Supporting frame for duct pieces of soil-disturbance-resistant split type shield tunnel

A shield tunnel segment, split-type technology, applied in tunnels, tunnel lining, earthwork drilling and mining, etc., can solve problems such as deformation of formed tunnel segments, achieve uneven force, eliminate safety and quality hazards, and unlucky Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

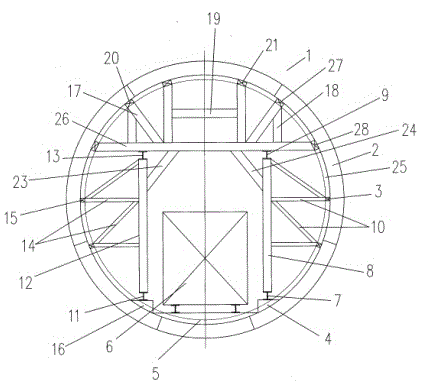

[0009] The present invention is described in detail below in conjunction with accompanying drawing:

[0010] An anti-soil disturbance split type shield tunnel segment support frame, comprising a shield tunnel surrounding rock hole side wall 1, a segment 2 is arranged on the shield surrounding rock hole side wall 1, and a bottom segment is respectively arranged The right sleeper 4 of the shield trolley and the left sleeper 16 of the shield trolley, the right support frame bottom beam 7 is arranged on the right sleeper 4 of the shield tunnel trolley along the tunnel direction, and the bottom beam 7 of the right support frame is arranged at equal intervals on the right support frame bottom beam 7 The right support frame column 8 is provided with the right support frame longitudinal beam 9 along the tunnel trend at the top of the right support frame column 8, and the right right triangle support 10 is fixedly arranged on the right side of the right support frame column 8, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com