No-dumping vibrationless pore-forming compaction processing method for mollisol foundations

A treatment method and soft soil technology, applied in soil protection, foundation structure engineering, sheet pile walls, etc., can solve problems such as no longer applicable, and achieve the effects of increased bearing capacity, high construction efficiency, and elimination of collapsibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

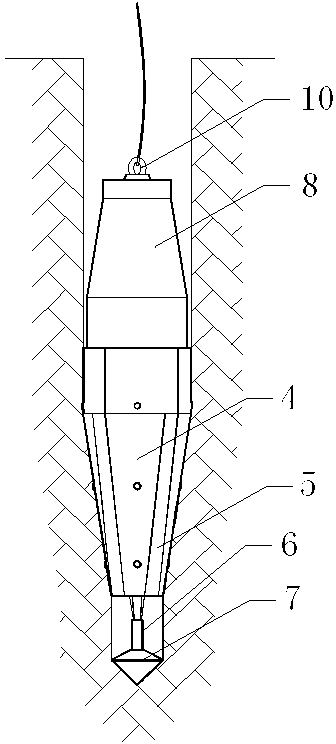

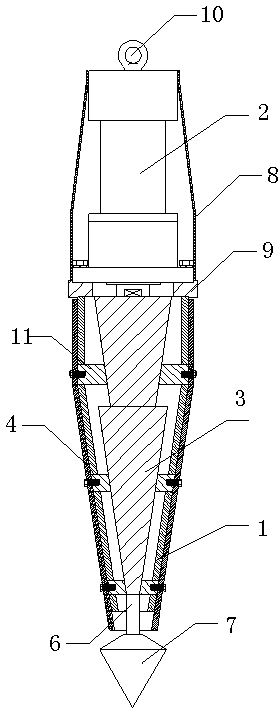

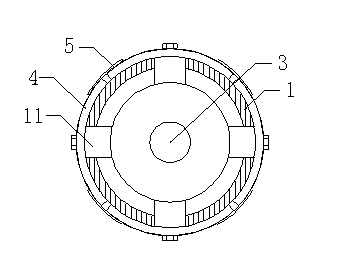

[0026] The structure of the self-propelled non-discharge and non-vibration compacting device of the present invention and the non-discharge and non-vibration compaction treatment method for soft soil foundations will be described in detail below through specific embodiments.

[0027] 1. Self-propelled non-drainage and non-vibration compacting device

[0028] The self-propelled non-drainage and non-vibration compaction device involved in the present invention includes a conical frame 1 and a hydraulic cylinder 2 connected to the conical frame 1 through a flange 9, and a casing 8 is arranged outside the hydraulic cylinder 2. The top of the hydraulic cylinder 2 is provided with a suspension ring 10 . A power cone 3 is arranged in the conical frame 1 (according to the construction site, two power cones can be stacked in the same direction in turn), and the power cone 3 and the piston rod of the hydraulic cylinder 2 are integrally connected by thread or welded; The outer circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com