Prefabricated part finished product quality detection system based on three-dimensional vision and application of system

A prefabricated component, three-dimensional technology, applied in the direction of comprehensive factory control, sorting, etc., can solve the problems of missed inspection, long troubleshooting time, wrong inspection, etc., to ensure the construction period, reduce the waste of resources, reduce time and cost The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

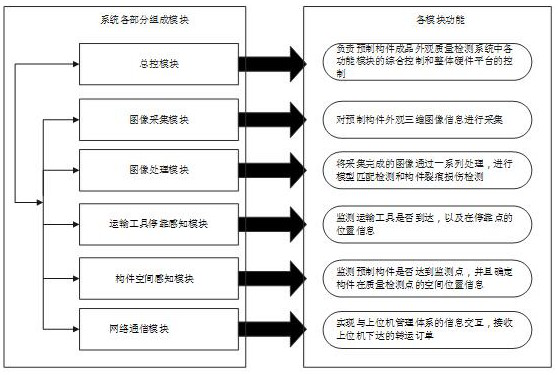

Method used

Image

Examples

Embodiment 1

[0045] The application of the prefabricated component finished product quality inspection system based on three-dimensional stereo vision in the device. The detection device includes a transport tool 1, a control box 2, a transport tool docking sensor 3, a component sensing module with infrared rays on both sides 4, and a binocular vision camera 5 , Suspension component 6, wrong parts area 7, bad parts area 8, component storage area 9, the control box 2 is equipped with a master control module, an image processing module and a network communication module, which are used to manually control the work of the entire quality inspection system Start and stop. Including the necessary work start and stop buttons when the quality inspection system is integrated with the aerial crane system as an independent system, it also includes some hardware equipment required by the entire quality inspection system, such as video transmission lines, image processors, development boards and process...

Embodiment 2

[0049] When the prefabricated component finished product quality inspection system based on three-dimensional stereo vision is integrated with the aerial crane system, it is used as an independent system for the detection method of prefabricated component quality inspection:

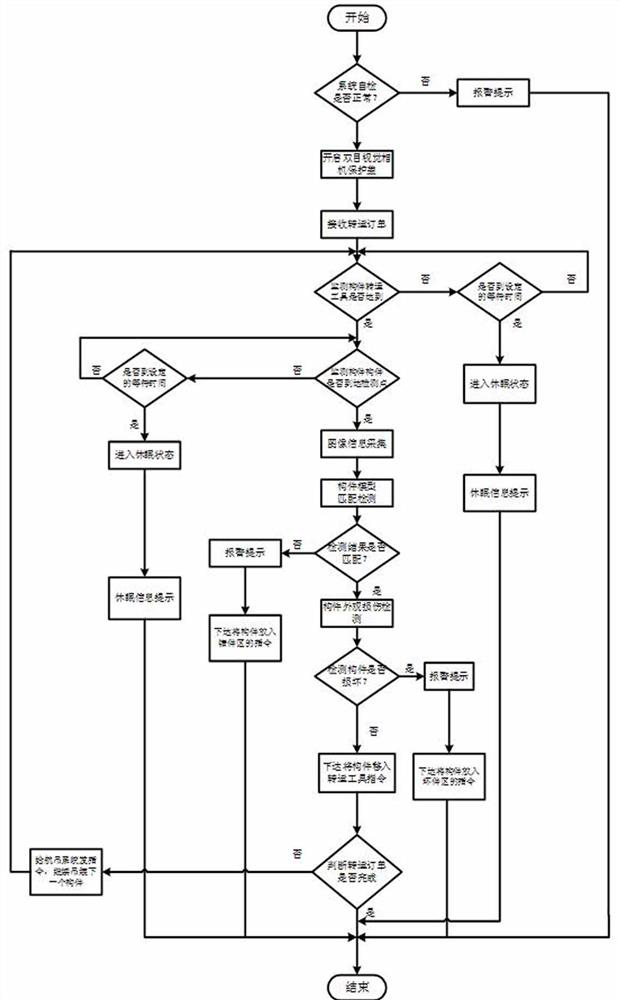

[0050] Step 1. After the 3D stereo vision prefabricated component quality inspection system receives the start work instruction (that is, manually starts the start button), the master control module will first conduct a self-inspection of the system under the control of the master control module in the quality inspection system to determine Whether the system can work normally, if the system can not work normally, it will transmit the failure instruction through the network communication module, and the quality inspection system will send out an alarm prompt to remind the on-site staff that there is a problem with the quality inspection system.

[0051] Step 2. If the self-inspection of the system is norm...

Embodiment 3

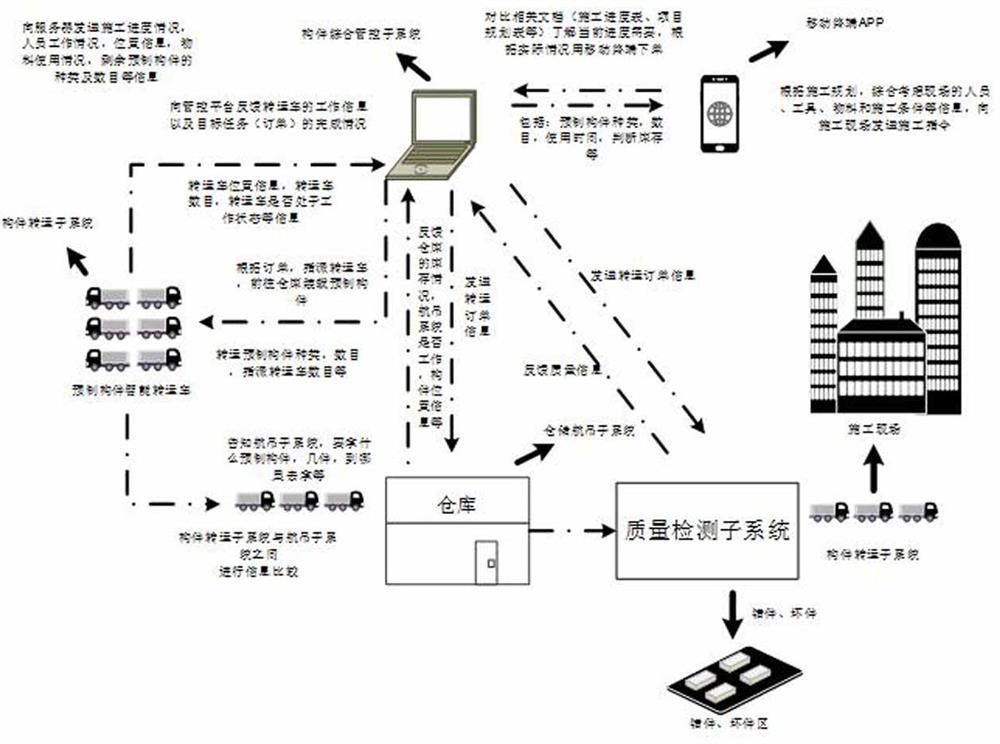

[0060] When the prefabricated component finished product quality inspection system based on 3D stereo vision is used as a subsystem in the component storage and transfer system, the working relationship with other systems, and the detection method used for prefabricated component quality inspection:

[0061] In the process of processing a transshipment order, after the manager edits the transshipment order on the mobile terminal, he releases the order to the component integrated management and control system, which will simultaneously provide component transfer subsystem, warehousing and crane subsystem and 3D stereo vision The prefabricated component finished product appearance quality inspection subsystem sends the transfer order, and at the same time, the component integrated control system sends the prefabricated component structural model to the prefabricated component finished product appearance quality inspection subsystem with 3D stereo vision. After the component trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com