Method assembling blade of paper cutting machine

An assembly method and technology of a paper shredder, applied in grain processing and other directions, can solve the problems of large shredding force, reduced shredding amount, and uneven force on the cutter shaft, so as to prolong the continuous operation time, improve the shredding effect, and solve the problem of The effect of uneven stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

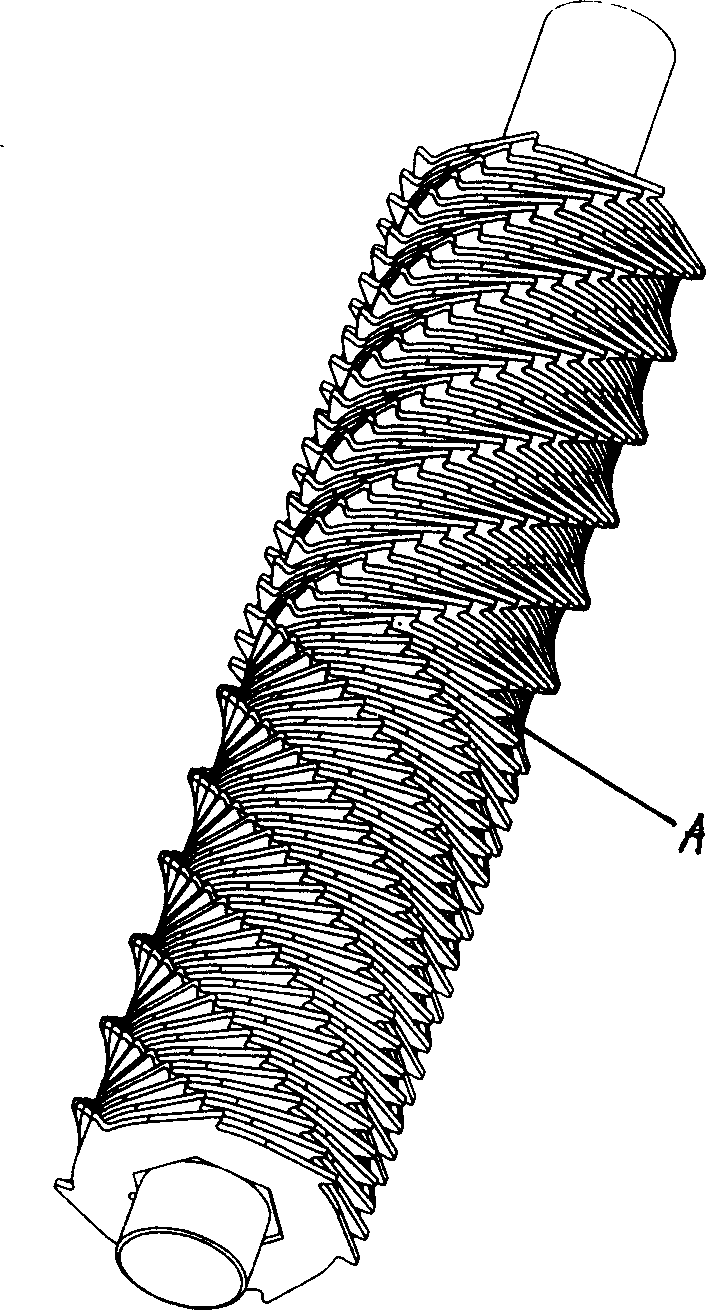

[0012] Embodiment 1. A shredder blade assembly method, including a spiral sheet body; with the center position of the cutter shaft as a boundary, the blade tips are arranged in a spiral line in both positive and negative directions on both sides.

Embodiment 2

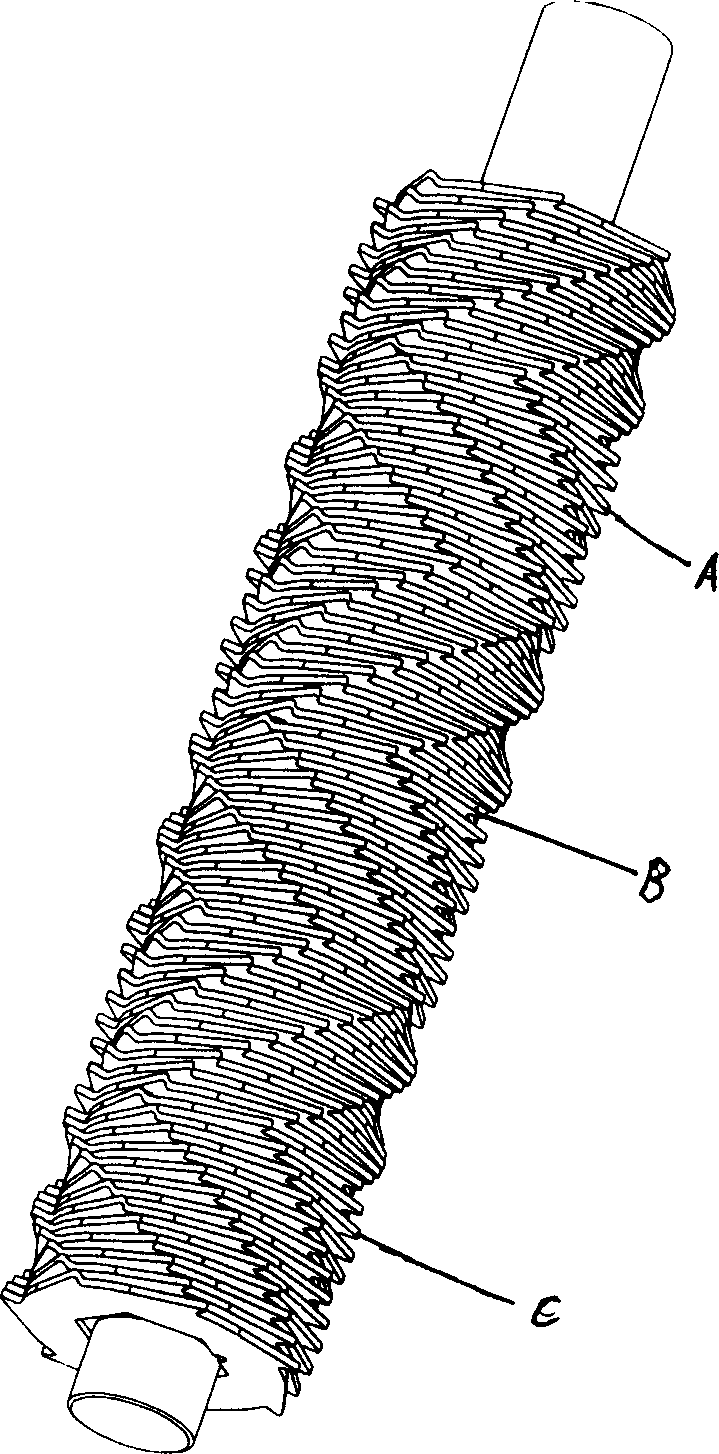

[0013] Embodiment 2, paper shredder blade assembly method, on the basis of embodiment 1, divide according to the length of the shaft to form several interface.

Embodiment 3

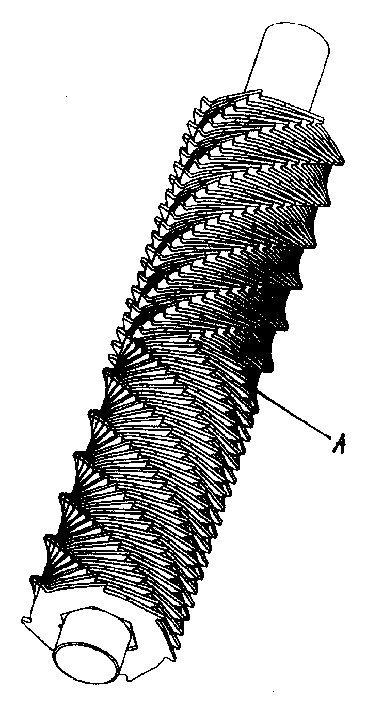

[0014] Embodiment 3, the paper shredder blade assembly method, on the basis of Embodiment 1, several interfaces are formed with different positions as boundaries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com