Shredding machine

A shredder and rack technology, which is used in mechanical material recovery, recycling technology, grain processing, etc., to achieve good shredding effect, efficient shredding, and high shredding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

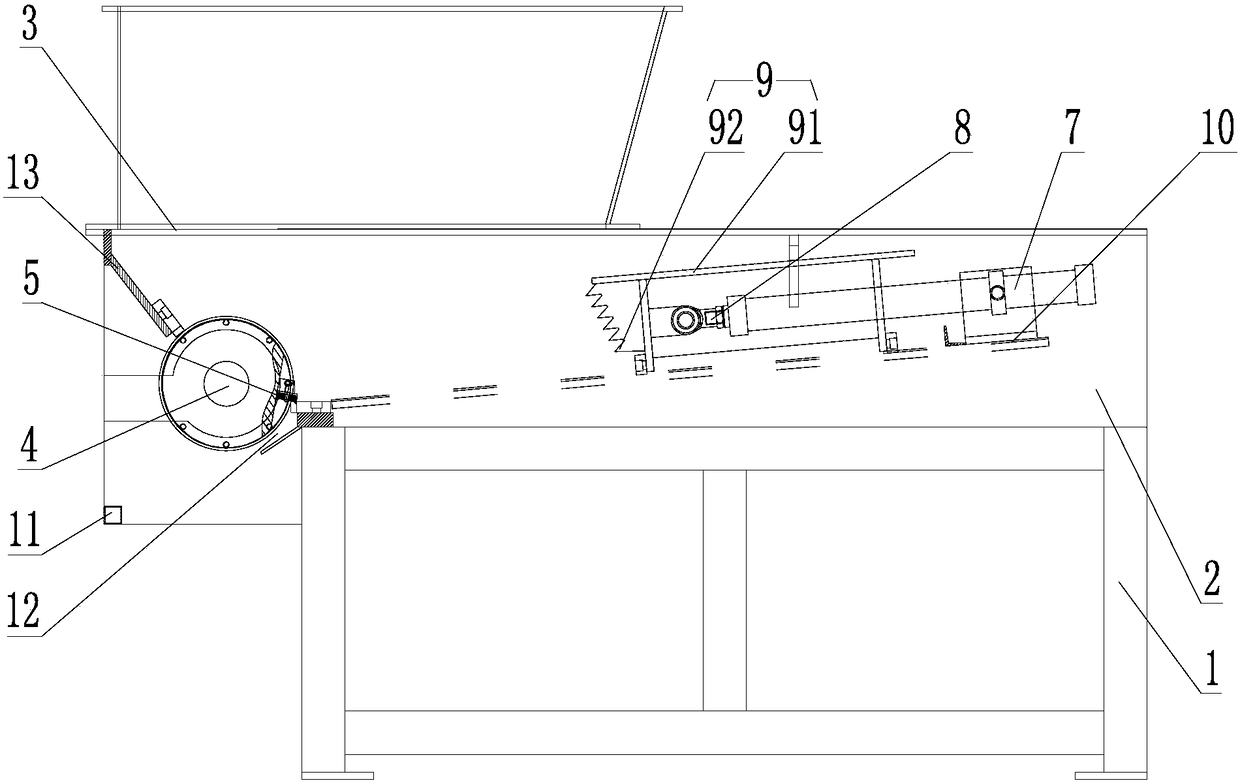

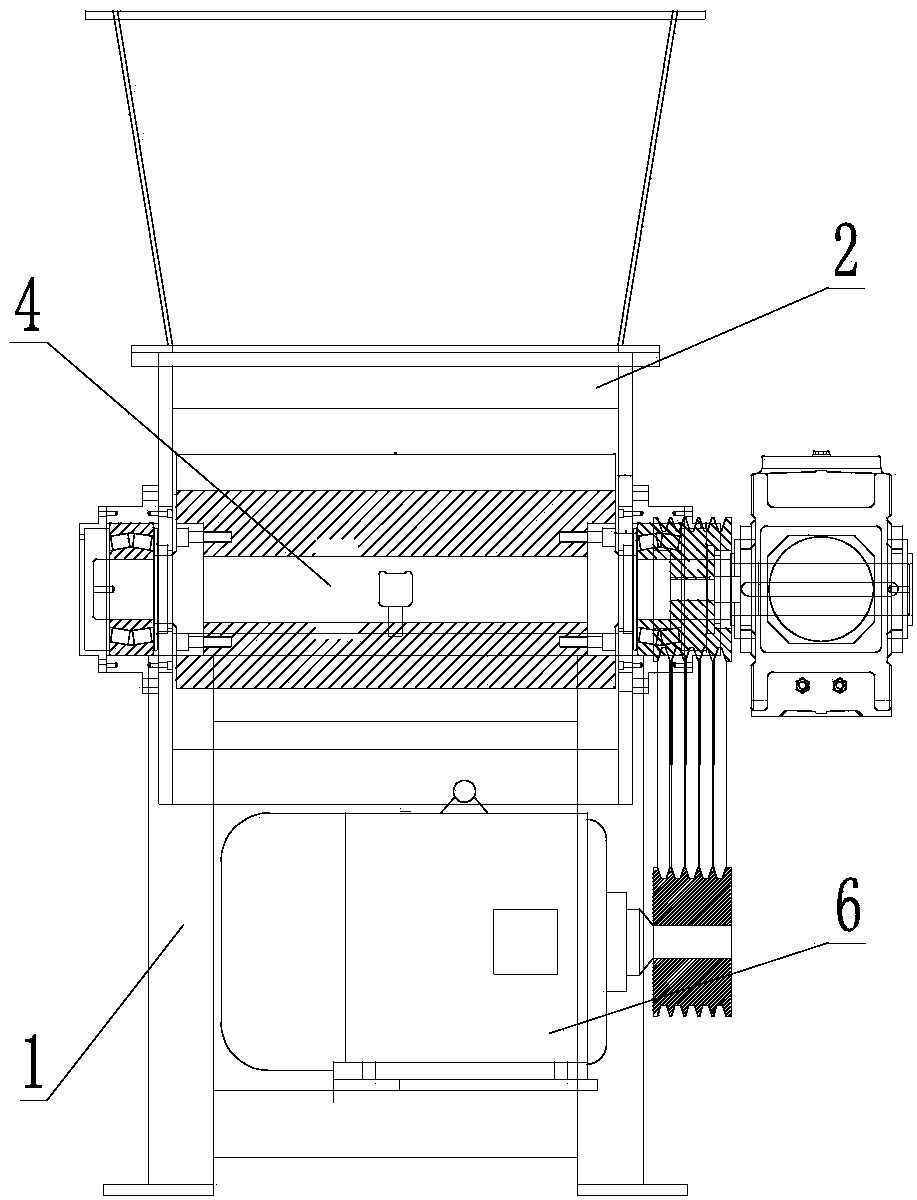

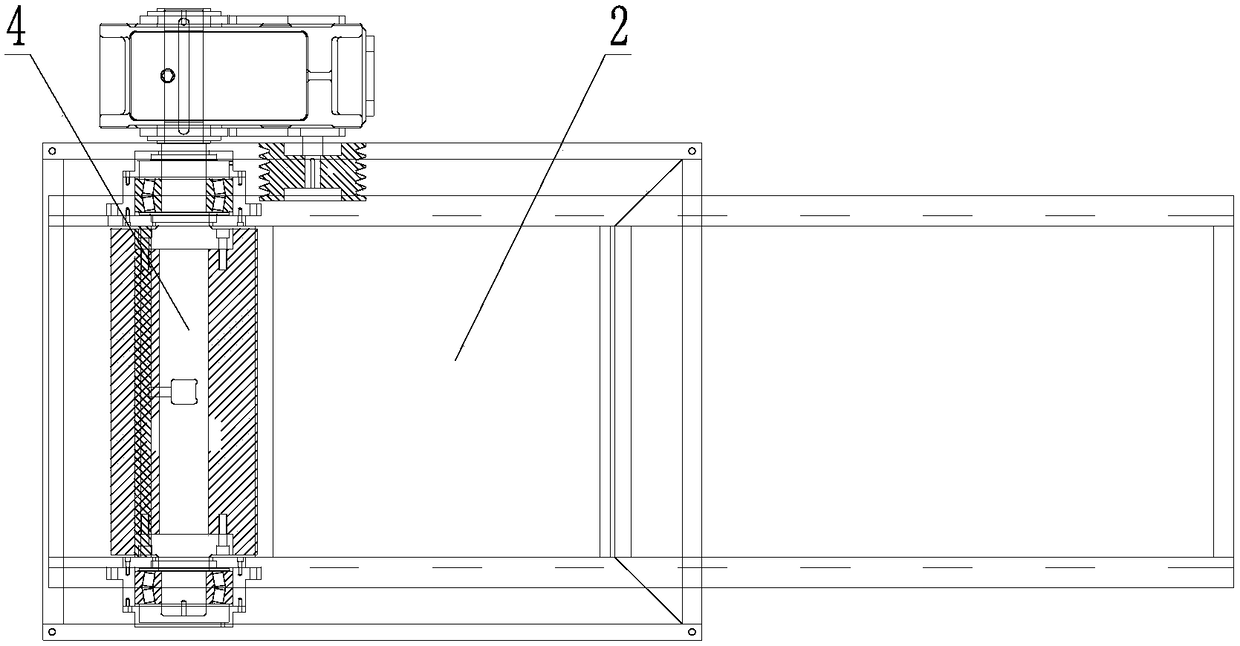

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see Figure 1-3 As shown, the above-mentioned shredder includes a frame 1, a hollow cavity 2 arranged on the frame 1, a feed port 3 provided on the hollow cavity 2, and a device that rotates around its own axis. The roller shaft 4 in the hollow cavity 2 , the cutter 5 arranged on the outer periphery of the roller shaft 4 , and the driving mechanism 6 for driving the roller shaft 4 to rotate. In this embodiment, the feeding port 3 is arranged above the roller shaft 4 , and a plurality of cutting knives 5 are arranged on the outer periphery of the roller shaft 4 , and the cutting knives 5 are detachably installed on the roller shaft 4 . The driving mechanism 6 is a driving motor arranged on the frame 1 , and the driving motor is located outside the hollow cavity 2 .

[0020] The shredder also includes a pushing mechanism provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com