Novel long and short pile foundation treatment structure of collapsible loess area and construction method

A technology for collapsible loess and foundation treatment, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of increasing construction time and testing time, large amount of foundation reinforcement works, long roadbed engineering lines, etc. The effect of construction period, saving project cost and improving foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

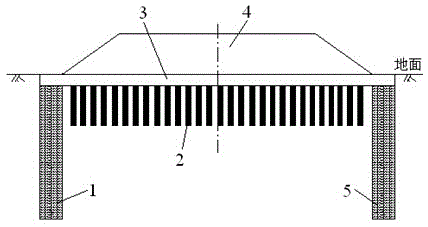

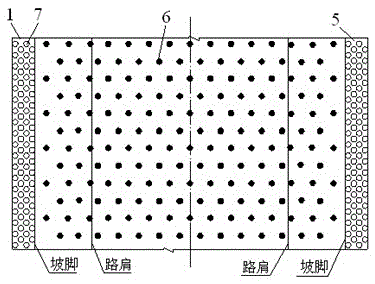

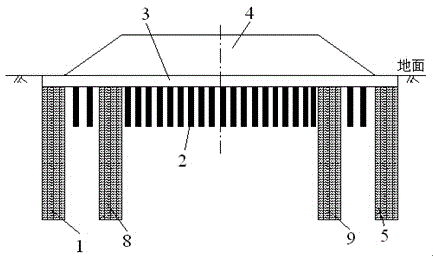

[0018] Such as figure 1 and figure 2 As shown, the first embodiment of the foundation treatment structure of the present invention includes a first water-proof curtain 1 and a second water-proof curtain 5 arranged side by side, and the side of the first water-proof curtain 1 facing the second water-proof curtain 5 and the roadbed 4 One slope toe of the subgrade is in the same vertical plane, the side of the second water-proof curtain 5 facing the second water-proof curtain 1 is in the same vertical plane as the other slope foot of the subgrade 4, the first water-proof curtain 1 and the second water-proof curtain The curtains 5 are all composed of four rows of compacted long piles 7, and the compacted long piles 7 in the water-proof curtain are arranged in a quincunx shape, that is, the three adjacent compacted long piles 7 are respectively lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com