Multi-span box girder integral ultrahigh alternate jacking construction system and method

A construction method and jacking technology, applied in the direction of bridge, bridge maintenance, bridge reinforcement, etc., can solve the problem that the integrity, safety, reliability, safety and reliability of the original bridge structure cannot be guaranteed, and the existing bridge displacement technology cannot be applied, etc. problems, to achieve the effect of ensuring the urban ecological environment, reducing building energy consumption, and ensuring the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

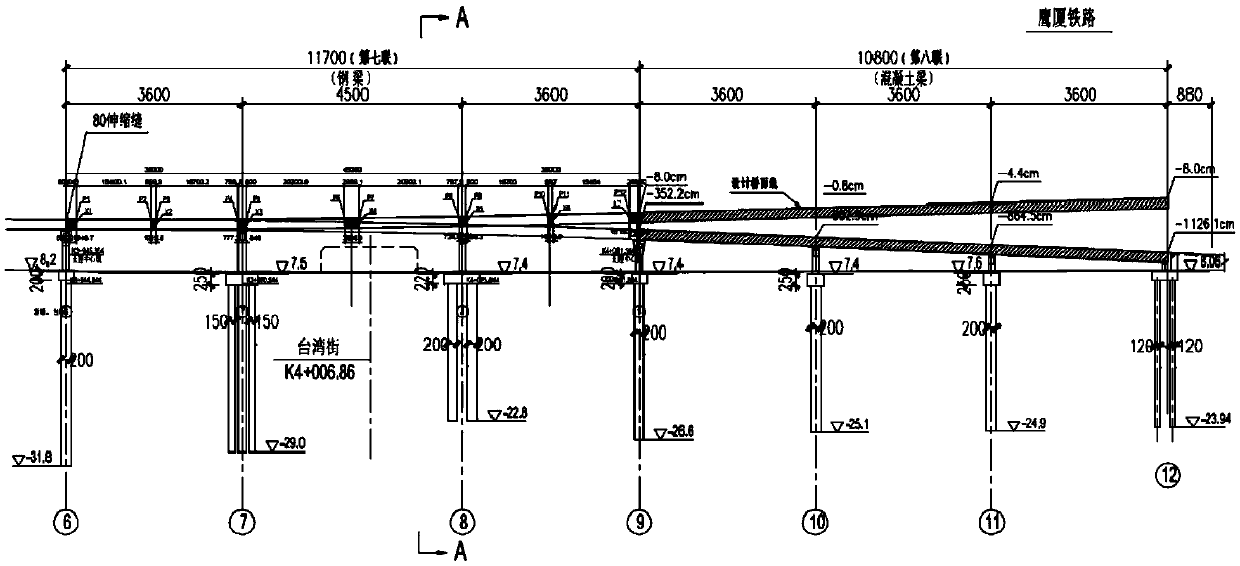

[0053] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

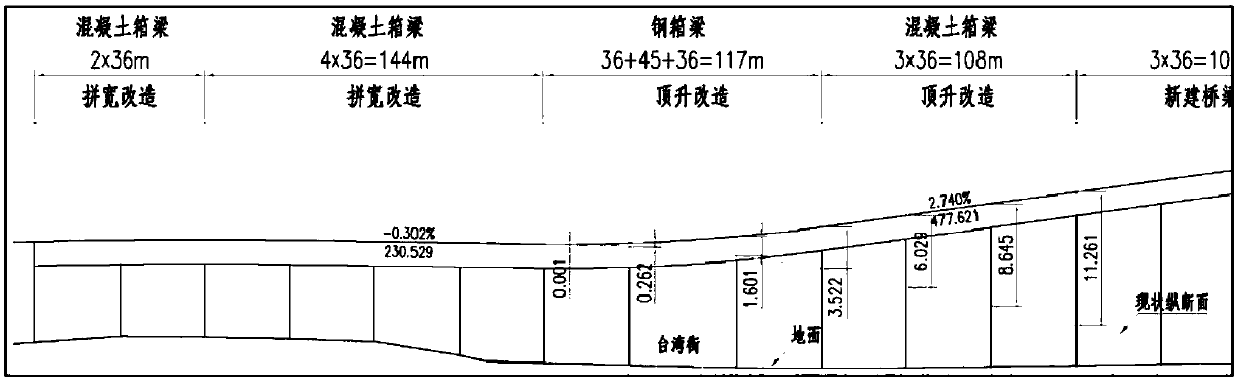

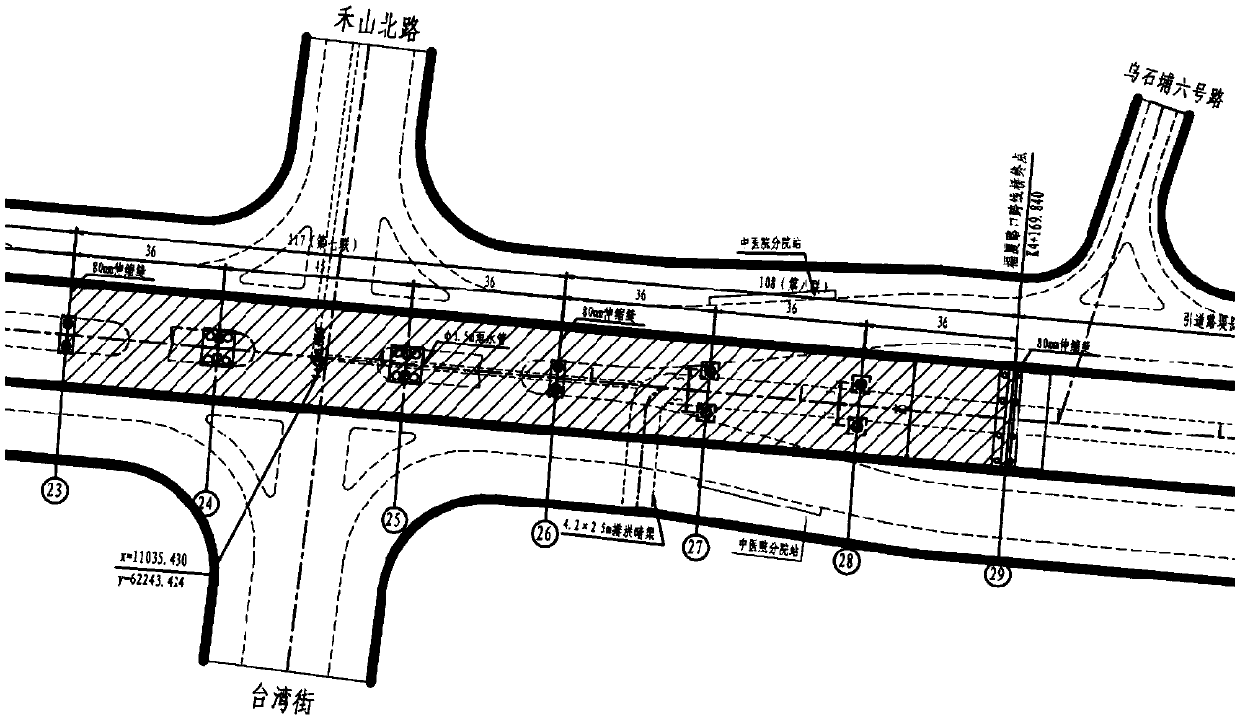

[0054] The existing overpass bridge involved in this example is the urban grade I main road, and the bridge is a full-length bridge with a width of 25m and two-way six lanes. Based on the establishment of viaducts along the whole line, it is necessary to renovate the bridge structure at the upper and lower bridges of the existing line bridge. In order to save engineering investment and reduce the social impact of demolition and reconstruction, in this example, the two box girders at the end of the existing overpass are jacked up to adjust the elevation or curve of the existing overpass to connect with the newly built viaduct, so as to Seek to save money to the greatest extent, protect the environment, and minimize the impact of traffic.

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com