Patents

Literature

556results about "Cutlery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

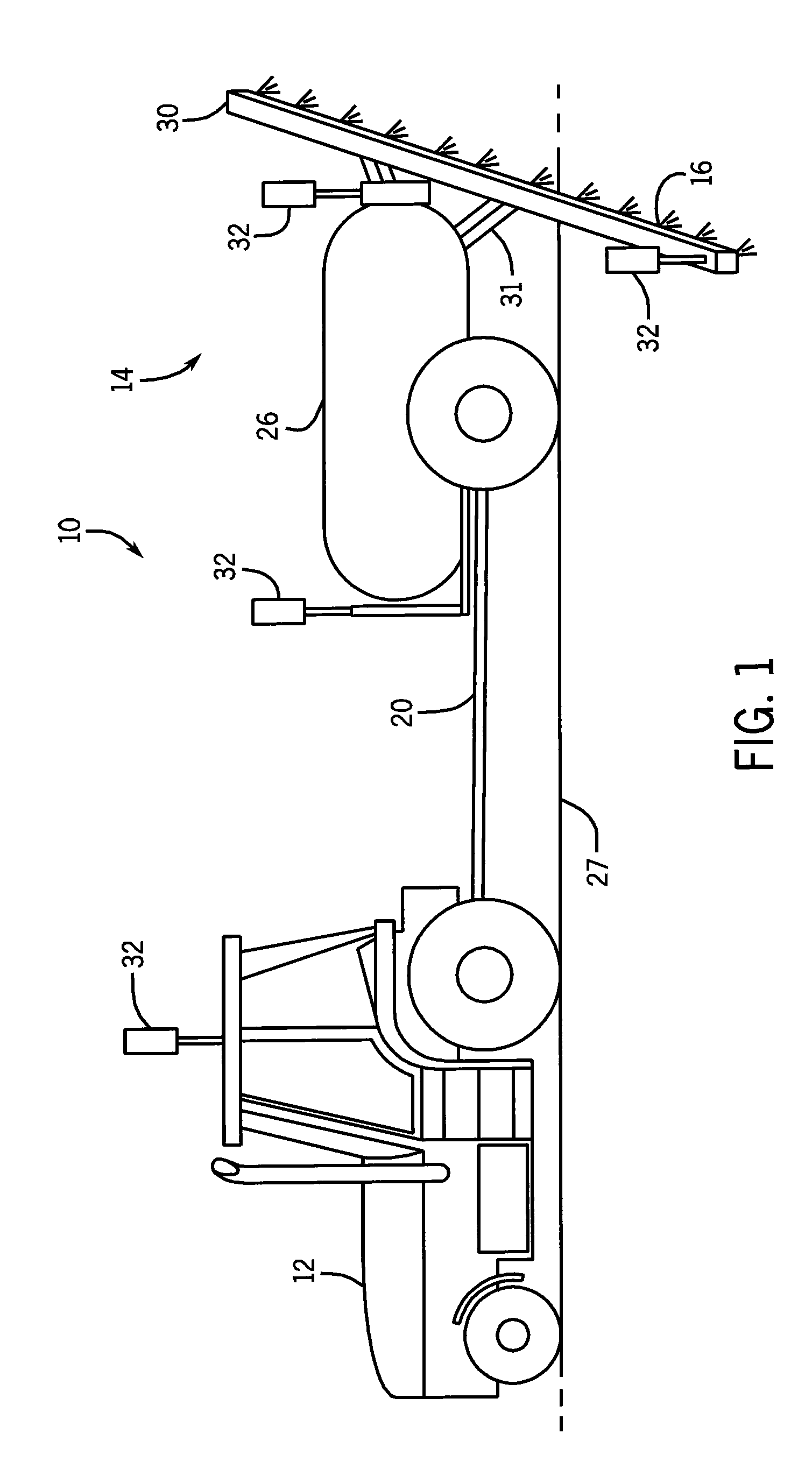

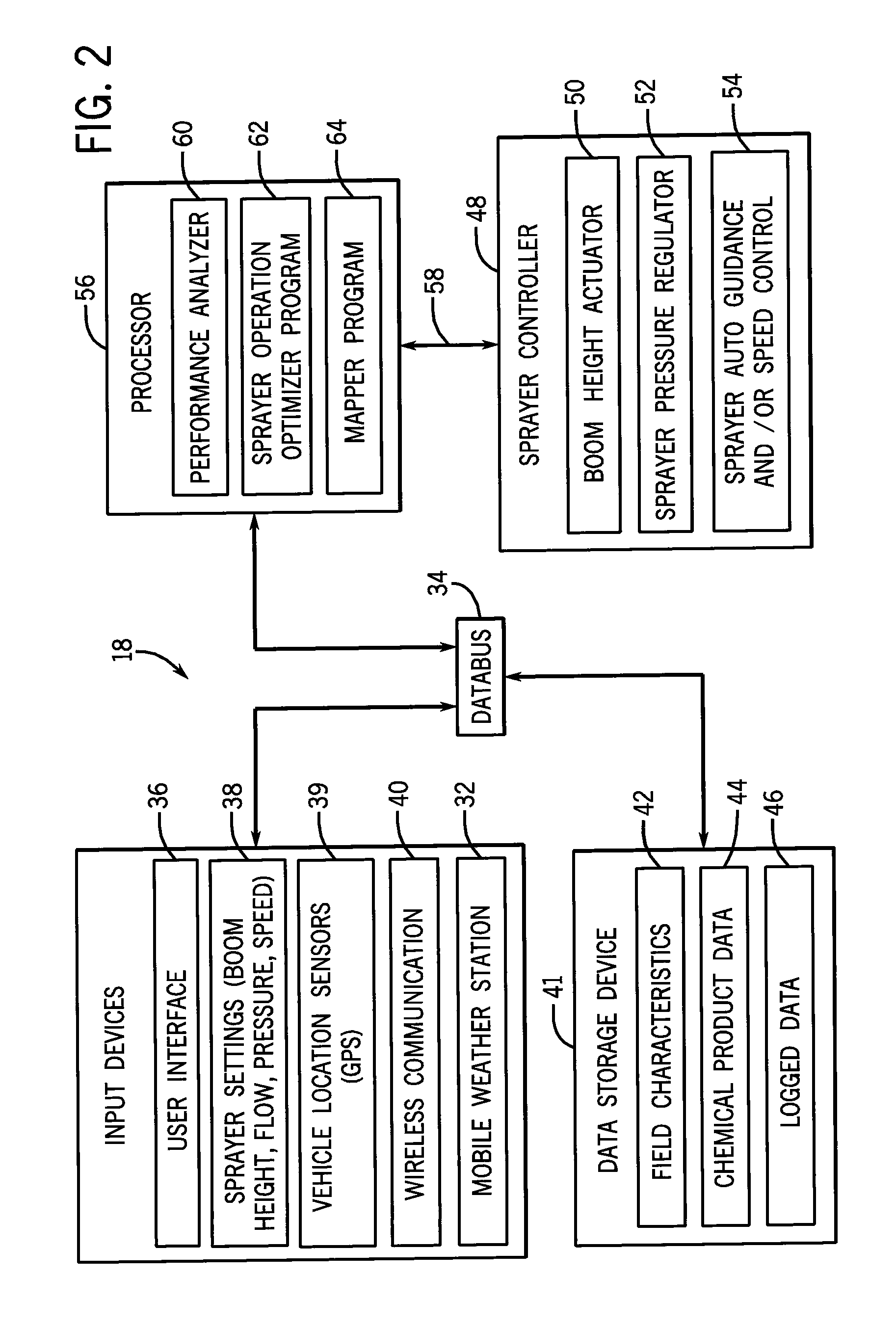

Method and apparatus for optimization of agricultural field operations using weather, product and environmental information

ActiveUS20090192654A1Reduce driftEasy to moveMowersMetal-working apparatusComputer scienceInput device

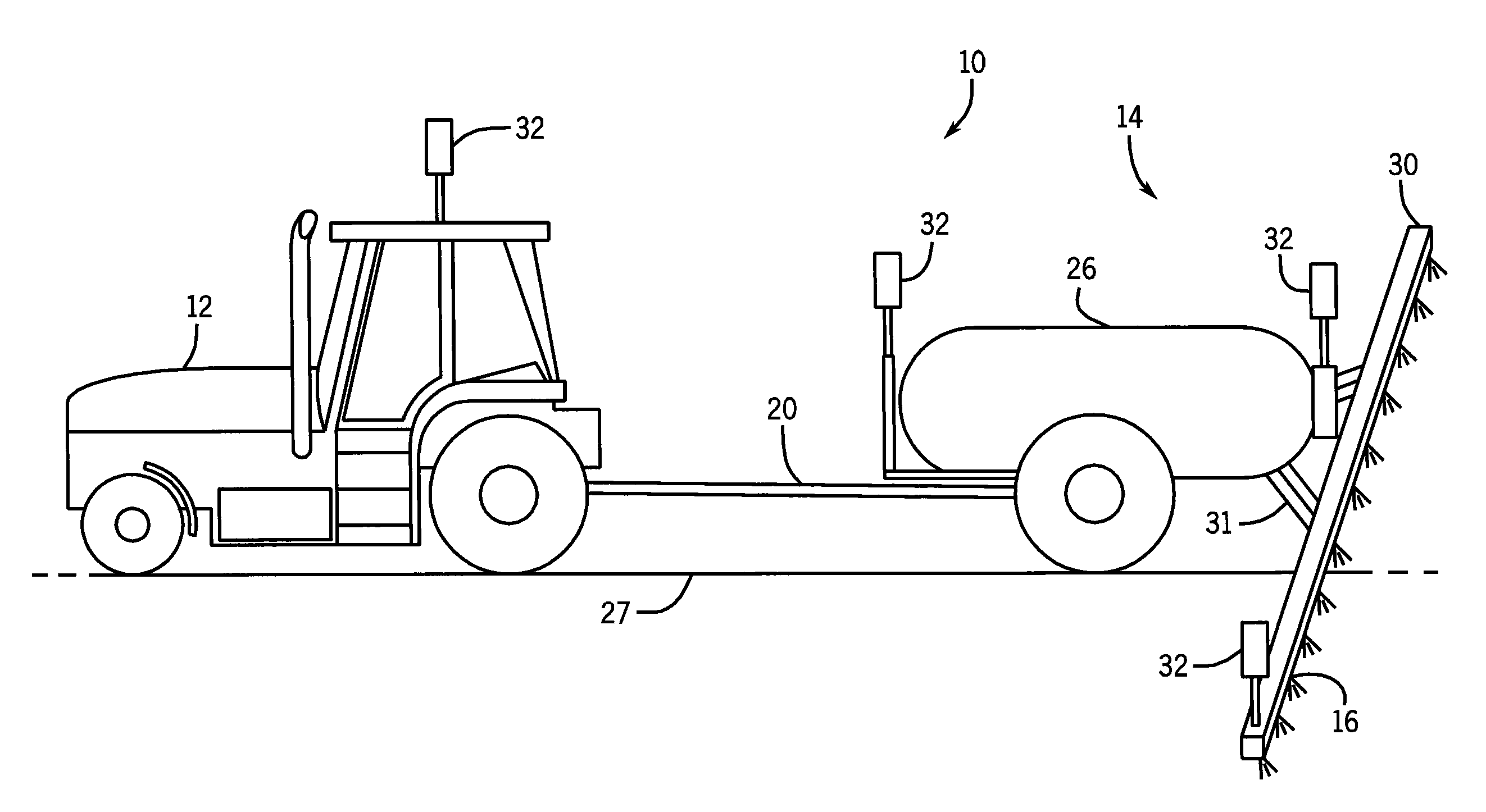

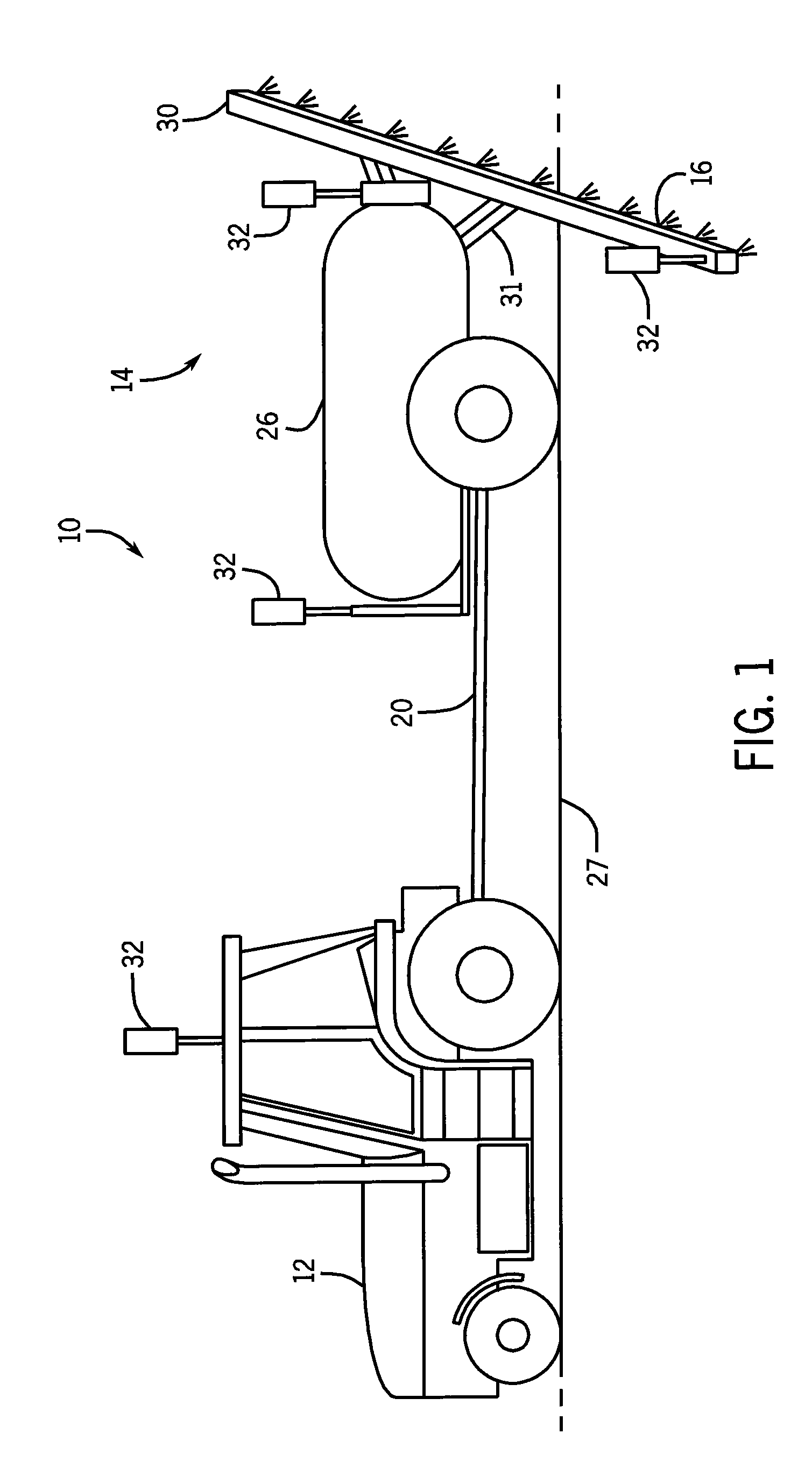

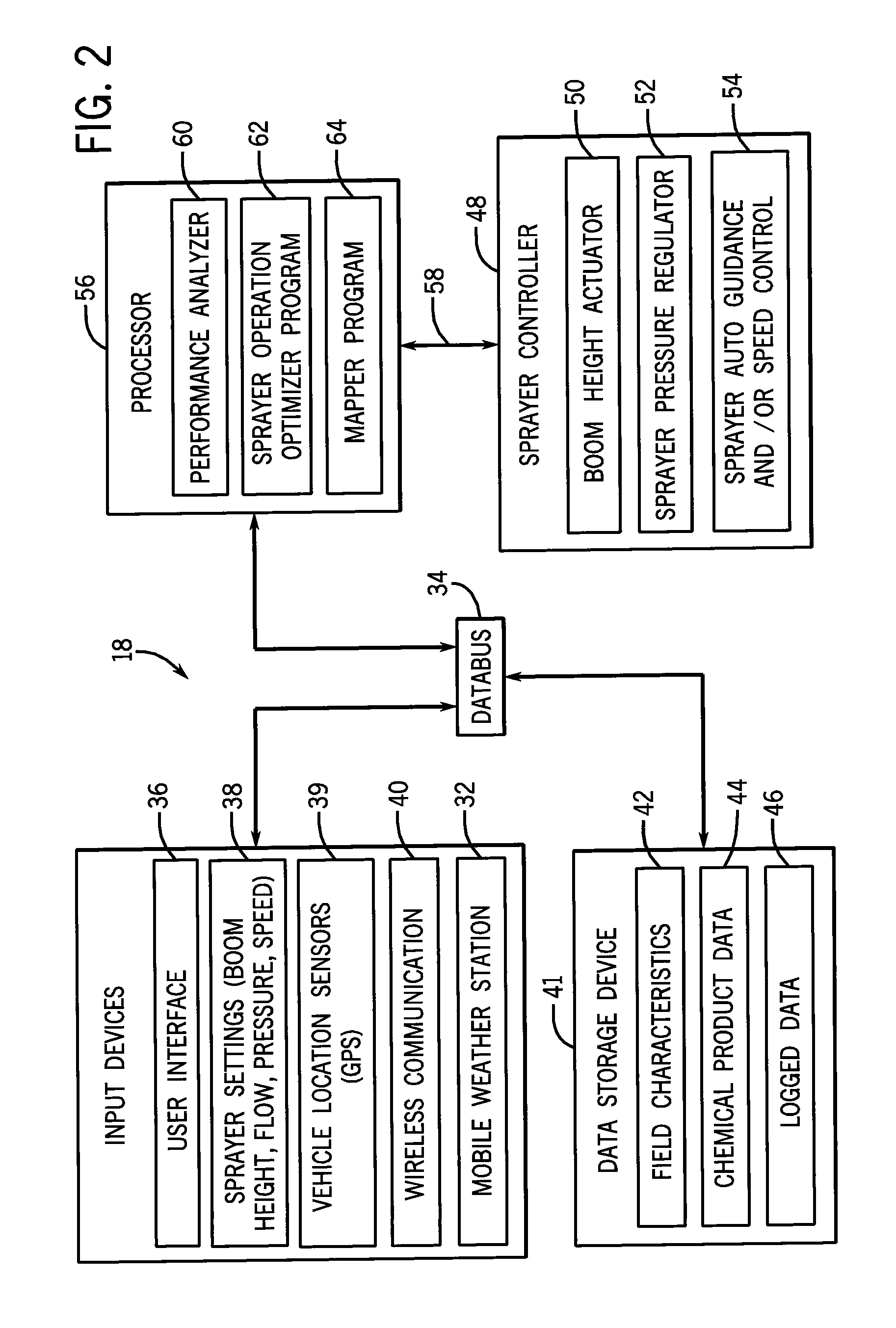

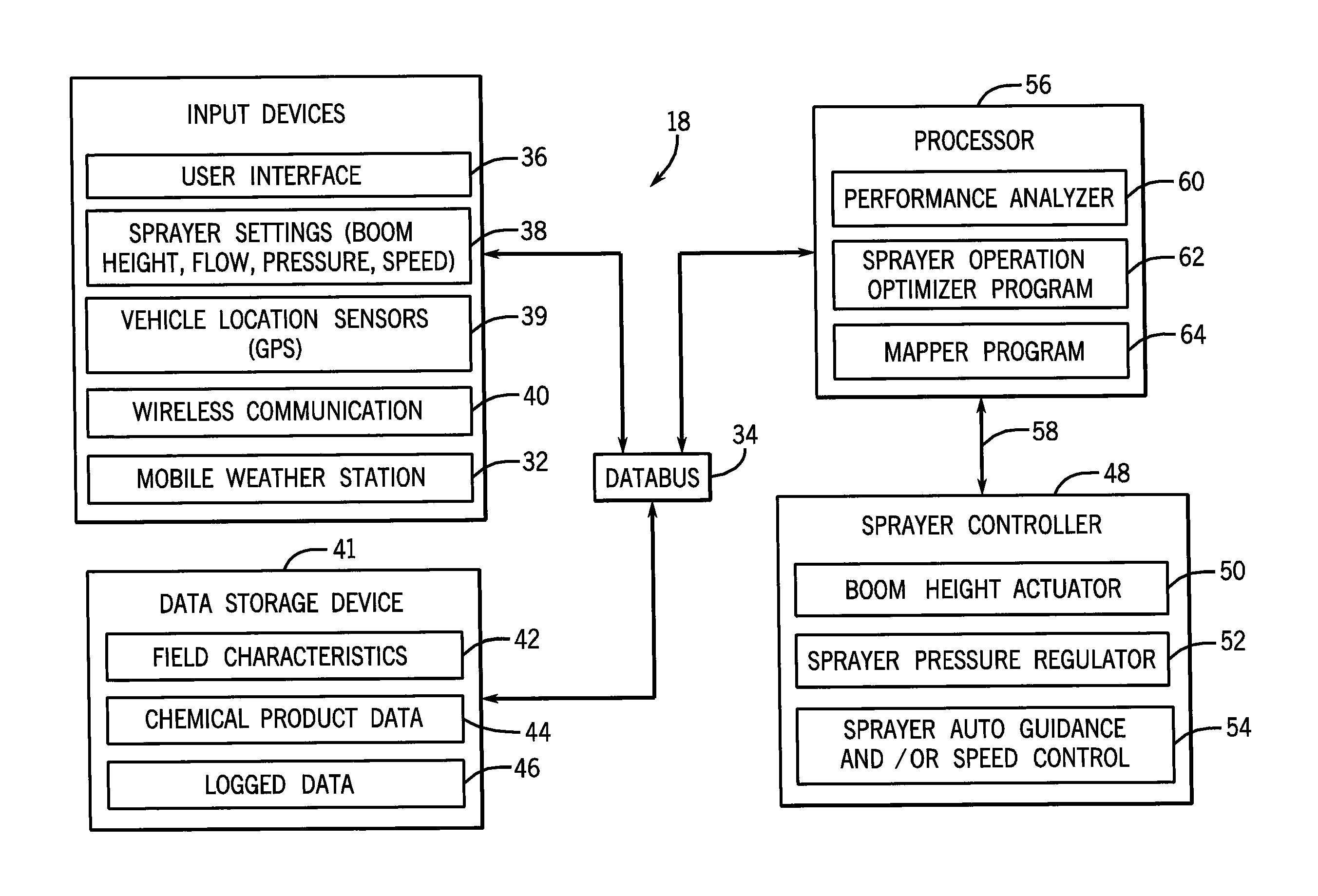

An agricultural system which includes at least one agricultural implement with at least one application device for applying crop inputs, where the agricultural implement includes an agricultural harvester and / or an agricultural planter. A databus is connected to the at least one agricultural implement, and at least one input device is connected to the databus. At least one data storage device is connected to the databus, and an application controller is connected to the at least one application device. A processor is connected to the databus and the application controller, where the processor applies inputs to the application controller to adjust and / or optimize in real time a current operation of the application device(s) in order to efficiently and accurately apply the crop inputs.

Owner:BLUE LEAF I P INC

Method and apparatus for optimization of agricultural field operations using weather, product and environmental information

An agricultural system which includes at least one agricultural implement with at least one application device for applying crop inputs, where the agricultural implement includes an agricultural harvester and / or an agricultural planter. A databus is connected to the at least one agricultural implement, and at least one input device is connected to the databus. At least one data storage device is connected to the databus, and an application controller is connected to the at least one application device. A processor is connected to the databus and the application controller, where the processor applies inputs to the application controller to adjust and / or optimize in real time a current operation of the application device(s) in order to efficiently and accurately apply the crop inputs.

Owner:BLUE LEAF I P INC

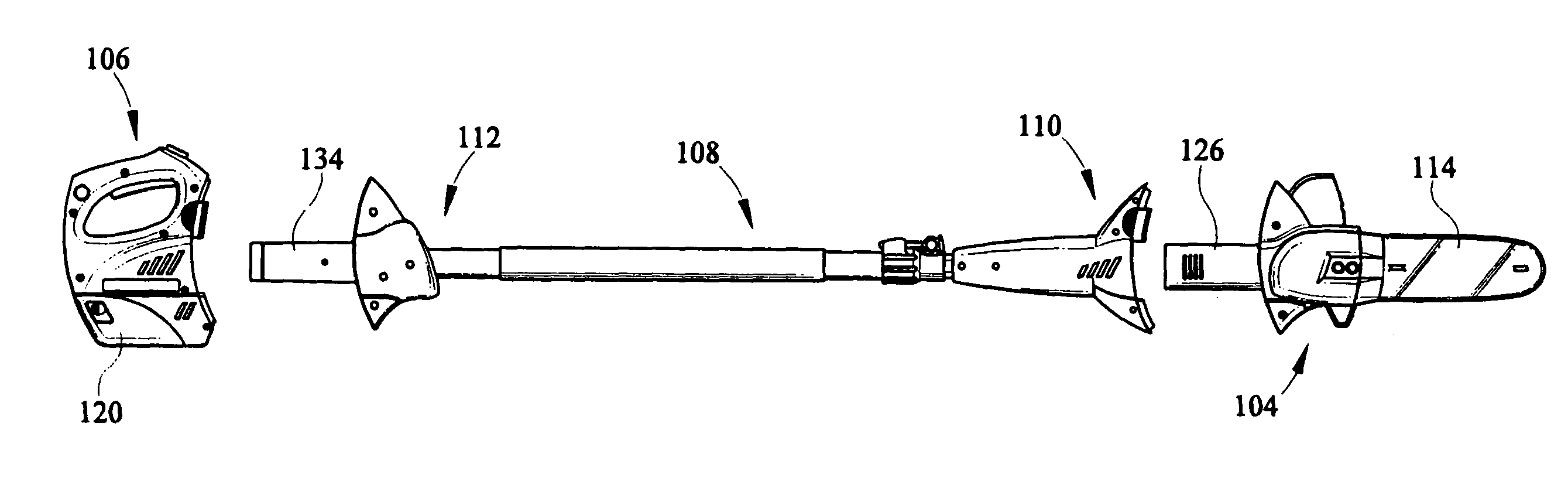

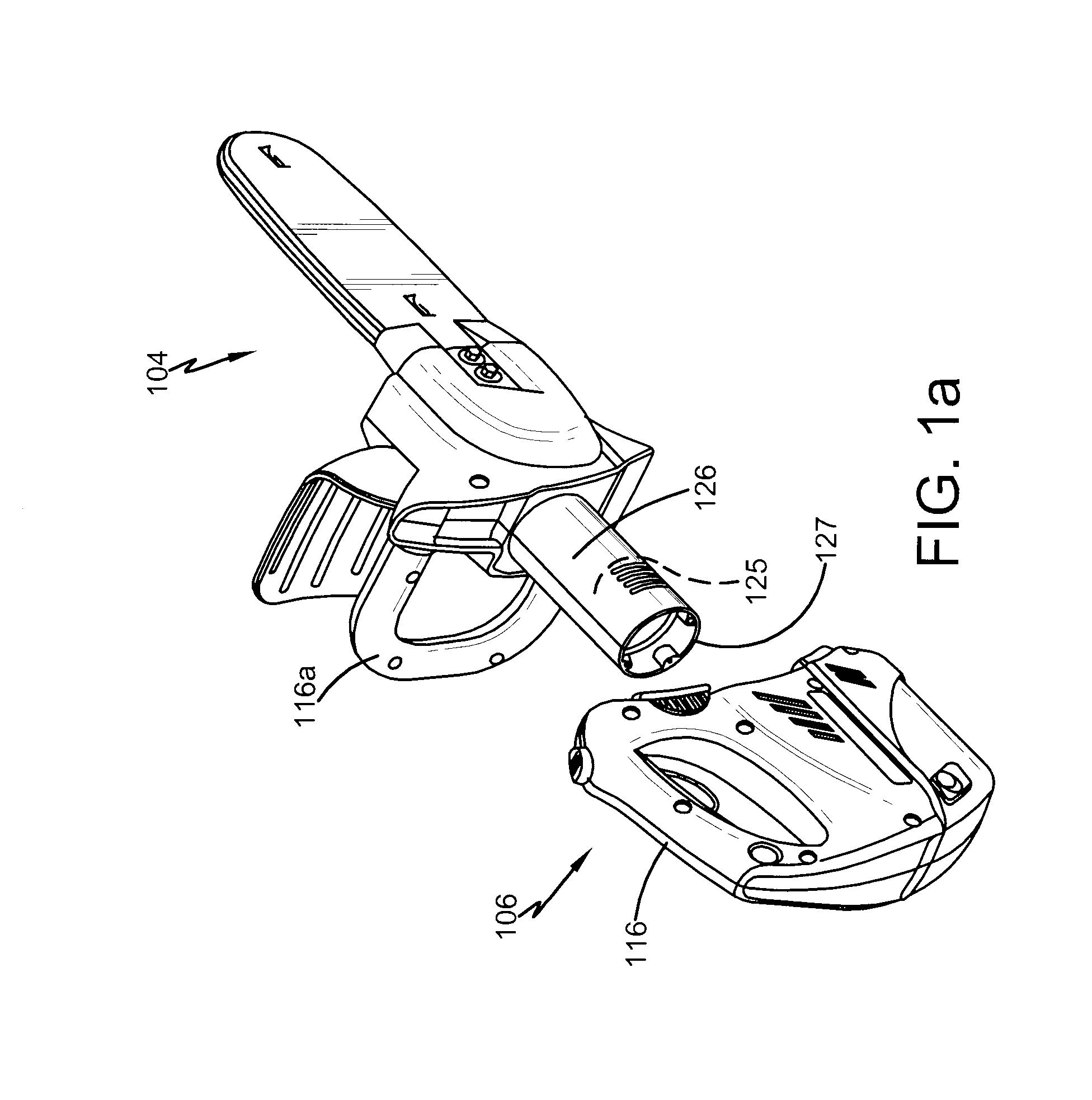

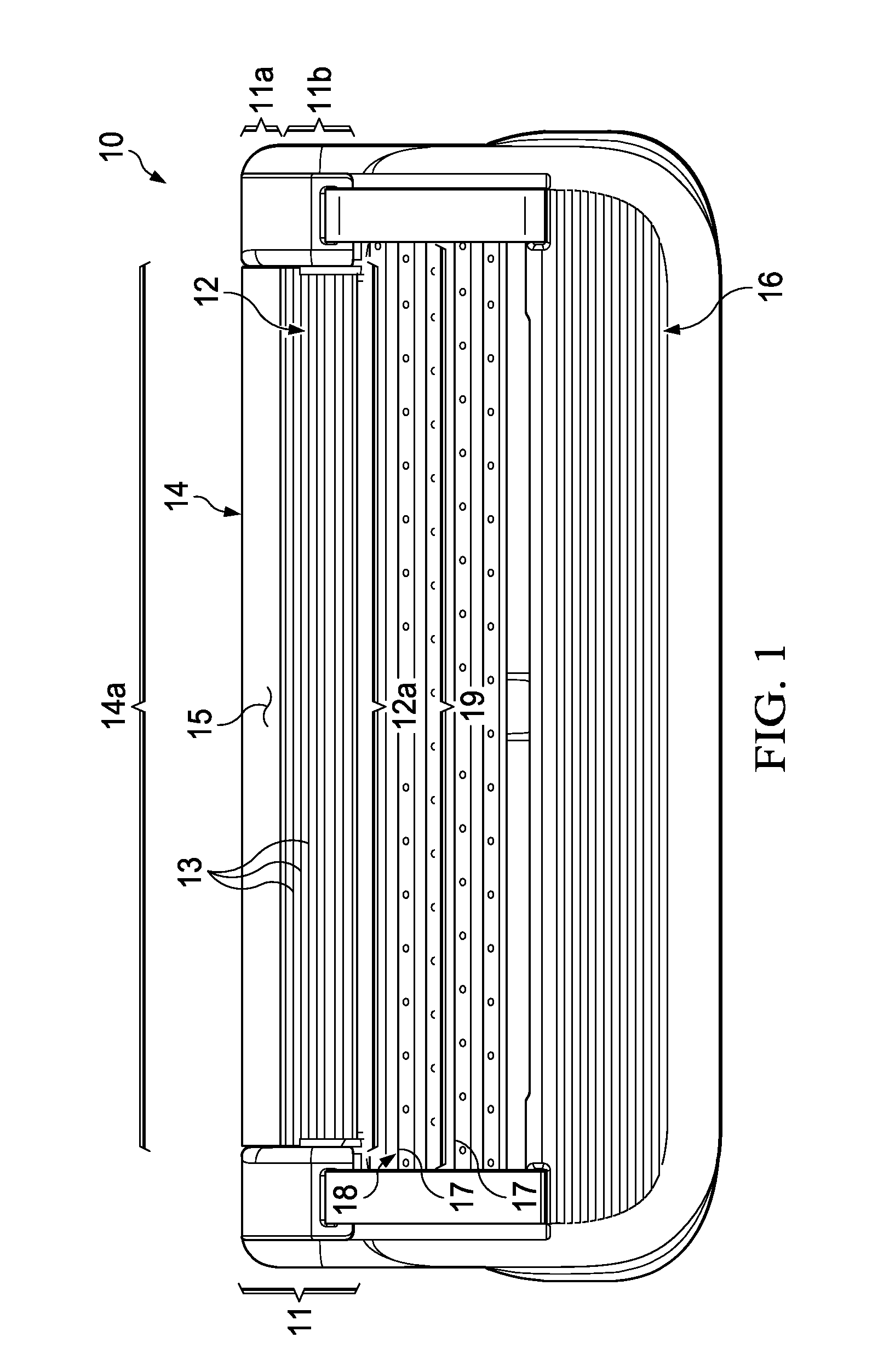

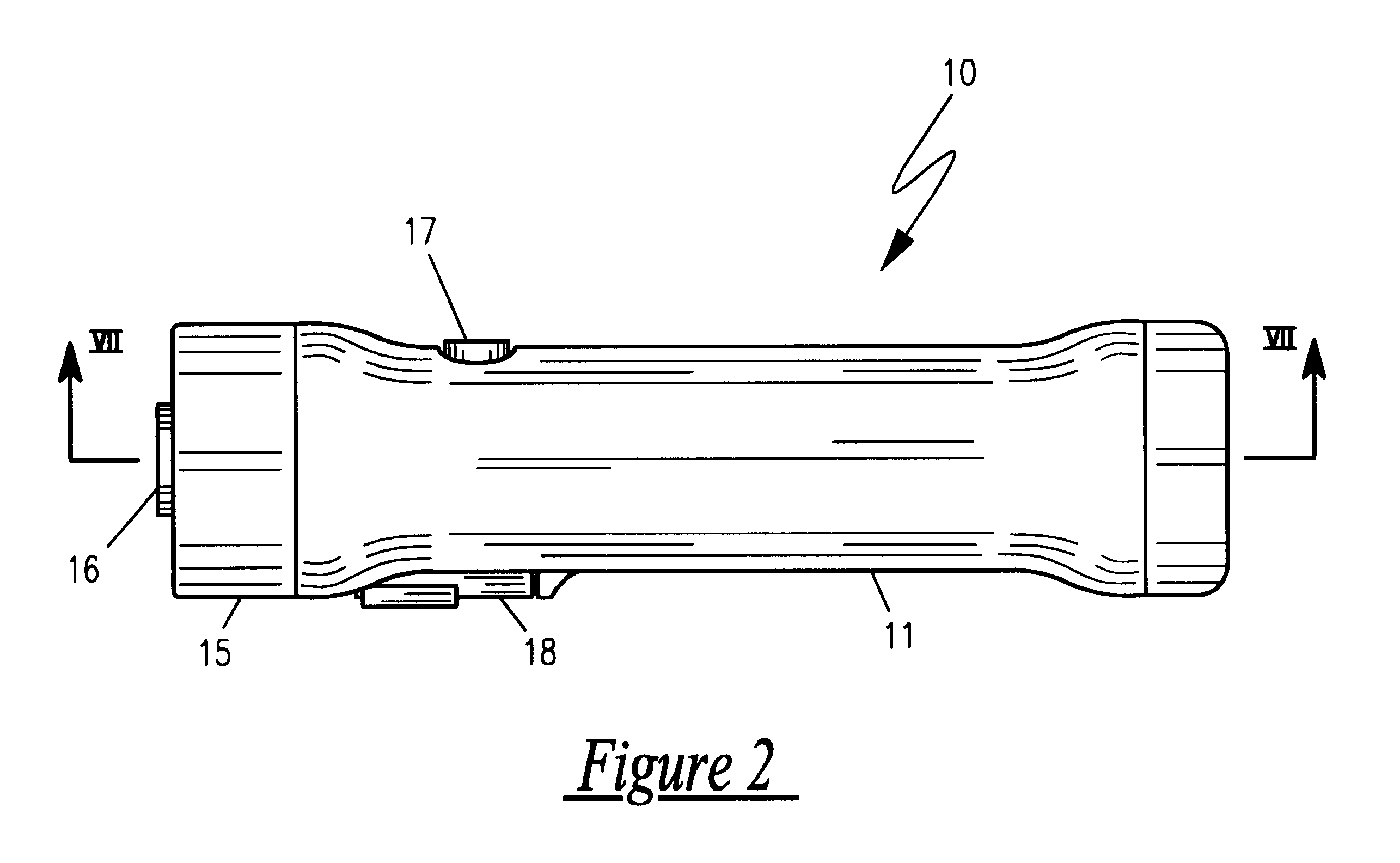

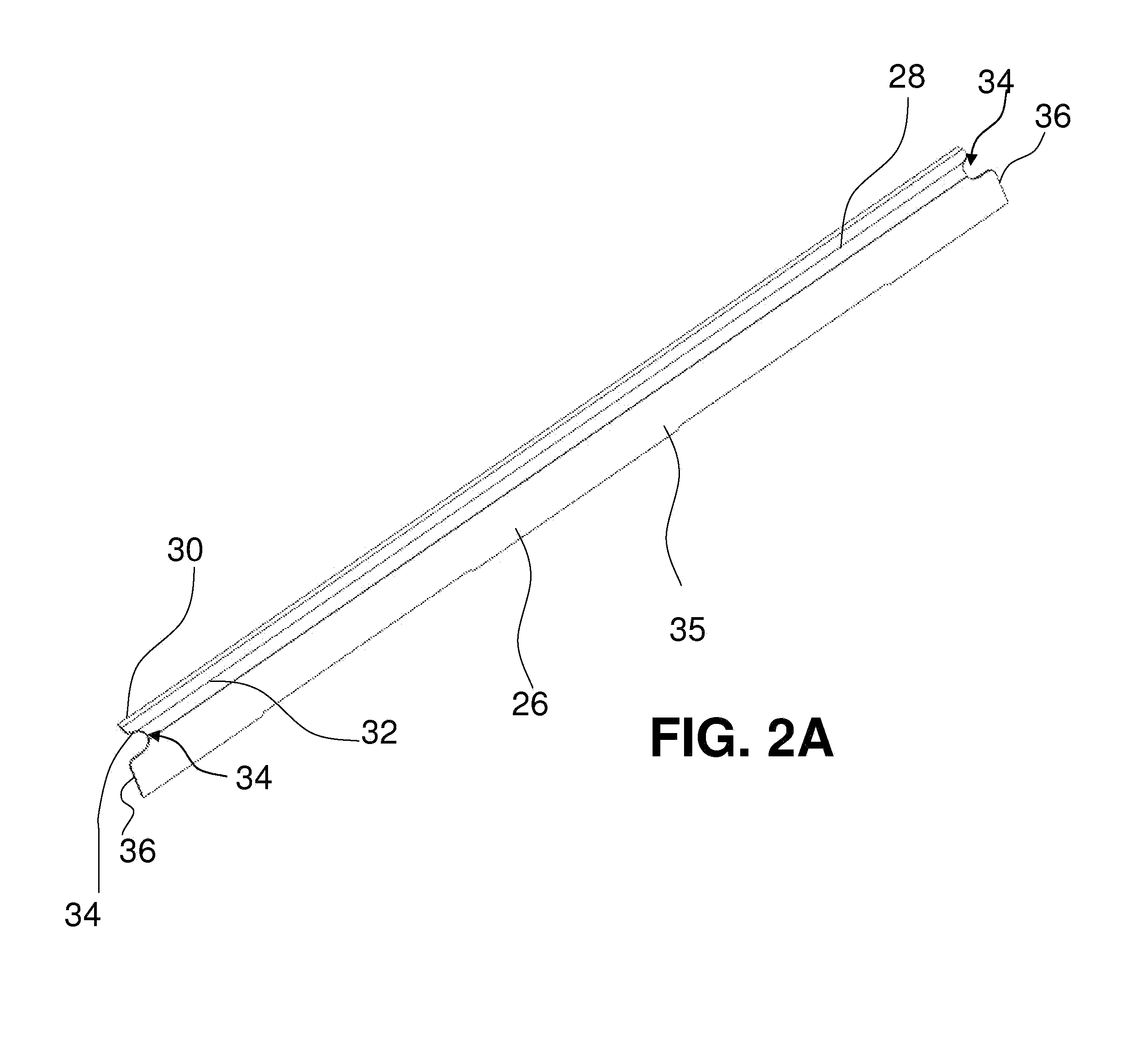

Split power tool with extension

An extendable hedge trimmer includes a housing having a handle end and a tool end. The handle end includes a battery and an electrical connector. The tool end includes a hedge trimming implement, a motor, and an electrical connector. The electrical connector of the tool end is electrically connected with the motor. Wiring is included within the handle end for electrically connecting the battery and the electrical connector of the handle end. The trimmer also includes a pole which is releasably connectable between the tool end and the handle end. The pole is configured for electrically connecting the handle end with the tool end. The trimmer also includes a latch mechanism for releasably attaching the pole between tool end and handle end. The trimmer also includes an input for receiving AC line power via a power cord, the trimmer configured for being powered by AC line power and / or battery power.

Owner:MTD PRODUCTS

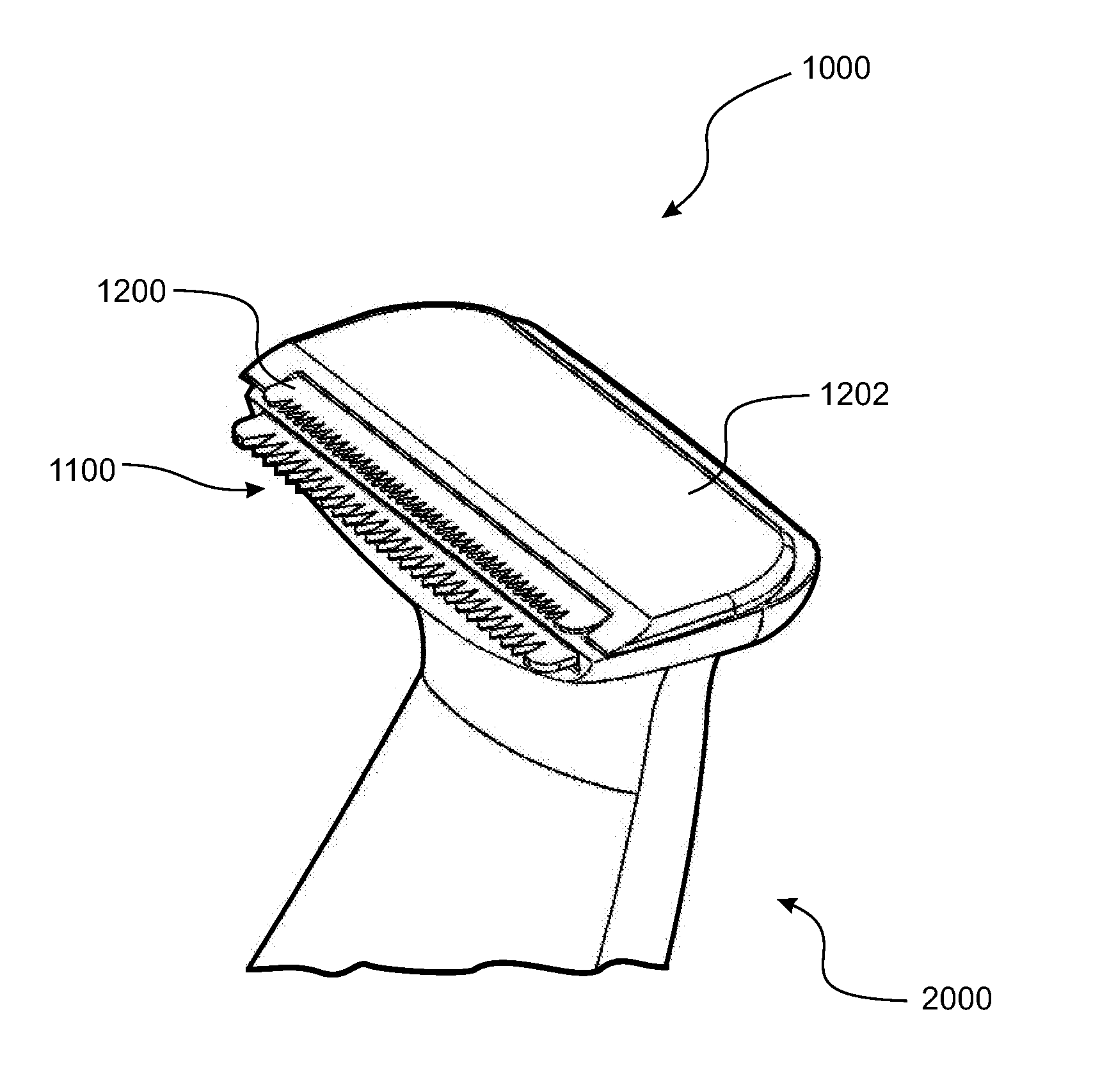

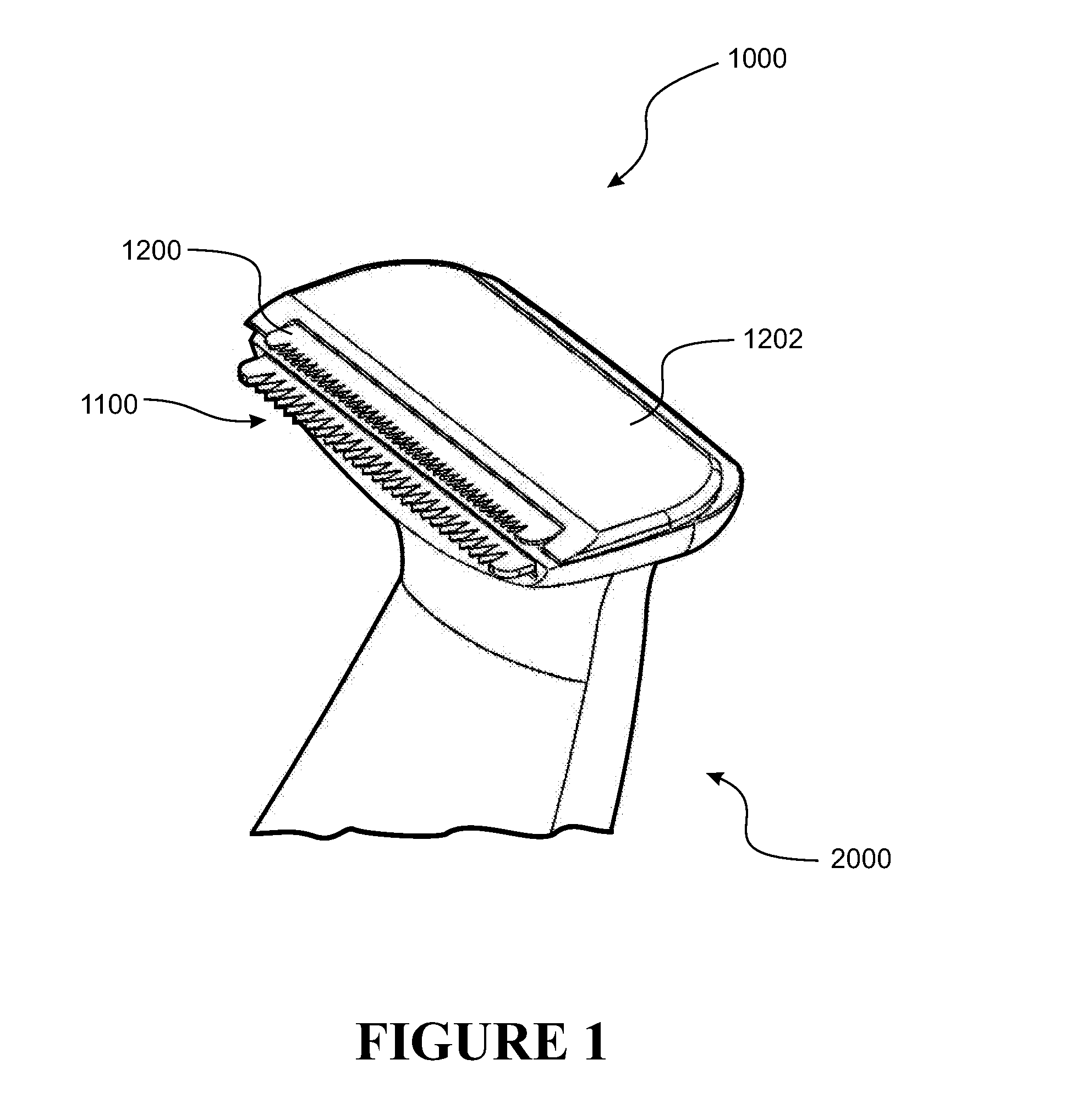

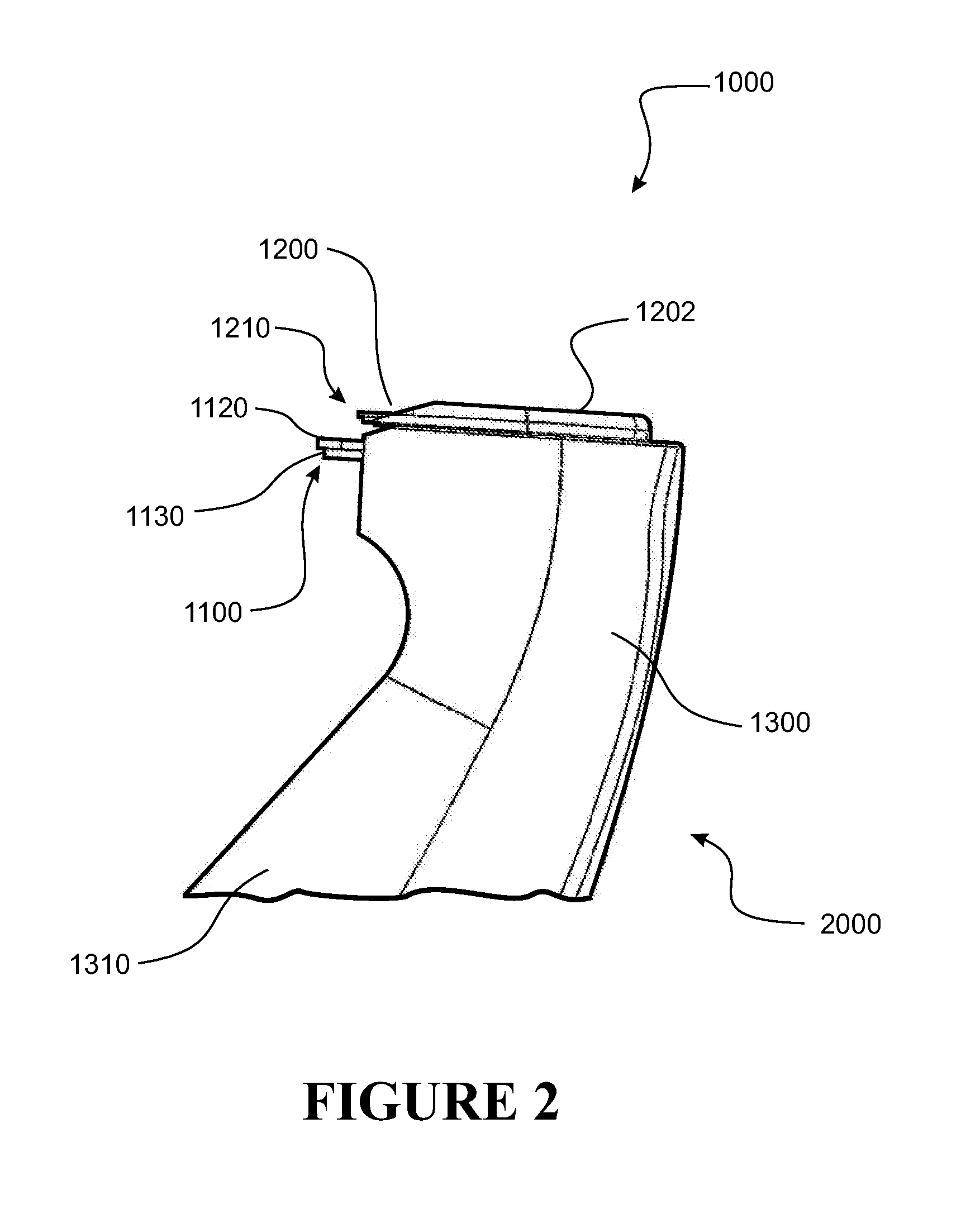

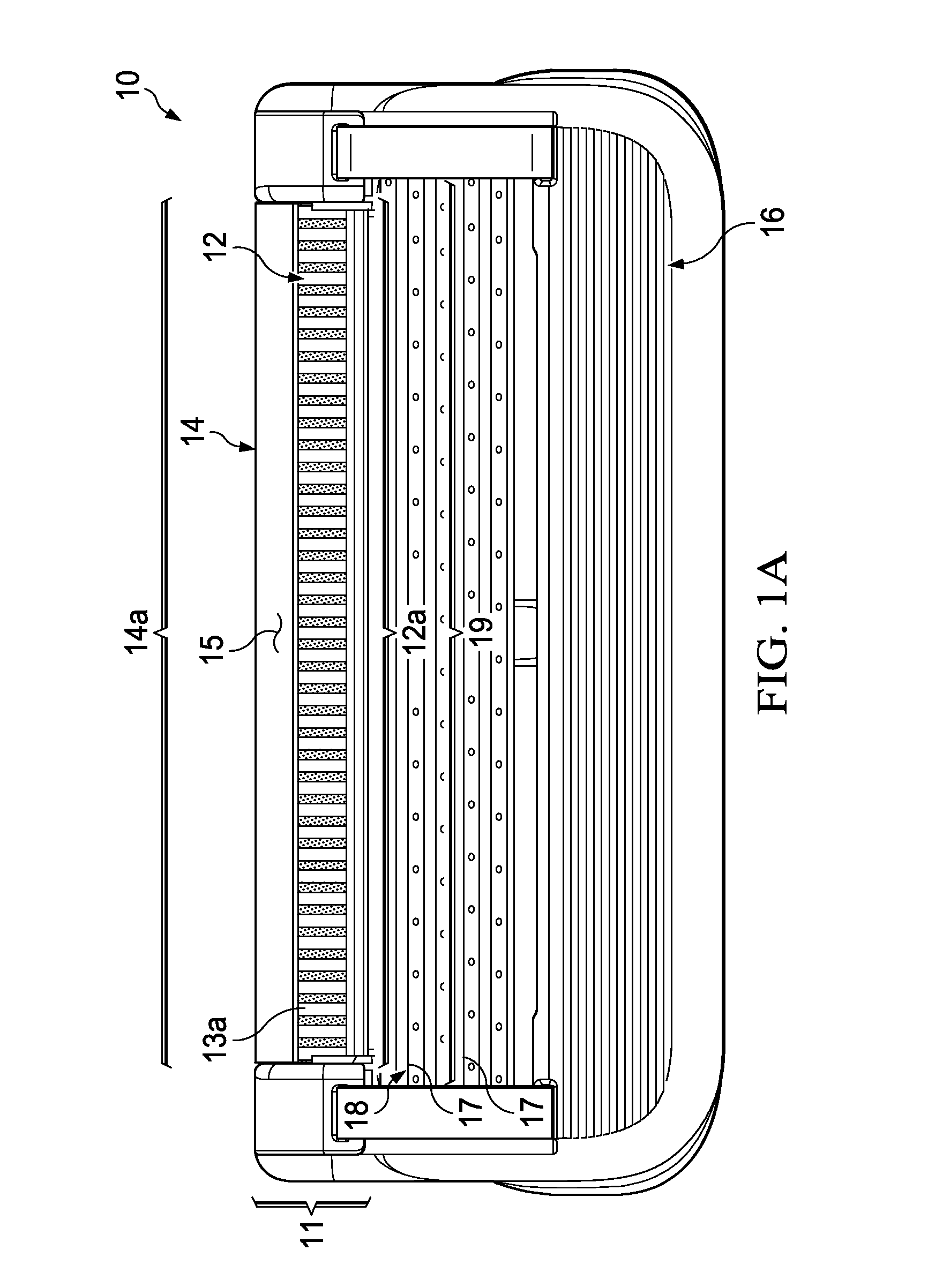

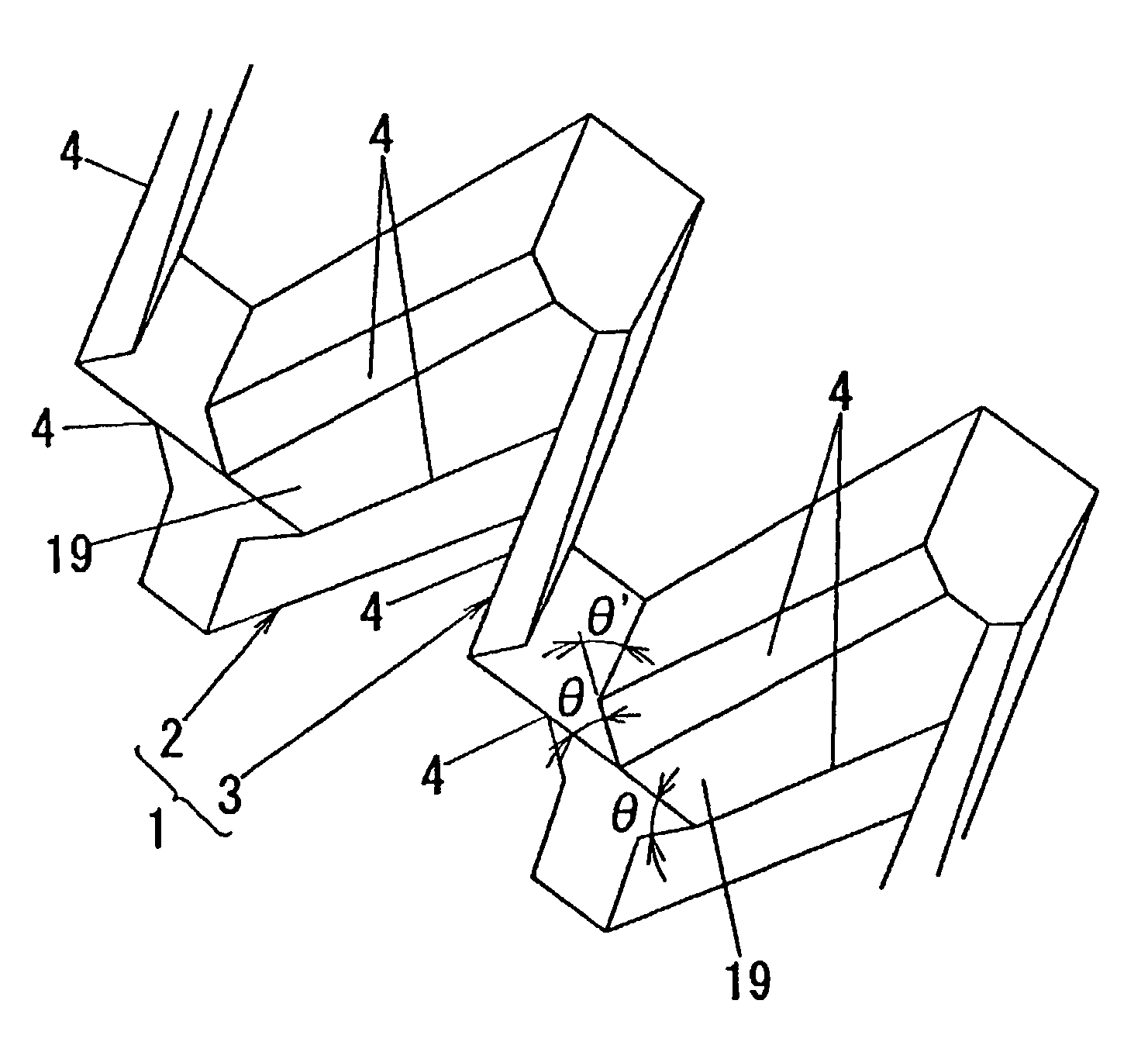

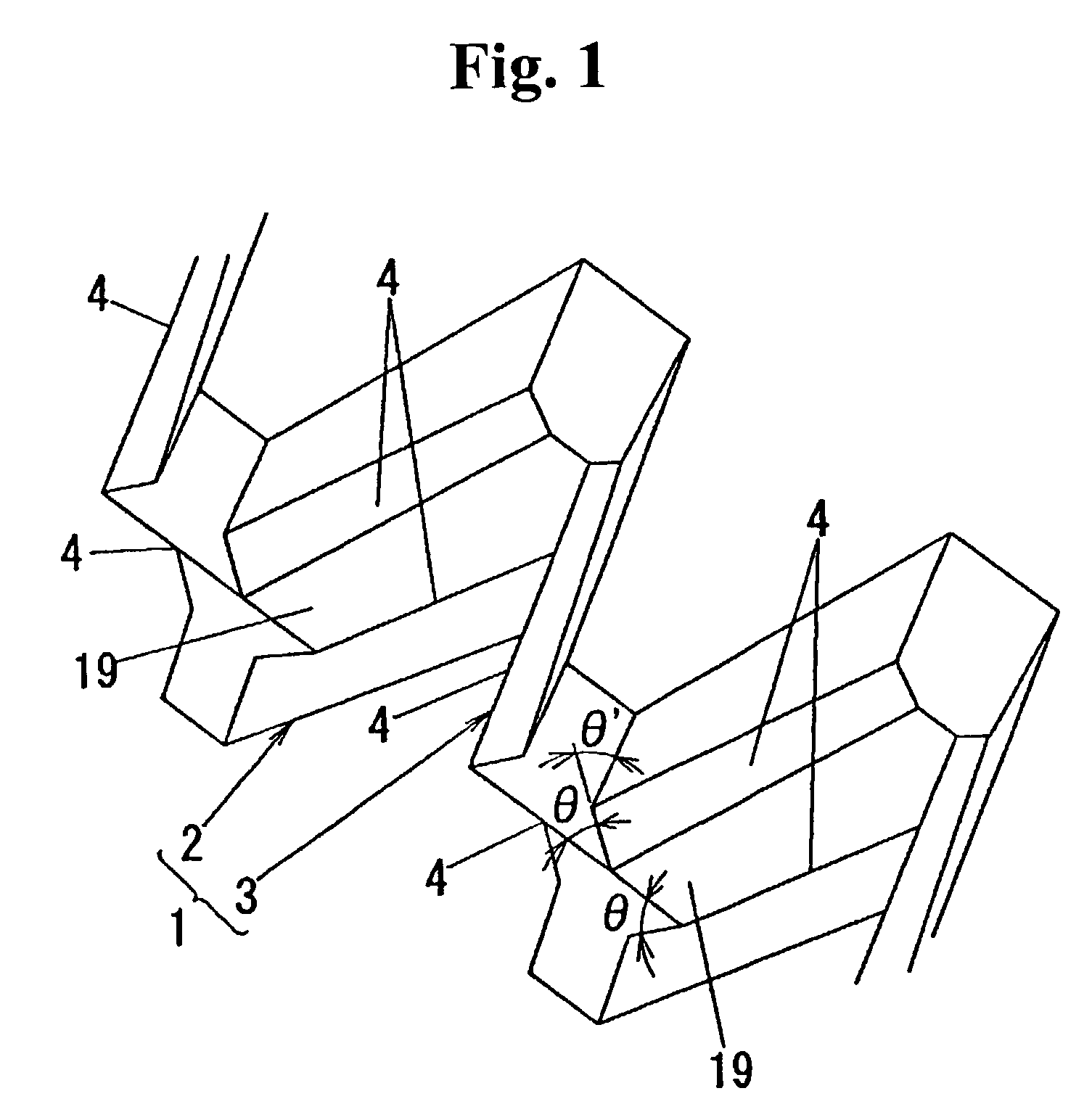

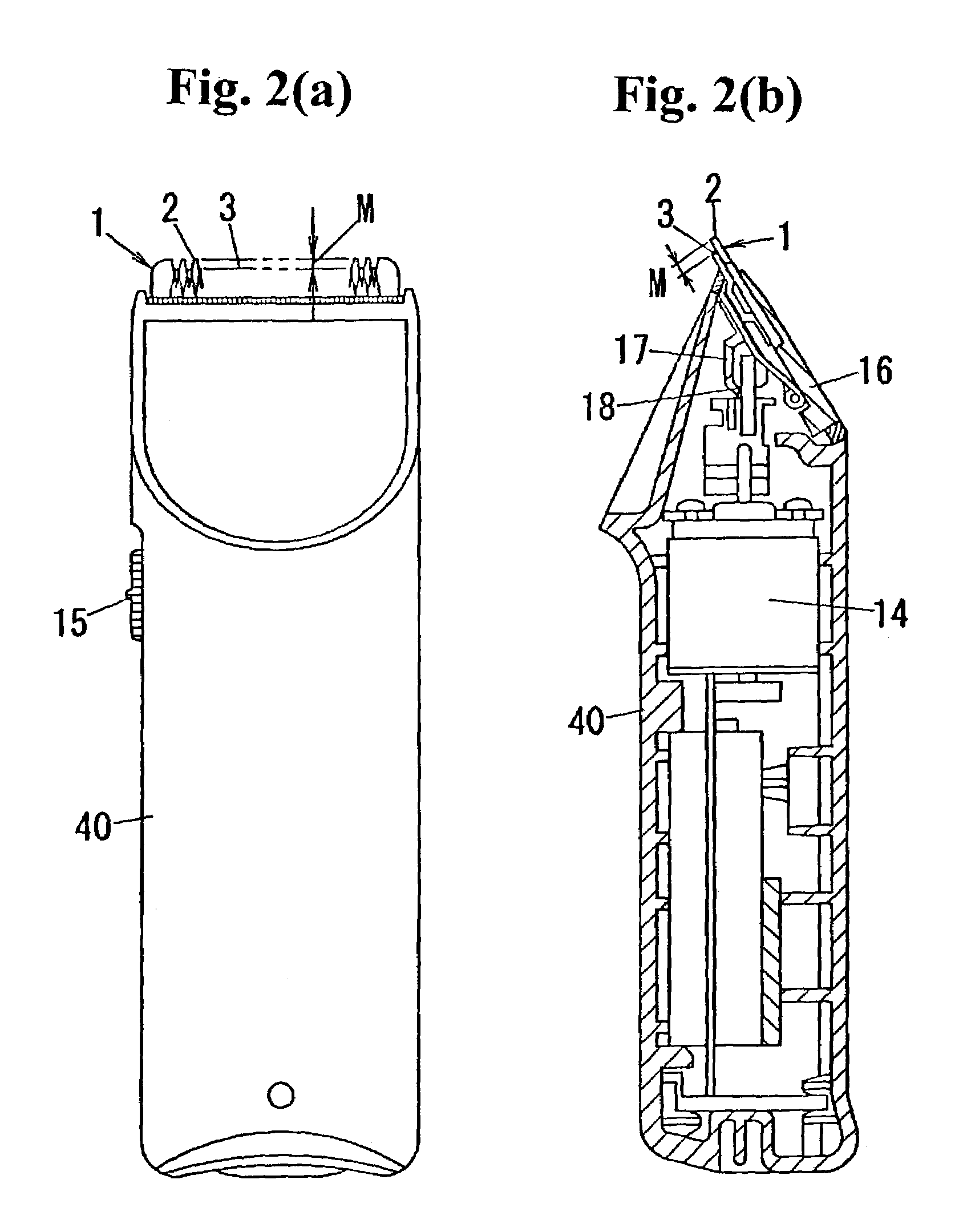

Trimmer mechanism, hair trimmer, hair trimmer attachment, blade arrangement and method therefor

A trimmer mechanism suitable for use in a hair trimmer and hair trimmer attachment is described. The trimmer mechanism allows for a linearly reciprocating motion to be used to obtain a close trim or shave. The trimmer mechanism includes two sets of blades that are moveable relative to each other to define a pair of cutting zones. One set of blades provides a coarse trim, while the following set of blades provides a finer trim. Also provides is a blade arrangement and a method of manufacture of a blade arrangement.

Owner:SPECIALIFE INDS

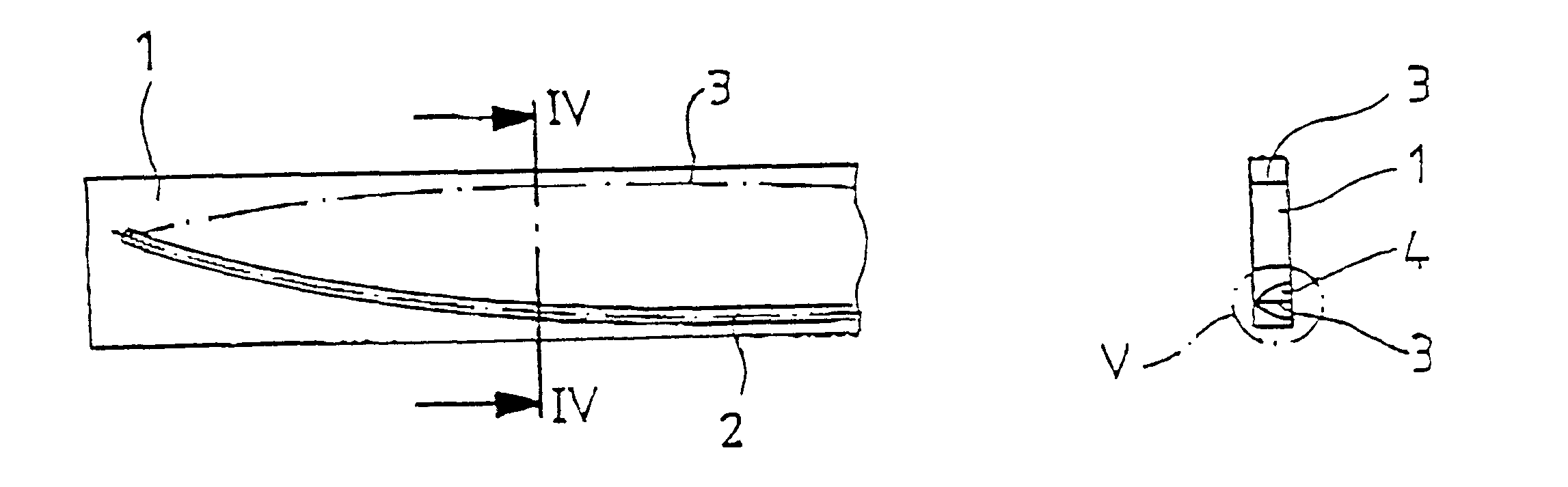

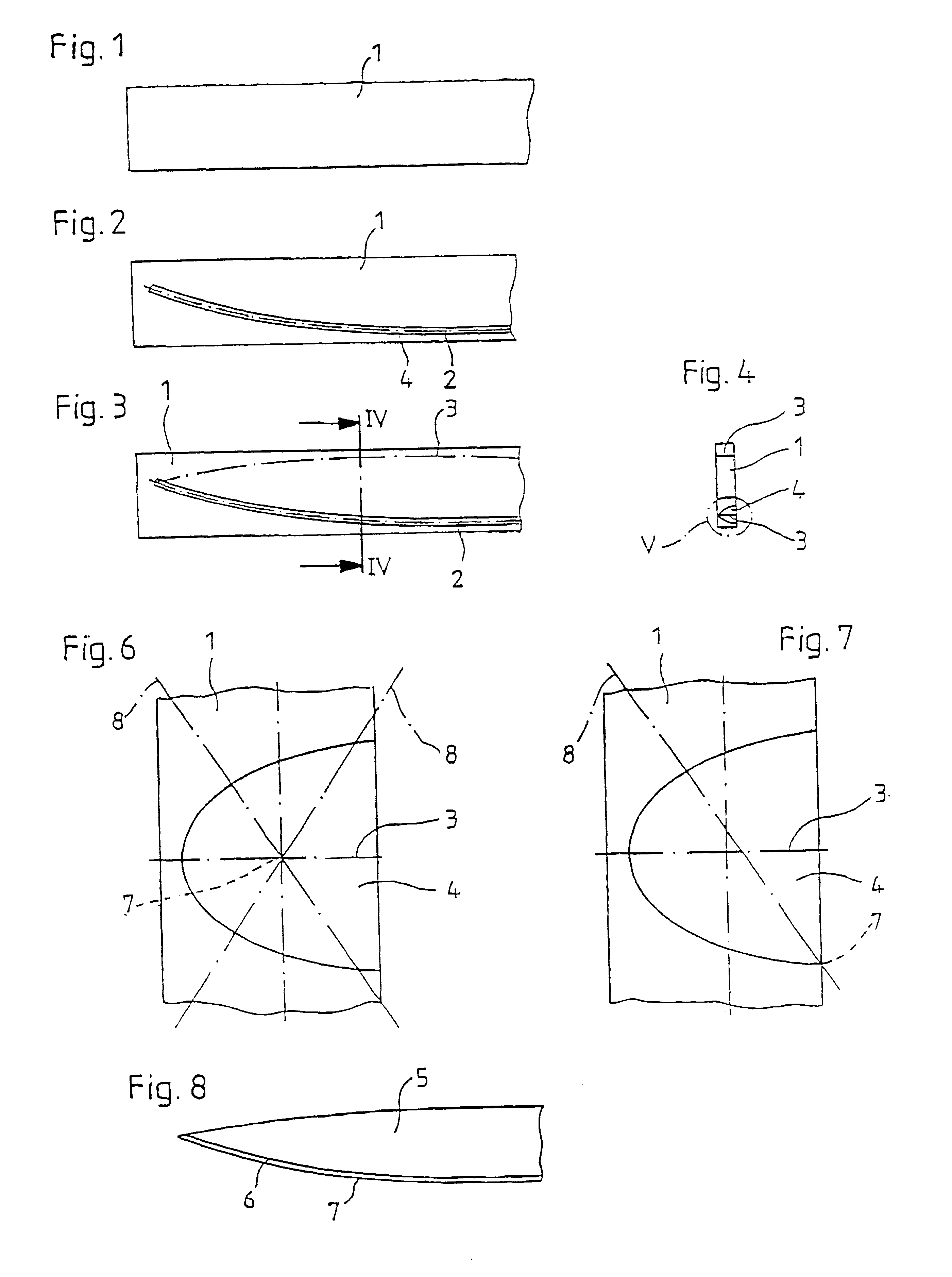

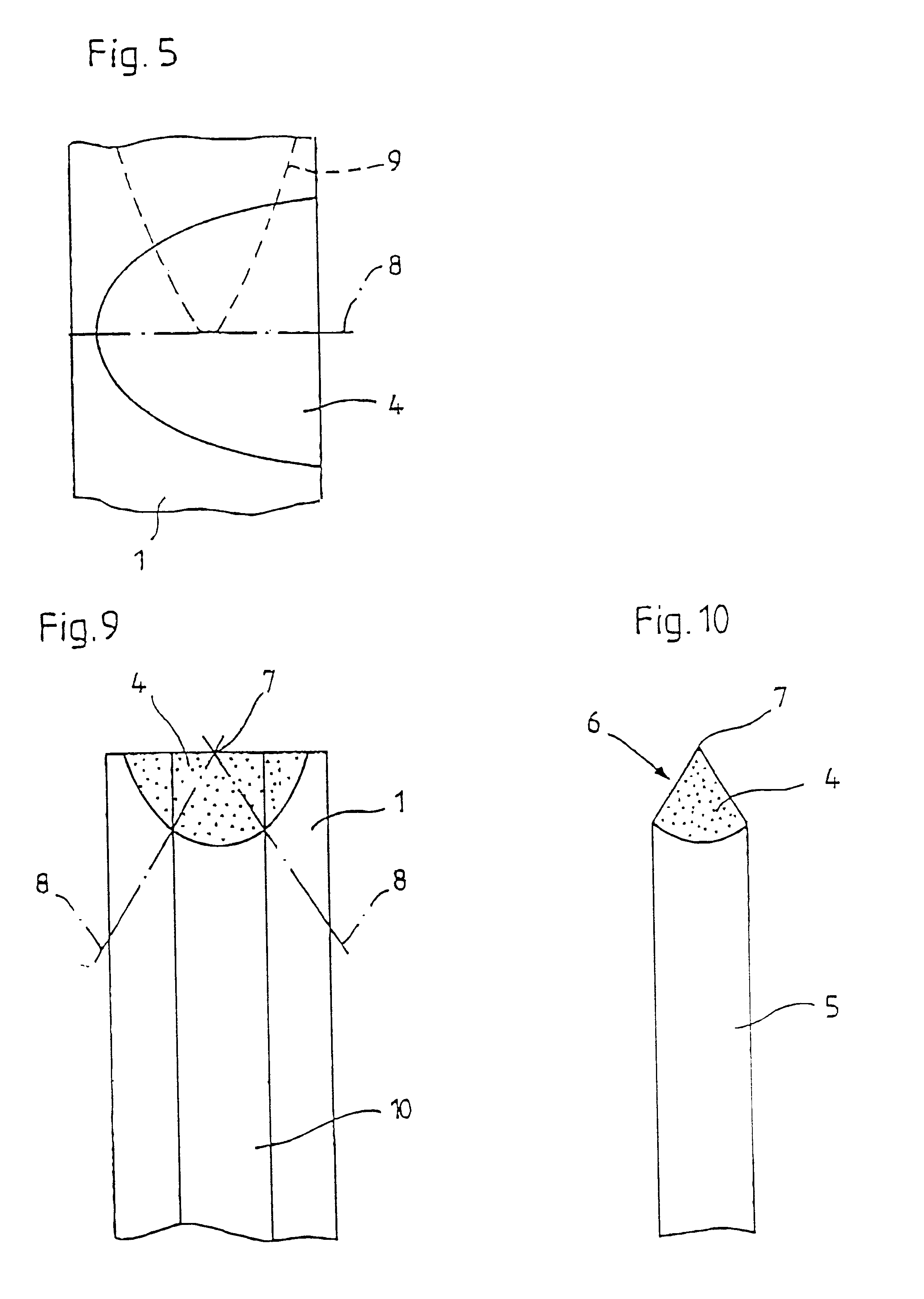

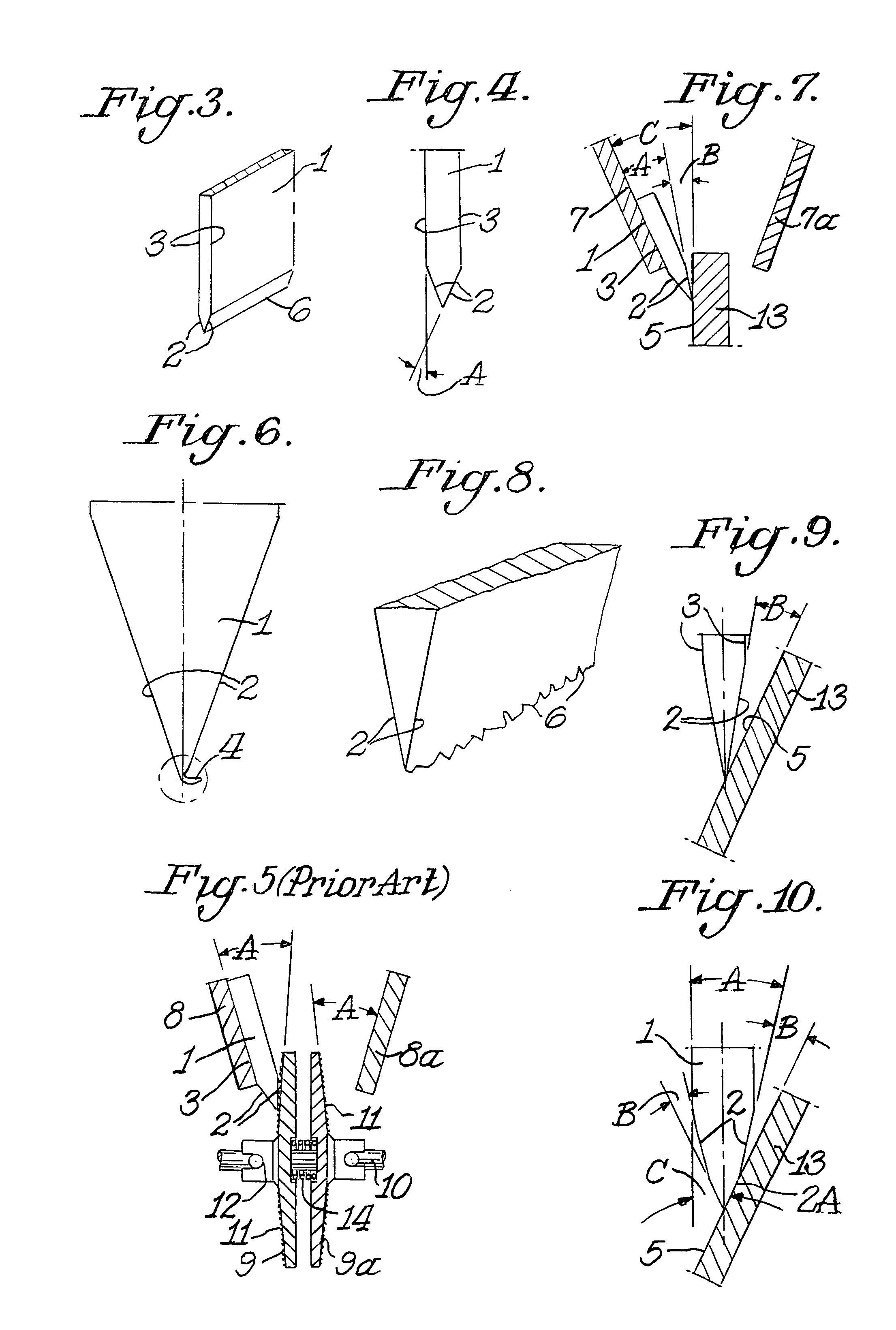

Process for manufacturing a blade of a cutting tool and product manufactured therewith

A method for manufacturing a blade of a cutting tool, in particular, a knife. In order to create a process with which influence is to be exerted in a targeted manner on the technological material properties of the blade and material chipping to be avoided, as well as permitting economical manufacturing, a process is carried out by treating a blade base material with a laser in a first process step along a curve contour determined by the final edge of the blade and, in a second process step, the edge of the blade is formed, in particular, cut to shape, along the curve contour determined by the final blade form inside the laser-treated area, or the blade base material is machined in a first process step by punching or trimming to form the final edge, subsequently the laser treatment is performed in a second process step on the narrow side forming the final edge and finally, in a third process step, the blade is formed, in particular, ground, inside the laser-treated area.

Owner:ZWILLING J A HENCKELS

Ceramic blade and production method therefor

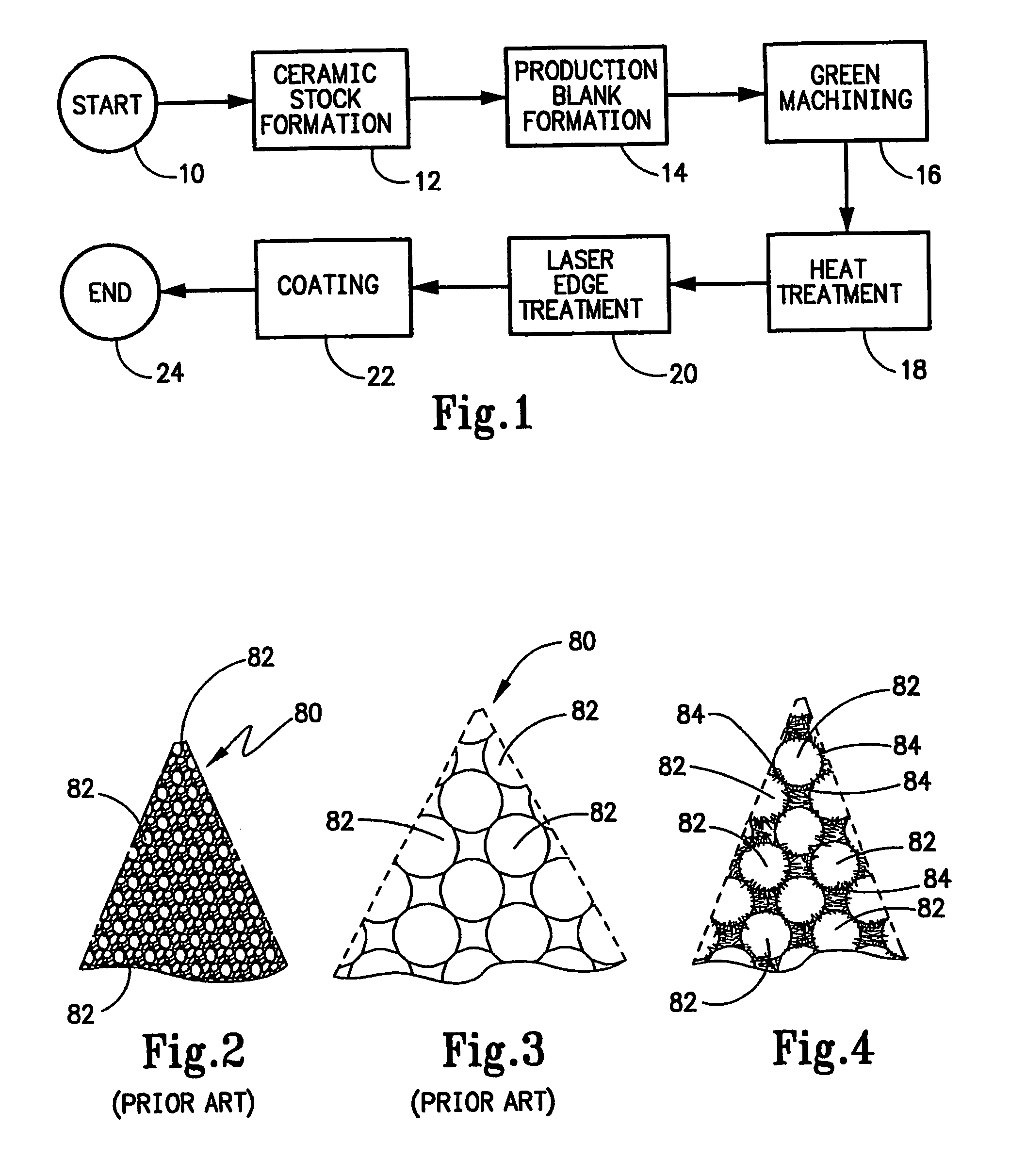

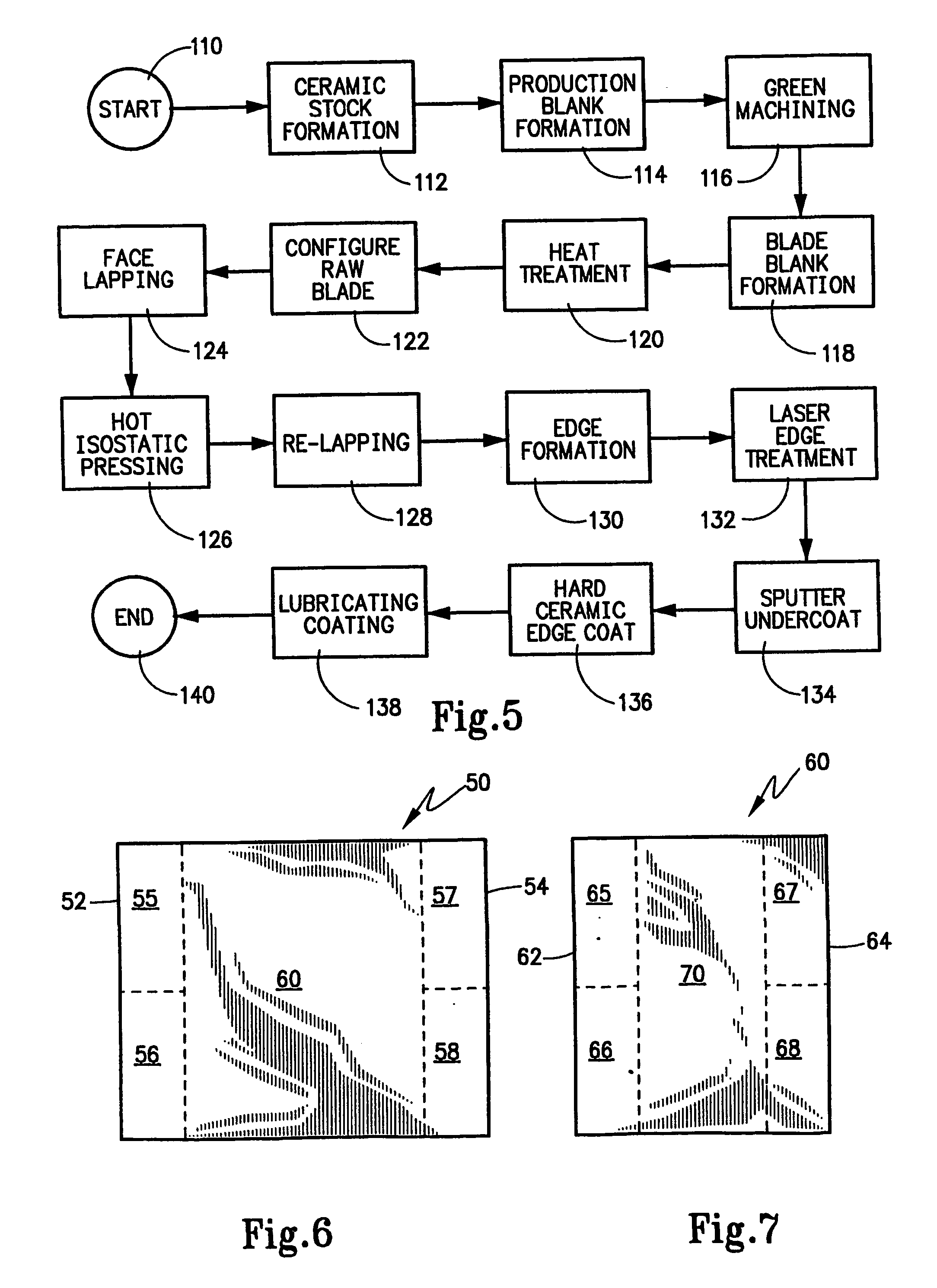

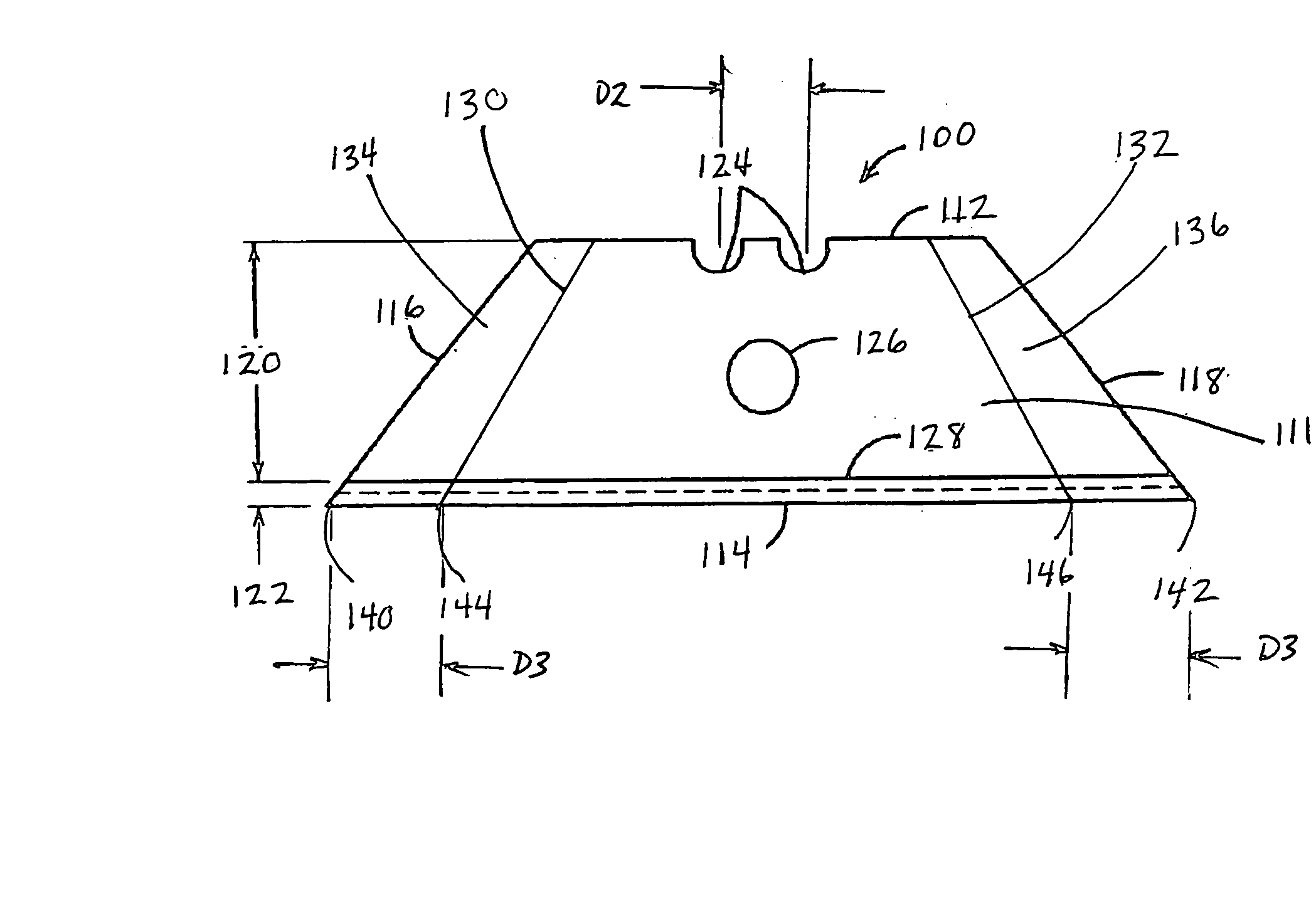

InactiveUS7140113B2Enhanced cutting edgeDurable edgeMetal working apparatusCutleryForming faceCeramic coating

A blade of ceramic material is treated to enhance the strength and sharpness of the cutting edge. In one embodiment, ceramic particles along at least one margin of an edge-forming face are fused, such as by a laser treatment. The edge mardin can have a hard ceramic coating of a different ceramic material such as a nitride of chromium, zirconium, titanium, titanium carbon or boron. The hard ceramic coating can be used alone or in conjunction with the laser treatment. The invention includes the methods of treating the edge, both to form the hard ceramic coating and to fuse the particles by scanning with laser, such as an ultraviolet laser.

Owner:LAZORBLADES

Four point utility blade

ActiveUS20070245574A1Prolong lifeLow costMetal working apparatusCutleryStructural engineeringKnife blades

A utility blade for use with conventional retractable and fixed blade utility knives comprising a blade body having a generally trapezoidal configuration defined by a cutting edge, an opposite back edge, a pair of opposing side edges and a pair of cutting points defined by the points of intersection between the side edges and the cutting edge. The blade further defines a pair of score lines, each proximate to one of the side edges. The score lines enable the user to remove a dulled or damaged cutting point, which in turn provides the user with two additional cutting points defined by the points of intersection between the score lines and the cutting edge. Further, the blade is configured with one or more notches strategically located on the back edge of the blade, such that each cutting point can extend from the utility knife at approximately the same distance.

Owner:BLACK & DECKER INC

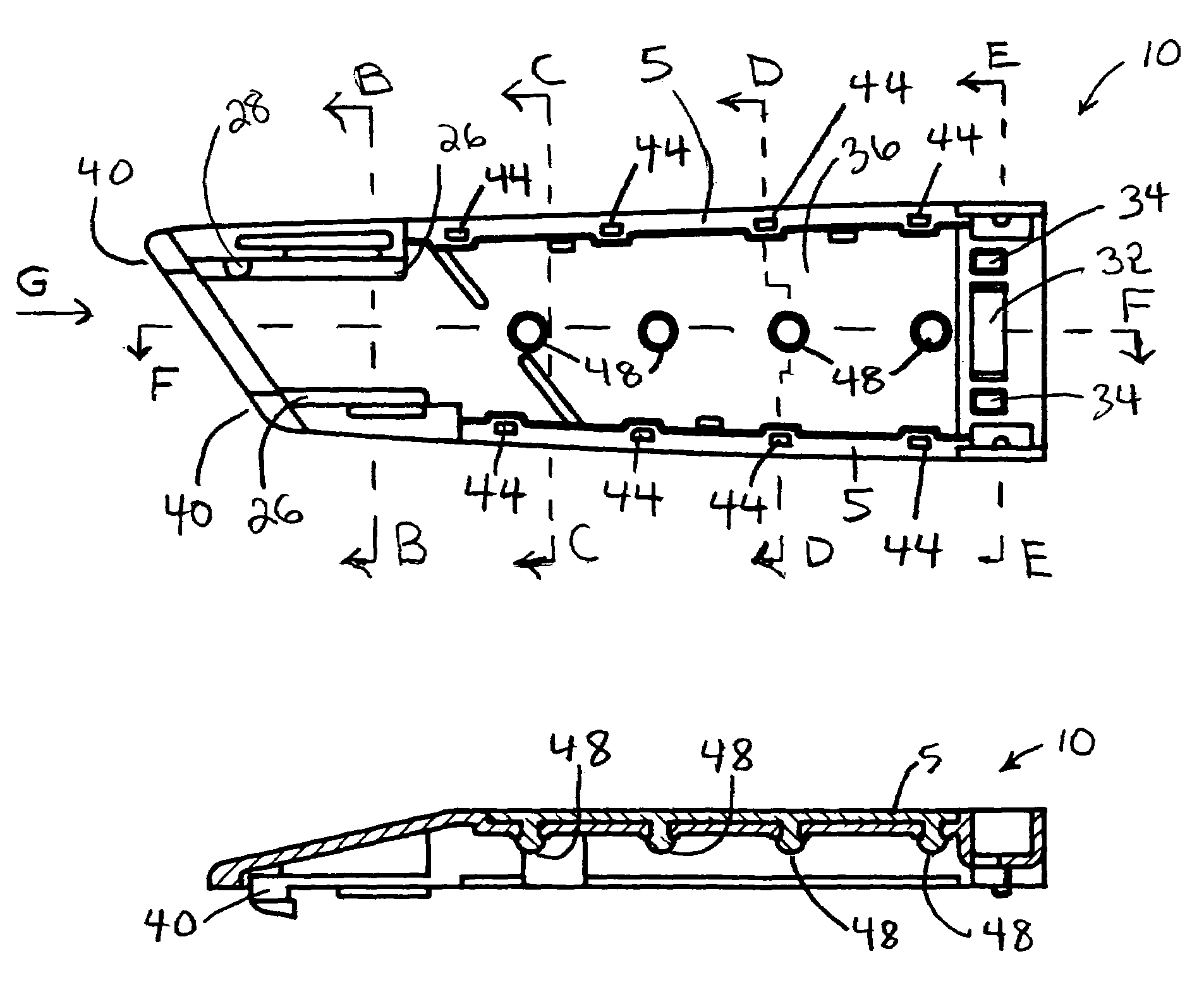

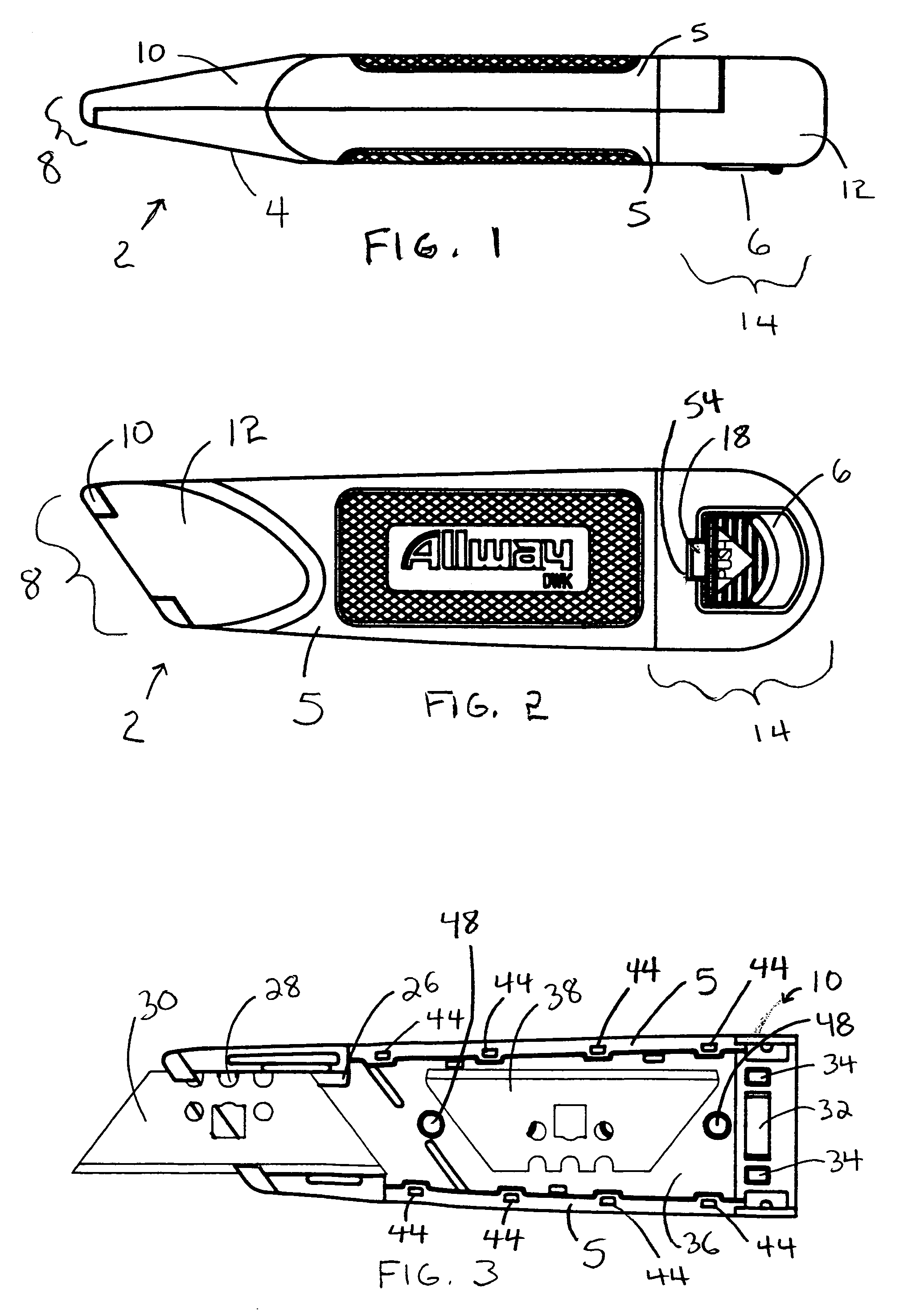

Soft handle non-retractable utility knife with quick release latch and method for making same

A metallic housing utility knife and method for making the device with a soft over molded elastomeric cover to provide blister free comfort and slip proof safety. The cover or skin is molded into the unique structure of the housing in a fashion that results in mechanical bonds that embrace the cover on the housing. The knife includes flexible posts from the cover that project into the blade storage compartment of the housing to prevent internally stored spare blades from moving within the storage compartment. An elastomeric blade clamp integrally formed with the cover serves to restrict lateral movement of blades of varying sizes when installed in a cutting position within the knife assembly. A rear quick release latch and interlocking housing sections provide a convenient way to open and close the knife and assure that it is also secure and firmly held when locked in a safe cutting position.

Owner:ALLWAY TOOLS

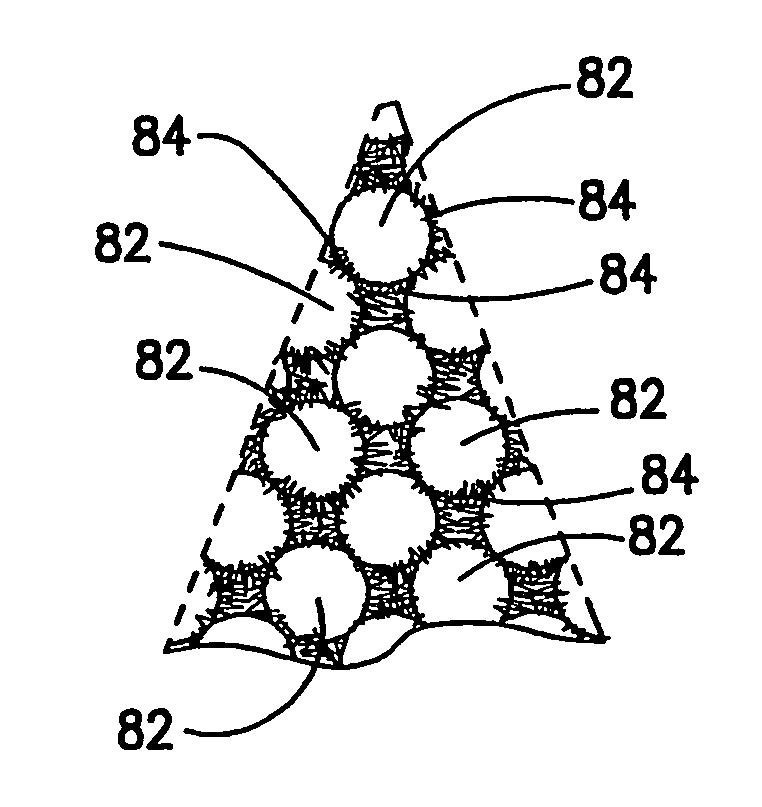

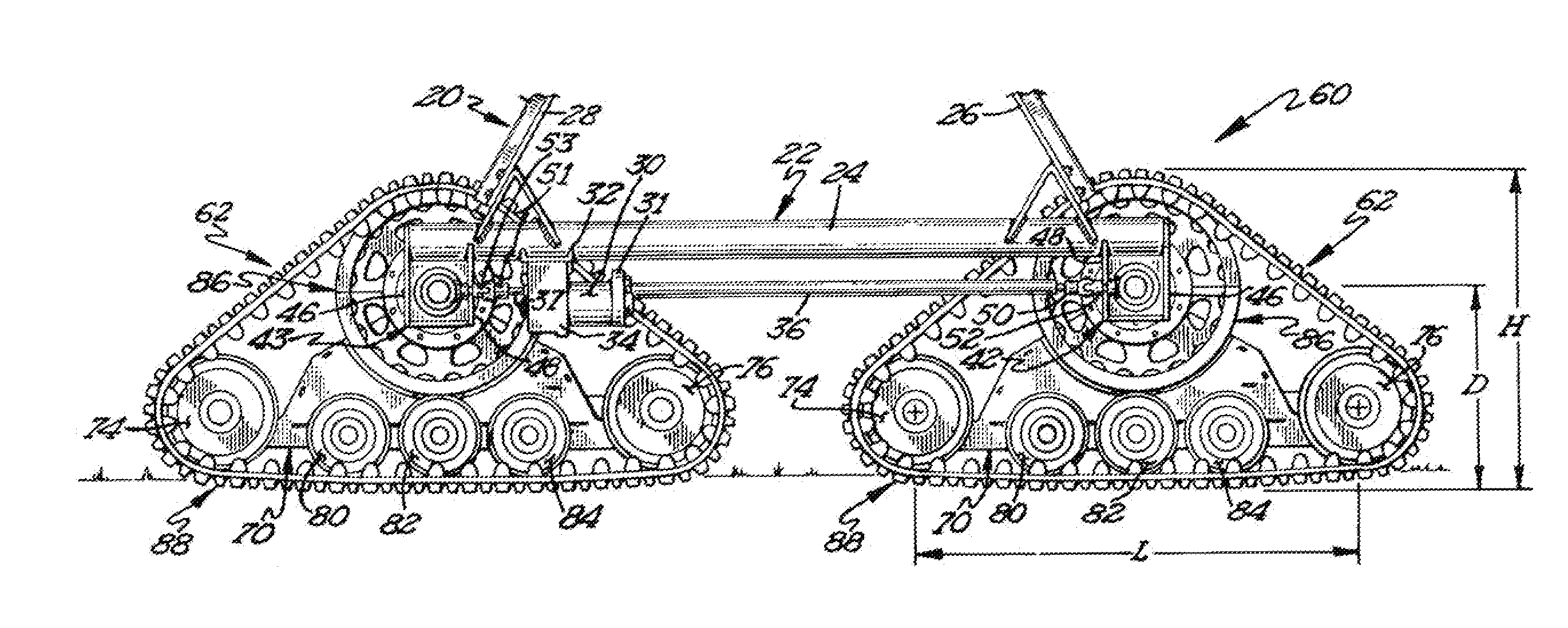

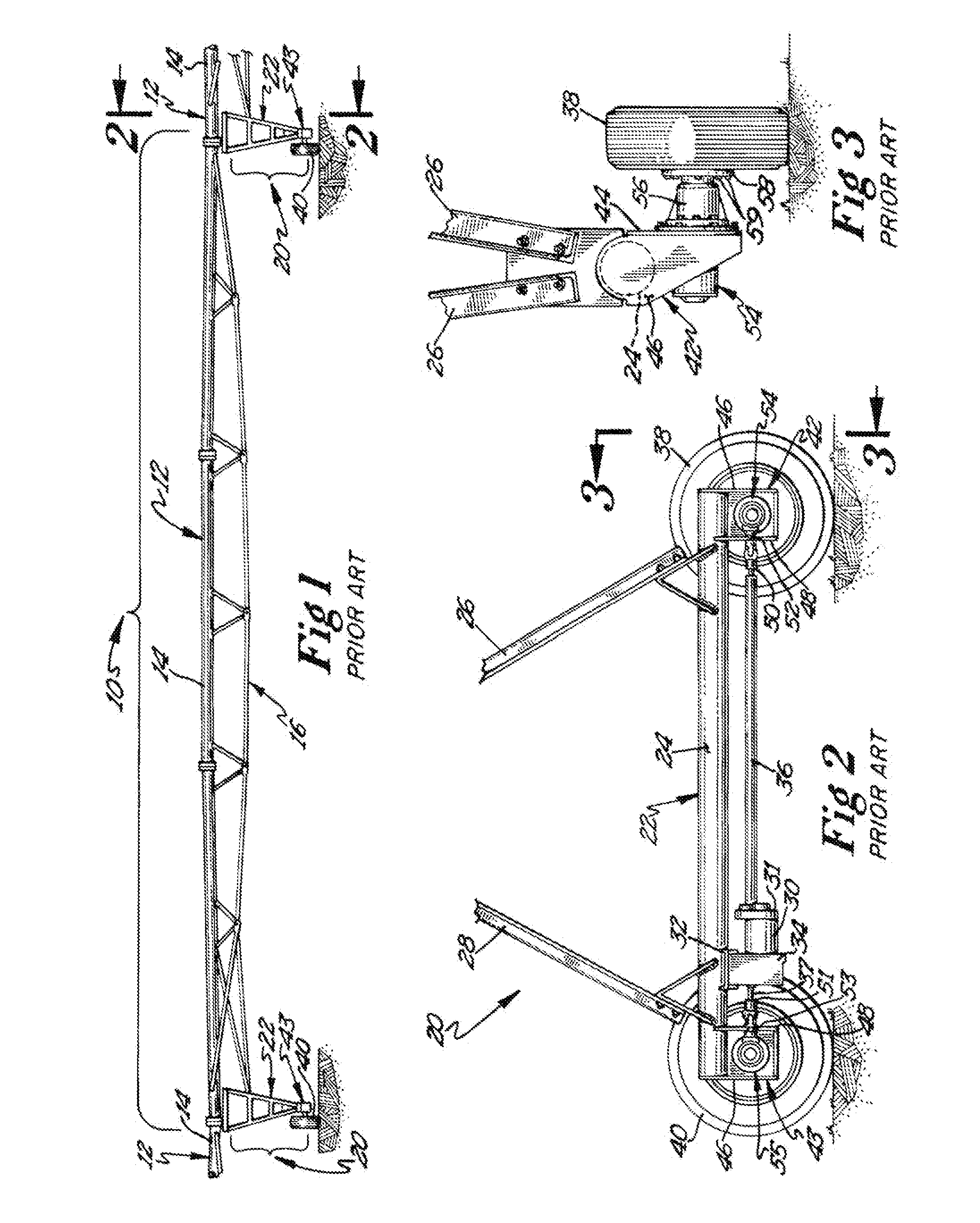

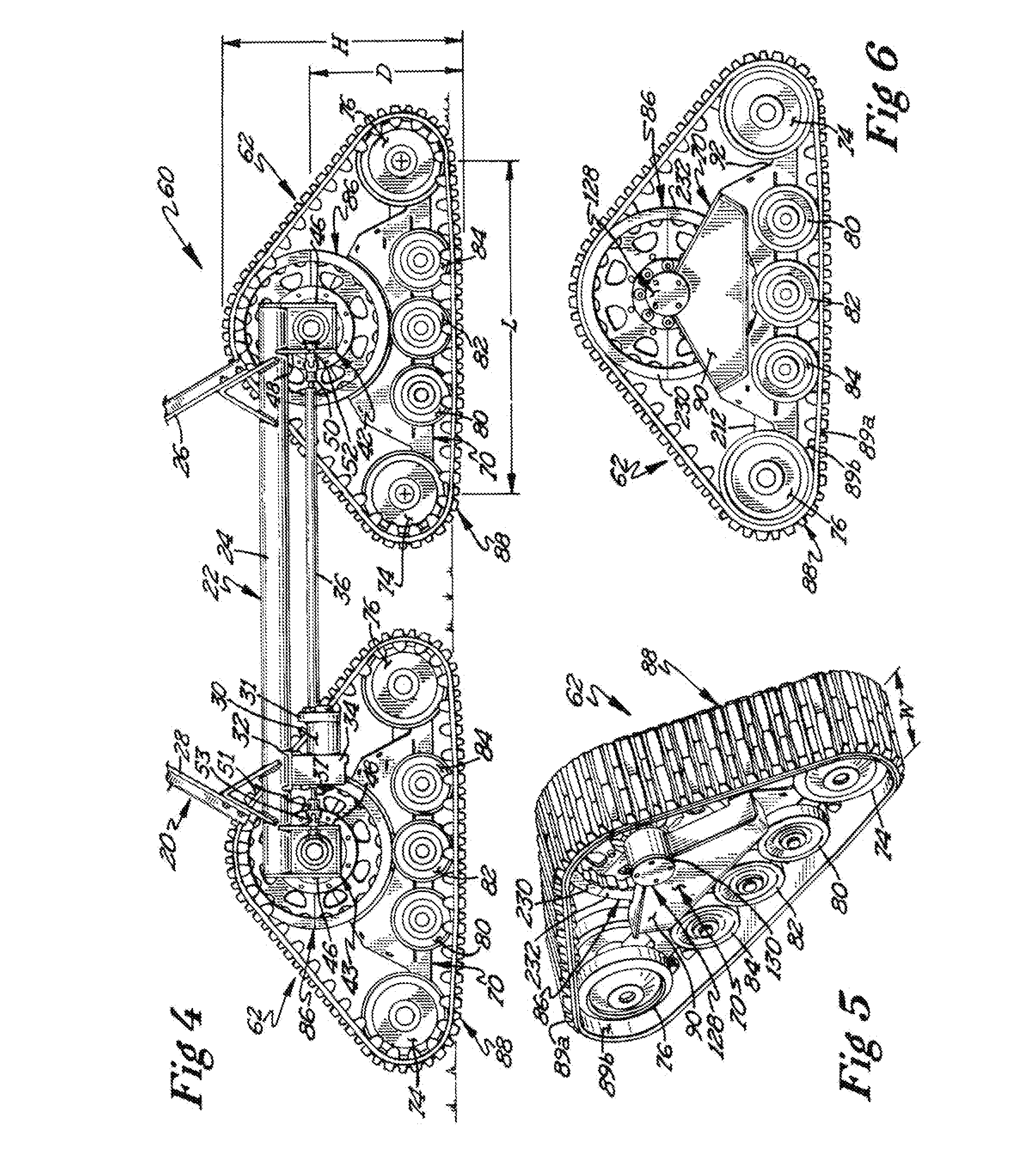

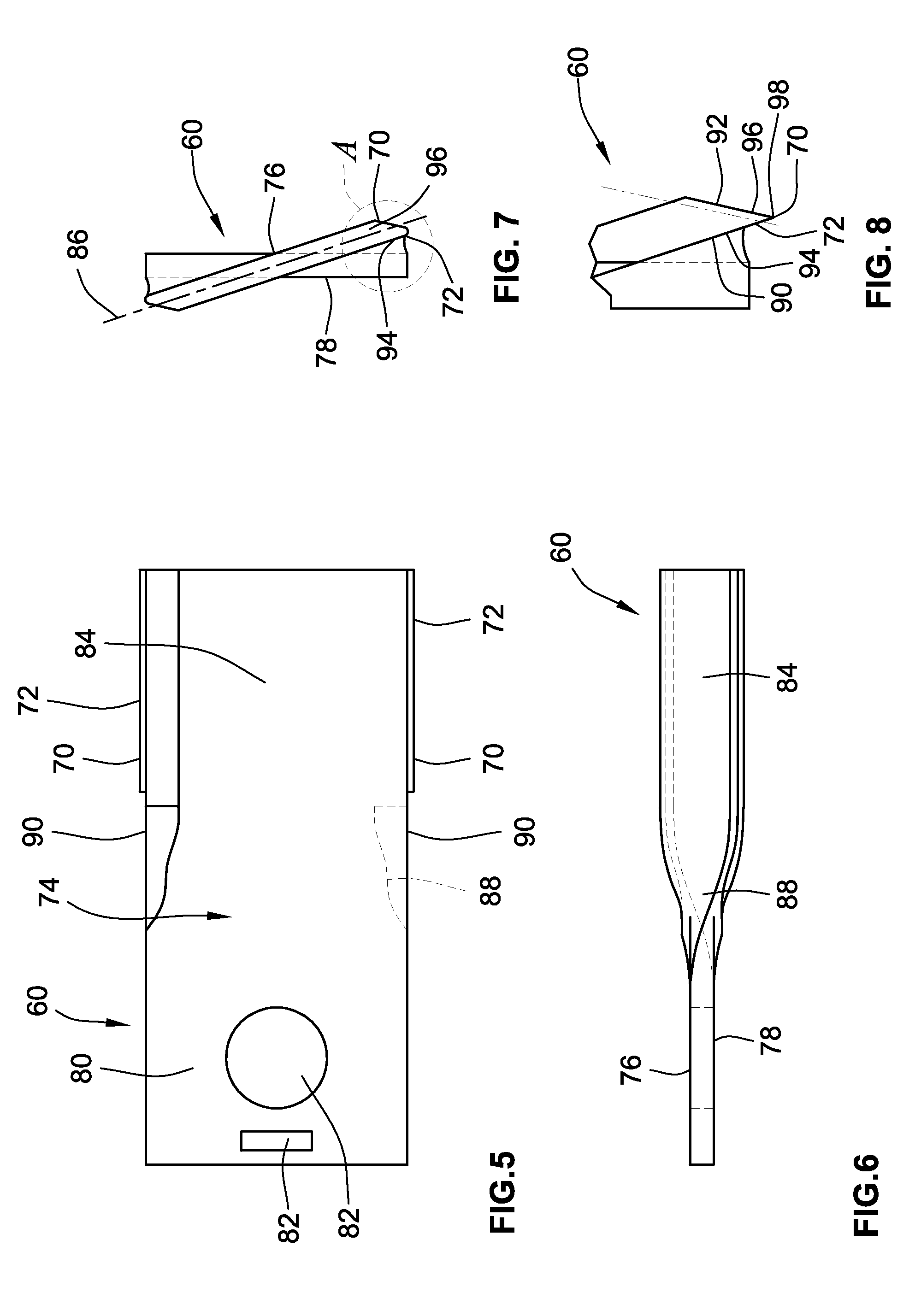

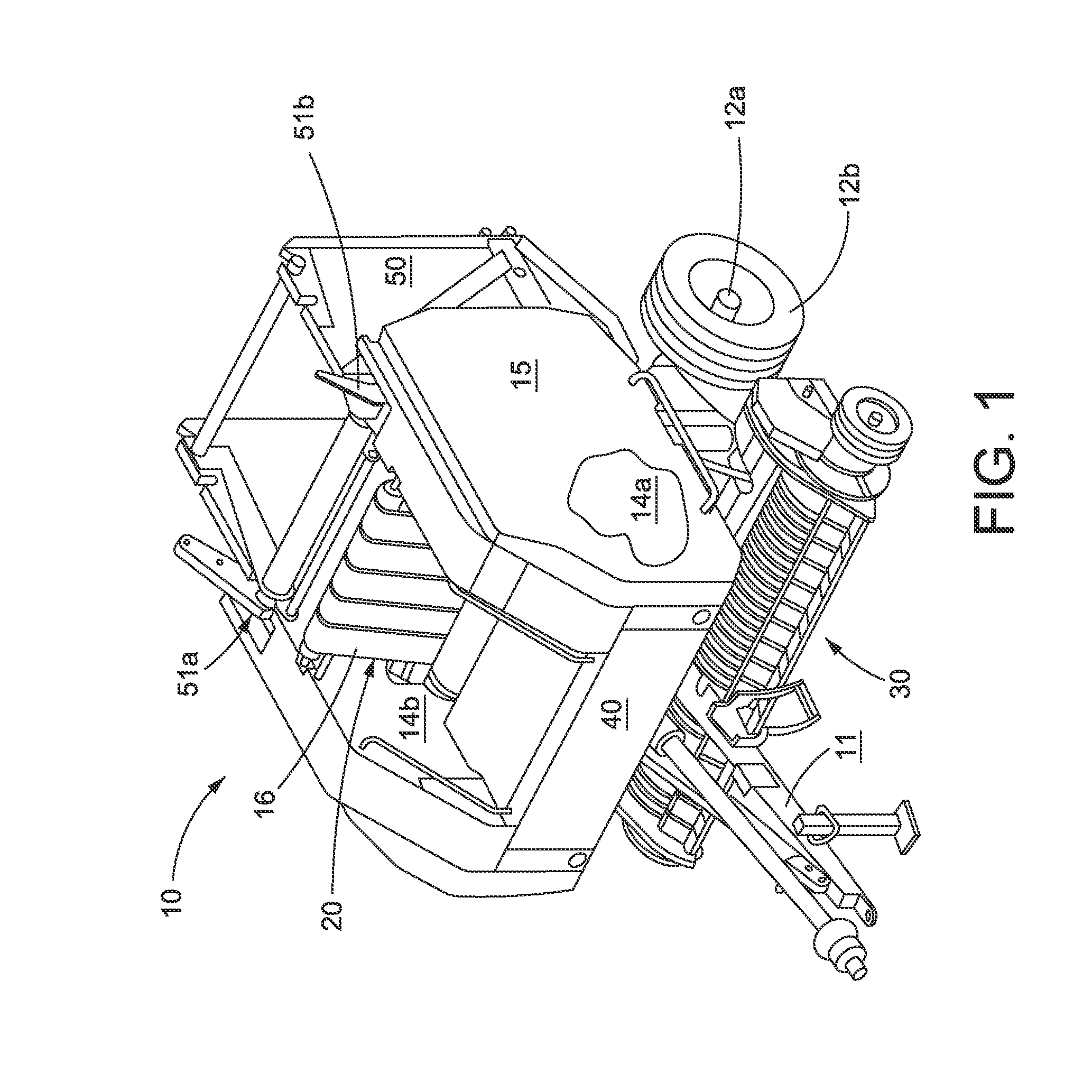

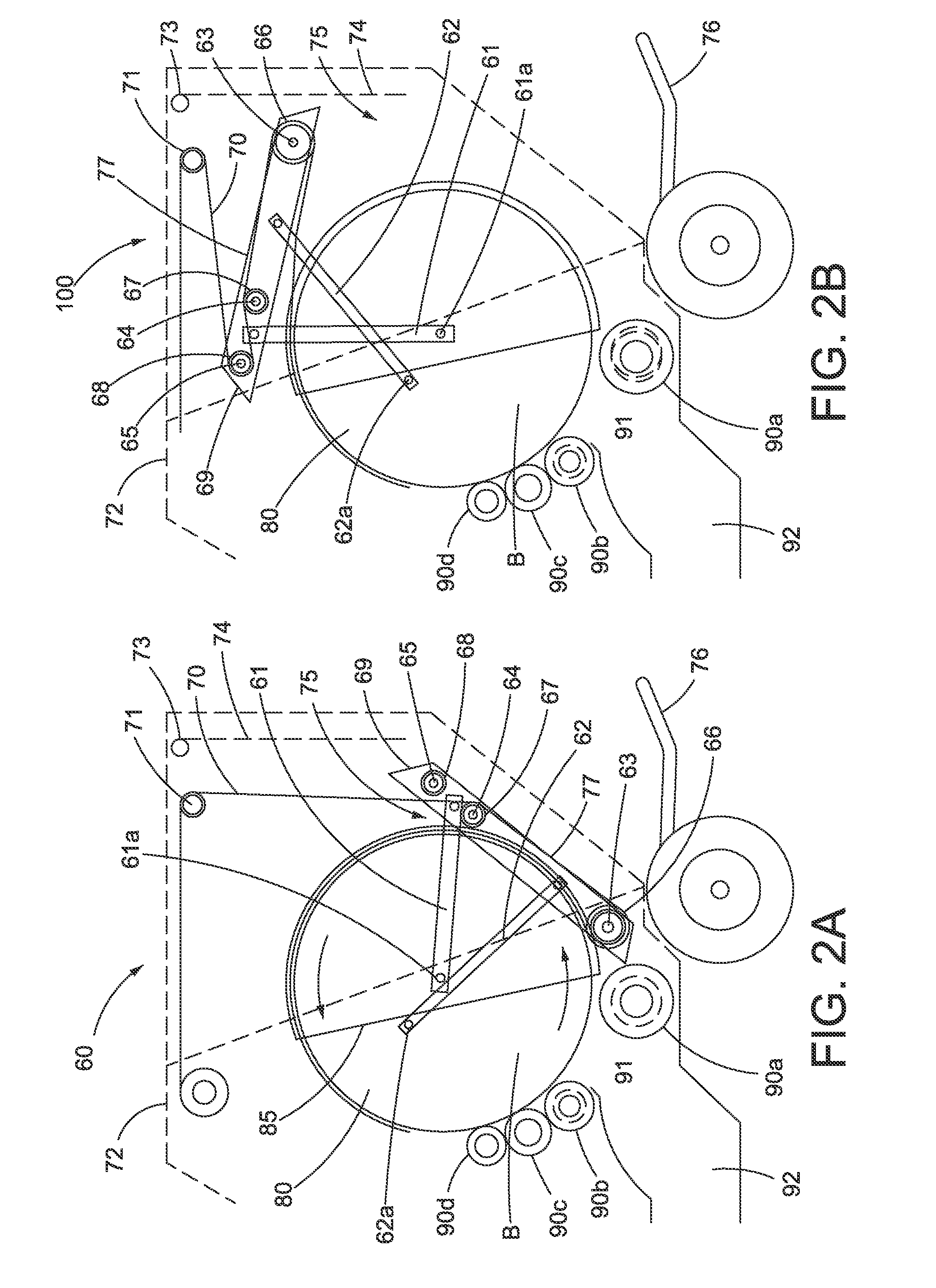

Apparatus for Converting a Wheeled Vehicle to a Tracked Vehicle

The invention relates to a self-propelled, wheeled irrigation vehicles (10) that may be converted into a multi-track self-propelled irrigation vehicle (60) using one or more track assemblies (62). Each track assembly (62) includes a carriage (70) with frames (92, 94) that support a plurality of pairs of idler wheels (74, 76), and pairs of bogey wheels (80, 82, 84). A portion of one of the frames (94) is telescopically received within a portion of the other frame (92), so that the frames (92, 94) may move relative to each other in a linear fashion. A tensioning apparatus (212) is connected to the frames (92, 94) so that the frames are adjustable relative to each other. Each carriage (70) also includes a hub support frame (90) that is connected to one of the frames (92) in an offset manner. The hub support frame (90) includes an aperture (132) that rotatably receives a spindle (262) of an adaptor (258). The adaptor (258) includes a peripheral flange (264) to which a segmented sprocket (86) may be connected, and a ring extension (268) that is able to be connected to an existing wheel hub of an irrigation vehicle whose drive wheel has been removed. A flexible endless track (88) is entrained about the wheels (74, 76, 80, 82, 84) and the sprocket (86). The track assembly (62) may be provided with one or more cleats (278) that are removably connected to the flexible, endless track (88), and which include a ground engaging member (281) that serves to increase the traction of the endless track (88).

Owner:ASV HLDG INC

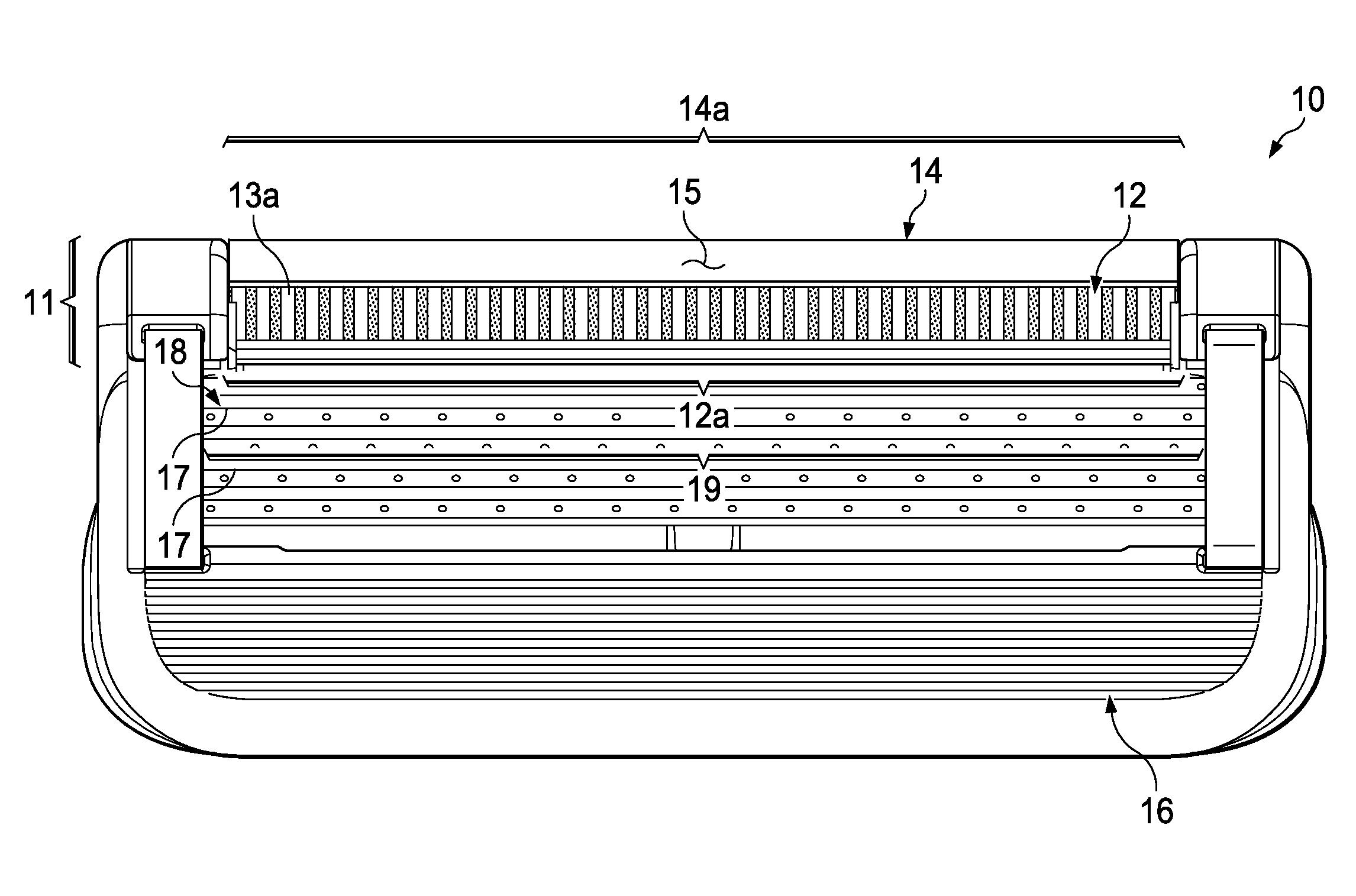

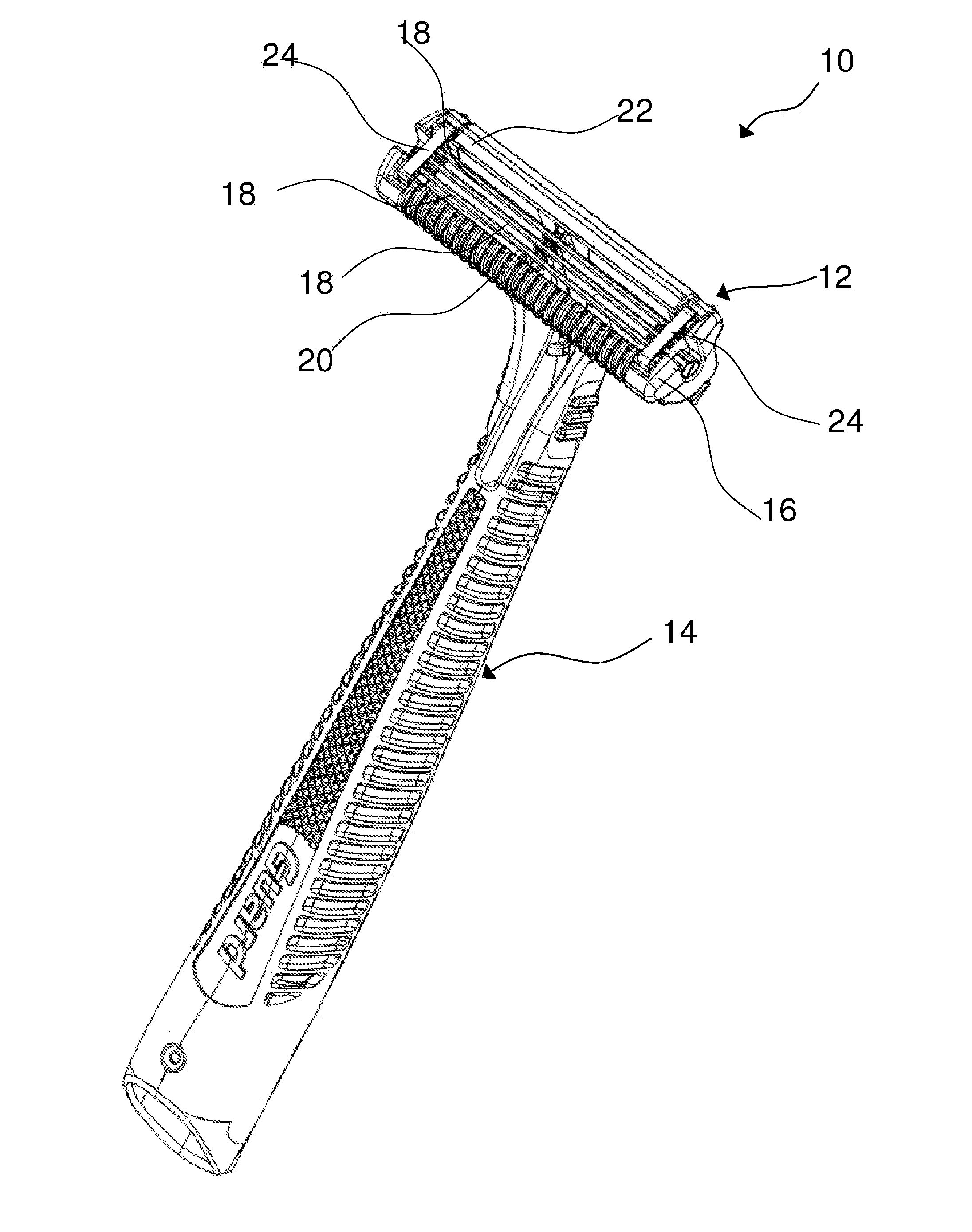

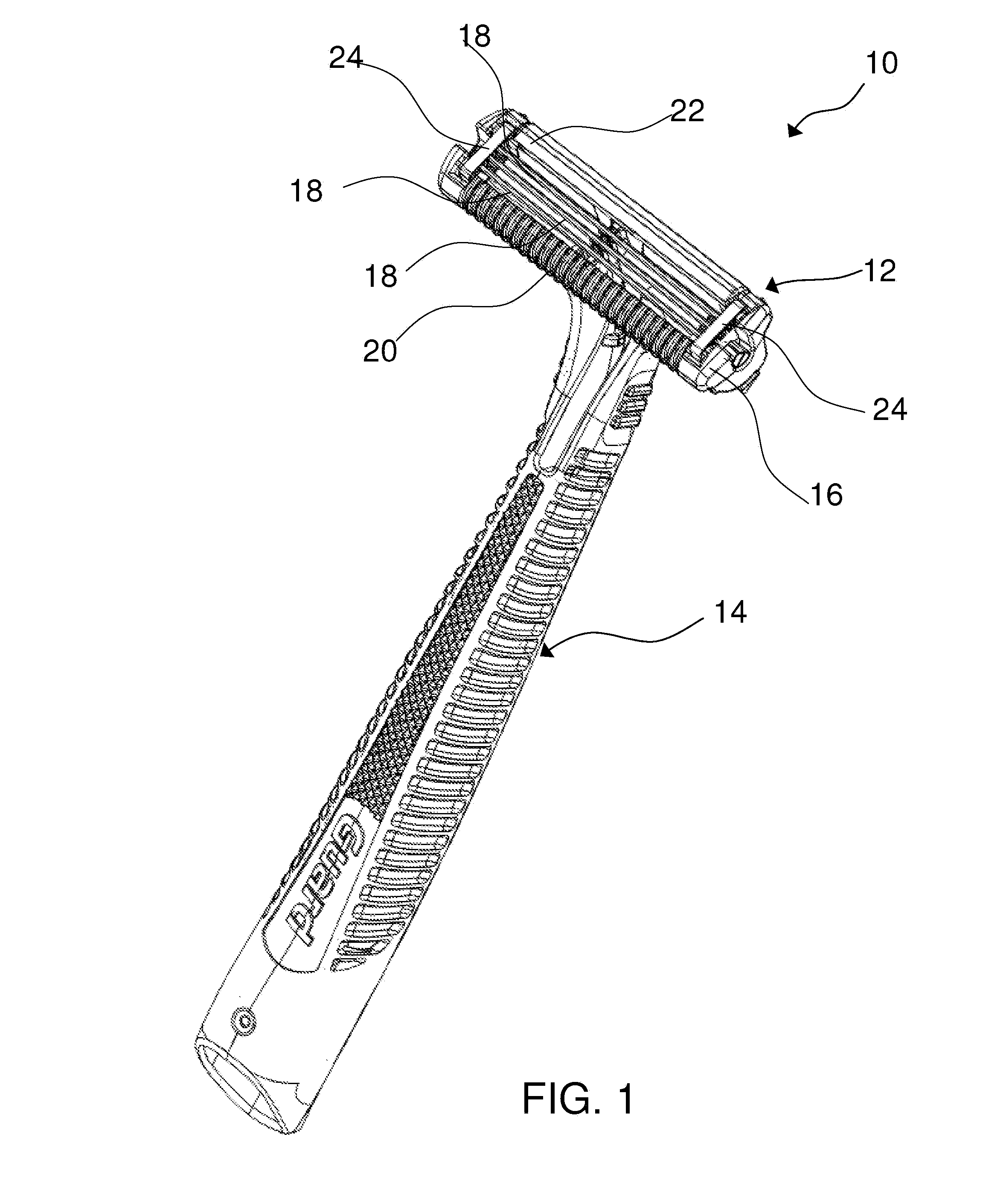

Razor Cartridge With Improved Cap Structure

A razor cartridge having blades and a cap structure in back of the blades where the cap structure extending across the length of the blades includes at least one skin engaging element and at least one shaving aid portion. The skin engaging element may comprise fin elements, elongated protrusions, bumps, nubs, or any combination thereof, and may be flexible to engage the user's skin in back of the blades for a comfortable shave. The shaving aid portion serves to deliver at least one shaving aid material (e.g., lubricant) to the skin. The shaving aid portion may be a lubricating strip, a soap / solid, a foam or sponge filled with shaving aid material or any combination thereof. The cap structure provides a synergy between the skin engaging element and the shaving aid portion. A percentage contact to a user's skin of the skin engaging element is from about 20% to about 90%.

Owner:THE GILLETTE CO

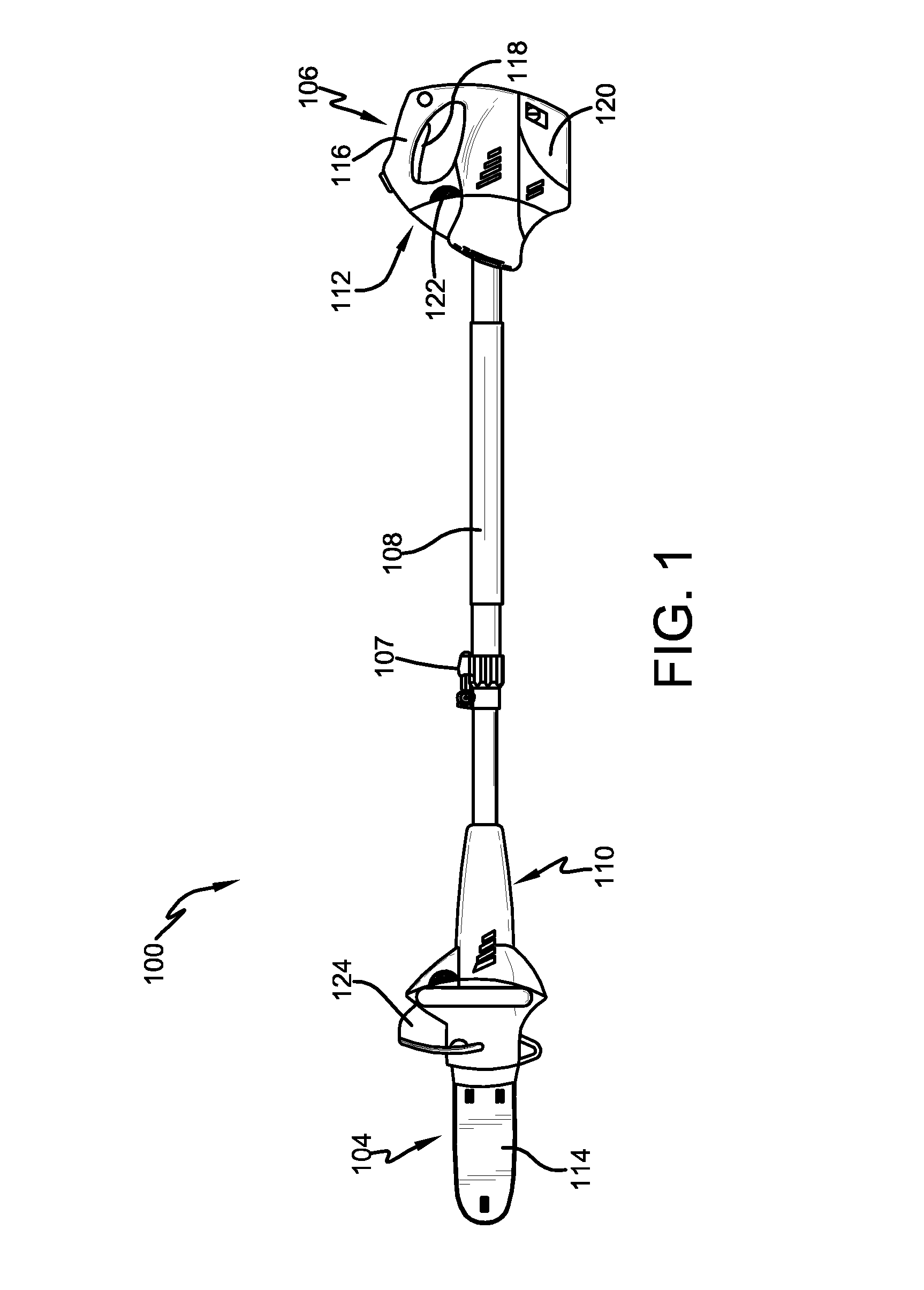

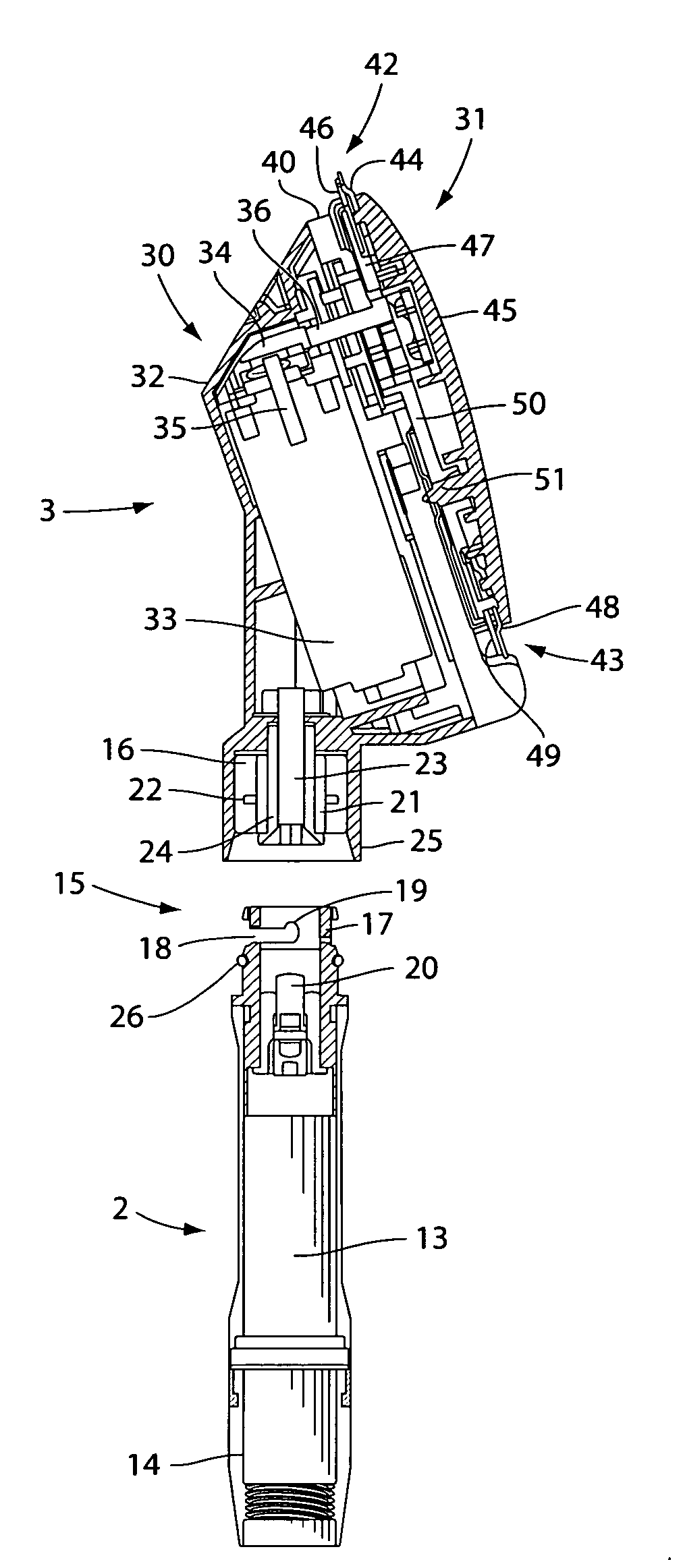

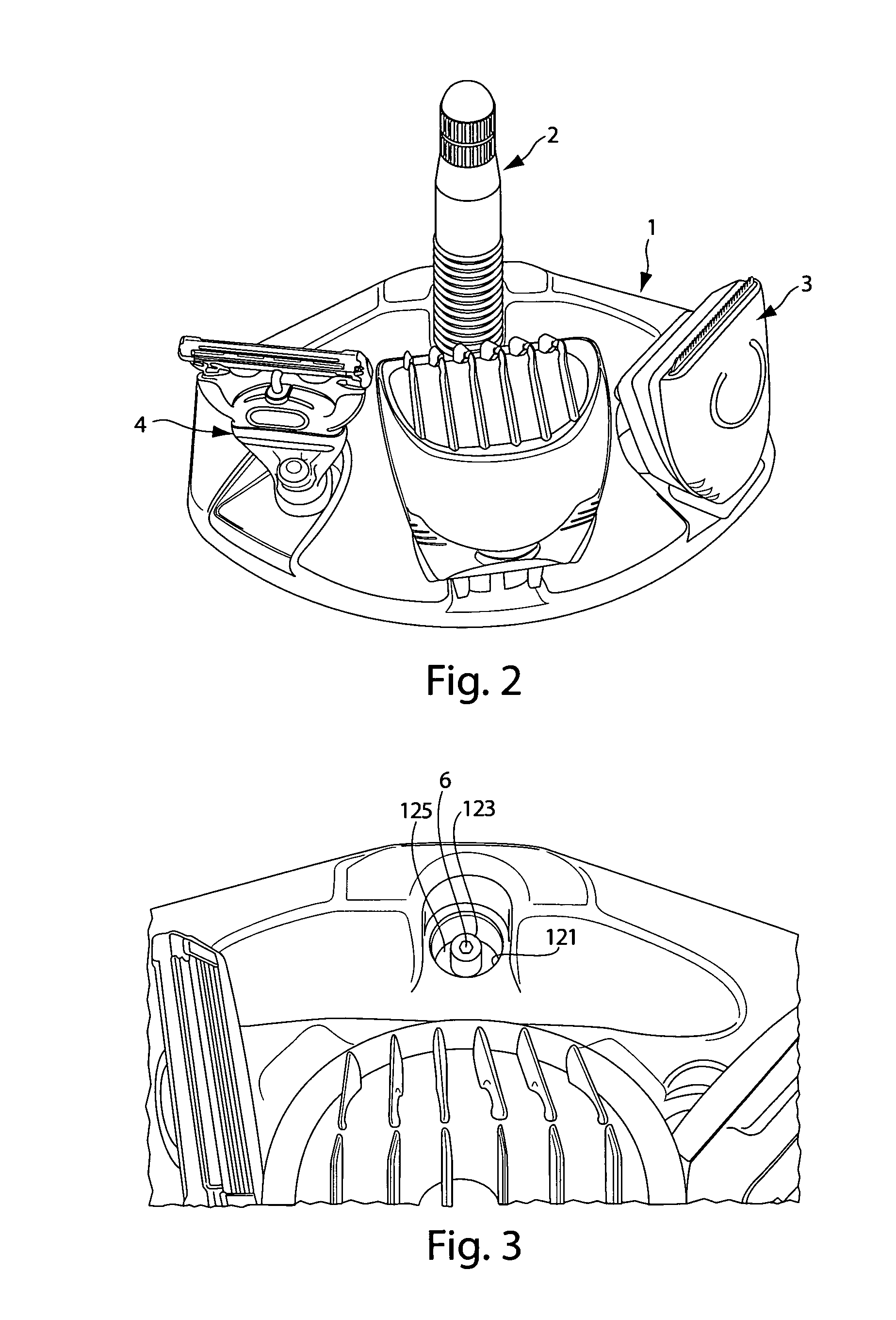

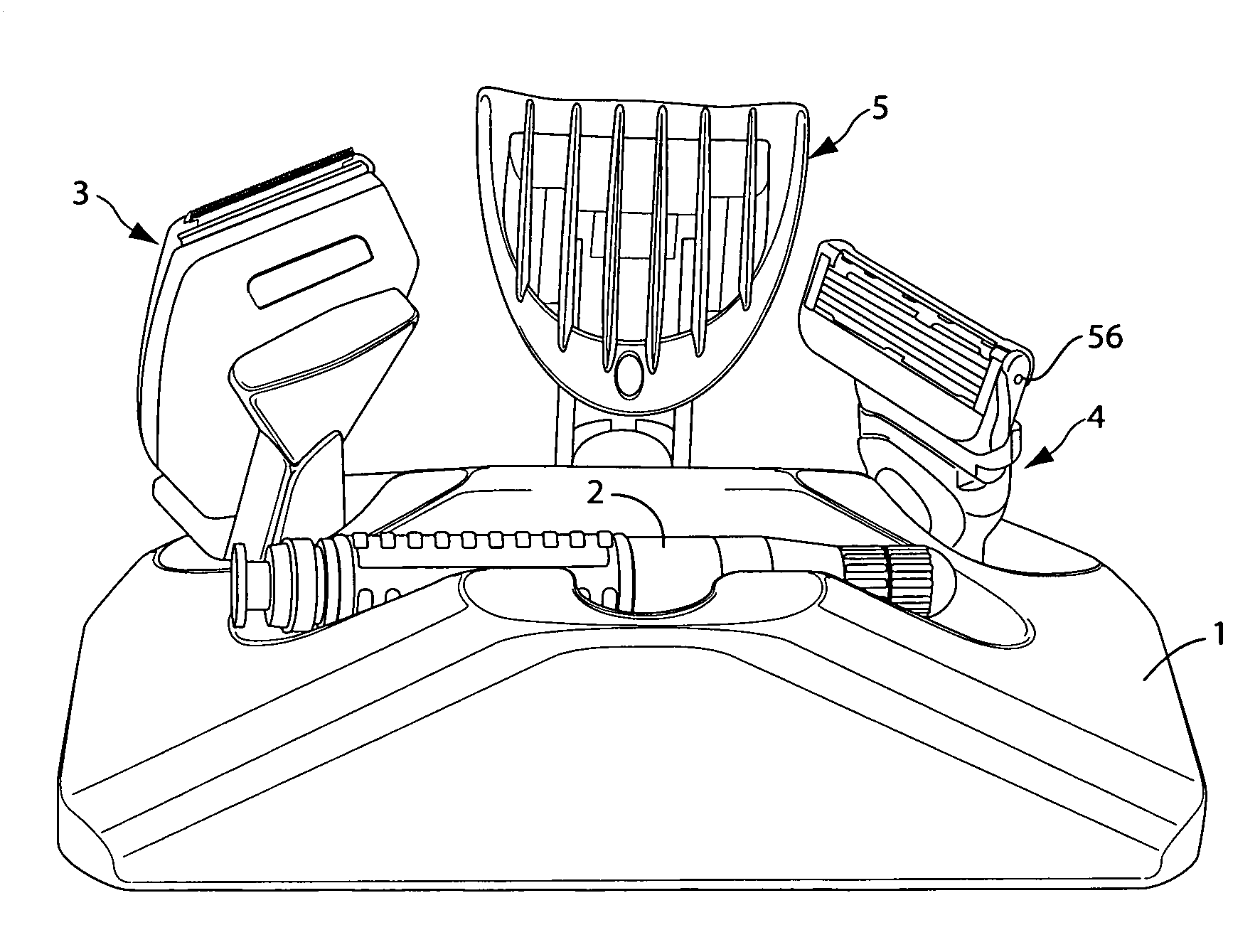

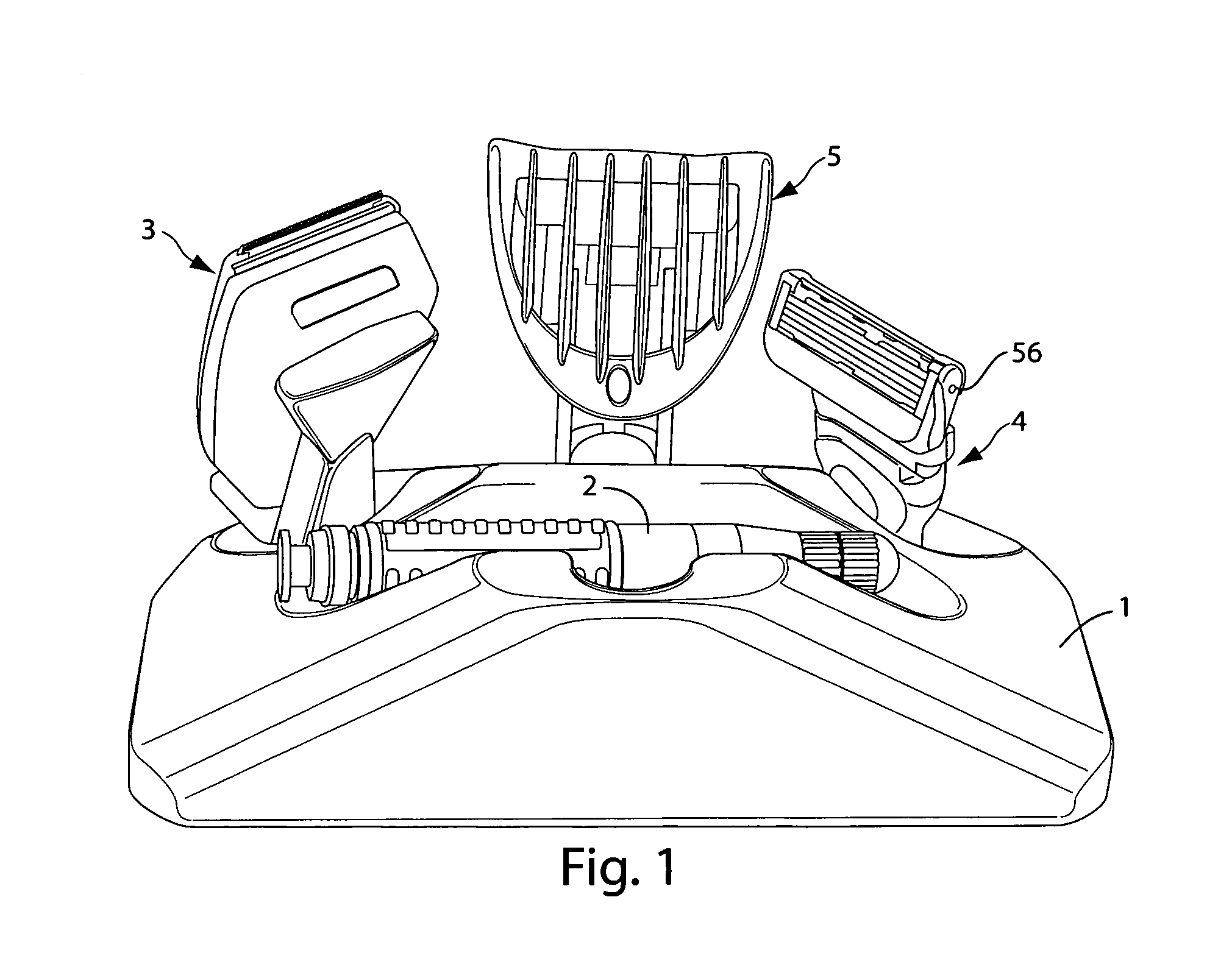

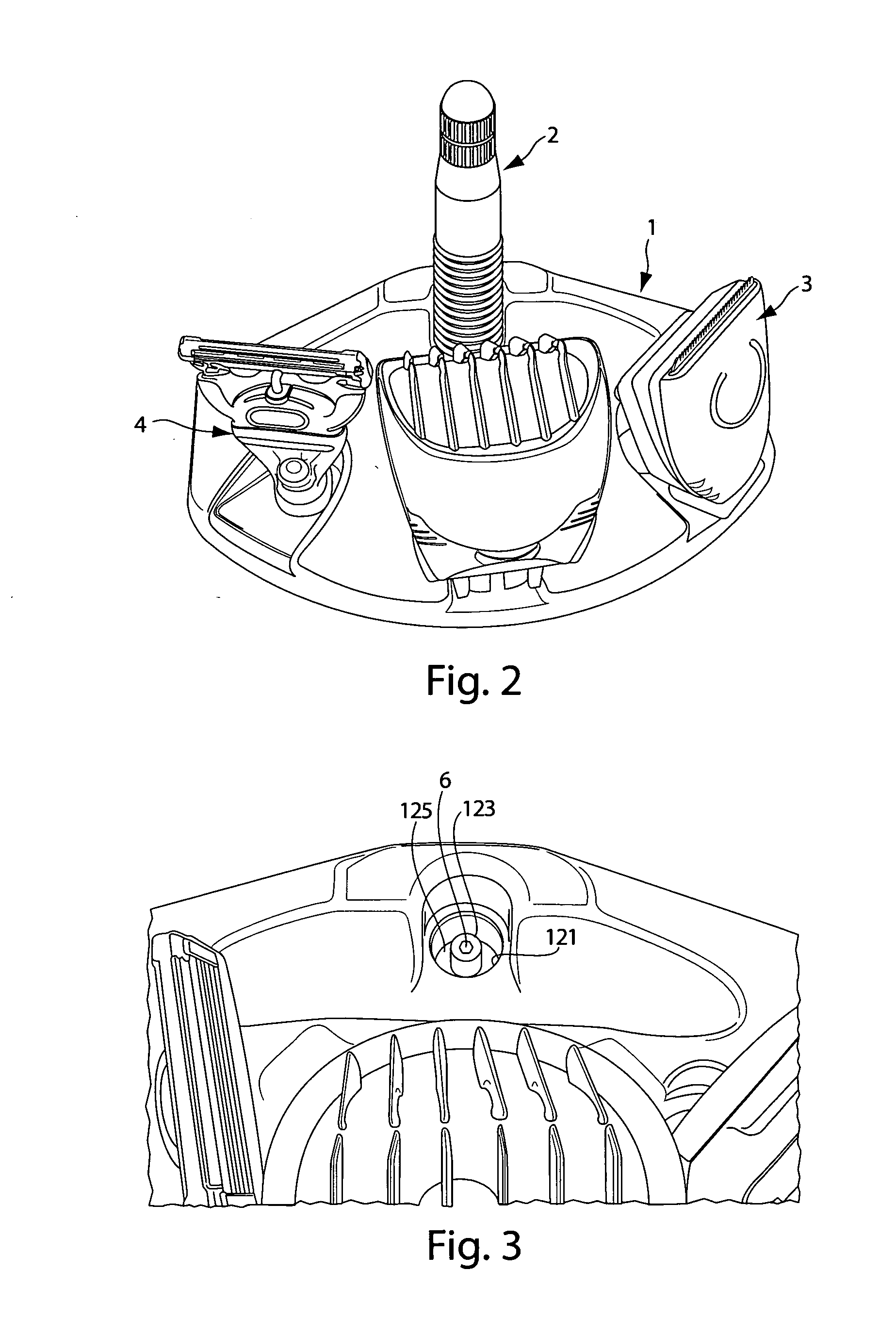

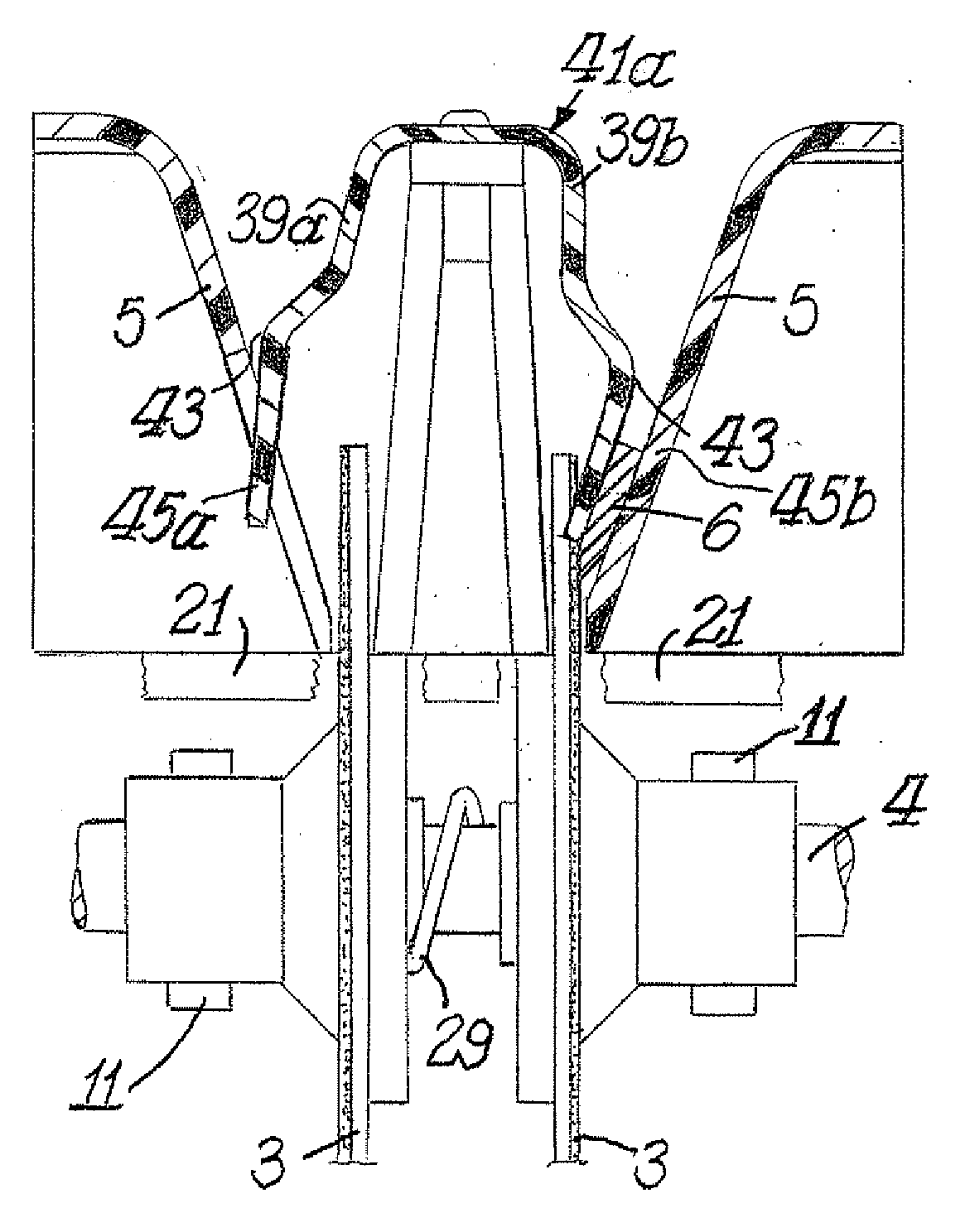

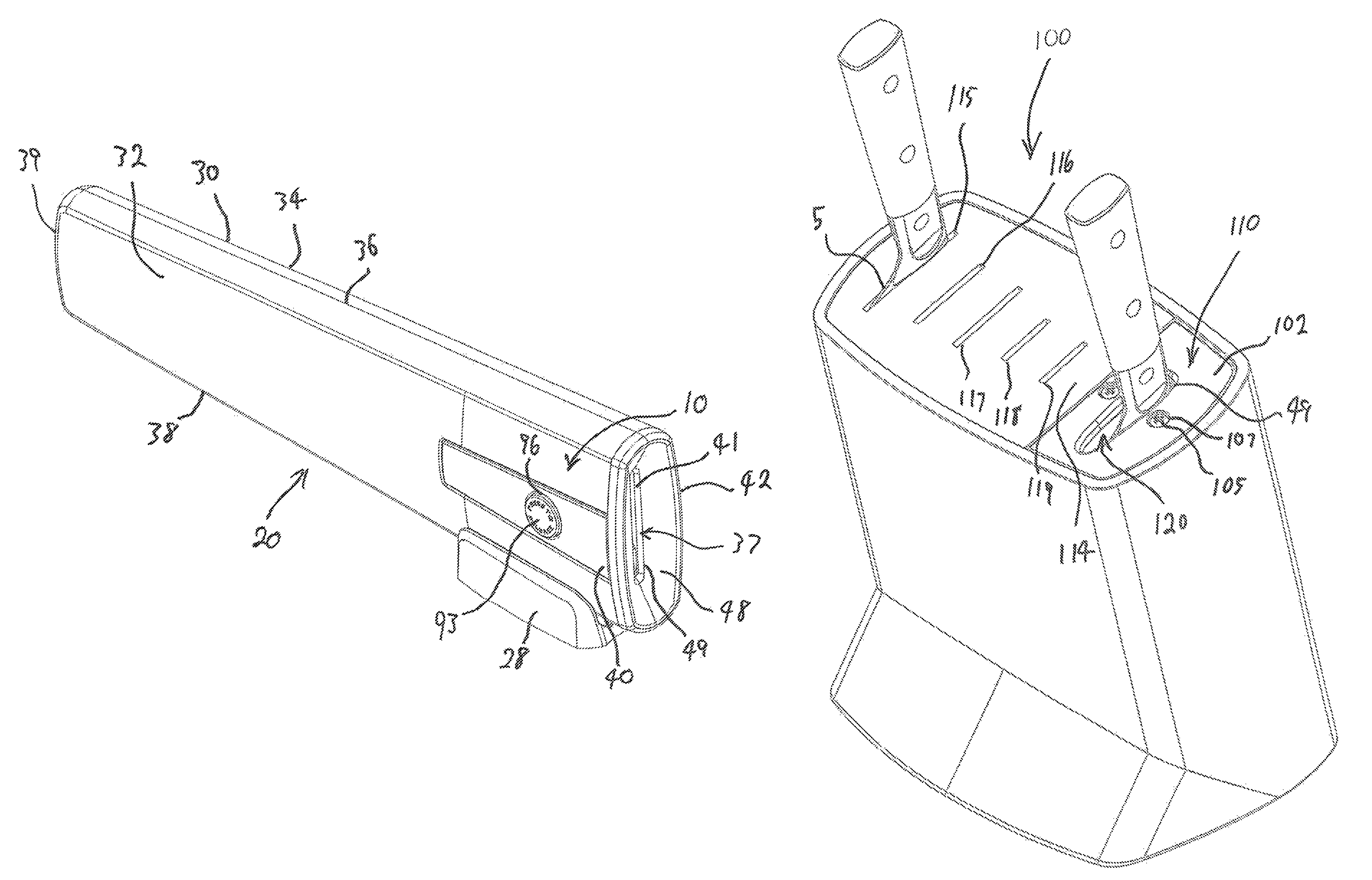

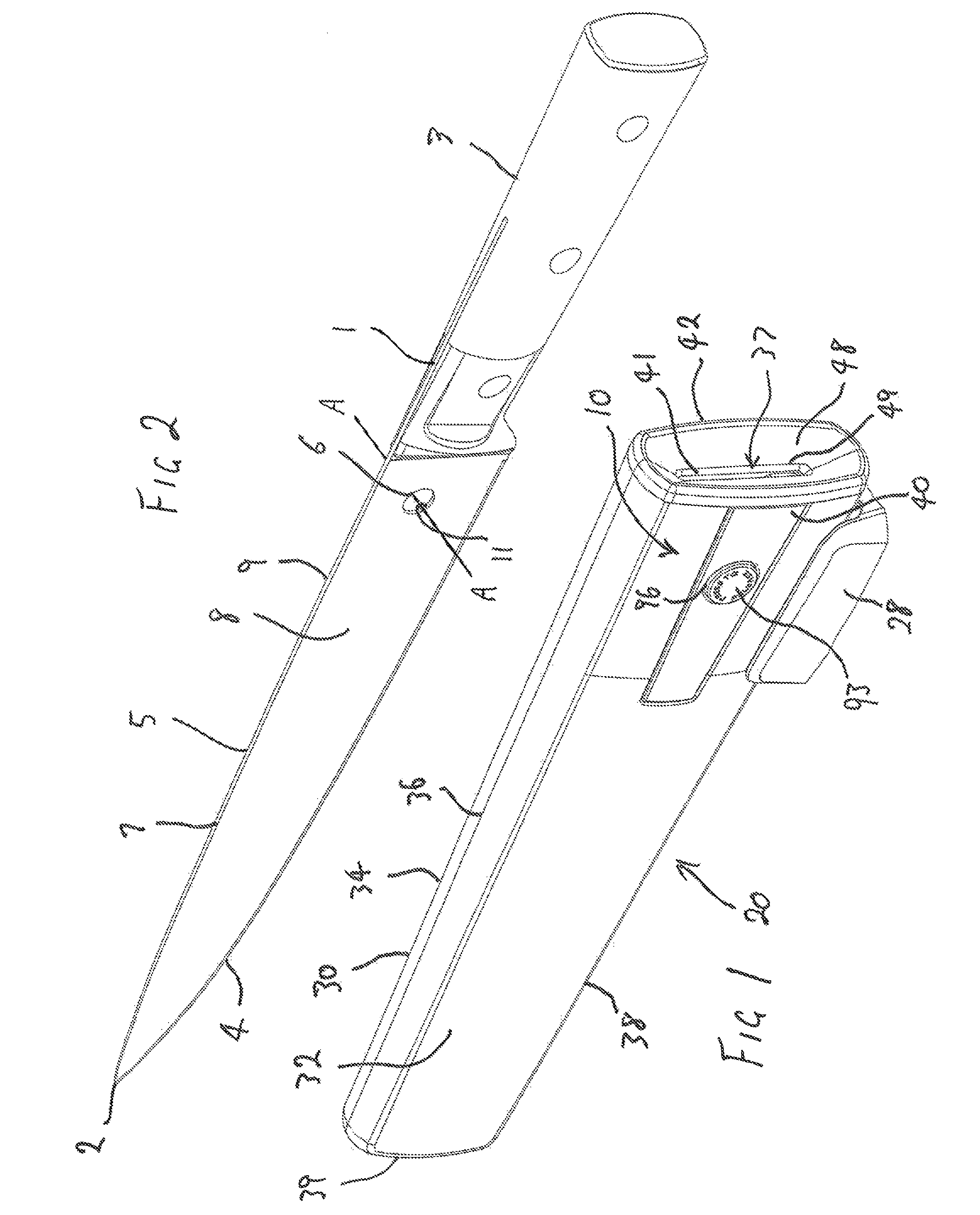

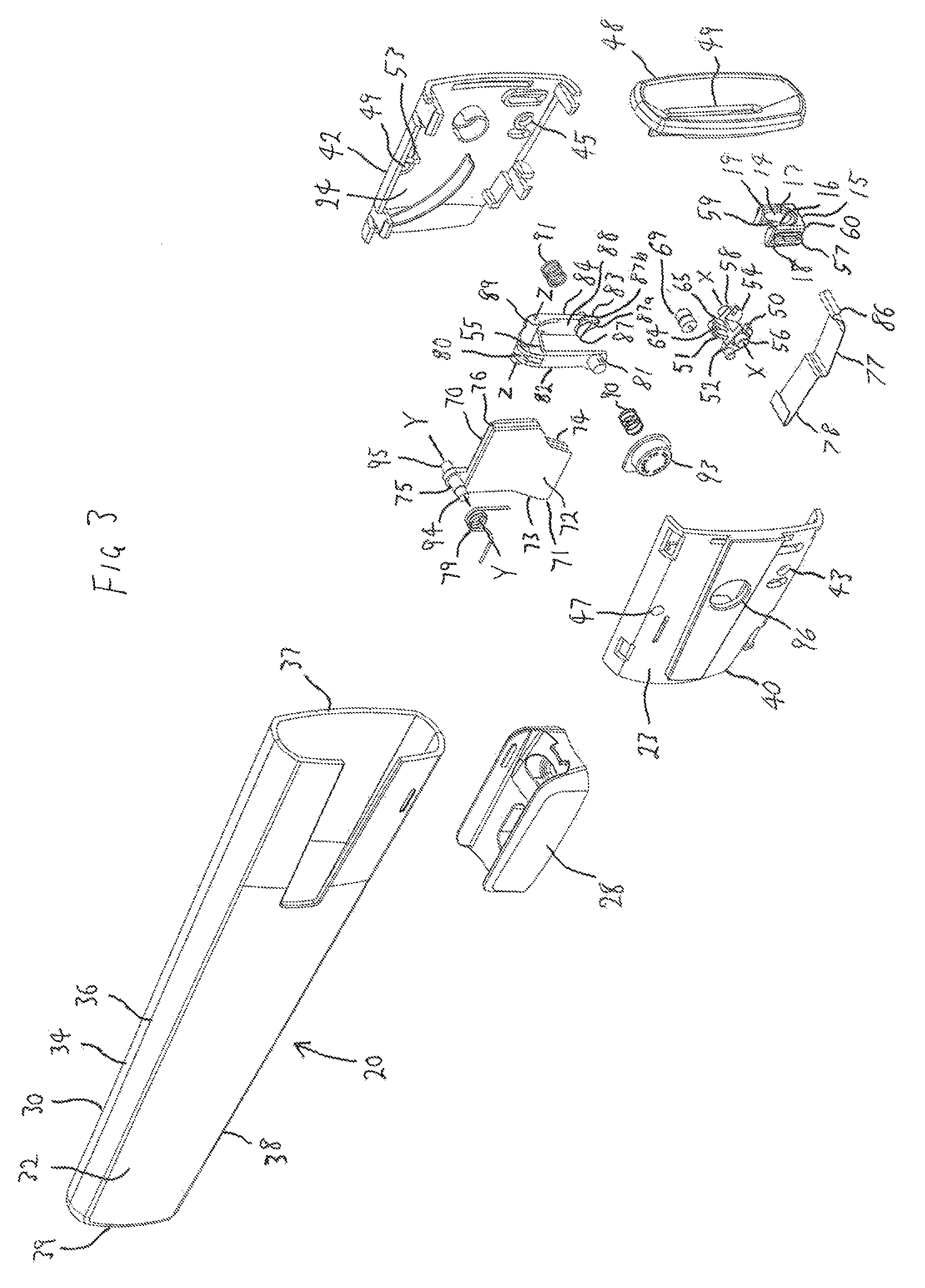

Personal care assembly

ActiveUS8141253B2Increase heightImprove performanceMetal working apparatusShaving accessoriesPersonal careBattery charge

A personal care apparatus includes a handle housing a rechargeable battery and a plurality of operating heads such as a vibrating safety razor head and a hair trimming device exchangeably mountable on the handle for assembling different hand-held appliances for performing respective body treatments. A base is included for storing the components of the apparatus when not in use and forms a battery charging device with a socket into which the handle plugs for recharging the battery. The operating heads include electrical devices, in particular electric motors, powered by the battery.

Owner:THE GILLETTE CO

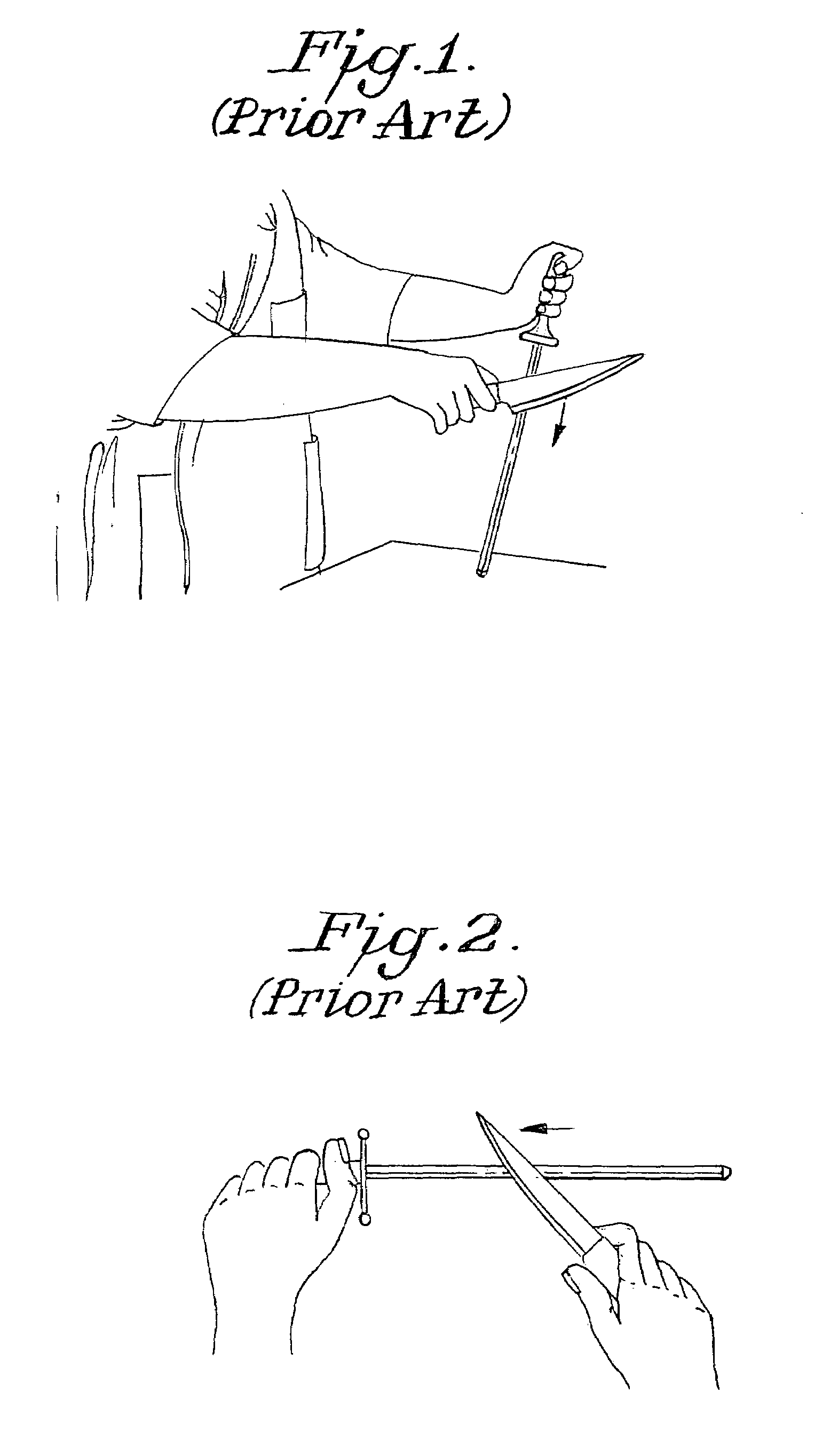

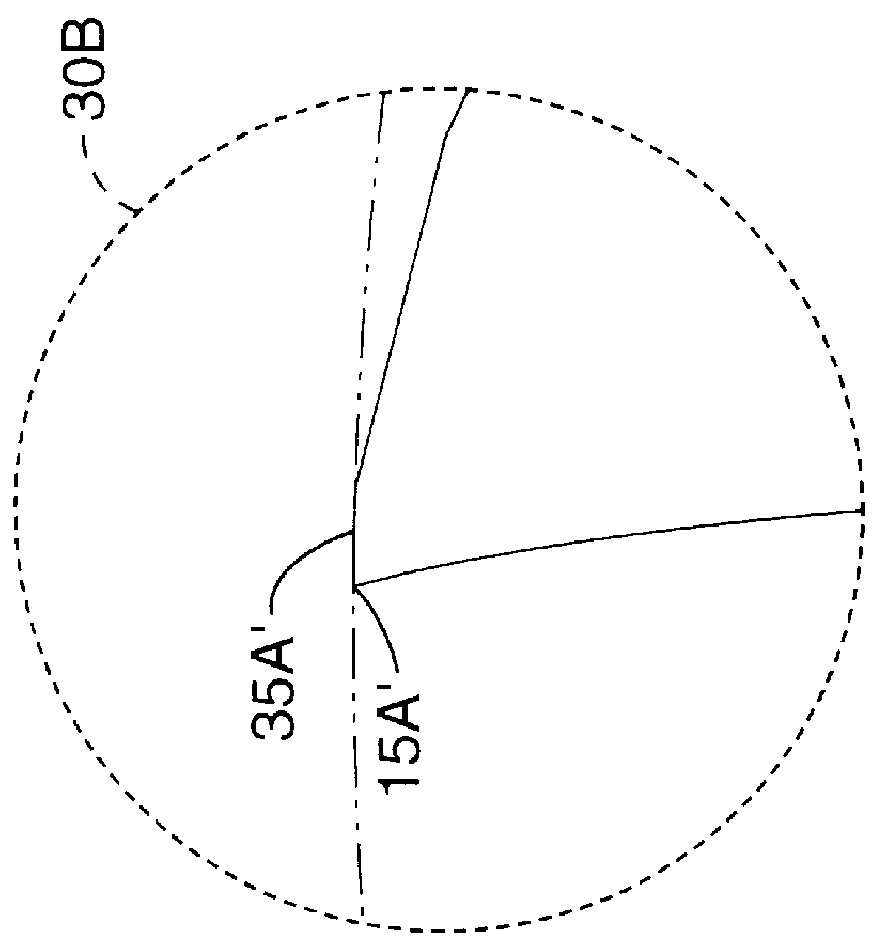

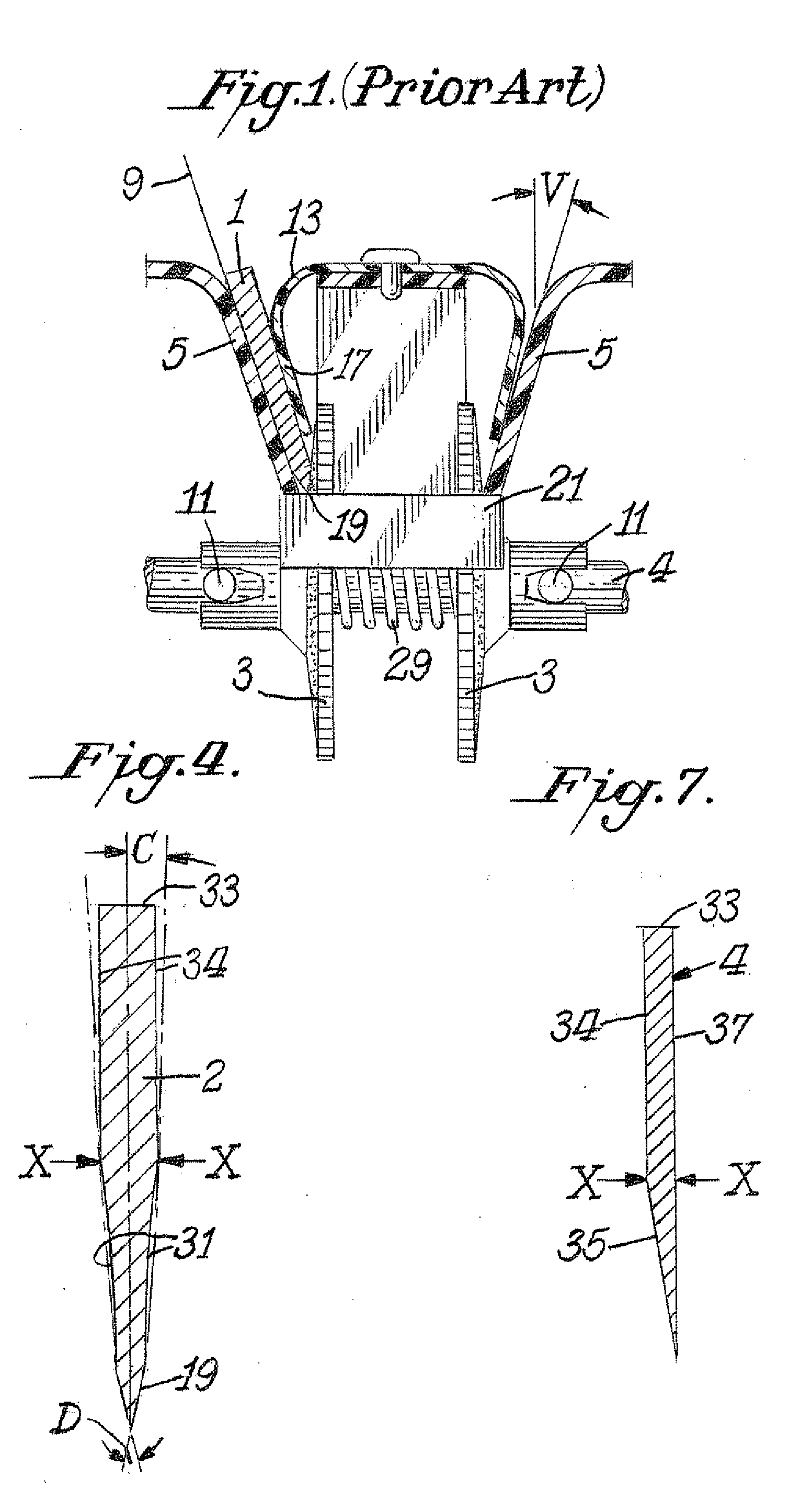

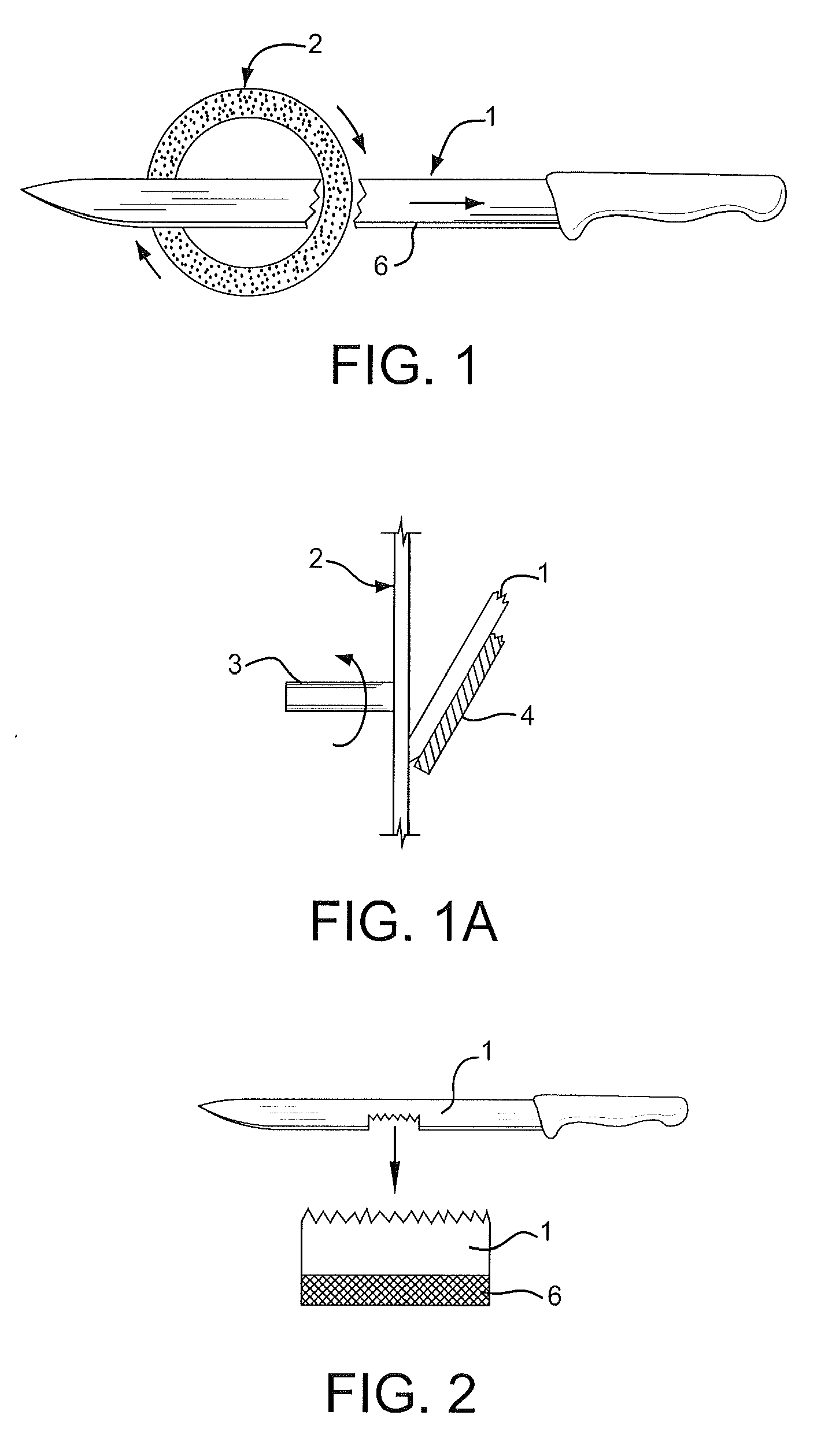

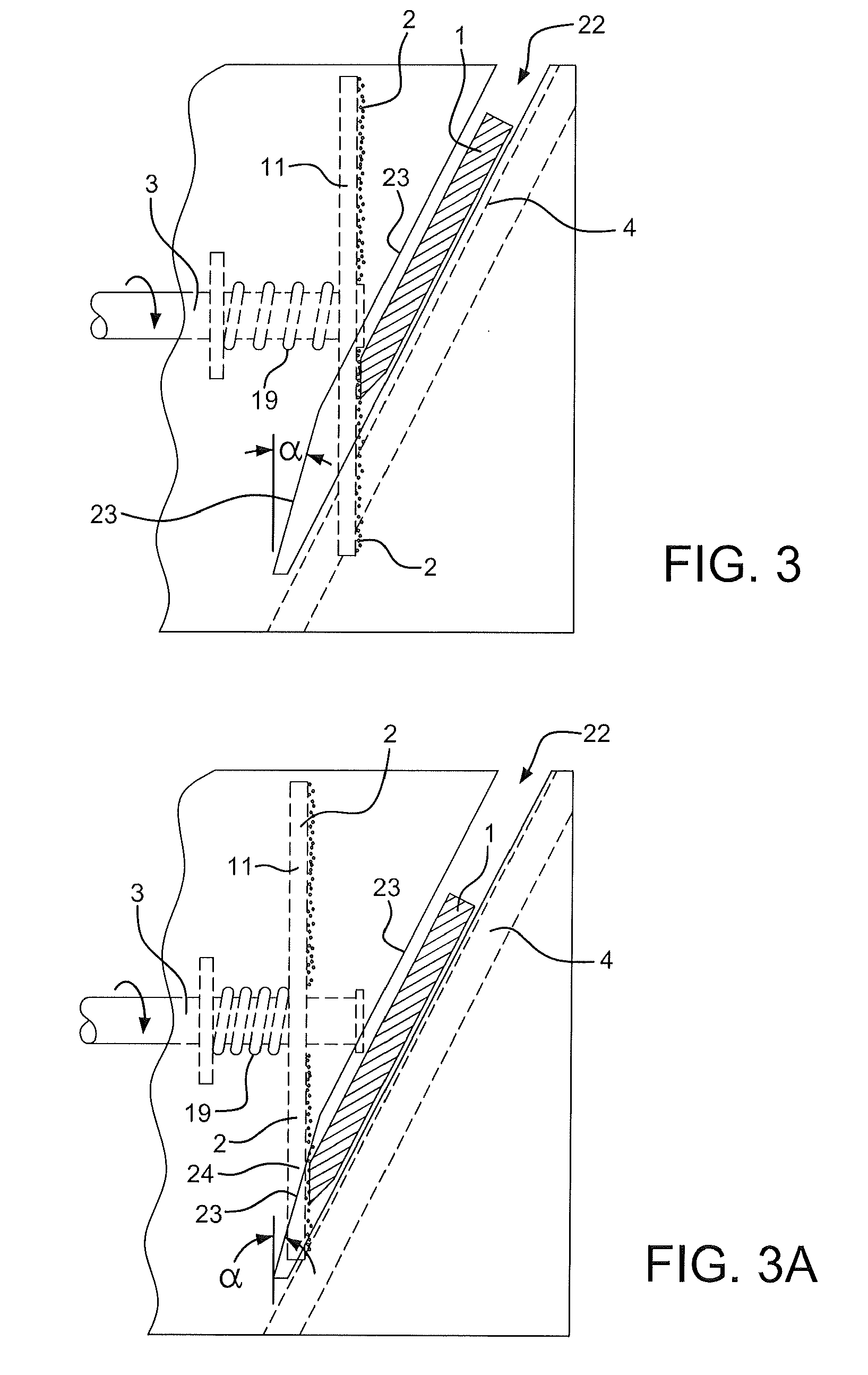

Apparatus for precision steeling/conditioning of knife edges

An apparatus for manually steeling or conditioning the edge of a knife blade comprises a precision angle guide attached to a manual sharpening steel. The angle guide establishes a guiding surface that provides for sustained sliding or rolling contact with the face of the knife blade such that the plane of at least one edge facet adjacent to the edge of the blade is maintained at a precisely established angle relative to the plane of the sharpening steel surface at the contact point of the facet with the surface of the sharpening steel.

Owner:EDGECRAFT

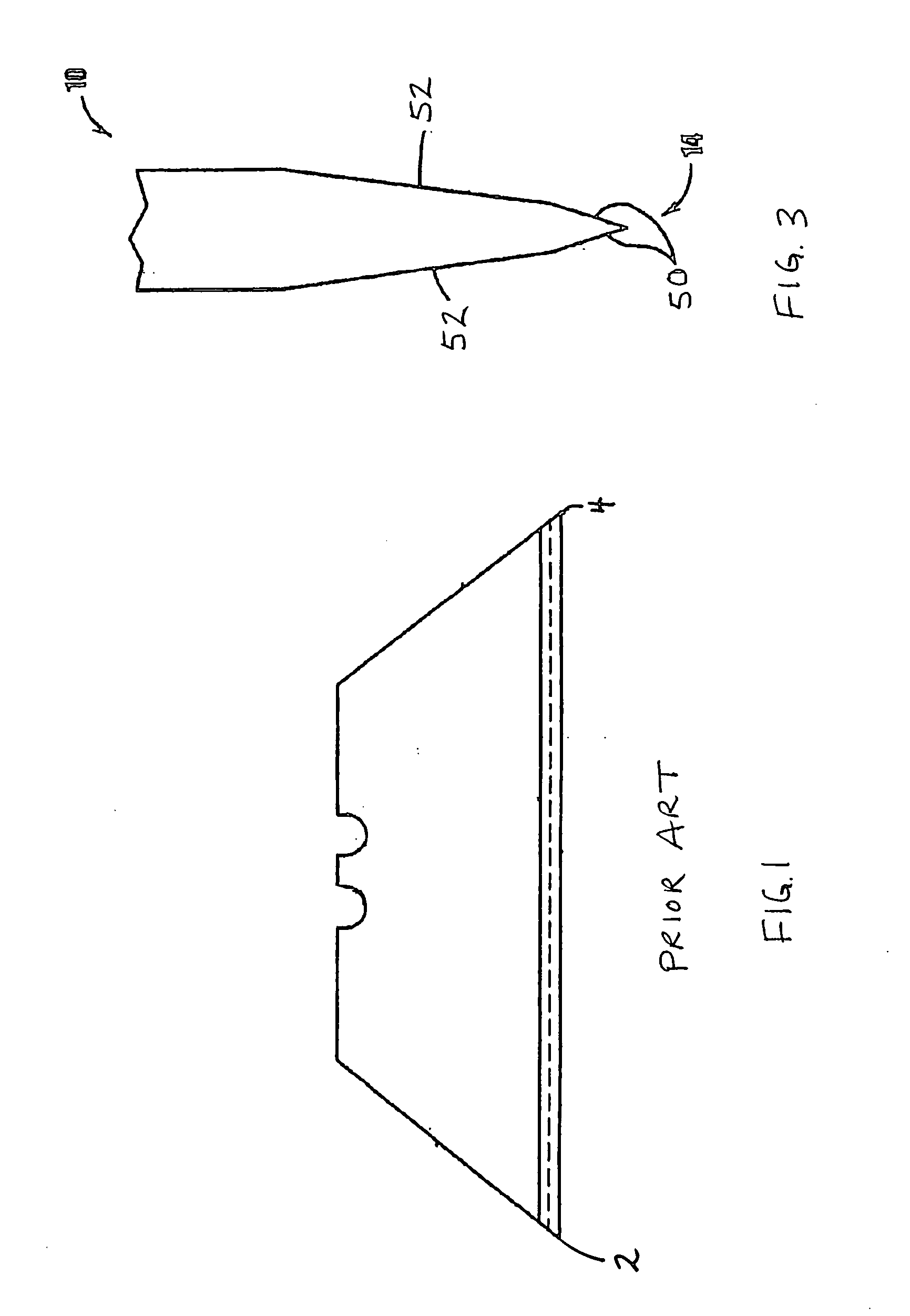

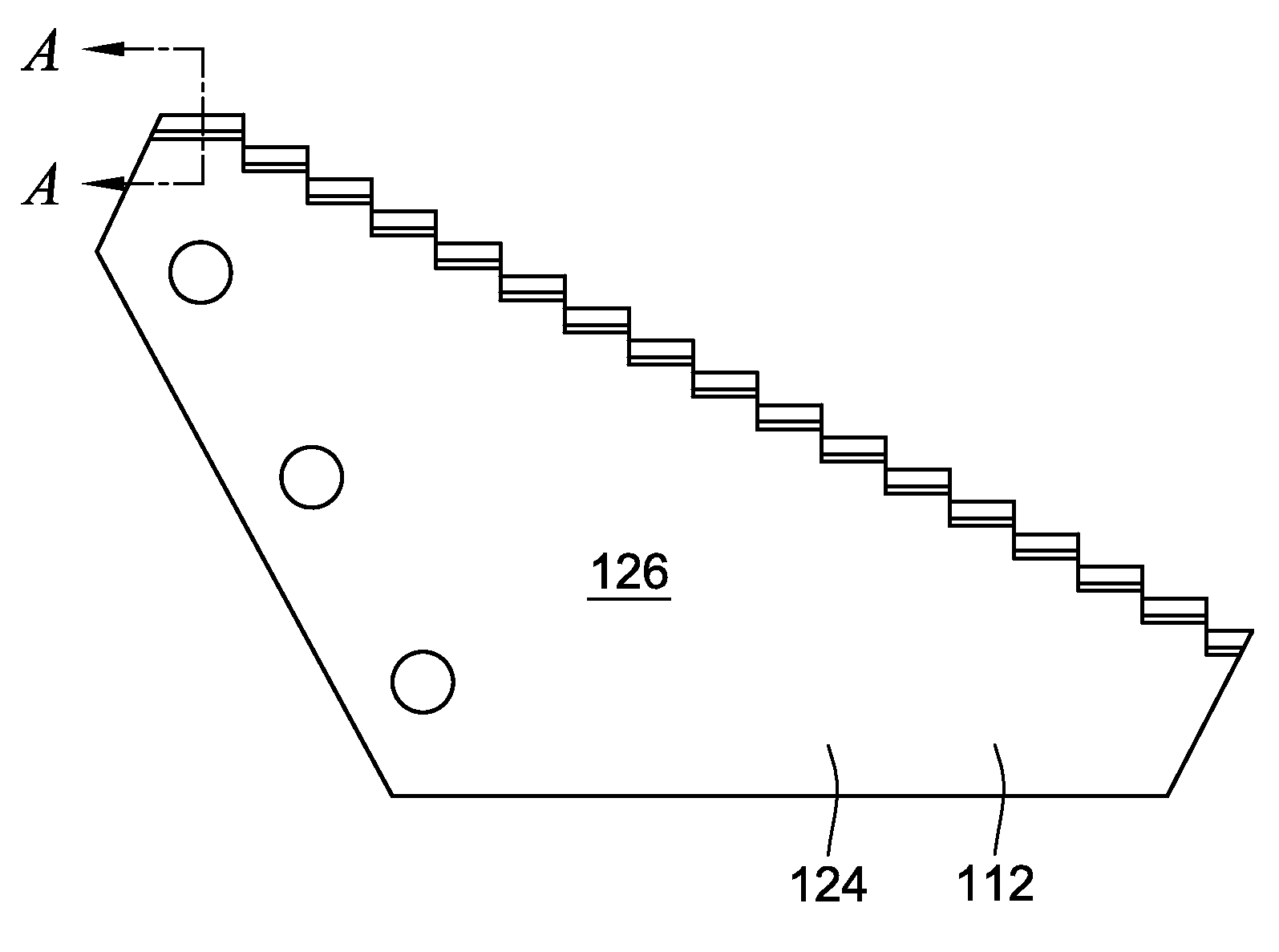

Laser Clad Cutting Edge for Agricultural Cutting Components

InactiveUS20130233145A1Reduce wearAvoid premature wearMetal sawing devicesMowersEngineeringKnife blades

An agricultural cutting blade has top and bottom surfaces and mounting apertures extending through top and bottom surfaces. A cutting edge support surface (e.g. that may be a flat, pointed or rounded) is formed on the cutting blade body with the cutting edge support extending along a side of the cutting blade body transversely between the top and bottom surfaces. A clad material deposited upon the cutting edge support such as by laser cladding process. The clad material can be built up, that is layered in partial or full overlapping relation to provide at least 2 and often more than 4 layers of clad material at one or more locations. A cutting edge provided by the clad material that may be a ground surface into a laser clad bead.

Owner:KONDEX CORP

Method for manufacturing hair clipper blade

A method for manufacturing a hair clipper blade includes providing a blank with a comb teeth shaped cutting edge portion, and forging the cutting edge portion to have an acute tip angle.

Owner:MATSUSHITA ELECTRIC WORKS LTD

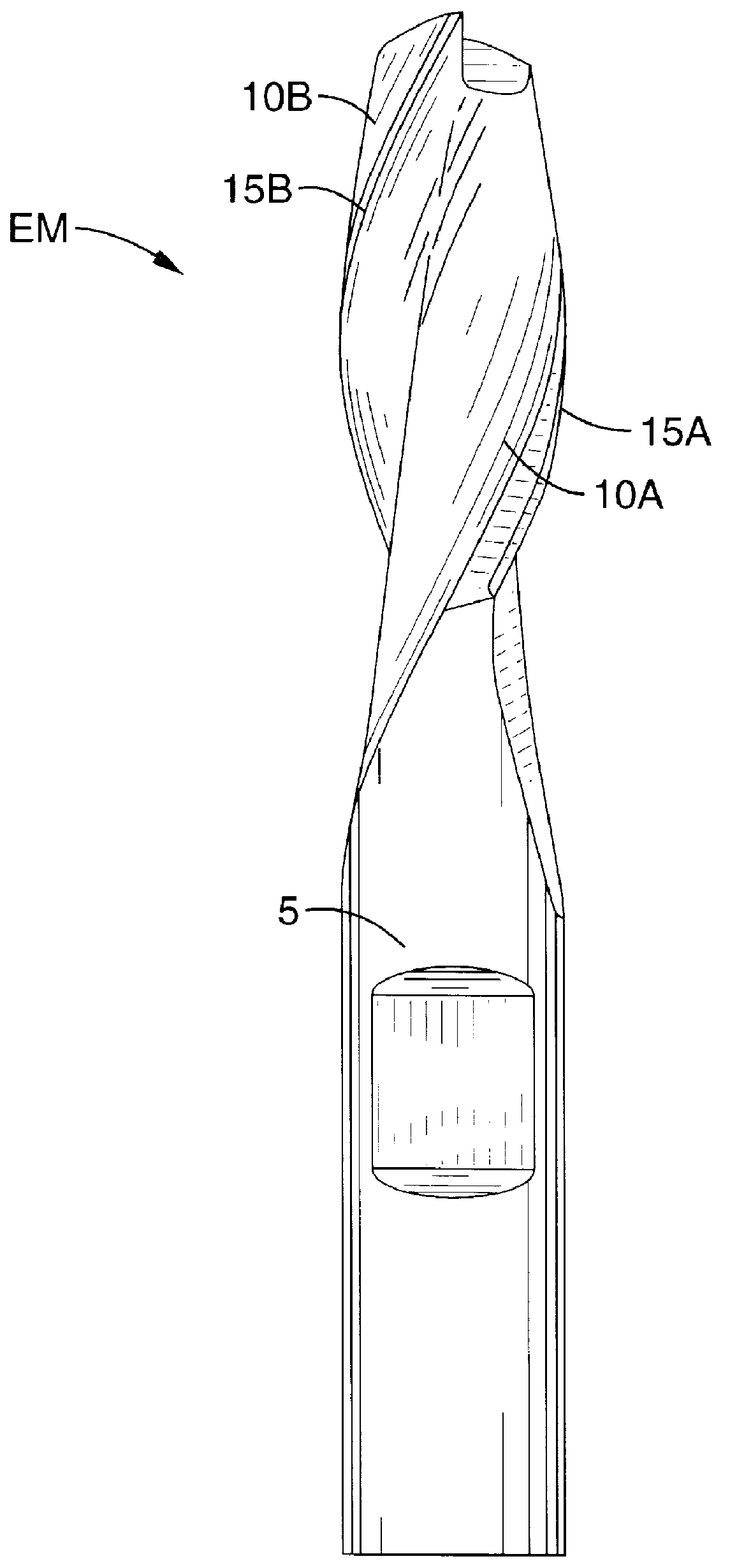

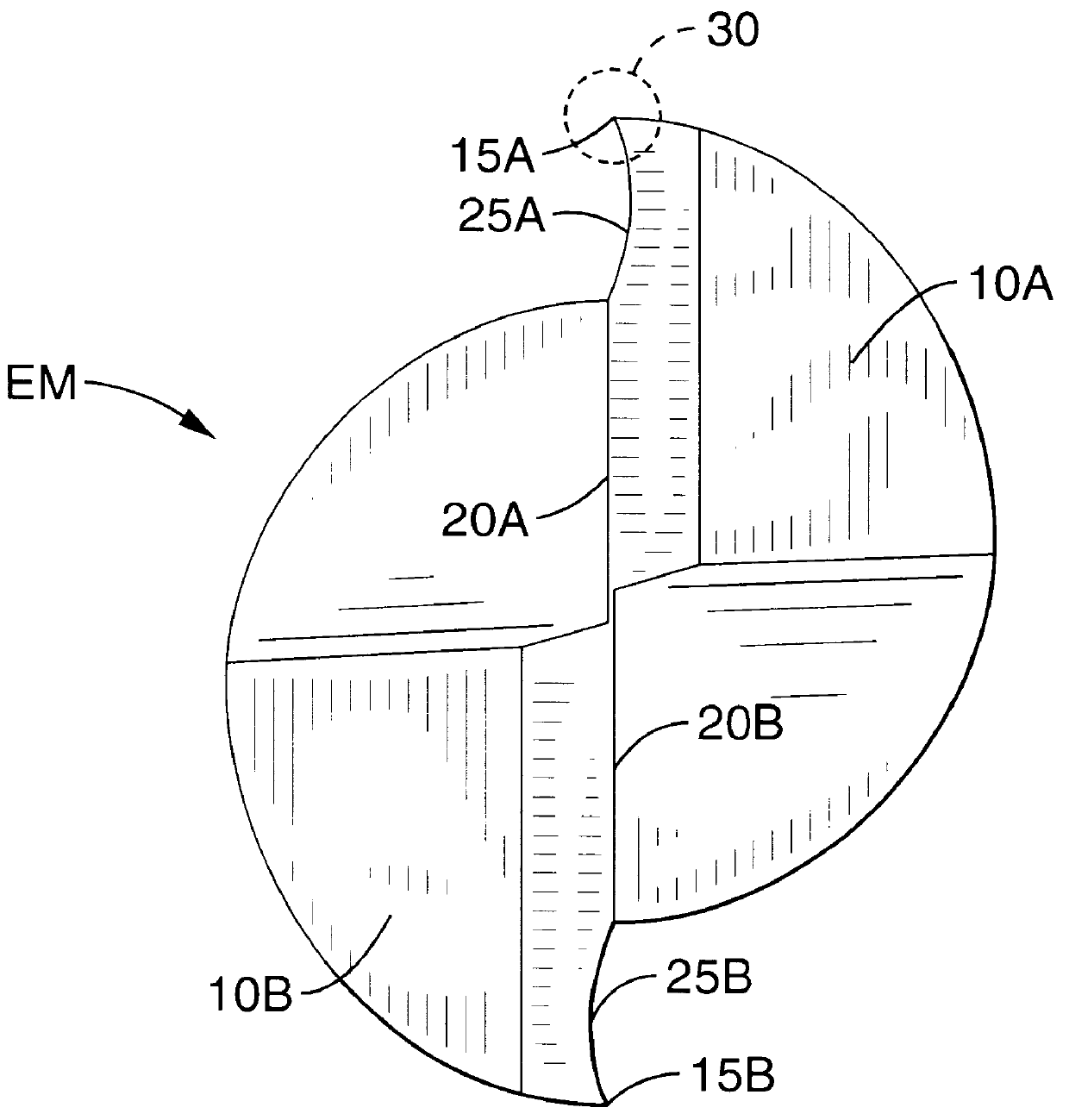

Method for preparing a cutting edge on an end mill

InactiveUS6105467AEasy to prepareReduce debrisMetal-working drilling toolsMilling cuttersMilling cutterEnd mill

A method of increasing the length of time a tool maintains sharp cutting edges utilizes the steps of manufacturing the tool with the cutting edges ground sharp and then partially dulling, to a lighter or heavier extent, those previously ground sharp cutting edges. Often the partial dulling is accomplished by means of applying a brush wheel to the selected cutting edges.

Owner:ROBBJACK CORP

Knife sharpener

InactiveUS7172500B1Easy to useExtend your lifeAgriculture tools and machinesCutting toolsKnife sharpenerEngineering

A knife sharpener has a housing, a base, a sharpening device and an adjustable device. The housing has a case, a cavity and a slot. The cavity is defined in the case and the slot is defined in the case and communicates with the cavity. The base is mounted on the housing and has a base board and two side walls formed on the base board. The sharpening device is movable mounted on the base and is received inside the housing. The sharpening device has two sharpening arms with sharpening rods. The adjustable device is mounted on the sharpening device mounted between the two sharpening arms. When the knife sharpener is used, the adjustable device is rotated to change the cross-position of the sharpening device. Therefore, a knife may be sharpened at a different site on the sharpening rods for prolonging the life span of the knife sharpener.

Owner:WU WEN CHIU

Personal care apparatus

ActiveUS20090056137A1Improve performanceIncreasing hair lengthMetal working apparatusShaving accessoriesPersonal careBattery charge

A personal care apparatus includes a handle housing a rechargeable battery and a plurality of operating heads such as a vibrating safety razor head and a hair trimming device exchangeably mountable on the handle for assembling different hand-held appliances for performing respective body treatments. A base is included for storing the components of the apparatus when not in use and forms a battery charging device with a socket into which the handle plugs for recharging the battery. The operating heads include electrical devices, in particular electric motors, powered by the battery.

Owner:THE GILLETTE CO

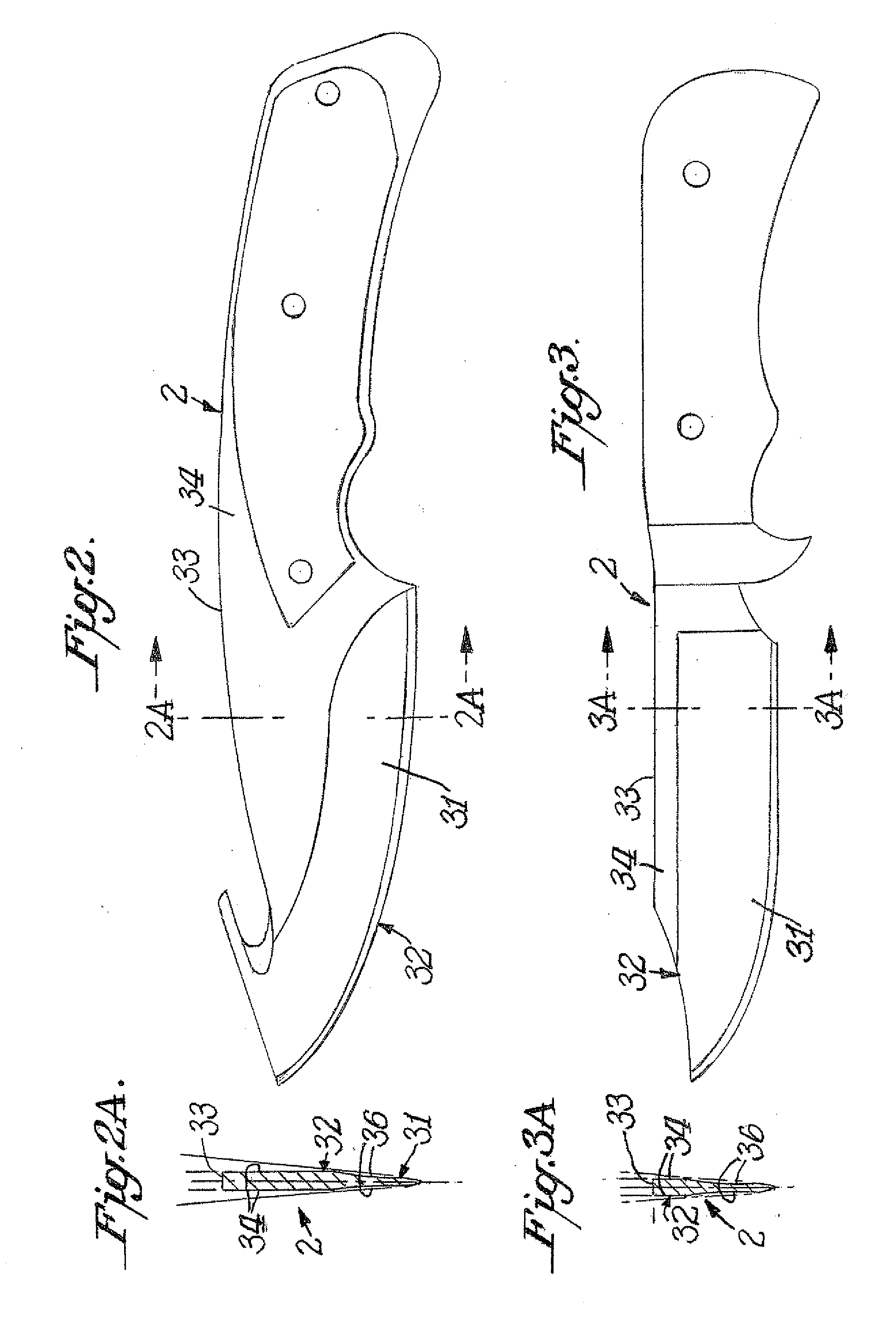

Precision sharpener for hunting and asian knives

ActiveUS20080261494A1Eliminate the problemPrecise alignmentEdge grinding machinesCutting toolsCoated surfaceKnife sharpener

A knife sharpener is provided which is capable of precision sharpening of hunting and similar knives that have a first and second blade face, each of which terminates at a facet that meets the corresponding facet to create the knife edge. At least the first of the blade faces has a lower distinct planar or concave section adjacent the edge facet with the lower planar or concave section of the face being set at an angle to the center line of the blade thickness that is different from the angle of the adjoining upper section of the same blade face located adjacent to the back of the blade. The sharpener includes a sharpening member such as one having an abrasive coated surface. The sharpener also includes a planar angle knife guide surface of a knife guide which is designed for intimate sliding and sustaining contact with the second face of the blade in order to position an edge facet on the first of the faces into precise angular relation with the sharpening surface. The sharpener also includes a knife holding spring that applies force against the first face of the blade predominantly at one or more locations on the lower planar or concave section of the first face that is adjacent to the edge facet being sharpened in order that the lower section adjacent the edge on the second face of the blade is pressured to align with and remain in intimate sliding alignment with the guide surface as the blade edge facet on the first face is being sharpened.

Owner:EDGECRAFT

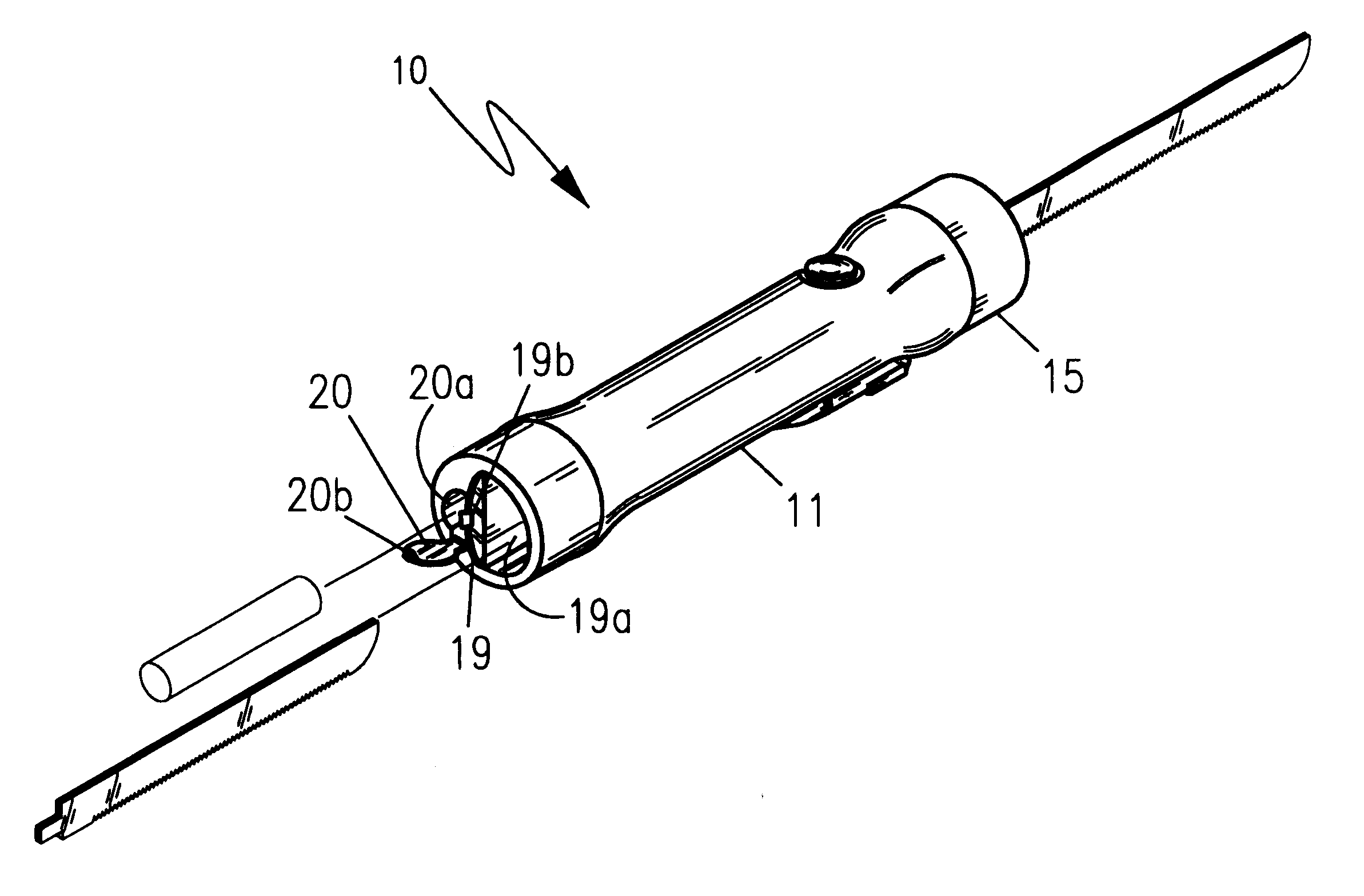

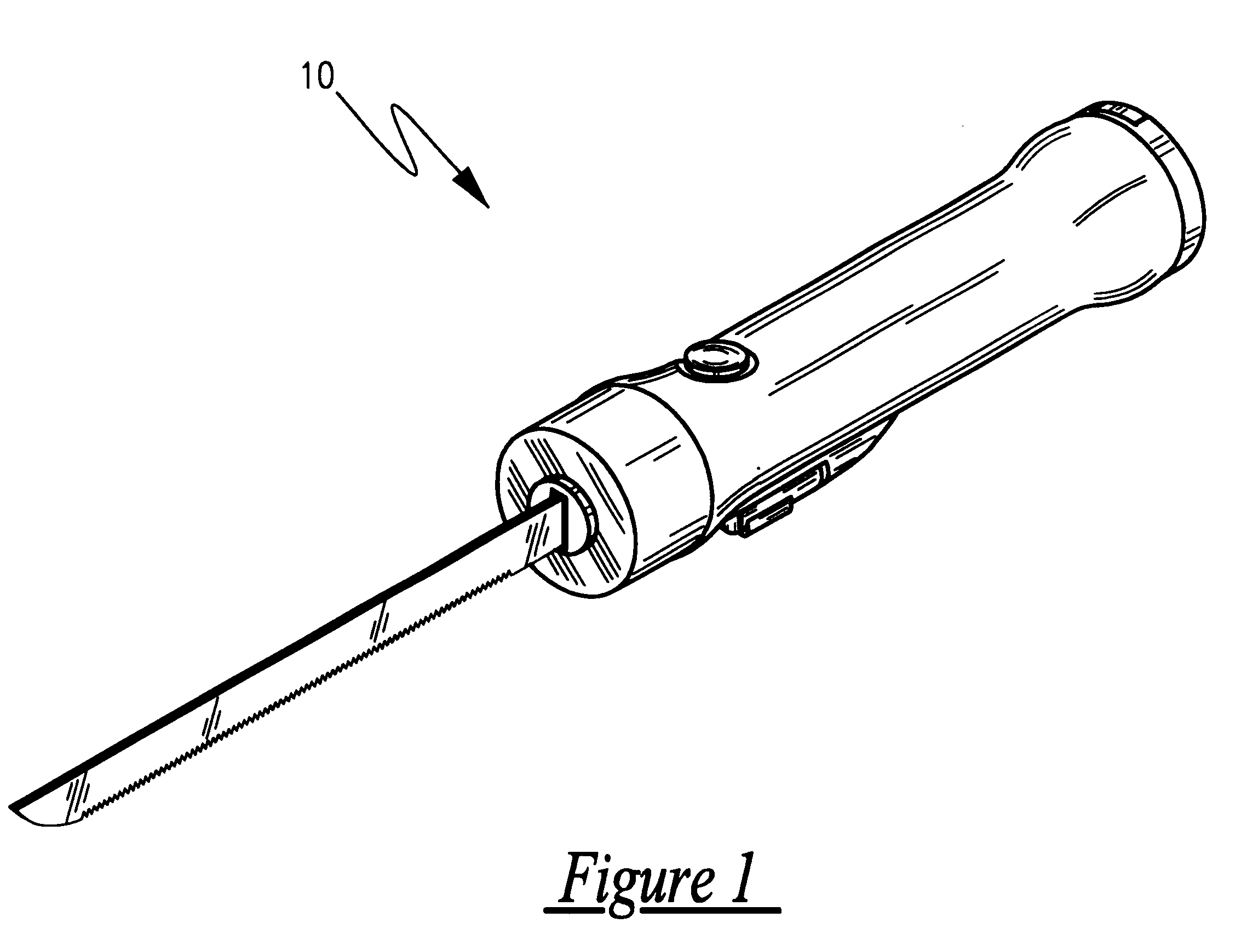

Interchangeable blade cordless electric knife

InactiveUS6434836B1Improve securityAvoid disadvantagesPortable power-driven toolsMetal working apparatusHeavy dutyKnife blades

The invention is an electric knife that runs on a battery or by use of a corded power converter. The handle housing has an electric reciprocating motor activated by a power button located on the handle of the knife. Different sizes and shapes of knife blades, dependent on the task, can be inserted into a locking slot in the front of the motorized head, and only released by a heavy-duty lock knife release button. The motorized head is powered directly by an electric motor located directly behind it in the handle.

Owner:OLIVARES HECTOR

Blade storage device including a blade sharpener and a honing device

ActiveUS8590427B2Improve featuresSharper cutting edgeCutting toolsThrusting weaponsScabbardEngineering

A housing including a honing device, a blade sharpener, a blade restraining mechanism, and a biased blade guide being received in a scabbard or a knife block. Wherein a knife is honed and sharpened upon insertion into the housing, or upon withdrawal from the housing, or both, and wherein the blade is retained within the housing after insertion therein.

Owner:FACKELMANN HOUSEWARES IP PTY LTD +1

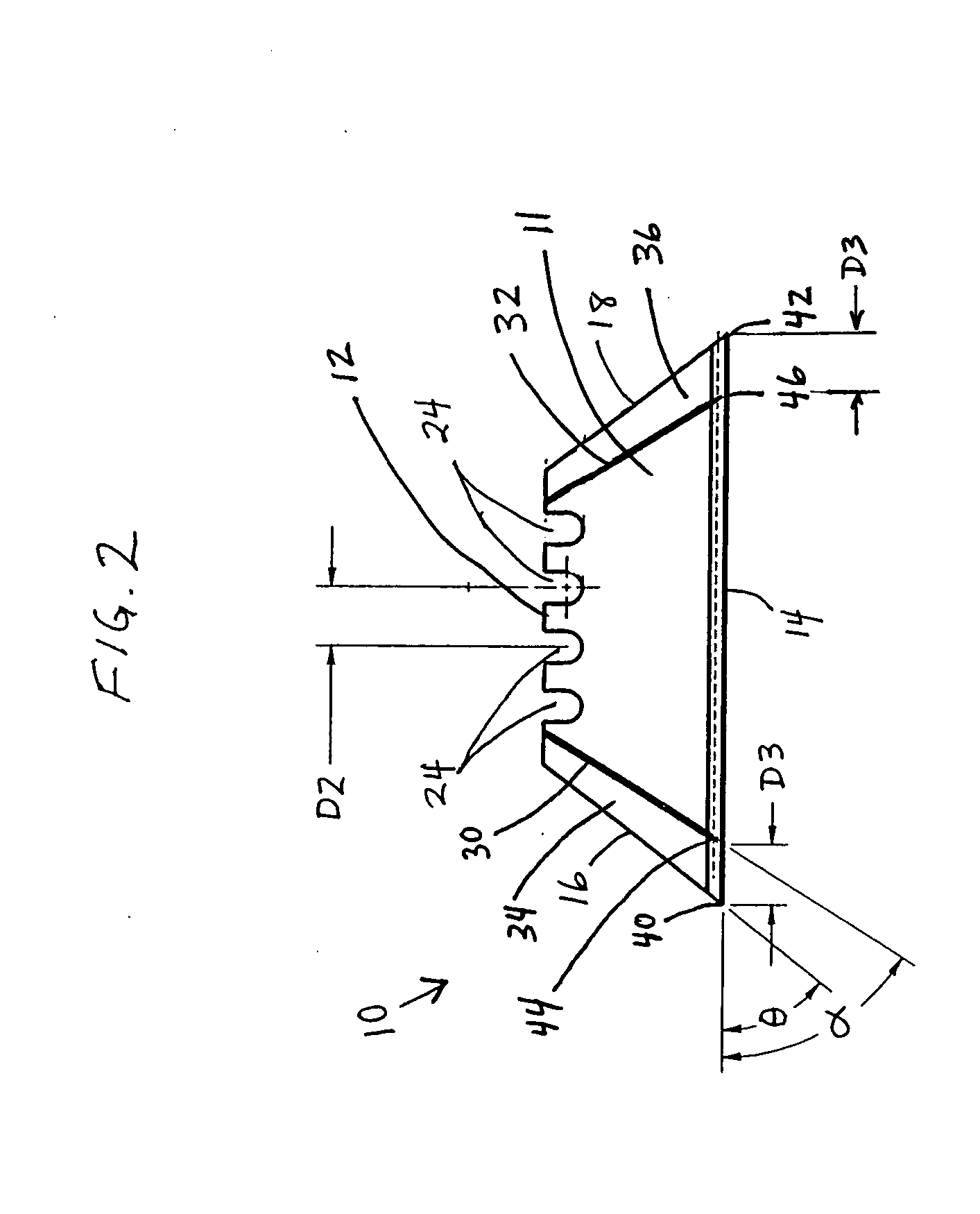

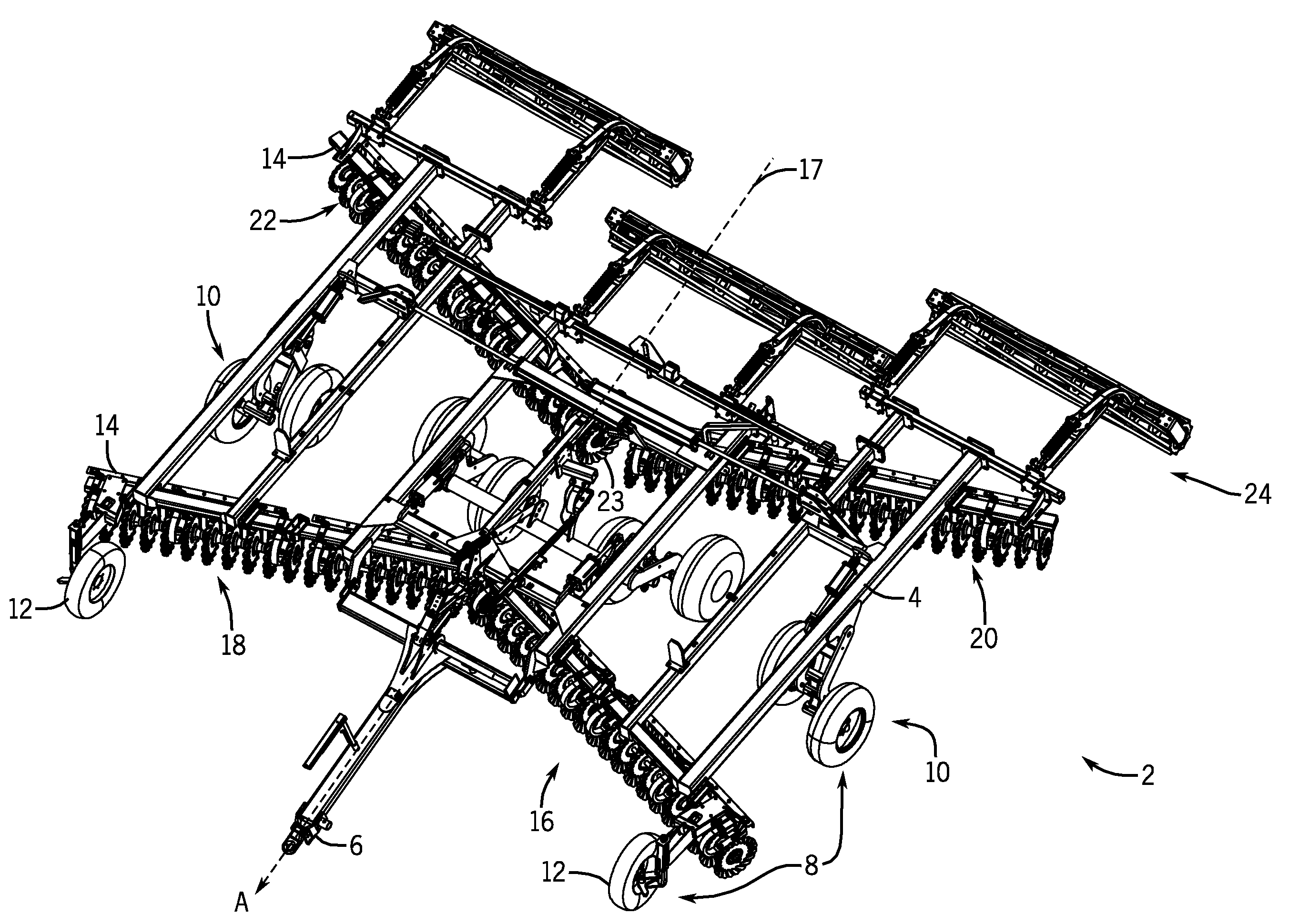

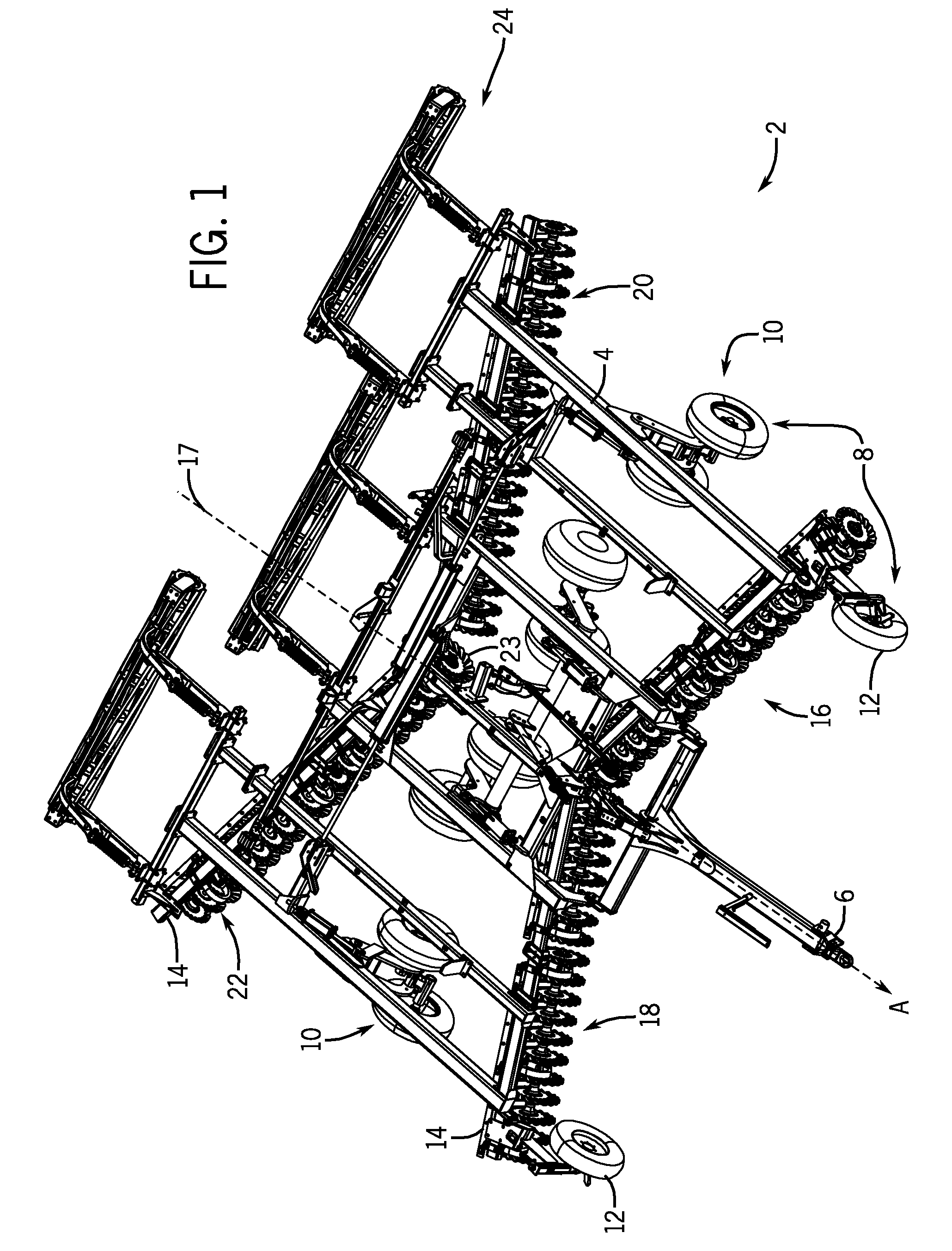

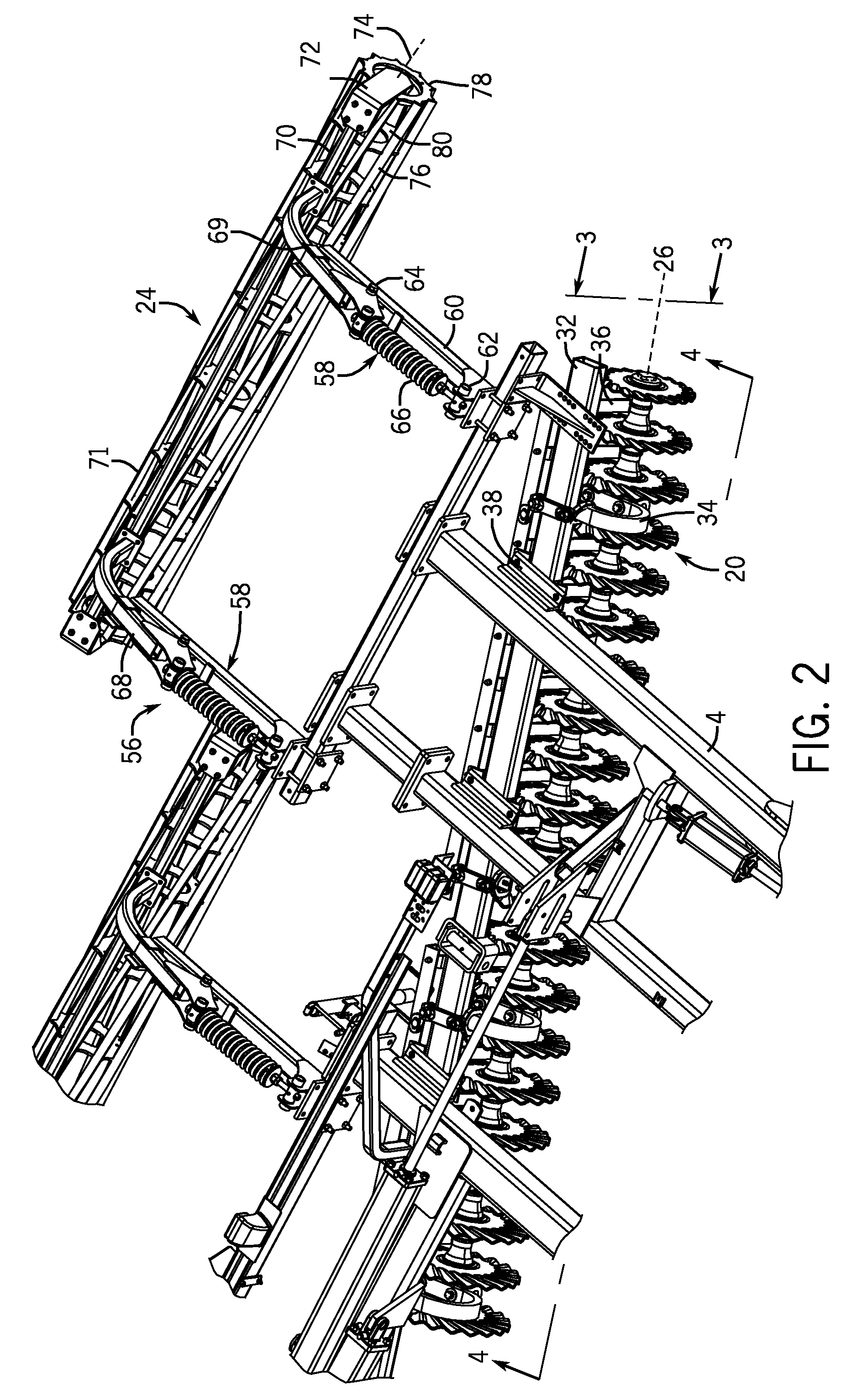

Vertical Tillage System

ActiveUS20090133888A1Reduces subsoil compactionOvercomes drawbackSpadesSoil-working equipmentsAgricultural engineeringSubsoil

A vertical tilling implement to be pulled behind and agricultural vehicle having a number of gangs of fluted-concave disc blades, rolling baskets, and wheels connected to a main frame. As the vertical tilling implement is pulled, the fluted-concave disc blades move the soil in a direction lateral to the side of the blades as well as up. Meanwhile, the rolling bars aid in leveling the seedbed and crushing the remaining large pieces of soil. The vertical tilling implement reduces the amount of subsoil compaction and cuts through heavy residue making it ideal for use in the fall or in the spring.

Owner:BLUE LEAF I P

Novel sharpeners to create cross-grind knife edges

ActiveUS20110034111A1Highly effectiveSmall sizeEdge grinding machinesRevolution surface grinding machinesCircular discEngineering

A sharpener for creating cross-grind knife edges includes a nominally flat annular abrasive sharpening member which could be a ring or a disk and is rotated about its center and held against a moving knife edge facet to simultaneously and sequentially abrade the knife edge at multiple locations on the abrasive member. The disk may be slidably mounted on a shaft in opposition to a spring restraining force. The disk is nominally disposed in a vertical orientation. The sharpener may include multiple stages including a manual stage having a pair of off axis conical shaped rotatable abrasive coated disks which have abrading lines on opposing facets which are not parallel but cross and intersect in a crossing pattern at the blade edge.

Owner:EDGECRAFT

Bent razor blades and manufacturing thereof

A razor blade manufactured by the process of cutting a strip of blade steel into discrete blanks each having an elongated edge and an elongated support portion extending between a pair of lateral end faces generally transverse to the elongated edge. The elongated edges are sharpened to form a cutting edge. The discrete blanks are deformed to form a bent portion. The lateral end faces are treated to remove cracks prior to being deformed.

Owner:THE GILLETTE CO

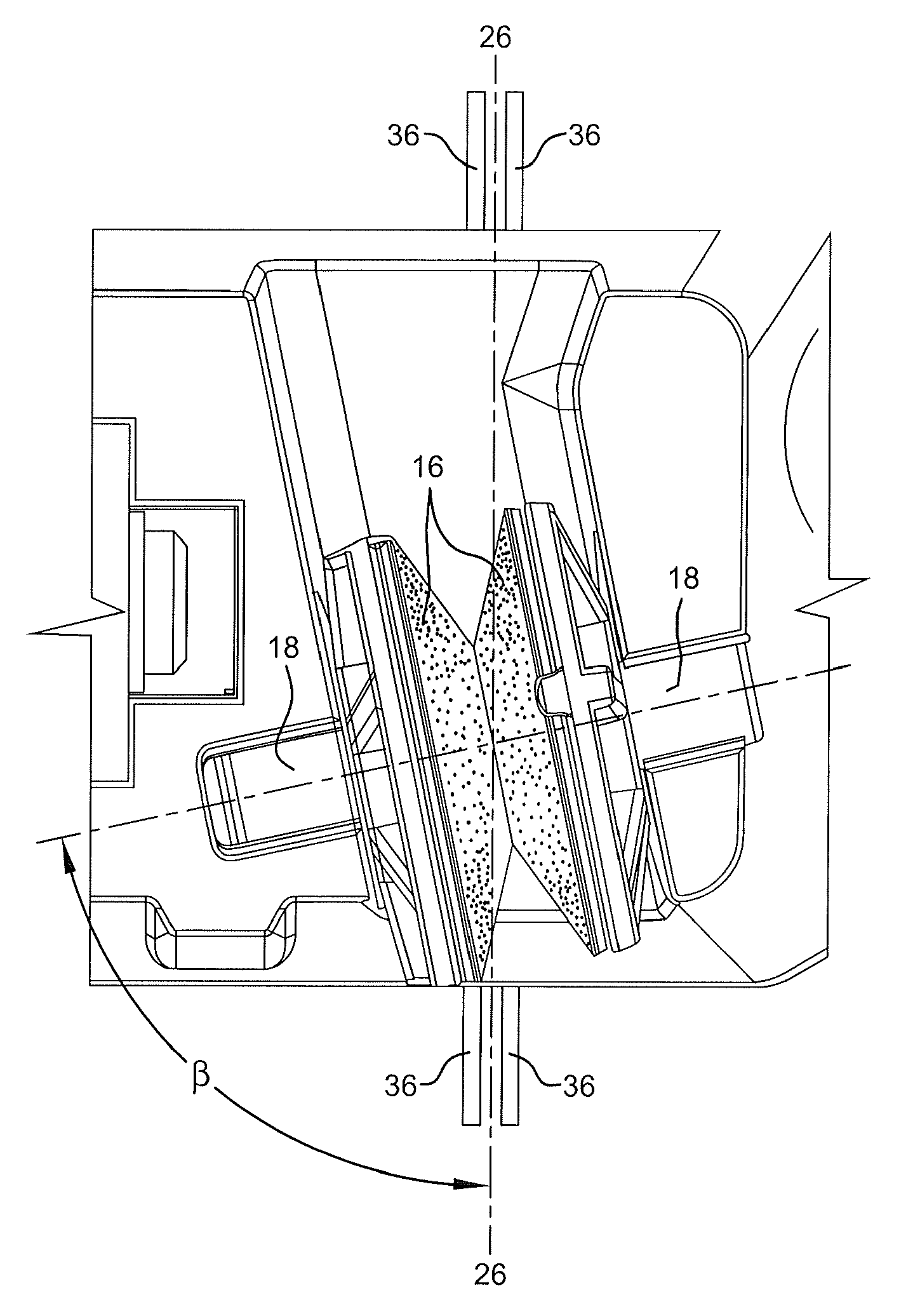

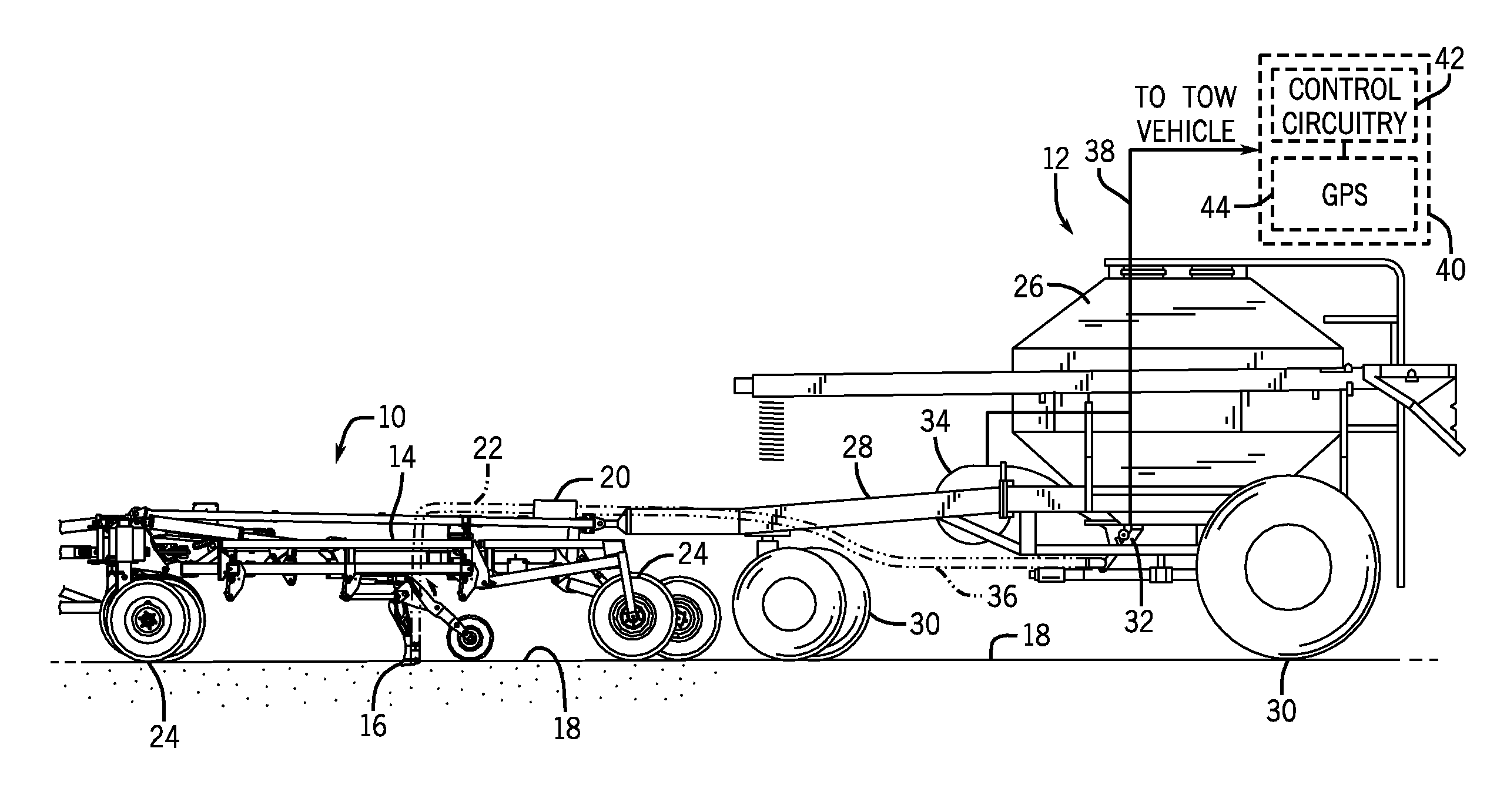

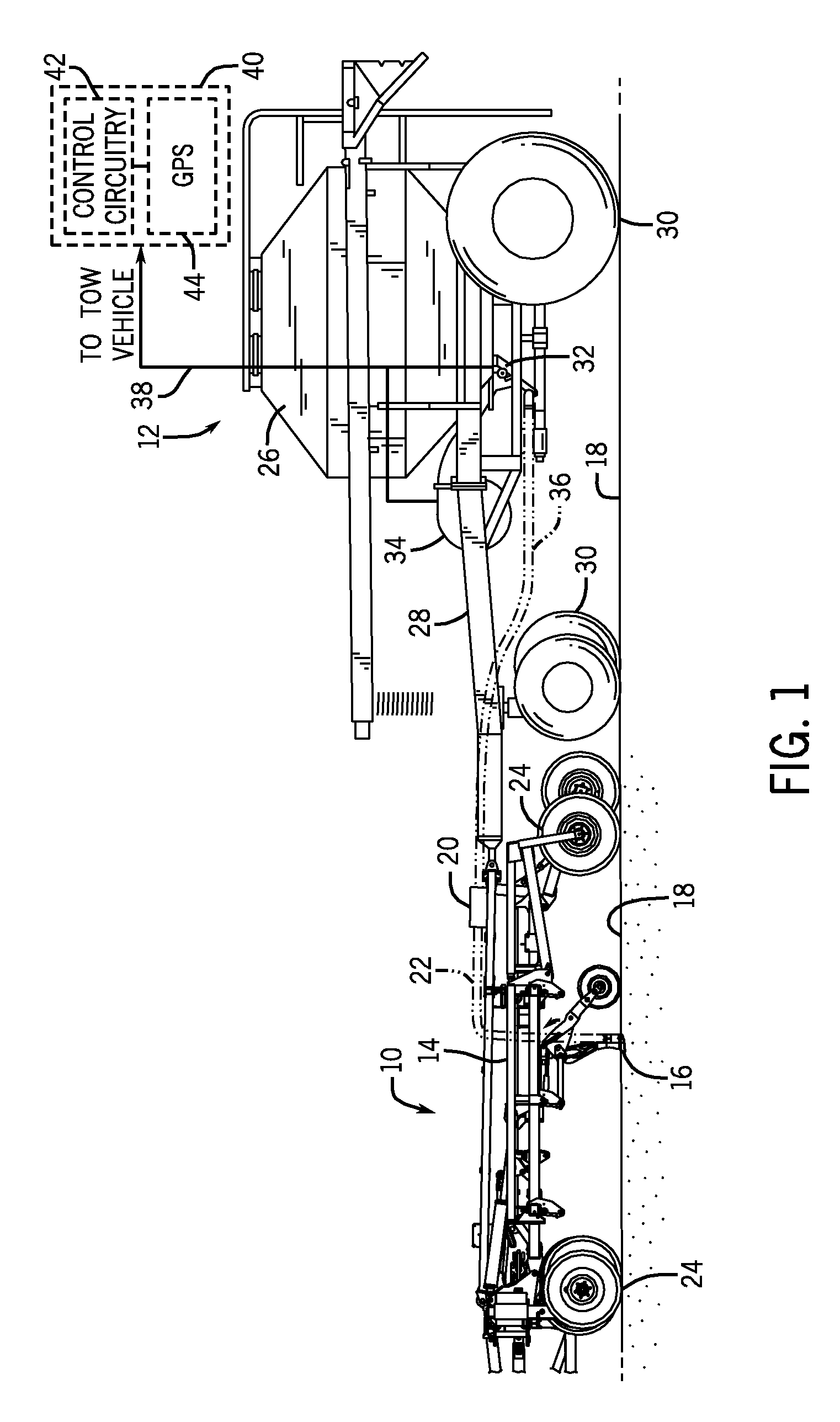

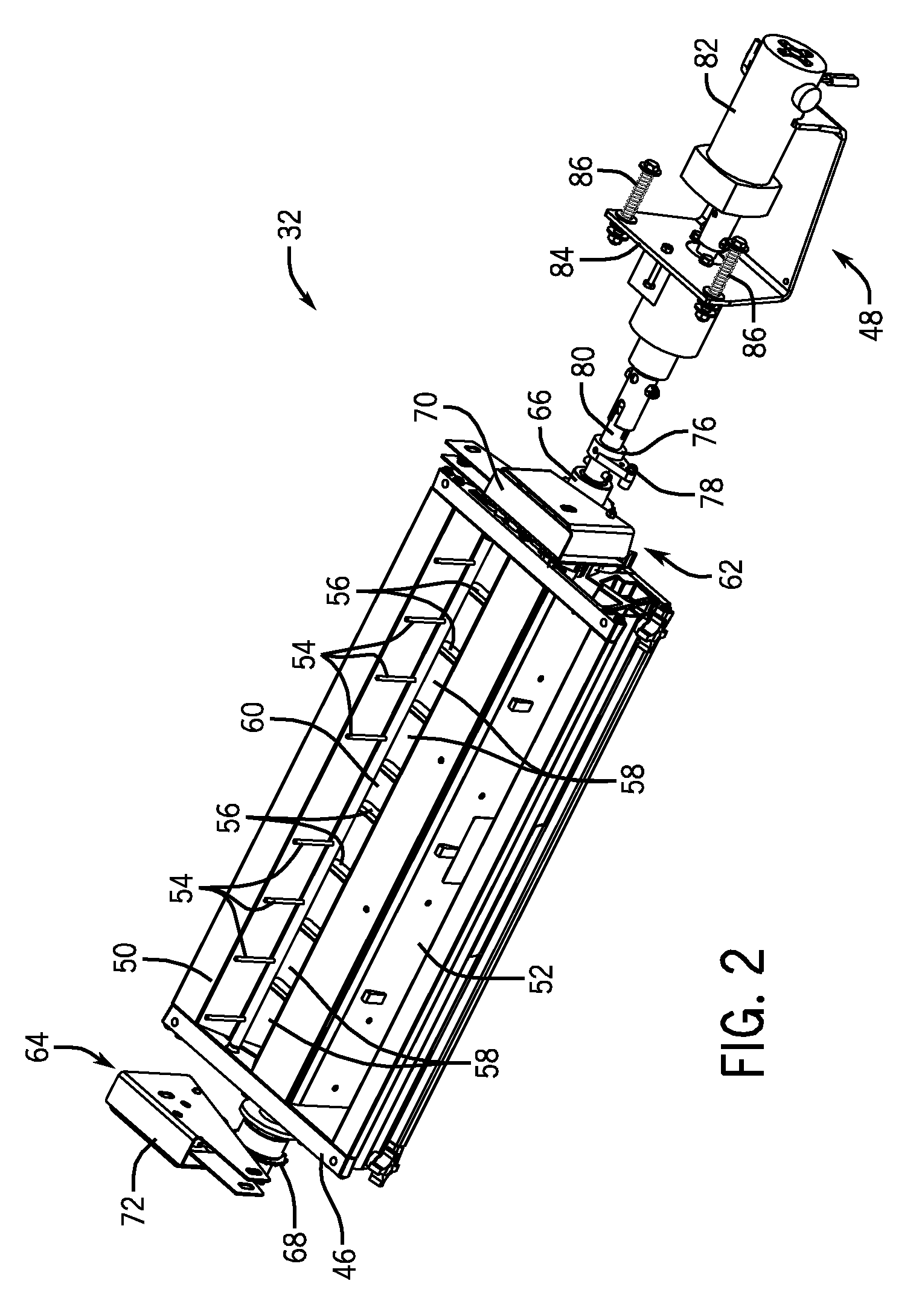

Sectioned metering system and method

ActiveUS20120325131A1Agriculture tools and machinesMetal-working apparatusEngineeringMechanical engineering

A sectioned metering system and method is provided. One metering system for distributing an agricultural product in a field includes a drive input and a rotary shaft assembly coupled to the drive input and configured to be driven in rotation by the drive input. The metering system also includes a first metering section driven by the rotary shaft assembly and at least two additional metering sections. Each additional metering section is selectively engageable to drive the respective additional metering section by the rotary shaft assembly. Each additional metering section is also selectively disengageable to interrupt driving of the respective additional metering section by the rotary shaft assembly while the first metering section remains driven.

Owner:CNH IND CANADA

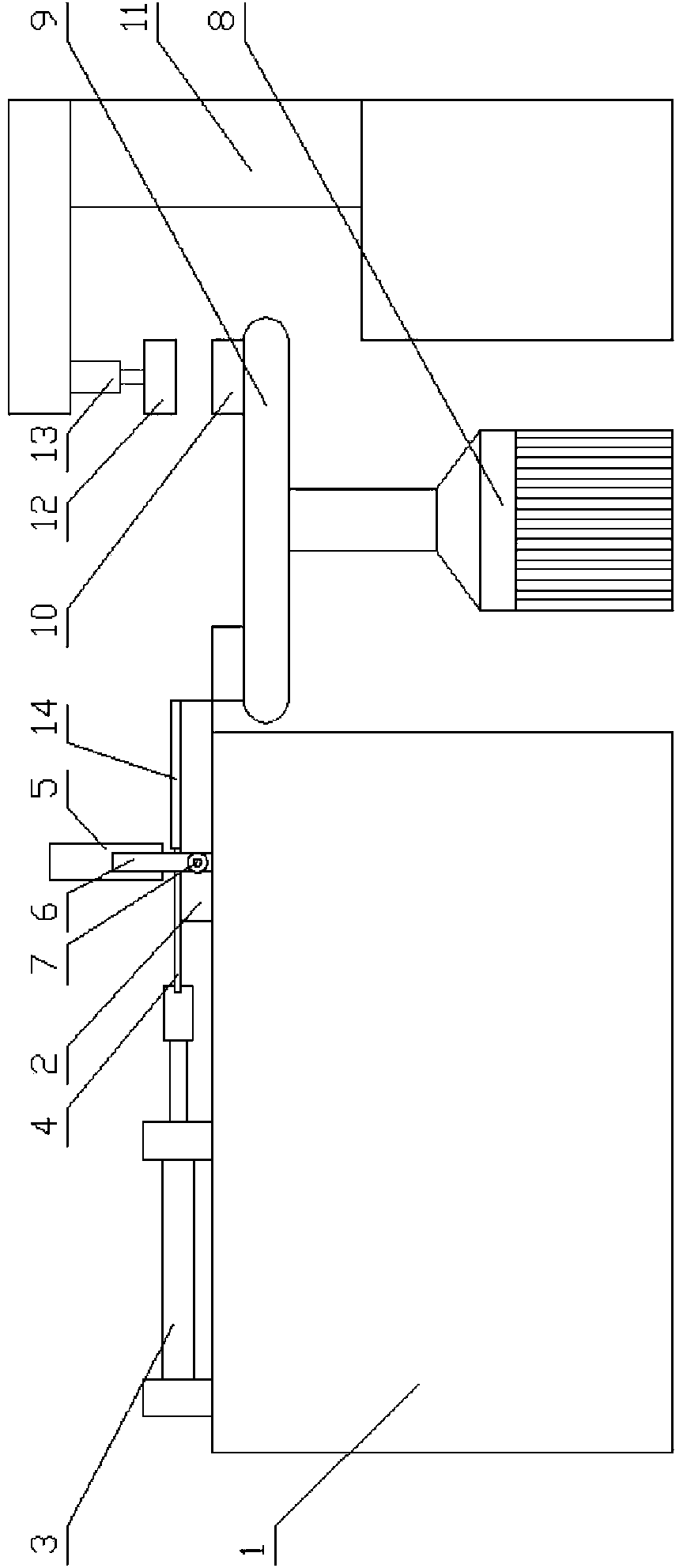

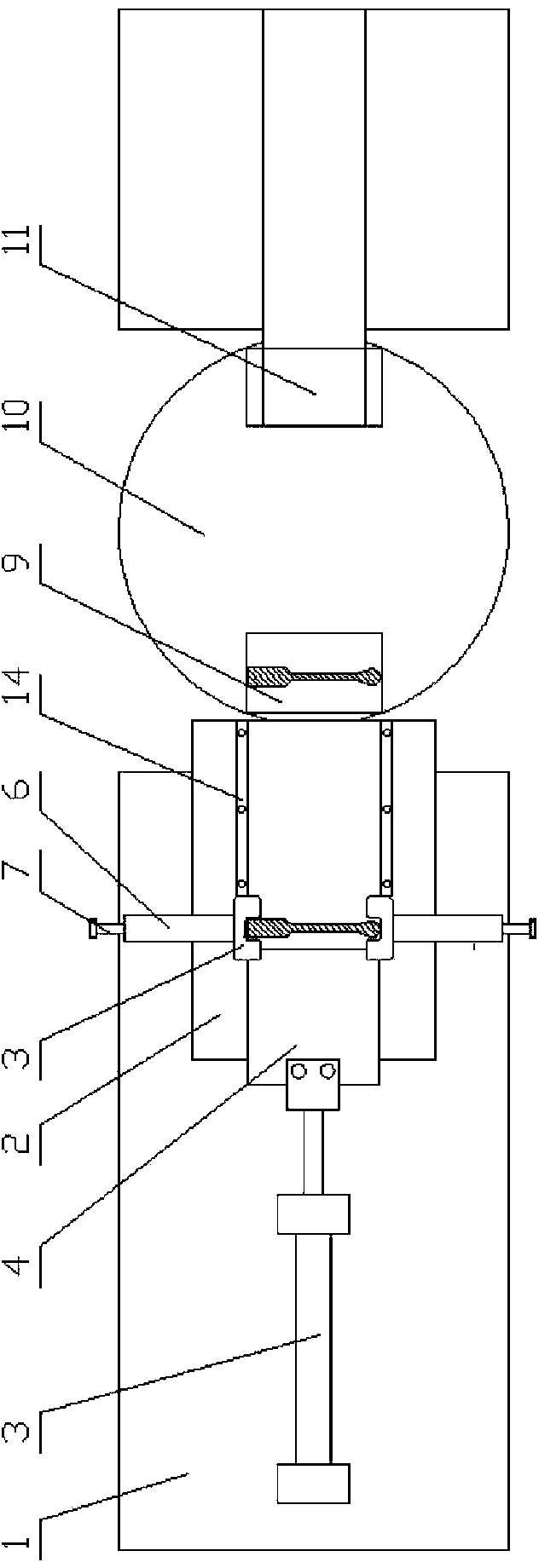

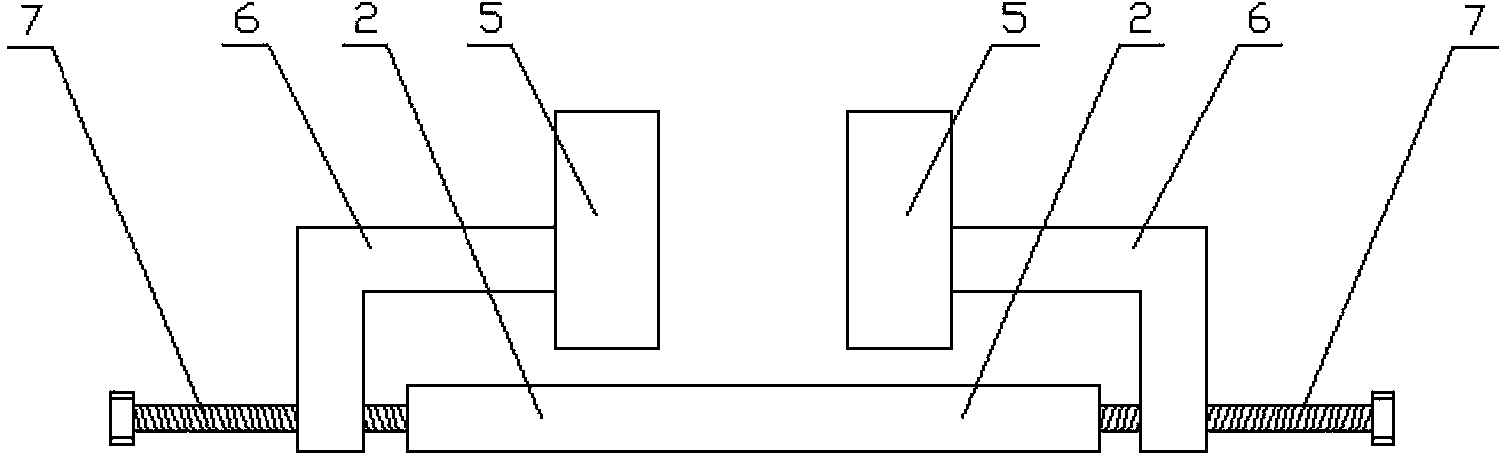

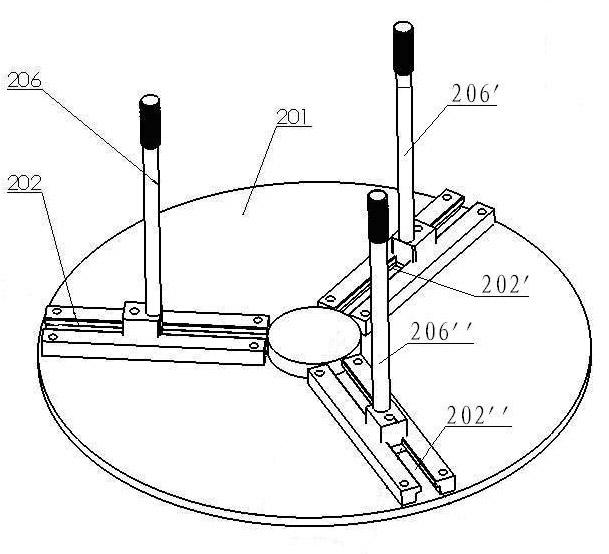

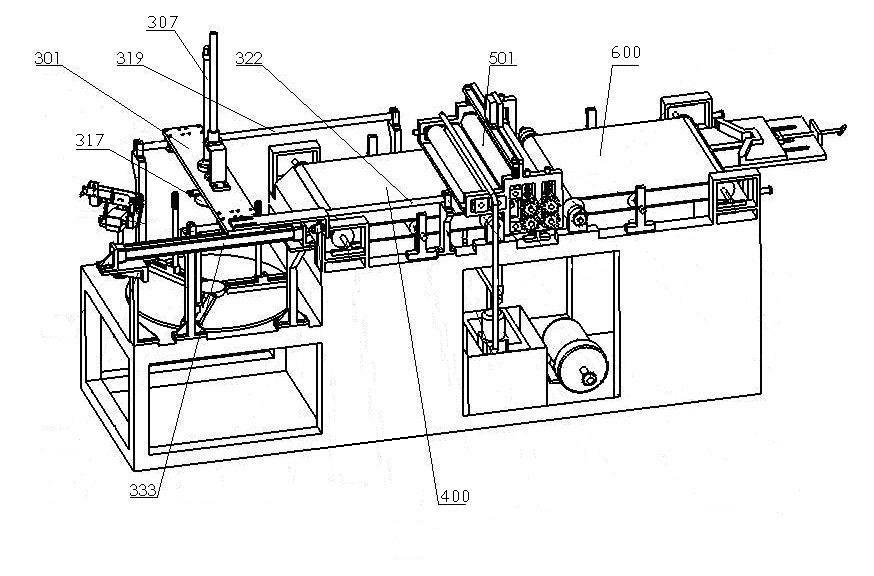

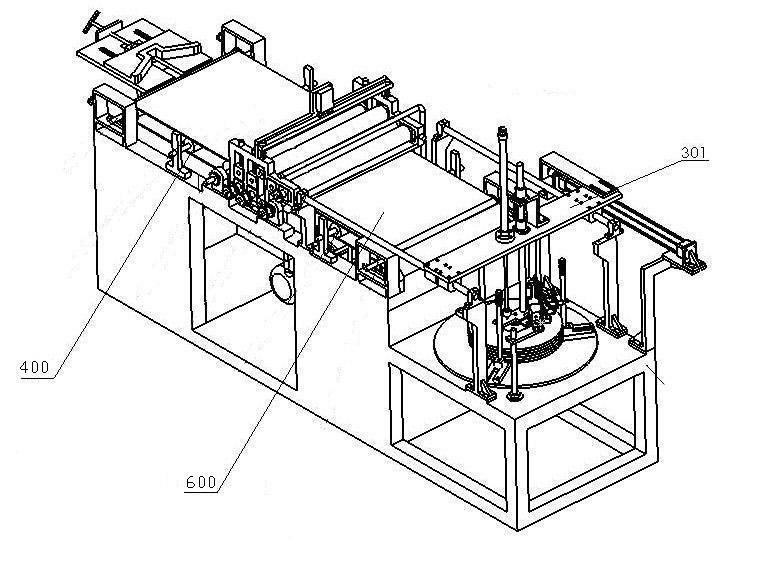

Tableware stamping and automatic feeding device

InactiveCN104368665AIncrease productivityShorten production timeShaping toolsMetal-working feeding devicesMechanical engineering

The invention provides a tableware stamping and automatic feeding device which comprises a pushing device, a rotary feeding device, a storage device and a stamping device. The pushing device comprises a base, a feeding plate and a pushing air cylinder. The pushing air cylinder is installed on the upper surface of the base. A horizontal pushing plate is installed at the front end of the pushing air cylinder. The feeding plate is horizontally arranged on the other side of the base. The storage device comprises a storage groove, fixing rods and bolts. The fixing rods are connected to the front side and the rear side of the feeding plate through the bolts in a threaded mode. The rotary feeding device comprises a rotary motor, a rotary table and two lower die bases arranged on the rotary table in a spaced mode. The output end of the rotary motor is fixedly connected to the center of the rotary table. The stamping device comprises a vertical rod, an upper stamping die and a stamping air cylinder. The stamping air cylinder is arranged at the position, facing the rotary table, of the vertical rod. The lower end of the stamping air cylinder is fixedly connected with the upper stamping die. The tableware stamping and automatic feeding device has the advantages that the working efficiency is improved, and the labor cost and operation dangerousness are lowered.

Owner:天津市津南区巨龙餐具有限公司

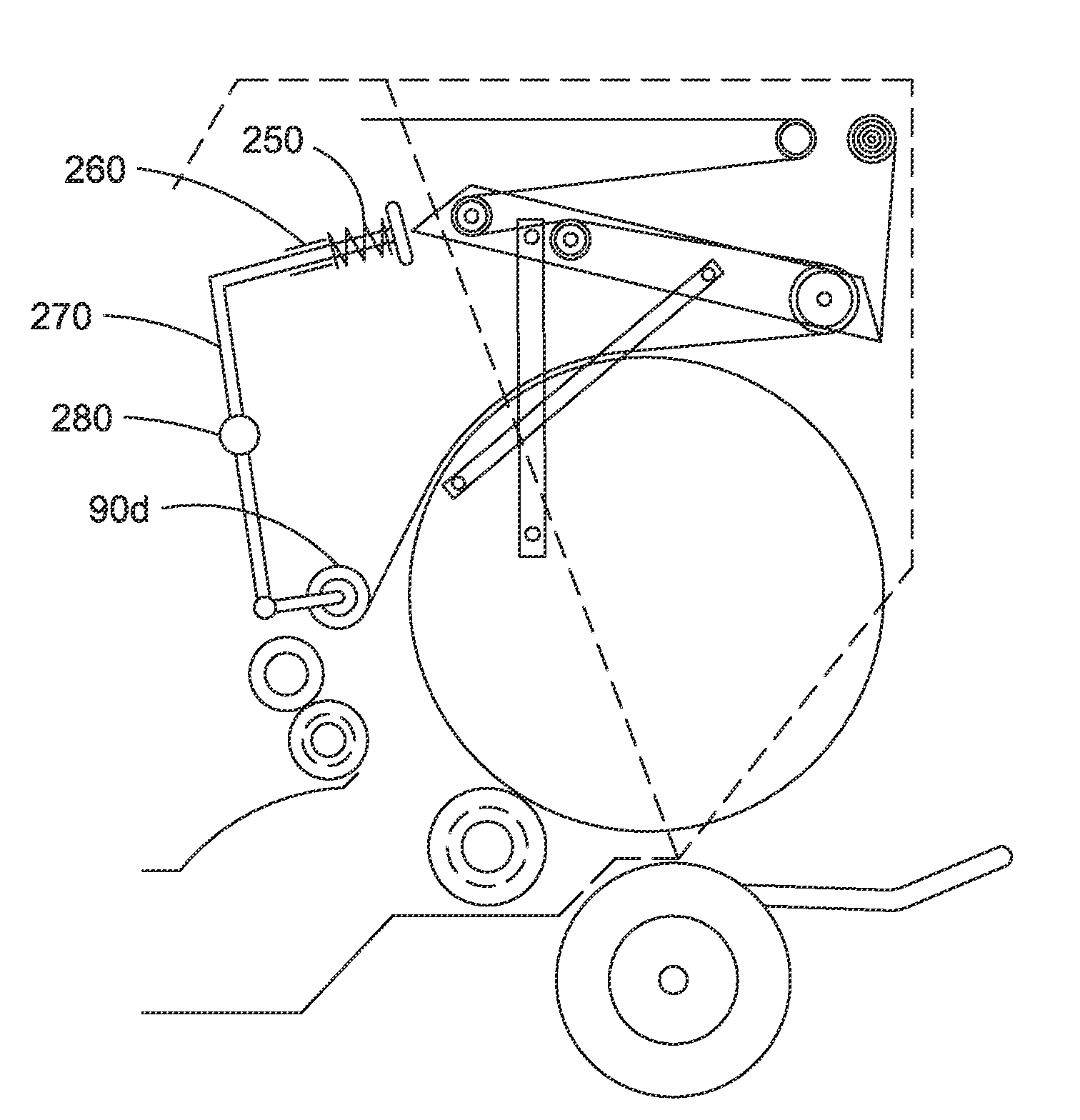

Dual-pivoted quick bale ejector for round baler

ActiveUS20130133530A1Improve efficiencyIncrease speedBalingMetal working apparatusEngineeringCombine harvester

The present invention relates to a baler ejection system that may be used with an agricultural harvester, such as a round baler, waste baler, combine, or cotton harvester. More particularly, the bale ejection system uses the motion of two pairs of parallel arms that extend transversely from the sidewalls of a bale chamber at two sets of distinct pivot points. When activated by the operator of the bale ejection system, the two pairs of parallel arms raise simultaneously to expose an outlet through which the bale may be ejected. The bale ejection system is designed to allow a larger outlet for the bale evacuation as compared to existing bale ejection systems that employ circular motion to expose the bale outlet. A formed bale may become ejected by one or more conveyer belts that exert a rearward force on the bale within the bale chamber. The bale becomes ejected through the outlet onto a field upon which the bale ejection system is operating or into a second bale chamber.

Owner:CNH IND CANADA

Knife Storage And Sharpening Apparatus

A knife storage and sharpening apparatus including a knife block having a plurality of elongate recesses each for receipt of a different knife and having a recess for receipt of a knife sharpening steel. The apparatus further includes another form of knife sharpening means specifically adapted for receipt in the recess for receipt of the steel. The knife sharpening means can be used to sharpen a knife while it is mounted in the sharpening steel recess. If the knife user prefers to use a sharpening steel, the knife sharpening means may be removed from the knife block to provide storage for the sharpening steel.

Owner:ROBERT WELCH DESIGNS

Strengthened razor blade

A razor blade including a substrate with a cutting edge, the substrate includes a mixed nitride-substrate interregion disposed at or beneath a surface of the substrate, the mixed nitride-substrate interregion being substantially free of a compound layer.

Owner:THE GILLETTE CO

Automatic deep-draw device for metal sheets

ActiveCN102489577AReduce labor intensityHigh degree of automationShaping toolsMetal-working feeding devicesComing outMetal sheet

An automatic deep-draw device for metal sheets comprises mechanisms of material stacking detection, oiling, location, centering and drawing and deep-draws metal discs. Work pieces are conveyed among the mechanisms through a feeding system including a vacuum chuck driven by a cylinder. The material stacking detection mechanism adopts a pair of detection pincers with a displacement amplification function to detect the thickness of the metal sheets sucked up from a material storage disc and avoid material stacking. The work pieces are conveyed from a first level feeding mechanism to a first section belt, enter the oiling mechanism and come out from a second section belt. The oiling mechanism comprises two pairs of oiling rollers and matched oil storage and conveyance rollers. After the V-shaped location and the four-claw disc centering, the metal sheets are conveyed into an oil press for drawing through a portal frame provided with a sucking disc and the like. The automatic deep-draw device for metal sheets is simple but achieves the purpose of improving work efficiency and quality and being safe in production, and is easy in popularization and application and suitable for middle andsmall enterprises in deep-draw processing of the metal sheets.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

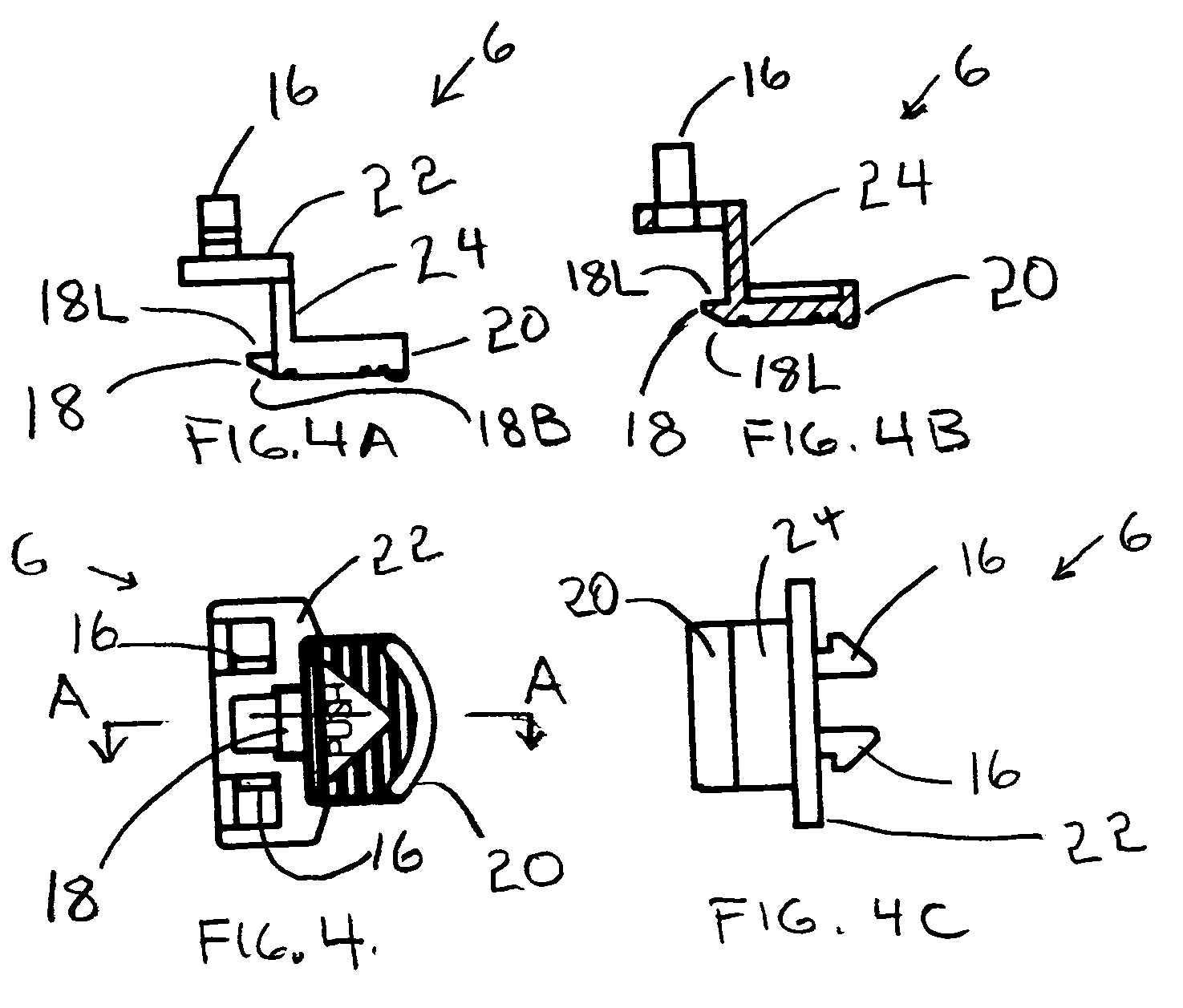

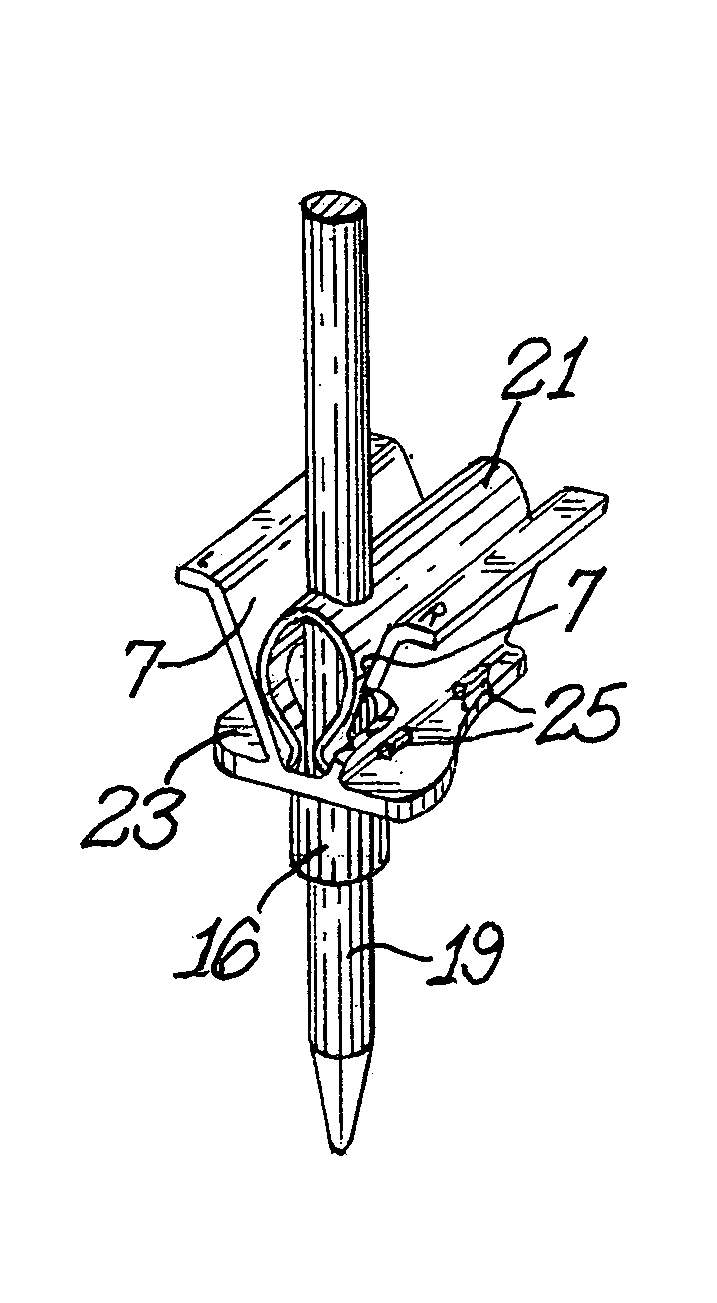

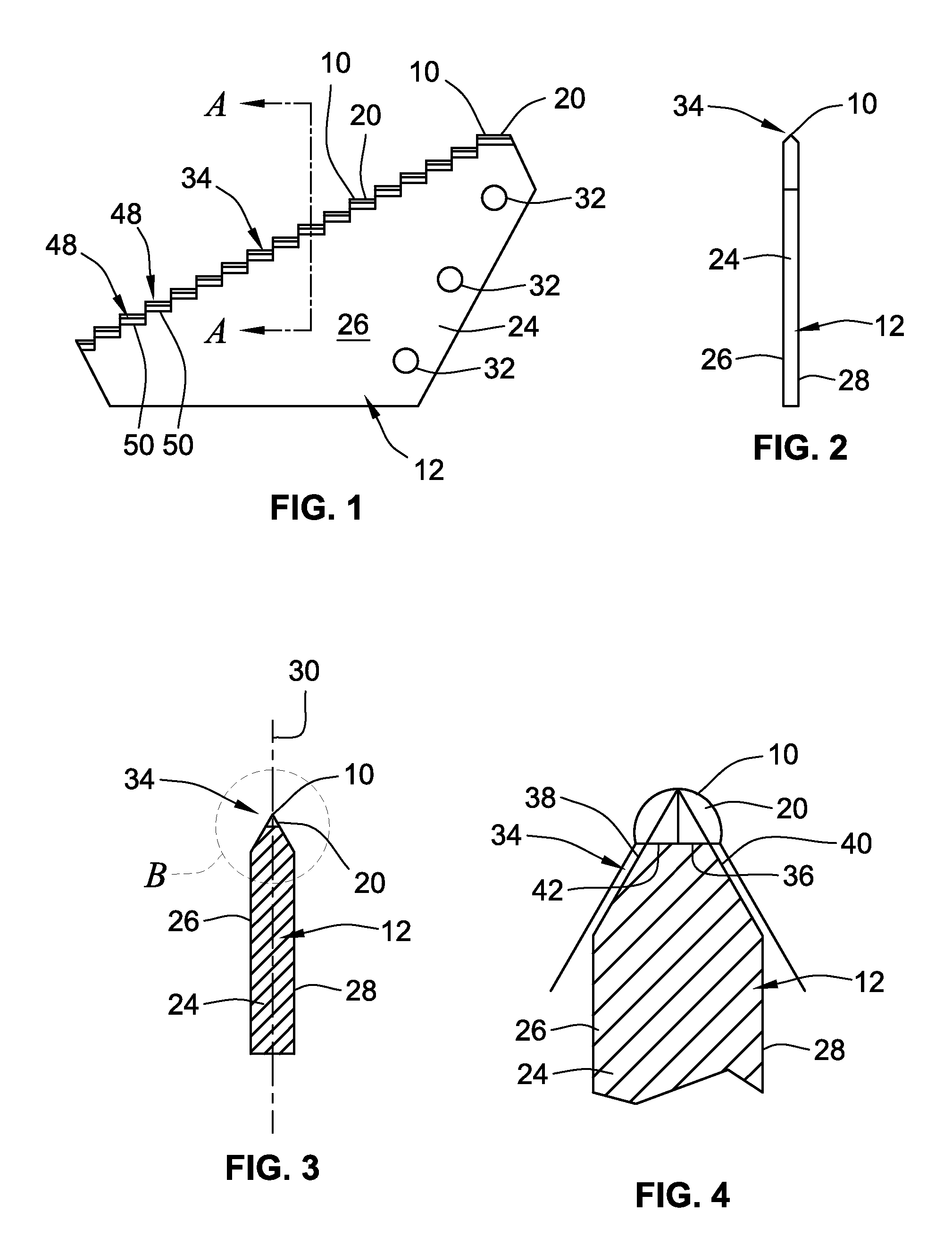

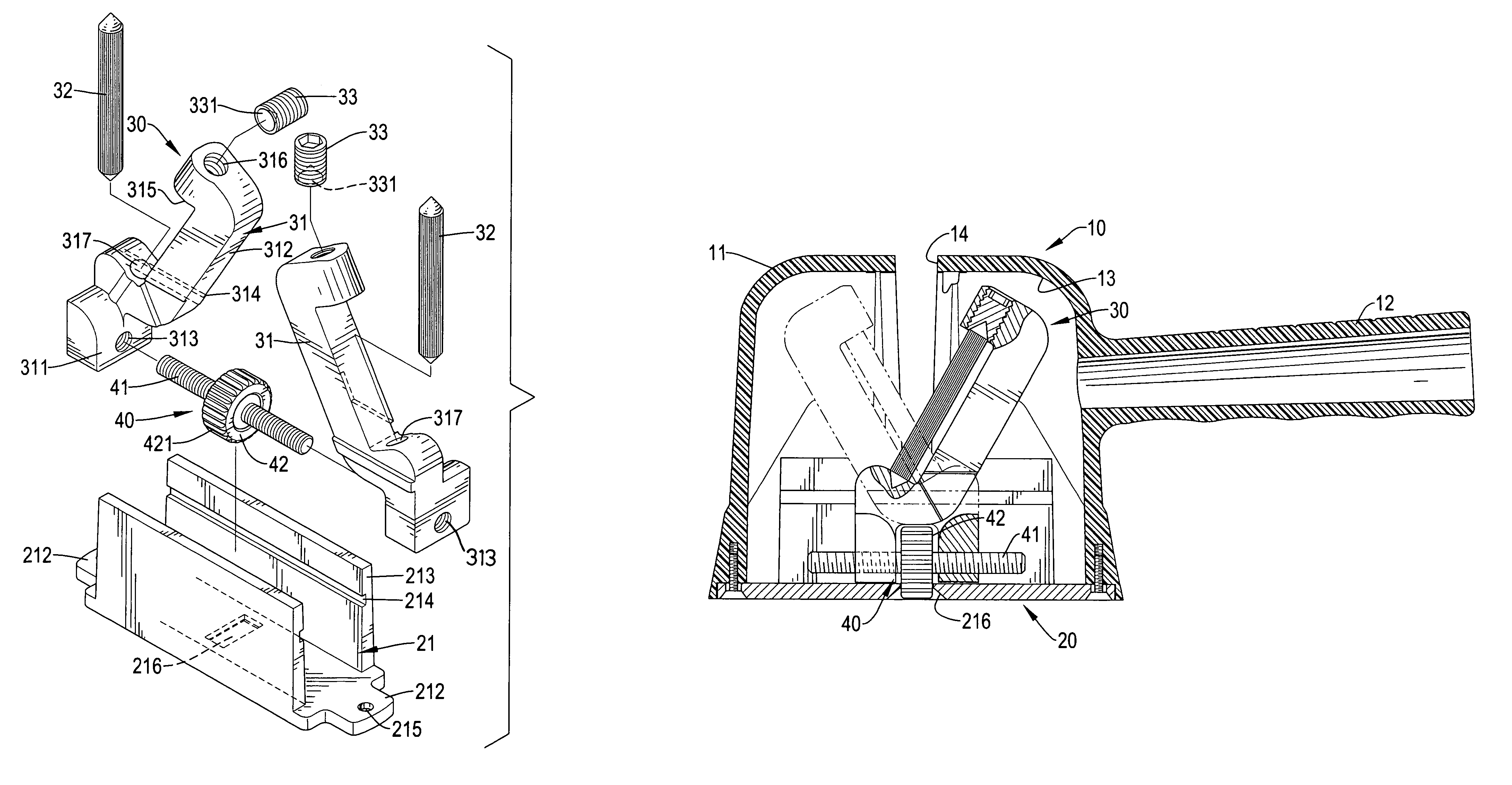

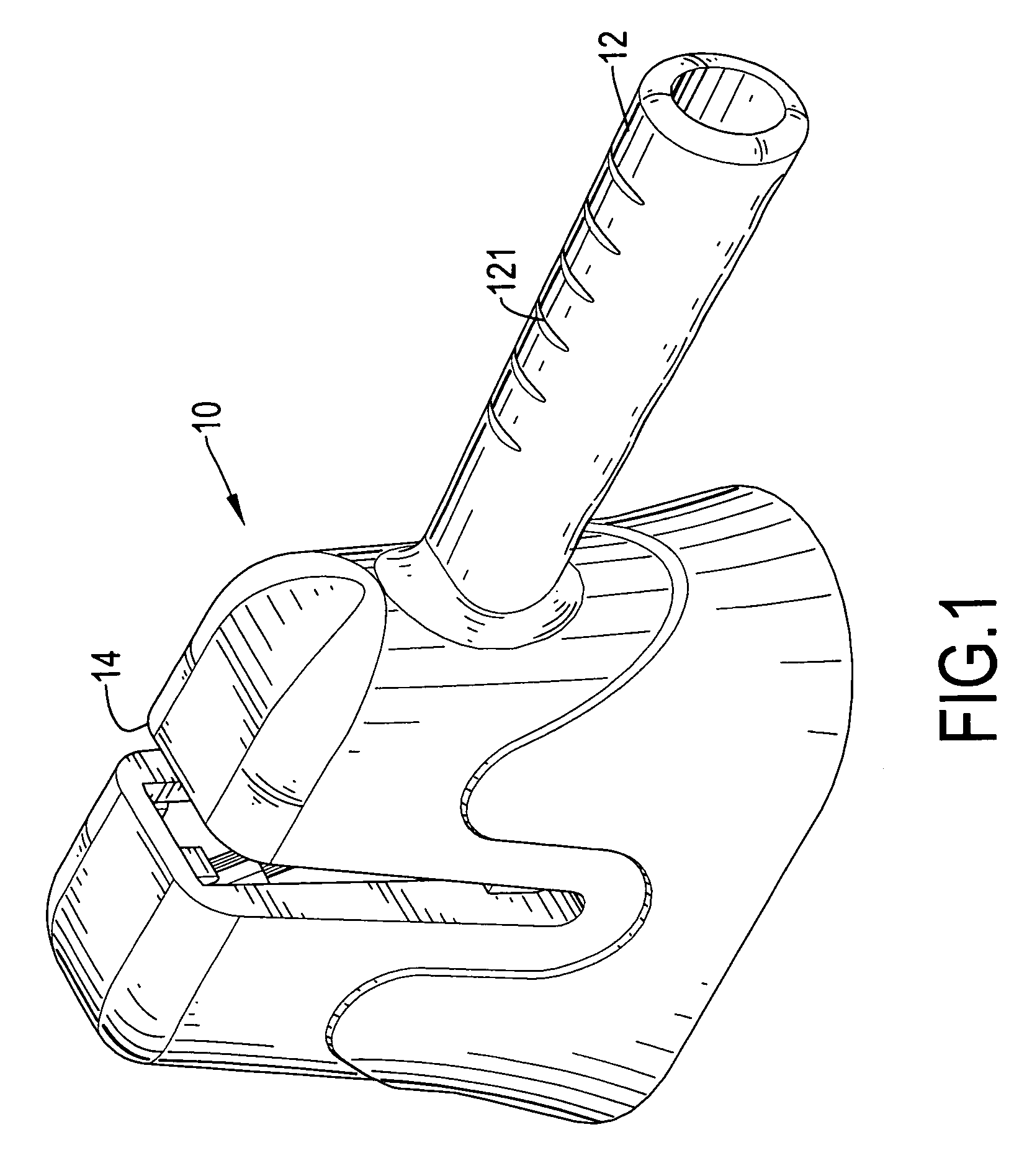

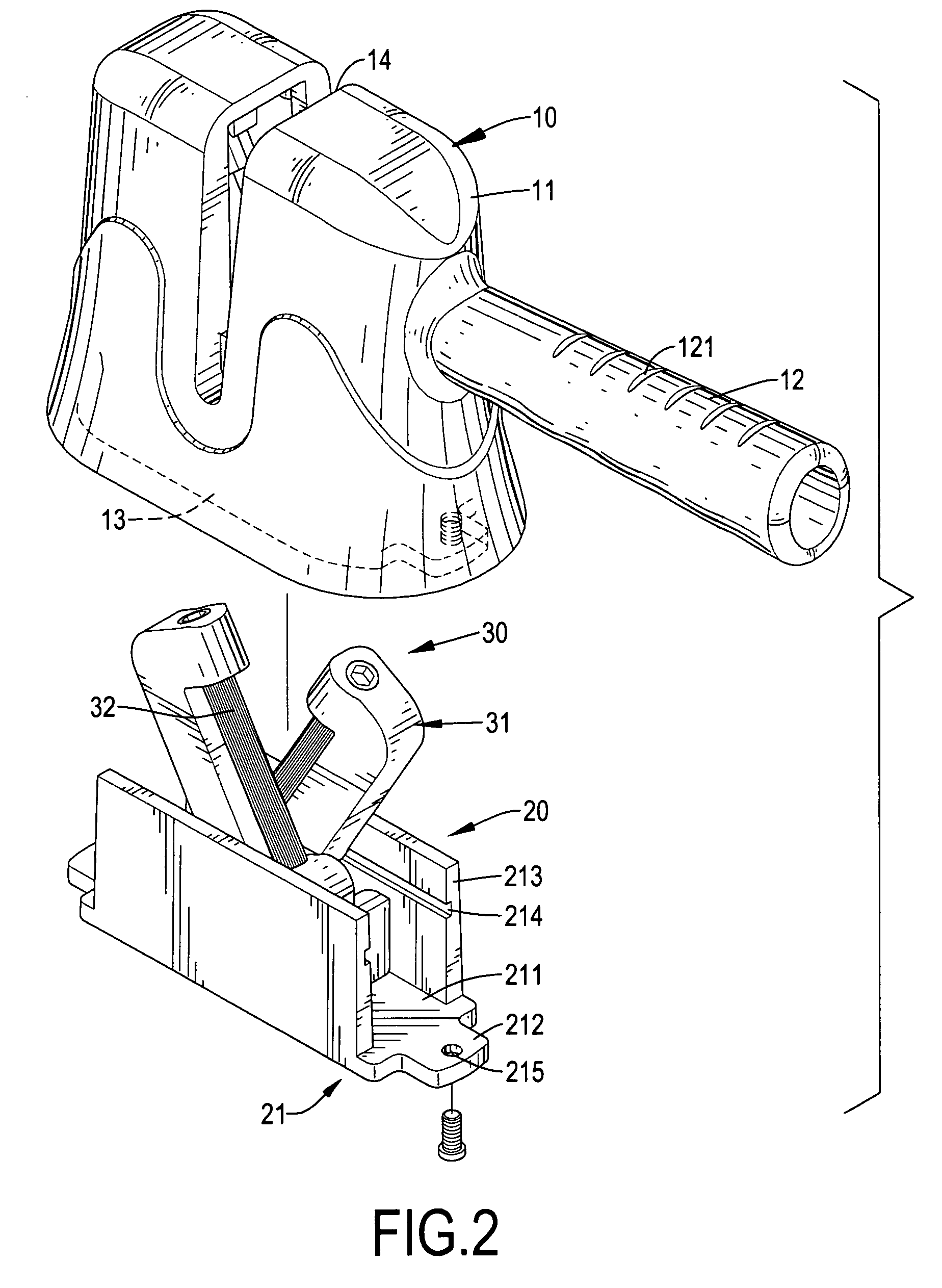

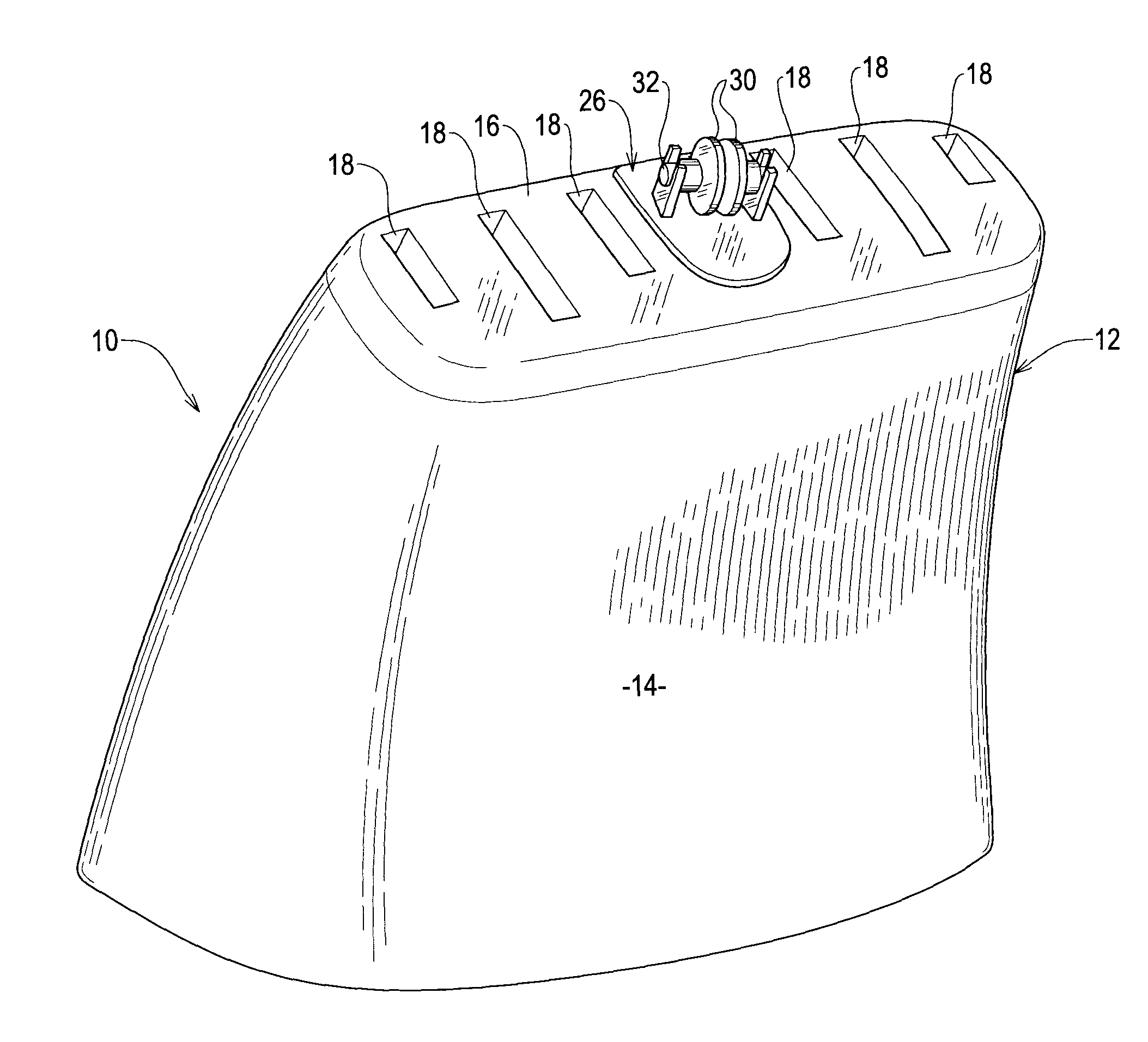

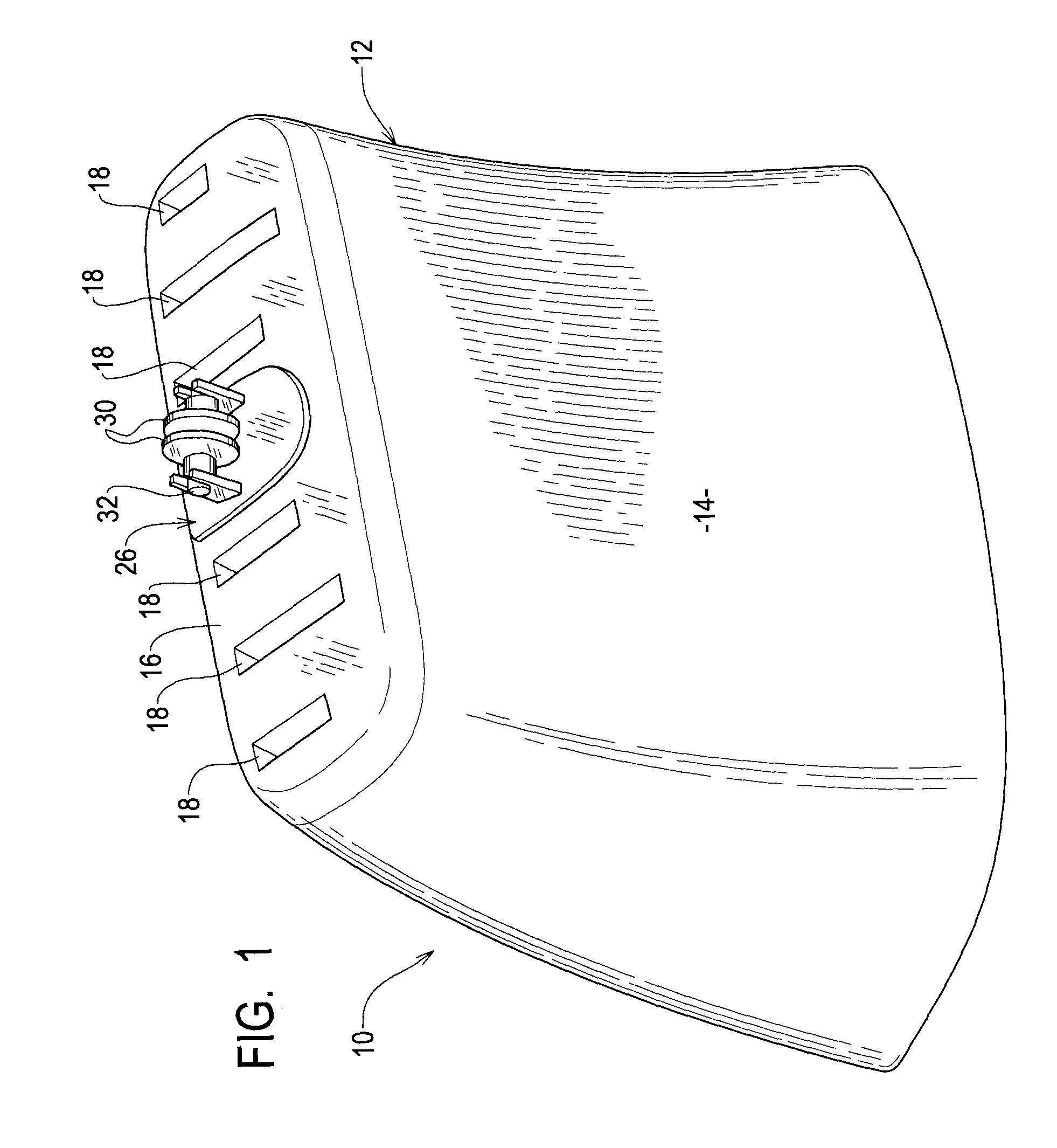

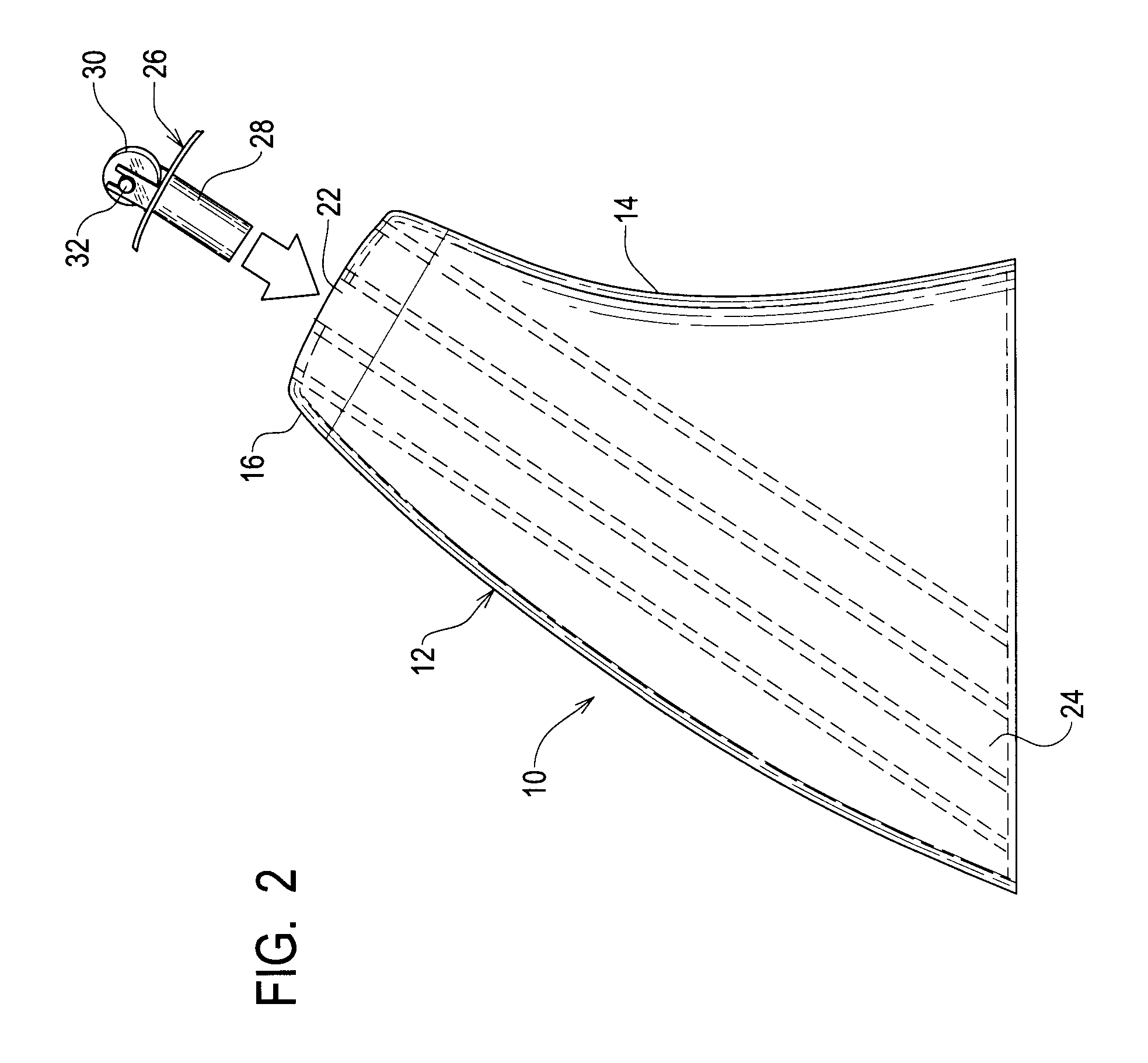

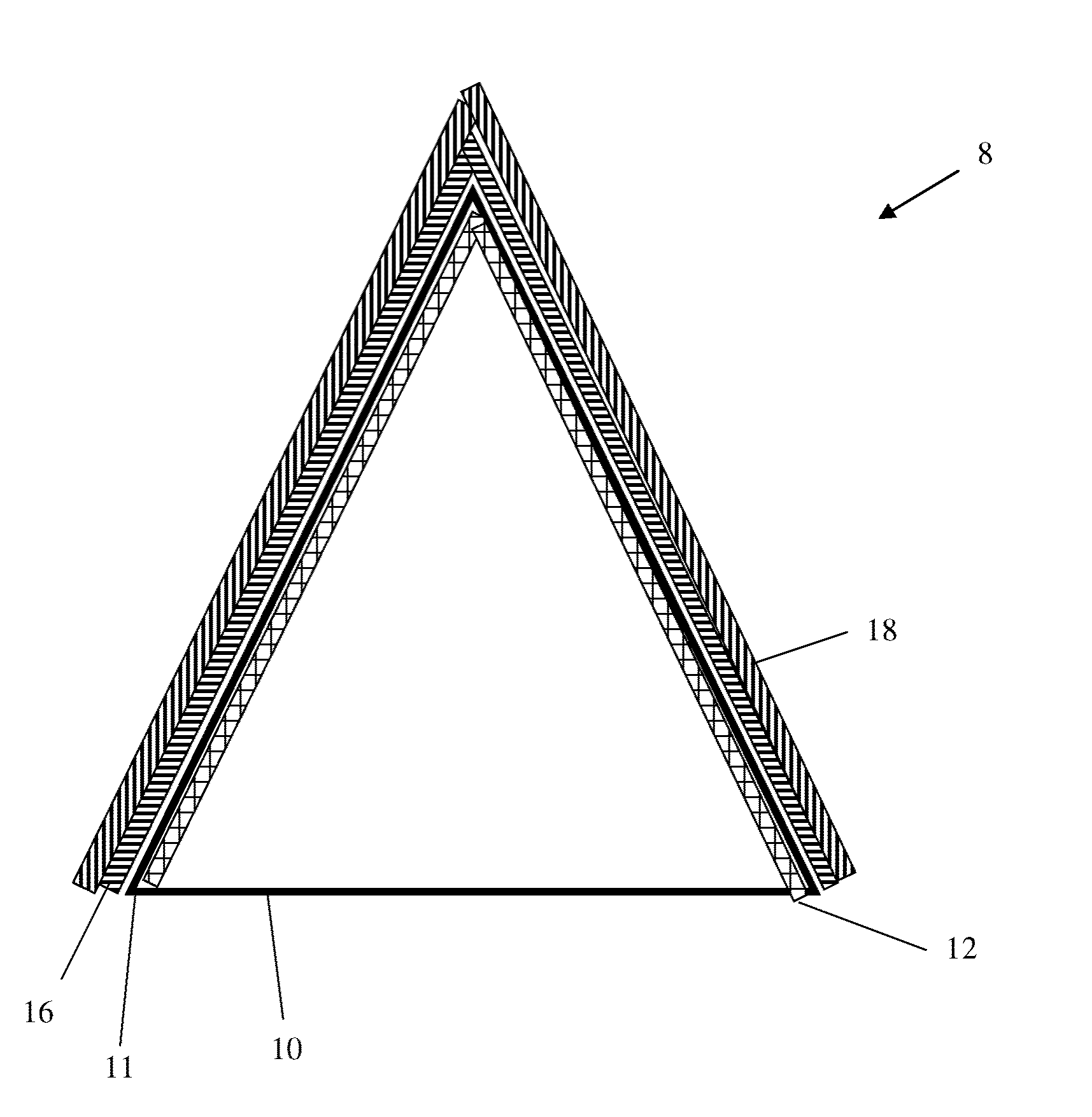

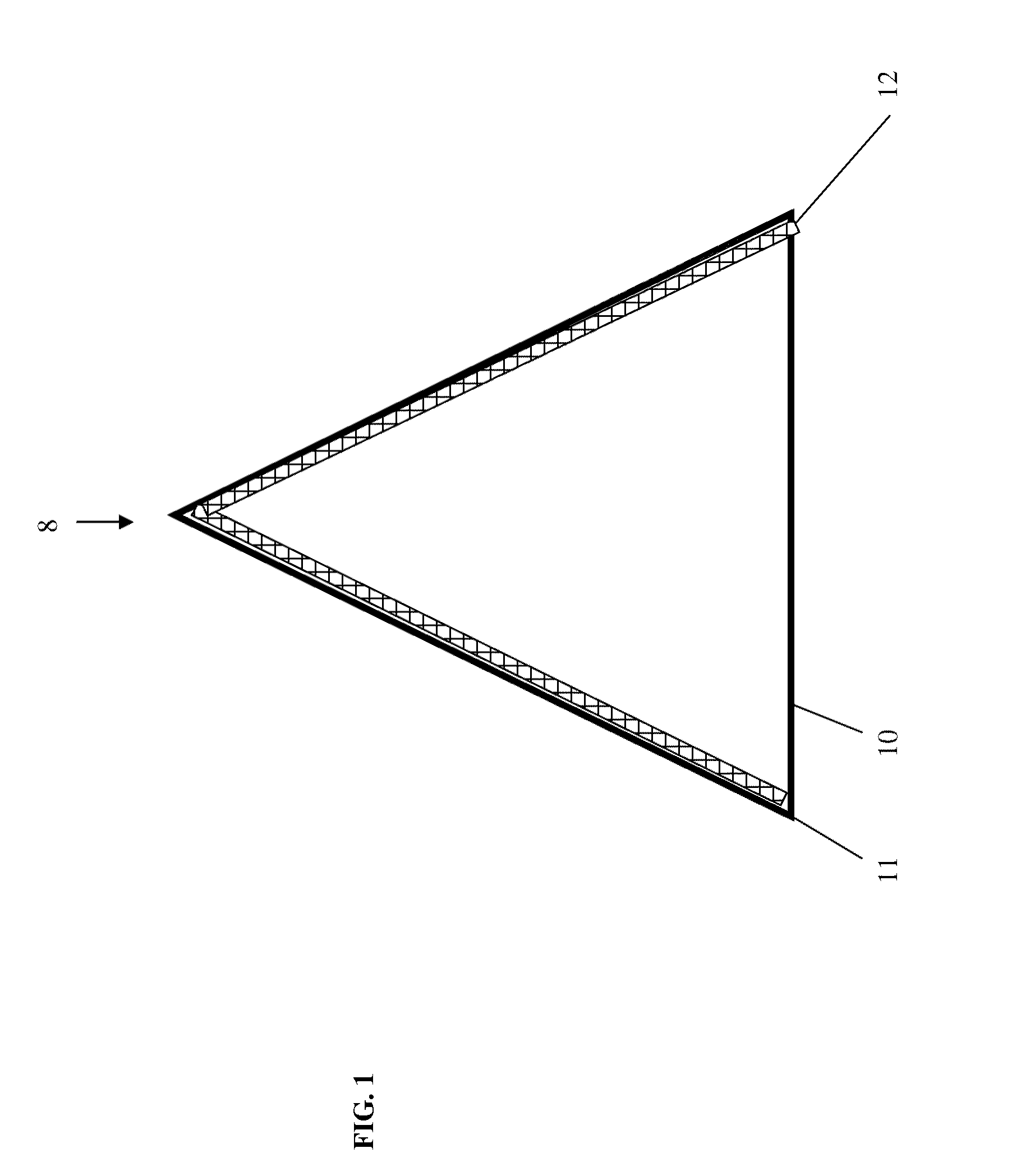

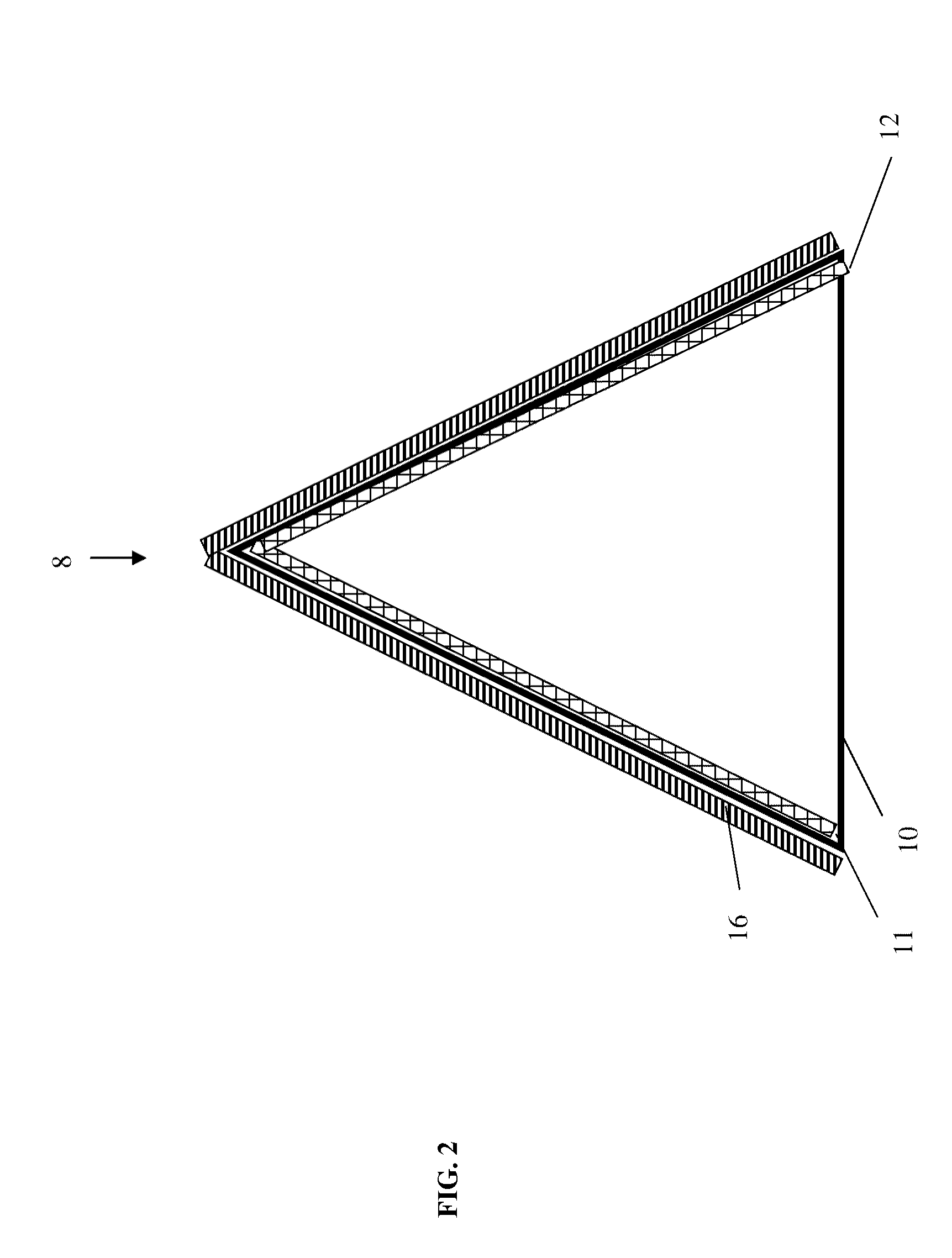

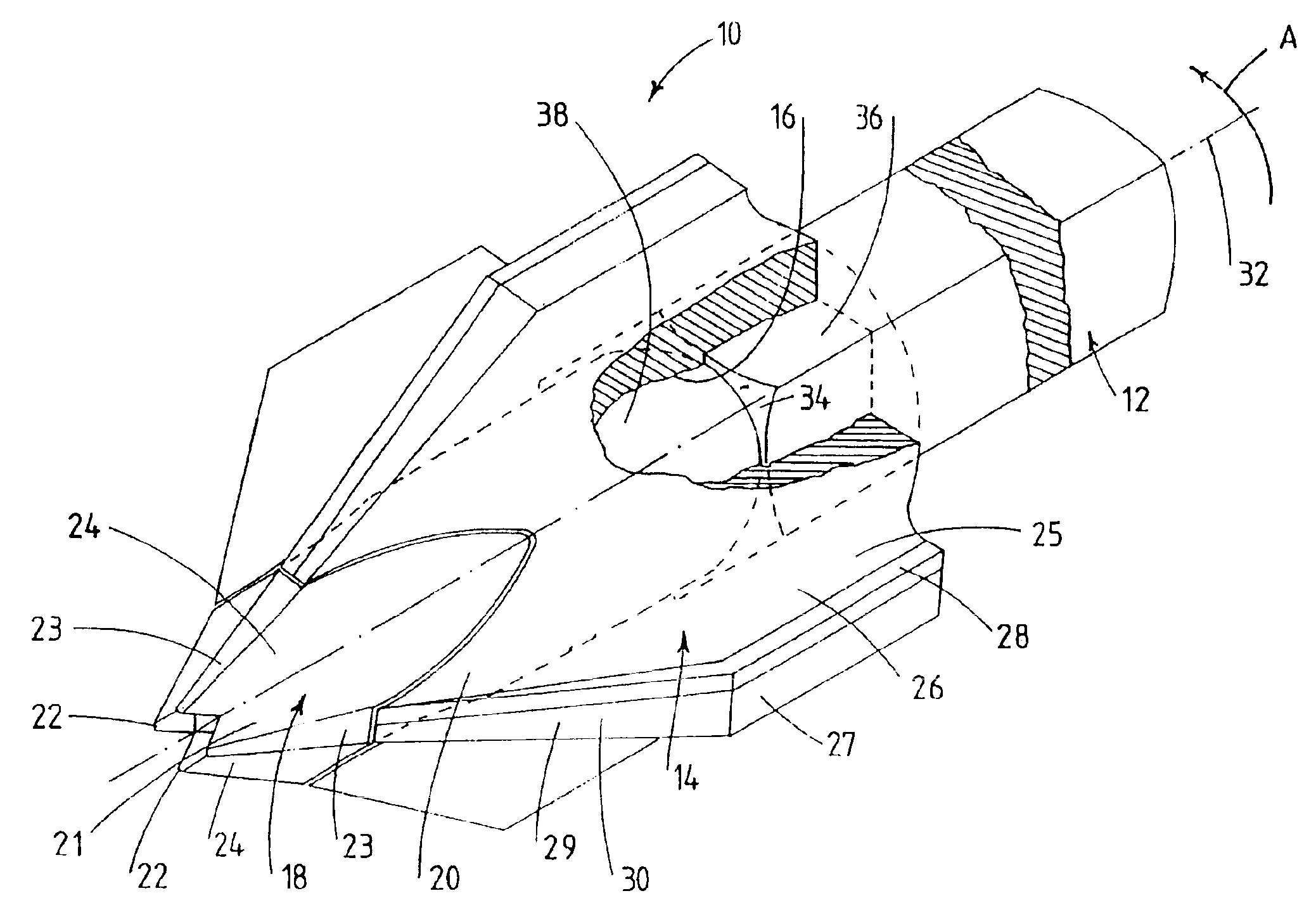

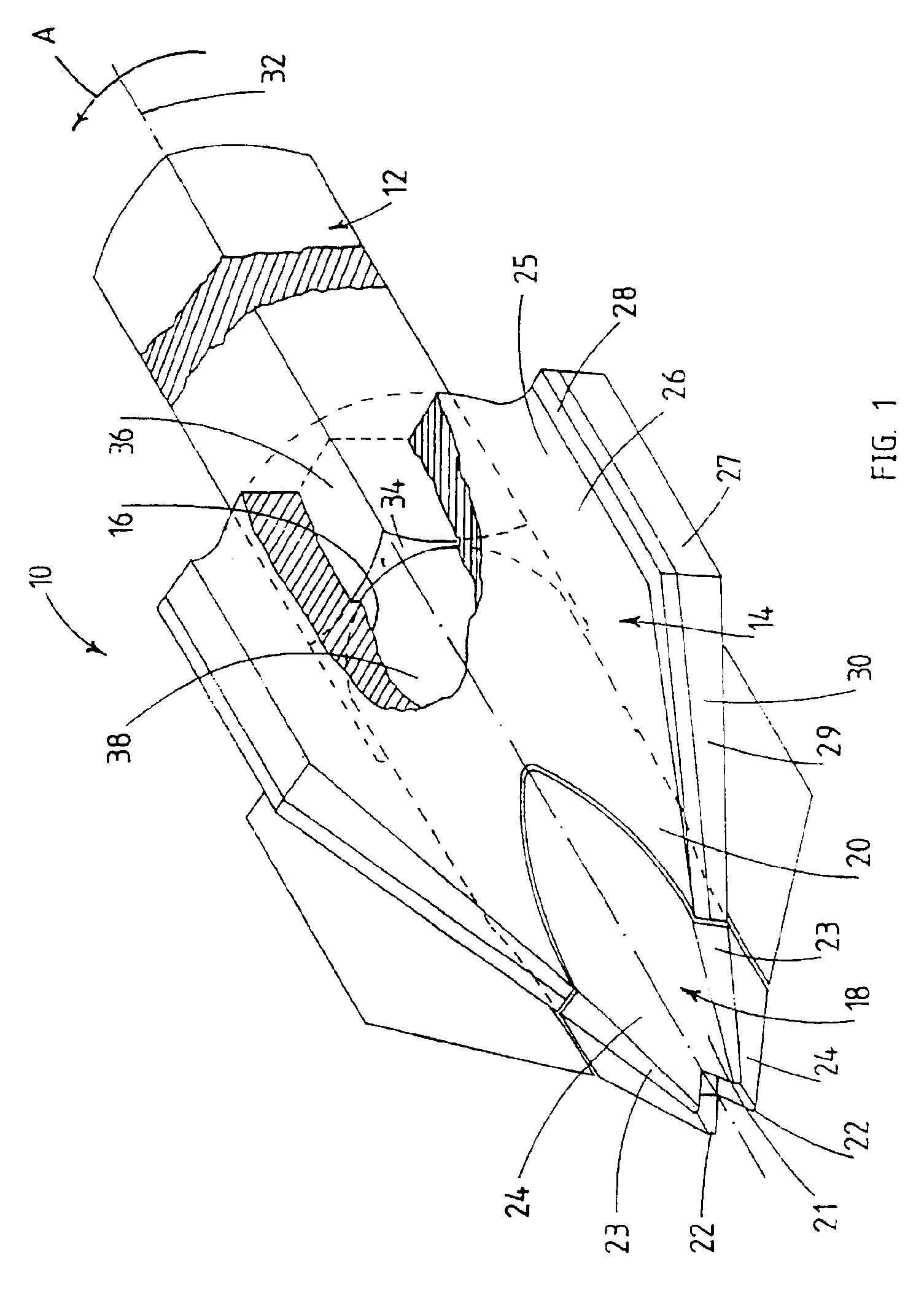

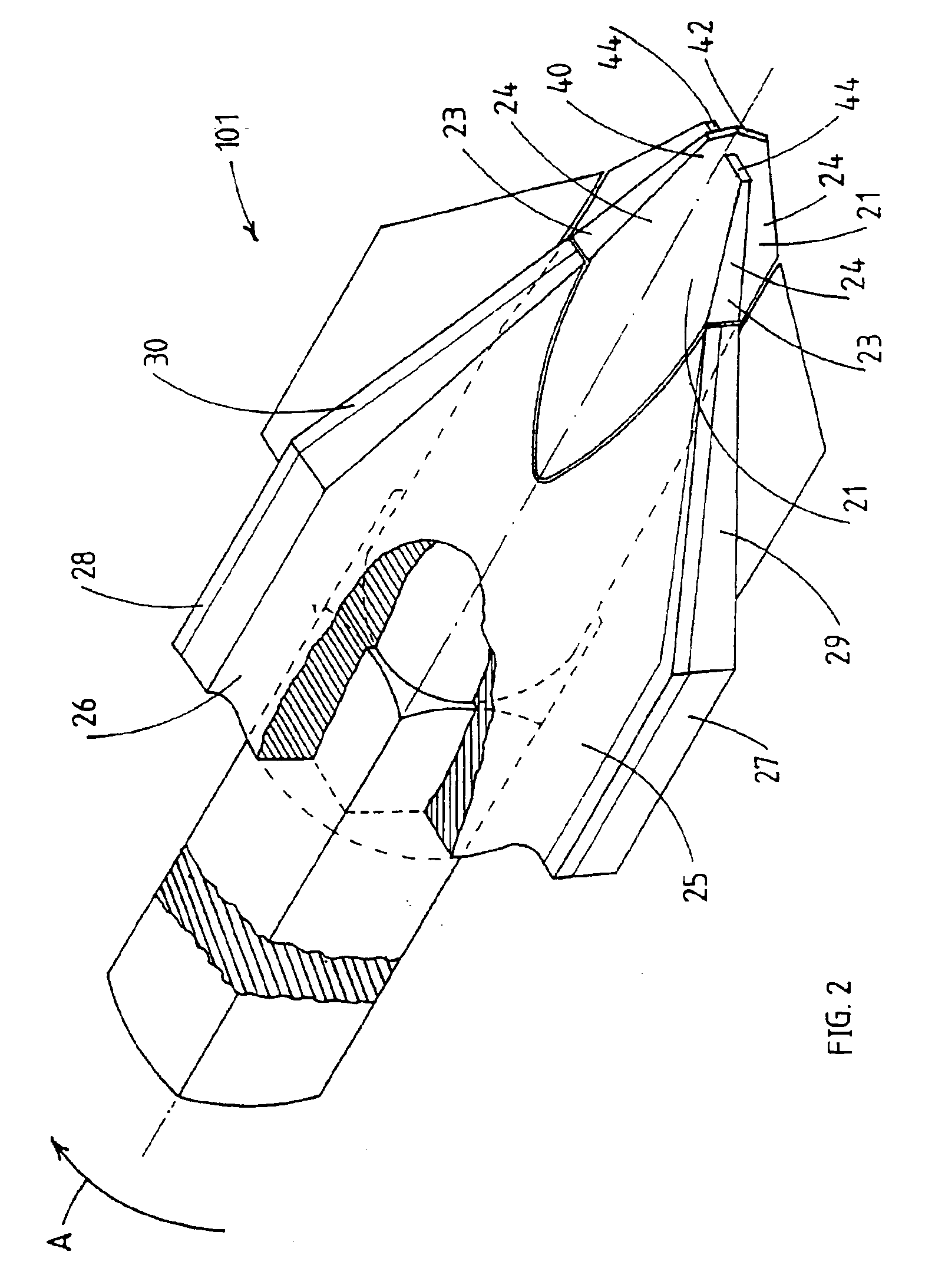

Screwdriving and countersinking bit

The invention provides a bit (10) for use with a rotatable tool, said bit including: a shaft (12) having a rearward end adapted to be held by a chuck of the rotatable tool, and a forward end (18) having cutting tips formed thereon; a reaming head (14) including a body having a bore (16) adapted to receive the shaft therethrough in a sliding fit, the body having a plurality of cutting blades (26) formed on at least one peripheral surface thereof; the bore and / or the shaft having formations thereon such that when the rearing head has the shaft operatively located in the bore the reaming head is rotationally locked into the shaft; the reaming head and the shaft being separable from each other to allow either component to be replaced independently of the other. The invention also provides a bit having a tip end and shank end for use with a rotatable tool, said bit having at least 4 blades (24) to engage ard drive a screw when said rotatable tool is rotated, each blade including at said tip end a bevel so as to form a cutter (22) at the extremity of said blade, each bevel and / or cutter being able to cut in the same rotational direction. The invention further provides a method of making a bit for use as a screwdriver and countersinker, said method including the steps of: 1) forming at least a four blade screw driving end onto one end of blank, 2) forming a bevel at the extremity of each blade, said bevel producing an inclined plane cutter.

Owner:SAVETIME PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com