Patents

Literature

236results about How to "Guaranteed construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas

ActiveCN103526748AThe process steps are simpleReasonable designEmbankmentsBulkheads/pilesStart timeUnderwater

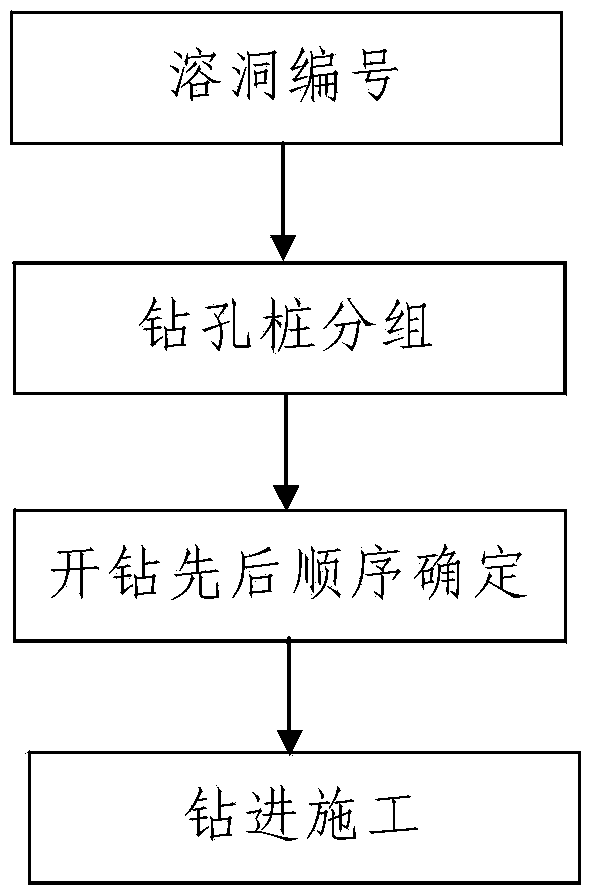

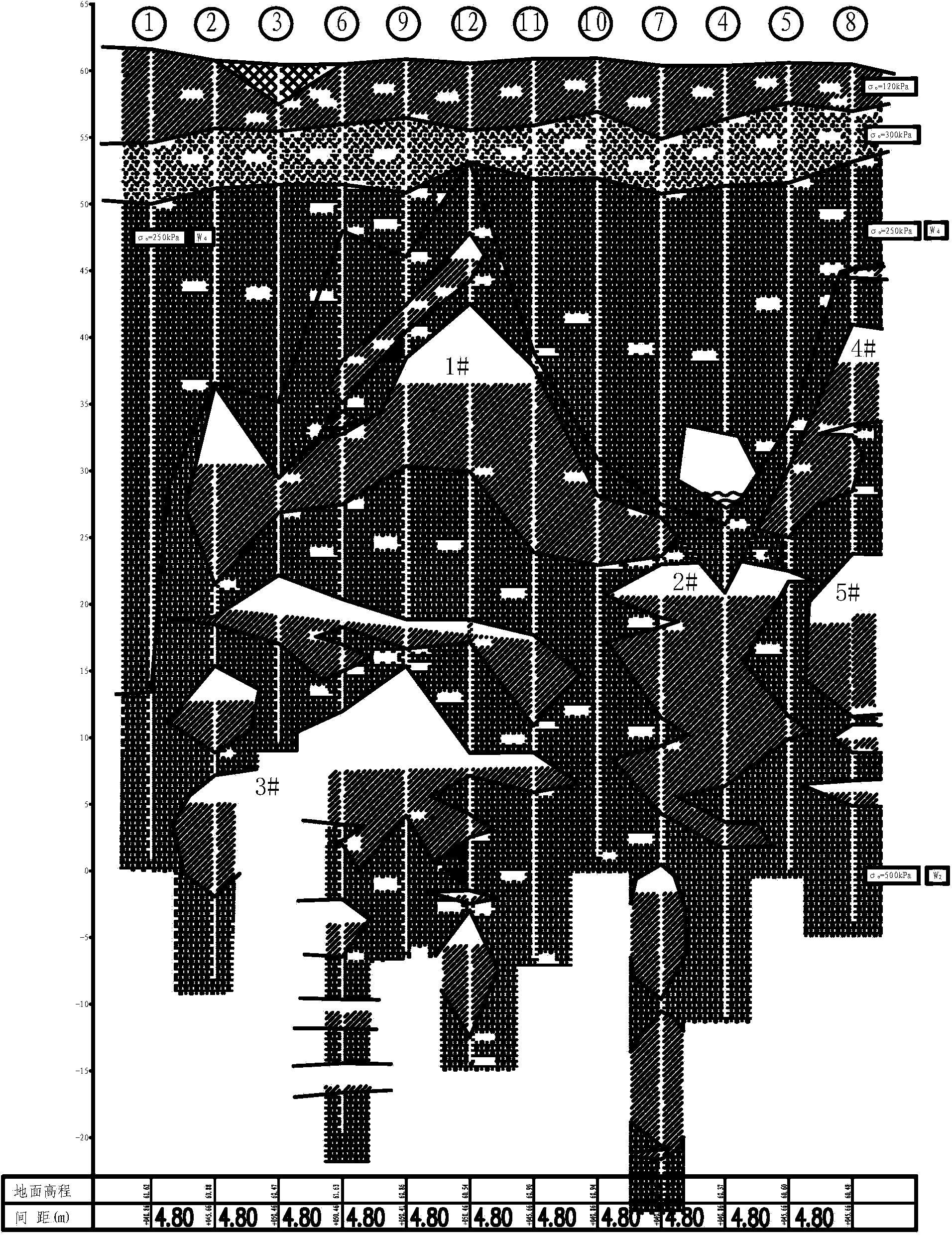

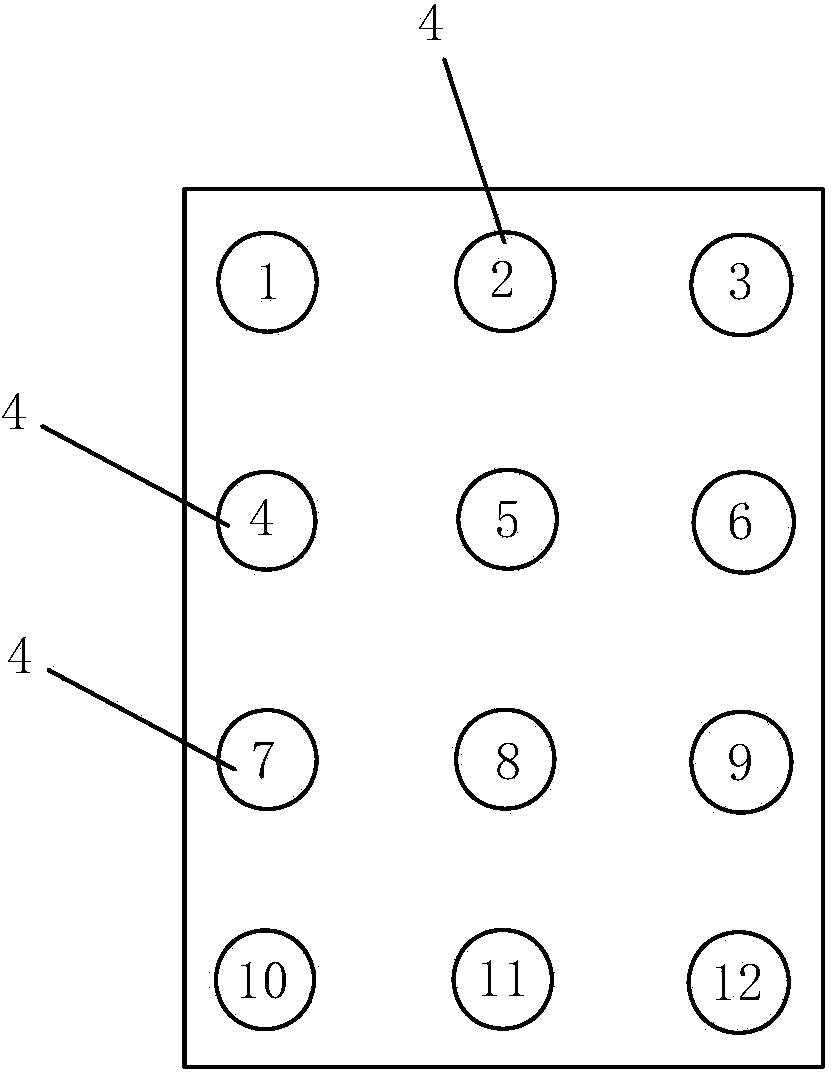

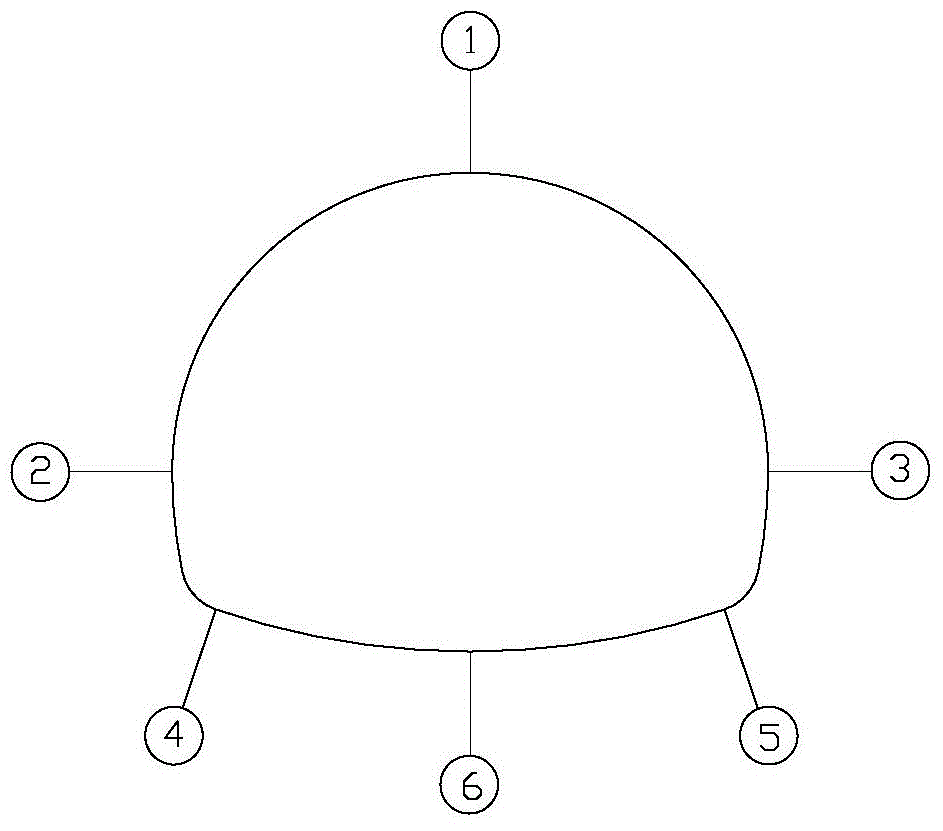

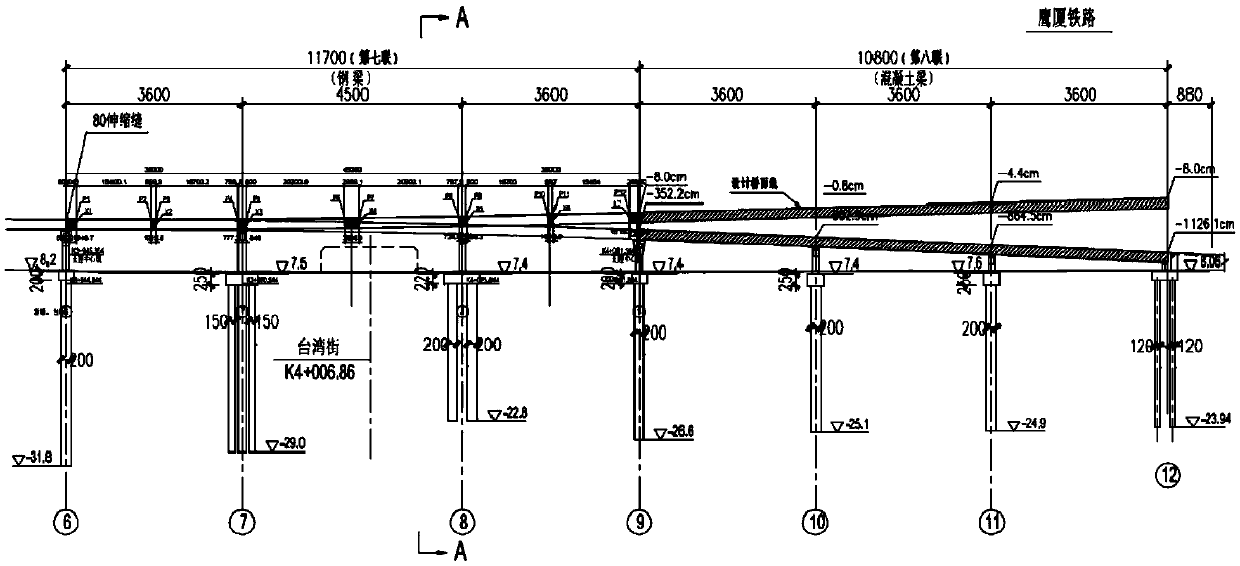

The invention discloses a technology for constructing deepwater bridge underwater pier large-diameter bored piles in bead-stringed type karst areas. A pile foundation of a constructed underwater pier comprises the multiple first bored piles, and the first bored piles all penetrate through a plurality of karst caves successively from top to bottom. The technology includes the steps of (1) numbering the karst caves, (2) grouping the bored piles: dividing the multiple first bored piles into multiple groups according to serial numbers of the karst caves which are penetrated from top to bottom, and enabling the karst caves which are penetrated by all first bored piles in the same groups from top to bottom for the first time to be the same, (3) determining the drilling starting sequence: determining the drilling starting sequence of all first bored piles in the same group in the step (2), and enabling the drilling starting time of the first bored piles, farther away from the middle of the karst cave penetrated for the first time, in the same group to be earlier, and (4) carrying out drilling construction. The technology is simple in step, reasonable in design, low in investment cost, convenient to achieve and good in construction effect, and large-diameter bored pile construction processes can be easily, conveniently and rapidly completed with low cost and high quality.

Owner:CHINA RAILWAY 20 BUREAU GRP

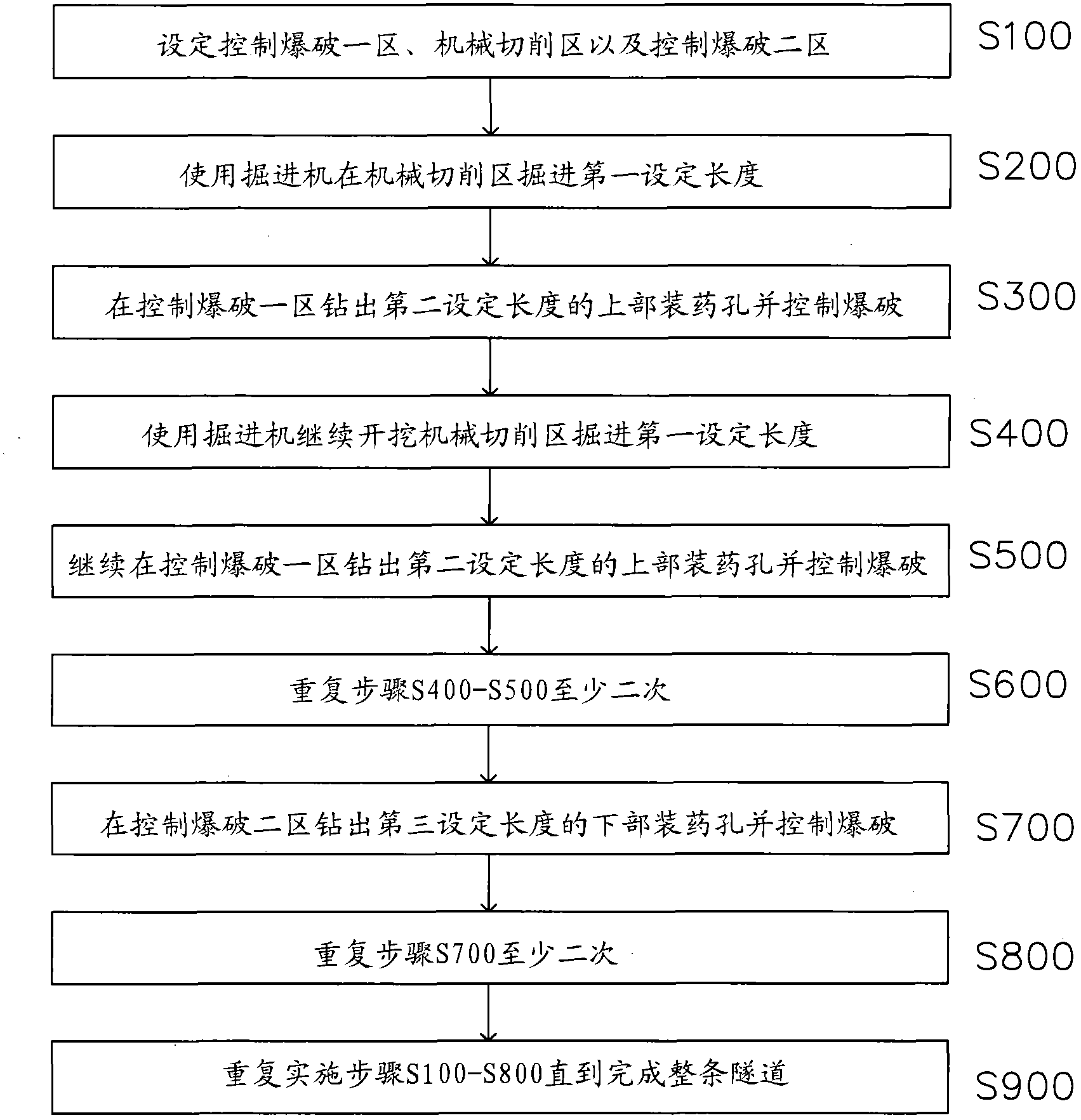

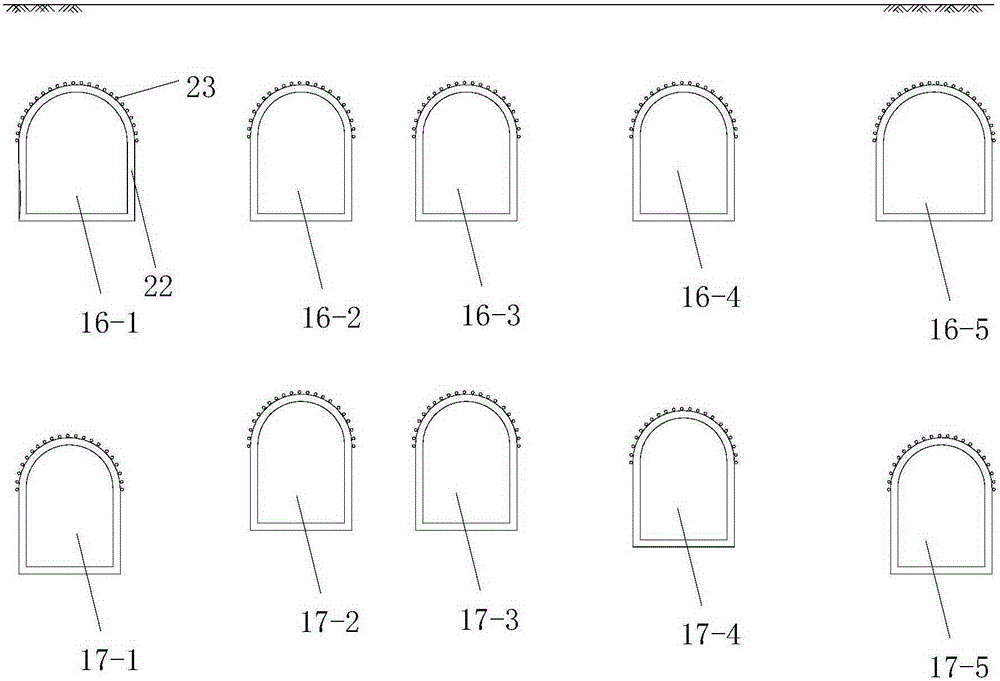

Process for excavating and constructing soft rock tunnels

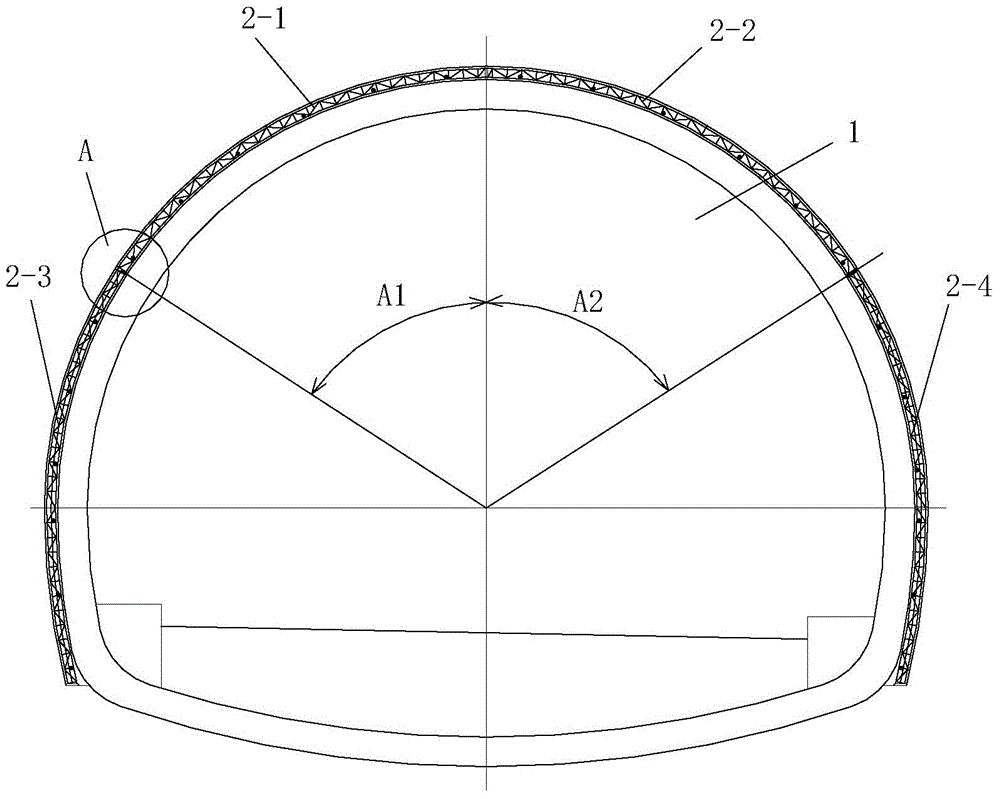

ActiveCN104453921AThe process steps are simpleReasonable designTunnel liningStructural engineeringRock tunnel

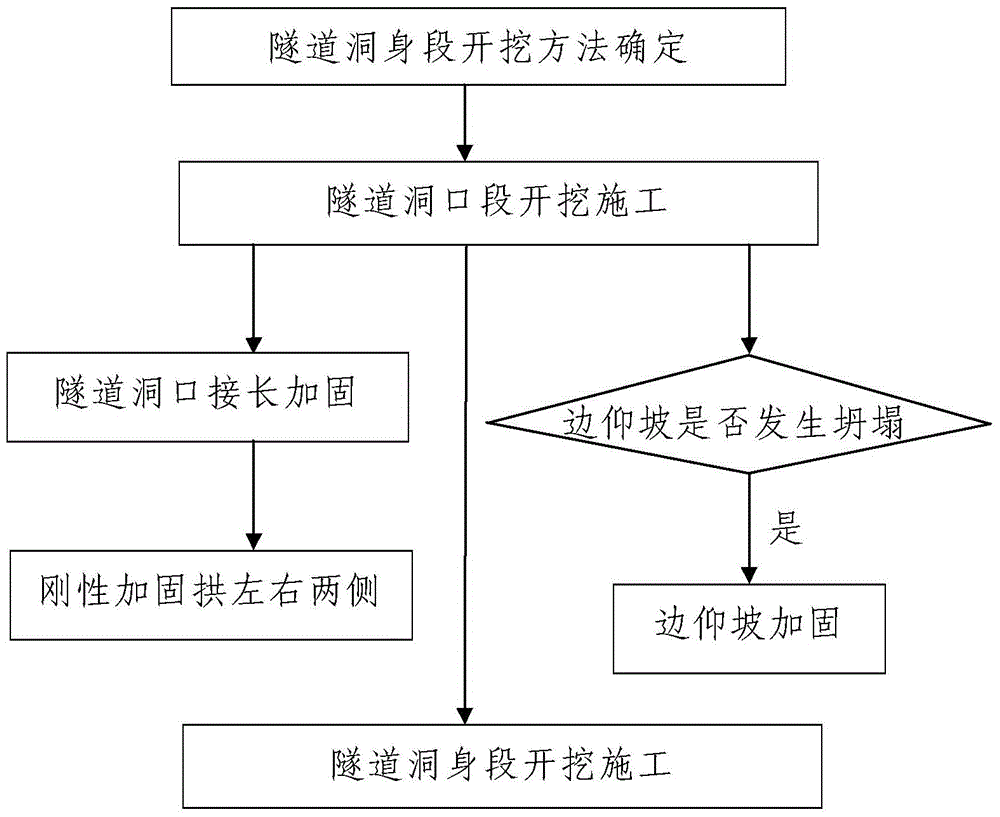

The invention discloses a process for excavating and constructing soft rock tunnels. Each constructed soft rock tunnel comprises two tunnel portal sections and a tunnel trunk section. Each tunnel trunk section is arranged between the two corresponding tunnel portal sections in a connected manner, surrounding rock level of two tunnel portals of each constructed soft rock tunnel is V level, surrounding rock level of each tunnel trunk section is IV level, and entrances and exits of the constructed soft rock tunnels simultaneously start to be constructed and are constructed in opposite directions. The process includes constructing procedures of firstly, determining methods for excavating the tunnel trunk sections, to be more specific, simulating excavating and constructing procedures by the aid of tunnel excavating and constructing simulation software, and determining the methods for excavating and constructing the tunnel trunk sections according to simulation results; secondly, excavating and constructing the tunnels, to be more specific, dividing each soft rock tunnel to be constructed into a plurality of sections from the rear of the corresponding tunnel portal to the front and starting to excavate and construct the multiple sections. The tunnel trunk sections are excavated in the excavating and constructing procedures by the aid of full-section techniques. The process has the advantages of simple steps, reasonable design, convenience in construction, good service effects, safe constructing procedures and capabilities of easily and conveniently completing the soft rock tunnel excavating and constructing procedures and guaranteeing the construction periods.

Owner:CHINA RAILWAY 20 BUREAU GRP

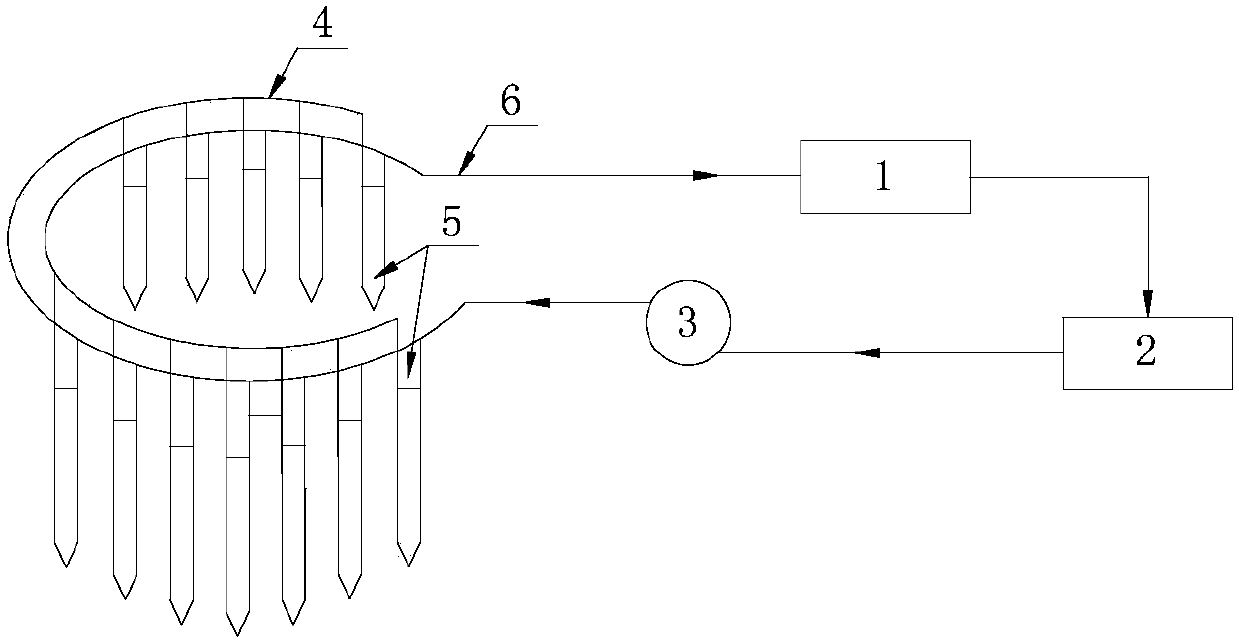

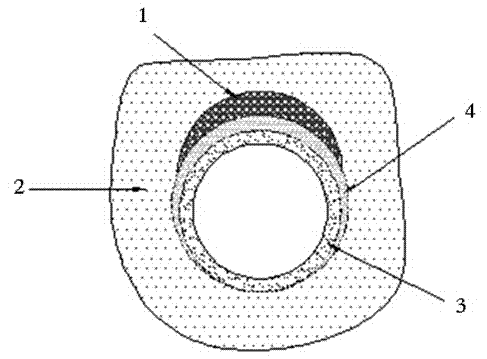

Freeze construction method for wellbore type underground parking garage

ActiveCN108035335AUnlimited construction depthAdapt to a wide rangeArtificial islandsUnderwater structuresTowerWellbore

The invention discloses a freeze construction method for wellbore type underground parking garage. A circular wellbore is built underground by sequentially using freeze construction, excavation construction, grouting and thaw grouting, and an elevator type and intelligent tower type stereo garage system currently applied at home and abroad is installed in the wellbore for operation. Before construction of the wellbore, an artificial freezing method is applied, water-bearing strata around the wellbore is frozen, a frozen wall having temporary load bearing and water isolating functions and meeting construction safety requirements is formed, and wellbore excavation is performed under protection of the frozen wall; the frozen wall is formed by mutual matching mutual complementing of inner ringfreezing holes and outer ring freezing holes; a cap beam is firstly constructed at the top of the wellbore; excavation construction of the outer wall of the wellbore, concrete pouring on the bottom plate of the wellbore and construction of the inner wall of the wellbore are performed in sequence; after freezing of the wellbore, lining is performed, and grouting and strata thaw are performed for grouting compensation.

Owner:CHINA COAL NO 5 CONSTR

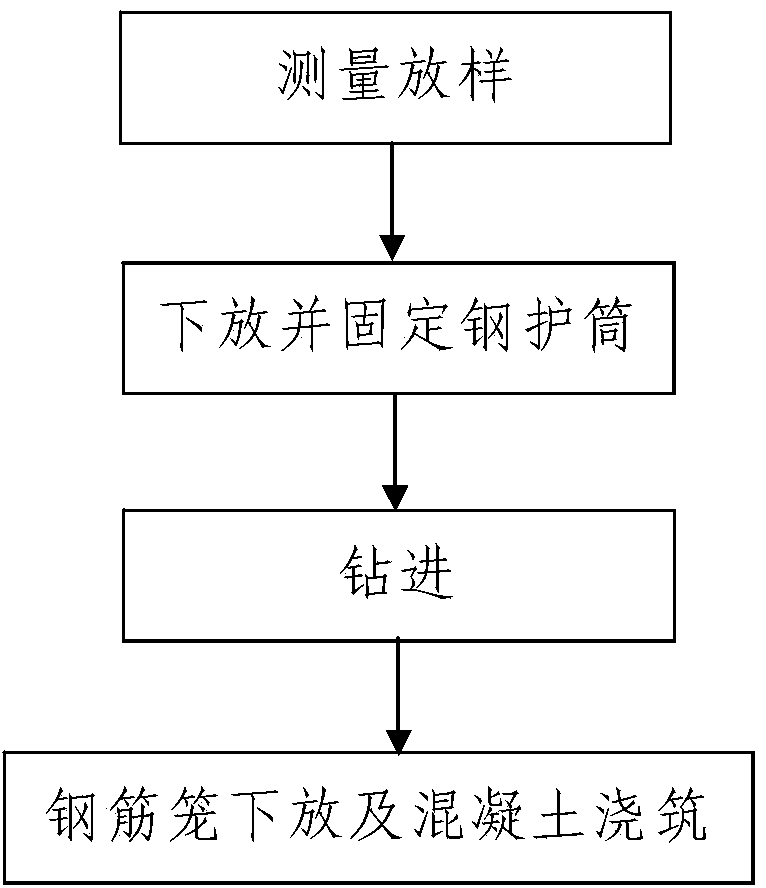

Karst-area underwater bridge pier drilled pile construction method

ActiveCN103469789AThe method steps are simpleReasonable designDrill bitsEmbankmentsEnergy transferUnderwater

The invention discloses a karst-area underwater bridge pier drilled pile construction method. The construction drilled pile passes through one or more karst caves from top to bottom according to the following steps that (1) measuring staking-out is conducted; (2) a steel protection barrel is put downwards and fixed; (3) drilling is carried out, namely, the steel protection barrel is put downwards and drilled from top to bottom through a percussion drill until the designed depth is reached, a slurry breast wall is adopted in the drilling process, when the drilled pile is drilled to enter the karst caves needing passing from top to bottom in the drilling process, an energy transfer method is firstly adopted to process the karst caves needing passing under the current state, then downward drilling is continuously carried out through the percussion drill; (4) a steel reinforcement cage is put downwards and concrete pouring is conducted. The karst-area underwater bridge pier drilled pile construction method is simple in step, reasonable in design, low in input cost, convenient to achieve, good in construction effect and capable of simply, conveniently and fast finishing the karst-area drilled pile construction process at a low cost in a high-quality mode.

Owner:中铁建安工程设计院有限公司 +1

Multi-node integral installation method for steel truss beam

The invention discloses a multi-node integral installation method for a steel truss beam, comprising the following steps: firstly, integral manufacturing is carried out in a factory, then the product is installed to form standard segments, the standard segments are temporarily fixed and pre-jointed in the factory, then the segments are transported to bridge location by large transportation equipment, integral lifting is carried out by a large lifting appliance and the segments are installed; the installation sequence is that firstly, a lower chord and an oblique web plate are installed, then a middle chord, an upper chord and a side upper chord are installed, at last, a lower lateral bracing, a lateral plate and a bridge deck in a welding way. The invention has the advantages that the linetype is easily controlled, the steel truss beam can be used as the operation platform, the installation speed is high, construction period is shortened and construction security is guaranteed.

Owner:THE 5TH ENG MBEC

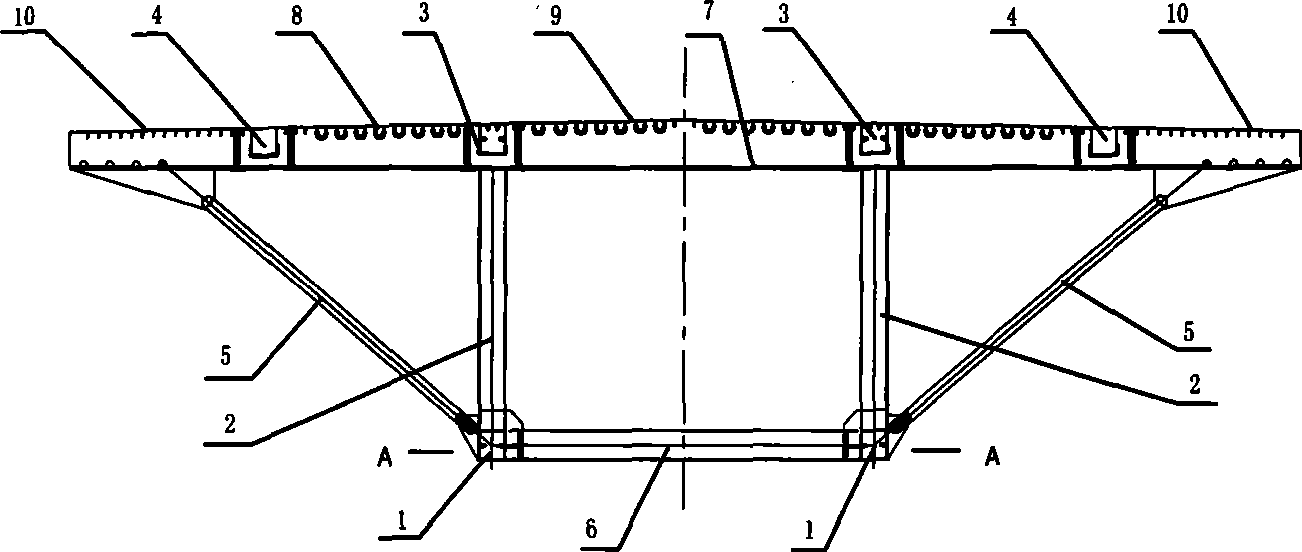

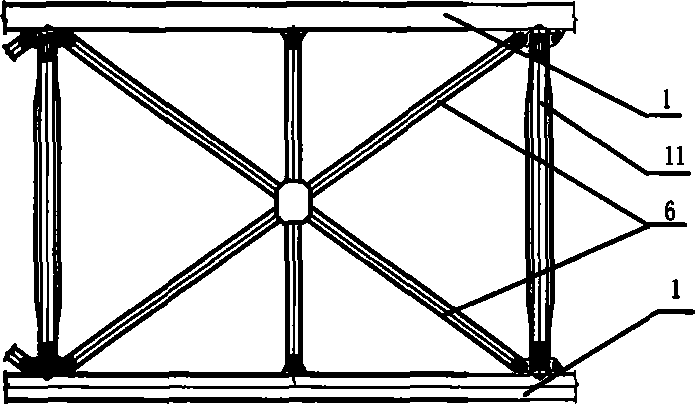

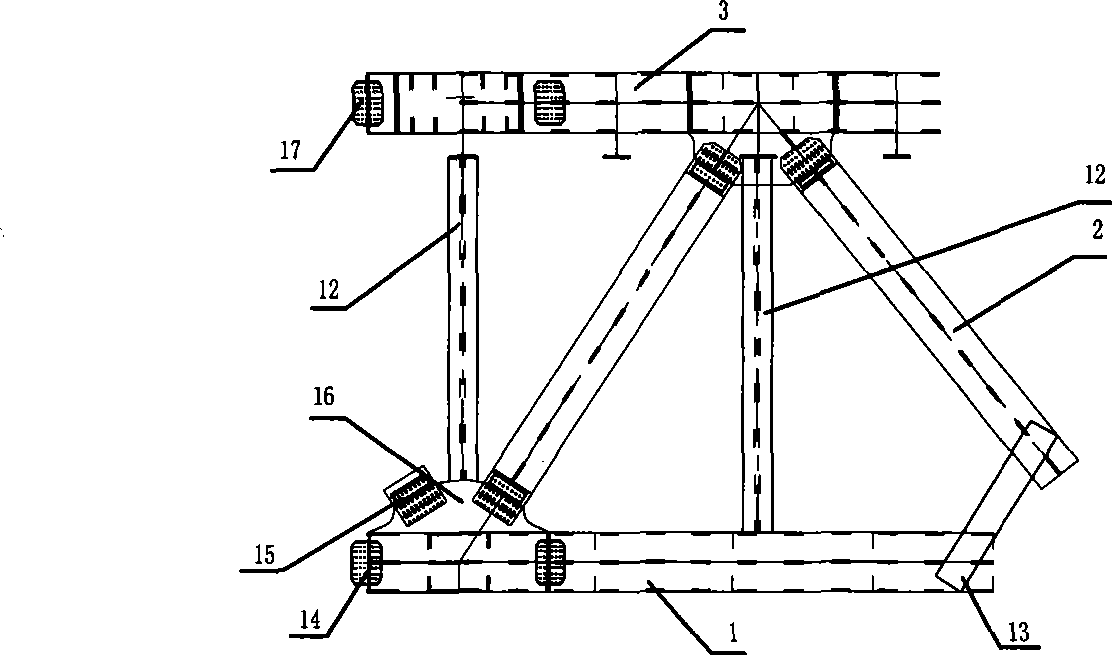

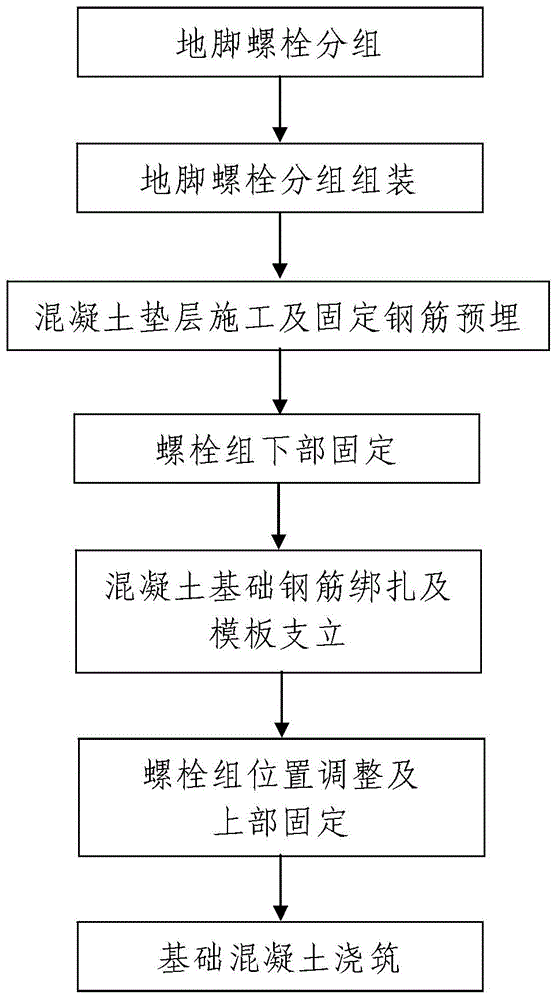

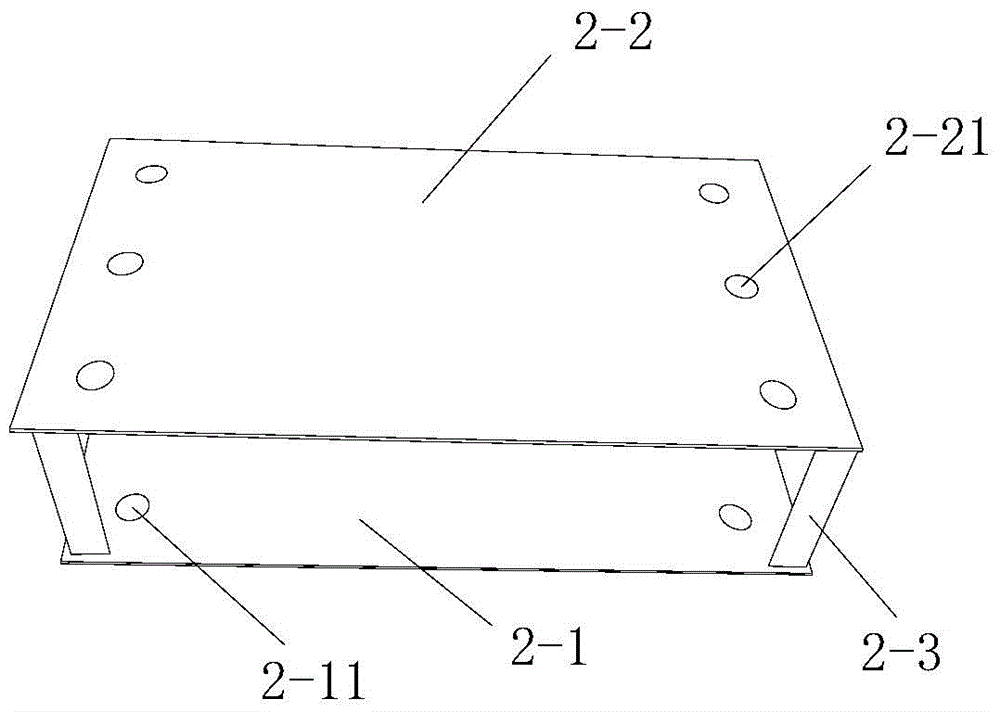

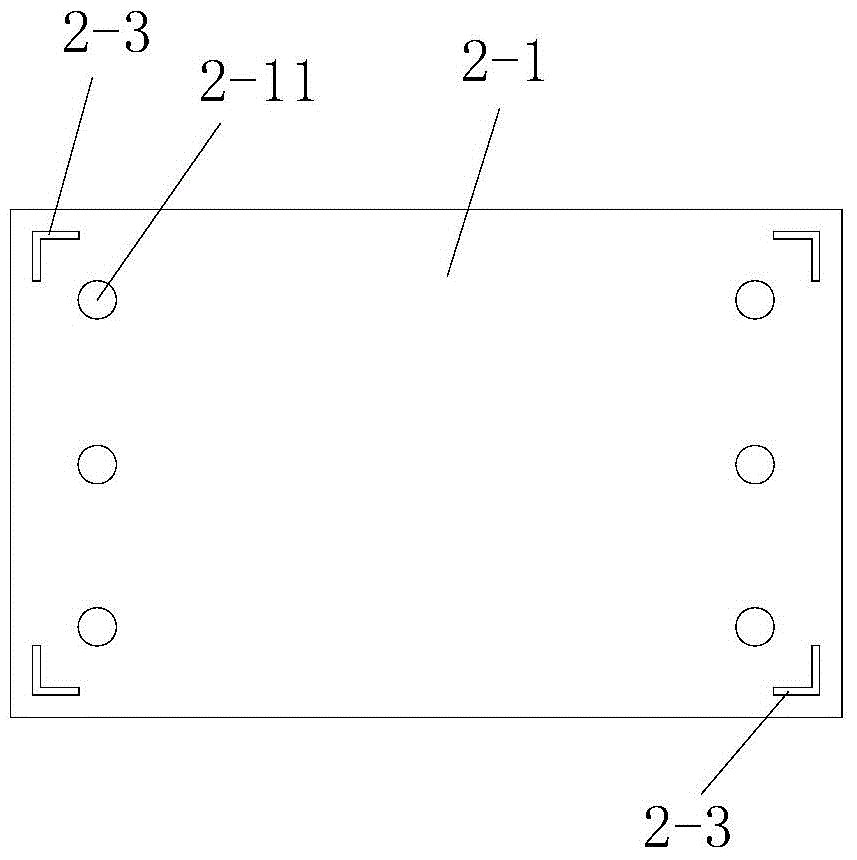

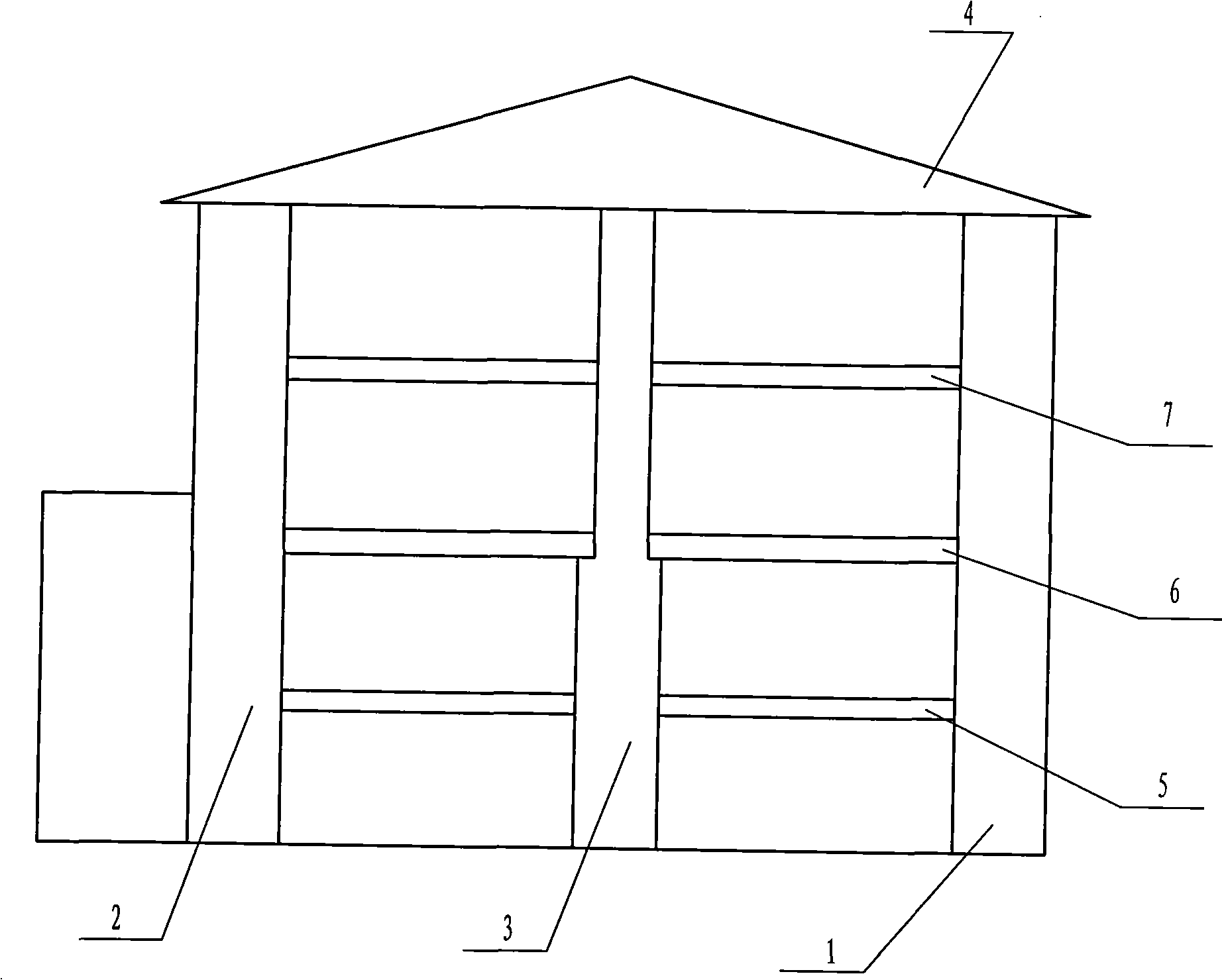

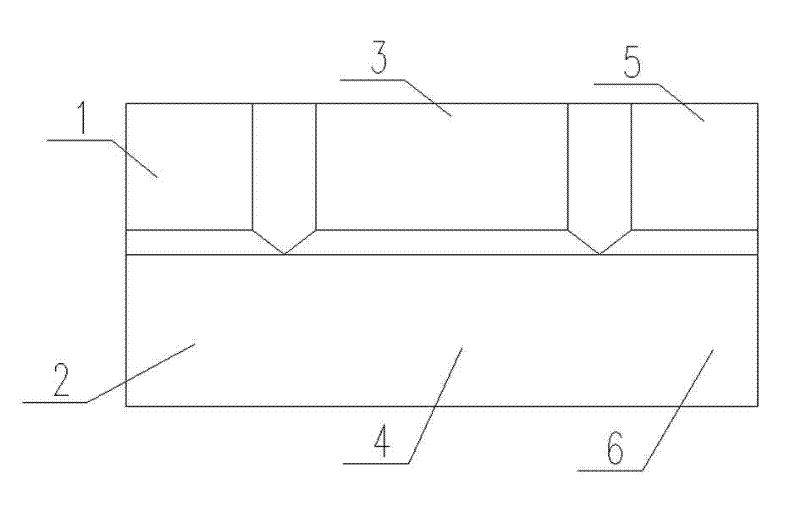

Steel structure building construction method for one-step pre-burying of foundation bolts

The invention discloses a steel structure building construction method for pre-burying of foundation bolts. The steel structure building construction method comprises the following steps: 1. grouping of the foundation bolts: all the foundation bolts to be pre-buried are divided into a plurality of groups, the groups of the foundation bolts are respectively distributed in a plurality of bolt pre-burying areas in a concrete foundation, and the foundation bolts in each group form a bolt group; 2. grouped assembly of the foundation bolts: the bolt groups are respectively assembled, and the assembly procedure comprises manufacturing of a positioning mold, inserting of the foundation bolts, fixing of the foundation bolts, and separating of the bolt groups from positioning mold; 3. concrete cushion construction and pre-burying of fixing steel bars; 4. lower part fixing of the bolt groups; 5. binding of the steel bars and support arrangement of a template erection in the concrete foundation; 6. a position adjustment and upper part fixing of the bolt groups; 7. concrete foundation pouring. The method provided by the invention is simple in procedure, reasonable in design, convenient in implementation, and good in use effects, and has the advantages that the construction process for the high-precision pre-burying of the foundation bolts in the concrete foundation can be simply, conveniently and rapidly completed with high quality.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

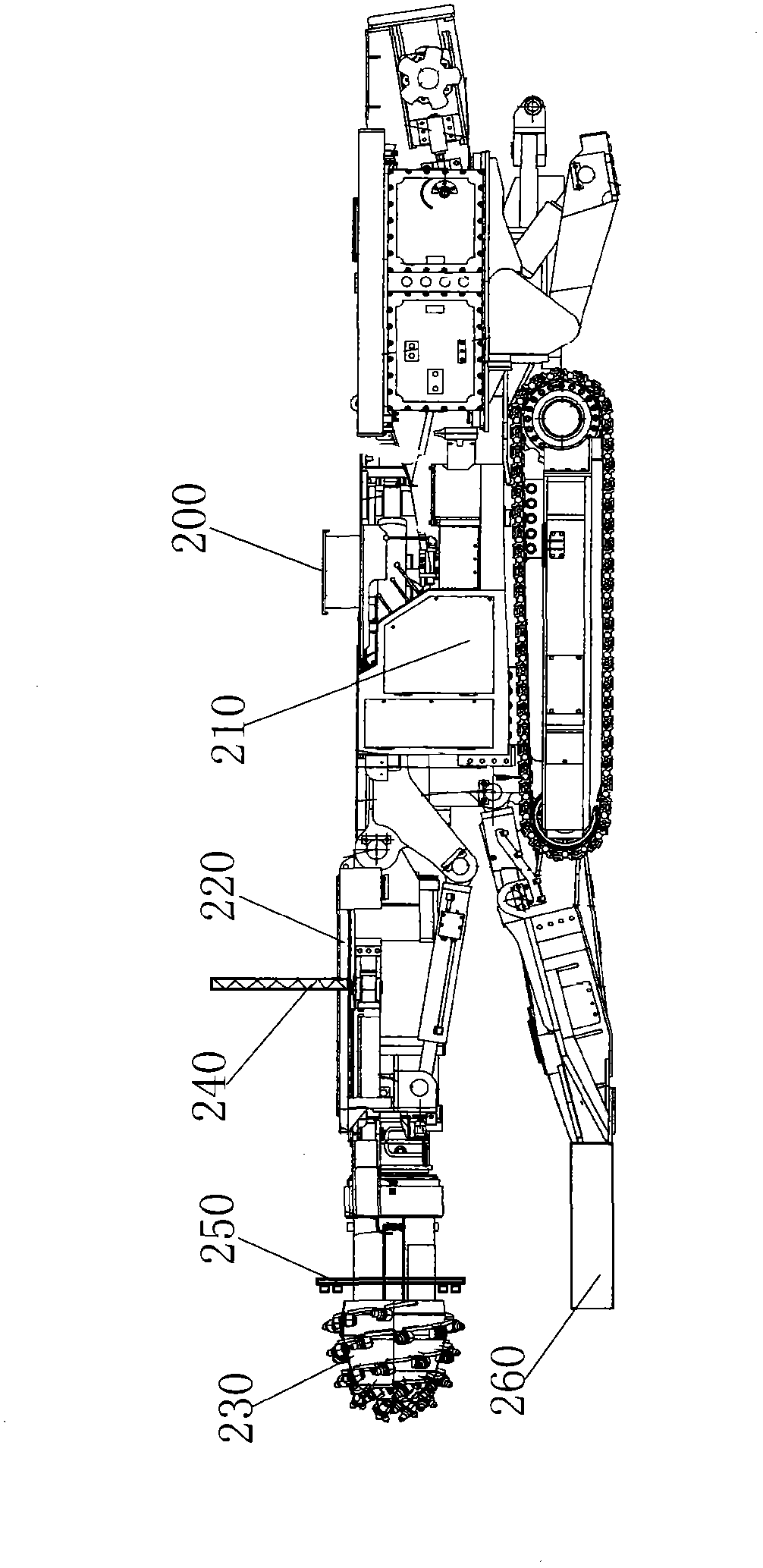

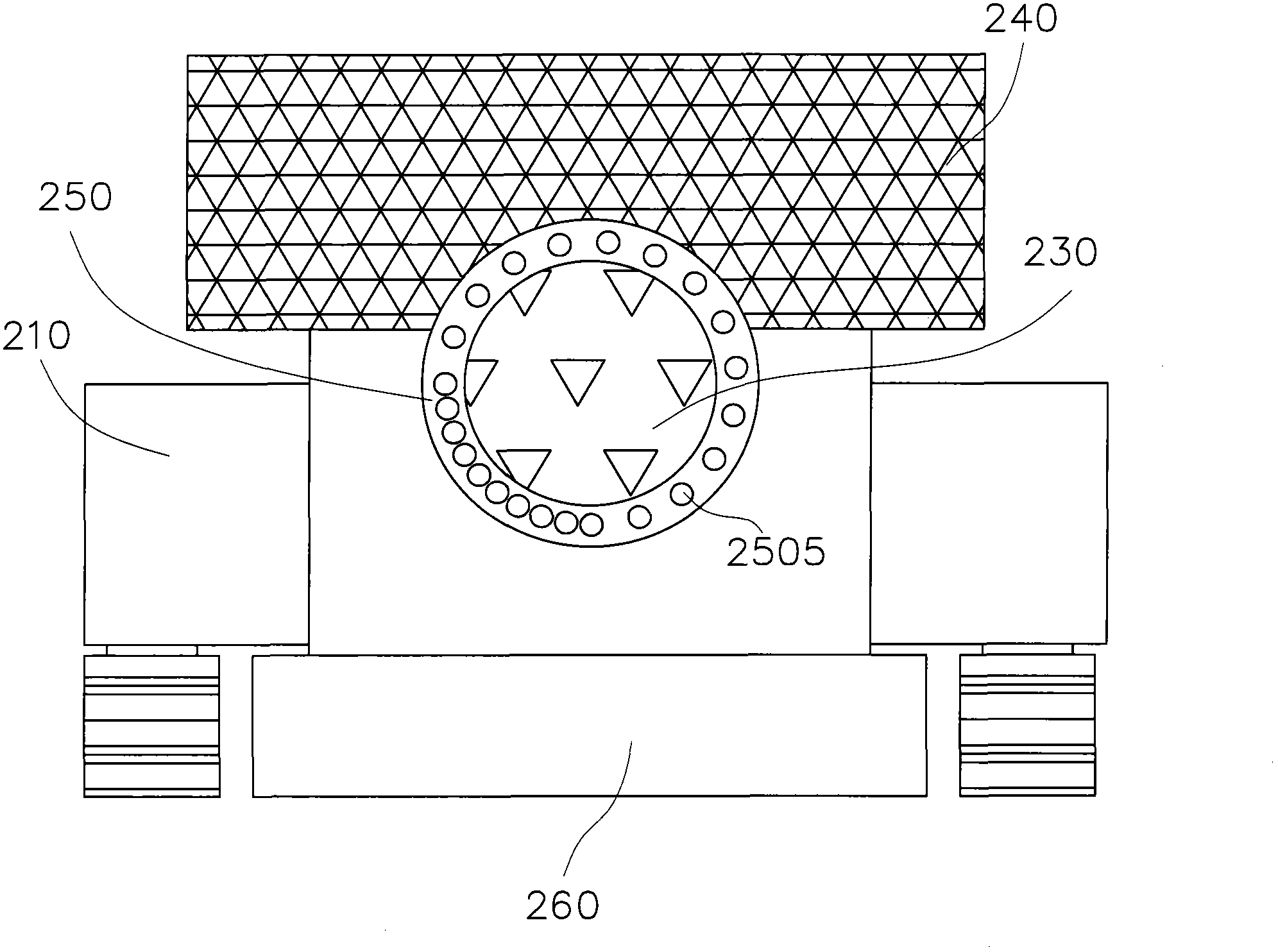

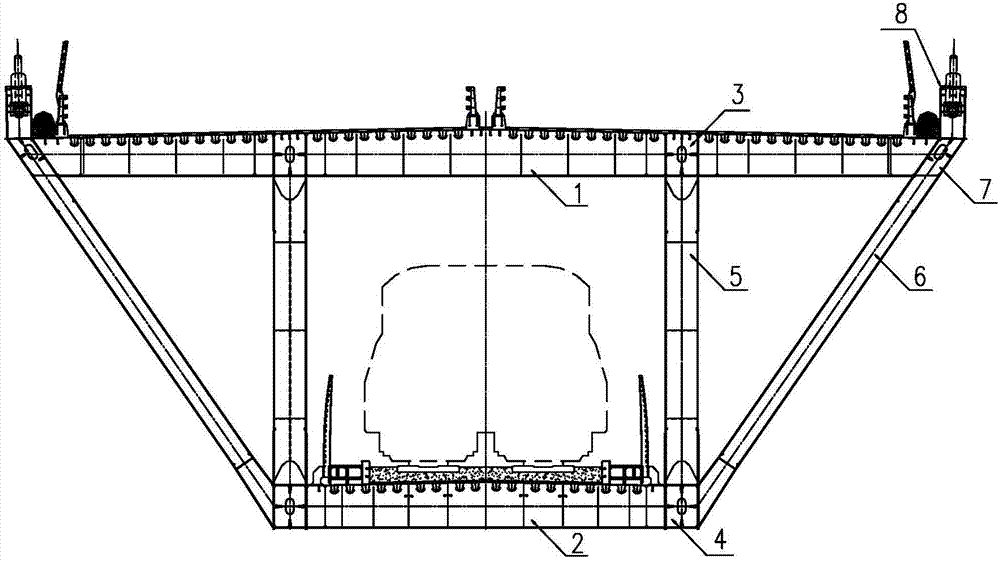

Boom-type roadheader for tunnel construction and tunnel construction method

InactiveCN103291308AAvoid influenceSettlement controlDust removalFire preventionArchitectural engineeringCantilever

The invention discloses a boom-type roadheader for tunnel construction and a tunnel construction method. The boom-type roadheader comprises an engine-driven body, a boom, a milling and excavating head and a water spraying and dust removing device, wherein the boom is connected to the engine-driven body in an extensible and / or swingable manner, and the milling and excavating head is mounted at the free end of the boom in a rotatable manner. The water spraying and dust removing device comprises a plurality of nozzles around the boom and adjacent to the milling and excavating head, and the nozzles are in non-uniform distribution in the circumferential direction. When the boom-type roadheader is used for excavating and milling the cross section of a tunnel, segments and segment strips are set for milling and excavation. When each strip of each segment is excavated and milled, and when the distribution density of the nozzles on the bottom right of the milling and excavating head is set to be higher than that of the nozzles in other regions, the milling and excavating head is driven by the boom to move from left to right; when the distribution density of the nozzles on the bottom left of the milling and excavating head is set to be higher than that of the nozzles in the other regions, the milling and excavating head is driven by the boom to move from right to left.

Owner:北京中铁瑞威基础工程有限公司

Reinforced concrete building top-down method construction process

InactiveCN101324088AGuaranteed structural constructionShorten the construction periodForms/shuttering/falseworksFoundation engineeringReinforced concreteSteel frame

The invention discloses a reinforced concrete building topdown method construction process, comprising the steps as follows: 1: the foundation, foundation and independent pile foundation construction is carried out; 2: a left supporting concrete column, a right supporting concrete column and a middle supporting concrete column of steel frame are established; 3: the areas between the left supporting concrete column and the middle supporting concrete column and areas between the right supporting concrete column and the middle supporting concrete column are used as hoisting passages of hoisting steel frame; each steel frame is hoisted onto the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; 4: all steel frames are hoisted on the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; after the connection and fixing operation, all steel frames are used as the roof of the reinforced concrete building; 5: in the roof, the indoor concrete frame structure is constructed. The method of the invention firstly constructs the side frame and the middle frame column structure, subsequently carries out the hoisting of the steel frame, and constructs the reinforced concrete structure in the clean area after the roof surface has no water, thus saving the construction period, reducing the cost, ensuring the safety hoisting, overcoming the effect of weather and ensuring the construction period and the construction quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

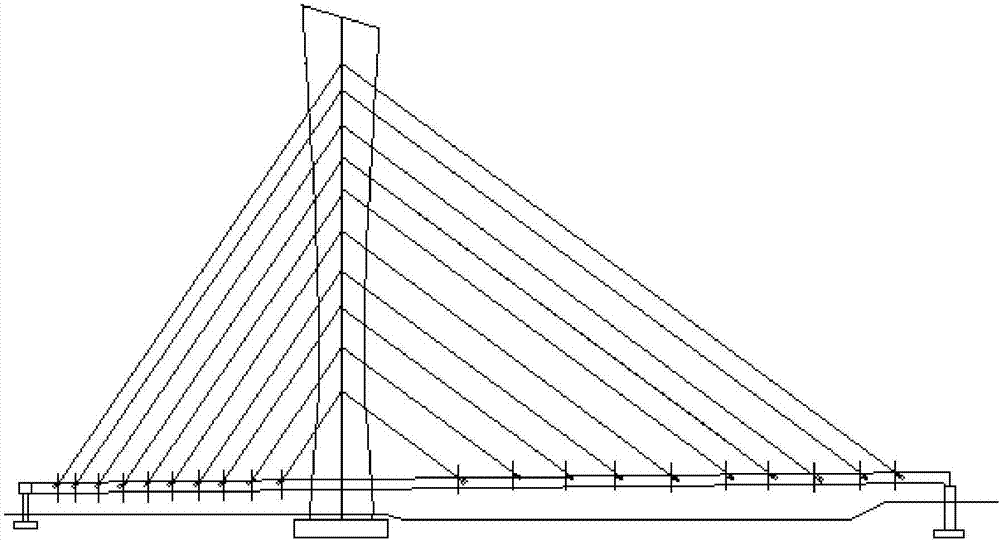

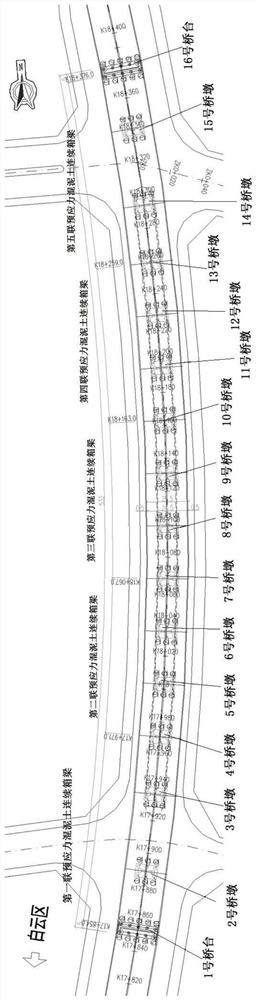

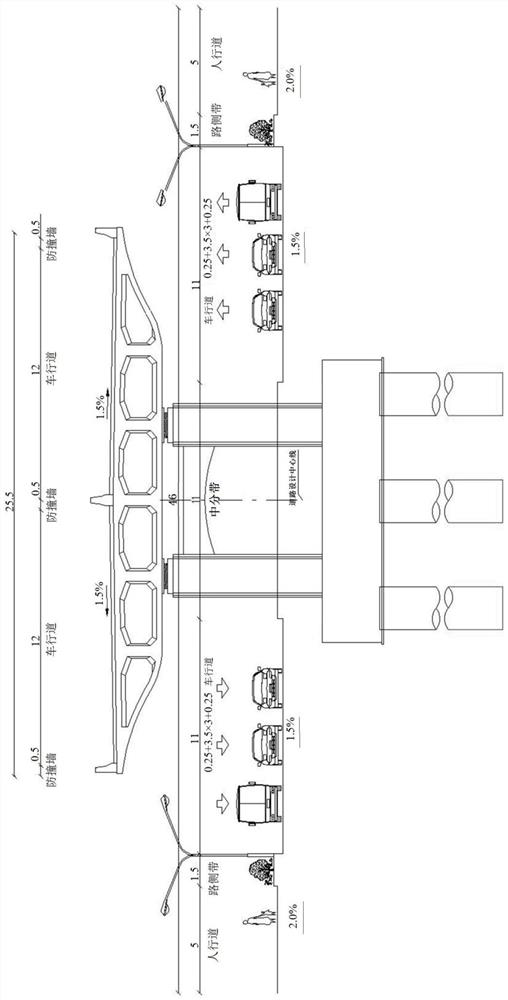

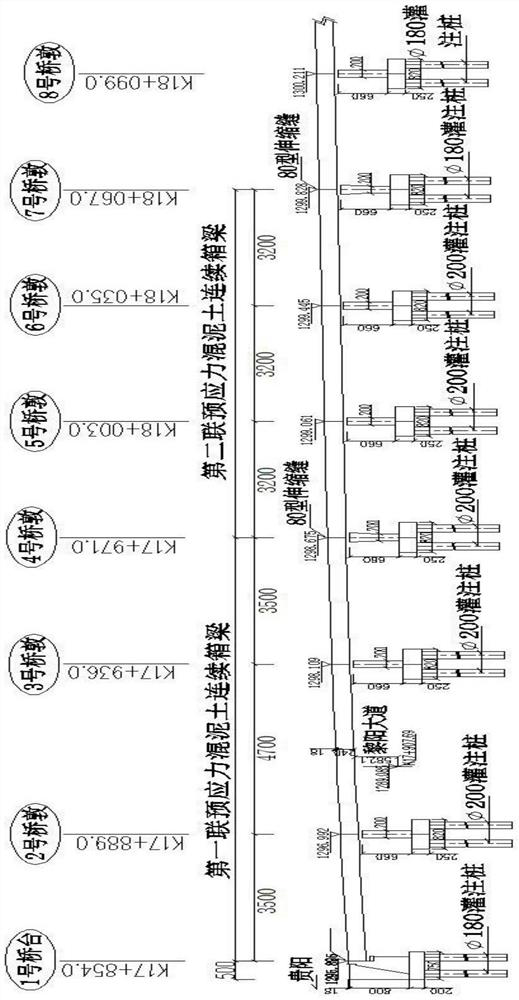

Segment assembled type combined highway and railway cable-stayed bridge with inconsistent bridge deck widths of highway and railway

ActiveCN103882801AReduce on-site workloadReduce construction difficultyCable-stayed bridgeCable stayedBridge deck

The invention relates to a girder type of a segment assembled type combined highway and railway cable-stayed bridge with inconsistent bridge deck widths of a highway and a railway. A girder is composed of a main truss, an auxiliary truss, a highway bridge face and a railway bridge face. The upper-layer bridge face is wide, the lower-layer bridge face is narrow, the width of the main truss is determined by the railway bridge face, and the width of the auxiliary truss is determined by the highway bridge face. Supporting rods for supporting the highway bridge face on the two sides are arranged on a main truss bottom chord in a suspension mode. Auxiliary truss upper chords and the supporting rods form the auxiliary truss together. Stay cables are anchored on the auxiliary truss upper chords through anchor tensile plates. The highway bridge face is welded to main truss upper chords and the auxiliary truss upper chords. The railway bridge face is welded to main truss bottom chords. The upper ends and the lower ends of flange plates of the auxiliary truss supporting rods are welded to the auxiliary truss upper chords and the main truss bottom chords respectively. Web plates of the auxiliary truss upper chords and the flange plates of the auxiliary truss supporting rods are identical in inclined angle. The segment assembled type combined highway and railway cable-stayed bridge with the inconsistent bridge deck widths of the highway and the railway is simple in structure, economical in manufacturing cost and clear and direct in stress, is manufactured by welding whole segments in a factory, and is assembled and erected through the whole segments on a construction site, the construction difficulty in the severe environment of straits is greatly lowered, and the bridge is adopted in the combined highway and railway cable-stayed bridge of the Pingtan strait.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

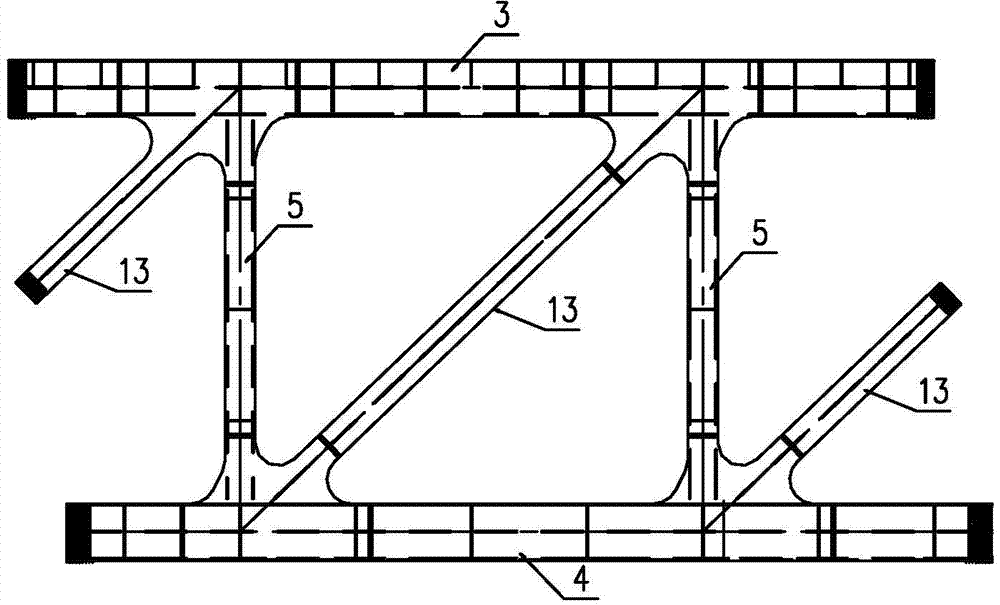

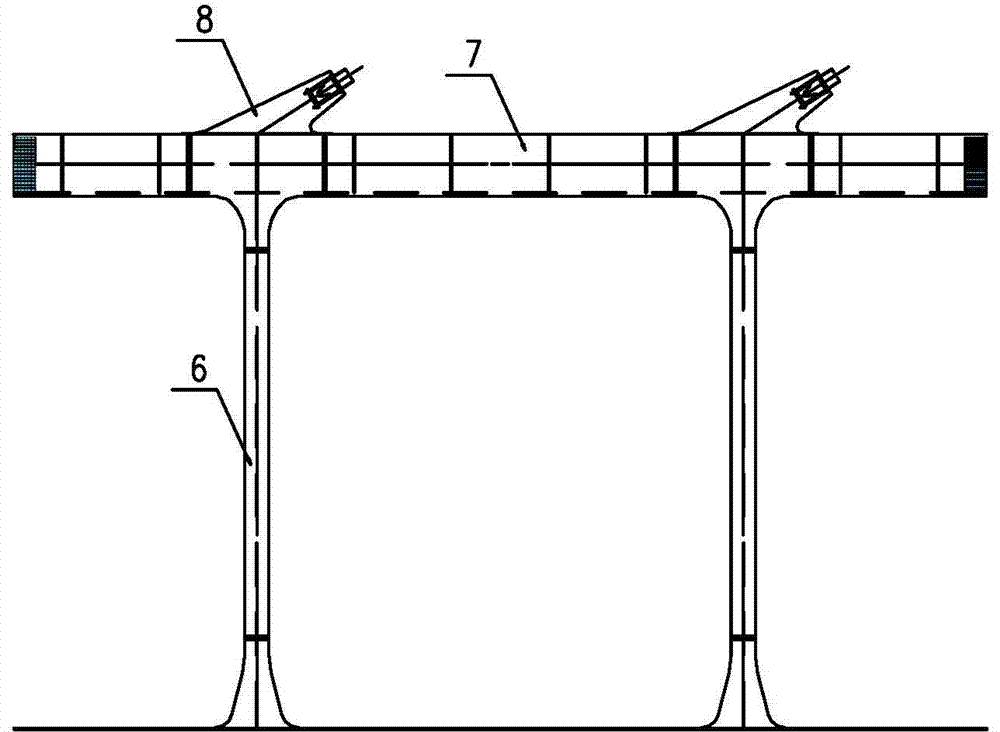

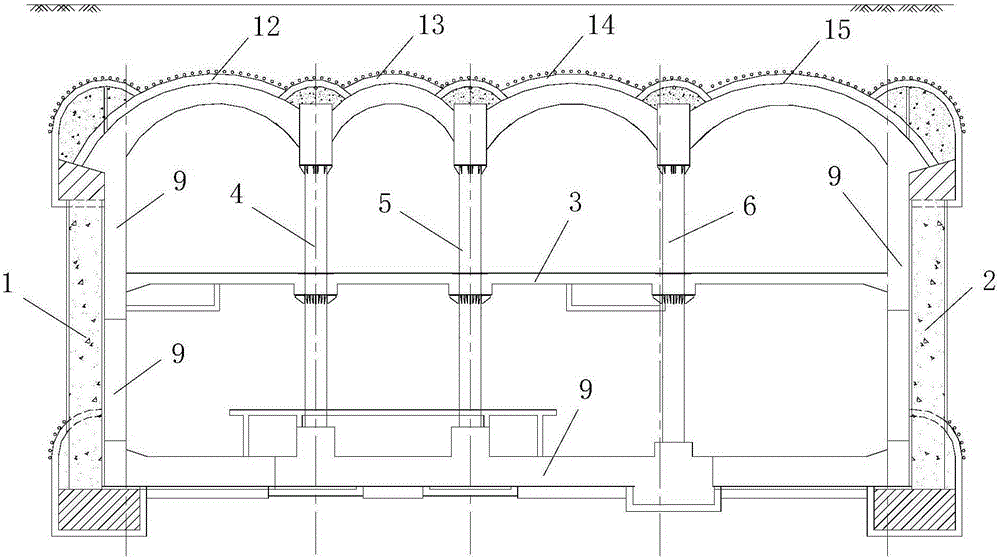

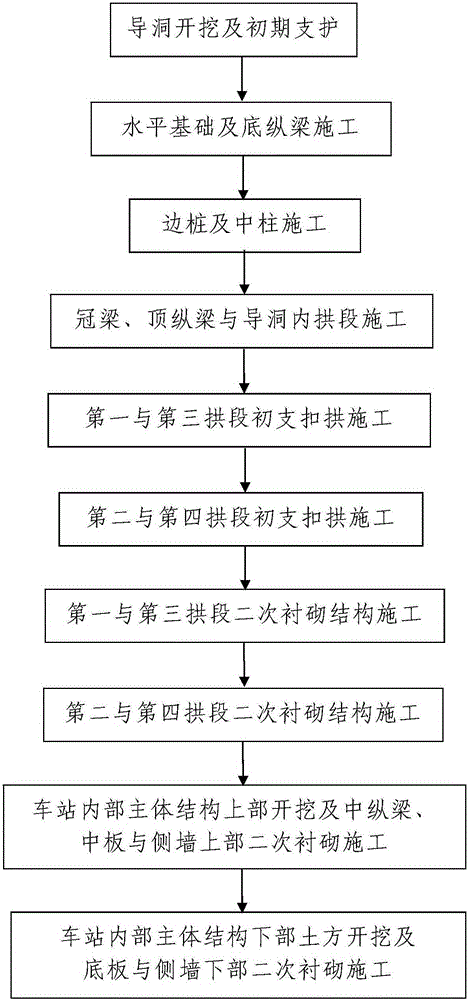

Subway station body structure and four-joint-arch PBA underground excavation construction method thereof

ActiveCN105201516AReasonable structural designStable structureUnderground chambersTunnel liningStructure of the EarthSubway station

The invention discloses a subway station body structure and a four-joint-arch PBA underground excavation construction method thereof. The subway station body structure comprises a station inner body structure, multiple left piles, multiple right piles, three sets of middle columns, middle plates and body arches. The body arches are four-joint arches. The construction method comprises the steps of pilot tunnel excavation and primary support; horizontal base and bottom longitudinal beam construction; side pile and middle column construction; crown beam, top longitudinal beam and pilot tunnel inner arch section construction; first and third arch section primary support buckle arch construction; second and fourth arch section primary support buckle arch construction; secondary lining structure construction of first and third arch sections; secondary lining structure construction of second and fourth arch sections; excavation of the upper portion of the station inner body structure, and secondary lining construction of the middle longitudinal beams, the middle plates and the upper portion of the side wall; earth excavation of the lower portion of the station inner body structure and secondary lining construction of bottom plates and the lower portion of the side wall. The construction is easy, the construction progress is fast, the subway station body structure constructed and formed is firm, and the using effect is good.

Owner:NO 1 ENG LIMITED OF CR20G

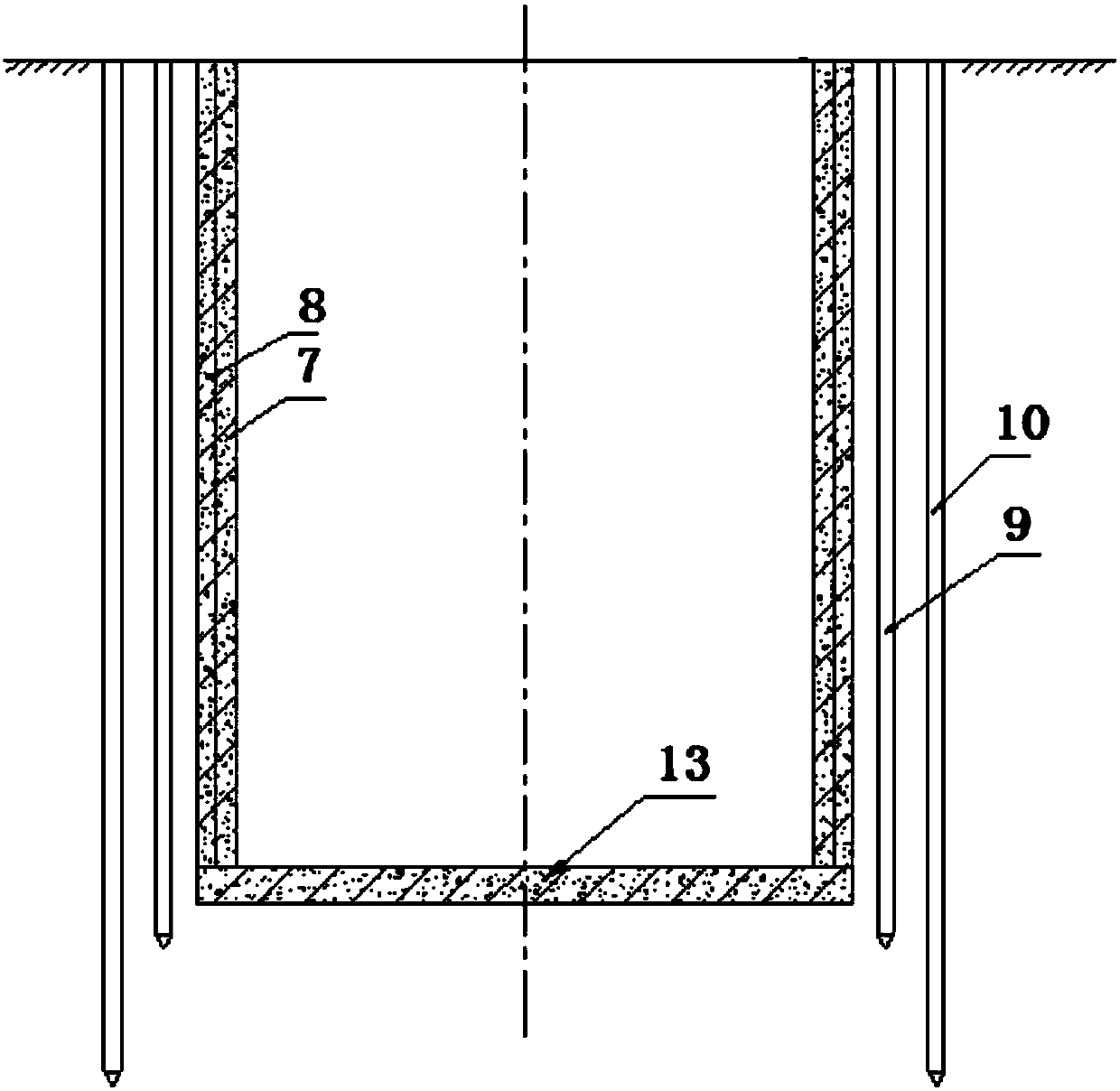

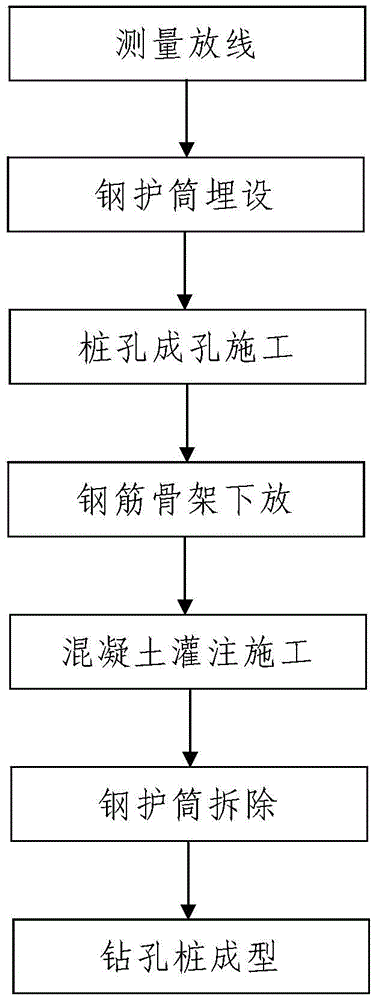

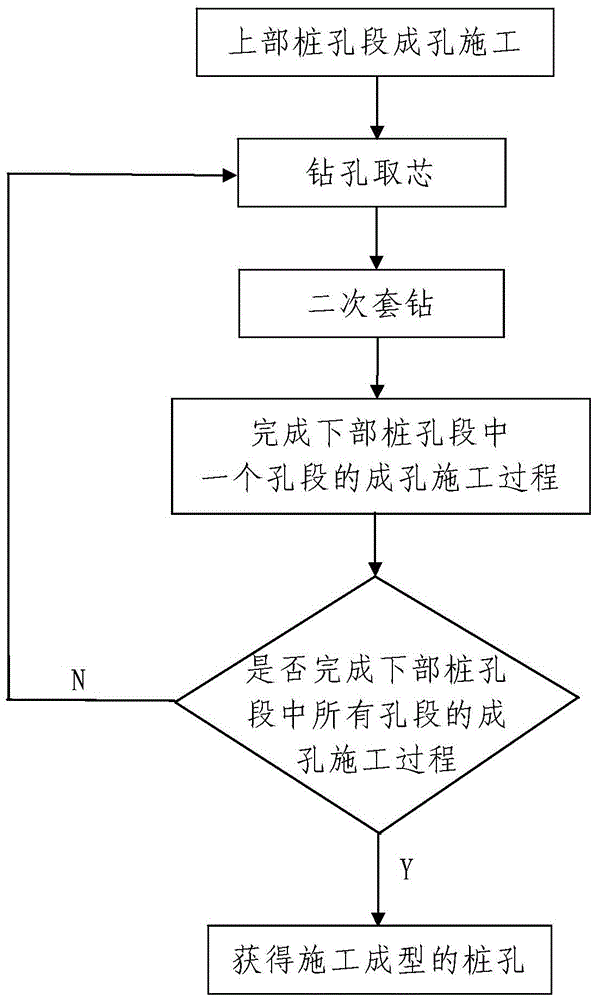

Construction method for bored pile of subway station enclosure structure of upper-soft lower-hard ground

ActiveCN105649012AThe method steps are simpleReasonable designDrill bitsCore removalSubway stationRebar

The invention discloses a construction method for a bored pile of a subway station enclosure structure of upper-soft lower-hard ground. The method includes the steps that firstly, measurement and paying-off are conducted, wherein measurement and paying-off are carried out at a pile position of the bored pile to be constructed, and the bored pile to be constructed is a cast-in-place pile constructed and formed in the upper-soft lower-hard ground; secondly, a steel casing is buried, wherein the steel casing is buried in the soft ground where the bored pile to be constructed is located; thirdly, drilling construction of pile holes is conducted; fourthly, a steel rib frame is laid down; fifthly, concrete pouring construction is conducted; sixthly, the steel casing is detached; seventhly, the bored pile is formed. Drilling construction of the pile holes includes the steps that 301, drilling construction is conducted on an upper pipe hole section and 302, drilling construction is conducted on a lower pile hole section, wherein the lower pile hole section is subjected to drilling construction by being divided into multiple pile hole section bodies from top to bottom, and when any hole section body is subjected to drilling construction, drilling for cores and secondary overcoring are conducted. The method is simple, design is reasonable, construction is easy and convenient, drilling difficulty of the pile holes is low, the use effect is good, and the bored pile construction process of the upper-soft lower-hard ground can be easily, conveniently and quickly completed.

Owner:CHINA RAILWAY FIRST GRP CO LTD

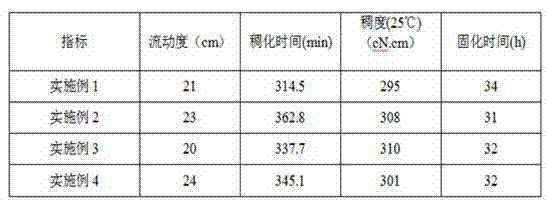

Modified thixotropic slurry and preparation method thereof

The invention provides a modified thixotropic slurry. The slurry comprises components of, by mass, 100 bentonite, 80 to 110 water, 8 to 15 sodium carbonate, 60 to 100 white plaster, 0.5 to 2 parts of flocculant and 0.2 to 0.4 of emulgator. The invention further provides a preparation method of the modified thixotropic slurry. The modified thixotropic slurry is provided with resistance reduction thixotropy and solidification properties and good consistence and can form outstanding slurry sleeves to produce certain support, and accordingly, the safety and the reliability of the soil mass on the upper portion during jacking of jacking pipes can be guaranteed, and soil mass collapse and road surface sinking are prevented.

Owner:金中天水利建设有限公司

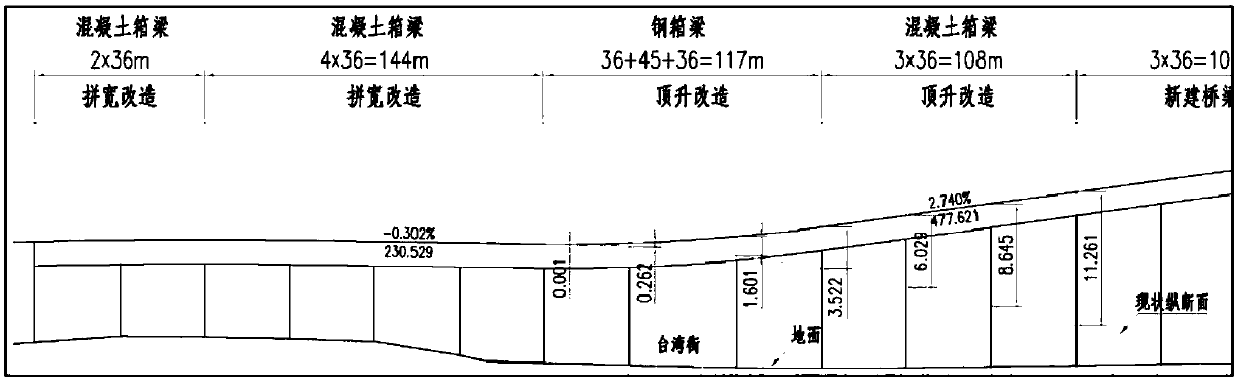

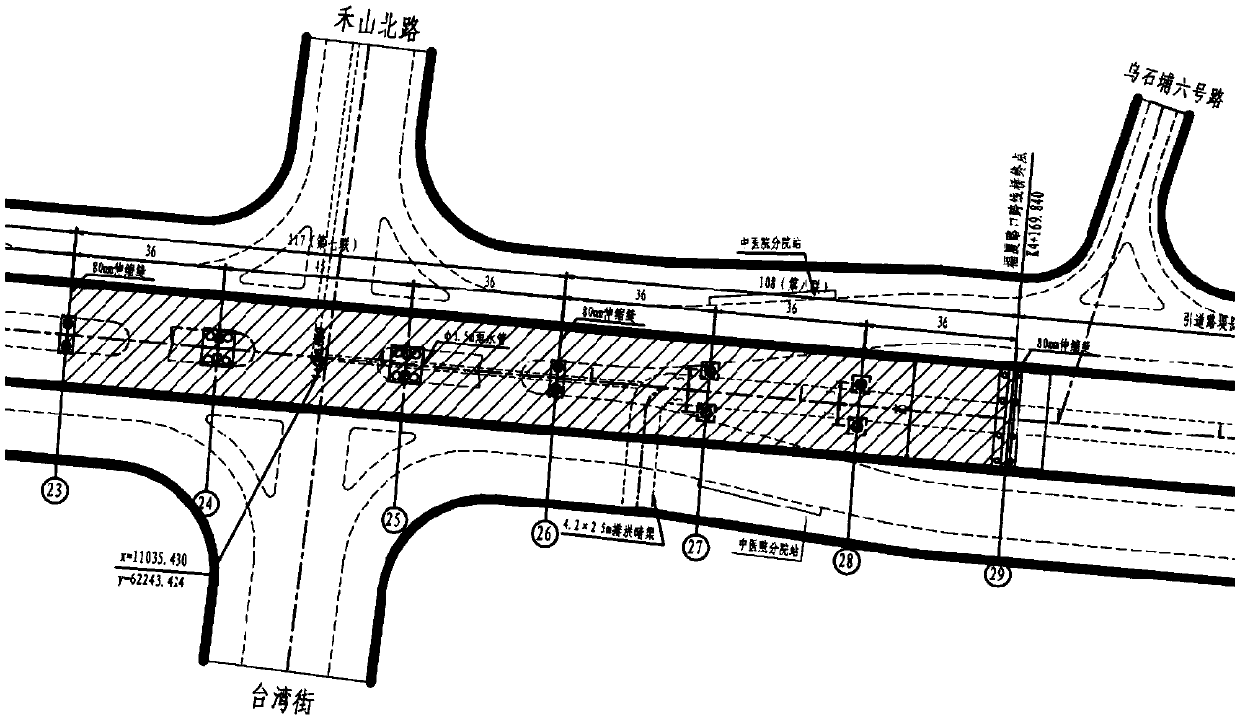

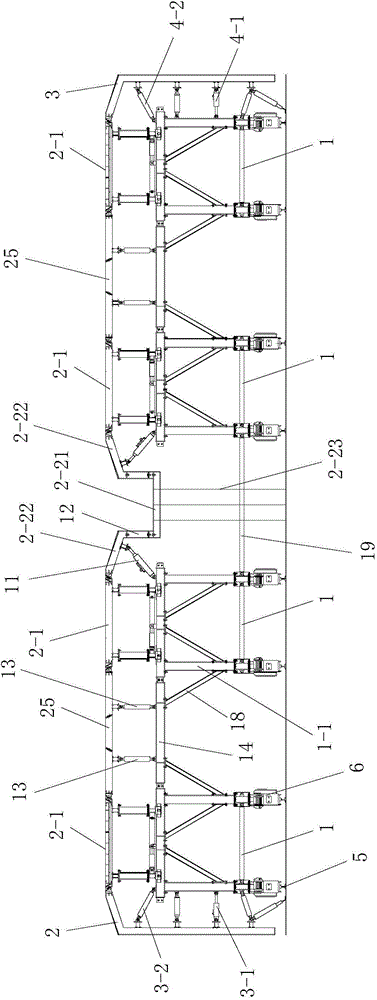

Multi-span box girder integral ultrahigh alternate jacking construction system and method

InactiveCN105507168AGuaranteed construction periodReduce building energy consumptionBridge erection/assemblyBridge strengtheningEcological environmentBuilding energy

The invention discloses a multi-span box girder integral ultrahigh alternate jacking construction system and method. By controlling two groups of jacks capable of positively applying a jacking force, after jacking of one group of jacks is finished, the jacking force of the group of jacks is uniformly linearly transferred to the second group of jacks for performing alternate continuous jacking operation. The overpass bridge ultrahigh alternate jacking construction solution can ensure that during jacking, a bridge structure is safe, the jacking precision and a line type after the whole bridge fall down meet design demands, a construction period is ensured, building energy consumption is reduced and an urban ecological environment is met.

Owner:CCCC THIRD HARBOR ENG +2

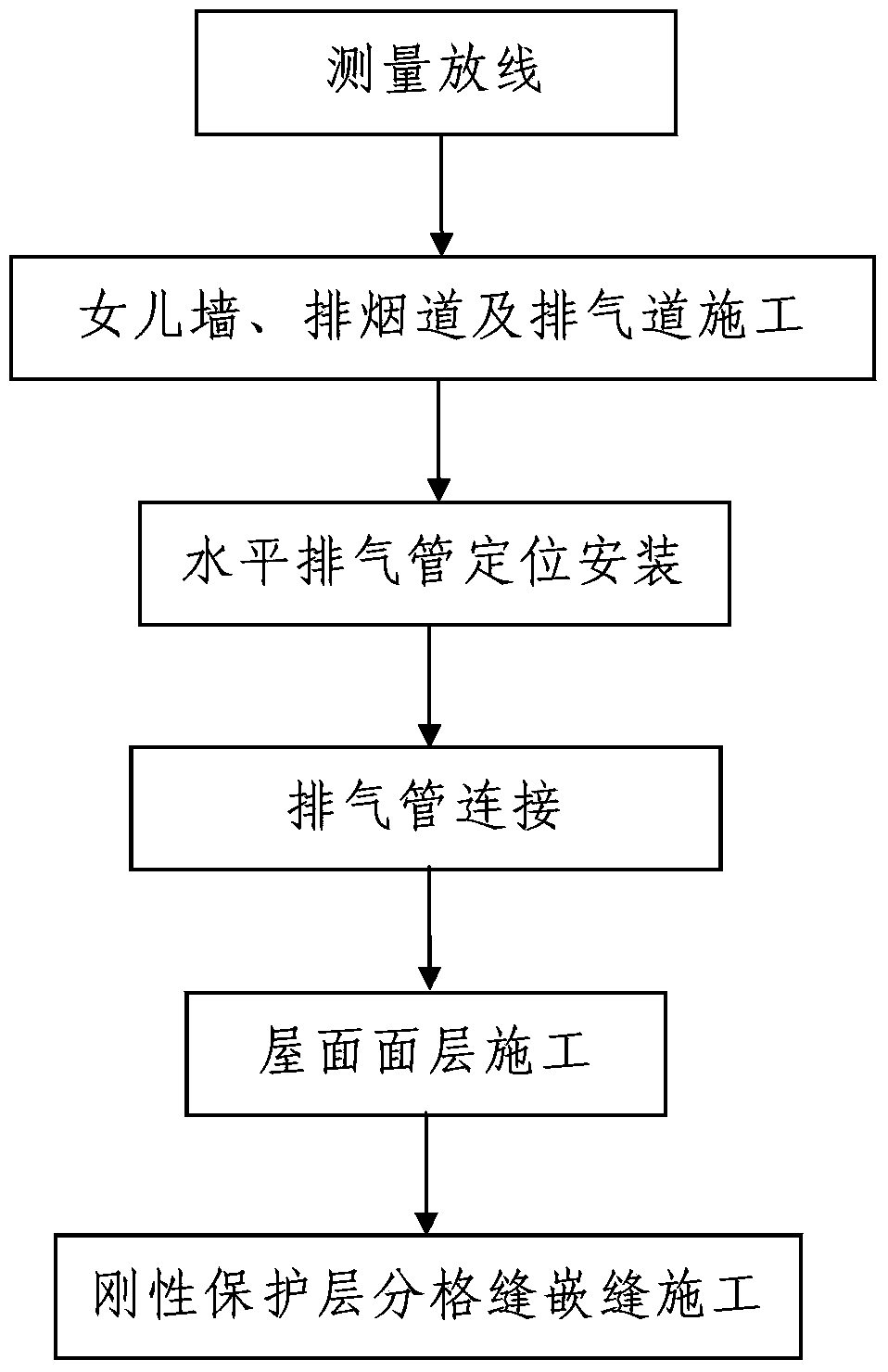

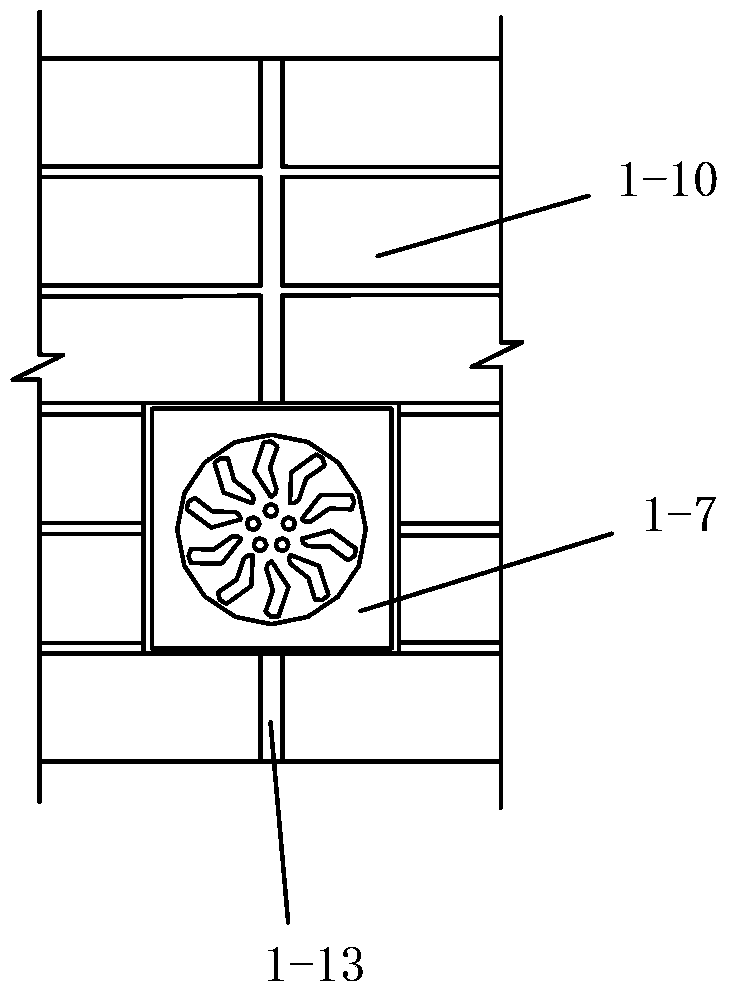

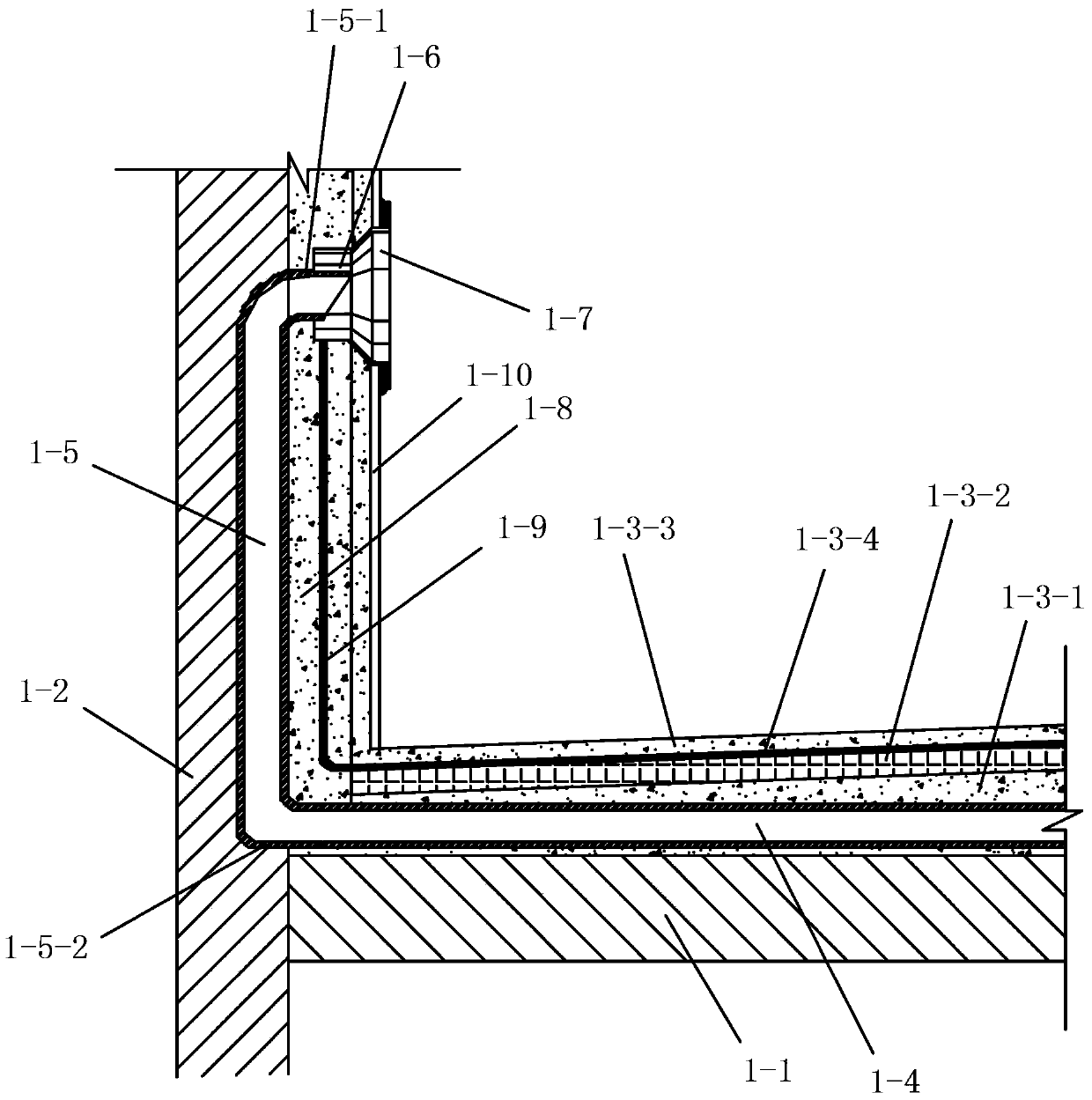

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

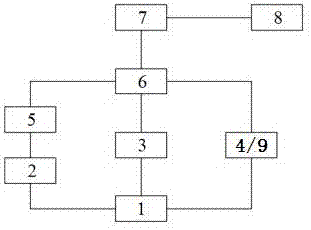

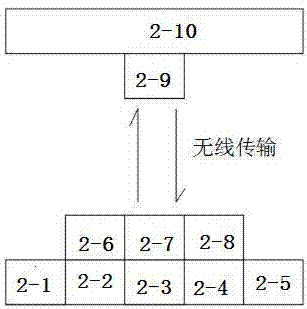

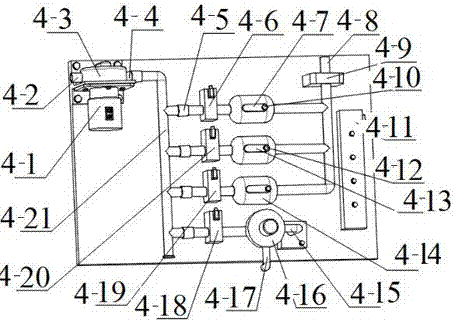

Shield/TBM online state monitoring system

ActiveCN107238416AMaster the working status in real timeImprove working conditionMeasurement devicesTotal factory controlInformatizationData set

The invention belongs to the technical field of device state monitoring, and provides a shield / TBM online state monitoring system. The shield / TBM online state monitoring system comprises mechanical-signal collection apparatuses and an oil-liquid-parameter-signal collection apparatus; the multiple mechanical-signal collection apparatuses are pasted on a shield / TBM; signals collected by the multiple mechanical-signal collection apparatuses are fed into a data concentration center and processed through a data collection conversion module; the oil-liquid-parameter-signal collection apparatus comprises a hydraulic-oil-parameter-signal collection apparatus body and a lubricating-oil-parameter-signal collection apparatus body; signals collected by the hydraulic-oil-parameter-signal collection apparatus body and the lubricating-oil-parameter-signal collection apparatus body are directly fed into the data concentration center and processed; the shield / TBM online state monitoring system also comprises a data calling module; the data calling module is communicated with the data concentration center. According to the shield / TBM online state monitoring system, real-time monitoring of the device working state is achieved, and a technology guarantee is provided for safer and more reliable construction, and the information level of engineering management is improved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

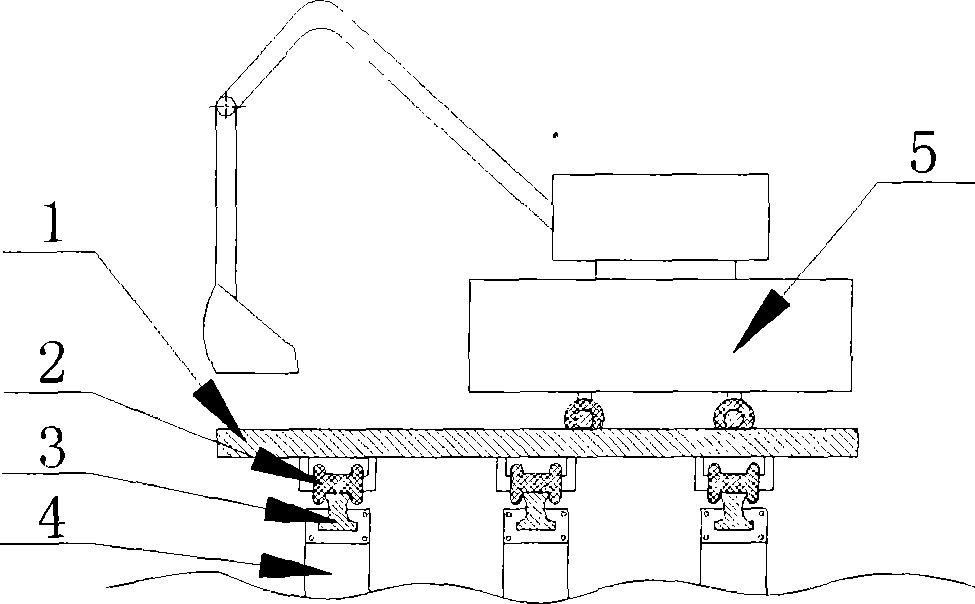

Fast excavation system and excavation method

The invention relates to a system for quick digging after completion of pile foundation and a digging method, and the system consists of an upper layer of a track, a lower layer of a track and a digging machine. The bottom of the upper layer of the track is provided with an idler wheel which is positioned on the lower layer of the track, the lower layer of the track is arranged on the pile foundation, and the bottom of the digging machine is provided with an idler wheel which is positioned on the upper layer of the track. The device has the advantages: 1. having novel, unique, simple and practical structural design; 2. avoiding the problems of derivation, breakage and damage of the pile foundation caused by directly applying the digging machine to a construction site of the pile foundation so as to fundamentally ensure safety in a process of digging of the pile foundation, ensure construction quality and make clear responsibility of construction dispute; and 3. having high digging efficiency and low cost to ensure construction period.

Owner:ZHEJIANG GUOTAI CONSTR GROUP

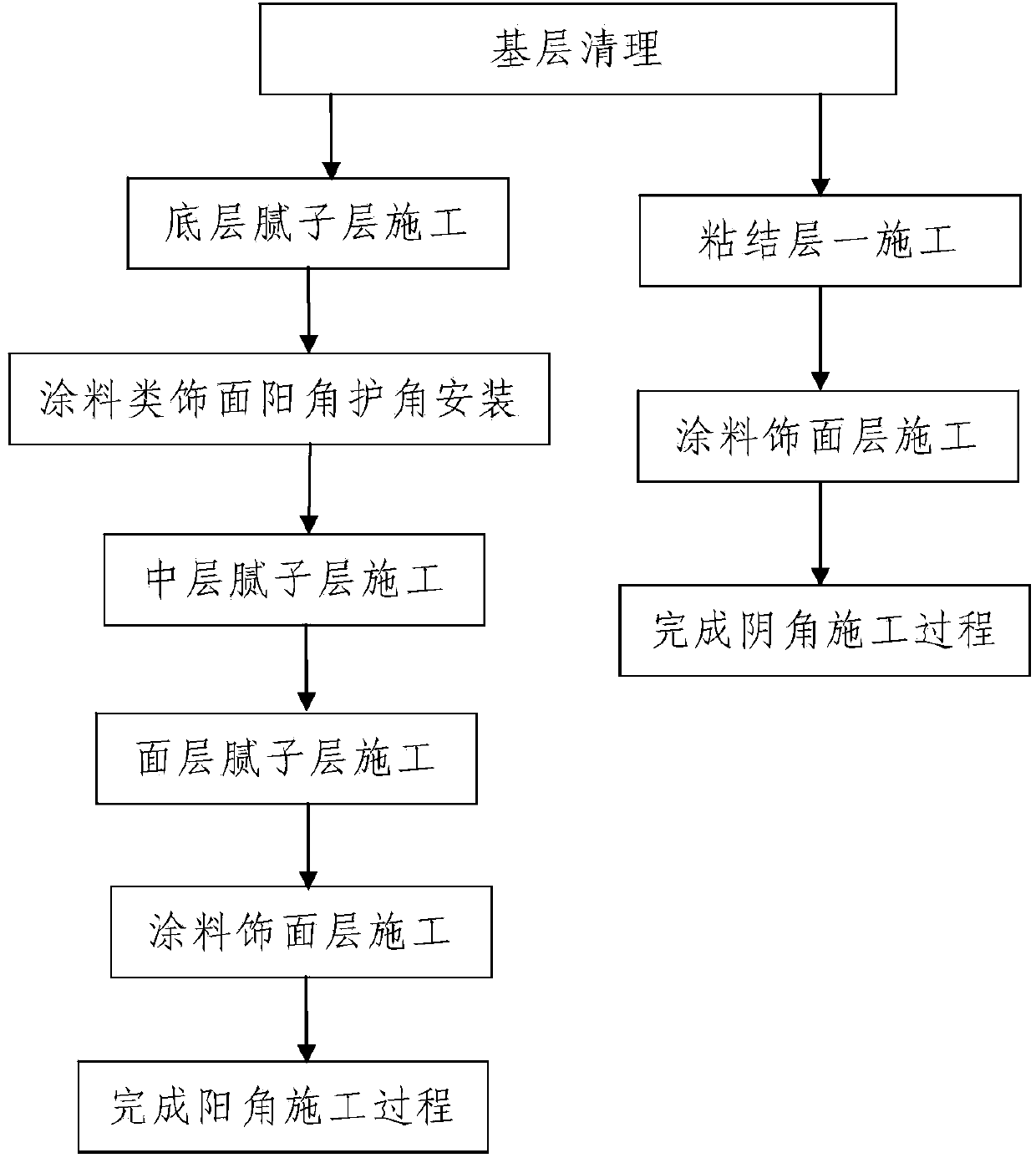

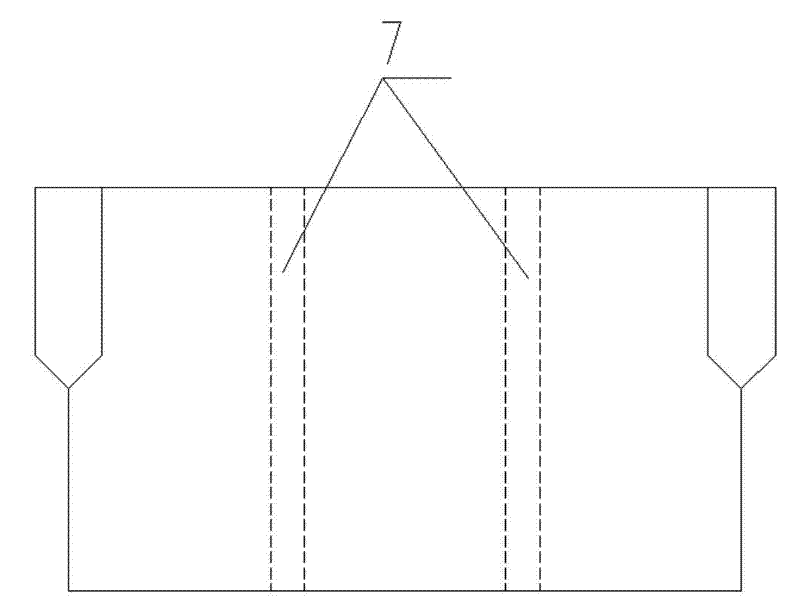

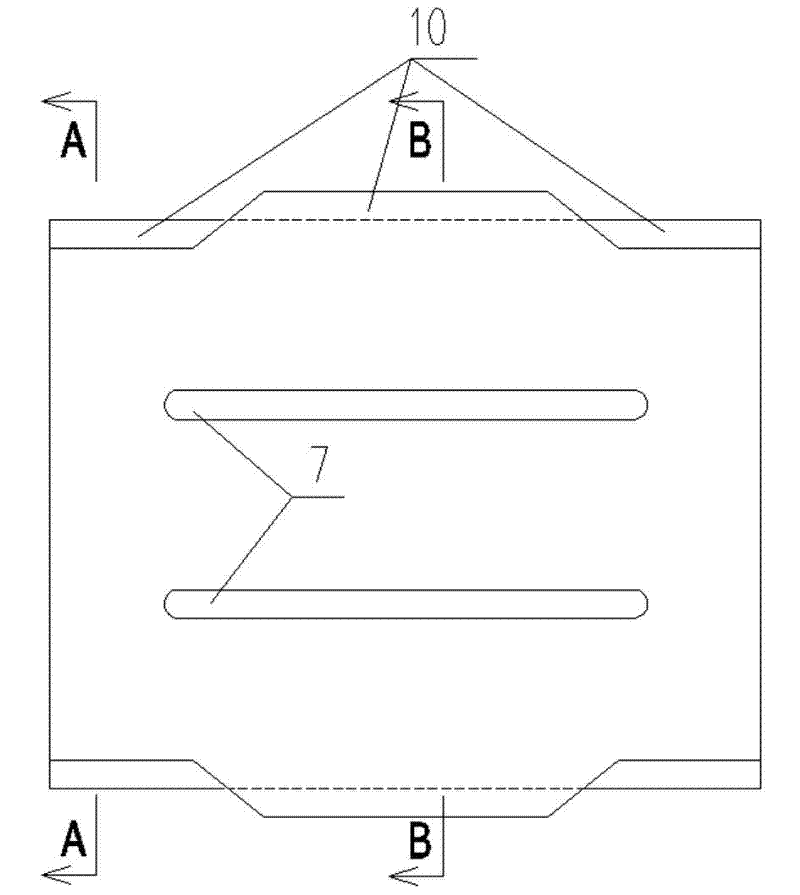

Plastic external corner angle bead for inner wall of building and construction method for internal and external corners of inner wall of building

The invention discloses a plastic external corner angle bead for an inner wall of a building and a construction method for internal and external corners of the inner wall of the building. The plastic external corner angle bead comprises a surface type veneer external corner angle bead or coating type veneer external corner angle bead for protecting the external corner of the inner wall in construction, wherein the surface type veneer external corner angle bead and the coating type veneer external corner angle bead are both arranged from front to back along the length direction of the protected external corner; the cross section of the coating type veneer external corner protector is Y-shaped and the external corner angle bead comprises a corner protector lath arranged on the protected external corner as well as a first pressure strip and a second pressure strip which are respectively connected with the inner end of the corner angle bead lath; the surface type veneer external corner angle bead comprises a corner angle bead strip and a third pressure strip arranged on the corner angle bead strip; the cross section of the corner angle bead strip is of a sector shape. The construction method for the internal and external corners comprises the following steps of: (I) base layer cleanup; (II) construction on the internal and external corners. The internal and external corner angle bead disclosed by the invention is simple in structure and reasonable in design; the construction method for the internal and external corners has simple steps and reasonable design, is convenient to realize and easy in control over the construction quality, and can be used for solving multiple problems of an existing construction method for the internal and external corners of the inner wall of the building.

Owner:陕西建工集团股份有限公司 +1

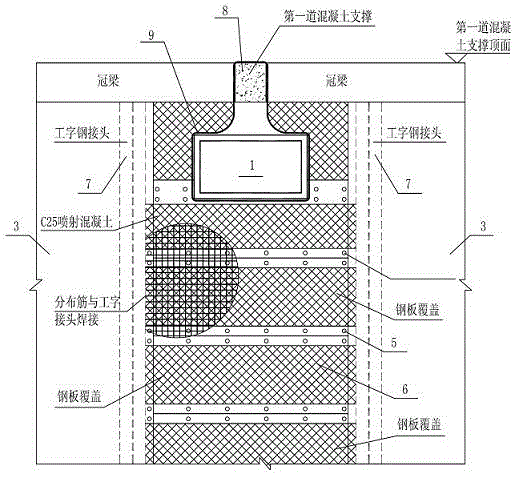

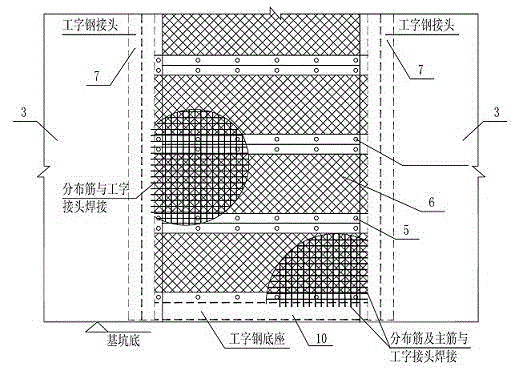

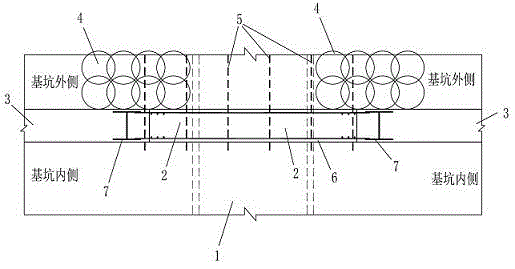

Construction method for reverse construction of continuous wall encountering underground pipeline

ActiveCN103603368ASave on relocation costsGuaranteed construction periodArtificial islandsUnderwater structuresShotcreteSurface layer

The invention relates to a construction method for reverse construction of a continuous wall encountering an underground pipeline. The method includes the steps: determining a continuous wall range in which the pipeline cannot be removed and reconstructed, and adjusting continuous wall framings; performing continuous wall construction on two sides of a reverse construction range, wherein the construction includes joint soldering of one side close to the pipeline, reverse construction range water stoppage and reinforcement outside a foundation pit at the joints by jet grouting piles; excavating soil within the pipeline range, performing step excavation, performing suspension protection treatment on the pipeline in the depth range, and constructing the continuous wall in the reverse construction range every one step of excavation, wherein the continuous wall comprises main layout reinforcements and distribution reinforcements; performing sprayed concrete construction, covering and reinforcing a sprayed concrete surface layer with steel plates which are welded with I-beam joints on two sides of the reverse-construction continuous wall; excavating to a base, disposing an I-beam base, and spraying concrete to form a seal bottom. By the steps, the construction method for reverse construction of the continuous wall encountering the underground pipeline is realized, so that pipeline removal and reconstruction cost is saved, and good effect of a construction period is guaranteed.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

Reinforced concrete girder bridge girder reinforcing structure and method

ActiveCN104947603ASimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:XIAN UNIV OF SCI & TECH

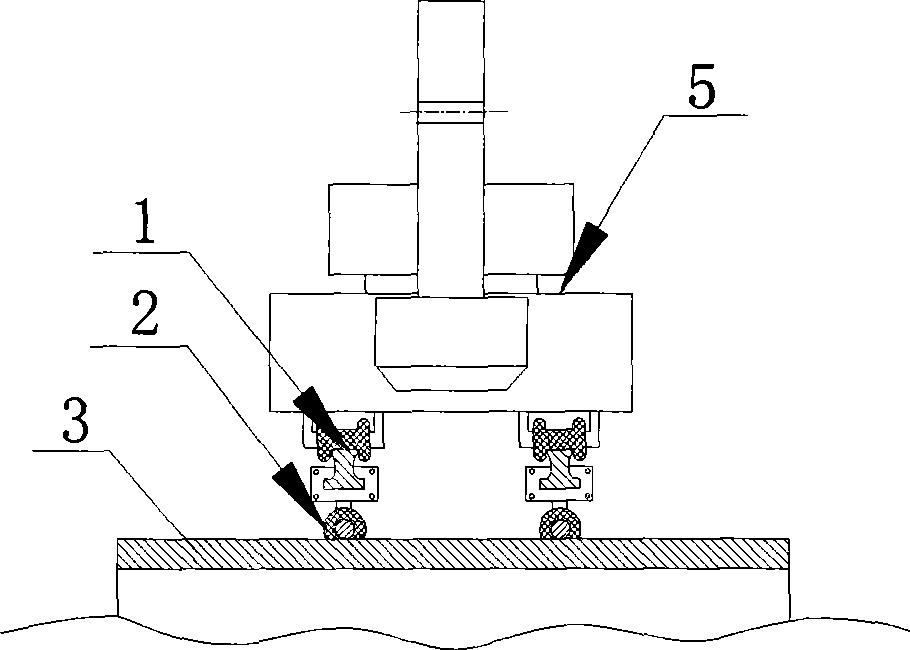

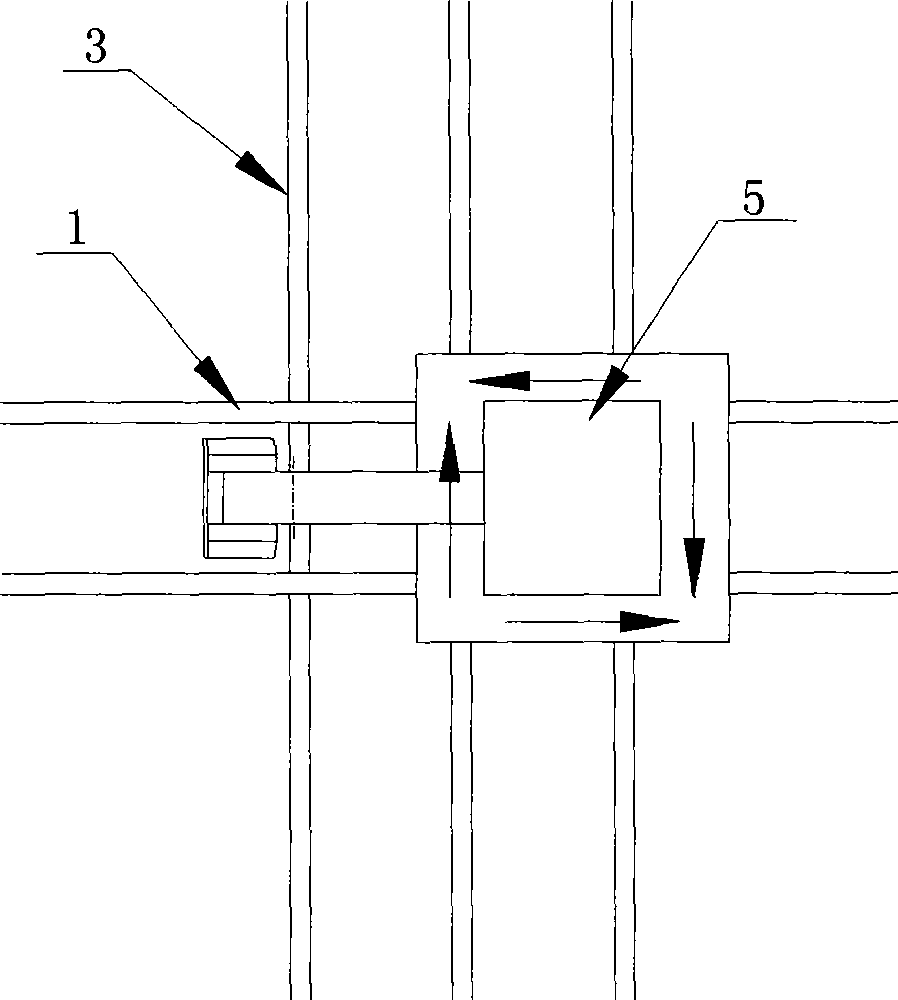

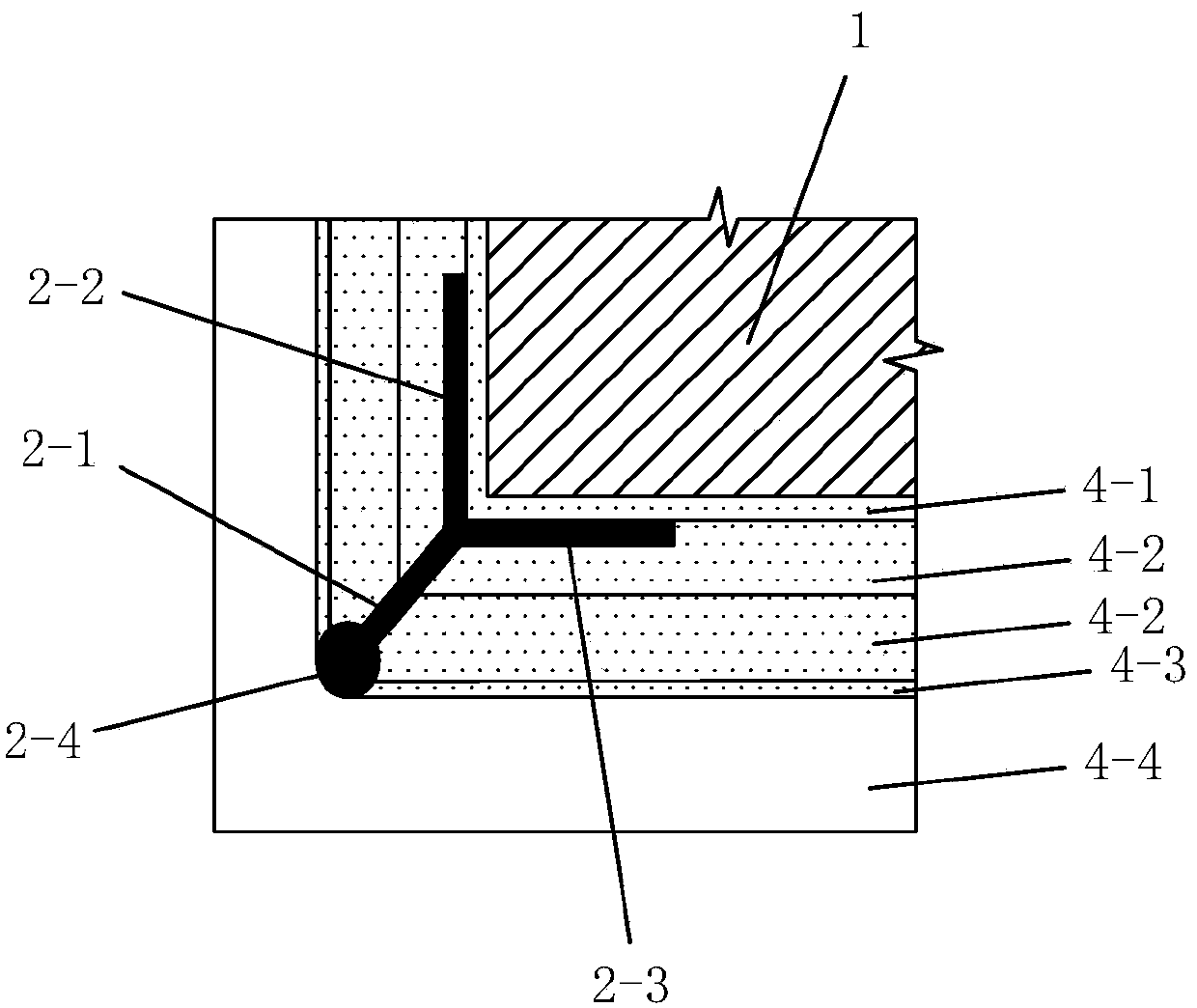

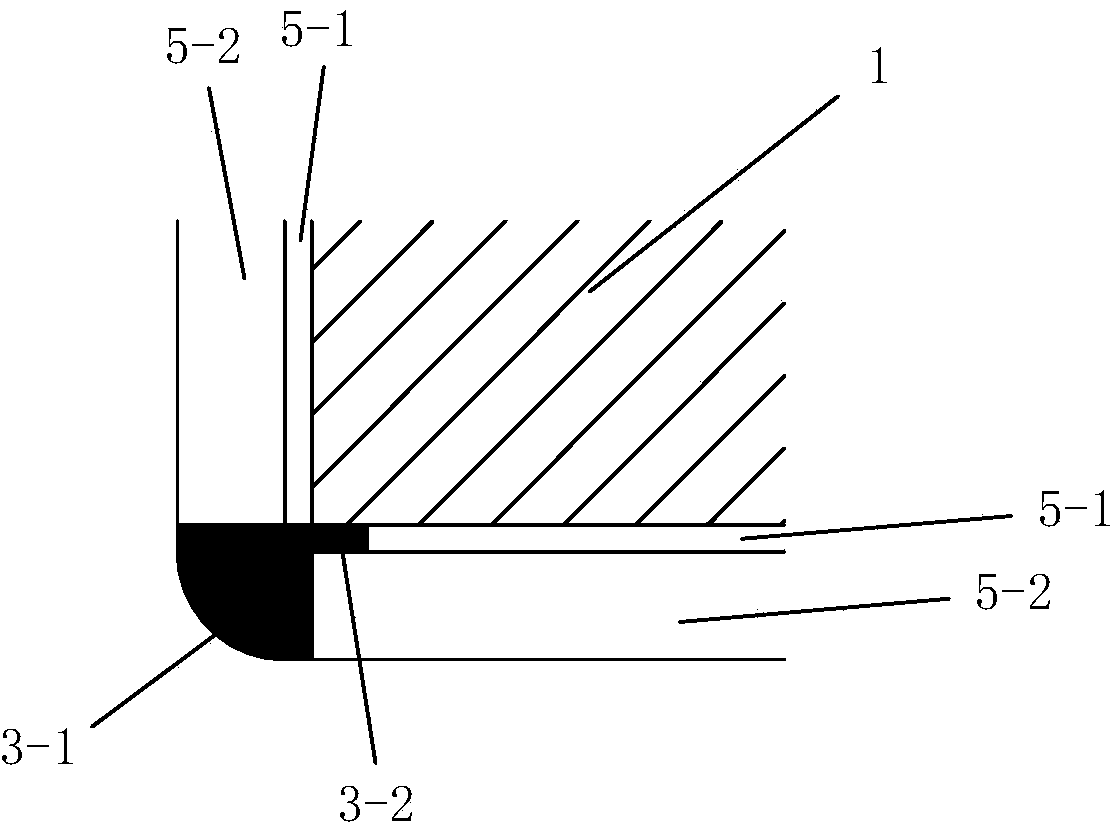

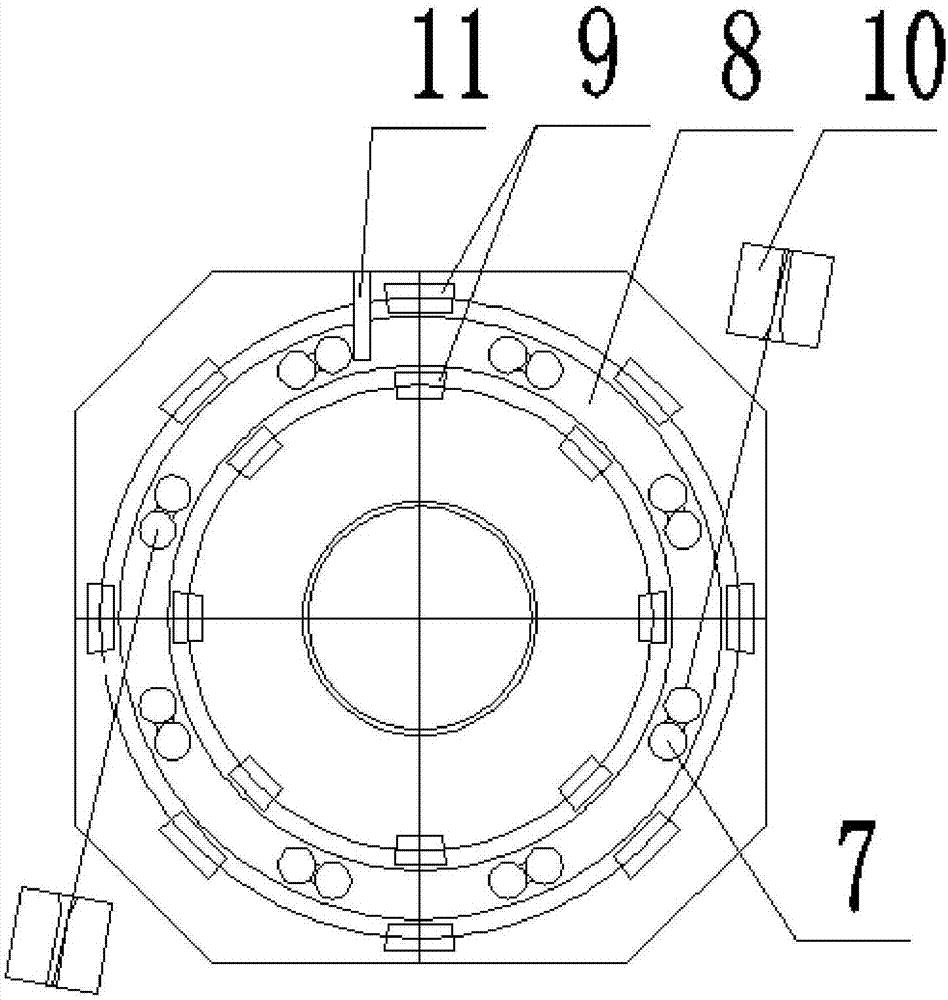

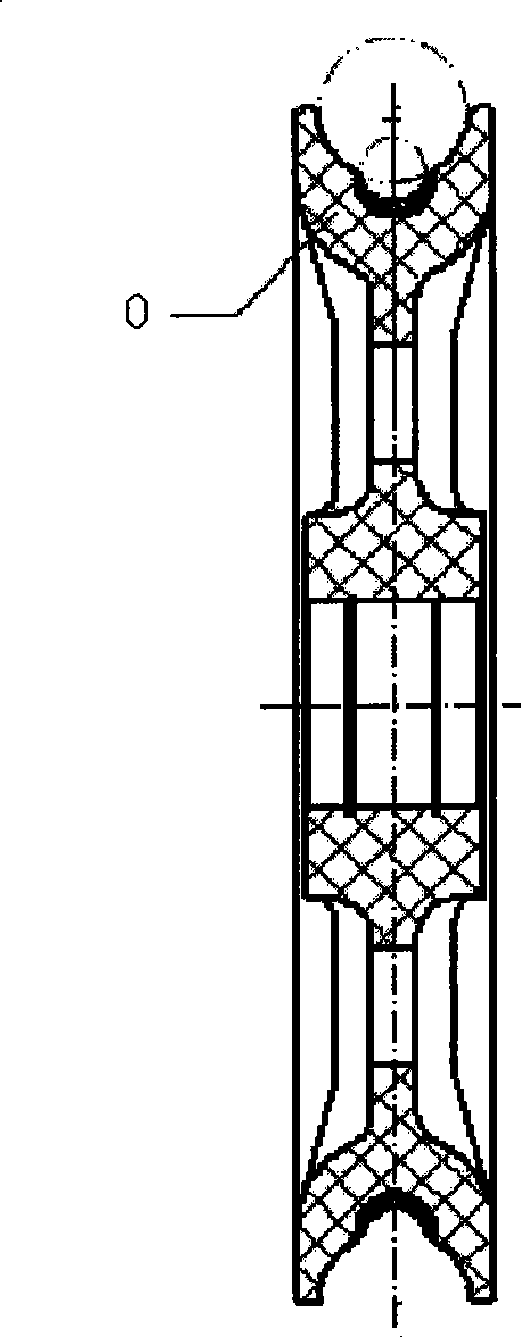

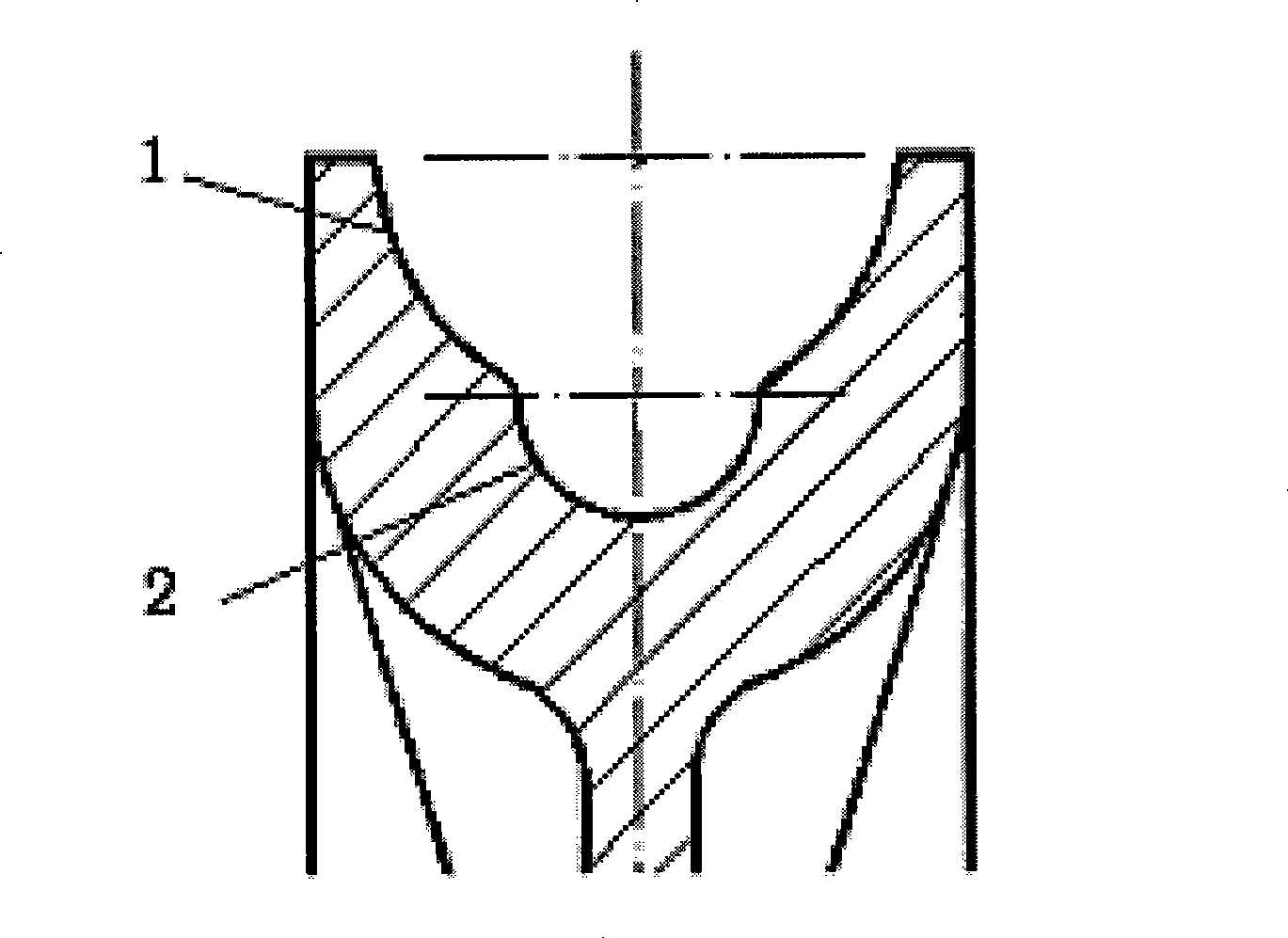

Horizontal rotation structure of ultra-large-tonnage asymmetric hybrid girder cable-stayed bridge and construction method thereof

PendingCN107964877AConstruction safetyShort construction periodBridge erection/assemblyCable stayedProcess complexity

The invention relates to the bridge construction technique, specifically to a horizontal rotation structure of an ultra-large-tonnage asymmetric hybrid girder cable-stayed bridge and a construction method thereof. The horizontal rotation structure of the ultra-large-tonnage asymmetric hybrid girder cable-stayed bridge comprises a concrete foundation pile, a bearing platform, rotating disks and a rotation sliding rail, wherein the bearing platform is divided into an upper bearing platform and a lower bearing platform; the rotation sliding rail is divided into support legs and a slideway; the upper bearing platform is provided with an upper rotating disk and the support legs; the lower bearing platform is provided with a lower rotating disk, a position-fixing pin and the slideway; the upperrotating disk and the lower rotating disk are connected by the position-fixing pin; the upper rotating disk fits the lower rotating disk; and the support legs fit the slideway. The horizontal rotationstructure of the ultra-large-tonnage asymmetric hybrid girder cable-stayed bridge and the construction method have obvious effects on solving the problems of complex construction process and high construction costs of a horizontal rotation structure of a large-tonnage asymmetric hybrid girder cable-stayed bridge in the prior art, and have the advantages of simple construction procedures, high construction speed, safety, reliability and low construction costs.

Owner:CHINA RAILWAY NO 9 GRP 2ND ENG +2

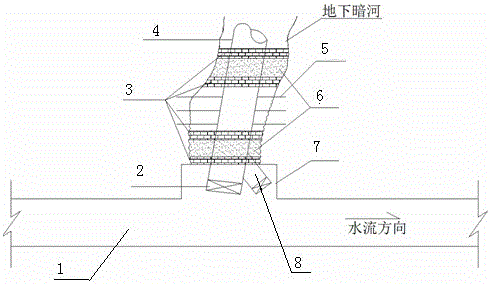

Tunnel underground river water burst blockage construction method

InactiveCN105064280AReduce processing construction costsOvercome the impact of pouring constructionMarine site engineeringEngineeringRetaining wall

The invention discloses a tunnel underground river water burst blockage construction method. The early drainage and the later closing are performed on the underground river water burst by using modes of a water retaining wall, mortar filling and a water closing gate sluice valve to realize the maximum control over the underground river water burst. The construction method overcomes the influence of the water burst on the concrete pouring construction to the greatest extent in the concrete construction process of tunnel with a lot of water burst, so that the concrete construction quality is improved, the construction period is guaranteed, and the water burst treatment construction cost is reduced.

Owner:SINOHYDRO BUREAU 14 CO LTD

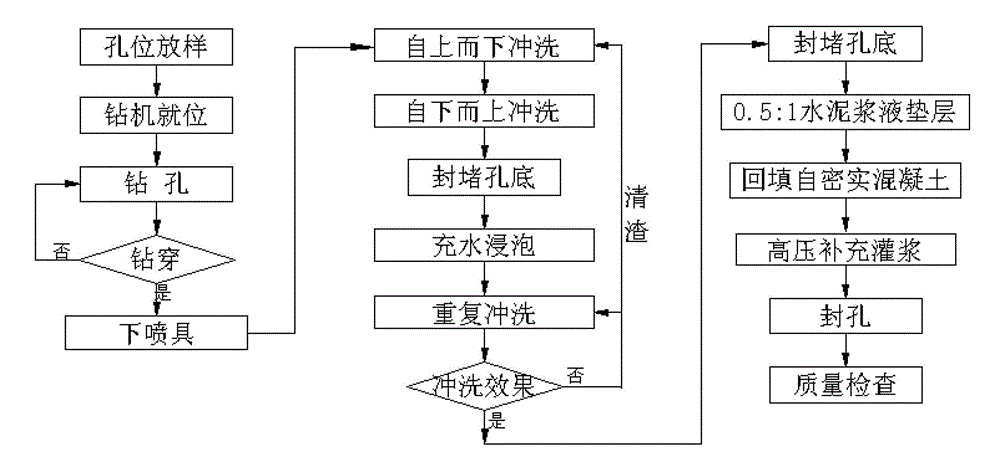

Foundation strengthening treatment method

ActiveCN102720176ASolve the reinforcement processing problemSave construction investmentSoil preservationWork periodHydroelectric development

The invention discloses a foundation strengthening treatment method comprising the following steps of drilling, washing, backfilling, carrying out high-pressure supplementary grouting and checking the quality. The drilling step mainly comprises the steps of drilling a main washing hole and / or an auxiliary washing hole; and the washing step mainly comprises the steps of washing, backfilling and carrying out high-pressure supplementary grouting under regulated conditions. The foundation strengthening treatment method disclosed by the invention effectively solves the strengthening treatment problem of a geological defect part which cannot be dug, solves impermeable treatment engineering and even can replace digging; the foundation strengthening treatment method solves the technical difficulty of relative engineering in the similar complicated engineering, shortens the work period, improves the engineering quality, reduces the engineering cost, saves the building investment of a hydropower station and guarantees the safety of a construction period and an operation period of the power station; and the foundation strengthening treatment method has important real guide meanings to supporting engineering, is used for accumulating data and providing reference to the similar engineering and the relative engineering, and has a wide application prospect in national western hydroelectric development and construction.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

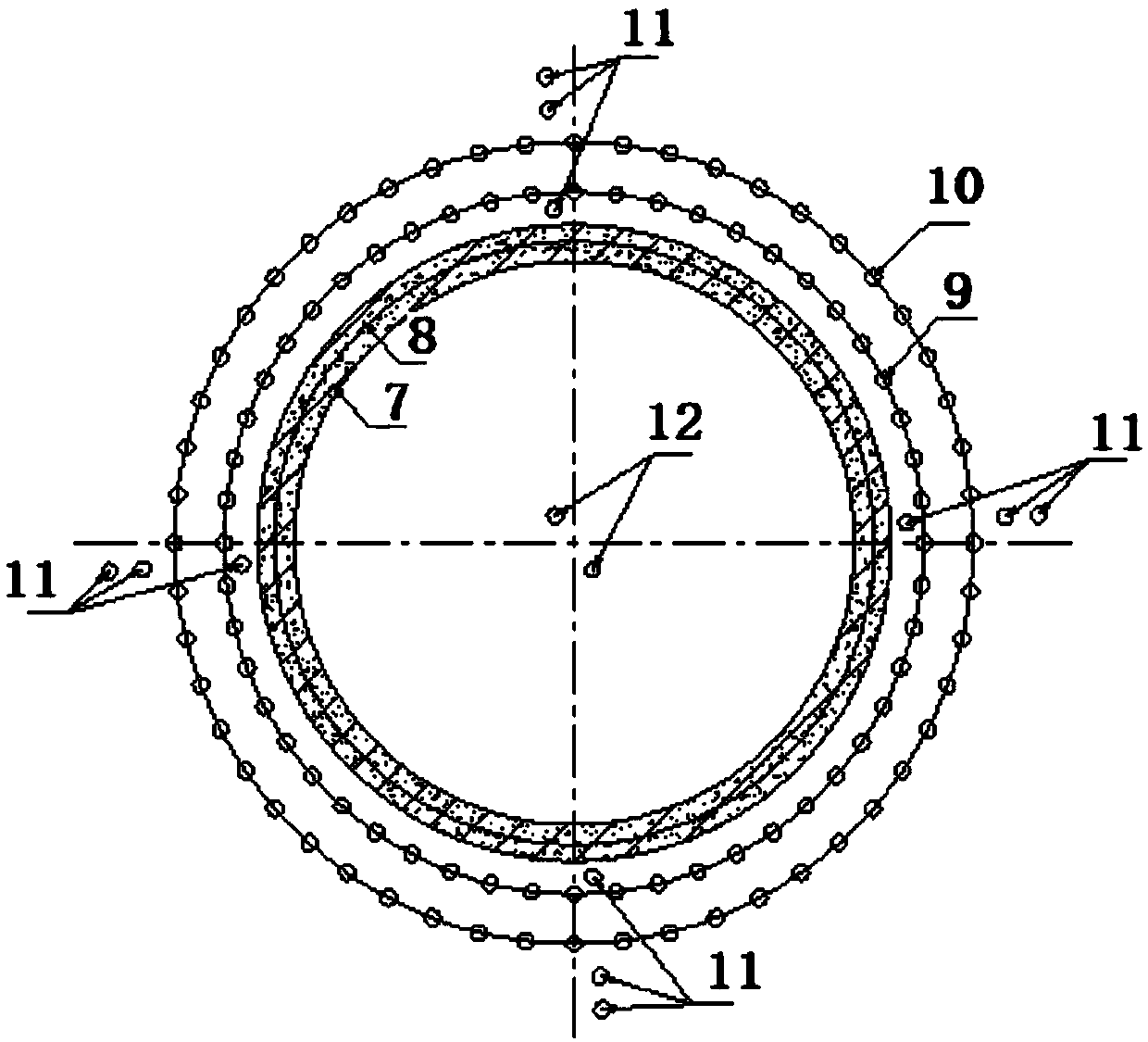

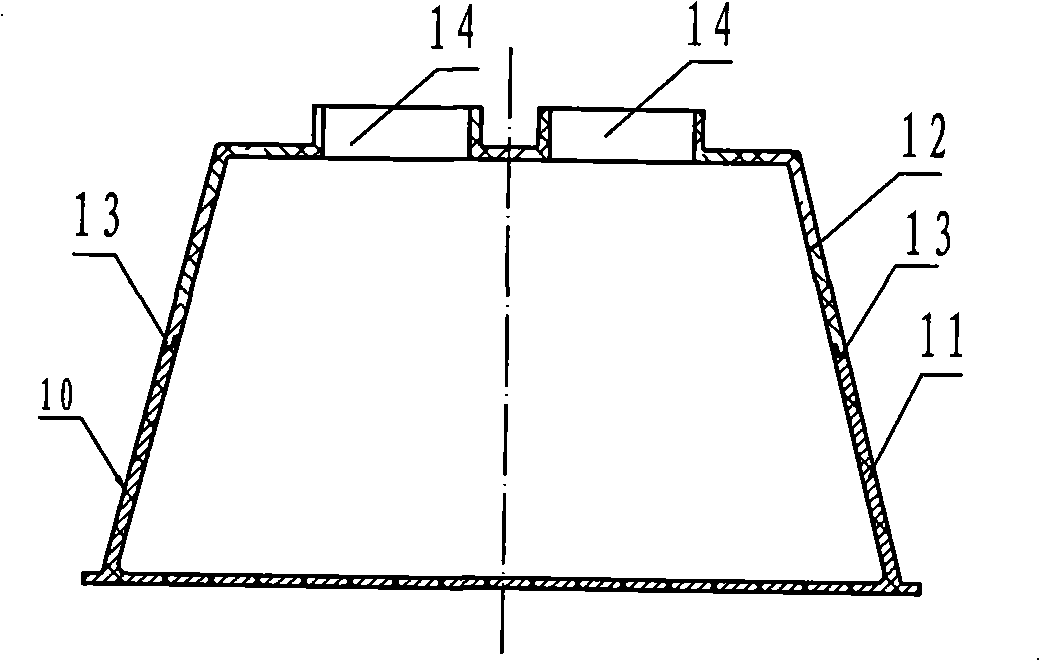

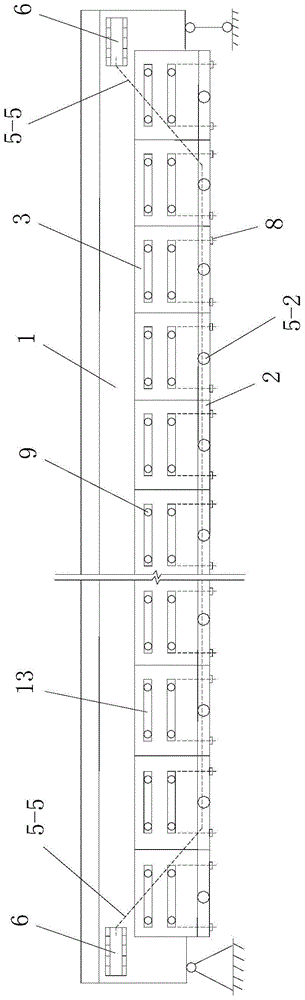

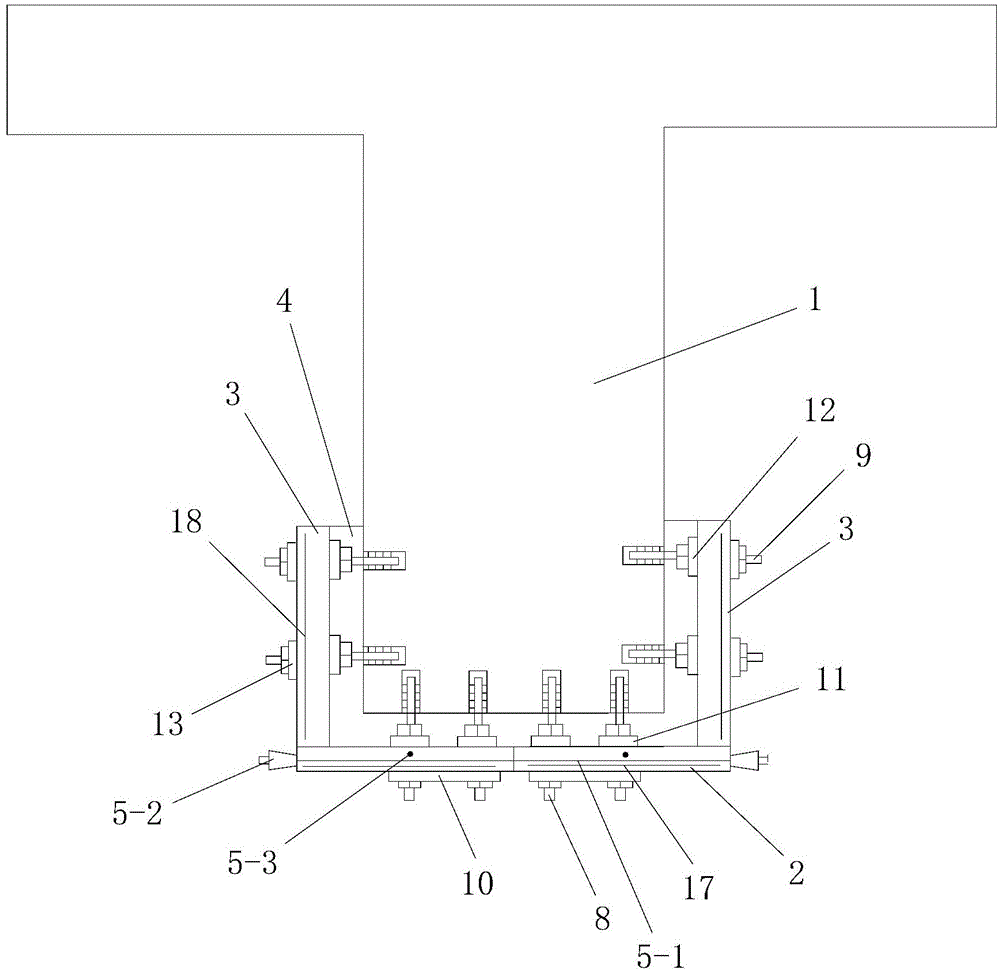

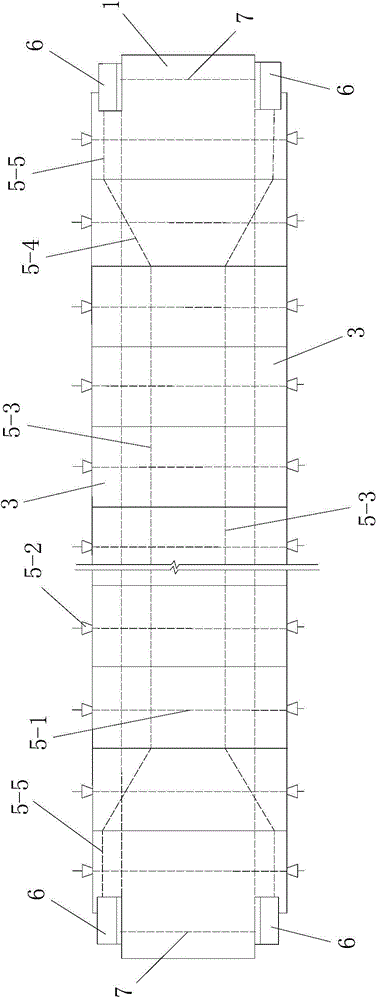

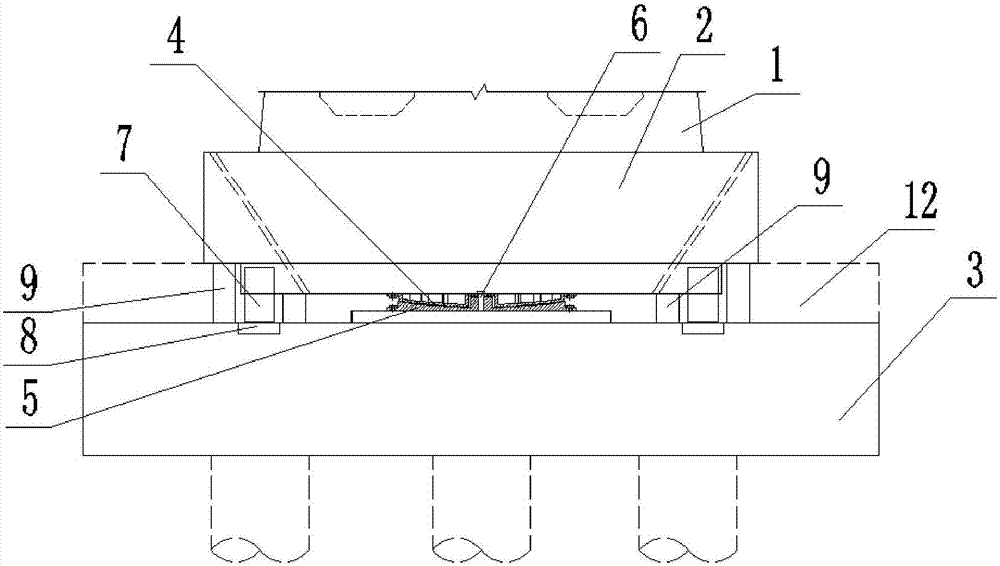

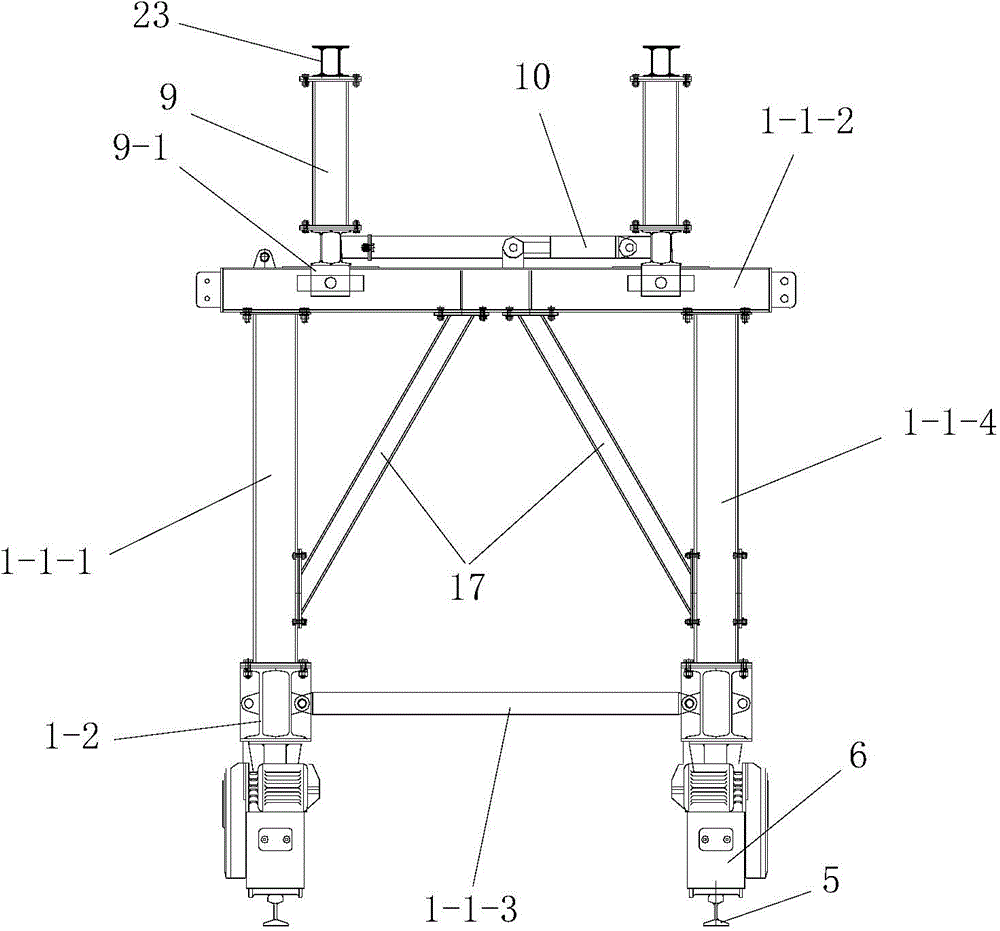

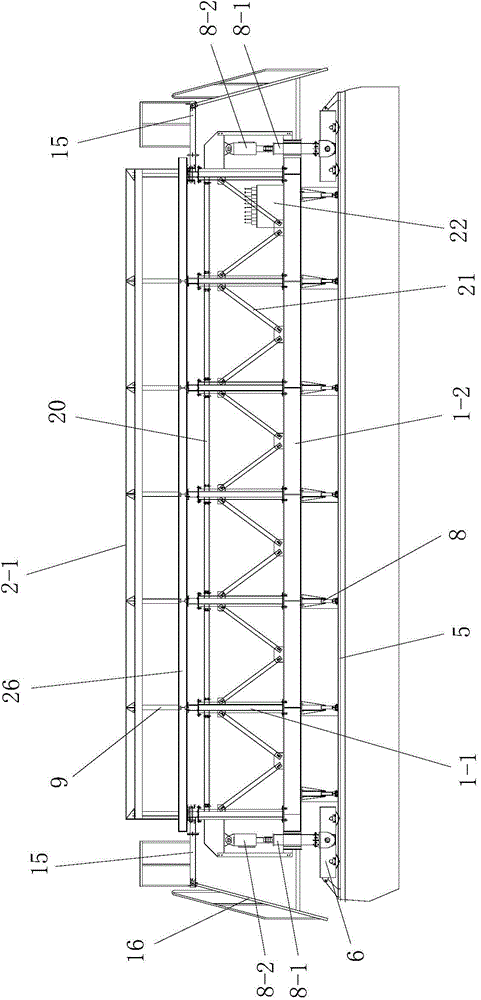

Combined lining formwork trolley for subway station

ActiveCN104453951ASimple structureReasonable designUnderground chambersTunnel liningSupporting systemEngineering

The invention discloses a combined lining formwork trolley for a subway station. The combined lining formwork trolley comprises a movable supporting system and a formwork assembly, wherein the movable supporting system is composed of a plurality of longitudinal moving trolley bodies capable of moving in the subway station under construction, the formwork assembly is arranged on the movable supporting system and conducts molding construction on secondary linings of the subway station under construction, and the longitudinal moving trolley bodies are arranged in the same horizontal plane from left to right; the formwork assembly comprises a combined top formwork and two side formworks, the two side formworks are symmetrically arranged on the left side and the right side of the combined top formwork respectively, and the combined top formwork comprises a plurality of trolley supporting top formworks mounted on the longitudinal moving trolley bodies respectively and middle connecting formworks connected between every two trolley supporting top formworks which are adjacent in a left-right mode; the middle connecting formworks are horizontal connecting formworks or groove type combined formworks. The combined lining formwork trolley is simple in structure, reasonable in design, easy and convenient to use and operate, good in usage effect and capable of solving the problems that construction is complex, the construction efficiency is low, the occupied space is large and the use effect is poor when a traditional subway station lining construction method is adopted.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

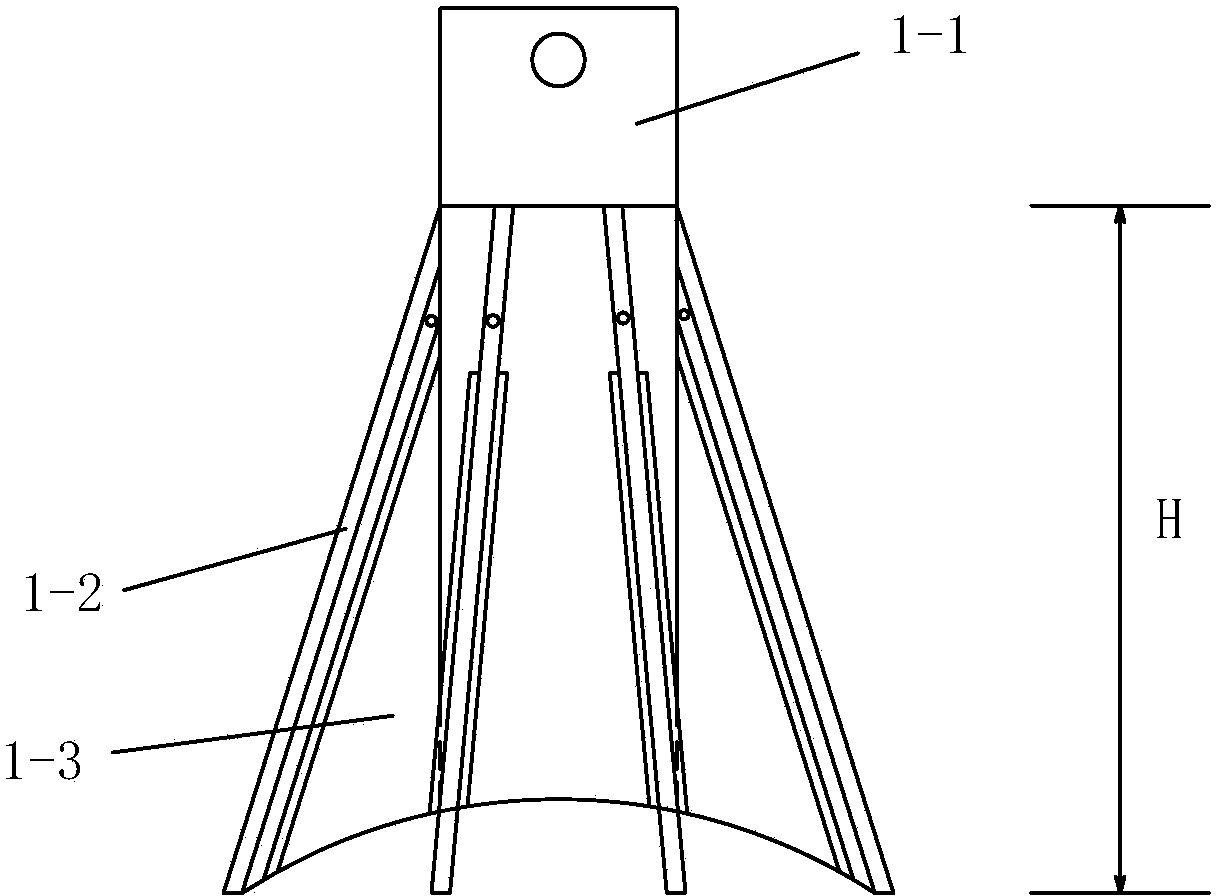

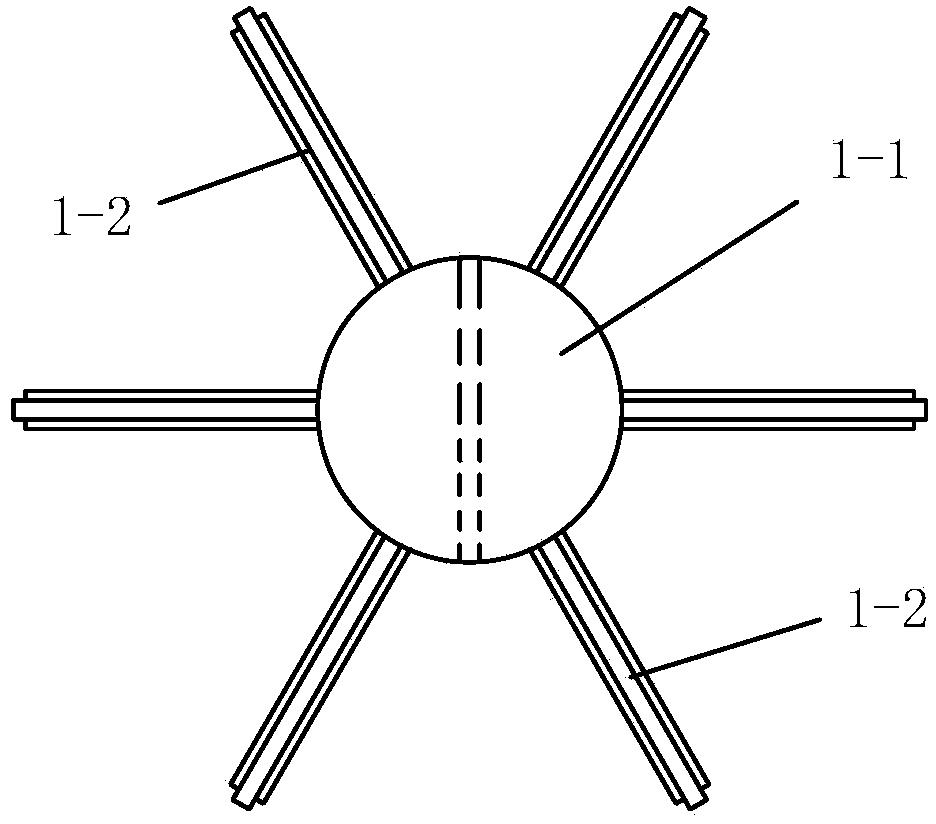

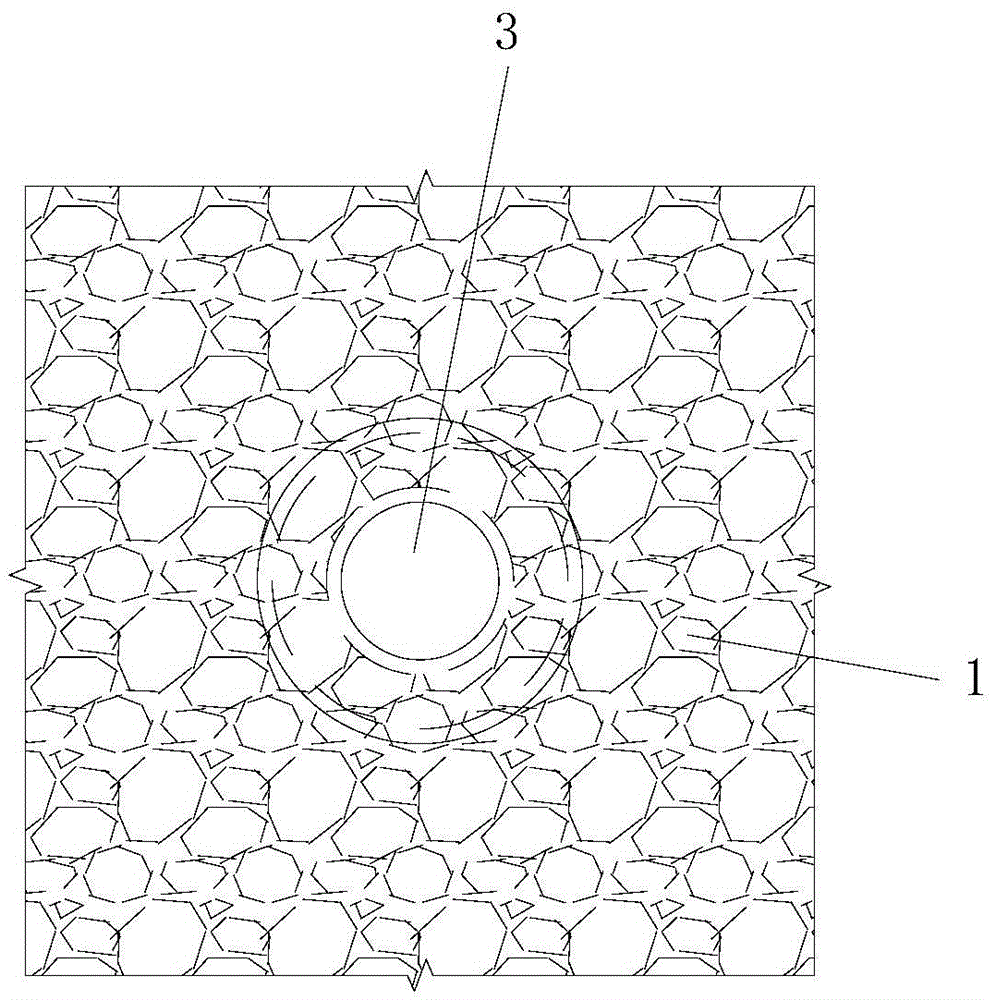

Complex geological karst hole pile foundation construction process

PendingCN113445498AScientific and reasonable designAvoid instabilityBulkheads/pilesKarstStructural engineering

The invention discloses a complex geological karst hole pile foundation construction process. The complex geological karst hole pile foundation construction process comprises the steps that a concrete backfilling karst cave pile foundation construction method or a double-steel-casing all-casing follow-up pile foundation construction method is adopted to perform hole pile foundation construction; when the karst cave where the karst cave pile foundation is located is a small karst cave, hole pile foundation construction is carried out through a concrete backfilling karst cave pile foundation construction method; and when the karst cave where the karst cave pile foundation is located is a large karst cave or a communicating type bead string karst cave group, hole pile foundation construction is carried out through the double-steel-casing all-casing follow-up pile foundation construction method. The conditions of mud loss, wall protection instability and the like of a traditional construction method can be effectively avoided, the construction safety can be effectively guaranteed, the construction period is guaranteed, and meanwhile, the construction cost can be reduced.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

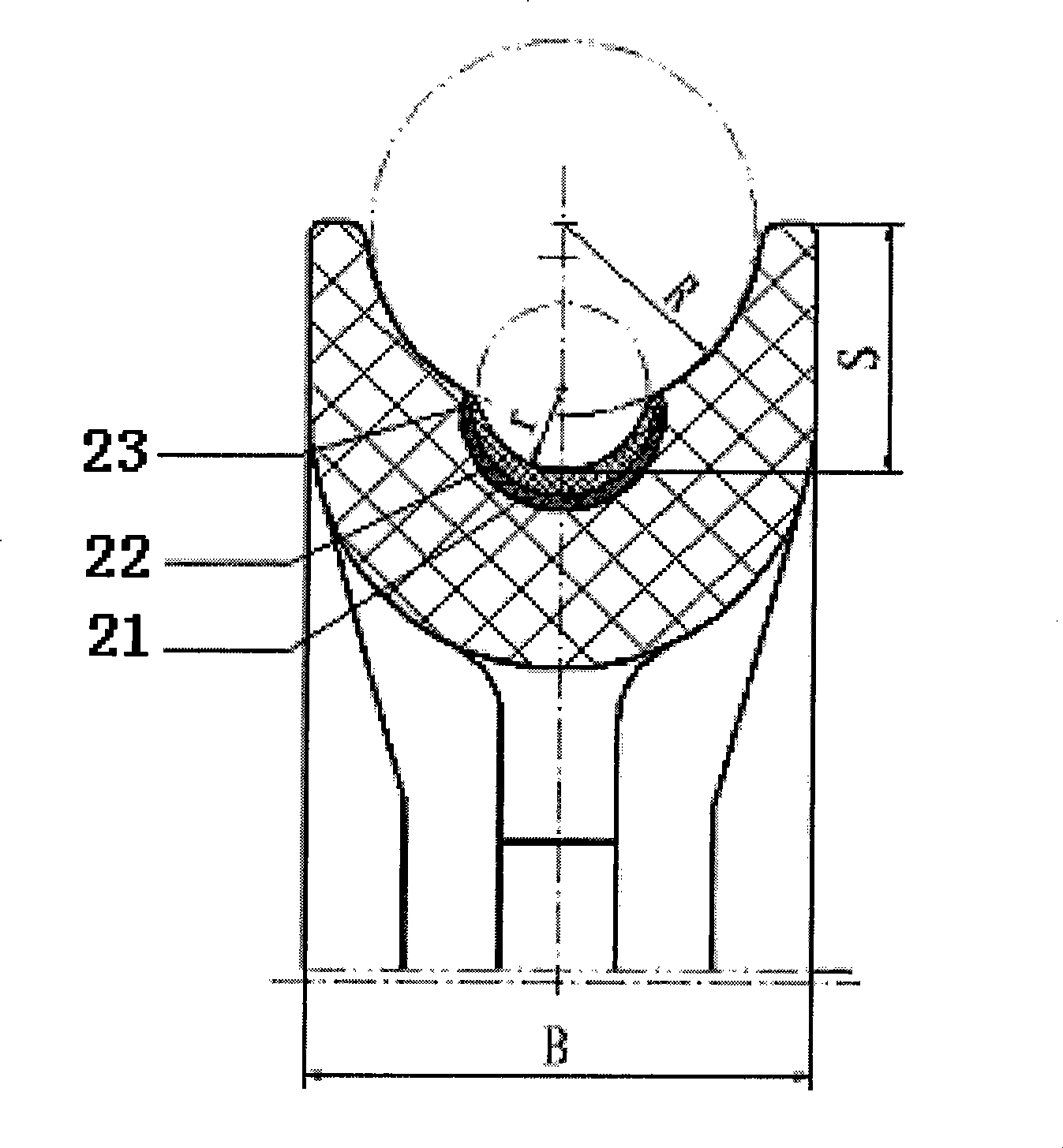

Glue-sizing double R groove shaped conductive thread expanding pulley

ActiveCN101364717AAvoid Squeeze CollisionsExtended service lifeApparatus for overhead lines/cablesArchitectural engineeringShort radius

The invention relates to a cementing double-R groove-shaped lead stringing pulley with a double-R groove-shaped pulley groove selection, which is composed of two types of circular arc with different radii. One circular-arc-shaped groove with a short radius is formed at the bottom of the arc-shaped groove with a large radius and a cementing layer is arranged on at least the internal surface of the arc-shaped groove with small radius. Cementing plays a certain role in protecting the lead. The service life of the lead stringing pulley is prolonged. The radii of the big and the small circular arcs are respectively matched with the radii of a connecting pipe protecting device and the lead, thereby enlarging the contact area between the lead and the pulley groove of the lead stringing pulley when the lead passes through a connecting pipe protecting device, and reducing the wear of the lead. At the same time, the small arc-shaped groove has a depth enough to avoid construction accident caused by the lead which leaves out of the pulley groove of the pulley during the stringing process. Therefore, the lead stringing pulley has the advantages that the wear of the lead is reduced, the service life of the lead stringing pulley is prolonged, the safety of stringing construction is improved and the maintenance cost of engineering is reduced.

Owner:CHINA ELECTRIC POWER RES INST

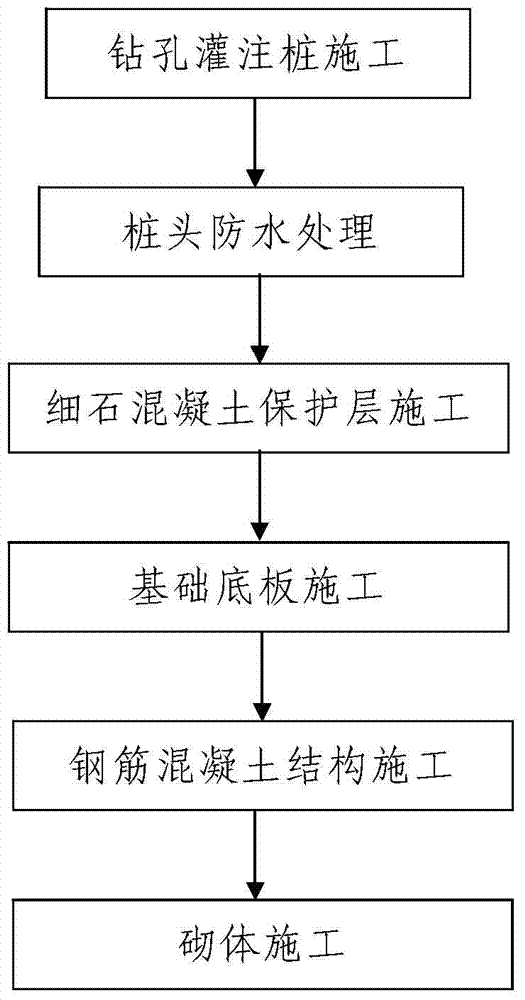

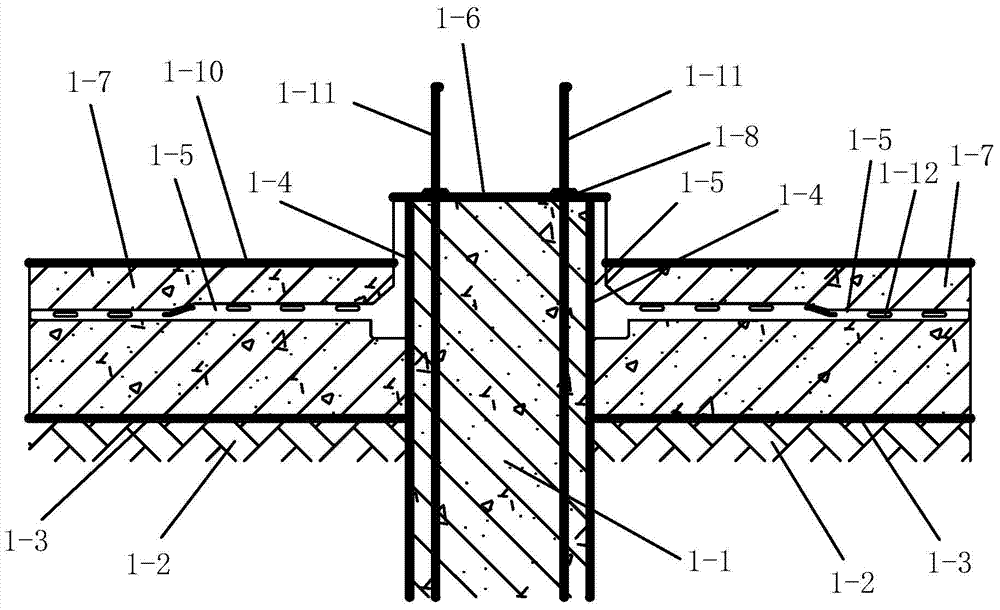

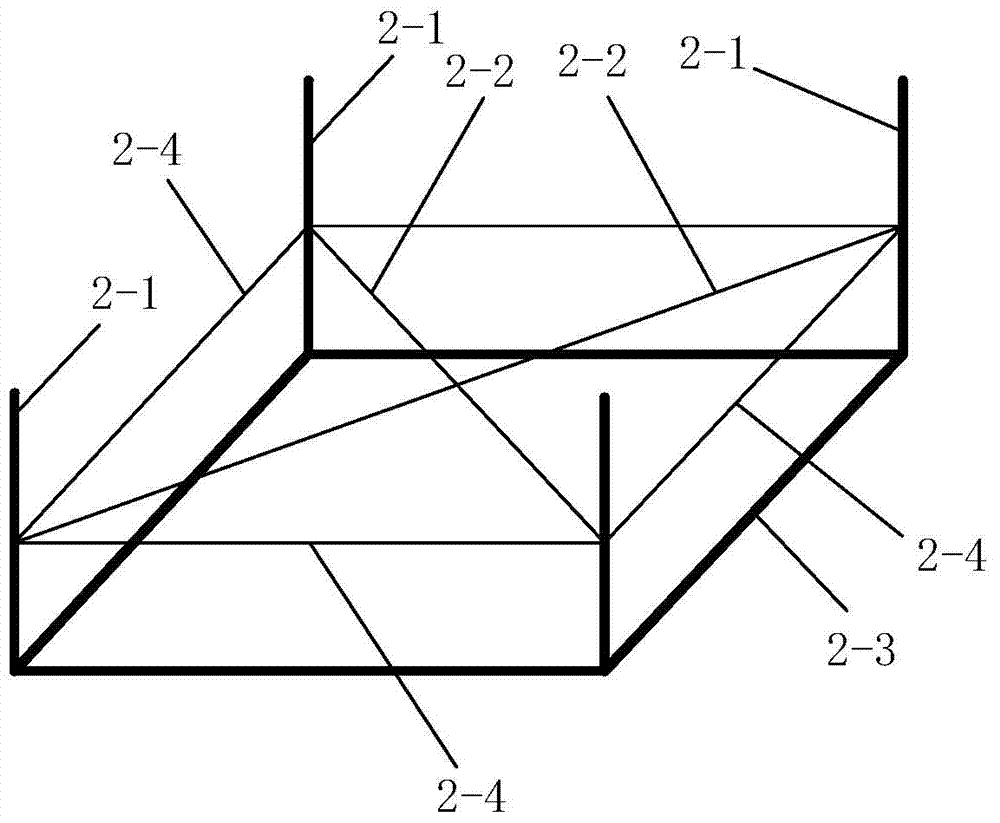

Construction technology for building foundation and main structure

ActiveCN103290924AGuarantee the construction qualityThe method steps are simpleBuilding material handlingBulkheads/pilesFloor slabReinforced concrete

The invention discloses a construction technology for a building foundation and a main structure. A constructed building is of a frame structure or a frame shearing wall structure. The technology includes the steps: firstly, constructing pile foundations; secondly, constructing reinforced concrete structures of the constructed building with a plurality of floors from bottom to top; and thirdly, constructing masonries. The pile foundation construction process includes: constructing cast-in-situ bored piles; performing waterproof treatment for pile heads; constructing fine aggregate concrete protection layers; and constructing foundation slabs. When the reinforced concrete structure of any floor of the constructed building, firstly, a bearing structure of the currently constructed floor is poured, and secondly, floor slabs of the currently constructed floor are poured. After the reinforced concrete structures are constructed, filler walls on the floors are constructed. The construction technology is simple in step, reasonable in design, high in operability, convenient to implement and fine in construction effect, and the construction quality of the building can be effectively ensured while construction period is ensured.

Owner:陕西建工集团股份有限公司 +1

Fence linkage block and production process thereof

ActiveCN102251500AImprove stabilityGood embedding abilityCoastlines protectionCeramic shaping apparatusEngineeringRaw material

Owner:河南省水利勘测设计研究有限公司

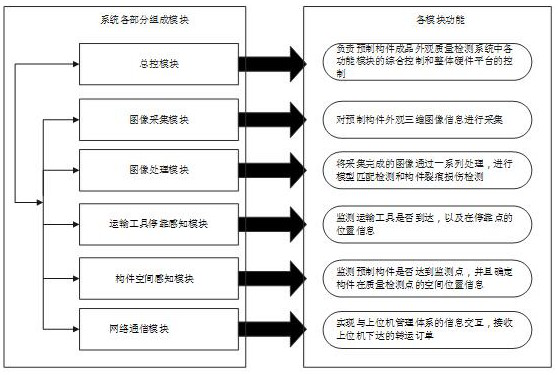

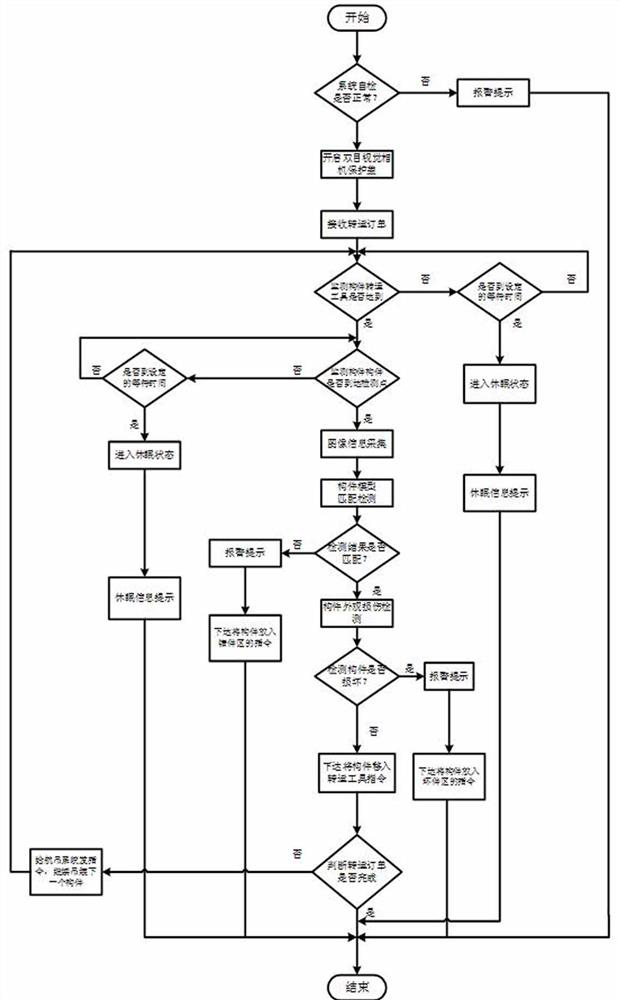

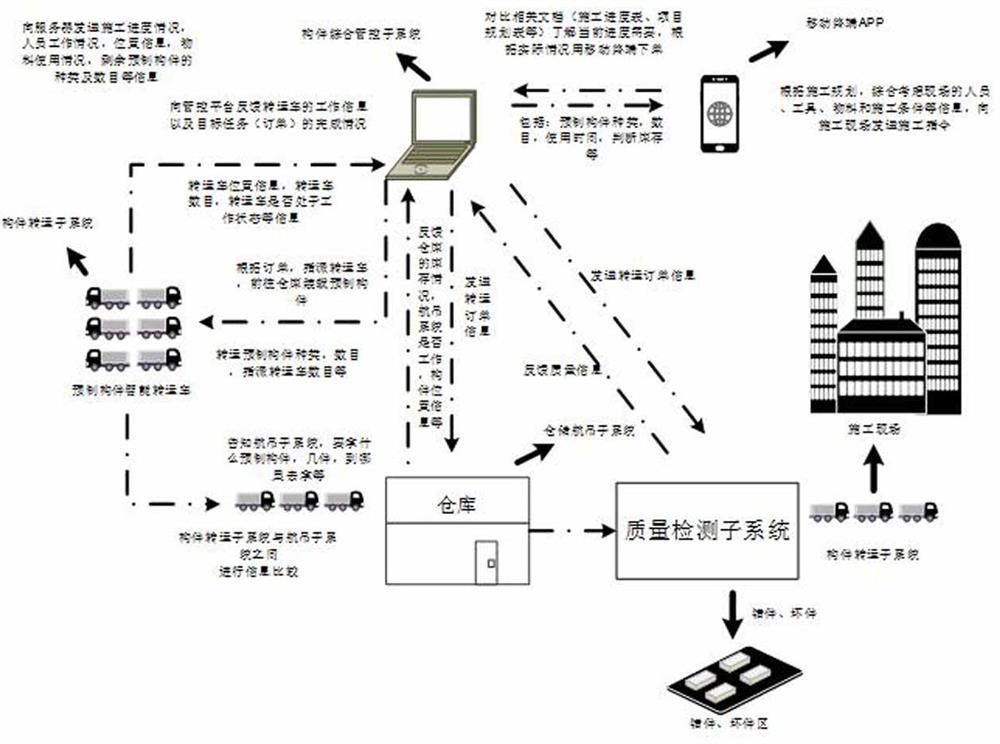

Prefabricated part finished product quality detection system based on three-dimensional vision and application of system

ActiveCN113102269AImprove the level of intelligenceAccurate and efficient quality inspection meansSortingTotal factory controlVideo transmissionNetwork communication

The invention discloses a prefabricated part finished product quality detection system based on three-dimensional vision and application of the system, and relates to the field of prefabricated part quality detection. A general control module is connected with an image acquisition module, an image processing module, a transportation tool parking sensing module, a part space sensing module and a network communication module; the general control module is responsible for comprehensive control and information interaction of all functional modules in the prefabricated part finished product appearance quality detection system based on three-dimensional vision and command and control of an overall hardware platform; a hardware part of the image acquisition module mainly comprises a binocular vision camera and a video transmission line of a component quality detection point; the image processing module detects prefabricated part model matching and prefabricated part appearance damage; the component space sensing module comprises an infrared detector for monitoring whether the prefabricated part to be subjected to quality inspection reaches a component quality detection point or not. Not only is an accurate and efficient quality inspection detection means provided, but also a basis is provided for inventory logistics of prefabricated part production enterprises and decision judgment of construction site engineering management personnel.

Owner:SHENYANG JIANZHU UNIVERSITY

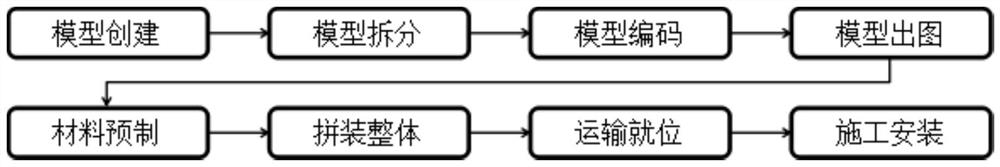

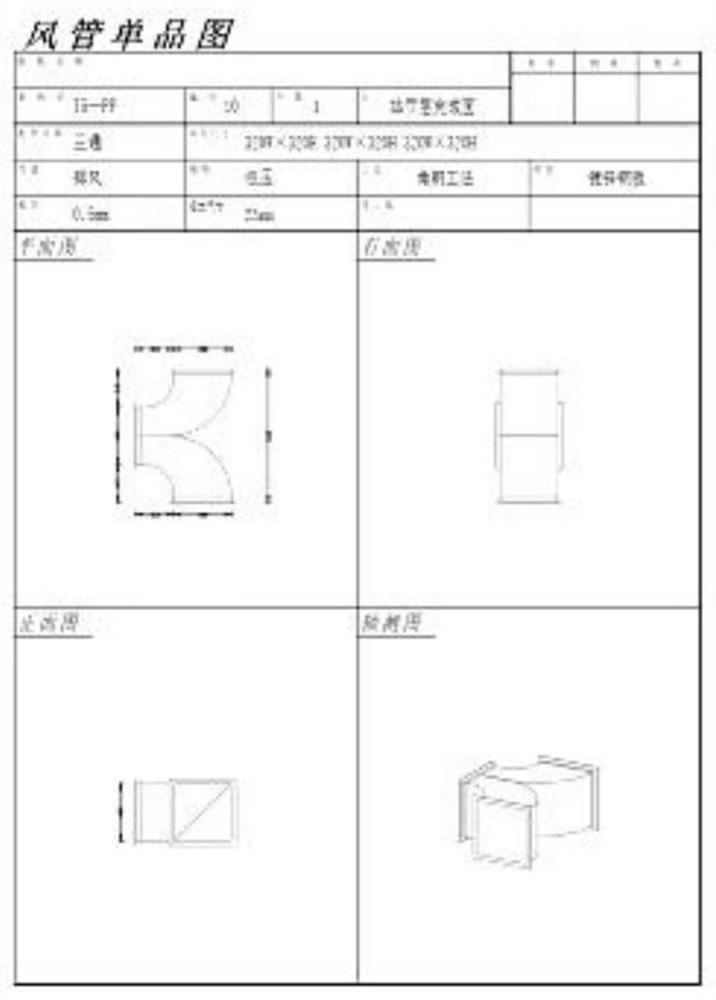

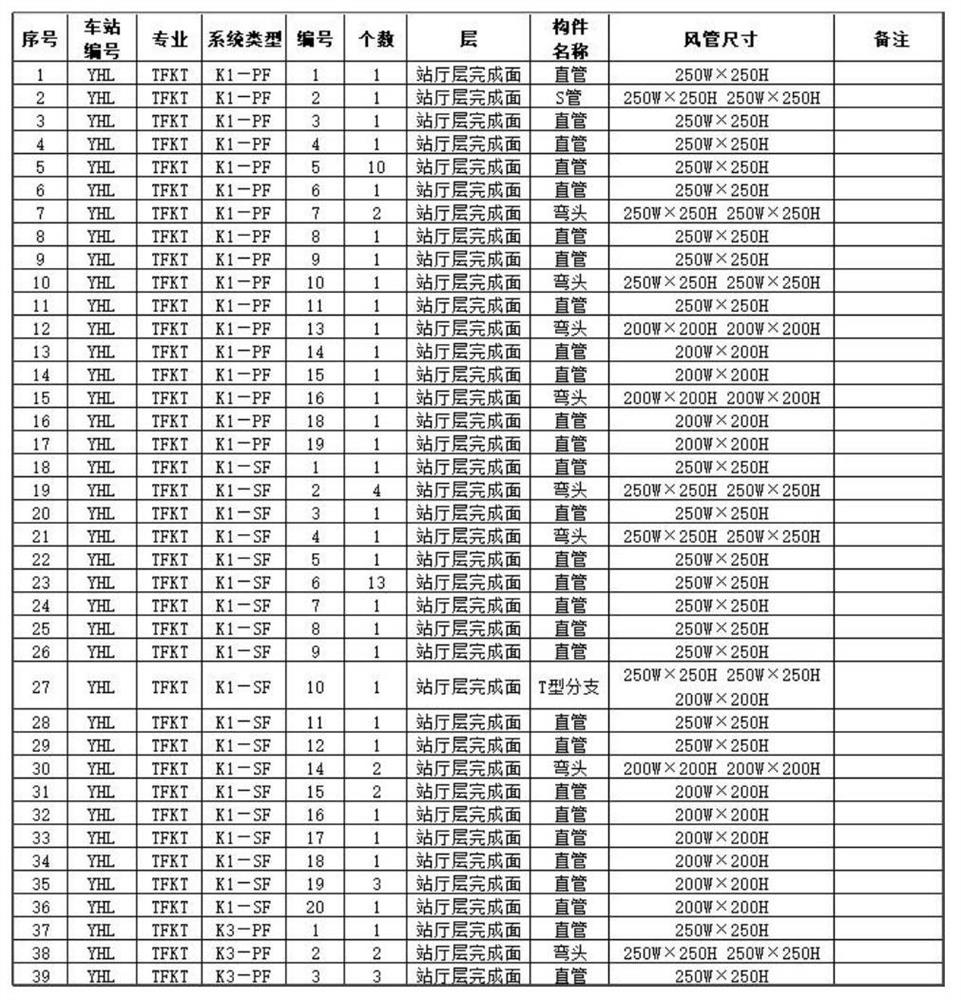

Integrated pipeline overall assembly method based on BIM technology

PendingCN112613100AReduce lossImprove efficiencyGeometric CADSpecial data processing applicationsProcess engineeringMaterial resources

The invention discloses a BIM technology-based integrated pipeline overall assembly method, which comprises the steps of creating a BIM model according to a drawing, then carrying out collision detection, and carrying out collision check by utilizing the BIM model, thereby being convenient, rapid, high in efficiency and low in error rate; carrying out three-dimensional visual disclosure on construction personnel by utilizing the BIM model, visually displaying the construction process, and ensuring that technical disclosure is in place; splitting the created model; after comprehensive pipeline segmentation is completed, carrying out pipeline and support coding, completing output of a material detail list and output of a machining drawing, carrying out accurate ordering according to the material detail list and the machining drawing, wherein material losses are low; enabling all pipelines to be subjected to factory prefabrication and assembly construction, so that the construction efficiency is improved; and transporting comprehensive pipelines in place at a time and installing the pipelines at a time, manpower, so that material resources and construction cost are saved, and the construction period is guaranteed.

Owner:中铁十一局集团电务工程有限公司 +1

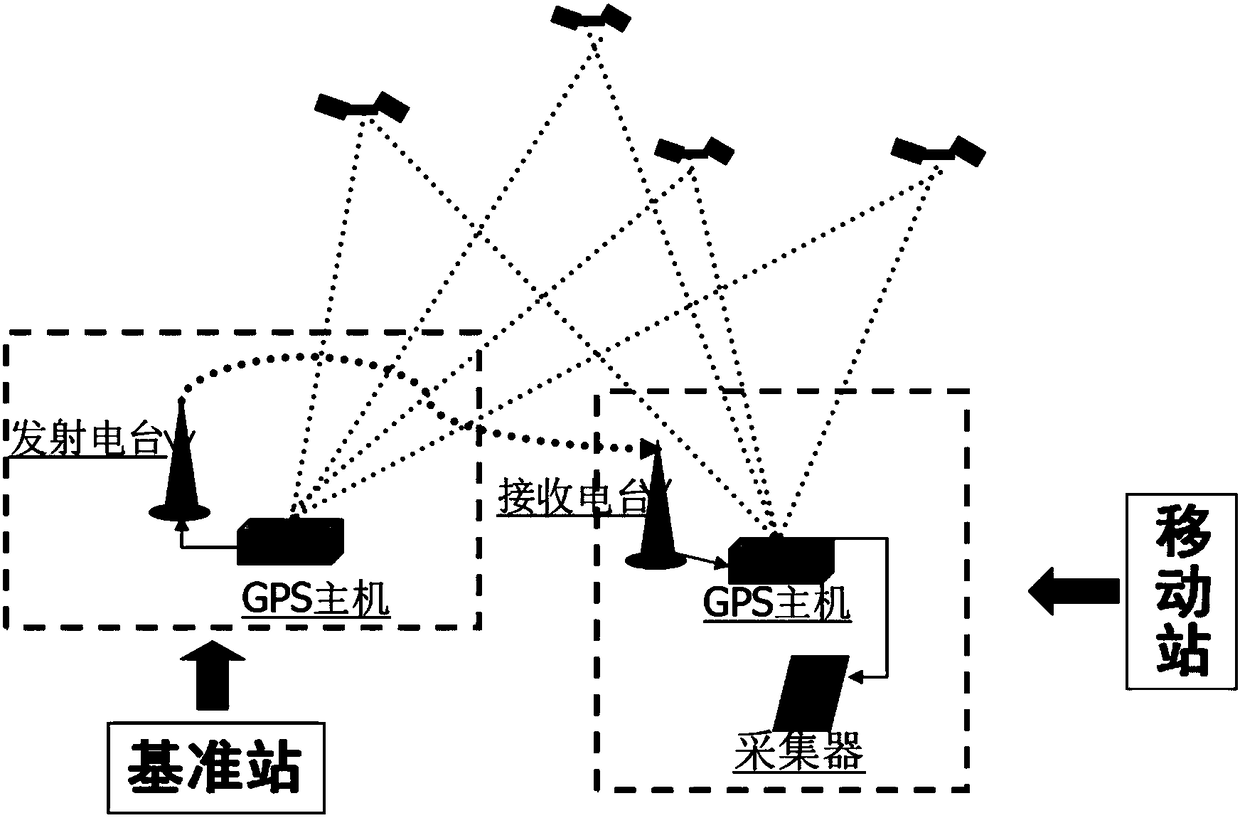

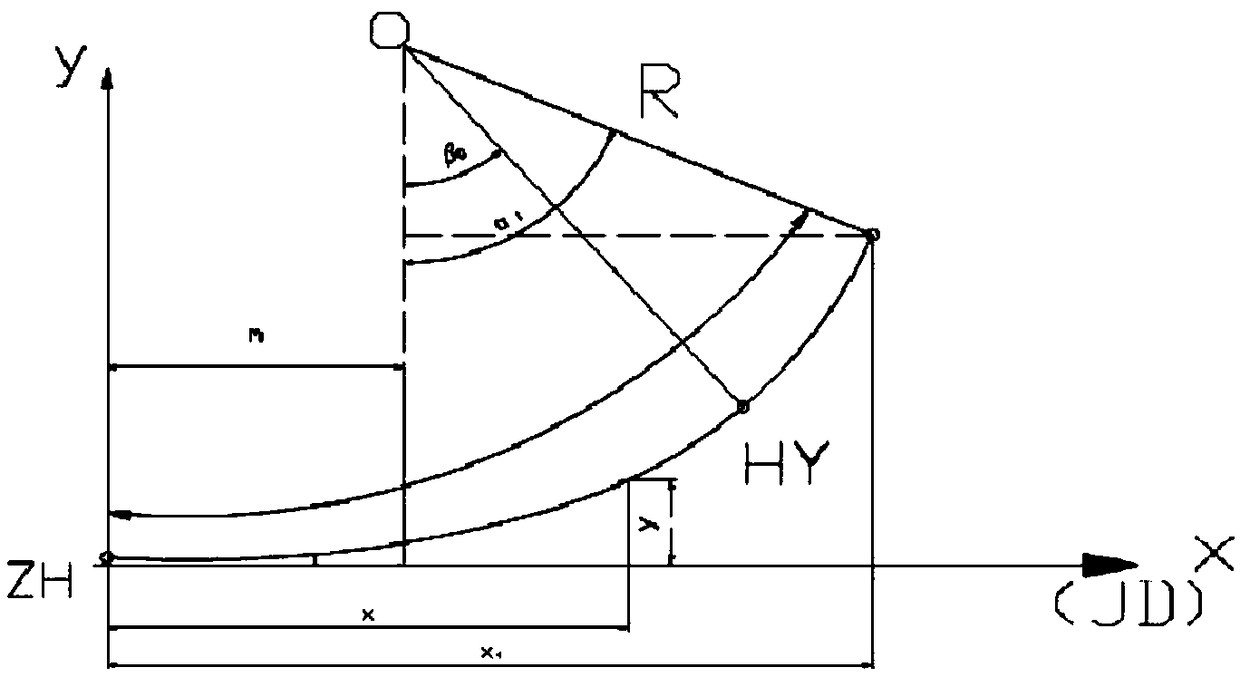

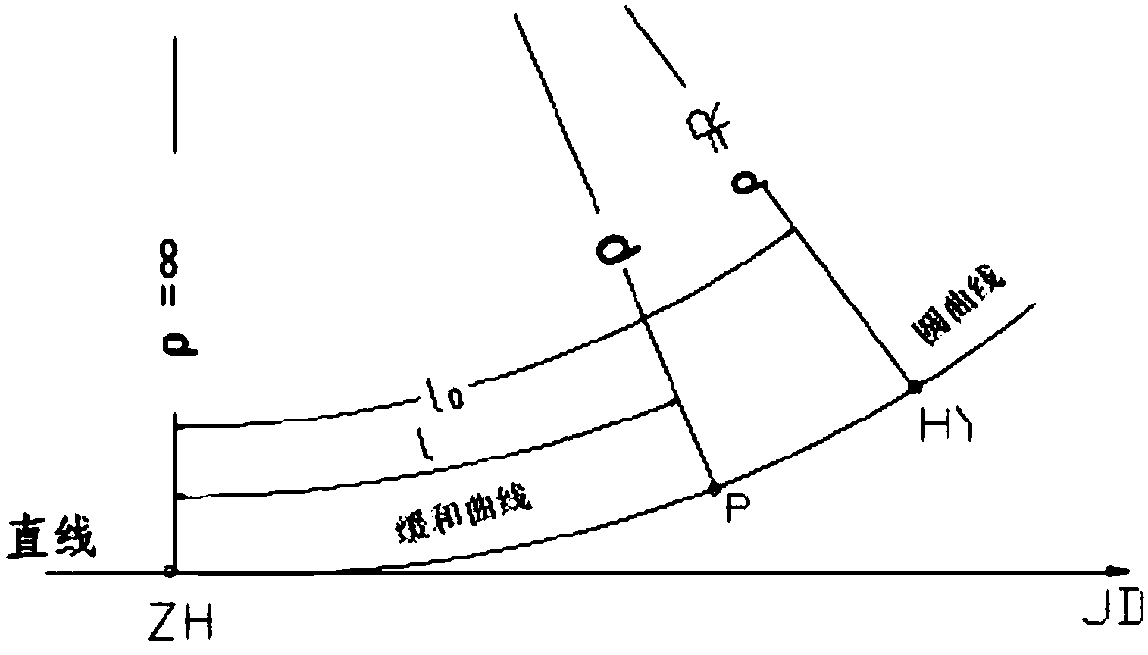

Method for determining side boundary of passenger dedicated line contact net pillar

ActiveCN108507452AEasy to installHigh measurement accuracySurveying instrumentsSatellite radio beaconingTerrainSimulation

The invention provides a method for determining the side boundary of a passenger dedicated line contact net pillar. The method includes the first step of obtaining parameters of all first-level control net CPIs and second-level control net CPIIs along a passenger dedicated line, as well as line parameters of the passenger dedicated line; the second step of using an RTK device to collect coordinates of each first-level control net CPI and coordinates of each second-level control net CPI, and performing single-point checkout to ensure data determinacy, measuring coordinates of each contact net pillar basic center, and calculating starting point and end point coordinates of a curve and intersection point coordinates; the third step of importing the line parameters of the passenger dedicated line and the measured coordinates of each contact net pillar basic center, and drawing a line center and basic center relative position diagram to measure the side boundary of the passenger dedicated line contact net pillar through terrain and cadastre mapping software. The problems of slow construction, long construction periods, many measurement workers and low measurement precision and the likeduring the measurement of the side boundary of the passenger dedicated line contact net pillar in the prior art are solved.

Owner:中铁建电气化局集团南方工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com