Patents

Literature

44results about How to "Efficient shredding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

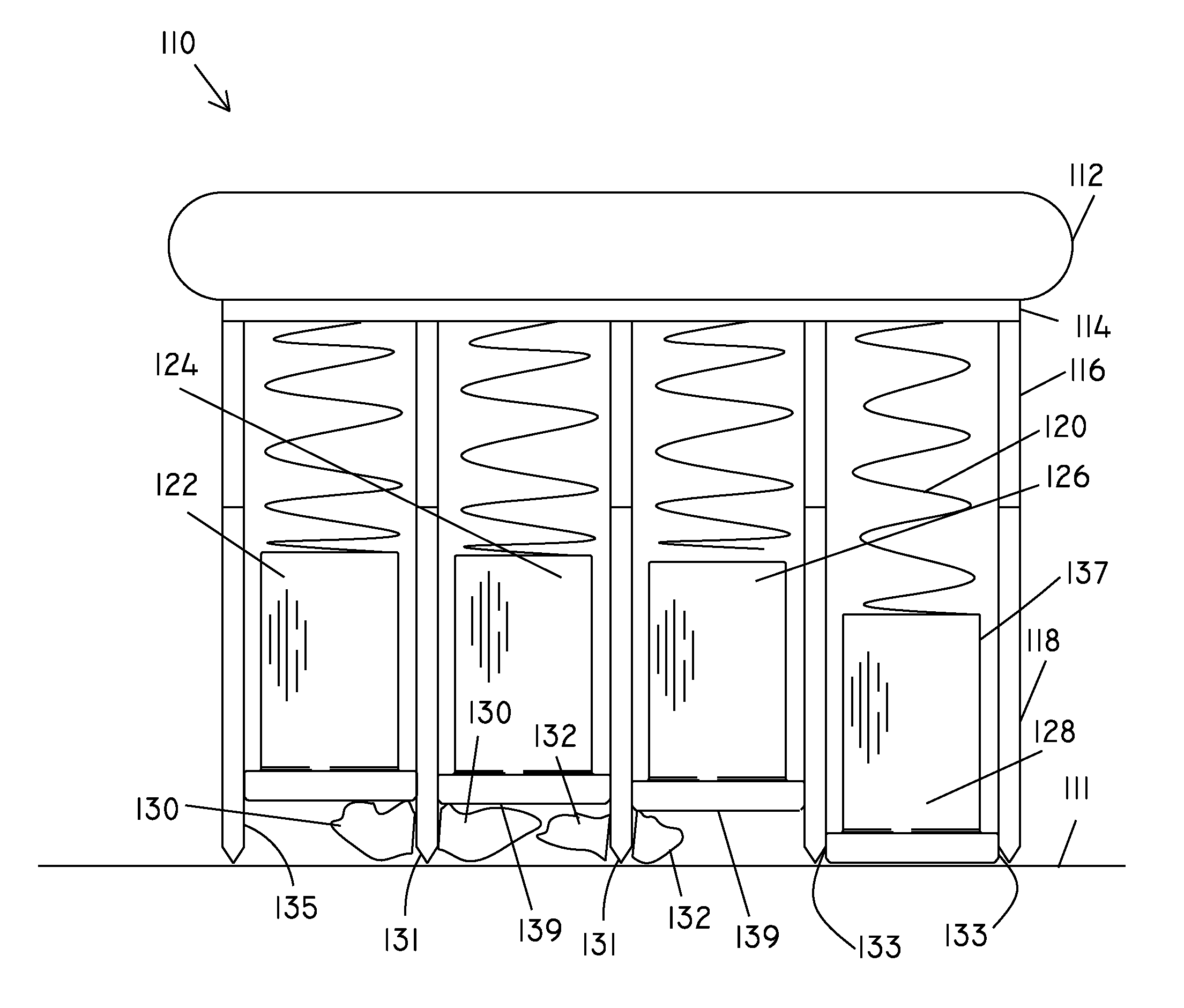

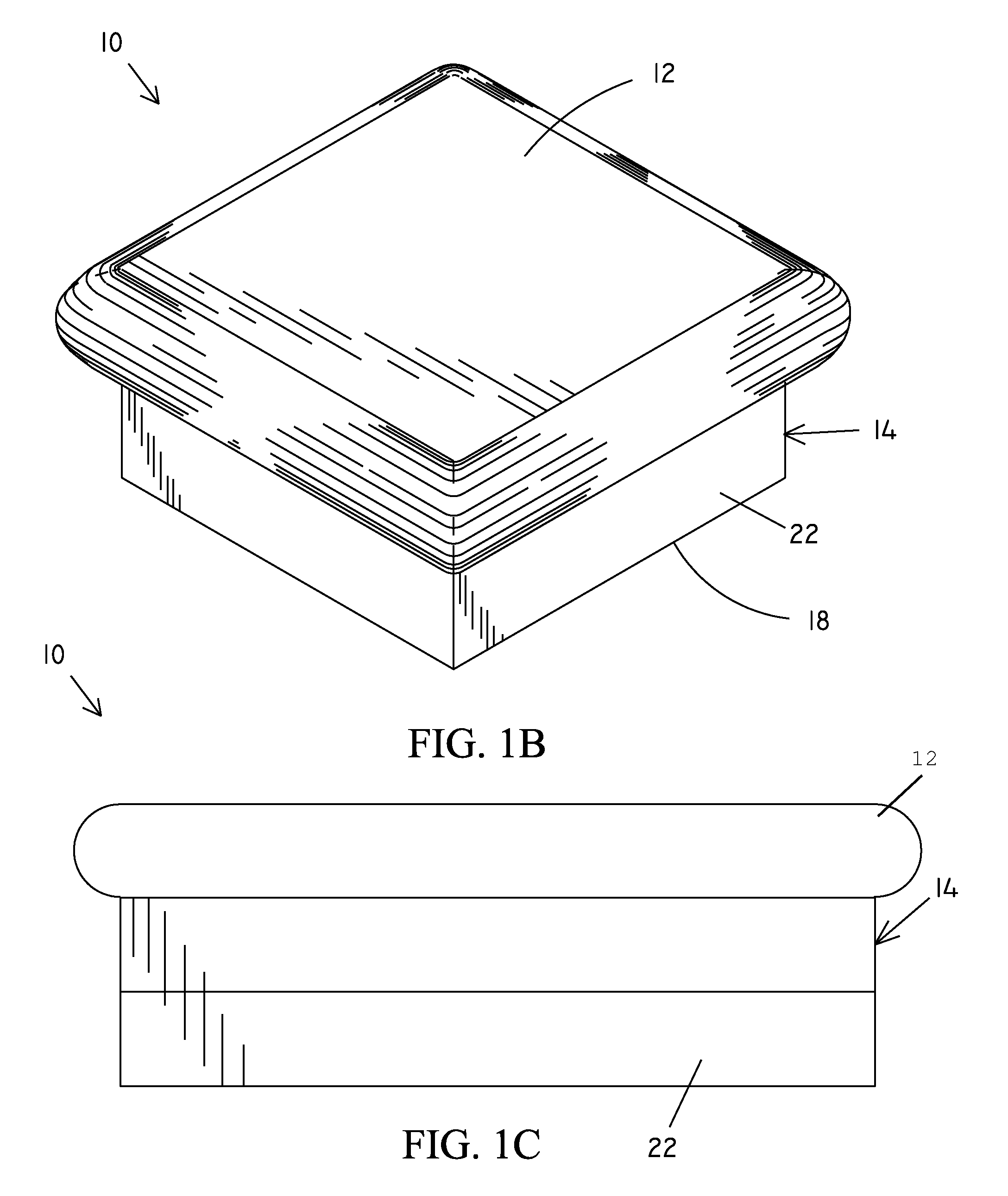

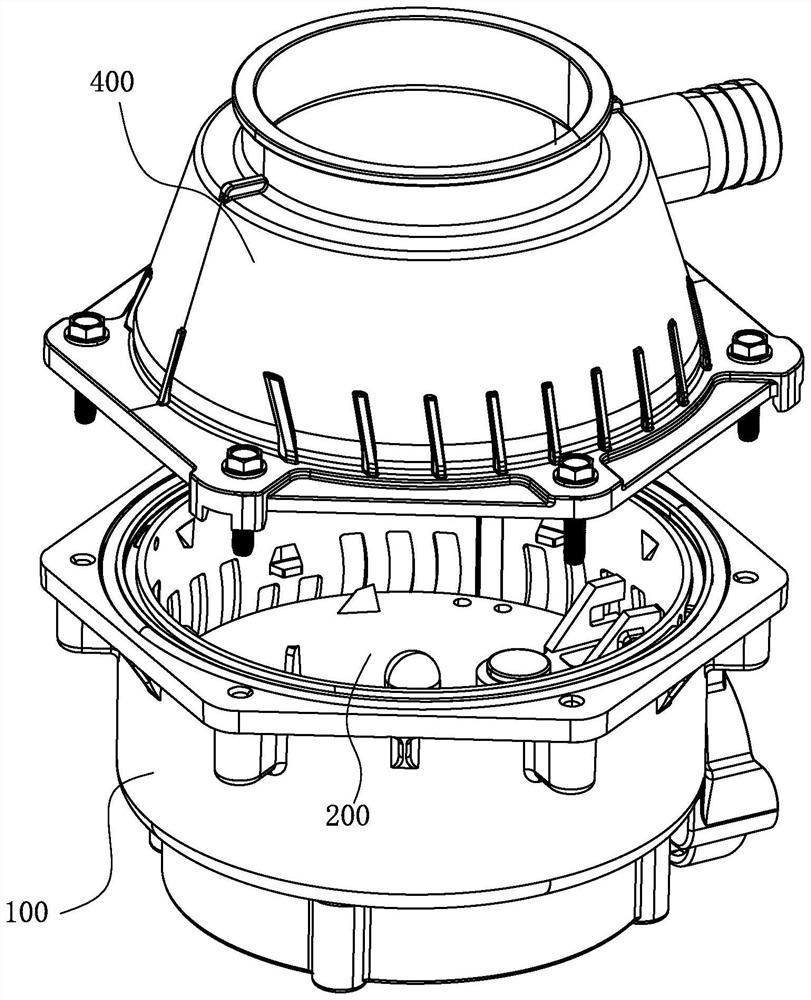

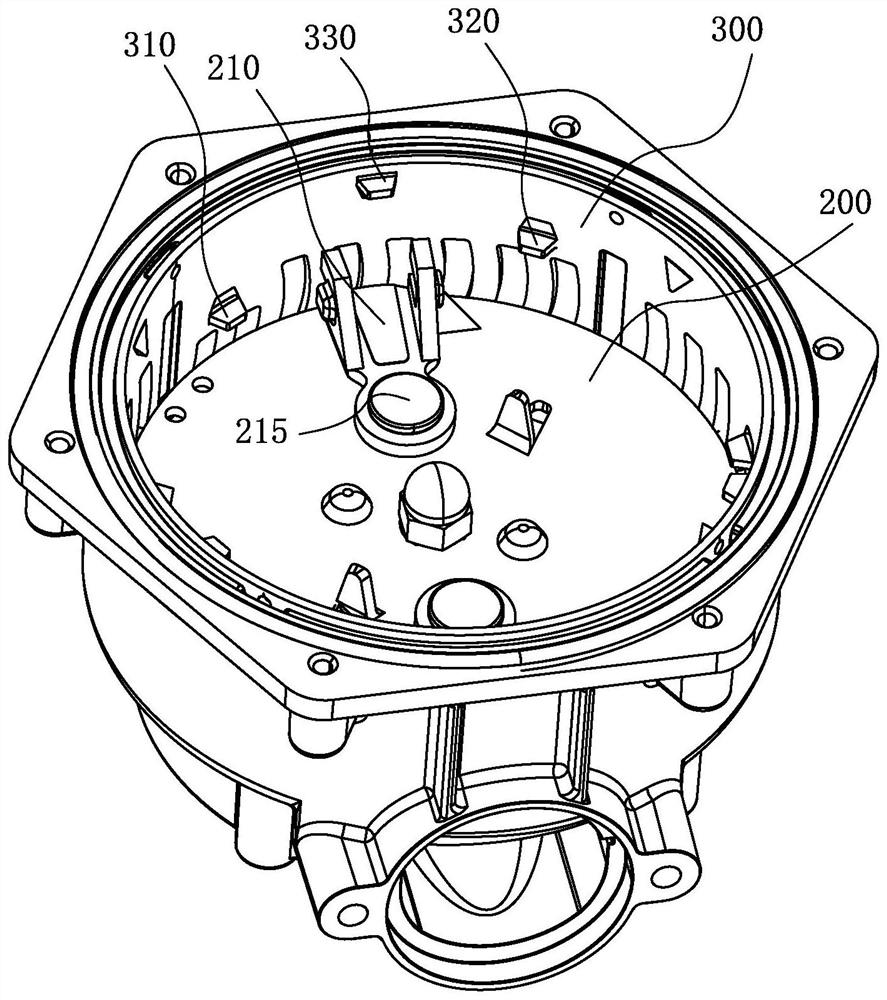

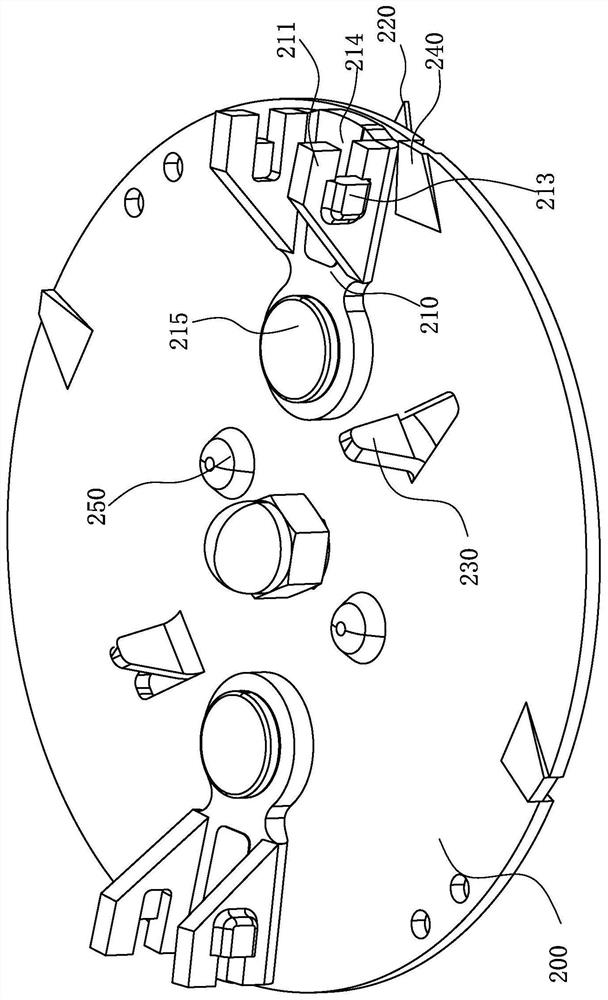

Waste Disposal Device

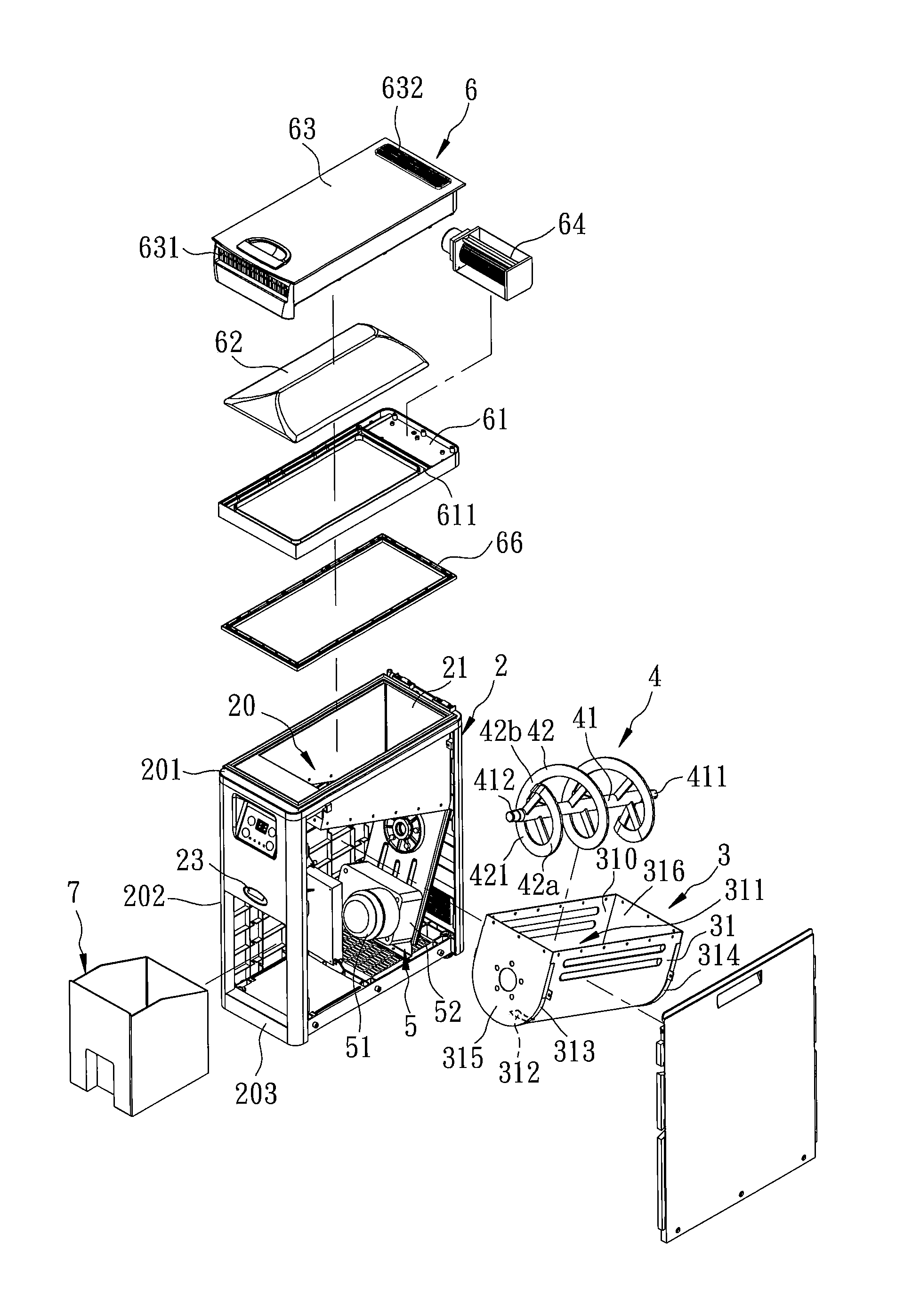

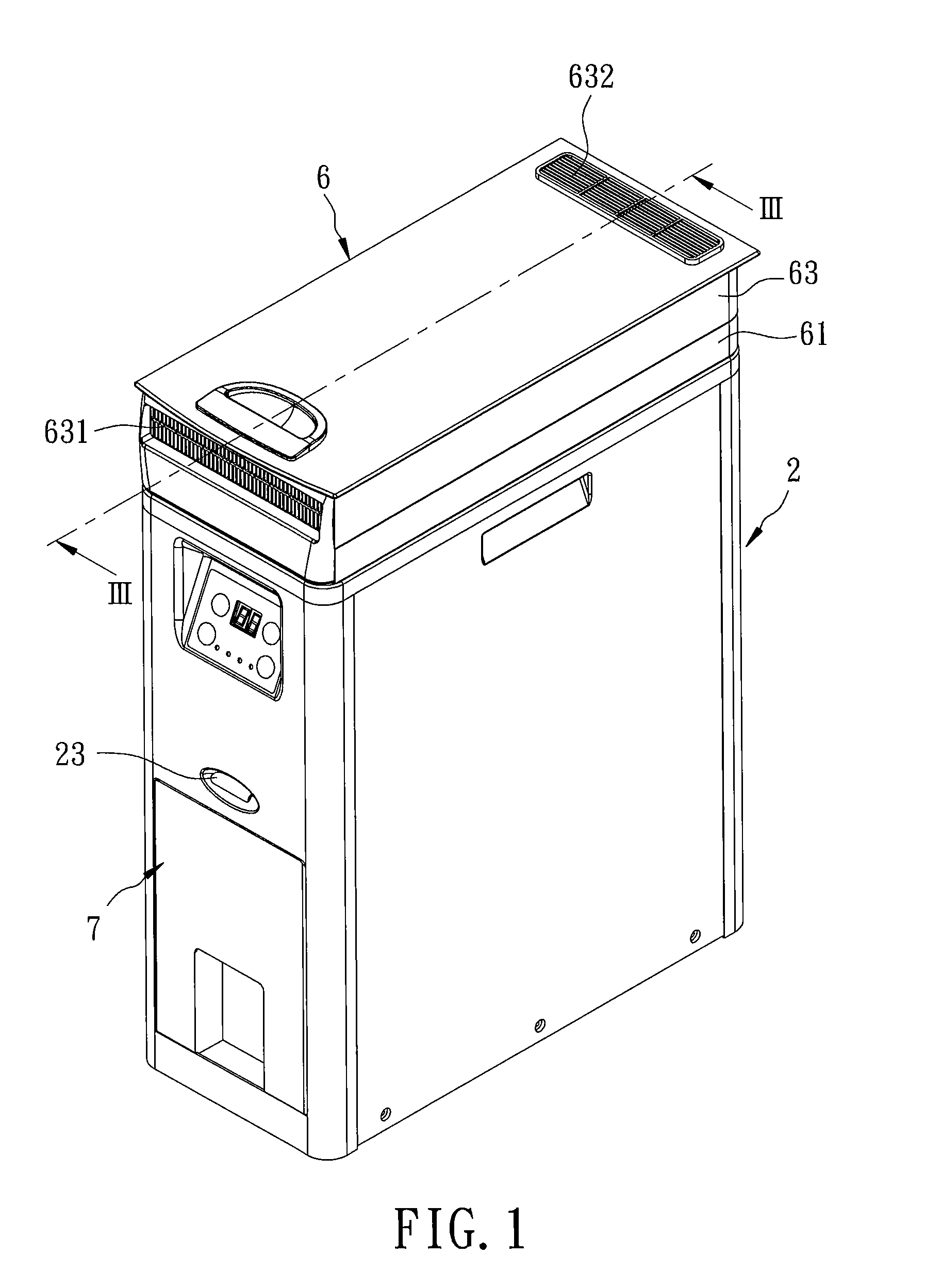

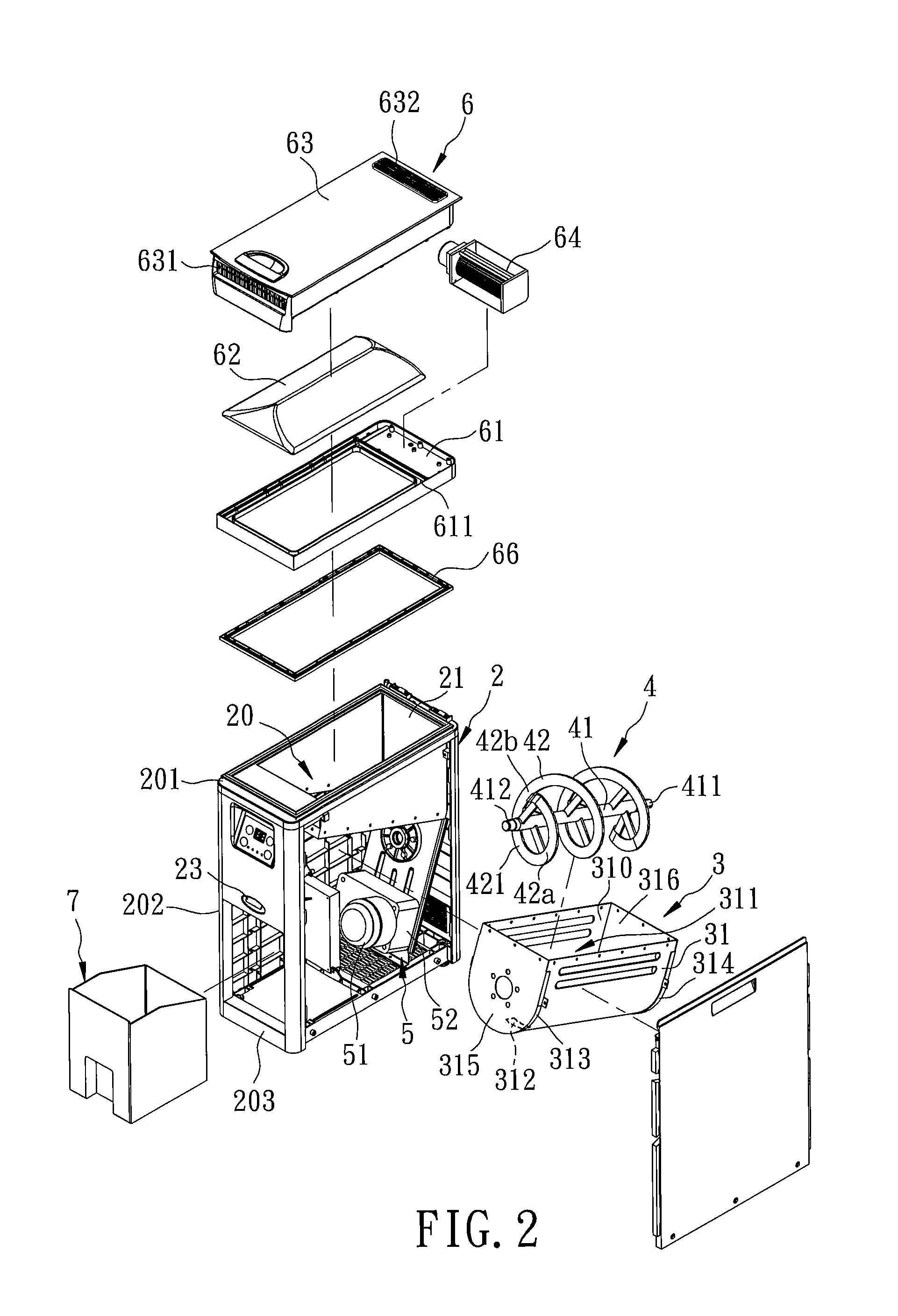

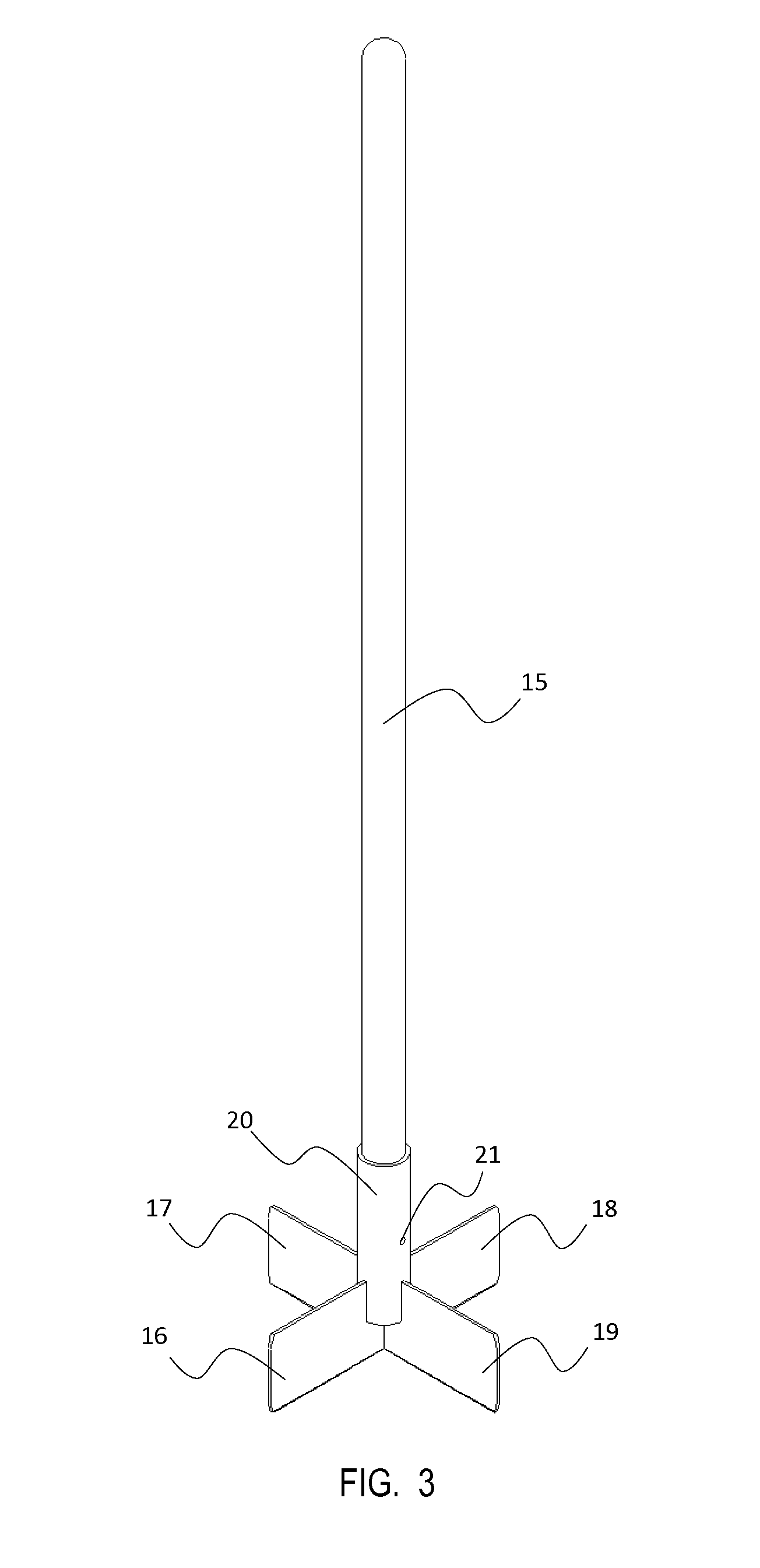

InactiveUS20130217111A1Effective stirringEfficient shreddingBioreactor/fermenter combinationsBiological substance pretreatmentsWaste disposal

A waste disposal device includes a grinder tank disposed within a housing and having an inner rounded surface angularly extending about an axis for loading of kitchen waste therein, and a grinder assembly rotatably mounted in the tank about the axis to stir and shred the waste and configured to force the waste to advance forward so that the shredding and drying process can be carried out efficiently. A condensing unit is disposed to cool and condense hot air in the housing into water which is drained through a drain port to thereby reduce leakage of unpleasant odor through an access opening of the housing.

Owner:KITCHEN UTENSIL

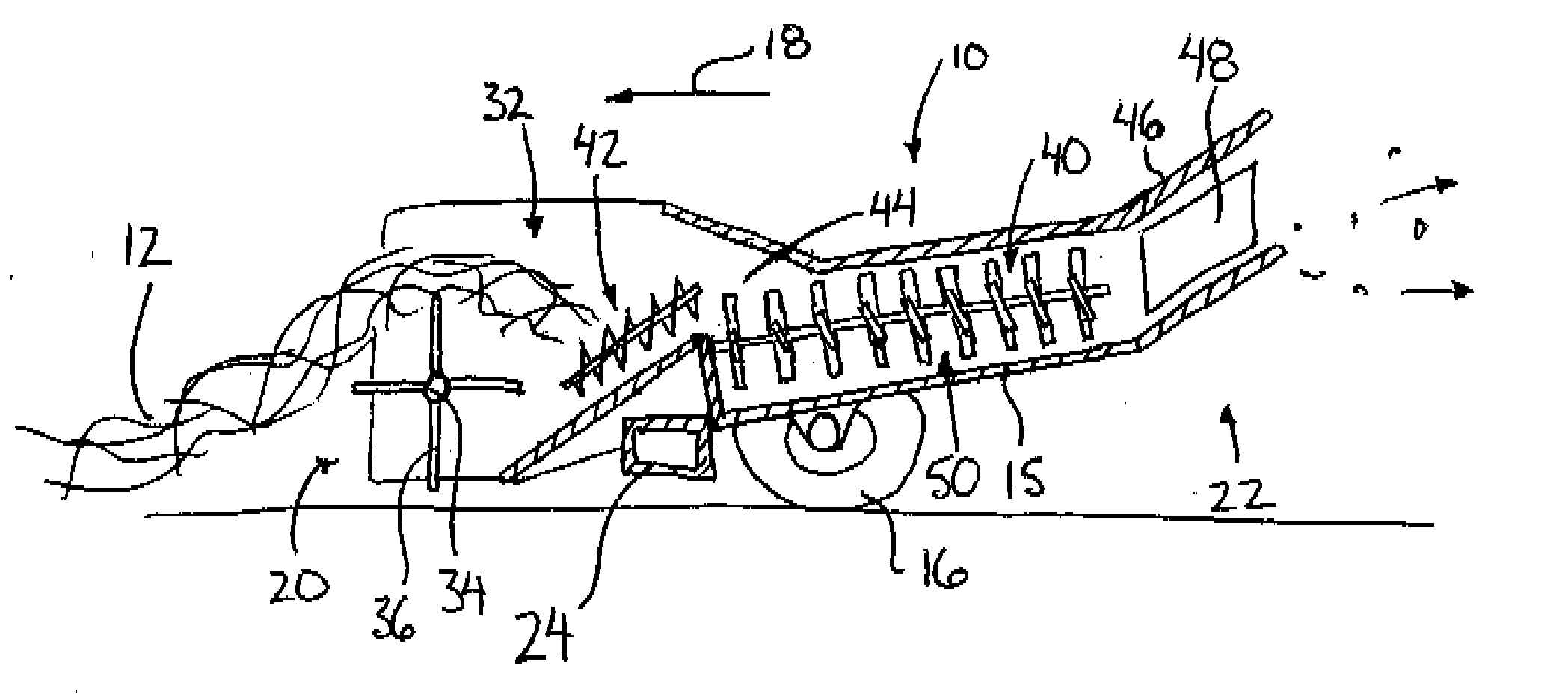

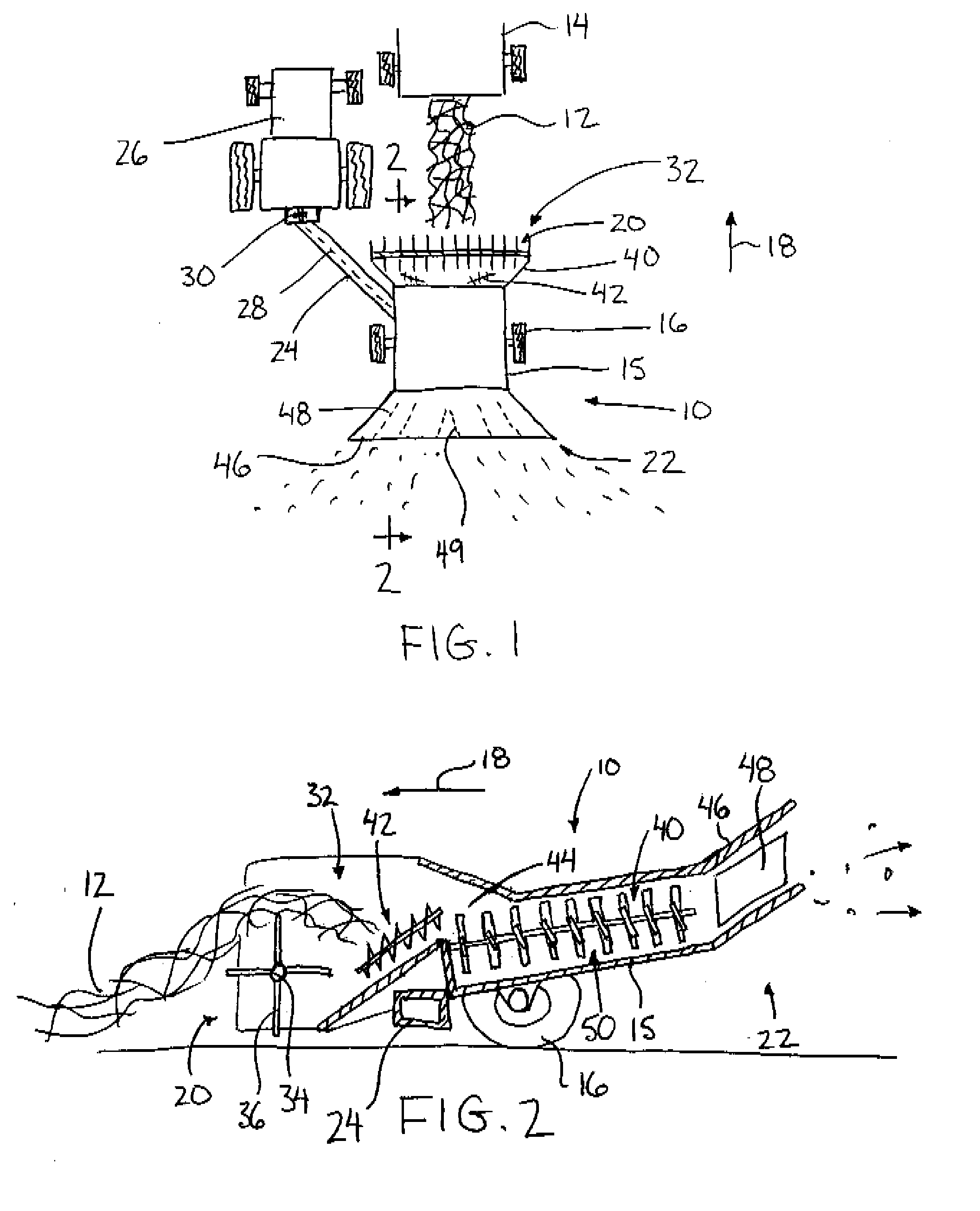

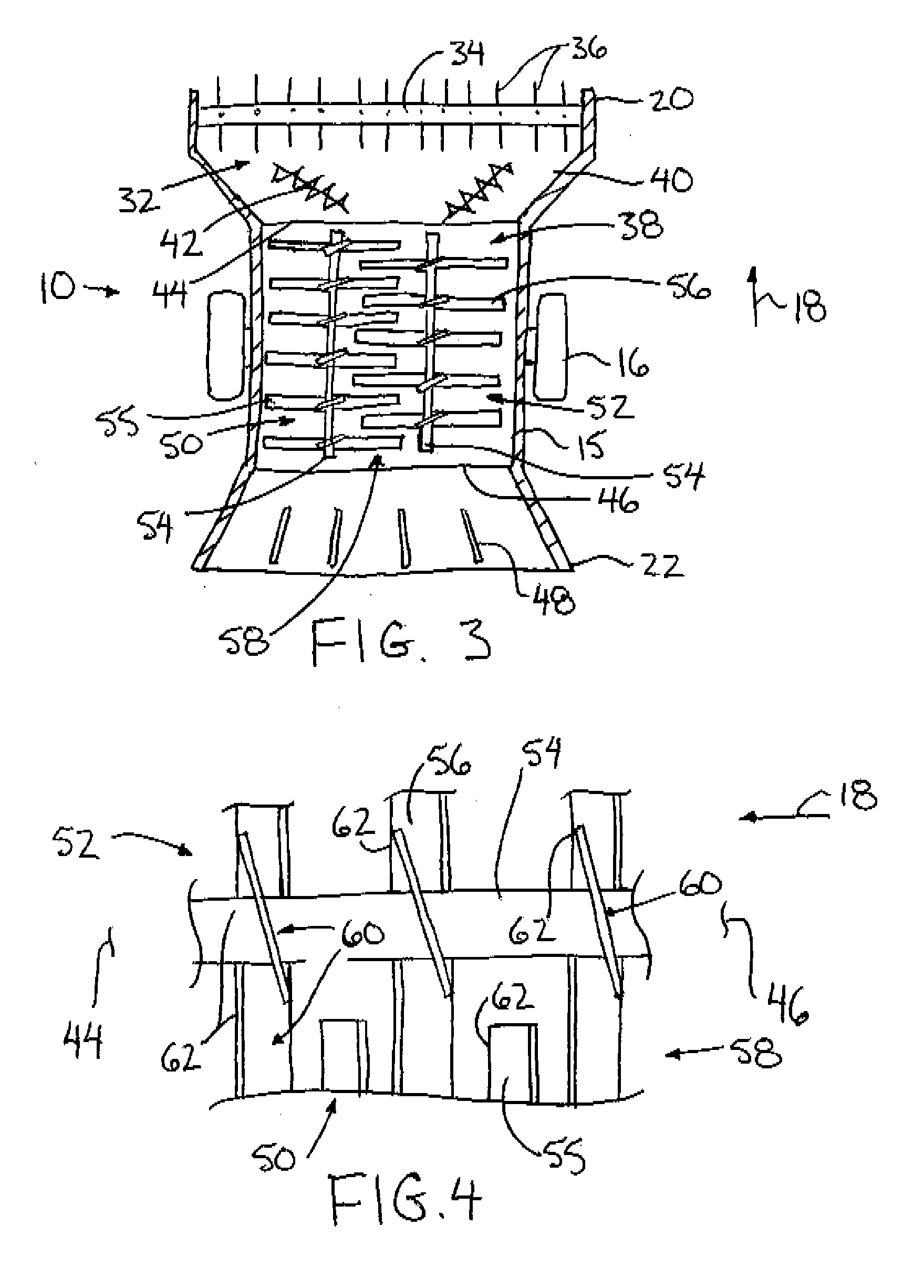

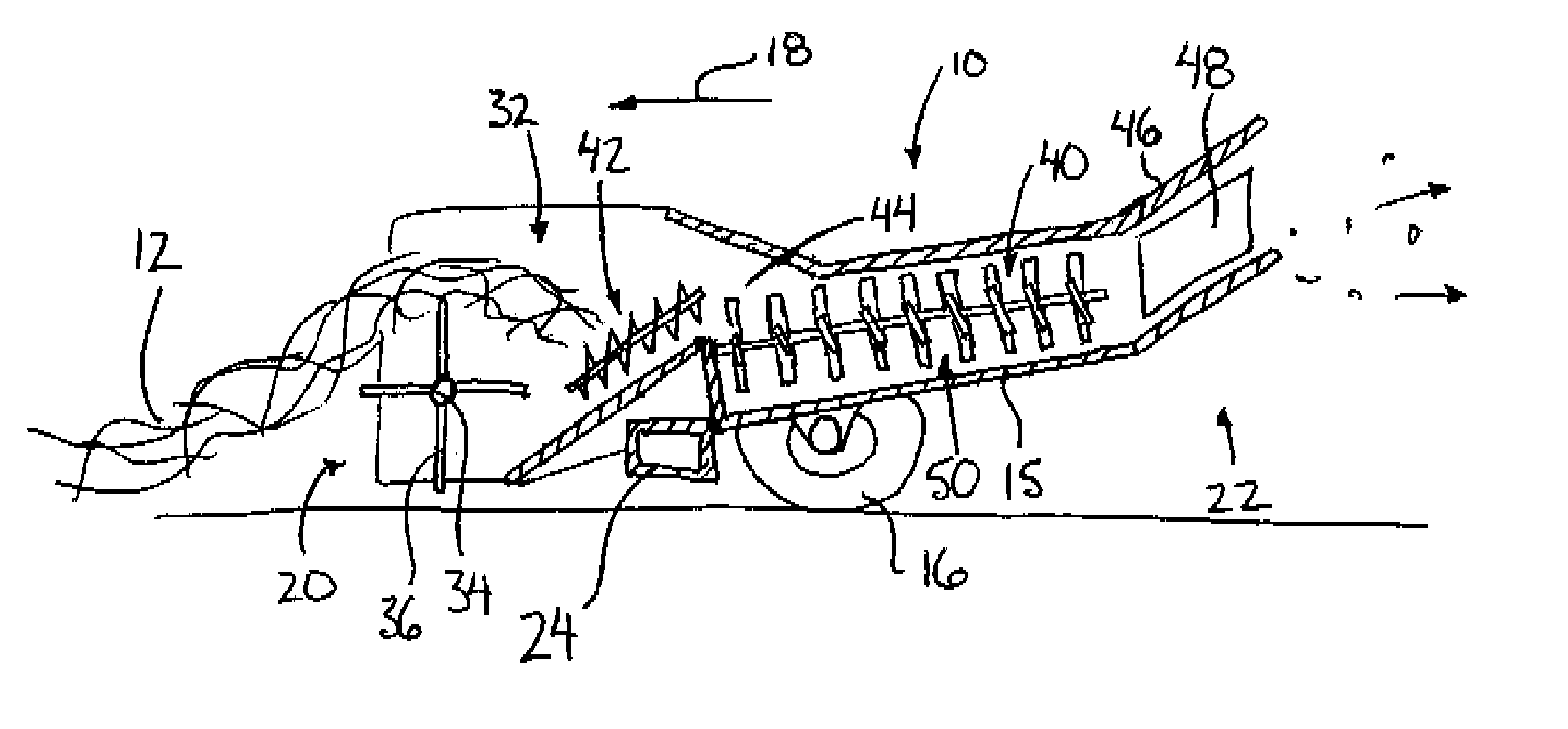

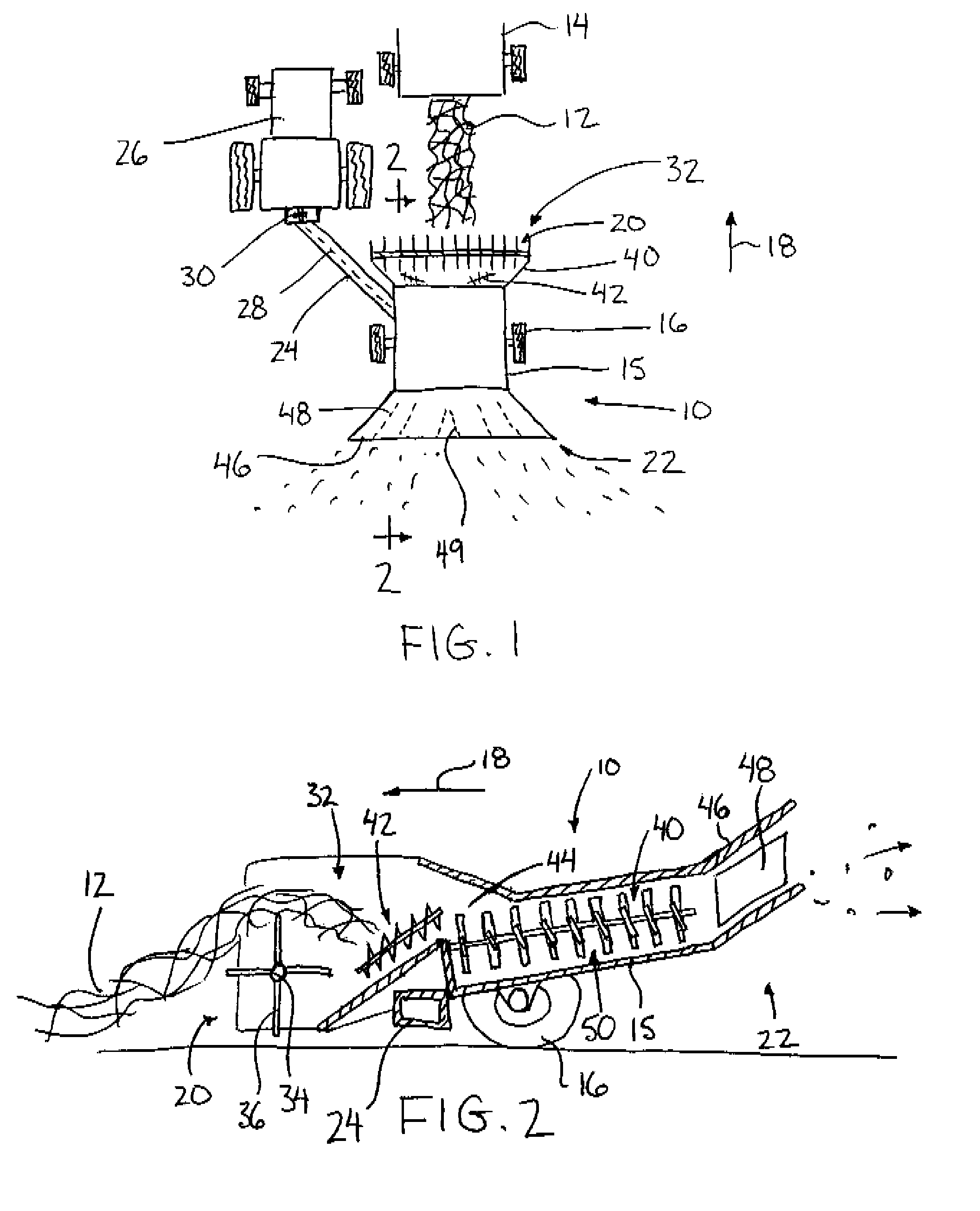

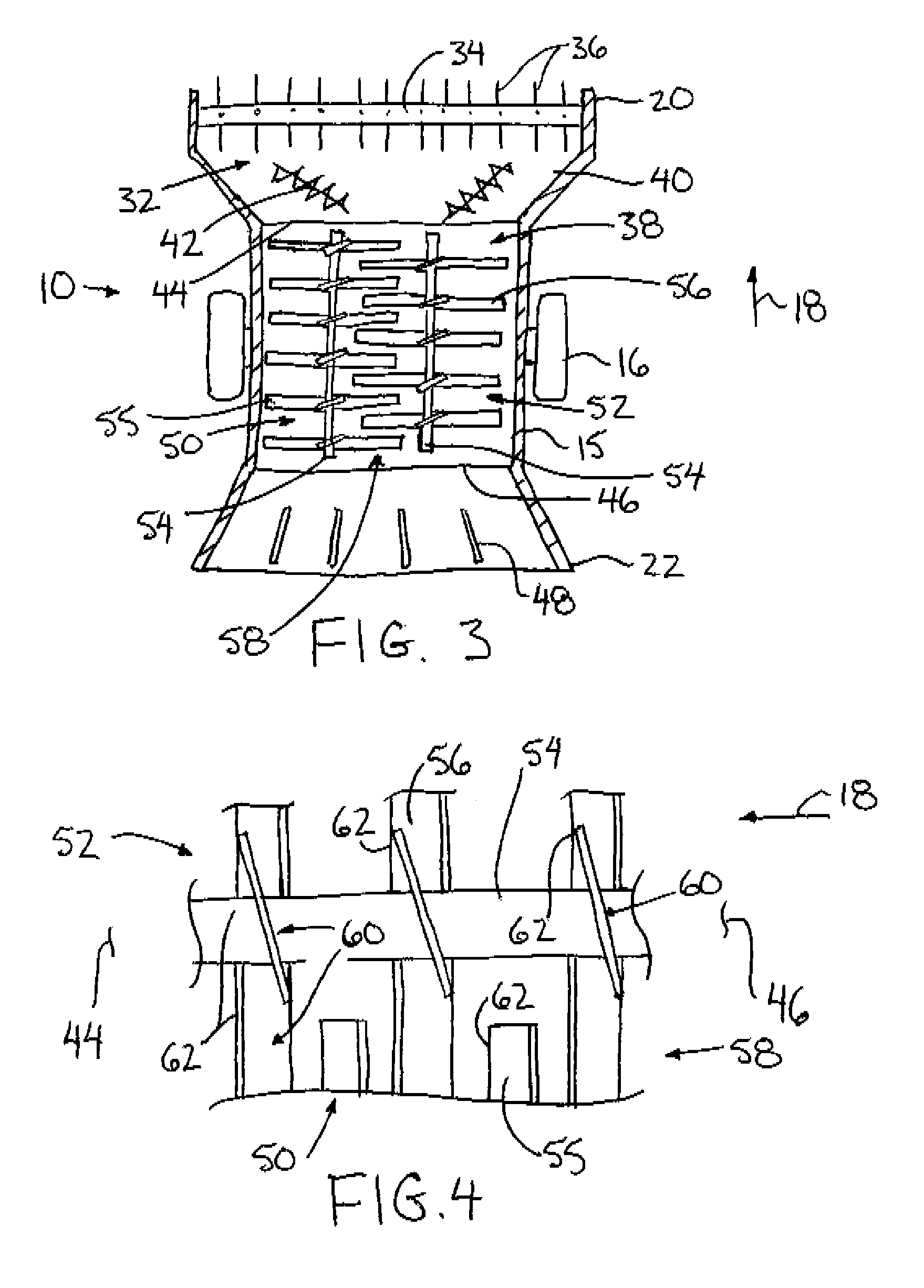

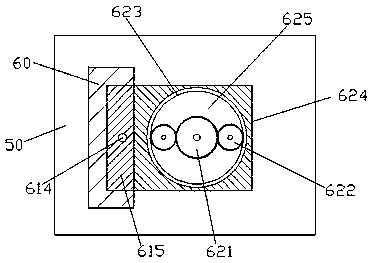

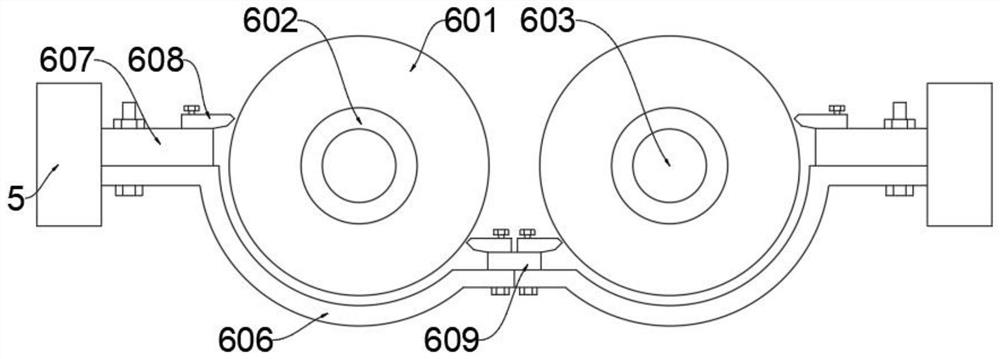

Straw Chopper

InactiveUS20080064457A1Add dimensionIncreasing the rearward thrust of airSolid waste disposalMowersImpellerEngineering

A straw chopper includes a pair of shafts supported in a chopping chamber for rotation about respective longitudinal axes extending generally in a forward working direction of the chopper. Chopping blades are supported on each shaft, offset in a direction of the longitudinal axes in relation to the chopping blades of the other shaft so that the shafts can be positioned with a sweep area of the blades overlapping one another. The shafts are rotated in a common direction of rotation such that the blades of one of the shafts are displaced in an opposite direction to the blades of the other one of the shafts at the overlap of the sweep areas. Each chopping blade includes an impeller surface sloped forwardly into a direction of rotation so as to generate a rearward thrust of air in the chopping chamber in the longitudinal direction of the axes from the inlet to the outlet of the chamber as the shafts are rotated.

Owner:LAMONT JOHN S

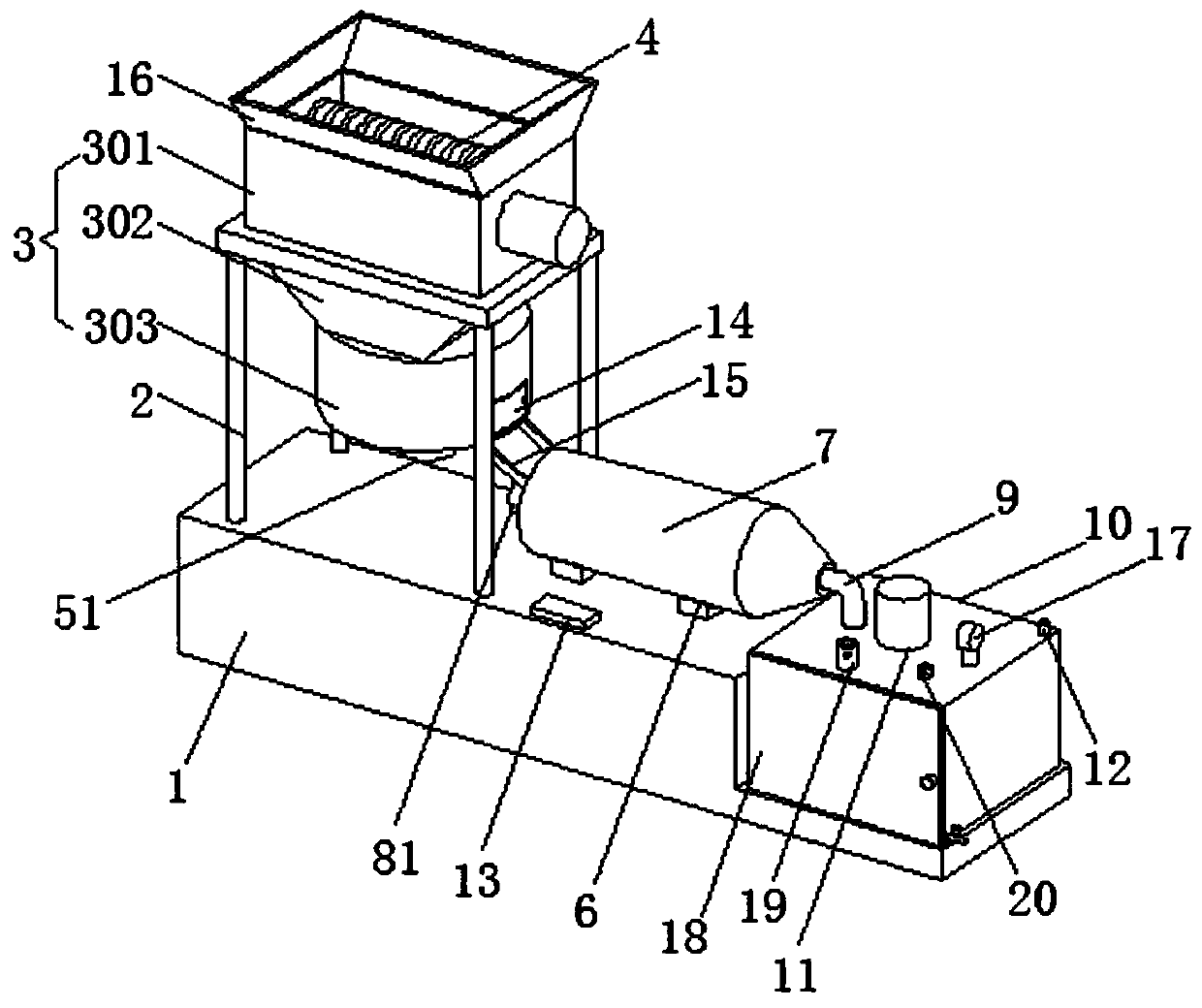

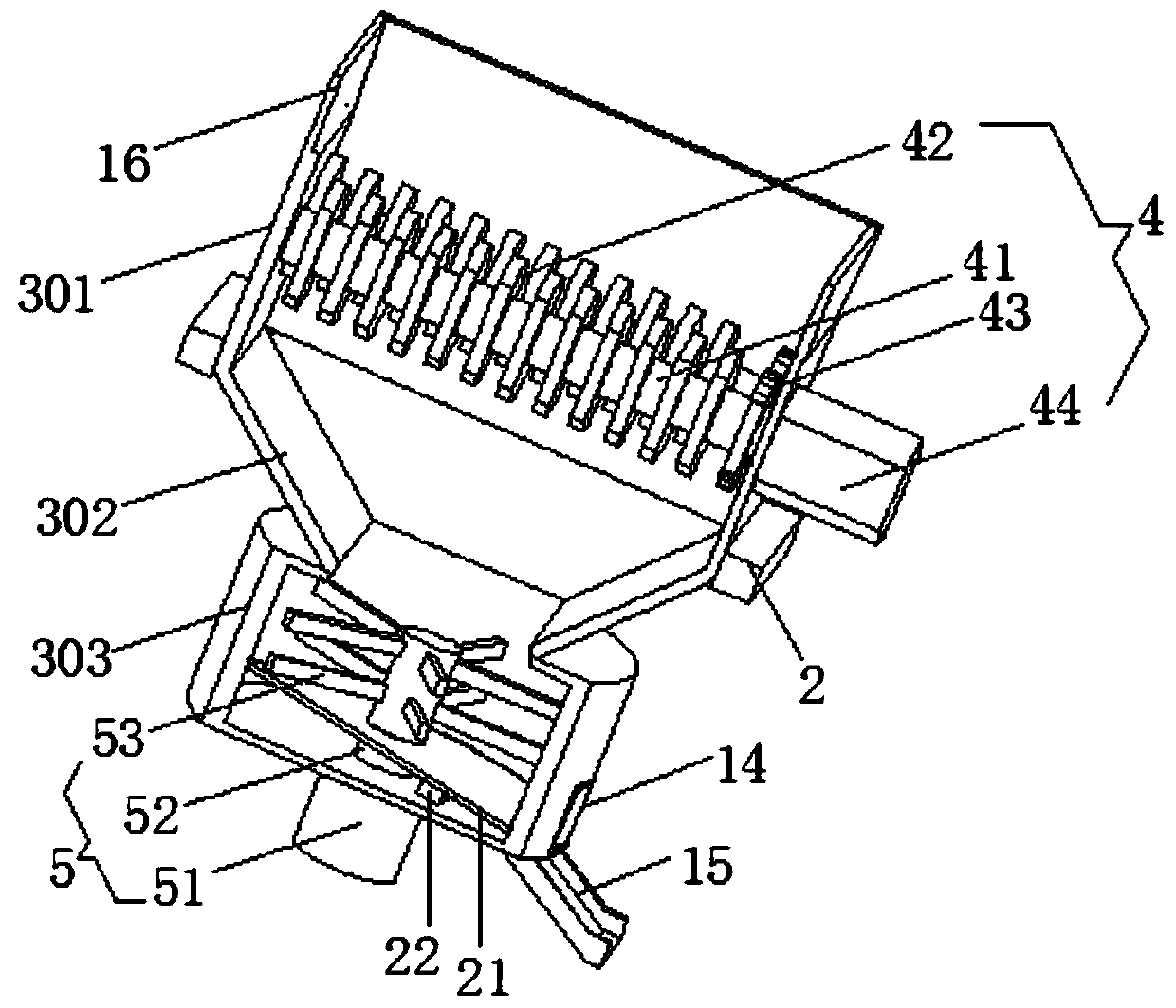

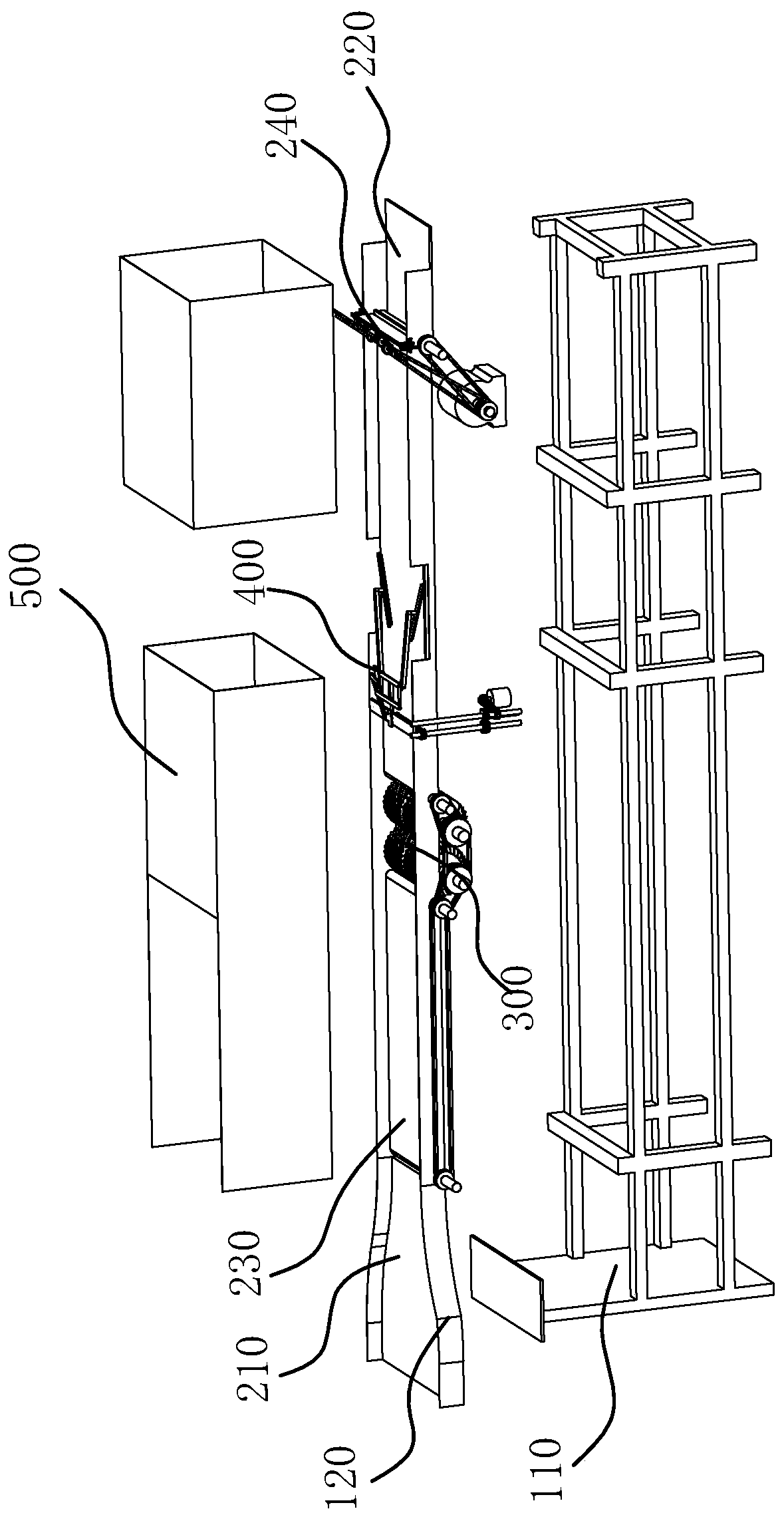

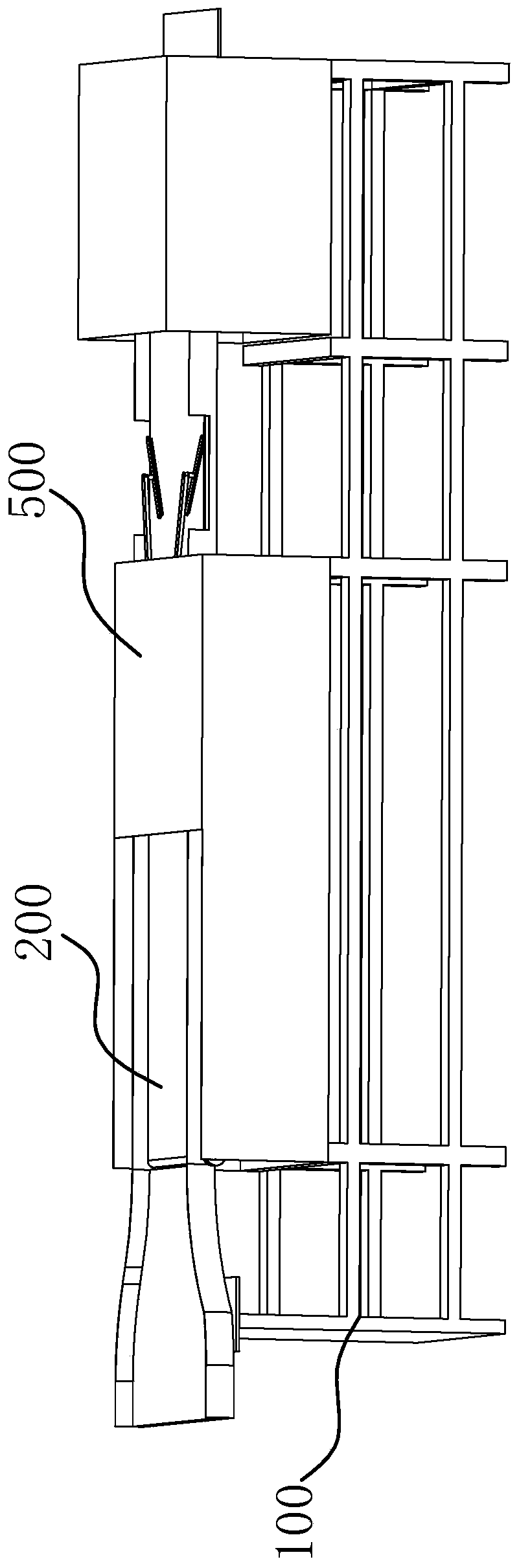

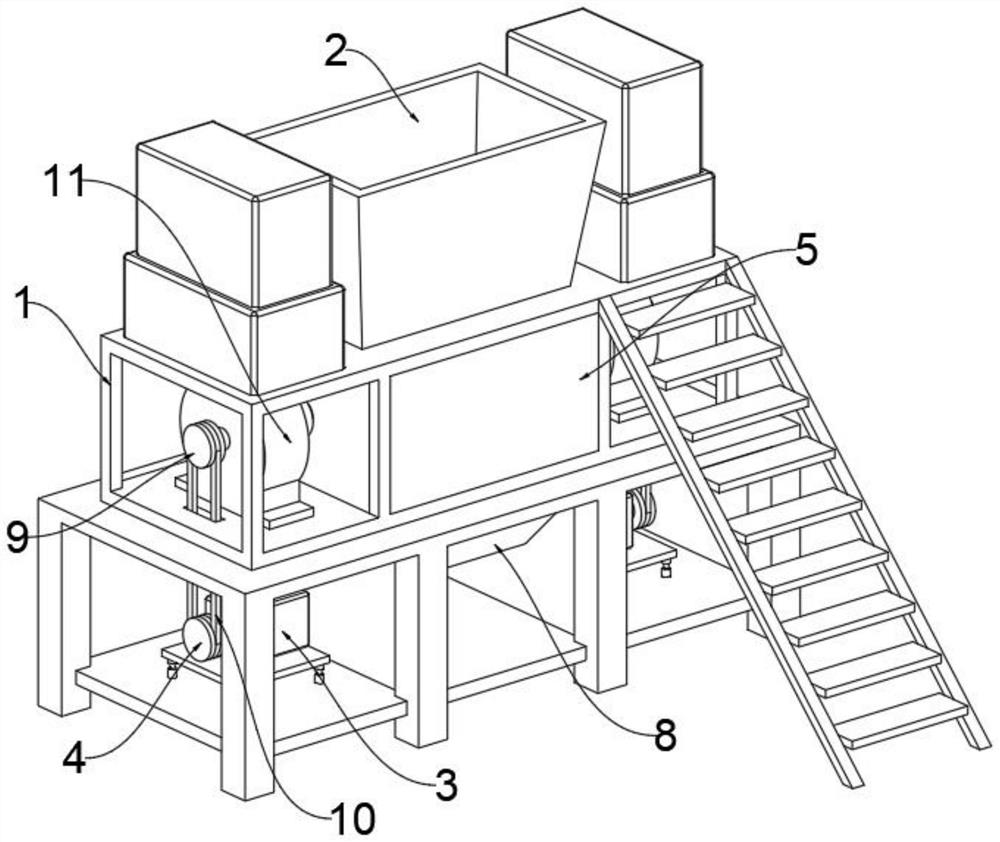

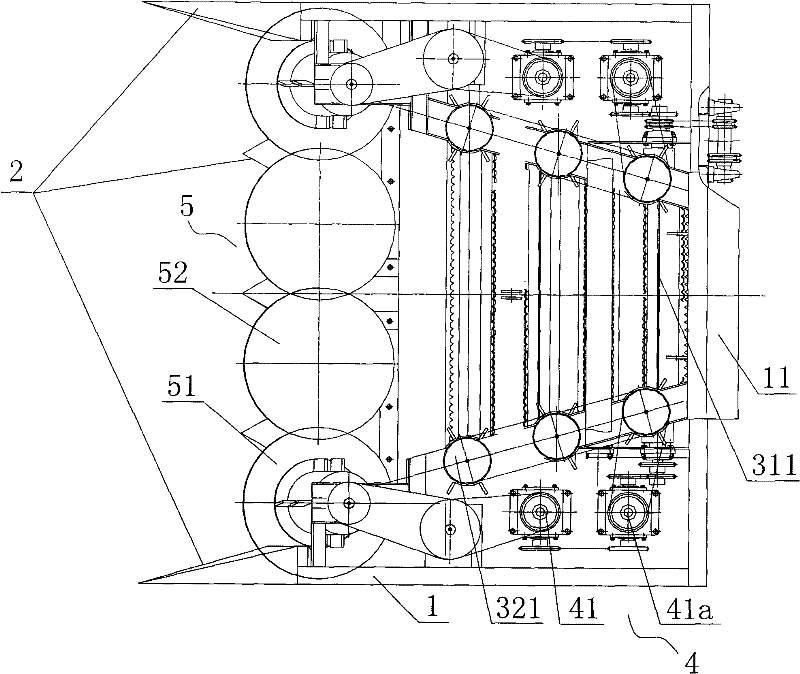

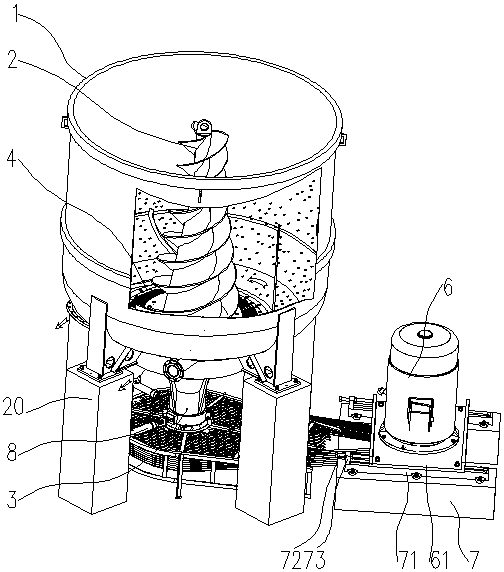

Harmless comprehensive utilization treatment device for field wastes

InactiveCN110326435AMake sure to smashEnsure a virtuous circle and sustainable developmentCuttersHeatDiseaseEngineering

The invention discloses a harmless comprehensive utilization treatment device for field wastes. The device comprises a step platen, a crushing box, a chopping device, a crushing device, a sterilization and conveying device, a stirring mechanism and a temperature control mechanism, wherein a mounting rack is arranged on the left side of the upper end of the step platen, two symmetrically distributed supports are arranged in the middle of the upper end of the step platen, and a conveying barrel is arranged at the upper ends of the supports in a matched manner. According to the harmless comprehensive utilization treatment device for field wastes, thorough crushing of the field wastes is guaranteed through two stages of crushing, minimization of materials is realized, later sterilization and fertilization are facilitated, high-temperature sterilization and turning conveying are performed simultaneously in the conveying process, a cross infection source of diseases is cut off, proper temperature for fermentation is guaranteed, biological implantation and breeding of microorganisms are accelerated, the well fermented and matched materials are returned to the field soil, organic matter and nutrients of the soil are greatly increased, the adverse factors such as soil hardening, poor tilth, excessive heavy metals and the like are solved, and virtuous cycle and sustainable development ofagriculture production are realized.

Owner:江苏艺轩园林景观工程有限公司

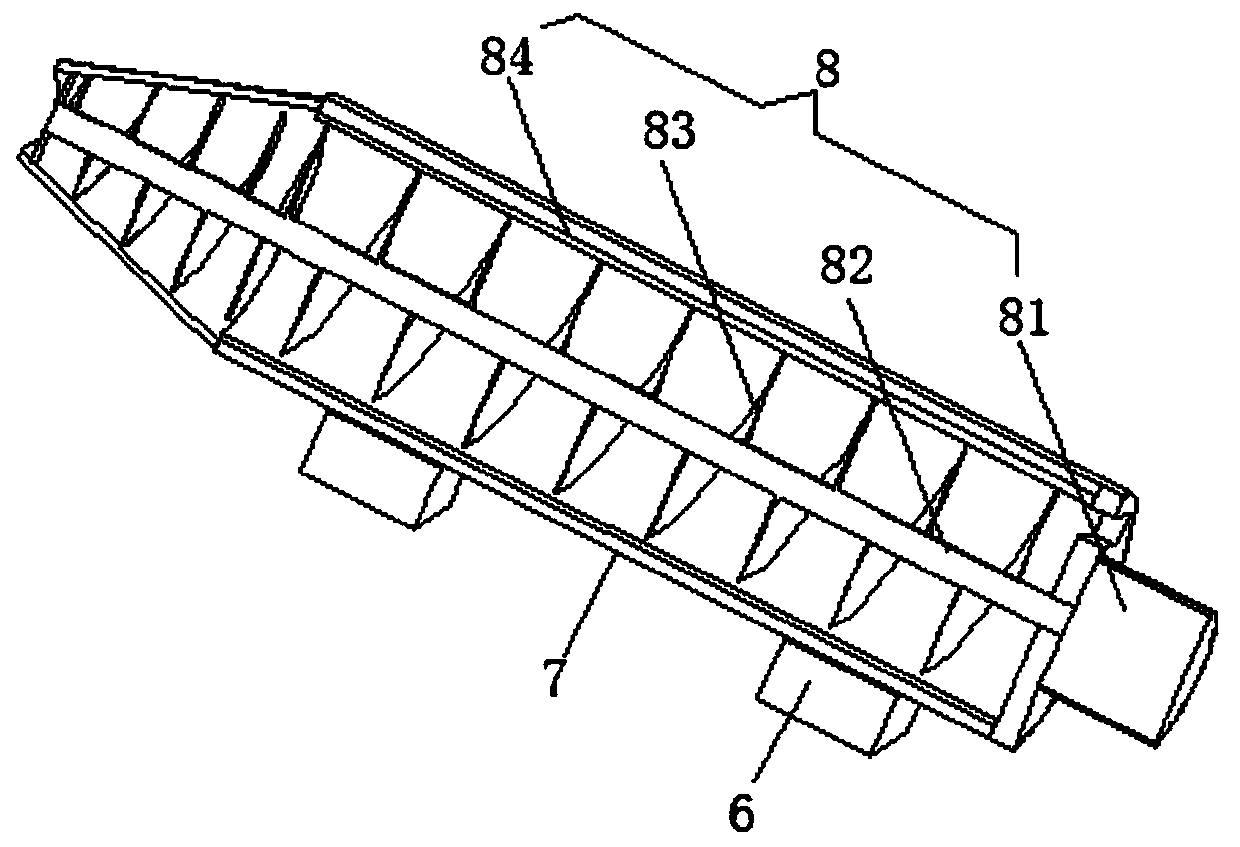

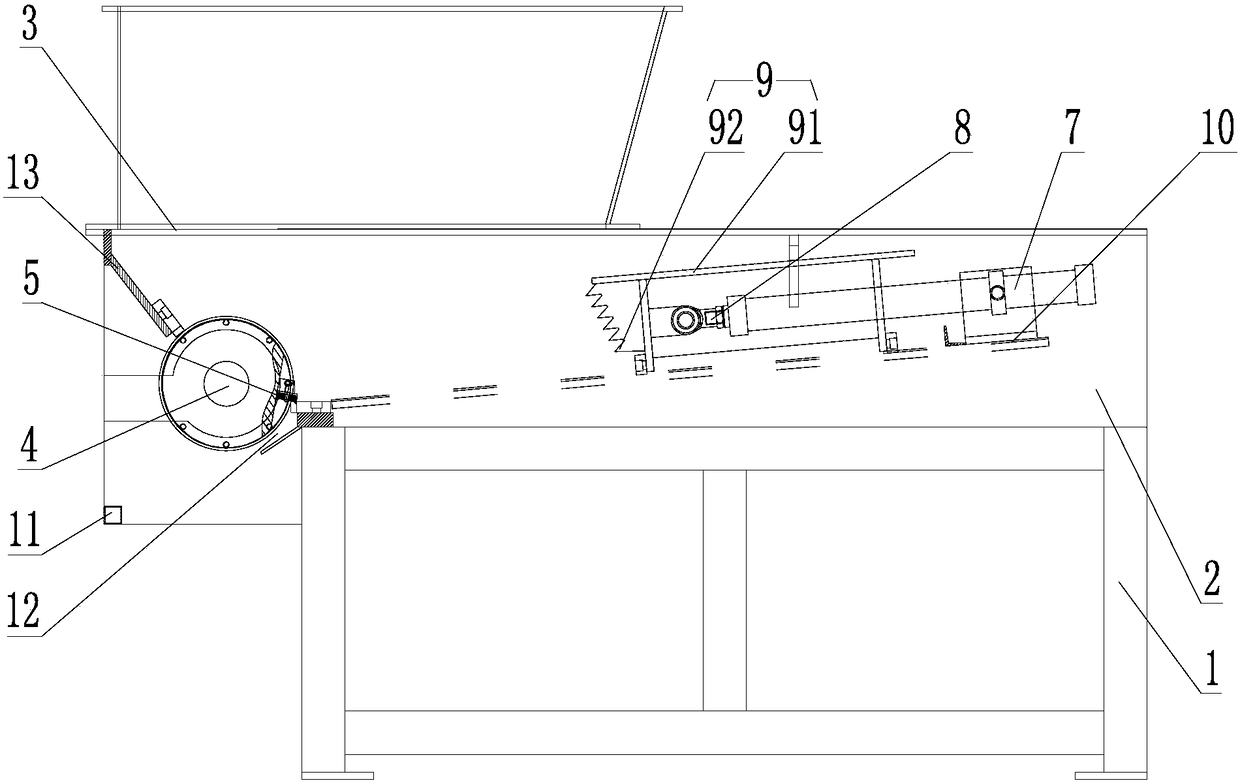

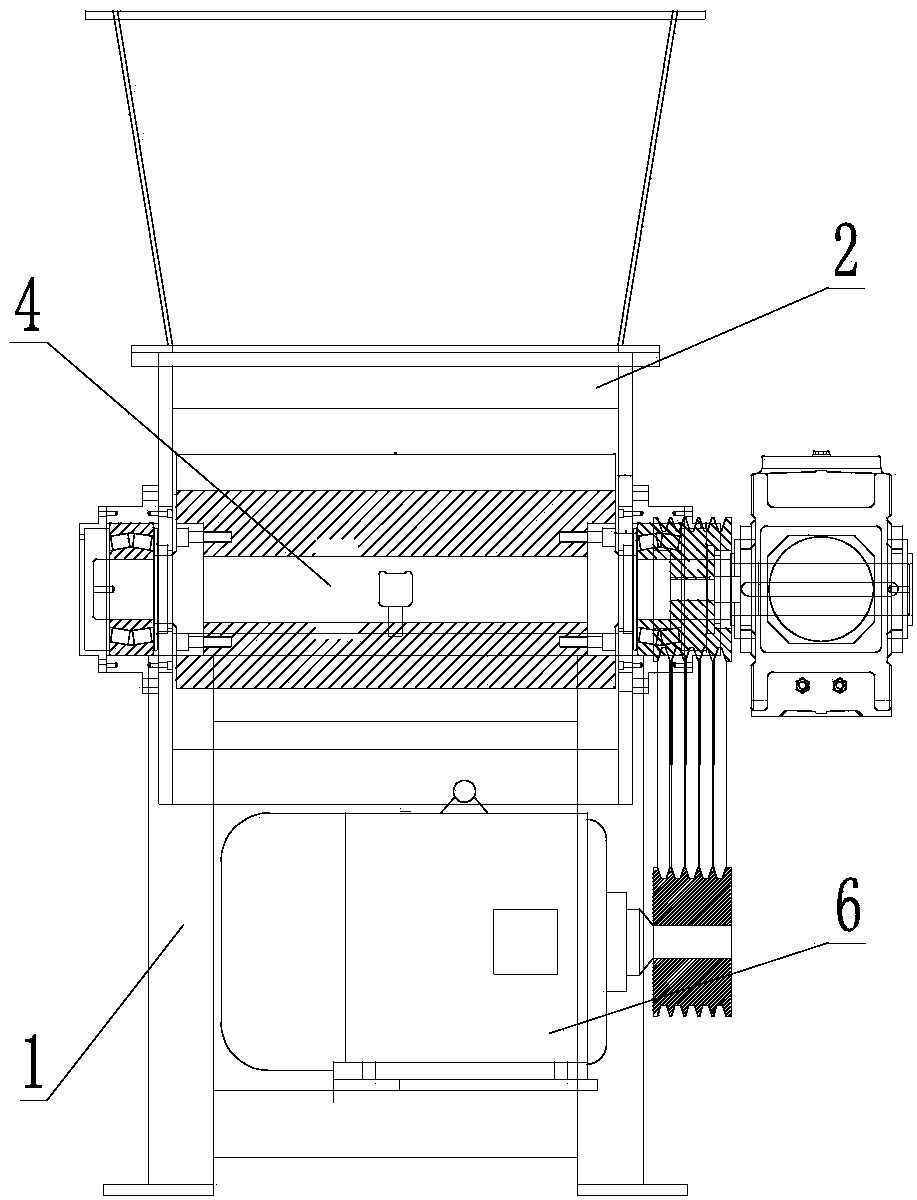

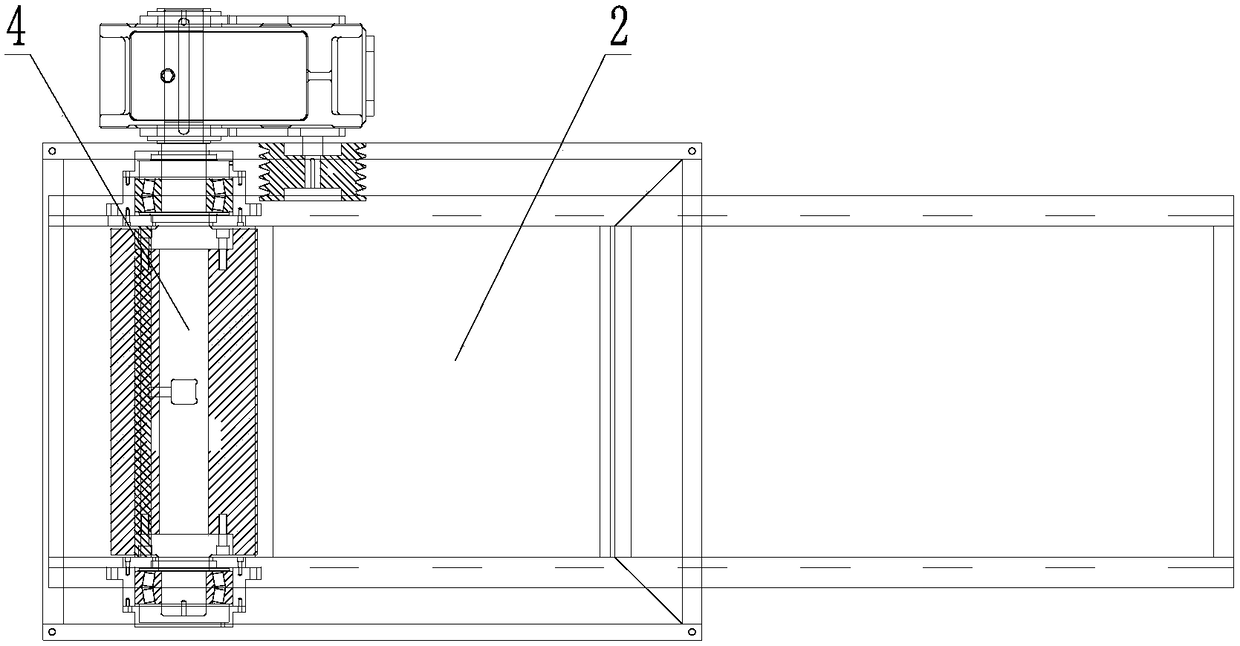

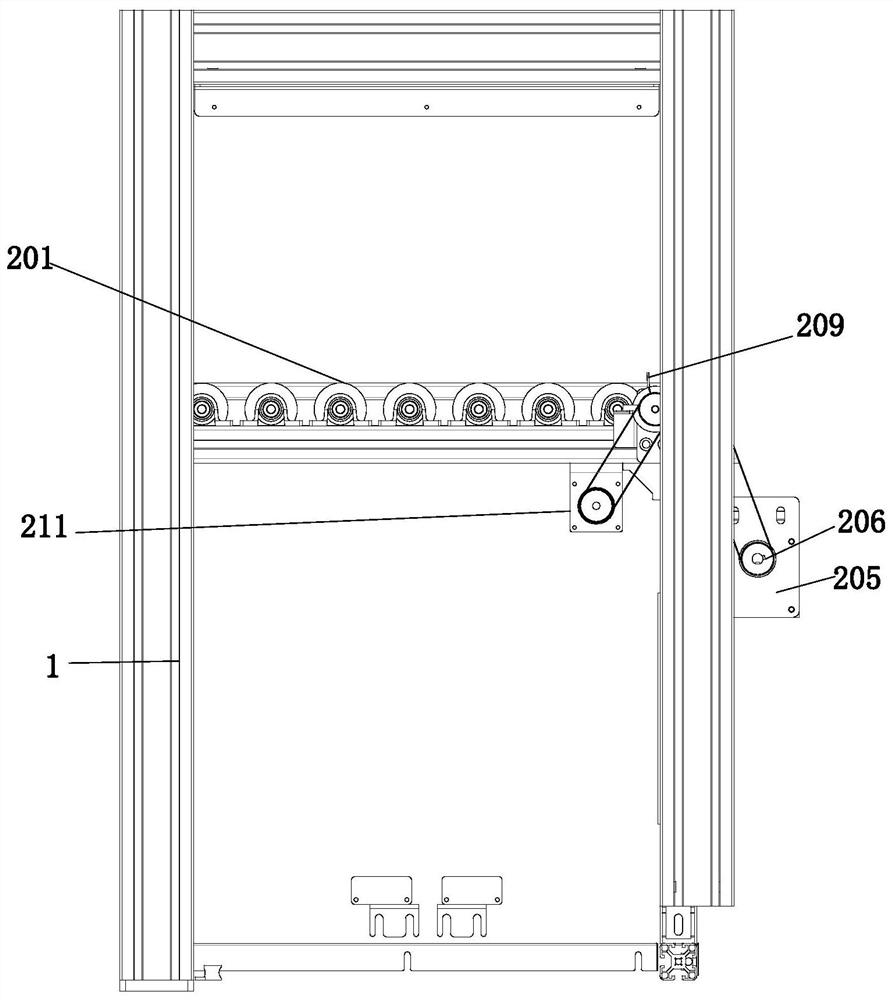

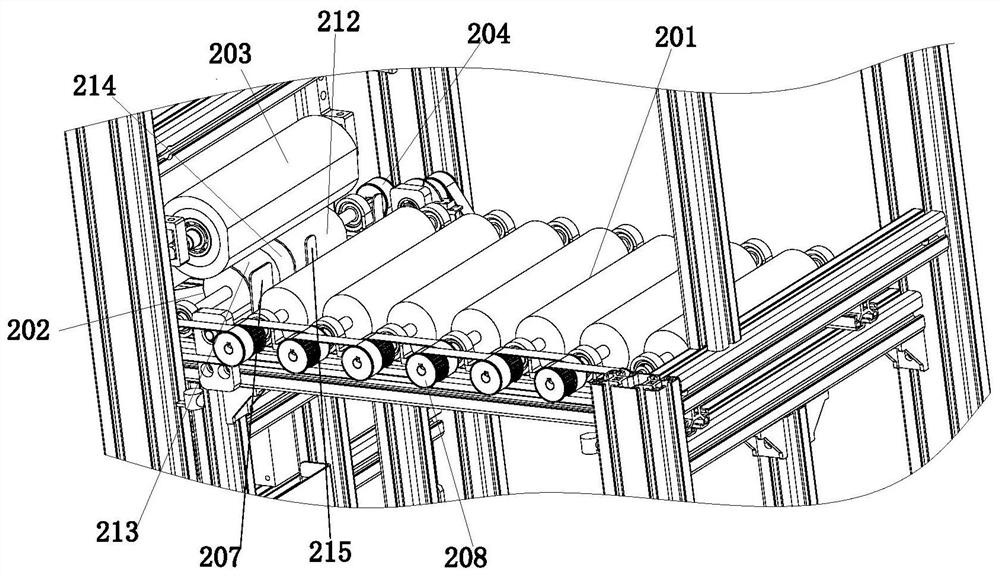

Shredding machine

PendingCN108215004AEfficient shreddingImprove shredding efficiencyPlastic recyclingGrain treatmentsEngineeringCutting force

The invention discloses a shredding machine. The shredding machine comprises a rack, a hollow cavity, a feeding inlet, a roller shaft, a cutter, a driving mechanism and a pushing mechanism, wherein the hollow cavity is formed in the rack; the feeding inlet is formed in the hollow cavity; the roller shaft is rotationally arranged in the hollow cavity around a self central axis direction; the cutteris arranged at the circumferential part of the outer side of the roller shaft; the driving mechanism is used for driving the roller shaft to rotate; the pushing mechanism is arranged in the hollow cavity along a direction which is close to or far away from the roller shaft in a sliding way, and is used for pushing materials to the roller shaft. According to the shredding machine disclosed by theinvention, the cutter is arranged on the roller shaft, the materials can be pushed to the roller shaft through the pushing mechanism, the materials can be effectively shredded by matching a pushing force generated by the pushing mechanism on the materials and a rotary cutting force of the cutter on the roller shaft, the shredding efficiency is higher, and a shredding effect is better.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

Straw chopper

InactiveUS7740198B2Add dimensionIncreasing the rearward thrust of airSolid waste disposalMowersImpellerEngineering

Owner:LAMONT JOHN S

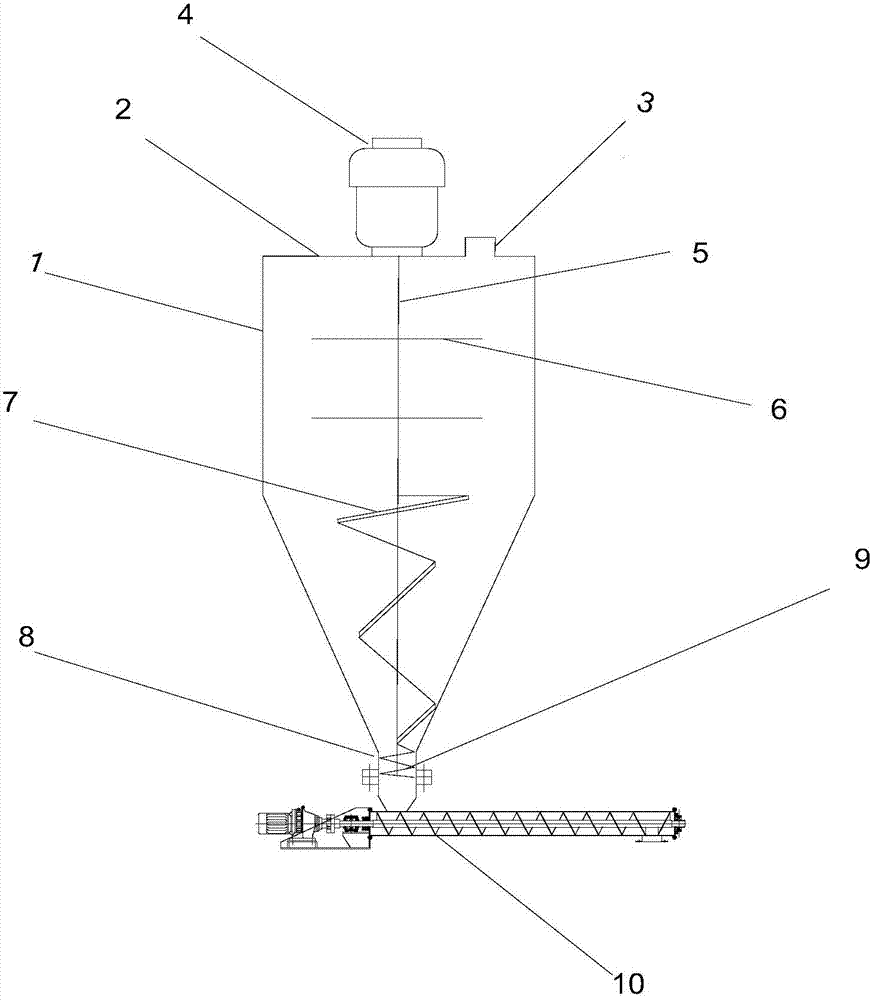

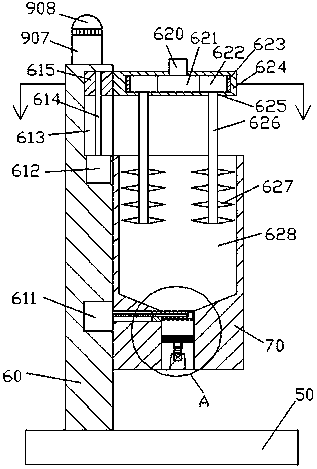

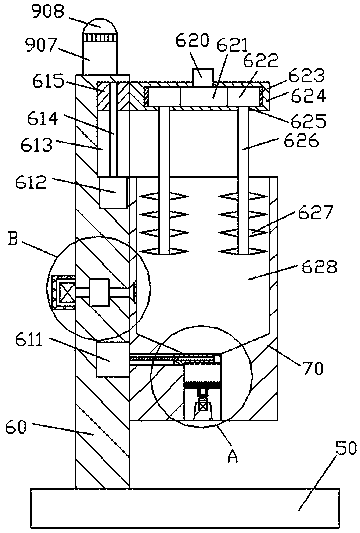

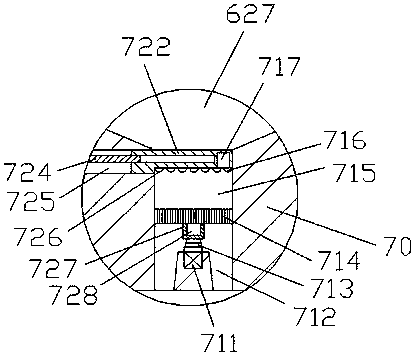

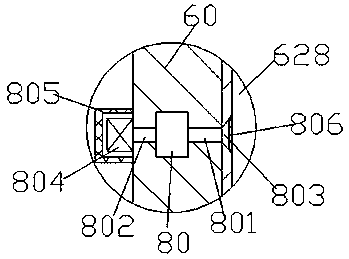

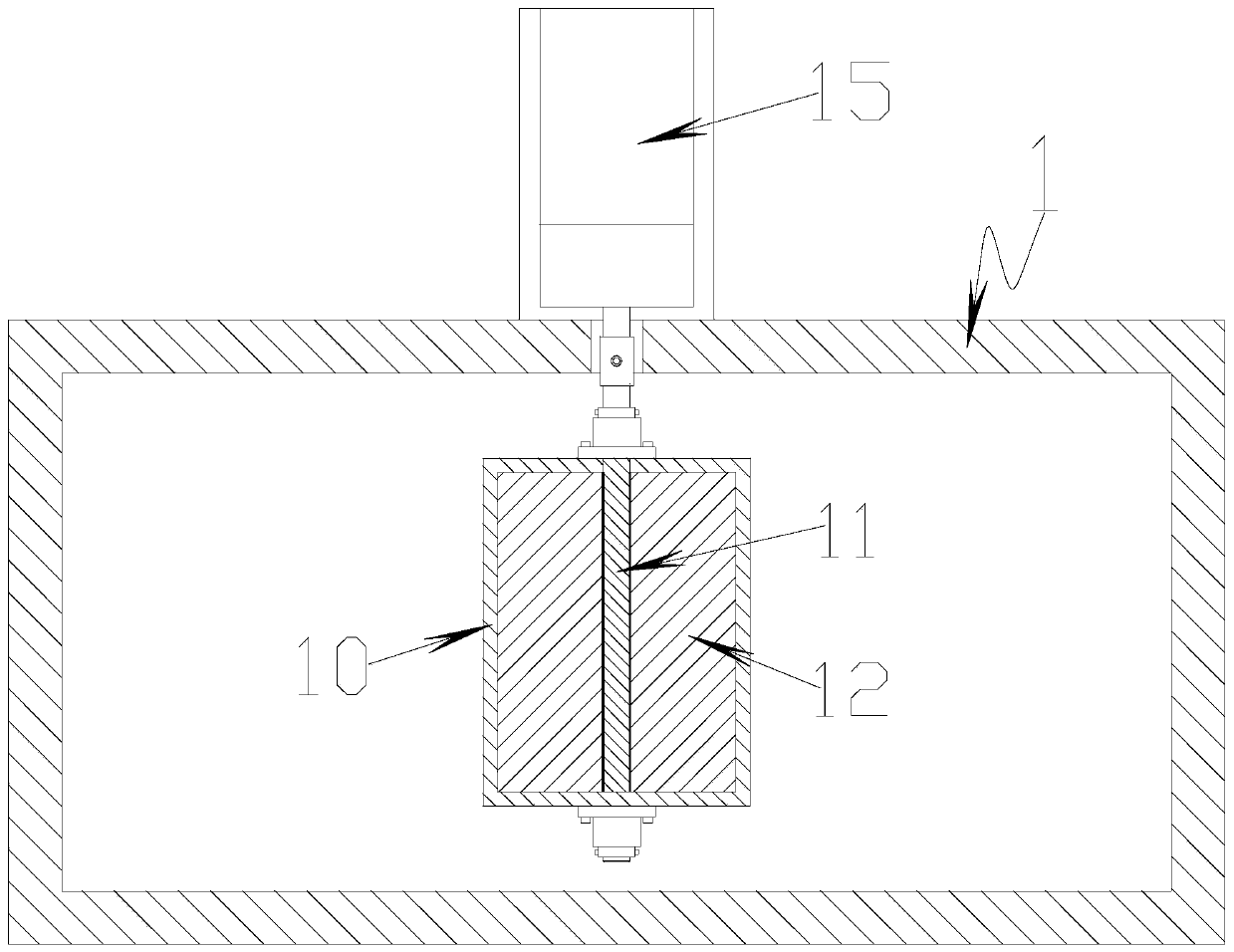

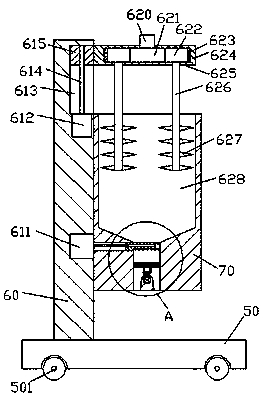

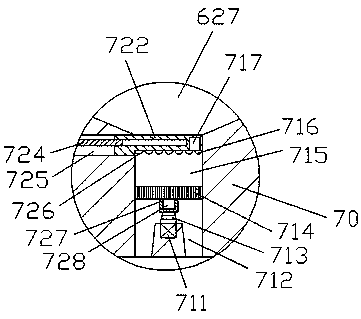

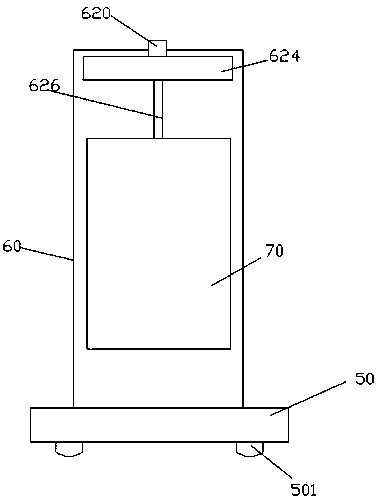

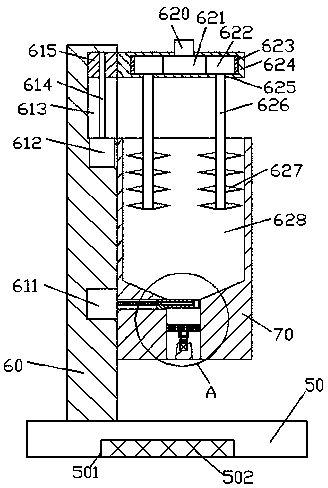

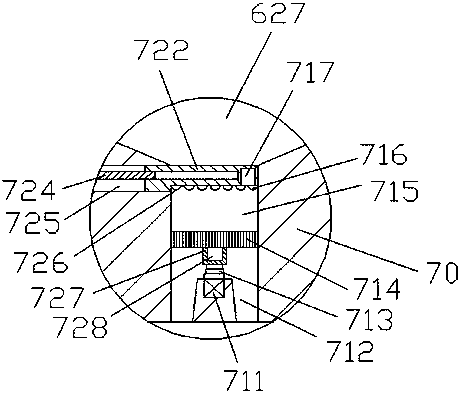

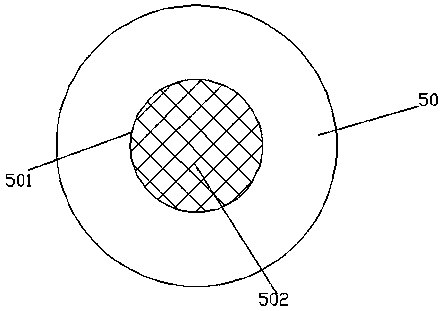

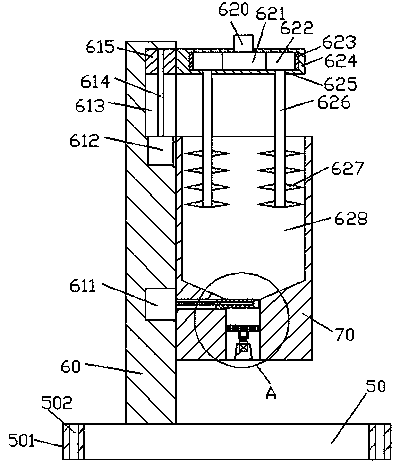

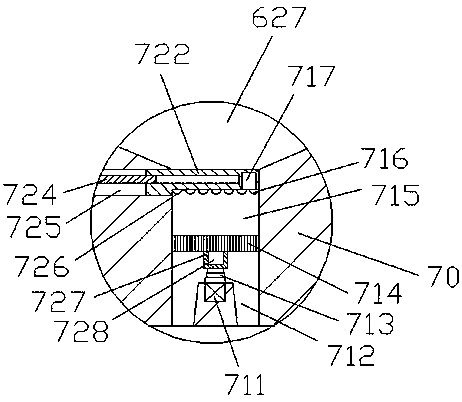

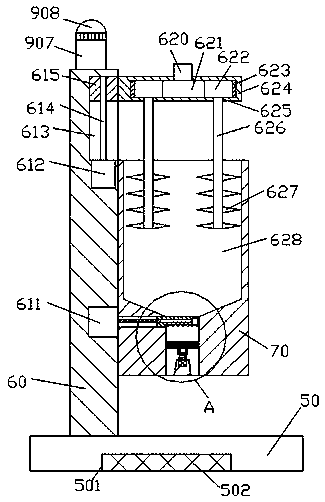

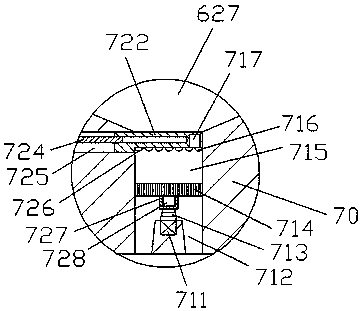

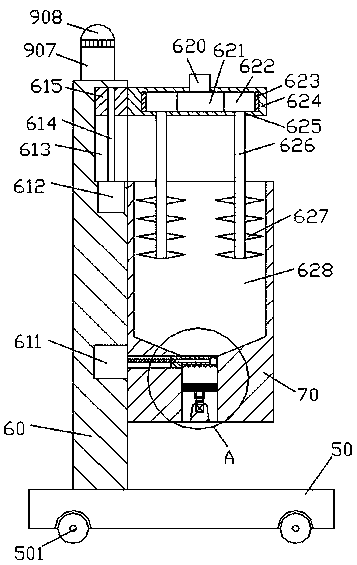

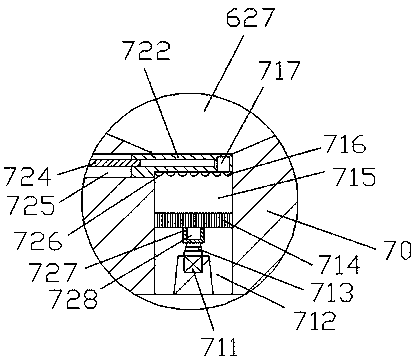

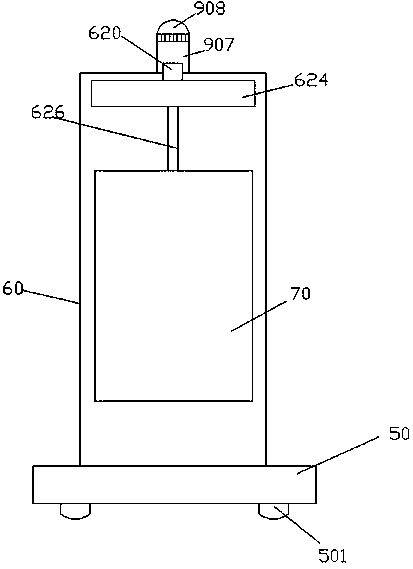

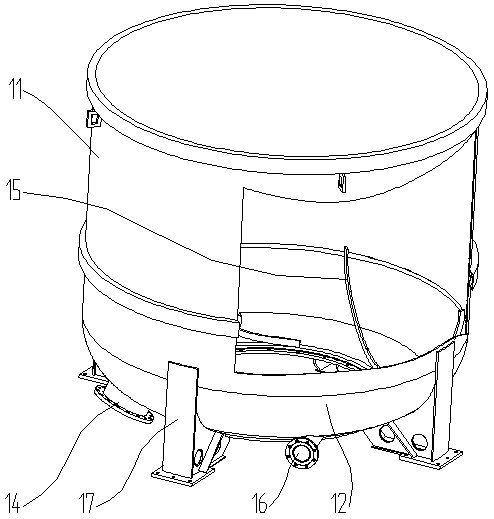

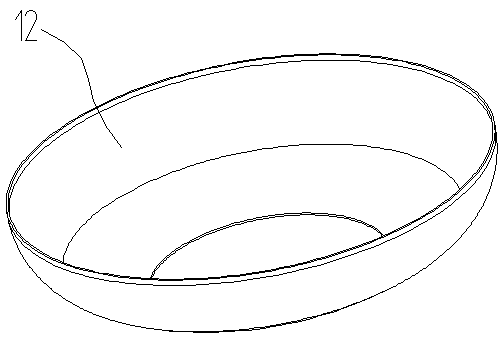

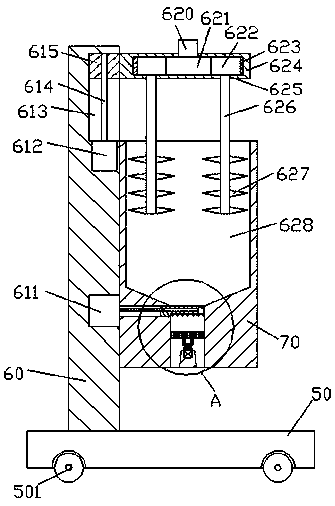

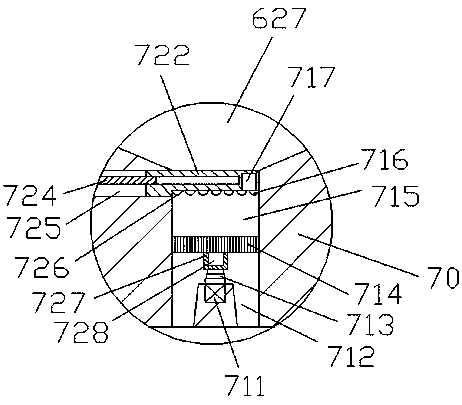

Vertical storage tank for efficient sludge scattering and ration feeding

ActiveCN103935648AGuaranteed deposit-free transportSafe storageLarge containersLoading/unloadingSludgeEngineering

The invention provides a vertical storage tank for efficient sludge scattering and ration feeding. The vertical storage tank comprises a tank body, a stirring device and a ration device. The upper portion of the vertical storage tank is designed to be round, the lower portion of the vertical storage tank is designed to be conical, and therefore non-deposition transportation of sludge can be achieved while the storage volume of the storage tank is guaranteed. A top cover is arranged on the top of the tank body, and therefore foul smell spreading during sludge processing can be effectively avoided, and clean and sanitary transportation is achieved. A combined type stirring device of a strong shear force stirrer and a cone base spiral belt type stirrer is arranged inside the storage tank, and therefore the sludge can be effectively scattered and smashed after entering the tank body through a feed port; the cone base spiral belt type stirrer is attached to the wall of the lower conical storage tank part, and therefore the sludge cannot adhere to the wall of the storage tank. A spiral part attached to the wall is installed in a discharge port of the storage tank, and therefore the high-viscosity sludge cannot block the discharge port. A closed type screw feeder is arranged at the bottom of the storage tank, and therefore ration feeding and clean transporting of the sludge can be achieved.

Owner:XI AN JIAOTONG UNIV

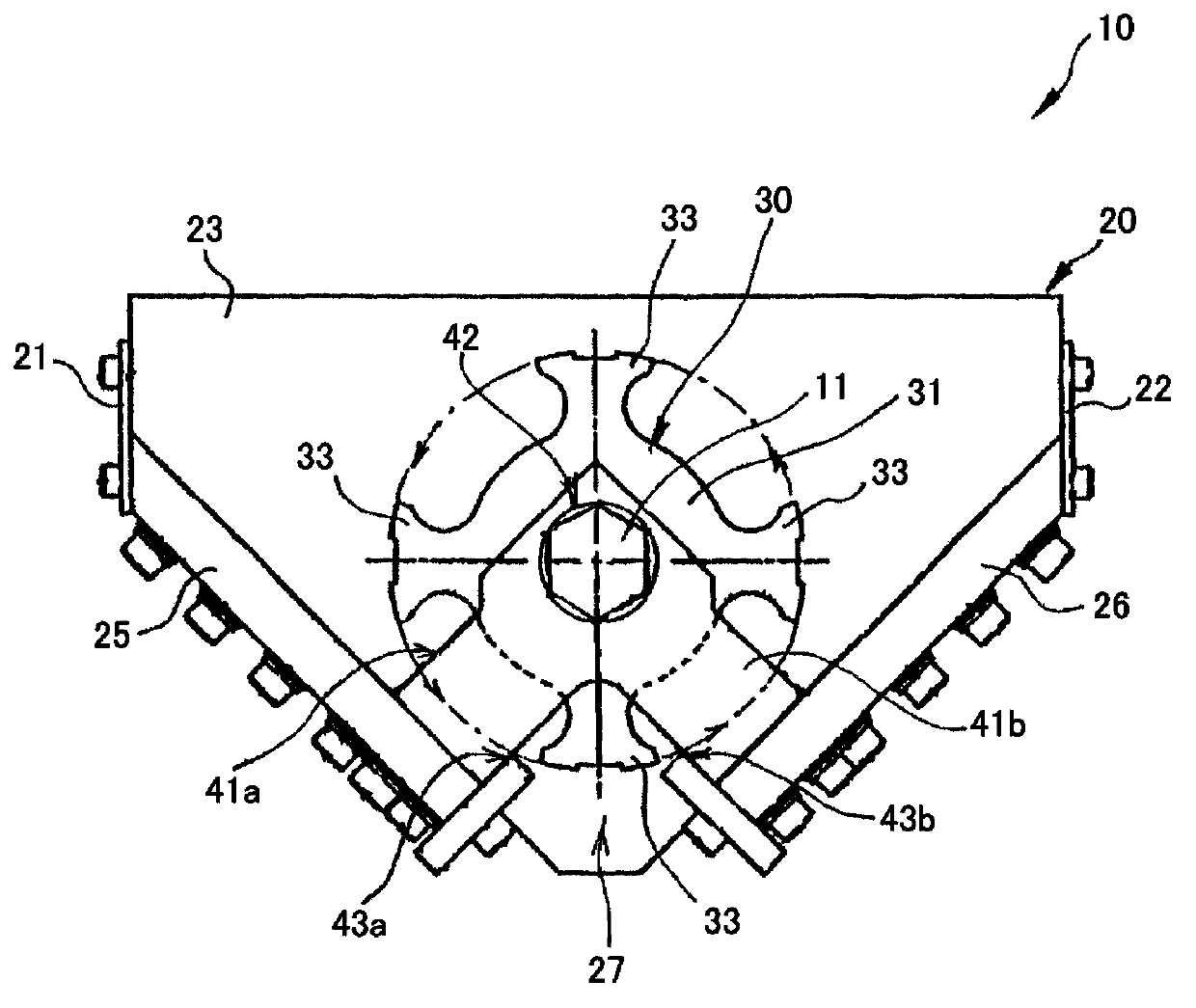

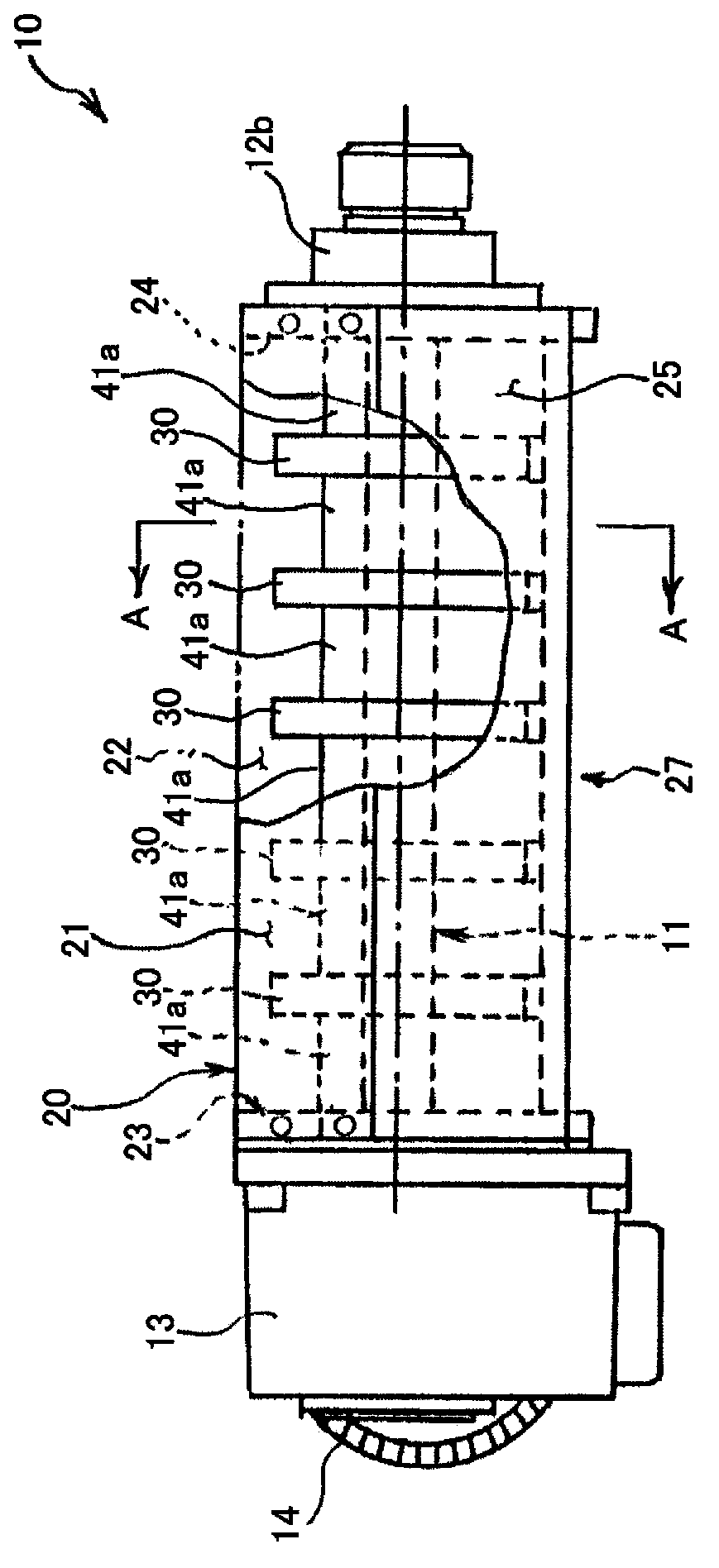

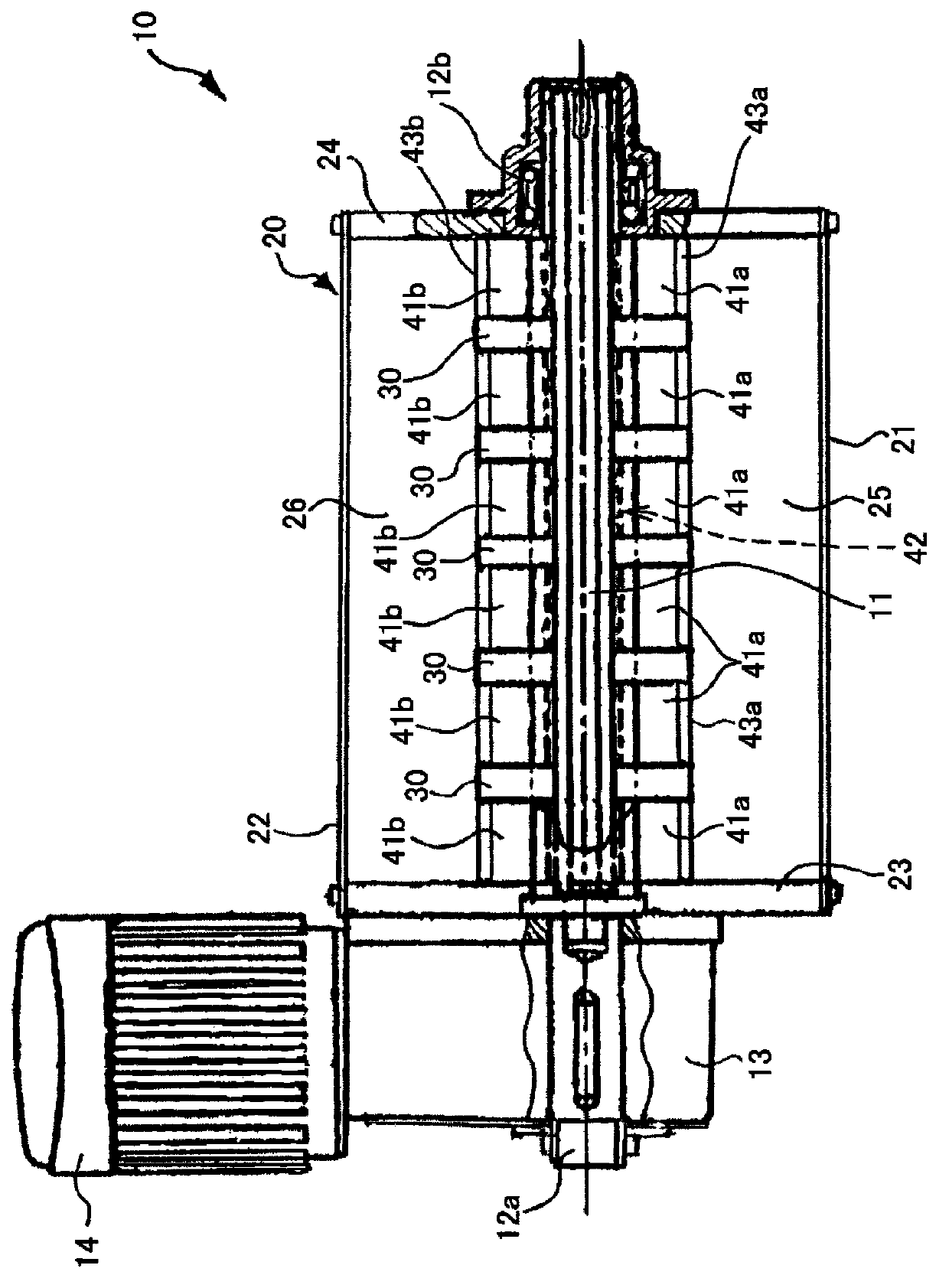

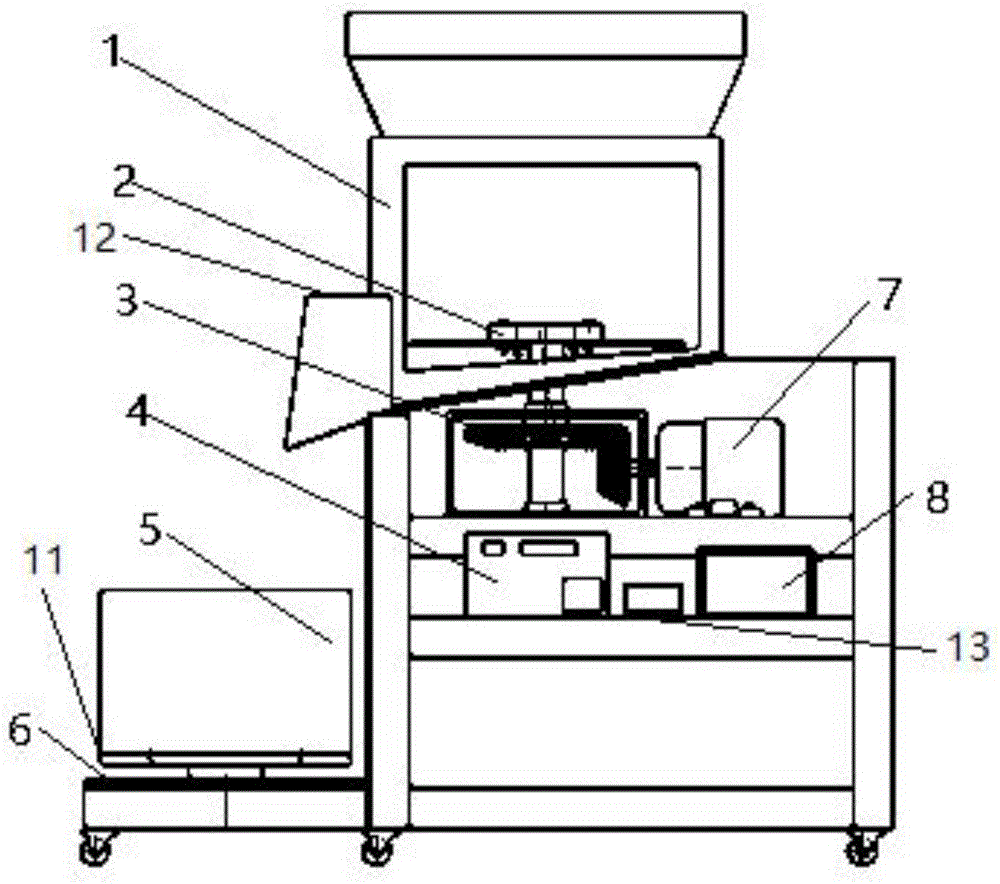

Cutting debris crushing device, cutting debris crushing blade, and cutting debris crushing data collection method

InactiveCN103657808AEfficient shreddingImprove shredding efficiencyGrain treatmentsDrive shaftEngineering

The invention provides a cutting debris crushing device which efficiently crushes long cutting debris or tangled cutting debris by making it difficult for cutting scraps to escape from a crushing blade. A cutting debris crushing device is provided with: multiple cutting debris crushing blades having base parts securely attached at an interval to a rotation drive shaft disposed within a casing that opens to the top surface, and at least one rotating blade which extends from the base parts in the outer circumferential direction; multiple first secure blades which come into contact with the side surfaces of the cutting debris crushing blades and which crush cutting debris in cooperation with the blade part on the side surface of the rotating blade of the cutting debris crushing blades and multiple second secure blades for crushing cutting debris in cooperation with the blade part on the outer circumference of the rotating blade of the cutting debris crushing blades. The rotating blade of the cutting debris crushing blades is provided with raking blades having a rake angle relative to the rotation circumferential direction, and straight blades extending in the outer circumferential direction from the rake blades.

Owner:AISIN AI CO LTD

Improved biological extracting device

InactiveCN108405098ASimple structureEasy to operateCocoaGrain treatmentsElectric machineryEngineering

The invention discloses an improved biological extracting device. The improved biological extracting device comprises a base fixedly mounted on the bottom end surface of a support base, and a machining base fixedly mounted on the right side end surface of the support base; a lifting device is arranged in the right side end surface of the support base on the upper side of the machining base; a crushing cavity is formed in the top end surface of the machining base; the bottom wall in the crushing cavity communicates with a lifting cavity; a first slide cavity penetrating out of the left side endsurface of the machining base is formed in the left side end surface of the machining base between the lifting cavity and the crushing cavity; a shielding plate is slidingly matched and mounted in the first slide cavity; a first thread rod is in threaded fit installation in the left side end surface of the shielding plate; a first motor is in power fit installation at the extension tail end of the left side of the first thread rod; the first motor is fixedly mounted in the right side end surface of the support base; an annular recess part is arranged at the right side end of the shielding plate; and multiple sets of crushing teeth are fixedly mounted on the bottom end surface of the annular recess part.

Owner:广州大正机械科技开发有限公司

Efficient self-cleaning food chopper

InactiveUS9073229B2Minimize wasteEfficient shreddingShaping utensilsMetal working apparatusMinced foodEngineering

Owner:ZARETABKY HOWARD

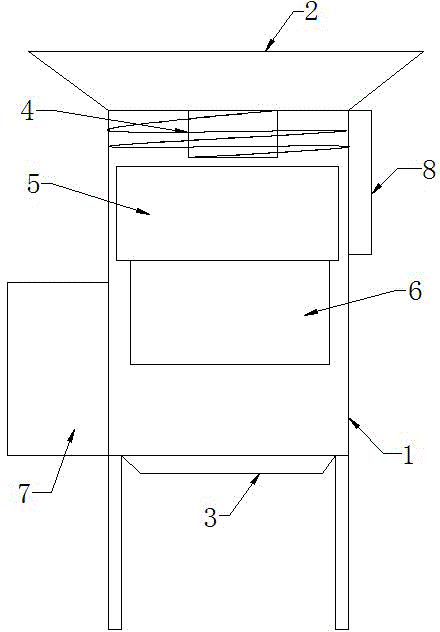

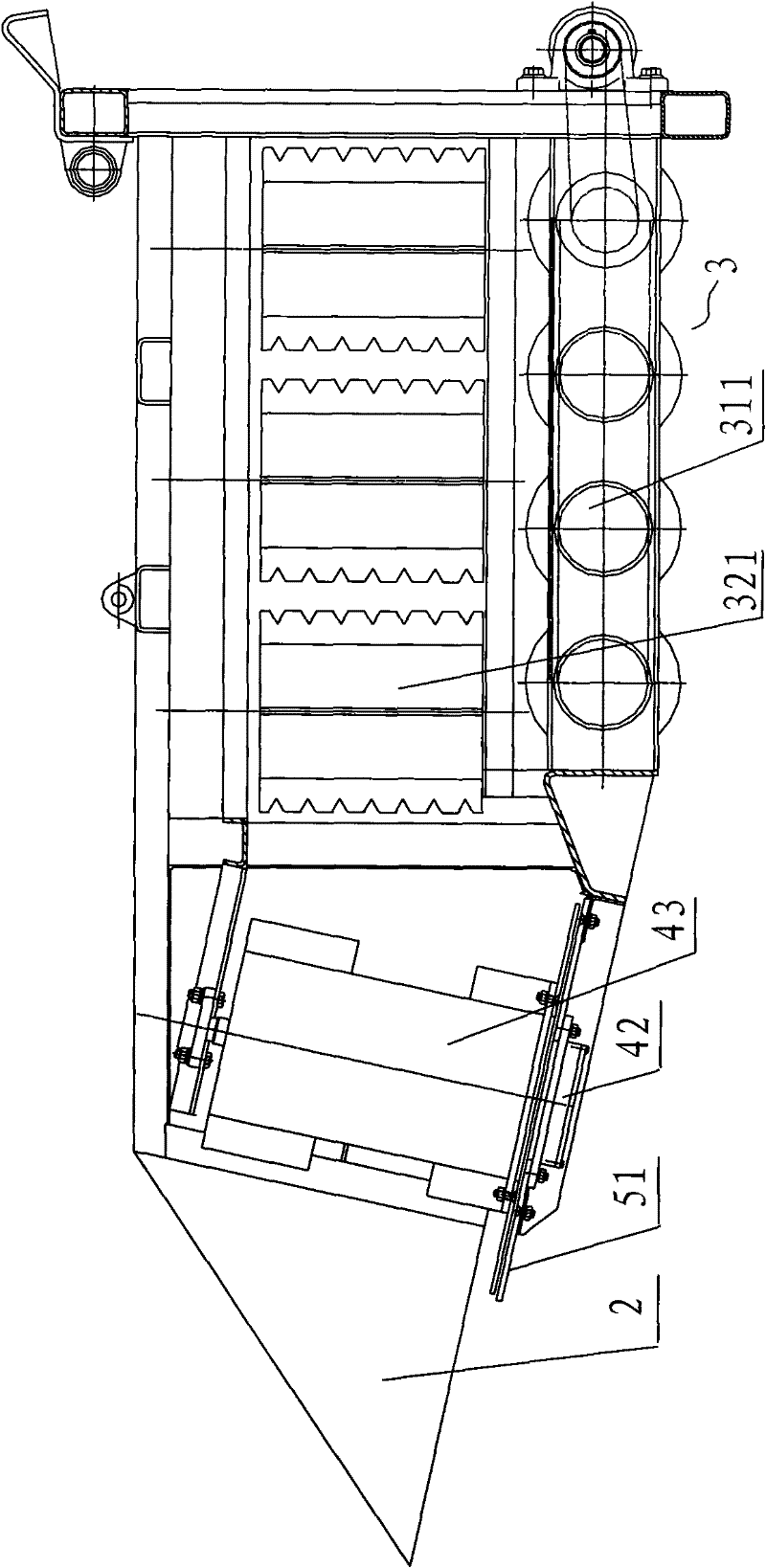

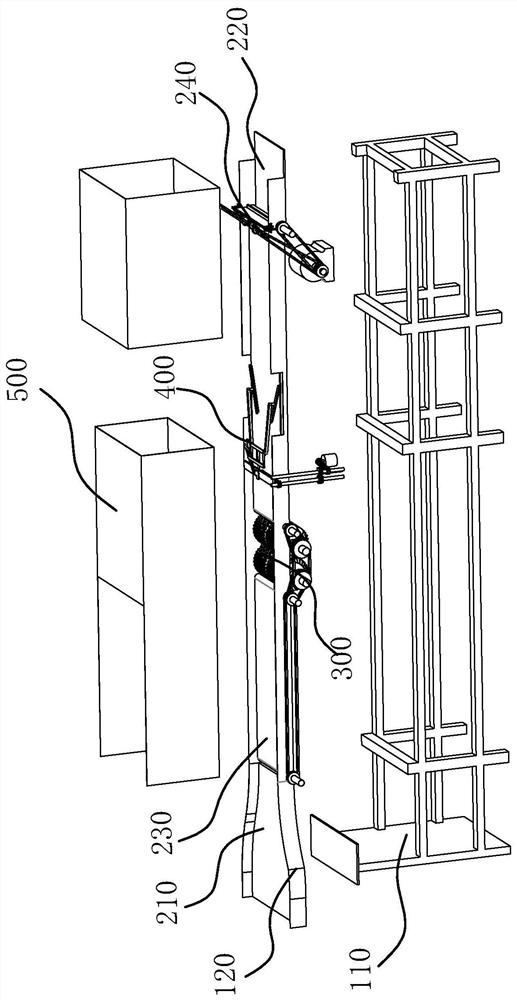

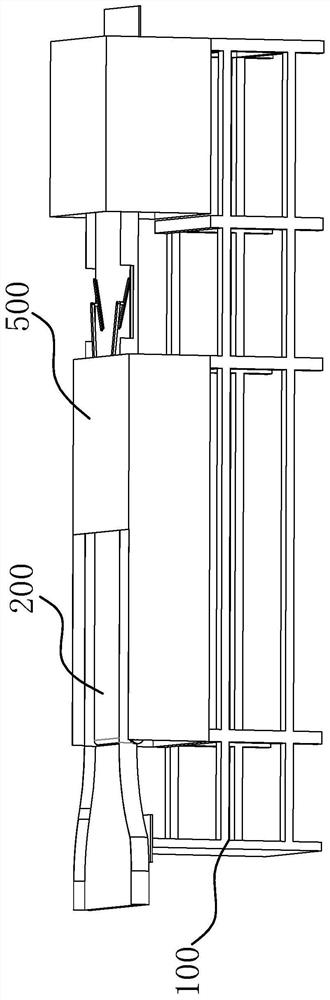

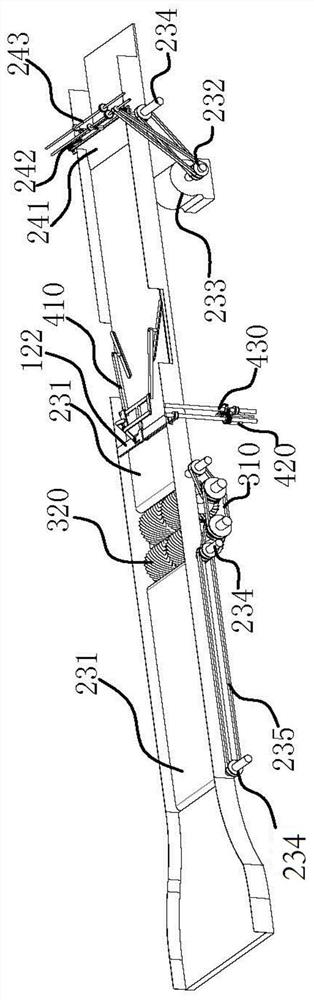

Fruit and vegetable waste collecting and treating mechanism

InactiveCN106238438AQuick chopEfficient shreddingSolid waste disposalClimate change adaptationMotor driveEngineering

The invention discloses a fruit and vegetable waste collecting and treating mechanism. The fruit and vegetable waste collecting and treating mechanism comprises a fermentation container, a rack, a cutting mechanism, a weighing mechanism and a lifting mechanism, wherein the cutting mechanism, the weighing mechanism and the lifting mechanism are arranged on the rack. The cutting mechanism comprises a cutting chamber, a disc cutter arranged at the middle portion of the cutting chamber, a motor and a power transmission assembly, wherein the motor and the power transmission assembly are arranged below the cutting chamber. The motor drives the disc cutter to rotate in the horizontal direction through the power transmission assembly. A fruit and vegetable waste charging port is formed in the upper portion of the cutting chamber, the side wall, close to the fermentation container, of the cutting chamber is provided with a discharging port, and the bottom face of the cutting chamber is an oblique face inclining towards the discharging port. The weighing mechanism comprises a weighing sensor, a weighing instrument, a PLC and a touch screen. The weighing sensor is electrically connected with the PLC through the weighing instrument, and the touch screen is electrically connected with the PLC. The fermentation container is provided with an opening capable of being sealed, the fermentation container is placed on the lifting mechanism and vertically ascends and descends between the position above the weighing sensor and the position below the discharging port along with the lifting mechanism. By means of the fruit and vegetable waste collecting and treating mechanism, the fruit and vegetable waste can be treated and resourcefully utilized, and waste reduction and recycling are achieved.

Owner:GUANGXI UNIV

Improved biomass fuel treatment device

The invention discloses an improved biomass fuel treatment device. The improved biomass fuel treatment device comprises a stand fixedly mounted on the bottom end surface of a support column, and a boxshell fixedly mounted on the right side end surface of the support column; a lifting device is arranged in the right side end surface of the support column on the upper side of the box shell; a cavity is formed in the top end surface of the box shell; the bottom wall in the cavity communicates with a push rising cavity; a first slide cavity penetrating out of the left side end surface of the boxshell is formed in the left side end surface of the box shell between the push rising cavity and the cavity; a baffle plate is slidingly matched and mounted in the first slide cavity; a first screw rod is matched and mounted in the left side end surface of the baffle plate; a first motor is in power fit installation at the extension tail end of the left side of the first screw rod; the first motoris fixedly mounted in the right side end surface of the support column; a concave groove is formed in the right side end of the baffle plate; and multiple sets of grinding teeth are fixedly mounted on the bottom end surface of the concave groove.

Owner:珠海句宸光电科技有限公司

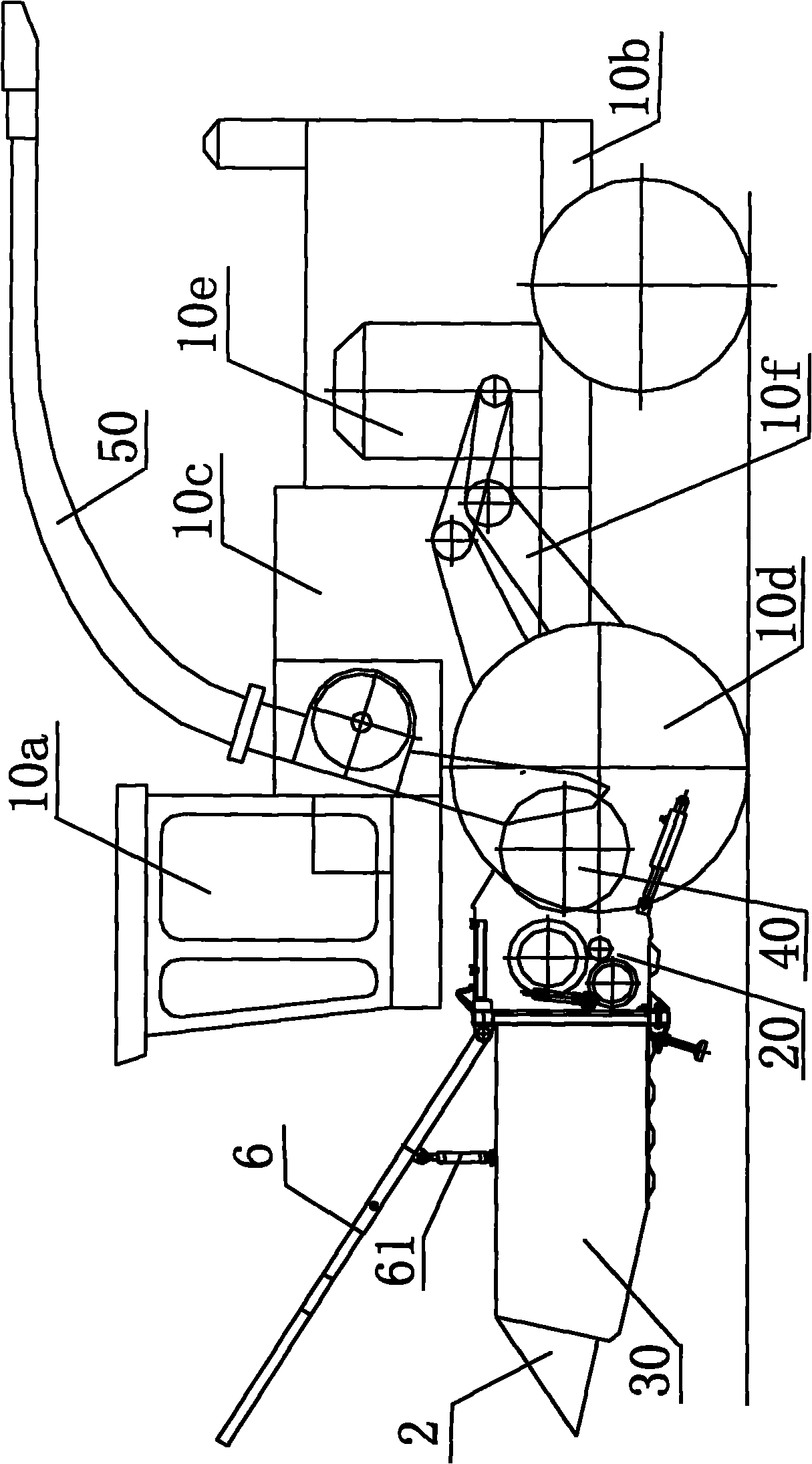

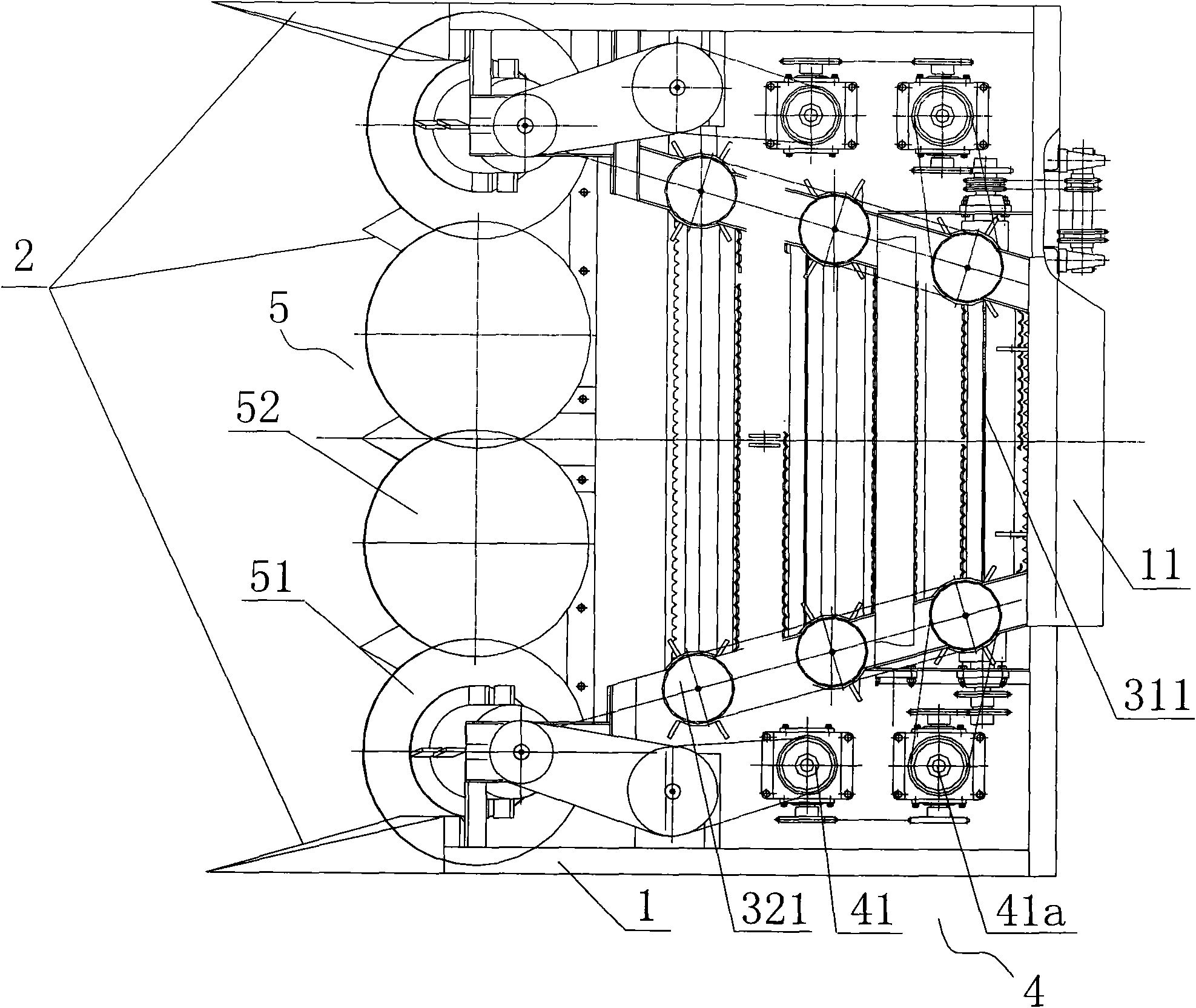

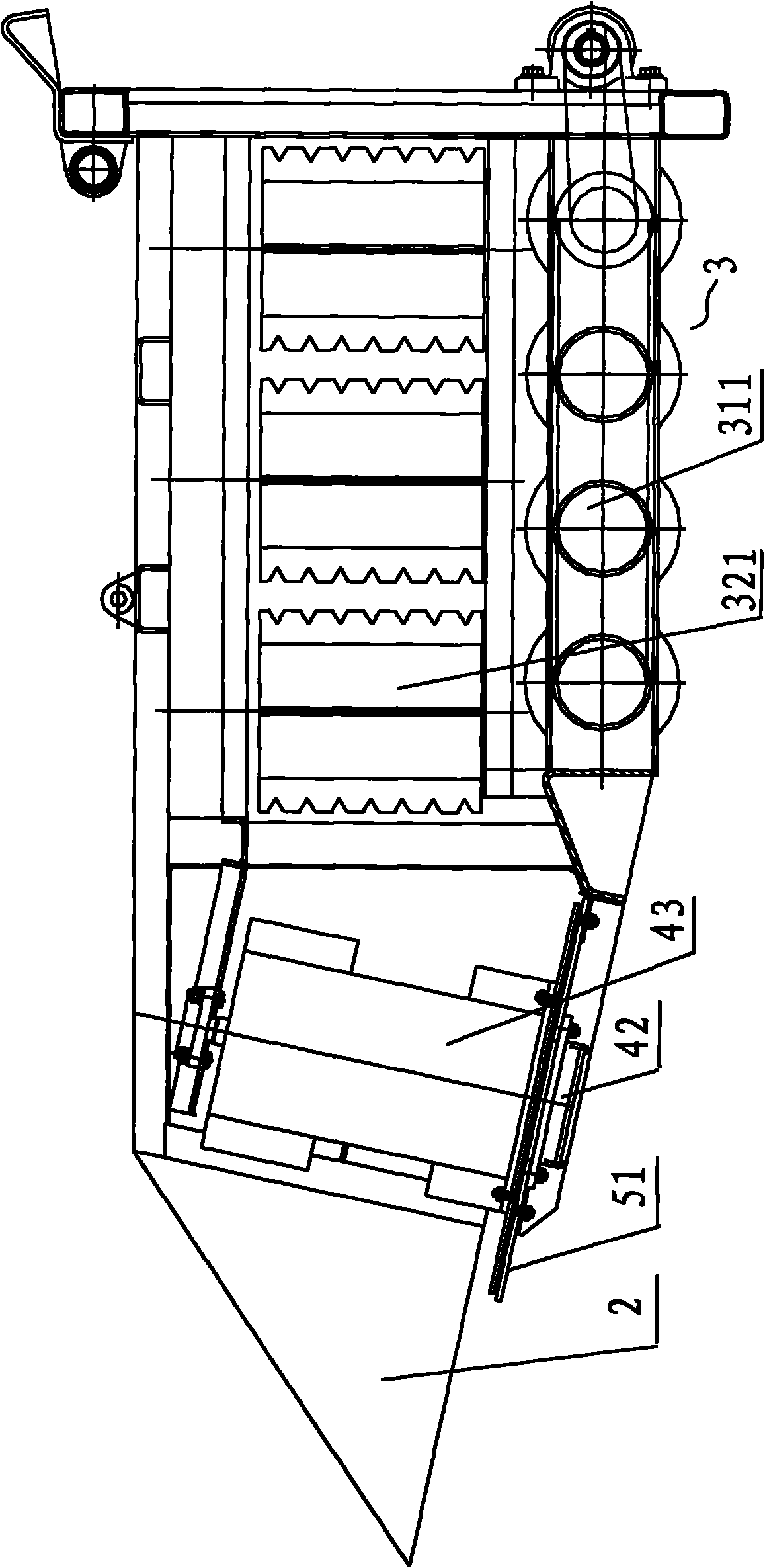

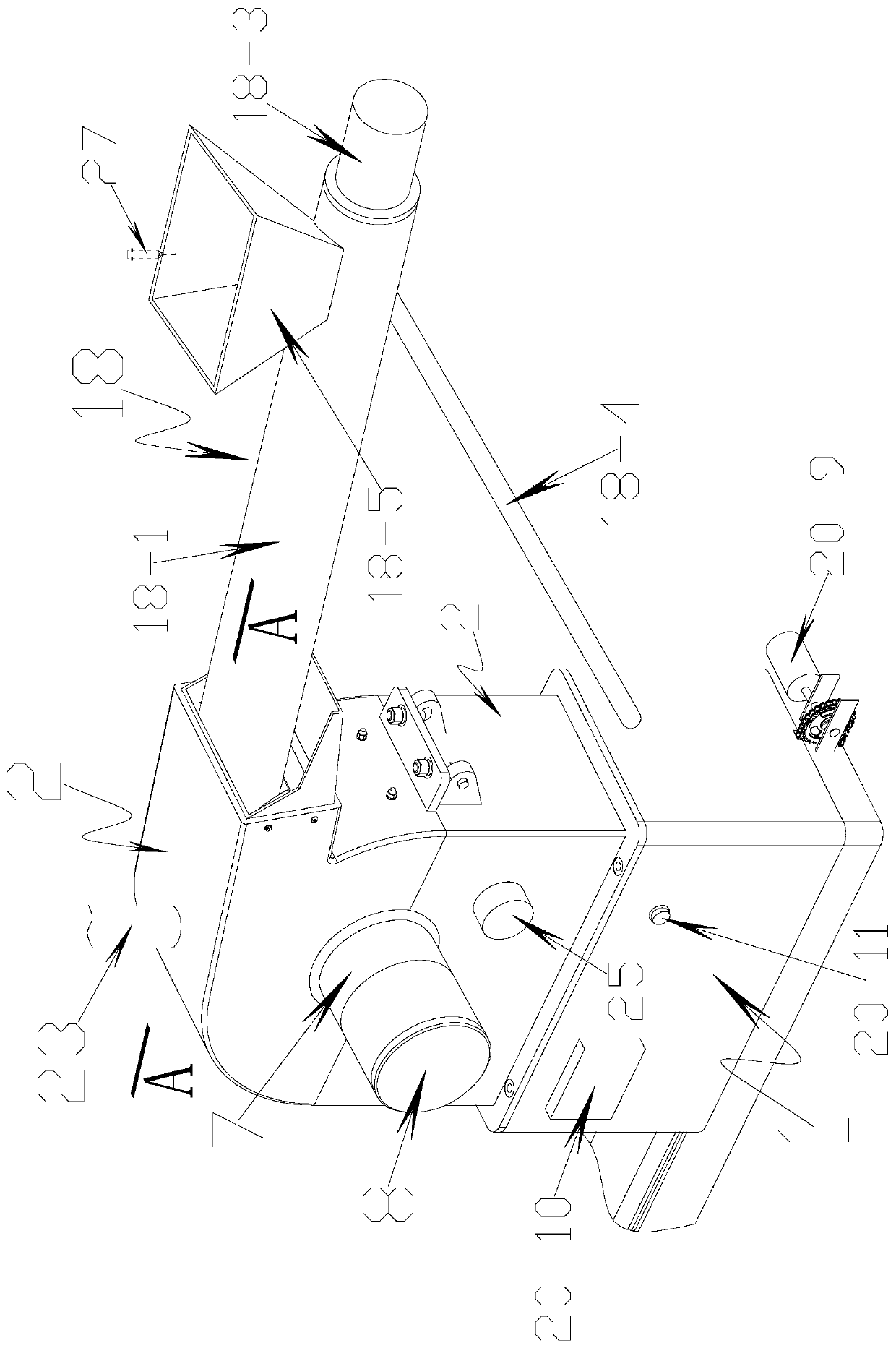

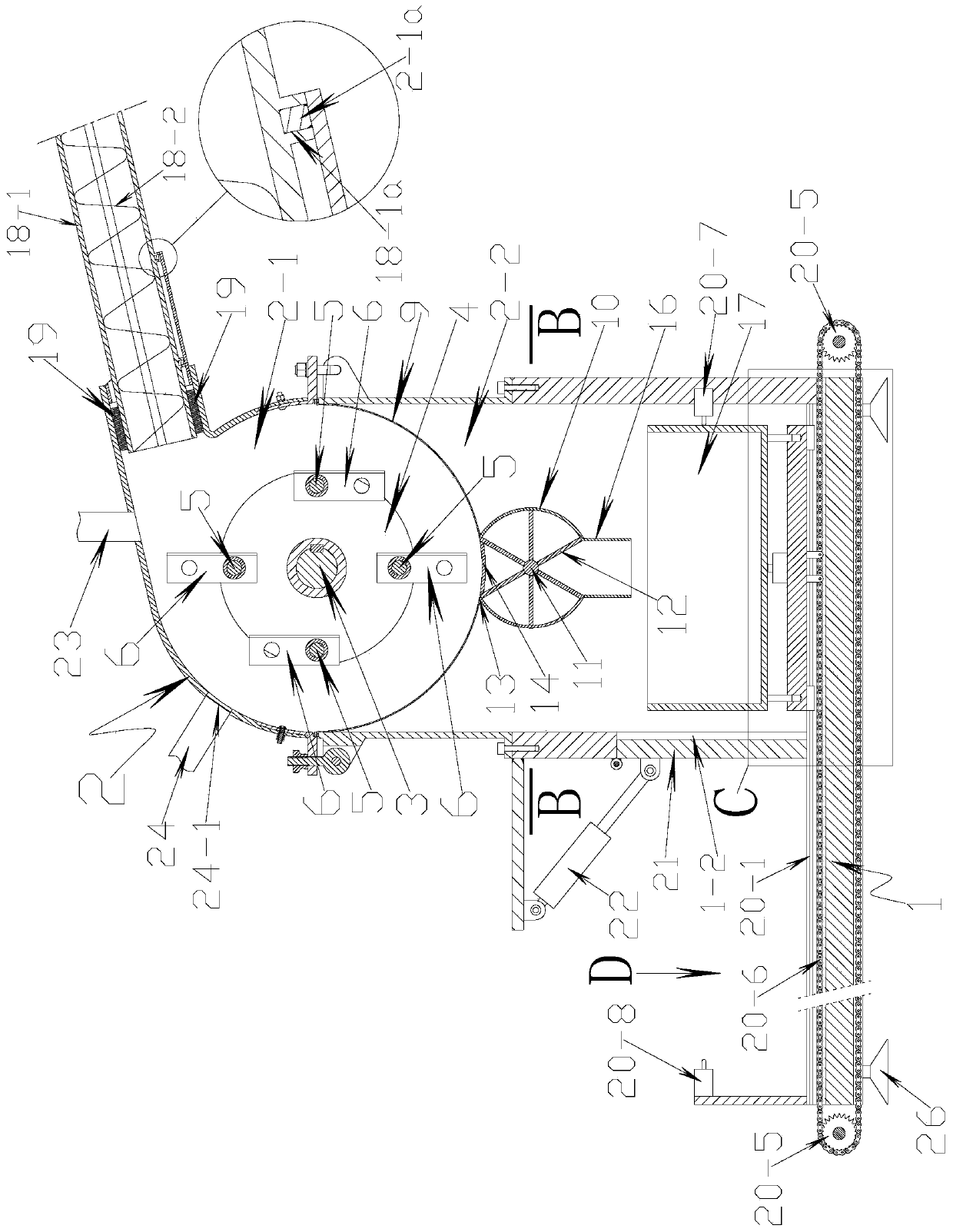

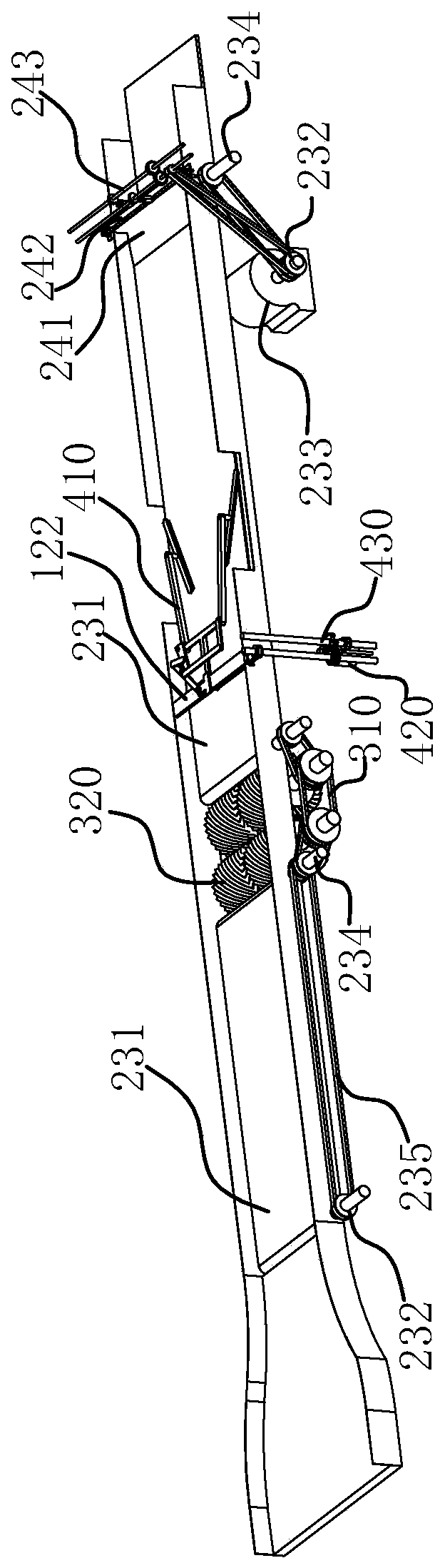

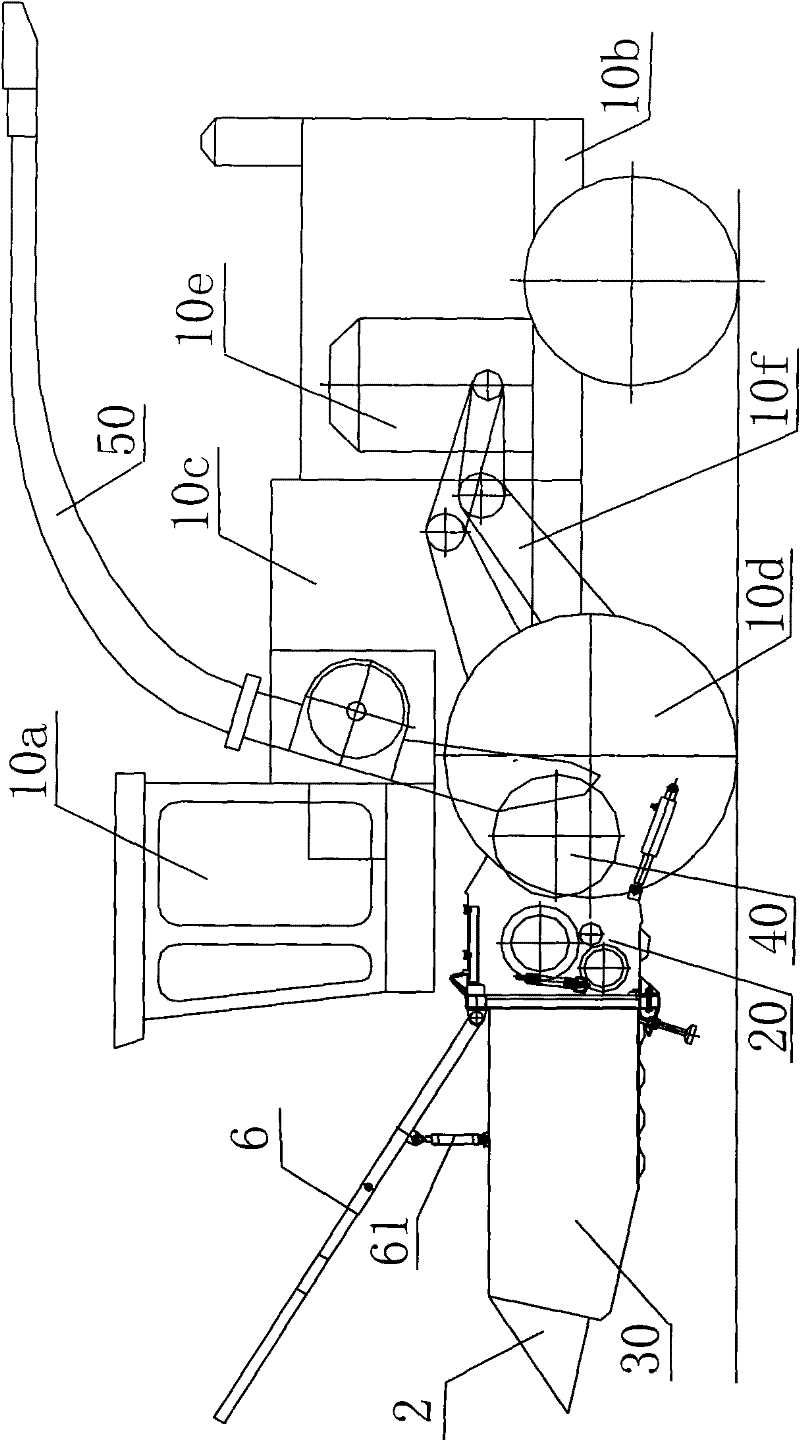

Energy source forest harvester

The invention relates to an energy source forest harvester comprising a chassis, a navigation bridge, a walking component, an engine, a power actuating device, a forced feeding device, a harvesting table, a cutting device and a throwing device, wherein the navigation bridge, the walking component, the engine, the power actuating device and the forced feeding device are arranged on the chassis; the forced feeding device is arranged below the navigation bridge; the rear part of the forced feeding device is successively connected with the cutting device and the throwing device; the throwing device is arranged above the rear part of the cutting device; the front end of the forced feeding device is connected with the harvesting table; the engine is connected with the harvesting table, the forced feeding device, the cutting device and the throwing device by the power actuating device; the harvesting table comprises a harvesting table rack, at least one group of nearside dividers, a cutter adopting a sawing mode, a delivery mechanism, a harvesting table power actuating mechanism and a pushing rack hinged with the harvesting table rack. The energy source forest harvester provided by the invention can efficiently cut, throw and aggregate energy source forest bush branches, improves the operation quality and efficiency, finishes the operations of cutting, transporting, cutting, throwing and entrucking for energy source forest plants once, and has good comprehensive economic benefit.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

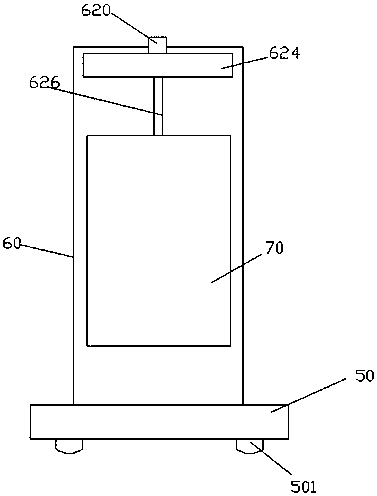

New syringe efficient mass treatment equipment

PendingCN110126135AChopped to handle large quantitiesEasy to chop and handlePlastic recyclingDrying gas arrangementsCombustionReduction drive

The invention discloses new syringe efficient mass treatment equipment. The equipment comprises a base body; the base body is provided with a shell; a first rotating shaft is arranged in the shell, and is provided with support circular plates; connecting rods are arranged between the two support circular plates; cutting blades are arranged on each connecting rod; a speed reducer is arranged on theshell, and is provided with a first servo motor; an arc separation plate is arranged under a cutter; a circular pipe is arranged under the arc separation plate, and is provided with a rotating shaft;poking plates are arranged on the rotating shaft; a communicating channel is formed between an upper cavity of the shell and a cavity of the circular pipe; arc covering plates are arranged between any two adjacent poking plates; a second servo motor is fixed on the shell; a discharge pipe is fixed on the circular pipe; a receiving frame is arranged under the discharge pipe; and a syringe feedingmechanism is arranged at the side part of the base body. The equipment can efficiently crush mass syringes, so that the receiving frame can receive more syringes for transportation to an incinerationplant for combustion, and both popularization and application are deserved.

Owner:LISHUI PEOPLES HOSPITAL

Fruit and vegetable shredding machine

InactiveCN104441036AEfficient cuttingSimple structureMetal working apparatusAgricultural engineeringDrive motor

The invention discloses a fruit and vegetable shredding machine. The fruit and vegetable shredding machine comprises a machine shell, a feeding barrel and a discharging opening; the feeding barrel is arranged on the top of the machine shell; the discharging opening is formed in the lower portion of the machine shell; a spiral feeding mechanism is arranged on the lower portion of the feeding barrel and is located inside the machine shell; a slicing mechanism is arranged below the spiral feeding mechanism; a shredding mechanism is located on the lower portion of the slicing mechanism; a controller is arranged on the right side of the machine shell; a driving motor is arranged on the right side of the machine shell; and the spiral feeding is adopted by the shredding mechanism, and slicing and shredding are carried out successively; and cutting is efficient, convenient and rapid. The high-efficiency cutting characteristic that in the small space, filamentous vegetables can be continuously cut is achieved. The fruit and vegetable shredding machine is a shredding tool for efficiently cutting fruits and vegetables in the catering industry and is simple in structure, convenient to operate and quite suitable for small restaurants.

Owner:HARBIN HONGRUIXIANG TECH DEV CO LTD

Longitudinal cutting type kelp cutting machine

ActiveCN110000822AFlexible distance adjustmentSimple structureMetal working apparatusMotor driveElectric machinery

The invention discloses a longitudinal cutting type kelp cutting machine. The longitudinal cutting type kelp cutting machine comprises a base body; the base body comprises a fixing base; the fixing base is provided with a fixing table; the fixing table is provided with a kelp shredding assembly; the kelp shredding assembly comprises a feeding port, a discharging port, a conveying device and a shredding device; the feeding port is arranged at the left end of the fixing table; the conveying device is arranged along the feeding port rightwards; the conveying device comprises a conveyor belt, a transmission wheel and a first motor; a shredding device is arranged on the fixing table along the conveyor belt rightwards; and the discharging port is arranged behind the shredding device. The motor drives the conveyor belt, a leveling device and the shredding device to move, the whole fast and efficient kelp cutting process is achieved, and the kelp cutting machine is simple in structure and lower in cost.

Owner:宁波象研科技服务发展有限公司

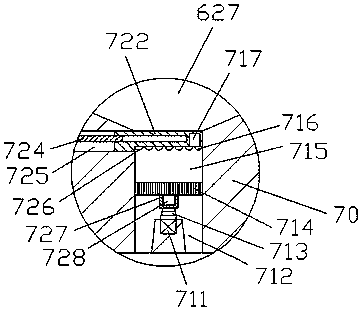

Kitchen waste crusher

PendingCN113502886AIncrease centrifugal forceIncrease heightDomestic plumbingGrain treatmentsAcute angleGravity center

The invention provides a kitchen waste crusher, belongs to the technical field of kitchen waste crushing equipment, and solves the problem of low crushing effect of a traditional garbage disposer on kitchen wastes. The kitchen waste crusher comprises a stand, a rotating disc, a rotating plate, knocking plates, included angles, a slag crushing sleeve and a cutter. Included angles are formed between the center lines of all the knocking plates and the rotating plate, and are acute angles, so that the distance from the gravity center of the rotating plate to a rotating column is effectively increased, that is, when the rotating plate rotates around the rotating column, the centrifugal force of the rotating plate is effectively increased, the rotating plate is higher in acceleration, and the knocking plates are higher in impact force on the kitchen wastes.

Owner:NINGBO XIANGLONG METAL PROD

Activated carbon breaking plant

InactiveCN108212486APerform shreddingEfficient shreddingGrain treatmentsActivated carbonGRINDING TOOTH

The invention relates to an activated carbon breaking plant which comprises a seat body fixedly installed on the end face of the bottom of a strut and a material box fixedly installed on the end faceof the right side of the strut. Rolling wheels are arranged at the bottom of the seat body in a rolling manner, a jacking device is arranged at the position, in the end face of the right side of the strut, of the upper side of the material box, a material cavity is arranged in the end face of the top of the material box, a pushing cavity is arranged on the inner bottom wall of the material cavityin a communicating manner, a first sliding connection cavity penetrating out of the end face of the left side of the material box is arranged in the end face of the left side of the material and arrange between the pushing cavity and the material cavity, a shielding plate is installed in the first sliding connection cavity in a sliding connection fit manner, a first spiral rod is installed on theend face of the left side of the shielding plate in a matched manner, a first motor is installed on a left-side extending tip of the first spiral rod and is fixedly installed on the end face of the right side of the strut, a sinking hole is formed in the right side of the shielding plate, and a plurality of grinding teeth are fixedly installed on the end face of the bottom of the sinking hole.

Owner:广州峥航机械设备有限公司

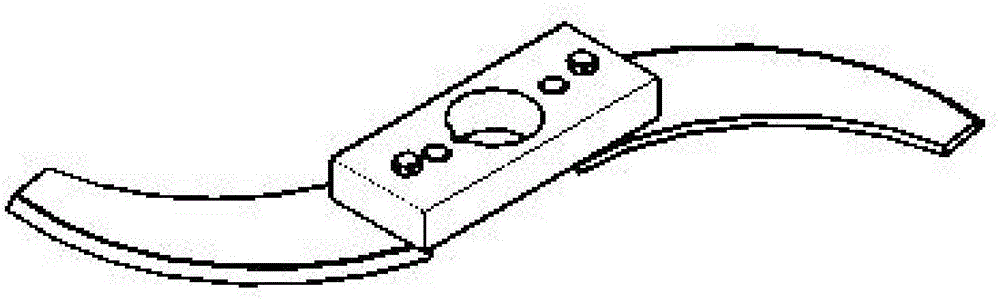

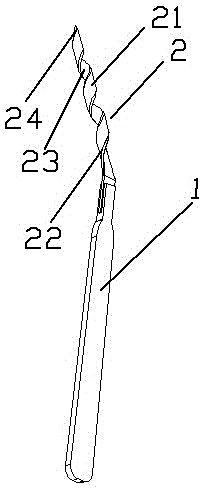

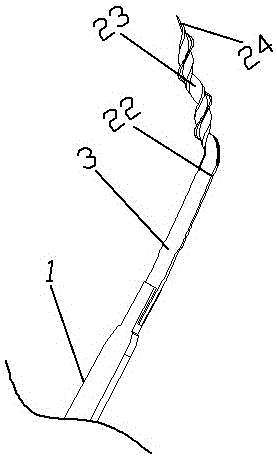

Cutter for uterus resection operation

ActiveCN104997554AEfficient shreddingEfficient extractionEndoscopic cutting instrumentsObstetrical instrumentsEngineeringUterus

The invention belongs to the field of medical apparatus, and relates to a cutter for a uterus resection operation. The cuter comprises a cutter handle and a cutting knife installed on the cutter handle, and is characterized in that the cutting knife comprises a knife back portion and at least one lade portion extending out from the knife back portion towards an outer side for cutting a uterus, wherein the blade portion is spirally arranged along a central axis forming an included angle alpha with the vertical axis of the cutter handle, the included angle alpha is an obtuse angle. The cutter provided by the invention is reasonable in structure and convenient to operate. For the condition that a uterus body is too large to be removed easily, the cutter can efficiently cut up and remove the uterus body, greatly improves the operation efficiency and mitigates the pain of a patient.

Owner:HUZHOU MATERNITY & CHILD CARE HOSPITAL

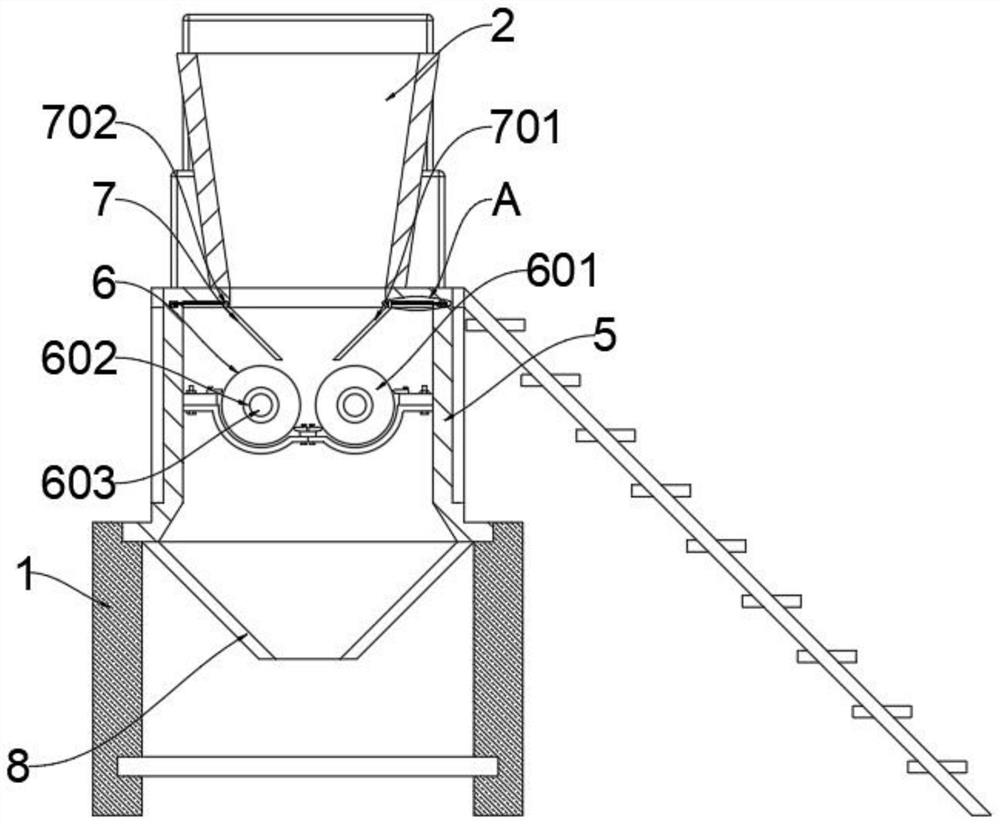

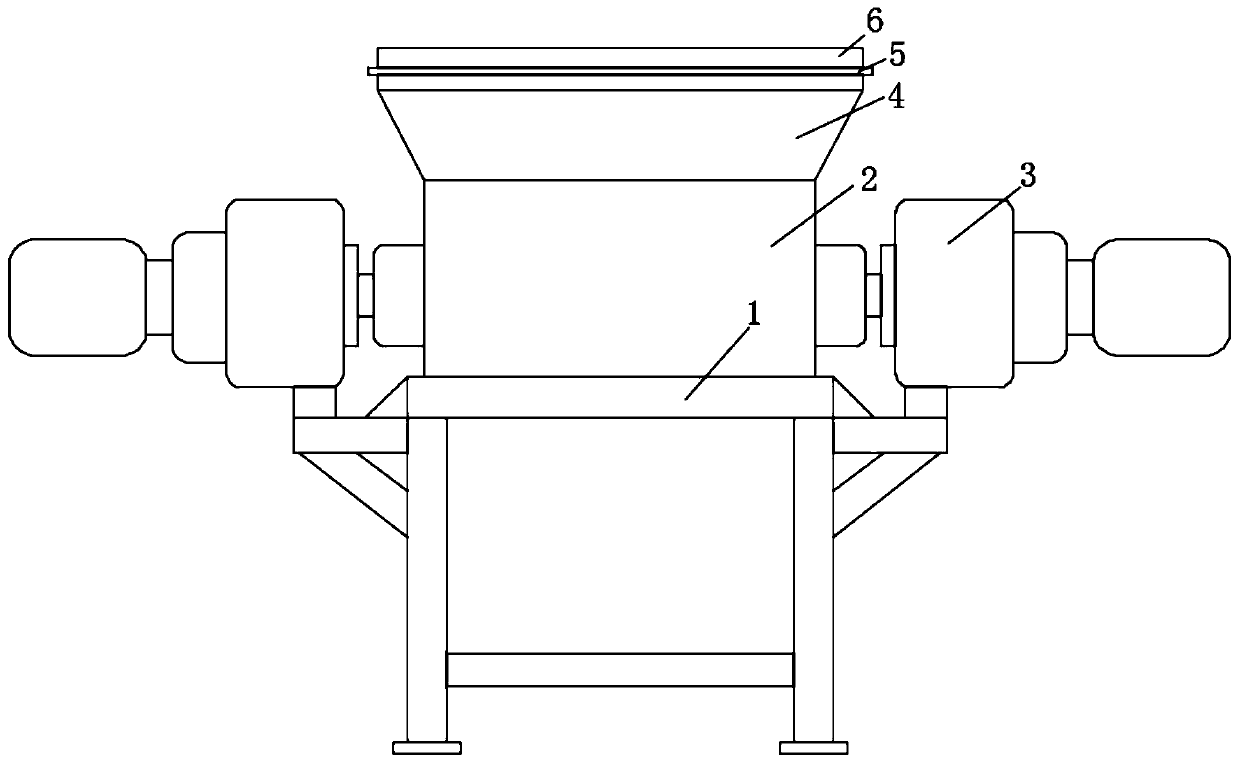

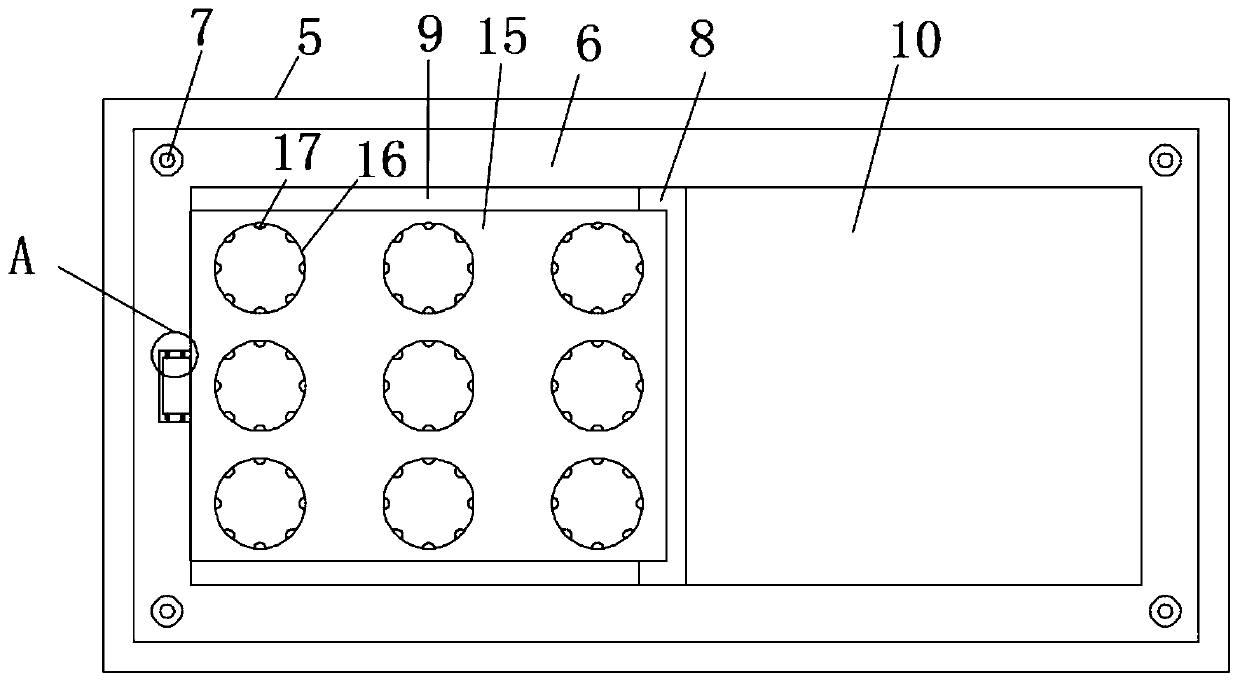

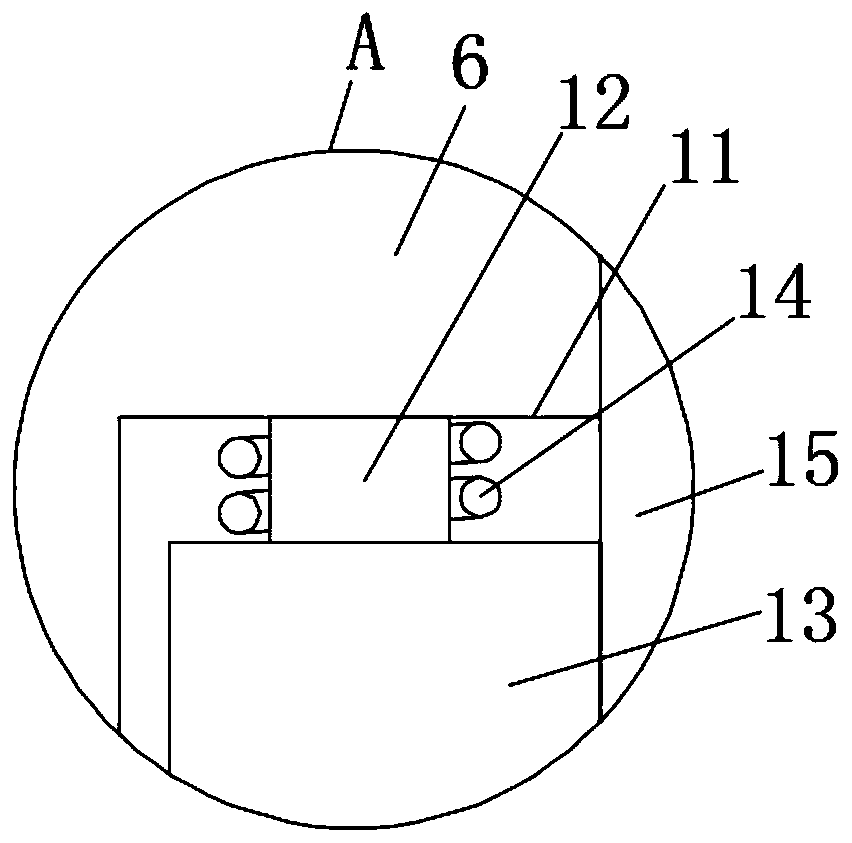

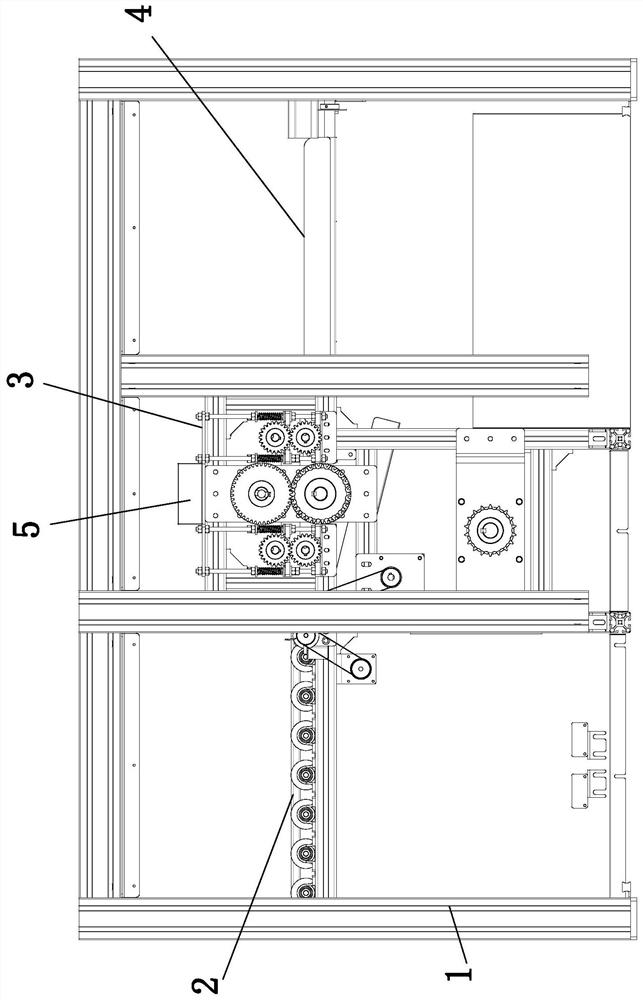

Double-shaft shredding machine

InactiveCN113522484AEfficient shreddingImprove crushing efficiencyGrain treatmentsElectric machineryStructural engineering

The invention discloses a double-shaft shredding machine, and relates to the technical field of solid waste recycling and crushing. The problems that a rubber block is worn by a blade of an existing shredding machine, most parts of the shredding machine need to be disassembled when the blade is replaced, maintenance and replacement are inconvenient, and when the shredding machine works, materials are easy to wind shafts, so that the machine is stuck are solved. The double-shaft shredding machine comprises a machine frame, a feeding hopper is arranged on the surface of the machine frame, a shredding box is arranged below the feeding hopper, the shredding box is located in the middle of the machine frame, a discharging hopper is arranged below the shredding box, and driving motors are arranged on the two sides of the discharging hopper. By arranging a shredding mechanism, a feeding adjusting mechanism and a shredding transmission mechanism, the material crushing efficiency of the shredding machine can be effectively improved, the situation that a shaft of the shredding machine is wound by materials is avoided, the machine is prevented from being stuck, damaged blades are conveniently replaced, and maintenance and overhaul are facilitated.

Owner:东莞市绿丰环保机械有限公司

Garbage disposal plant

InactiveCN108212377APerform shreddingEfficient shreddingGrain treatmentsElectric machineryGarbage disposal

The invention relates to a garbage disposal plant. The garbage disposal plant comprises an additional weight base fixedly installed on the end face of the bottom of an upright tube and a containing box fixedly installed on the end face of the right side of the upright tube, an additional weight groove is formed in the bottom of the interior of the additional weight base, an additional weight blockis fixedly arranged in the additional weight groove, a driving device is arranged at the position, on the end face of the right side of the upright tube, of the upper side of the containing box, a containing cavity is arranged in the end face of the top of the containing box, a pushing cavity is arranged at the bottom wall of the interior of the containing cavity in a communicating manner, a first sliding cavity penetrating the end face of the left side of the containing box is arranged in the end face of the left side of the containing box and arranged between the pushing cavity and the containing cavity, a plugging plate is installed in the first sliding cavity in a movable fit manner, a first stud is installed in the end face of the left side of the plugging plate in a matched manner,a first motor is installed at the left-side extending tail end of the first stud in a power fit manner and is fixedly installed on the end face of the right side of the upright tube, a sinking grooveis formed in the right side end of the plugging plate, and a plurality of protruding teeth are fixedly installed on the end face of the bottom of the sinking groove.

Owner:钟志勇

Novel tobacco preparation device

The invention discloses a novel tobacco preparation device. The device comprises a frame seat fixedly arranged on the bottom end face of a vertical column and a containing box fixedly arranged on theright side end face of the vertical column, the four corners of the frame seat are all provided with fixing blocks, each fixing block is internally provided with a fixing hole, a telescopic device isarranged in the right side end face of the vertical column at the upper side of the containing box, a containing cavity is formed in the top end face of the containing box, the inner bottom wall of the containing cavity is communicated with a pushing cavity, the left side end face of the containing box between the pushing cavity and the containing cavity is provided with a first sliding cavity penetrating outside the left side end face of the containing box, a closing plate is smoothly and cooperatively arranged in the first sliding cavity, a first threaded rod is cooperatively arranged in theleft side end face of the closing plate, the extending tail portion of the left side of the first threaded rod is dynamically and cooperatively provided with a first motor, the first motor is fixedlyarranged in the right side end face of the vertical column, the right side end of the closing plate is provided with a recessed cavity, and the bottom end face of the recessed cavity is fixedly provided with multiple sets of convex teeth.

Owner:佛山市庐米文化传播有限公司

A kind of energy forest harvester

An energy forest harvester, comprising a chassis, a driving platform mounted on the chassis, a frame, a walking part, an engine, a power transmission device, a forced feeding device, a harvesting platform, a chopping device and a throwing device, and a forced feeding device It is located under the driving platform, and its rear is connected with the shredding device and the throwing device in sequence. The throwing device is located above the rear of the shredding device, and the front end of the forced feeding device is hung with the harvesting table. , the forced feeding device, the shredding device and the throwing device are connected, wherein the harvesting table includes: a harvesting table; at least one group of croppers; a cutter adopting a sawing method; a conveying device; Hinged push-up rack for harvesting gantry. The energy forest harvester of the invention can realize efficient chopping and throwing of aggregates of the shrub branches of the energy forest. The operation quality and efficiency are improved, and the cutting, conveying, chopping, throwing and loading of energy forest plants can be completed at one time, and the comprehensive economic benefits are good.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

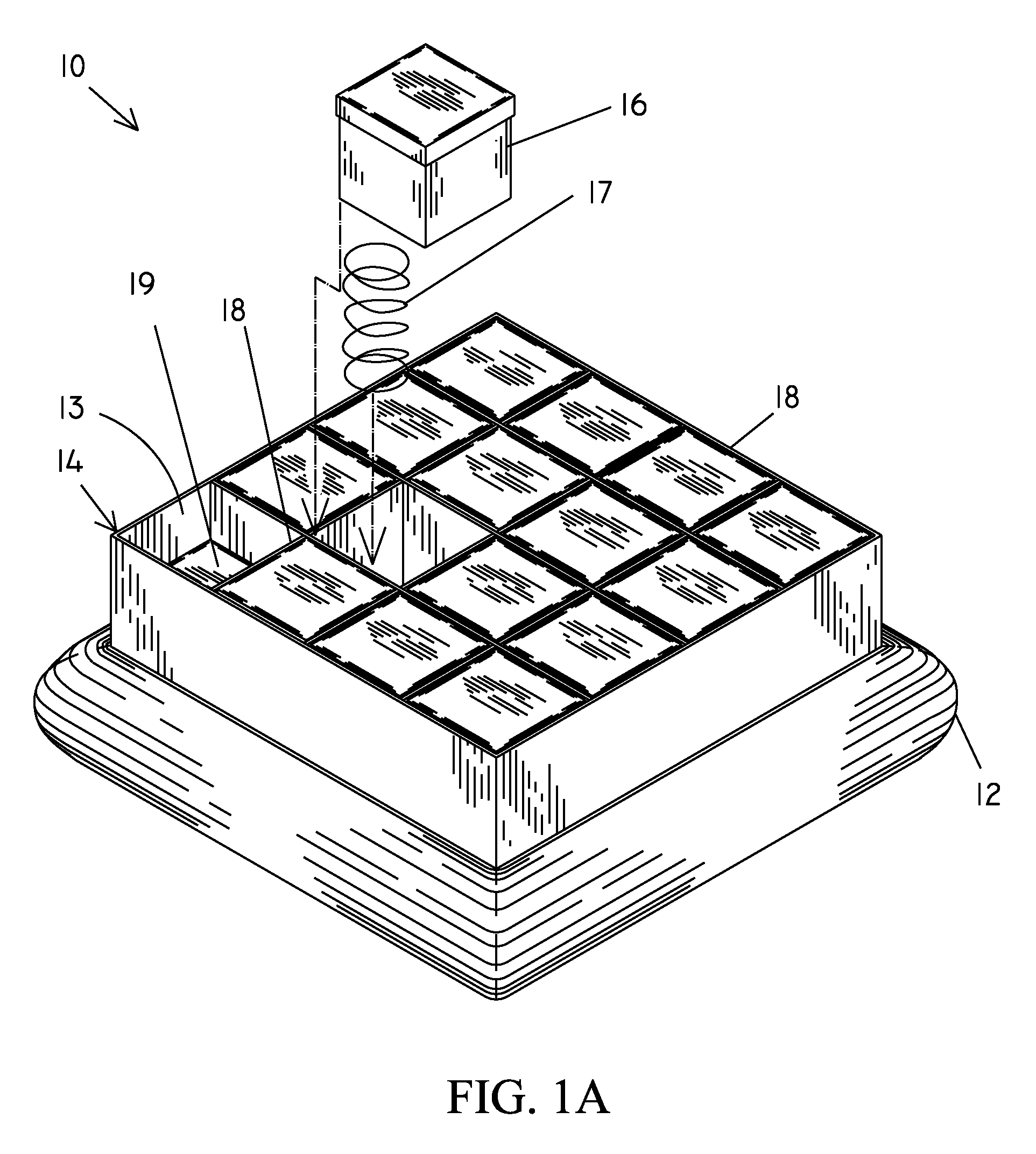

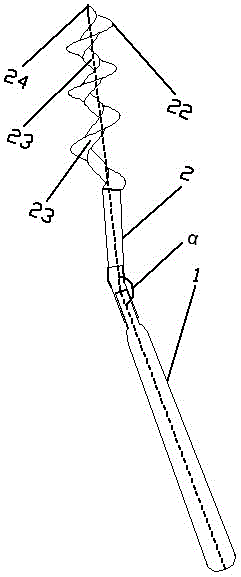

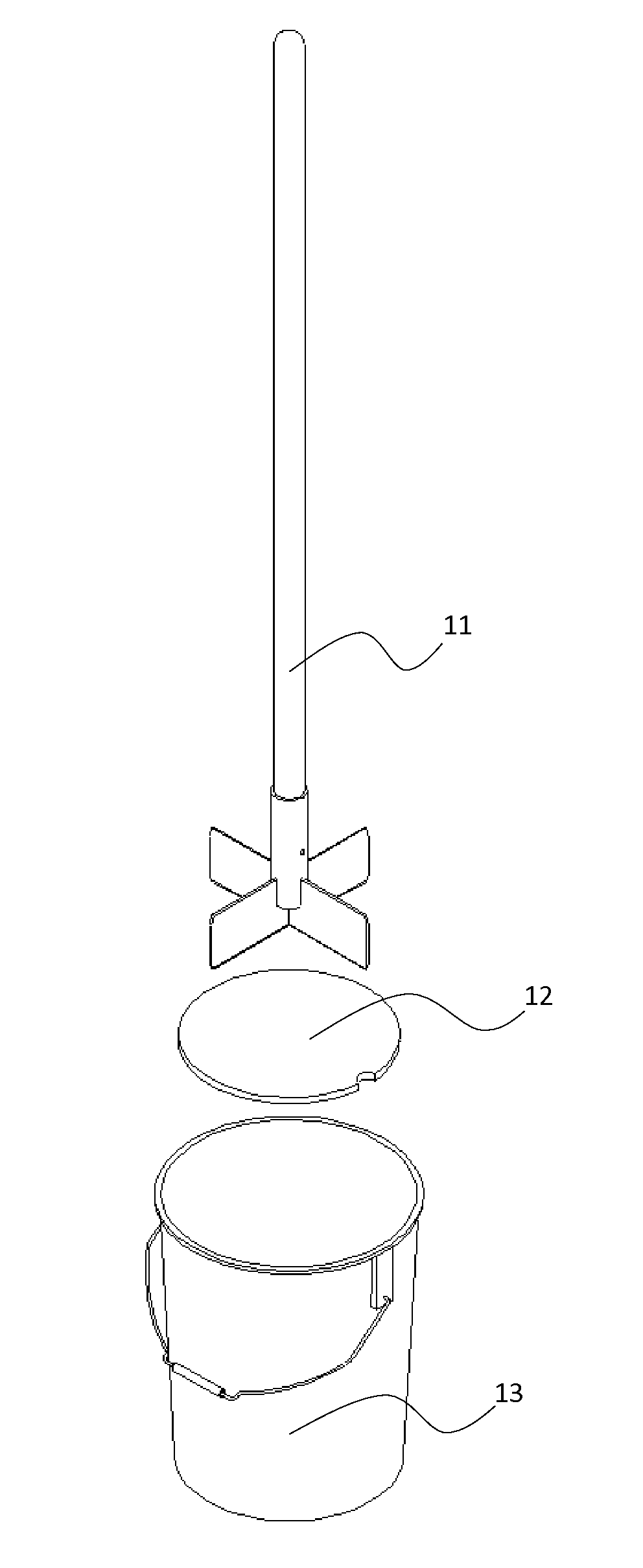

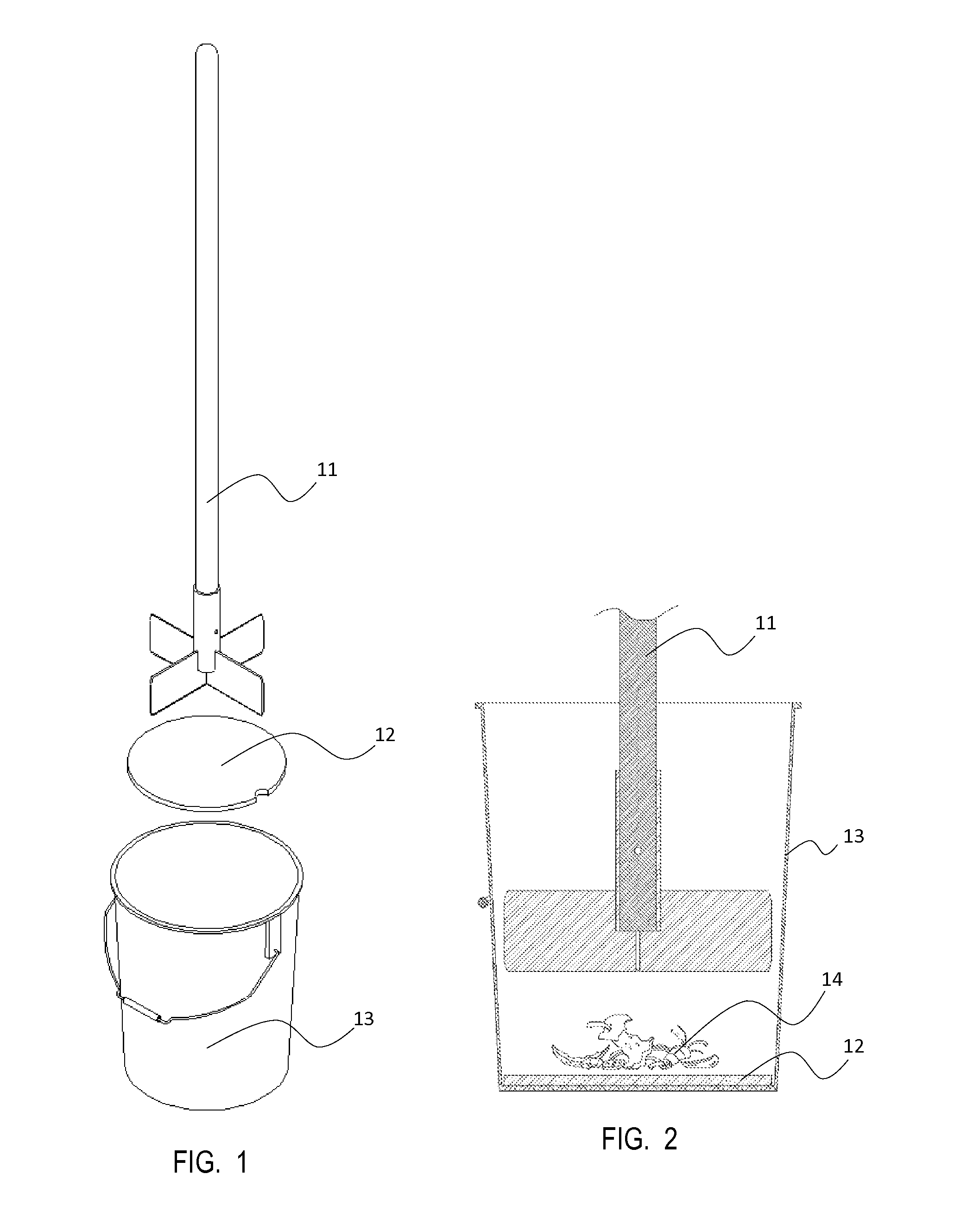

Device and method for chopping organic matter

InactiveUS20140197256A1Efficient shreddingReed/straw treatmentCork treatment detailsEngineeringOrganic matter

A device and method for chopping organic matter includes a chopping device consisting of a handle and a plurality of flat, sharpened blades attached radially around one end of the handle's axis; a chopping board, which acts as a chopping surface and conforms to the inside, bottom shape of a containment vessel; and the containment vessel, which stores, contains, and transports organic matter for chopping and handling. The chopping board is placed on the inside bottom surface of the containment vessel, organic matter is placed into the containment vessel and on top of the chopping board, and the chopping device is placed inside the containment vessel. The chopping device is repeatedly thrust downward, chopping the organic matter between the chopping board and the chopping device. Embodiments of the chopping device and the chopping board may be scaled proportionally to fit predetermined sizes of containment vessels.

Owner:BOES EDWARD +3

Improved garbage treatment device

The invention relates to an improved garbage treatment device. The device comprises a counterweight seat fixedly installed on the bottom end surface of a vertical rod and a containing box fixedly installed on the right end surface of the vertical rod, a counterweight groove is formed in the inner bottom of the counterweight seat, a counterweight block is fixedly arranged in the counterweight groove, a driving device is arranged in the right end surface of the portion, on the upper side of the containing box, of the vertical rod, a containing cavity is formed in the top end surface of the containing box, a pushing ejecting cavity is formed in the inner bottom wall of the containing cavity in a communicating mode, a first sliding cavity penetrating through the left end surface of the containing box is formed in the left end surface of the portion, between the pushing ejecting cavity and the containing cavity, of the containing box, a blocking plate is movably installed in the first sliding cavity in a matched mode, a first stud is installed in the left end surface of the blocking plate in a matched mode, the left extending tail end of the first stud is provided with a first motor ina power matched mode, the first motor is fixedly installed in the right end surface of the vertical rod, a concave groove is formed in the right end of the blocking plate, and a plurality of groups ofconvex teeth are fixedly installed on the bottom end surface of the concave groove.

Owner:陈建江

Improved activated carbon crushing equipment

InactiveCN108325721APerform shreddingEfficient shreddingGrain treatmentsActivated carbonGRINDING TOOTH

The invention discloses improved activated carbon crushing equipment. The equipment comprises a base fixedly mounted on the bottom end surface of a support rod and a material box fixedly mounted on the right end surface of the support rod, wherein rolling wheels are arranged at the bottom of the base in a rolling manner, a jacking device is arranged in the right end surface of the support rod on the upper side of the material box, a material cavity is formed in the top end surface of the material box, a push cavity is communicated with the inner bottom wall of the material cavity, a first sliding connection cavity penetrating through the outside of the left end surface of the material box is formed in the left end surface of the material box between the push cavity and the material cavity,a cover plate is mounted in the first sliding connection cavity in a sliding connection fit manner, a first screw rod is matched and mounted in the left end surface of the cover plate, a first electric motor is mounted at the left extension tip of the first screw rod in a power fit manner, the first electric motor is fixedly mounted in the right end surface of the support rod, concave holes are formed in the right end of the cover plate, and multiple grinding teeth are fixedly mounted on the bottom end surfaces of the concave holes.

Owner:广州峥航机械设备有限公司

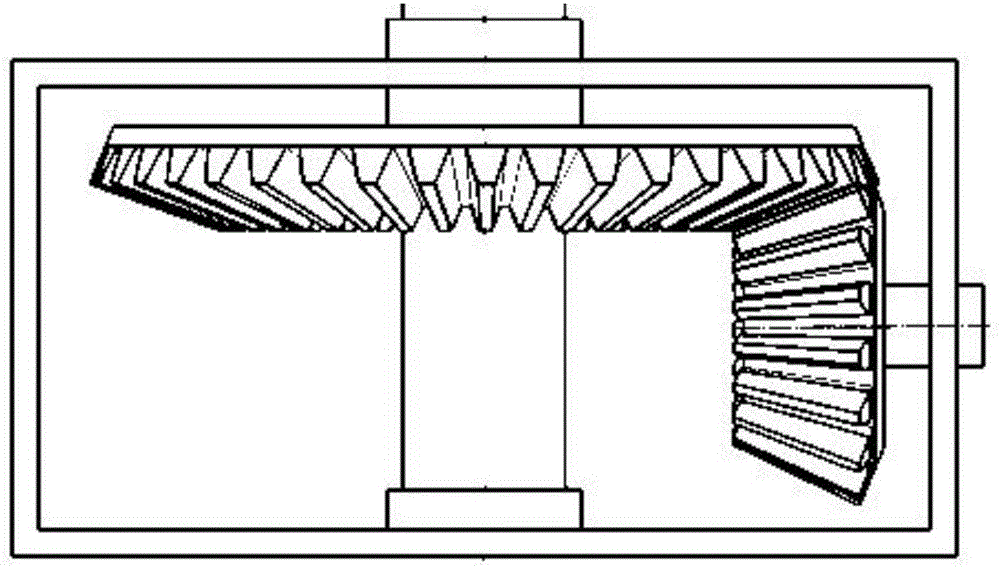

High-concentration hydrapulper with sieve plate

ActiveCN111424450AEfficient shreddingChange filterPaper recyclingRaw material divisionSpiral bladePulp treatment

The invention discloses a high-concentration hydrapulper with a sieve plate. The high-concentration hydrapulper comprises a tank body and a rotor arranged in the tank body, wherein the rotor is connected with a transmission device, the sieve plate is arranged below the rotor in a matched mode, a fine pulp chamber is formed below the sieve plate, and a pulp outlet is formed in the fine pulp chamber; the tank body is mainly composed of a barrel and a lower end socket coaxially connected to the lower end of the barrel; the lower end socket is of a smooth transition spherical surface structure, and flow guide plates diffusing outwards are arranged on the inner wall of the lower end socket around the sieve plate in a circumferential direction; the rotor is a spiral rotor and is mainly composedof a mandrel, a spiral blade arranged on the mandrel and a rotor base plate arranged at the bottom of the mandrel; the mandrel comprises a conical mandrel section at the lower portion and a straight mandrel section at the upper portion; and the small-diameter end of the upper end of the conical mandrel section and the straight mandrel section are coaxially fixed in a butt joint mode. With the high-concentration hydrapulper, waste paper can be quickly disintegrated under the condition of a high concentration, the pulp property of the waste paper is kept as much as possible, a pulp treatment concentration can reach 10%-15%, working efficiency is greatly improved, and energy conservation and consumption reduction are achieved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Novel activated carbon crushing apparatus

InactiveCN108380369APerform shreddingEfficient shreddingGrain treatmentsActivated carbonGRINDING TOOTH

The invention discloses a novel activated carbon crushing apparatus. The novel activated carbon crushing apparatus comprises a base body and a material box. The base body is fixedly installed on the end face of the bottom of a supporting rod. The material box is fixedly installed on the end face of the right side of the supporting rod. Rolling wheels are arranged at the bottom of the base body inthe manner of being capable of rolling. A jacking device is arranged on the upper side of the material box and in the end face of the right side of the supporting rod. A material chamber is formed inthe end face of the top of the material box. A pushing chamber is arranged in the inner bottom wall of the material chamber in a communicating manner. A first sliding connection chamber is arranged inthe end face of the left side of the material box and between the pushing chamber and the material chamber, and penetrates out of the end face of the left side of the material box. A cover plate is installed in the first sliding connection chamber in a matched manner. A first spiral rod is installed in the end face of the left side of the cover plate in a matched manner. A first motor is installed at the extension tail end of the left side of the first spiral rod in a dynamic fit manner. The first motor is fixedly installed in the end face of the right side of the supporting rod. A concave hole is formed in the right end of the cover plate. A plurality of groups of grinding teeth are fixedly installed on the end face of the bottom of the concave hole.

Owner:广州峥航机械设备有限公司

A longitudinal cutting kelp shredding machine

ActiveCN110000822BFlexible distance adjustmentSimple structureMetal working apparatusElectric machineryEngineering

The invention discloses a longitudinal cutting type kelp cutting machine. The longitudinal cutting type kelp cutting machine comprises a base body; the base body comprises a fixing base; the fixing base is provided with a fixing table; the fixing table is provided with a kelp shredding assembly; the kelp shredding assembly comprises a feeding port, a discharging port, a conveying device and a shredding device; the feeding port is arranged at the left end of the fixing table; the conveying device is arranged along the feeding port rightwards; the conveying device comprises a conveyor belt, a transmission wheel and a first motor; a shredding device is arranged on the fixing table along the conveyor belt rightwards; and the discharging port is arranged behind the shredding device. The motor drives the conveyor belt, a leveling device and the shredding device to move, the whole fast and efficient kelp cutting process is achieved, and the kelp cutting machine is simple in structure and lower in cost.

Owner:宁波象研科技服务发展有限公司

Efficient double-shaft shredder for paint bucket

The invention discloses an efficient double-shaft shredder for a paint bucket. The efficient double-shaft shredder comprises a supporting base, a shredding box is fixedly mounted above the supportingbase, and an isolating plate is fixedly mounted in the middle of a locating frame. The locating frame can be divided into a first feeding port and a second feeding port conveniently, so that the paintbucket carries out classify shredding, and the work efficiency is improved. A rotary shaft is movably connected in a cavity formed in the upper surface of the left side of the locating frame, and a limiting plate does turnover motion on the rotary shaft conveniently through a connecting block. A feeding limiting hole is formed in the surface of the limiting plate, a universal ball bearing is mounted in the feeding limiting hole, and discharging guiding and limiting functions can be achieved on the paint bucket conveniently. A magnet II is fixedly mounted in a limiting groove, the limiting plate and the magnet II are attracted conveniently through a magnet I, the limiting plate can be attracted on the isolating plate better, the position of the limiting plate cannot shift easily, and the stability of discharging is improved.

Owner:金华景腾科技有限公司

A whole-process monitoring license plate shredder and its usage method

Owner:HANGZHOU BOAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com