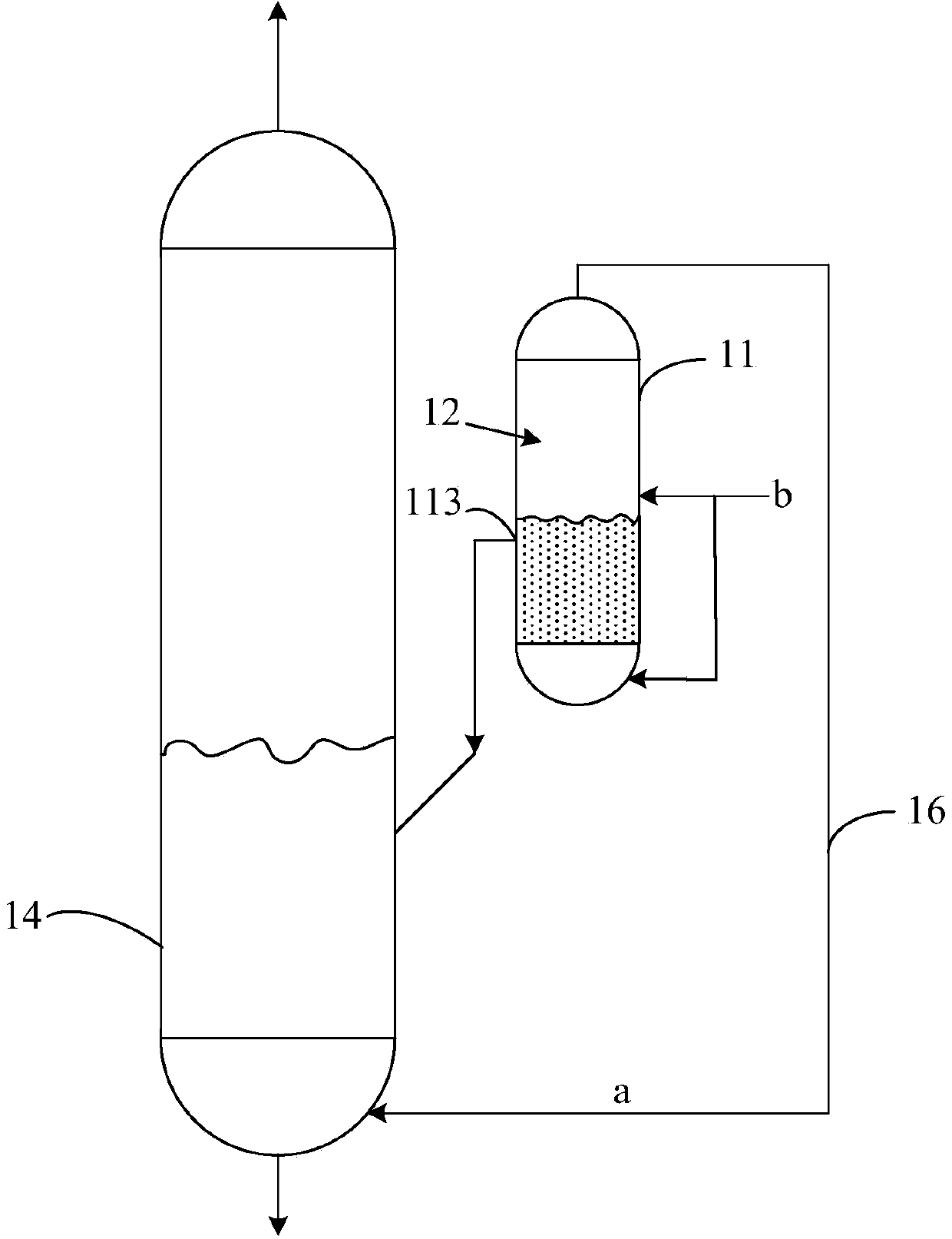

Catalytic gasification method and device

InactiveCN103992822AWill not stickThe catalytic gasification process does not affectGranular/pulverulent flues gasificationCinderBlast furnace

The invention discloses a catalytic gasification method and device, relating to the technical field of catalytic gasification. The method and device can lower energy consumption in the gasification process, prevent the molten blast furnace cinder from being coated on the surface of the coal powder granules, and prevent the coal powder granules from adhesion and agglomeration, so that the gasification reaction can be performed more thoroughly, thereby enhancing the utilization ratio of coal. The catalytic gasification method disclosed by the invention comprises the following steps: granulating the blast furnace cinder to obtain solid-state blast furnace cinder granules; supplying a carbon raw material, a catalyst, a gasifying agent and the blast furnace cinder granules into a gasification facility; and carrying out gasification reaction on the carbon raw material and the gasifying agent in the gasification facility in the presence of the catalyst and the blast furnace cinder granules. The catalytic gasification method and device disclosed by the invention are suitable for a catalytic gasification process of coal.

Owner:ENN SCI & TECH DEV

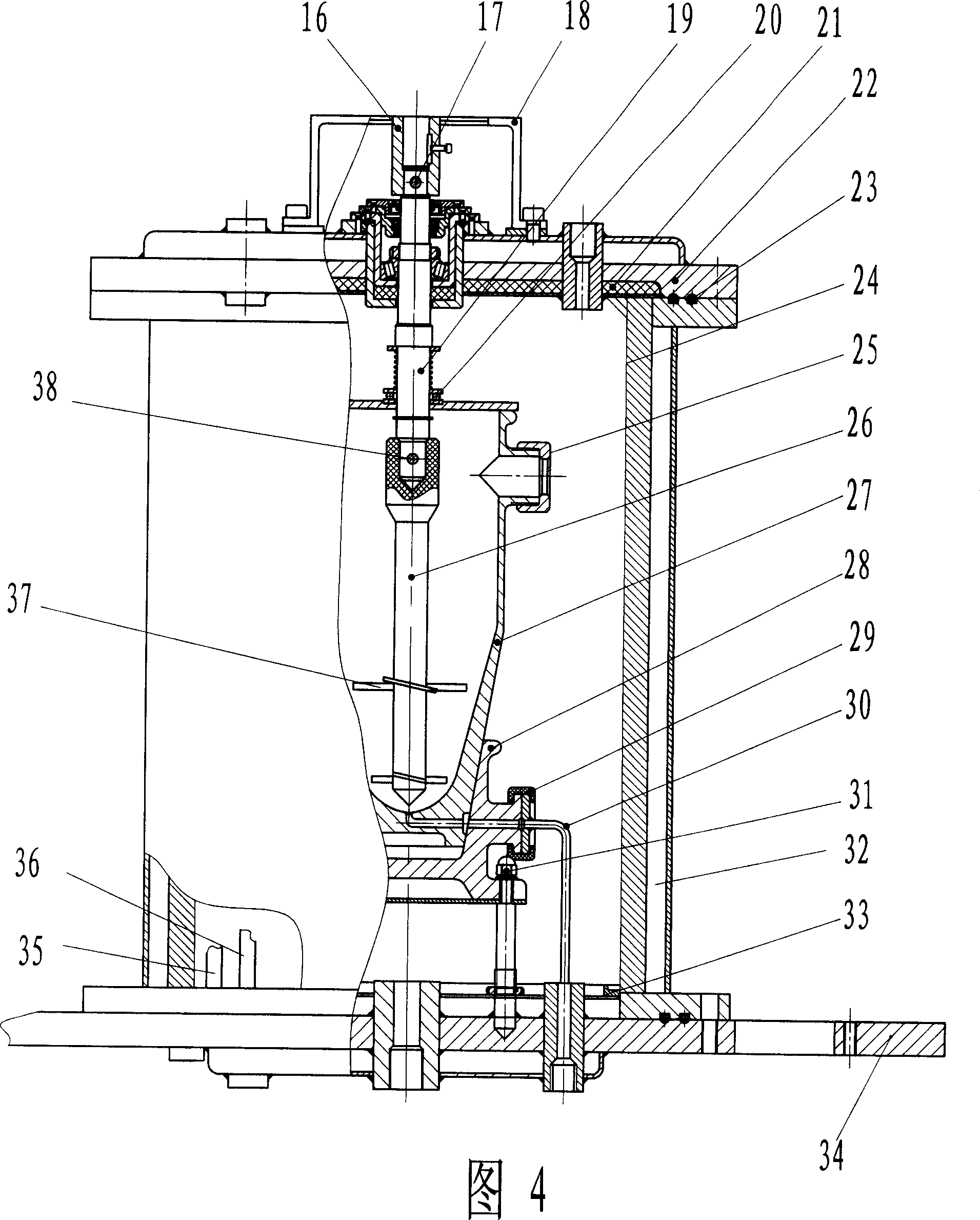

Instant New-year-cake processing method and its extruding-formation apparatus

The processing method of convenience (fast food) New Year cake (made of glutinous rice flour) includes the following steps: preparing raw materials, uniformly mixing raw materials, cooking, press forming by means of press forming machine, film-forming, vacuum packaging, heating and sterilization, then bagging or boxing and seating. The press-forming machine is formed from fixed plate, positioning plate, inner layer tube and mold nozzle plate, etc.

Owner:叶义伦

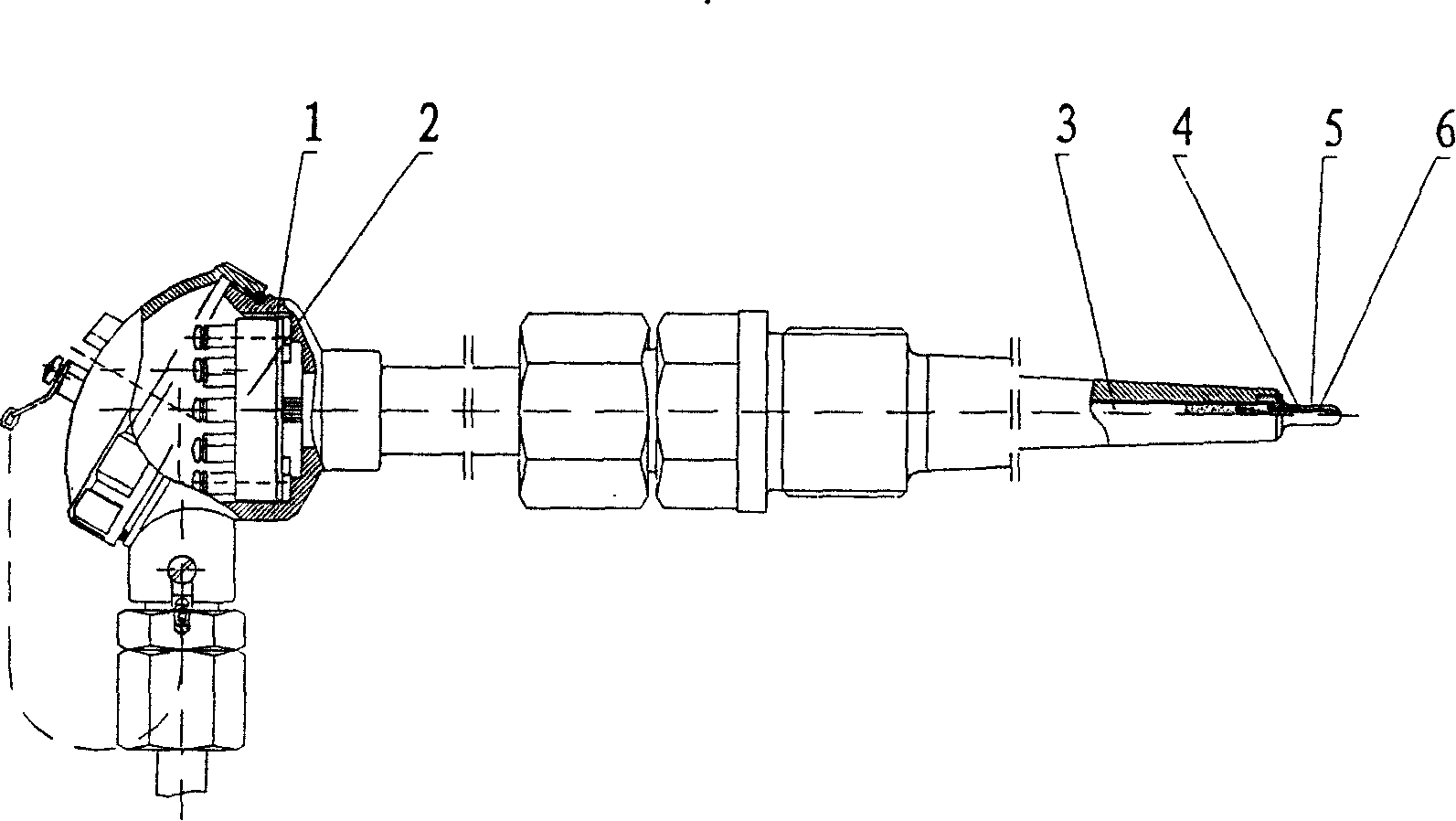

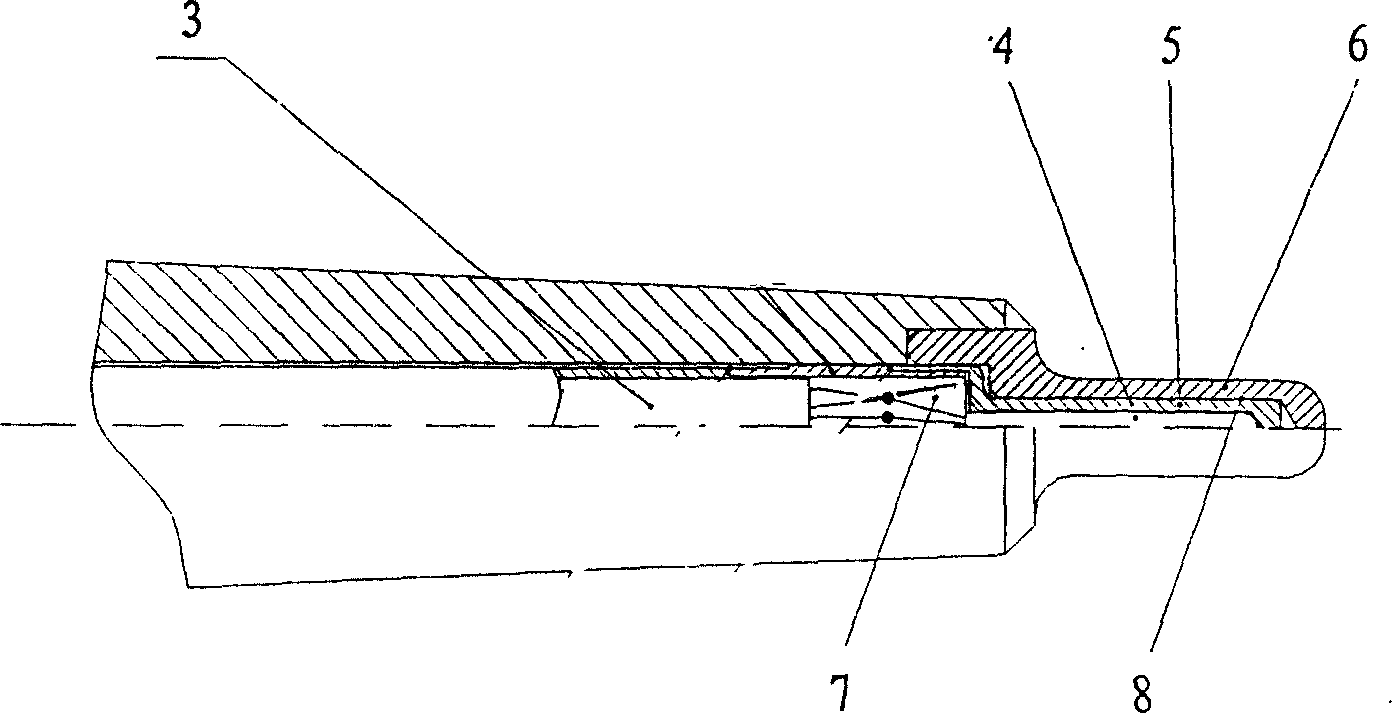

Nuclear grade platinum resistance thermometer and its method for reducing thermal response time

InactiveCN101173873AWill not stickShort thermal response timeThermometer detailsThermometers using electric/magnetic elementsPlatinum resistanceNuclear grade

The invention relates to a nuclear-grade platinum resistance thermometer and the method for reducing thermal response time with the invention, comprising a terminal box, a wiring board arranged in the terminal box, and a protective sleeve with a built-in platinum resistance element, wherein, the temperature sensing surface of the platinum resistance element is clung tightly to the inner surface of the protective sleeve, and no MgO powder is filled between the platinum resistance element and the protective sleeve; the outer surface of the protective sleeve is clung tightly to the inner surface of an external protective tube; the platinum resistance element is welded with an armored leading wire; MgO powder is filled in the armored leading wire; a metal coat is plated on the outer surface of the protective sleeve. The invention has the advantages that due to the temperature sensing surface of the platinum resistance element clung tightly to the protective sleeve and the protective sleeve clung tightly to the external protective tube, the heat conductivity of the thermometer is improved; the thermal response time is reduced; the earthquake resistant requirement for nuclear power station is satisfied; due to wear-resistant, heat-resistant, and oxidation-resistant special metal coating on the surface of the protecting sleeve, the protecting sleeve does not stick to the protective tube due to oxidation corrosion.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

Production technology of medical sterilization three-dimensional roll bags

InactiveCN104029422AWill not stickDoes not cause stickingBox making operationsPaper-makingProduct inspectionEngineering

The invention discloses a production technology of medical sterilization three-dimensional roll bags. The production technology includes the steps of glue solution preparation, dry lamination, curing, slitting, curing, printing, bag manufacturing, finished product inspection, warehousing and the like. The production technology has the advantages of being simple in preparation technology and simple and convenient to operate; in the glue solution preparation process, a glue solution is clear and free of sundry, and therefore convenience is brought to the next printing step. The rolled and sealed edges of the roll bags manufactured through the technology are free of opening, free of split, easy to tear and free of paper scrapes after being torn. After sterilization is conducted on the packaging bags, adhering between articles contained in the packaging bags and the packaging bags can be avoided.

Owner:NANTONG WANDA PACKAGING

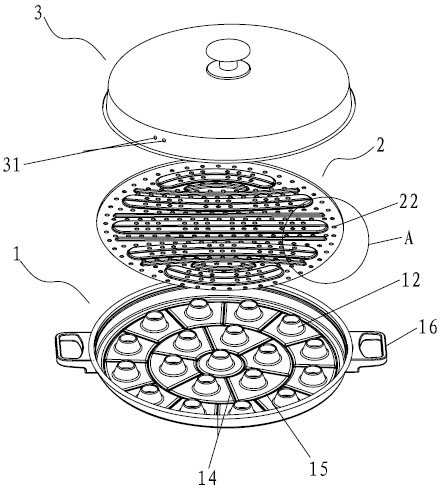

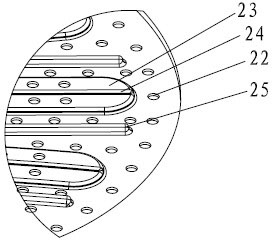

Barbecue pan

The invention discloses a barbecue pan. The barbecue pan comprises a pan body and a barbecue disc and is characterized in that: heat energy holes are arranged at the bottom of the pan body; a hole cover extending towards the pan body is formed on each heat energy hole; each hole cover is provided with a side wall surface and a top heat energy outlet; supporting blocks are arranged on the bottom surface of the barbecue disc; the supporting blocks correspond to the heat energy holes one to one; the supporting blocks extend into the hole covers; heat energy dividing holes are formed between the supporting blocks and the inner walls of the hole covers; and through holes are formed on the barbecue disc except for the position corresponding to the heat energy outlets of the top of the hole covers. The barbecue pan has the advantages of wide application range, simple structure, good barbecue effect, convenience for use, energy conservation and capacity of effectively avoiding harmful gas generated by combustion of dropped high-temperature oil.

Owner:薛芳

Method for preparing TiCl4 from titanium-containing furnace slag

ActiveCN101418383BChlorination is not easyDoes not destroy the fluidized stateTitanium halidesProcess efficiency improvementSlagReducer

The invention discloses a method for preparing TiCl4 through titanium-contained slag. The TiO2 content in the slag is 30 to 45 percent. The method is characterized in that the titanium-contained slag is directly reduced at a high temperature; and the reduced slag is used to prepare the TiCl4 through low-temperature boiling chlorination. According to the method, the titanium-contained slag, a reducer and a binding agent are mixed evenly and are used to make pellets; the pellets are reduced at the high temperature; the reduced pellets are crushed after being cooled down; and then the TiCl4 is obtained through the low-temperature boiling chlorination. The method has the advantages of low reducing temperature, short technical process, high total titanium recovery rate, and the like.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

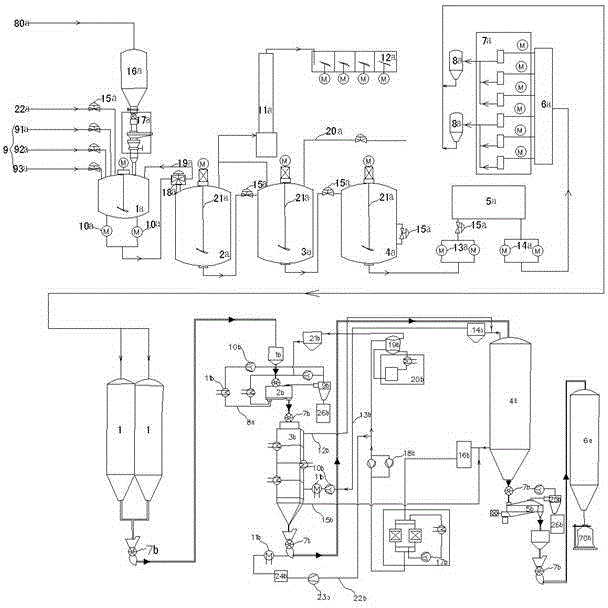

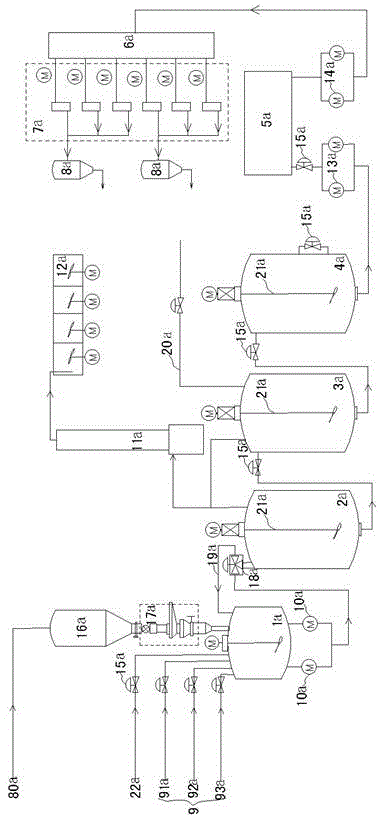

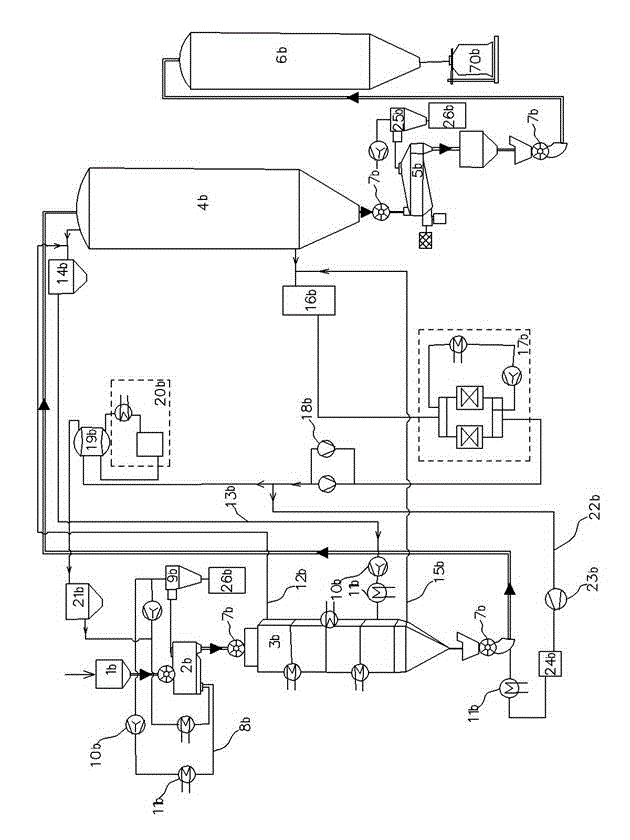

PET (Polyethylene Terephthalate) slice production system and production process thereof

ActiveCN104086760ALow molar reactionReduce the temperaturePolyesterPolyethylene terephthalate glycol

The invention discloses a PET (Polyethylene Terephthalate) slice production system and a production process thereof and aims to provide a PET slice production system which is high in production efficiency, low in energy consumption, high in quality and high in yield and a simple, convenient and efficient production process of the PET slice production system. The PET slice production system comprises a polyester device, a solid-phase polycondensation device and a plurality of buffer bins (1) arranged between the polyester device and the solid-phase polycondensation device. The production process of the PET slice production system comprises the steps: slurry preparation; esterification reaction; pre-polycondensation reaction; final polycondensation reaction; slicing; storing; pre-crystallizing; slow preheating; solid-phase polycondensation reaction; cooling; gas purification; and storing. The PET slice production system and the production process thereof are applied to the technical field of PET slice production.

Owner:ZHUHAI HUARUN PACKAGING MATERIALS

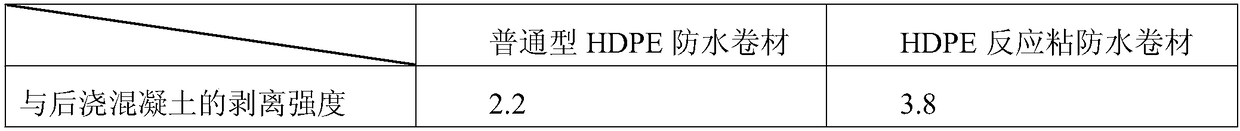

HDPE chemical bonding type self-adhesive waterproof coiled material

ActiveCN108192522AStrong adhesionWill not stickMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerThermoplastic elastomer

The invention provides an HDPE chemical bonding type self-adhesive waterproof coiled material. According to the invention, through arrangement of a self-adhesive adhesive layer and a matrix, the adhesive layer can be firmly adhered to a concrete layer and has high peel strength; through arrangement of an isolation layer and a non-adhesive coating layer, easy construction and no adhesion to construction personnels are realized; through addition of a diblock SDS thermalplastic elastomer and an SIS thermoplastic elastomer, a hot-melt pressure-sensitive adhesive has meltability and thermoplasticity of plastic and elasticity and toughness of rubber; through limitation of shore hardness of the SIS thermoplastic elastomer, the hot-melt pressure-sensitive adhesive has meltability and thermoplasticity of the plastic and elasticity and toughness of the rubber; through limitation of the type of a compatibilizer, a product has widened construction temperature range; through limitation of carbon-5petroleum resin, the waterproof coiled material has good construction temperature, and the hot-melt pressure-sensitive adhesive has better adhesiveness; and through limitation of the type of a tackifier, the hot-melt pressure-sensitive adhesive can maintain good peel strength at a normal temperature.

Owner:武汉市恒星防水材料有限公司

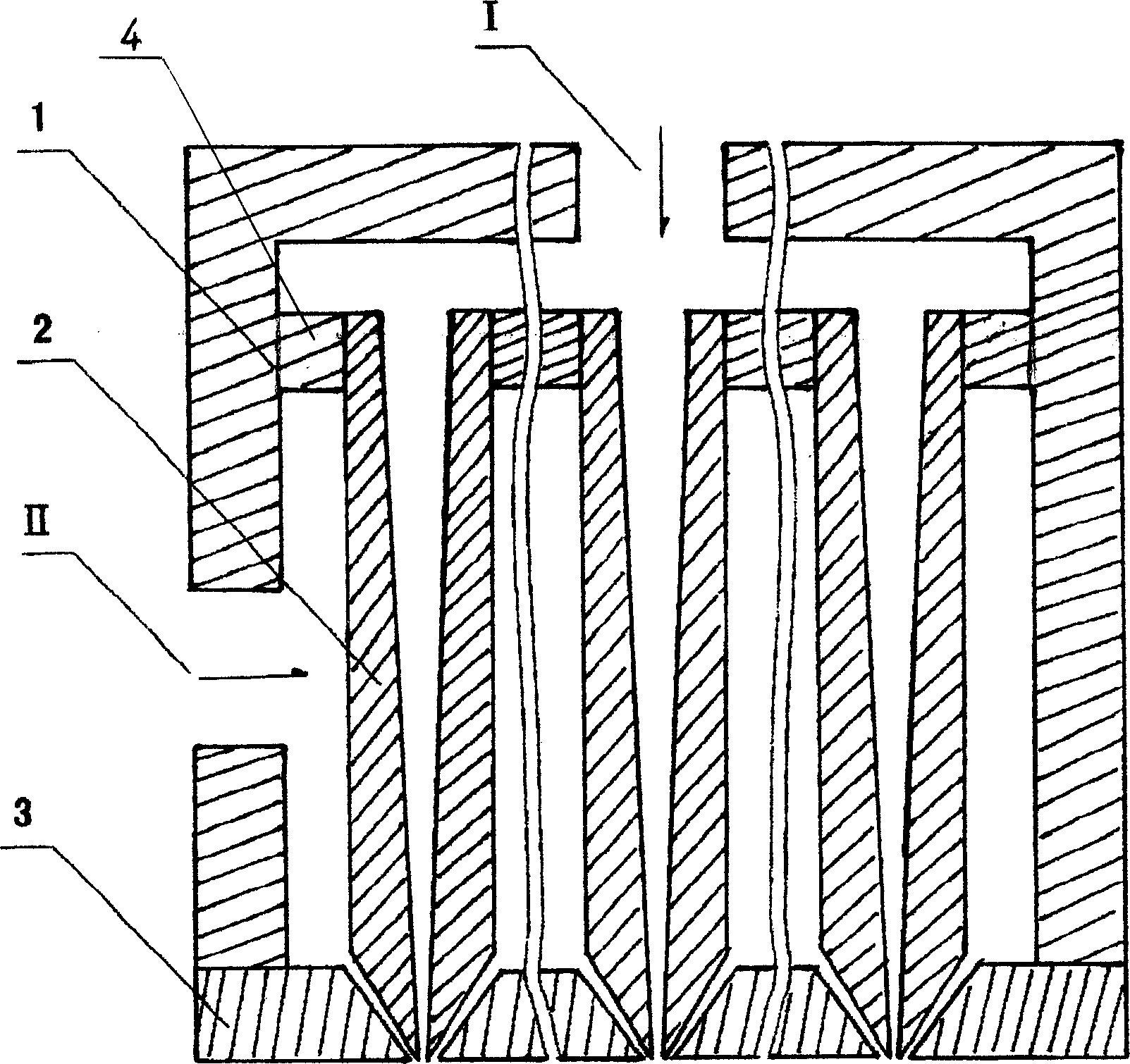

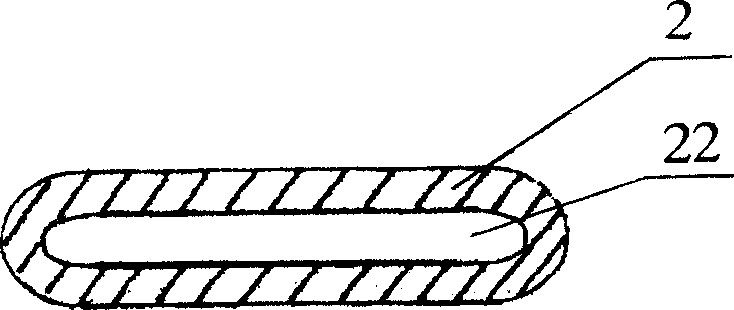

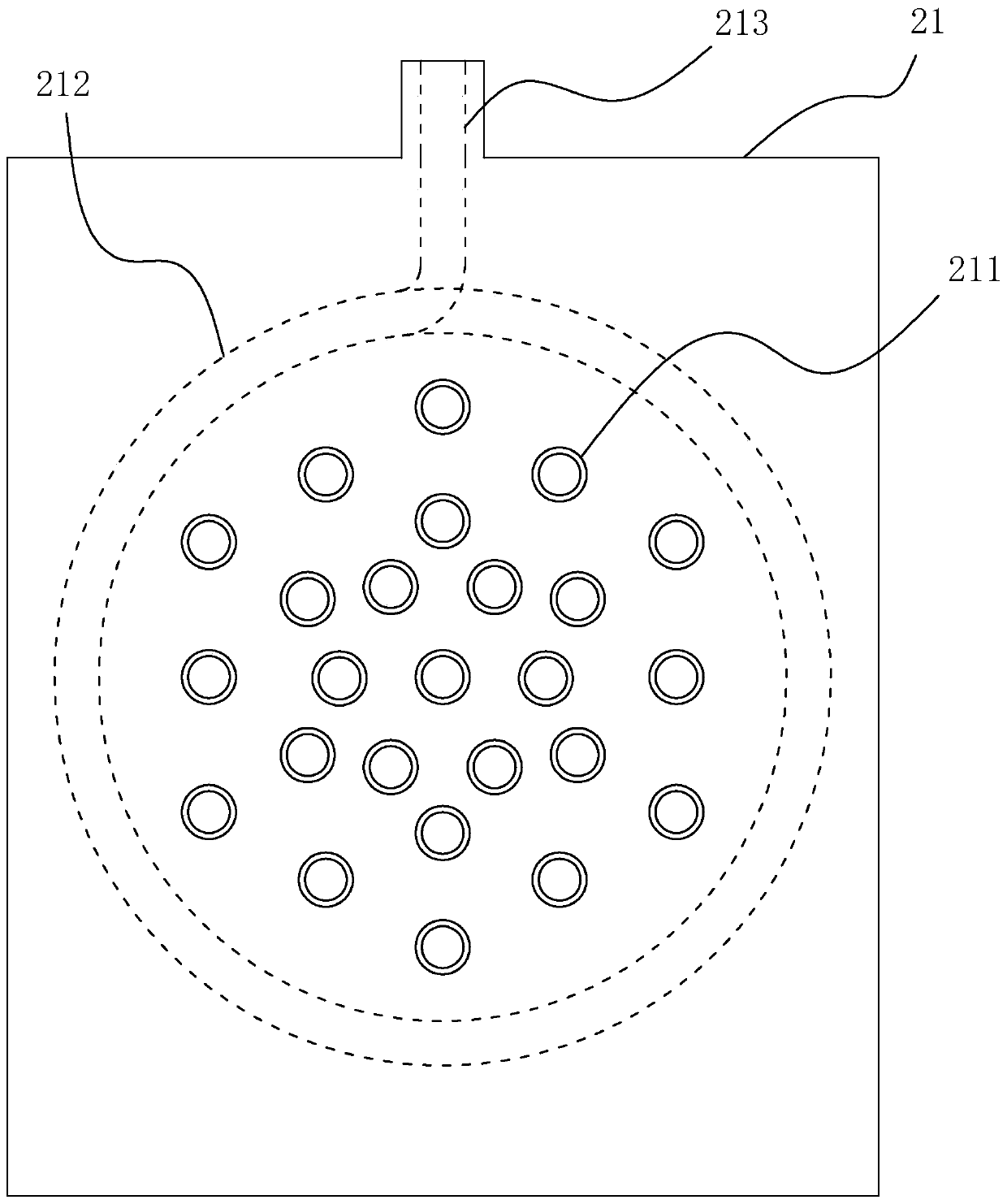

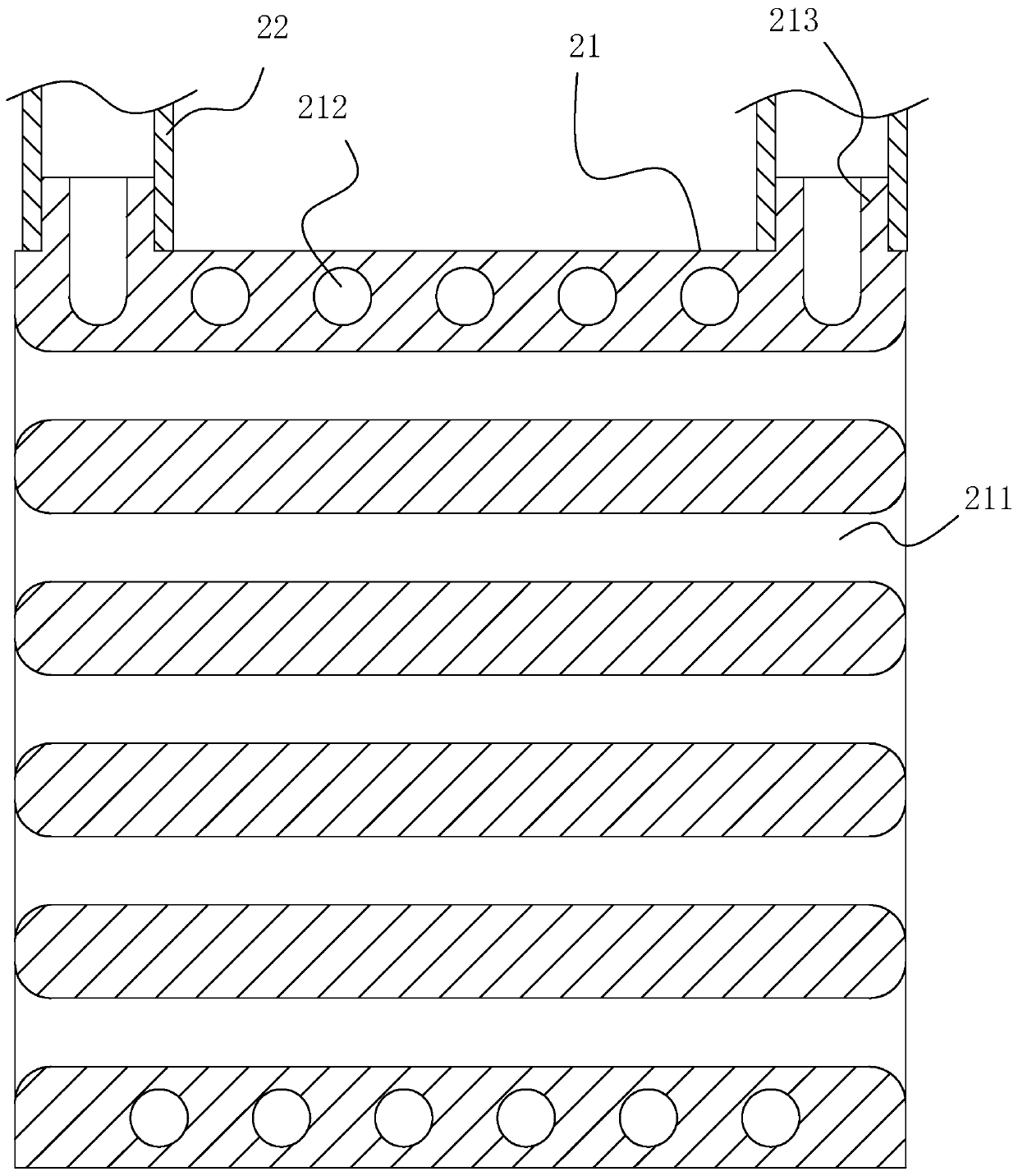

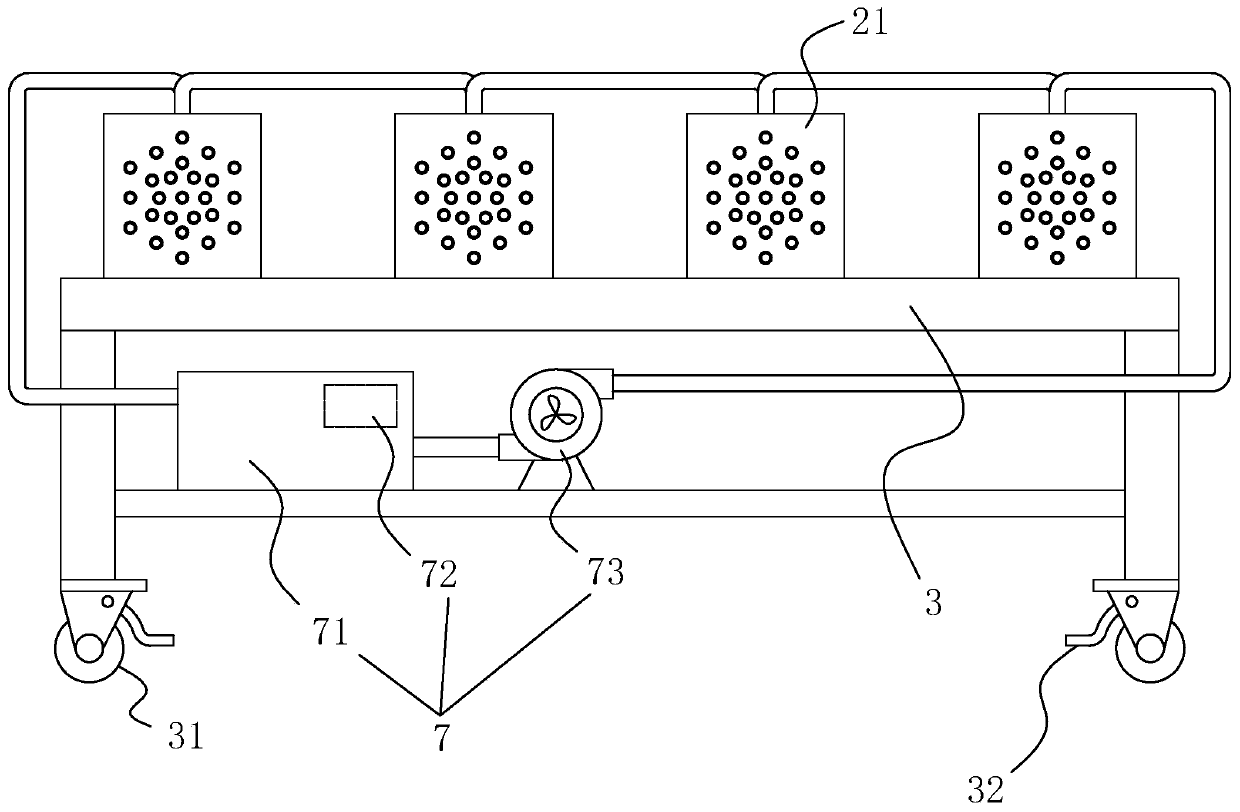

Polyester pre-oriented yarn production equipment

ActiveCN109881274AReduce manufacturing costWill not stickArtificial thread manufacturing machinesFilament manufactureYarnPolyester

The invention discloses polyester pre-oriented yarn production equipment, and relates to the technical field of polyester pre-oriented yarn production. The technical problem is solved that the production efficiency of polyester pre-oriented yarn is low. According to the technical scheme, the polyester pre-oriented yarn production equipment includes screw extrusion spinning machines, circulating air blowing devices, a channel and a winding device which are arranged in sequence; each screw extrusion spinning machine includes a screw extrusion machine and a spinning box which is arranged at the discharging end of the screw extrusion machine and further includes a metal cooling part which is arranged between the discharging opening of the spinning box and the feeding opening of the corresponding circulating air blowing device; a cooling part formed by a plurality of tow paths is arranged on each metal cooling part, and anti-sticking coatings coat the inner walls of the tow paths. The polyester pre-oriented yarn production equipment has the advantage of improving the polyester pre-oriented yarn production efficiency.

Owner:浙江恒百华化纤有限公司

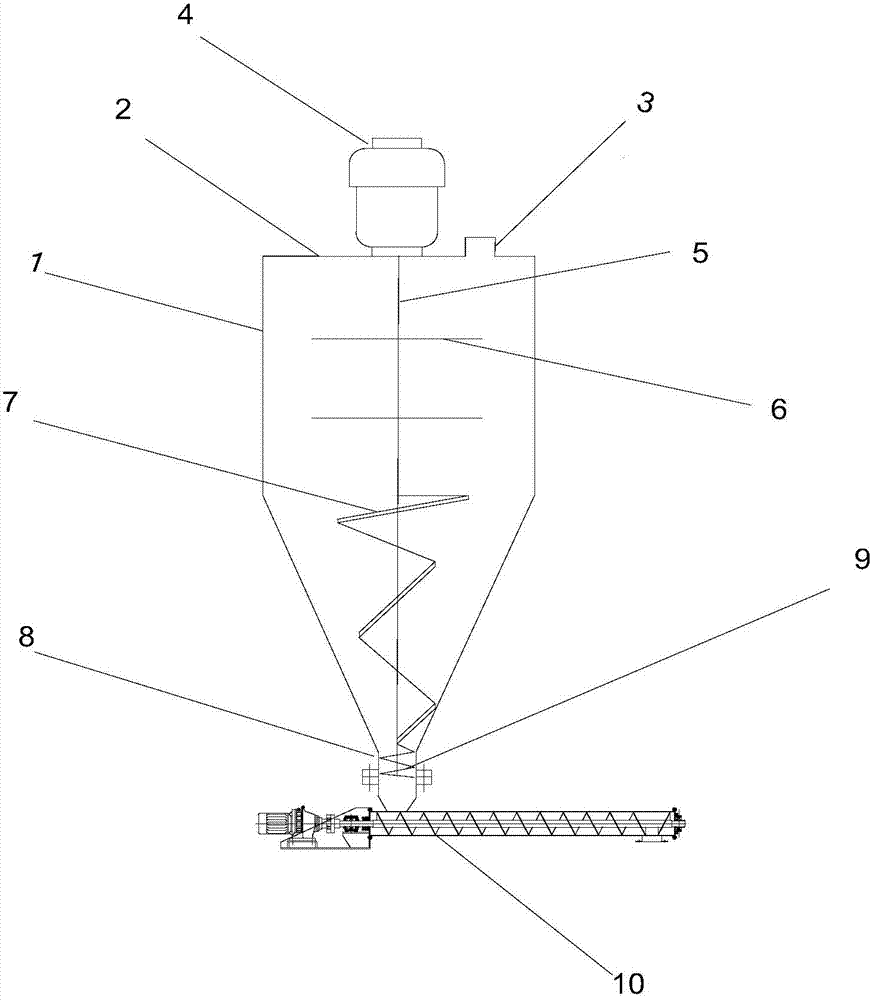

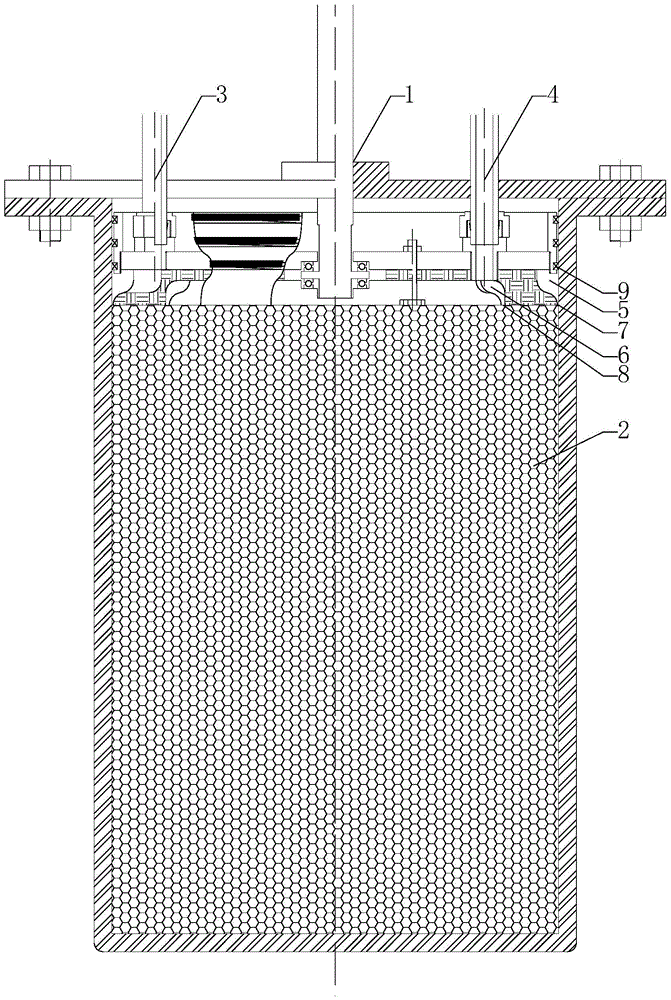

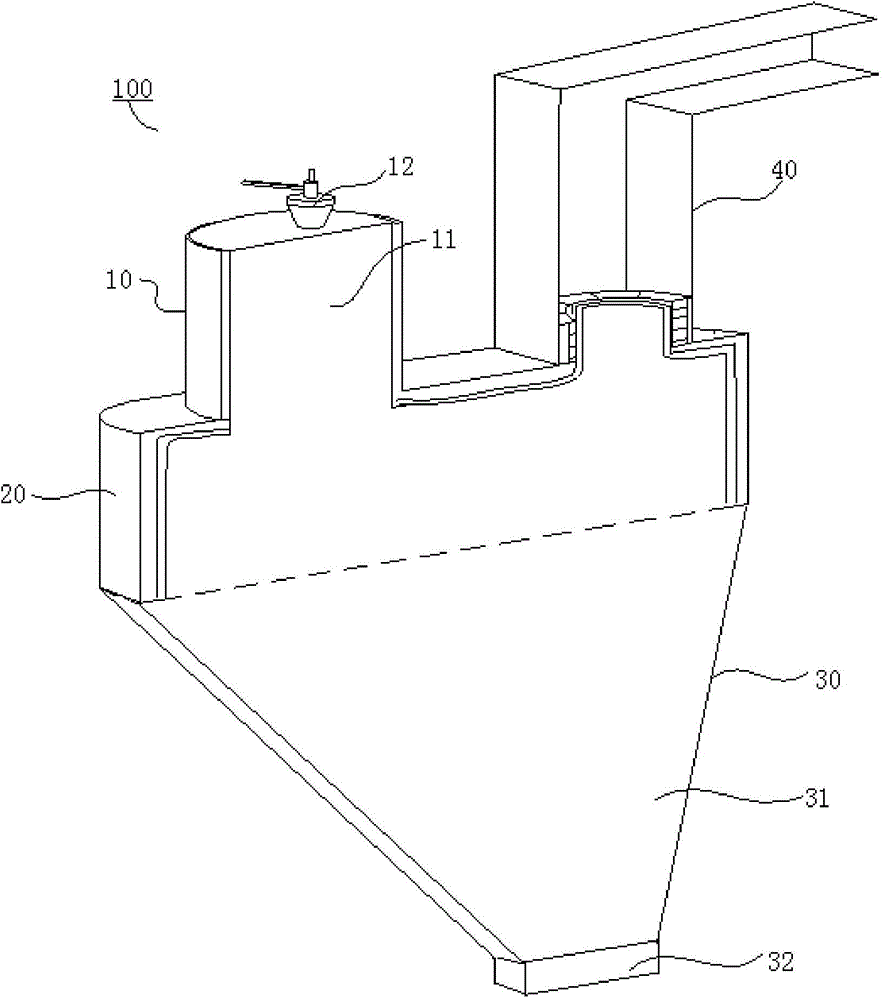

Vertical storage tank for efficient sludge scattering and ration feeding

ActiveCN103935648AGuaranteed deposit-free transportSafe storageLarge containersLoading/unloadingSludgeEngineering

The invention provides a vertical storage tank for efficient sludge scattering and ration feeding. The vertical storage tank comprises a tank body, a stirring device and a ration device. The upper portion of the vertical storage tank is designed to be round, the lower portion of the vertical storage tank is designed to be conical, and therefore non-deposition transportation of sludge can be achieved while the storage volume of the storage tank is guaranteed. A top cover is arranged on the top of the tank body, and therefore foul smell spreading during sludge processing can be effectively avoided, and clean and sanitary transportation is achieved. A combined type stirring device of a strong shear force stirrer and a cone base spiral belt type stirrer is arranged inside the storage tank, and therefore the sludge can be effectively scattered and smashed after entering the tank body through a feed port; the cone base spiral belt type stirrer is attached to the wall of the lower conical storage tank part, and therefore the sludge cannot adhere to the wall of the storage tank. A spiral part attached to the wall is installed in a discharge port of the storage tank, and therefore the high-viscosity sludge cannot block the discharge port. A closed type screw feeder is arranged at the bottom of the storage tank, and therefore ration feeding and clean transporting of the sludge can be achieved.

Owner:XI AN JIAOTONG UNIV

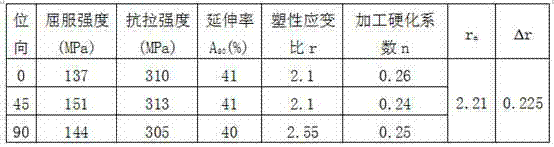

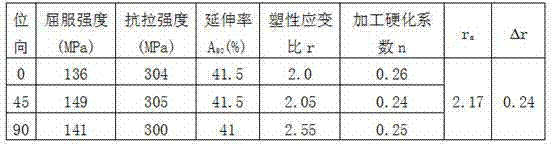

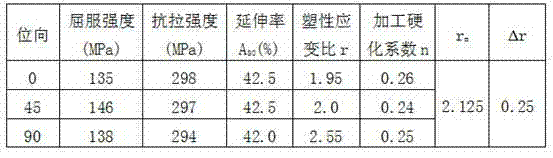

Production method of ultralow-carbon interstitial free soft steel

The invention discloses a production method of ultralow-carbon interstitial free soft steel, which comprises the following steps: hot rolling, cold rolling and cover annealing. The casting blank adopted by the hot rolling comprises the following components in percentage by weight: at most 50 ppm of C, at most 0.15% of Mn, at most 0.010% of S, at most 0.020% of P, greater than or equal to 0.10% and less than or equal to 0.20% of Si, at most 0.070% of Ti, 200-500 ppm of Als, at most 25 ppm of Ca, at most 50 ppm of N and the balance of Fe. In the hot rolling, a forepart cooling process is adopted, the finishing temperature is 900+ / -20 DEG C, and the coiling temperature is 700+ / -20 DEG C. In the cold rolling, the reduction in cold rolling is greater than or equal to 70%. In the cover annealing, an all-hydrogen cover annealing furnace is adopted, the dew point is lower than -50 DEG C, the hot-spot temperature is 740+ / -10 DEG C, the cold-point temperature is 720+ / -10 DEG C, and the holding time is 20-25 hours. By improving the steel grade components, improving the production process by Si alloying and enhancing the processability of the finished product, the method has the advantages of simple technique and no additional increase of cost; the experimental production is performed to obtain the expected effect; and the production process is stable, and the finished product has excellent performance.

Owner:HEBEI IRON AND STEEL

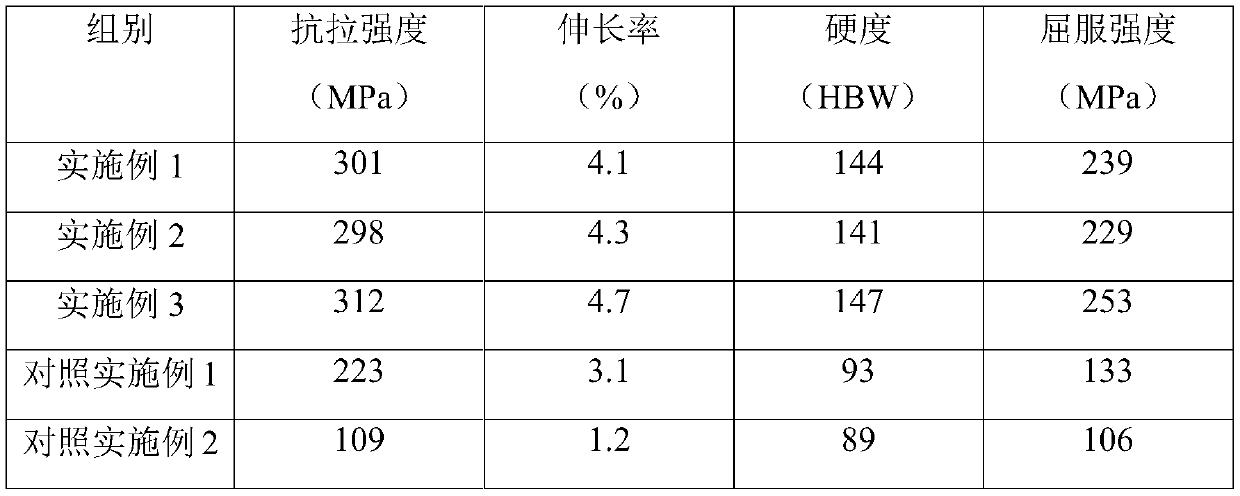

Alloy improved material and preparation method thereof

InactiveCN109943742APrevent impurity phase segregationEliminates slag removal stepHardnessSilicon oxide

The invention relates to an alloy improved material and a preparation method thereof and relates to the field of aluminum alloy modifier. The alloy improved material is composed of spraying depositionpowder, sodium salt modifier and a binding agent. The weight ratio of the spraying deposition powder to the sodium salt modifier to the binding agent is (5-10):(1-3):1. Three modifiers strontium, sodium and rare earth neodymium are combined according to the characteristic, the modification activity is effectively retained, and the alloy improved material has the characteristics of being short inmodification incubation period, long in effective modification time and stable in modification effect. Kaolinite clay powder in raw materials can serve as a modifier carrier to remove gas and slag, the smelting efficiency is improved, and rich aluminum oxide and silicon oxide can improve hardness of an alloy. The luminescence property of a neodymium element enables the aluminum alloy to have the luminescence characteristics, and coating of luminescent materials is not needed. According to the preparation method, the spraying deposition method is adopted for further smelting and preparing tinyintermediate alloy powder, the intermediate alloy powder is bonded with the sodium modifier for extrusion forming, the modifier can be dissolved and dispersed rapidly, the incubation period is shortened, and rapid and effective modification is achieved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

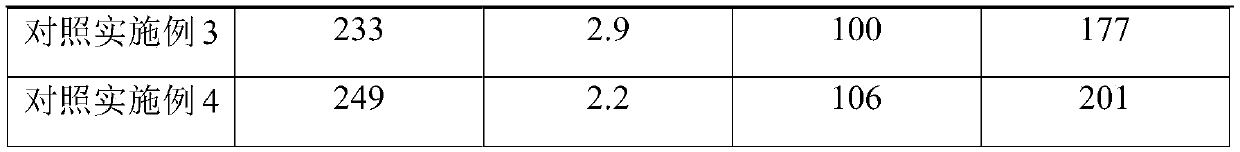

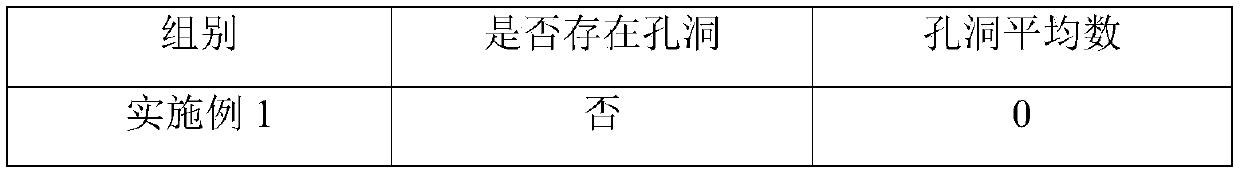

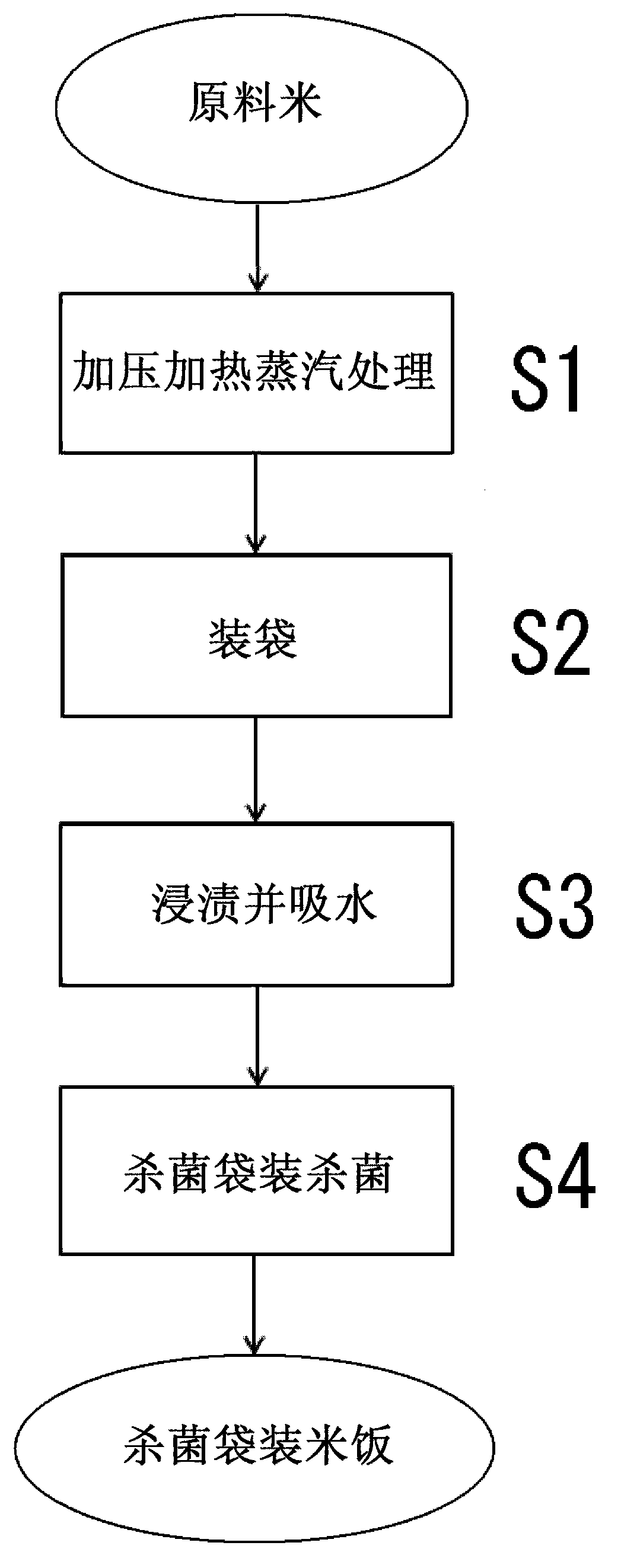

Method for manufacturing retort rice, and retort rice

InactiveCN102958380AAbsorbs water and soaks fastImprove water absorptionFood preservationFood preparationSurface layerRice dishes

Owner:SATAKE CORP

Overturning stirring machine

ActiveCN103749875AEffective regulationEasy to adjustRotating receptacle mixersTransportation and packagingAgricultural engineeringFood processing

The invention belongs to the technical field of food processing tools, particularly relates to an overturning stirring machine. The overturning stirring machine comprises a stander, and is characterized in that the stander is movably provided with an overturning connecting rod, one end of the overturning connecting rod is connected with a scroll bar device, the scroll bar device is connected with a handle, the overturning connecting rod is provided with a motor, the motor is connected with a worm speed reducer through a belt, the worm speed reducer is connected with a rotating shaft through a gear, the rotating shaft is fixedly connected with a rotary drum, and a plurality of scrapers are arranged in the rotary drum. The bottom of the stander is further provided with universal wheels. The overturning stirring machine can be effectively moved through the universal wheels.

Owner:ZHEJIANG MOCCAS FOOD IND

HDPE reaction sticky waterproof coil material

InactiveCN108690513AHigh peel strengthWill not stickNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer chemistrySelf adhesive

The invention relates to an HDPE reaction sticky waterproof coil material, which sequentially comprises a separation layer, a non-sticky coating film layer, a self-adhesive layer and a base body fromtop to bottom, wherein the separation layer is a linear saturated polyester resin separation film, the non-sticky coating film layer is made of the following components by mass: 80-95% of an acrylic emulsion, 4-20% of an alcohol organic solvent and 0.3-1% of an A reaction aid, the non-sticky coating film layer comprises a strong adhesion type hot melt pressure sensitive adhesive and a B reaction aid, the content of the B reaction aid is 0.3-1%, the base body is a HDPE homogeneous sheet layer, and the A reaction aid and the B reaction aid respectively are a silane coupling agent. According to the present invention, the HDPE reaction sticky waterproof coil material has much higher peeling strength compared to the ordinary HDPE self-adhesive waterproof coil material, is easy to construct, andcannot stick to the construction personnel.

Owner:武汉市恒星防水材料有限公司

Extraction method of neomycin sulfate

InactiveCN106317138AReduce consumptionGood for occupational healthSugar derivativesSugar derivatives preparationFiltration membraneSolvent

The invention relates to an extraction method of neomycin sulfate, comprising the steps of pre-treating neomycin fermentation broth, filtering the fermentation broth by micro-filtration membrane, concentrating the broth by nanofiltration membrane, crystallizing the broth in acetone solvent, obtaining crude neomycin by suction filtration, dissolving the crude neomycin in the water, salting the sulfuric acid, dewatering by activated carbon, and then obtaining neomycin sulfate product by fine filtering, spraying and drying. The extraction rate can be improved above 6% in such a manner that the crystallization technology is used for purifying and concentrating to extract the neomycin sulfate, and it is beneficial for improving the economic benefit. The method reduces wastewater discharge and is beneficial for environment protection. The method has small energy consumption without releasing and emitting pungent smell, and is beneficial for the occupational health of staffs on the position.

Owner:NINGXIA TAIYICIN BIOTECH CO LTD

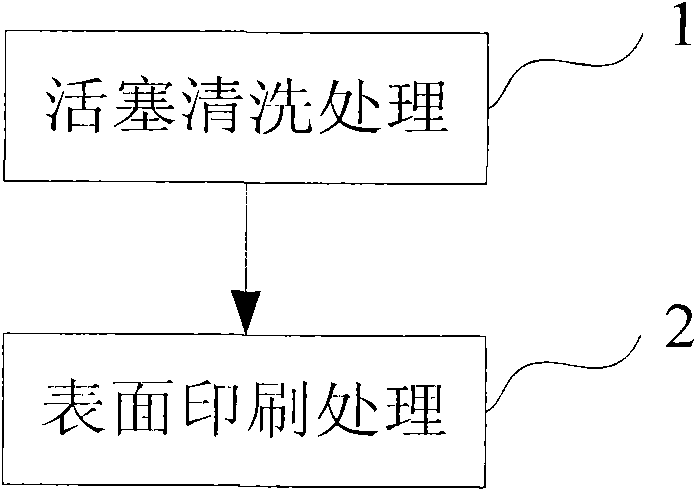

A kind of piston and its production process

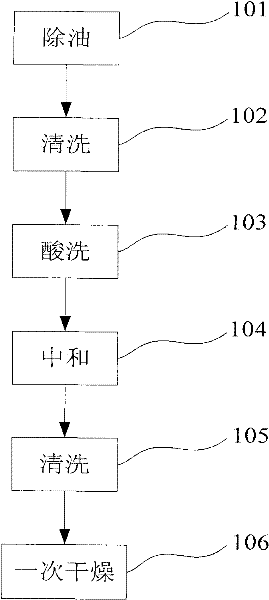

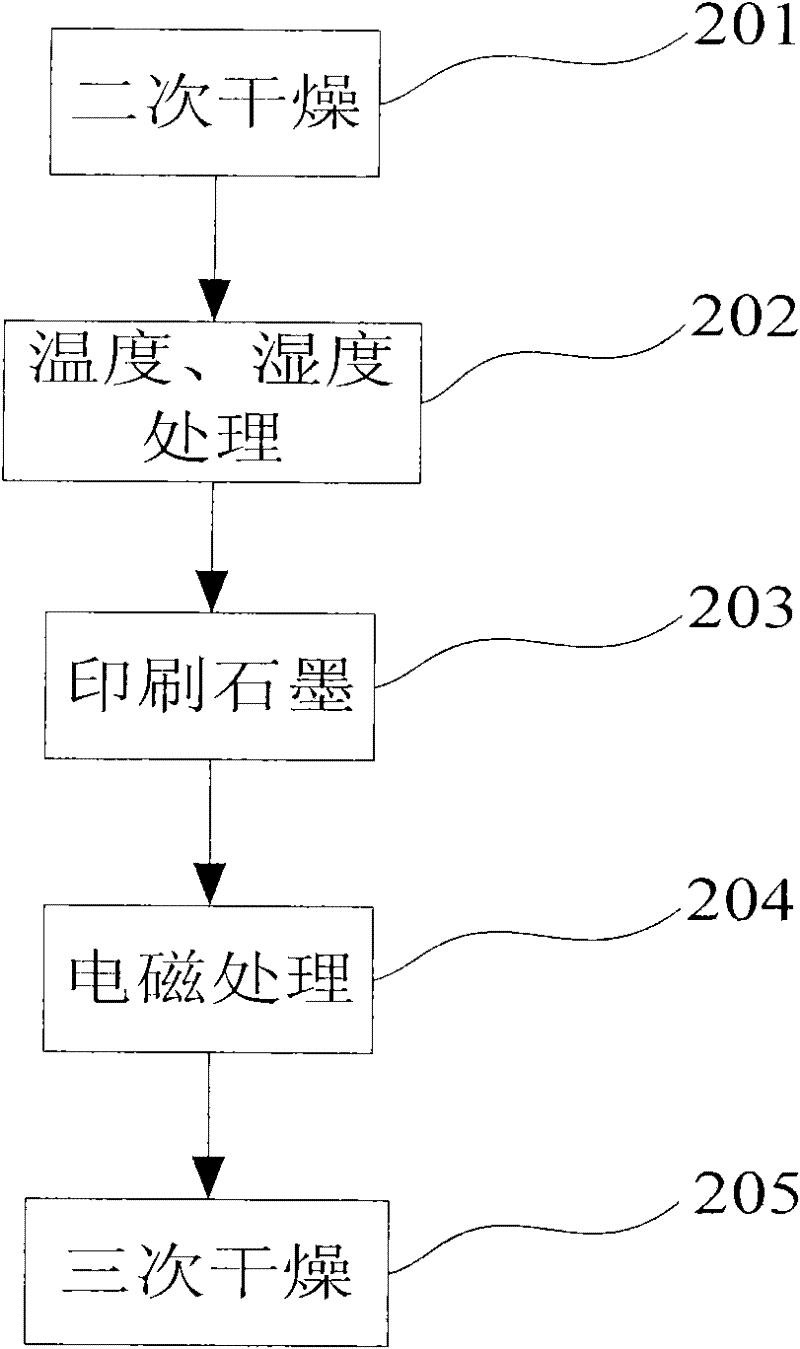

The invention discloses a piston, which comprises a piston body and a graphite layer covered on the skirt surface of the piston body. The invention also discloses a manufacturing process of the piston, comprising the steps of: printing graphite on the surface of the skirt of the piston body. The piston provided by the present invention, on the basis of the existing piston, is provided with a graphite layer on its skirt, which can play the role of a high-temperature isolation layer, will not cause the cylinder and the piston to bond, and can improve the reliability of the engine, because Graphite powder itself is soft and has lubricity, so when the engine is starting, or when lubrication is difficult due to other accidents, the graphite layer on the surface of the piston skirt can lubricate in a short time, making the piston Get through the emergency safely.

Owner:陈殿宽

Technology producing dimensional bags with frame adhesive

The invention discloses a technology producing dimensional bags with frame adhesive. The technology comprises the following steps: a, formulating adhesive liquid, that is, weighing 3 to 5 parts of vinyl acetate by weight, 1.5 to 2 parts of crystal paraffin by weight, 3 to 5 parts of gasoline by weight with a platform balance, placing the vinyl acetate, the crystal paraffin and the gasoline into an adhesive dissolving tank, mixing the vinyl acetate, the crystal paraffin and the gasoline, placing the adhesive dissolving tank into an adhesive dissolving water furnace, heating the adhesive dissolving water furnace to dissolve the adhesive dissolving tank; b, printing the frame adhesive, that is, placing dialyzing paper on an unwinding rack of a printing press, filling the adhesive liquid obtained through the step into an adhesive plate, pouring printing ink mixed in a qualified manner into an ink fountain, adjusting the tension of a winding and unwinding roll to a preset value, starting operation, printing the front side of dialyzing paper due to traction, coating the adhesive liquid on the back side of the dialyzing paper through an offset plate, stoving with 190 DEG C to 230 DEG C high-temperature, winding and forming to obtain a frame adhesive printing roll; c, producing bags; d, inspecting bag products; and e, placing the bag products into a warehouse. The invention has the advantages that the preparation technology is simple; packing bags prepared by adopting the technology have high air permeability; no paper scrap is formed when the packing bags are torn; and after sterilization, the packing bags cannot be bonded with objects in the packing bags.

Owner:NANTONG WANDA PACKAGING

Drying equipment for amino acid organic fertilizer production

InactiveCN112197536AWill not stickSpread evenlyManure dryingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention discloses drying equipment for amino acid organic fertilizer production. The drying equipment comprises a fixing frame, wherein a drying box is mounted at the top of the fixing frame, arotating cylinder is horizontally arranged at the middle of the interior of the drying box, one end of the rotating cylinder is connected with the drying box through a first rotating shaft, and the other end of the rotating cylinder is connected with the drying box through a second rotating shaft; and a first bearing corresponding to the first rotating shaft and a second bearing corresponding to the second rotating shaft are embedded at the middles of two ends of the drying box. According to the drying equipment for amino acid organic fertilizer production, air in the drying box is heated through an electric heating pipe, a stepping motor drives organic fertilizer materials in the rotating cylinder to turn over, heat exchange is conducted through a breathable grid cover, generated humid air is exhausted to the outside through a dehumidifier, the interior of the rotating cylinder is always in a dry environment, the organic fertilizer materials are evenly scattered through partition plate strips, the situation that the organic fertilizer materials are stacked and connected together and cannot be dried, is avoided, and the drying effect is good.

Owner:JIANGSU HANLING FERTILIZER IND

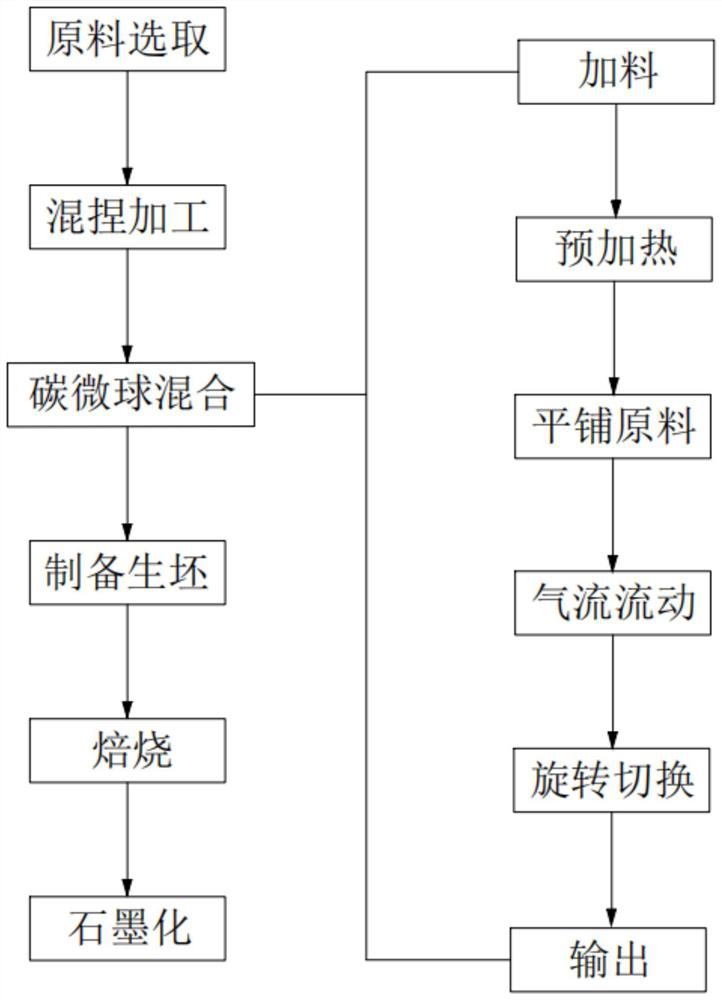

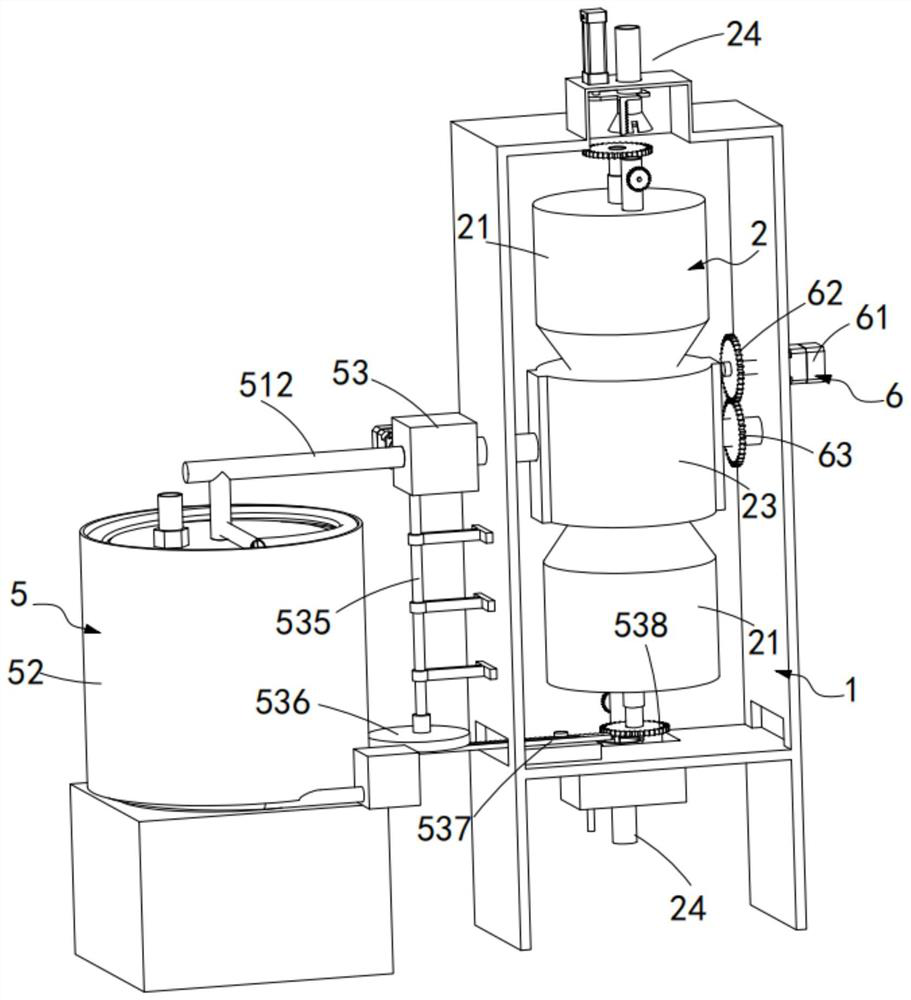

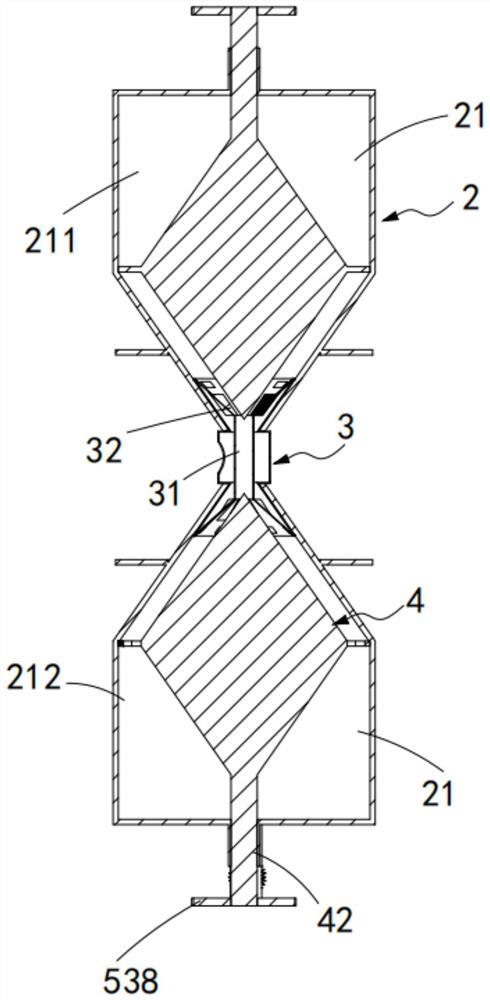

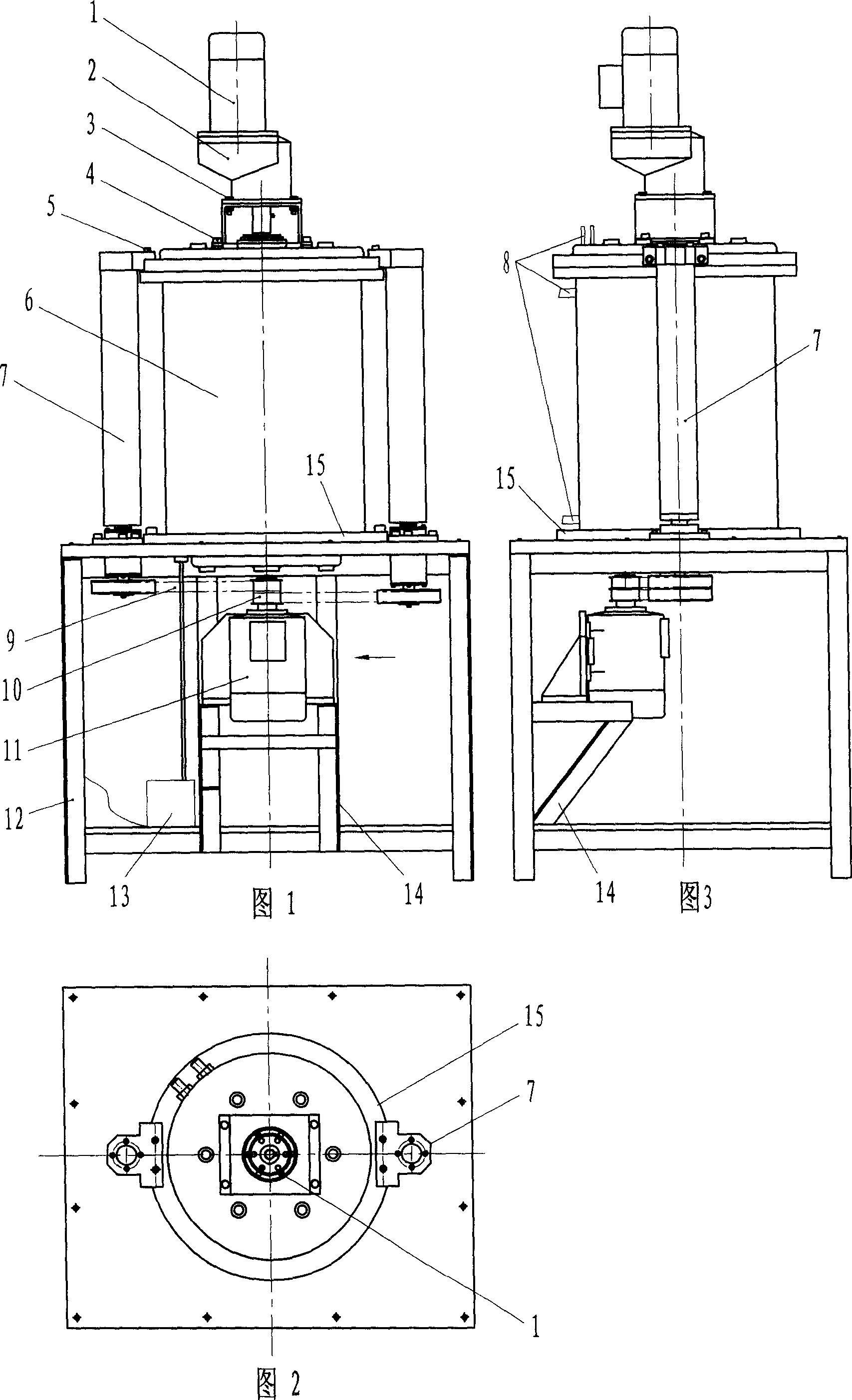

Preparation method of high-strength isostatic pressing graphite

The invention relates to the technical field of preparation of high-strength isostatic pressing graphite, in particular to a preparation method of high-strength isostatic pressing graphite, which comprises the following steps: selecting raw materials, kneading, mixing carbon microspheres, preparing a green body, roasting and graphitizing, wherein the carbon microsphere mixing comprises the steps of feeding, preheating, raw material paving, airflow flowing, rotary switching and outputting, in the carbon microsphere mixing step, paste powder and asphalt mesophase carbon microspheres are uniformly mixed according to a certain proportion, and in the mixing process, the asphalt mesophase carbon microspheres are preheated, so that the asphalt mesophase carbon microspheres are uniformly mixed according to a certain proportion. The heated asphalt mesocarbon microbeads are injected into the tiled paste powder layer, and heat carried by the asphalt mesocarbon microbeads is used for bonding withasphalt in the paste powder layer, so that mixed bonding of the asphalt mesocarbon microbeads and the paste powder is realized, and the problem that the asphalt mesocarbon microbeads and the paste powder cannot be uniformly mixed even if the asphalt mesocarbon microbeads and the paste powder are mixed by traditional mixing equipment is solved. The fixed-ratio mixing of the asphalt mesocarbon microbeads and the paste powder of each part cannot be ensured.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Dynamic fluidization atmosphere furnace

InactiveCN101011650AWill not stickWon't leak inFrom solid stateFluidised-bed furnacesAtmospheric airPropeller

The dynamic fluid atmospheric oven for the making of sodium powder comprises oven components, oven cover lifting device, material container, air leakage protective device, operation and circuit control device and air control device, two air channels, spiral blending bar sticking vertically from the center of the top cover of the material container to the inner cavity of the container, with one being the channel blowing from the bottom of the container to the atmospheric air, the other entering into the inner heating well type atmospheric oven air channel. It can produce the effect of recovery, coating oxidation protective film, off core, and so on without sediment, sticky and damage.

Owner:WUHAN UNIV OF TECH +1

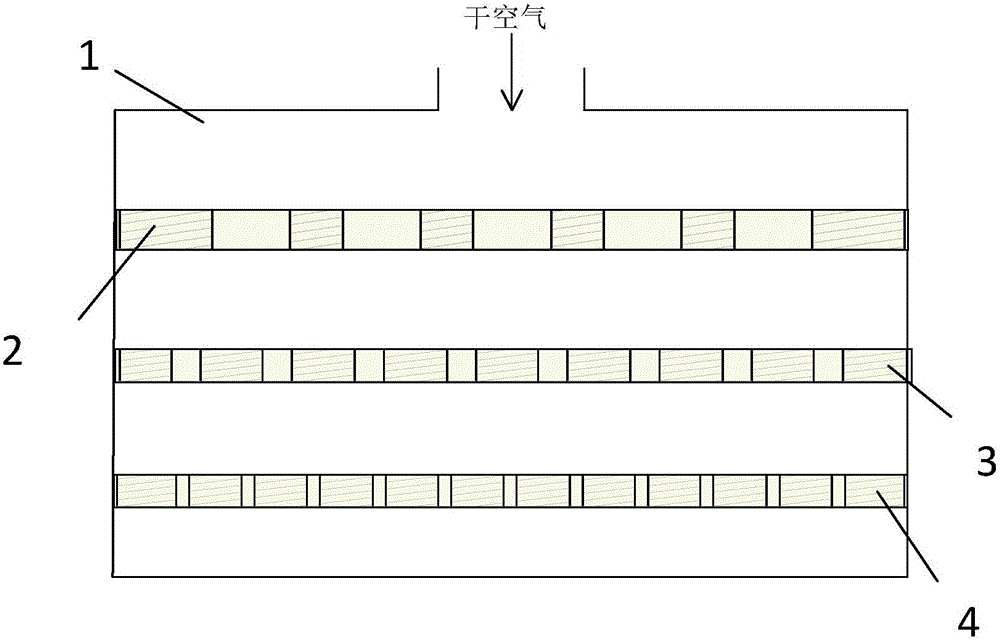

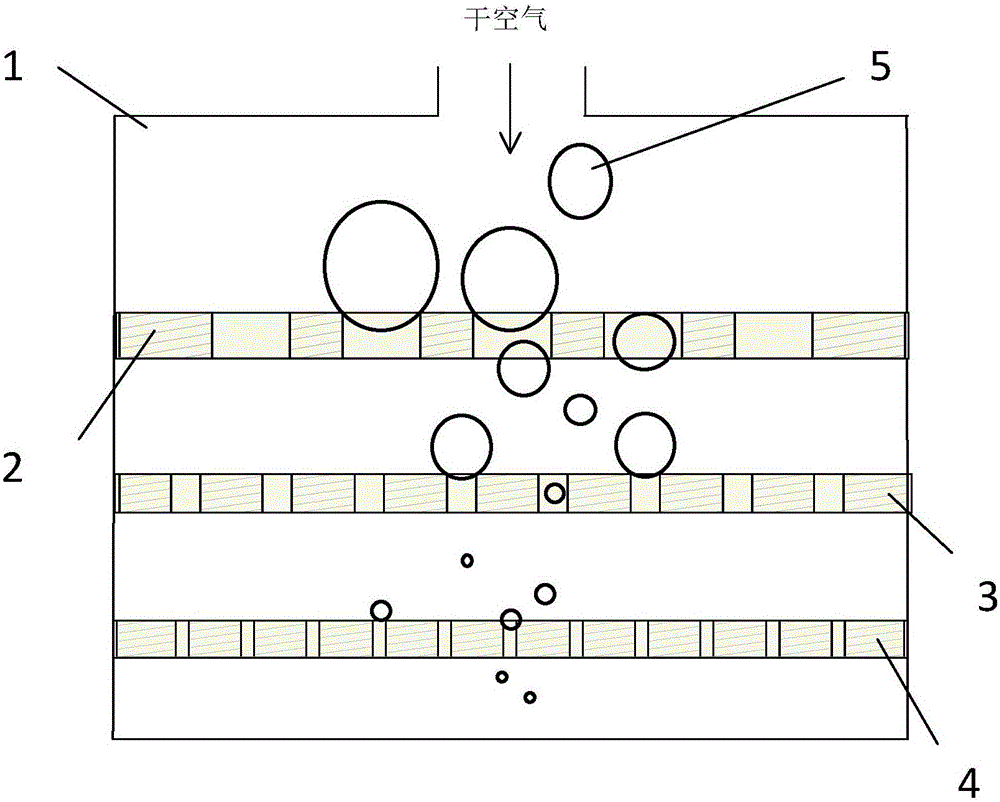

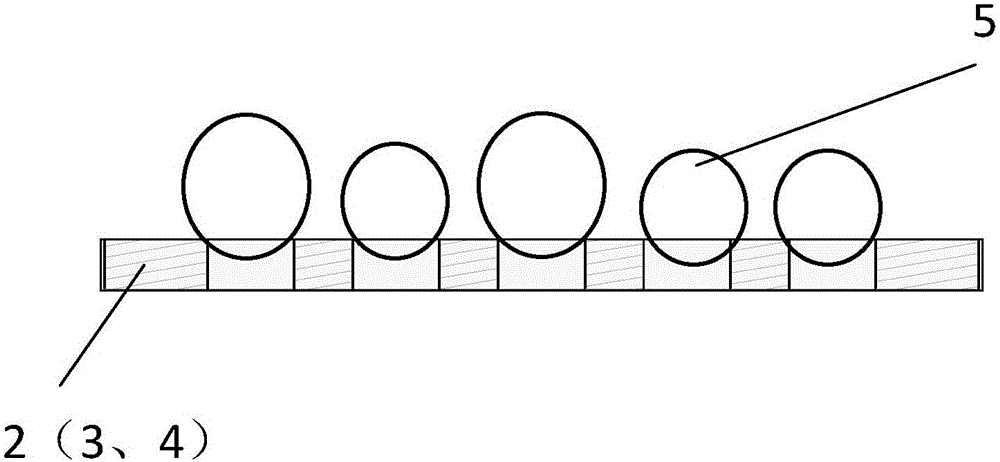

PM2.5 monitoring method based on particle size

InactiveCN105717005AThe monitoring results are accurate and reliableWill not stickParticle size analysisEngineeringManufacturing technology

The invention discloses a PM2.5 monitoring method based on the particle size. A certain amount of dried air to be tested is introduced into a closed container, the closed container is provided with two or more filter nets of different through hole diameters from top to bottom; then, the closed container is closed, standing is performed for 10-30 min, and fine particles in the air to be tested are filtered sufficiently through the filter nets; all the filter nets are taken from the closed container a few days later, the fine particles of the corresponding particle size are extracted from the filter nets of different through hole diameters, and detection analysis is performed. The method is achieved through uniformly-distributed arrayed through holes of different sizes formed in the filter nets by adopting the fine manufacturing technology, the shape precision of the through holes is controllable, and therefore the monitoring result is accurate and reliable.

Owner:GUANGDONG UNIV OF TECH

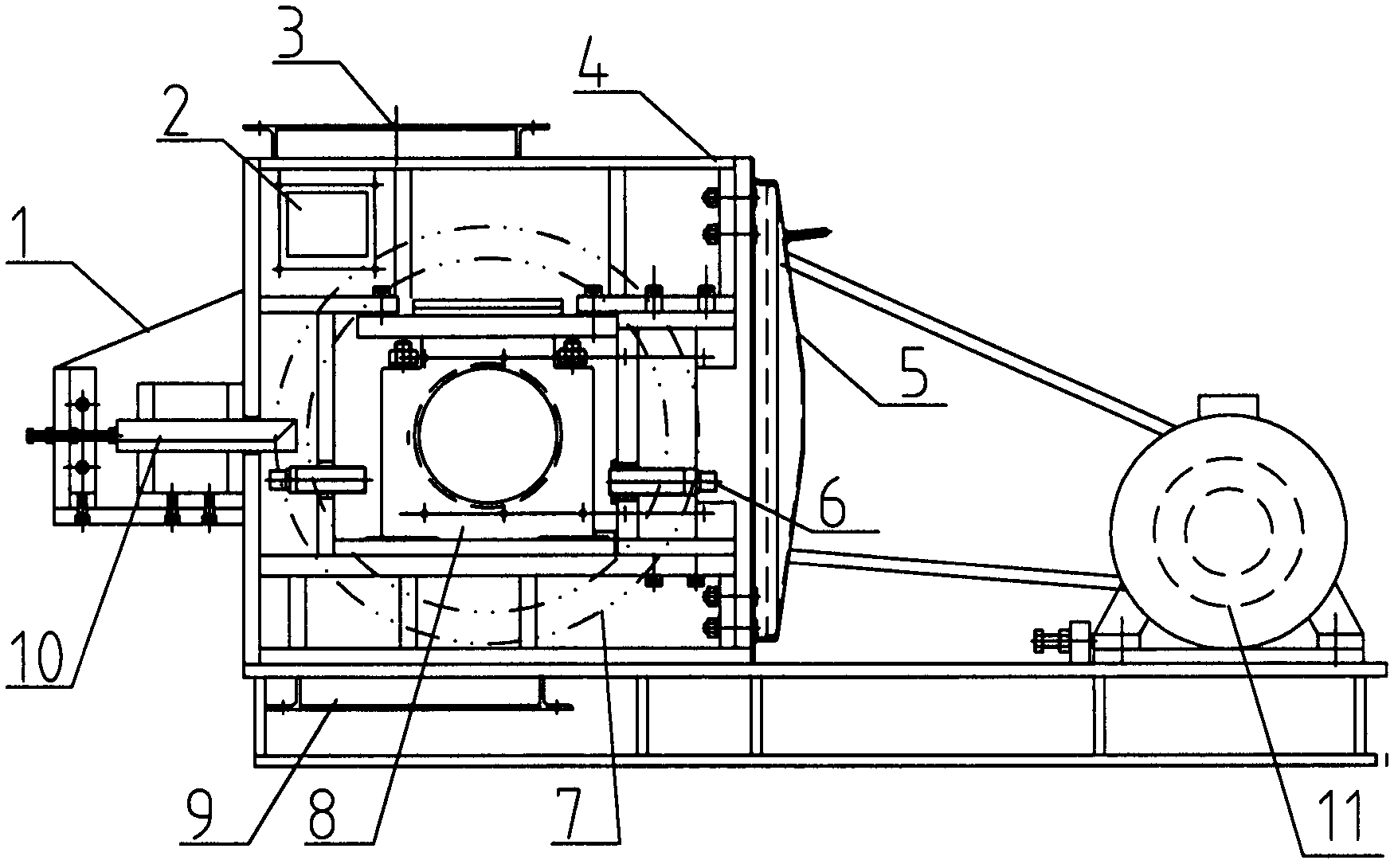

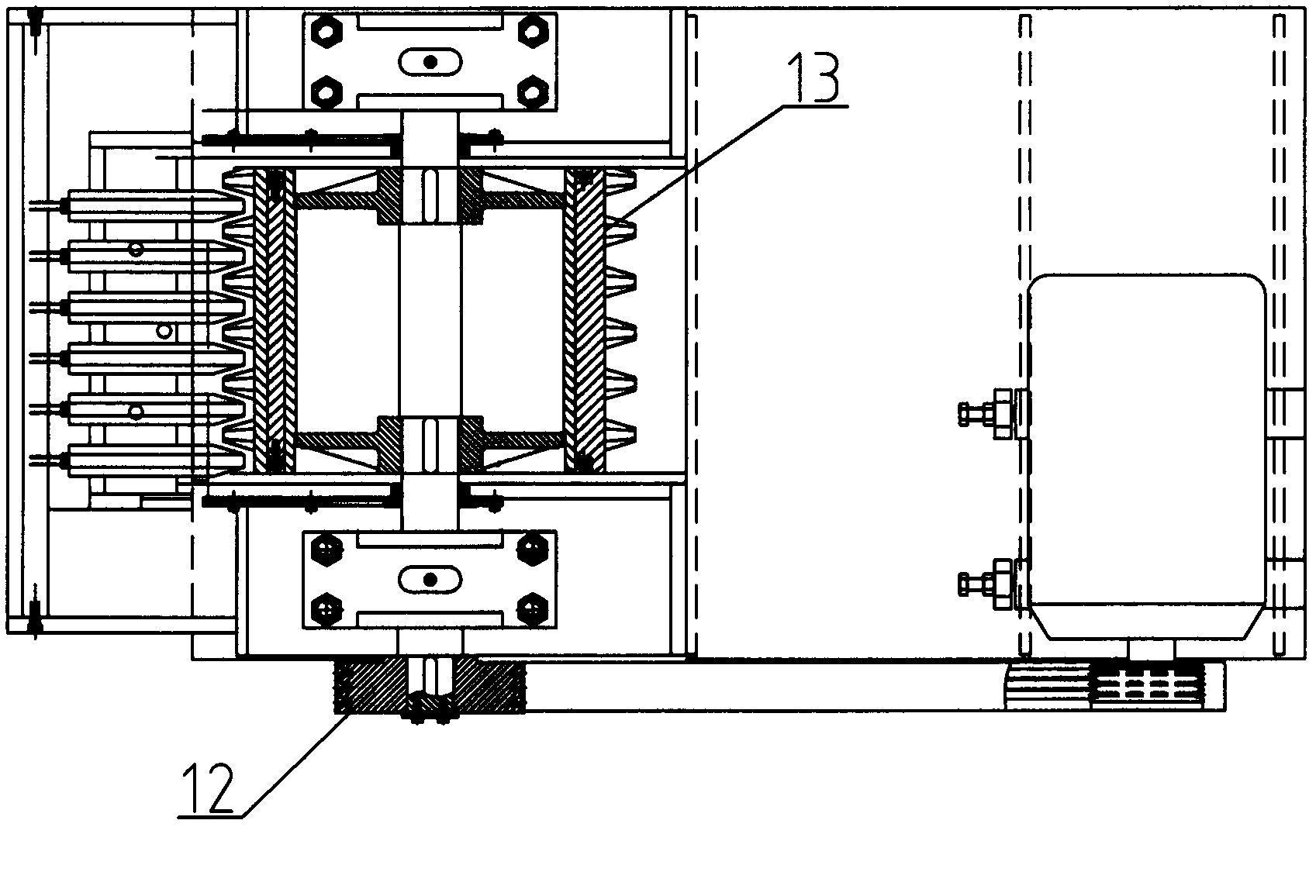

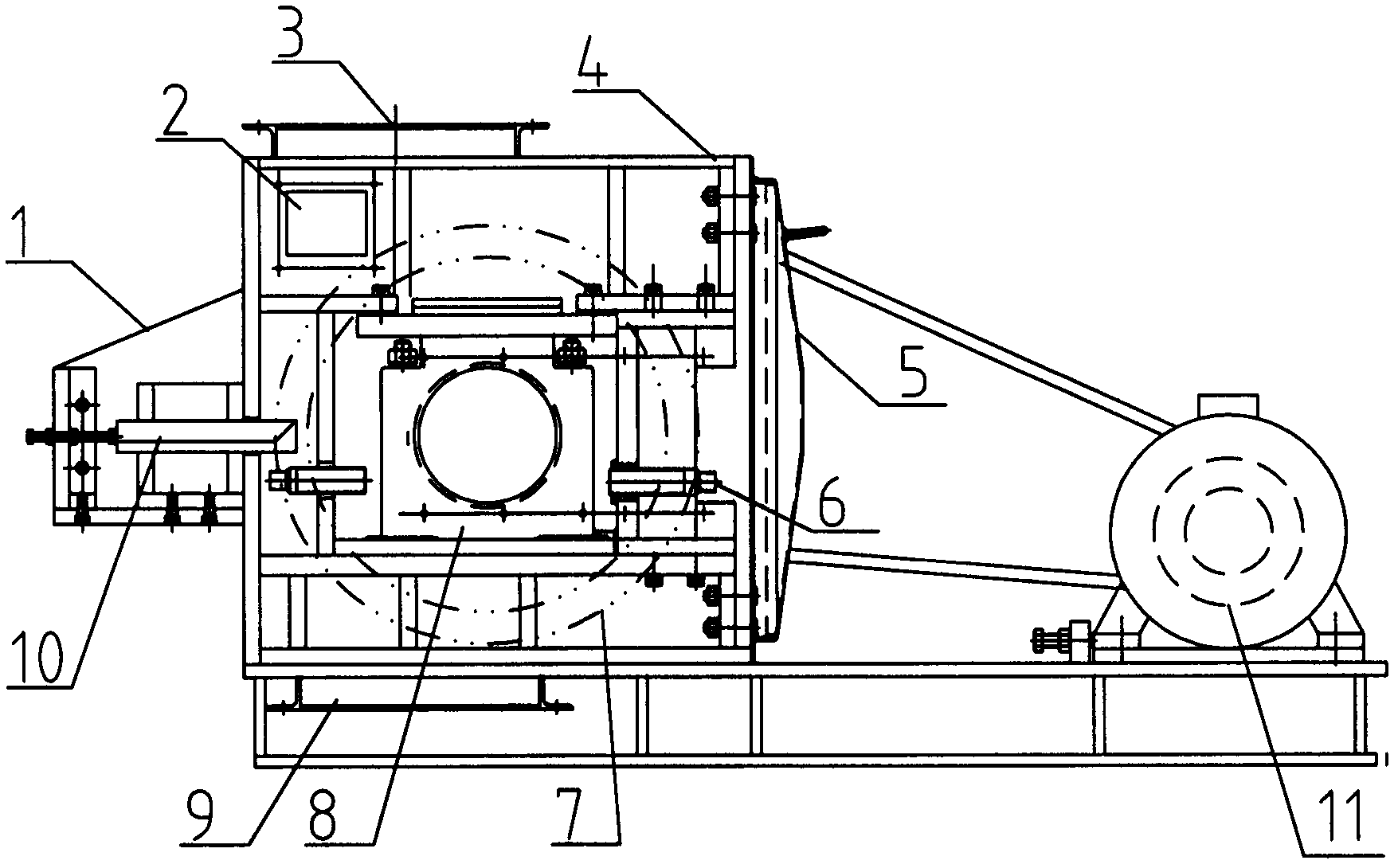

Heavy-duty crushing machine

The invention relates to a heavy-duty crushing machine. According to the invention, a motor and a rotor of the crushing machine are connected by using a belt; a feeding port is arranged on the top of the heavy-duty crushing machine, and is connected to a frame; a discharging port is arranged below the heavy-duty crushing machine; and the rotor is arranged on a bearing pedestal, and is fixed on the frame. With the crushing machine, during a material crushing procedure, adhesion or blocking does not occur, an over crushing rate is low, the noise is low, the vibration is low, a dust amount is low, the energy consumption is low, and the land occupation is low. There is no requirement on the water content of the material requiring crushing.

Owner:广西南宁东创通用机械设备工程有限公司

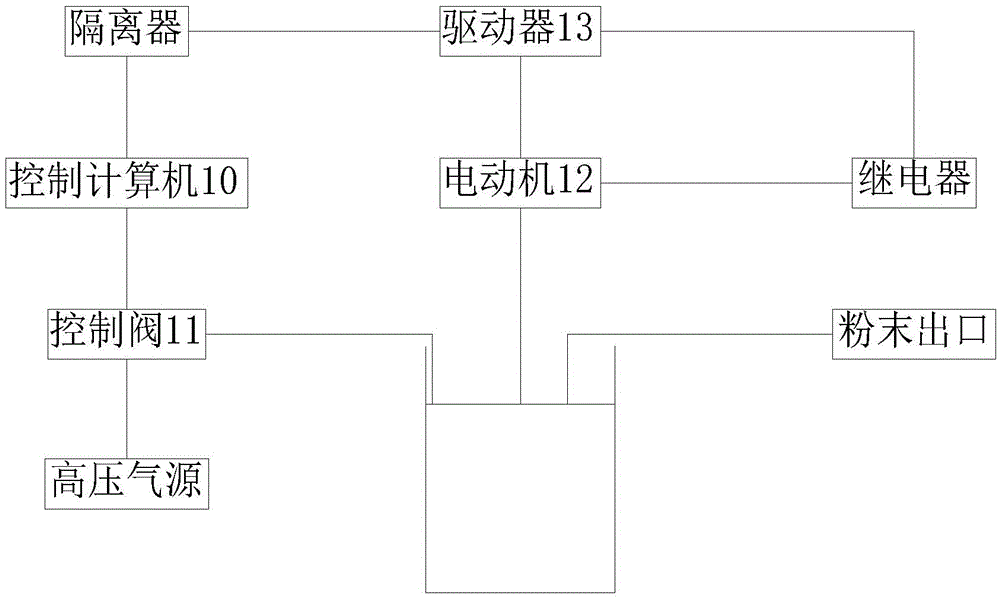

Metal powder fuel supply device based on overpressure sealing

ActiveCN105485708AGuaranteed uptimeImprove charging capacityFuel feeding arrangementsLump/pulverulent fuel feeder/distributionEngineeringMetal particle

The invention aims at providing a metal powder fuel supply device based on overpressure sealing. A piston and transmission assembly driven by a motor is arranged at the upper end of a nanometer metal powder grain, and an annular nozzle is arranged at the edge of the piston and the transmission assembly. An annular gas collecting cavity is formed between a piston and the wall. A plurality of sealing rings are arranged between the annular gas collecting cavity and the external. An annular fluidization chamber is formed inside the piston and formed in the manner that an upper workpiece is connected with a lower workpiece through bolts. By means of the metal powder fuel supply device, the influences, caused when all metal powder is pushed by a piston for feeding and fluidization, on normal running and stable feeding of a system can be avoided; the difference between the gas pressure inside the annular nozzle and the gas pressure outside the annular nozzle forms overpressure sealing, and nanometer metal powder can not reflux to permeate upwards into the edge of the piston; due to a clean gap of the piston, the replacement frequency of the sealing rings is reduced, abrasion of the wall of the piston is reduced, and the environment is created for use of lubricating oil; and the nanometer metal powder is mainly used, and it can be avoided that metal particles are preheated and pre-burnt during fluidization to improve burning stability.

Owner:HARBIN ENG UNIV

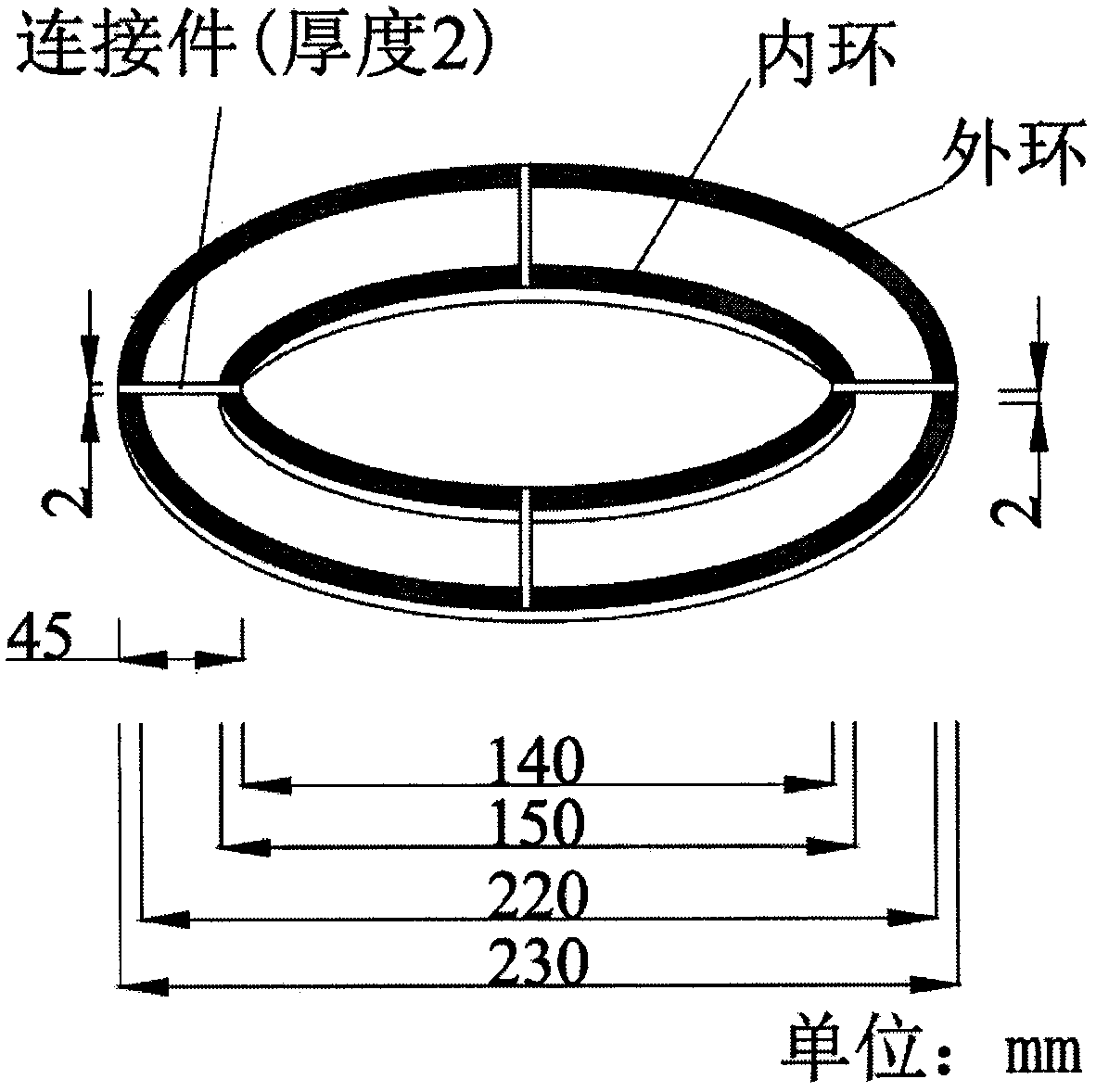

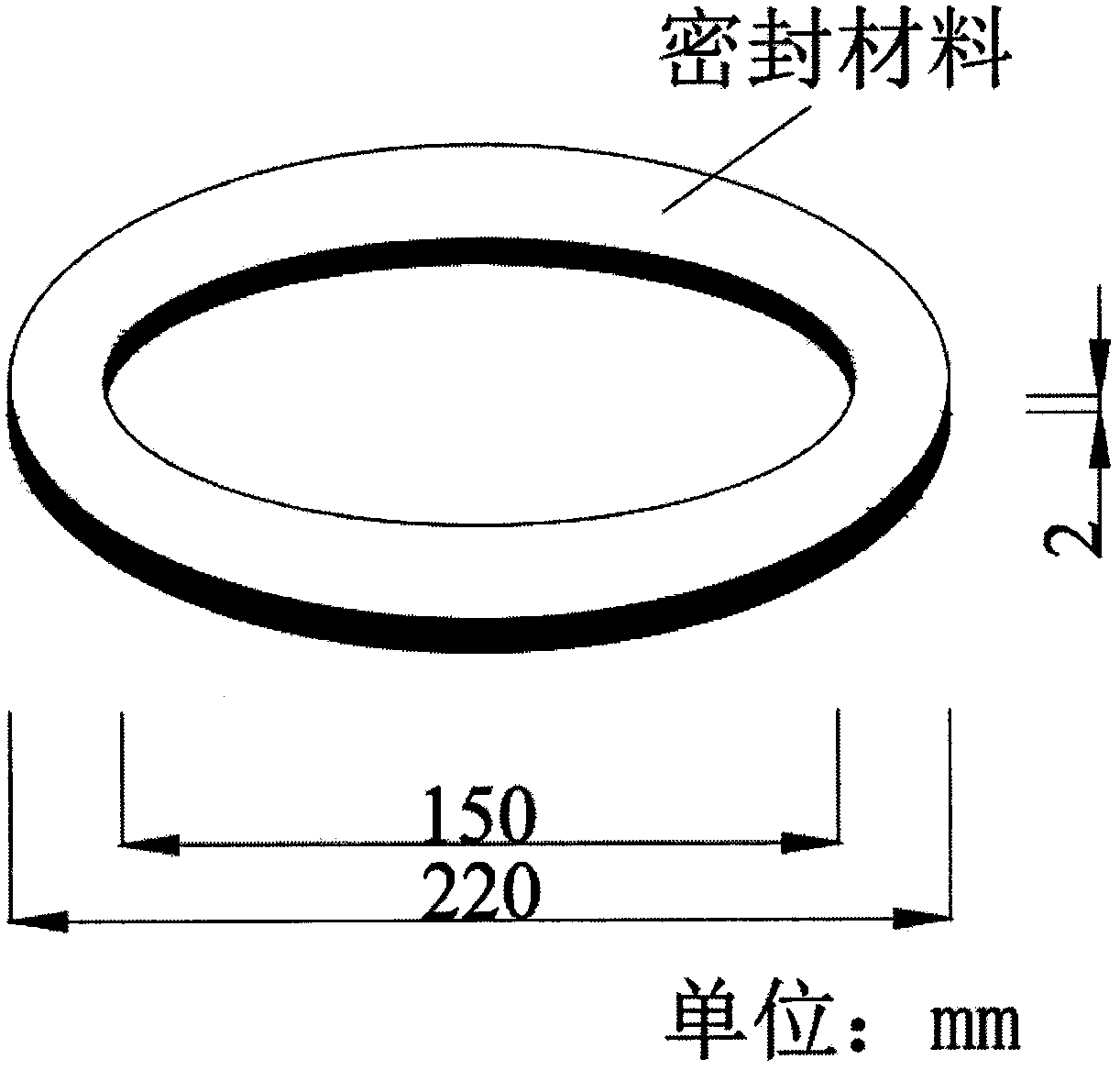

Sealing device and method for detecting water permeability coefficient of asphalt pavement

InactiveCN110346256AAchieving tightnessImprove sealingPermeability/surface area analysisRoad surfaceSilica gel

The invention discloses a sealing device and method for detecting the water permeability coefficient of an asphalt pavement. The sealing device is composed of an inner ring, an outer ring and connecting member. The inner ring has the inner diameter of 140 mm, the outer diameter of 150 mm, the width of 5 mm, and the thickness of 2 mm; the outer ring has the inner diameter of 220 mm, the outer diameter of 230 mm, the width of 5 mm, and the thickness of 2mm; and each connecting member has the width of 2mm, the length of 45mm and the thickness of 2mm. The four connecting members are distributed uniformly and are connected at the inner and outer rings. All components of the sealing device are made of silica gel materials. In addition, the invention also discloses a method for water permeabilitycoefficient detection of the pavement based on the device. According to the method, after cleaning of the asphalt pavement, the sealing device is arranged on the flat pavement; the road petroleum asphalt heated at the temperature of 125 DEG C is poured between the inner ring and the outer ring; after the surface temperature of the asphalt drops to about 50 DEG C, the sealing device is removed; awater seepage device is pressed against the surface of the annular sealing material by forces a counterweight is added to prevent flowing of pressure water out of the space between the base and the pavement. Therefore, a complete sealing effect is realized.

Owner:NANJING FORESTRY UNIV

Flash roasting treatment method for nickel laterite ores

The invention discloses a flash roasting treatment method for nickel laterite ores. The method comprises the following steps: performing roasting treatment on the nickel laterite ores in a flash roasting furnace in a reducing gas-containing atmosphere to obtain a nickel, cobalt and iron-containing product, wherein the roasting treatment is carried out at 800 to 1,200 DEG C, and the atmosphere contains less than 65 percent of reducing agent. According to the method, the flash roasting furnace is used for the roasting treatment of the nickel laterite ores, so that energy consumption can be remarkably reduced, the roasting efficiency of the nickel laterite ores can be improved, and the reduction rate of nickel is greatly increased.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com