Automatic deep-draw device for metal sheets

A metal sheet and metal disc technology, applied in the field of metal sheet automatic processing devices, can solve the problems of high production technical requirements, unsuitable for production batches, unstable processing quality, etc., to improve work efficiency and operation quality, easy to popularize and apply, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

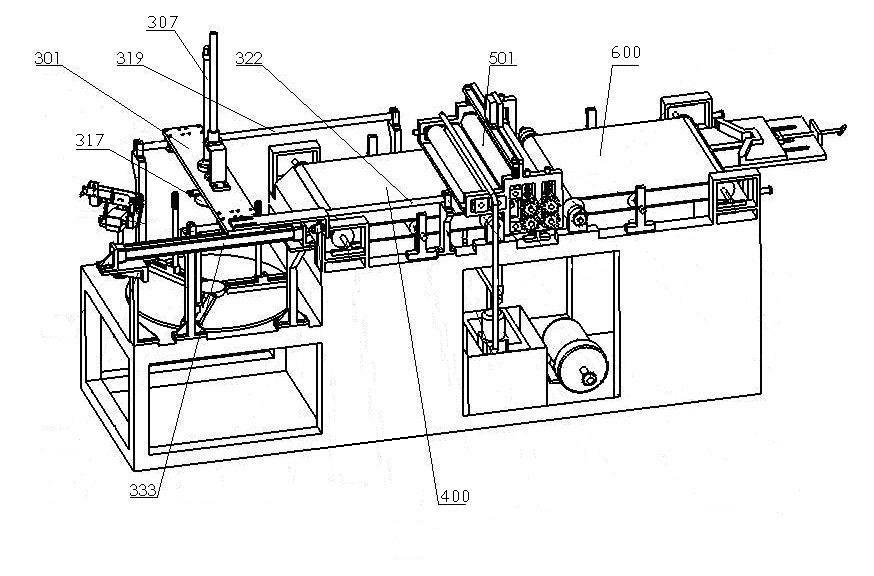

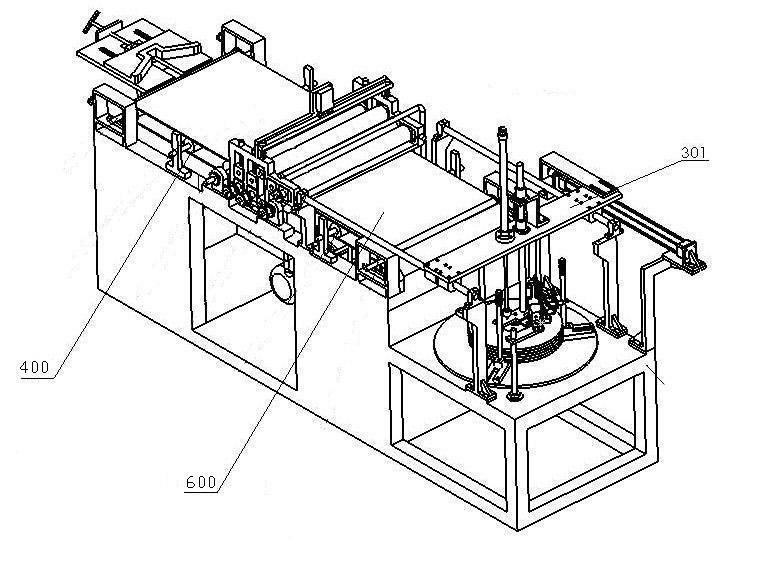

[0039]On a frame arranged in an "L" shape, the mechanical part of the stretching device of the present invention is installed, and the console of the device is separately provided with an automatic control area and a manual control area. Manipulate the operation of each equipment machine in the rack. Such as figure 1 As shown, the equipment of the device of the present invention includes a stacking detection mechanism 100, a three-claw storage tray 200, a first-stage feeding mechanism 300, a first section belt 400, an oiling mechanism (500), and a second section belt 600, a positioning device 700, a second-stage feeding mechanism 800, a four-jaw centering disc 50, a third-stage feeding mechanism 900, and the hydraulic press 1 and the deep drawing die 2 inside it.

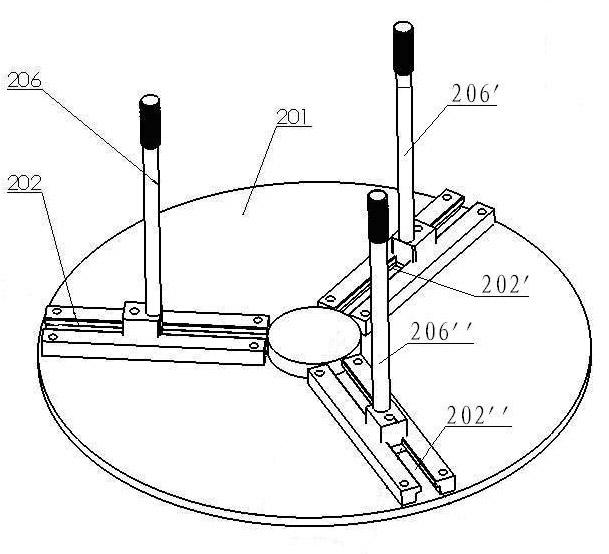

[0040] The feeding detection mechanism 100 of the device of the present invention includes a three-claw storage tray 200 and a stacking detection mechanism 100 . Such as figure 2 , image 3 As shown, the stack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com