Device and method based on static pressure immersed tube hole forming heavy hammer tamping compaction pile

A technology of compacting pile and static pile driver, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of polluting the environment, high noise of diesel hammer, and increasing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

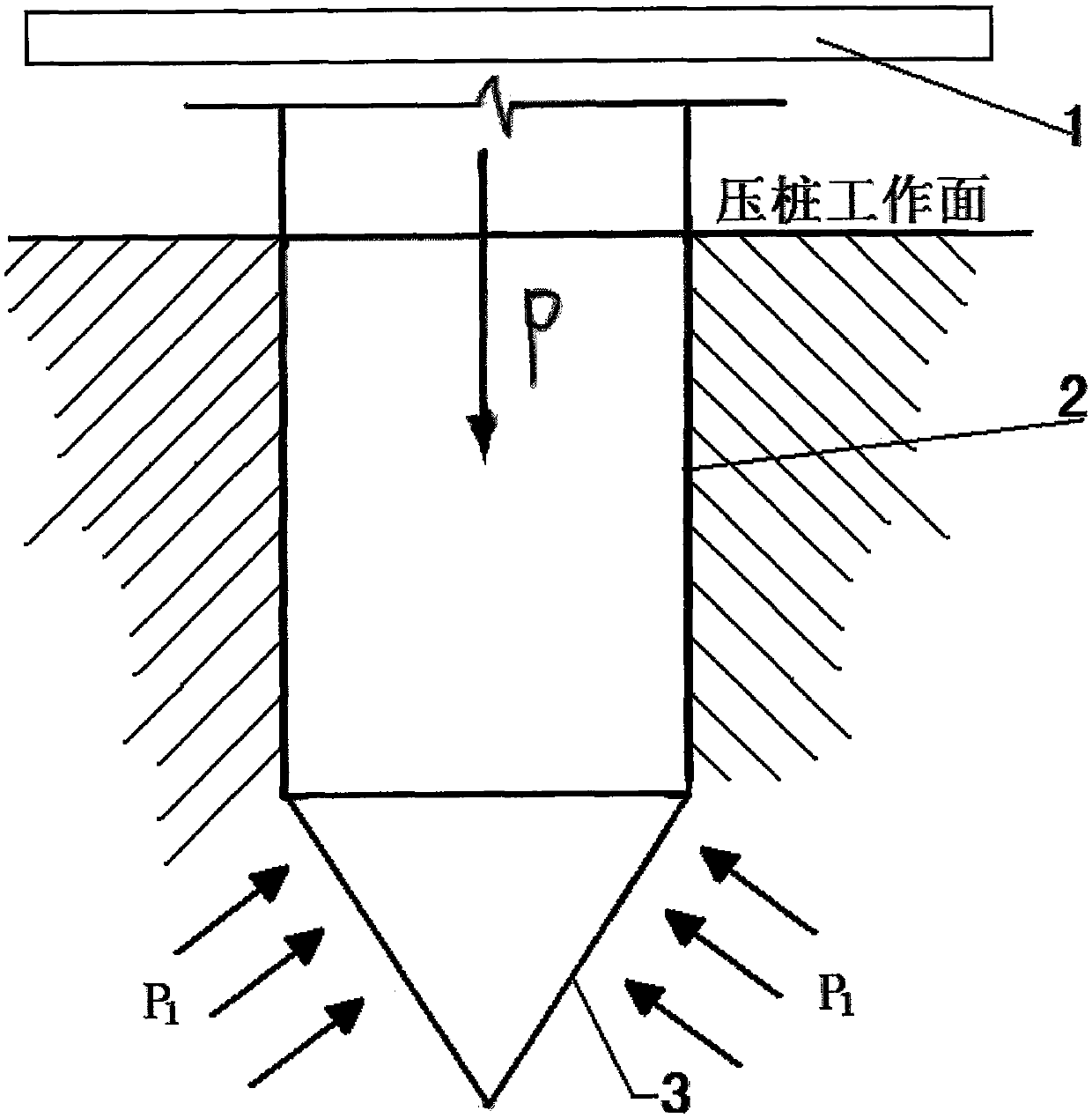

[0033] Poly Qujiang Spring Garden 11# residential building has 33 floors above ground and 2 floors underground. The building site is a self-weight collapsible loess site, and the stratum within 13 meters below the cutting board is collapsible, and its collapsibility grade is III. The foundation treatment plan is to first eliminate the subsidence of the foundation completely, and then build the static pressure pipe pile foundation.

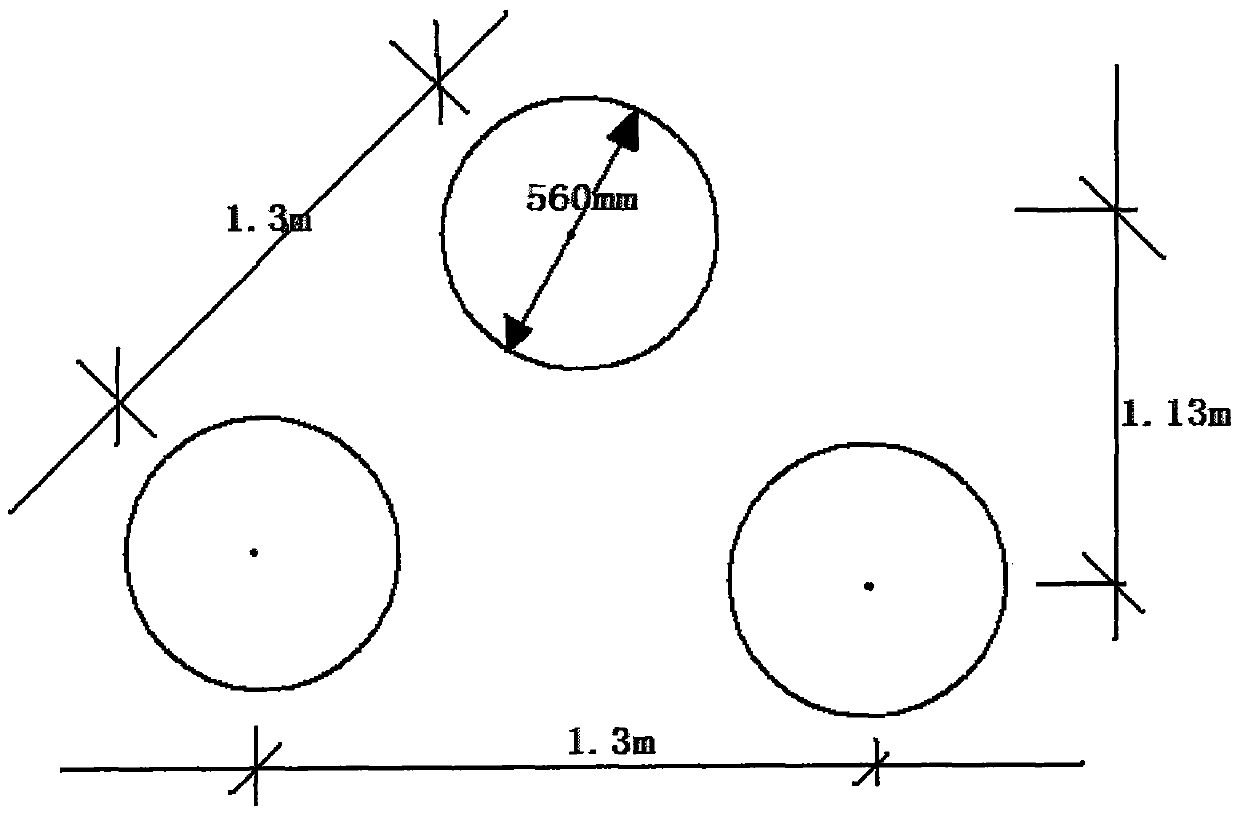

[0034] To eliminate the subsidence of the foundation, the compacted piles are compacted with long auger drilled holes and heavy hammers. The designed hole diameter is 400mm, the pile diameter is greater than 550mm, and the pile spacing is 850mm. The piles are arranged in an equilateral triangle, and the pile length is 13 meters. After the foundation treatment, the average compaction coefficient of the soil between the piles is required to be not less than 0.90, and the compaction coefficient of the pile body is not less than 0.97.

[0035] Eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com