Boom-type roadheader for tunnel construction and tunnel construction method

A cantilever roadheader and tunnel construction technology, applied in tunnels, earth-moving drilling, dust-proofing, etc., can solve the problems of endangering the safety of personnel and equipment, high equipment manufacturing costs, and high construction costs, and ensure the safety of personnel and equipment. The effect of reducing manufacturing and operating costs and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, the cantilever boring machine for tunnel construction and the tunnel construction method of the present invention will be described in detail with reference to the accompanying drawings.

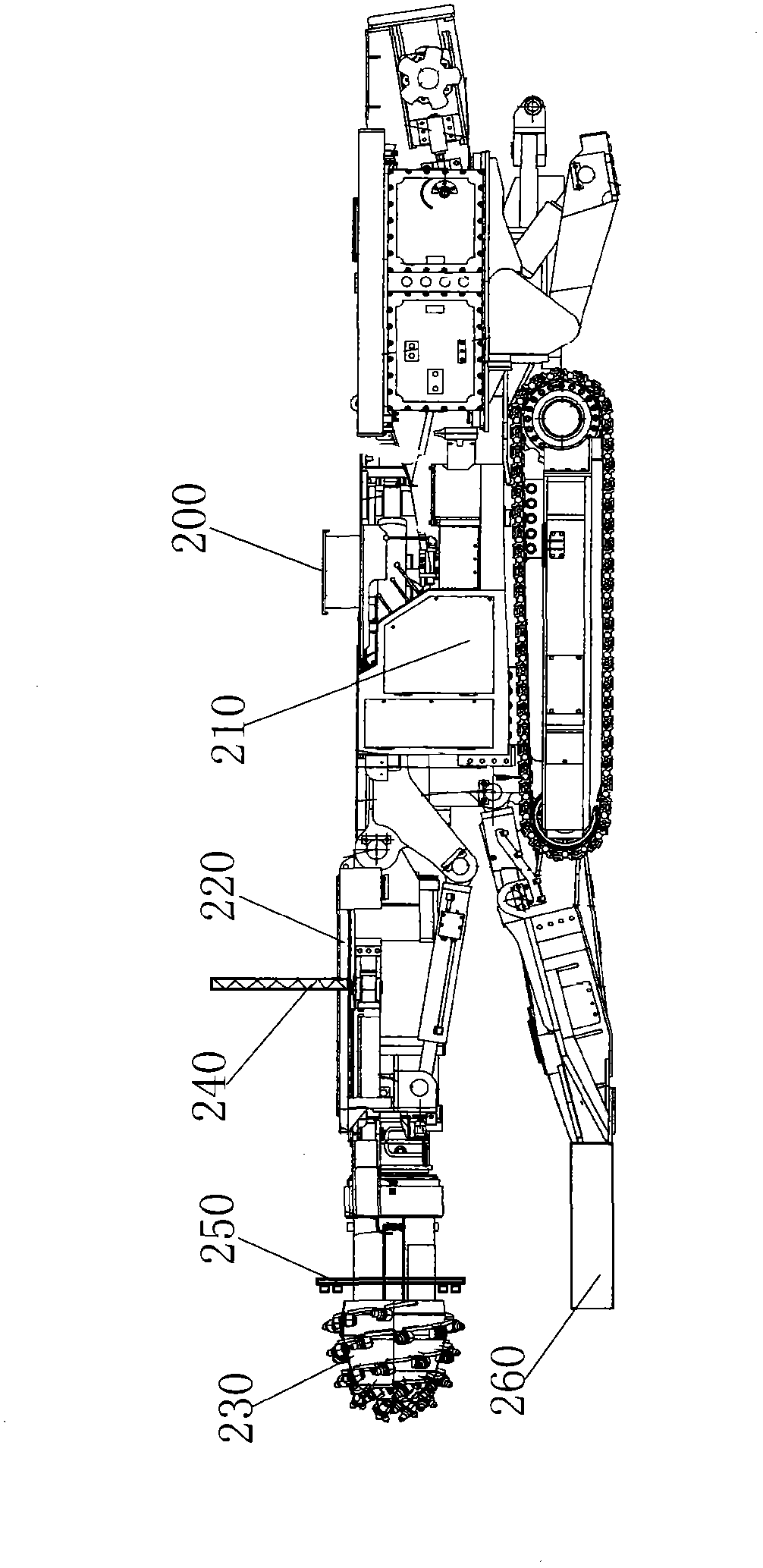

[0046] Please refer to figure 1 , as a non-limiting example, the boom boring machine 200 for tunnel construction of the present invention includes a motor body 210, a boom 220 connected to the motor body in a telescopic and horizontally and vertically swingable manner, and a rotatable The milling head 230 , the protective net 240 , the water spray dust removal device 250 and the dust suction device 260 installed on the free end of the cantilever 220 .

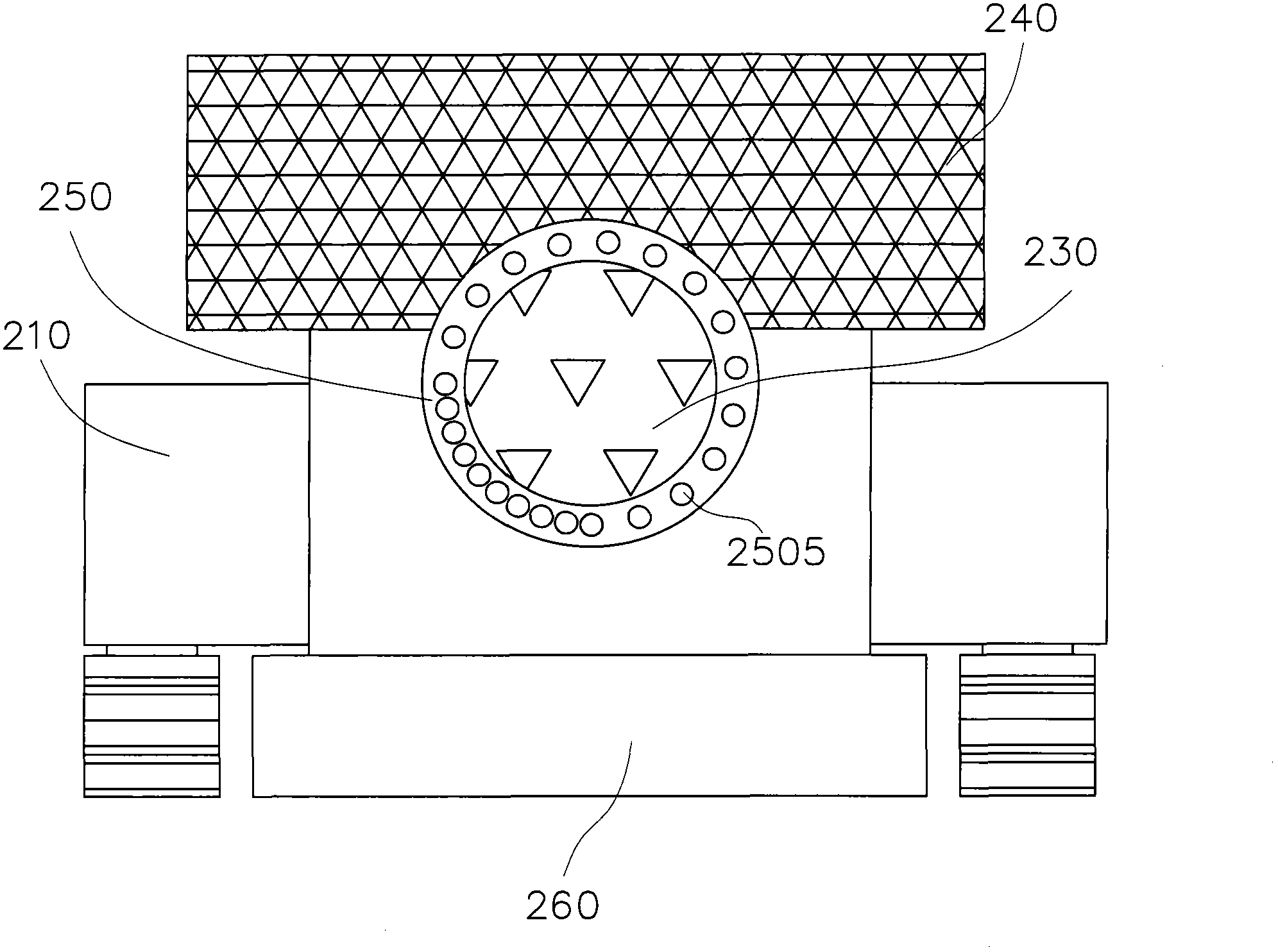

[0047] Please refer to figure 2 , the water spray dedusting device 250 includes several nozzles 2505 arranged around the boom 220 and adjacent to the milling head 230, and the several nozzles 2505 are non-uniformly distributed in the circumferential direction. As a non-limiting example, perpendicular to figure 2 The outward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com