Kitchen waste crusher

A kitchen waste and shredder technology, which is used in indoor sanitary piping devices, grain treatment, water supply devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

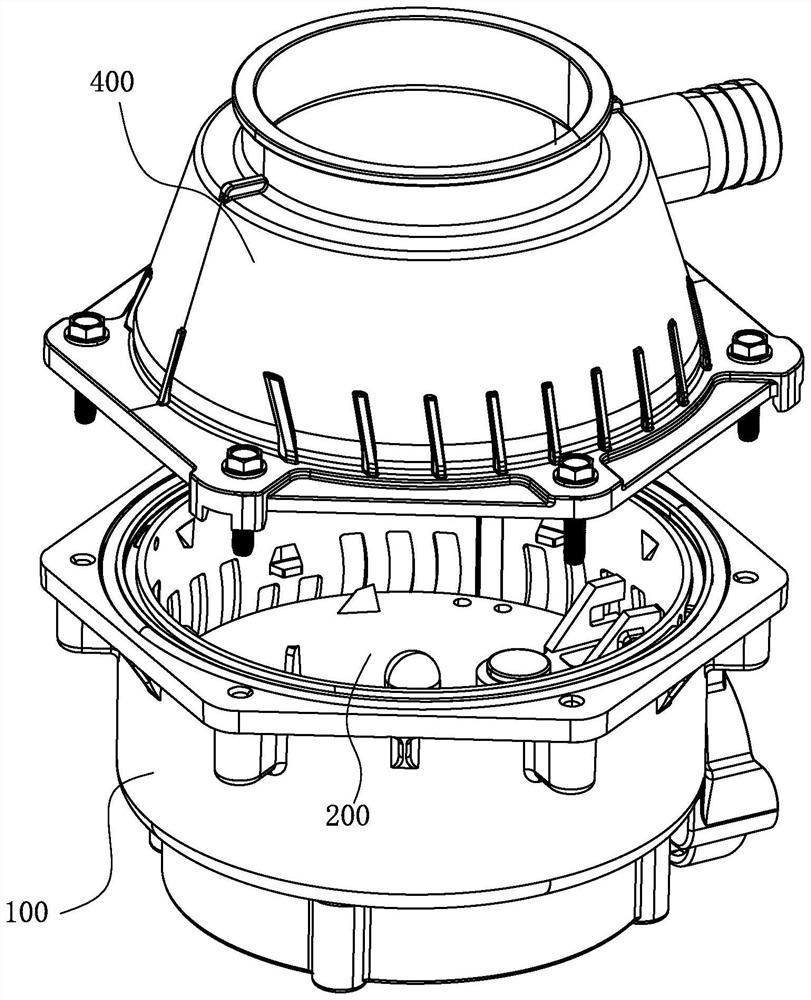

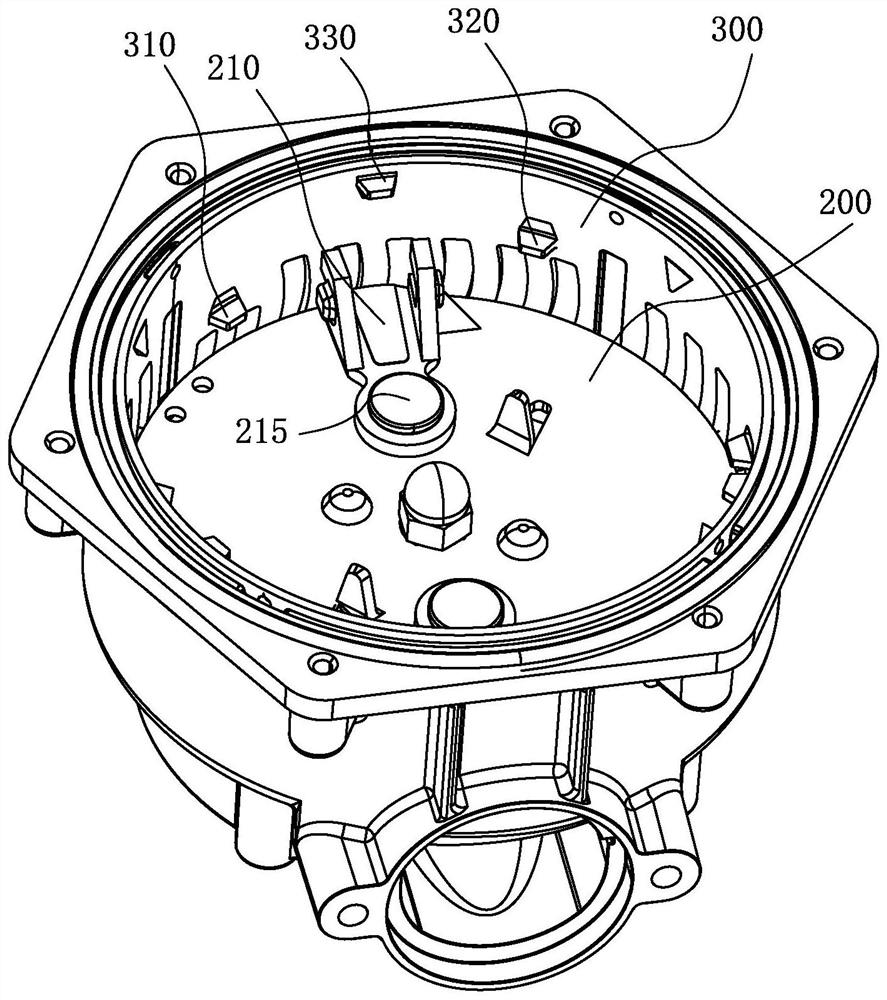

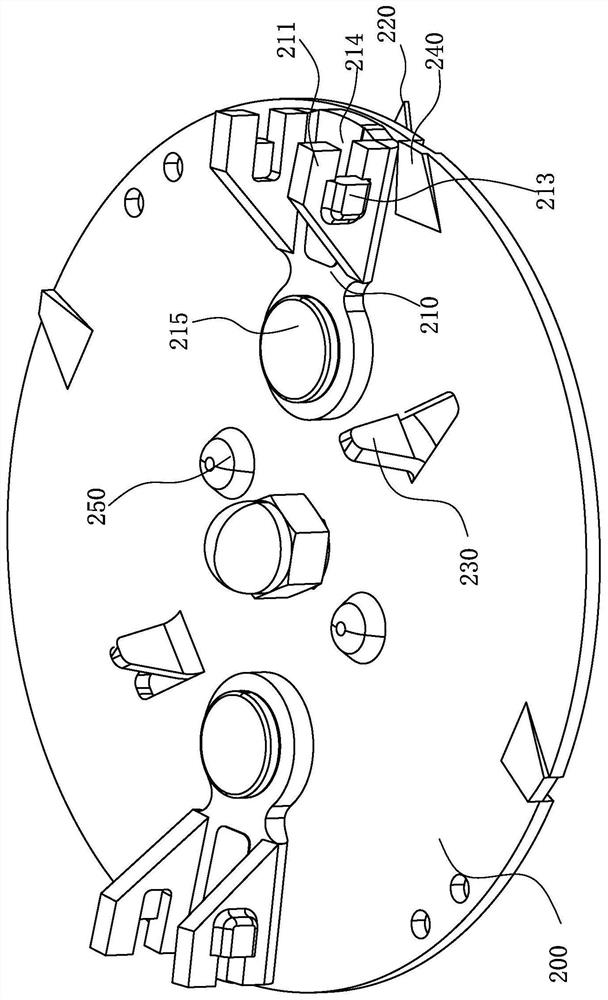

[0030] Such as figure 1 — Figure 7 As shown, a kitchen waste shredder of the present invention includes a machine base 100 , a rotating disk 200 , a rotating plate 210 , a knocking plate 211 , an included angle a, a slag cover 300 and a cutting knife 220 .

[0031] The rotating disk 200 is movably installed in the machine base 100, and at least one pair of rotating plates 210 are hinged on the rotating disk 200, and knocking plates 211 are arranged on the edges of both sides of the rotating plate 210, and on the rotating disk 200 A rotating column 215 for hinged rotating plate 210 is provided. During work, the rotating plate 200 rotates. Because the rotating plate 210 is hinged on the rotating plate 200 through the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com