Hydrophobic anti-scouring loess solidifying agent

A curing agent and hydrophobic technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of scattered layout, severe flood control safety of check dams, and low flood control standards of check dams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of liquid waterproof composition is:

[0038] Mix the above materials in a reaction kettle at 60-80°C for 2 hours until they are uniform, and then the liquid waterproof component is obtained.

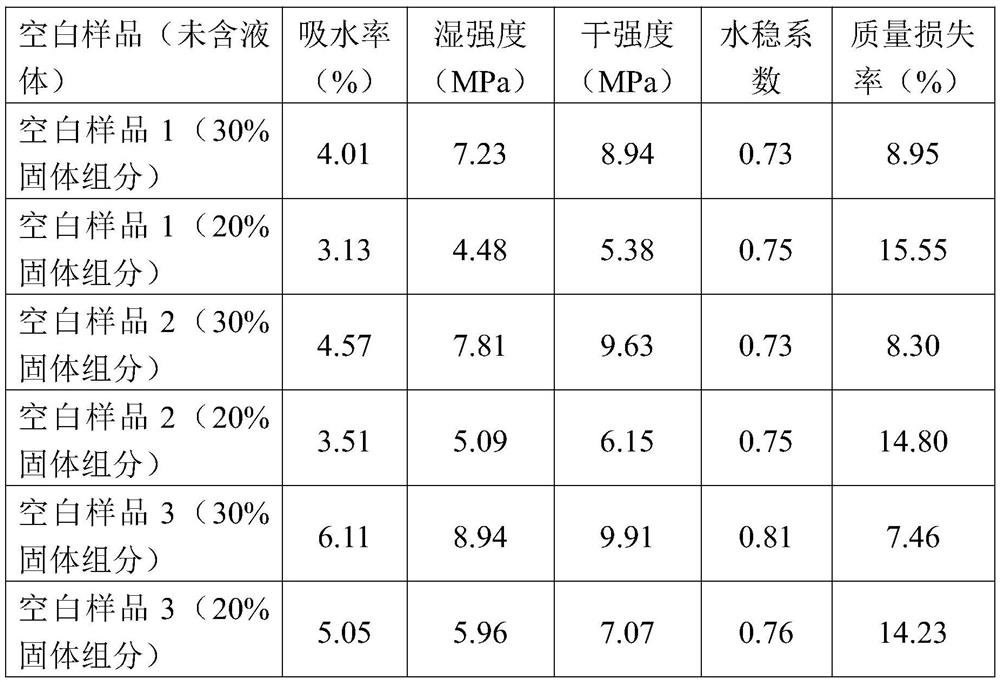

Embodiment 1

[0040] The hydrophobic type anti-scouring curing agent for the loess plateau area of the invention is composed of a powder curing component and a liquid waterproof component. Wherein the composition of powder solidification component is:

[0041] Commercially available slag powder 70 parts, cement 15 parts, fly ash 10 parts, synthetic fiber 2 parts, calcium sulfate 2 parts, calcium hydroxide 1 part.

[0042] Mix the above powder materials in a high-speed mixer for 3-5 minutes, then add fiber materials, and mix them at a low speed for 2-3 minutes until they are evenly mixed.

[0043] Wherein the preparation method of liquid component is:

[0044] Hydrophobic agent: 10 parts of white oil, 10 parts of coconut oil;

[0045] Interface agent: 2 parts of polyether modified silicone oil, 8 parts of cocamidopropyl betaine;

[0046] Stabilizer: 5 parts of potassium coconut fatty acid;

[0047] 65 parts of water.

[0048] Mix the above materials in a 60°C reactor for 2 hours until t...

Embodiment 2

[0050] The hydrophobic type anti-scouring curing agent for the loess plateau area of the invention is composed of a powder curing component and a liquid waterproof component. Wherein the composition of powder solidification component is:

[0051] Commercially available slag powder 65 parts, cement 20 parts, fly ash 10 parts, synthetic fiber 2 parts, calcium sulfate 2 parts, calcium hydroxide 1 part.

[0052] Mix the above powder materials in a high-speed mixer for 3-5 minutes, then add fiber materials, and mix them at a low speed for 2-3 minutes until they are evenly mixed.

[0053] Wherein the preparation method of liquid component is:

[0054] Hydrophobic agent: 15 parts of silicone oil, 8 parts of liquid paraffin;

[0055] Interface agent: 6 parts of lauryl amidopropyl betaine, 10 parts of coconut amphoteric imidazoline;

[0056] Stabilizer: 10 parts of triethanolamine oleic acid soap;

[0057] 62 parts of water.

[0058] Mix the above materials in a 60°C reactor for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com