Reflux device of rectifying tower

A technology of reflux device and rectification tower, which is applied in the field of rectification tower reflux device, and achieves the effect of simple structure and unique design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

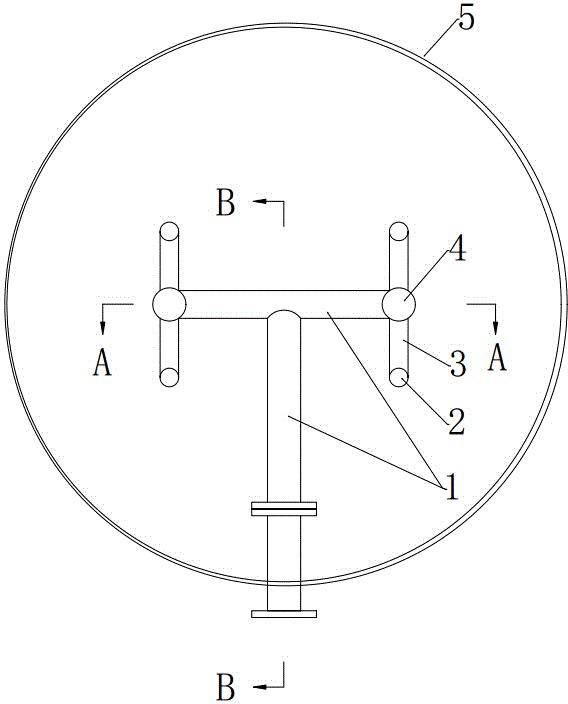

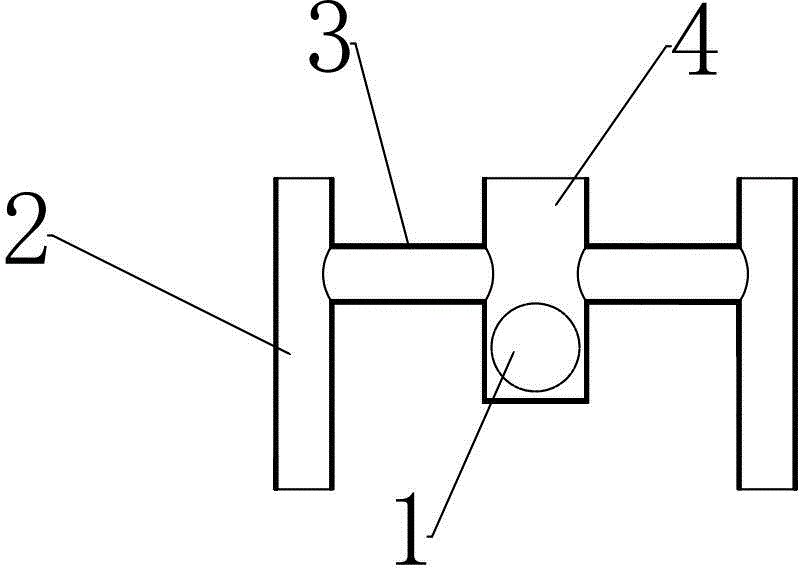

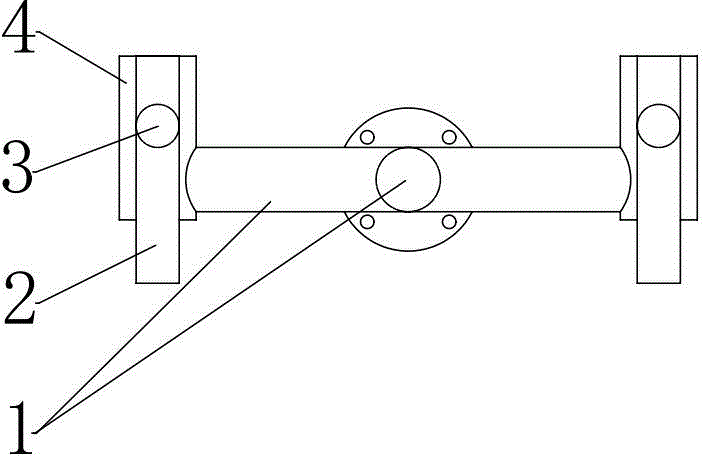

[0011] A rectification column reflux device described in this embodiment 1, such as figure 1 , figure 2 and image 3 As shown, it includes the reflux pipe 1 installed on the top of the rectifying tower 5, the reflux pipe branch is connected with a symmetrical and unconnected liquid seal pipe 4, the upper part of the liquid seal pipe is connected with the reflux pipe, and the middle and upper part of the liquid seal pipe passes through The distribution pipe 3 is connected with the lower liquid pipe 2, and the bottom of the distribution pipe is higher than the top of the return pipe. The liquid-sealed tube is provided with a liquid-sealed structure. The return pipe is always filled with liquid to ensure that the return pipe is always filled with liquid, thereby completely eliminating the possibility of hammering in the return pipe.

[0012] The reflux device is designed for the reflux of large rectification towers, so it is designed with four feeding pipes. For small rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com