Supporting system of water-rich drifting sand stratum full-weathering surrounding rock tunnel and construction method

A fully weathered, tunnel-based technology, applied in tunnels, tunnel linings, drainage, etc., can solve problems such as the inability to strengthen steel frame arch feet, pipe shed lock feet, high risk of partitions during demolition, and settlement of the overall initial support structure. The effect of convenient operation, large construction space and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

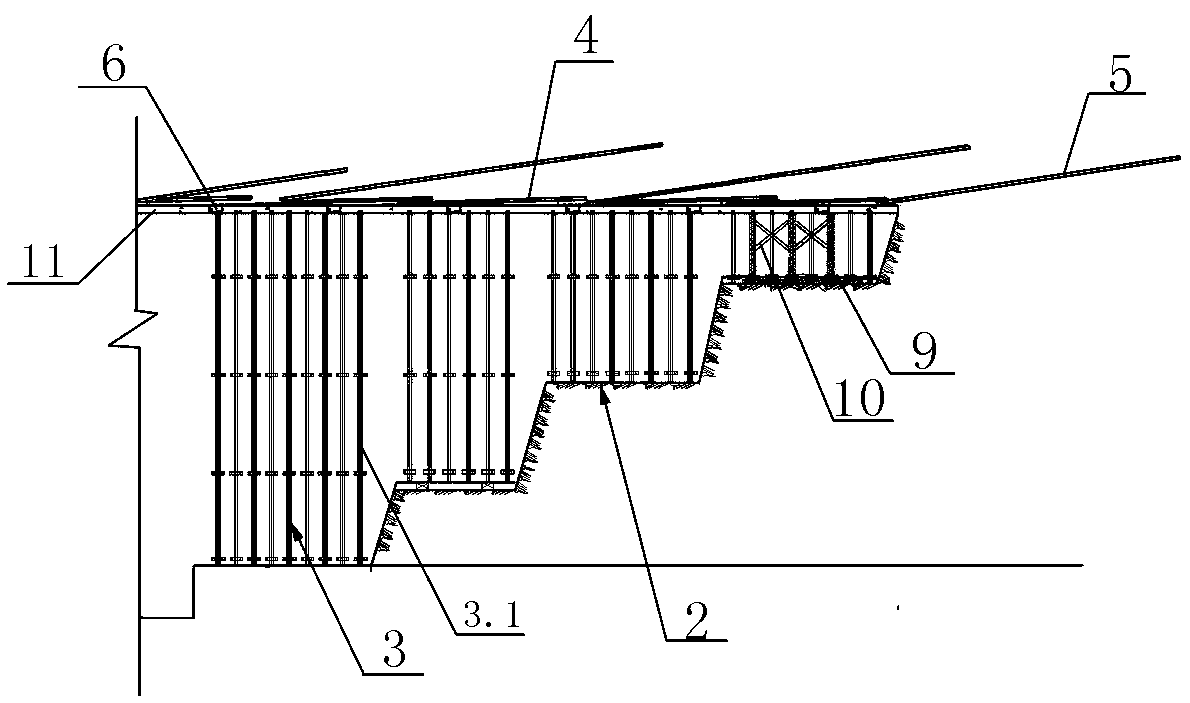

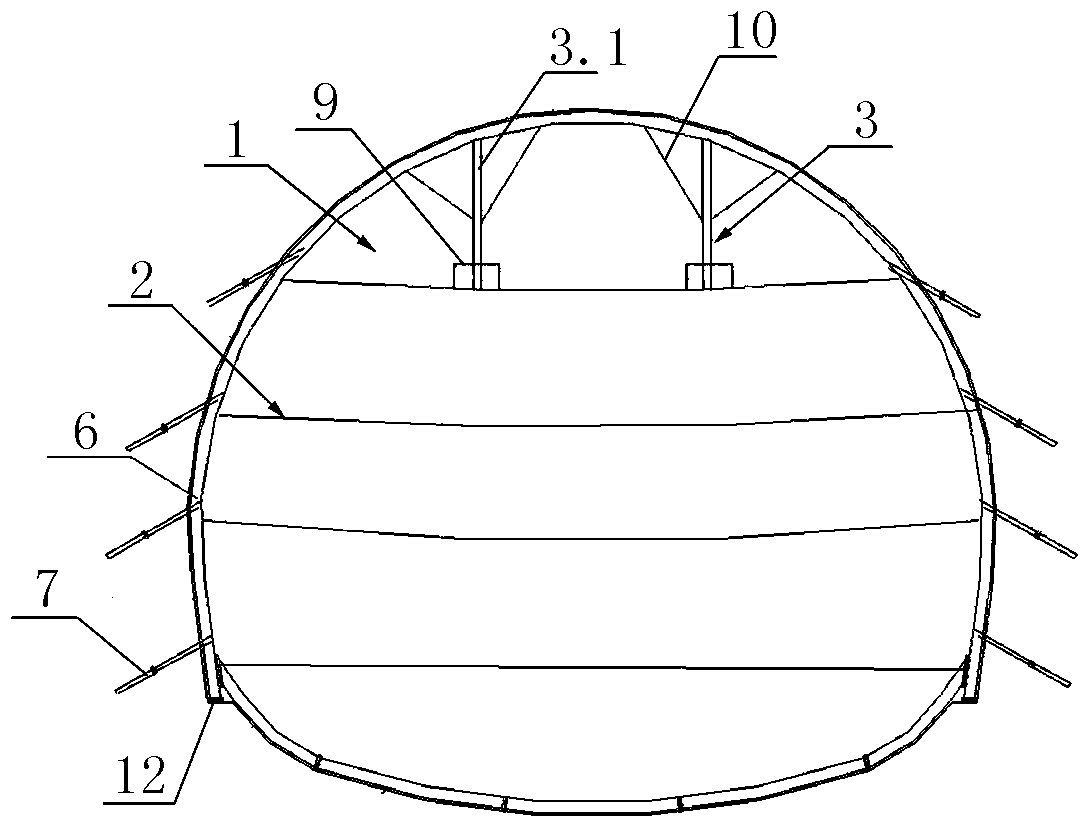

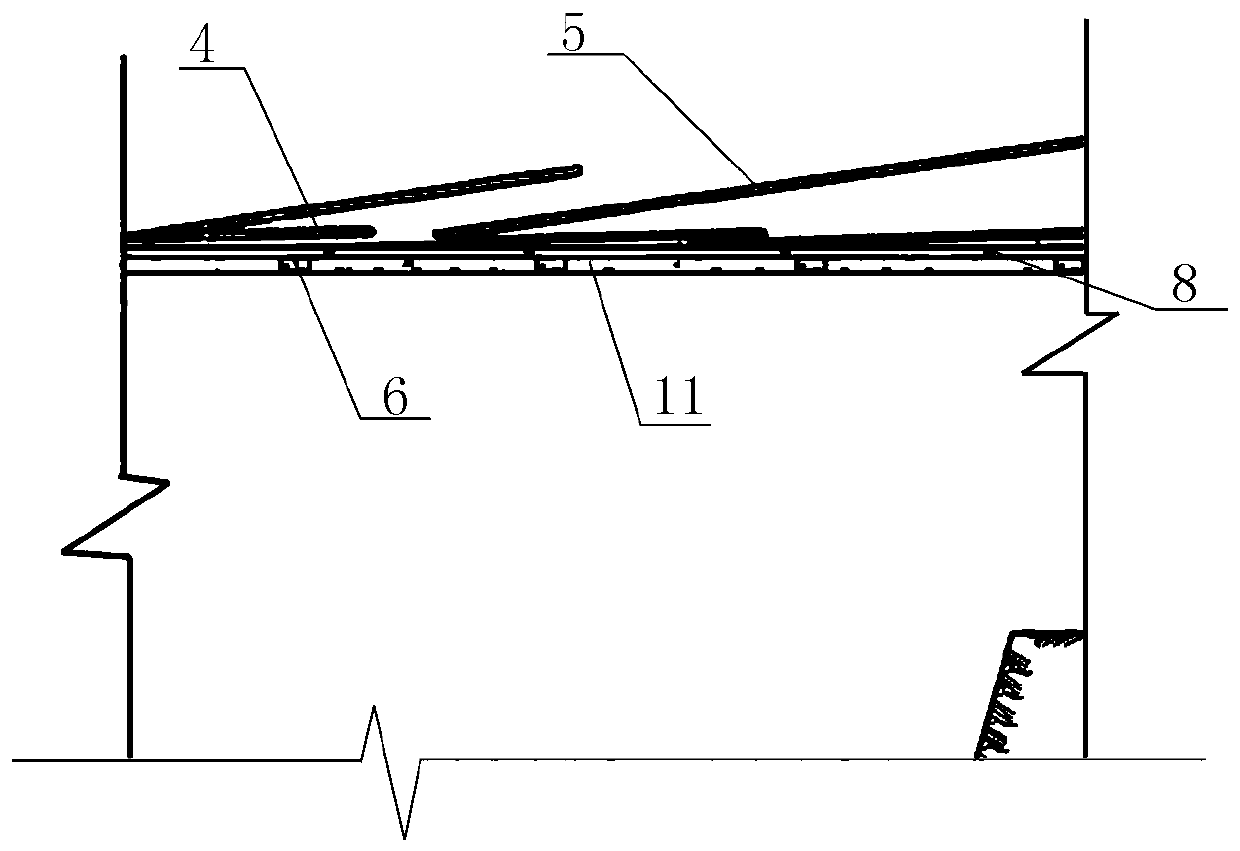

[0040] The cross-sectional size of the tunnel is large, the stress distribution is uneven, and the water-rich sand and rocks are easy to collapse; therefore, the one-time excavation of tunnel 1 is not only very difficult to construct, but also has a great safety risk. The method of the present invention generally adopts four steps 2 to divide the tunnel section into four parts for excavation and construction in sequence. Firstly, the first step at the top is excavated, and initial support is carried out in time, and steel bent frame support 3 is applied on the first step at the same time. Then carry out the excavation and support of the second step, the third step and the fourth step in turn; then add the pipe shed lock feet 7 on both sides of each step 2, and inject double slurry. At the same time, water diversion inside the cave, surface grouting outside the cave and surface deep hole grouting 1m away from the side wall are adopted to strengthen comprehensive measures to effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com