Patents

Literature

1092results about How to "Improve job quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

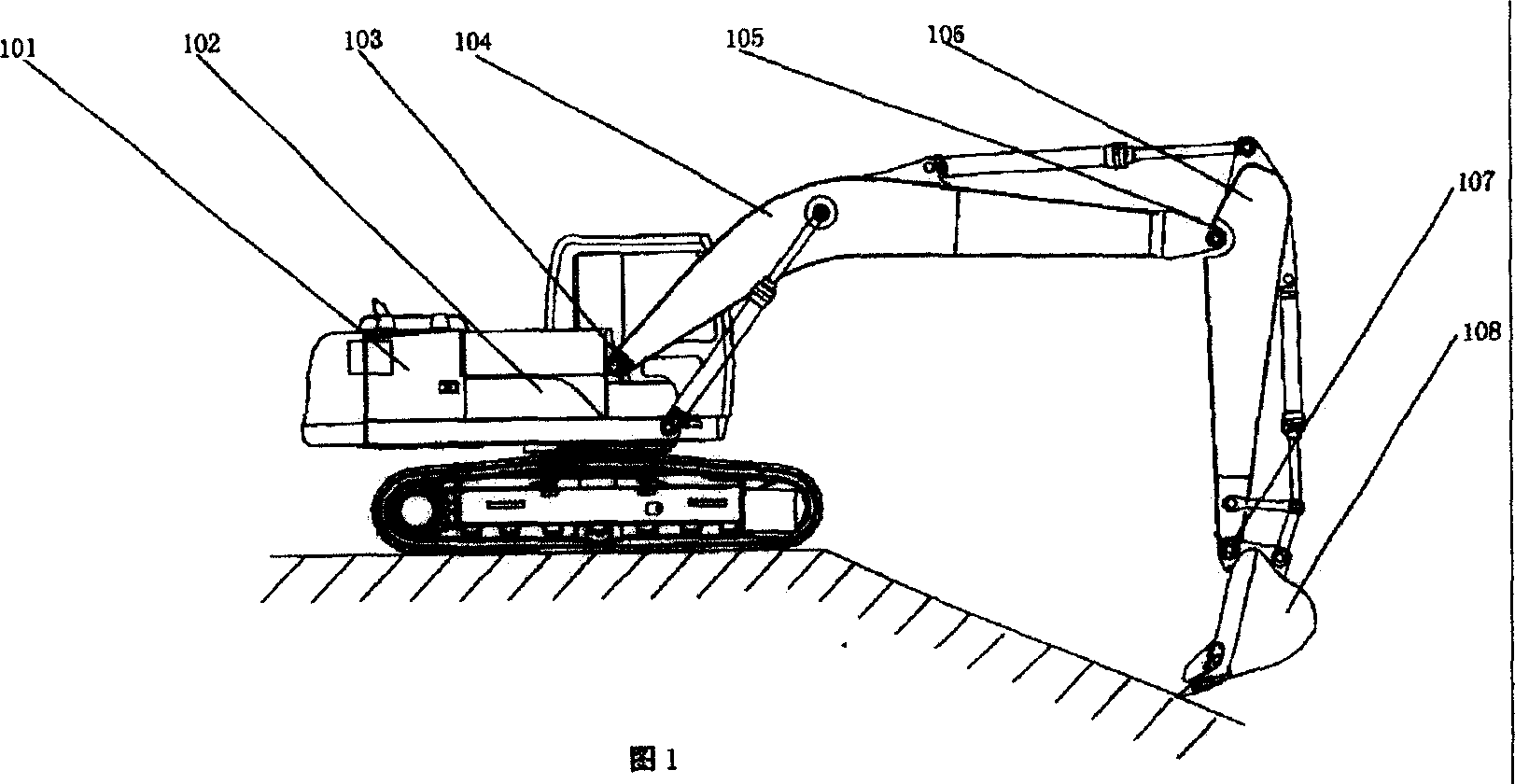

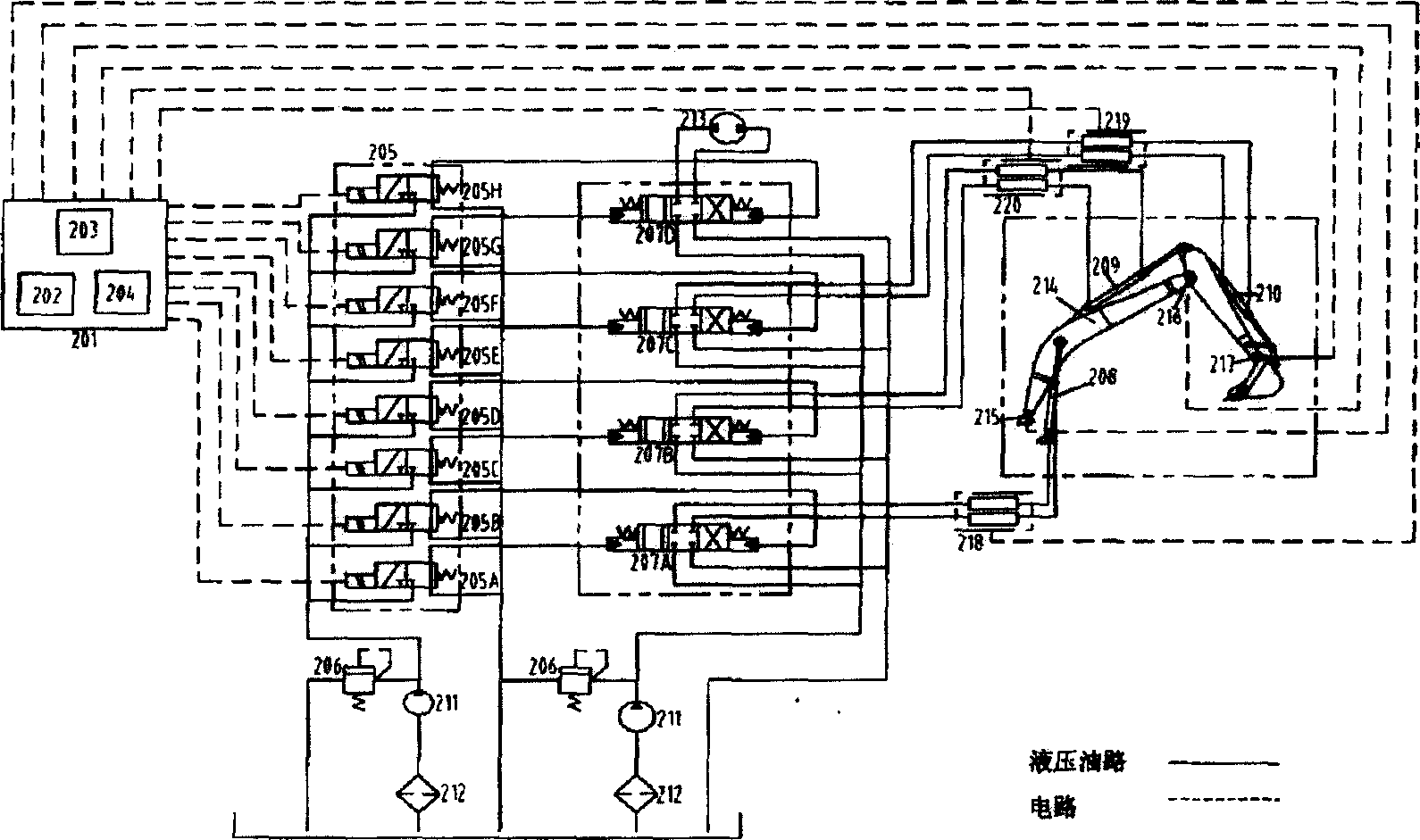

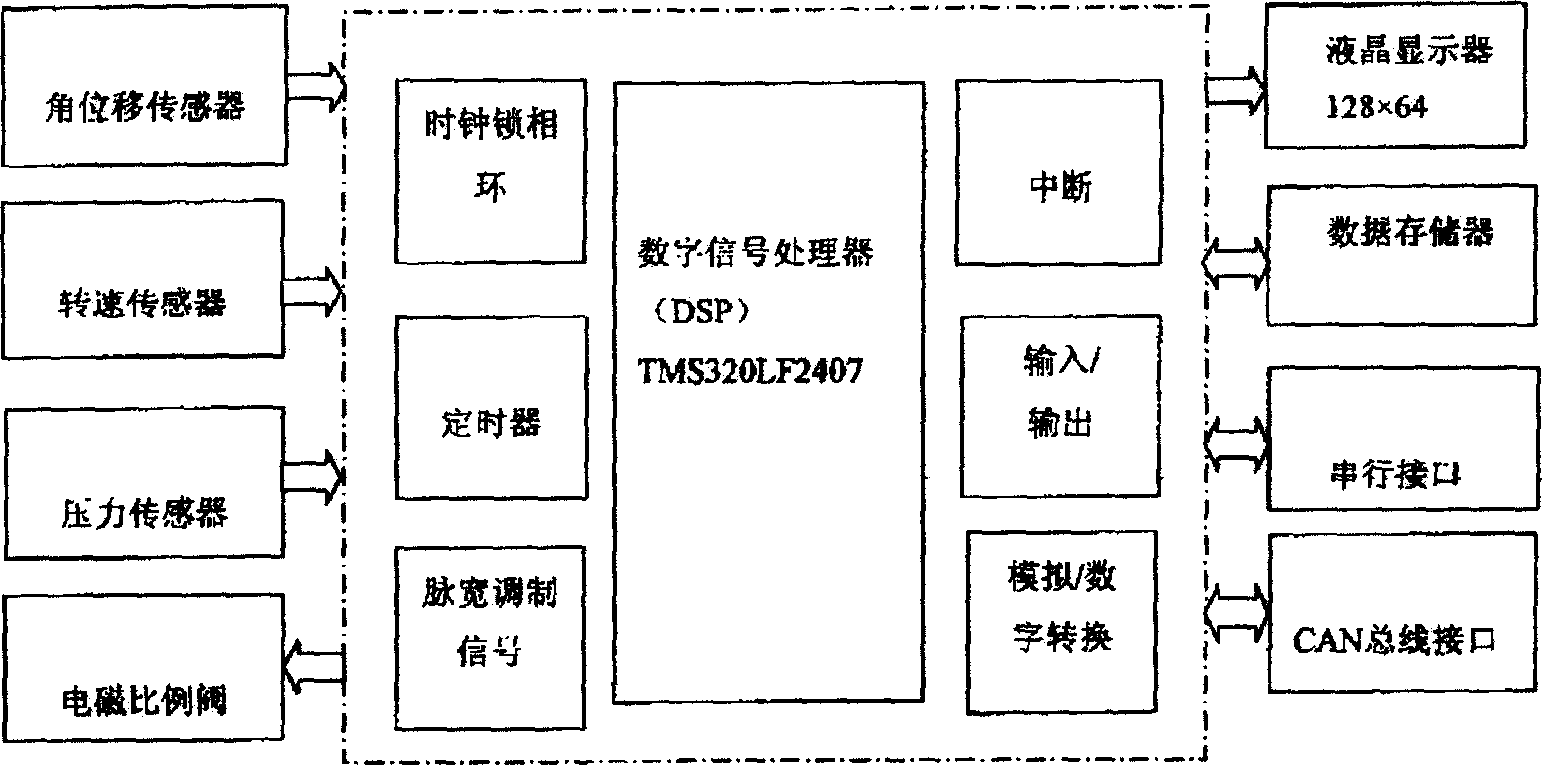

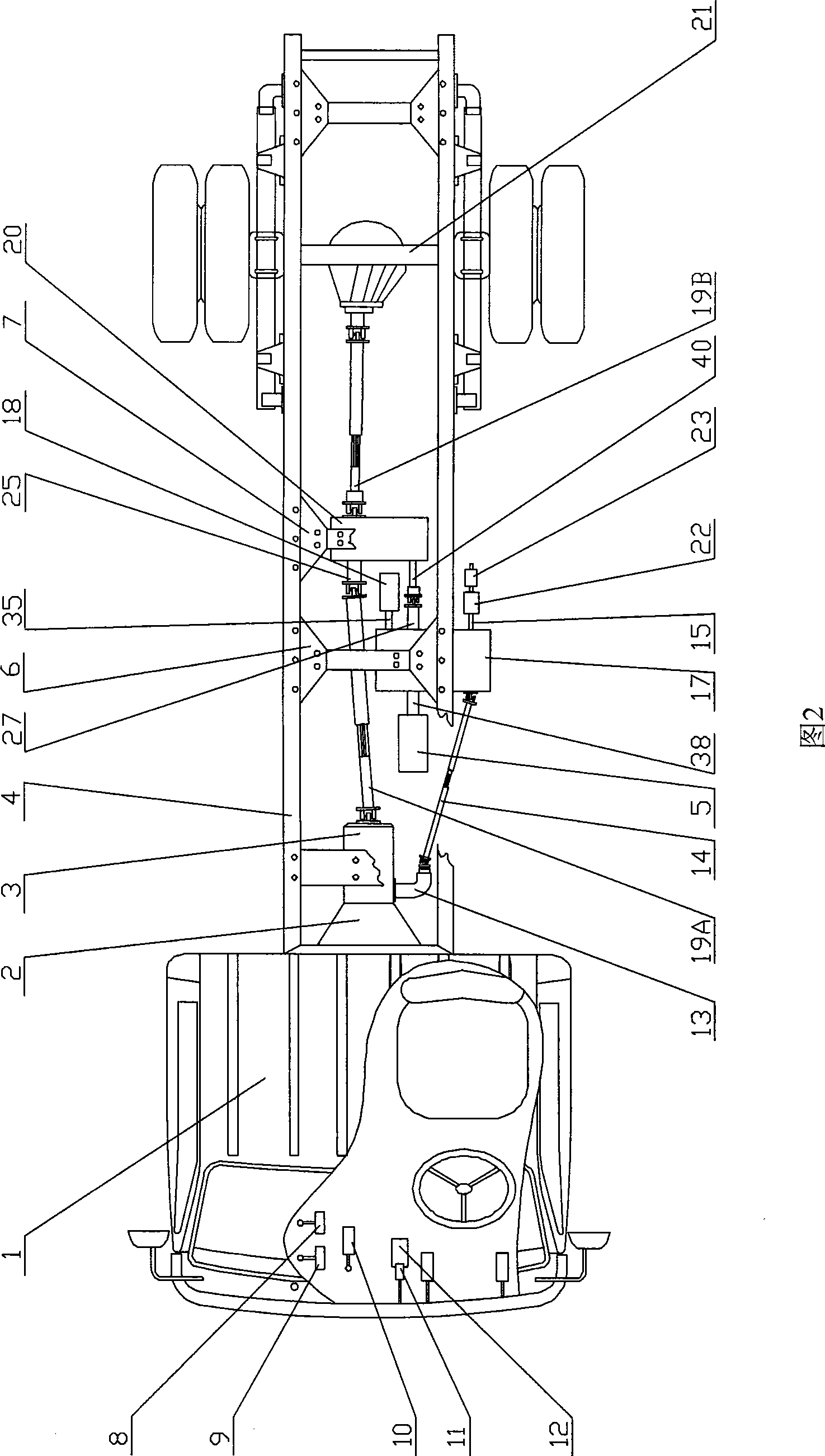

Path control system used for hydraulic digger operating device and its method

InactiveCN1651666ARealize automatic manipulationPrecise and stable positionSoil-shifting machines/dredgersPosition/direction controlHydraulic cylinderAutomatic control

The present invention relates to a track control system for hydraulic excavator working equipment and its method. Said system includes the following main components: DSP, moving arm angle detection mechanism, bucket arm angle detection mechanism, bucket angle detection mechanism, hydraulic cylinder, engine, working equipment and its driving cylinder and CAN bus. Said invention also provides the concrete steps of said control method. It can implement automatic control of hydraulic excavator working equipment, and can accurately and stably control the position and attitute of said hydraulic excavator working equipment so as to raise its working efficiency.

Owner:GUANGXI LIUGONG MASCH CO LTD

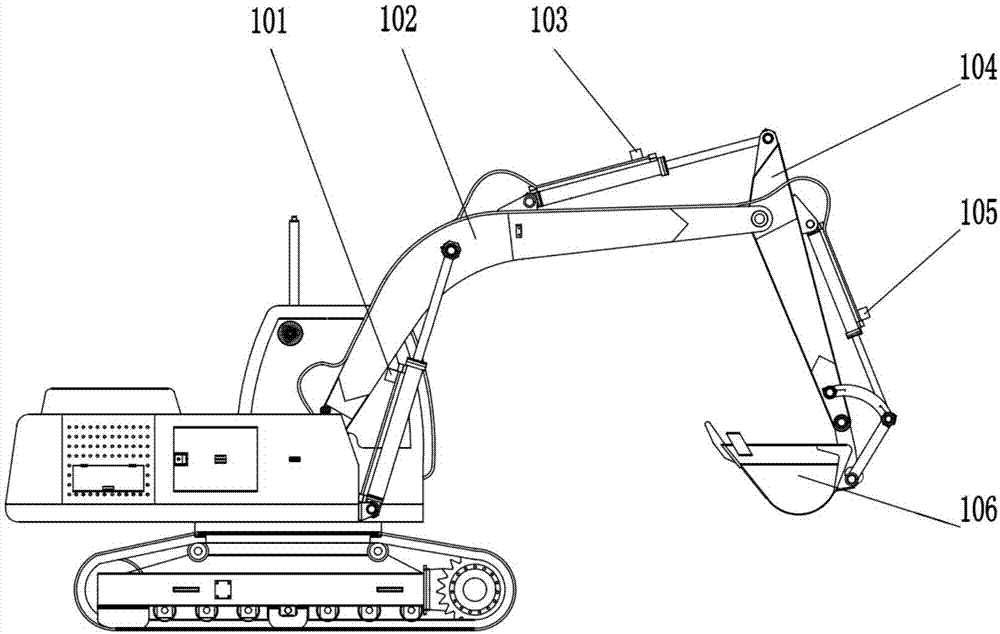

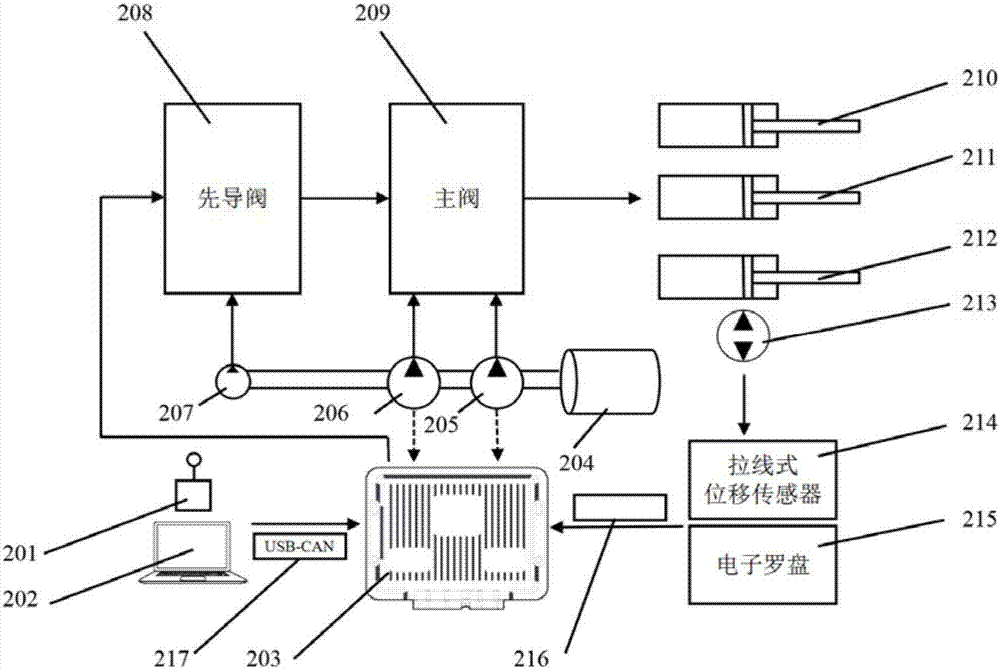

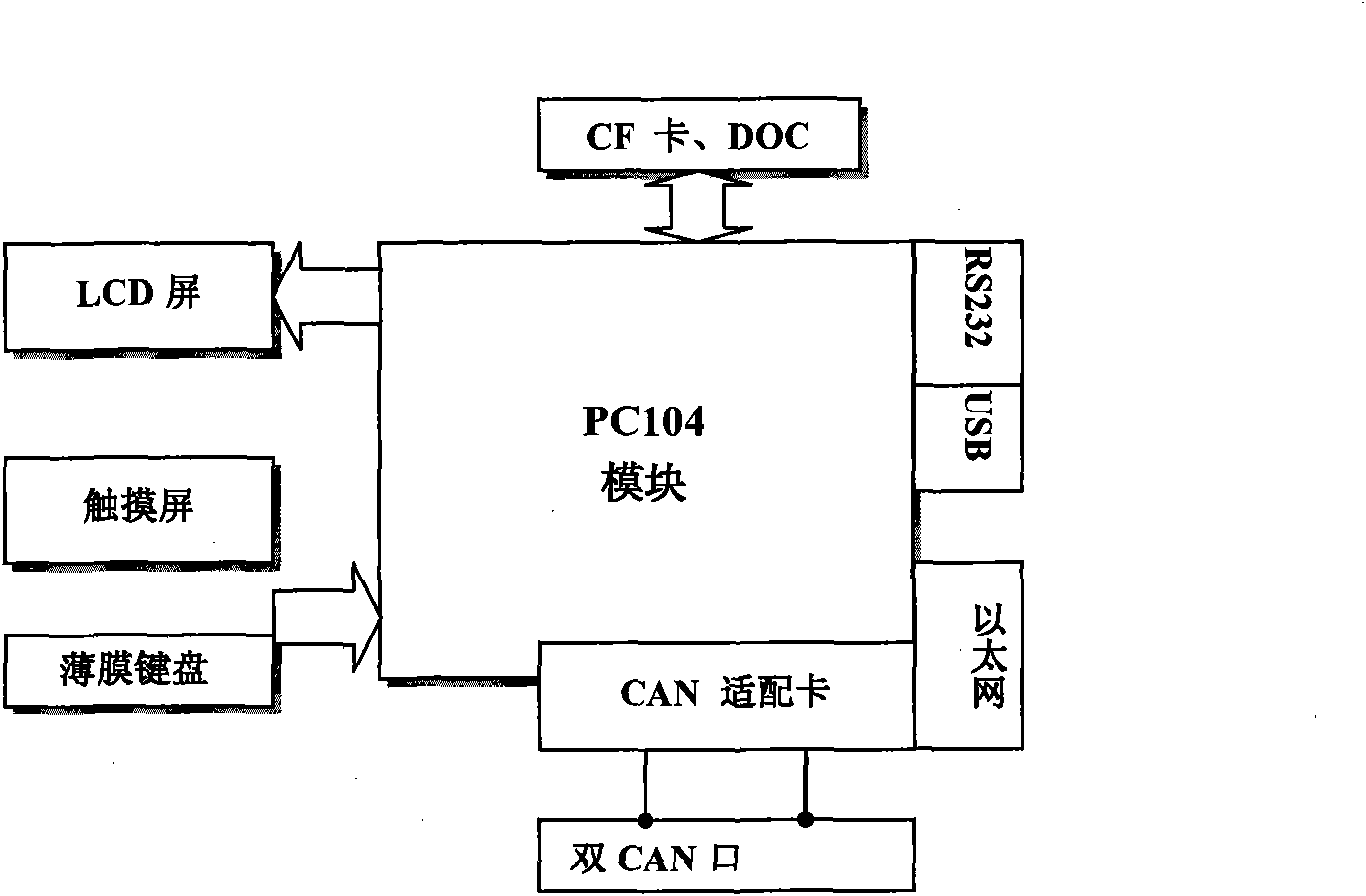

Three-dimensional attitude display and remote automatic control system of excavator

ActiveCN107882103ARealize remote automatic controlReal-time display of 3D animation simulation postureMechanical machines/dredgersAutomatic controlWeb service

The invention discloses a three-dimensional attitude display and remote automatic control system of an excavator. A pull line type displacement sensor is adopted to acquire a displacement signal of amoveable arm hydraulic cylinder, a bucket rod hydraulic cylinder and a scraper bucket hydraulic cylinder, and the displacement signal is sent to a computer through a data acquisition card; a car bodyrotation angle signal is acquired through an electronic compass, and the car body rotation angle signal is sent to the computer through an RS232 serial port; the computer is used for storing and processing data, so that a three-dimensional animated simulation attitude of the excavator is displayed in real time; an expected track of a scraper bucket tail end is planned; according to a practical displacement and car body rotation signal of a working device, a control algorithm is run by performing kinematic conversion on the practical displacement and car body rotation signal and comparing the practical displacement and car body rotation signal subjected to kinematic conversion with expected track data so as to correct the track; a CAN communication mode is adopted for realizing data communication between the computer and a special DSP controller of the excavator; operation state information is monitored in real time; operation track of tooth tips of X, Y and Z-axis scraper bucket and athree-dimensional displacement curve of the tooth tips of the scraper bucket are displayed in real time; and remote automatic control is realized through WEB service of a virtual instrument.

Owner:NANJING UNIV OF TECH +1

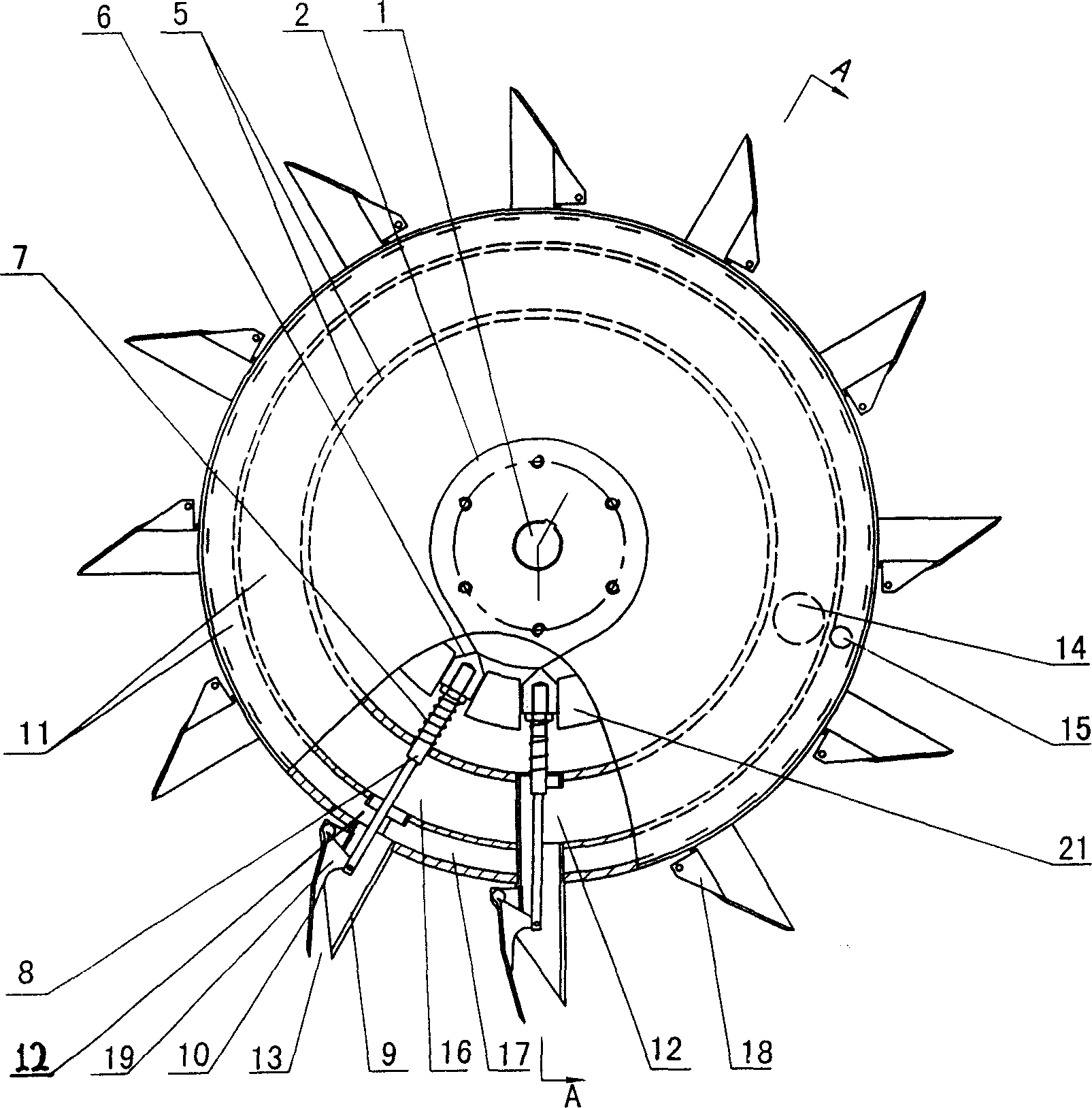

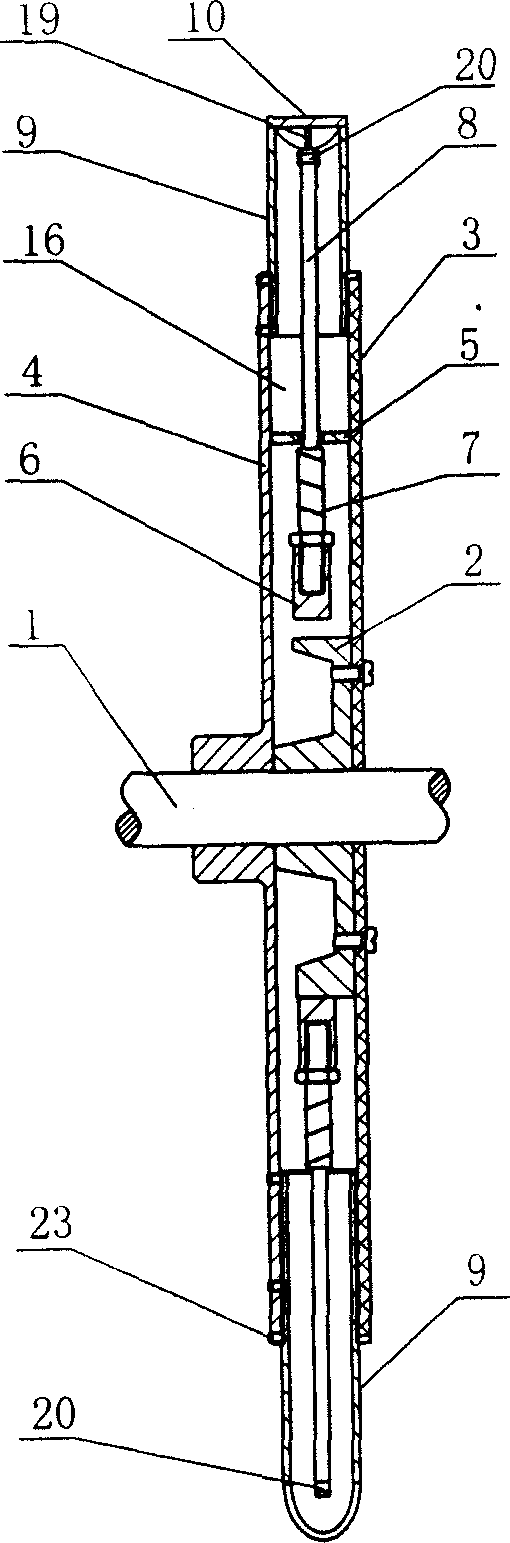

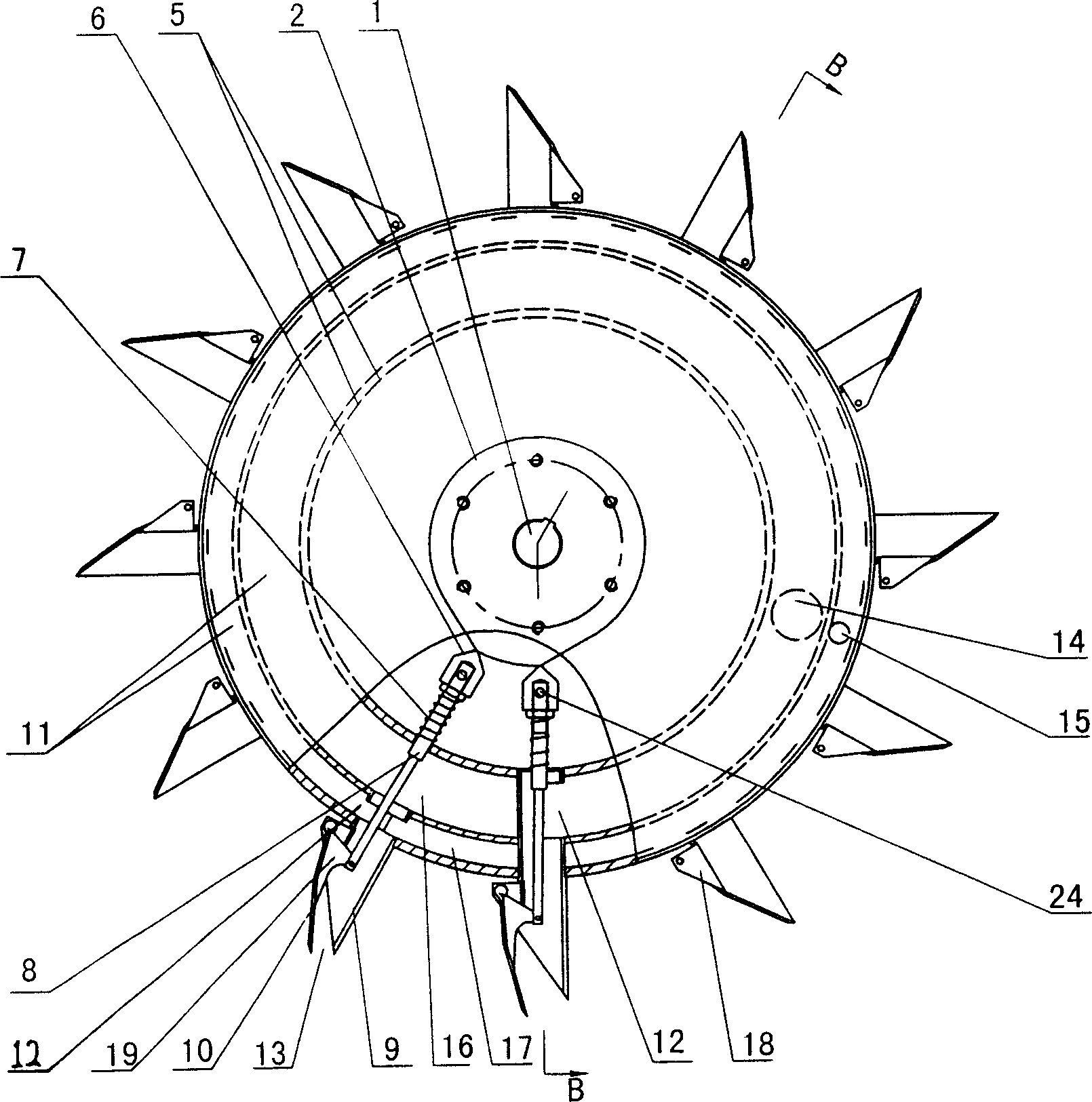

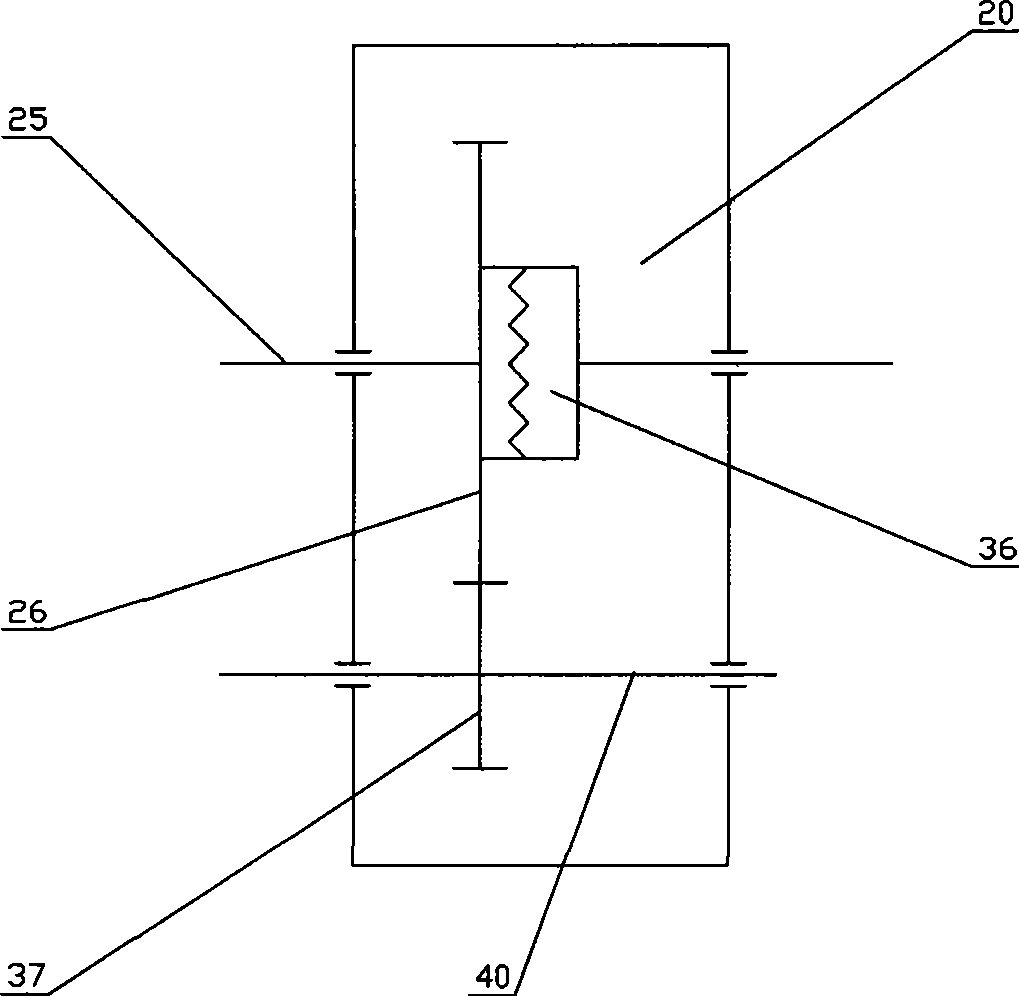

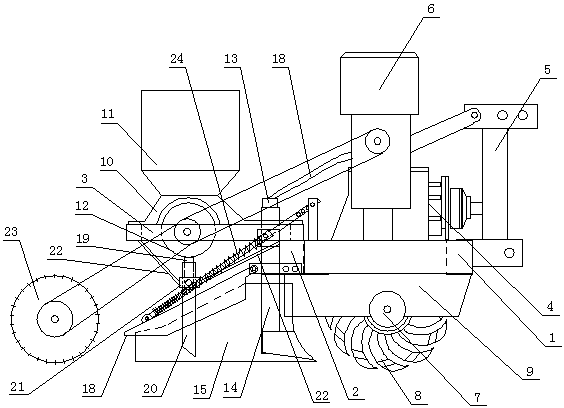

Steering wheel type dibbler for separately hole sowing fertilizer

InactiveCN1726749AWith mandatory internal investment functionFertilizer is accurateFertiliser and seeding apparatusSteering wheelEngineering

A steering wheel type hill sower able to respectively apply fertilizer, form pits and seed in the pits is composed of a seed discharging wheel and multiple pit forming assemblages. Said seed discharging wheel consisting of axle, cam fixed to the axle, wheel disk and the cover of said wheel disk. Said multiple pit forming assemblages radically arranged on said wheel disk to form a steering wheel is composed of several pit forming units consisting of slide block, spring, ejecting rod, sleeve pipe with tangent lower end and pressing plate.

Owner:SHANDONG UNIV OF TECH

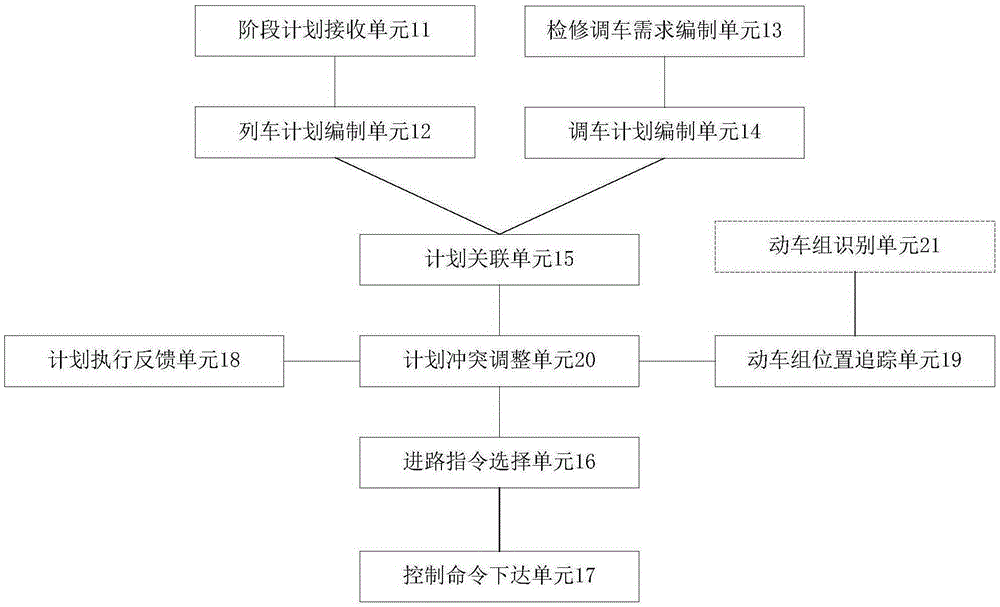

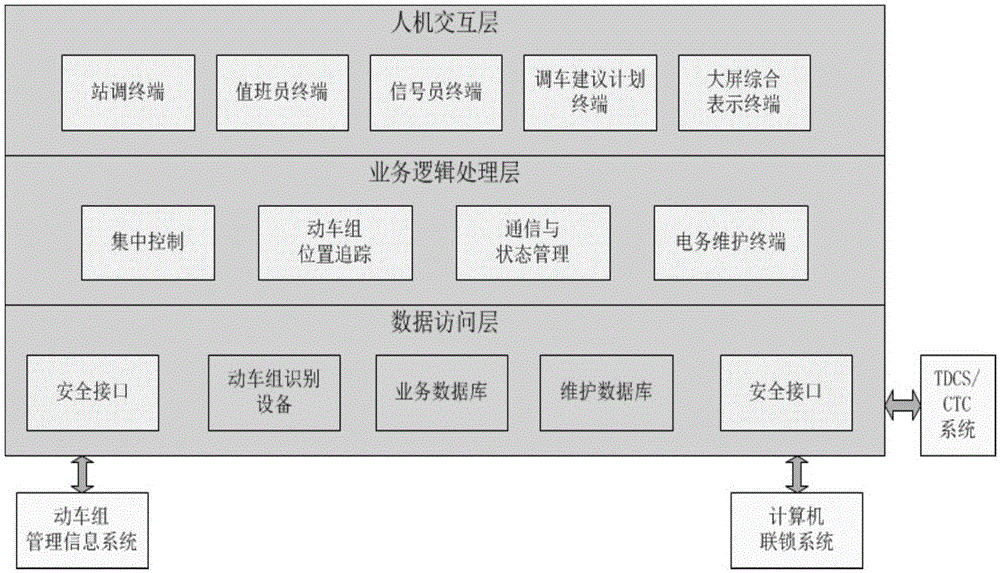

Multiple-unit train maintenance base (station) centralized control system

ActiveCN105278379AFully automatedMeet the needs of on-site production operationsProgramme control in sequence/logic controllersControl systemLocation tracking

The invention discloses a multiple-unit train maintenance base (station) centralized control system. The control system includes a train operation adjustment plan receiving unit, a train plan adjustment unit, a shunting suggestion plan making unit, a shunting plan adjustment unit, a plan correlation unit, a route command scheme selection unit, a control command issue unit, a plan conflict adjustment unit, a plane execution feedback unit and a multiple-unit train location tracking unit and a multiple-unit train identification unit. With the multiple-unit train maintenance base (station) centralized control system of the invention adopted, scheduling personnel of a multiple-unit train maintenance base (station) and a multiple-unit train maintenance unit can perform centralized control on signal equipment in the maintenance base and unit, directly command and manage trains and shunting operation, and automation of a scheduling process of the multiple-unit train maintenance base (station) and the multiple-unit train maintenance unit can be realized. The multiple-unit train maintenance base (station) centralized control system is a key link for realizing management and control integration of the multiple-unit train maintenance base (station) and the multiple-unit train maintenance unit, and can fully meet on-site production operation needs and can assist in improving production efficiency and work quality.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

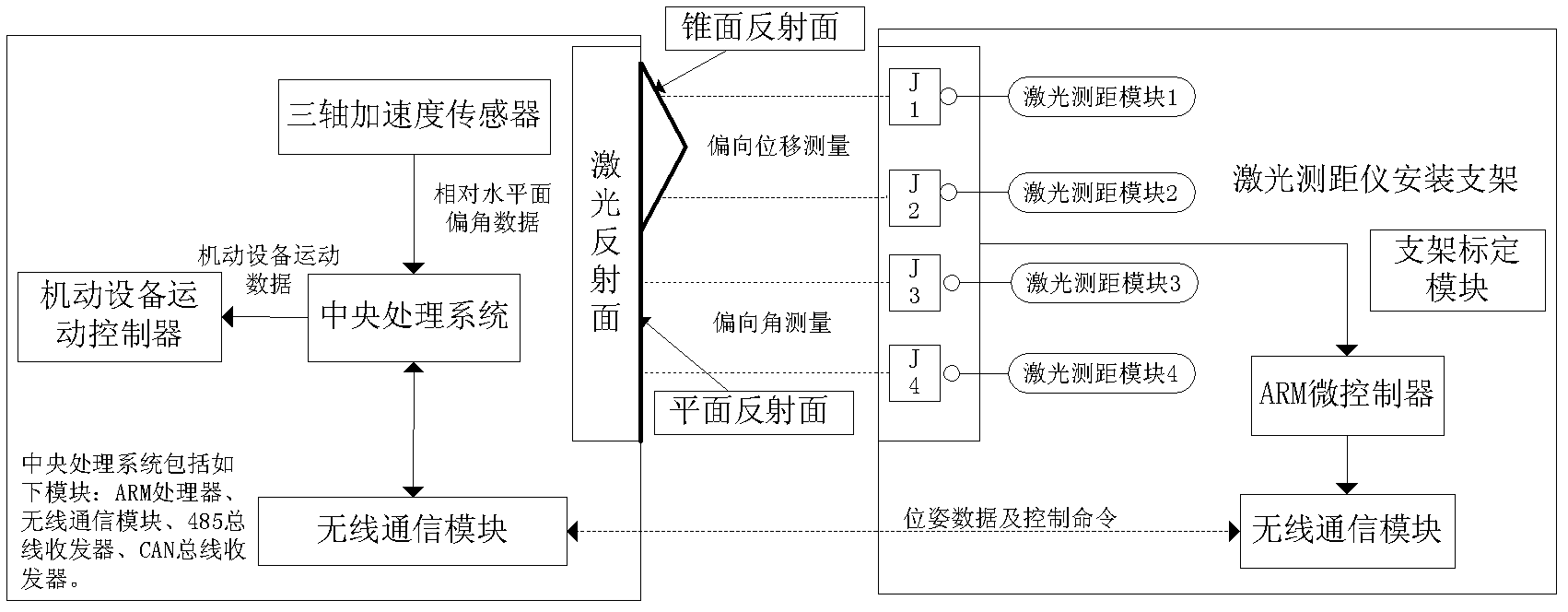

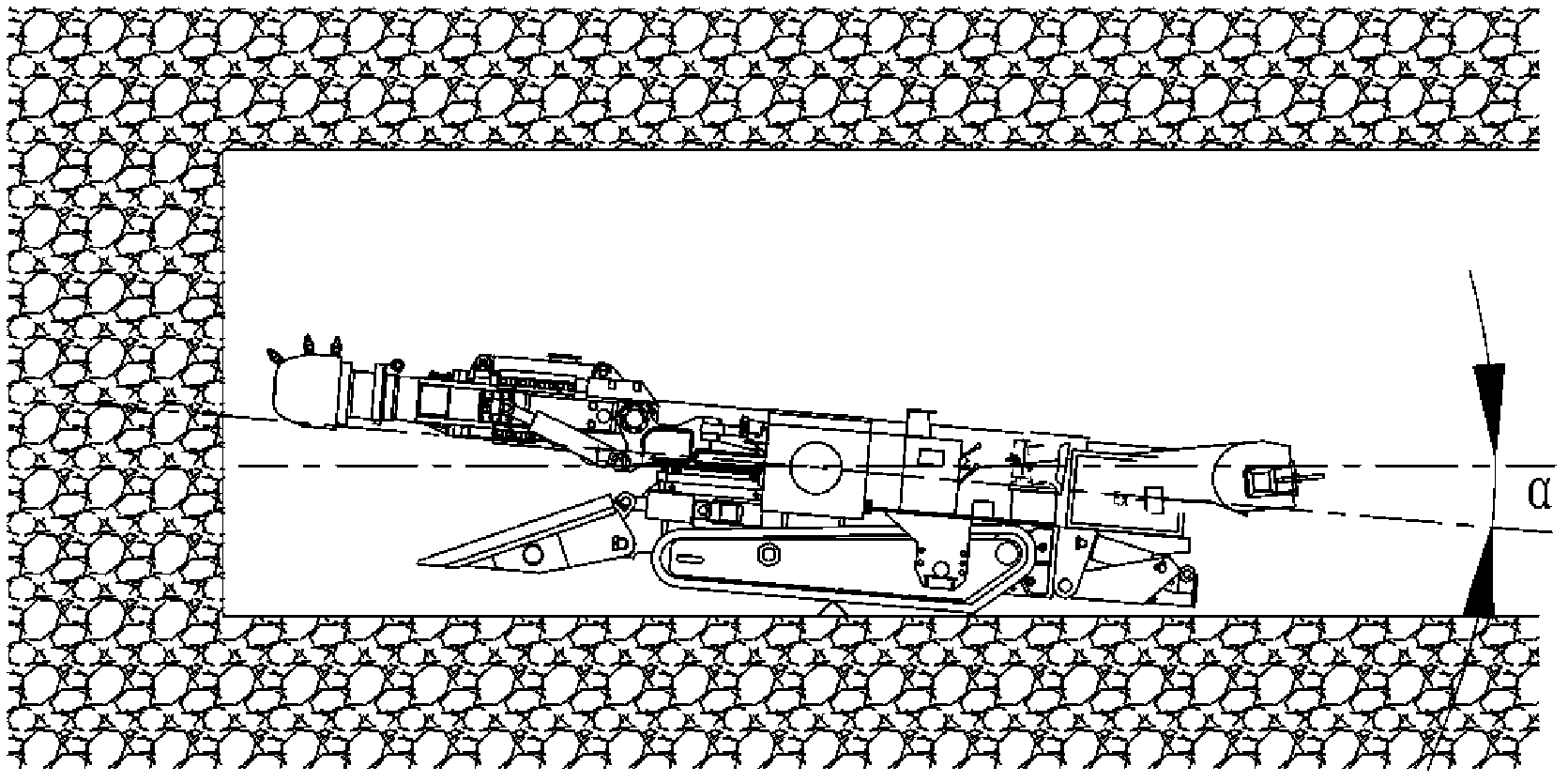

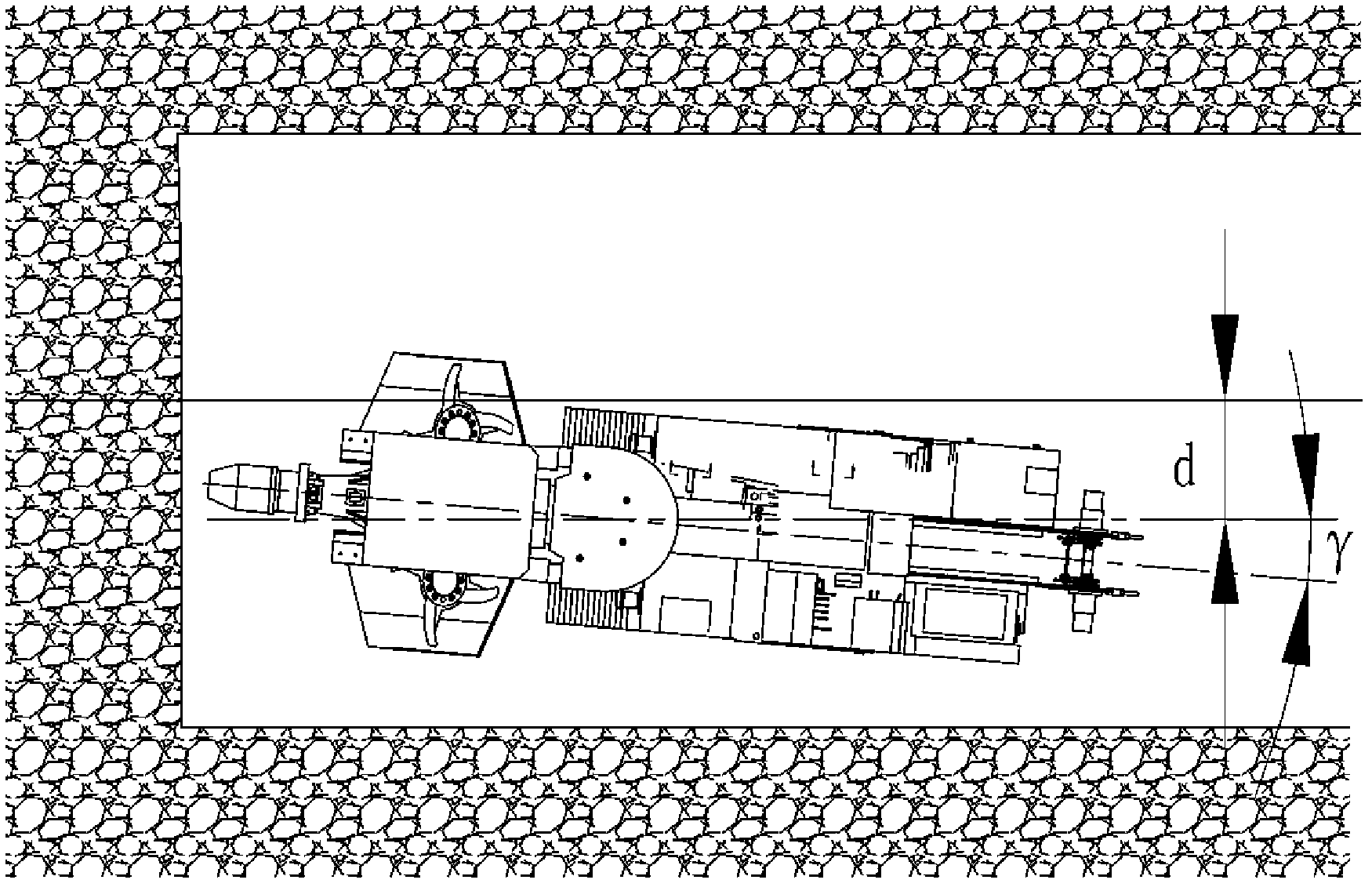

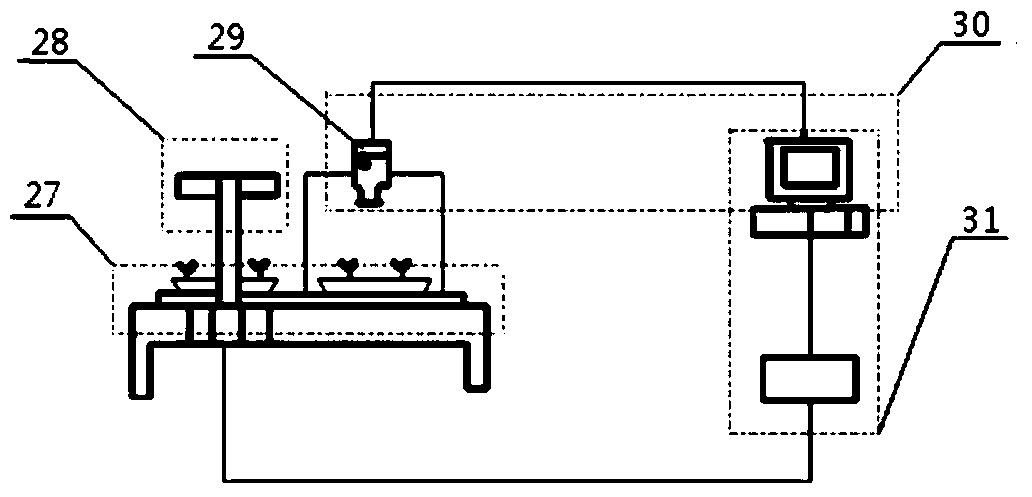

Position and posture measuring system and method for mechanical equipment

InactiveCN102322857AThere is no error accumulation processRealize automatic controlAngle measurementOptical rangefindersLaser rangingComputer module

The invention relates to a position and posture measuring system and method for mechanical equipment. The position and posture measuring system is characterized in that: four laser distance-measuring modules are arranged at the top of an alley at the back of the mechanical equipment to measure points of special positions on the mechanical equipment so as to obtain four different distances; position offset of the mechanical equipment relative to a predetermined track and angular offset of the mechanical equipment on a vertical surface are calculated based on the four distances; offset data is transmitted to a central processing system on the mechanical equipment through a wireless communication module; position and posture parameters of the mechanical equipment and positioning navigation data can be obtained in combination with a dip angle of the mechanical equipment relative to a horizontal plane, wherein the dip angle is measured by a triaxial acceleration sensor which is arranged onthe mechanical equipment; and the central processing system is used for transmitting the positioning navigation data to a control box of the mechanical equipment. The position and posture measuring system has the advantages of high measuring speed, good real-time performance, high measurement accuracy and no accumulated error, and is suitable for the position and posture measurement as well as the positioning navigation of underground mechanical equipment.

Owner:WUHAN UNIV OF TECH

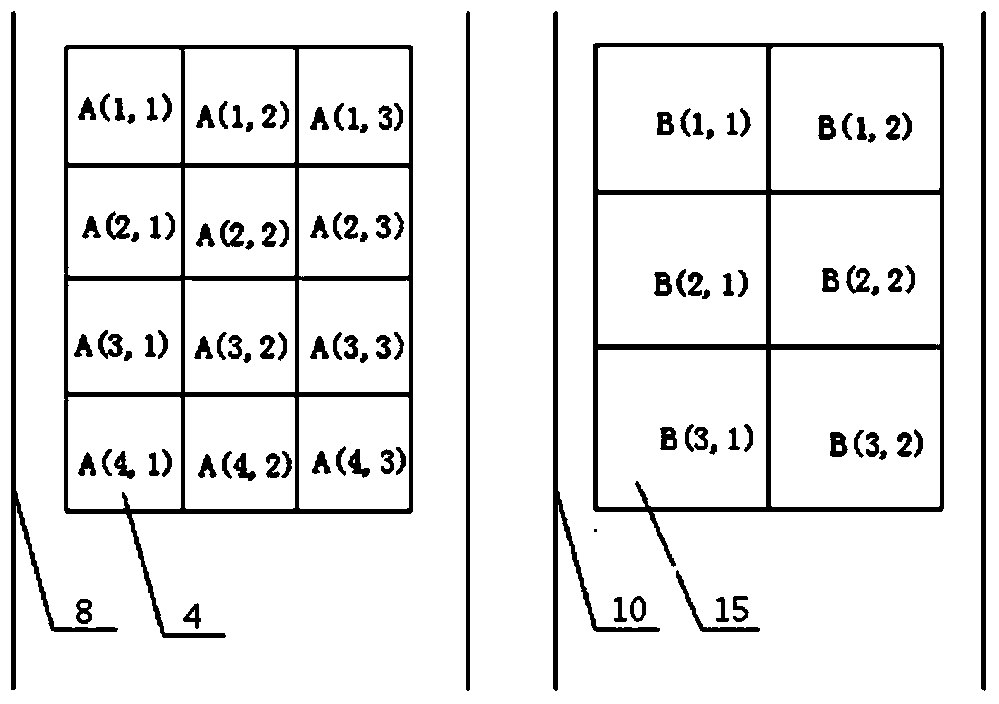

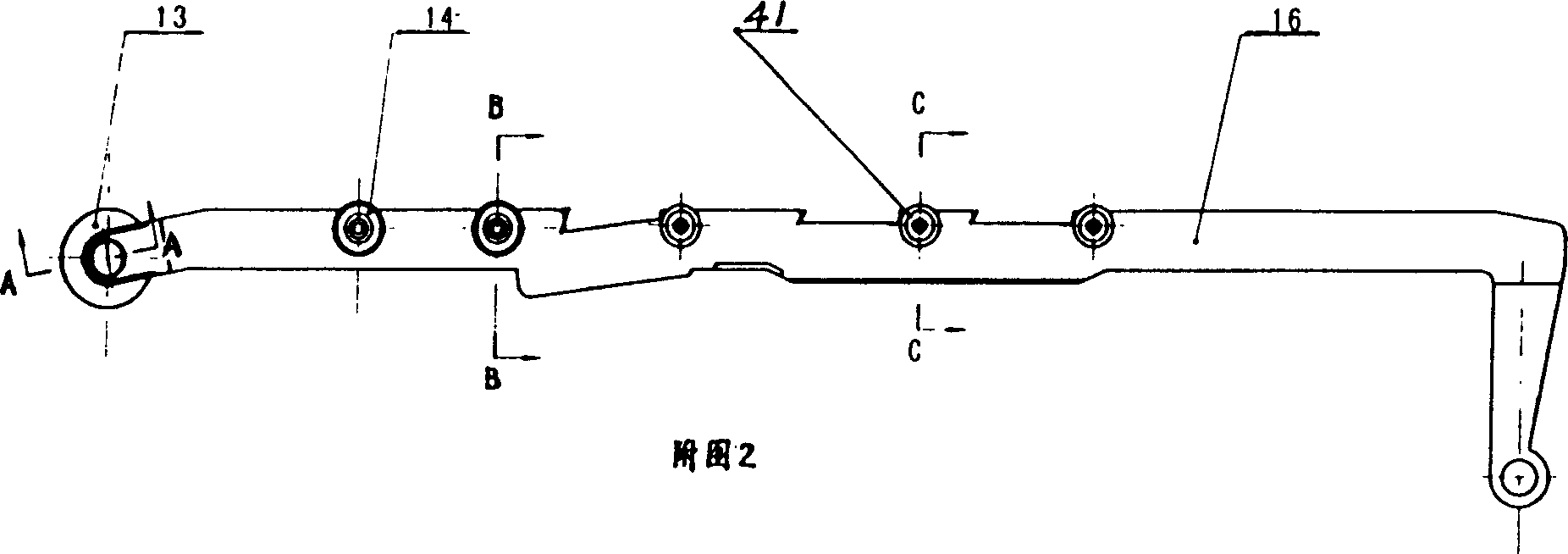

Conveying and positioning device and method used for automatic potted tray seedling transplanter

InactiveCN103787051AAvoid damageAdaptableControl devices for conveyorsTransplantingMotor driveChain device

The invention provides a conveying and positioning device and method used for an automatic potted seedling transplanter. A conveying platform is fixedly mounted on a conveying rack, a seedling tray conveying guide device is mounted on the conveying platform, seedling supplying and planting trays are placed among conveying guide rails on the conveying platform, horizontal conveying chain devices are mounted on two sides of the conveying rack, a plurality of potted tray pushing plates are mounted on each horizontal conveying chain, and a transmission chain device is mounted on the outer side of the conveying platform. When a servo motor drives a transmission chain to rotate by one cycle, the potted tray pushing plates on the horizontal conveying chains move for a certain distance along with the transmission chain to realize positioning and conveying of the seedling supplying and planting trays. Adjusting devices used for adjusting transverse positions of the potted trays are mounted on two sides of the conveying rack, and the adjusting devices execute seedling tray transverse position adjusting instructions given by a transplanting control center to realize transverse accurate positioning of the seedling supplying and planting trays. The conveying and positioning device is high in accuracy and good in stability and reliability, damage to potted tray seedling pots can be reduced, and transplanting efficiency of potted tray seedlings can be improved.

Owner:JIANGSU UNIV

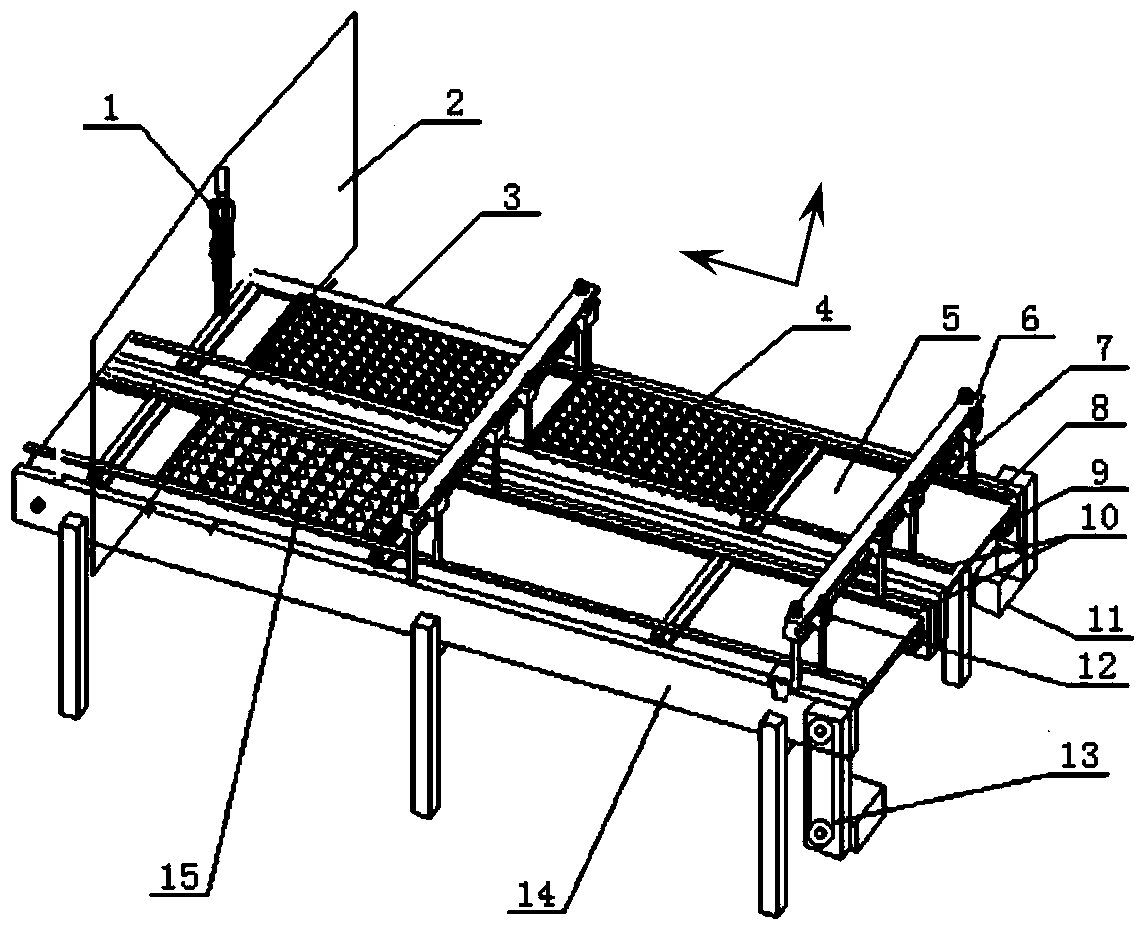

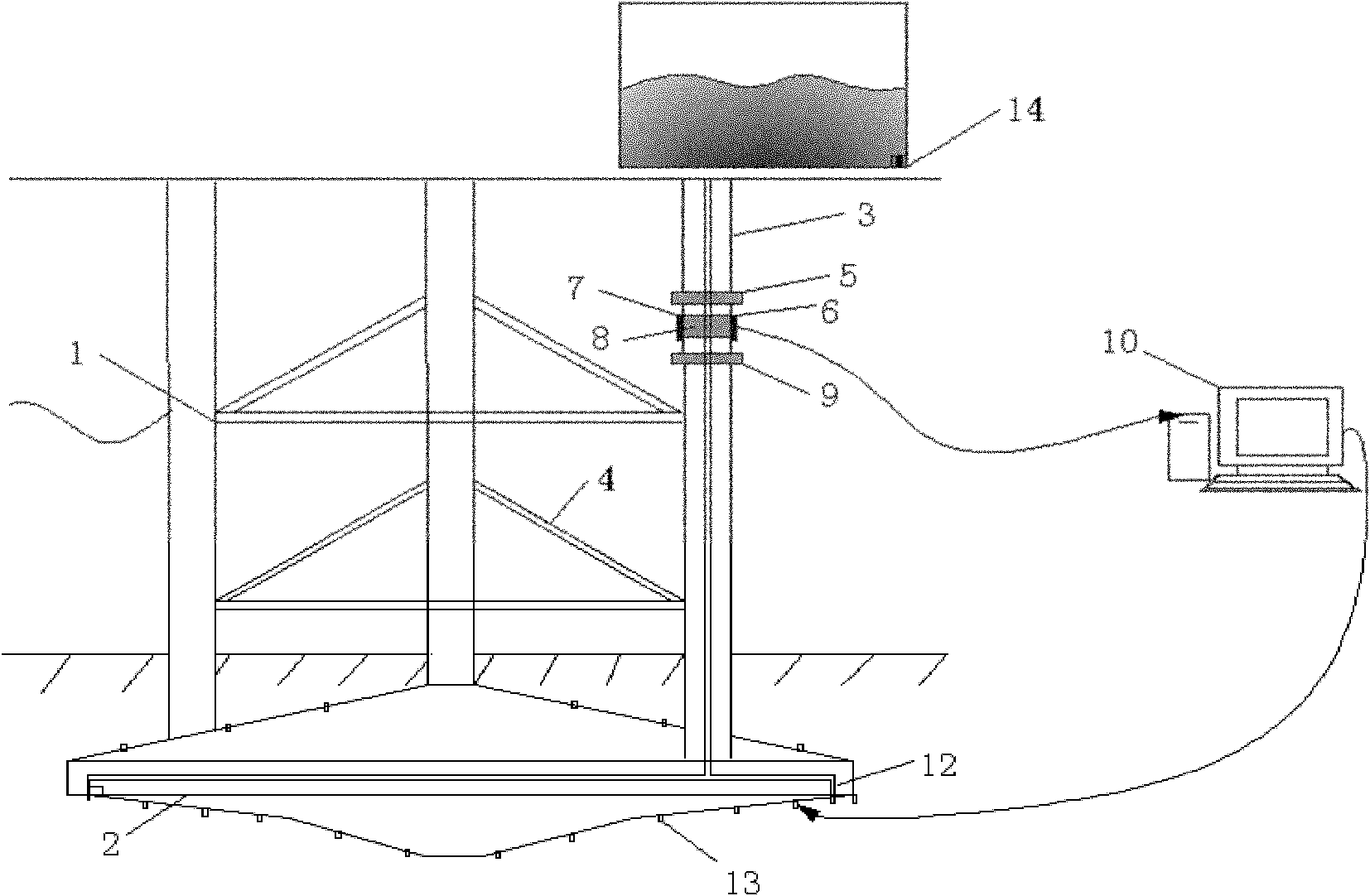

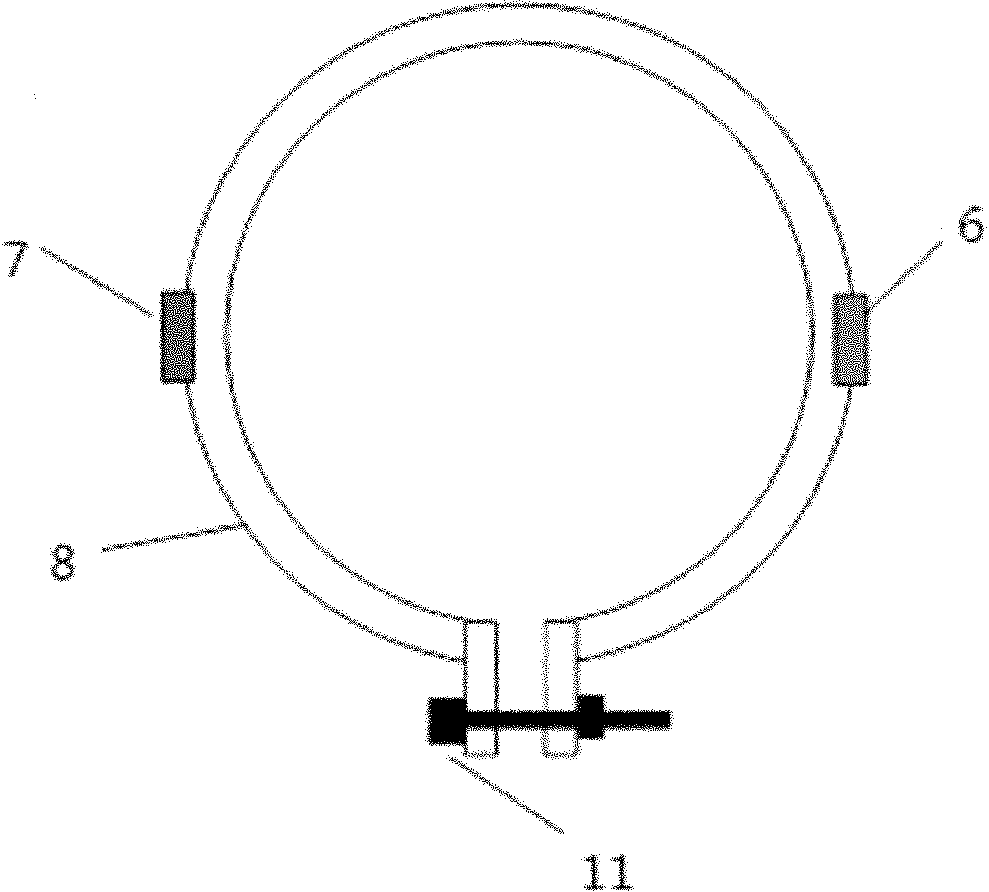

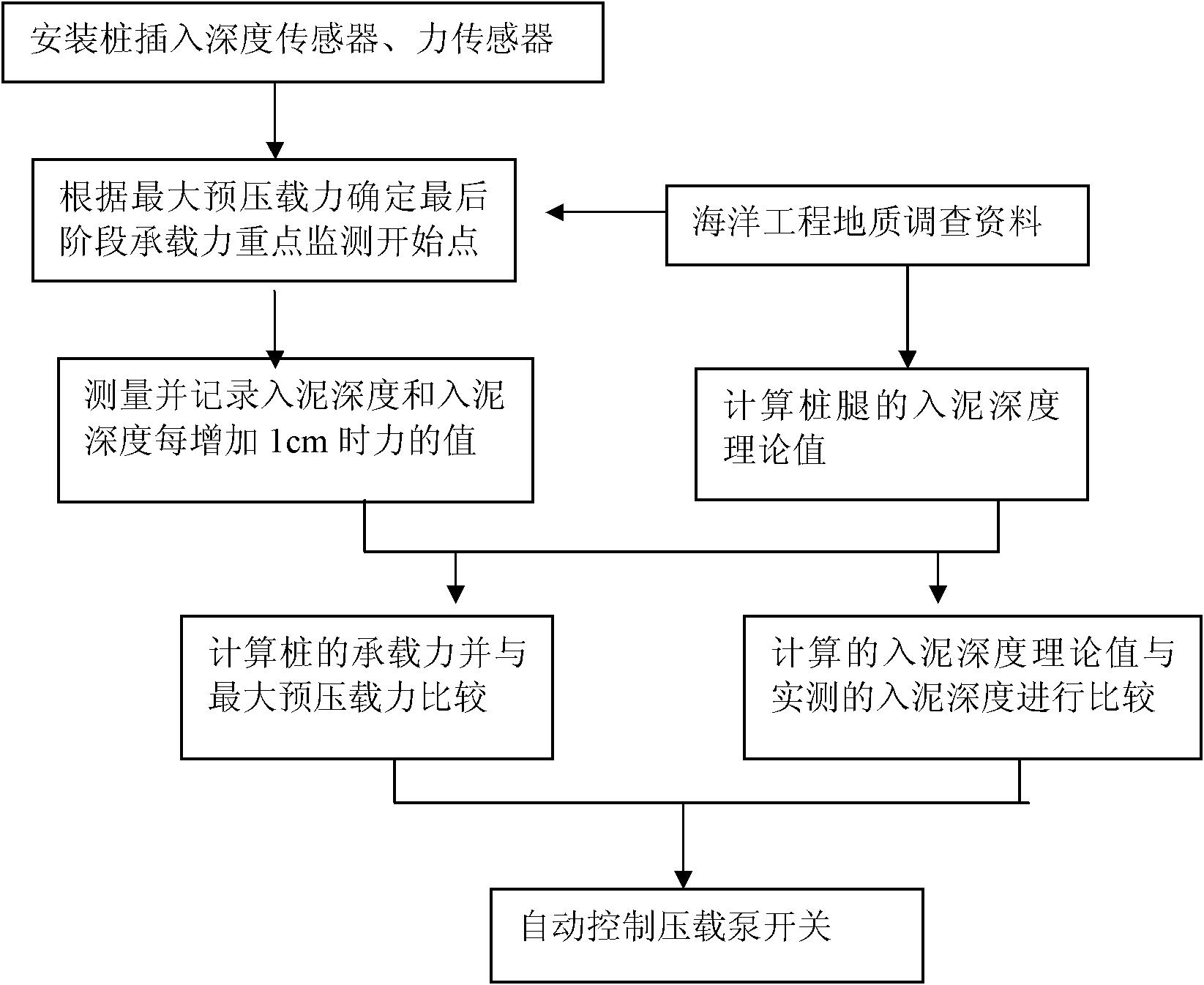

Offshore self-elevating drilling platform pile pitching and pile pulling automatic control device and method

InactiveCN102071690AReal-time monitoring of mud entry depthRealize automatic controlOperating means/releasing devices for valvesPump controlPull forceAutomatic control

The invention relates to an offshore self-elevating drilling platform pile pitching and pile pulling automatic control device and method. The offshore self-elevating drilling platform pile pitching and pile pulling automatic control device comprises a displacement sensor, a force sensor, a computer detection control system, a ballast pump switch and a pile washing valve, wherein the displacement sensor and the force sensor are arranged on a chord member of a pile leg, the ballast pump switch is arranged at a ballast pump control system of a ballast tank, the pile washing valve is arranged on a pile shoe and is connected with a pile washing pipeline. The displacement sensor and the force sensor are respectively used for measuring the driving depth of a pile body, the bearing capacity of the pile leg and a pile pulling force and transmitting the measured data in pile pitching and pile pulling processes into a computer detection control system to be processed, whether the bearing capacity of the pile in the pile pitching process is maximum or not, whether pile washing is required in the pile pulling process and whether the pile is completely pulled out are automatically judged, and the ballast pump switch, the pile washing valve and a pile pulling operation control switch are controlled according to the judging result, thus realizing the offshore self-elevating drilling platform pile pitching and pile pulling automatic control.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Well site data integration cooperative work platform

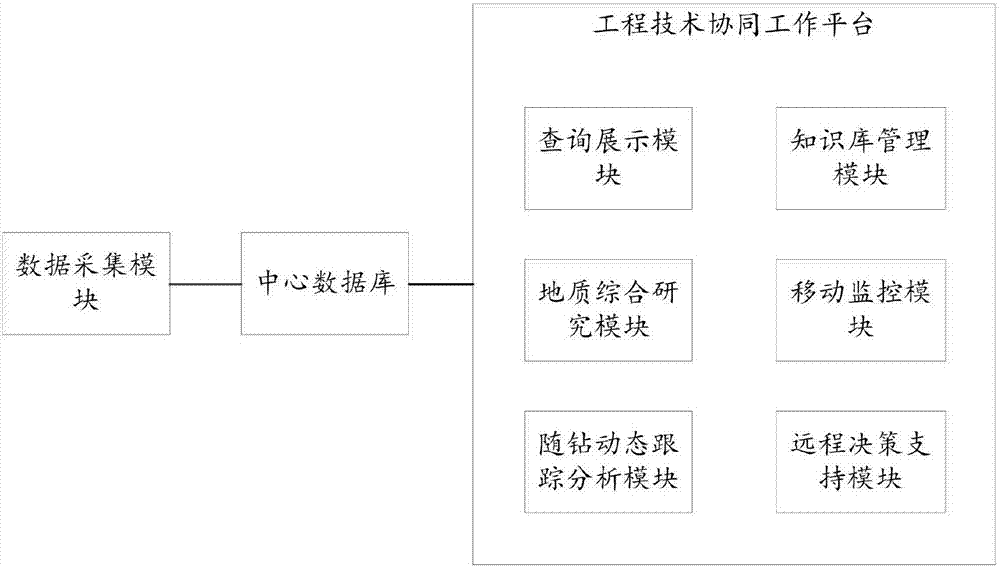

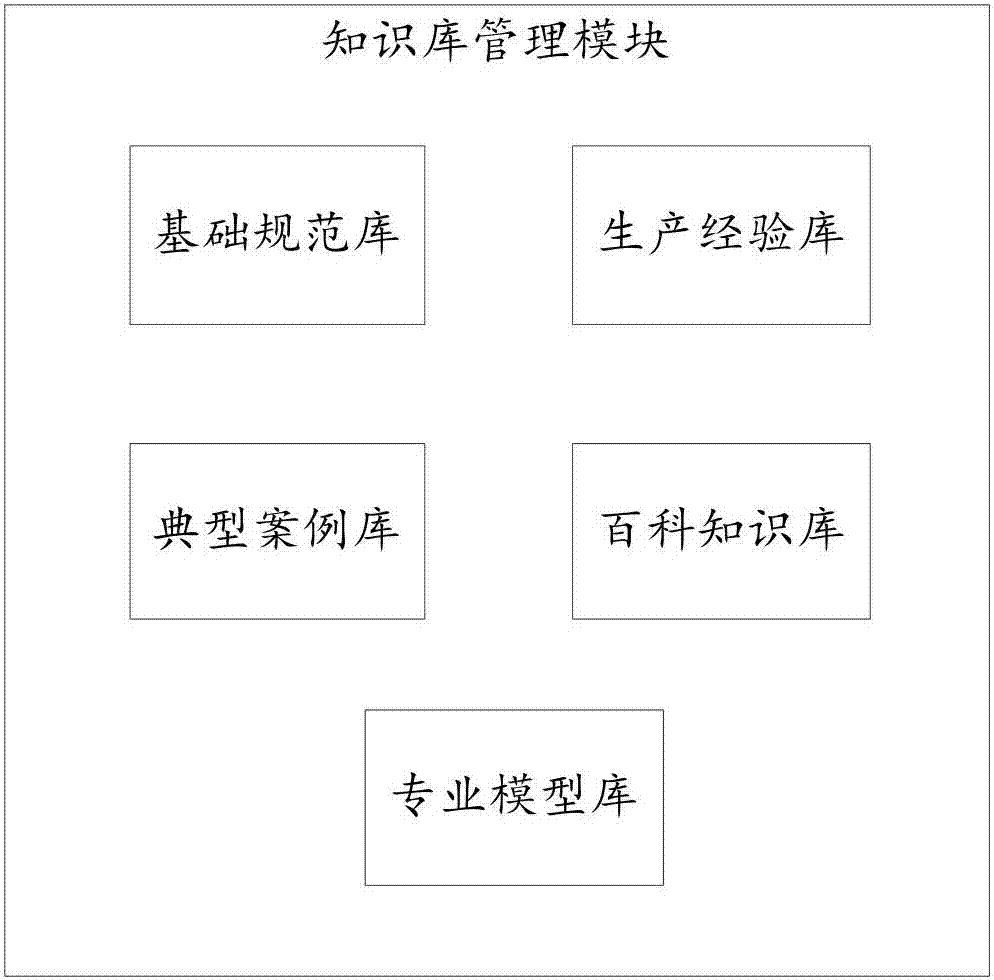

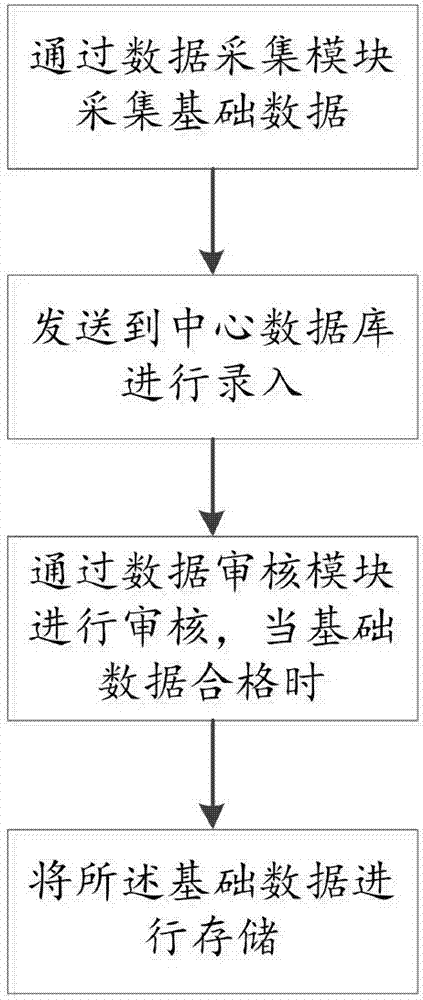

ActiveCN106897839AEliminate silosImprove efficiencyOffice automationResourcesData synchronizationData acquisition

The invention relates to a well site data integration cooperative work platform that comprises a data acquisition module, a central database and an engineering technology cooperative work platform. The engineering technology cooperative work platform comprises a query display module, a geological comprehensive research module, a while-drilling dynamic tracking and analysis module, a knowledge base management module, a mobile monitoring module and a remote decision support module. The well site data integration cooperative work platform builds a standardized and unified big data management platform, achieves production site information comprehensive application, achieves well site and base field data synchronization analysis application, eliminates information isolated island, provides an integrated cooperative work platform for drilling engineers, geologists, reservoir engineers and managers, fully shares information, makes decisions more intuitively and rapidly, guides field operation in real time, improves the efficiency and quality of well site operation management, and brings the reformation of production management modes.

Owner:WUHAN SHENGHUAWEIYE TECHNOLGY CO LTD

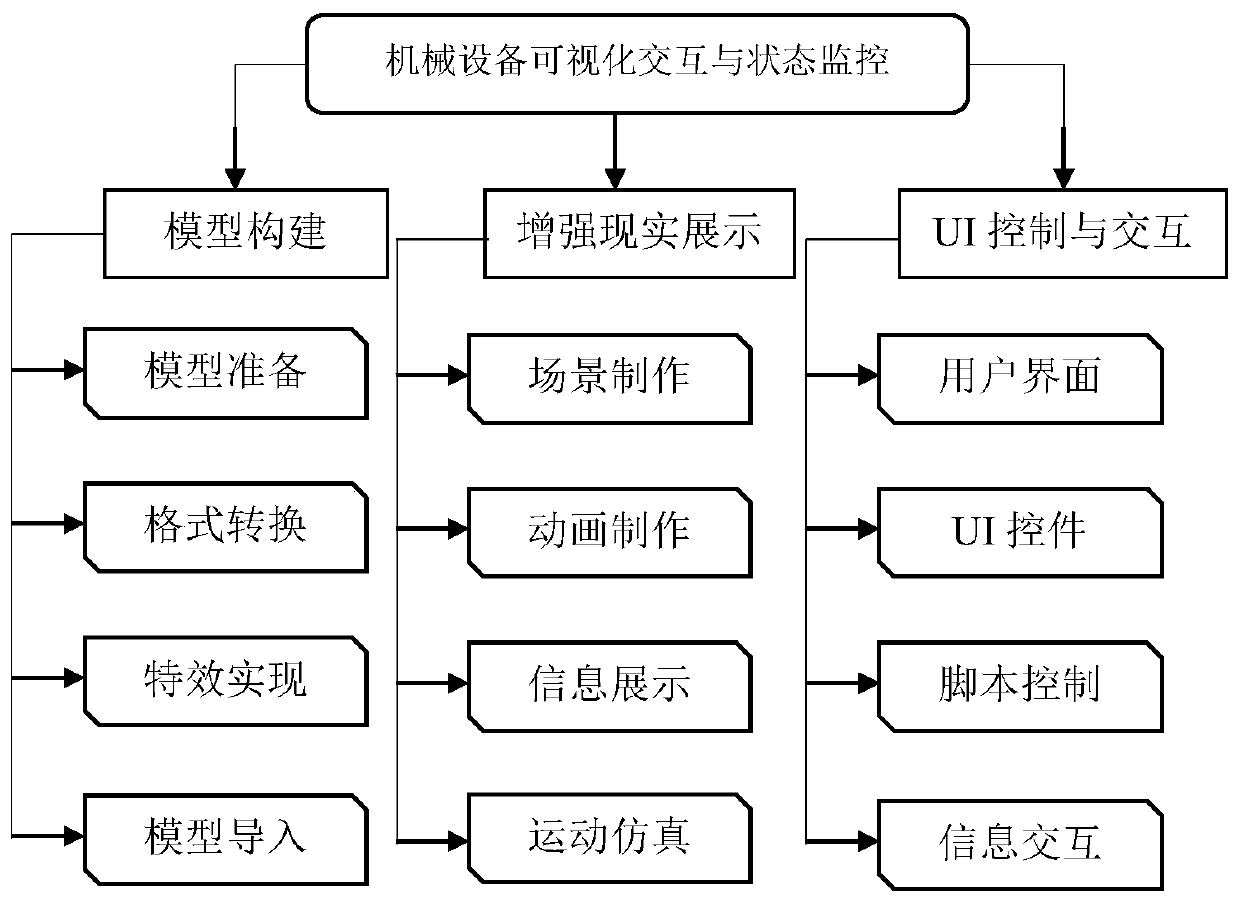

Mechanical equipment visual interaction and equipment state monitoring system and method based on augmented reality

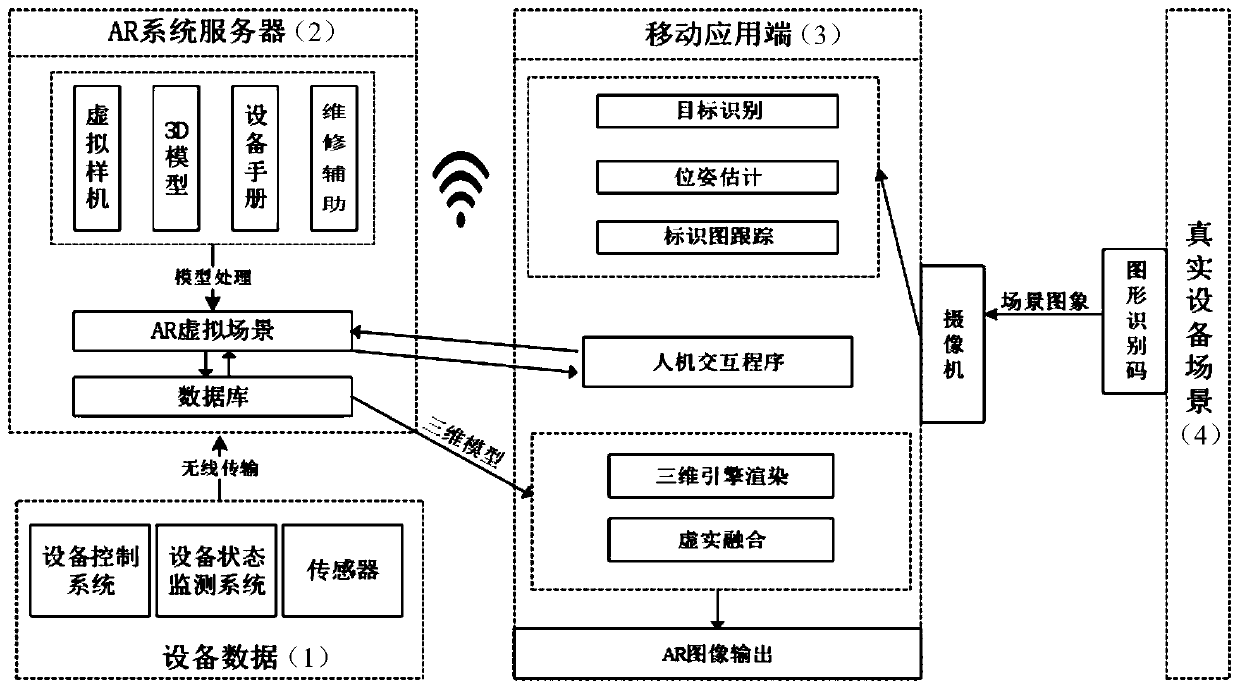

PendingCN110599603AReduce monitoring wiringRealize real-time maintenance operation guidanceImage data processingDaily operationState parameter

The invention discloses a mechanical equipment visual interaction and equipment real-time monitoring system and method based on augmented reality, and the system consists of four modules: an equipmentdata module, an AR system server module, a mobile application end module, and a real equipment scene module. The equipment data module collects and summarizes mechanical equipment state parameter data, and transmits data to the AR system server module through a wireless network. Model processing and data superposing work is completed in the AR system server. An equipment AR virtual scene is constructed, corresponding scene contents are sent to the AR virtual scene according to the requirements of a mobile application terminal module. A scene image and a graphic identification code of a real equipment scene are shot by a camera of a mobile application terminal, to match a tracking identifier, provide man-machine interaction, render the scene, and output an AR image. According to the invention, through augmented reality interaction management of production field equipment, the difficulty and error source of daily operation are reduced, and the operation quality and efficiency of the equipment in a production environment are improved.

Owner:SHANGHAI UNIV

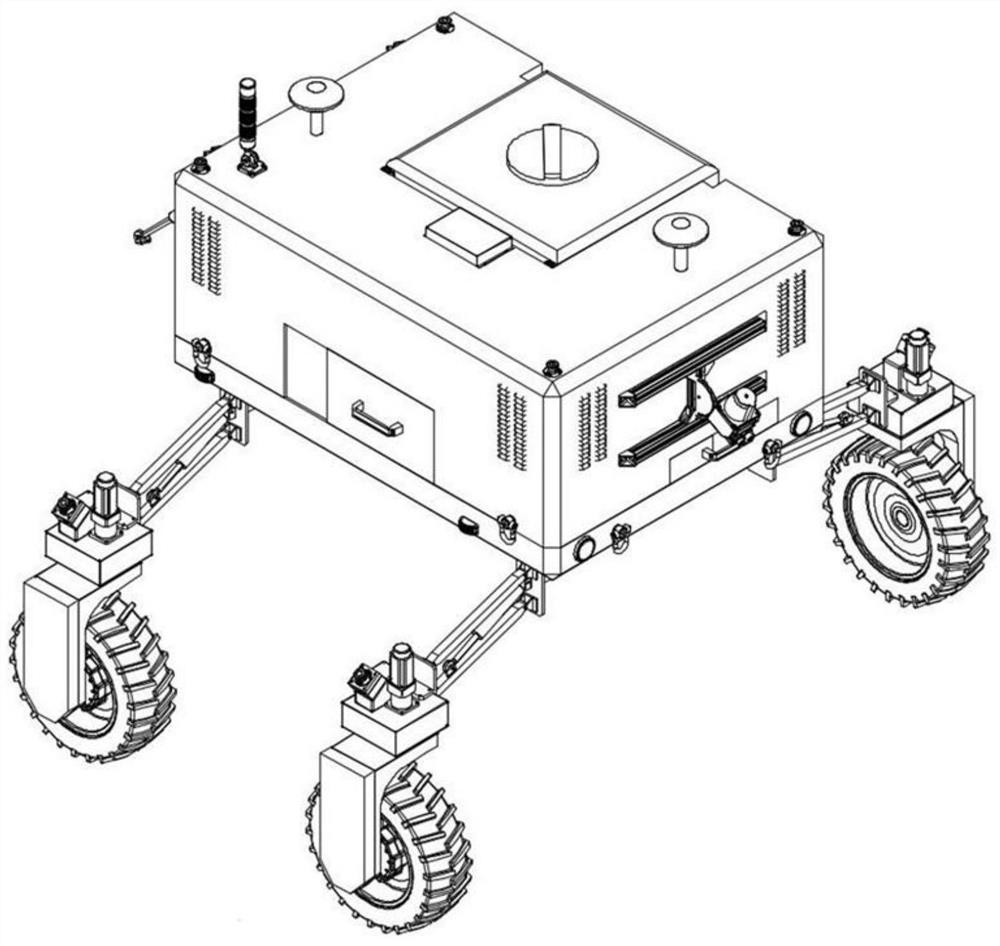

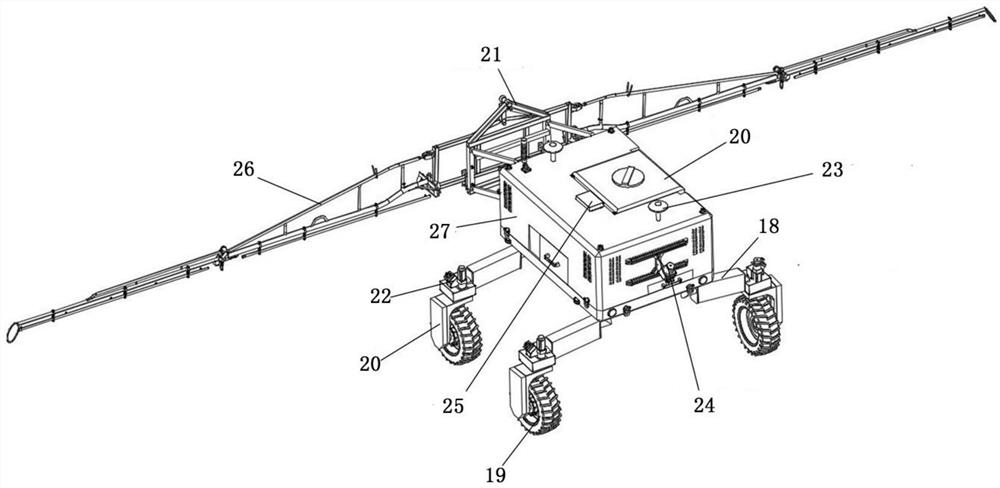

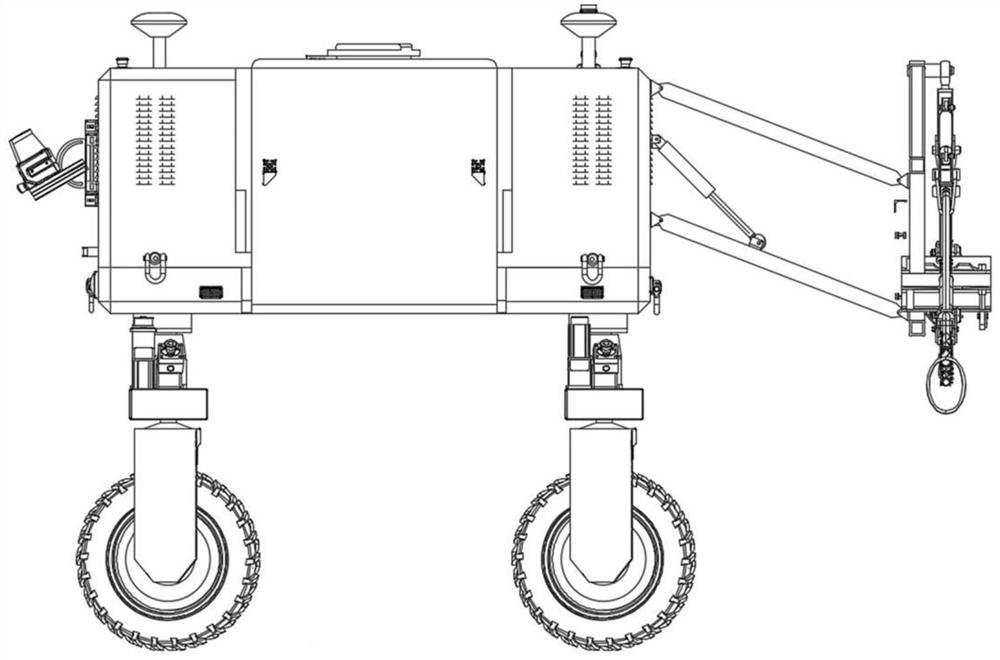

Wheeled farmland management robot with flexible profiling chassis and profiling control method

ActiveCN111645478AExtension of timeReduce use costResilient suspensionsAgricultural undercarriagesAutomotive engineeringAgricultural engineering

The invention provides a wheeled farmland management robot with a flexible profiling chassis and a profiling control method. The robot can carry out flexible profiling control on the posture of a vehicle body chassis according to an uneven crop canopy / ground surface; a machine hung on a chassis rack of the vehicle body is basically parallel to a crop canopy / ground below the vehicle body; the chassis / machine tool is prevented from touching the ground or damaging seedlings, the distance between the chassis / machine tool and the crop canopy / ground is always controlled within an ideal range, the robot is suitable for multiple terrains and can adapt to growth changes of crops, the application scene and the use time period of the robot are effectively widened, the operation efficiency is improved, and the overall use cost of the robot is reduced. According to the further scheme, a stable and reliable wheel leg driving structure is further provided, shaking of an operation machine tool can beeffectively reduced, the operation quality is improved, and the wheel leg driving structure is particularly suitable for the profiling control process of real-time adjustment of a wheel leg mechanismand has good durability.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

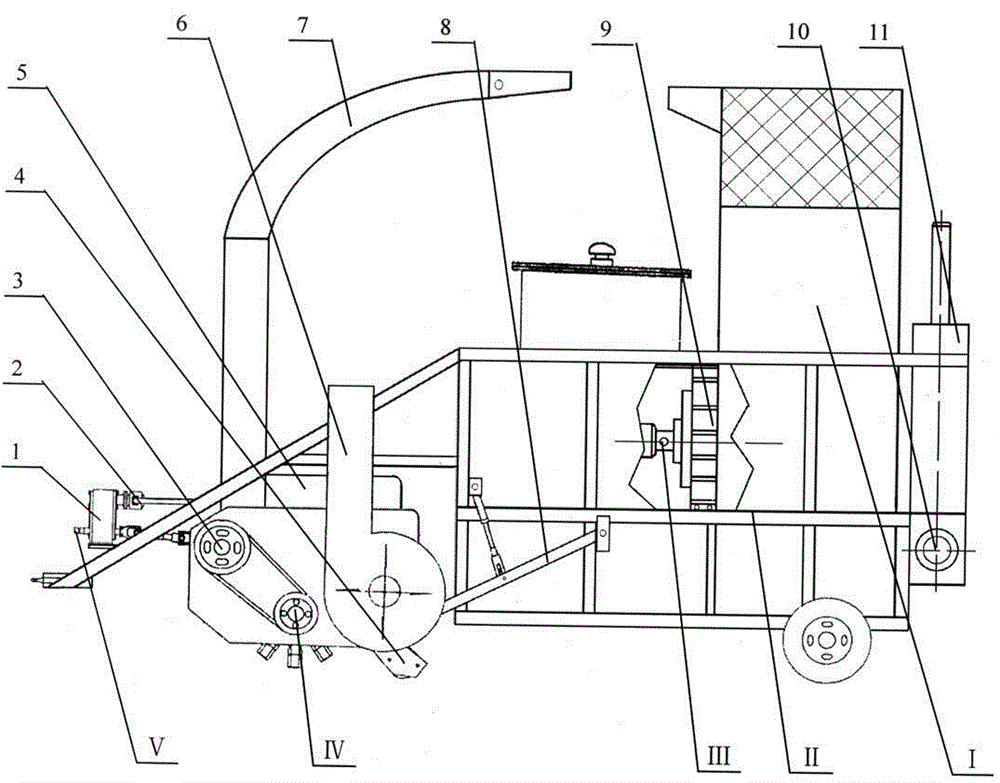

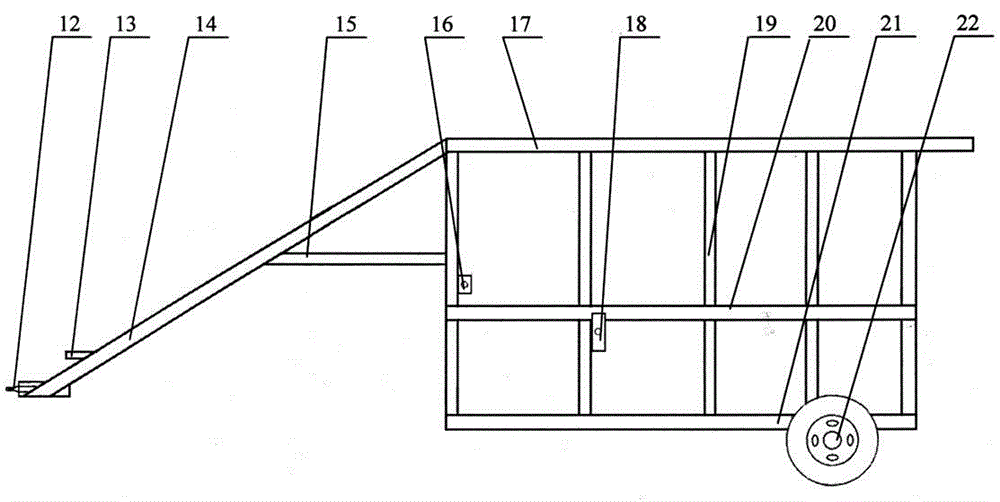

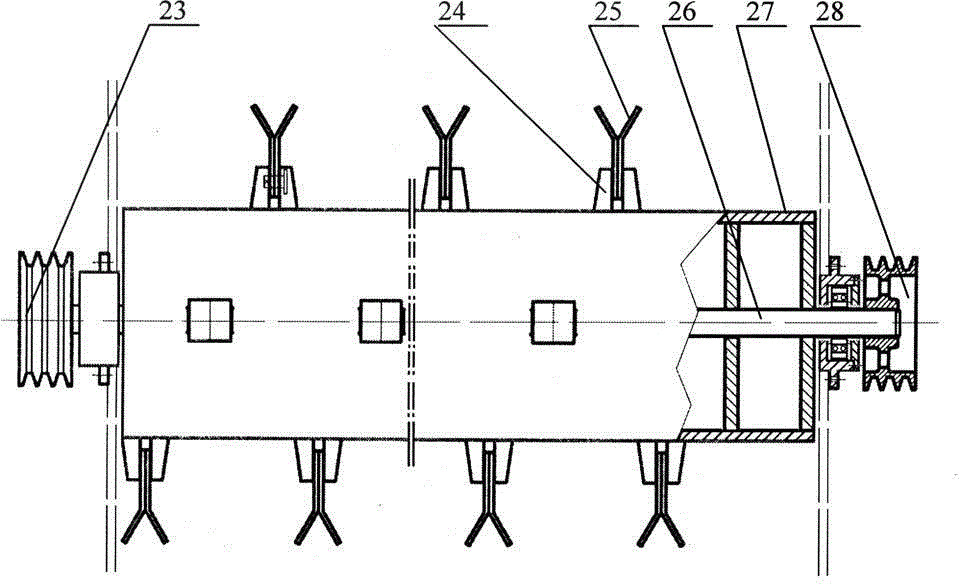

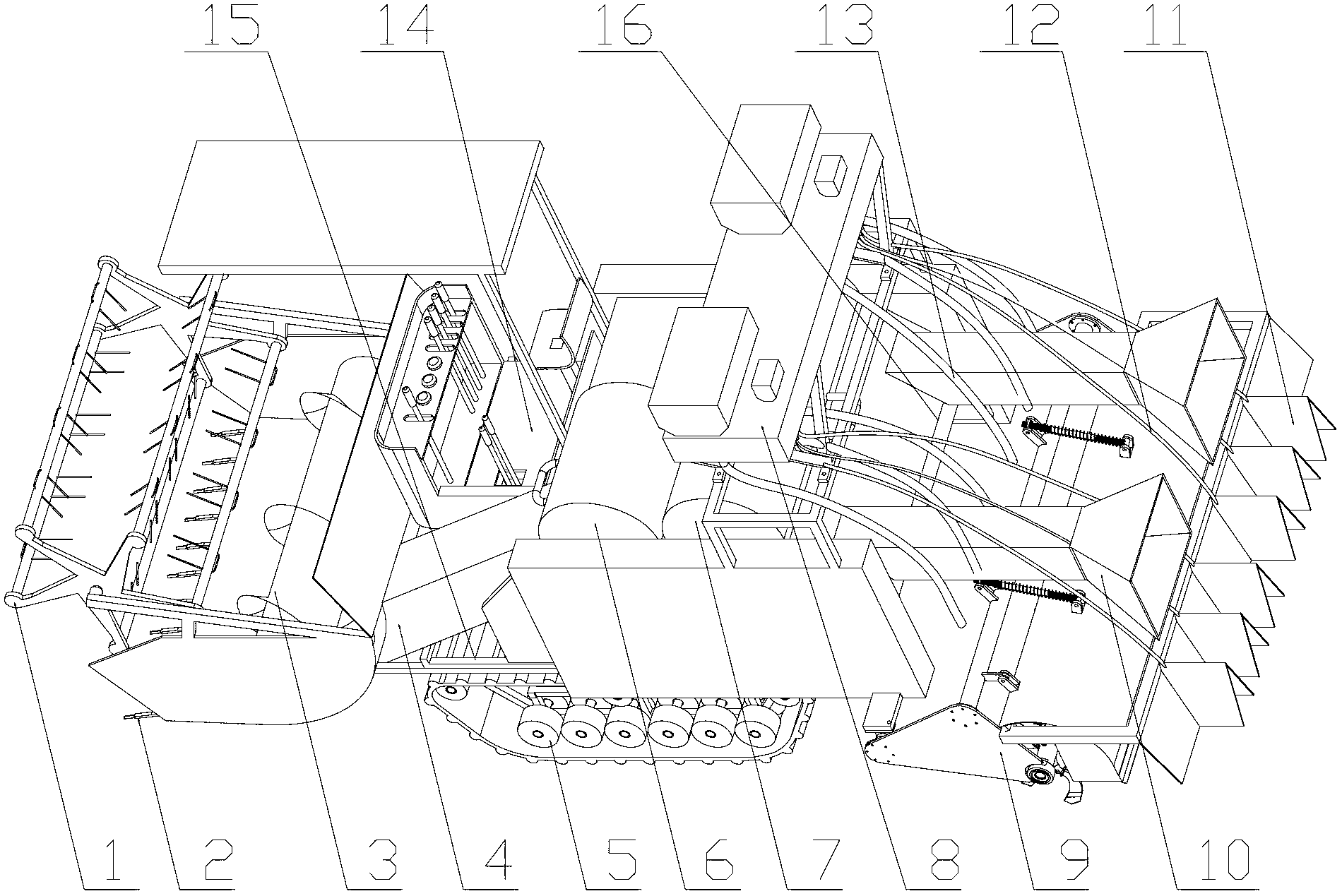

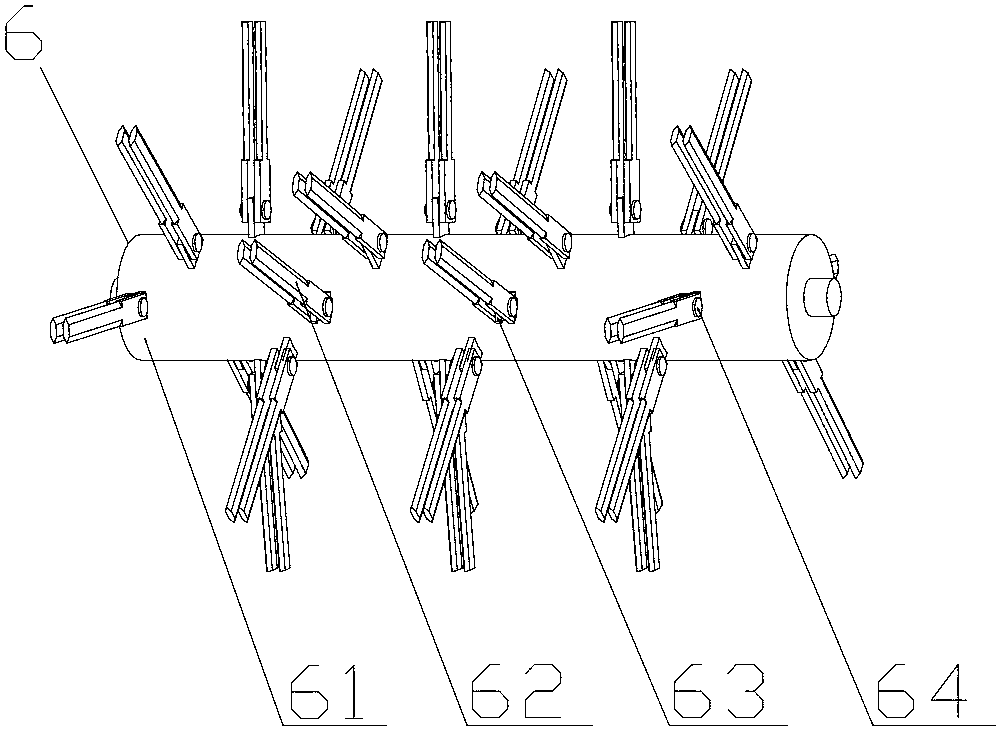

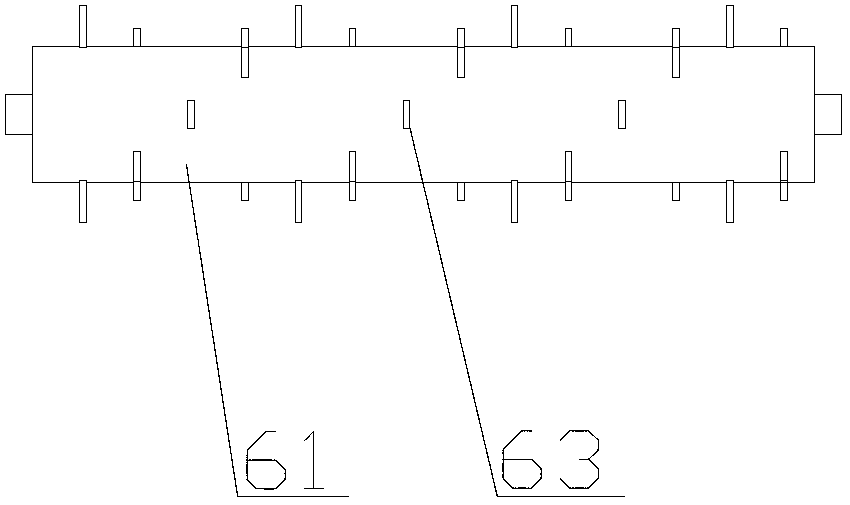

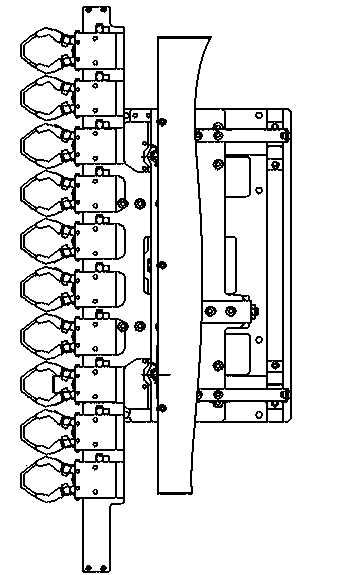

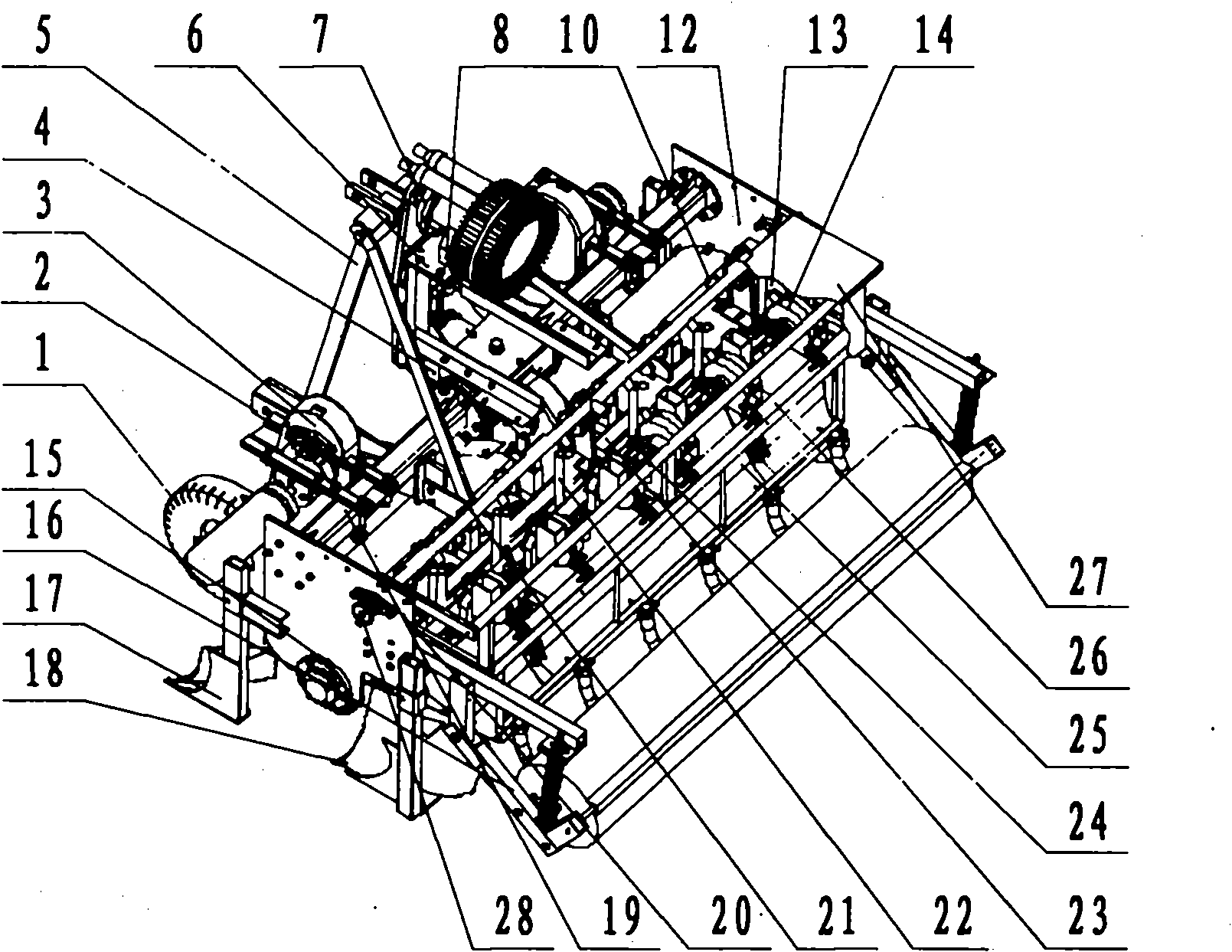

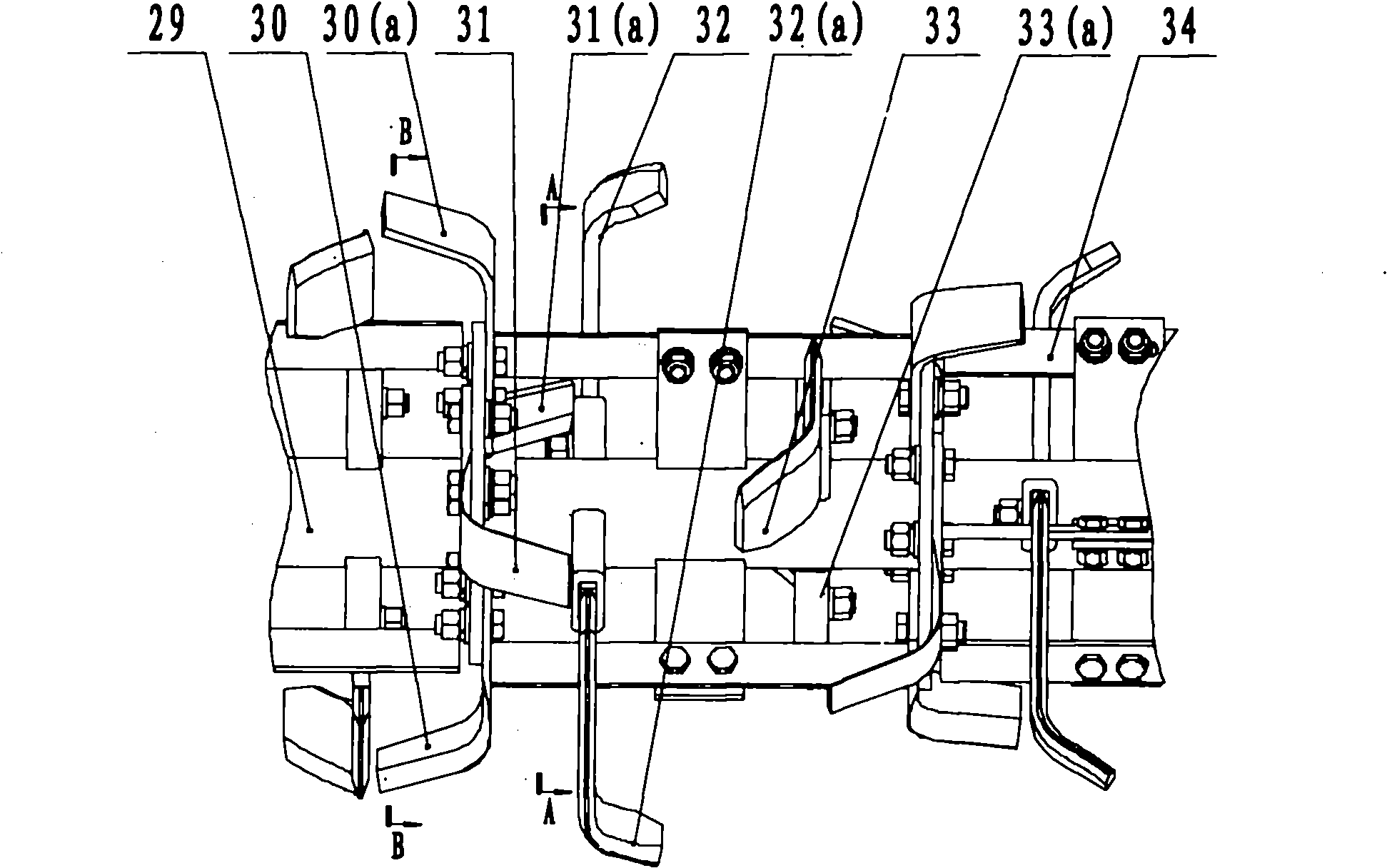

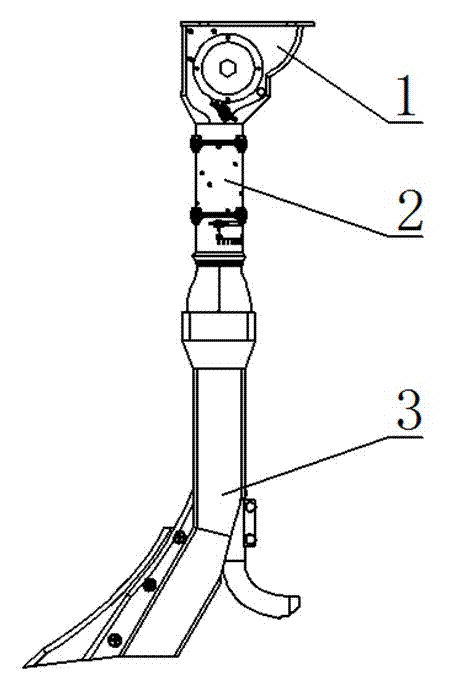

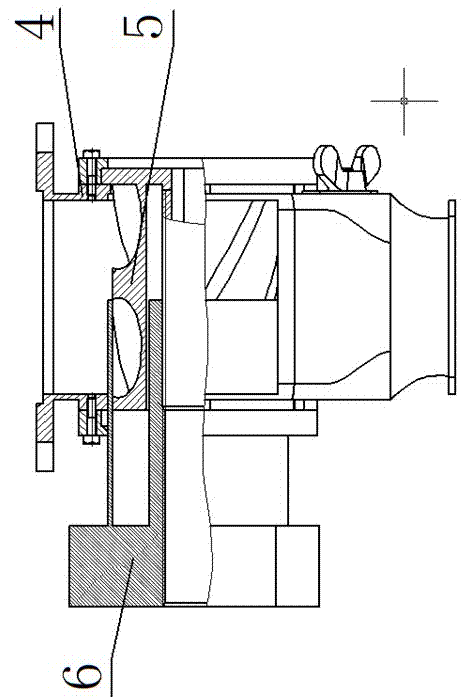

Pull-type picking, kneading, bundling and bagging machine for straw feed

ActiveCN104904437AGood rigidityGood precise shape and position benchmarkLoadersBalingGrazingEngineering

The invention discloses a pull-type picking, kneading, bundling and bagging machine for straw feed. The pull-type picking, kneading, bundling and bagging machine comprises an integral rack, a picking, kneading and transporting device, a straw smashing filling bin, a straw compacting, bundling and bagging device and a powder transmission system. The innovative technologies such as the picking kneading and transporting device being front-arranged to suspend and hydraulically lift, deep tearing, kneading and smashing processing conducted on coarse hard section head and dense surface of corn straw, straw smashing three-direction hydraulic strong compaction and bundling to transport, straw compaction bundling, automatic packing after manual bagging are adopted, and combination processes of picking and smashing, compacting and bundling, bagging and packing are conducted on corn straw in the field. And the pull-type picking, kneading, bundling and bagging machine for the straw feed has the advantages that the technology is advanced, the structure is reasonable, the production efficiency is high, and the working quality is good. Straw feed compaction bales made by the machine has good sealing environment, microbial fermentation action can also occur in a natural condition, the slaking degree is improved, the nutrition ingredient is increased, and the palatability, the grazing rate and the digestion and absorption rate are improved when cattle and sheep are fed.

Owner:四平市顺邦农机制造有限公司

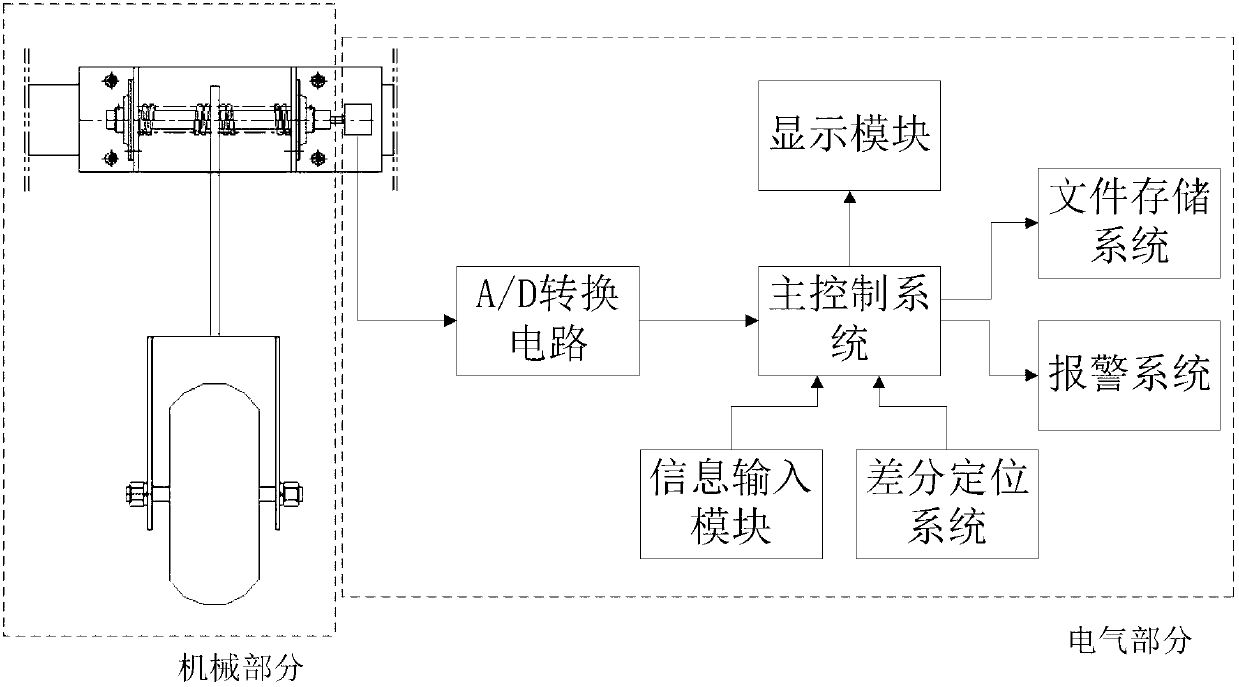

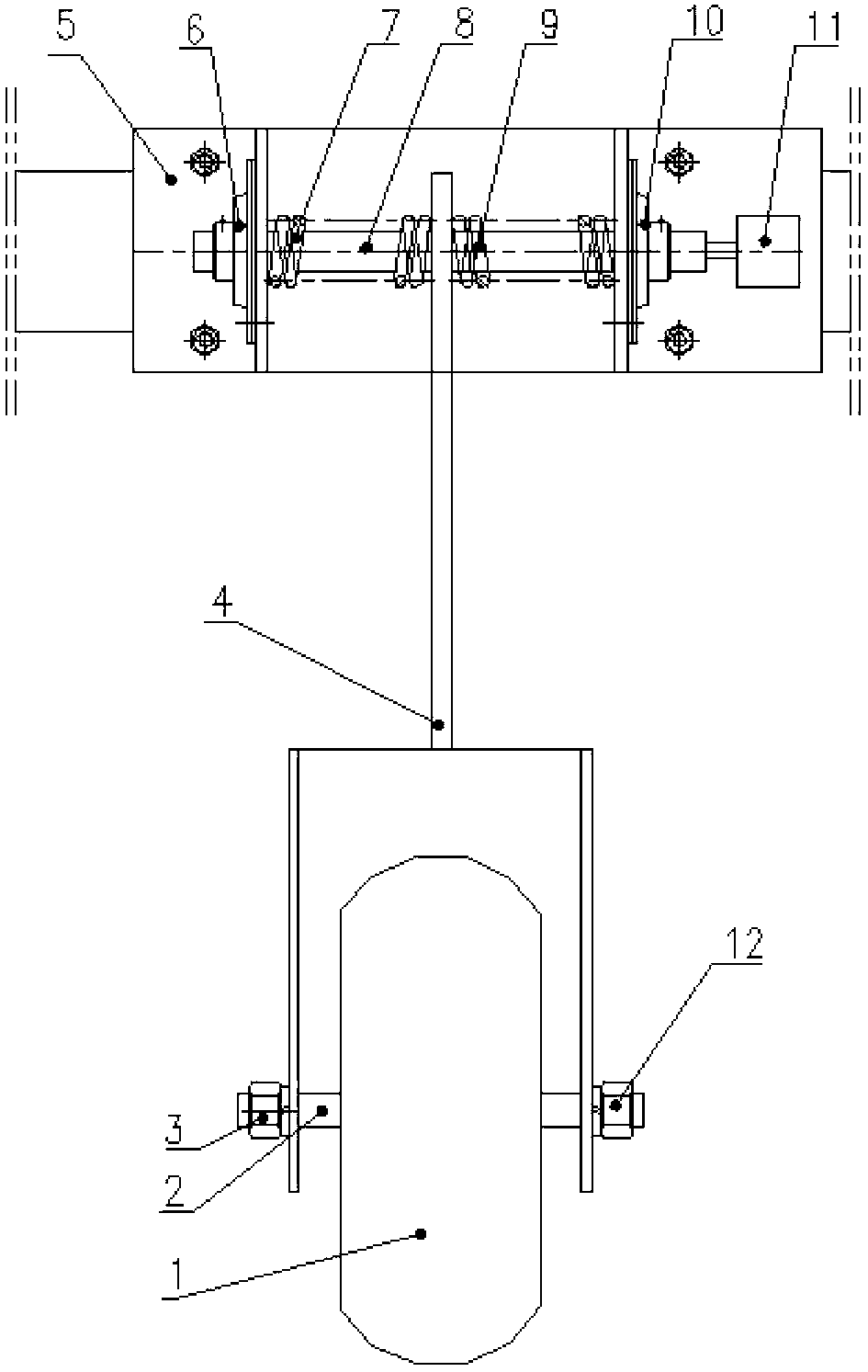

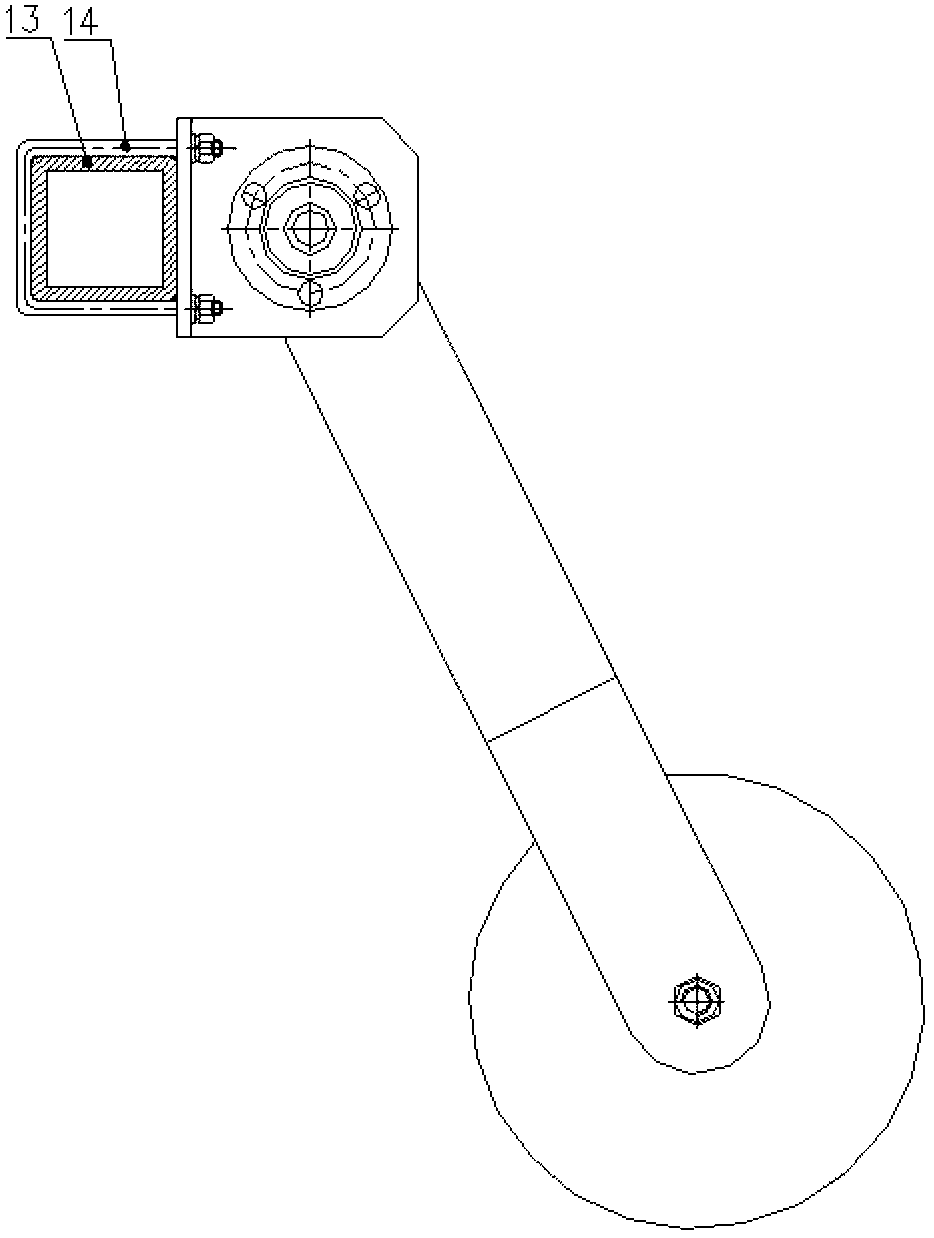

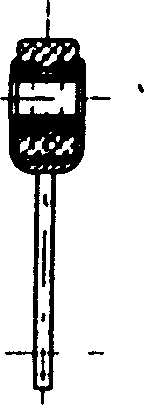

Real-time monitoring system and real-time monitoring method of tilling depth of agricultural implements

InactiveCN103134457AReal-time monitoring of plowing depthReal-time monitoring of tillage depthMeasurement devicesAgricultural scienceControl system

The invention discloses a real-time monitoring system of the tilling depth of agricultural implements and belongs to the technical field of agricultural machinery testing. According to the real-time monitoring system of the tilling depth of agricultural implements, a forward and reverse torsion spring is arranged on a main shaft and can exert a current torque to a wheel carrier, avoid fluctuation of land wheels used for ground copying, enable the land wheels to be closely attached to the ground, and therefore measuring of the tilling depth is more accurate. An angle measuring device is coaxially connected with the main shaft and a tilling depth signal measured can be controlled, converted, alarmed and displayed through an electrical portion composed of an alternating / direct (A / D) switching circuit, a main control system with a microprocessor as a core, a displaying module, a file storage system, an alarming system, an information inputting system and a differential global positioning system. To sum up, by means of the real-time monitoring system and a real-time monitoring method of the tilling depth of the agricultural implements, the tilling depth of operation implements can be monitored in real time, an area with abnormal tilling depth can be cautioned, tilling depth data can be stored at any time, and therefore the real-time monitoring system and the real-time monitoring method of the tilling depth of the agricultural implements lay the foundation for timely adjustment of operators, improvement of operation, and analysis and treatment in lateral period and provide the new system and the new method for development of modern agricultural machinery.

Owner:JILIN UNIV

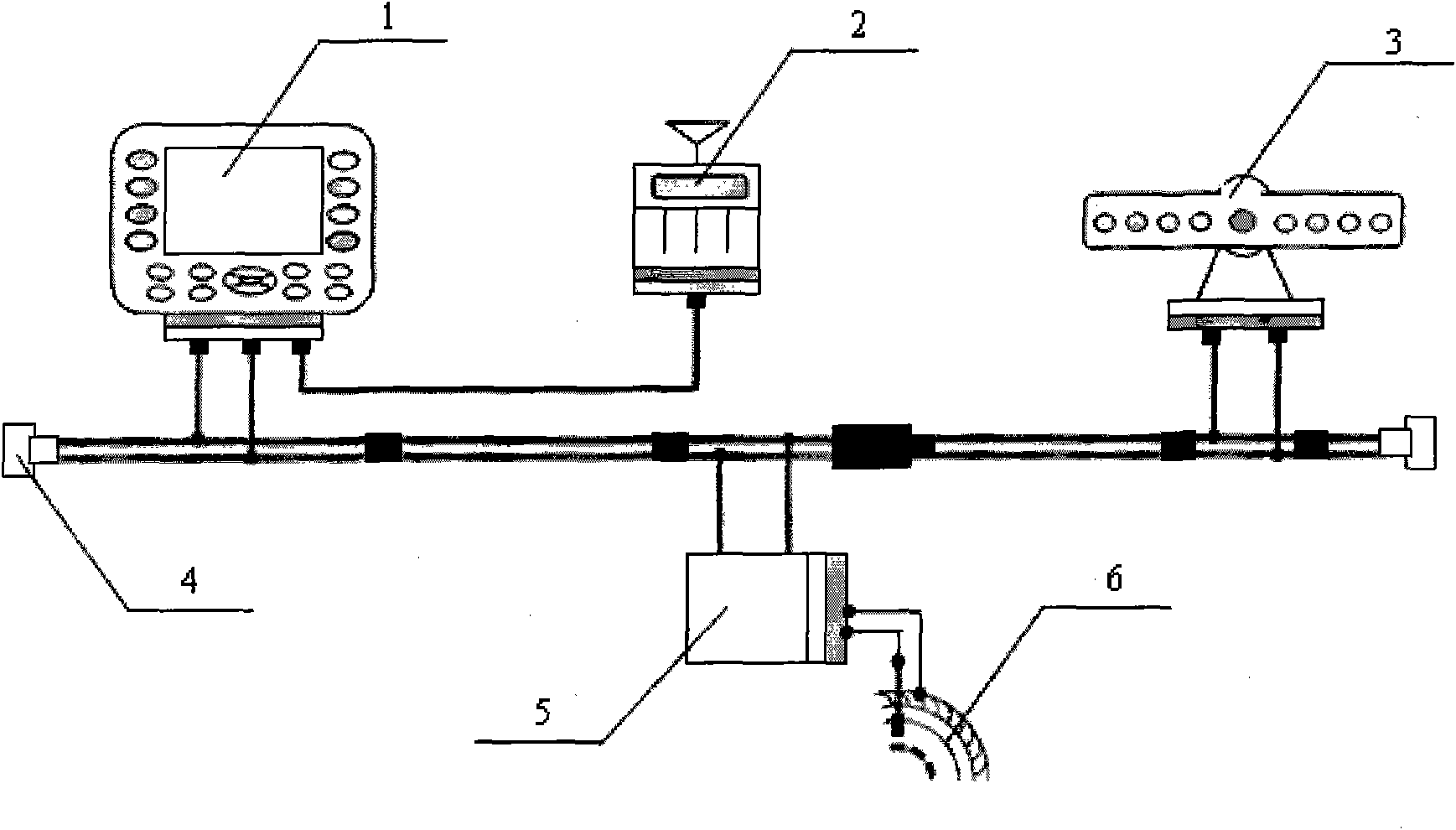

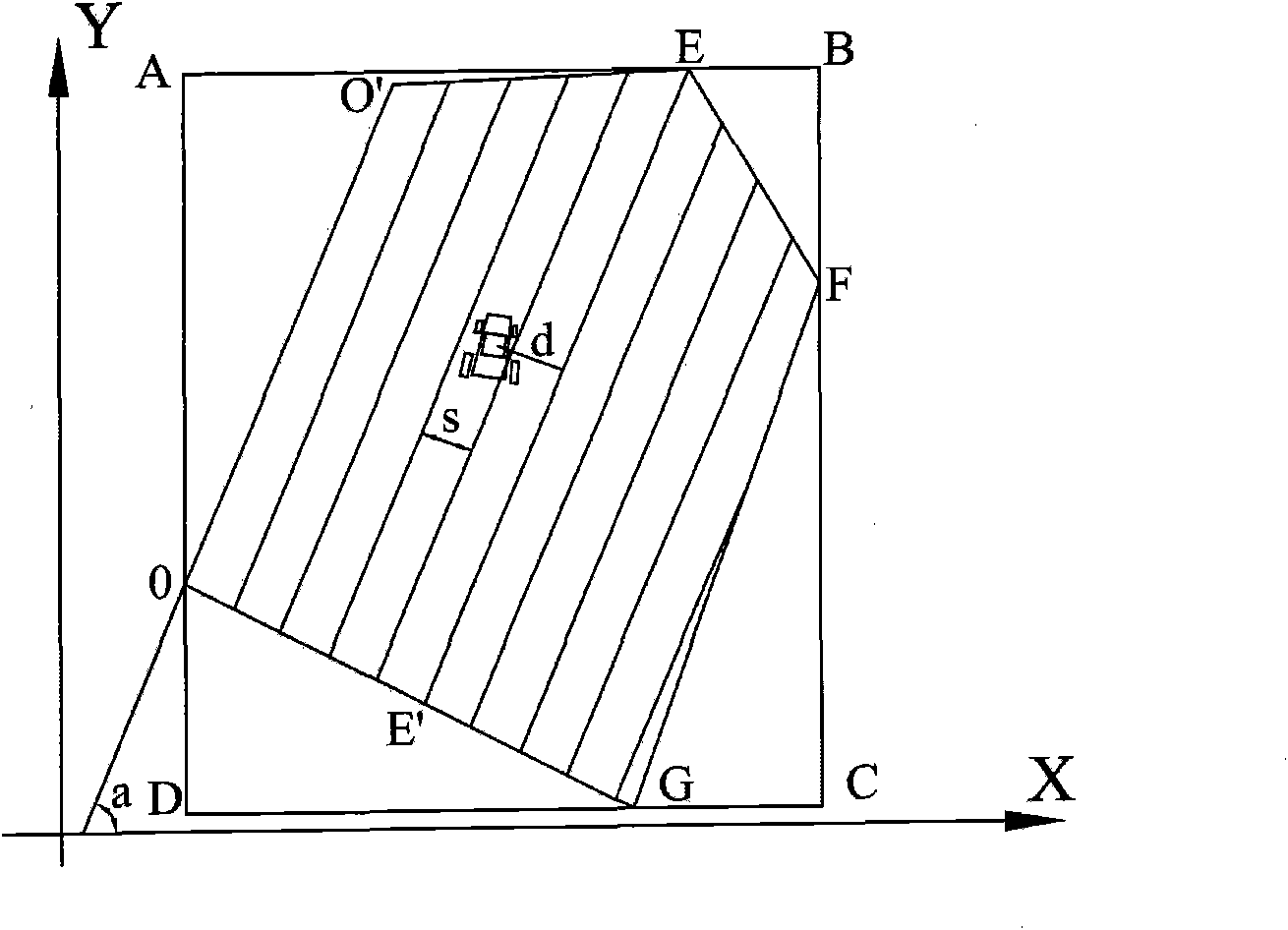

Auxiliary linear tracking control system for operation of distributed agricultural machine

ActiveCN101592957AAchieving straight-line tracking assist controlImprove job qualityInstruments for road network navigationLinear/angular speed measurementControl systemAgricultural engineering

The invention relates to an auxiliary linear tracking control system for operation of a distributed agricultural machine, which comprises a GPS receiver for receiving information on the current operation position coordinate of the agricultural machine, a control terminal for calculating the yawing distance between the agricultural machine and the current operation navigation line according to the position coordinate and transmitting the yawing distance information to a navigation indicating controller, and the navigation indicating controller comprises a two-color light-emitting diode and a plurality of single-color light-emitting diodes and controlling the different light-emitting states of the two-color light-emitting diode and the single-color light-emitting diodes according to the yawing distance. The auxiliary linear tracking control system achieves the linear tracking auxiliary control of a tractor in the operation process based on the digital design of an operation navigation target route of the tractor, the GPS navigation and an embedded control technique, is more precise than conventional tractor operation navigation techniques with a scriber, foam spraying and the like, is not limited by the farmland operating environment, and improves the operation quality and the efficiency.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

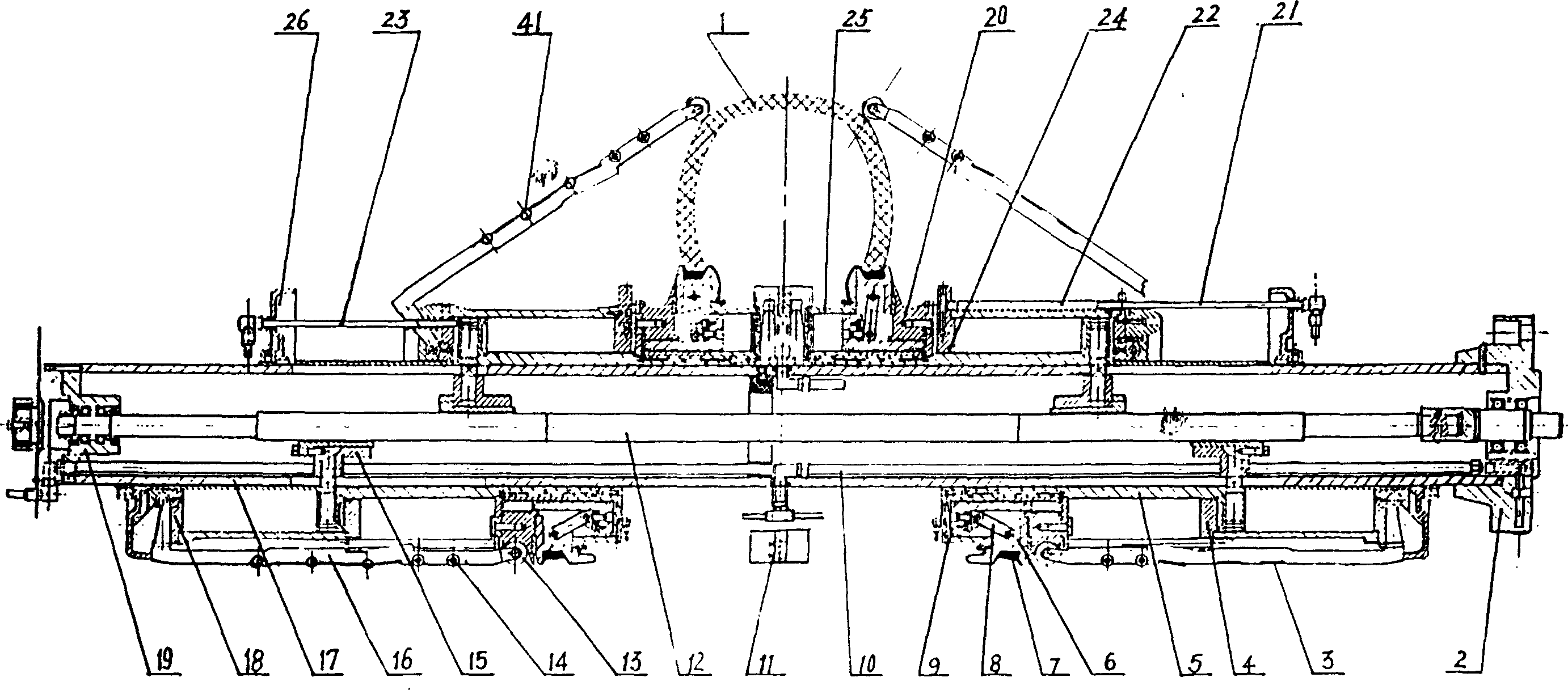

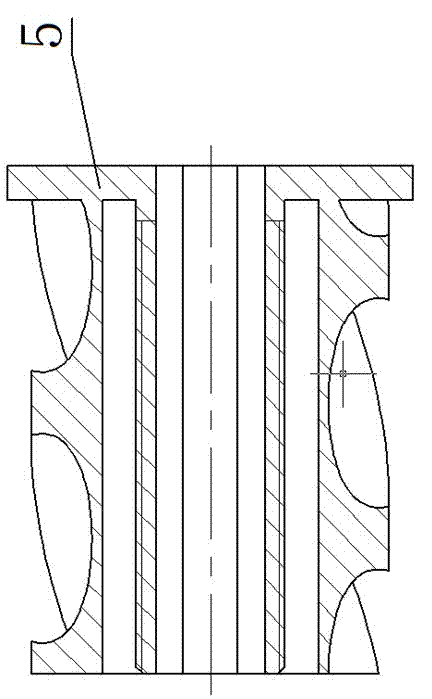

Formation drum of automatic back-edging roller press

The present invention relates to an automatic back contact rolling mechanical forming drum, including coupling flange, back contact rolling arm elastic rubber ring, drive back contact rolling piston component and cylinder body sleeve the the front end of which is equipped with sector block cylinder body, drive sector block piston group, sector block connecting bar group, fastening tire body sector block group and sector guide disk. The rear end of the described piston component is symmetrically equipped with back contact rolling arm component, back contact rolling wheel group and free guide bearing group. The rear end of the described cylinder body sleeve is equipped with dished pushing disk, and a slide-fit cylinder body rear end cover is mounted on the cylinder body sleeve, and the rear portion of the described back contact rolling arm component is connected at the rear end cover place of the cylinder body.

Owner:TIANJIN PLASTIC RUBBER MACHINERY INST

Multifunctional direct seed sowing machine for coating grass on rape

ActiveCN103299734ATo achieve moisture conservationAchieve heat preservationSpadesCrop conditionersVehicle frameAgricultural engineering

The invention discloses a multifunctional direct seed sowing machine for coating grass on rape. The multifunctional direct seed sowing machine comprises a walking system, a vehicle frame, a towing bracket, a sowing and fertilizing system, and a rotary tillage ditching system, wherein the vehicle frame is arranged on the walking system; the towing bracket is connected with the vehicle frame and arranged behind the walking system; a horizontal header, a straw chopping and conveying system and a throwing about mechanism, which are connected with each other in sequence, are arranged on the vehicle frame from front to back; the rotary tillage ditching system is arranged on the towing bracket below the throwing about mechanism; the sowing and fertilizing system is arranged on the vehicle frame; and the sowing ports and the fertilizing ports of the sowing and fertilizing system are arranged before and behind shallow winter breaking and ditching formed ridges respectively. According to the multifunctional direct seed sowing machine, six processes such as shallow ploughing, stubble cleaning, sowing, fertilizing, ridge forming ditching, and grass coating between sowed rows can be fulfilled simultaneously, so as to effectively solve the problems of complex processes, low efficiency, and grass winding and mud hilling on soil operation components, greatly improve the working performance, efficiently realize soil moisture conservation and heat insulation on rape ridges due to secondary utilization of former plant stubble, and improve the operation quality of sowing.

Owner:HUNAN AGRICULTURAL UNIV

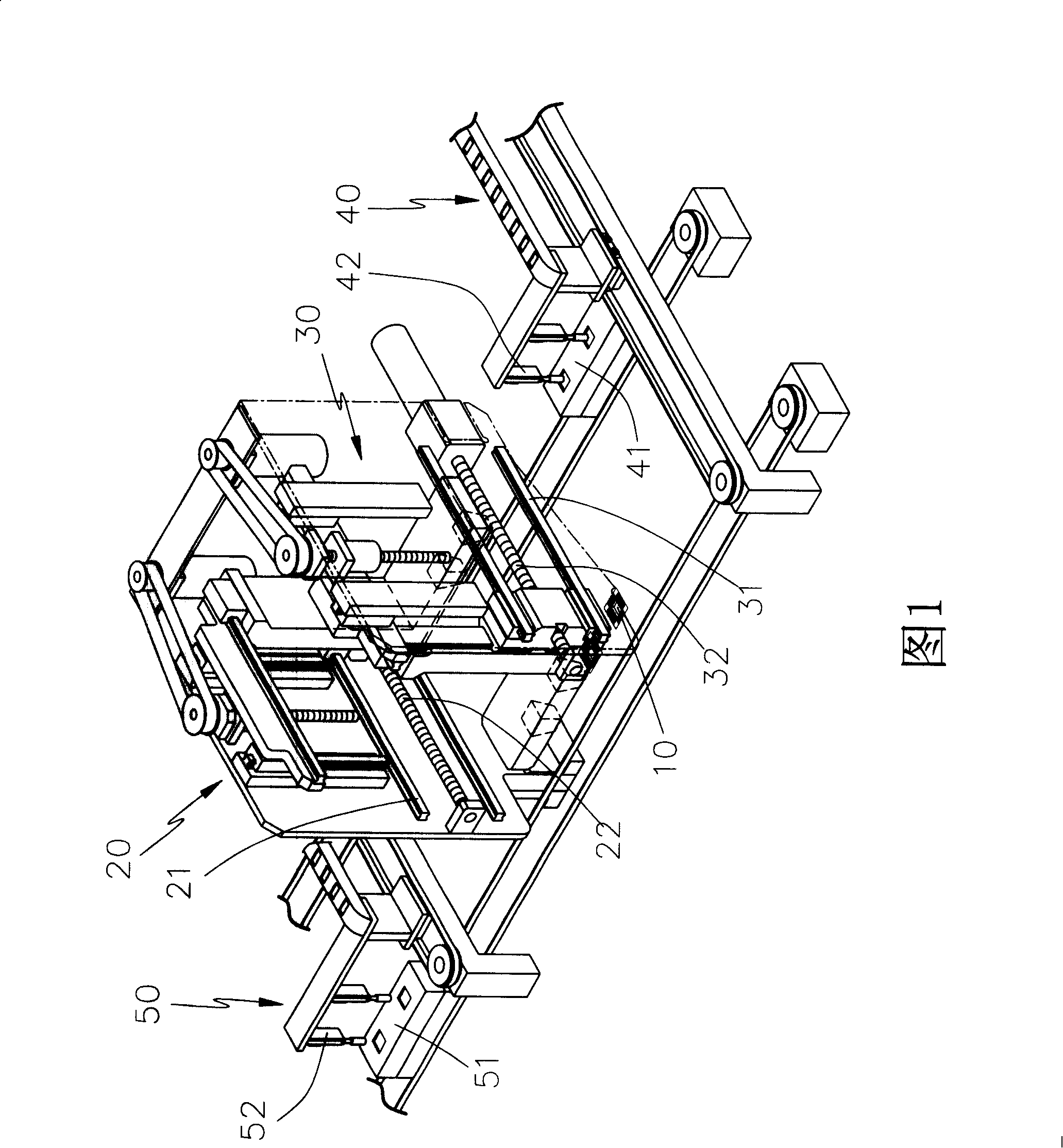

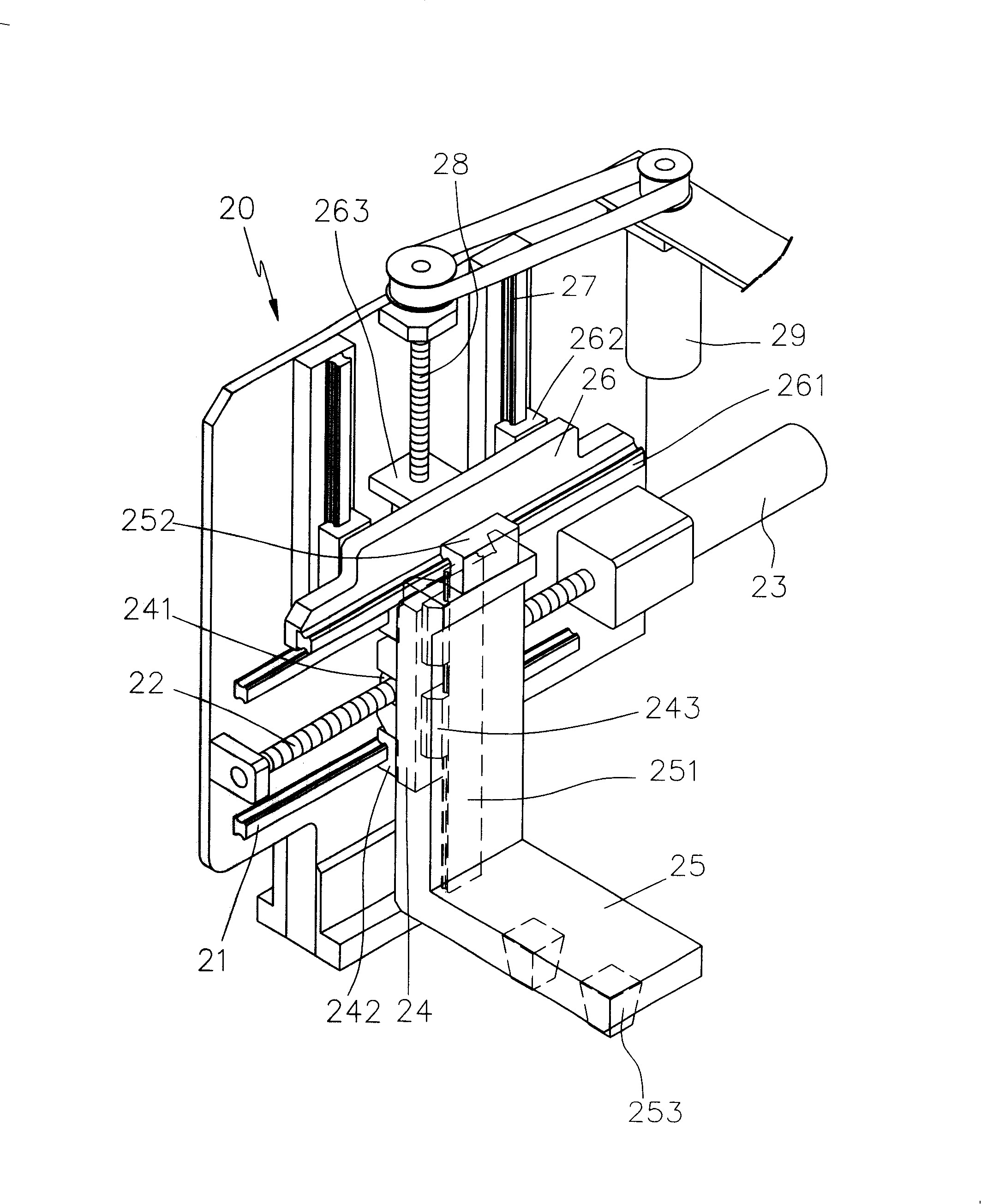

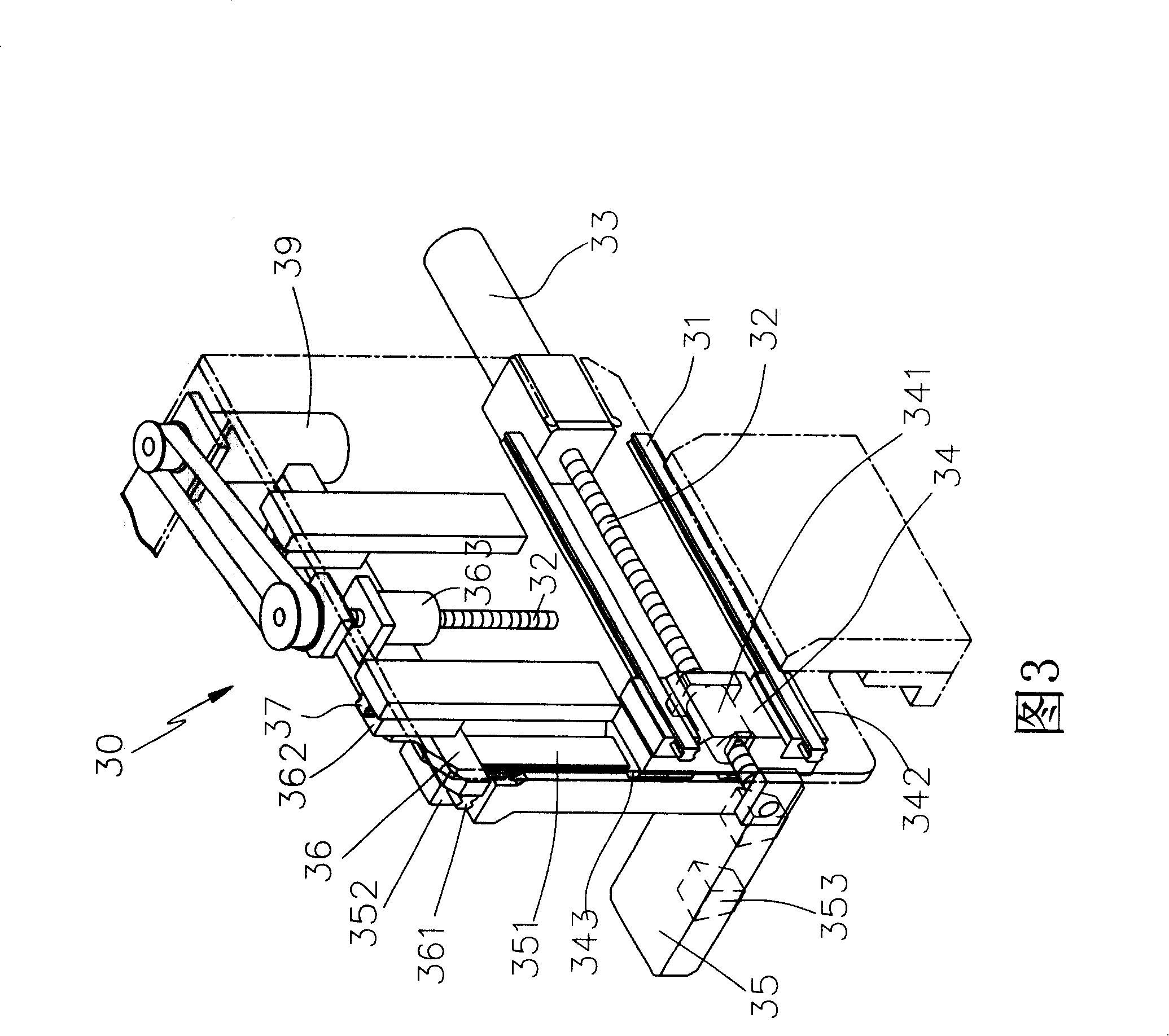

Electronic component transfer loading device and method

ActiveCN101234704AEasy to manufactureReduce manufacturing costSemiconductor/solid-state device testing/measurementElectronic circuit testingElectronic componentWork quality

The invention relates to an electronic component transferring device and a method, comprising at least a work station for the transferring of the electronic device to work and executing work, a first feeding carrier arranged on a side of the work station to bear the electronic device to work, a second feeding carrier arranged on another side of the work station to bear the electronic device to work, a first material receiving carrier arranged on the same side with the first feeding carrier to bear the electronic device finishing work, a second material receiving carrier arranged on the same side with the second feeding carrier to bear the electronic device finishing work, a first transferring taking and placing device arranged on a chassis above the work station through a slide group frame to slide in three axial directions and transfer the electronic device for executing work, and a second transferring taking and placing device arranged on the chassis above the work station through the slide group frame to slide in three axial directions and transfer the electronic device for executing work. Therefore, the invention achieves the purpose of stably transferring the electronic device into the work station for executing work, facilitating the manufacture, and easily improving the work quality.

Owner:HON PRECISION INC

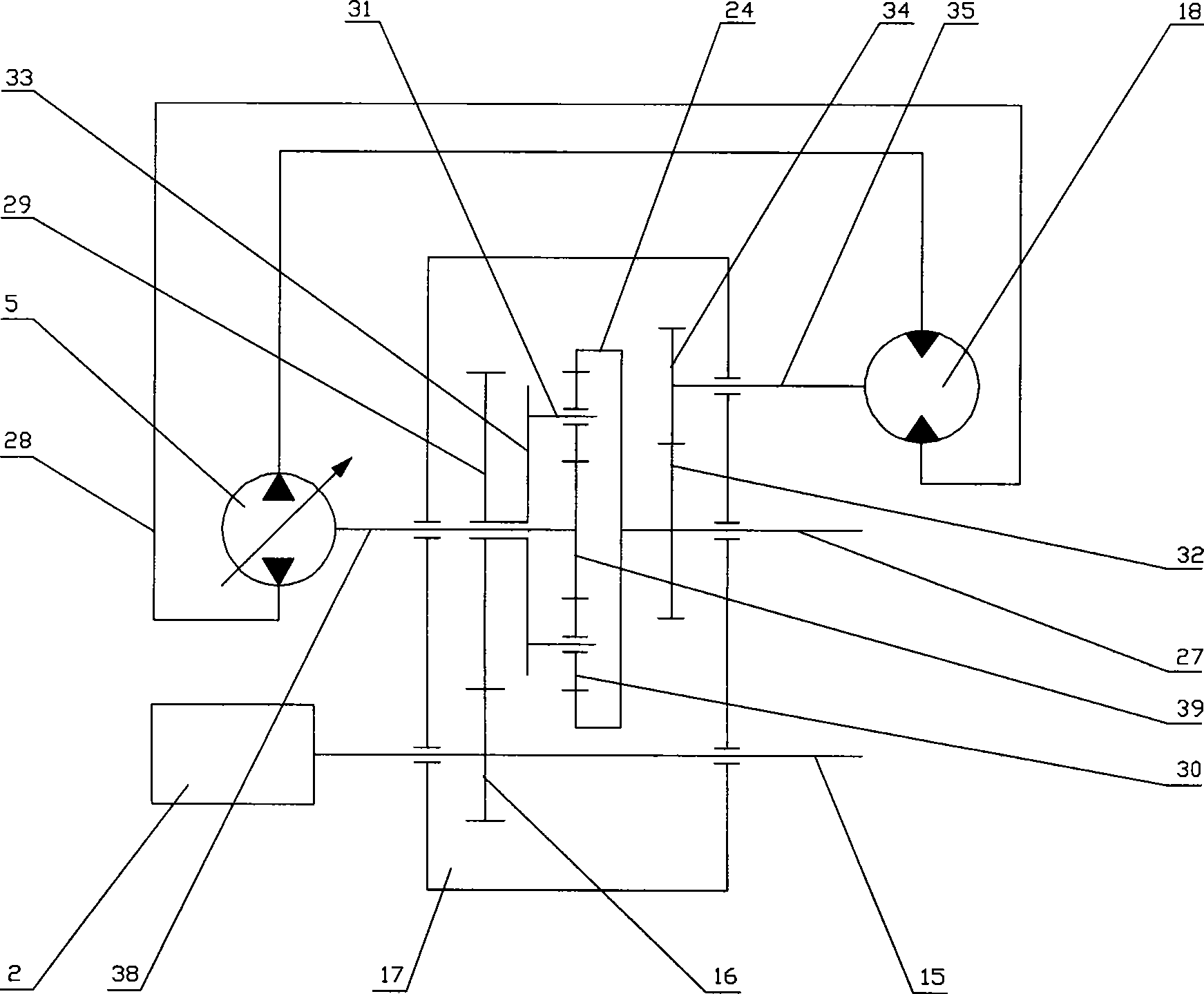

Mechanical and hydraulic combined transmission device

InactiveCN101413572AImprove transmission efficiencyReduce fuel consumptionFluid gearingsControl devicesHydraulic motorPower flow

The invention relates to a mechanical and hydraulic compound transmission device which comprises an engine, a speed changer, a planetary gear box, a hydraulic variable pump, a hydraulic motor and a reduction gearbox; the engine is sequentially connected with the transmission speed changer and the planetary gear box, and a planetary gear mechanism of the planetary gear box distributes the power driven by the motor to respectively drive the hydraulic variable pump and a center gear; the hydraulic variable pump is sequentially connected with a transmission hydraulic motor and a half shaft, the half shaft converges mechanical power flow driven by the center gear and hydraulic power flow driven by the hydraulic motor and protrudes outside the planetary gear box to output the power, and a transmission gear box is connected with the half shaft to redrive a rear shaft to drive a vehicle. A special vehicle refit by the technology with a single-engine configuration can run at a stepless variable speed in a mechanical and hydraulic compound transmission mode, meanwhile, the vehicle can drive a vehicle-mounted operating device in the mechanical transmission mode; during transition, the mechanical transmission mode can be adopted to cause the device to run quickly, the power system occupies little vehicle space, and has low emission, high transmission efficiency and low oil consumption.

Owner:赵宏坚 +1

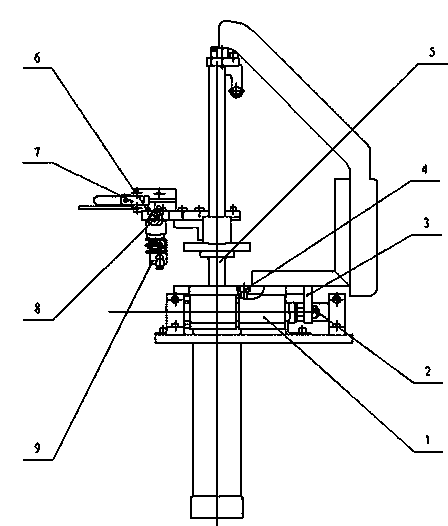

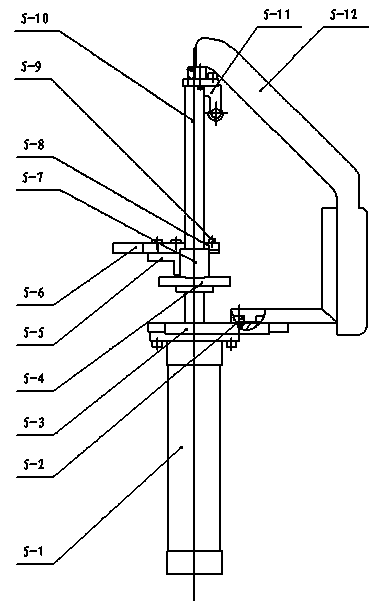

Automatic cop drawing device and method of ring spinning frame

The invention discloses an automatic cop drawing device and method of a ring spinning frame, relates to an automatic doffing cop drawing device of a ring spinning frame, in particular to an automatic cop drawing device and method of a ring spinning frame for separating and collecting the cop and a spindle. The automatic cop drawing device comprises a pneumatic manipulator (7), a horizontal moving assembly (1), a lifting assembly (5), a yarn cutting part (9) and a bobbin collecting device; up-down one dimension motion of a lifting cylinder and the clamping and releasing of the pneumatic manipulator are realized by the steps of initializing, horizontal moving to a rear position, vertically moving to a lower position, cop clamping, drawing the bobbin to an upper position, overturning, yarn cutting, bobbin collecting and the like, so the cop is drawn and descended, harm to the yarns in the bobbin drawing process is avoided, no radial force is generated to an ingot, and the automatic cop drawing device has the beneficial effects of reducing labor intensity of a worker and worker number and improving operation efficiency and doffing quality.

Owner:RIZHAO YUXIN MOTIVE POWER

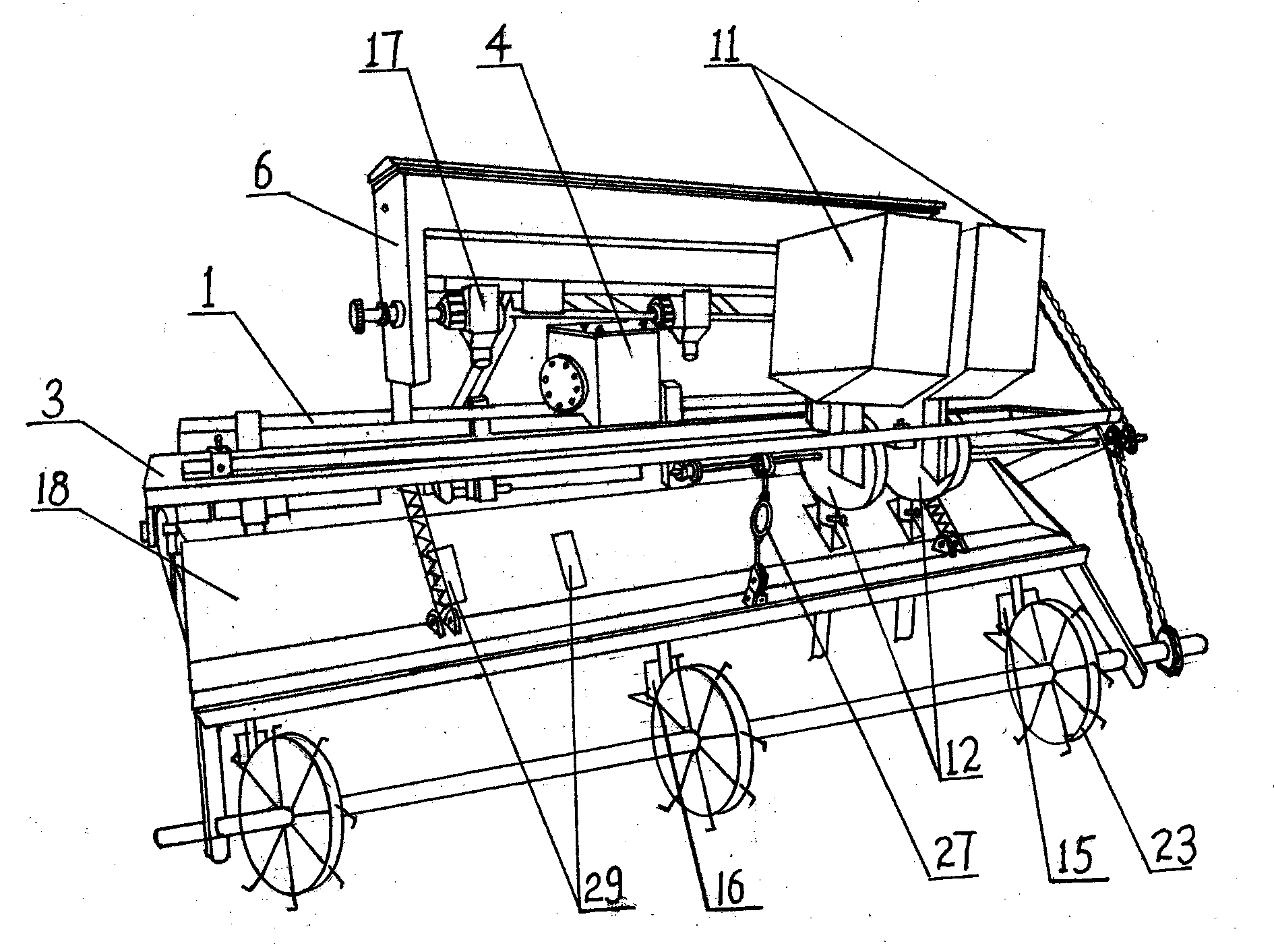

Rotary tillage, ridging, sowing and fertilizing all-in-one machine

InactiveCN104255099AAvoid destructionGuaranteed stabilitySpadesPloughsAgricultural engineeringTillage

The invention discloses a rotary tillage, ridging, sowing and fertilizing all-in-one machine. By adopting a rack structure which is composed of a front beam, a back beam and a square bracket, arranging a fertilizer box above a gearbox, and fusing ditching, ridging, fertilizing and sowing into an integral structure, fertilization and sowing are finished in the ditching and ridging process; the all-in-one machine is not only compact and flexible, but damage from gathered soil to a fertilizing part is also avoided in the ditching and ridging process as a fertilizing leg is located in the middle of a ditcher, and stability of the soil at the fertilizing part is ensured; meanwhile, a sowing pipe is located between the fertilizing leg and the ditcher in the transverse direction, is located between side wing plates of the ditcher in the lengthways direction and is located below a soil covering plate in the vertical direction, to be short, is located at the place where soil is gathered and shaped, so that the soil is basically in a steady structure at the place, and stability of the position of a seed sown at the place can be guaranteed efficiently, row distance, plant distance and planting depth can be controlled and mastered conveniently, and precise sowing is realized.

Owner:南阳市金海洋农机有限公司

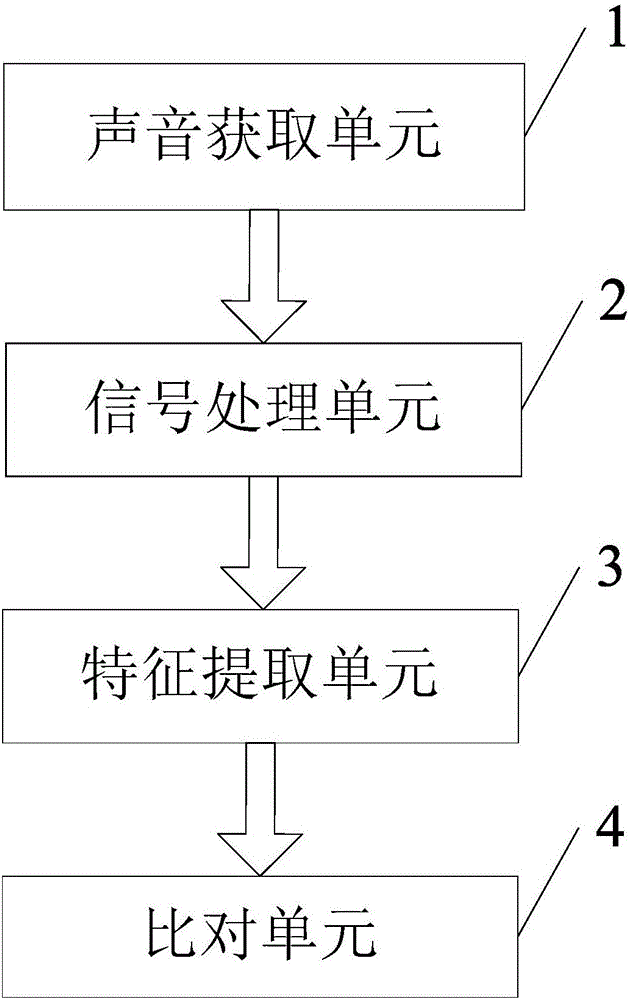

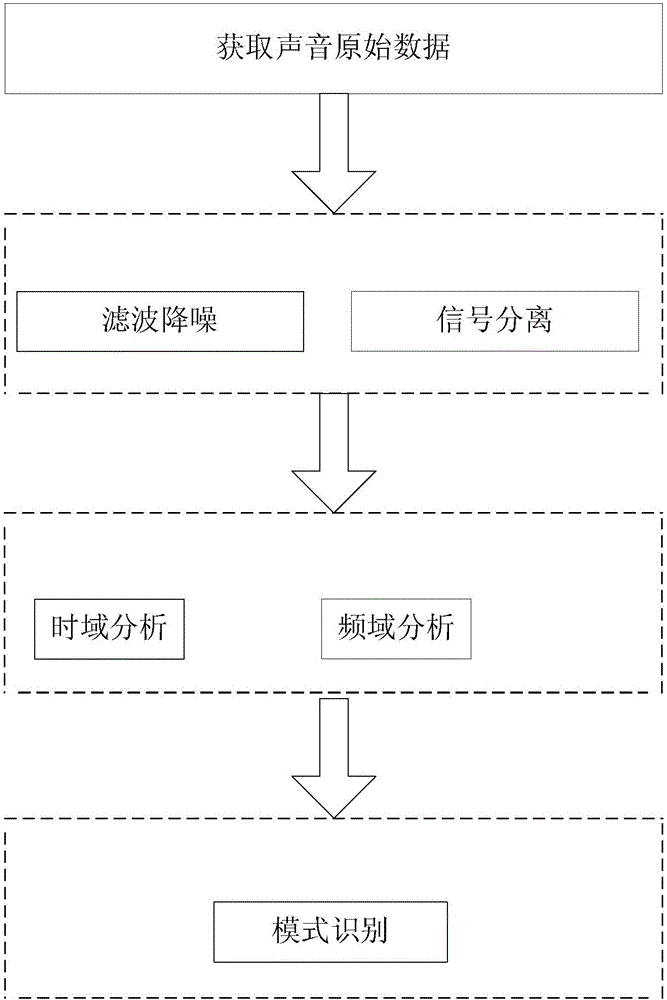

Railway vehicle fault vehicle-mounted acoustic detection system and method

InactiveCN106198062AGuaranteed uptimeEasy to detectRailway vehicle testingTime domainFeature extraction

The invention belongs to the field of rail transit tool safety detection, and provides a railway vehicle fault vehicle-mounted acoustic detection system and a detection method. According to the technical scheme of the invention, the system and the method solve the problems in the prior art that the existing manual detection is difficult in operation and low in accuracy and a dynamic detection system installed on the ground is poor in detection real-time performance. A sound obtaining unit is used for obtaining an original sound signal. A signal processing unit is used for carrying out the filtering treatment and the data separation treatment on the original sound signal. A feature extraction unit is used for carrying out the feature extraction on the processed sound signal. A comparison unit is used for performing the time-domain and frequency-domain analysis on the extracted feature to obtain a characteristic value matrix of the sound signal. The characteristic value matrix is compared with a sound characteristic database without a fault standard. During the comparison process, based on the domain and frequency domain combination method, whether a fault exists or not, and the existence degree of the fault are judged in the time domain firstly. Secondly, the comparison is further performed in the frequency domain to obtain a corresponding fault diagnosis result. Therefore, the system and the method are used for the fault detection of various rail vehicles.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

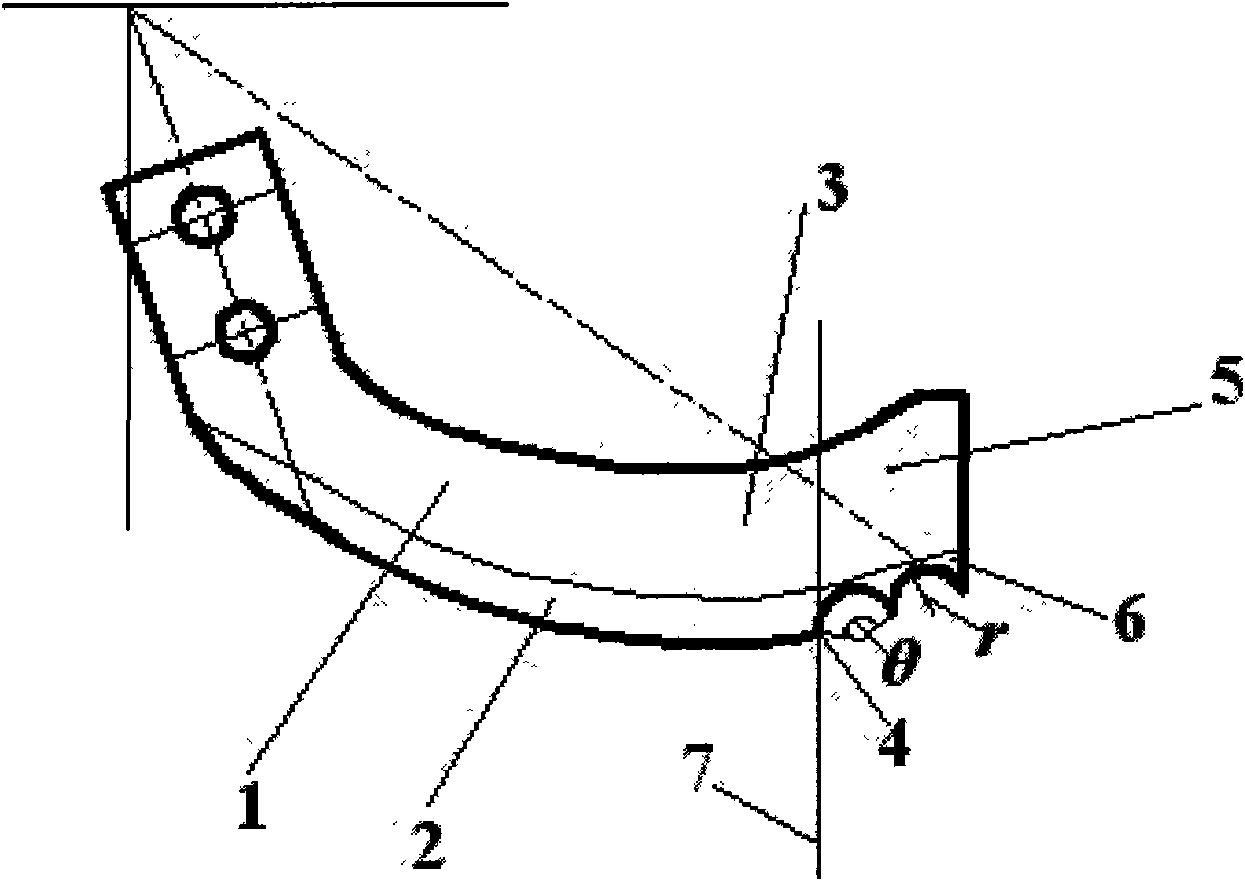

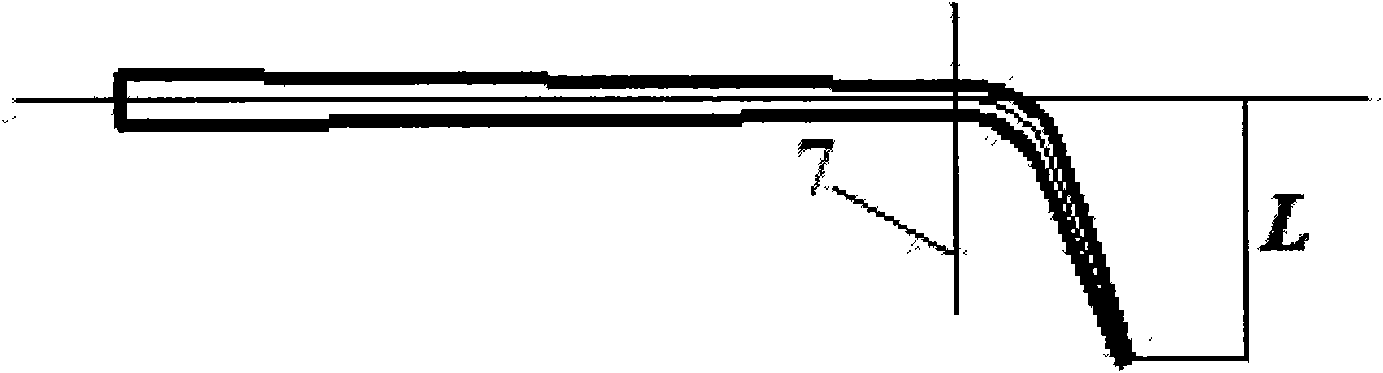

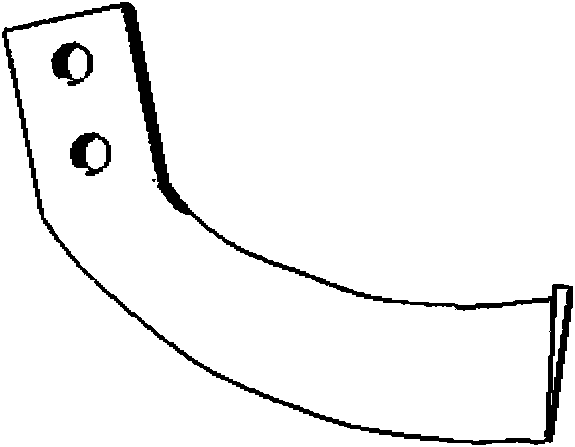

Cultivation rotation working part with bionic geometric structure

InactiveCN101548592ASoil cutting resistance is smallReduce power consumptionTilling equipmentsResearch ObjectClaw toe

The present invention relates to a geometric structure of rotation working part of used for driving type rototilling-tillage machine, and especially to a cultivation rotation working part with bionic geometric structure. The invention takes the fore leg claw toe of mole with high-efficient digging capability as a bionic researching object, extracts the special geometric structure characteristic and applies the geometric structure characteristic for designing the rotation working parts (rotary blade or stubble breaking blade) on the cultivation machinery. The component is mainly composed of a side cutting surface with a side cutting edge, a front cutting surface with positive cutting blade, a transition surface for connecting the front cutting surface and the side back surface, and a transition edge for connecting the front cutting edge and the side cutting edge. The invention is characterized in that the front cutting edge (6) adopts a bionic circular arc structure. The geometric shape is confirmed by the following equation: when the operation breadth of single blade of front cutting edge is L, the corresponding central angle of circular cutting edge is (theta), the corresponding radius is (r), and the number of circular arcs is (n), the corresponding expression is as follows: L / 2nr=sin(theta / 2). The cultivation rotation working part with bionic geometric structure according to the invention can greatly reduce the energy consumption in cultivation operation under the precondition that the cultivation quality is ensured.

Owner:JILIN UNIV

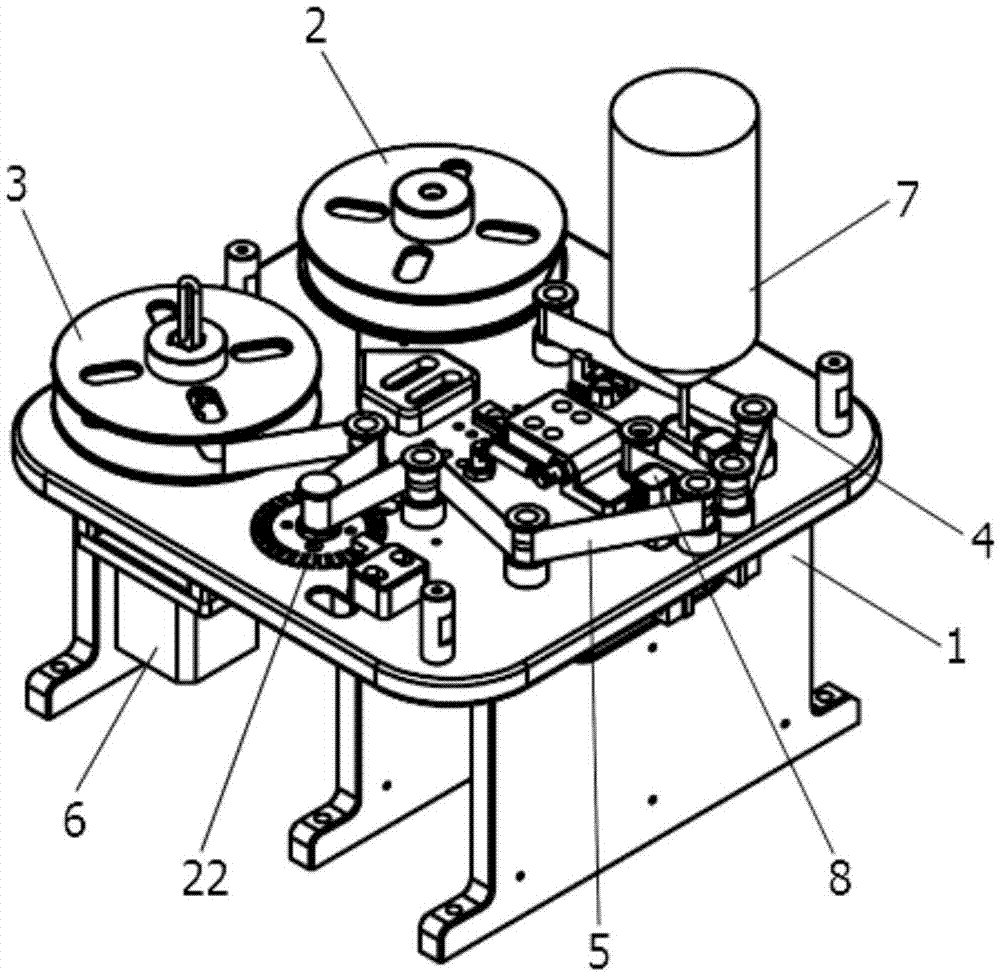

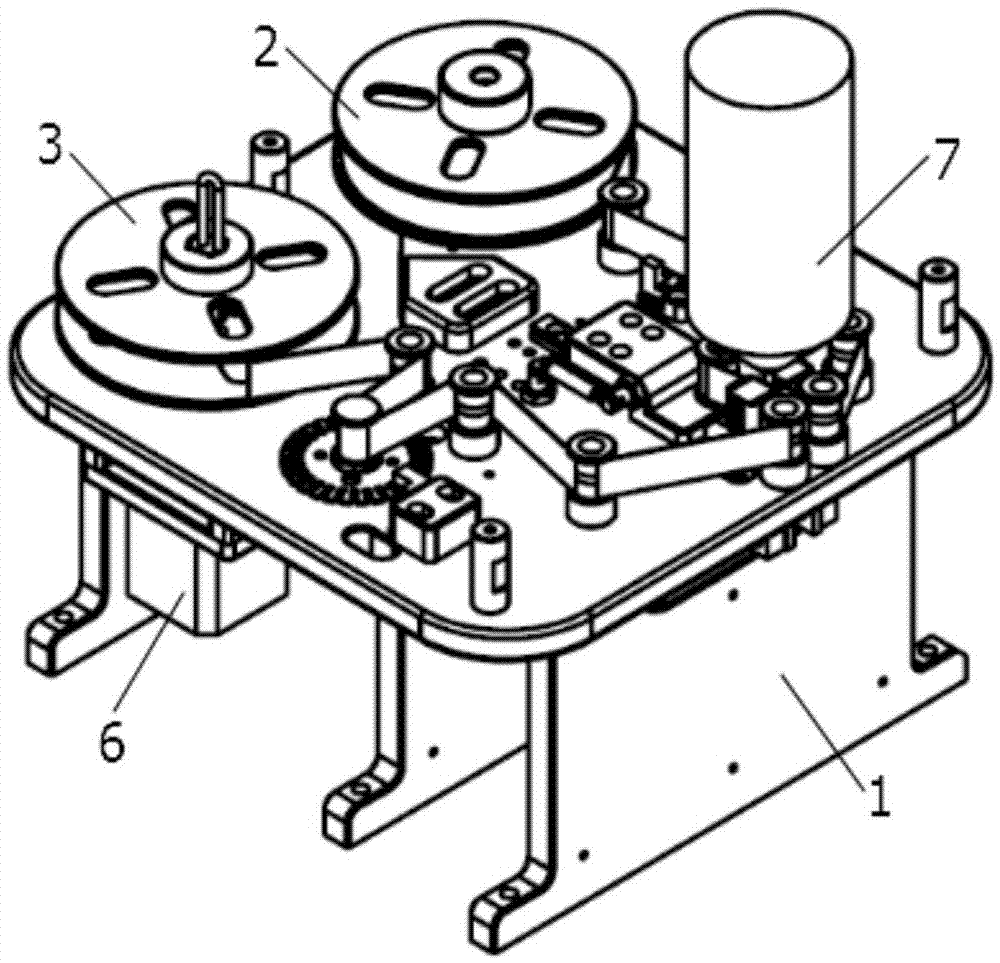

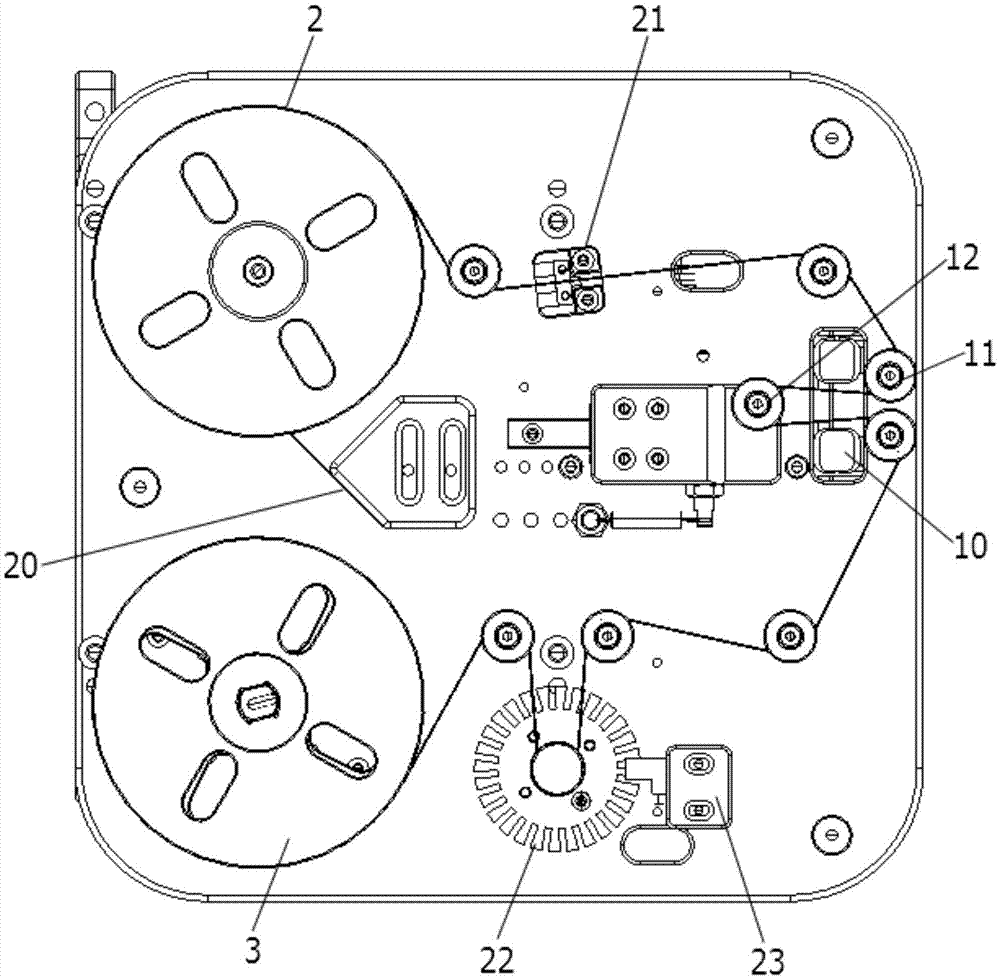

Needle glue removing mechanism and dispenser

ActiveCN105436037AAutomate cleaningImprove cleanlinessLiquid surface applicatorsSpraying apparatusMotor driveWorking environment

The invention discloses a needle glue removing mechanism which comprises a cabinet, wherein a material tray, a material receiving tray and a pulley block are fixed on the cabinet; a material band is rolled in the material tray, and one end of the material band is led out from the material tray and then sequentially passes each pulley of the pulley block to be connected with the material receiving tray; the bottom of the material receiving tray is connected with a stepping motor, and the stepping motor drives the material receiving tray to rotate, so that the material band is rolled into the material receiving tray; and at least three pulleys in the pulley block fold the material band into U shape, the middle of the U-shaped material band is used for insertion of a to-be-cleaned dispenser needle, and two sides of the U-shaped material band are respectively provided with a chuck which is used for clamping the material band and the needle. According to the invention, the stepping motor is used for driving the material receiving tray and the material band to move, and due to clamping friction of the material band and the needle, residual glue on the needle can be cleaned up, thus overcoming inconvenience of manual operation, realizing automatic cleaning of the needle, and greatly improving the working quality; and since a material rolling form is adopted, used material band can be recycled in rolls, pollution of the field due to production of rubbish can be avoided, and the cleanness of the working environment can be improved.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

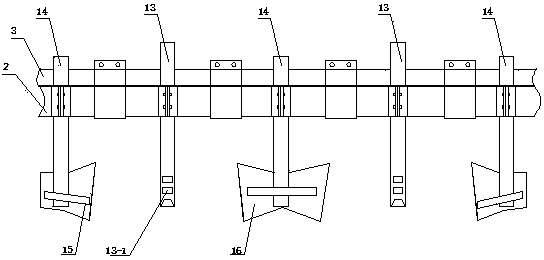

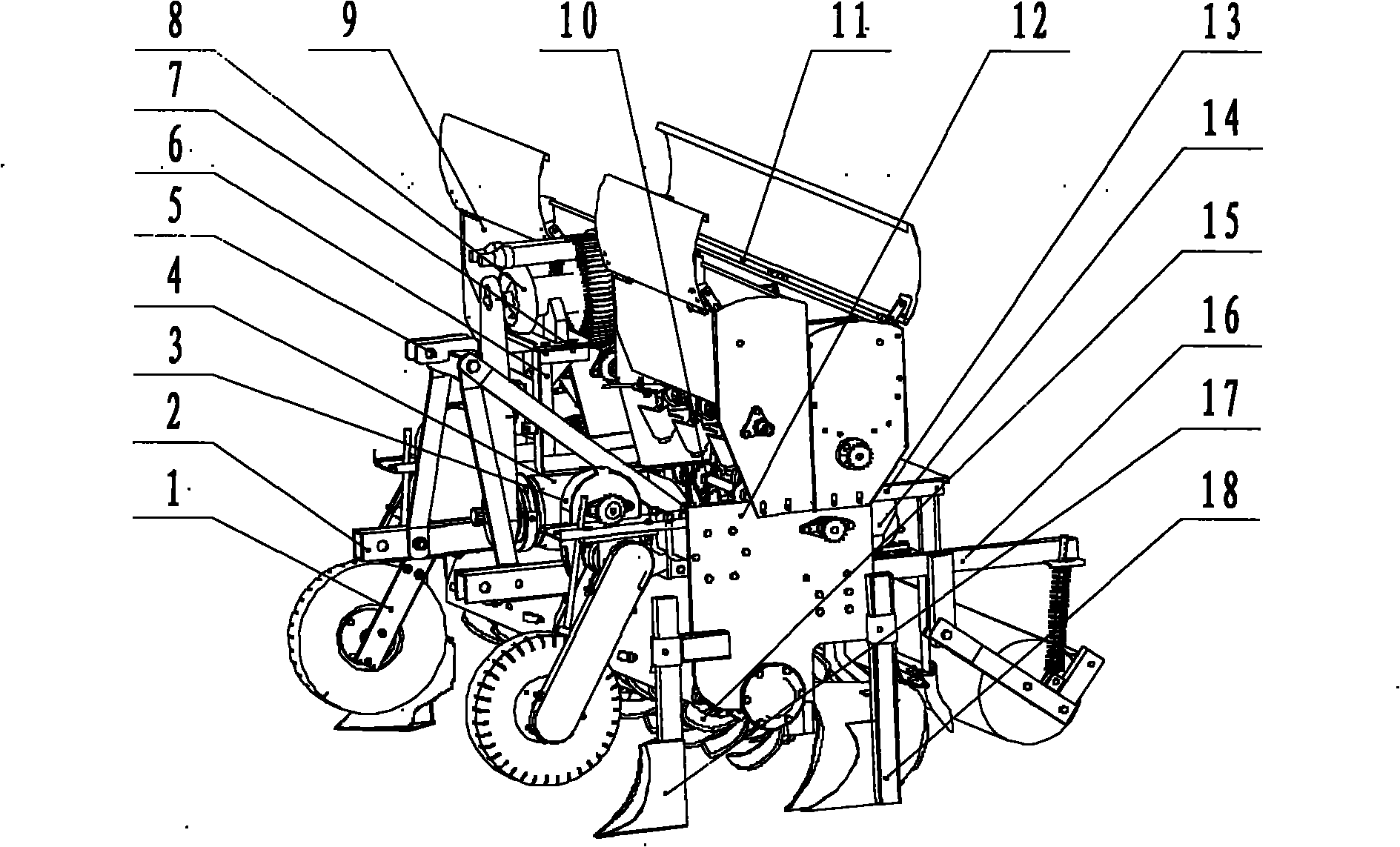

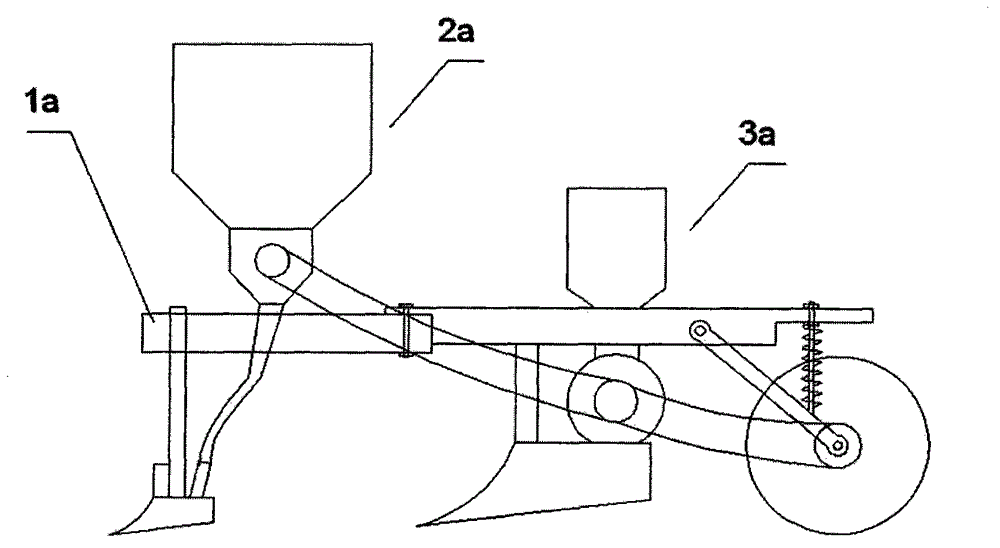

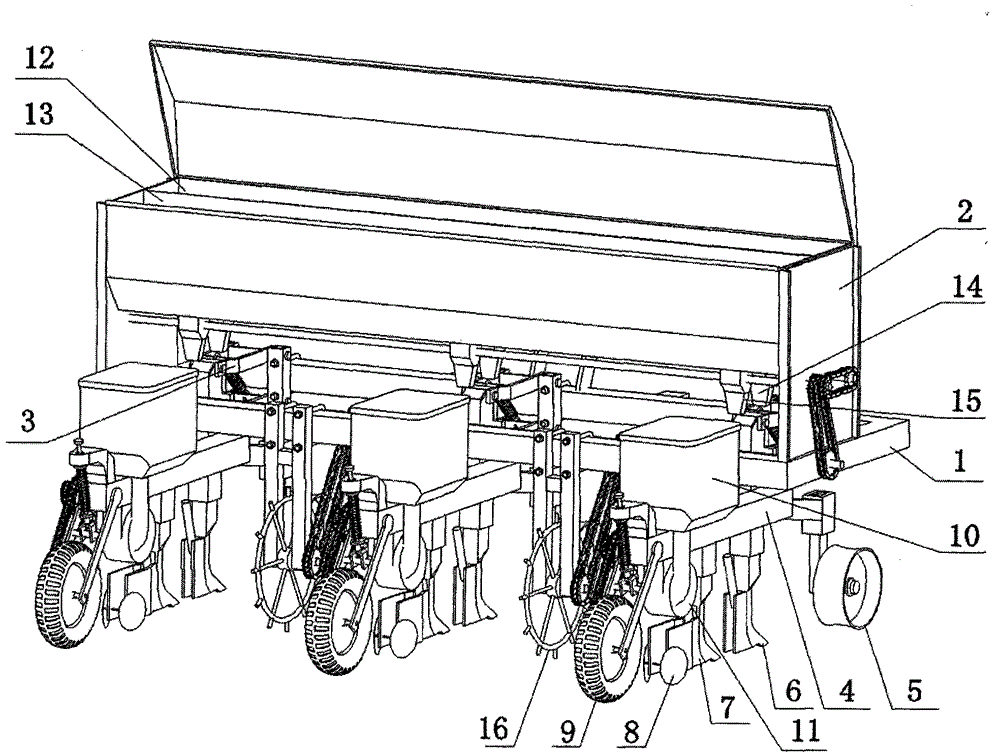

Rape-wheat seeding machine

InactiveCN102577678AImprove efficiencySave farming timeSpadesPloughsAgricultural engineeringLand preparation

The invention belongs to the technical field of seeding machines in agricultural machinery, in particular to a rape-wheat seeding machine, which is characterized by comprising a land wheel profiling drive unit, a positive-negative pressure unit, a fertilizer discharging unit, a transition shaft unit, a wheat seed discharging unit, a main frame, an auxiliary frame, a positive-negative pressure combination type rape seed precision metering device, a central gearbox, a rotary tillage unit, a profiling compaction unit, a furrowing combination, a furrow forming combination, a furrowing, fertilizing and seeding unit, and a covering unit. The rape-wheat seeding machine is capable of operating once to complete procedures of belt rotary tillage, stubble cleaning, furrowing (bed furrows and seed furrows), land preparation, fertilizing, sowing seeds (rape or wheat), covering with earth, profiling and compacting and the like. The rape-wheat seeding machine is simple in structure, low in power consumption and low interference on soil, can be used for precision seeding of rape and row planting of wheat, and is low in re-seeding rate and sowing missing rate, and high in seeding quality.

Owner:HUAZHONG AGRI UNIV

Proportional layering fertilizer applying device

InactiveCN102783299AIncrease profitPromote growthFertiliser distributersAgriculture gas emission reductionAgricultural engineeringBarrel Shaped

The invention discloses a proportional layering fertilizer applying device, belonging to agricultural machinery. The proportional layering fertilizer applying device is formed by connecting an outer channel wheel type fertilizer feeder, a fertilizer amount regulating, controlling and distributing assembly and a layering fertilizer applying device, wherein the outer channel wheel type fertilizer feeder comprises a shell, a spiral linear outer channel wheel and a fertilizer amount regulating and controlling sleeve; the spiral linear outer channel wheel is installed in the shell; through the connection and fit of an internal screw thread on the fertilizer amount regulating and controlling sleeve and an external screw thread on the spiral linear outer channel wheel, the fertilizer amount regulating and controlling sleeve is axially and movably arranged on a side part of the spiral linear outer channel wheel, and a cylindrical barrel-shaped outer wall of the fertilizer amount regulating and controlling sleeve entirely covers the spiral linear outer channel wheel; and the layering fertilizer applying device is formed by assembling a fertilizer delivering pipe, a separating plate, a pipe base, an elastic fastener assembly, a rear fertilizer applying tail pipe, a front fertilizer applying pipe and a furrow opener. The proportional layering fertilizer applying device disclosed by the invention achieves the purpose of proportionally applying seed fertilizer and additional fertilizer at one time in a layering way, and has the characteristics of simple and reasonable structure, good working quality, high efficiency, low cost, convenience in regulation and control, high utilization efficiency of fertilizer, and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

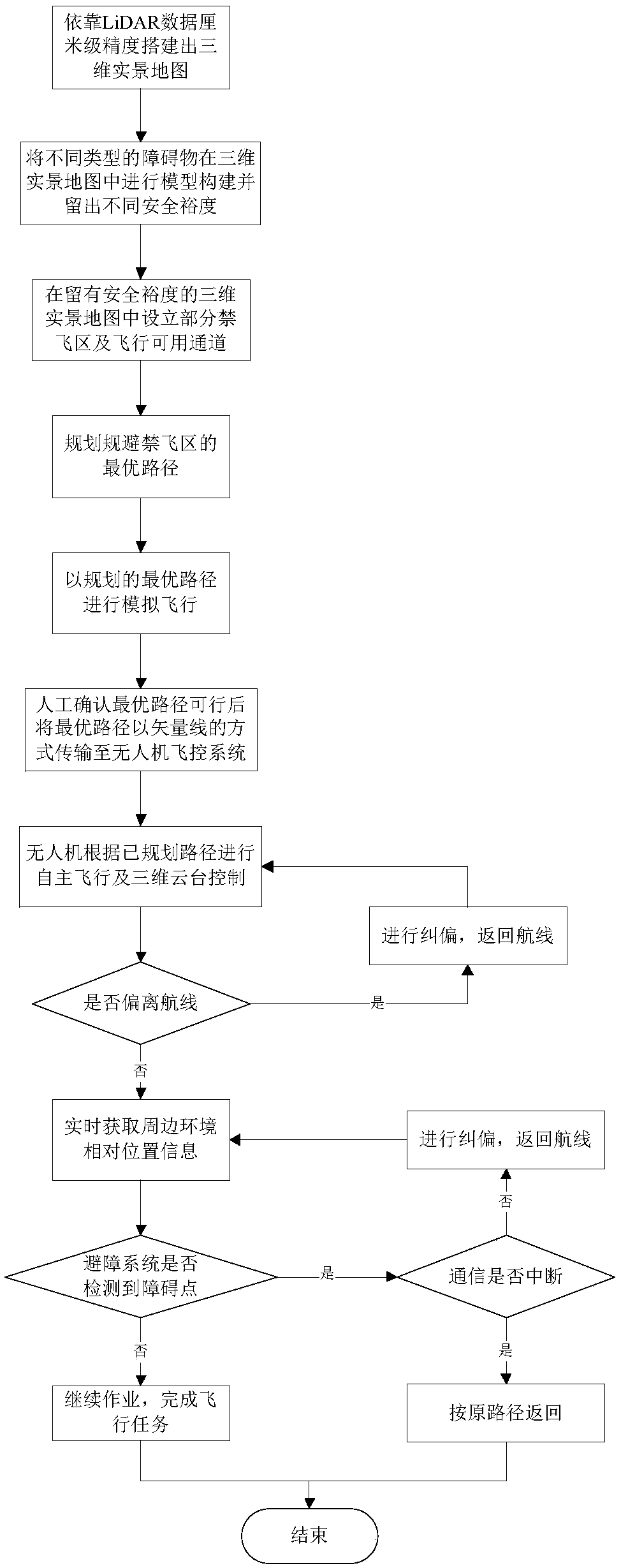

Unmanned aerial vehicle autonomous flight method for constructing three-dimensional real scene based on LiDAR data

PendingCN110888453APrevent crashSolve efficiency problemsPosition/course control in three dimensions3D modellingNo-fly zoneRadar

The invention discloses an unmanned aerial vehicle autonomous flight method for constructing a three-dimensional real scene based on LiDAR data. The unmanned aerial vehicle autonomous flight method comprises the steps of constructing an autonomous flight no-fly zone, carrying out route autonomous planning and flying, and autonomously performing route correction and obstacle avoidance, wherein theno-fly zone is in the three-dimensional real scene constructed on the basis of LiDAR point cloud data, and a flyable block and a no-fly block are divided by using an algorithm; the route autonomous planning flight is the process of combining differential GPS with the LiDAR data and autonomously planning the optical flight route of unmanned aerial vehicle electric power inspection according to a specified principle and realizing autonomous flying; and the route correction and obstacle avoidance regards a planned flight path and airborne radar data as judgment standards, conducts flight path correction on the situation that flight deviates from the flight path due to internal and external factors, and can realize autonomous original-path return can be achieved when necessary. The unmanned aerial vehicle autonomous flight method solves problems of large line patrol potential safety hazards, low line patrol efficiency and redundant personnel allocation of an existing unmanned aerial vehicle.

Owner:杨扬

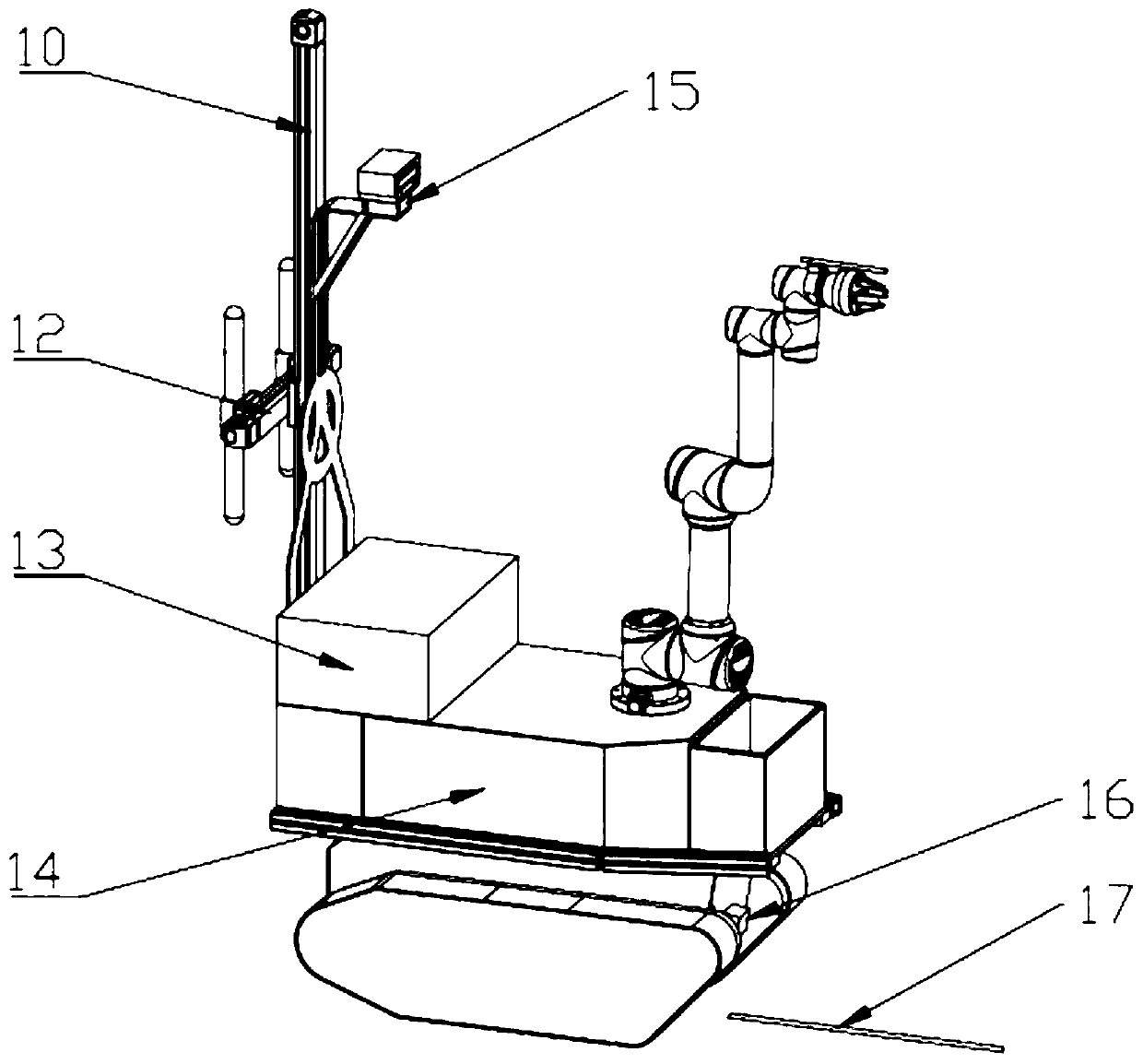

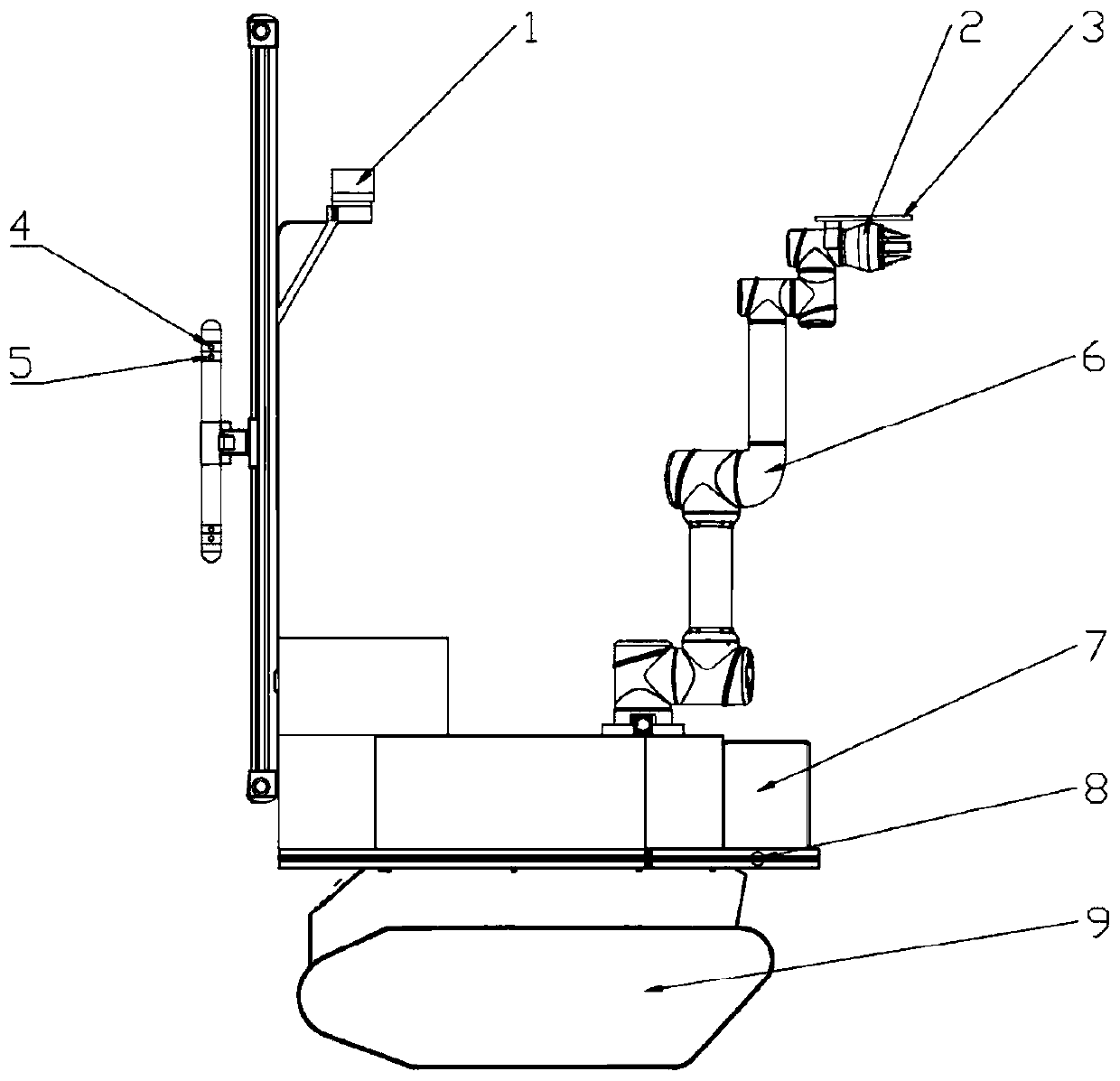

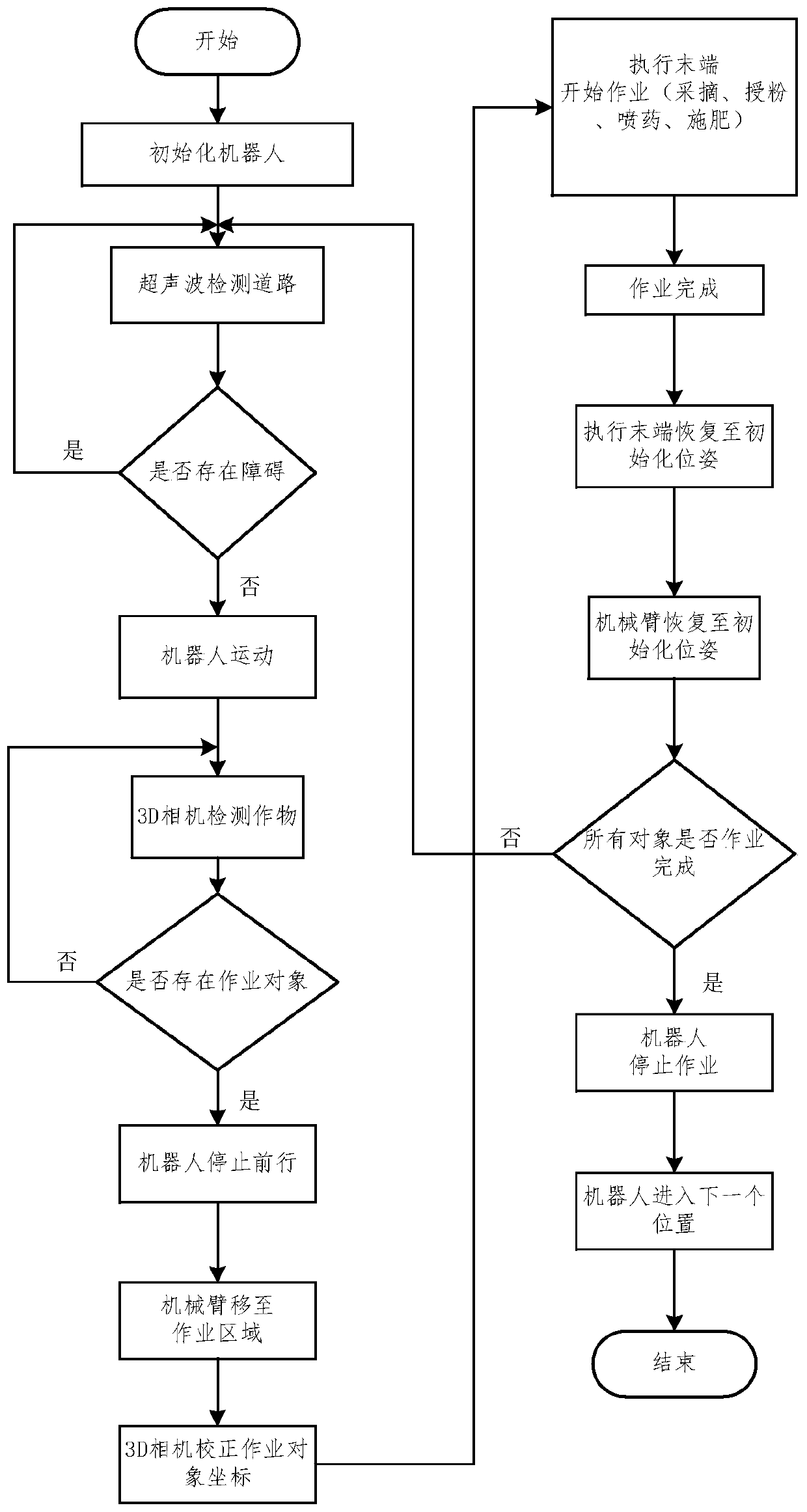

Intelligent agricultural robot and control method thereof

ActiveCN110692352AReduce labor intensityImprove labor productivityProgramme-controlled manipulatorLiquid fertiliser distributionAgricultural scienceAgricultural engineering

The invention provides an intelligent agricultural robot and a control method thereof. The intelligent agricultural robot comprises a moving mechanism, a visual navigation mechanism, an ultrasonic ranging sensor, a control mechanism, a visual mechanism and an execution tail end, the visual navigation mechanism, the ultrasonic ranging sensor, the control mechanism, the visual mechanism and the execution tail end are arranged on the moving mechanism, the visual mechanism is used for target detection, the ultrasonic ranging sensor detects obstacles in the advancing direction in real time, and themoving mechanism moves according to data acquired by the visual navigation mechanism and the ultrasonic ranging sensor; the visual mechanism is used for detecting target crops, the control mechanismacquires three-dimensional coordinate information and crop information of the target crops through position data and then determines an execution area according to the three-dimensional coordinate information and the crop information, and the execution tail end picks, pollinates, sprays pesticide to or fertilizes the target crops correspondingly. The intelligent agricultural robot integrates multiple functions of picking, fertilizing, pollinating and pesticide spraying and is suitable for each growth stage of various tomatoes, labor productivity and operation quality can be improved, labor intensity of planters can be lowered, and manpower resources are saved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

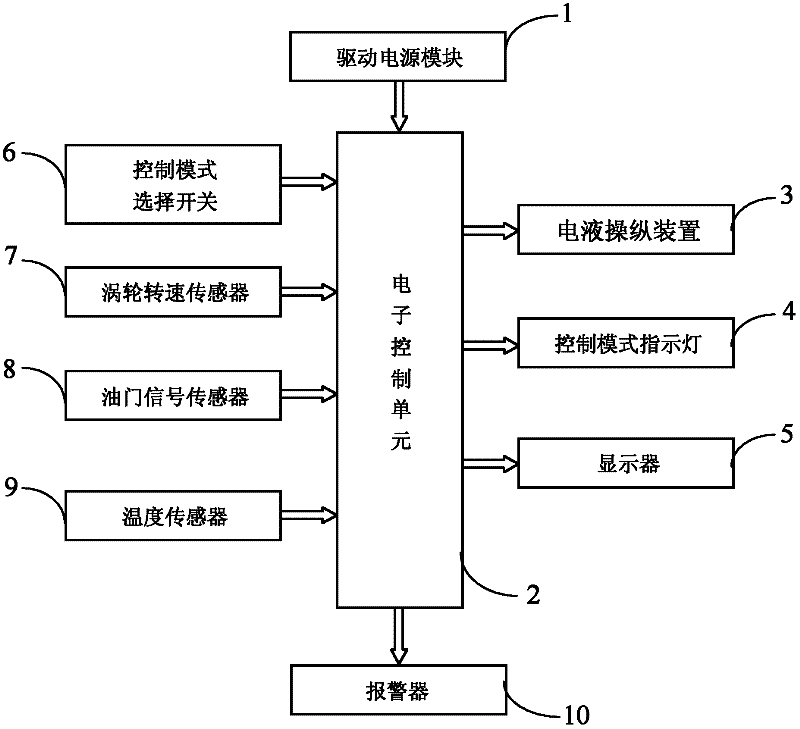

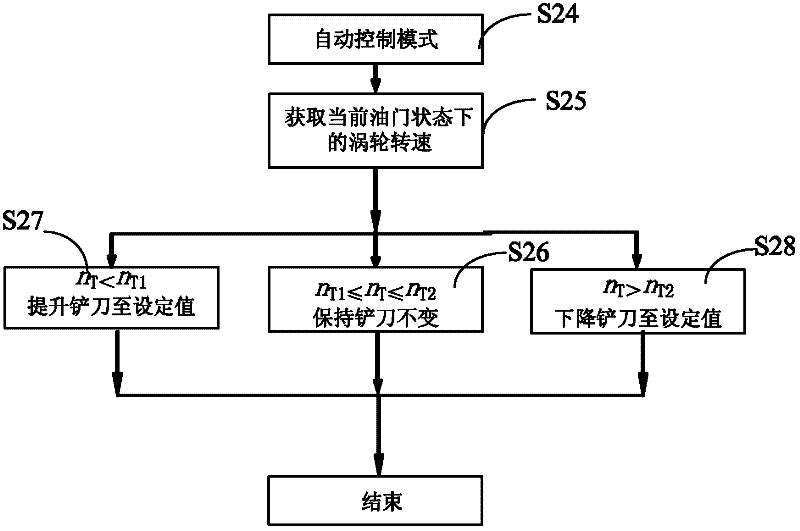

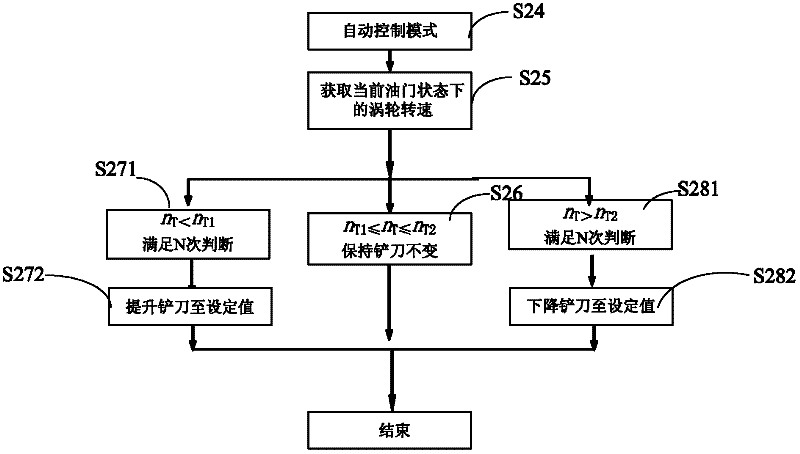

Automatic control system and automatic control method for scraper knife of hydraulic bulldozer

ActiveCN102330442AIncreased depth of cutSoil cut depth reducedMechanical machines/dredgersAutomatic controlControl system

The invention discloses an automatic control method for a scraper knife of a hydraulic bulldozer. The automatic control method comprises the steps of acquiring the rotating speed of a turbine under the current accelerator state, and keeping the scraper knife at the current position when the rotating speed of the turbine is within a first preset range under the accelerator state; descending the scraper knife and increasing the soil cutting depth when the rotating speed of the turbine is higher than the maximum rotating speed of the turbine in the first preset range, and stopping the descendingaction of the scraper knife until the rotating speed of the turbine is reduced within the first preset range; and ascending the scraper knife and reducing the soil cutting depth when the rotating speed of the turbine is lower than the maximum rotating speed of the turbine in the first preset range, and stopping the ascending action of the scraper knife until the rotating speed of the turbine is reduced within the first preset range. The invention can realize the automatic control on ascending and descending of the scraper knife by taking the relationship between the rotating speed of the turbine and the first preset range as judgment basis for whether the scraper knife is ascended or descended, thus improving the production efficiency and operation quality of the traditional bulldozer, and lightening the labor intensity of a driver.

Owner:SHANTUI CONSTR MASCH CO LTD

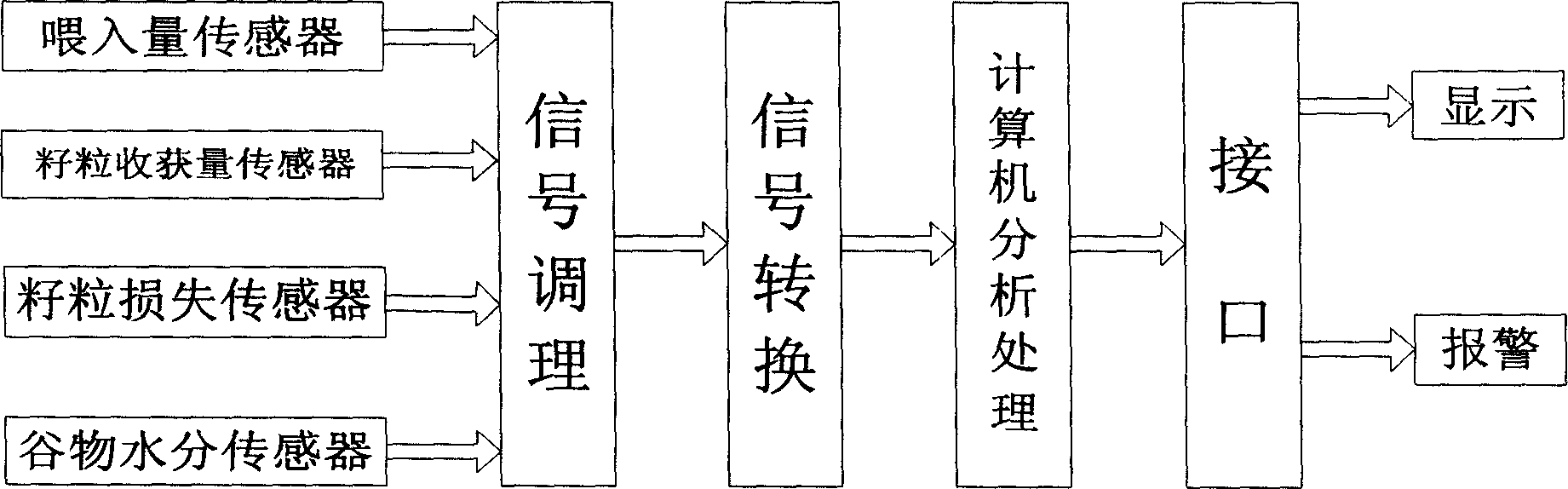

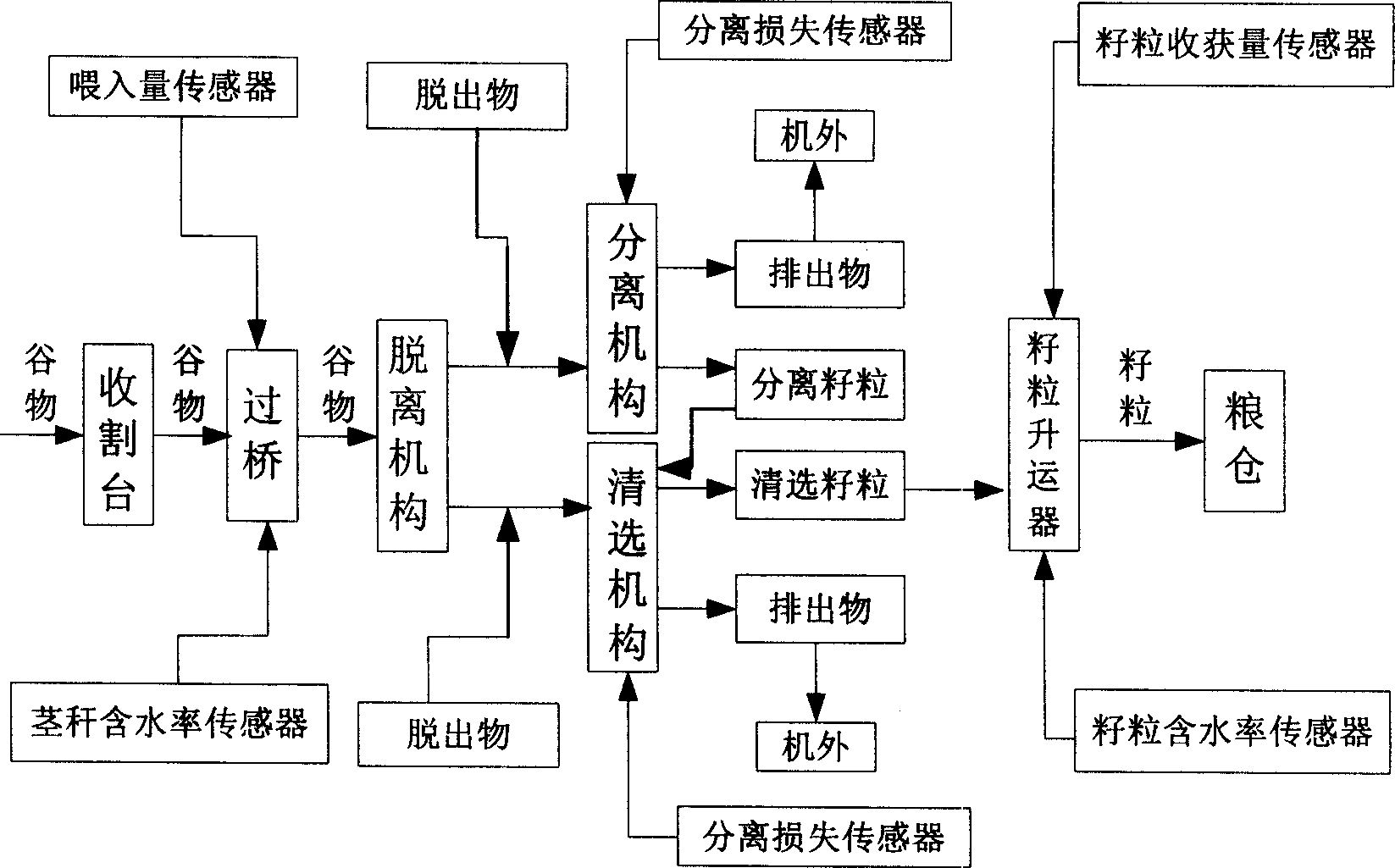

Real time monitoring method for random loss rate of combine

InactiveCN1748451AEliminate lagImprove productivity and work qualityMowersRandom lossInterface circuits

The present invention relates to real-time monitoring method of random loss rate of combine. Feeding sensor, seed collecting amount sensor, seed loss sensor and grain moisture sensor are used simultaneously the acquire loss rate related signals, the signals are regulated, A / D converted and transmitted to computer for processing and analysis, and the results are fed via interface circuit to display and alarm device for the display and alarm of feeding amount, straw / grain ratio, grain moisture, separation loss rate, sorting loss rate and total loss rate. The present invention can measure the random loss rate and monitor the main factors to affect the loss rate and thus the operation state of the combine, so as to ensure the high operation quality of the combine.

Owner:HENAN UNIV OF SCI & TECH

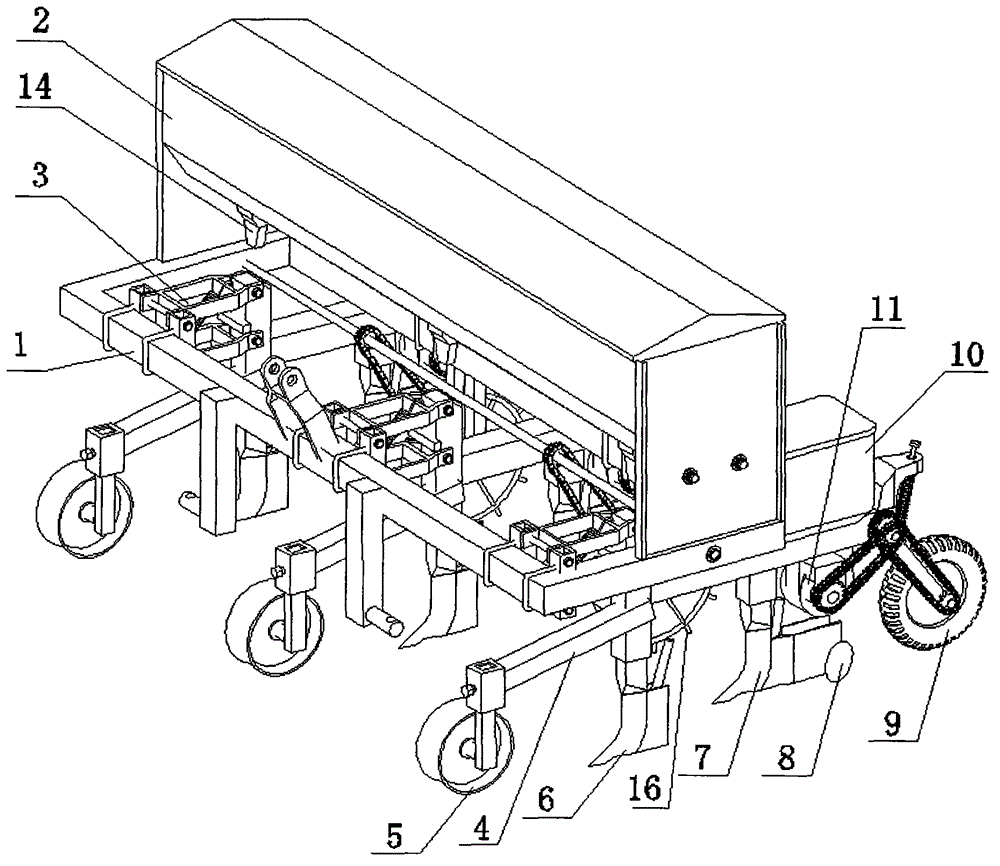

No-tillage profiling precision seeder

InactiveCN102714954AEnsure consistencyPrevent jumpingAgriculture gas emission reductionSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a no-tillage profiling precision seeder, which comprises a main rack. A fertilizer box is arranged on the main frame. A seeding rack is fixedly arranged in each seeding row below the main rack through a profiling four-link mechanism. A depth limiting wheel, a base fertilizer furrow opener, a seed furrow opener, a soil covering device, a compaction wheel, a seed box and a seed feeder are installed on each seeding rack. The internal part of the fertilizer box is divided into a front base fertilizer hopper and a rear seed fertilizer hopper. Base fertilizer feeders and seed fertilizer feeders are arranged at the bottoms of the front base fertilizer hopper and the rear seed fertilizer hopper at positions corresponding to each seeding row. Fertilizer feeding pipes below the base fertilizer feeders are communicated with the base fertilizer furrow openers. Fertilizer feeding pipes below the seed fertilizer feeders are communicated with the seed furrow openers. The no-tillage profiling precision seeder can adapt to and meet the requirements on seeding operation on sloping farmlands or uneven lands, can realize no-tillage precision seeding, and has the characteristics of consistent depth, high operation quality, strong adaptability, few fault and high use safety and reliability.

Owner:赵玉茹

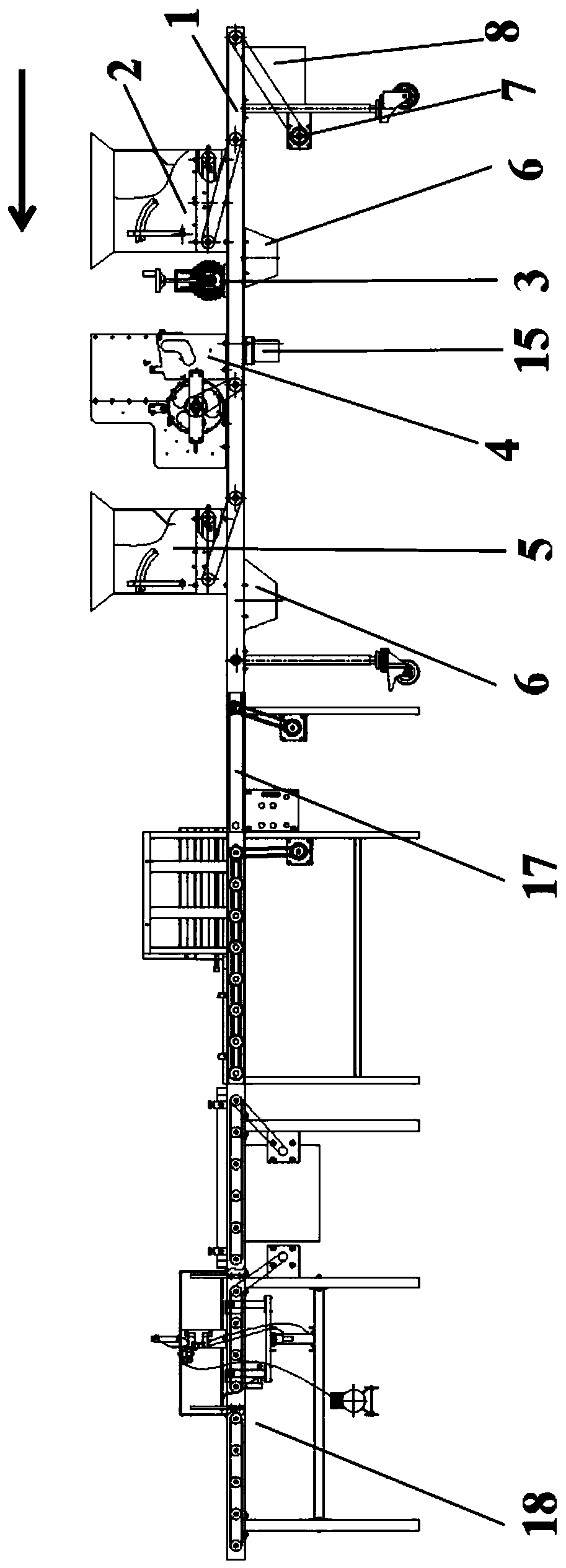

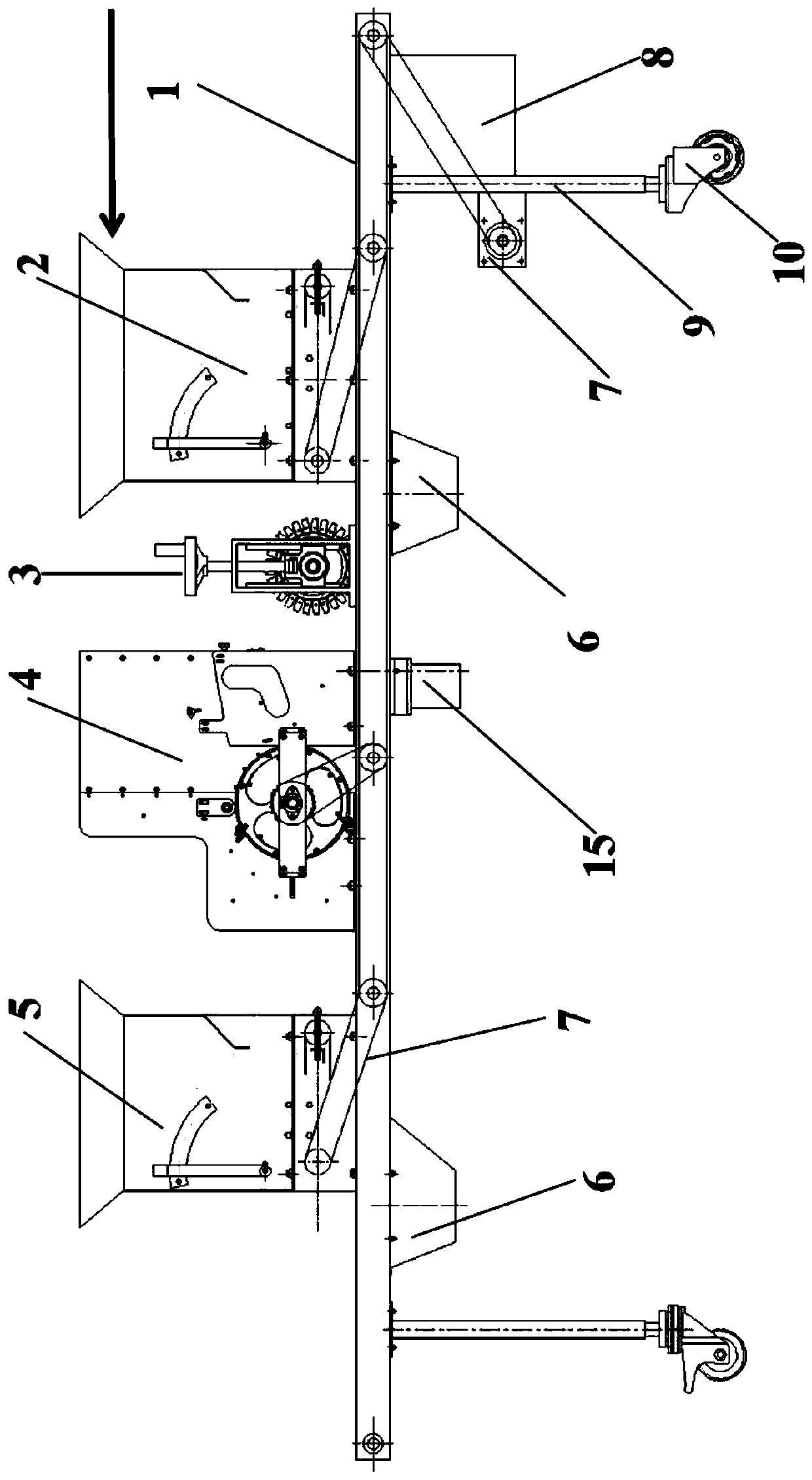

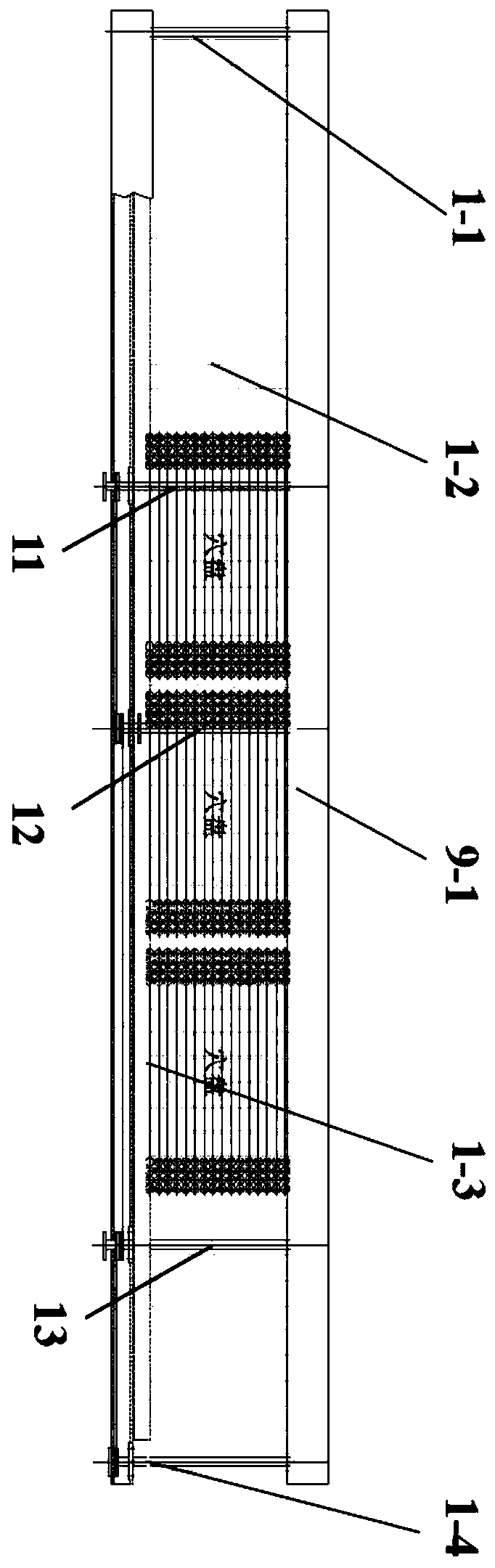

Efficient automatic rice tray seedling raising precise sowing production line

ActiveCN110337862AIncrease productivityHigh production efficiency, high degree of automationPlantingDibble seedersProduction lineElectric control

The invention discloses an efficient automatic rice tray seedling raising precise sowing production line. The production line is composed of a steel wire chain feeding mechanism, a subsoil laying device, a subsoil compacting device, an intelligent double filling type hole drum sowing device, a topsoil laying device, an electric control box, a power motor, a soil collecting bucket, a seed receivingtank, a tray embedding device, an automatic tray stacking device and a rack. Accordingly, synchronous positioning and transportation on soft plastic pot body seedling trays, subsoil laying and compaction, precise sowing, topsoil covering, hard tray embedding and automatic stacking can be performed at a time; by means of the subsoil compaction device, the tray subsoil is compacted, the amount of subsoil is increased, and the later period seedling planting and inserting are facilitated; on the basis of the detection and control technology, an intelligent precise sowing device comprising a seedfilling performance detection system is researched and developed, and 1-3 grain / hole sowing of hybrid rice is achieved; by arranging the tray embedding and automatic tray stacking devices, the automation degree of the production line is improved, the functions are complete, and by means of the soft plastic pot body seedling tray operation, the current rice light simplified cultivation operation requirements are met.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com