Collapsible foundation immersed tube pile forming treatment method

A treatment method and a collapsible technology, which is applied in the field of sinking pipe piles for collapsible foundations, can solve the problems of large safety hazards, uneconomical, and adsorption in deep foundation pit operations, and achieve good pile formation and compaction effects, Safety and environmental protection are guaranteed, and the operation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

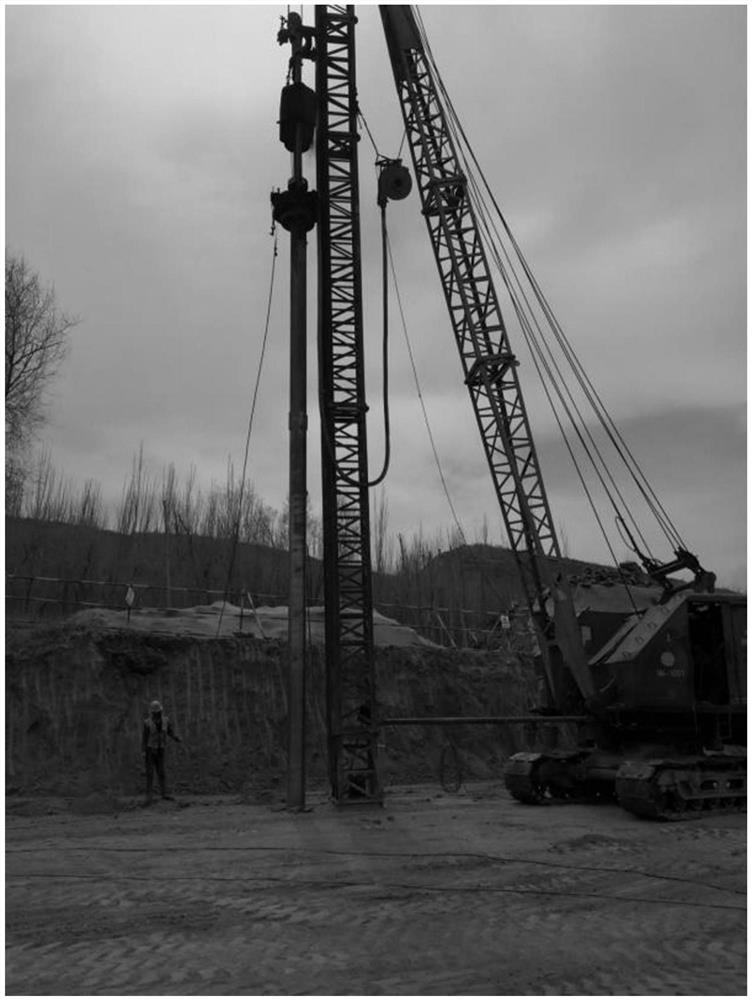

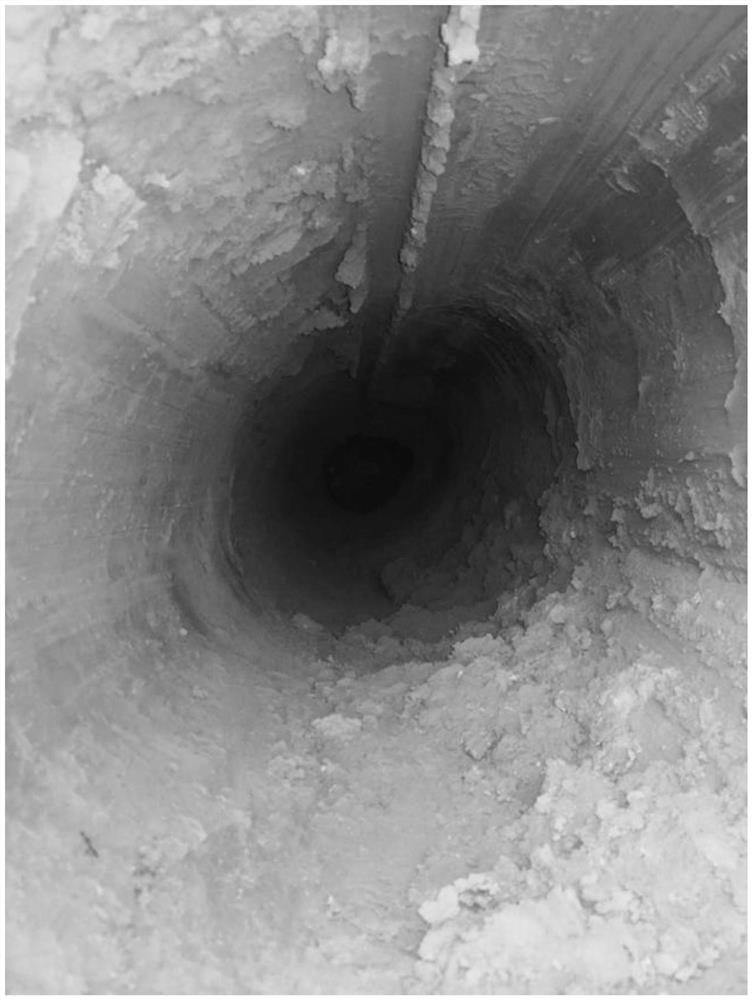

[0038] see Figure 1-9 A treatment method for sinking piles of a collapsible foundation is shown, comprising the following steps:

[0039] (1) Actual working conditions: When compacted plain soil piles are used to treat collapsible loess foundations using conventional immersed tubes for hole-forming construction, serious shrinkage cavities will appear after the tubes are pulled out, and it is impossible to directly backfill the plain soil in layers, The conventional method of layered tamping is normally carried out in the next process to tamp and fill into pile construction.

[0040] (2) For the above actual working conditions, a plan adjustment was made. In view of the phenomenon of hole formation and shrinkage of the immersed tube, a long auger drill was used to excavate the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com