Patents

Literature

76results about How to "Good shredding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

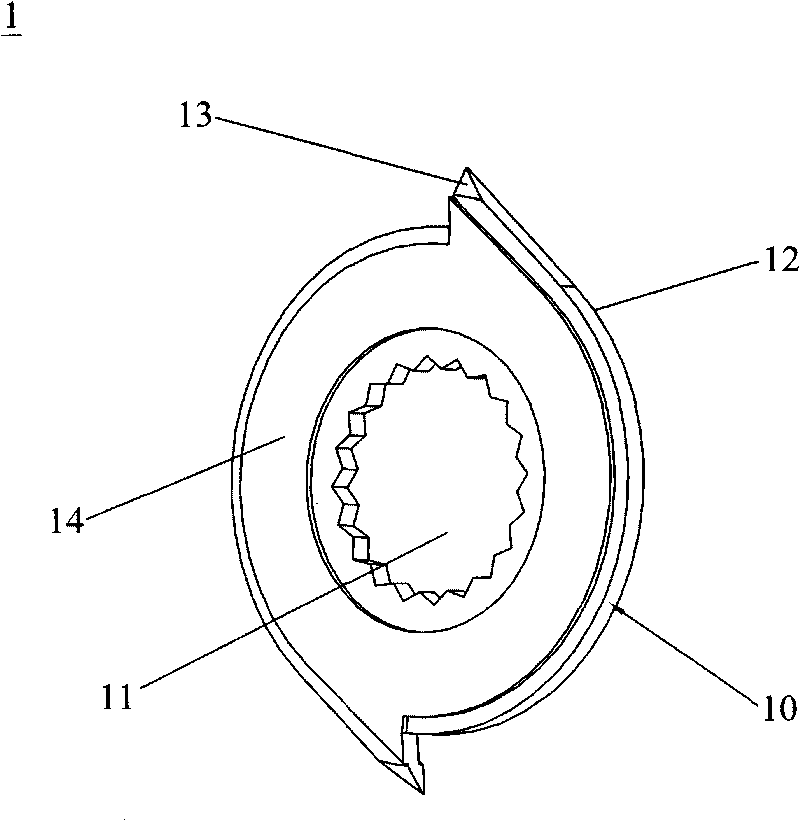

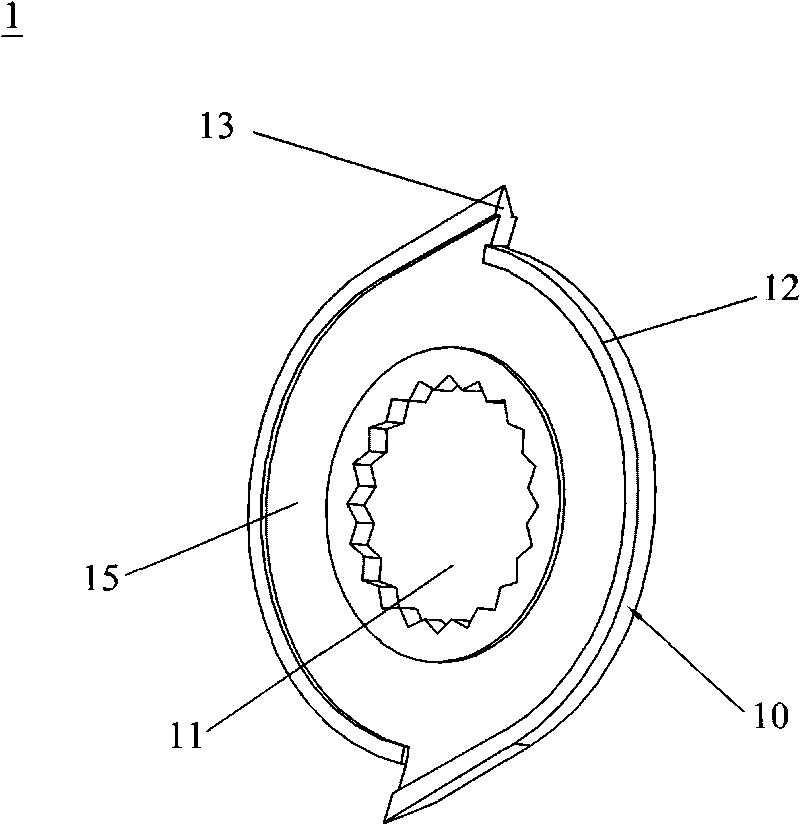

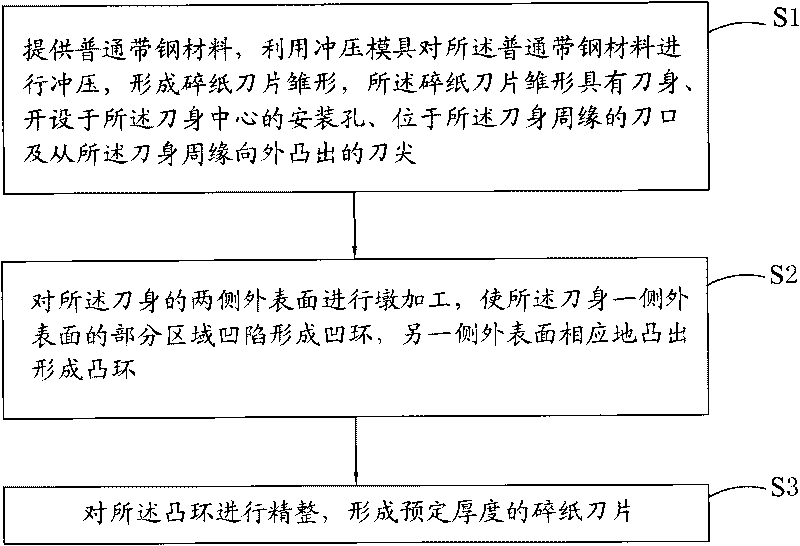

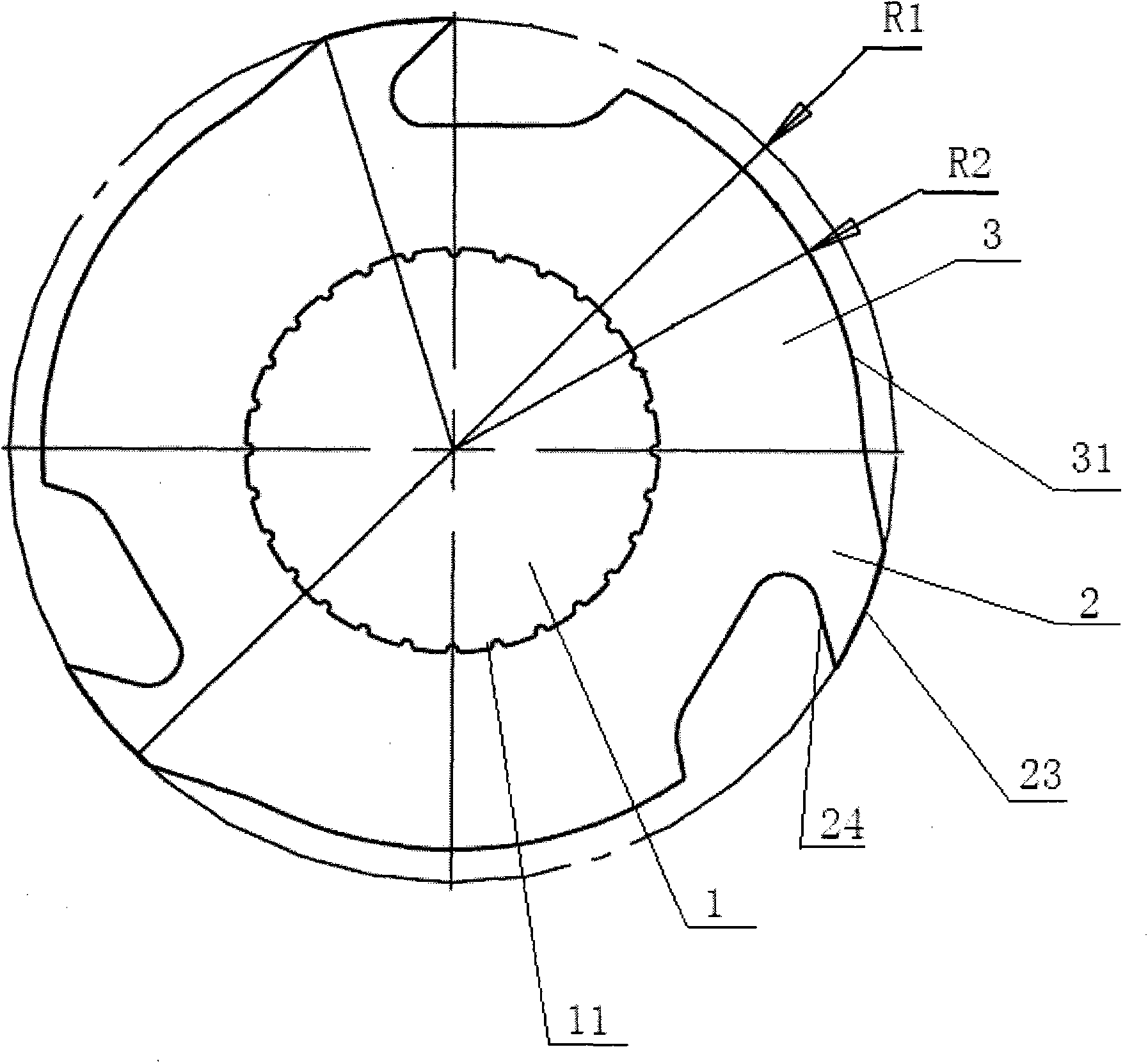

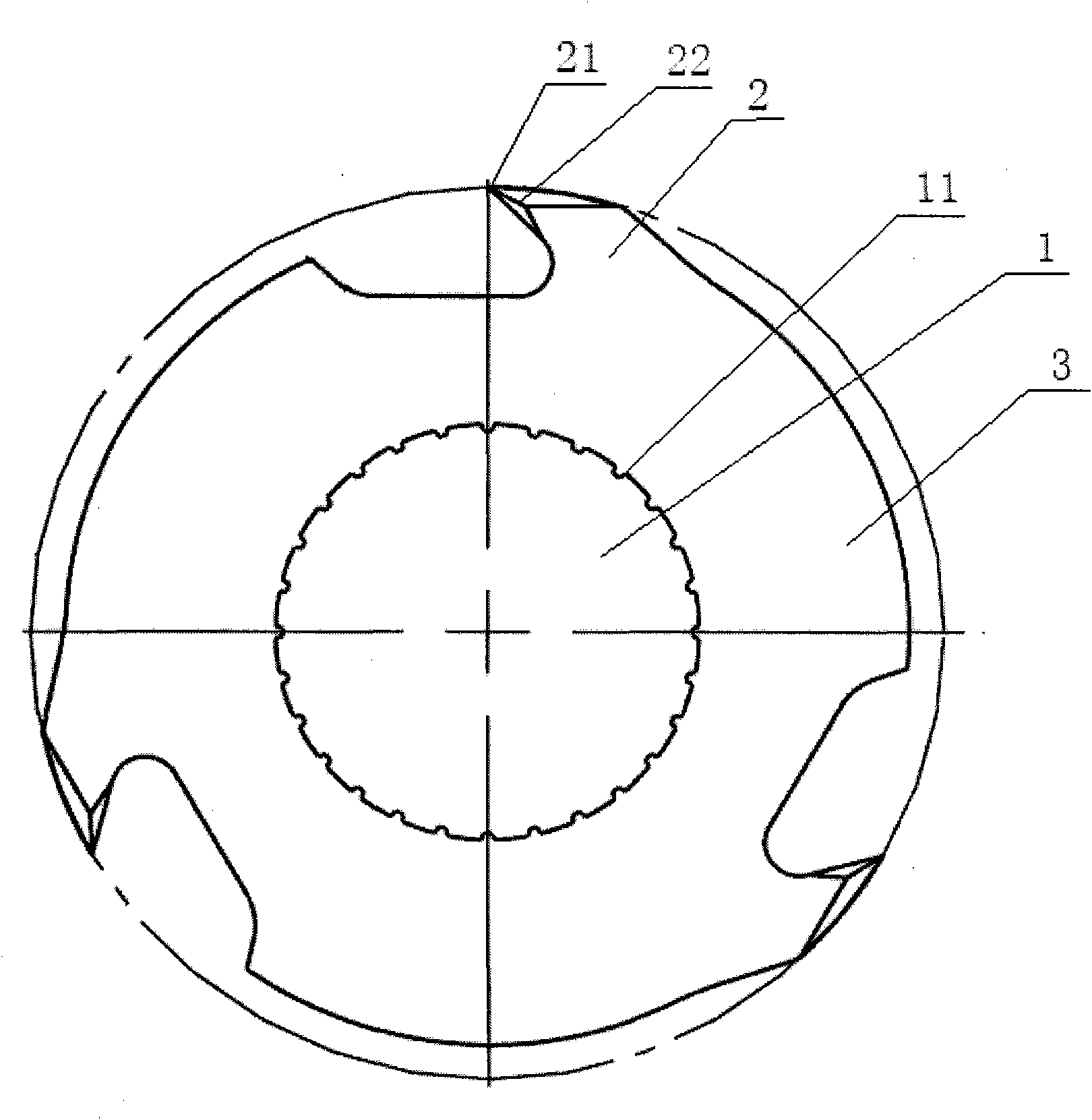

Paper chopping blade and machining method thereof

ActiveCN101722252AThickness dimension accuracy requirements are not highReduce energy consumptionGrain treatmentsCutleryStrip steelPulp and paper industry

The invention discloses a machining method of a paper chopping blade, which comprises the following steps of: (1) providing a common strip steel material, and stamping the common strip steel material by utilizing a stamping die to form a prototype of the paper chopping blade, wherein the prototype of the paper chopping blade is provided with a blade body, an installing hole formed at the center of the blade body, a blade edge positioned at the periphery of the blade body and a blade tip which protrudes outward from the periphery of the blade body; (2) tamping the outer surfaces of two sides of the blade body so that the partial region of the outer surface of one side of the blade body sags to form a concave ring, and the outer surface of the other side correspondingly protrudes to form a convex ring; and (3) finishing the convex ring to form the paper chopping blade with the preset thickness. The machining method of the paper chopping blade of the invention can be used for producing a paper chopping blade with a precise size without finely machining the strip steel which is finely rolled, thereby having simple machining processes, small machining energy consumption, low cost, high production efficiency and wide material sources. The invention simultaneously discloses the paper chopping blade produced by the machining method.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD

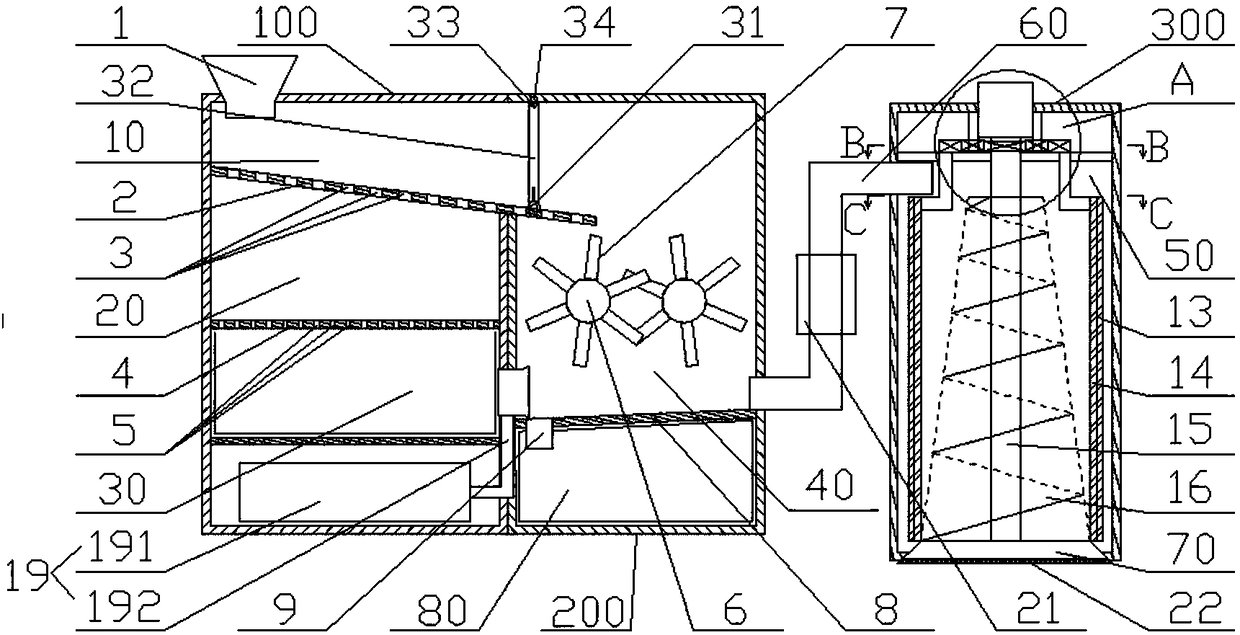

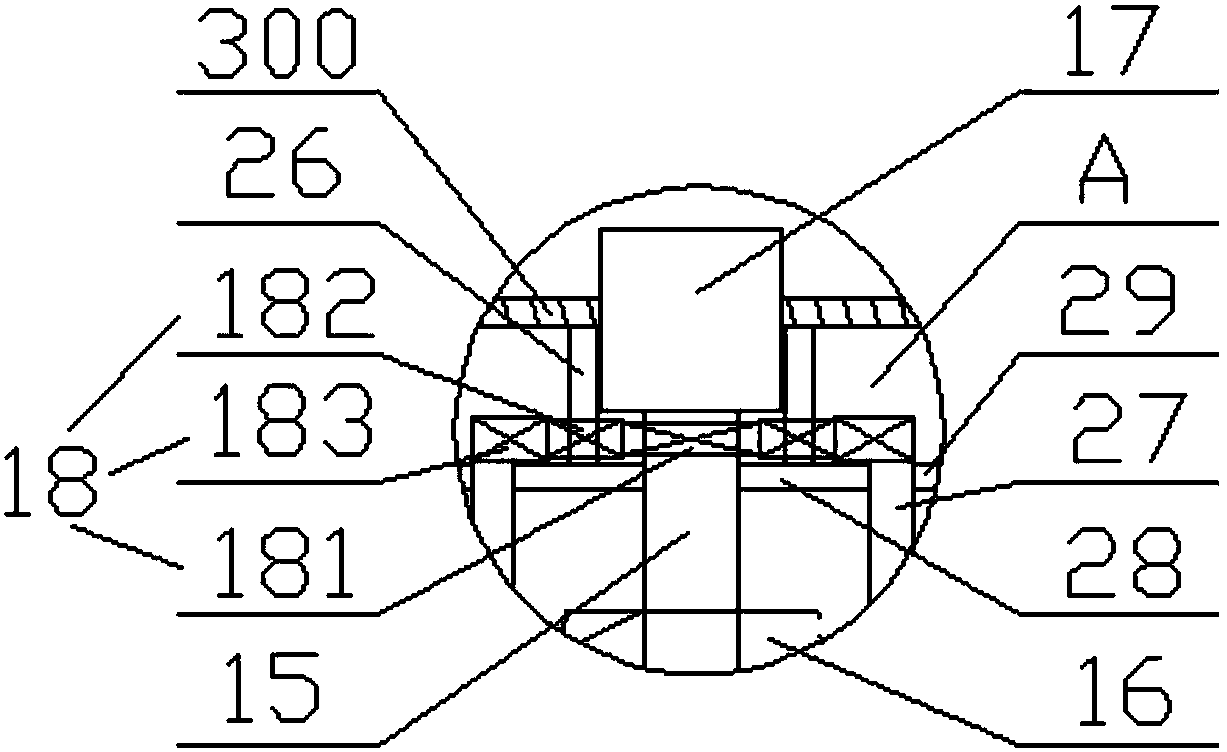

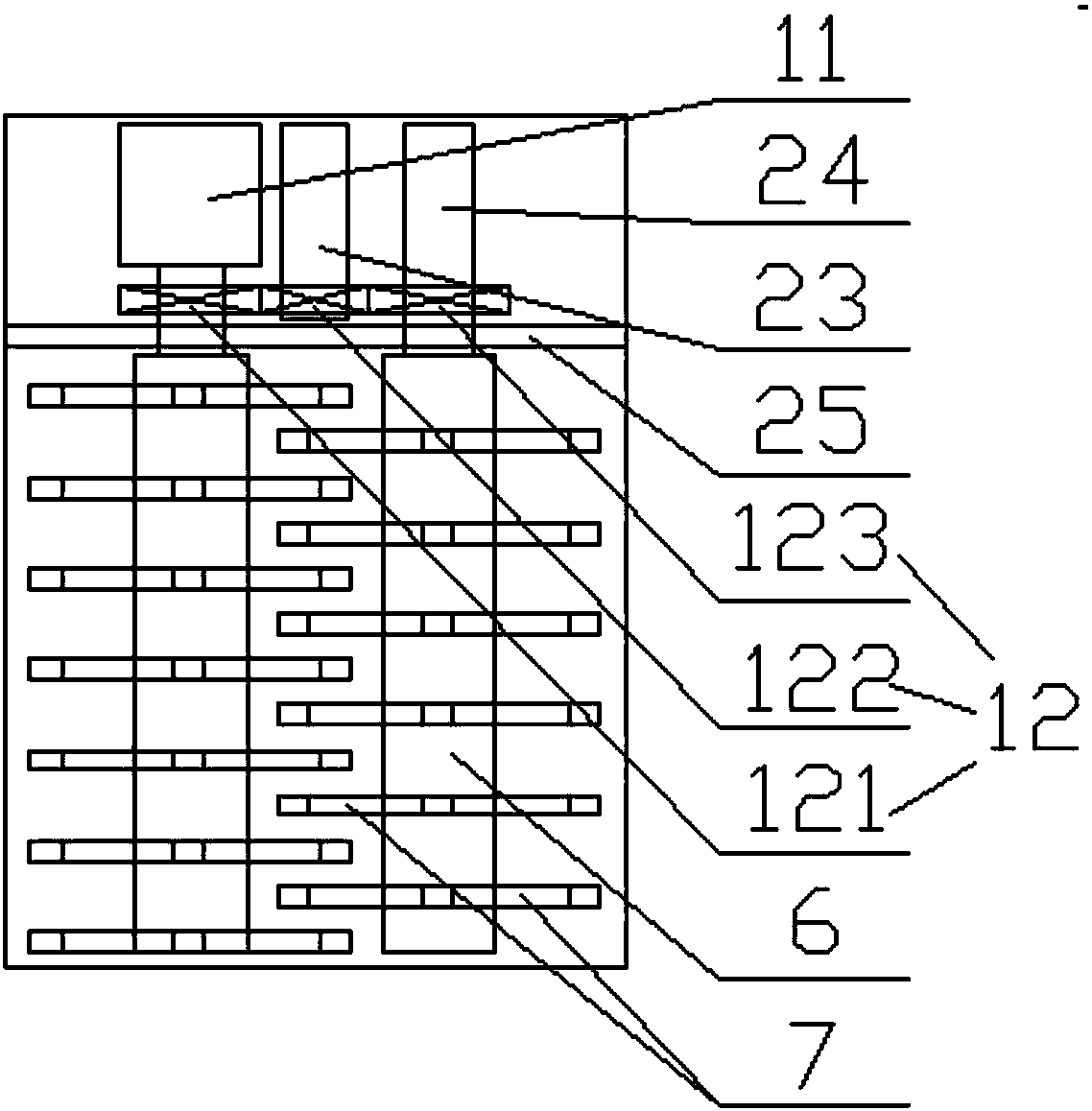

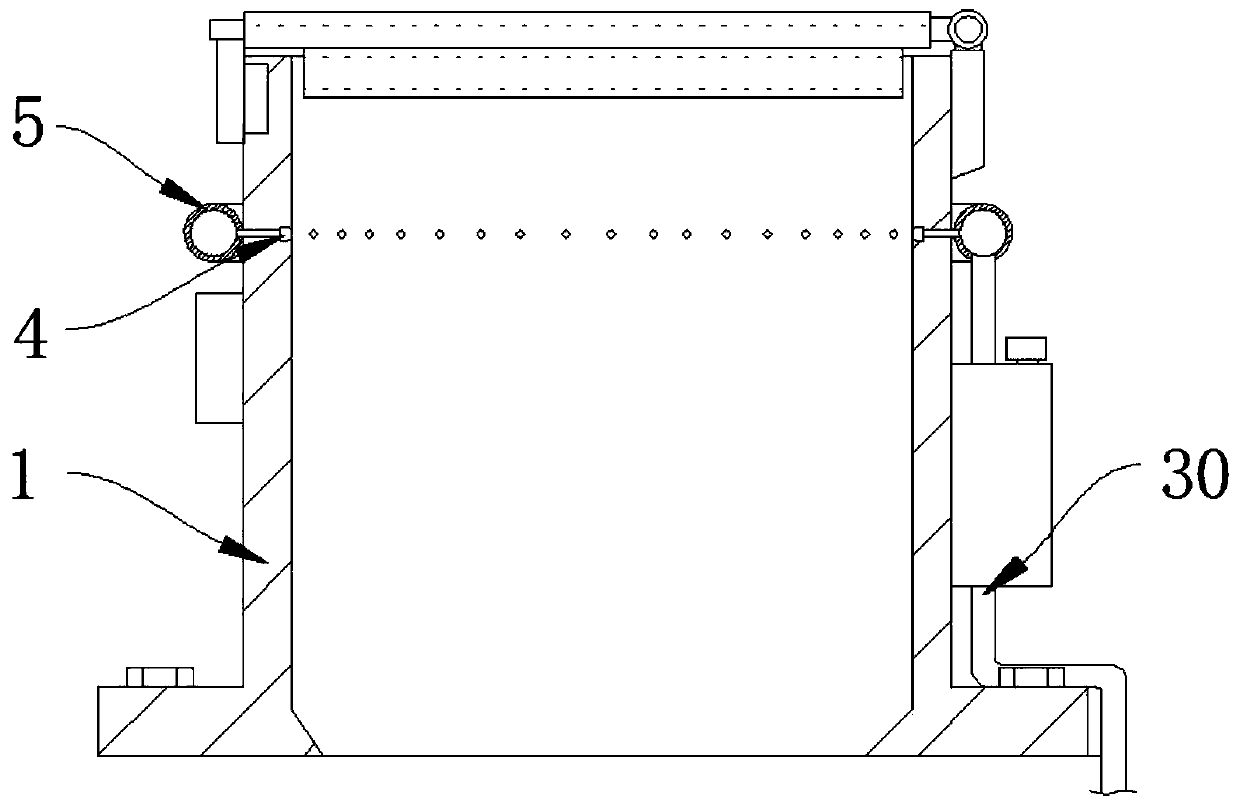

Household garbage shredding device

InactiveCN108339637AReduce wearGuaranteed service lifeGrain treatmentsStationary filtering element filtersLitterDomestic waste

The invention discloses a household garbage shredding device and belongs to the field of household garbage treatment. The device comprises a feeding mechanism, a shredding mechanism and a dischargingmechanism. The feeding mechanism comprises a liquid collecting cavity, a solid-liquid separating cavity and a feeding channel which are designed longitudinally from bottom to top in a stacked mode. The shredding mechanism comprises a primary shredding cavity communicating with the feeding channel and a secondary shredding cavity communicating with the primary shredding cavity. The discharging mechanism comprises a first discharging channel connected with an outlet of the primary shredding cavity and an inlet of the secondary shredding cavity, and a second discharging channel arranged at an outlet of the secondary shredding cavity. According to the household garbage shredding device, garbage materials can be classified before being shredded, garbage materials such as metal which does not need to be shredded are separated out, abrasion of products such as metal to tools can be reduced, and the working efficiency of the device is improved; and the garbage materials can be subjected to primary shredding, then continuous incremental shredding acting force is provided, and the shredding effect on the garbage materials is obviously good.

Owner:刘泰麟

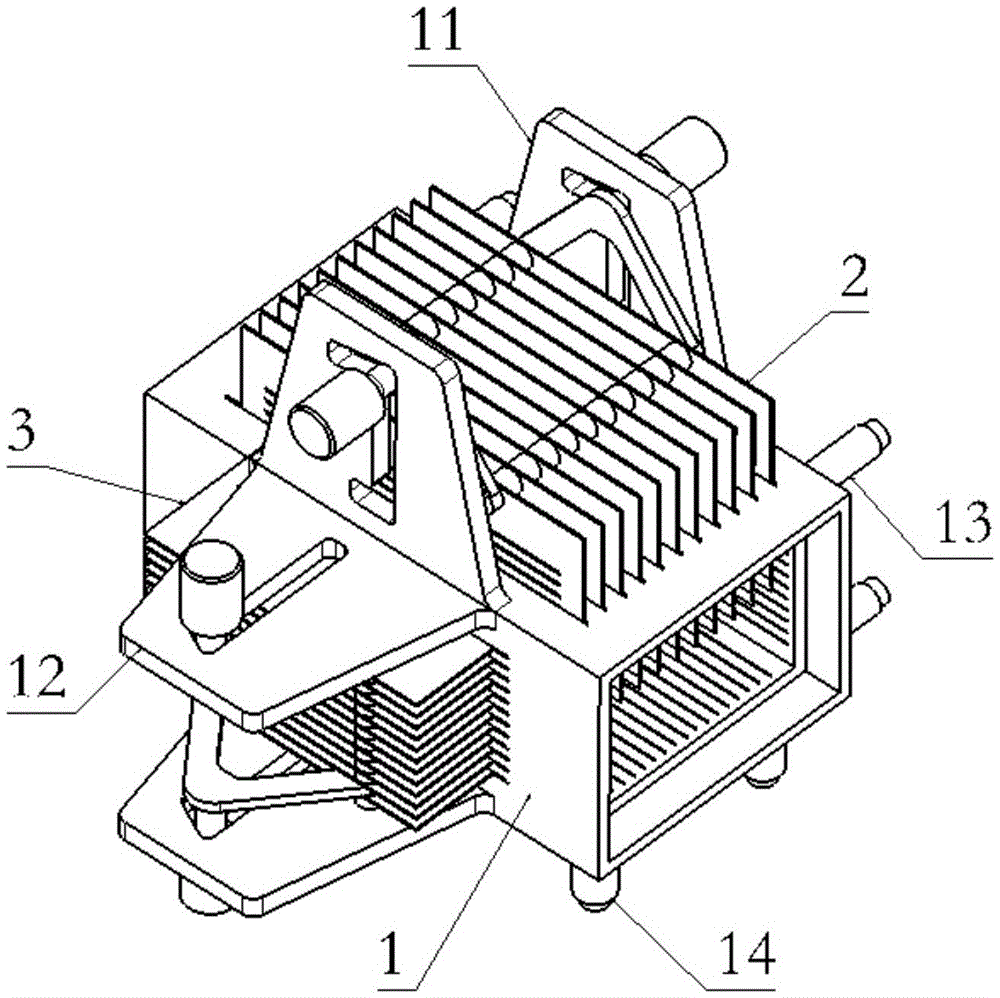

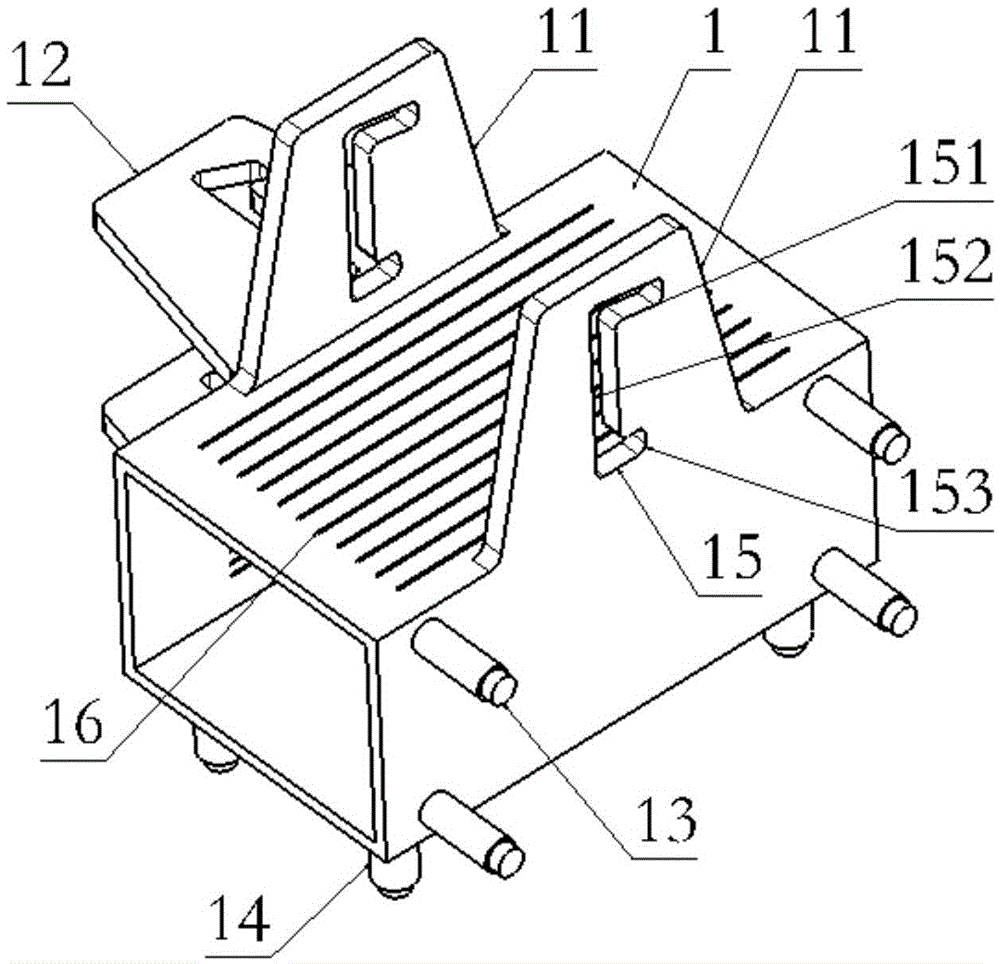

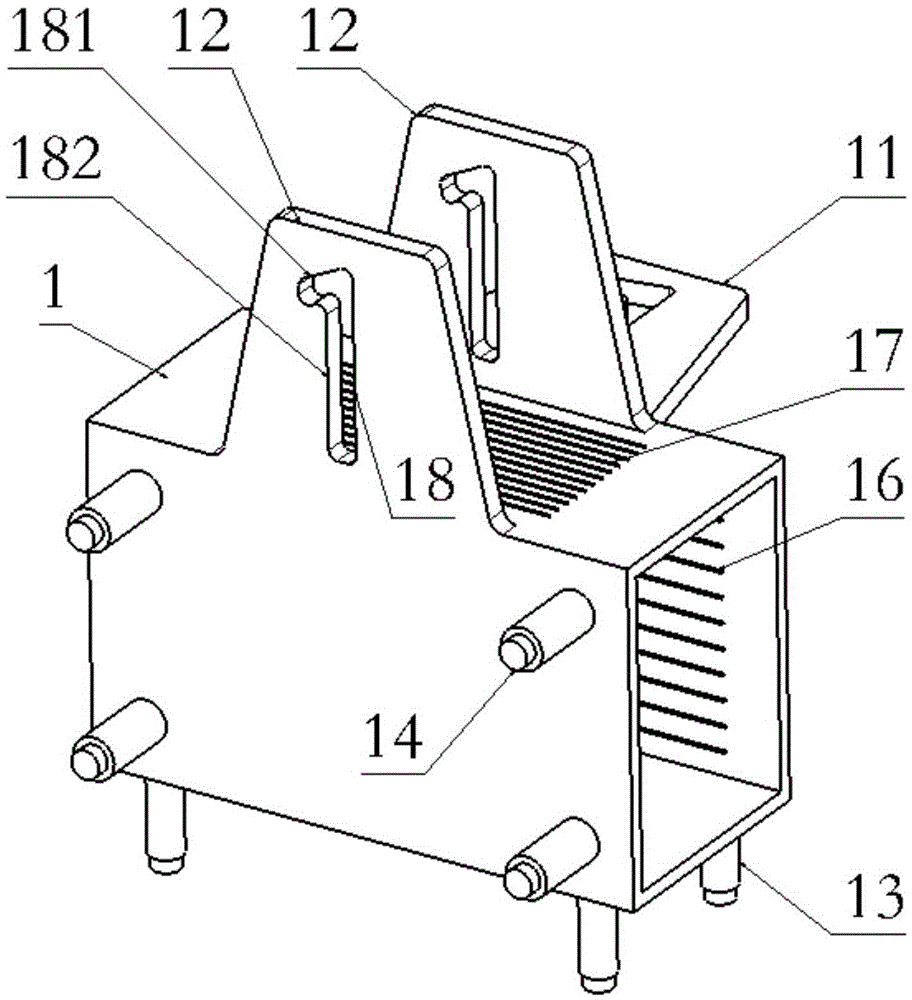

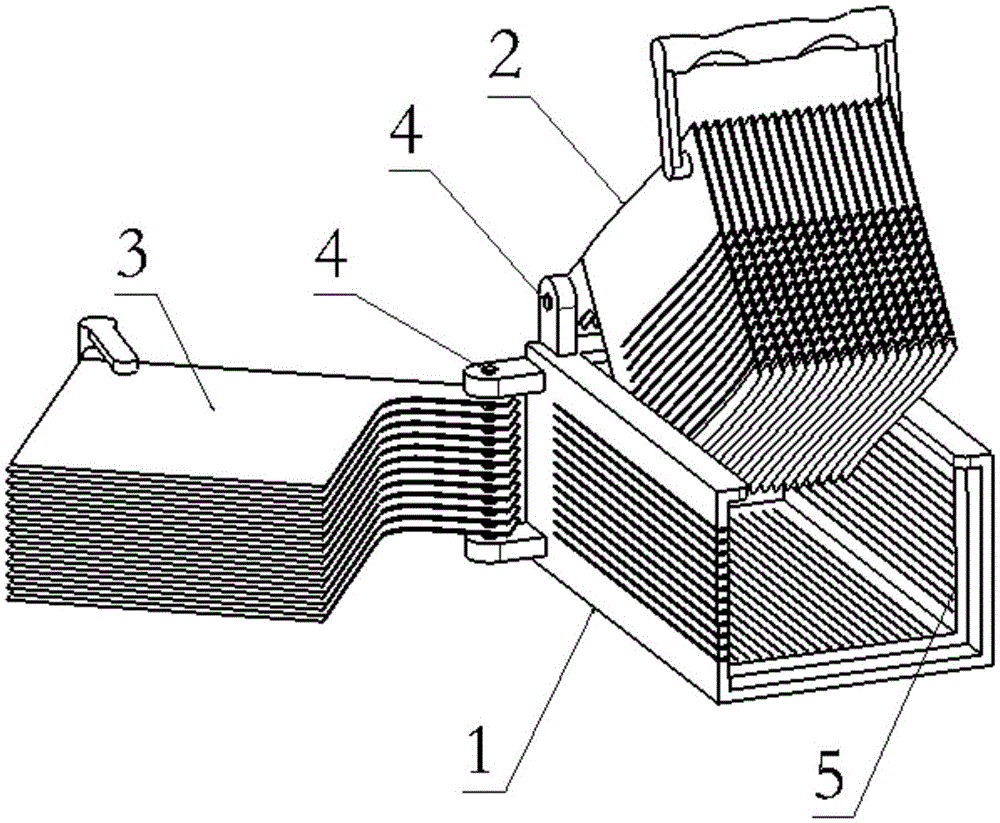

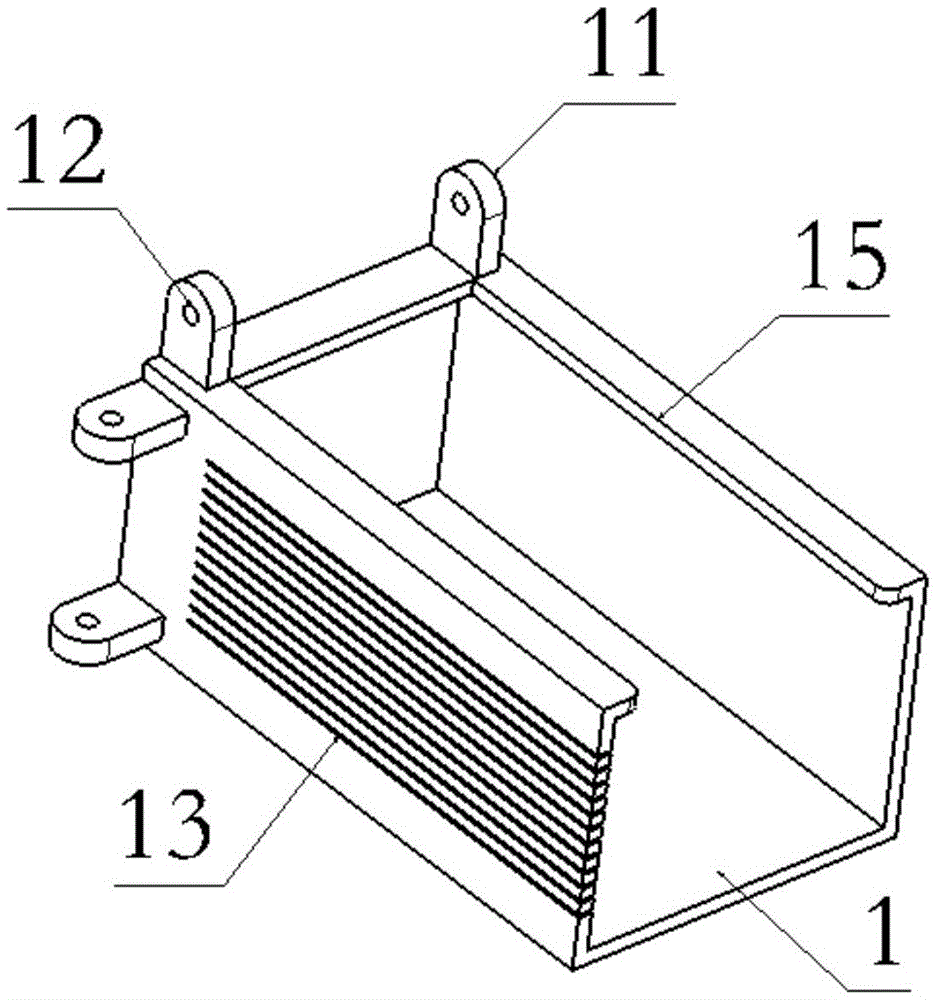

Shredding box for kitchen

The invention discloses a shredding box for a kitchen, which comprises a box body, a first row of knives, a second row of knives and an anvil block. Blocky vegetables are put in the box body and are slightly positioned by the anvil block; the first row of knives move downwards, and first knife edges pass through gate slots to cut the vegetables into pieces; under the situation of keeping the first row of knives immobile, the second row of knives are rotated to be vertical; the second row of knives move downwards, and second knife edges pass through the grate slots and cross slots to cut the pieces into filaments. The shredding box disclosed by the invention is convenient and quick and simple in structure; the knife edges are inside the box body, so that the safety of a user is ensured; meanwhile, the shredding effect is obvious, so that everyone can become a chef.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

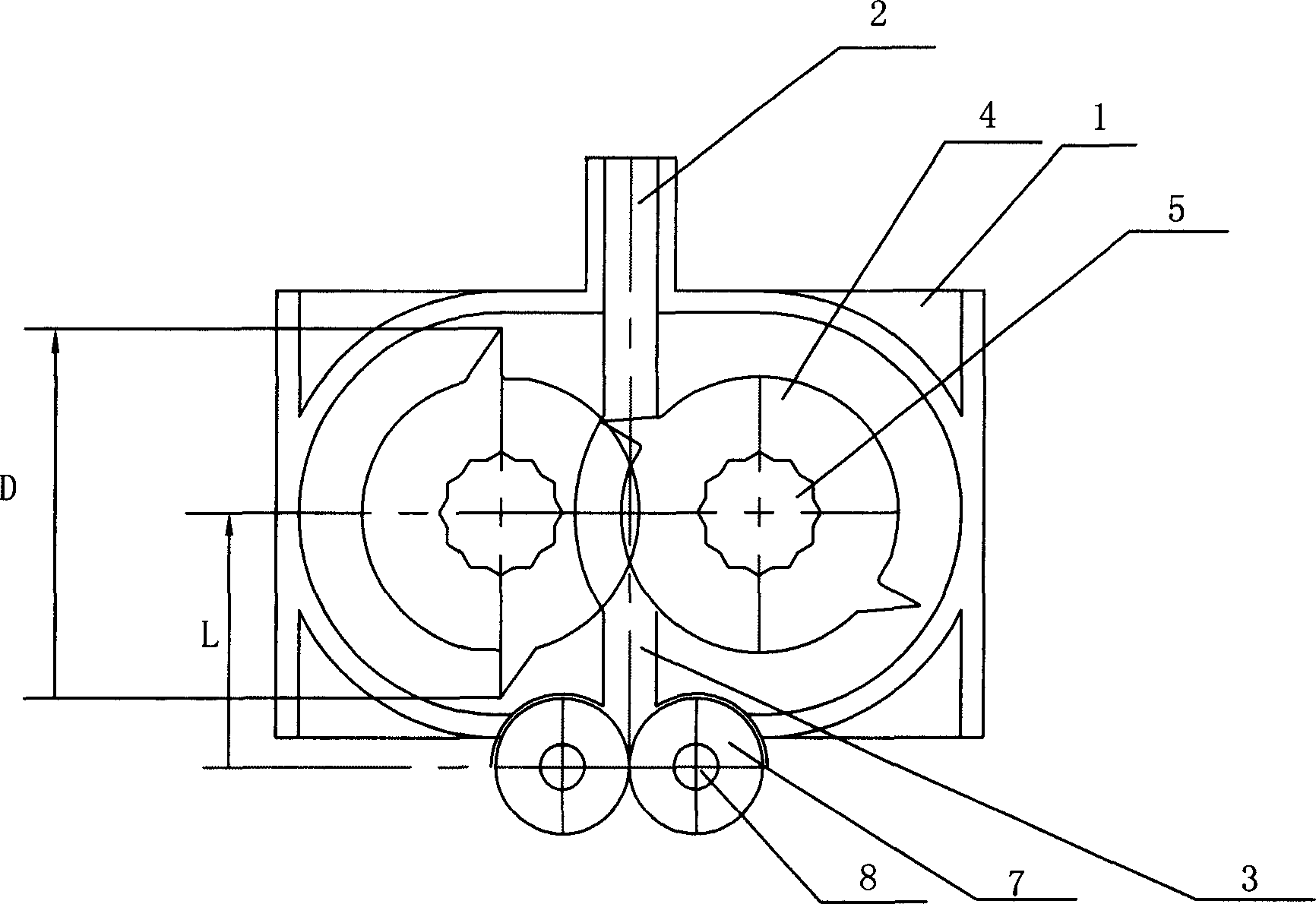

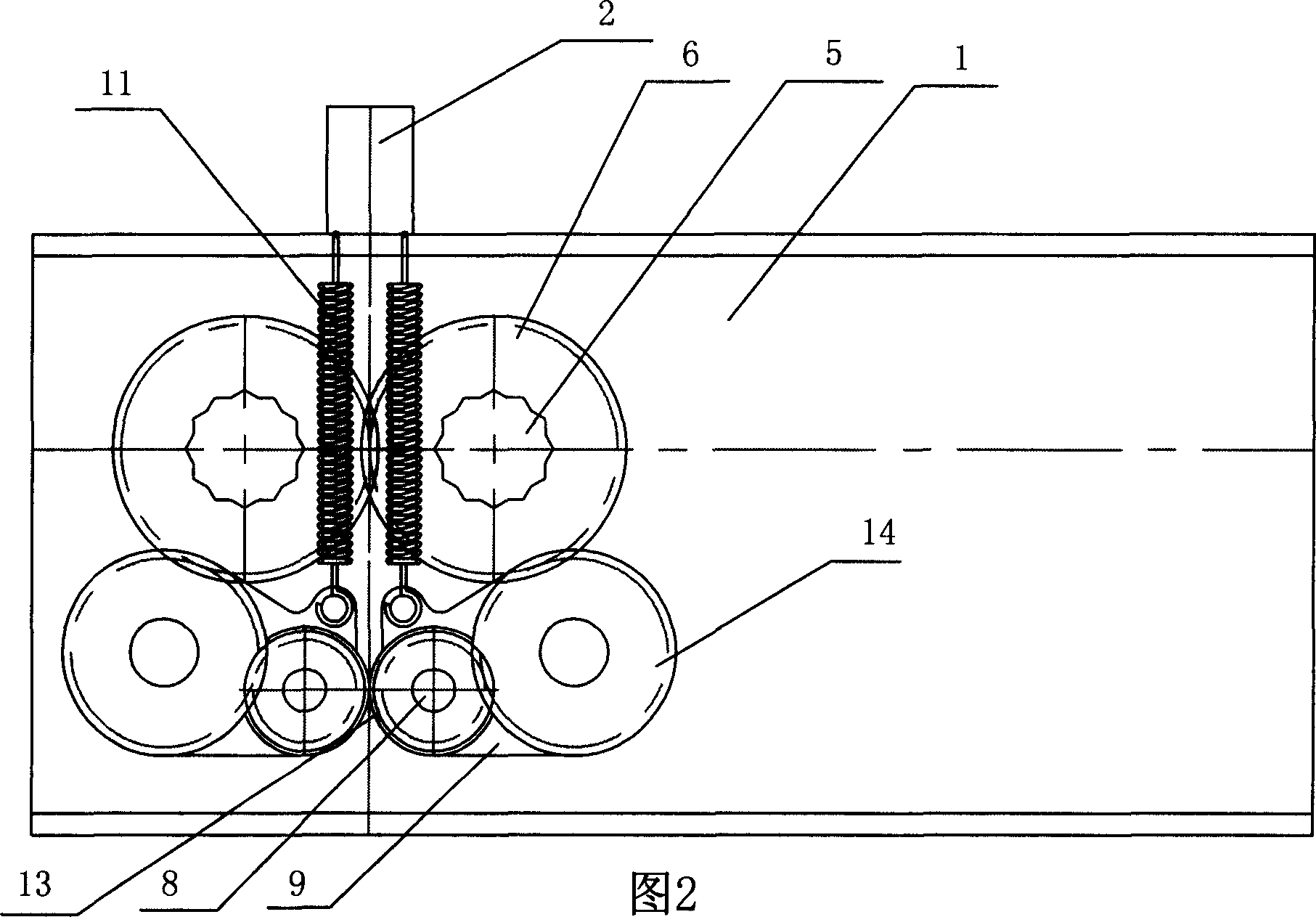

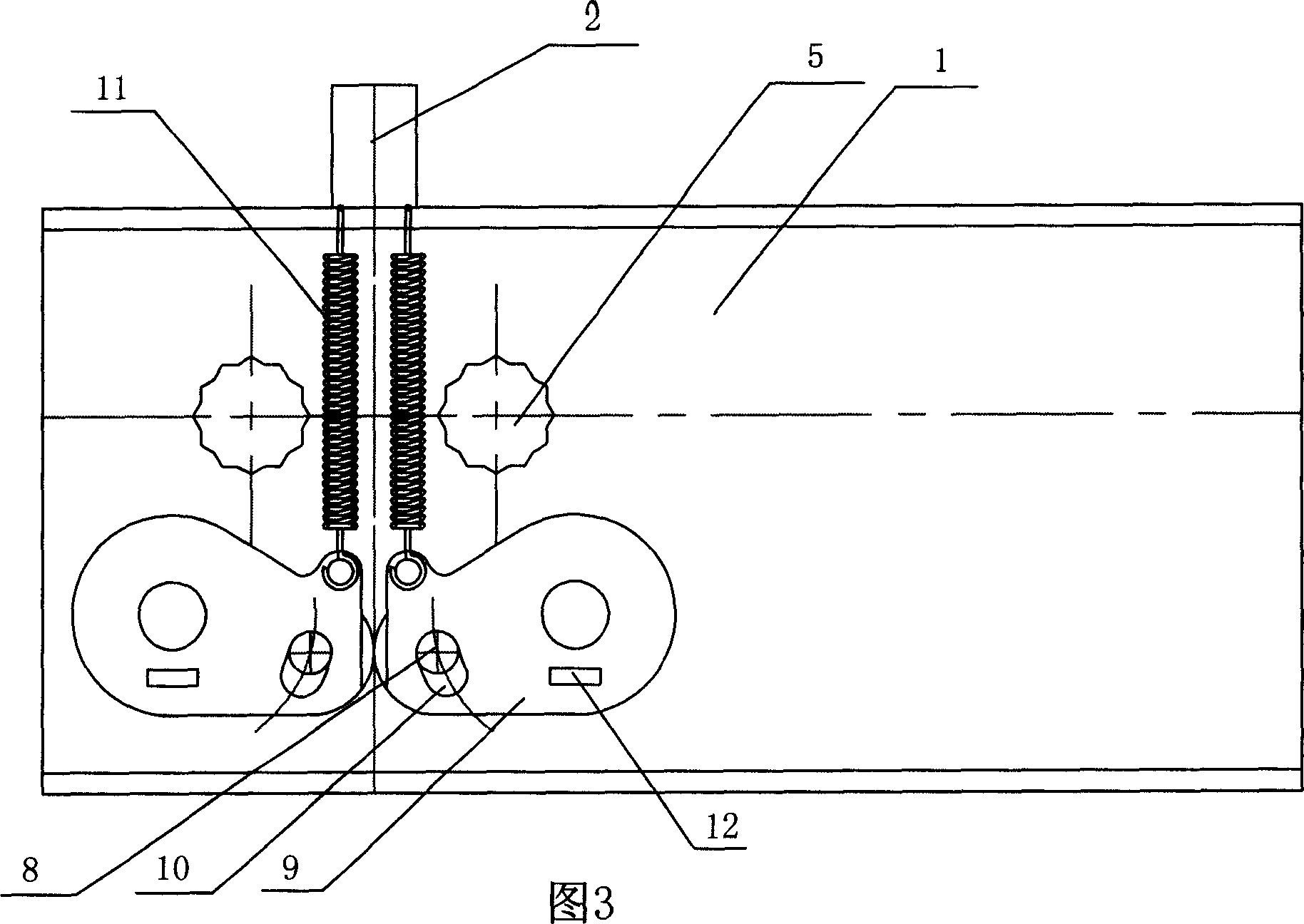

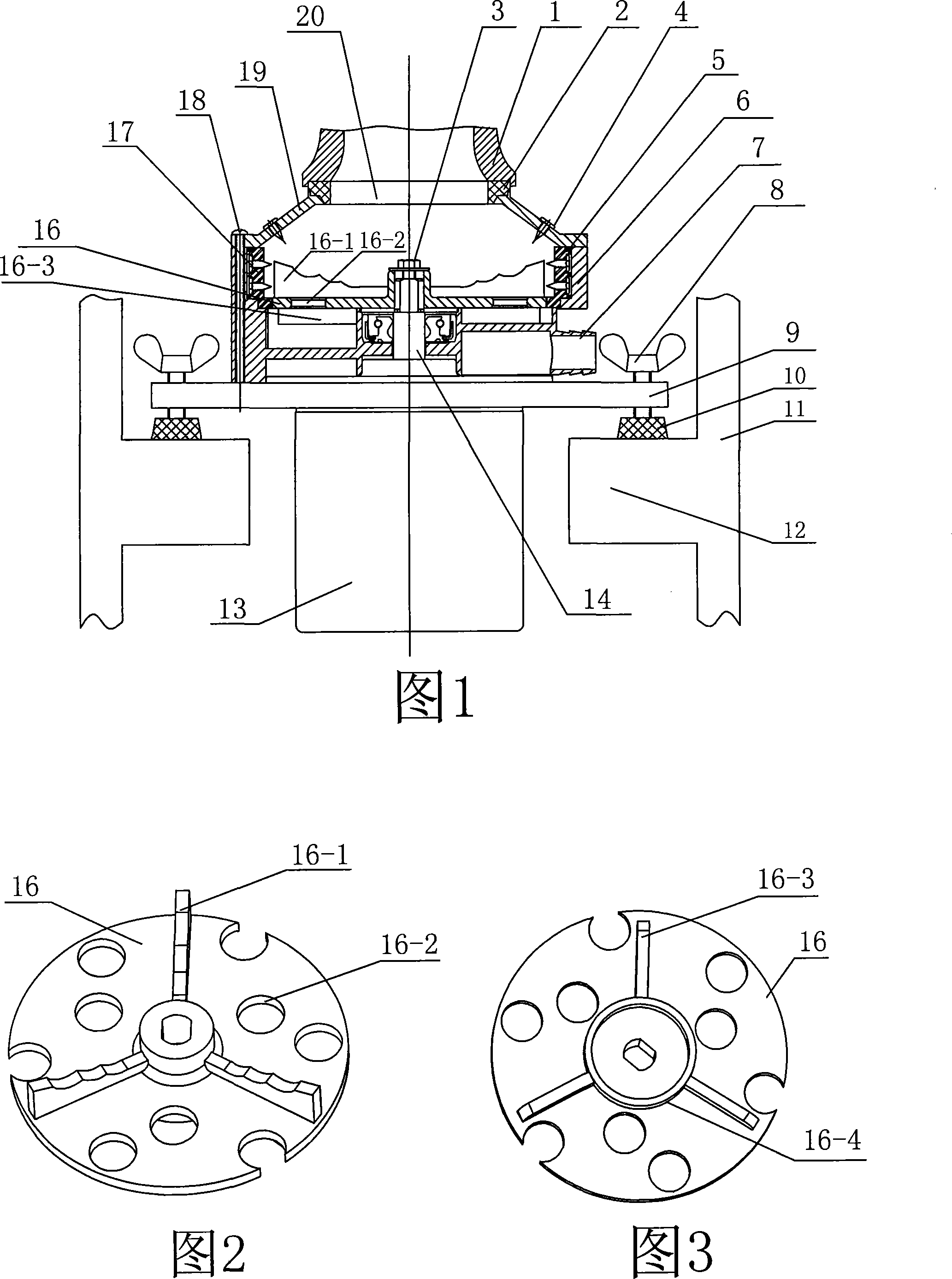

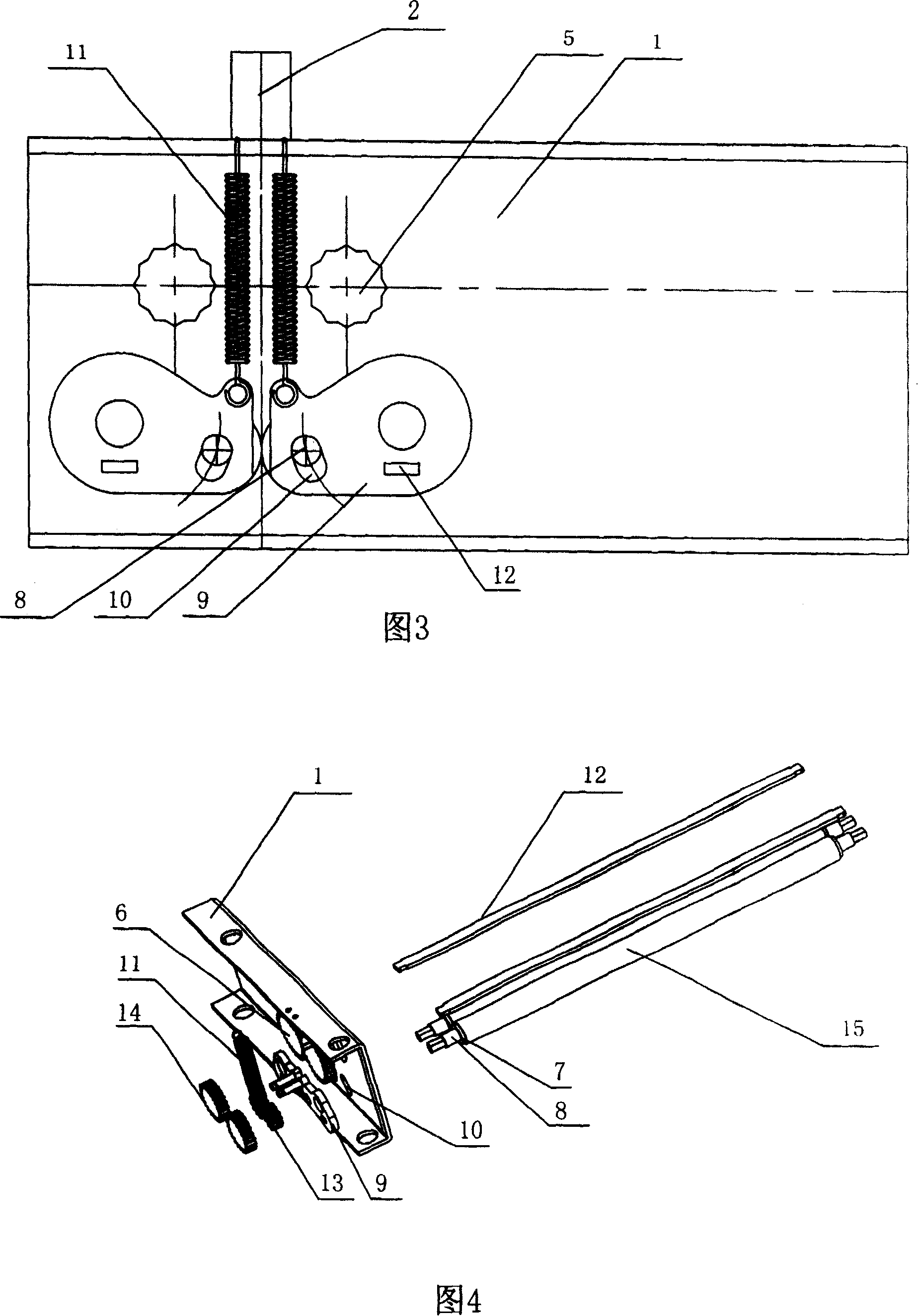

Machine core of paper pulverizer

InactiveCN1911519ANot easy to failExtend your lifeGrain treatmentsPulp and paper industryPaper sheet

Owner:黄铭玉

Novel garbage pulverizer

The invention discloses a novel garbage pulverizer. The novel garbage pulverizer comprises a shell, the inside of the shell is provided with a first cavity, a second cavity and a power cabin respectively, the second cavity is located right below the first cavity, and the power cabin is located on the right side of the second cavity, the inner bottom wall of the first cavity is equipped with a material port, the inner side wall of the first cavity is fixedly connected to first teeth and is equipped with a through-hole, the first cavity is internally equipped with an extrusion block, the left side of the extrusion block is fixedly connected to second teeth, the right side of the extrusion block is fixedly connected to support rod, one end of the support rod far from the extrusion block runsthrough the through-hole and extends to the inside of the power bin, the inner top wall of the power bin is fixedly connected to a first bearing, the inner side wall of the power bin is fixedly connected to a first motor, and the output end of the first motor is fixedly connected to a curved bar. The novel garbage pulverizer can improve the overall paper shredding effect and meet the needs of users, has high practical value, and is beneficial to popularization.

Owner:江苏万通塑业有限公司

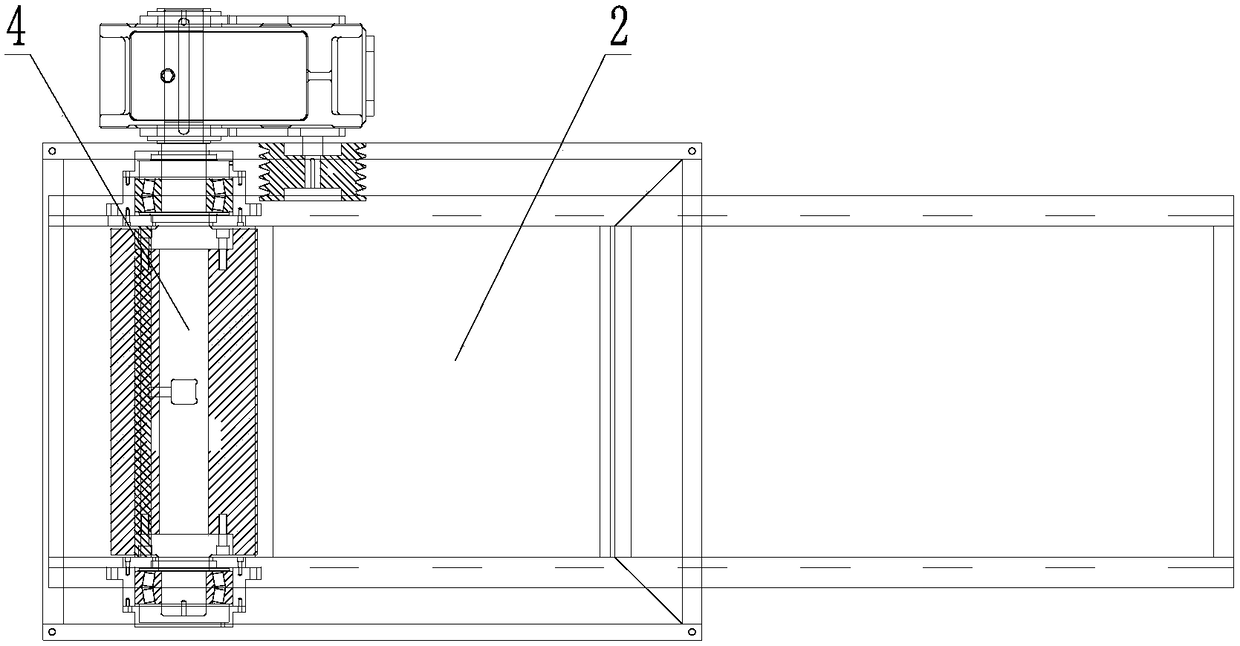

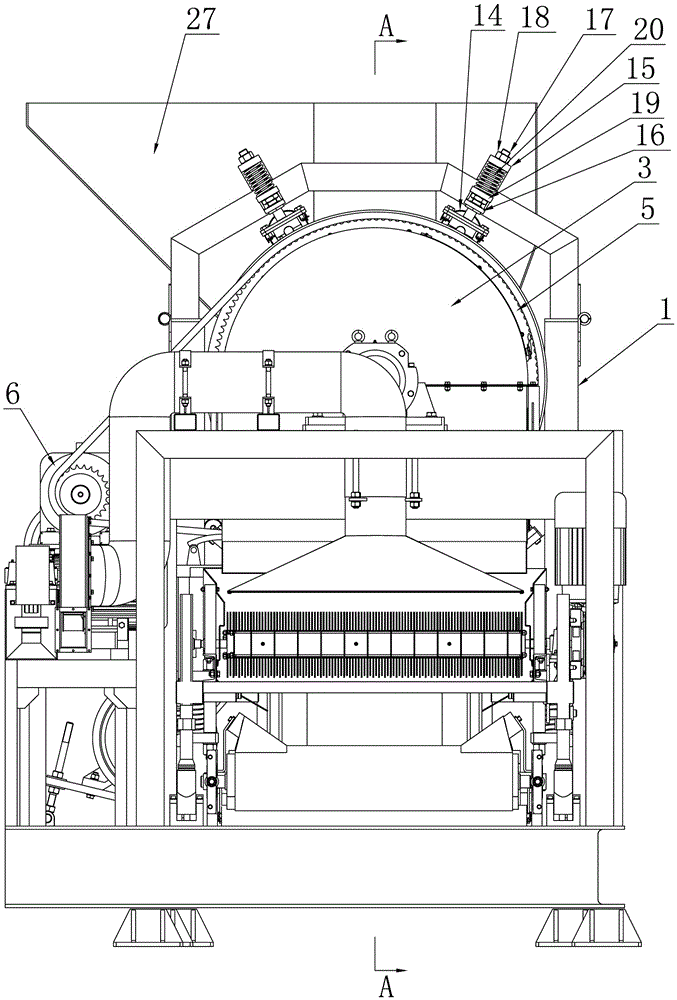

Shredding machine

PendingCN108215004AEfficient shreddingImprove shredding efficiencyPlastic recyclingGrain treatmentsEngineeringCutting force

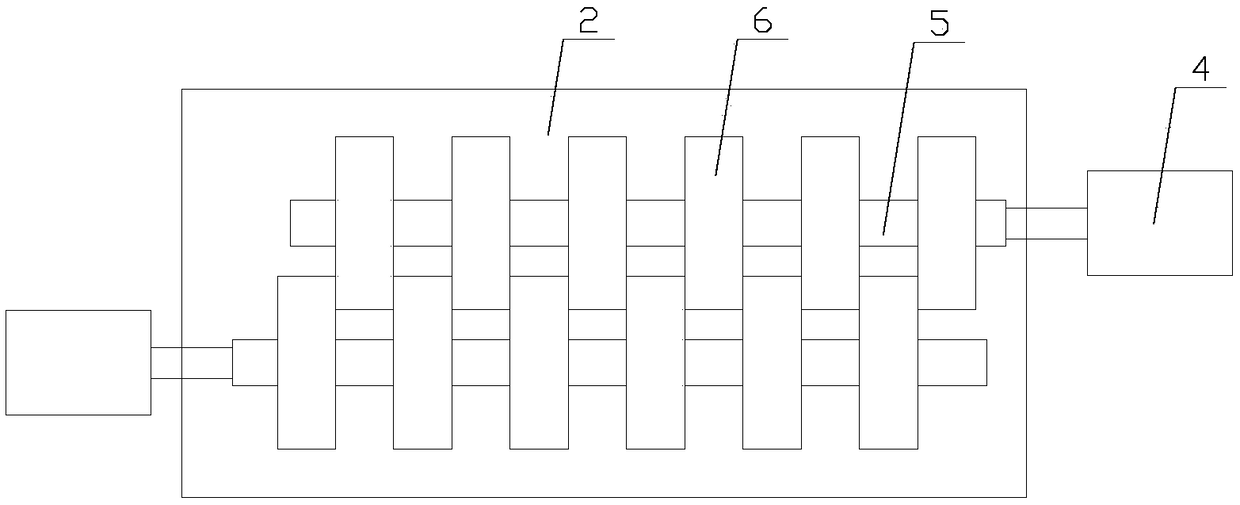

The invention discloses a shredding machine. The shredding machine comprises a rack, a hollow cavity, a feeding inlet, a roller shaft, a cutter, a driving mechanism and a pushing mechanism, wherein the hollow cavity is formed in the rack; the feeding inlet is formed in the hollow cavity; the roller shaft is rotationally arranged in the hollow cavity around a self central axis direction; the cutteris arranged at the circumferential part of the outer side of the roller shaft; the driving mechanism is used for driving the roller shaft to rotate; the pushing mechanism is arranged in the hollow cavity along a direction which is close to or far away from the roller shaft in a sliding way, and is used for pushing materials to the roller shaft. According to the shredding machine disclosed by theinvention, the cutter is arranged on the roller shaft, the materials can be pushed to the roller shaft through the pushing mechanism, the materials can be effectively shredded by matching a pushing force generated by the pushing mechanism on the materials and a rotary cutting force of the cutter on the roller shaft, the shredding efficiency is higher, and a shredding effect is better.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

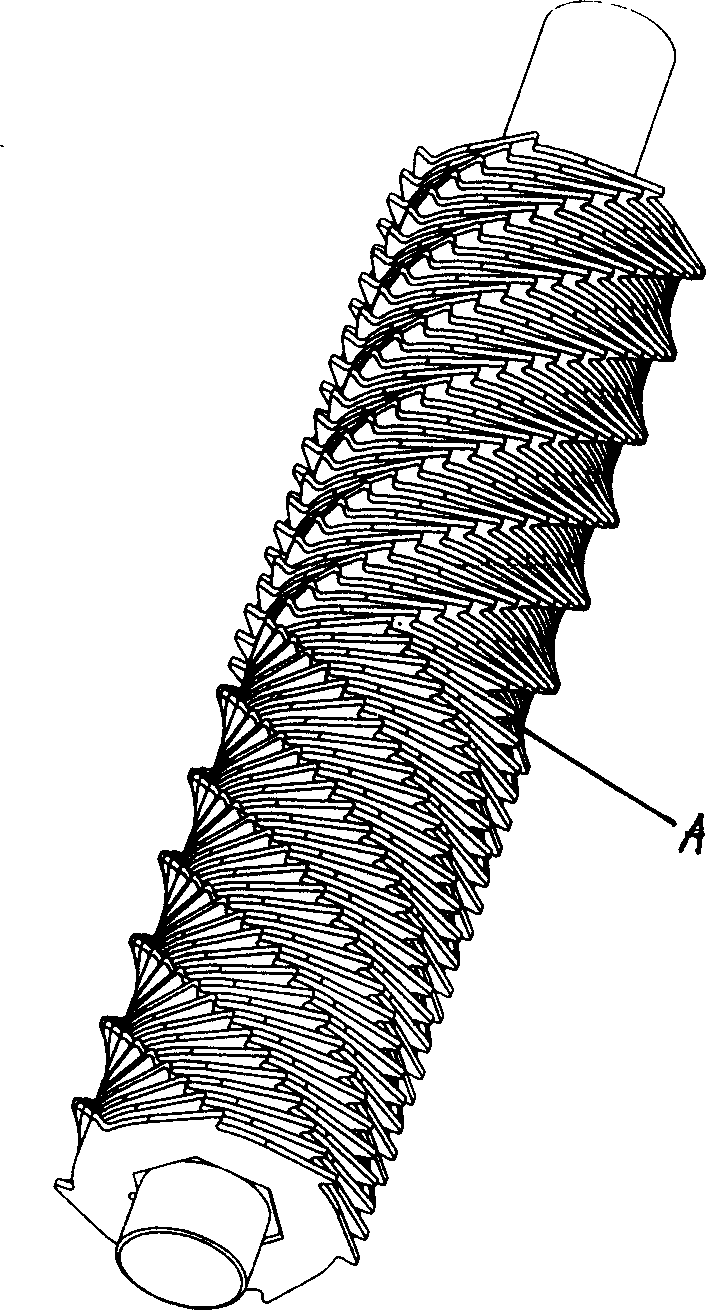

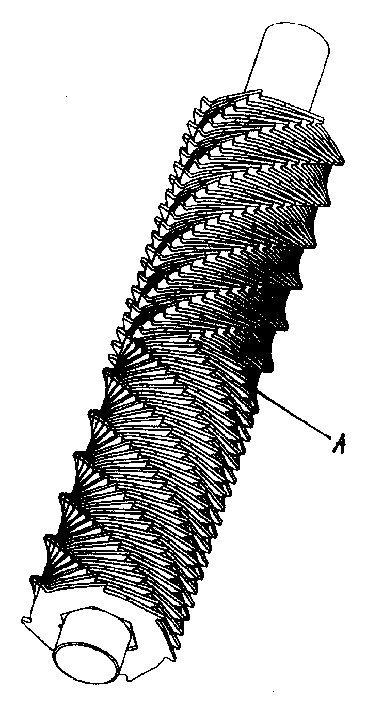

Method assembling blade of paper cutting machine

InactiveCN1418732ASolve uneven forceIncrease shreddingGrain treatmentsHelical linePulp and paper industry

The present invention relates to a blade variety of cone breaker. It includes helical blade body, the central position of cutter shaft is used as boundary, and the blade tips are respectively arranged toward two sides according to the forward and backward two-directional halical lines, this arranged blade tips can make the paper pieces simultaneously move toward two sides in the breaking process,so that it can effectively solve the problem of that the force applied on the cutter shaft is not uniform, said blade tip arrangement not only increase paper-breaking quantity, but also raise its breaking efficiency.

Owner:林中选

Hollow bamboo shoot shredding device

PendingCN108422460ASolve the problem of leftovers caused by unstable vertical placement and easy to fall downReasonable structureMetal working apparatusEngineeringWaste material

The invention relates to the technical field of agricultural machinery devices, in particular to a hollow bamboo shoot shredding device. Compared with the prior art, the hollow bamboo shoot shreddingdevice is characterized in that a conveying device is arranged at the right upper end position of a machine frame, meanwhile, a feeding hole of a shredding and discharging device is formed right abovethe center point of a shredding and discharging cylinder, a conveying belt guide rail is sleeved with the feeding hole, so that the transverse cutting position of a cutter and a shredding cutter andthe position of the feeding hole are in a right-angle relation, then, when bamboo shoots are cut, the hollow bamboo shoots can be transversely placed on the conveying belt, and are conveyed to the position of the feeding hole through the conveying belt and then are shredded under the cooperation of the cutter, transverse shredding is carried out on the transversely-placed hollow bamboo shoots by the rotary cutter, so that the problem of leftovers caused by the fact that the hollow bamboo shoots are unstable when being vertically placed and then are prone to falling down is solved, the hollow bamboo shoots are completely cut into bamboo shoot slice, and waste materials are avoided; and the device has the advantages of being reasonable in structure, stable in use, good in shredding effect and the like.

Owner:卢伟

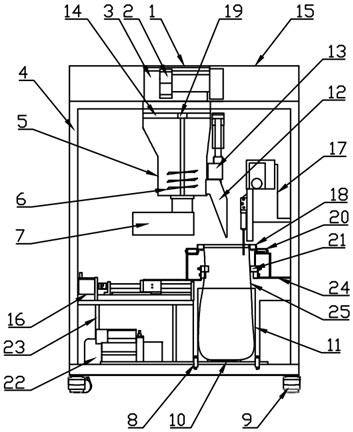

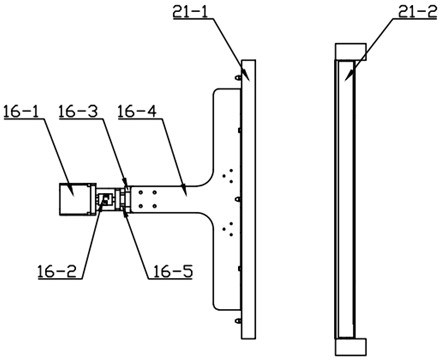

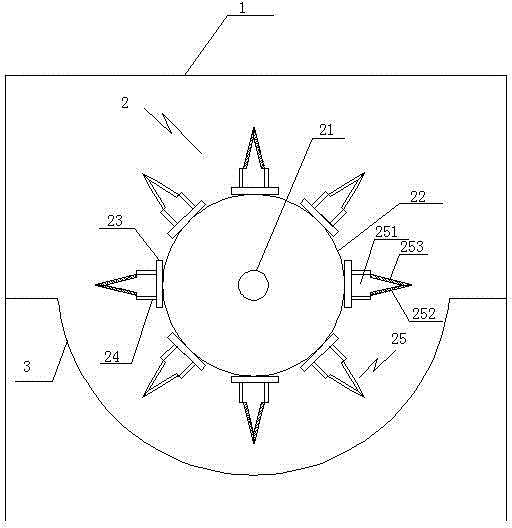

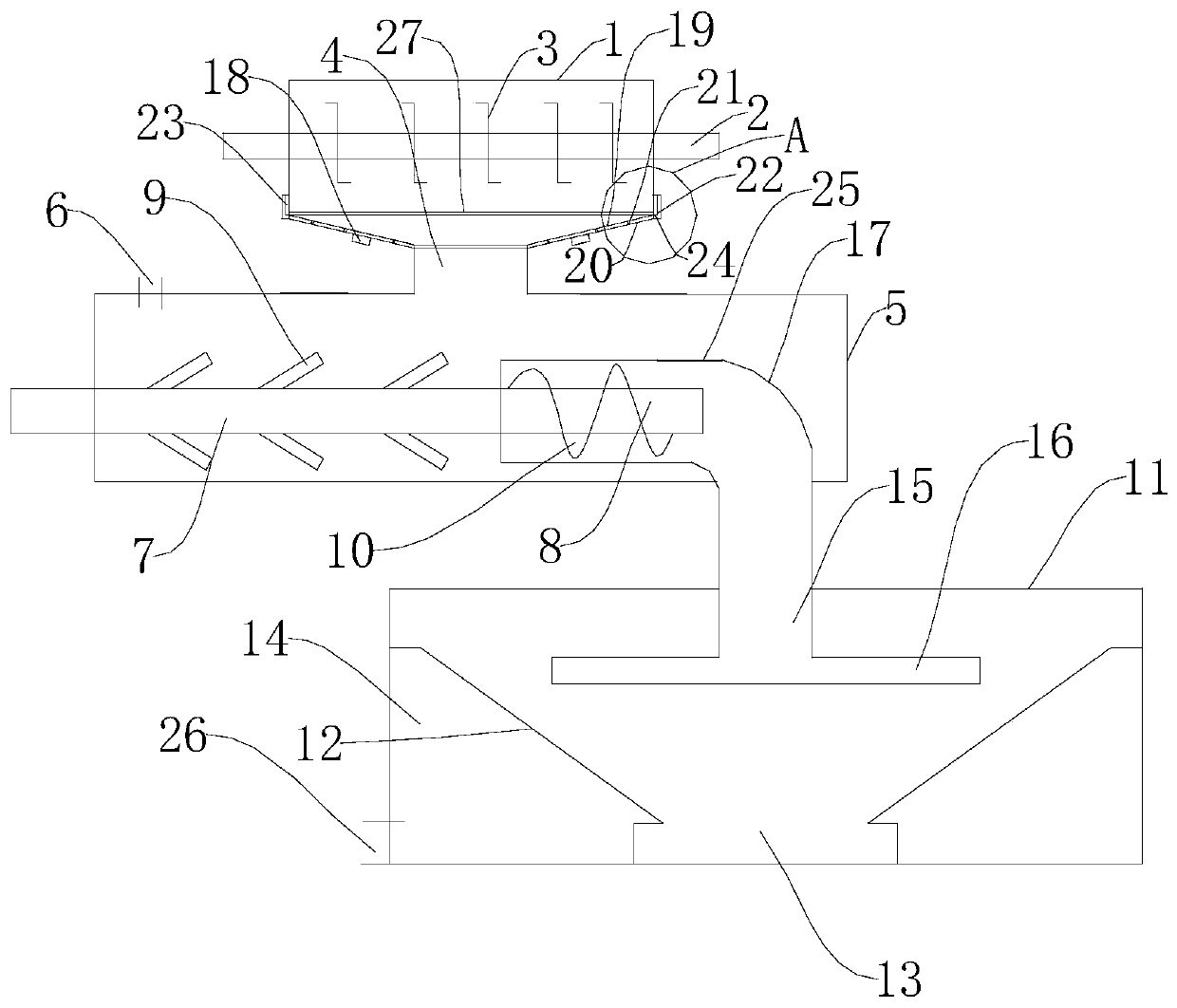

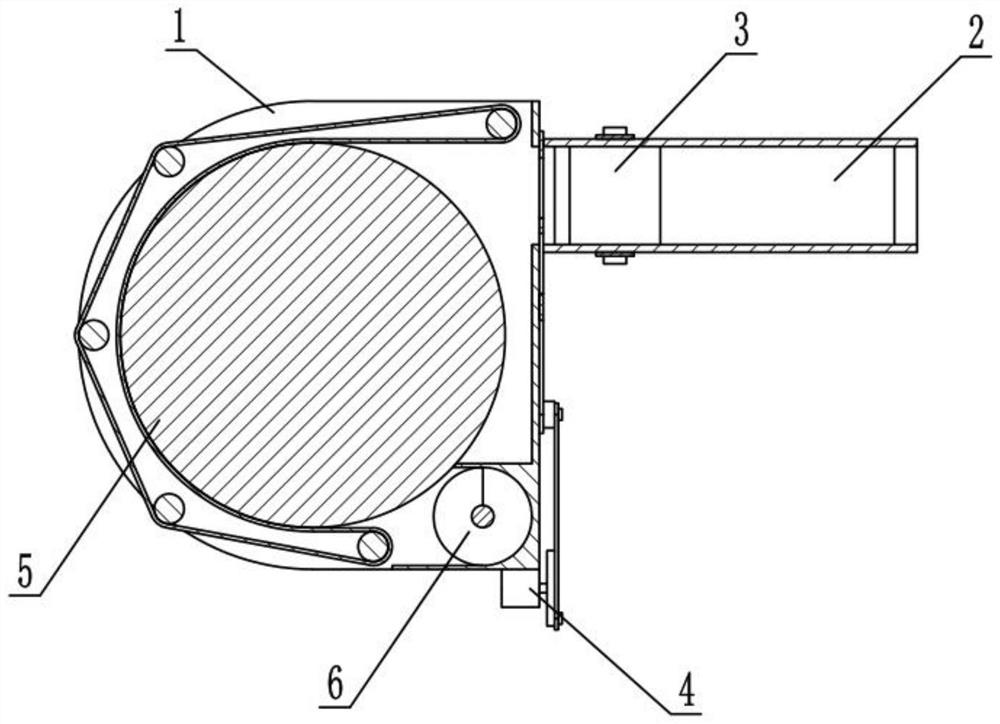

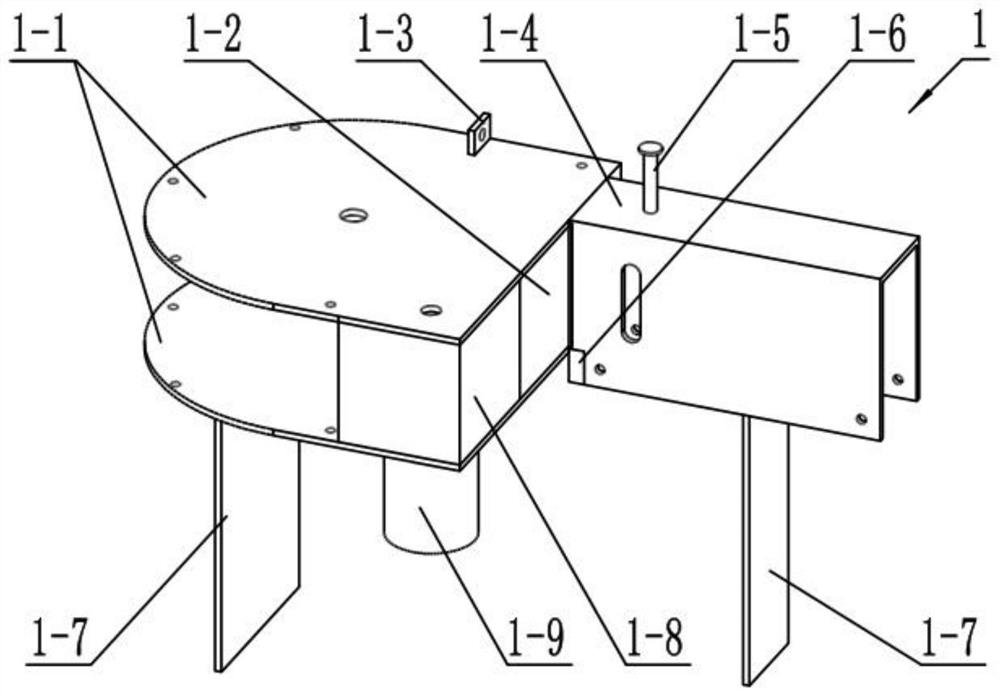

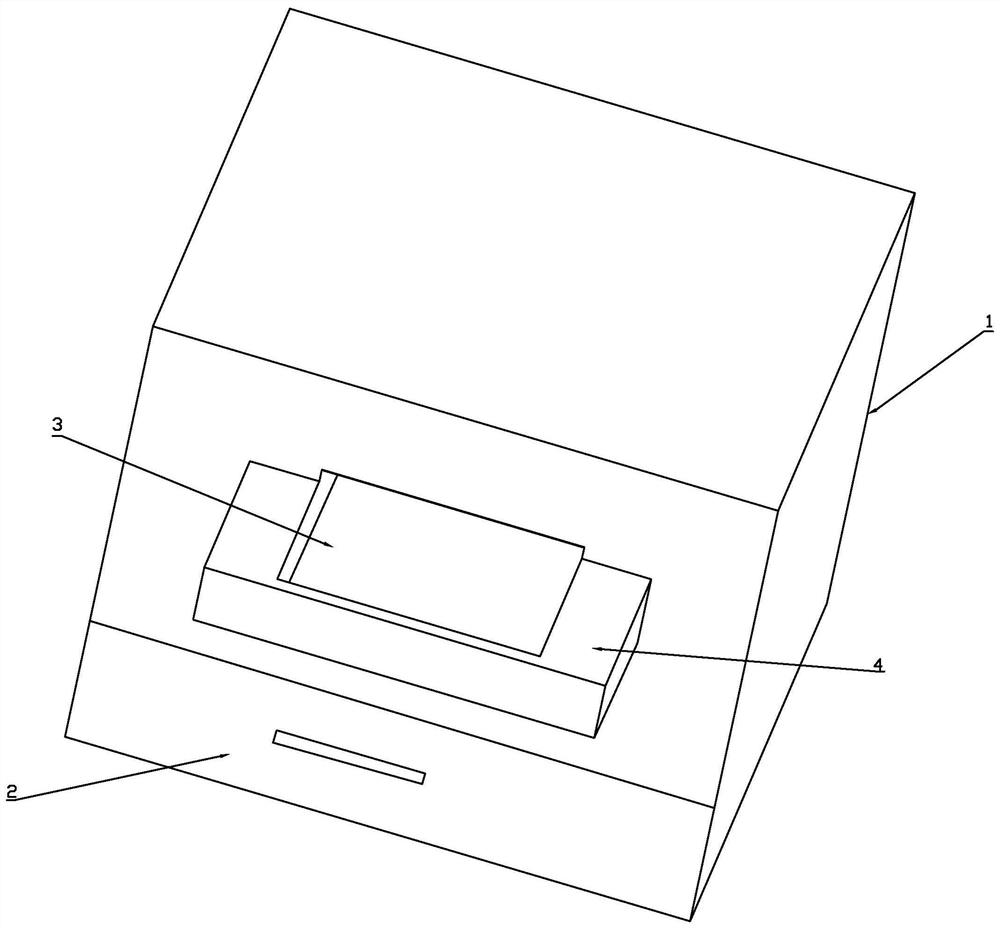

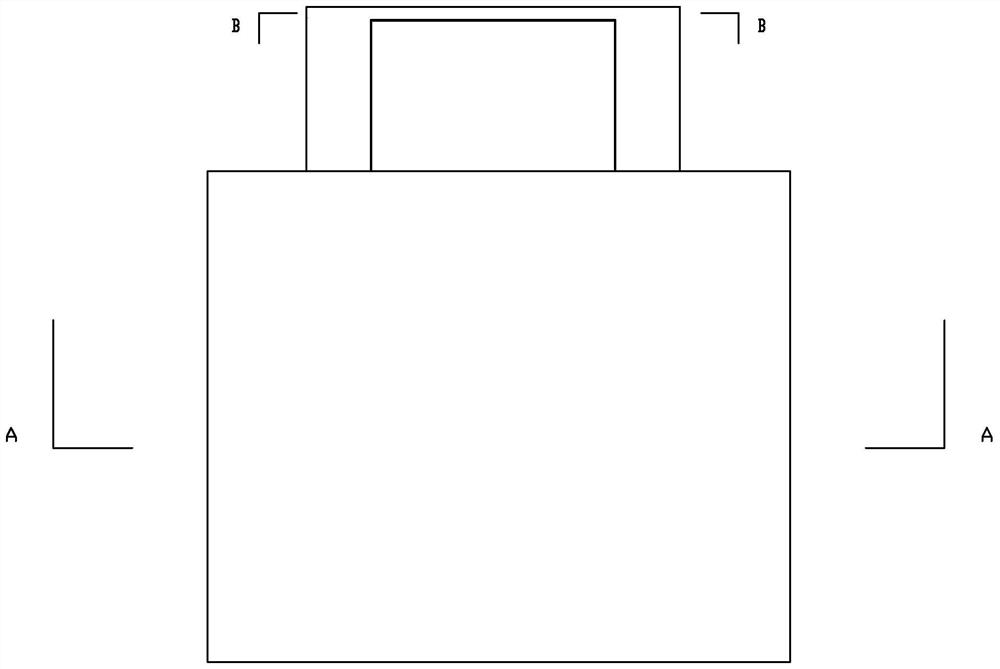

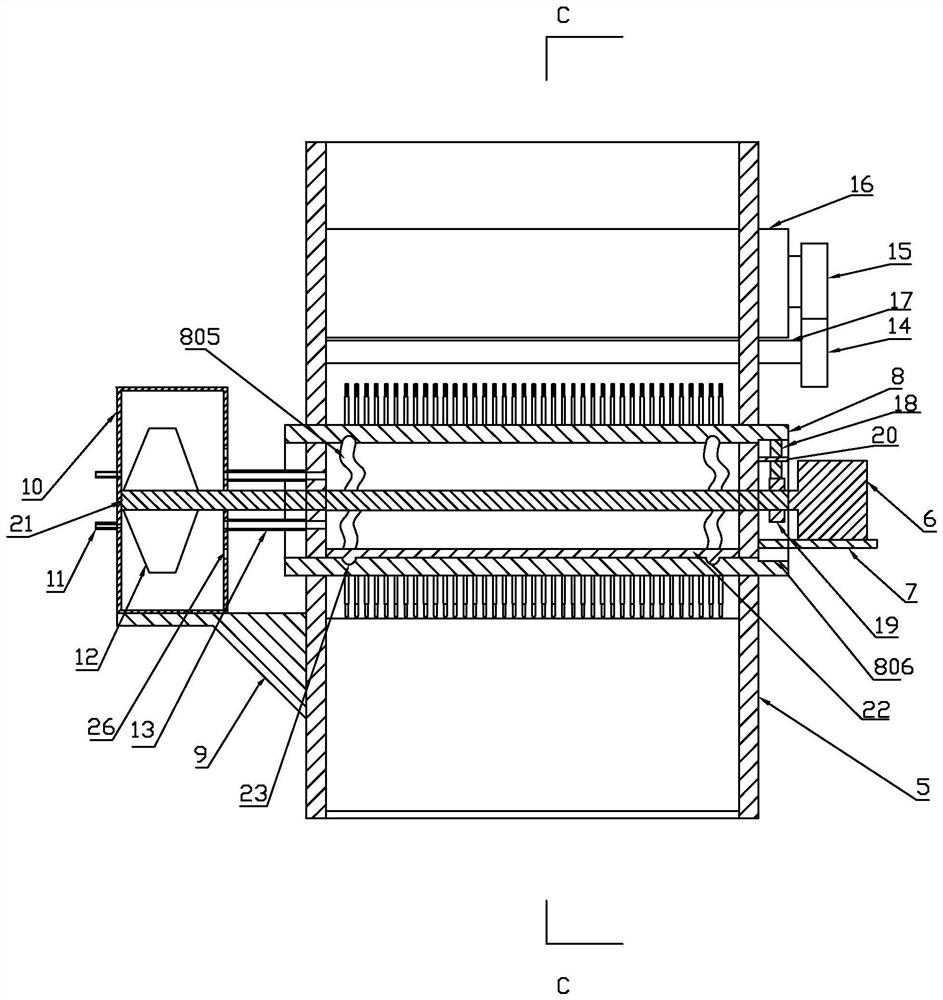

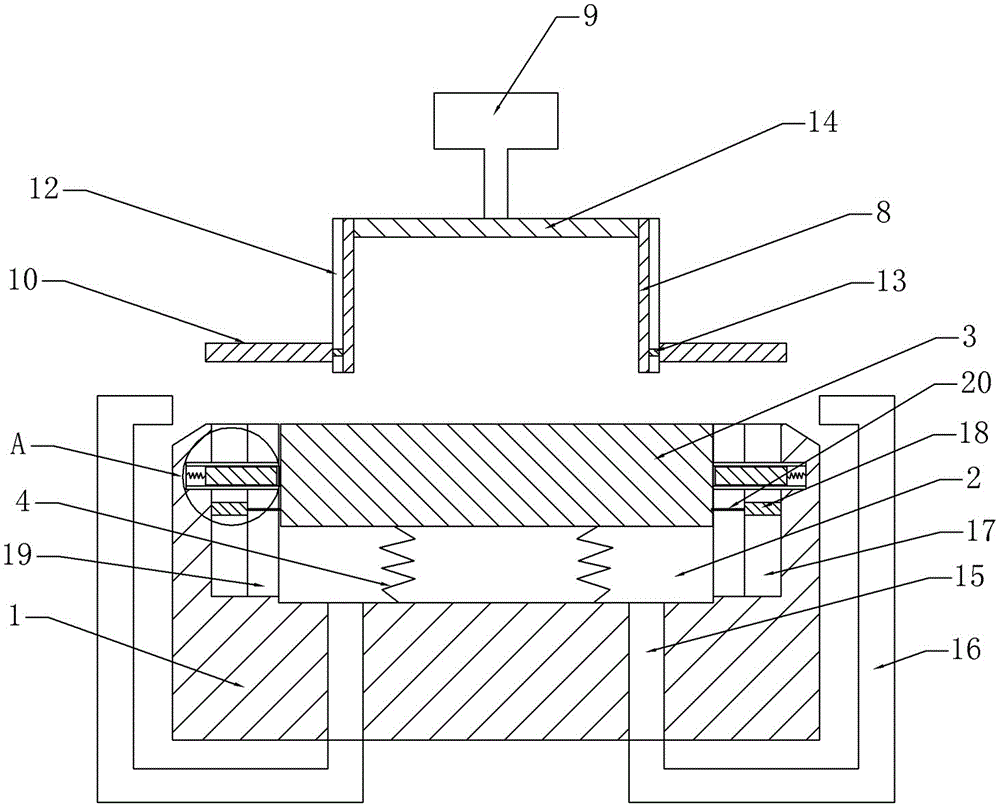

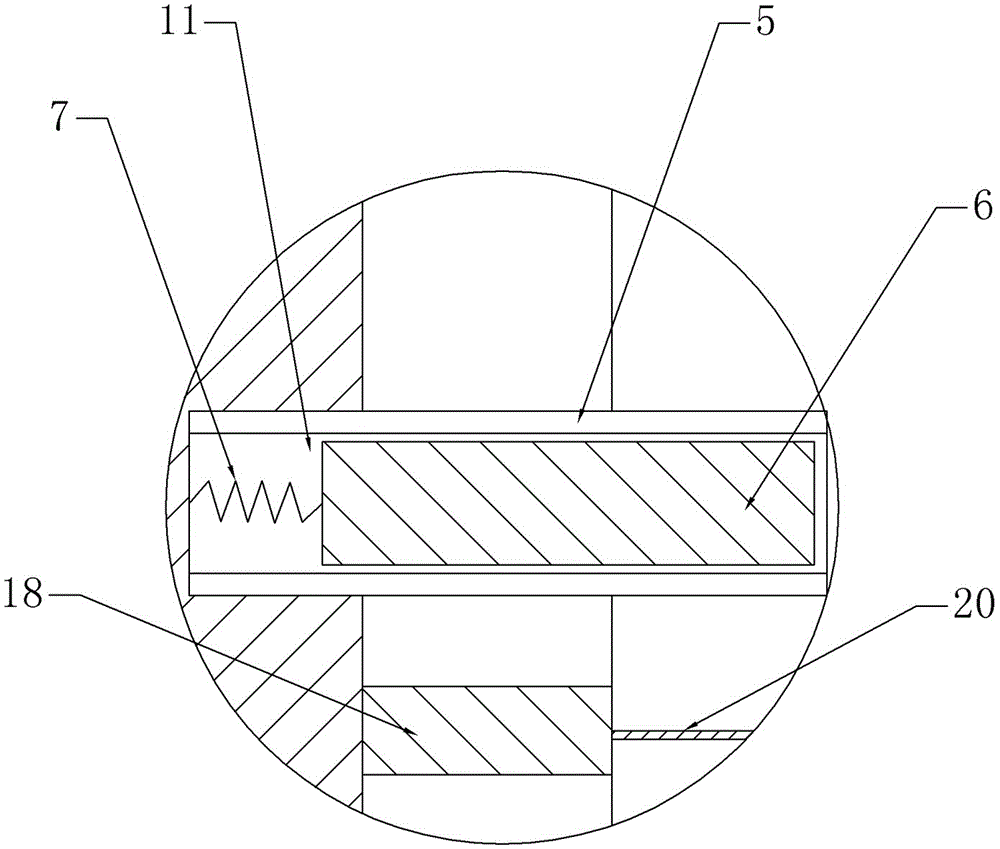

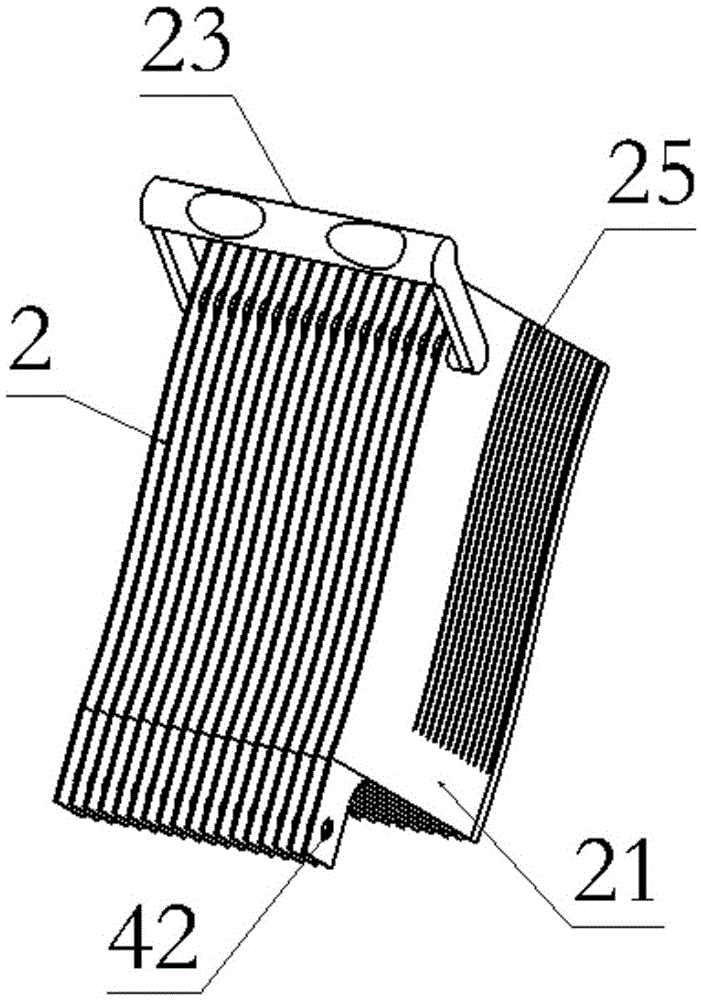

Two-stage paper shredding recovery device and using method

ActiveCN111672585ANot to be leakedGood shredding effectPackaging by pressurising/gasifyingWrapper twisting/gatheringPaper dustElectric machine

The invention discloses a two-stage paper shredding recovery device and a using method. The recovery device comprises a paper inlet, a first-stage motor, a first-stage paper shredding knife and a rack, and the first-stage motor and the first-stage paper shredding knife are connected and parallelly arranged on the upper end face of the rack by gears. The recovery device also comprises a second-stage cylinder, a second-stage knife shaft, a second-stage motor, a waste paper bucket, a discharge port, a blocking device, a rack upper cover, a magnet, a bearing, a bracket, a vacuum pump, a module pushing mechanism, a heat sealing device, a vacuum device, a bag supporting mechanism and vacuum bag. A4 paper is shredded into flocs in two stages, the effect is better than the paper shredding effect produced by conventional paper shredders at present. In addition, after entering the vacuum bag, the paper scraps are packed by vacuum and heat sealing, the volume is effective compressed, recovery isconvenient, and utilization is facilitated for users.

Owner:TIANJIN ZHONGHUAN ELECTRONICS COMP

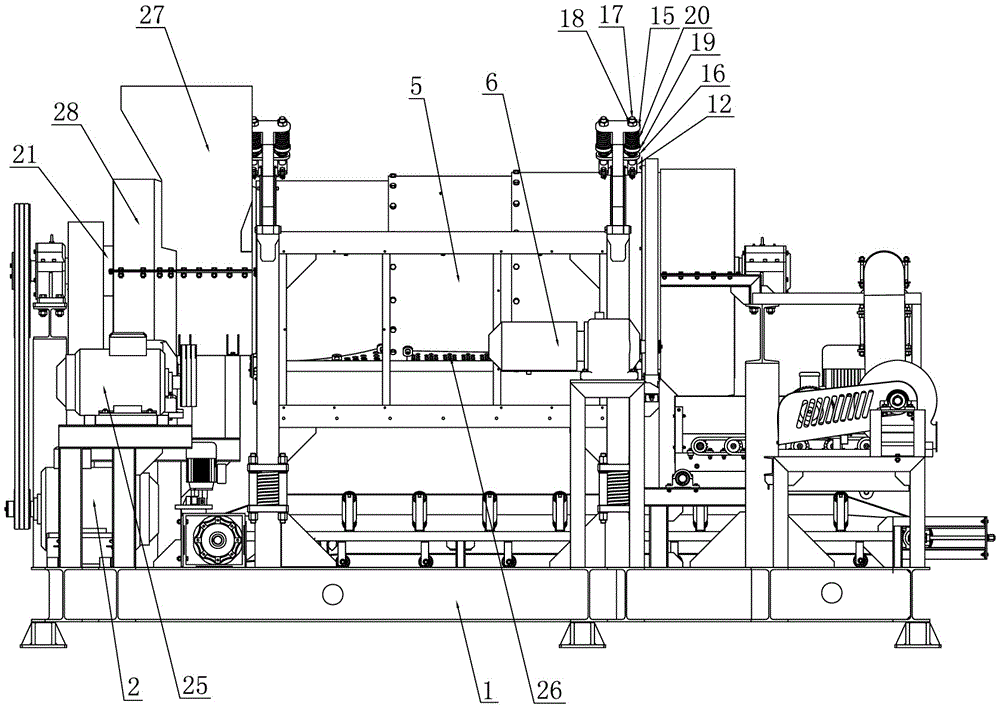

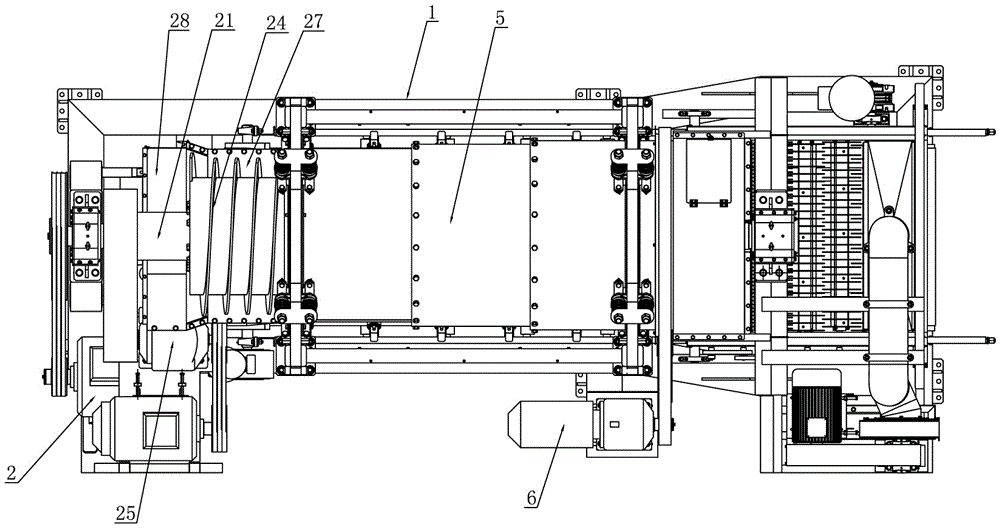

Film shredder

The invention discloses a film shredder. The film shredder comprises a rack supporting a rotor. A knife claw is arranged on the outer wall of the rotor. The rotor is sleeved with rollers at intervals. A knife claw is arranged on the inner wall of each roller. A shredding channel is formed between the rotor and the rollers, and a film can be cut oppositely, shredded and conveyed backwards in the shredding channel. The shredding channel is composed of several sub shredding channels. In the conveying direction of the film, the distance between the rotor and the rollers in the later sub shredding channel is smaller than that between the rotor and the rollers in the former adjacent sub shredding channel, and the number of the knife claws in the later sub shredding channel is larger than that of the knife claws in the former adjacent sub shredding channel. A feed port of the shredding channel is communicated with a feed bin, the feed bin is communicated with a material temporary storage box, and a screw conveyer is arranged in the feed bin. A discharge port of the shredding channel is communicated with a discharge bin, a film sorting and recovering mechanism is arranged on the portion, below a discharge port of the discharge bin, of the rack, and an impurity turnover conveyer is arranged in the rack. The film shredder has the advantages of being good in film shredding and sorting effect and high in shredding and sorting efficiency.

Owner:ZHANGJIAGANG BEIER MACHINERY

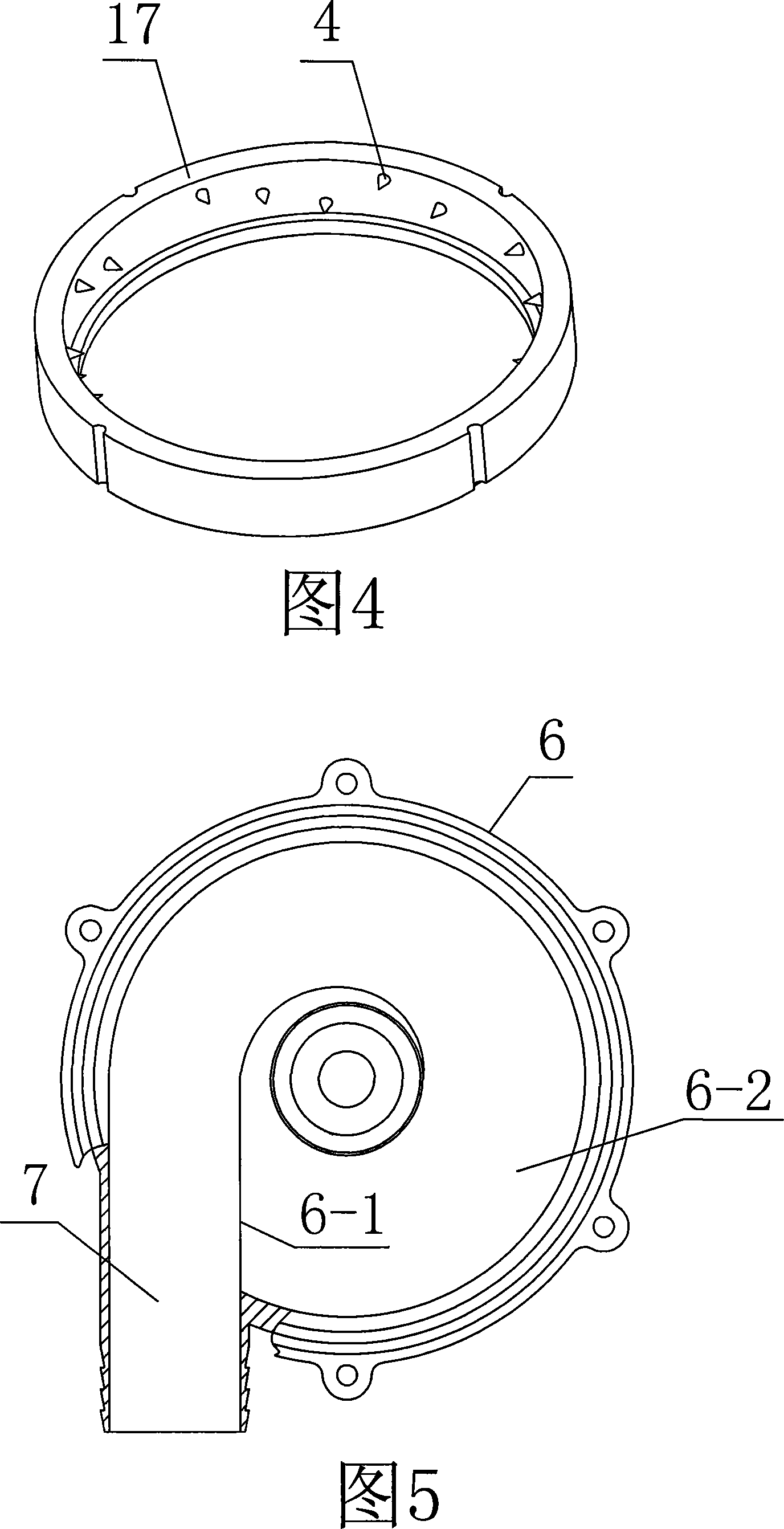

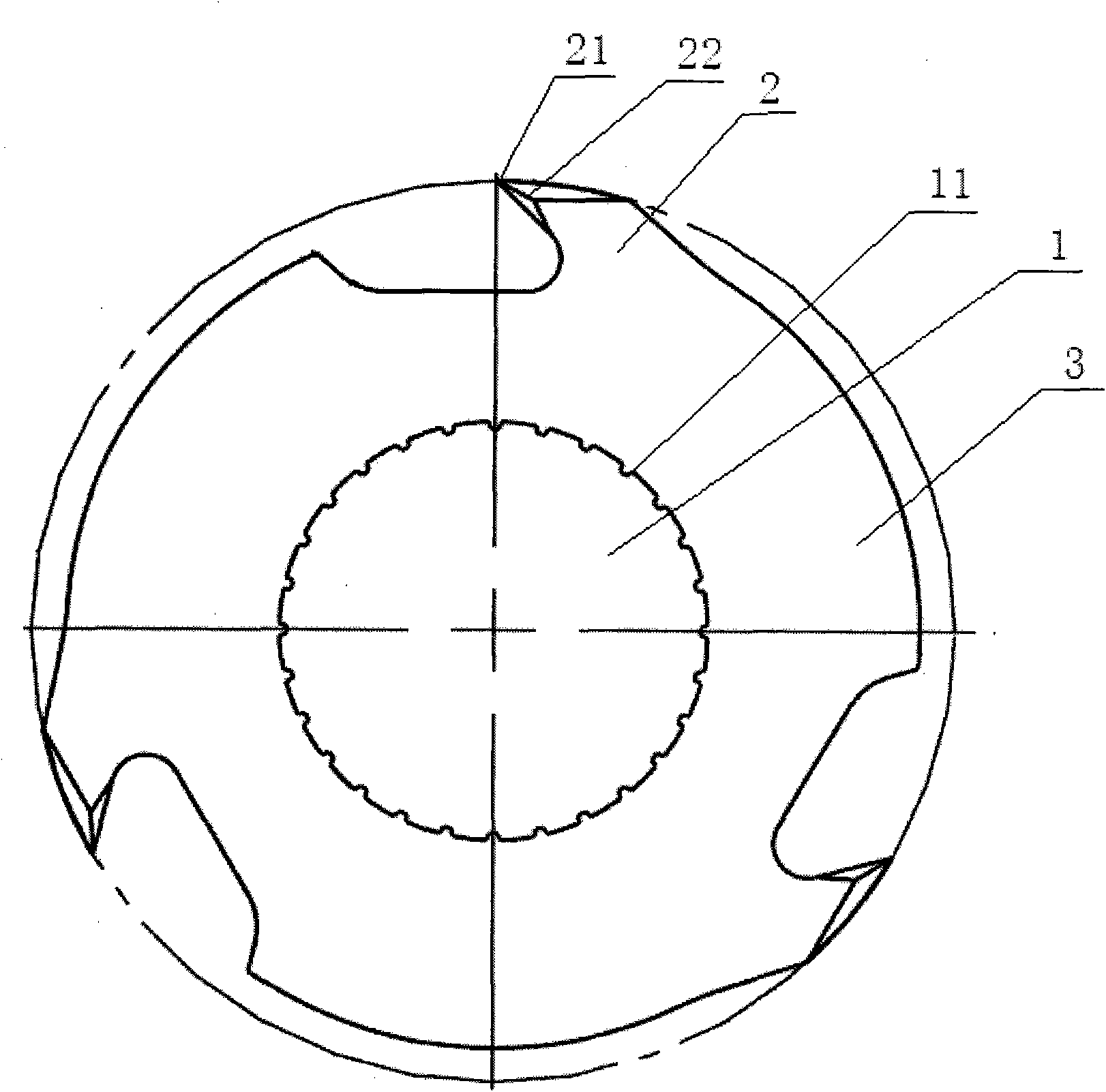

Ceramic closet having vacuum shredded paper suction and discharging function

InactiveCN101177951AGood shredding effectThe drainage channel is smoothFlushing devicesLavatory sanitoryEngineeringWater tanks

The invention discloses a ceramic squatting pan with a function of vacuum sucking, discharging and shredding paper, which only needs a small quantity of water to mash and tear toilet paper, sanitary towel, excrement and sundries to suck and discharge them out of the squatting pan, so as to ensure that a drain pipe is not blocked and has relatively low production cost. A vacuum sucking and delivering shredder is arranged below the water tank of the ceramic squatting pan and a shredding ring is embedded inside the inner wall of the lower cylindrical shell of an upper shredding cavity arranged on the vacuum sucking and delivering shredder; shredding nails with inward nail points are fully distributed on the periclinal wall of the shredding ring; an upper flaring cover is provided with shredding nails with inward nail points; a sundry collar which has the same center with a rotary cutter head and a group of radial suction and delivery vanes corresponding to shredding vanes are arranged at the lower surface of the cutter head; the bottom of the lower shell is provided with a ringent boosting road and the thickness of the two sides of the opening of the ringent boosting road becomes smaller and smaller along the rotary direction of the rotary cutter head.

Owner:卢士乾

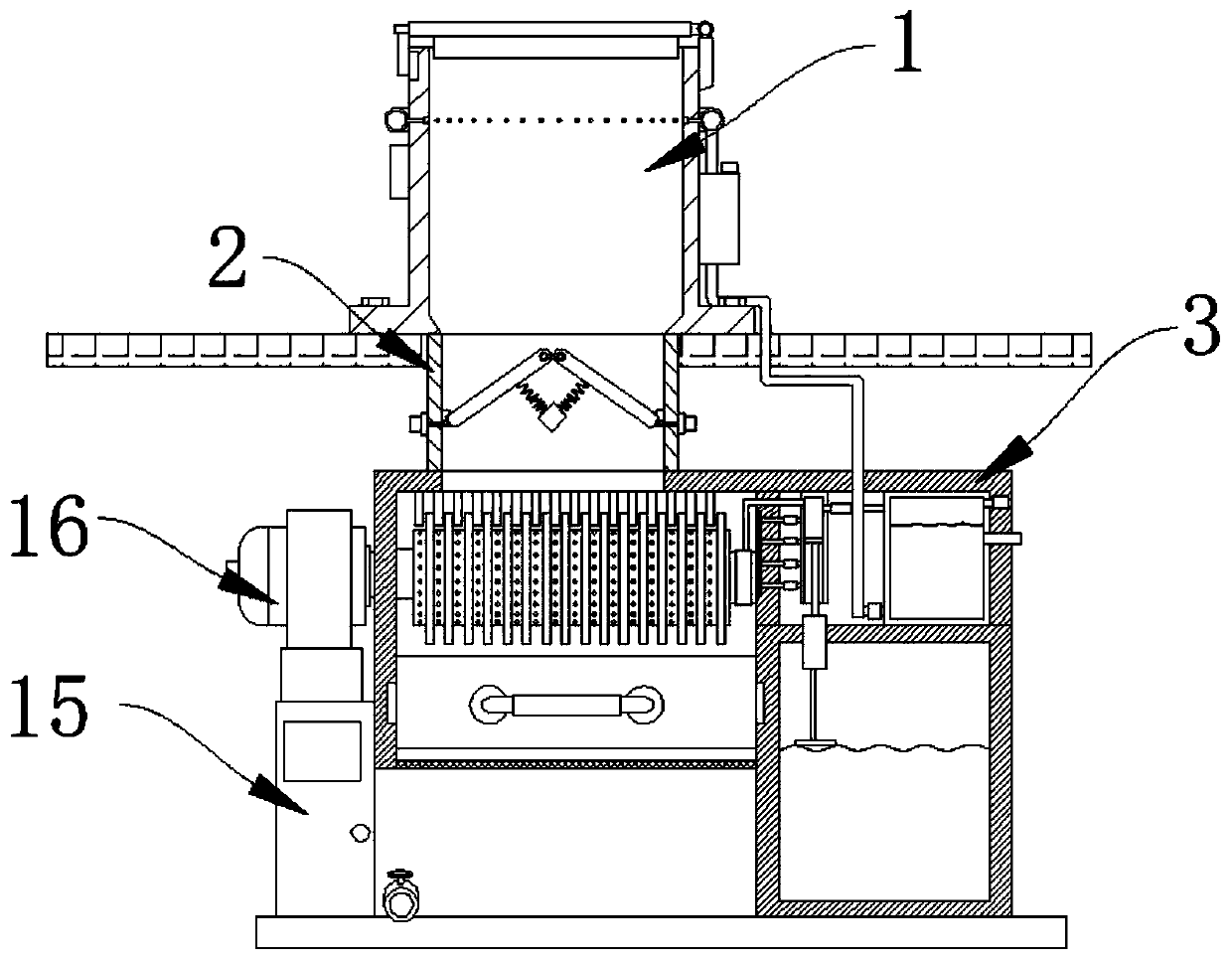

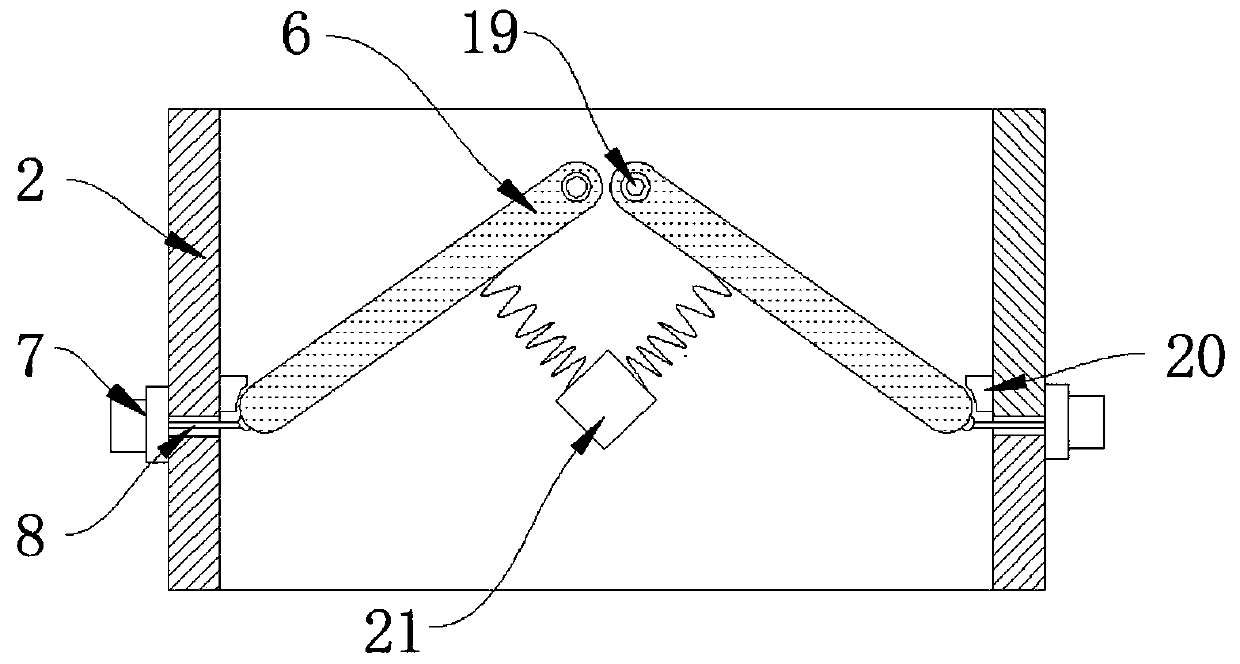

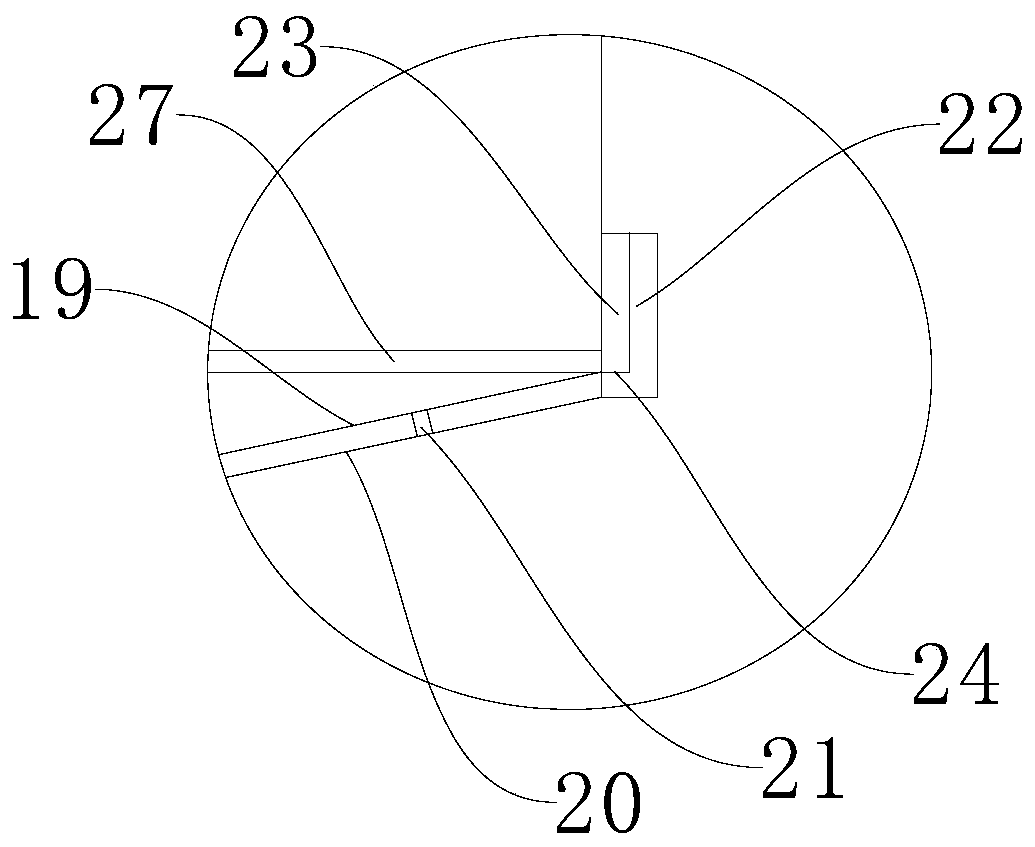

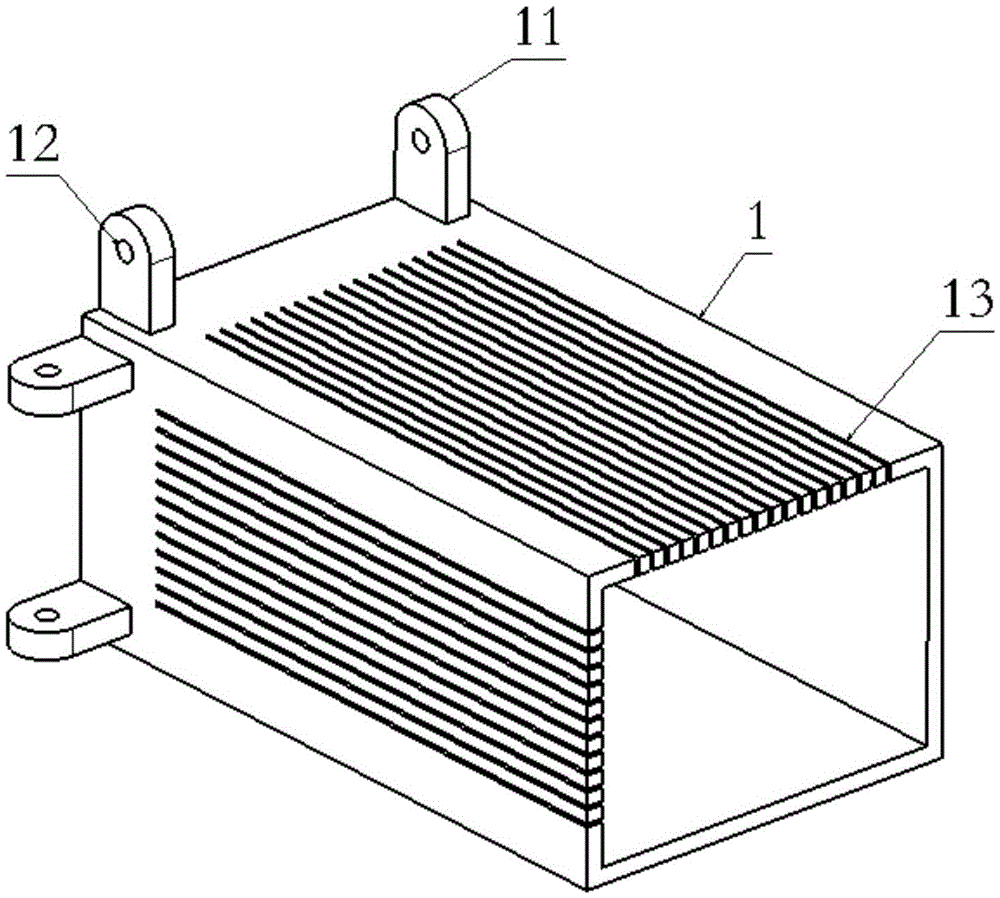

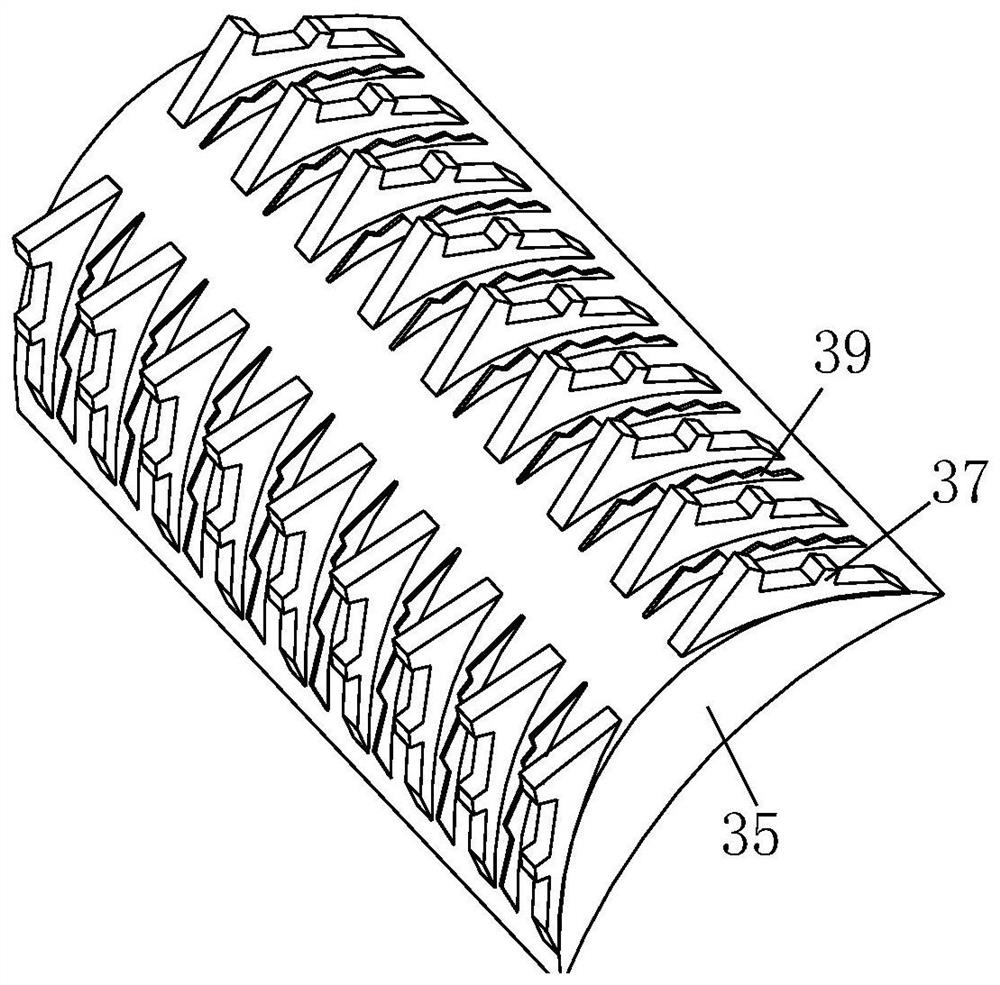

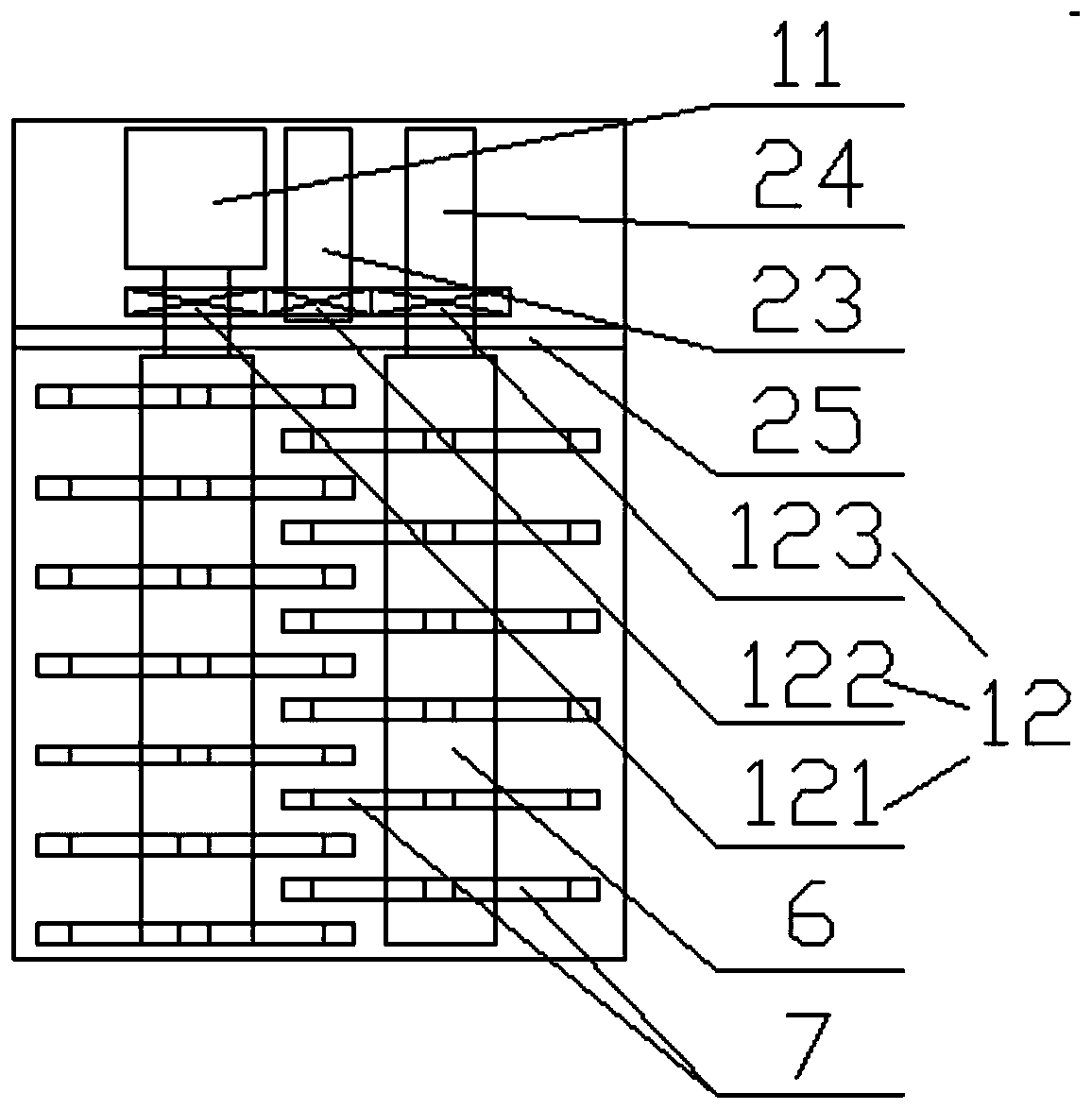

Shredding mechanism for peanut seedling kneading machine

ActiveCN104472127AGood shredding effectSimple structural designCuttersEngineeringMechanical engineering

The invention discloses a shredding mechanism for a peanut seedling kneading machine. The shredding mechanism comprises an outer cover, a blade roller and an arc-shaped screen arranged below the blade roller. The blade roller comprises a blade roller rotating shaft, three support turnplates and a plurality of connecting plates, the support turnplates are arranged on the blade roller rotating shaft at equal intervals, and the connecting plates are arranged among radial edges of the support turnplates evenly. A plurality of blade bearings are arranged evenly on the connecting plates. A cutting blade is connected to each blade bearing. The shredding mechanism has the advantages that the shredding mechanism is simple and reasonable in structural design, pre-pressed peanut seedlings are cut by the cutting blades on the blade roller, blade bodies with sawtoothed edges are arranged on the cutting blades, and the directions of the sawtoothed edges of the cutting blades on every two adjacent connecting plates are opposite, so that shredding effect of the peanut seedlings is better due to staggered cutting, and working efficiency is improved.

Owner:山东新圣泰机械制造有限公司

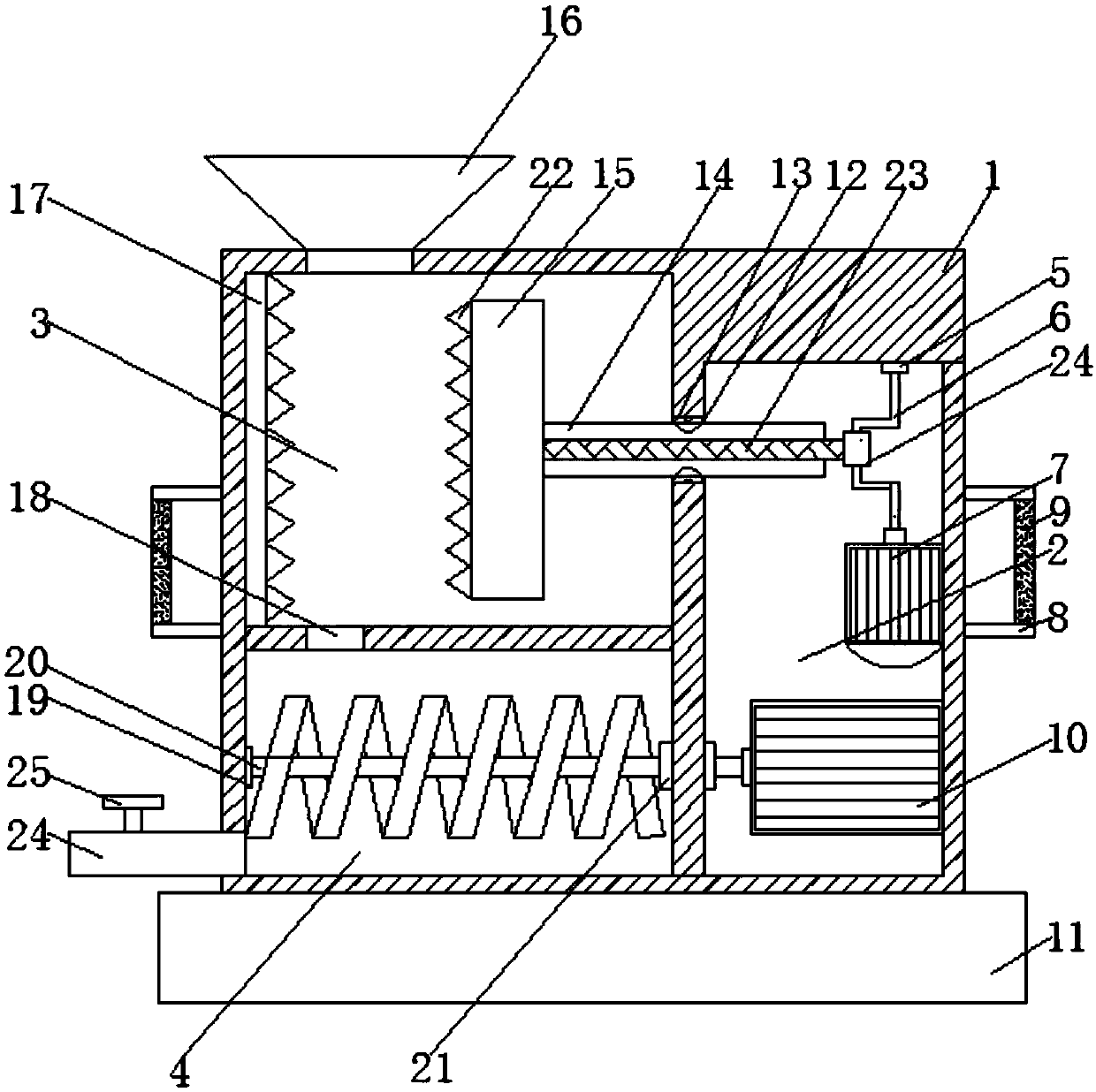

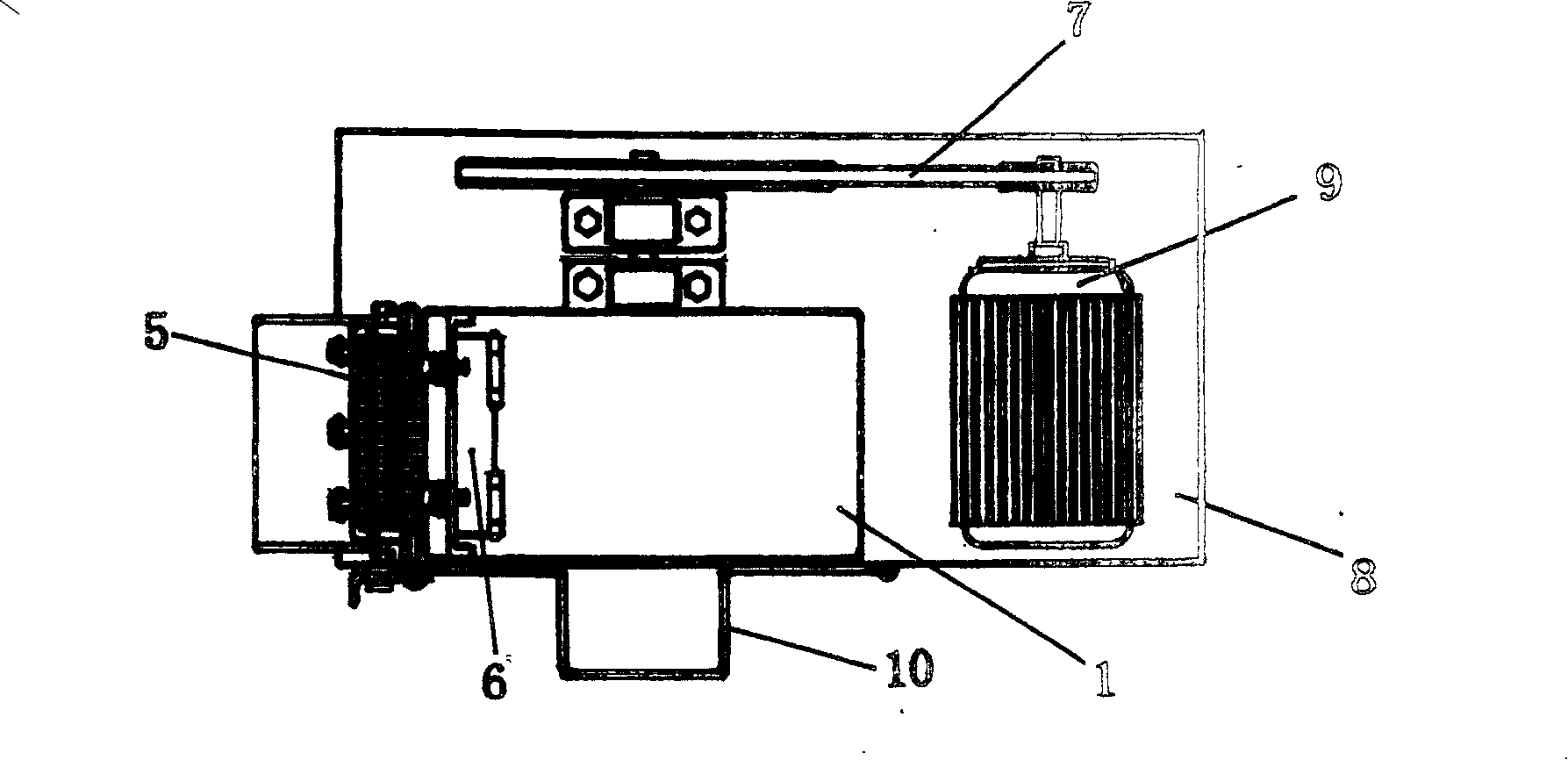

Vehicle-mounted multifunctional garbage shredder

PendingCN110899299AIncrease storage capacityReduce physical exertionSolid waste disposalHollow article cleaningIn vehicleControl valves

The invention discloses a vehicle-mounted multifunctional garbage shredder. The shredder is composed of a vehicle-mounted garbage can, a conveying channel and a shredder body. The vehicle-mounted garbage can is installed on the surface of a bottom plate in a carriage, the shredder body is installed above a bus chassis and located below the bottom plate in the carriage, the shredder body is communicated with the vehicle-mounted garbage can through the conveying channel, and the vehicle-mounted garbage can is of an up-down through hole type square structure or a tubular structure of other shapes. According to the vehicle-mounted multifunctional shredder, quantitative and automatic shredding is achieved through a shredding roller and the conveying channel, and manual control is not needed; byarranging a water tank, a piston cylinder, a pressurizing pipe and an electromagnetic control valve, automatic spraying and deodorizing operation are achieved; by arranging the shredding roller withan airflow outlet hole, a third connecting pipe, an air conveying ring and an air inlet hole, garbage adhering to the surface of the shredding roller can be air-dried conveniently; the garbage shredder has the advantages of removing peculiar smell, automatically and quantitatively shredding, improving the garbage storage amount, saving energy and protecting the environment.

Owner:马鞍山欧科重工机械制造有限公司

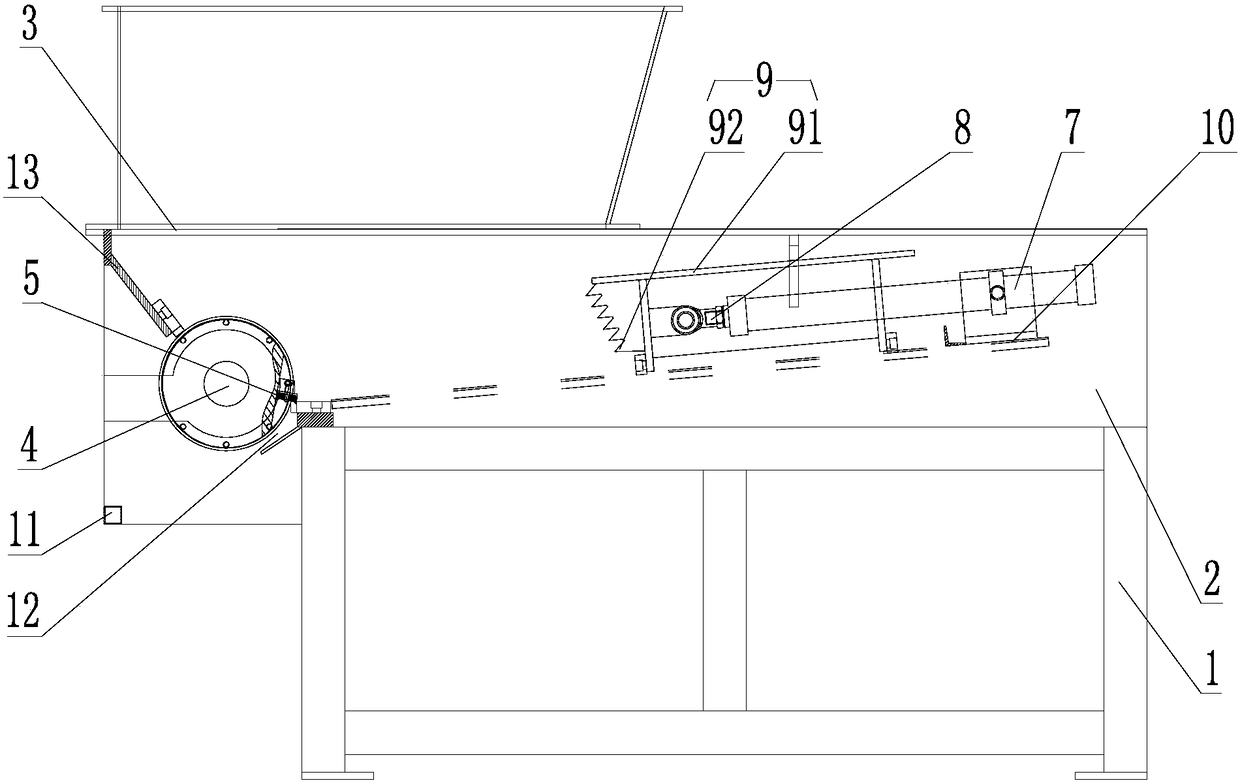

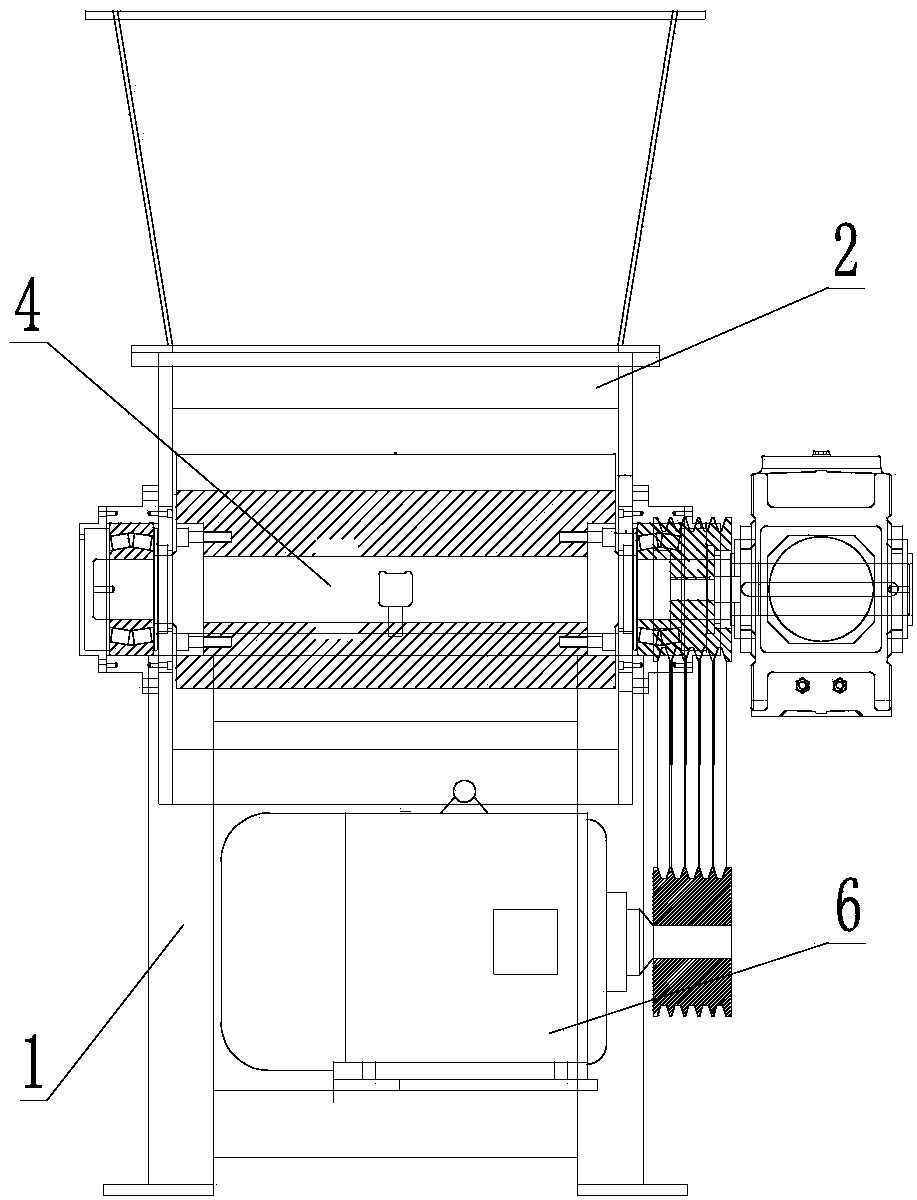

Dual plastic shredding machine

InactiveCN106426651AA large amountNo need for manual cleaningPlastic recyclingMechanical material recoveryElectric machineryEngineering

The invention discloses a dual plastic shredding machine. The dual plastic shredding machine comprises a base on which supporting legs are arranged, wherein a shredding box body B is connected to the upper ends of the supporting legs; a shredding box body A is connected to the upper end of the shredding box body B; a feeding bucket is arranged at the upper end of the shredding box body A, and a feeding port is arranged above the feeding bucket; a shredding roller A is arranged in the shredding box body A; shredding blades A are arranged on the shredding roller A; the shredding roller A is connected with a motor A through a rotating shaft; a discharging port of the shredding box body A is arranged at the lower end of the shredding box body A; the shredding box body B is connected to the lower end of the discharging port of the shredding box body A; a shredding roller B is arranged in the shredding box body B. The dual plastic shredding machine is compact in structure design, stable to run, and good in shredding effect.

Owner:ZHANGJIAGANG CITY LIANKE MACHINERY

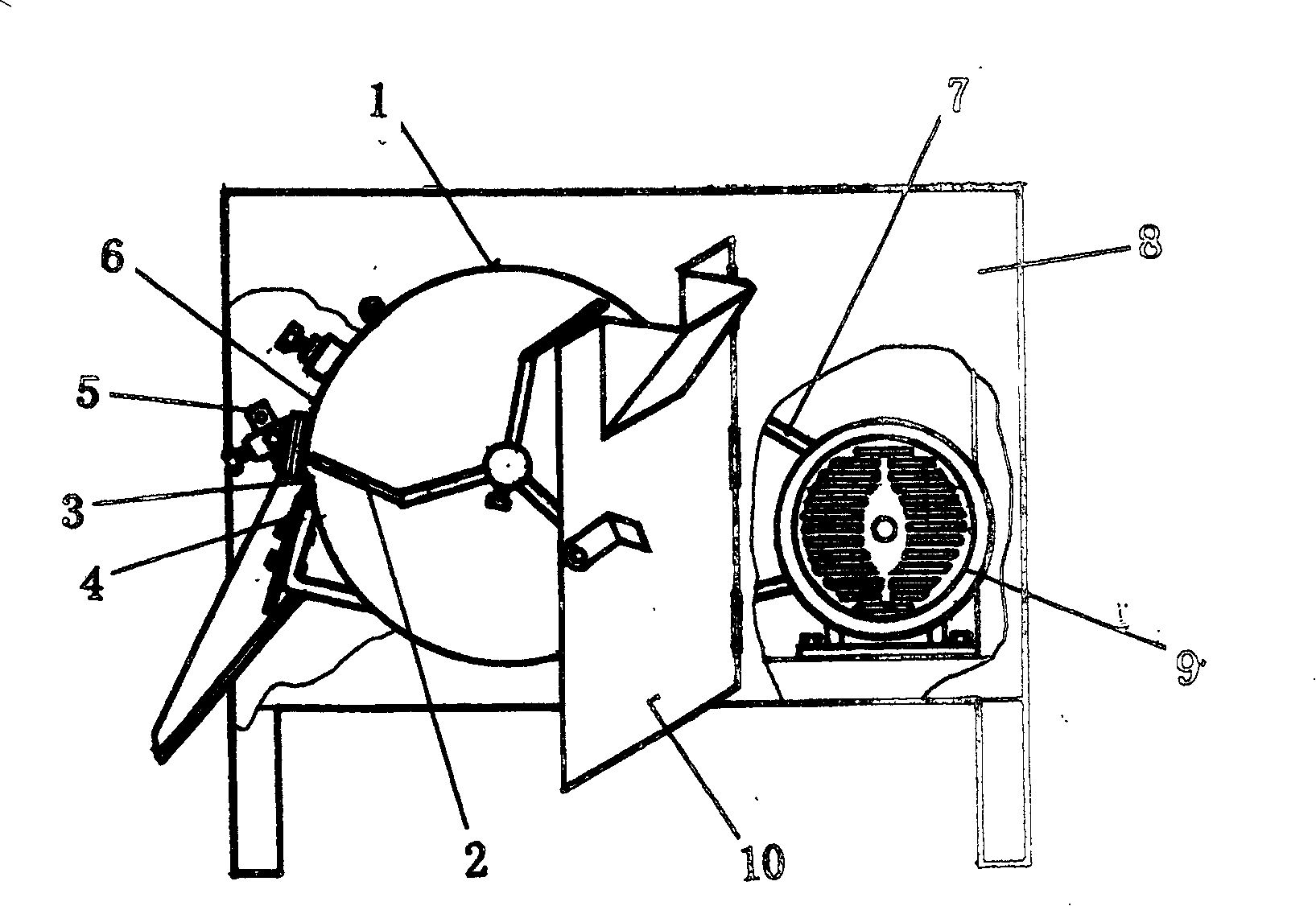

Radish and kohlrabi pickles filament cutter

InactiveCN101190530AHigh speedGood shredding effectMetal working apparatusGasolineAgricultural engineering

The invention provides a radish and large-head salted vegetable shredding machine. A rotary shaft in the middle of a material cylinder in a frame is provided with a plurality of rotary plates; a transverse opening at the external side is fixed with a flat blade and a plurality of vertical blades; an adjusting baffle, the opening width of which can be adjusted, is arranged on the upward side; a transmission device at the internal side can be connected with a motor or a gasoline engine and a diesel engine. The invention can cut radish or large-head salted vegetable into slices for one time, with more than 1000kg per hour; furthermore, the thickness of the pieces can be adjusted according to requirements at any moment, and the invention has the obvious effects of fast speed and good cutting quality.

Owner:张则金

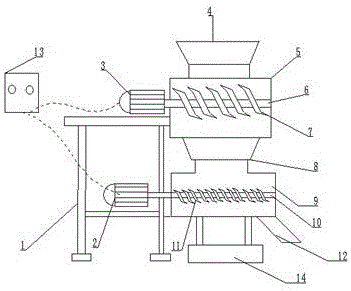

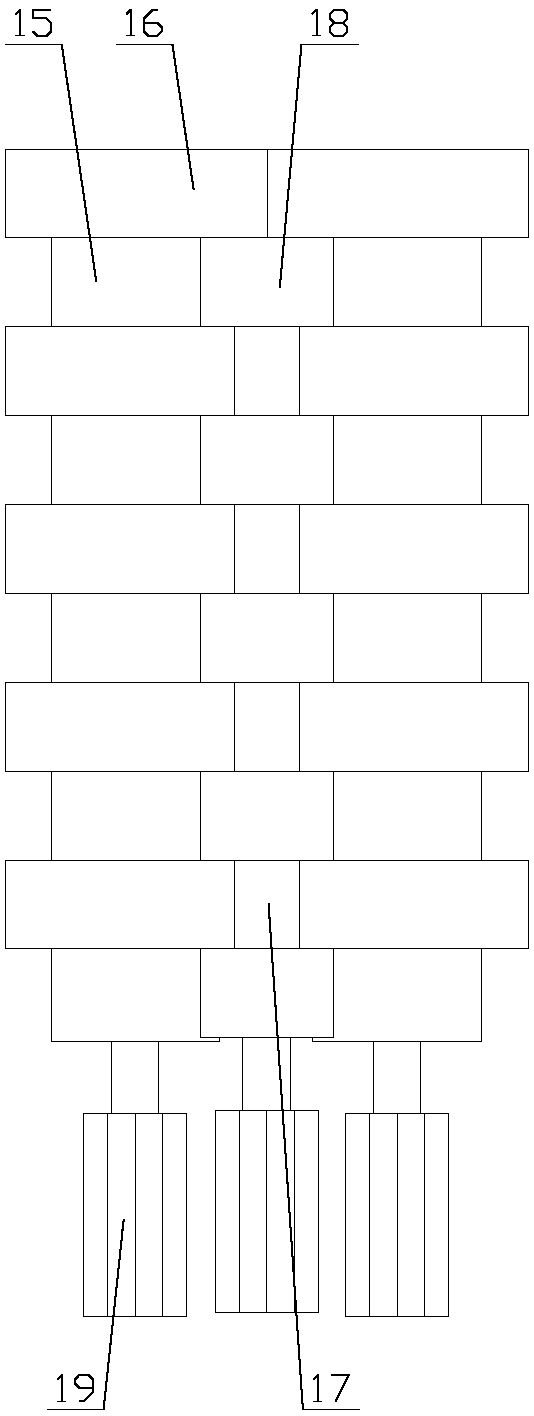

Pulping equipment for papermaking

ActiveCN111041877APrevent backflowAvoid blockingPaper recyclingCellulose material pulpingHelical bladePapermaking

The invention provides pulping equipment for papermaking. The pulping equipment comprises a paper shredding device, a primary pulp mixing device, a pulping device and a pulp return pool, wherein the paper shredding device comprises a first device shell; a paper inlet is arranged on the upper end surface of the first device shell; a rotating shaft is arranged in the first device shell; a pluralityof paper shredding knives are fixedly arranged on the rotating shaft; a shredded paper outlet is arranged at the bottom part of the first device shell; the primary pulp mixing device comprises a second device shell; a water inlet is arranged on the second device shell; a stirring shaft is arranged in the second device shell and comprises a stirring section and an extrusion section; stirring bladesare fixedly arranged at the stirring section; and spiral blades are arranged at the extrusion section. According to the invention, by utilization of the paper shredding device, waste paper is cut into shredded paper; the shredded paper and water are mixed through the primary pulp mixing device and stirred through the stirring blades to form a mixed pulp; the mixed pulp is conveyed to a barrel-shaped shell under the rotating thrust action of the stirring blades inclining towards the extrusion section; the shredded paper is further continuously torn in the barrel-shaped shell and then discharged to the pulp forming device; and the pulp is further filtered through a filter screen in the pulping device to obtain a finished pulp.

Owner:JIANGSU JINLIAN PAPER

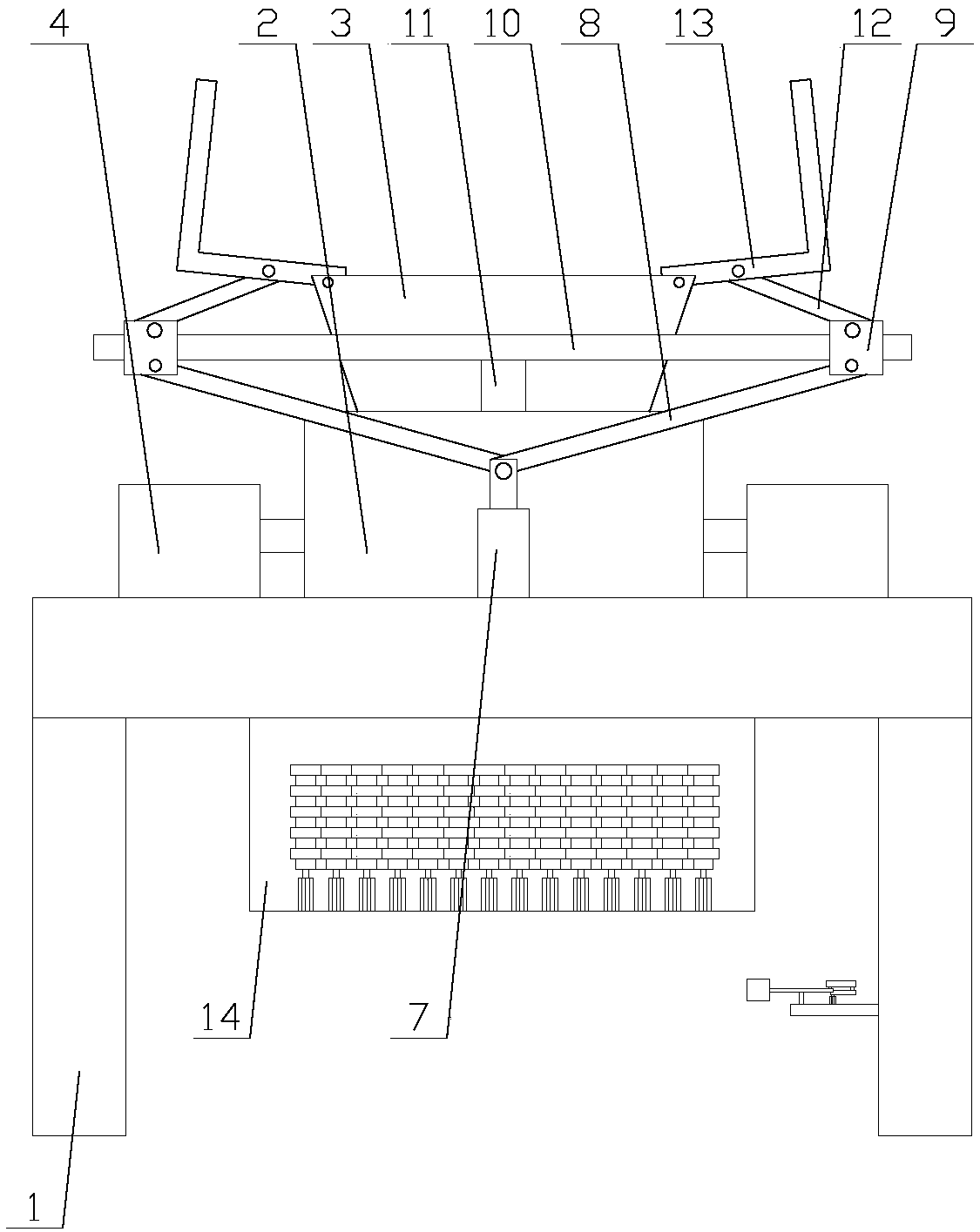

Feed and preparation process thereof

InactiveCN112314773AImprove shredding effectFacilitate feed fermentationFeeding-stuffFood processingEngineeringMechanical engineering

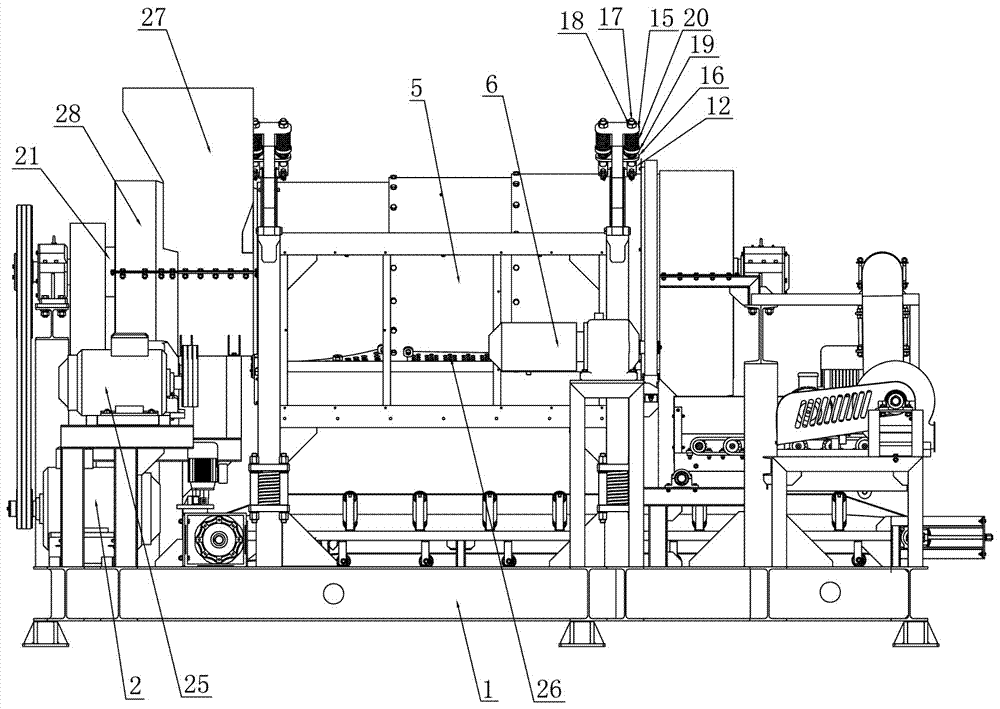

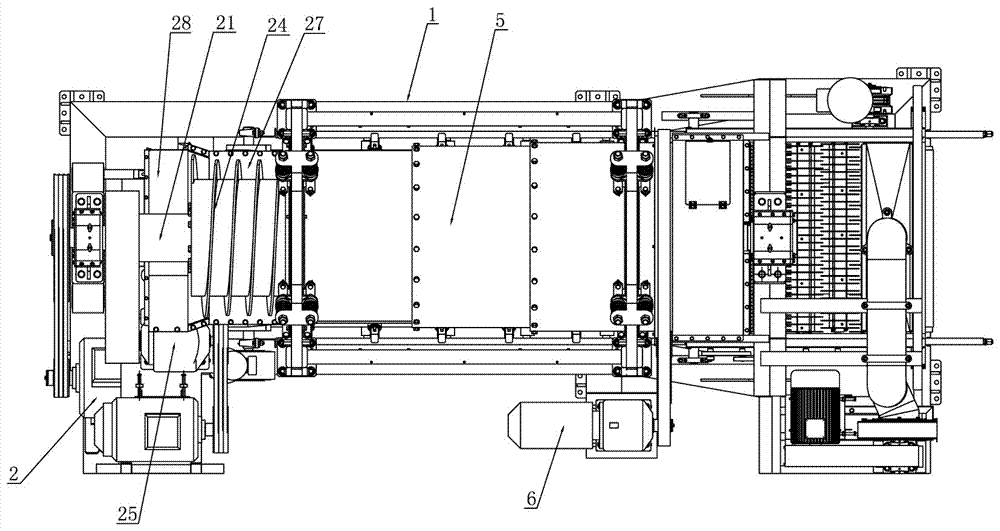

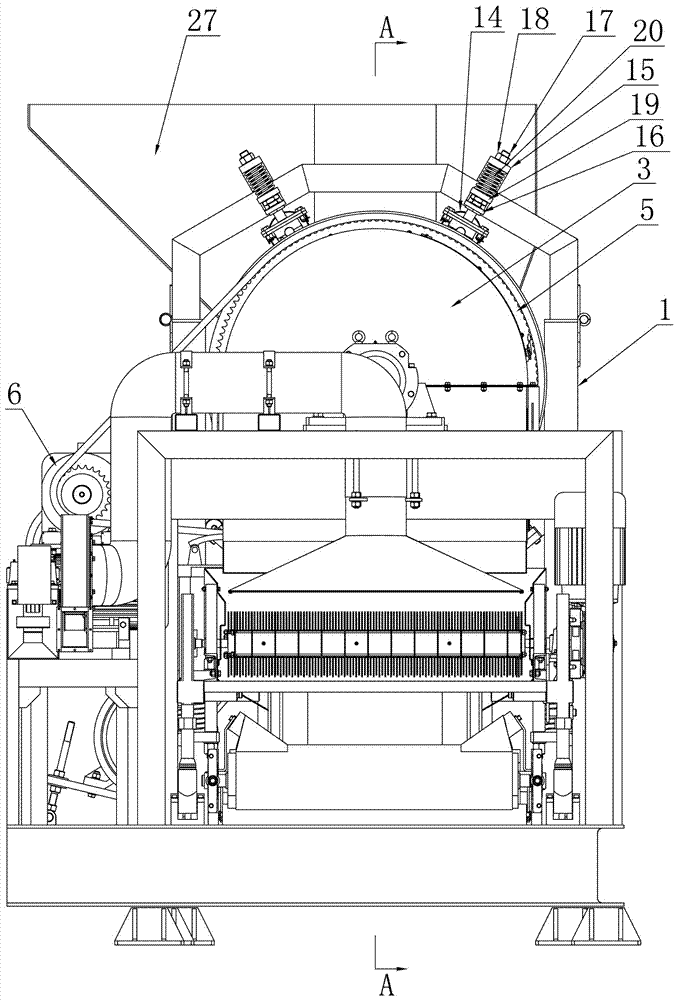

The invention relates to the field of feed, in particular to feed and a preparation process thereof. The feed comprises straw, water, fermentation strains and protein raw materials. The process comprises the following steps that Step 1, the straw is taken and shredded, and the shredded straw is mixed with other raw materials; Step 2, a strain mixed solution is prepared; and Step 3, the mixture obtained in Step 1 is mixed with the strain mixed solution, and fermentation is performed so as to obtain finished product feed. The invention further relates to a feed preparation device. The device comprises an outer frame, a feeding conveying mechanism, a clamping mechanism, a cutter mechanism, a kneading mechanism, a discharging mechanism and a speed reducing mechanism, wherein the feeding conveying mechanism is connected to the front end of the outer frame, the clamping mechanism is connected to the front end of the outer frame in a sliding mode and located at the upper end of the feeding conveying mechanism, the cutter mechanism is connected to the outer frame, the kneading mechanism is connected in the outer frame, the discharging mechanism is rotatably connected in the outer frame andis in transmission connection with the kneading mechanism, and the speed reducing mechanism is fixedly connected to the outer frame and is fixedly connected with the kneading mechanism.

Owner:赵国欣

Shredding device for kitchen

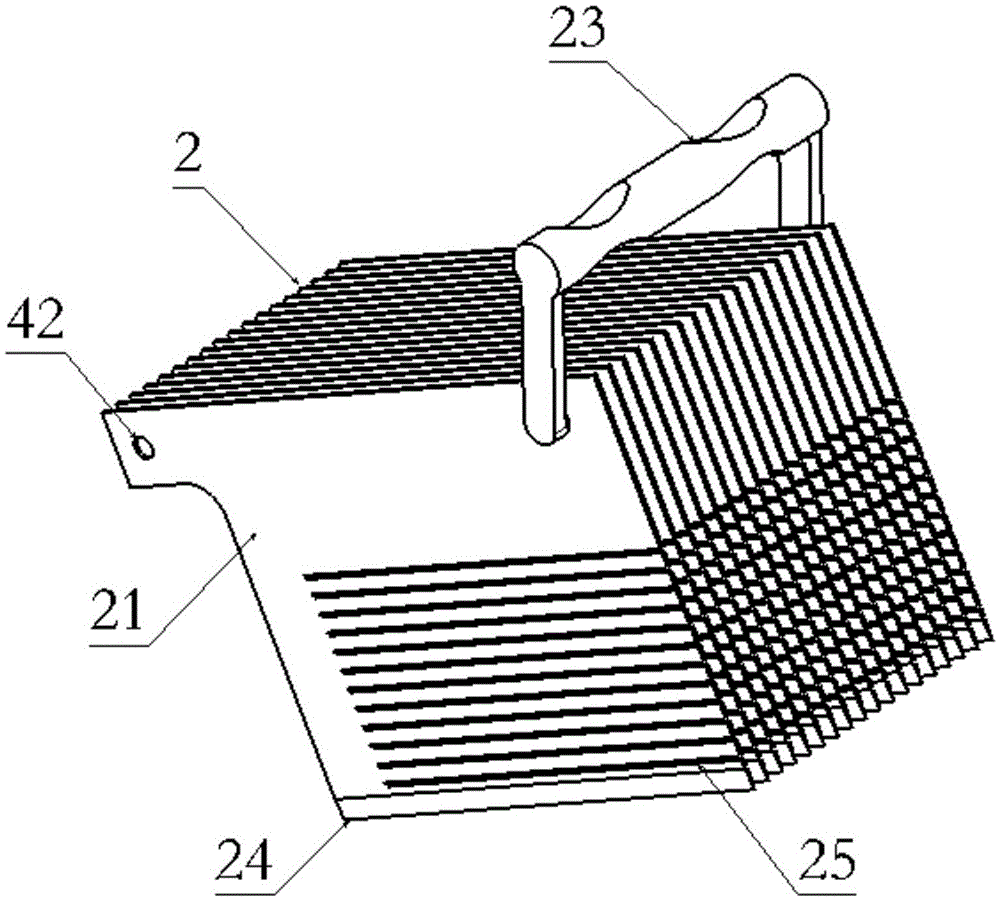

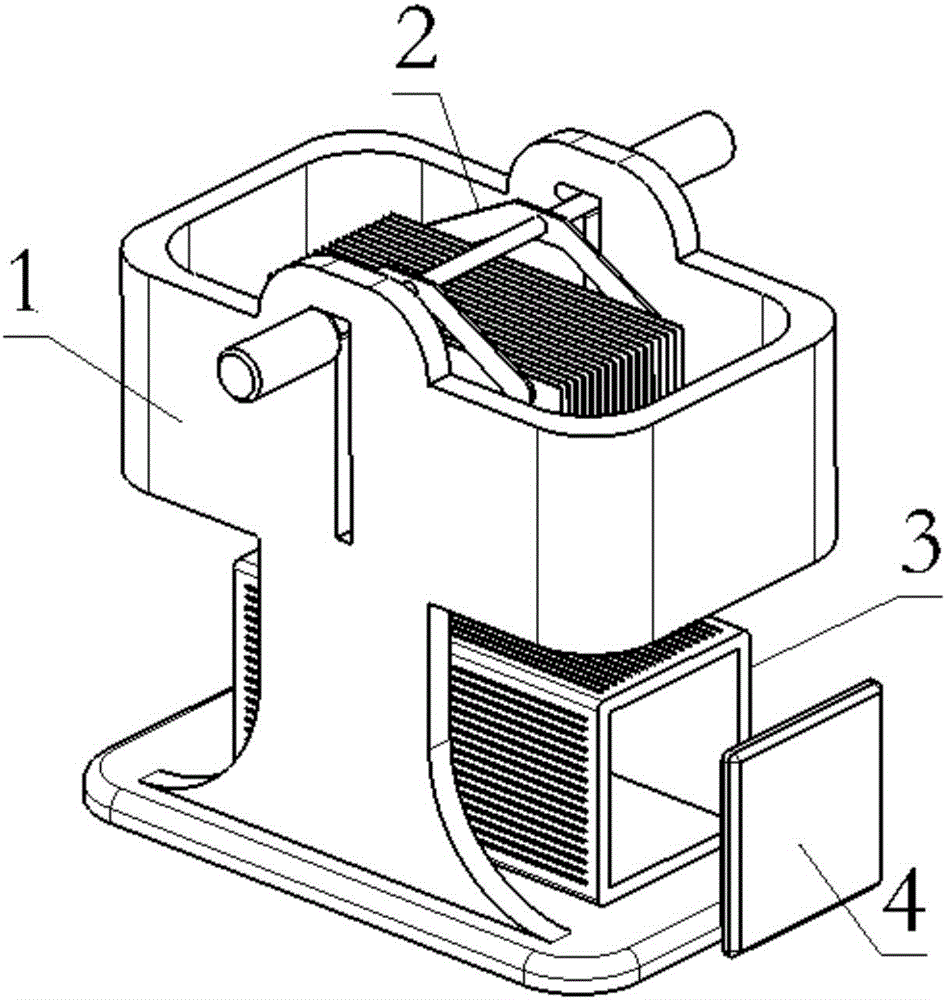

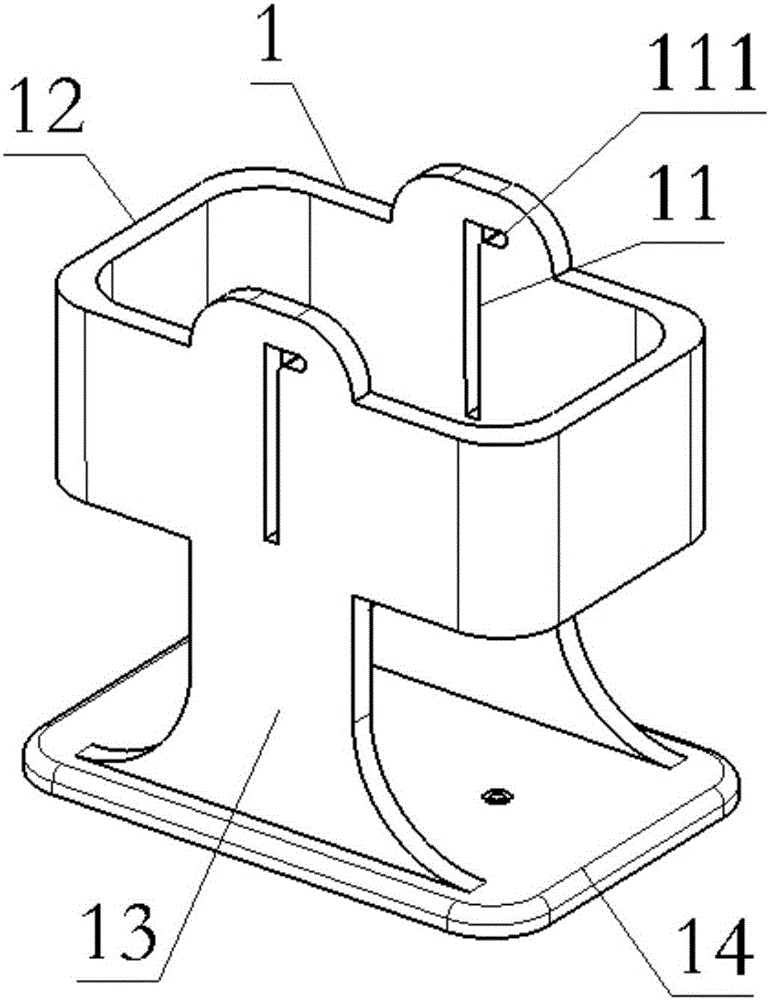

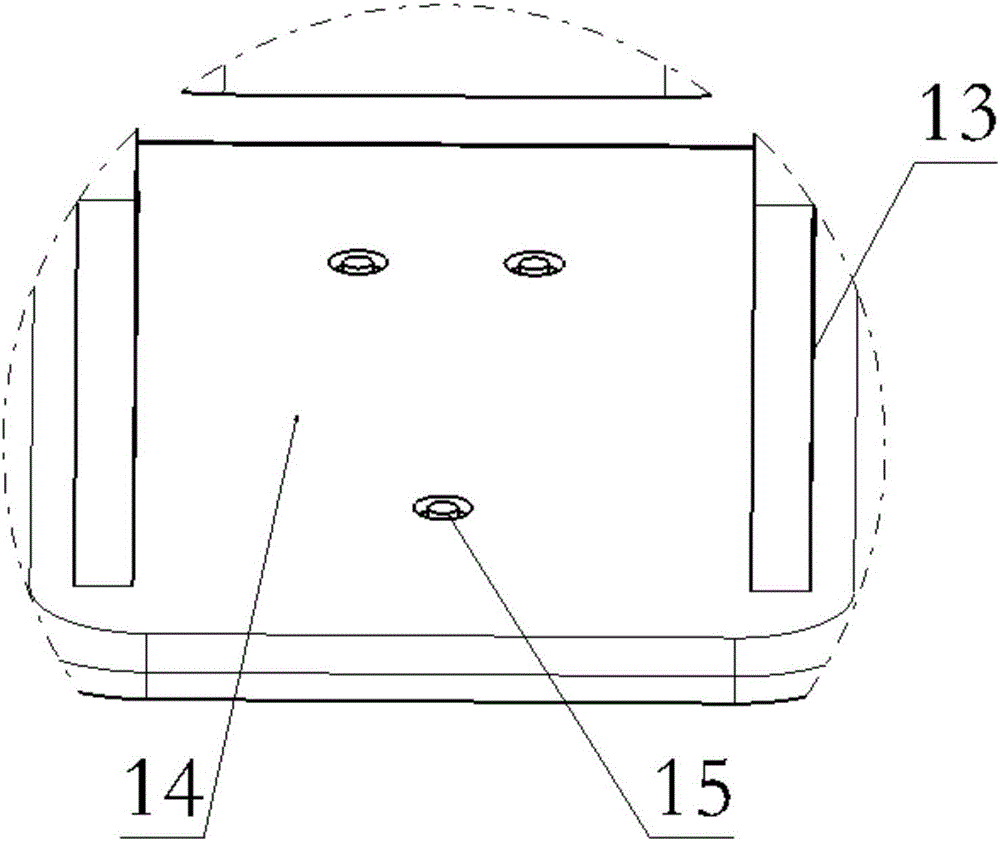

ActiveCN105563540ASimple structureShredded effect is goodMetal working apparatusTransverse grooveEngineering

The invention discloses a shredding device for a kitchen. The shredding device comprises a box body, a first row tool, a second row tool, limiting rotating shafts and a stop anvil. Massive vegetables are placed in the box body and slightly positioned by the stop anvil, the first row tool is rotated, and first blades penetrate through grid slots to cut the massive vegetables into slices; the first row too is kept still, the second row tool is rotated, and second blades penetrate through grid slots and transverse grooves to cut the slices into shredded shapes. The shredding device is convenient, quick and simple in structure and has the significant shredding effect, and everyone can be a chef by the aid of the shredding device.

Owner:江苏海泰新材料科技有限公司

Square shredding device used for kitchen

The invention provides a square shredding device used for a kitchen. The square shredding device comprises a base, a row knife, a square box and a top cover. Positioning hole pillars and positioning groove pillars are matched for positioning so that the square box can be rapidly positioned at a to-be-cut position. Linear grooves are formed in the spaced three faces of the square box. Block-shaped vegetables placed in the square box are cut through the perpendicular vertical movement of the row knife, after a single face is cut, the square box is overturned, the cutting action is repeated, and the block-shaped vegetables are cut into triangular shreds. The square shredding device is convenient and fast to use and simple in structure, a cutting edge is not exposed outside, the safety of users is ensured, and meanwhile a shredding effect is obvious.

Owner:FUJIAN SUOLUO COMPOSITE MATERIAL RES CO LTD

Paper shredder

ActiveCN113941418AAvoid Paper JamsImprove confidentialityPaper recyclingGrain treatmentsElectric machineCarton

The invention relates to the technical field of paper shredders, in particular to a paper shredder which comprises a box body, a paper feeding mechanism is arranged on one face of the box body, the face where the paper feeding mechanism is arranged is the front face, a paper storage box is arranged at the bottom of the box body, two wallboards which are vertically installed and perpendicular to the front face are arranged in the box body, and a paper shredding mechanism and a wind power mechanism are arranged on the wallboards; the paper feeding mechanism comprises a paper inlet fixed to the box body, and closed cavities are formed in the two sides of the paper inlet; the paper shredding mechanism comprises a motor arranged on the side, away from one wallboard, of the other wallboard, and a first output shaft penetrating through the two wallboards is fixedly connected to the motor; and the wind power mechanism comprises an air bellow arranged on the side, away from the one wallboard, of the other wallboard without the motor, and an air bellow support fixedly connected with the wallboards is arranged below the air bellow. According to the paper shredder, people can be freed from manually aligning with the paper inlet to shred paper, the paper is automatically shredded, the problem of paper jam is avoided, the paper shredding capability of the paper shredder is further enhanced, and the confidentiality is improved.

Owner:MAOXIN HARDWARE PROD SHENZHEN

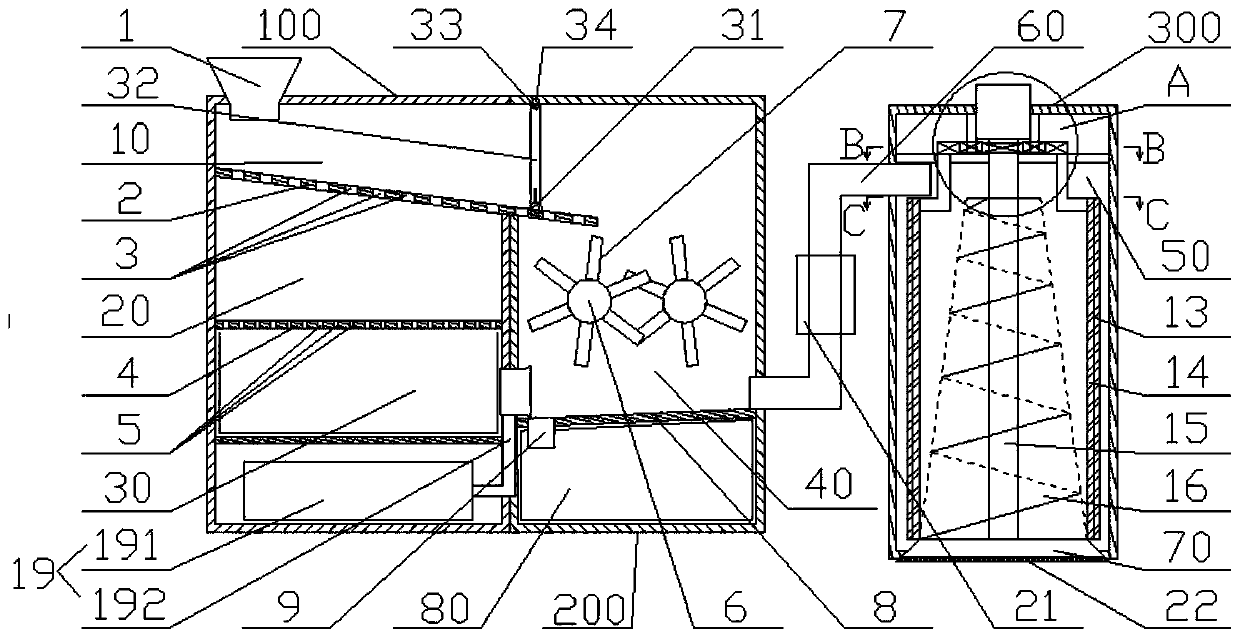

Efficient-type shredding machine with dust isolation function

ActiveCN108339632AAvoid pollutionEnhance the effect of shreddingDirt cleaningGrain treatmentsEngineeringElectrical and Electronics engineering

The invention relates to an efficient-type shredding machine with a dust isolation function. The efficient-type shredding machine comprises a machine base, a shredding chamber, a hopper, a plurality of first motors, a plurality of driving shafts and a plurality of blades and further comprises a dust isolation mechanism and a fine treatment mechanism. According to the efficient-type shredding machine with the dust isolation function, when certain materials prone to generating flying dust are treated, by starting the dust isolation mechanism, the top of the hopper is isolated from the outside world, impurities such as the dust are prevented from flying in air, thus health of the respiratory tract of a worker is prevented from being influenced, and certain pollution to the air is also avoided; secondly, by arranging the fine treatment mechanism below the shredding chamber of the shredding machine, the certain materials difficult to process are smashed through the blades of the shredding machine and then enter the fine treatment mechanism to be further processed, the shredding effect is enhanced, compared with the existing mode that pretreating equipment is arranged in the front of theshredding machine, the situation that the large space is occupied due to transferring equipment additional arrangement is avoided, and cost input can further be reduced.

Owner:梅州市锦发再生资源科技有限公司

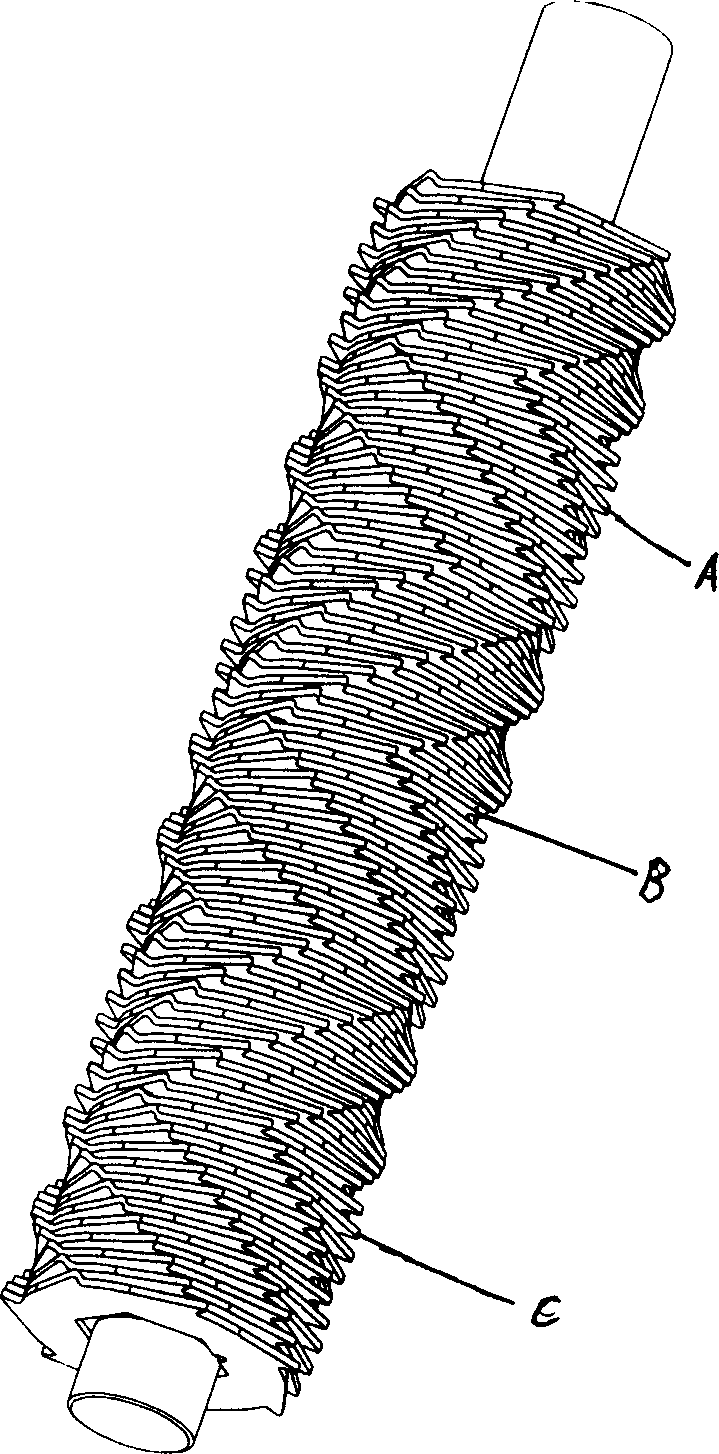

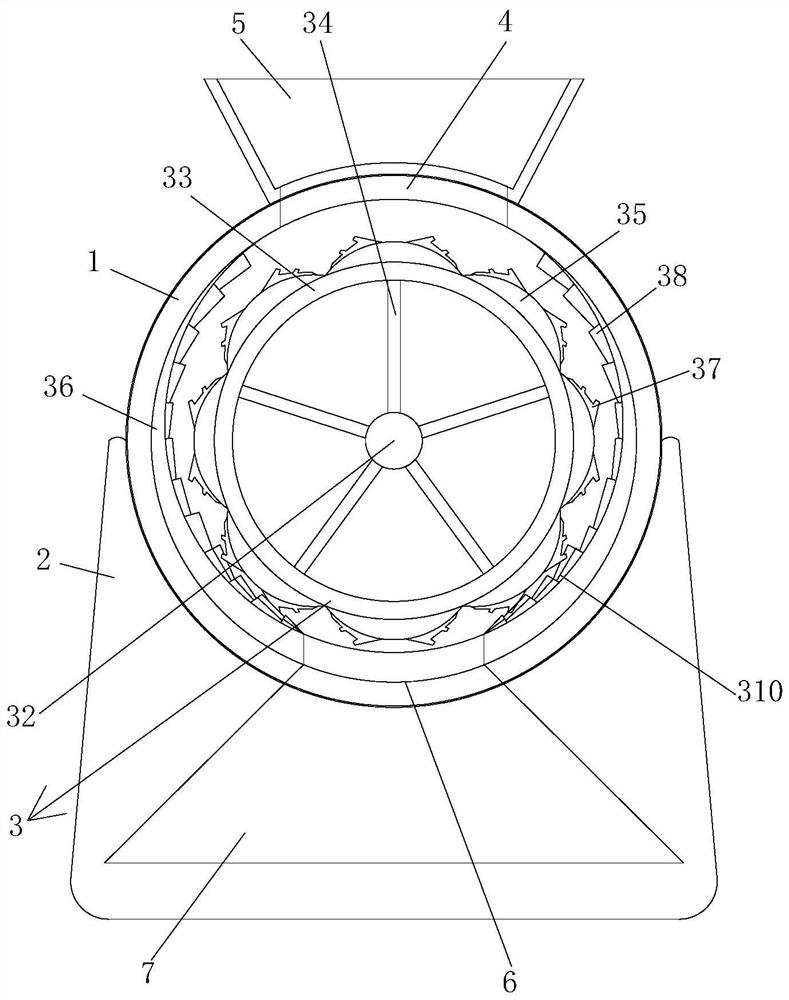

Waste metal treatment device based on building material processing

InactiveCN113680478ABomb safetyImprove work efficiencyGrain treatmentsTool bitConstruction engineering

The invention provides a waste metal treatment device based on building material processing. The waste metal treatment device comprises a shredding cylinder used for shredding metal, a supporting base used for supporting the shredding cylinder and a staggered cutter grading shredding mechanism used for grading and shredding the metal, and the bottom of the shredding cylinder is fixedly connected with the supporting base. The staggered cutter shredding mechanism is arranged on the shredding cylinder. The invention relates to the field of high-efficiency energy conservation. According to the waste metal treatment device based on building material processing, a special structure for extruding and shredding step by step in the circumferential direction is designed according to the problems that a sawtooth tool bit of an existing shredding device is poor in shredding effect and has a shredding dead angle, and therefore the problems that a sawtooth tool bit of a common shredding machine is blunt and thick, a shredding machine has shredding dead angles, fine materials such as hollow pipes are difficult to effectively shred, reworking treatment is often needed, and the machining efficiency is affected to a certain degree are solved.

Owner:江峰

Device for edge-cutting coconut fiber board

ActiveCN106827121AImprove processing efficiencyLarge working spaceOther plywood/veneer working apparatusMetal working apparatusFiberVertical edge

The invention relates to the technical field of mattress processing, in particular to a device for edge-cutting a coconut fiber board. A forming groove is formed in the upper end of a containing platform. A platform is slidably connected into the forming groove. Multiple first springs are arranged at the lower end of the platform and are fixedly connected with the bottom of the forming groove. A first groove is formed in each of the four side walls of the forming groove. The length of the first grooves is the same as that of the side wall of the forming groove. A fiber-cutting tool is horizontally arranged in each first groove. A second spring with one end fixedly connected with the fiber-cutting tool is arranged on the tool back of each fiber-cutting tool. The other ends of the second springs are fixedly connected with the bottoms of the first grooves. Four vertical edge-cutting tools are arranged above the forming groove. The length of the edge-cutting tools is smaller than that of the side wall of the forming groove. The four edge-cutting tools form a cuboid-shaped tool cylinder. A hydraulic machine is fixedly connected to the tool cylinder. A horizontal positioning plate is slidably connected to the sides, outside the tool cylinder, of the edge-cutting tools. By the adoption of the device, the problem that coconut fibers cannot be cut off easily, and the quality of the coconut fiber board is influenced can be solved.

Owner:重庆市永川区植成家俱厂

Shredder blade

The invention discloses a shredder blade which comprises a round thin blade body, wherein the middle of the thin blade body is provided with a mounting hole; the upper part of the outer circle is provided with a set of tool bits; each tool bit comprises a tool nose and a cutting edge formed by two inclined surfaces; the wall of the mounting hole is of an annular toothed structure; the upper surface of the tool bit is a section of circular arc which is concentric with the mounting hole; and the lower surface of the tool bit is pitched in the blade body to form the tool nose. The shedder blade has the advantages of reasonable structural design, favorable shredded paper effect, firm fixation with rotating shaft, and low processing cost.

Owner:CHANGSHU XUNDA POWDER METALLURGY

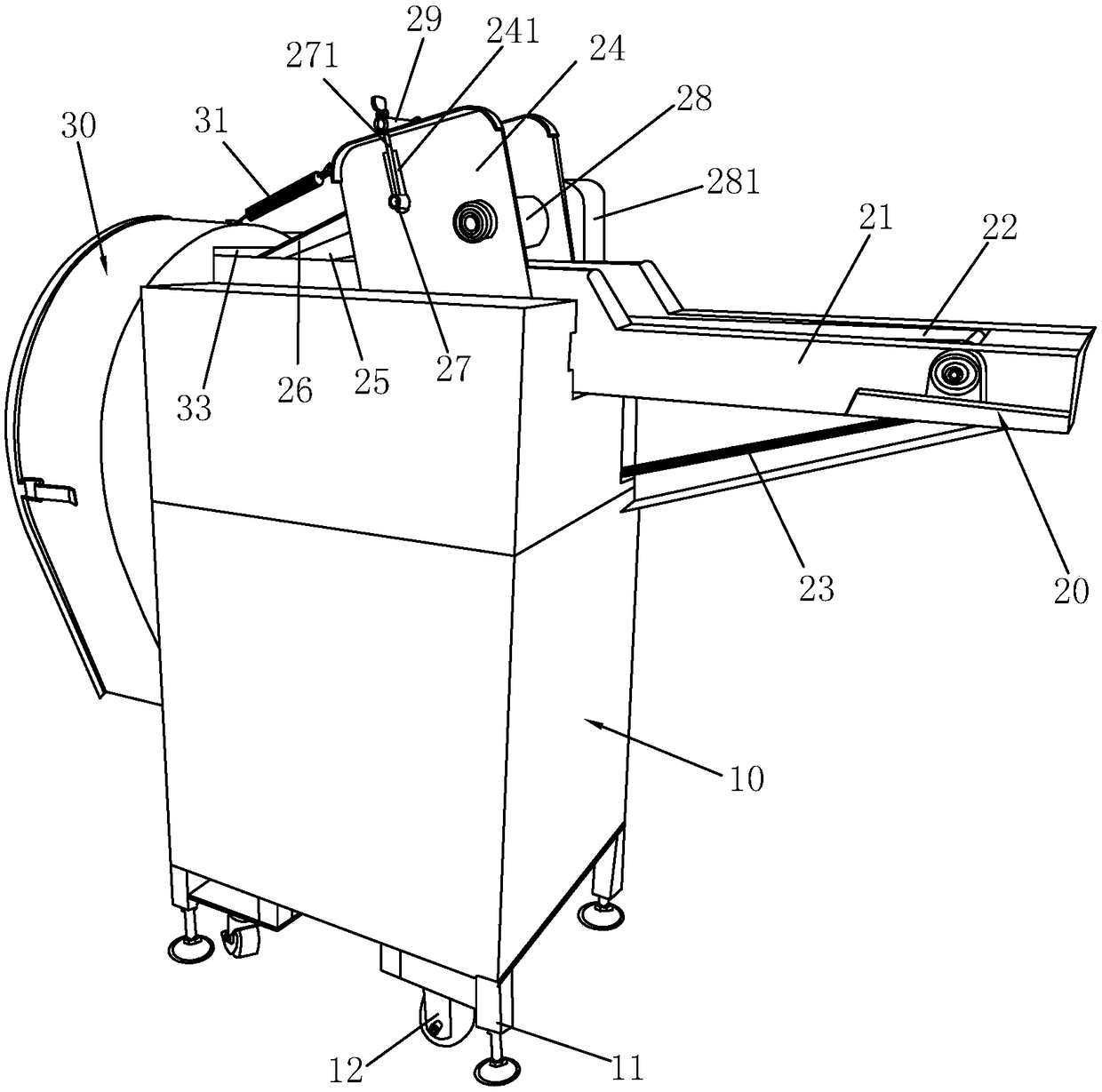

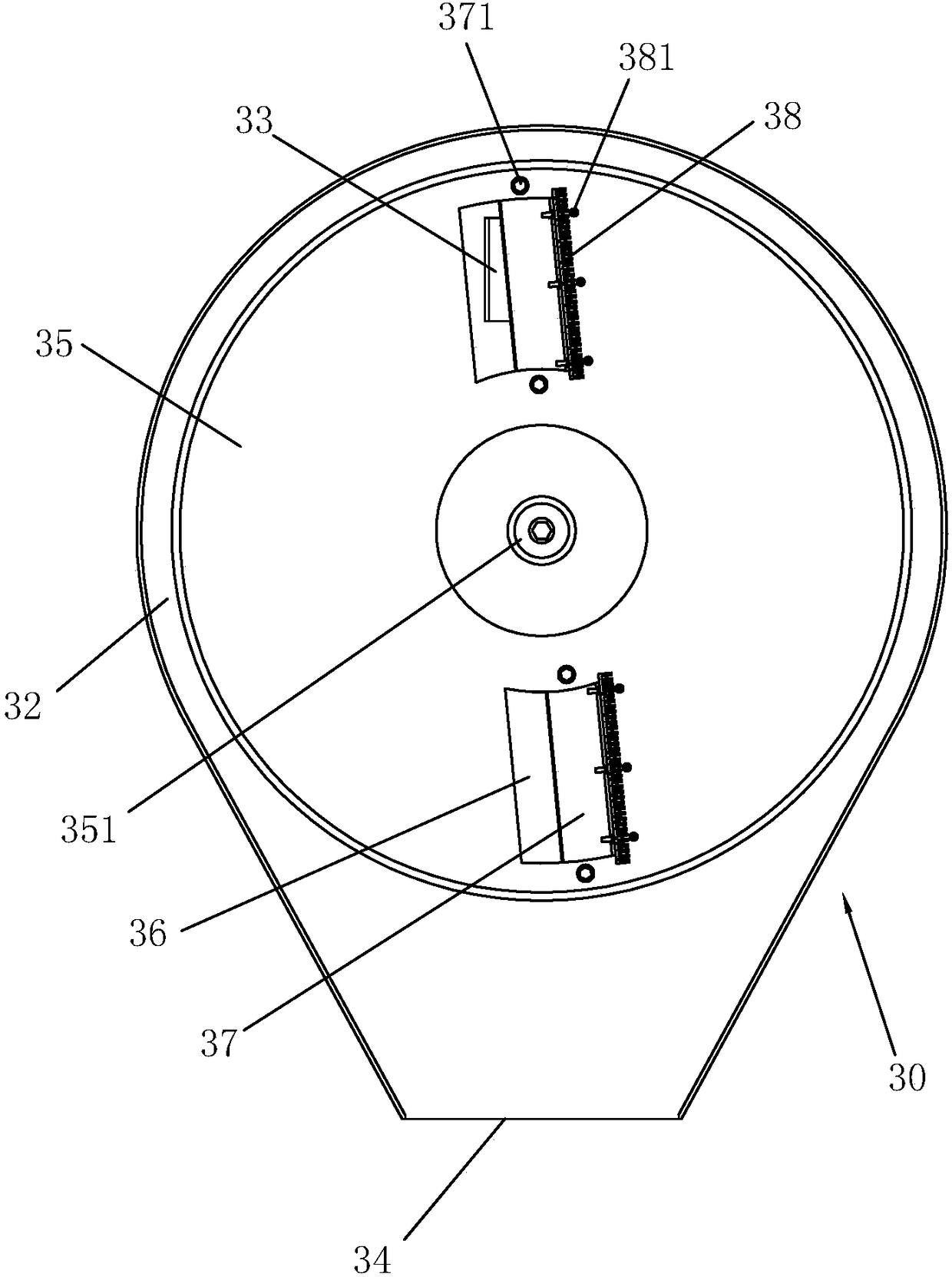

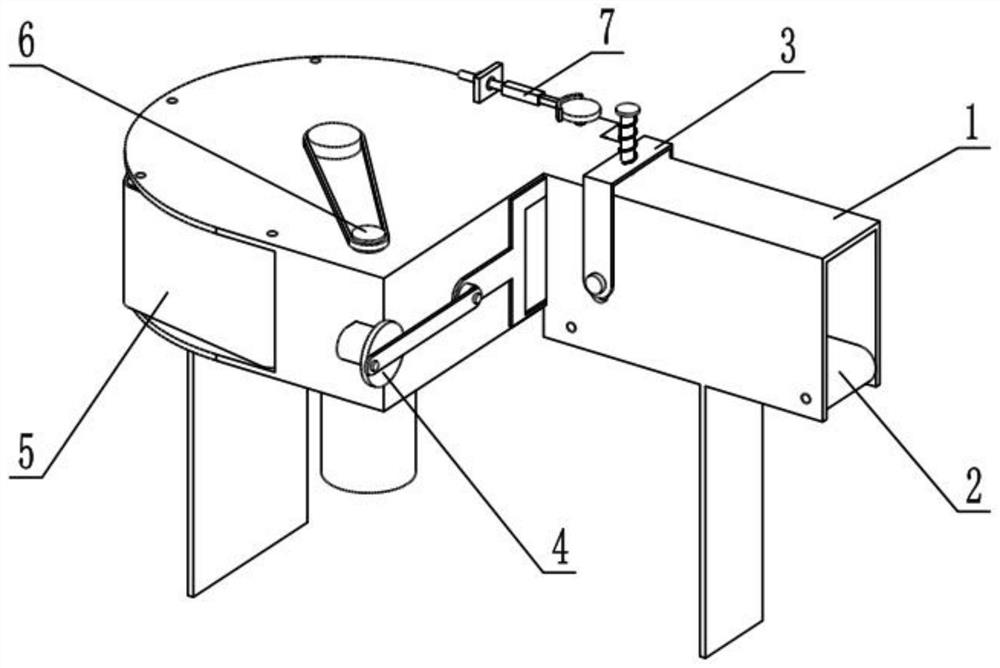

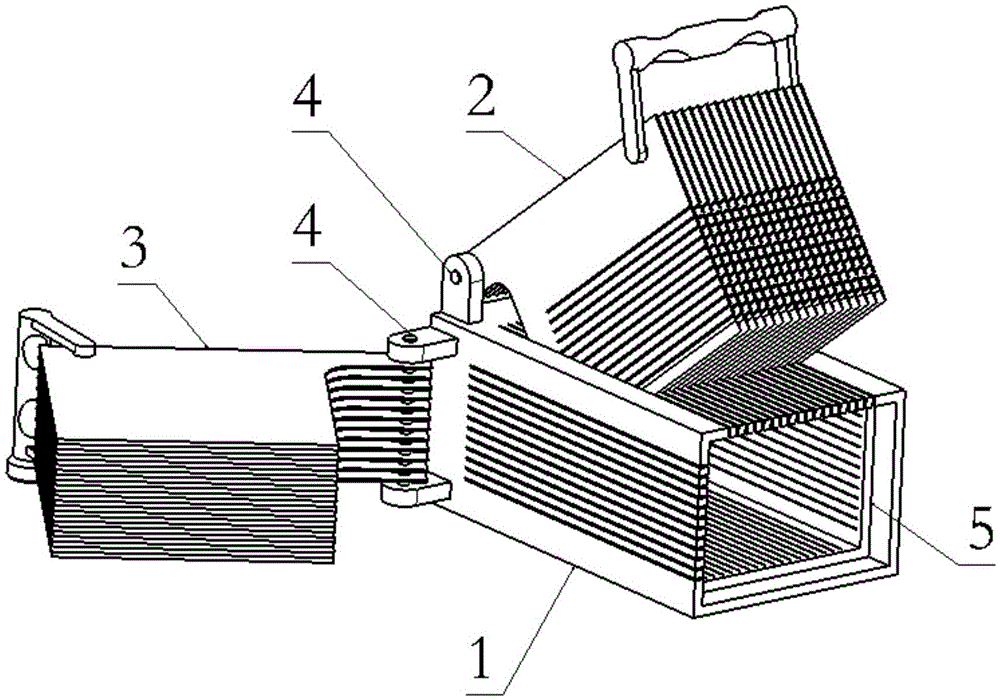

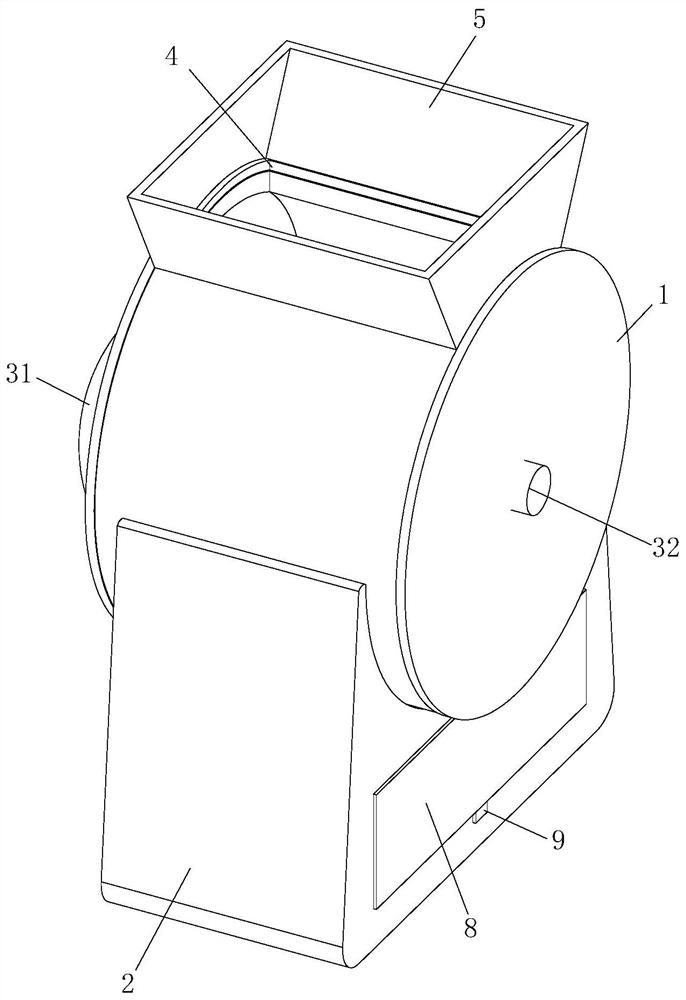

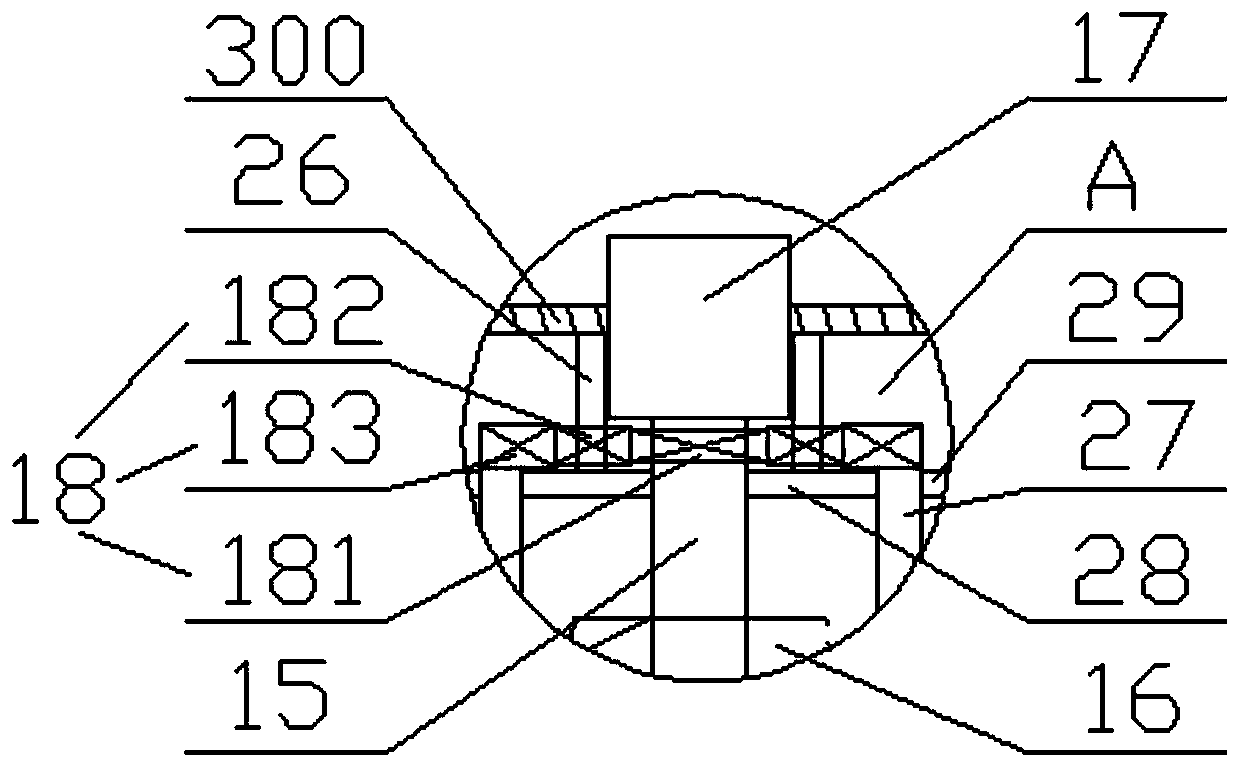

Thin film feeding and shredding device

ActiveCN105563697AGood shredding effectImprove shredding efficiencyPlastic recyclingMechanical material recoveryEngineeringScrew conveyor

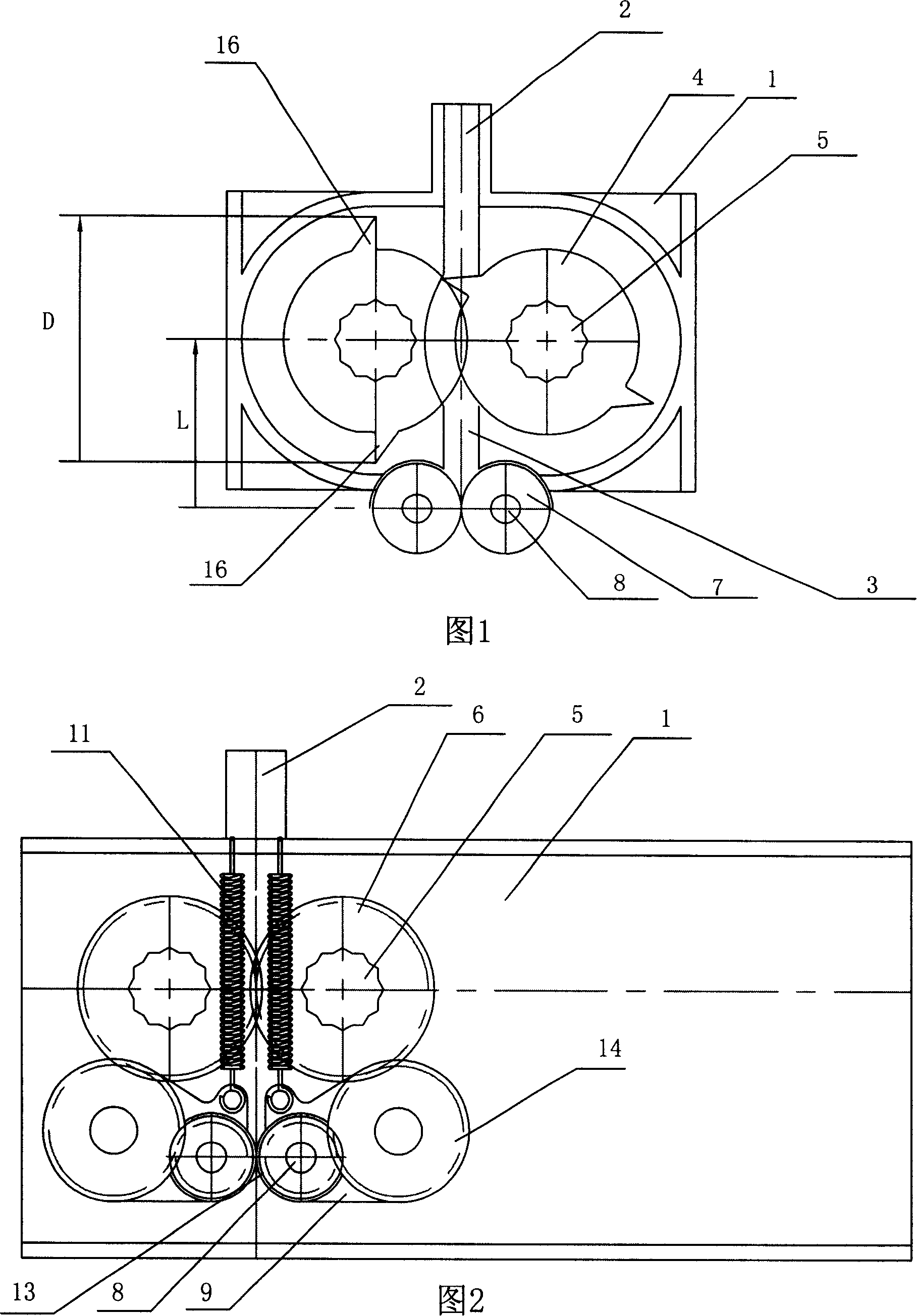

The invention discloses a thin film feeding and shredding device which comprises a machine frame. A main shaft is movably supported by the machine frame and provided with a rotor. Cutter claws are arranged on the outer wall of the rotor, the outside of the rotor is sleeved with rollers at intervals, the inner walls of the rollers are also provided with cutter claws, and a shredding channel is formed between the rotor and the rollers and can cut and shred thin films in pairs and convey the shredded thin films backwards. The shredding channel is composed of a plurality of shredding sub-channels. In the thin film conveying direction, the distance between the rotor and the corresponding roller in the next shredding sub-channel is smaller than the distance between the rotor and the corresponding roller in the previous adjacent shredding sub-channel, and the number of the cutter claws in the next shredding sub-channel is larger than the number of the cutter claws in the previous adjacent shredding sub-channel. A front end feed inlet of the shredding channel is communicated with a feed bin, the feed bin is provided with a feed inlet, the front end of the feed bin is provided with a front end discharge opening, the front end discharging opening of the feed bin is communicated with a material temporary storage box, and a spiral conveyer is further disposed in the feed bin. The thin film feeding and shredding device has the advantages of being good in thin film shredding effect and high in shredding efficiency.

Owner:ZHANGJIAGANG BEIER MACHINERY

Processing and making method of shredded shiitake mushrooms

InactiveCN107439671AGood shredding effectReduce churnFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingFreeze-dryingShiitake mushrooms

The invention discloses a processing and making method of shredded shiitake mushrooms. The processing and making method of the shredded shiitake mushrooms comprises the following steps of a, performing prebaking; b, performing baking and steaming; c, performing shredding; d, performing quick freezing; e, performing vacuum freeze-drying; and f, performing metal detection: artificially and carefully selecting materials after being subjected to vacuum freeze-drying in step e to remove broken shredded shiitake mushrooms and impurities, and then detecting the shredded shiitake mushrooms through a metal detector so that finished products of the shredded shiitake mushrooms are obtained. The processing and making method disclosed by the invention has the advantages that the shredded shiitake mushrooms after shredding are tidy and beautiful in shape, so that the running off of nutrient substances in the shredded shiitake mushrooms is greatly reduce, the preservation time of the shredded shiitake mushrooms is prolonged, the dried shredded shiitake mushrooms are good in rehydration effect, and the shredded shiitake mushrooms after being subjected to rehydration are good in mouth feel and high in nutrient value.

Owner:湖北昇泰食品有限公司

A household garbage shredding device

InactiveCN108339637BReduce wearGuaranteed service lifeGrain treatmentsStationary filtering element filtersLitterDomestic waste

The invention discloses a household garbage shredding device and belongs to the field of household garbage treatment. The device comprises a feeding mechanism, a shredding mechanism and a dischargingmechanism. The feeding mechanism comprises a liquid collecting cavity, a solid-liquid separating cavity and a feeding channel which are designed longitudinally from bottom to top in a stacked mode. The shredding mechanism comprises a primary shredding cavity communicating with the feeding channel and a secondary shredding cavity communicating with the primary shredding cavity. The discharging mechanism comprises a first discharging channel connected with an outlet of the primary shredding cavity and an inlet of the secondary shredding cavity, and a second discharging channel arranged at an outlet of the secondary shredding cavity. According to the household garbage shredding device, garbage materials can be classified before being shredded, garbage materials such as metal which does not need to be shredded are separated out, abrasion of products such as metal to tools can be reduced, and the working efficiency of the device is improved; and the garbage materials can be subjected to primary shredding, then continuous incremental shredding acting force is provided, and the shredding effect on the garbage materials is obviously good.

Owner:刘泰麟

Film feed shredding device

ActiveCN105563697BGood shredding effectImprove shredding efficiencyPlastic recyclingMechanical material recoveryScrew conveyorTemporary storage

The invention discloses a thin film feeding and shredding device which comprises a machine frame. A main shaft is movably supported by the machine frame and provided with a rotor. Cutter claws are arranged on the outer wall of the rotor, the outside of the rotor is sleeved with rollers at intervals, the inner walls of the rollers are also provided with cutter claws, and a shredding channel is formed between the rotor and the rollers and can cut and shred thin films in pairs and convey the shredded thin films backwards. The shredding channel is composed of a plurality of shredding sub-channels. In the thin film conveying direction, the distance between the rotor and the corresponding roller in the next shredding sub-channel is smaller than the distance between the rotor and the corresponding roller in the previous adjacent shredding sub-channel, and the number of the cutter claws in the next shredding sub-channel is larger than the number of the cutter claws in the previous adjacent shredding sub-channel. A front end feed inlet of the shredding channel is communicated with a feed bin, the feed bin is provided with a feed inlet, the front end of the feed bin is provided with a front end discharge opening, the front end discharging opening of the feed bin is communicated with a material temporary storage box, and a spiral conveyer is further disposed in the feed bin. The thin film feeding and shredding device has the advantages of being good in thin film shredding effect and high in shredding efficiency.

Owner:ZHANGJIAGANG BEIER MACHINERY

Machine core of paper pulverizer

InactiveCN100400166CNot easy to failExtend your lifeGrain treatmentsPulp and paper industryPaper sheet

Owner:黄铭玉

Kitchen tool for corrugated shred cutting

The invention discloses a kitchen tool for corrugated shred cutting. The kitchen tool comprises a box, a corrugated knife row, a straight-grain knife row, limiting rotary shafts and a blocking anvil. Blocky vegetables are put in the box and are slightly located through the blocking anvil, the corrugated knife row is rotated, and corrugated cutting edges penetrate grid seams to cut the blocky vegetables into a corrugated sheet shape. The corrugated knife row is kept fixed, the straight-grain knife row is rotated, straight-grain cutting edges penetrate the grid seams and cross grooves, and the sheet-shaped vegetables are cut into a corrugated shred shape. The kitchen tool is convenient and rapid to operate, simple in structure and remarkable in shredding effect, and everyone can be a chef.

Owner:江苏海泰新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com