Construction method of shallow-buried large-span tunnels

A technology for tunnel construction and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as construction safety risks, and achieve the effects of small single pile engineering, fast construction, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

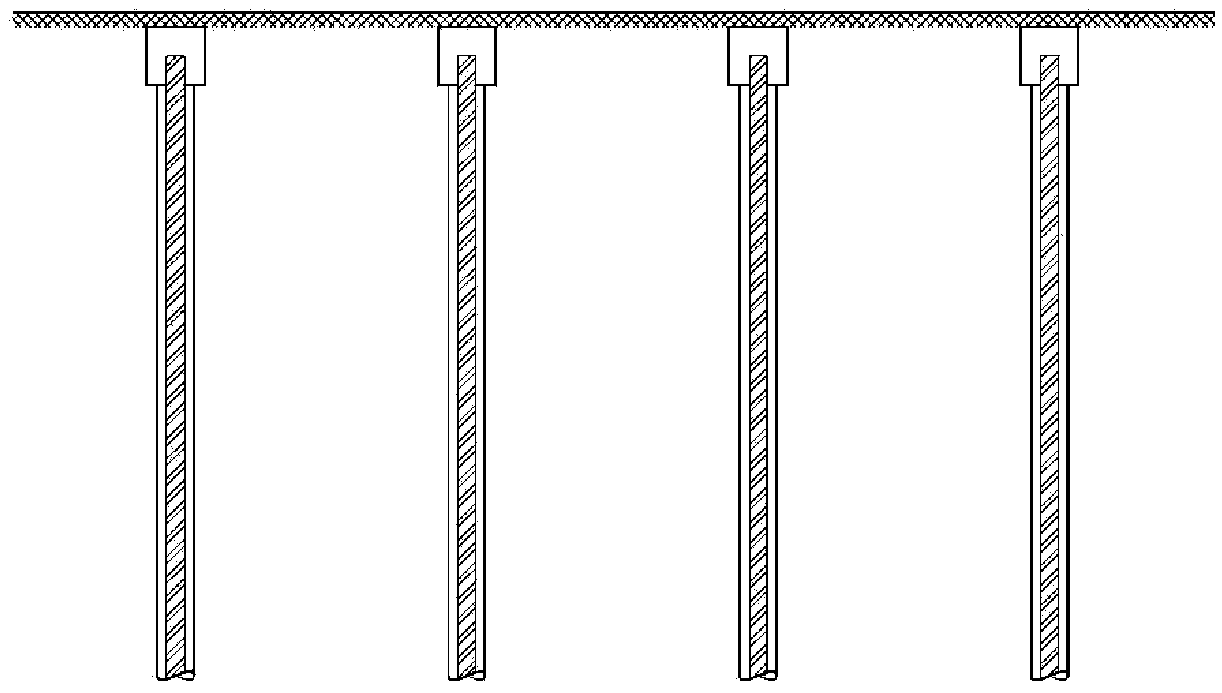

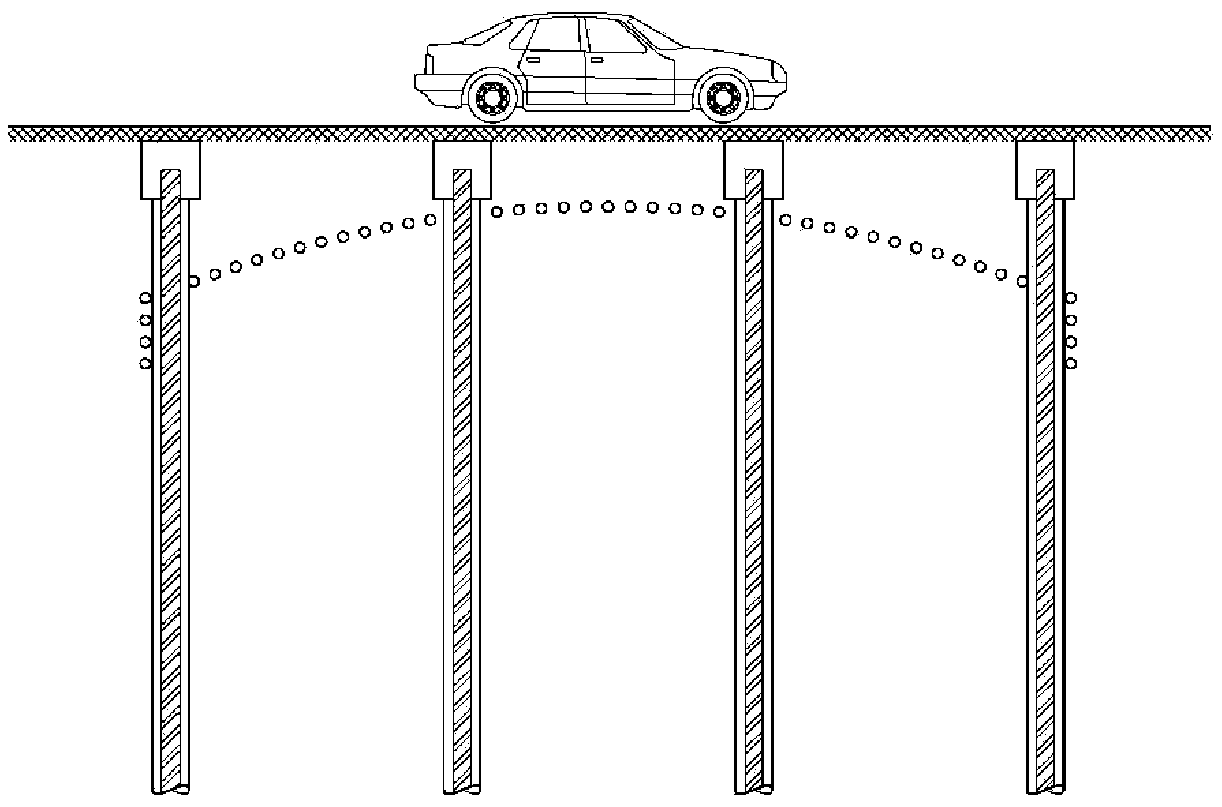

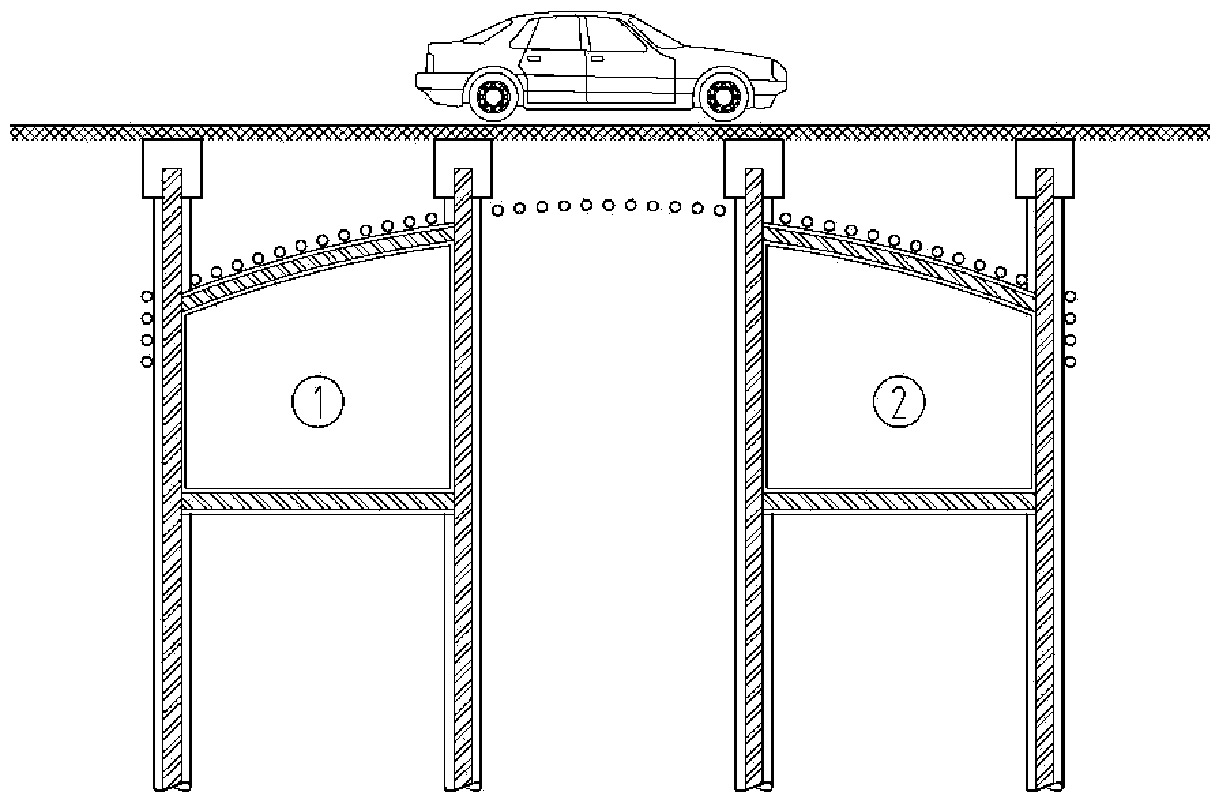

[0047] The method and steps of the present invention are as follows:

[0048] ①Using the shallow buried characteristics of the tunnel, vertical piles are built from the ground, and the bottom of the pile is placed under the arch bottom of the proposed tunnel with a stable bearing layer, that is, along the periphery of the proposed tunnel and in the ground before the undercut construction of the tunnel. , The vertical support piles were left in advance. In the subsurface excavation construction, the horizontal support of the initial support structure is connected with the preset vertical support piles through the partial excavation, and the ground disturbance and displacement caused by the tunnel excavation are transmitted to the deeper and more stable ground to control the surface settlement .

[0049] ②In order to reduce the engineering risk after the initial support vertical temporary support is removed and before the strength of the secondary lining reinforced concrete structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com