Large-tonnage low-retraction pres-stress anchor and tightening device thereof

A prestressed, large tonnage technology, applied in the field of prestressed anchorage with large tonnage and low retraction and its tensioning device, to achieve the effects of improving efficiency, reducing stress concentration, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

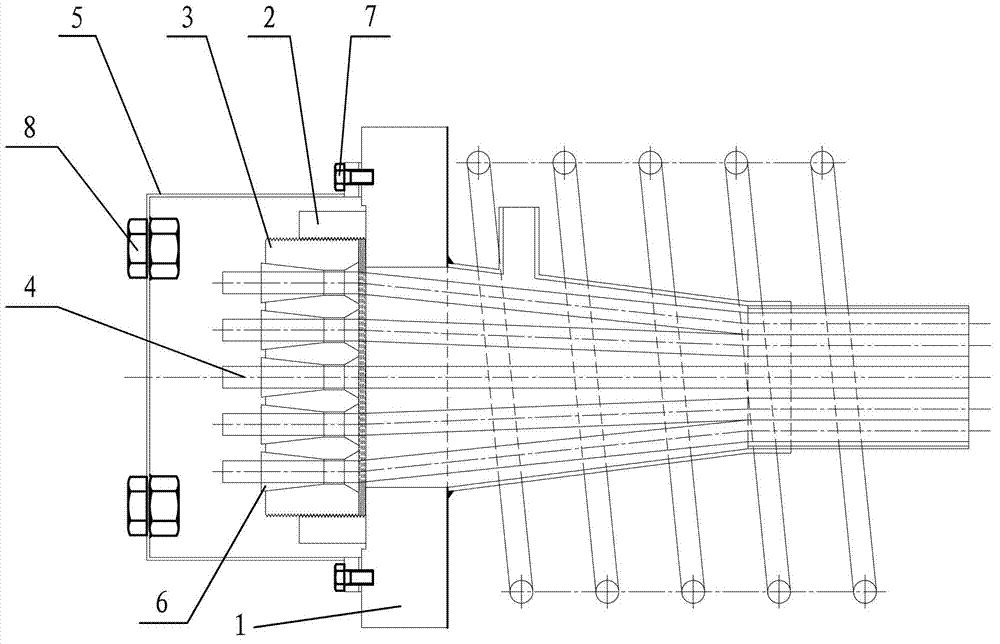

[0028] Such as figure 1 As shown, a prestressed anchor with large tonnage and low retraction includes: bearing plate 1, anchor block 3 and bearing nut 2;

[0029] The pressure plate 1 has a through hole for the prestressed steel strand 4 to pass through, and the prestressed steel strand 4 passing through the pressure plate 7 is positioned through the prestressed hole of the anchor block 3 through the clip 6;

[0030] The anchor block 3 is threadedly matched with the pressure bearing nut 2, and the pressure bearing nut 2 is closely attached to the pressure bearing plate 1;

[0031] A stainless steel protective cover 5 is provided on the pressure bearing plate 1, and the stainless steel protective cover 5 is fixed on the pressure bearing plate 1 by mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com