Pull-type picking, kneading, bundling and bagging machine for straw feed

A technology of straw feed and bagging machine, which is applied in the direction of loaders, agricultural machinery and implements, threshing equipment, etc., to achieve the effect of smooth and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

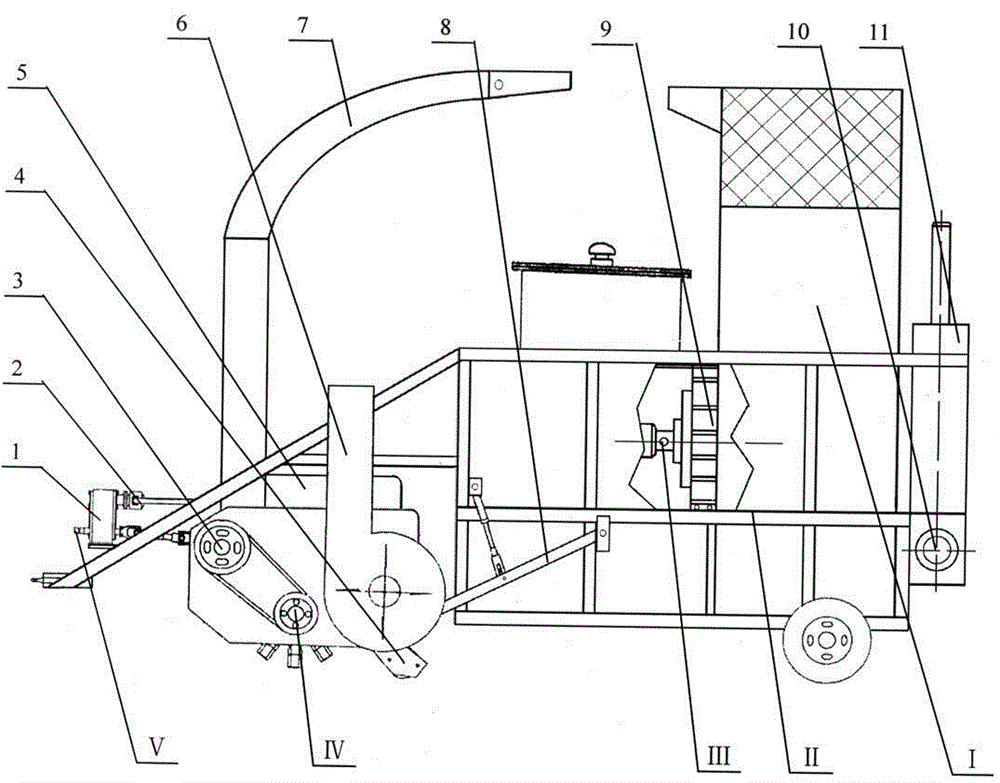

[0049] as attached figure 1 As shown, the patented traction type straw feed picking, kneading, and bagging machine of the present invention includes a complete machine frame (II), a picking and kneading conveying device (IV), a crushed straw filling bin (I), and a straw compacted and packed bagging machine. Device (Ⅲ), power transmission system (Ⅴ) and other operating functional components.

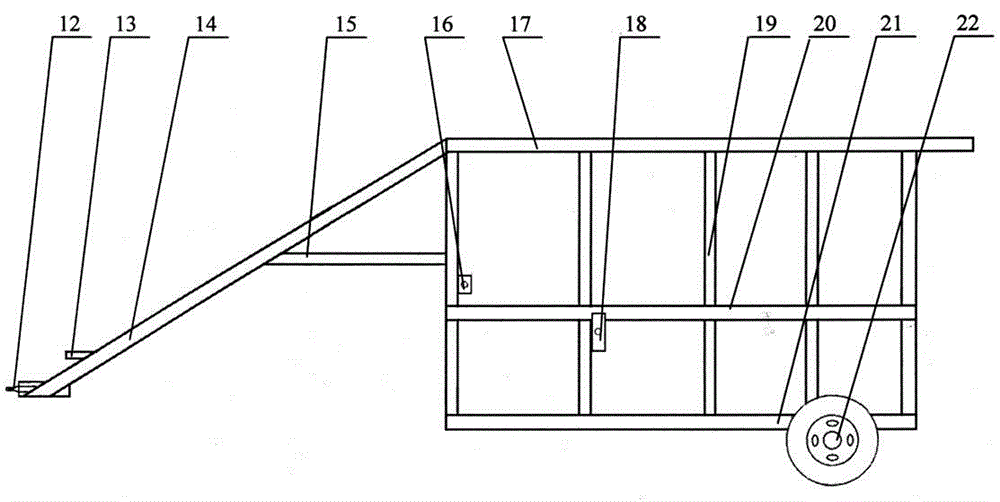

[0050] as attached figure 1 , attached figure 2 As shown, the complete machine frame (II) includes a main machine frame, a traction frame, and road wheels (22); the complete machine frame (II) forms a traction-type The whole machine image of the straw feed picking and kneading into bundle bagging machine.

[0051] The main machine frame is composed of a top frame (17) connected by a top beam and a cross beam, a middle frame (20) is composed of a middle beam and a cross beam, and a chassis (21) is formed by a bottom beam and a cross beam. (19) Connect to form a frame structure form; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com