Vertical storage tank for efficient sludge scattering and ration feeding

A technology of quantitative feeding and vertical storage tanks, which is applied in the storage and transportation of urban sludge, and can solve problems that affect residents' lives and social stability, high organic content, and polluted groundwater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

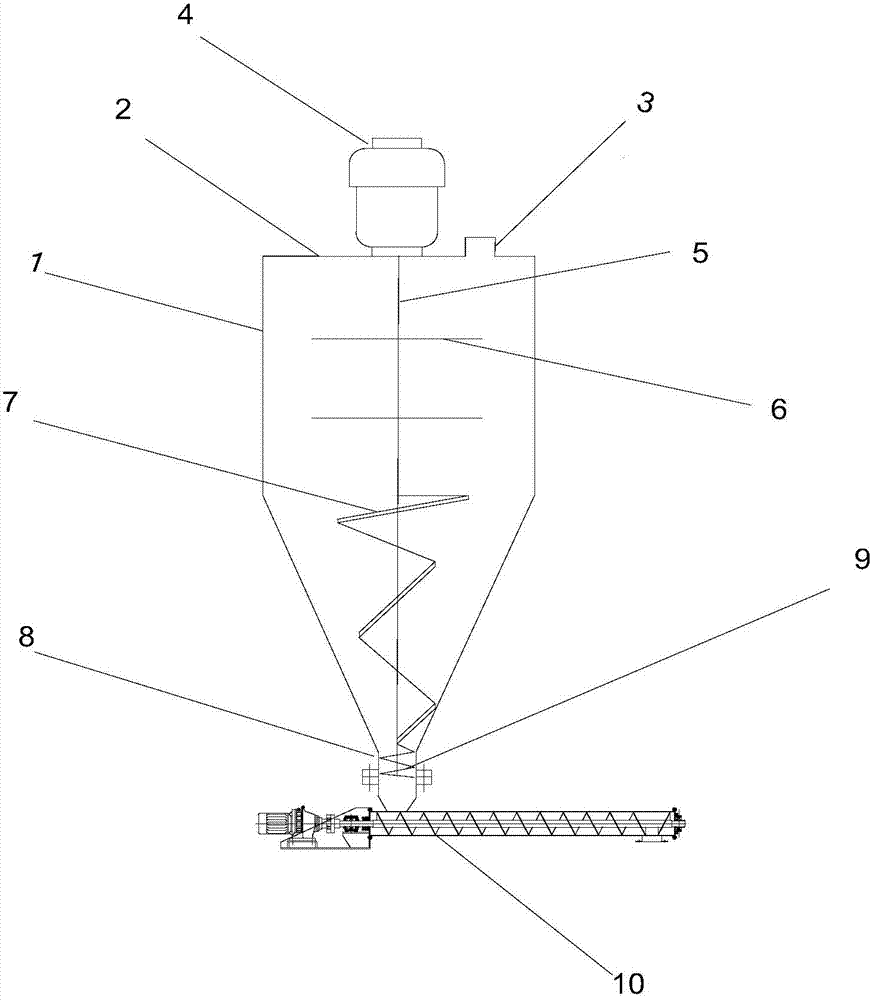

[0023] see figure 1 As shown, a vertical storage tank for efficient sludge dispersion and quantitative feeding of the present invention includes a fully sealed tank body 1, and the fully sealed tank body 1 is composed of an upper cylindrical cylinder and a lower conical cylinder. A top cover 2 is arranged above the cylindrical barrel. The top cover 2 is provided with a feeding port 3 . The rotating shaft 5 driven by the motor 4 is installed at the center of the top cover 2 and runs through the entire inside of the tank body 1 to the discharge port 8 . The rotating shaft 5 is sequentially equipped with a combined stirring device and a helical blade 9 from top to bottom. The combined stirring device is composed of a strong shear force agitator 6 installed in the cylindrical area of the tank body 1 and a conical bottom ribbon agitator 7 installed in the conical area of the tank body 1 and attached to the wall. There are 8 feeding ports. The connection between the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com