Patents

Literature

292results about How to "Settlement control" patented technology

Efficacy Topic

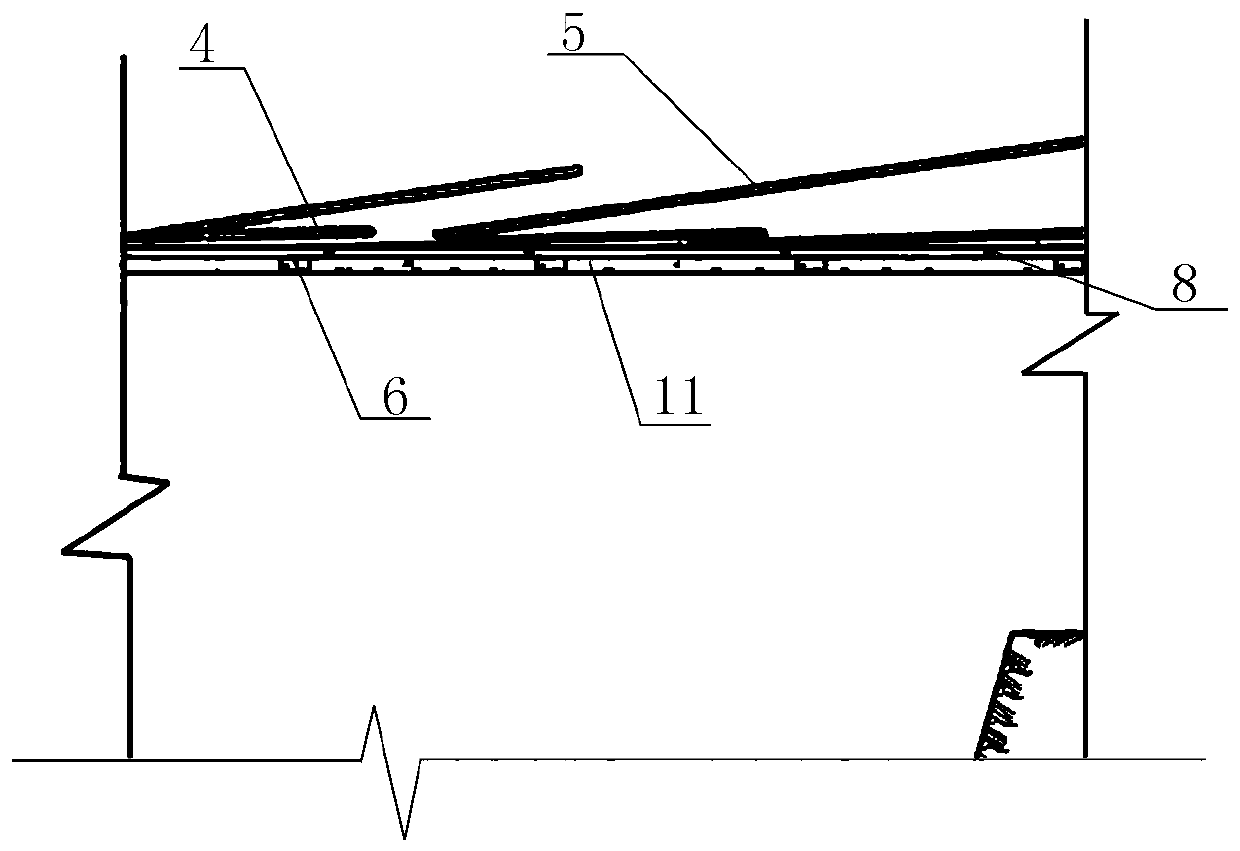

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

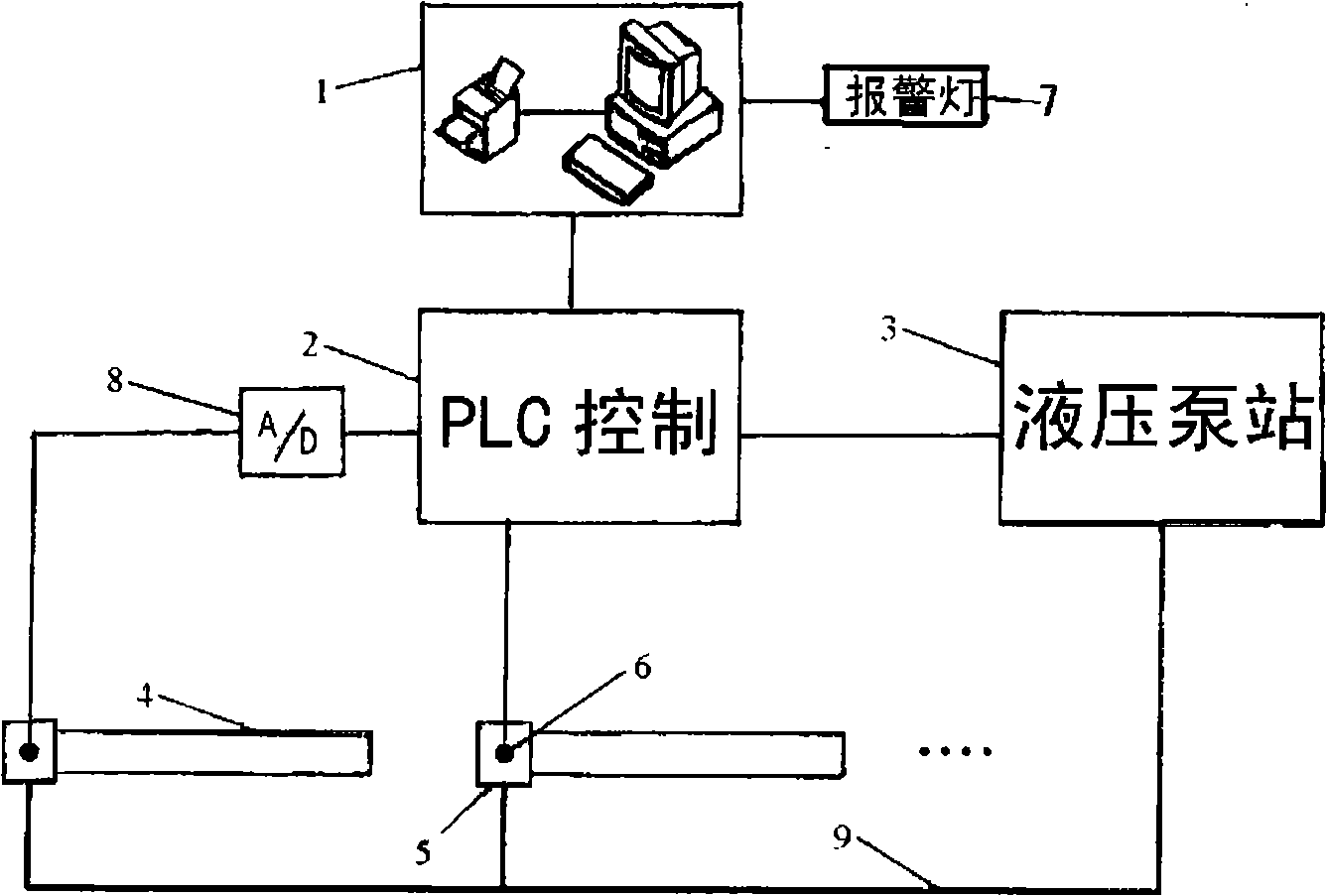

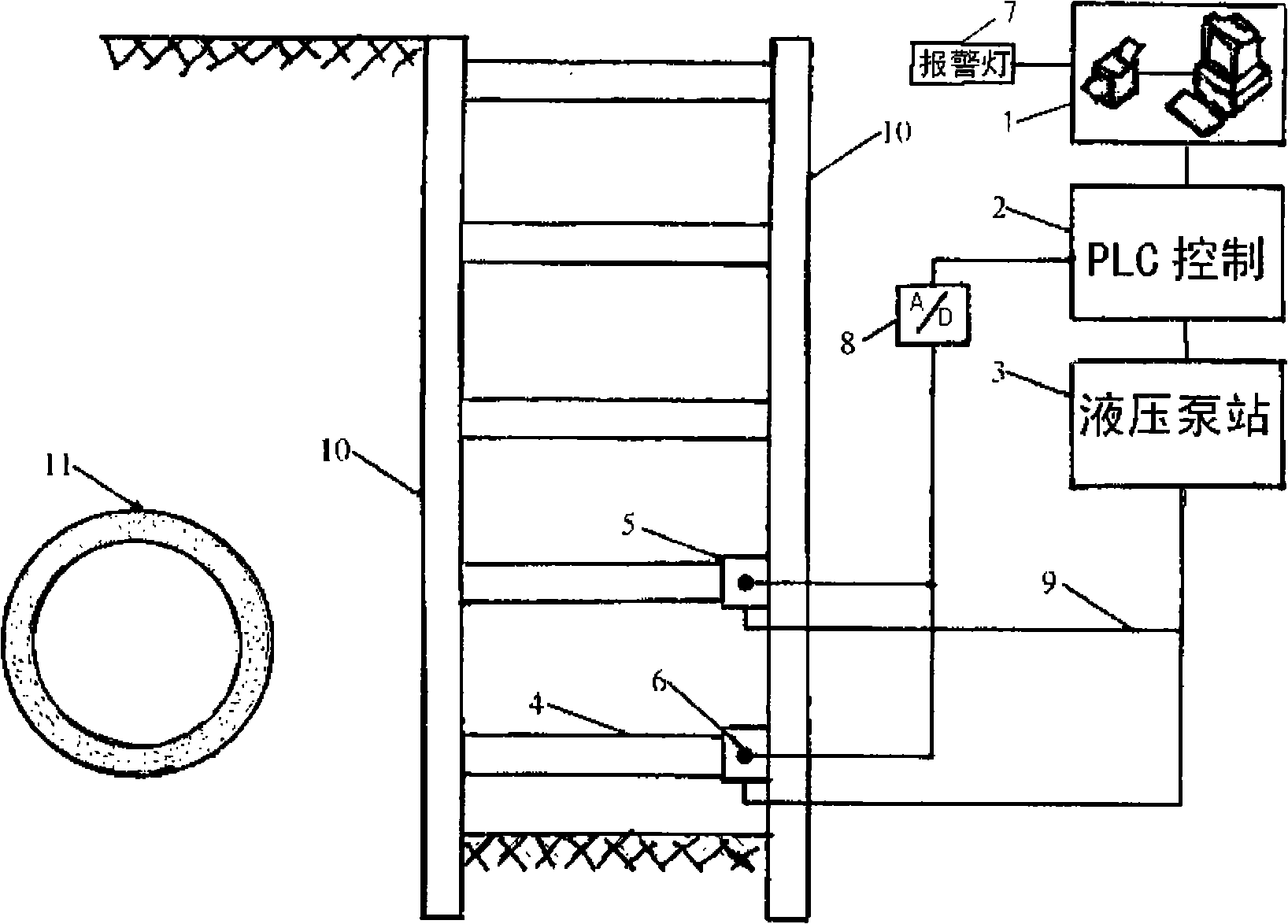

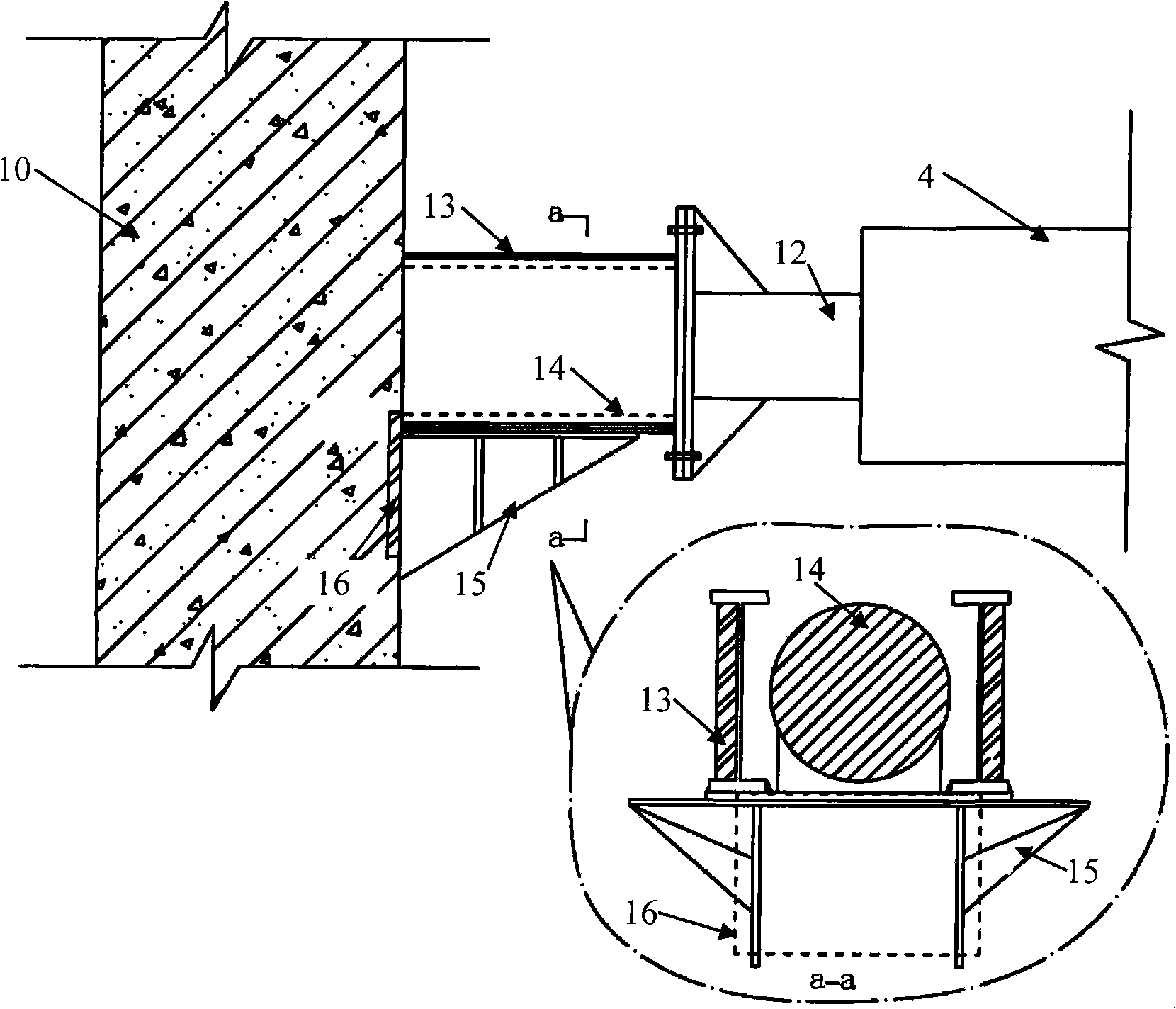

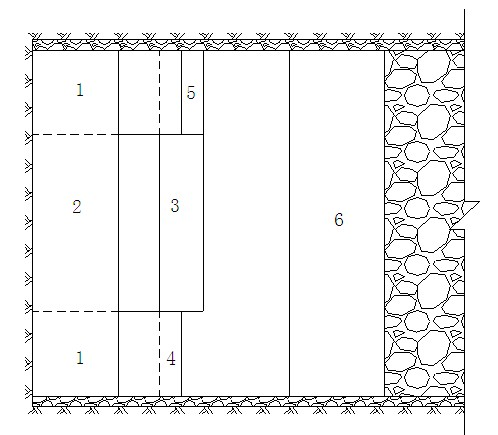

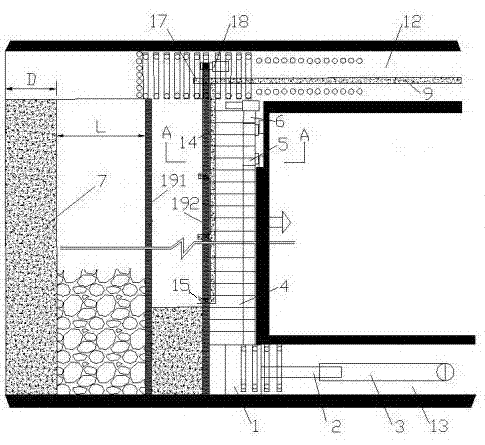

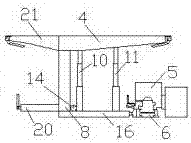

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

Foundation treatment method for controlling post-construction settlement and deformation of soft soil

InactiveCN102226335AIncrease effective preloadEffective reinforcementSoil preservationEngineeringCut and fill

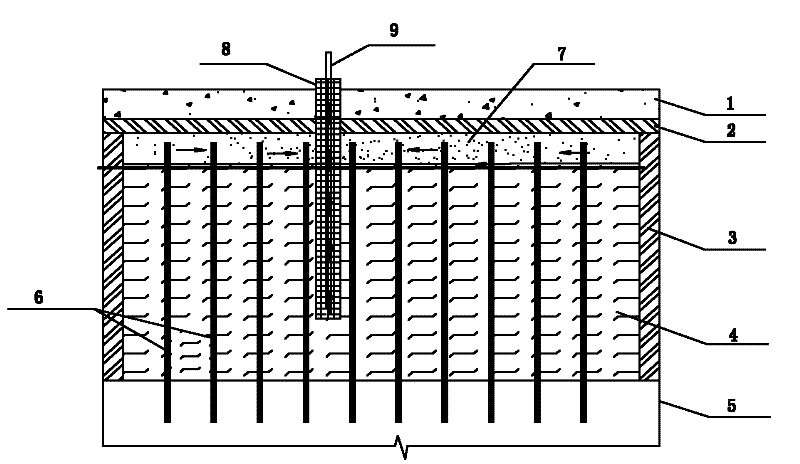

The invention discloses a foundation treatment method for controlling the post-construction settlement and deformation of soft soil. the method sequentially comprises the following steps: setting a vertical envelope wall around an area to be reinforced; inserting vertical drainage systems and laying horizontal drainage systems in the area to be reinforced; paving sealing materials on the surface of a foundation; backfilling settlement refills or exerting pre-loads on the foundation; carrying out vacuumizing, well-point dewatering or vacuum well-point dewatering on the drainage systems so as to reinforce the foundation; and after the consolidation degree of the foundation reaches 60-90%, carrying out sealing on all the vertical and horizontal drainage systems. The method disclosed by the invention is used for simultaneously carrying out reinforcement and plugging on an untreated soft soil foundation, so that the post-construction settlement can be controlled while the foundation is treated. Duo to the one-time treatment, the treatment time can be saved, and the treatment cost can be reduced, thereby achieving the purpose of effectively reinforcing the foundation and controlling the post-construction settlement.

Owner:CCCC FOURTH HARBOR ENG INST +4

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

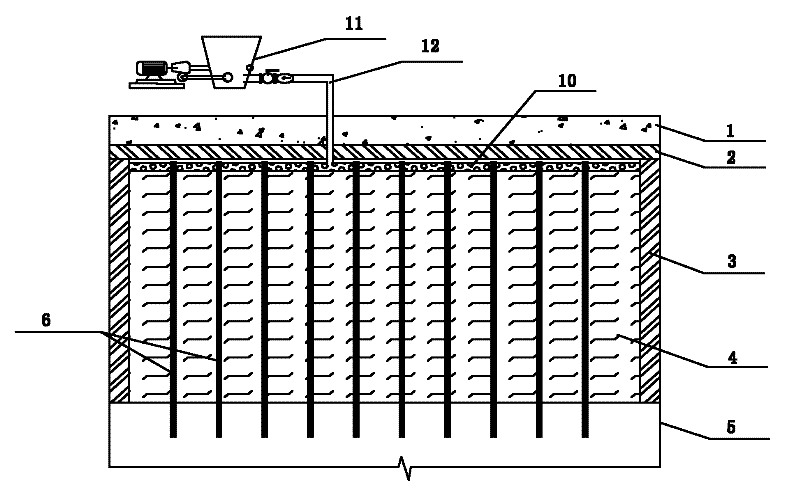

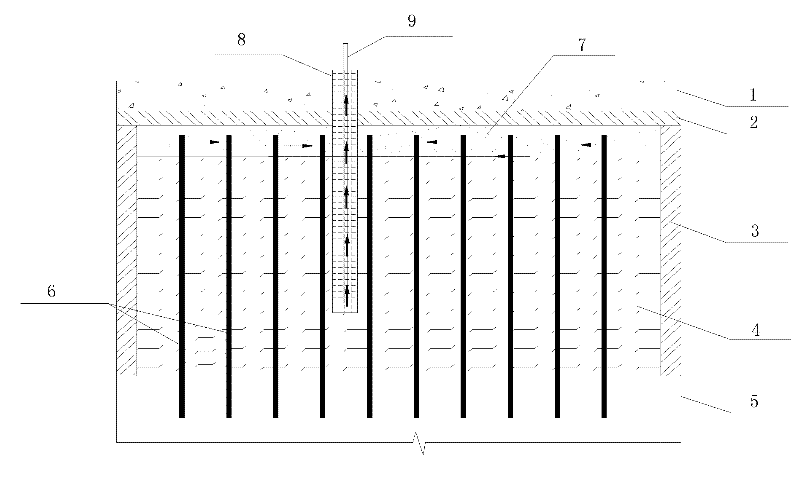

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

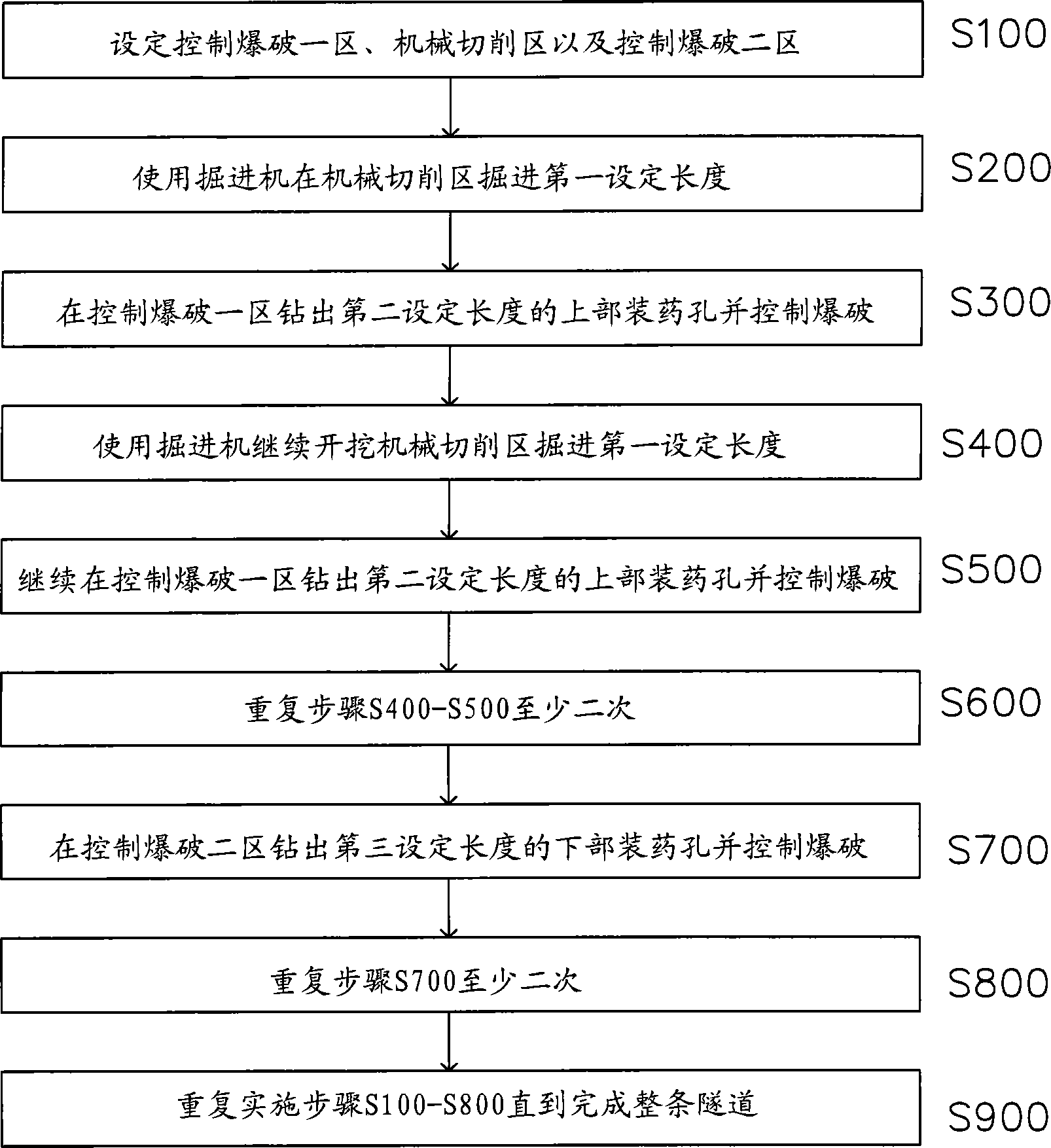

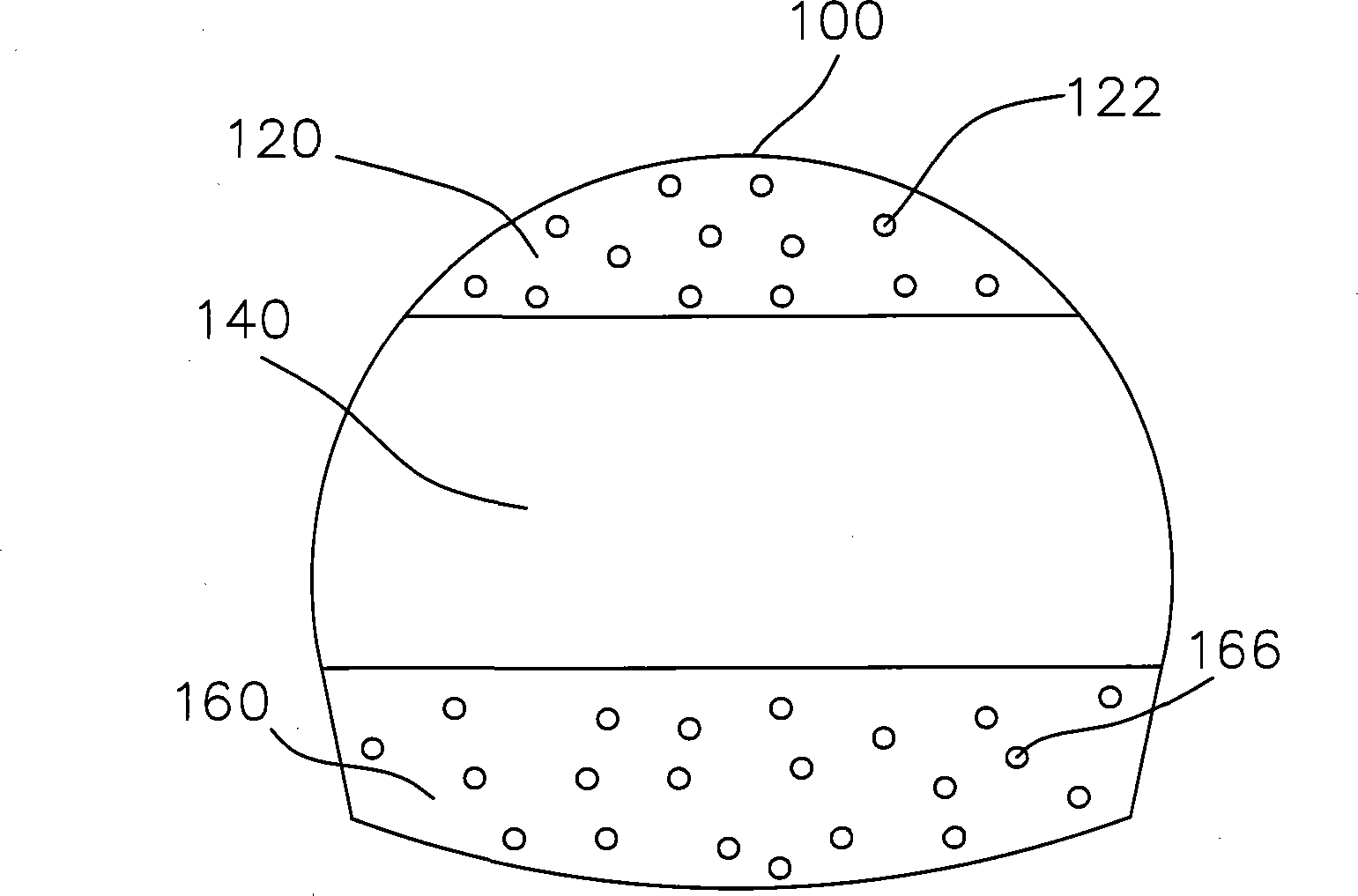

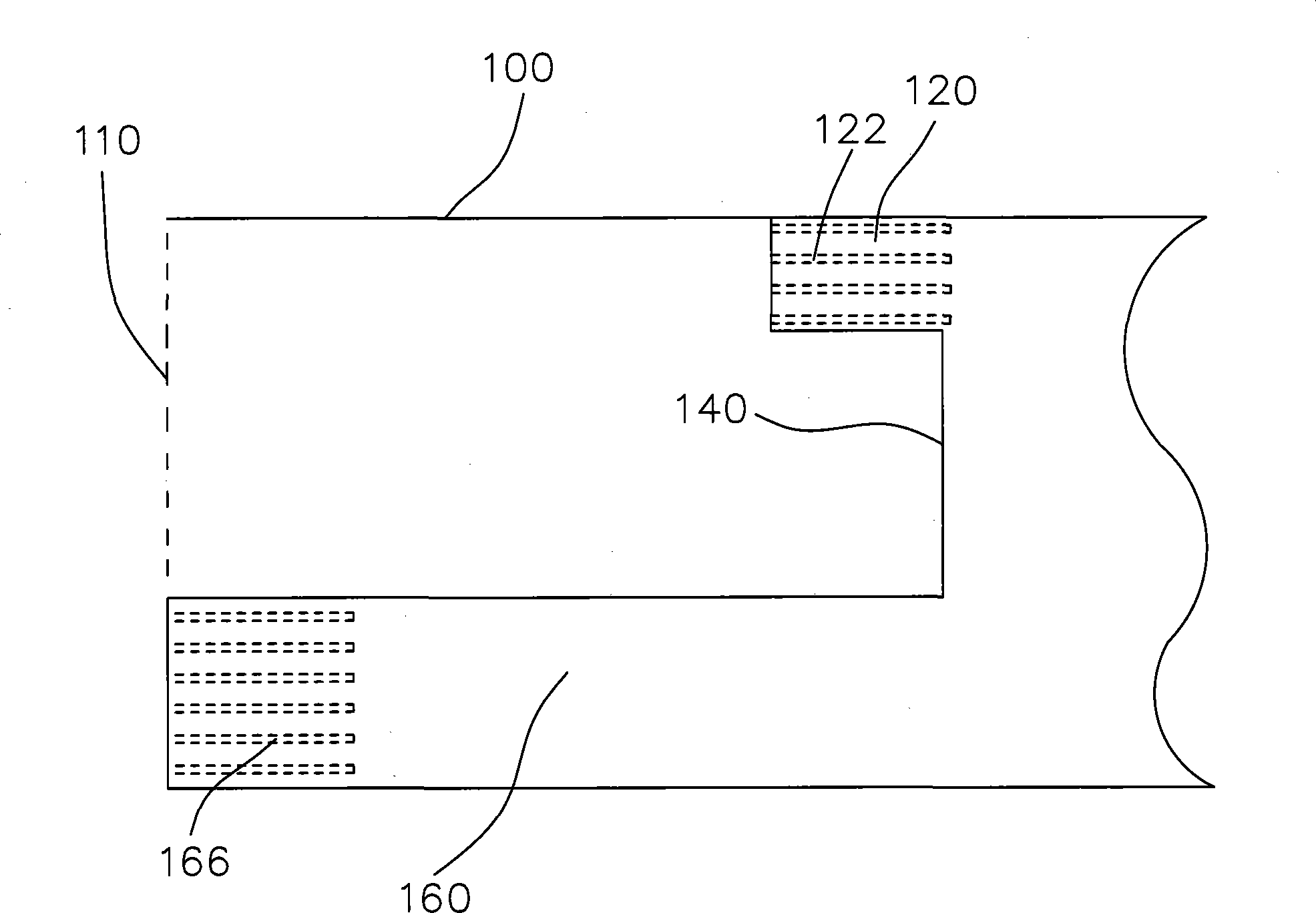

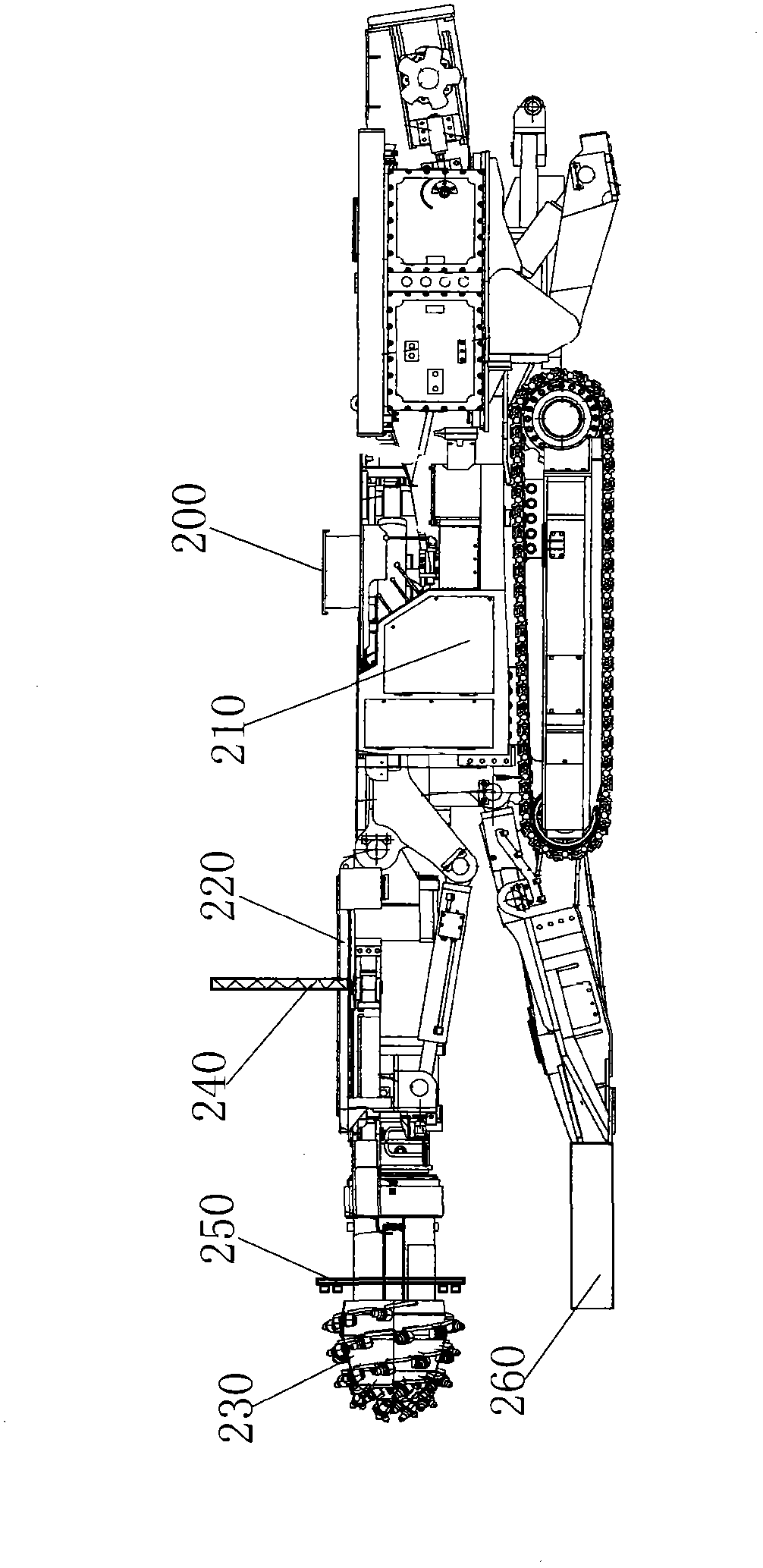

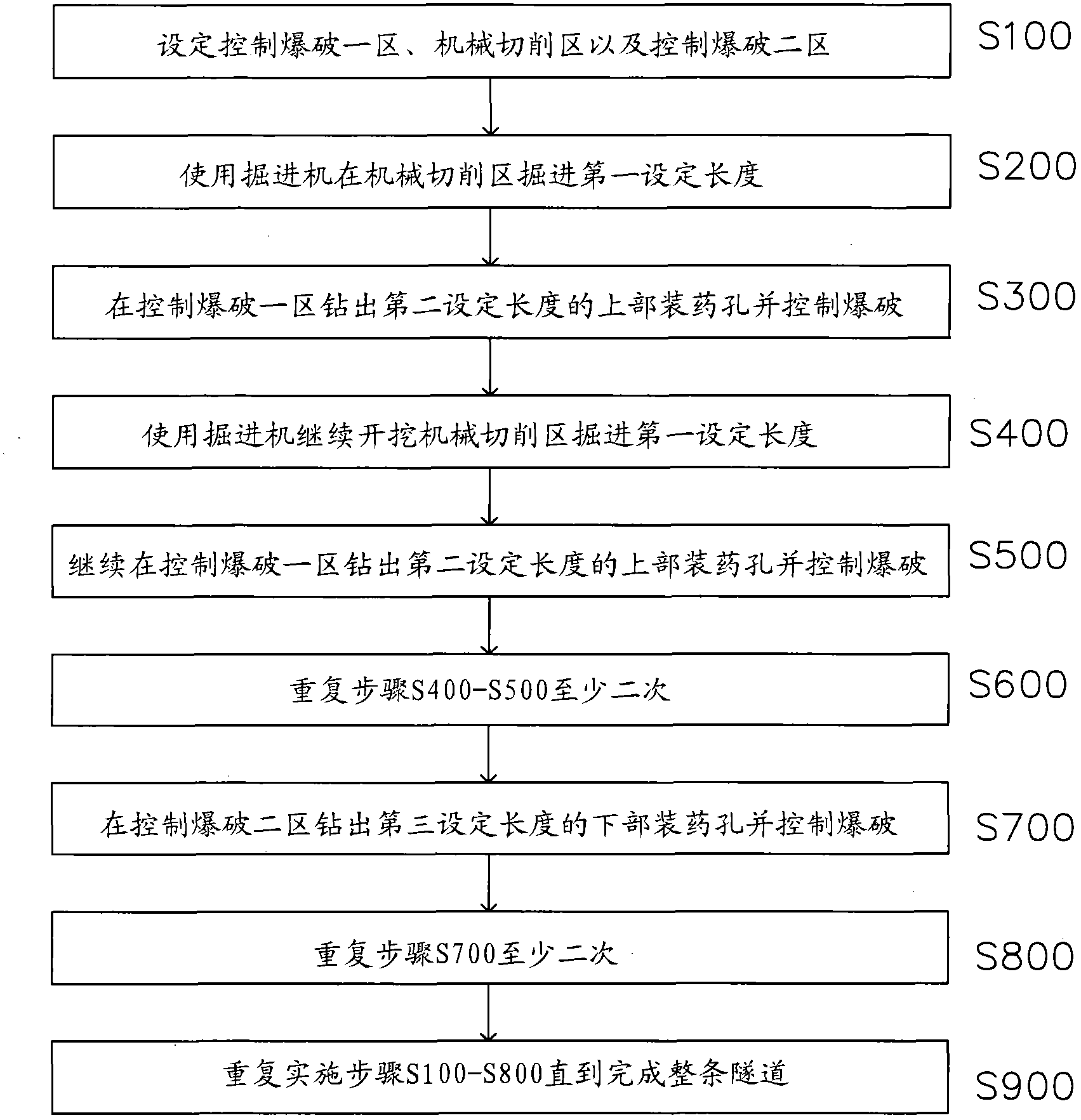

Mechanical mode and control blasting combined tunneling method

InactiveCN103321644AFlexible settingsControl land subsidenceUnderground chambersBlastingSlagMechanical engineering

The invention discloses a mechanical mode and control blasting combined tunneling method which includes utilizing a tunneling machine to excavate a set mechanical cutting zone on a tunnel face, conducting tunneling for first set length along the vertical direction of a tunnel, stopping tunneling, retreating the tunneling machine, drilling a plurality of upper explosive filling holes with second set length in a first control blasting region set above the mechanical cutting region on the tunnel face in the vertical direction of the tunnel, filling explosive in the plurality of upper explosive filling holes, conducting control blasting, clearing rock slag in the tunnel after the first control blasting region is subjected to the control blasting, repeating the steps twice or more than twice to obtain a section of upper middle space in the tunnel, drilling a plurality of lower explosive filling holes with third set length in a second control blasting region set under the mechanical cutting zone on the tunnel face in the vertical direction of the tunnel, filling the explosive in the plurality of lower explosive filling holes, conducting control blasting, clearing rock slag in the tunnel after the second control blasting region is subjected to the control blasting and repeating the construction till the whole tunnel is obtained.

Owner:北京中铁瑞威基础工程有限公司

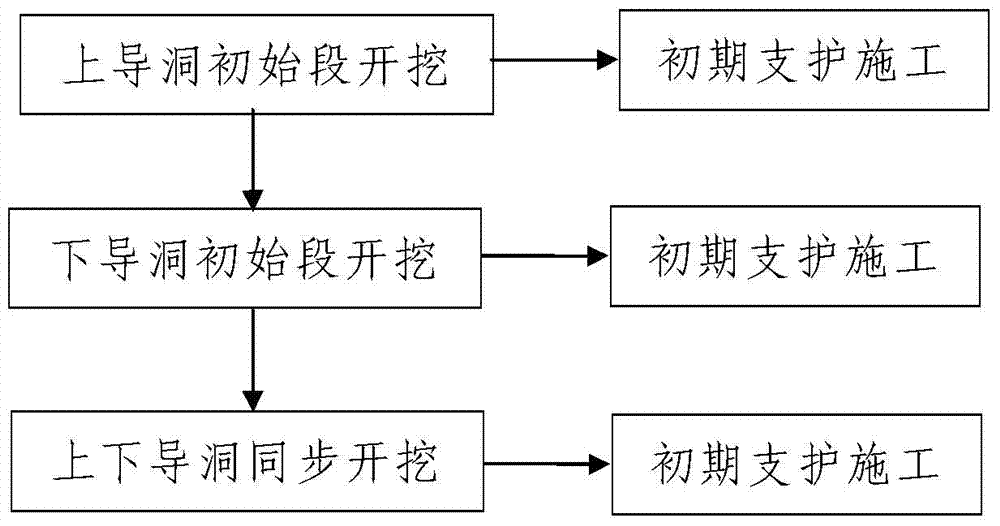

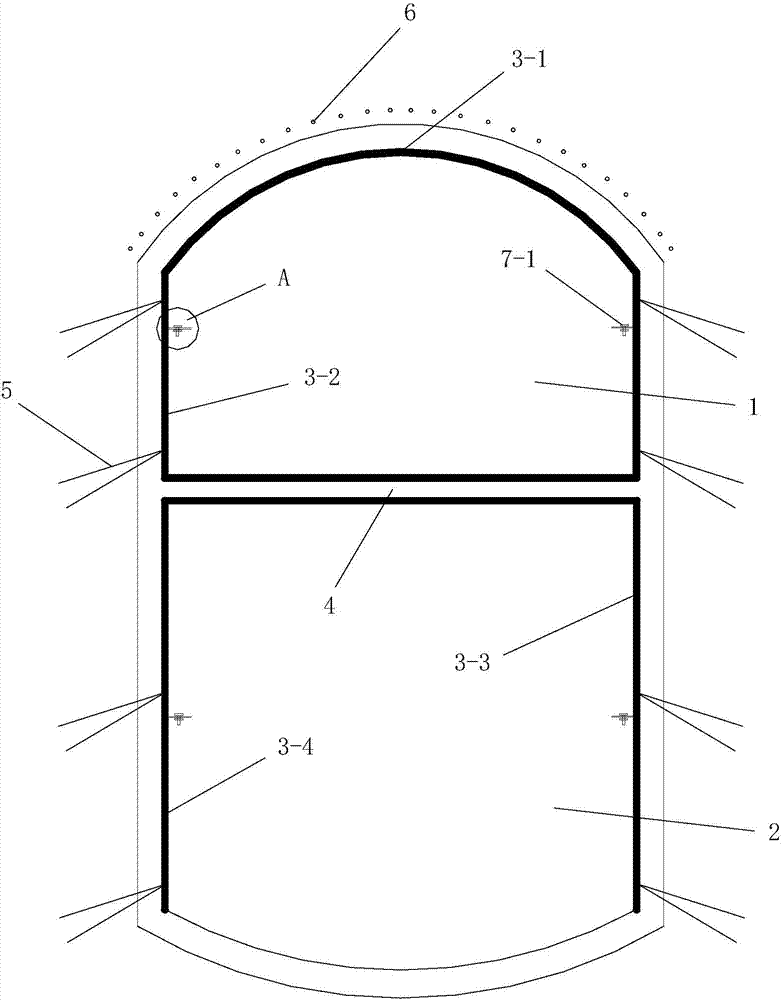

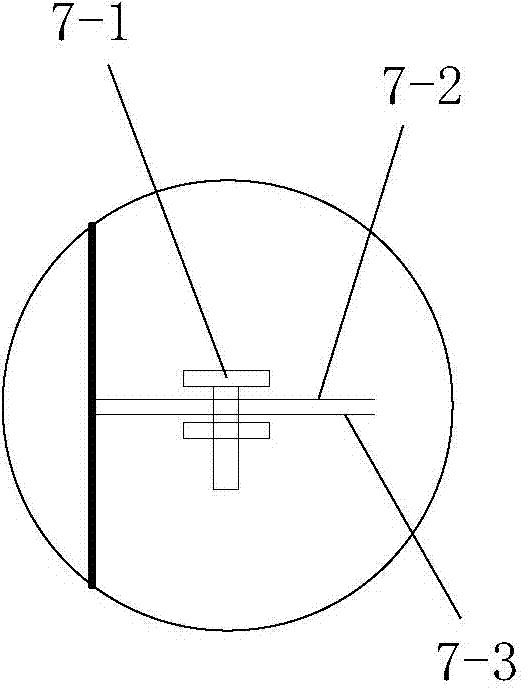

Construction method for enabling shallowly buried and darkly excavated tunnel to pass through cottage area

ActiveCN104500077AThe method steps are simpleReasonable designUnderground chambersTunnel liningRebarInitial segment

The invention discloses a construction method for enabling a shallowly buried and darkly excavated tunnel to pass through a cottage area. The construction method comprises the following steps: excavating a tunnel hole of the constructed shallowly buried and darkly excavated tunnel from back to front through a step excavation process, and performing preliminary bracing on the tunnel hole formed by excavating from back to front in an excavating process, wherein the tunnel hole consists of an upper guide hole and a lower guide hole positioned right below the upper guide hole, the rear part of the tunnel hole is connected with a vertical well, the preliminary bracing structure of the tunnel hole comprises a plurality of grating steel frameworks for supporting the tunnel hole from back to front, a layer of bar-mat reinforcement suspended on the inner wall of the tunnel hole and a concrete layer jetted on the inner wall of the tunnel hole. The process for excavating the tunnel hole of the shallowly buried and darkly excavated tunnel comprises the following steps: I, excavating the initial segment of the upper guide hole; II, excavating the initial segment of the lower guide hole; III, synchronously excavating the upper and the lower guide holes. The construction method disclosed by the invention is simple in step, reasonable in design, convenient in construction, good in construction effect, capable of simply completing the construction process of the shallowly buried and darkly excavated tunnel that passes through the cottage area, and safe and reliable in a construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

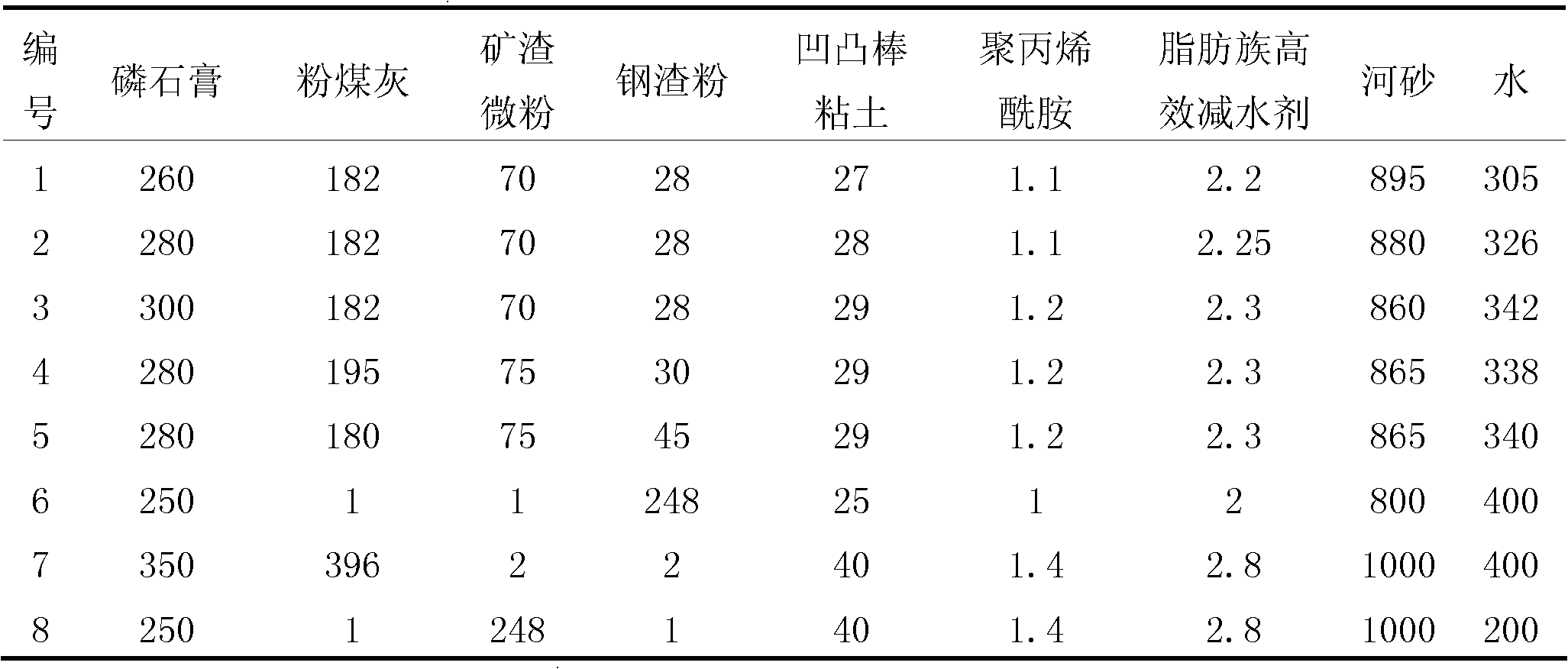

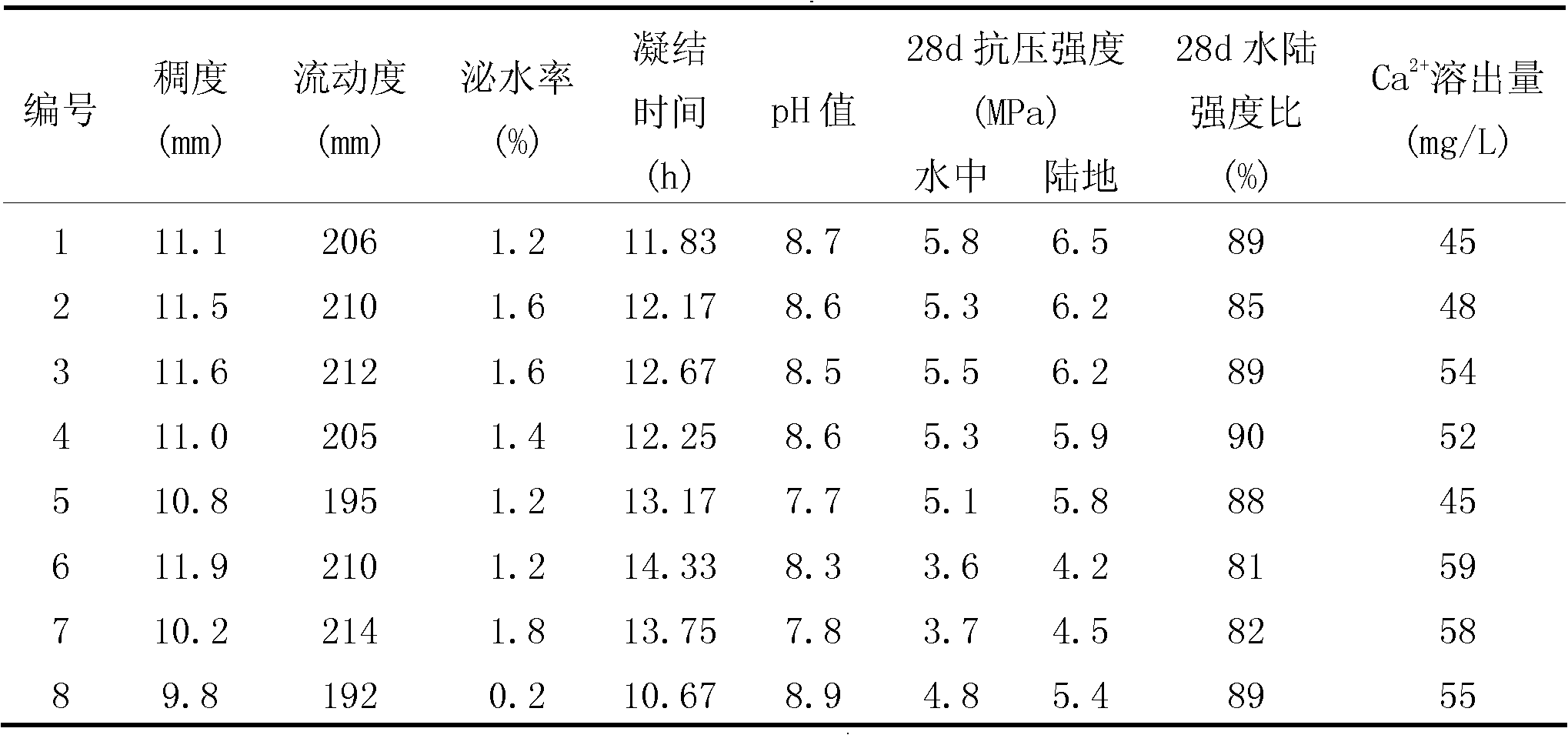

Cement-free anti-water dispersion and anti-water corrosion synchronous grouting material and its preparation method

InactiveCN102617095AResistant to water dispersionWith water corrosion resistanceSlagSuperplasticizer

The invention relates to a synchronous grouting material of shield tunneling and its preparation method. A cement-free anti-water dispersion and anti-water corrosion synchronous grouting material is mainly composed of the following components by weight ratio: 250-350kg / m<3> of phosphogypsum, 250-400kg / m<3> of fly ash, slag powder and steel slag powder, 25-40kg / m<3> of attapulgite clay, 1-1.4kg / m<3> of polyacrylamide, 2-2.8kg / m<3> of an aliphatic high efficiency water reducer, 800-1000kg / m<3> of river sand, and 200-400kg / m<3> of water. Specifically, for the sum of the weight of the fly ash, the slag powder and the steel slag powder, the fly ash accounts for 0.5-99%, the slag powder accounts for 0.5-99%, and the steel slag powder accounts for 0.5-99%. Mixing and stirring of the materials can obtain the required synchronous grouting material, which has the characteristics of anti-water dispersion, anti-water corrosion, good fluidity, good construction performance, no pipe blockage, long usable time, and fast increase of later strength.

Owner:WUHAN METRO GROUP +1

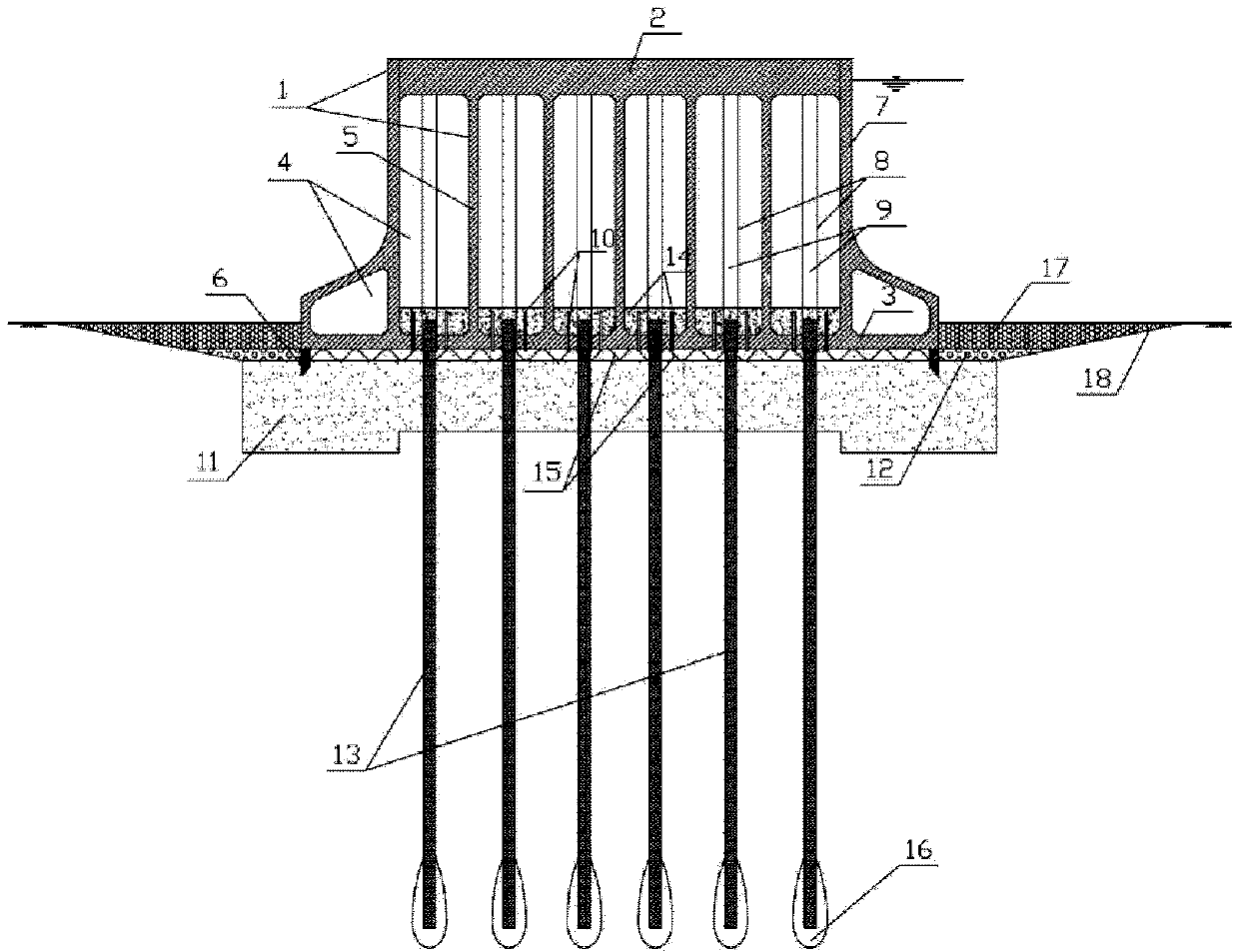

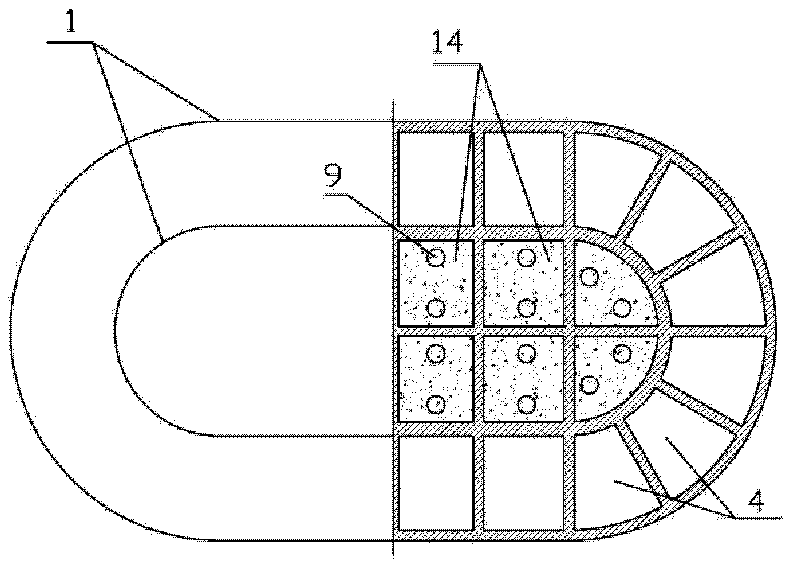

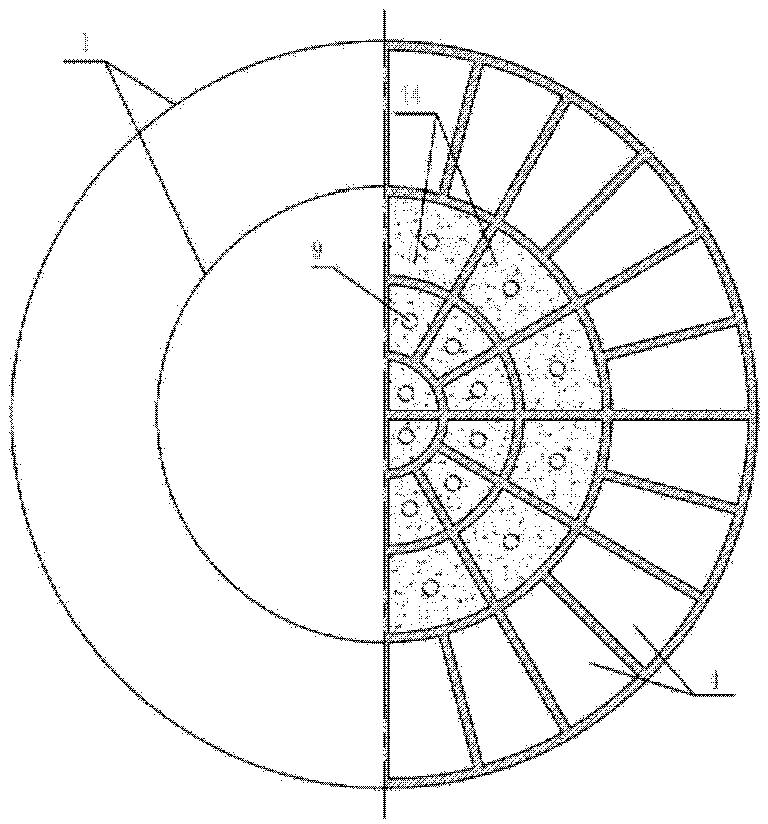

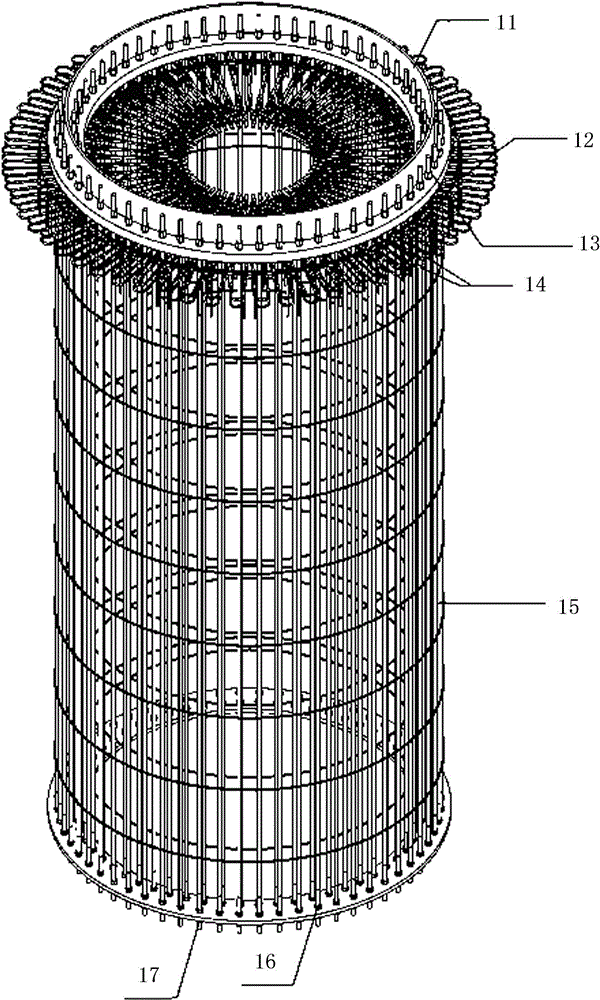

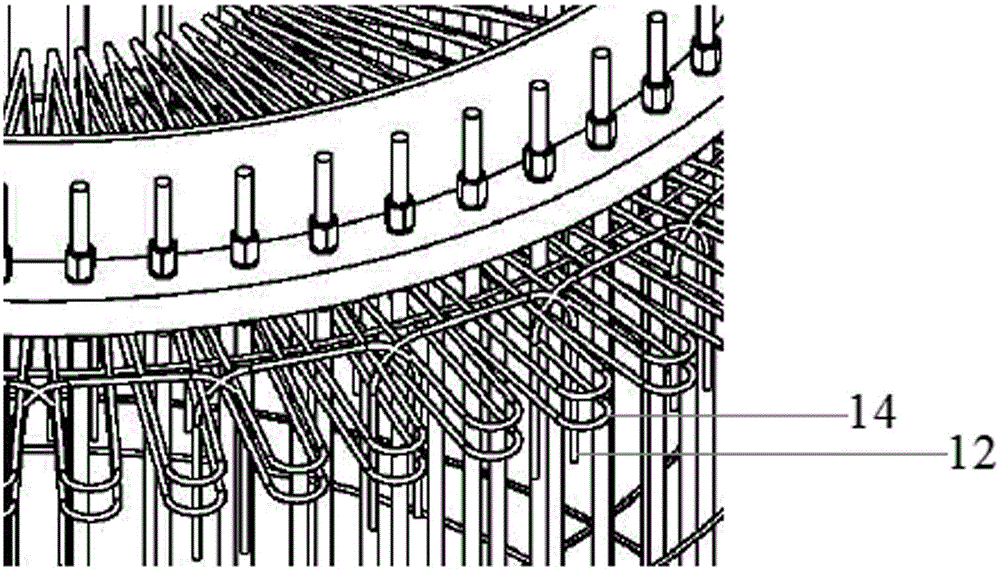

Caisson and pile combined foundation of consolidated subsoil and construction method of caisson and pile combined foundation

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

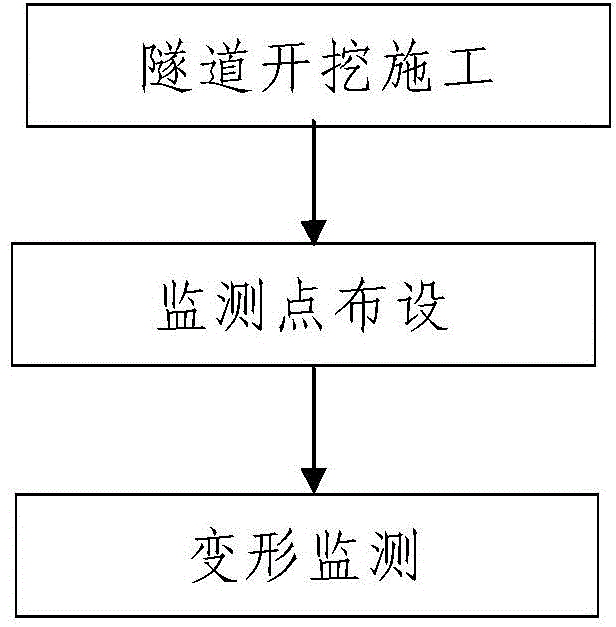

Deformation monitoring method for shallow-buried excavation tunnel construction

ActiveCN104564128AThe method steps are simpleReasonable designMining devicesUnderground chambersTunnel constructionCondition monitoring

The invention discloses a deformation monitoring method for shallow-buried excavation tunnel construction. The deformation monitoring method comprises the following steps: 1) digging a tunnel: digging a tunnel cavity for a constructed shallow-buried excavation tunnel from back to front, primarily supporting the dug tunnel cavity from back to front during the digging process, and forming a primary supporting structure, wherein the primary supporting structure comprises a plurality of grating steel frames for supporting the tunnel cavity from back to front, and each grating steel frame is composed of an arch supporting steel frame and left and right vertical supporting steel frames; 2) arranging monitoring points: arranging multiple sets of supporting state monitoring points on the primary supporting structure of the constructed tunnel cavity from back to front during the digging process, and meanwhile, arranging a plurality of ground surface settlement monitoring points in a construction area of the constructed shallow-buried excavation tunnel from back to front; 3) monitoring the deformation. The method provided by the invention has the advantages of simple steps, reasonable design, convenience in construction, good use effect and capability of effectively monitoring the stability of the constructed shallow-buried excavation tunnel and the ground surface settlement.

Owner:CHINA RAILWAY 20 BUREAU GRP

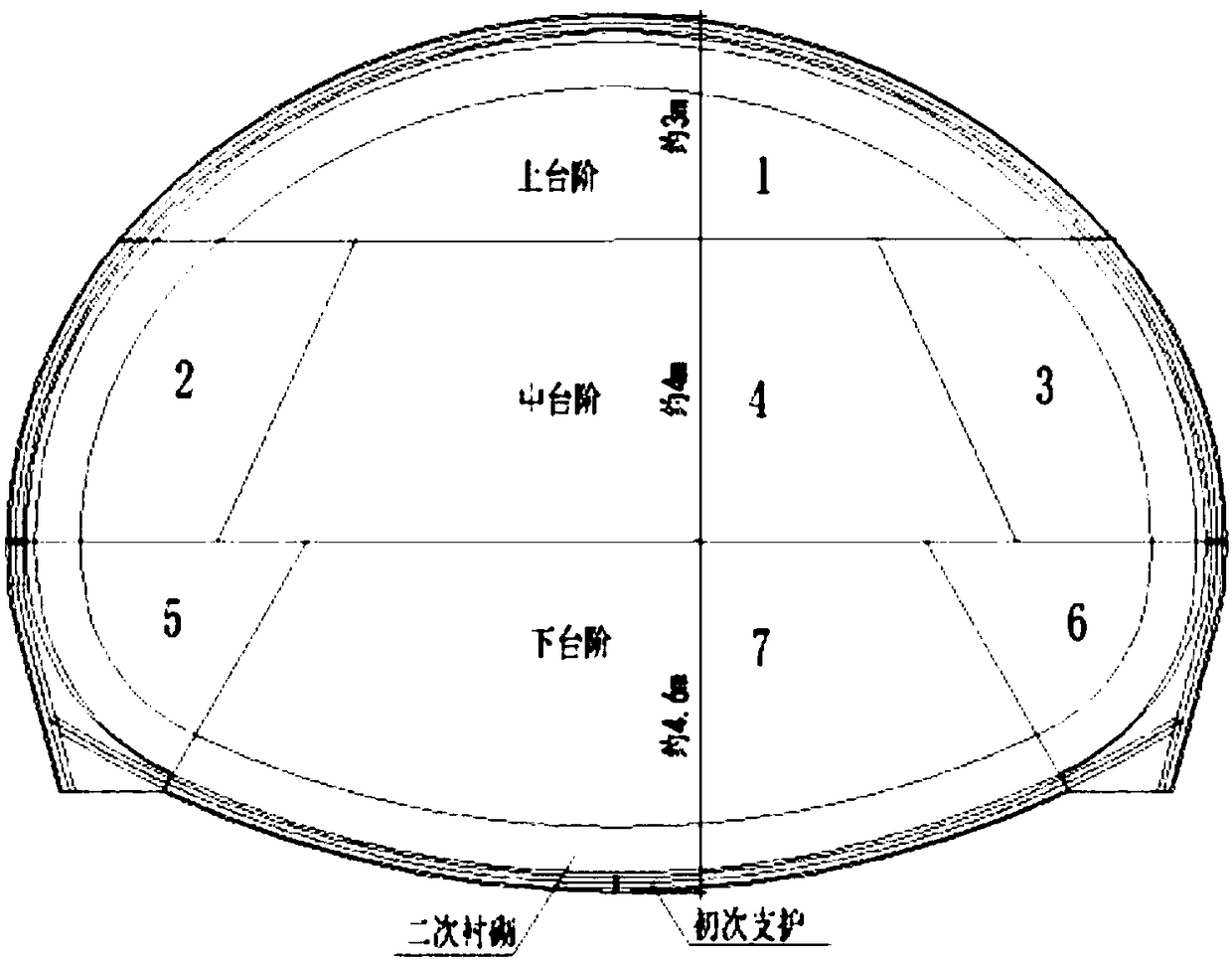

Loess tunnel construction method

InactiveCN102140918ASuitable construction methodEffective control of sinkingUnderground chambersTunnel liningTunnel constructionLoess

The invention relates to a loess tunnel construction method, which can lower the construction difficulty and ensure the construction safety and the structure stability. The method comprises the following steps: (1) rapidly excavating the tunnel; (2) immediately constructing a primary support; (3) erecting an invert trestle, and constructing a primary support invert in time to make the primary support form a closed integral body; (4) erecting an invert trestle, and carrying out invert backfilling and short wall construction as earlier as possible; and (5) constructing a secondary lining at a proper moment meeting the deformation rule of the loess tunnel.

Owner:CHANGAN UNIV

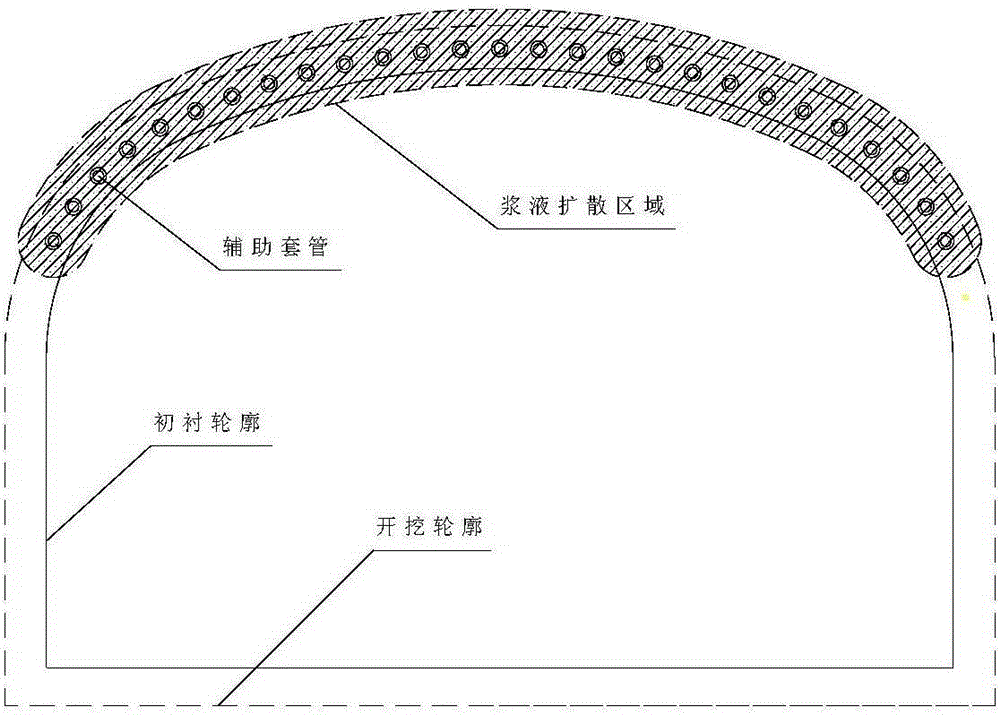

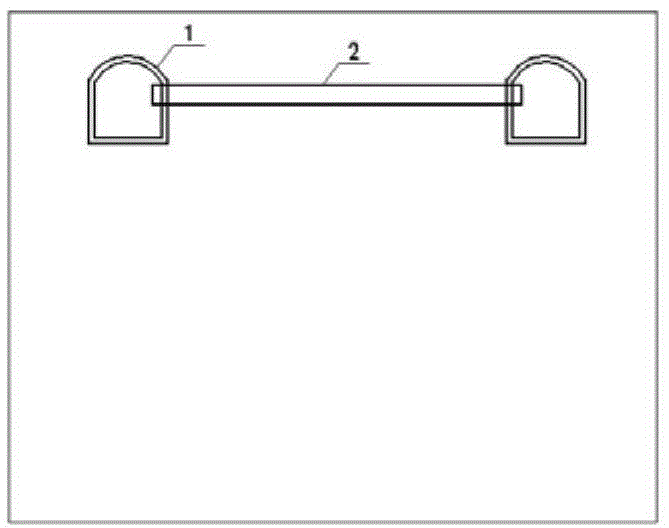

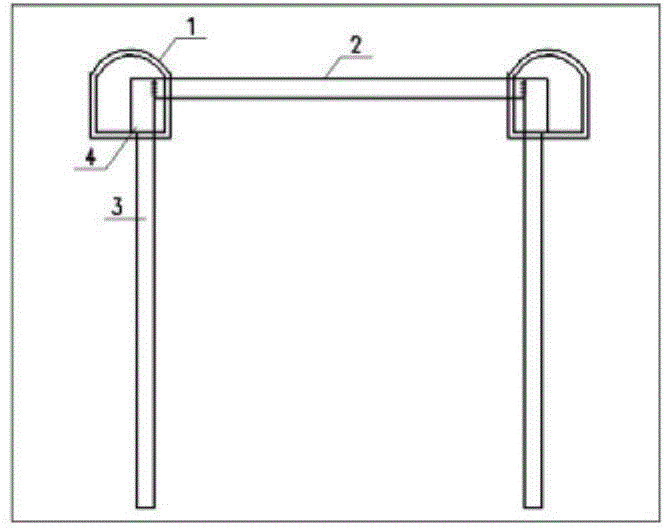

Advanced pre-grouting device suitable for shallow-buried tunnel construction in sand soil layer and construction process

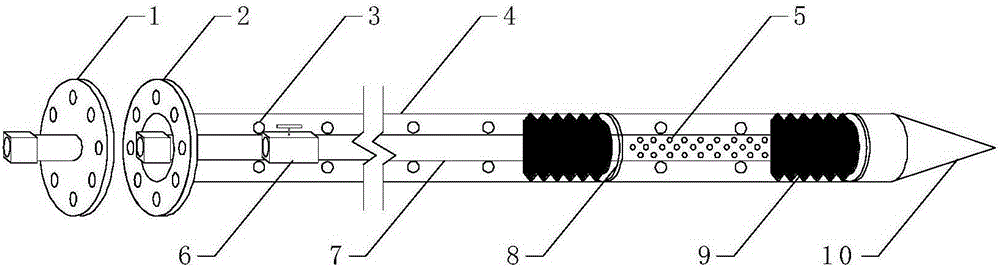

InactiveCN105350519AThe structure of the grouting device is simpleThe grouting device and process are simpleTunnelsSoil preservationPistonUnderground pipeline

The invention discloses an advanced pre-grouting device suitable for shallow-buried tunnel construction in a sand soil layer and a construction process. The advanced pre-grouting device comprises an auxiliary casing pipe and a grouting inner pipe. The grouting inner pipe is sleeved with two rubber pistons. Two flanges are welded to the grouting inner pipe. Slurry outlet holes are distributed between the two rubber pistons. Grouting and reinforcing conducted on strata of different depths are achieved by moving the grouting inner pipe in the auxiliary casing pipe. One-way slurry outlet holes are formed in the auxiliary casing pipe and can effectively prevent slurry from flowing back. After grouting is completed, the auxiliary casing pipe forms a curtain together with slurry veins by serving as a supporting framework. According to the advanced pre-grouting device and the construction process, segmented and domain-controlled grouting is achieved through movement of the grouting inner pipe, it is ensured that the strata are evenly reinforced, no blind points are generated, and disasters are avoided; slurry is effectively utilized; meanwhile, influences on the overlying strata and the ground surface are reduced, and damage to underground pipelines, ground surface road surfaces and above-ground buildings is prevented; and the auxiliary casing pipe is left in the strata and plays a role of a high-strength beam, slurry is dispersed around the auxiliary casing pipe, and a soil body and the auxiliary casting pipe can form the whole curtain.

Owner:SHANDONG UNIV

Prepn process of in-situ grain reinforced refractory aluminium-base composite material

The in-situ grain reinforced refractory aluminum-base composite material consists of Si 11-13 wt%, Mg 0.5-1.5 wt%, Cu 0.8-1.3 wt%, Ni 0.5-1.5 wt%, and TiB2 1-20 wt% except Al. The preparation process includes the following steps: 1. adding ZL102 alloy and Al-Si intermediate alloy or industrial pure aluminum into crucible, melting, heating and covering with covering agent; 2. mixing KFB4 and KTiF6, stoving and adding into the melt via stirring; 3. taking out the side product after reaction, adding industrial pure Mg, Al-Ni intermediate alloy and Al-Cu intermediate alloy, scumming, pumping vacuum and letting stand; and 4. low pressure casting formation. The composite material of the present invention has reinforcing TiB2 grains with clean interface and even distribution, excellent structure and performance, excellent high temperature strength, high plasticity and high modulus, and the present invention is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

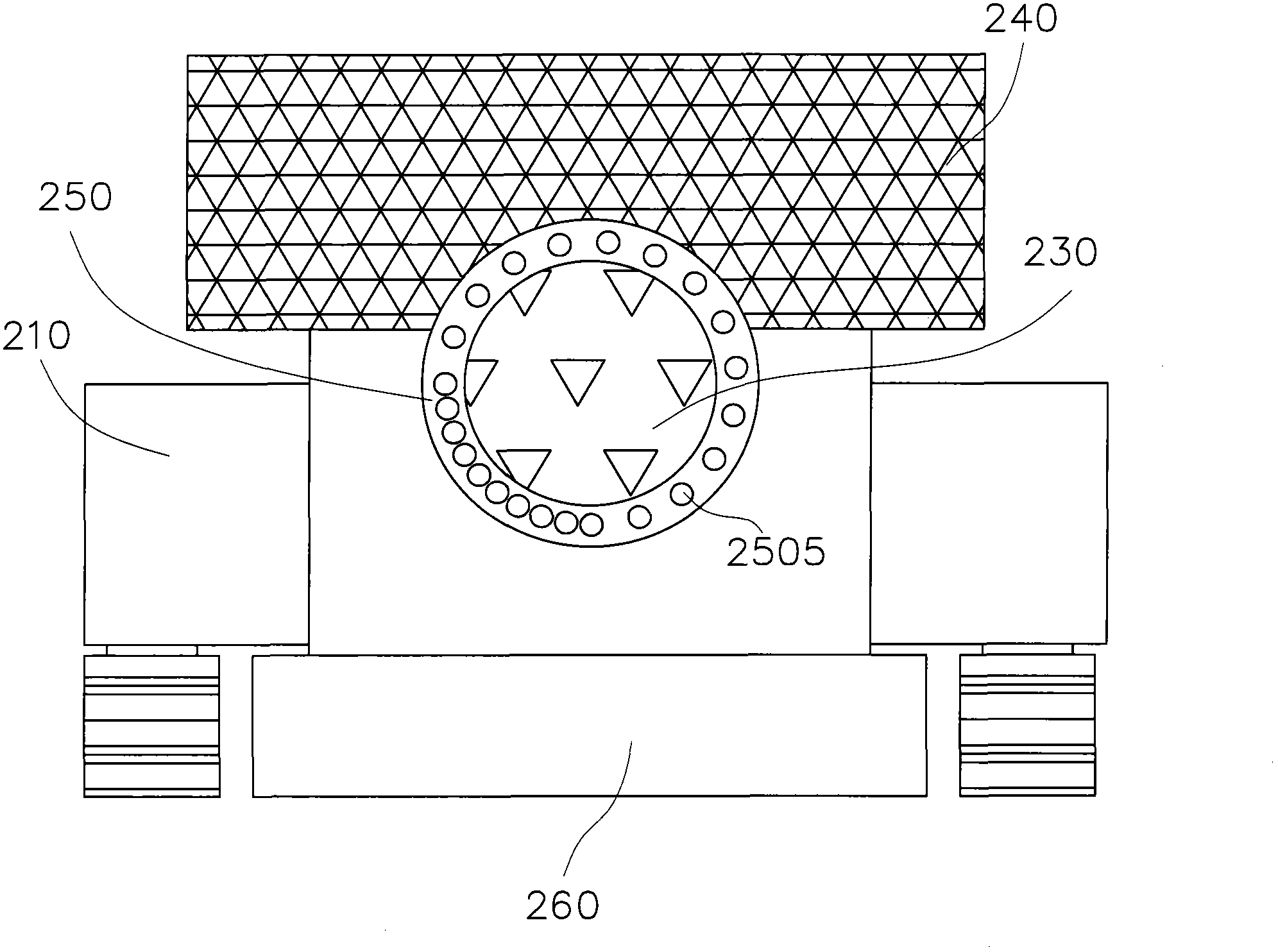

Boom-type roadheader for tunnel construction and tunnel construction method

InactiveCN103291308AAvoid influenceSettlement controlDust removalFire preventionArchitectural engineeringCantilever

The invention discloses a boom-type roadheader for tunnel construction and a tunnel construction method. The boom-type roadheader comprises an engine-driven body, a boom, a milling and excavating head and a water spraying and dust removing device, wherein the boom is connected to the engine-driven body in an extensible and / or swingable manner, and the milling and excavating head is mounted at the free end of the boom in a rotatable manner. The water spraying and dust removing device comprises a plurality of nozzles around the boom and adjacent to the milling and excavating head, and the nozzles are in non-uniform distribution in the circumferential direction. When the boom-type roadheader is used for excavating and milling the cross section of a tunnel, segments and segment strips are set for milling and excavation. When each strip of each segment is excavated and milled, and when the distribution density of the nozzles on the bottom right of the milling and excavating head is set to be higher than that of the nozzles in other regions, the milling and excavating head is driven by the boom to move from left to right; when the distribution density of the nozzles on the bottom left of the milling and excavating head is set to be higher than that of the nozzles in the other regions, the milling and excavating head is driven by the boom to move from right to left.

Owner:北京中铁瑞威基础工程有限公司

Forward coal mining by filling method

InactiveCN101749020ASolve stressSolve problems such as air leakage in gobsUnderground miningSurface miningMining engineeringEarth surface

The invention provides a forward coal mining technique by a filling method, comprising the following characteristics: simultaneously pushing the working surface and the gate road of coal mining, thereby tunneling, mining and filling old empty region. The invention can reduce 20-30% of tunneling rate and 10-15% of workers, the filling ratio of the goaf reaches over 95%. The problems that the maintenance is difficult to carry out because of great pressure of the surrounding rock along retaining, the goaf leaks air, the production is continuously tense, coal resource is wasted and the like are solved, and the non-disturbance of earth surface is effectively controlled.

Owner:ZIBO WANGZHUANG COAL MINE

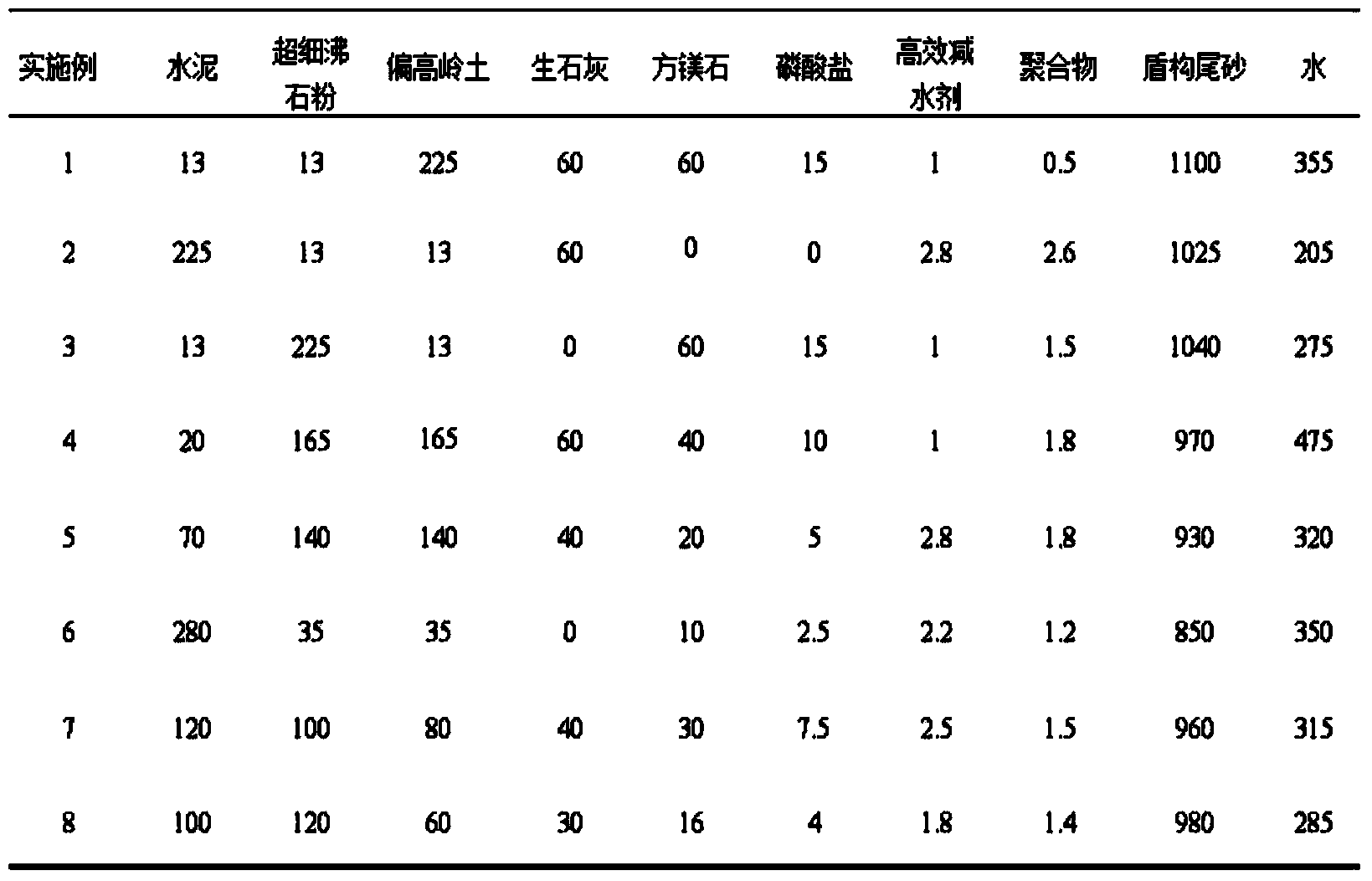

Early-strength micro-expanding synchronous grouting material prepared from shield tailings and preparation method of synchronous grouting material

InactiveCN103449762AGood working performanceImproved flow and pumpabilitySolid waste managementPericlaseBuilding material

The invention belongs to inorganic non-metallic building materials, and particularly relates to a synchronous grouting material for shield tunnels and a preparation method of the synchronous grouting material. The synchronous grouting material disclosed by the invention comprises the following components in parts by weight (kg / m<3>): 250-350 parts of a cementing material, 0-60 parts of quick lime, 0-60 parts of periclase, 0-15 parts of phosphates, 1-2.8 parts of a high-efficiency water reducing agent, 0.5-2.6 parts of polymers, 850-1100 parts of shield tailings, and 205-475 parts of water. The synchronous grouting material prepared from the shield tailings is good in early strength, micro-expanding performance, working performance and water dispersion resistance. According to the synchronous grouting material disclosed by the invention, underground tailings brought out in the process of shield construction are reasonably used, thus the impact on the environment is reduced; the synchronous grouting material is simple in ingredients, low in manufacturing cost, easy to produce, and good in workability, and can satisfy the requirements of grouting equipment.

Owner:WUHAN UNIV OF TECH +1

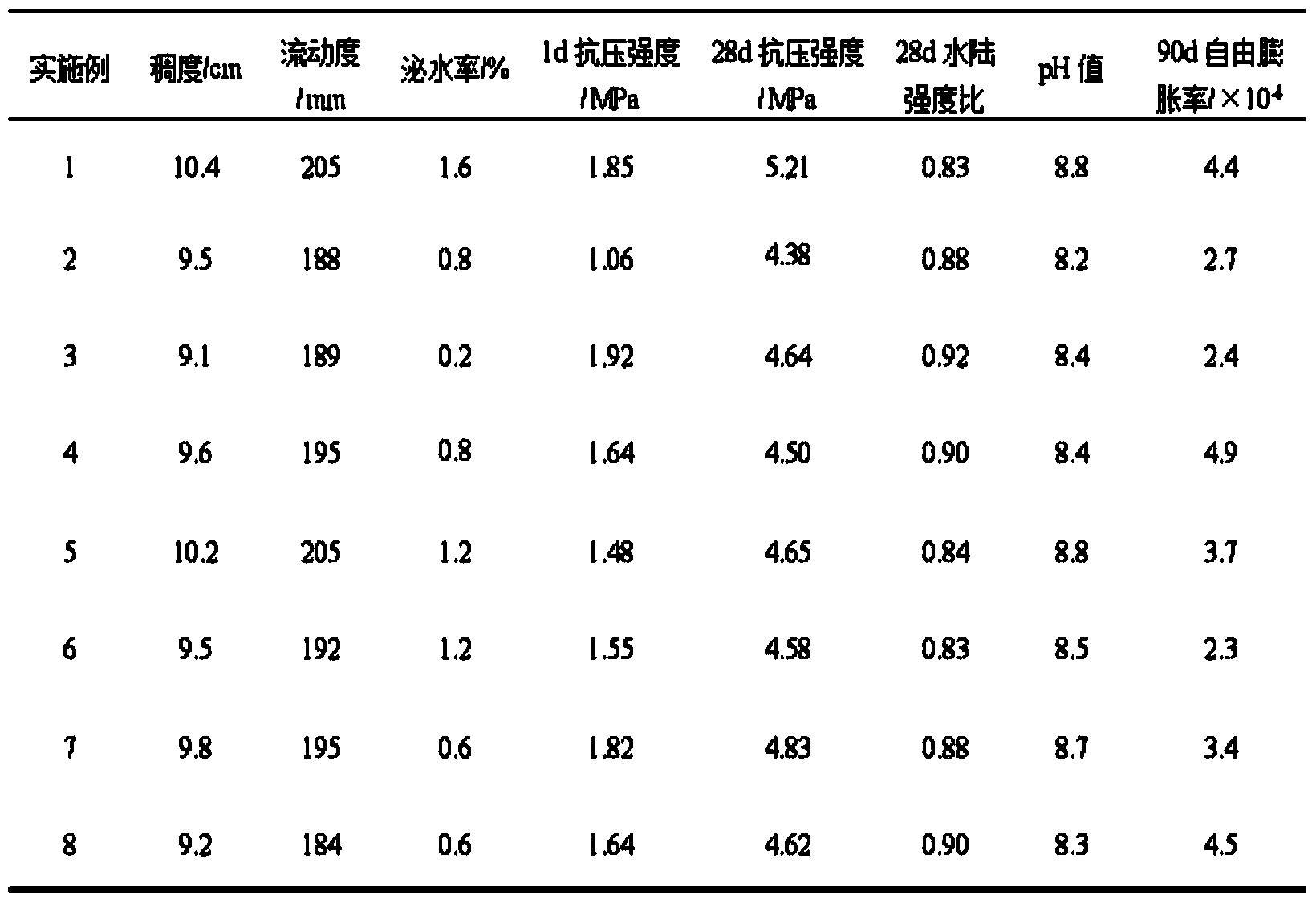

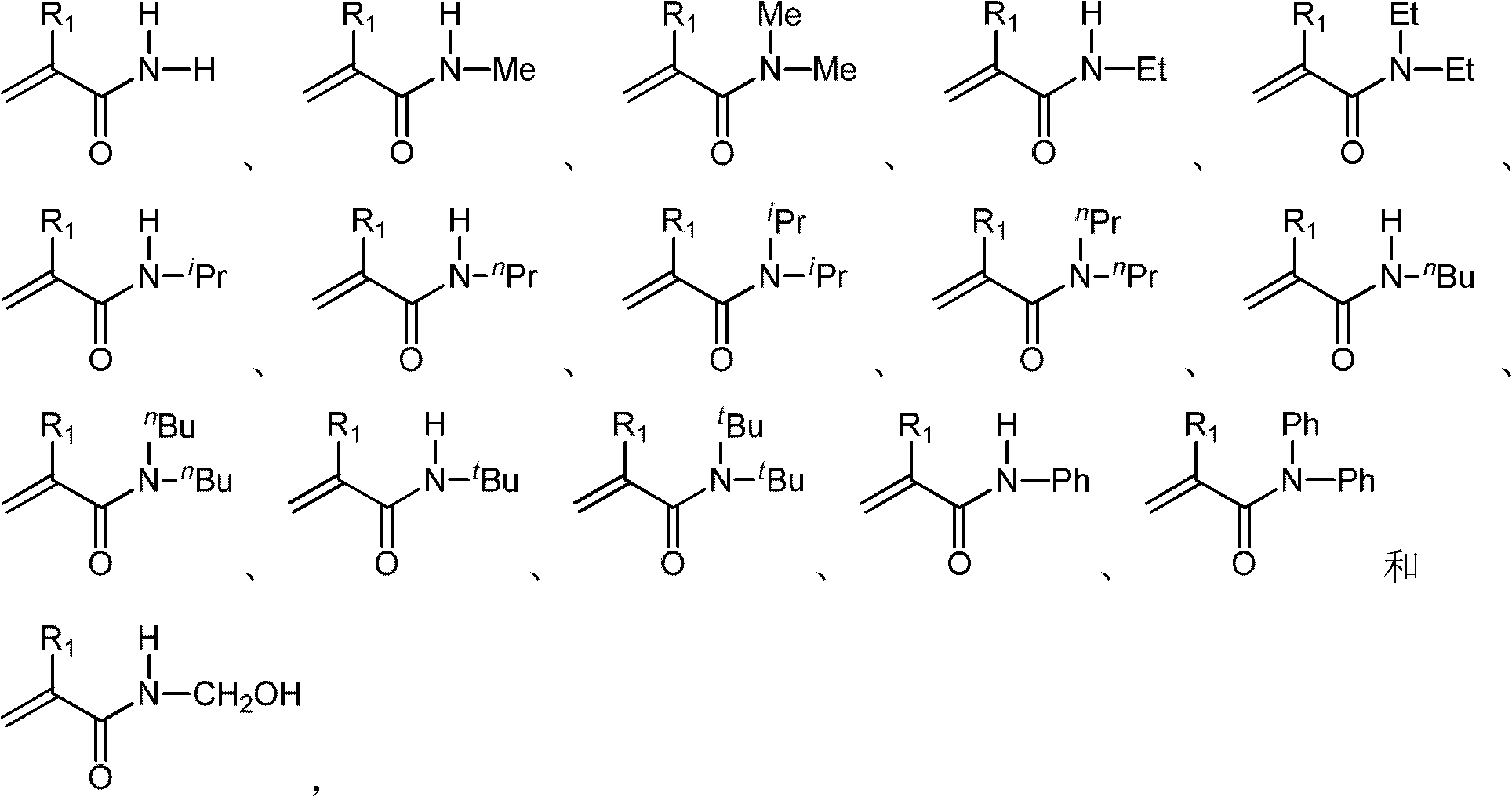

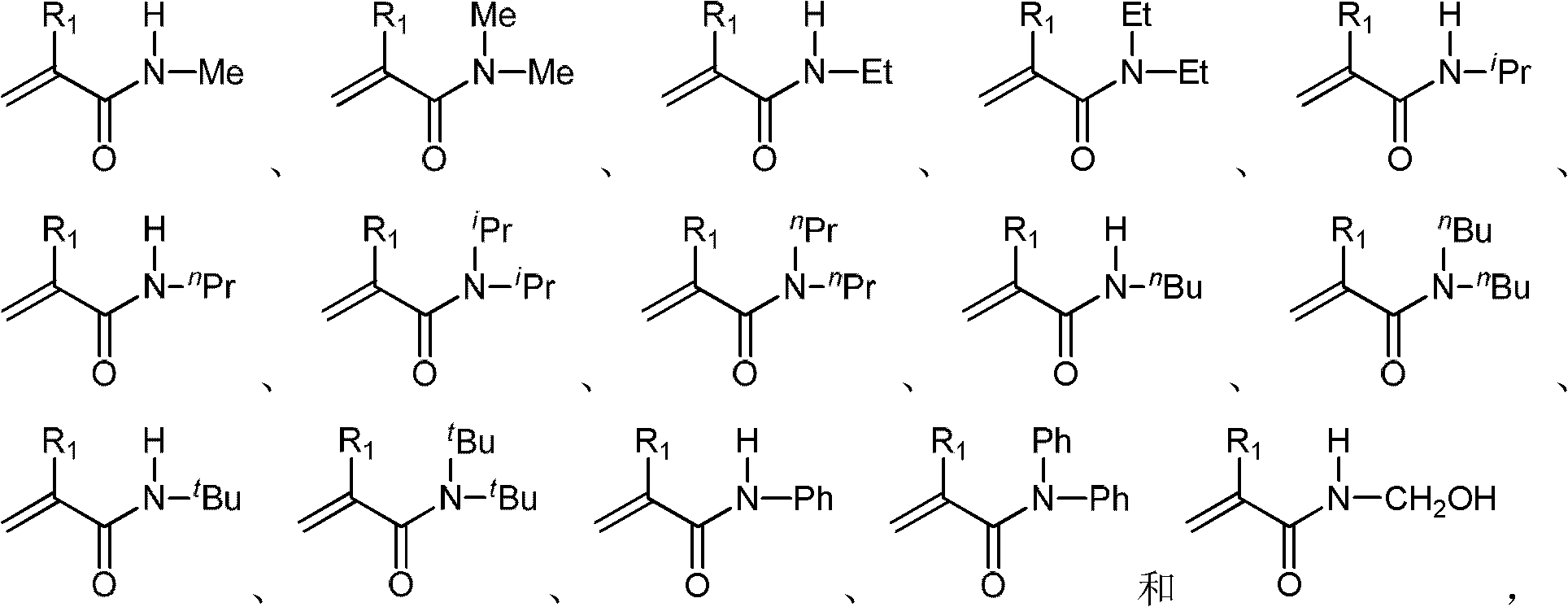

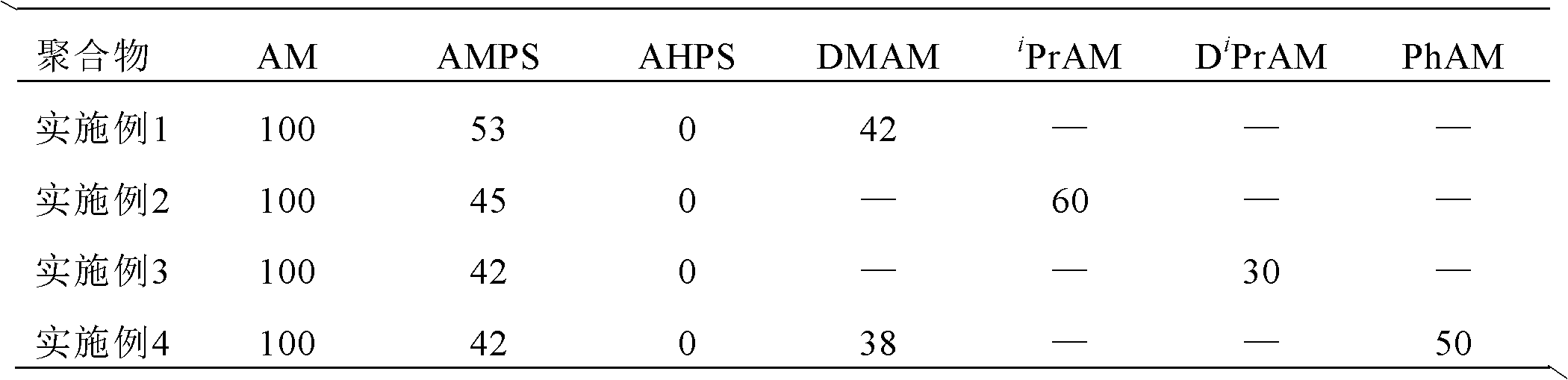

Filtration-reducing agent for synthetic polymer oil-well cement

The invention discloses a filtration-reducing agent for synthetic polymer oil-well cement. The filtration-reducing agent is prepared by copolymerizing an acrylamide monomer, a cross-linking agent and other monomers. The polymer has high stability under the conditions of high temperature, high pressure and strong basicity, can effectively enhance the filtration reducing performance of a well cementation cement slurry system in the environments of high temperature, high pressure and high salinity, solves the sedimentation problem of cement to the greatest extent, greatly solves the delayed coagulation problem, and is particularly suitable for cement well cementation of an oil well with super depth, ultrahigh temperature and ultrahigh pressure. The polymer can stabilize a well cementation cement slurry system, avoids free fluid in cement slurry and increases the cement intensity. Under a general condition (80 DEG C), the required dosage of the polymer is only 0.5 percent BOWC. Under the conditions of high temperature, high pressure and high salinity, the required dosage of the polymer is only 1.0 percent BOWC, so that the aim of reducing filtration of well cementation cement can be fulfilled, and the economic effect is very remarkable.

Owner:JIANGSU AOLUNDA HIGH TECH IND

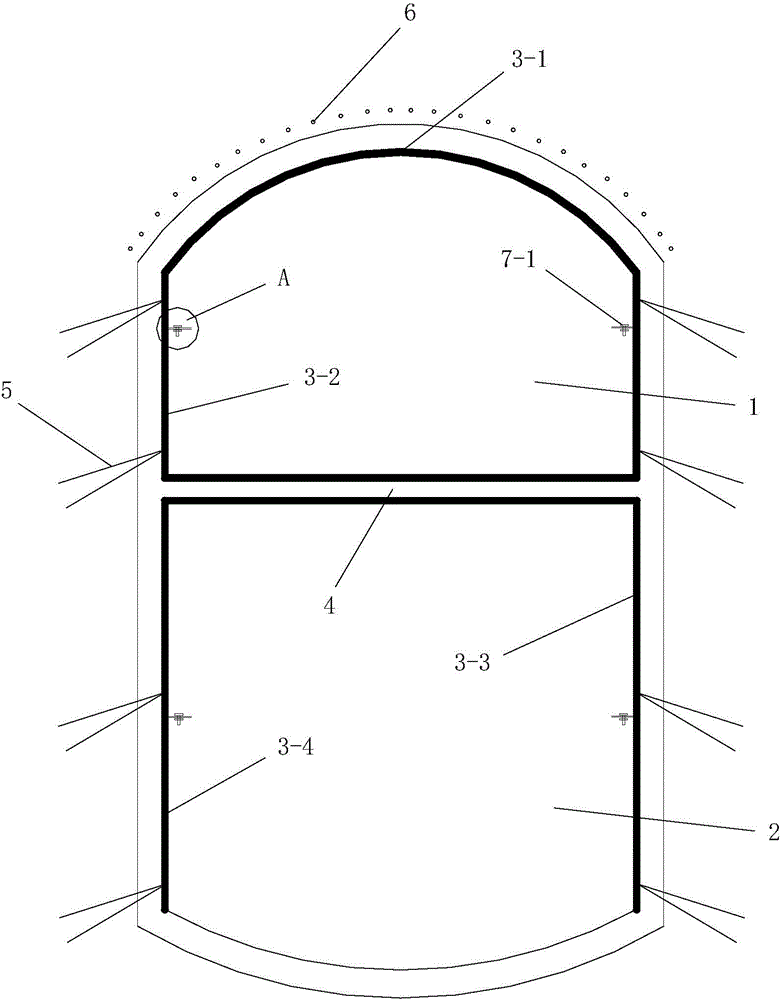

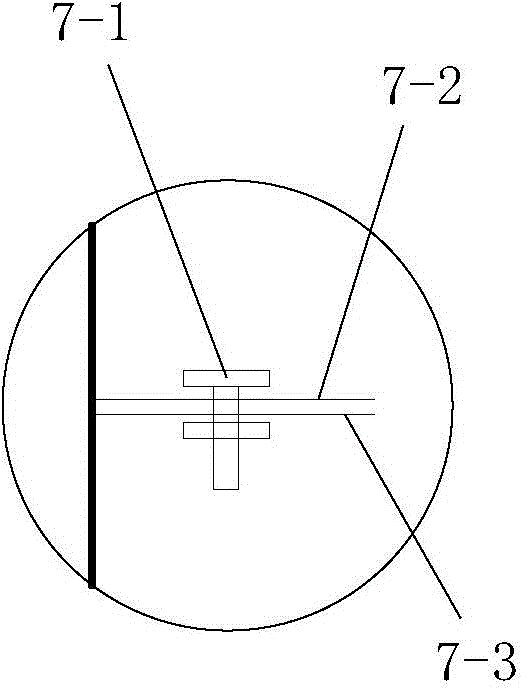

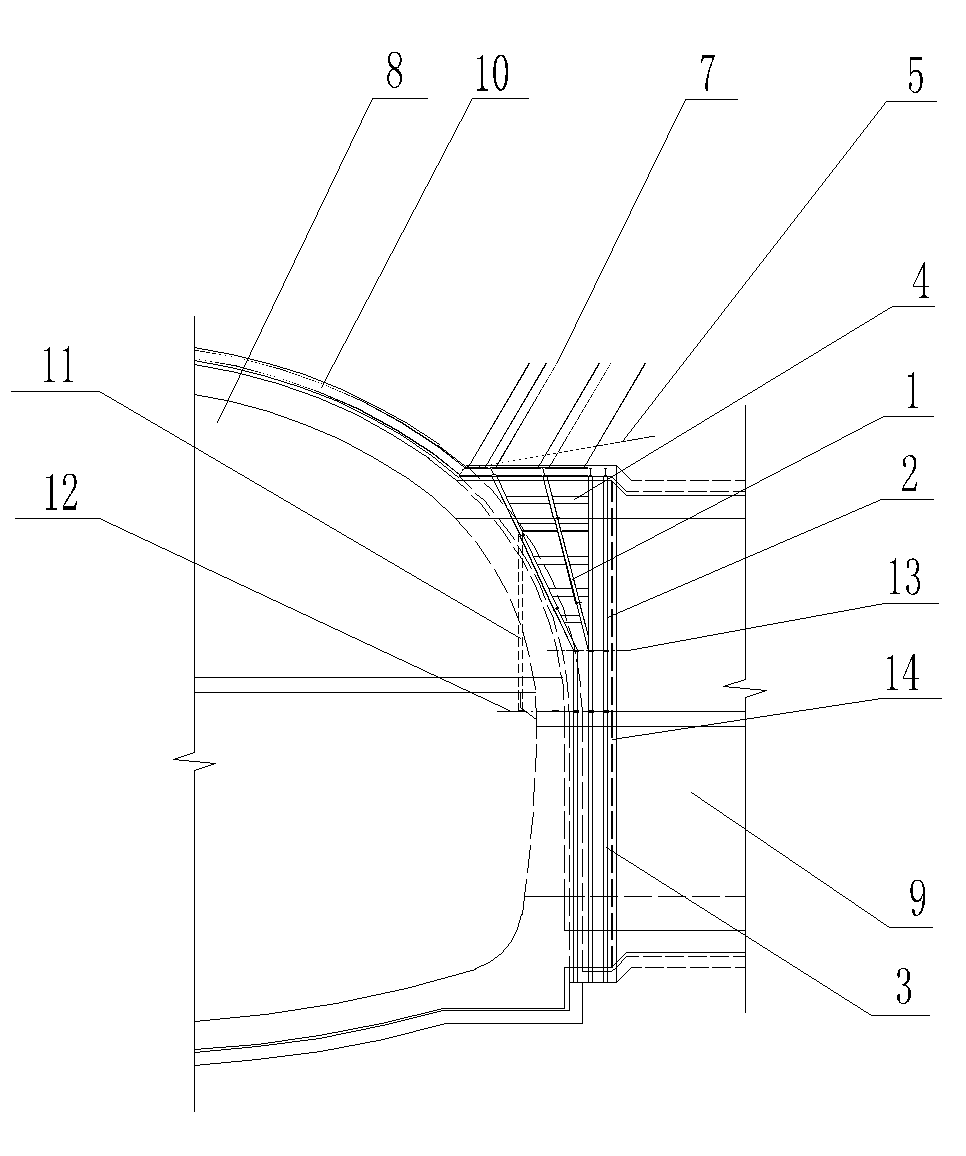

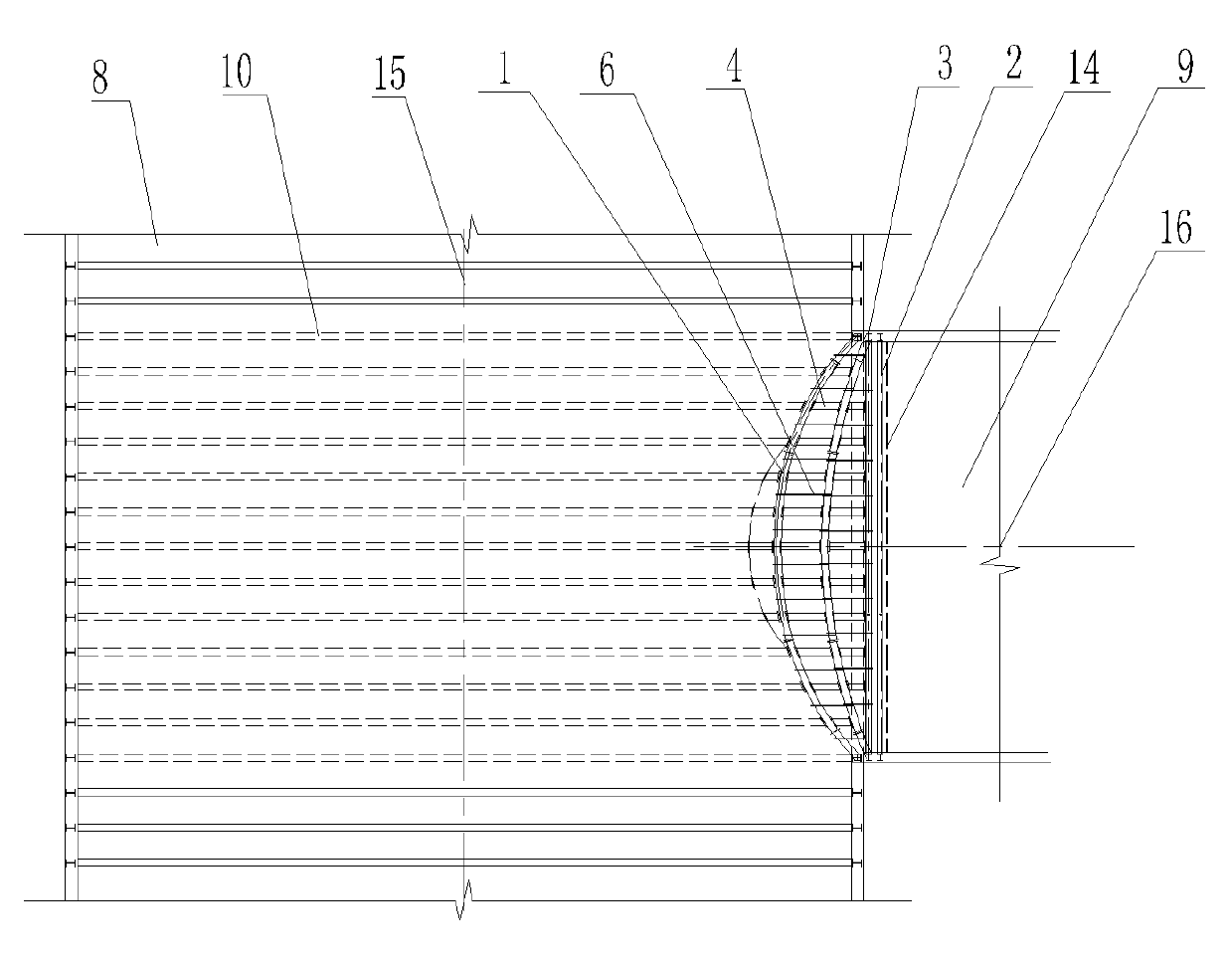

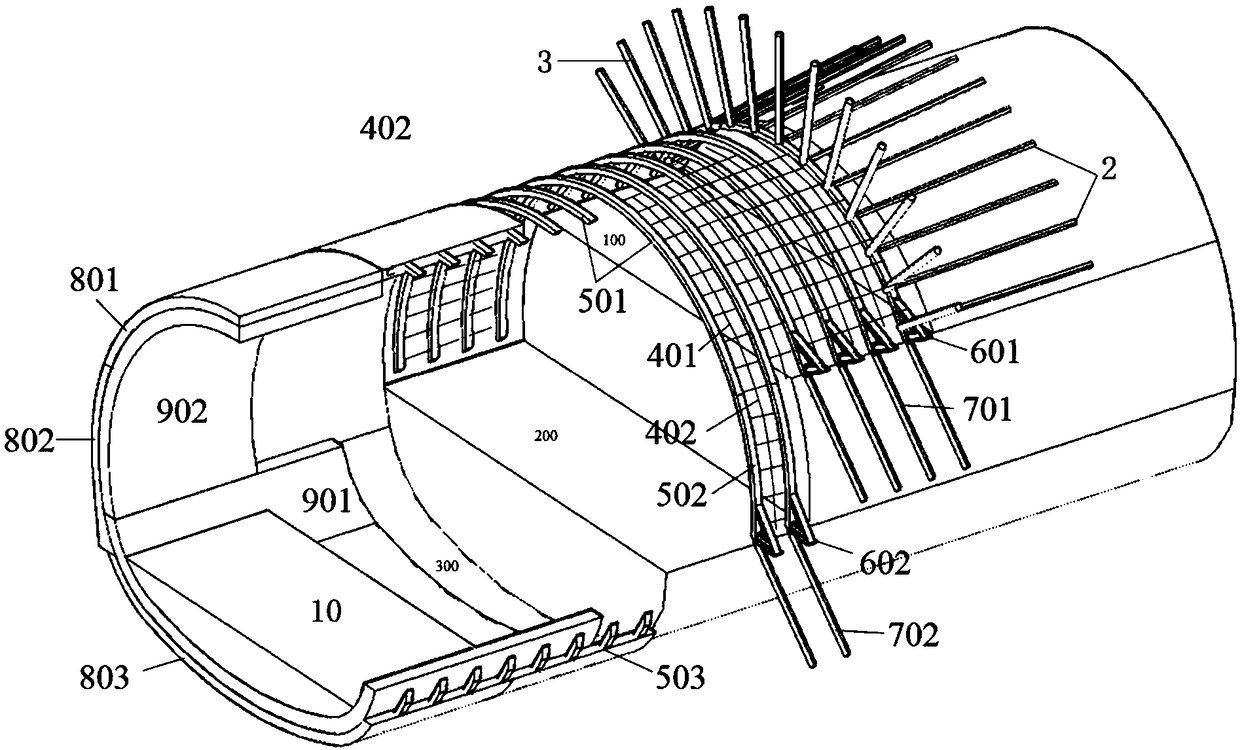

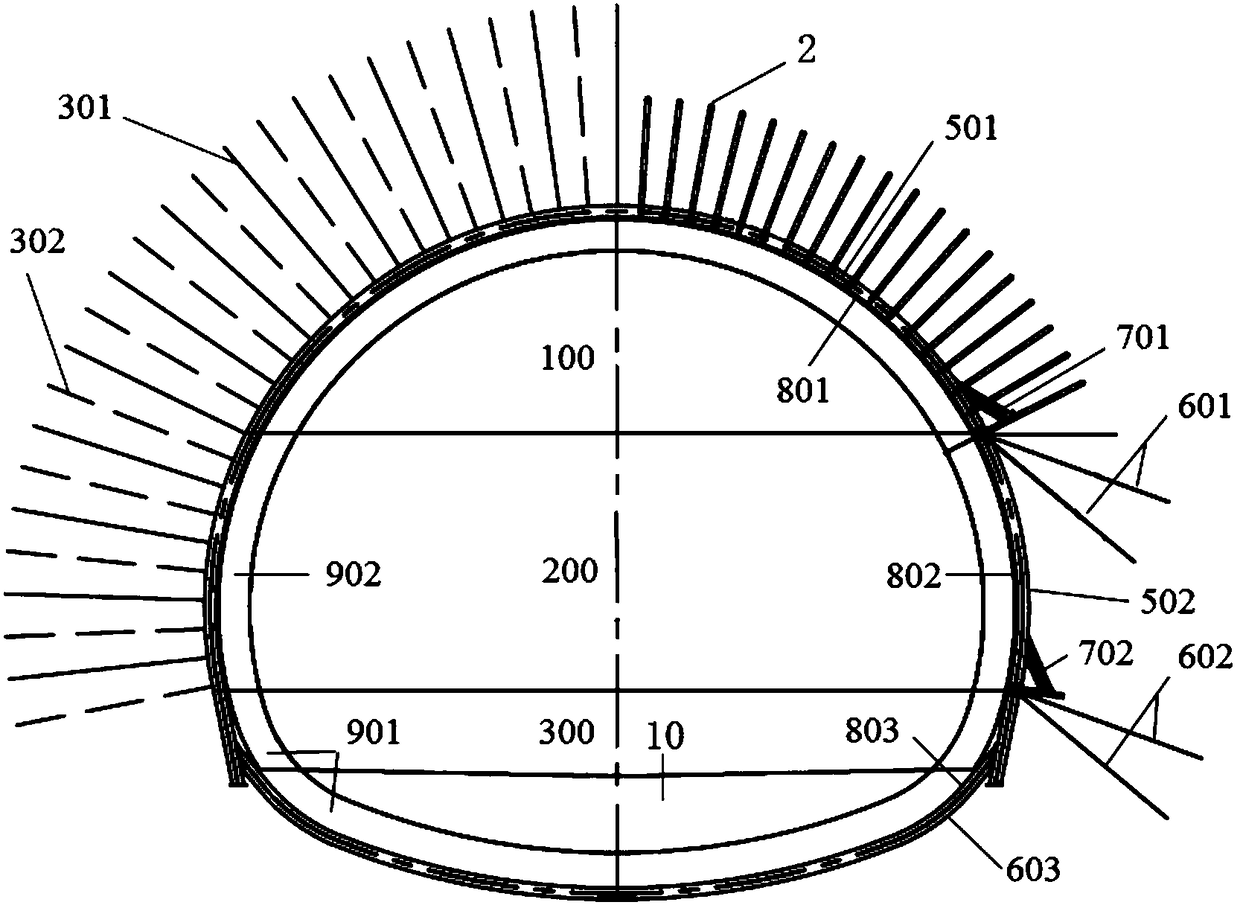

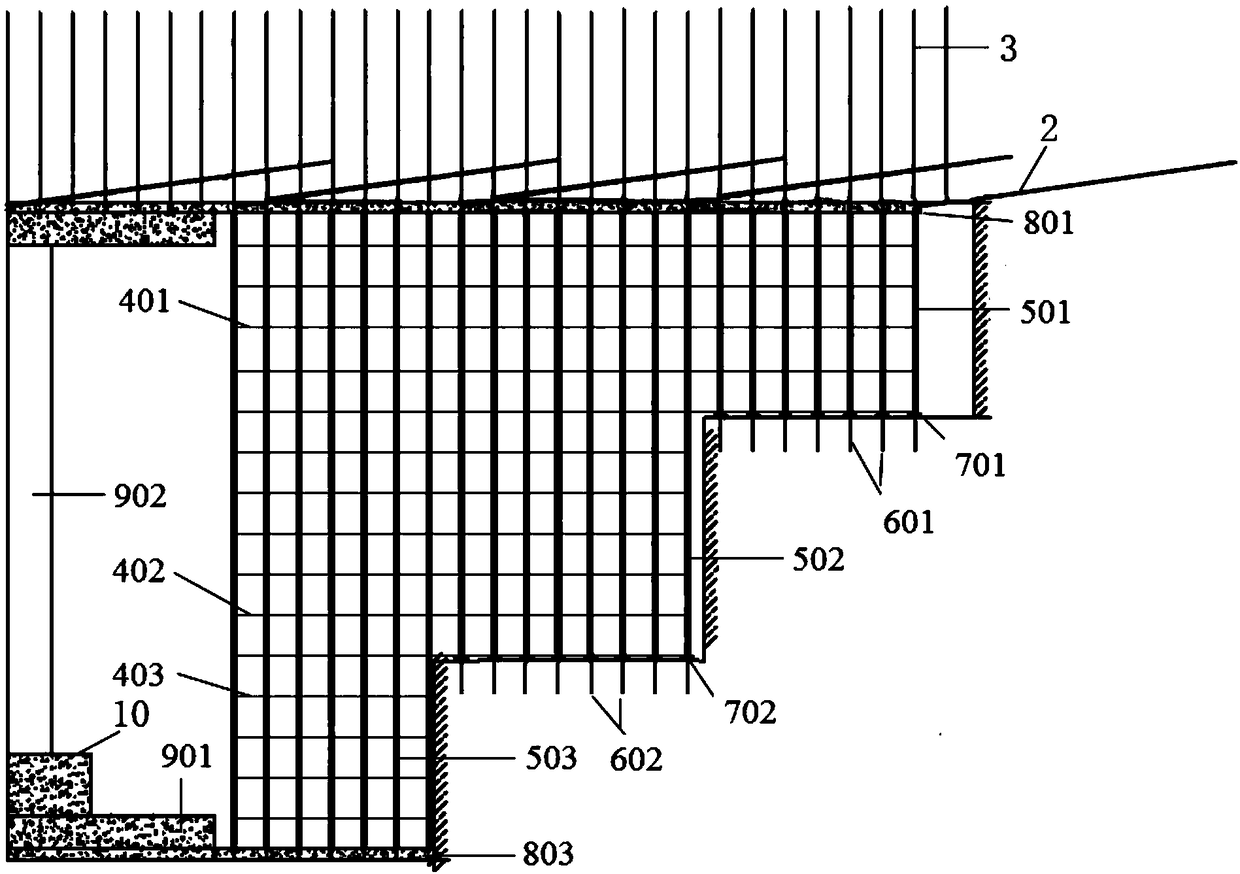

Joint steel frame supporting system for excavating auxiliary tunnel on main-tunnel arch wall and construction method of joint steel frame supporting system

ActiveCN103277118AActive connectionSettlement controlUnderground chambersTunnel liningSupporting systemArchitectural engineering

The invention relates to a joint steel frame supporting system for excavating an auxiliary tunnel on a main-tunnel arch wall and a construction method of the joint steel frame supporting system. The auxiliary tunnel of a single-arch large-span type underground-excavated station is required to be connected with the main-tunnel arch wall at a main-tunnel arch wall position. The higher is a cross section of the auxiliary tunnel, the larger is a span. The longer is a free face of a joint arch portion, the larger is excavating risk. Multiple lower straight-wall steel frames are vertically arranged on straight walls on two sides of a joint. The upper ends of the lower straight-wall steel frames are connected through arc-shaped steel frames, the arc-shaped steel frames close to a main tunnel incline to the main tunnel, and the arc-shaped steel frames are connected through perpendicularly-arranged horizontal connecting steel frames. Inclined arch portion arc-shaped steel frames adjacent to the main tunnel are connected with cut-off steel frames of the main tunnel through the perpendicularly-arranged horizontal connecting steel frames to form a firm supporting framework. The arc-shaped steel frames are utilized on a free section of a joint arch portion to realize effective connection between main tunnel steel frames and auxiliary joint steel frames, load of a main tunnel arch portion can be transmitted effectively, settlement of a tunnel vault can be controlled effectively, and construction risk for punching on the arch wall is reduced.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

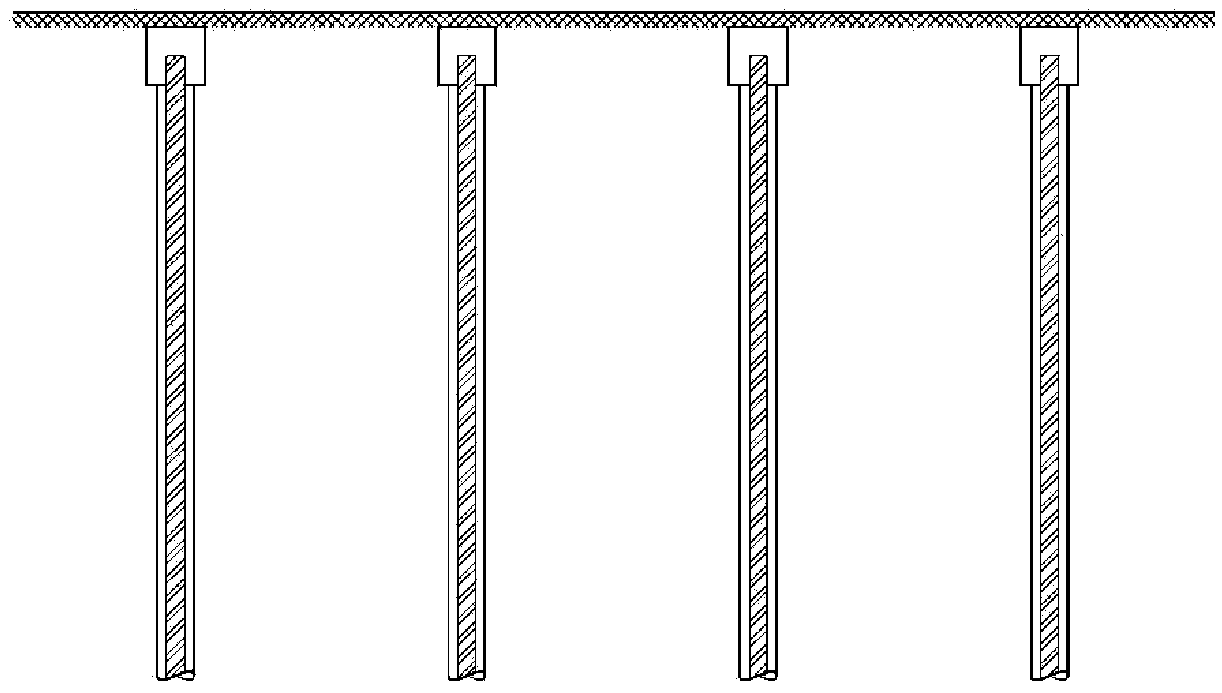

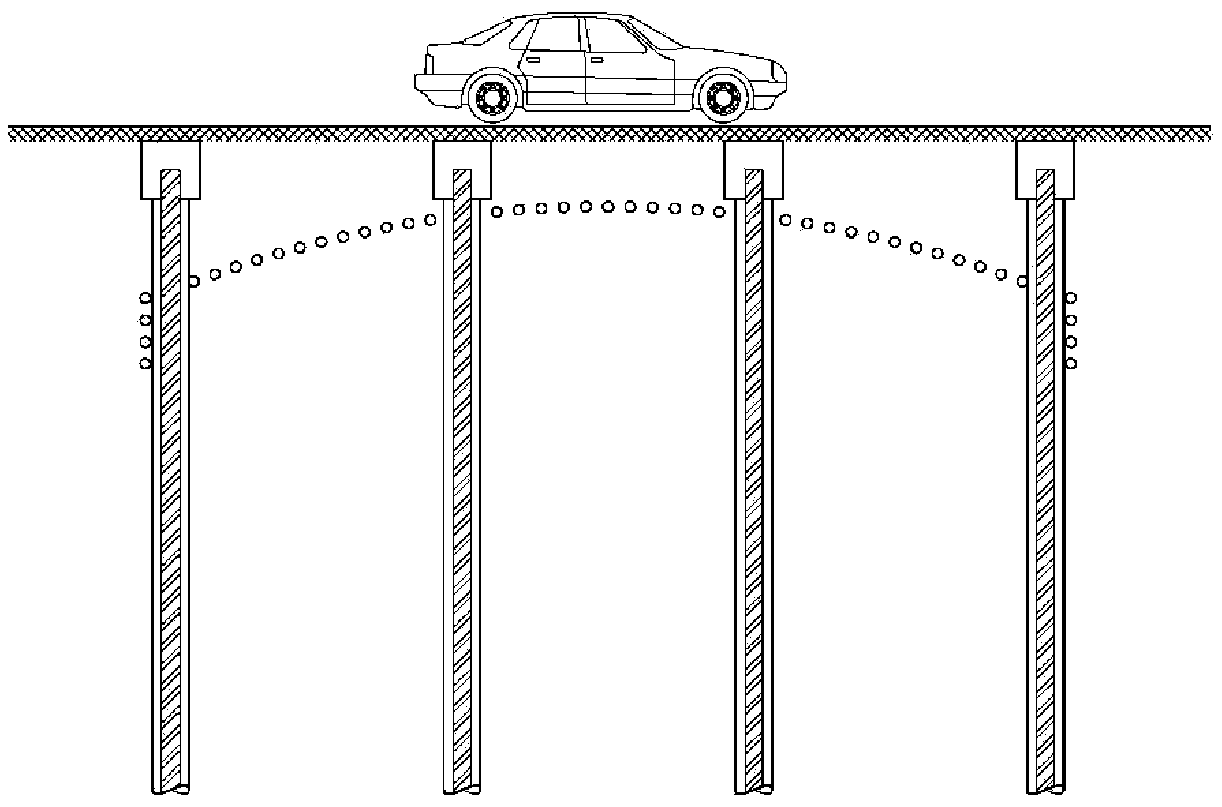

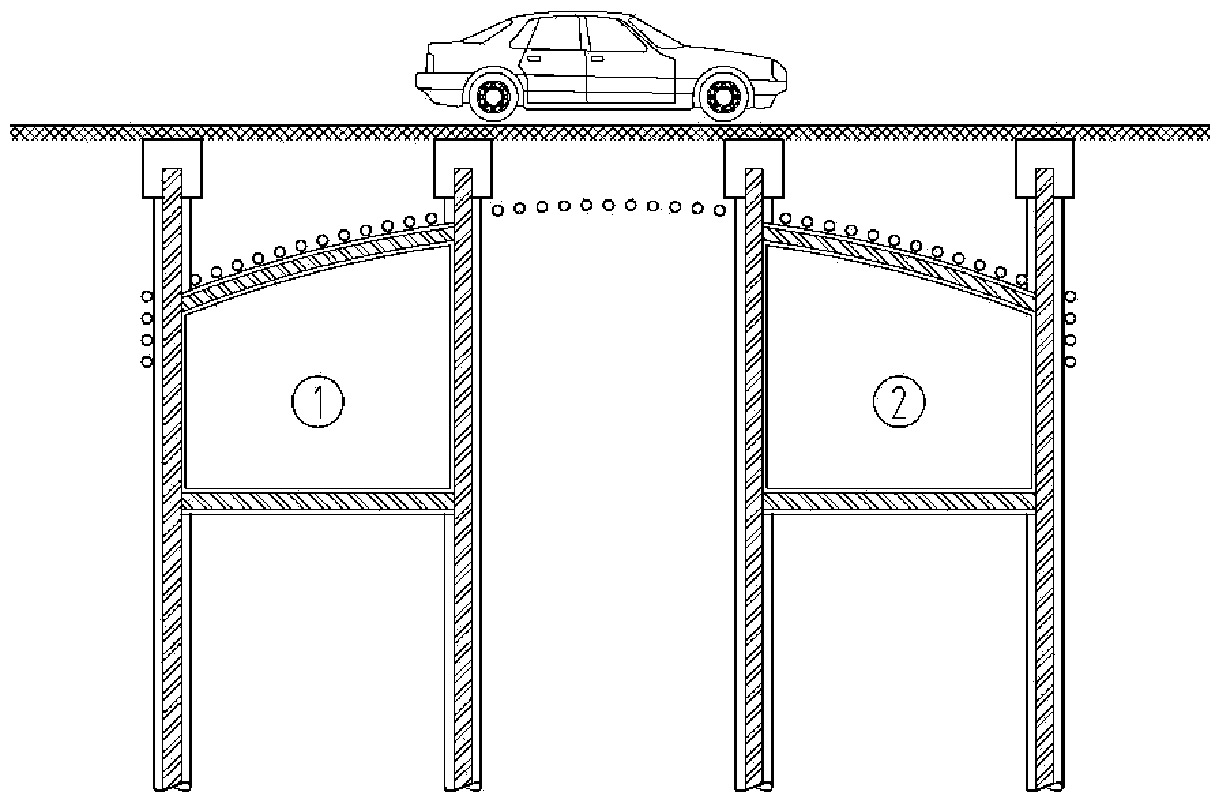

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

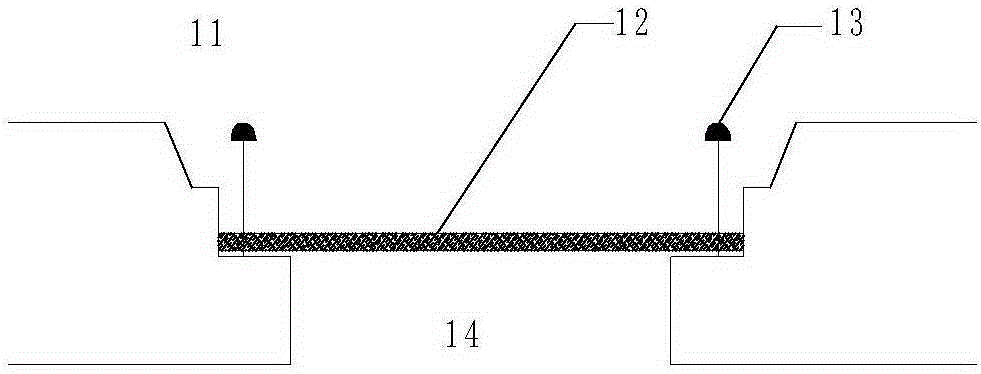

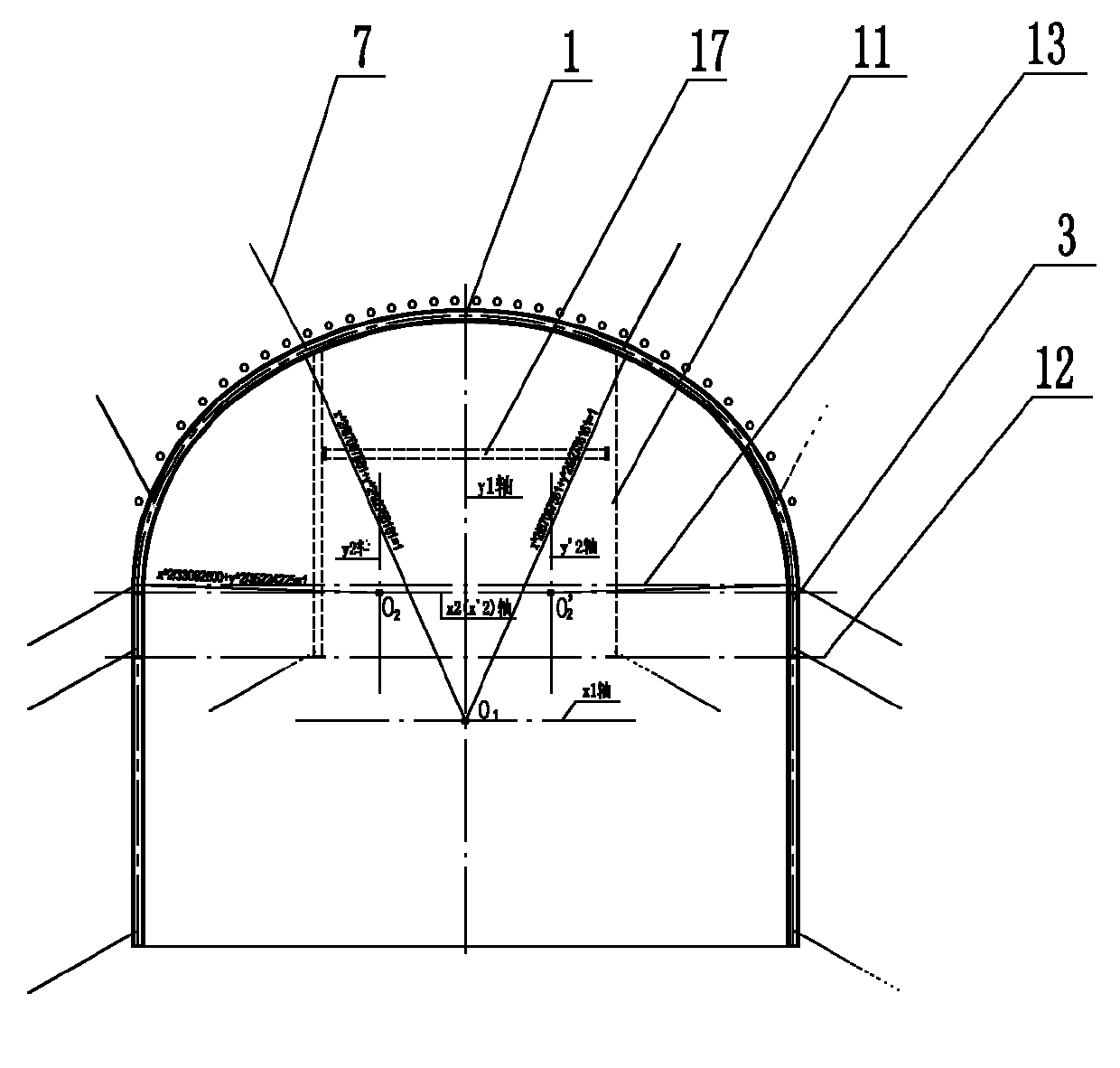

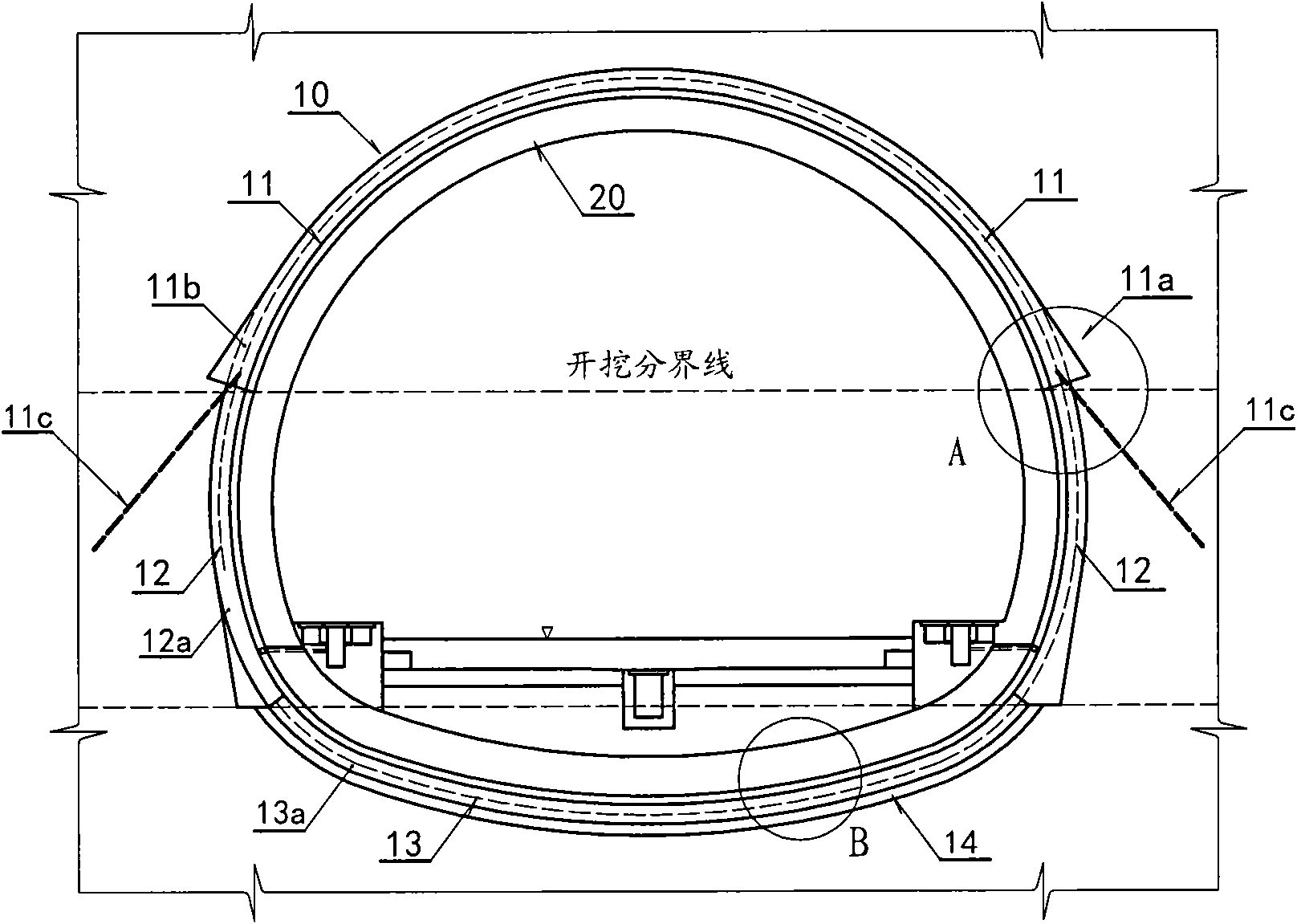

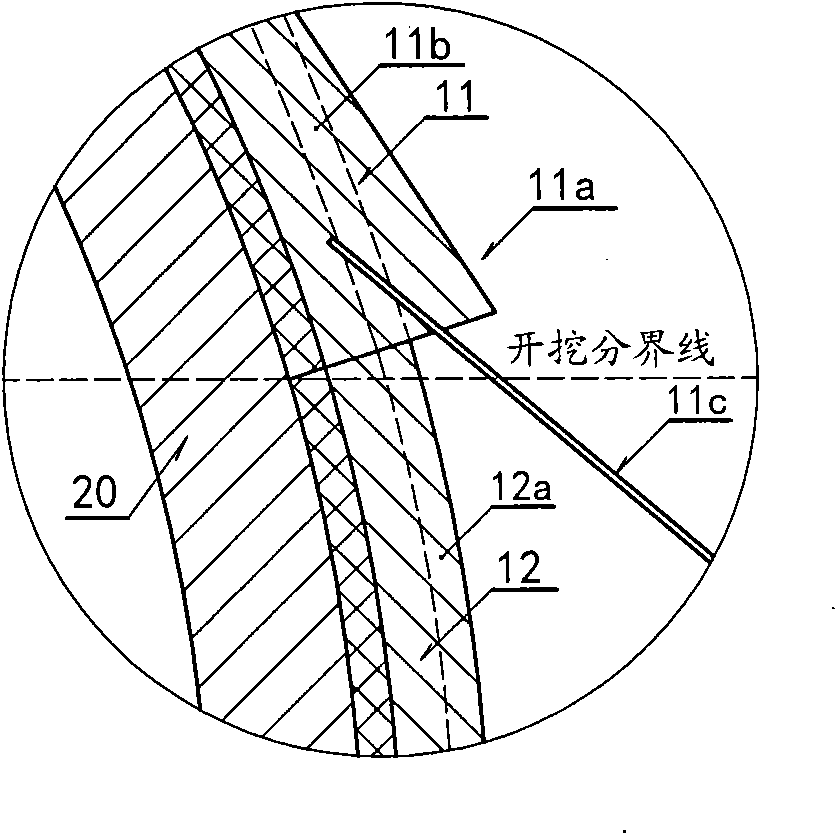

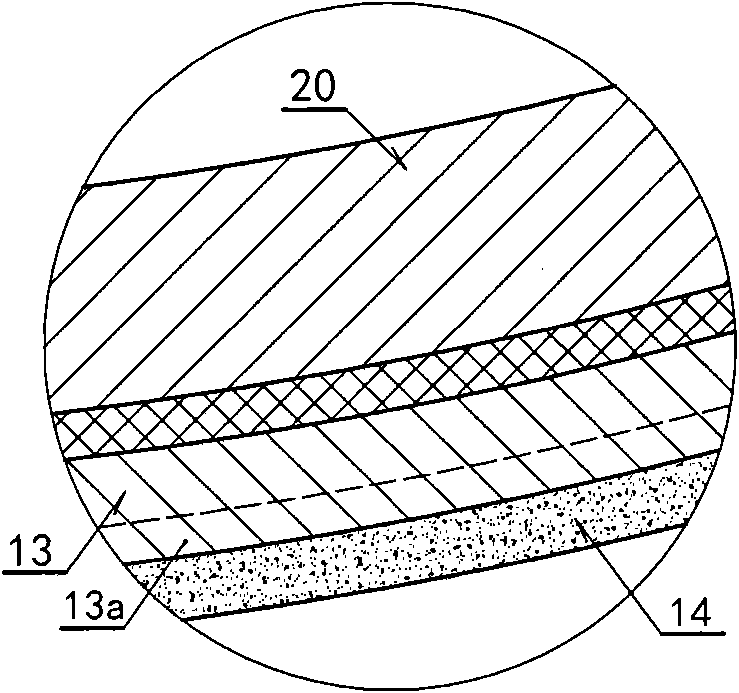

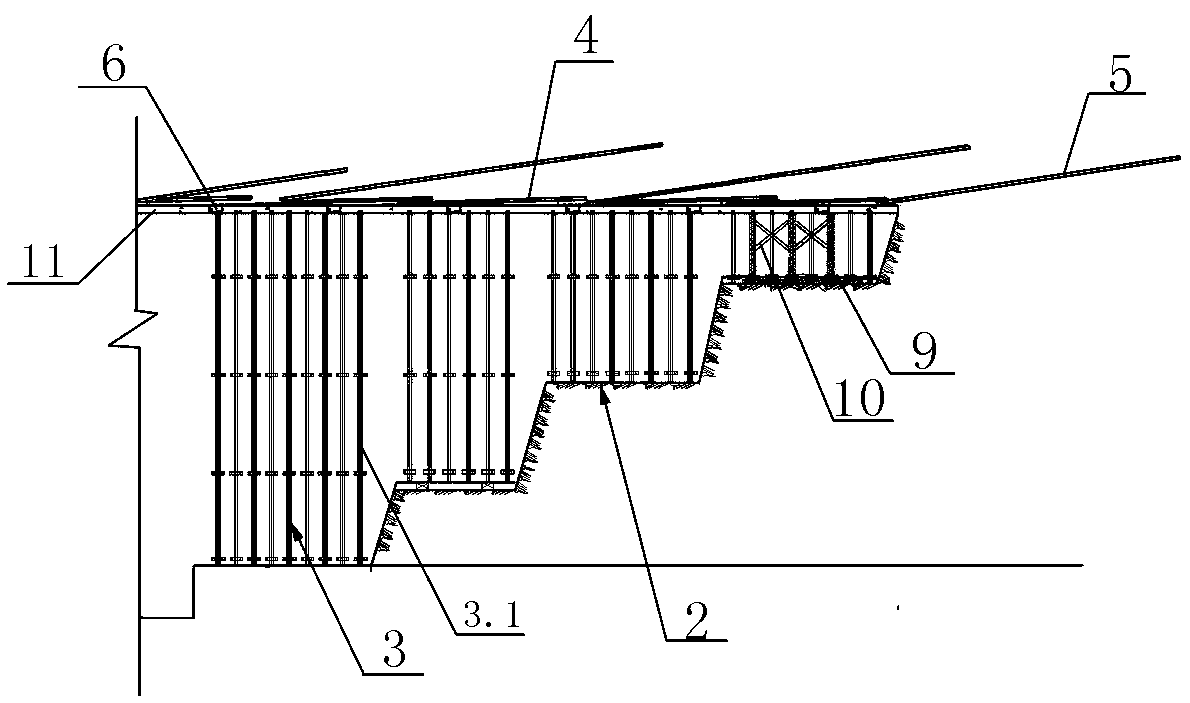

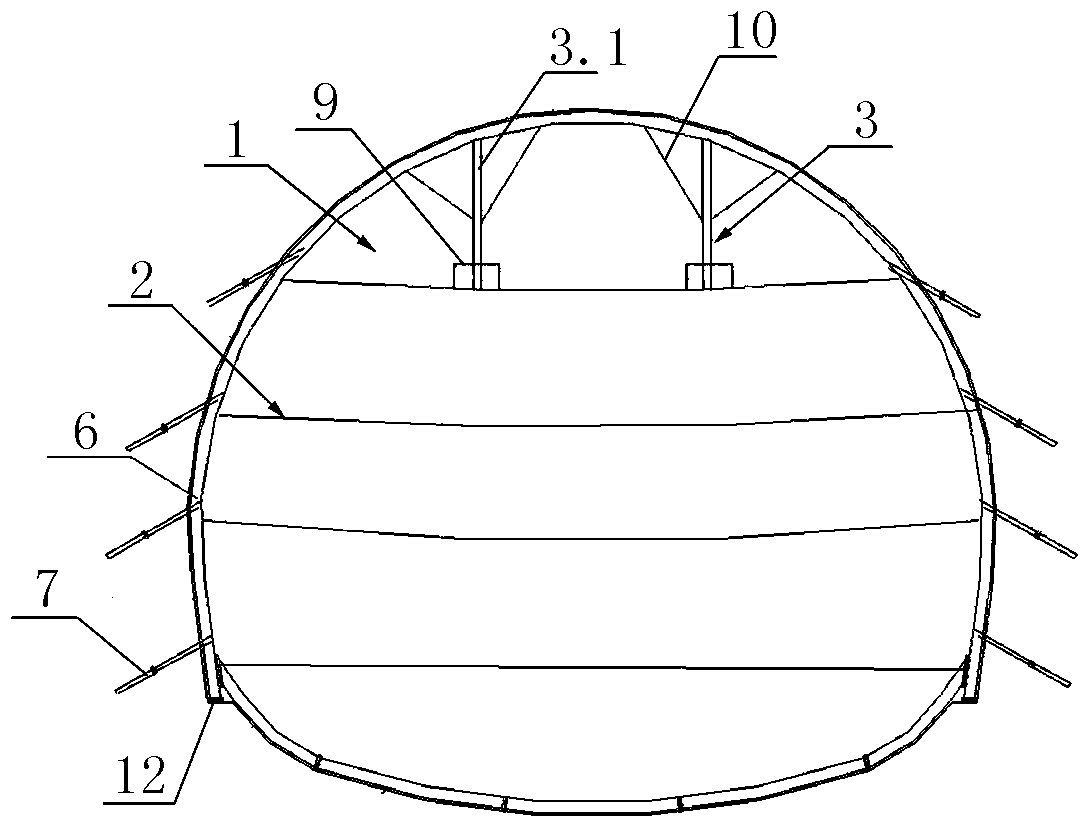

Lining structure for super large section water-rich loess tunnel of high-speed railroad

InactiveCN101598028ASettlement controlSolve technical problems in constructionUnderground chambersTunnel liningClerestoryLine structure

The invention discloses a lining structure for a super large section water-rich loess tunnel of a high-speed railroad, aiming at effectively controlling the post-construction sedimentation of a tunnel structure and maintaining long-term stability. The lining structure comprises an outer lining (10) and an inner lining (20), wherein, the outer lining (10) comprises an arch crown section (11), an archwall section (12) and an inverted arch section (13) which seal loess wall rock; and the arch springing part (11a) of the arch crown section (11) is transversely widened, an arch crown steel frame (11b) which is extended in a circumferential direction is embedded in the arch springing part (11a), and the arch crown steel frame (11b) is anchored on the loess wall rock by a locking anchor bar (11c). The invention has the advantages of solving the technical problems of the construction of the super large section water-rich loess tunnel under the condition of water-rich loess geology, and can effectively control the post-construction sedimentation of the tunnel structure and maintain long-term stability; proved by the field shock excitation test simulating the running of high-speed train, the accumulated sedimentation of the filling surface of the inverted arch in the tunnel is not higher than 0.5mm after the 20 years running of the high-speed train.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

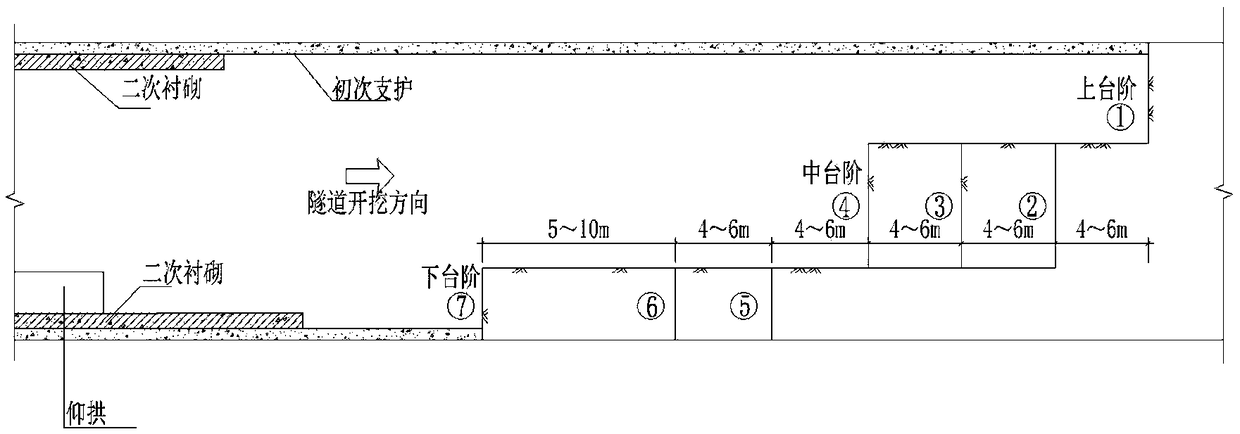

Construction method suitable for penetrating water supply pipe below tunnel in composite stratum with soft upper part and hard lower part

InactiveCN109372517ASmall deformation perturbationReduce disturbanceUnderground chambersBlastingStructure of the EarthSteel frame

The invention discloses a construction method suitable for penetrating a water supply pipe below a tunnel in a composite stratum with the soft upper part and the hard lower part, and belongs to the technical field of civil engineering. The construction method aims to strictly control tunnel arch settlement and prevent the situation that settlement overrun affects the water supply pipe to cause a structure (arch culvert) failure. By synthesizing the factors, the overall construction scheme is as follows: firstly, an advance support is constructed; after the design effect is achieved, the composite stratum with the soft upper part and the hard lower part is constructed through a three-step method, specifically, the upper step, namely the soft stratum is excavated through a mechanical method,the middle and lower steps, namely rock strata are excavated through a blasting method, and the circulation footage of a control area is one steel frame interval; manual work cooperates with mechanical excavation as far as possible, timely closure for ring forming is achieved, and arch sinking is inhibited; a secondary lining closely follows the excavation surface, and one-time pouring forming isachieved through a formwork trolley arch wall; and hole interior and ground surface settlement monitoring of the control area, as well as vibration speed monitoring within the blasting impact range are strengthened, and information is fed back in time to guide the design and construction.

Owner:BEIJING JIAOTONG UNIV +2

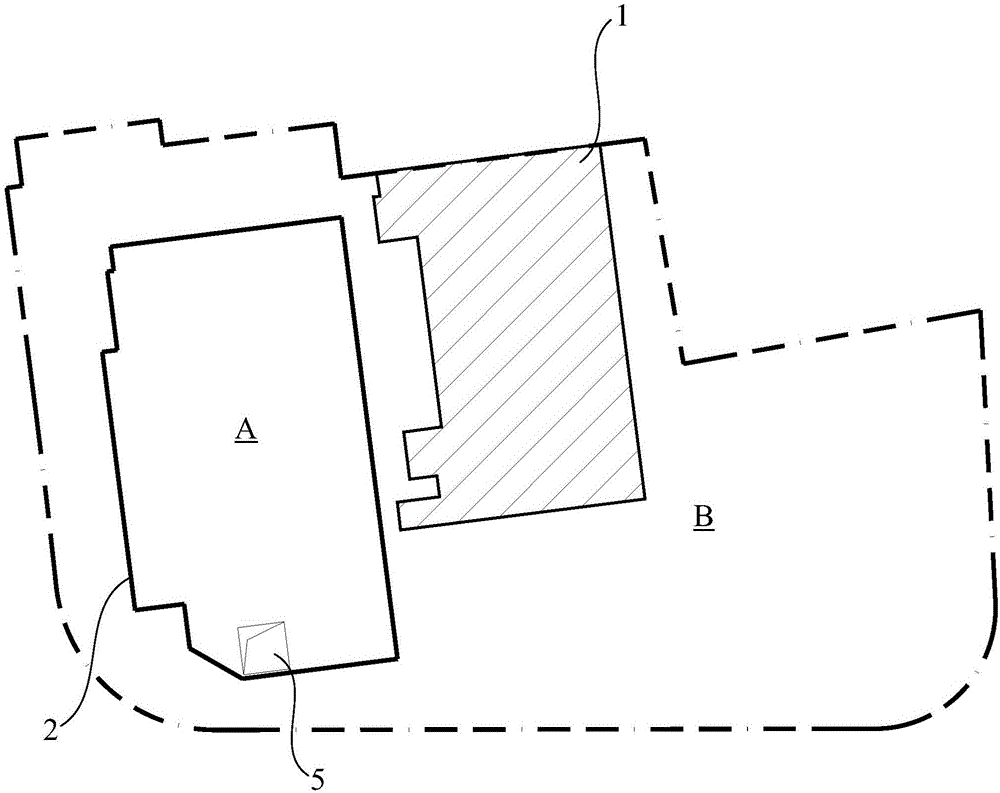

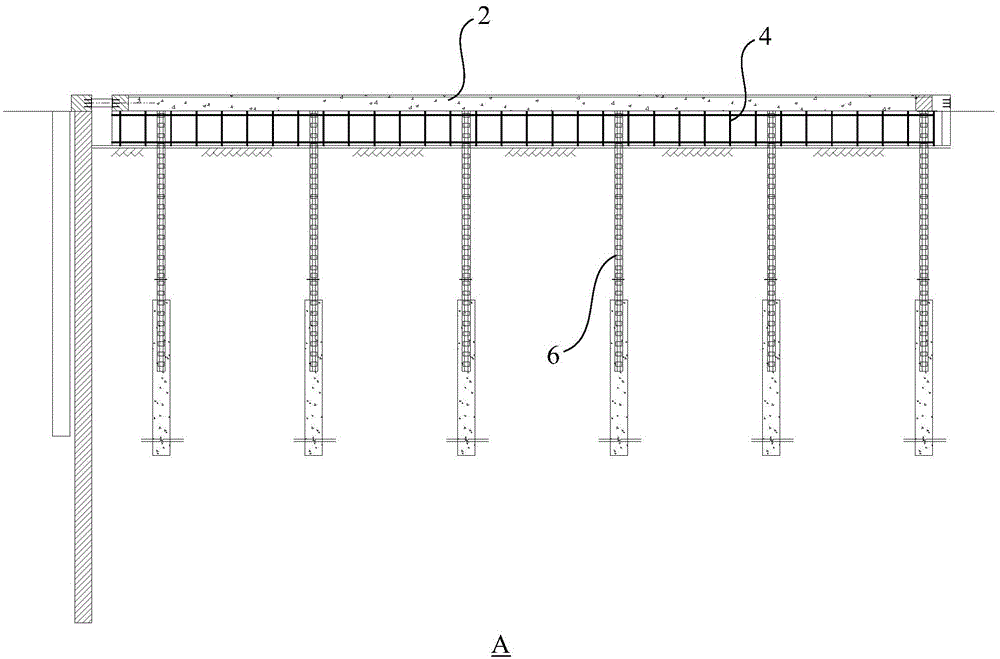

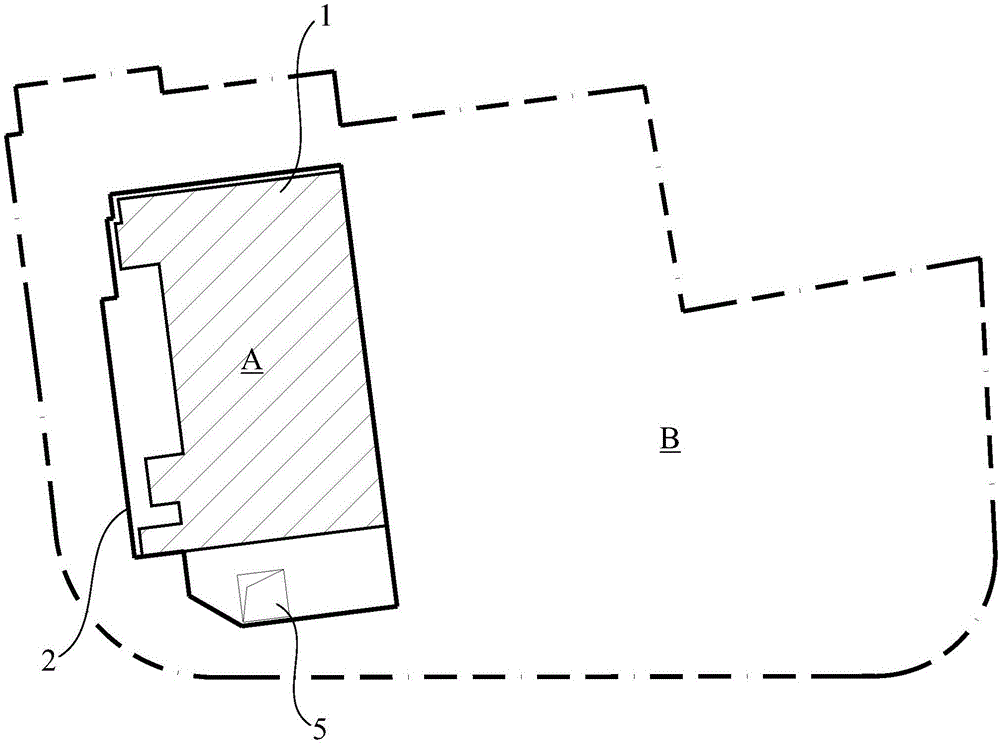

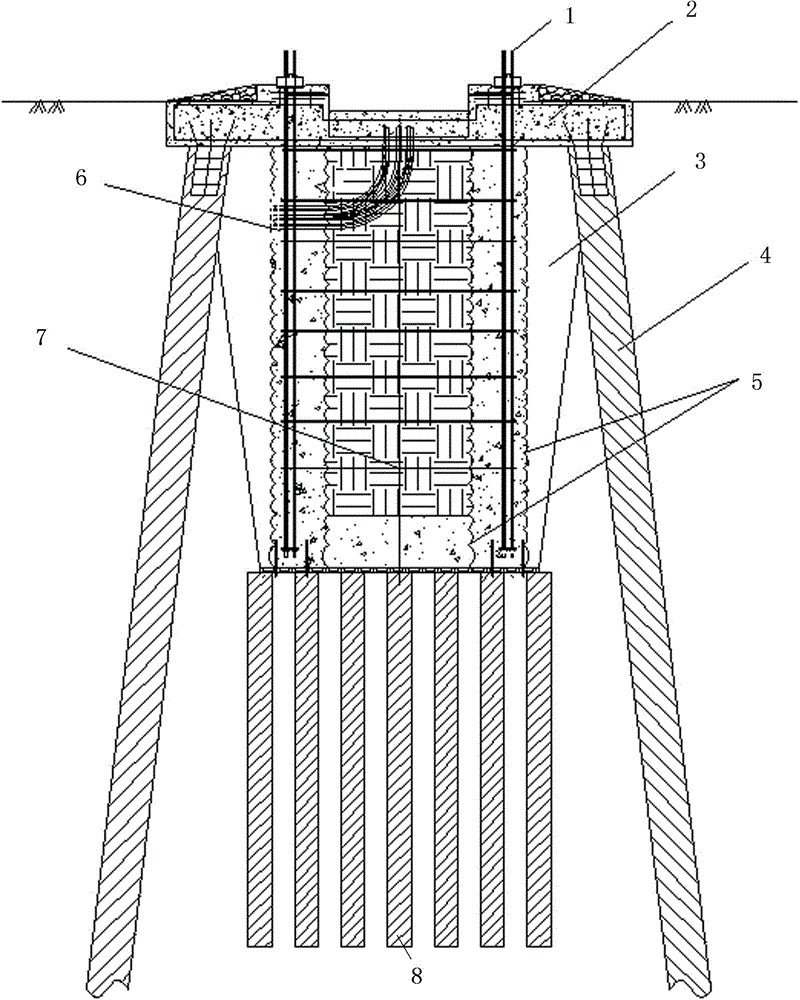

Construction method for newly-built large deep foundation pit basements under protection building

The invention provides a construction method for newly-built large deep foundation pit basements under a protection building. According to the construction method, on the premise that the protection building is not disassembled, within a limited foundation range, a mature building translation technology and a reverse foundation pit construction method are combined, and overall construction of the first-region and second-region basements is directly performed after the protection building and a top plate of the first-region basement are connected in an anti-seismic butt joint mode. On the basis of guaranteeing structural stability of the protection building, construction working conditions and construction steps of the basements are reduced, the construction period is shortened, safety and stability of the protection building are improved, overall construction quality and efficiency are improved, ambient environment is effectively controlled, the number of dividing strips between first and second regions is reduced, and time benefits, space benefits and stable benefits are maximized.

Owner:SHANGHAI YUBANG CONSTR ENG CO LTD

Pressure reducing horizontal reinforcing process for soft soil layer

A horizontal reinforcing technology for decreasing the pressure to soft earth stratum includes such steps as construction preparation, horizontal drilling, and horizontally spinning and spraying the hardening grout for reinforcing the soft earth stratum. The drilling rod is swung by 180 deg. for cutting earth while the hardening grout and compressed air are sprayed out via respective nozzles. The high-pressure water is sprayed out at same time for draining the sludge in time.

Owner:SHANGHAI FOUND ENG GRP

Fan pile pier foundation and construction method thereof

The invention relates to a fan pile pier foundation and a construction method thereof, and discloses a fan pile pier foundation, which comprises a center pier foundation. The fan pile pier foundation is characterized in that an anchor rod pile is arranged at the bottom part of the center pier foundation, 8-12 inclined piles are arranged around the center pier foundation, a concrete pile cap is arranged at the top part of the center pier foundation, a reinforced bar at the top part of each inclined pile is connected with a reinforced bar of the concrete pile cap, the concrete pile cap is cast together with the inclined piles, and a prestressed anchor rod is arranged in the center pier foundation. The fan pile pier foundation has the advantages that the problems of insufficient bearing capacity and loess collapsibility of soft soil are solved; at the premise of meeting the domestic standard requirements, the material is saved, the construction period is shortened, the whole safety, stability and settling control property are sufficiently guaranteed, and the higher practicality is realized for the ground foundation reinforcing and foundation design of wind power generators in eastern coastal areas and northwestern collapsibility loess areas of China.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Supporting system of water-rich drifting sand stratum full-weathering surrounding rock tunnel and construction method

InactiveCN110541721ASettlement controlEnsure stability and securityUnderground chambersDrainageSupporting systemStructure of the Earth

The invention discloses a supporting system of a water-rich drifting sand stratum full-weathering surrounding rock tunnel and a construction method. At least four layers of steps are arranged in a tunnel. Steel row frame supports are arranged between the steps and the top of the tunnel. An advanced small guide pipe and an advanced pipe shed are arranged at the top of the tunnel. A group of steel arch frames are arranged in the tunnel and are arranged at intervals in the longitudinal direction. The shapes of the steel arch frames are matched with the shape of the section of the tunnel. Pipe shed lock feet are arranged on the two sides of each layer of steps and on the steel arch frames respectively. Steel bar mesh pieces are laid and hung on the portions, between adjacent steel arch frames,of the inner lateral side of the tunnel. Concrete layers fully sprayed on the outer sides of the steel arch frames and the steel bar mesh pieces. Bar-shaped foundations are arranged on the positions,corresponding to the steel row frame supports, of the horizontal planes of the steps. Inclined supports are arranged between the steel row frame supports and the steel arch frames. The supporting system of the water-rich drifting sand stratum full-weathering surrounding rock tunnel and the construction method solve the technical problems that a traditional construction method easily causes settlement of an integral initial support structure, the construction space is small, steel frame arch foot pipe shed locking feet cannot be reinforced, the risk of median septum dismantling is large, the working procedures are complex and the construction speed is low.

Owner:中国建筑土木建设有限公司

Micro disturbance tunneling method used for shield machine to tunnel under building on rich water weak formation

InactiveCN103527209ASettlement controlEffective control of settlementTunnelsGround layerShield machine

The invention discloses a micro disturbance tunneling method used for a shield machine to tunnel under a building on a rich water weak formation, and belongs to the technical field of shield machine tunneling engineering. The method includes the steps of (1) selecting a shield machine cutter head suitable for the rich water weak formation, (2) inspecting work performance of the shield machine before the shield machine crosses the building, (3) carrying out muck improvement according to different soil layers, (4) setting soil pressure according to the upheaval degree in front of the cutter head, (5) setting tunneling speed according to the different soil layers, (6) determining synchronous grouting amount and secondary compensation grouting amount, pressure and grouting time, and (7) arranging and monitoring observation points when the shield machine tunnels under the building. When the shield machine tunnels under the building, the preceding processes are strictly carried out, micro disturbance caused by shield machine tunneling for the building is achieved, the settlement value of the building can be controlled to range from 3mm to negative 10mm, influences are hardly caused for the building, and safety of the building above the shield tunnel is guaranteed.

Owner:BEIJING JIAOTONG UNIV

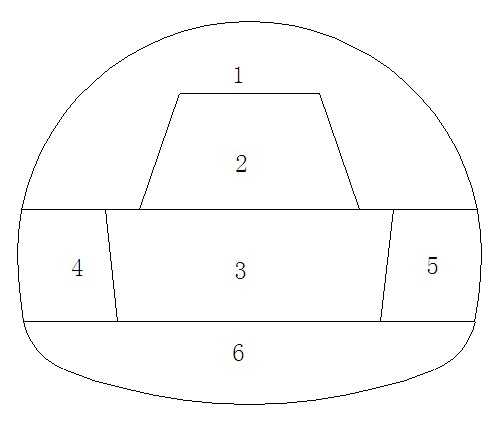

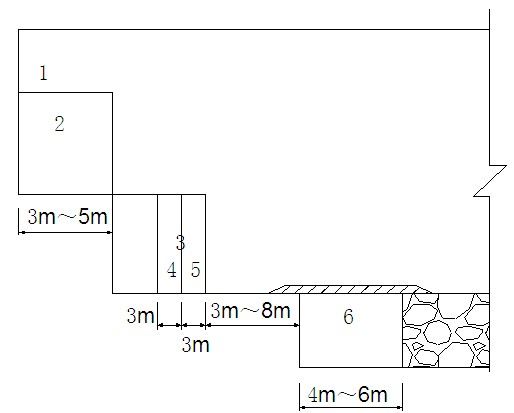

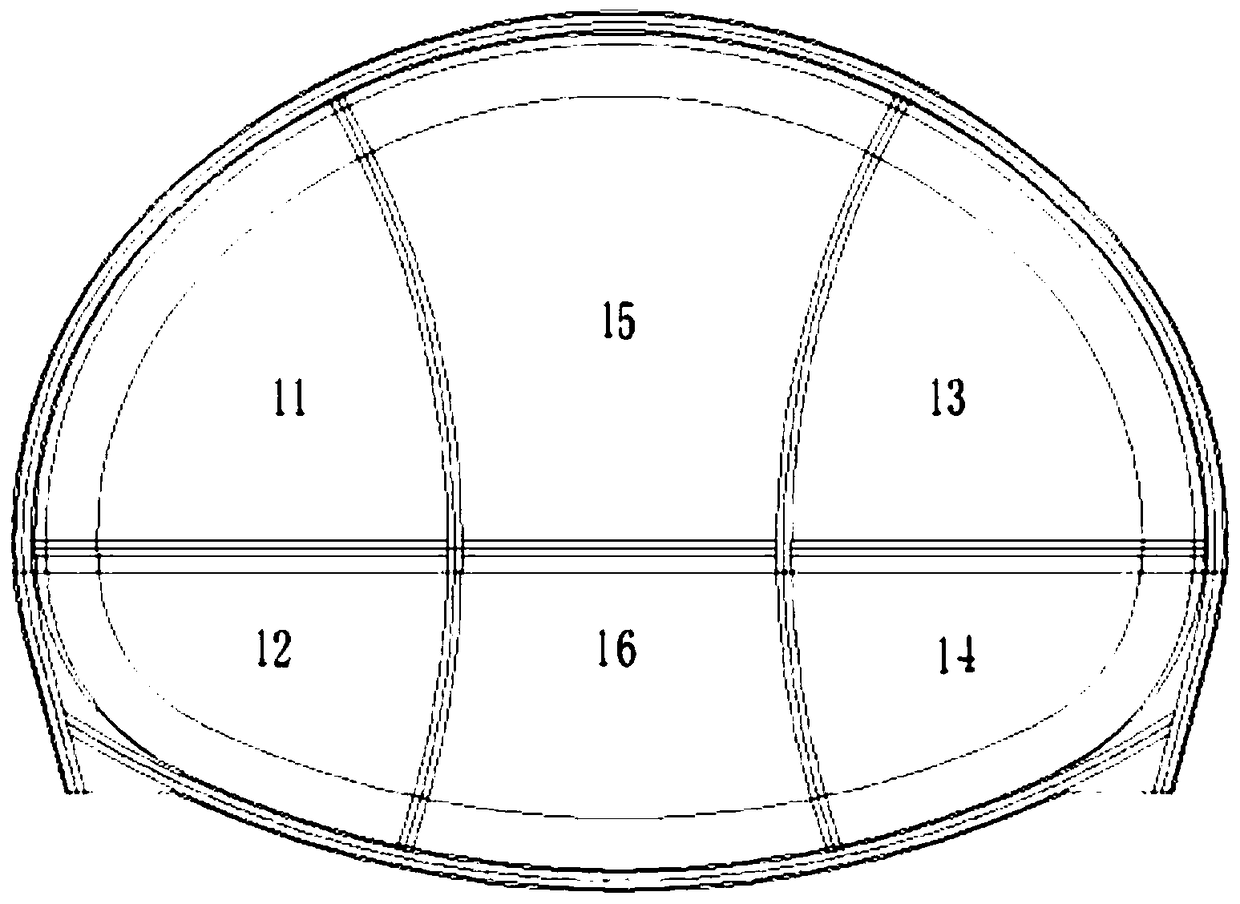

Large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports

PendingCN108278115AConstruction safetyLarge amount of workUnderground chambersTunnel liningDeformation controlFoot type

The invention discloses a large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports. Short pipe sheds are constructed through a hole interior non-work-room pipe shed construction technology to reinforce and support surrounding rock in front of a tunnel face in advance; large arch feet are arranged at bases all stages of steps; and under dual controlmeasures, the tunnel cross section is sequentially excavated by three steps, according to the specific processes, firstly, short pipe shed advance supports are constructed within a certain range alongan arch part of a tunnel, the upper, middle and lower steps are sequentially excavated with alternate distances, after excavation of each step, the primary supports are constructed instantly, footings of the primary supports are designed to of a large-arch-foot type, and when the lower step is away from a secondary lining of a former cycle by the tunnel diameter, an inverted arch, side walls, a filled layer and a secondary lining are constructed. The problem that under the condition of the shallow-buried weak surrounding rock, deformation control over the tunnel is difficult is solved, and meanwhile the disadvantages that under the same condition, a traditional construction method is many in subsection, numerous in working procedure, slow in construction, many in temporary support and thelike are further overcome.

Owner:CENT SOUTH UNIV

Full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike

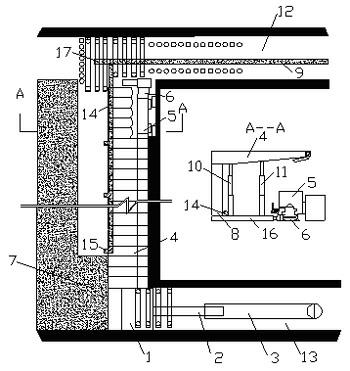

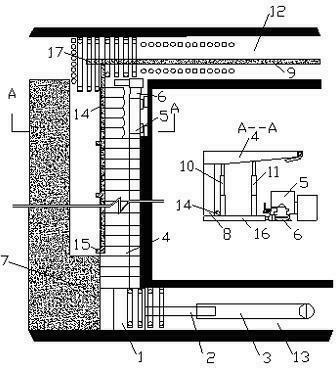

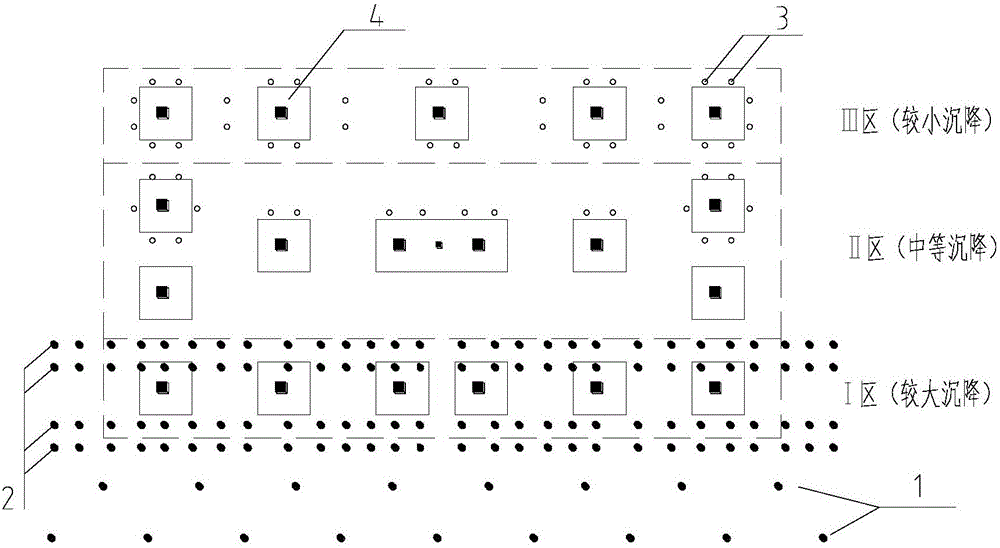

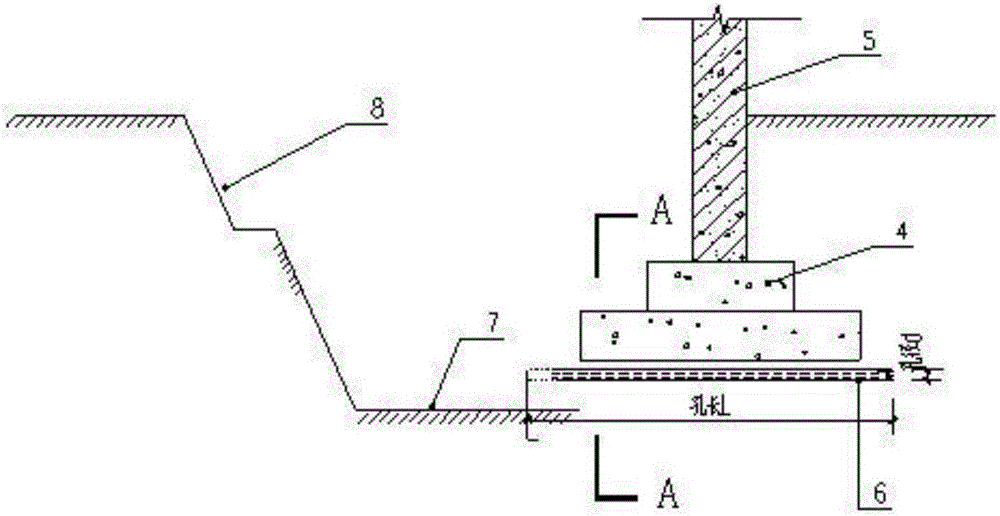

InactiveCN106968708ASettlement controlReduce distortionUnderground miningSurface miningLithologyMining engineering

The invention discloses a full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike. According to the principle, the method includes the steps that after a steeply inclined coal seam field is divided into mining areas, a long-wall fully mechanized coal mining face is arranged along the coal seam strike, and after advancing in the coal mining face, a goaf is subjected to sublevel filling along the coal seam strike. According to the rock mechanics principle and the lithology of overlying rock of the coal mining face, the dimensions D and strength of sublevel filling bodies and the limited span L of sublevel filling are determined under the condition that the upper roof of the overlying rock is not broken. A filling-body filling area is divided into inclined sealing filling areas by sublevel small coal pillars and rectangular air bags, and paste filling is conducted in the sealing areas through pipelines. By means of the method, the filling amount can be reduced, the filling cost is lowered, the resource recovery rate is increased, and the safe, environmental-friendly and economical coal mining effects are achieved.

Owner:HUNAN UNIV OF SCI & TECH

Inclination rectification and reinforcement method for existing building

InactiveCN106320403AReduce disturbancePrevent excessive rectificationFoundation engineeringStructural engineeringEngineering

The invention discloses an inclination rectification and reinforcement method for an existing building. The method specifically comprises the following steps: firstly, drilling vertical small holes in a relatively large depression area, grouting and reinforcing; secondly, vertically drilling in a medium depression area and a relatively small depression area and taking out soil from a deep layer to perform inclination rectification; thirdly, forming grooves by excavating the sides of base bearing platforms of the medium depression area and the relatively small depression area, horizontally drawing out soil to perform inclination rectification in the base of the bottom of each base bearing platform; fourthly, downwards drilling each base bearing platform to form a small hole until the small hole reaches a rock stratum, arranging an H-shaped steel or small steel reinforcement cage in the hole, and grouting the hole; finally reinforcing the base by adopting an overall plate. The method disclosed by the invention is capable of reasonably and effectively controlling settlement and inclination degree of a house and preventing excessive inclination rectification caused by drilling and soil picking during the inclination rectification process.

Owner:WUHAN UNIV OF TECH

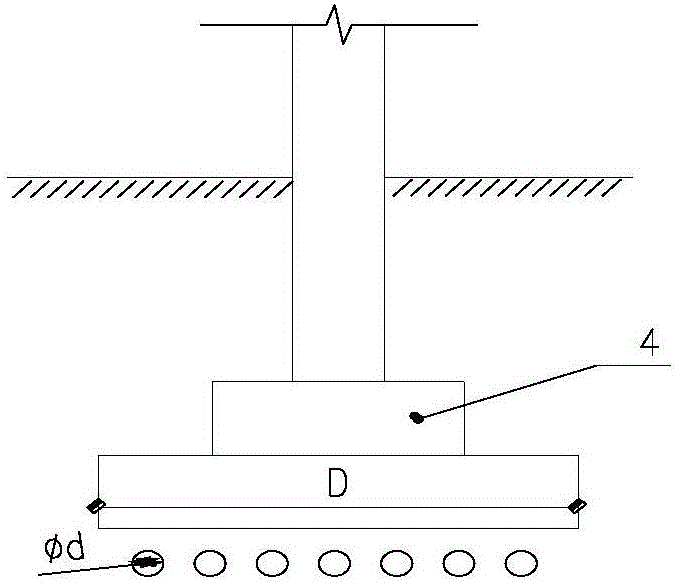

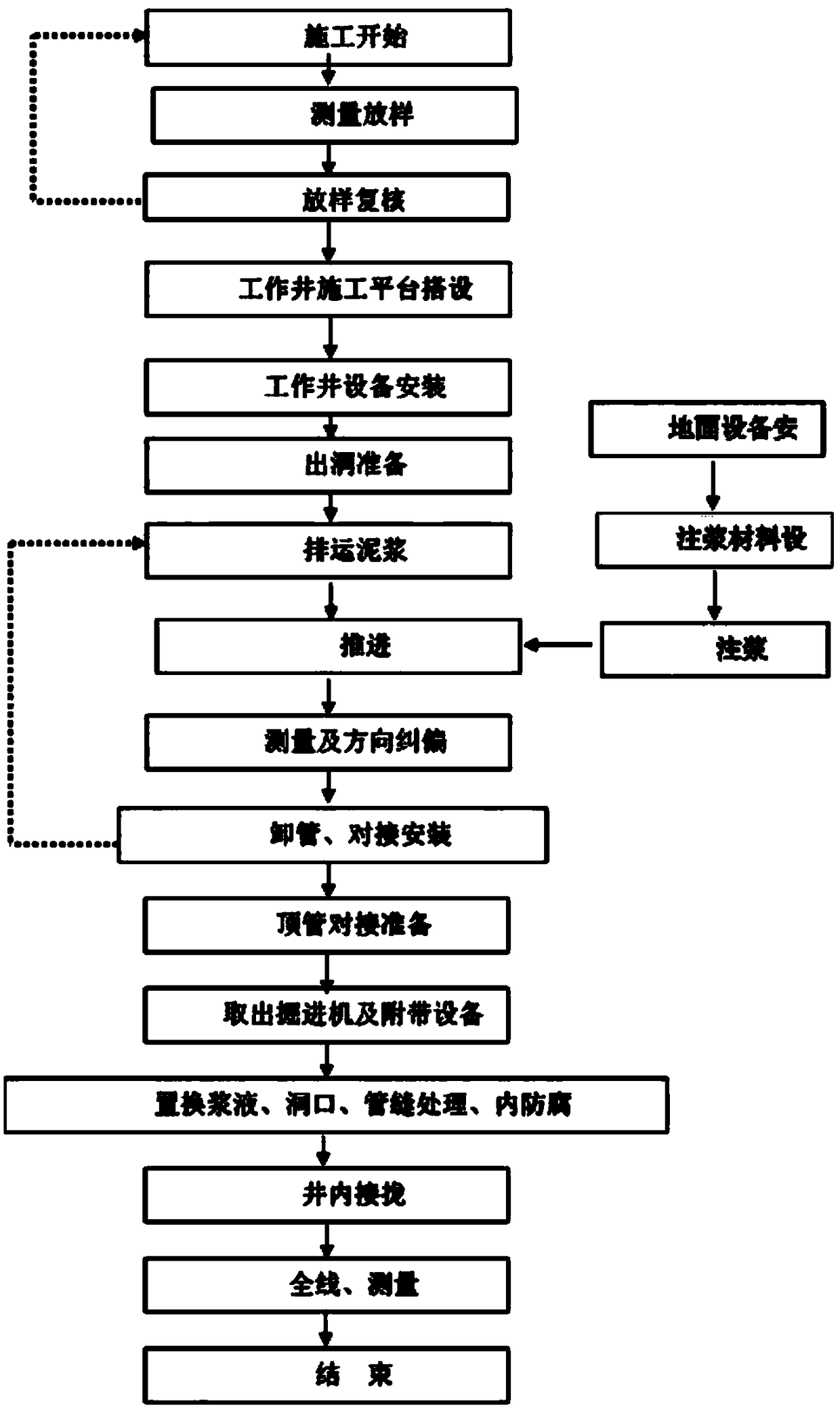

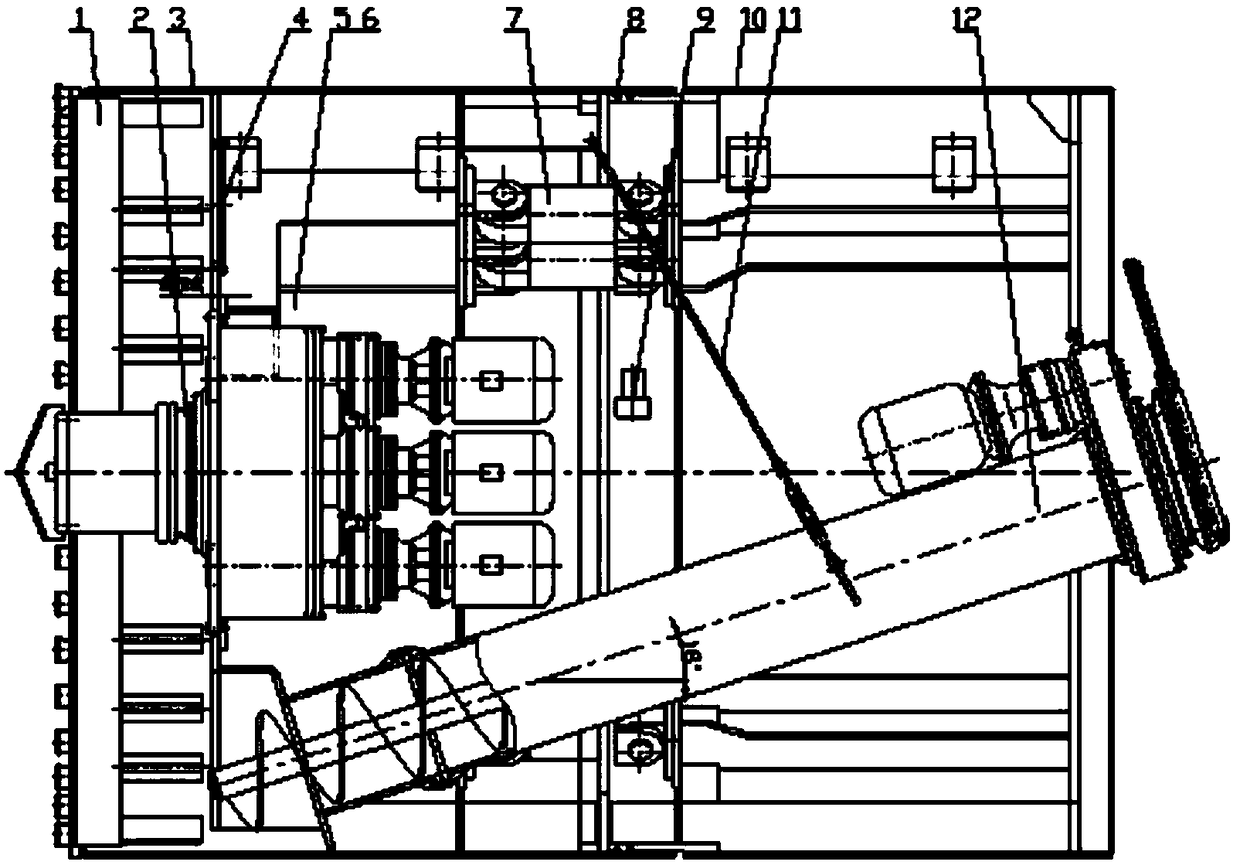

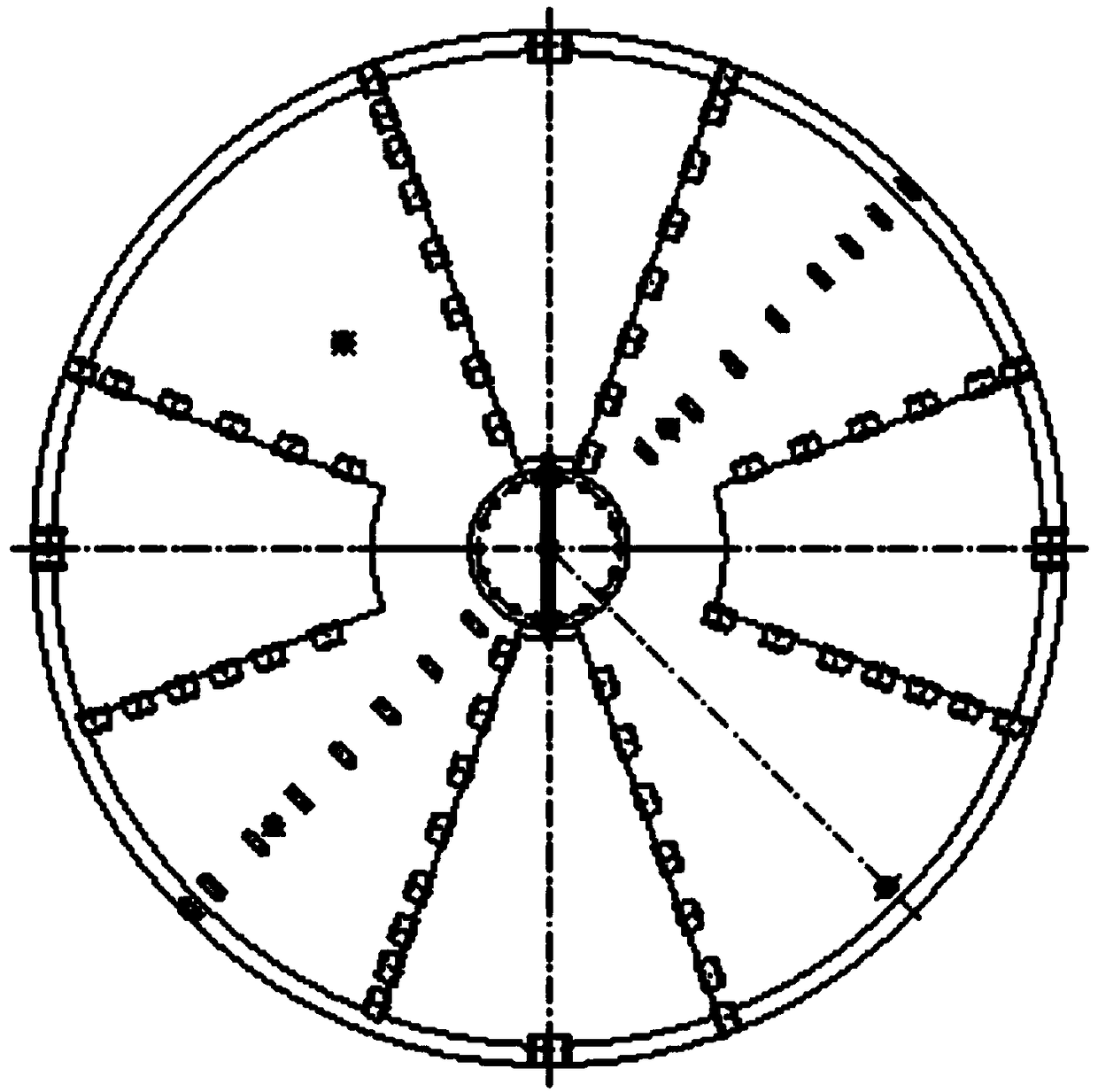

Pipe jacking construction method in complex terrain environment

InactiveCN109372532AReduce disturbanceReduce extrusion stressBuilding constructionsOrganic fertilisersTerrainEarth pressure balance

The invention discloses a pipe jacking construction method in a complex terrain environment. A panel type 3.5m large cutter head earth pressure balance pipe jacking heading machine is adopted; cut soil enters a muddy water cabin from gaps of a main cutting edge; soil in the muddy water cabin is broken into mud under the joint action of a stirring bar behind a cutter head and muddy water; and the water and earth pressure of excavation surfaces is balanced by controlling the mud and water pressure and the mud weight of the muddy water cabin, so that the excavation surfaces are always in a stablestate. As for sections with poor soil quality and a large buried depth of pipelines, or sections located in a prosperous region with buildings (structures) or traffic trunks above and strict restrictions on displacement and groundwater by surrounding environments, the large-diameter earth pressure balance pipe jacking method is easy and safety in construction, high in quality, low in investment and short in construction period, extrusion of surrounding pipelines and settlement of the ground are effectively controlled, and smooth operation of ground transportation is ensured while important underground pipelines are protected during construction.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

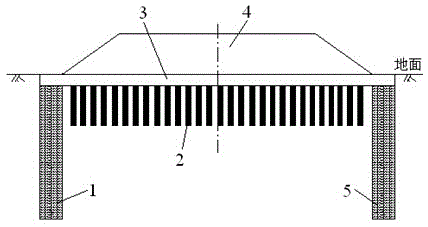

Construction method of shallow-buried large-span tunnels

InactiveCN105370288AThe pile forming process is matureQuality improvementUnderground chambersTunnel liningRoad surfaceUltimate tensile strength

The invention discloses a construction method of shallow-buried large-span tunnels. The method comprises the following steps: (1) building vertical piles on the ground by using the shallow-buried characteristics of the tunnels, putting the pile bottoms in a stable force-keeping layer below the bottoms of the tunnel arches to be built, namely reserving vertical support piles in advance in the peripheries and the lands of the tunnels to be built before carrying out underground excavation construction of the tunnels; (2) carrying out partial excavation during underground excavation construction, and connecting transverse supports of initial bracing structures to the preset vertical support piles; and (3) completing a process of pouring secondary linings under the condition that the initial vertical temporary supports are not removed; and removing the vertical temporary supports in the structures after the secondary linings form the strength and completing structure construction. Through the construction method of the shallow-buried large-span tunnels, the technical problems of the construction safety risk during pouring the secondary linings and the sedimentation control of the poured road surface can be solved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

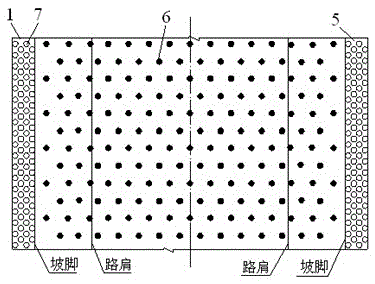

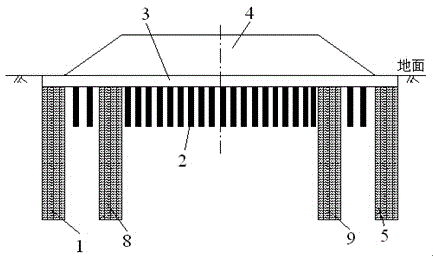

Novel long and short pile foundation treatment structure of collapsible loess area and construction method

ActiveCN105464068AEliminate collapsibilityImprove the bearing capacity of the foundationSoil preservationQuincunxSubgrade

The invention relates to a novel long and short pile foundation treatment structure of a collapsible loess area and a construction method. The structure comprises two rows of waterproof curtains and a plurality of rows of reinforcing row piles between the waterproof curtains. The interior of each of the two rows of waterproof curtains and one slope toe of a roadbed are located in the same vertical plane. Each waterproof curtain is composed of four rows of compact long piles, wherein every three adjacent compact long piles are located at the three vertexes of an equilateral triangle respectively. The reinforcing row piles are composed of a plurality of compact short piles, and the compact short piles are arranged in a quincunx shape. The waterproof curtains and the reinforcing row piles are covered with a waterproof cushion layer. A soil sample is subjected to indoor soil testing, and the height of the roadbed is determined; leveling, surveying and setting out are carried out; and the waterproof curtains and the reinforcing row piles are built on the outer sides of the slope toes of the roadbed according to the existing construction technology, the waterproof cushion layer is built on the waterproof curtains and the reinforcing row piles, and construction of the foundation treatment structure is completed. The foundation treatment structure is used in highway and railway projects of the collapsible loess area, the requirements of the projects of the roadbed for the bearing capacity and deformation of the foundation are met, the construction period is shortened, the project cost is reduced, and line operation safety is guaranteed.

Owner:NORTHWEST RES INST CO LTD OF C R E C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com