Patents

Literature

62results about How to "Reduce extrusion stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

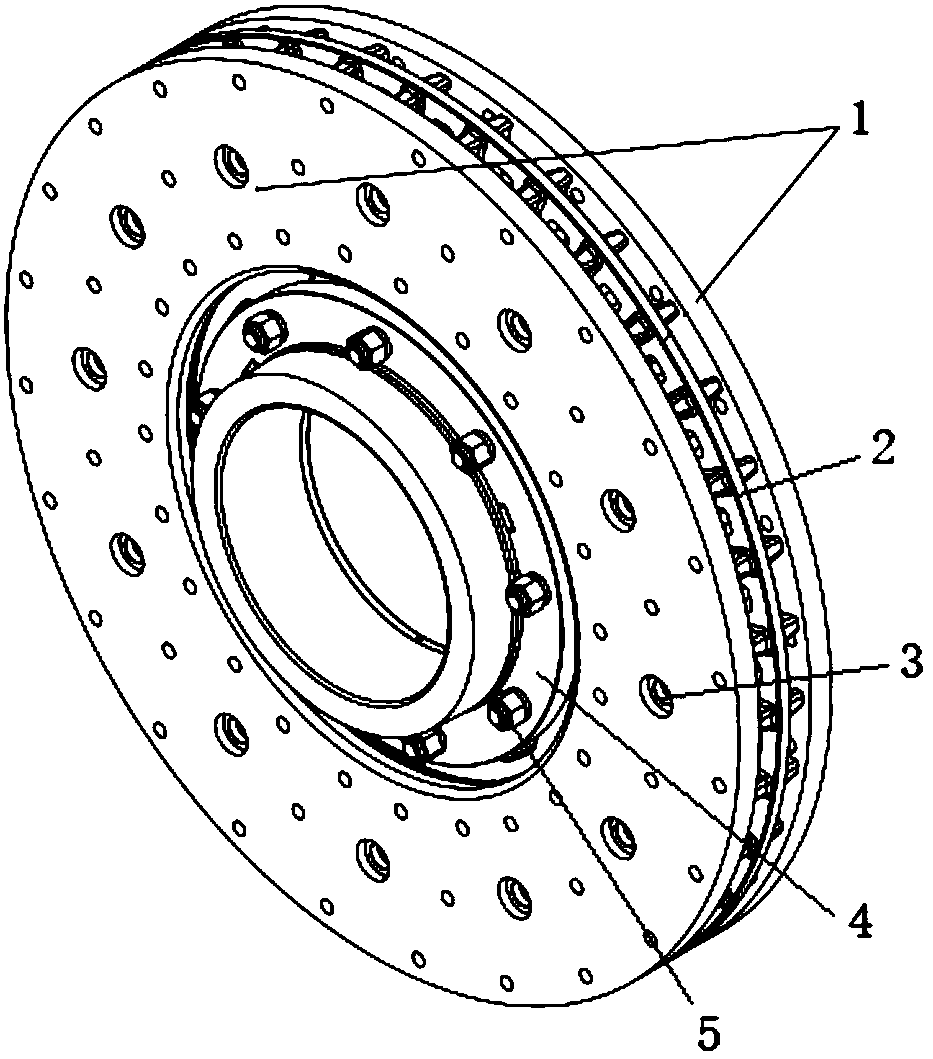

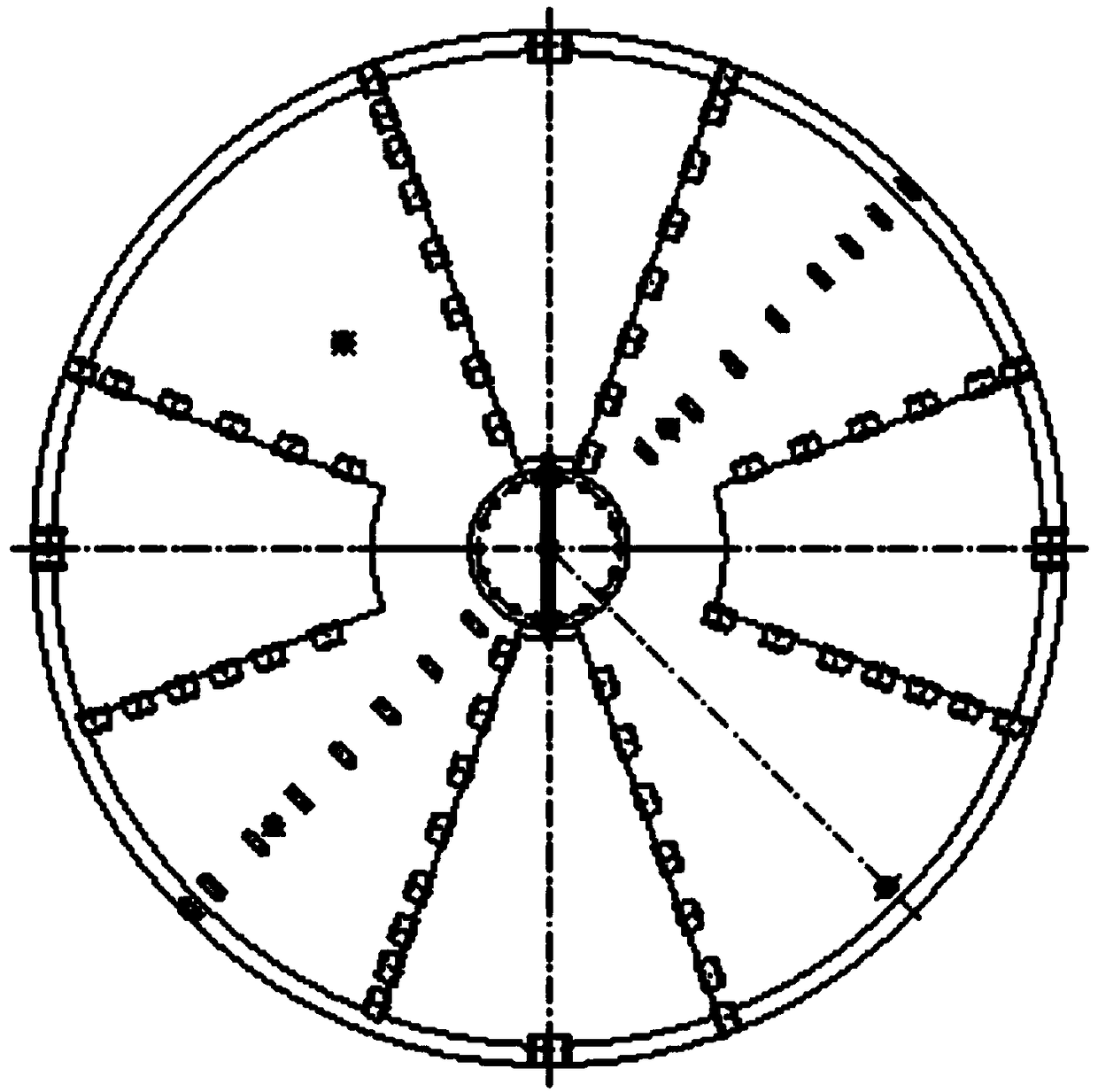

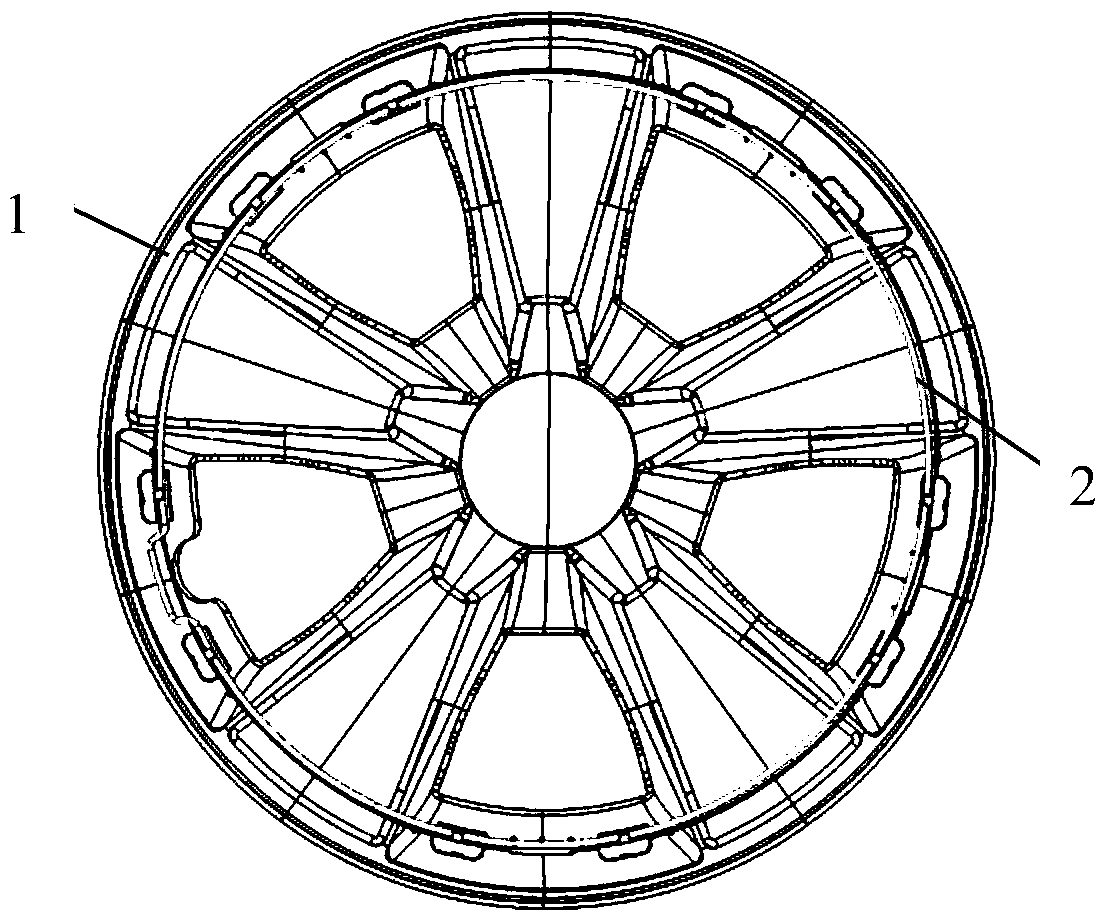

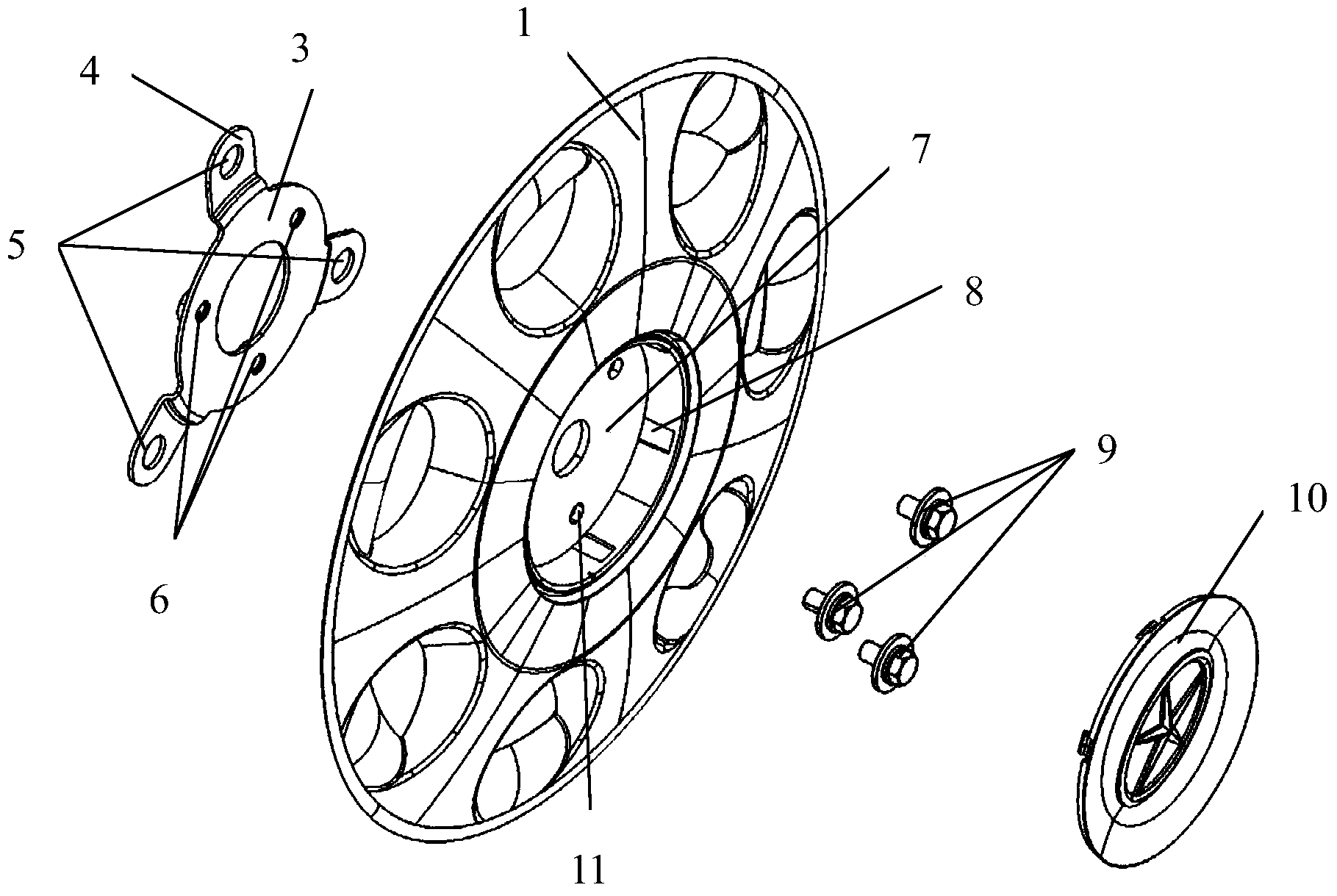

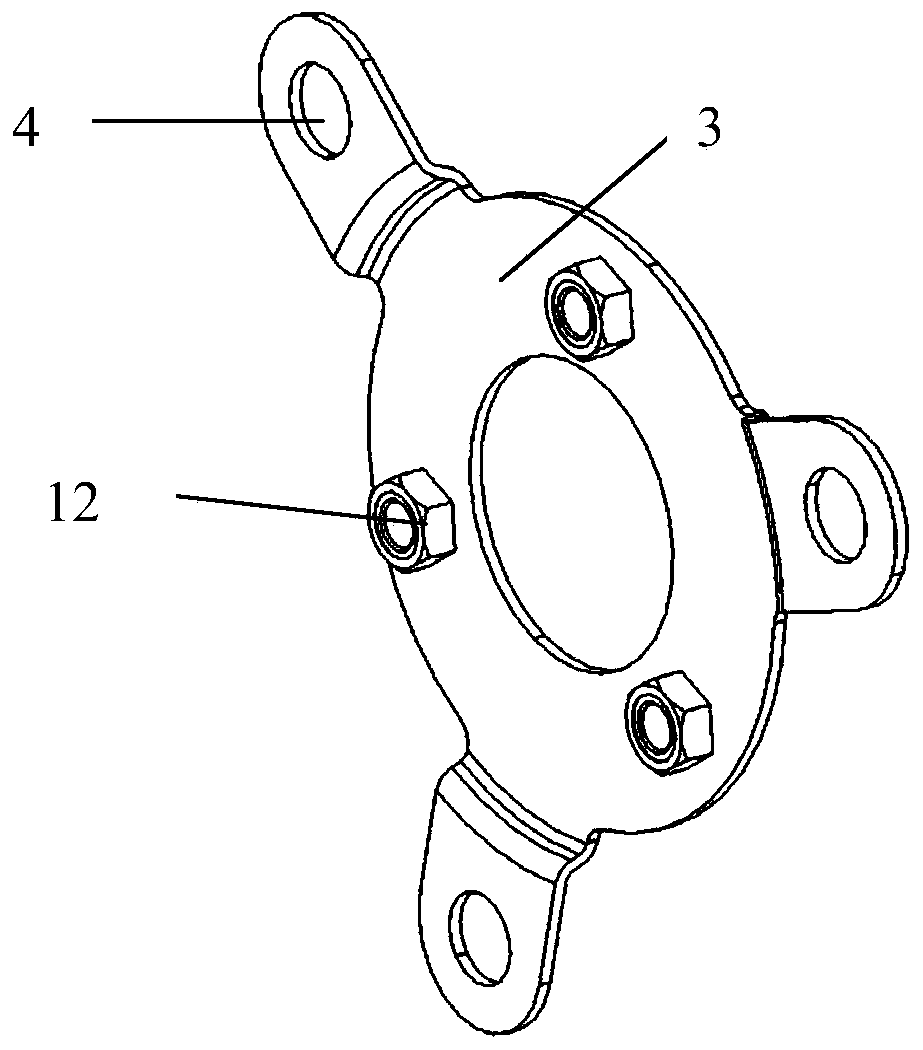

Shaft-mounted brake disc module for high-speed train

PendingCN108317194ASolve processing technology problemsSolve the cooling problemBraking discsTemperature resistanceEnergy consumption

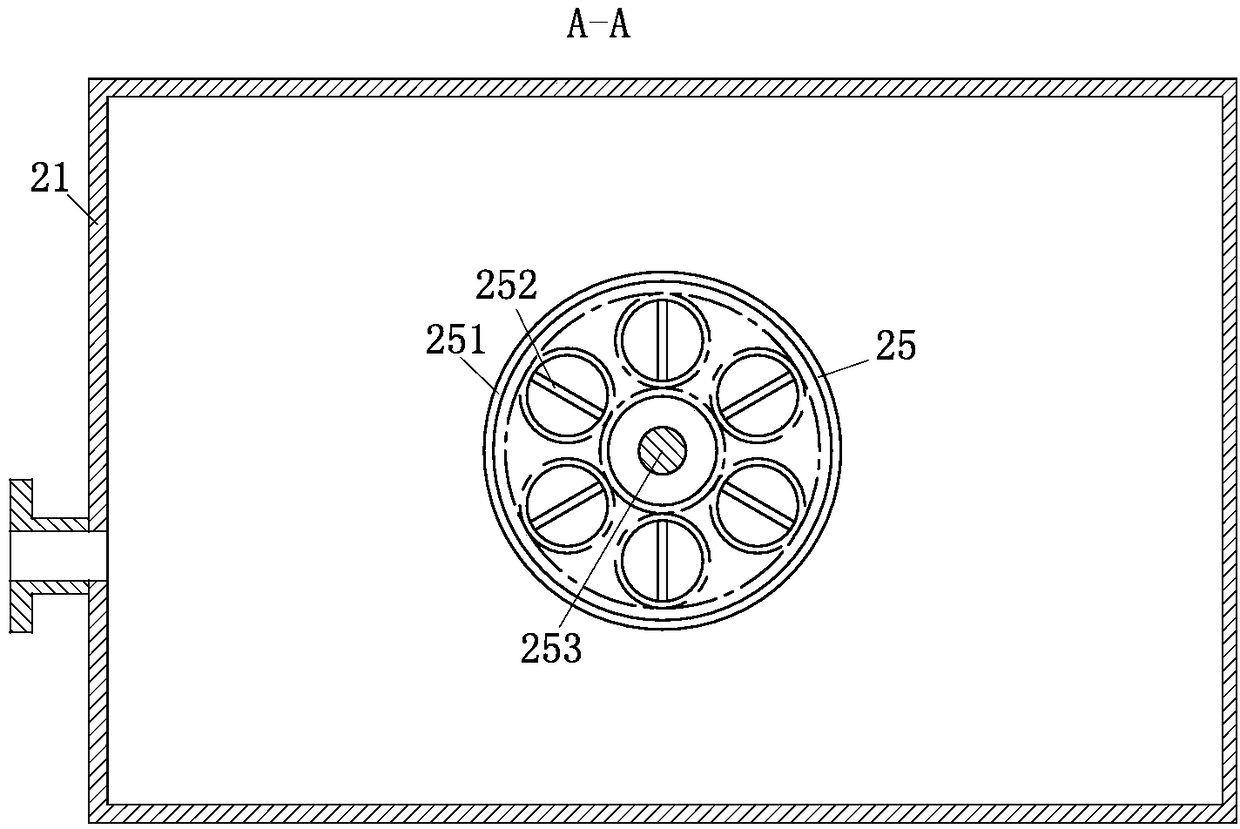

The invention discloses a shaft-mounted brake disc module for a high-speed train. The module comprises brake discs, a support disc and a disc hub; two sets of brake discs are provided, are coaxially laminated on the disc surfaces on the two sides of the support disc, and are clamped and locked with the support disc through first connecting structures; the brake discs are composite material brake discs with smooth disc surfaces on two sides; heat dissipating structures are arranged on the disc surfaces on the two sides of the support disc, and are laminated with the brake discs to form heat dissipating channels; and a connecting flange is arranged on an inner ring of the support disc, and is fixedly sleeved with the disc hub through a second connecting structure. Compared with a traditionaloverall brake disc, the module has the characteristics of simple structure, reliable connection, high-temperature resistance, convenience to maintain, light weight and good braking effect, reduces the energy consumption in operation and braking of the high-speed train, realizes application of a composite friction material to a high-speed train braking system, and greatly saves the high-speed train company operation and maintenance costs.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

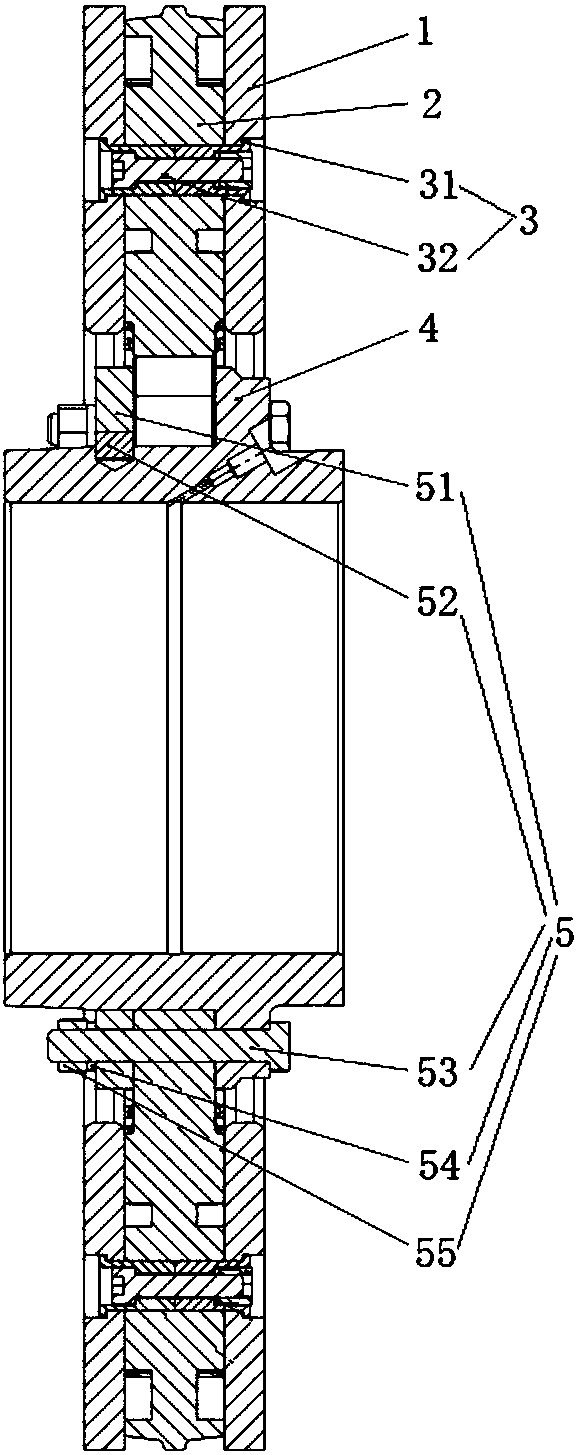

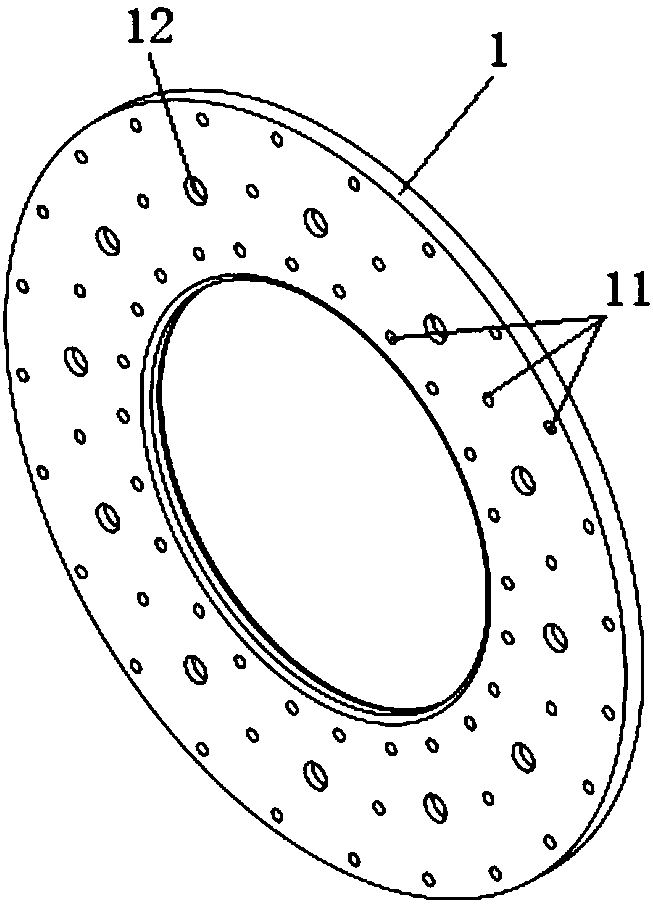

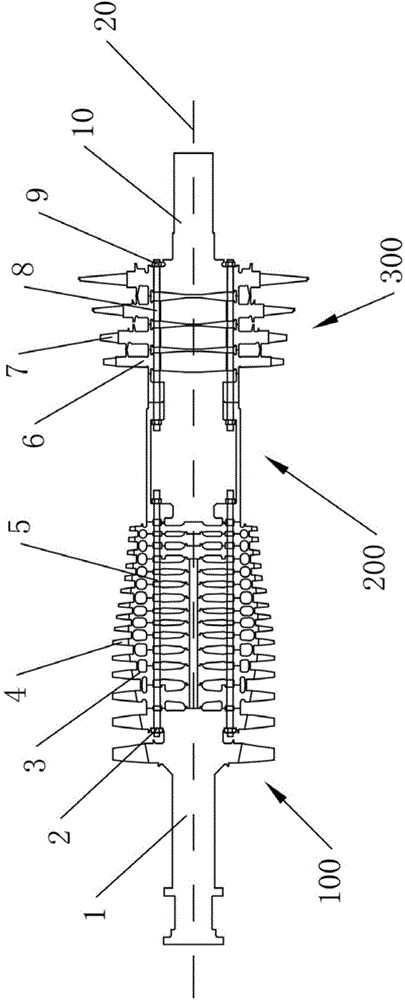

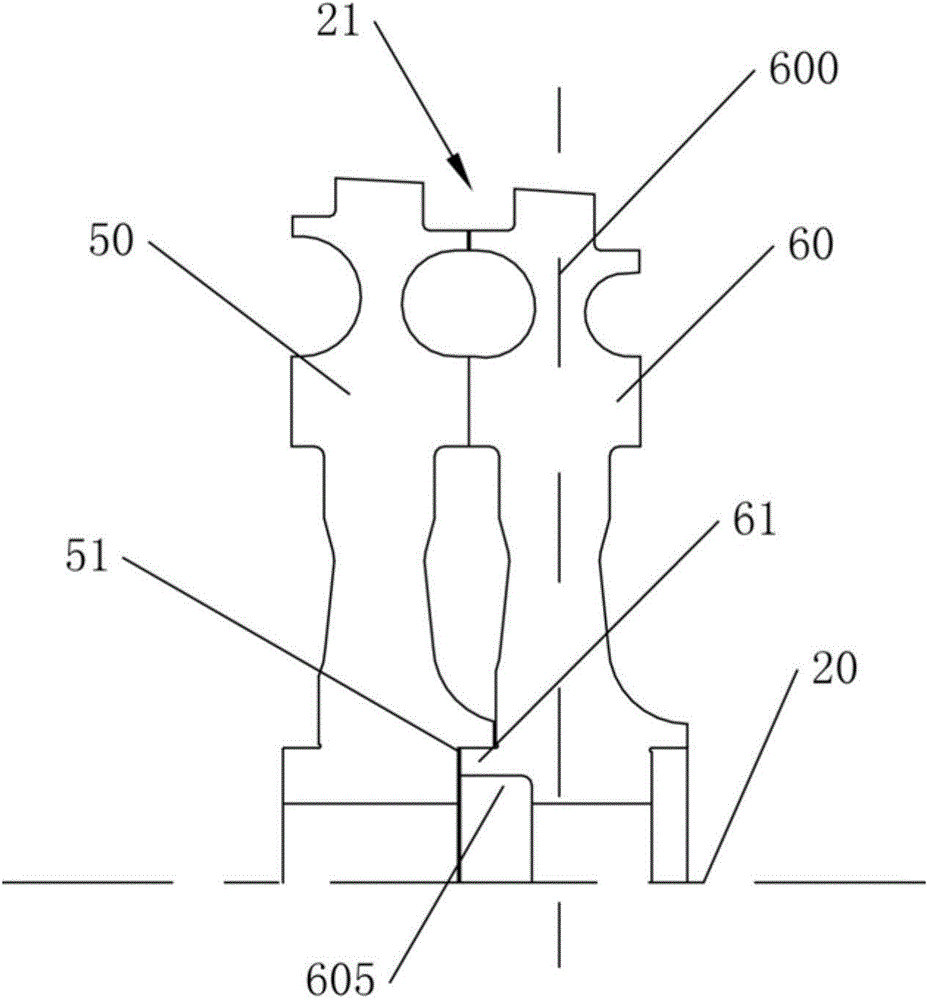

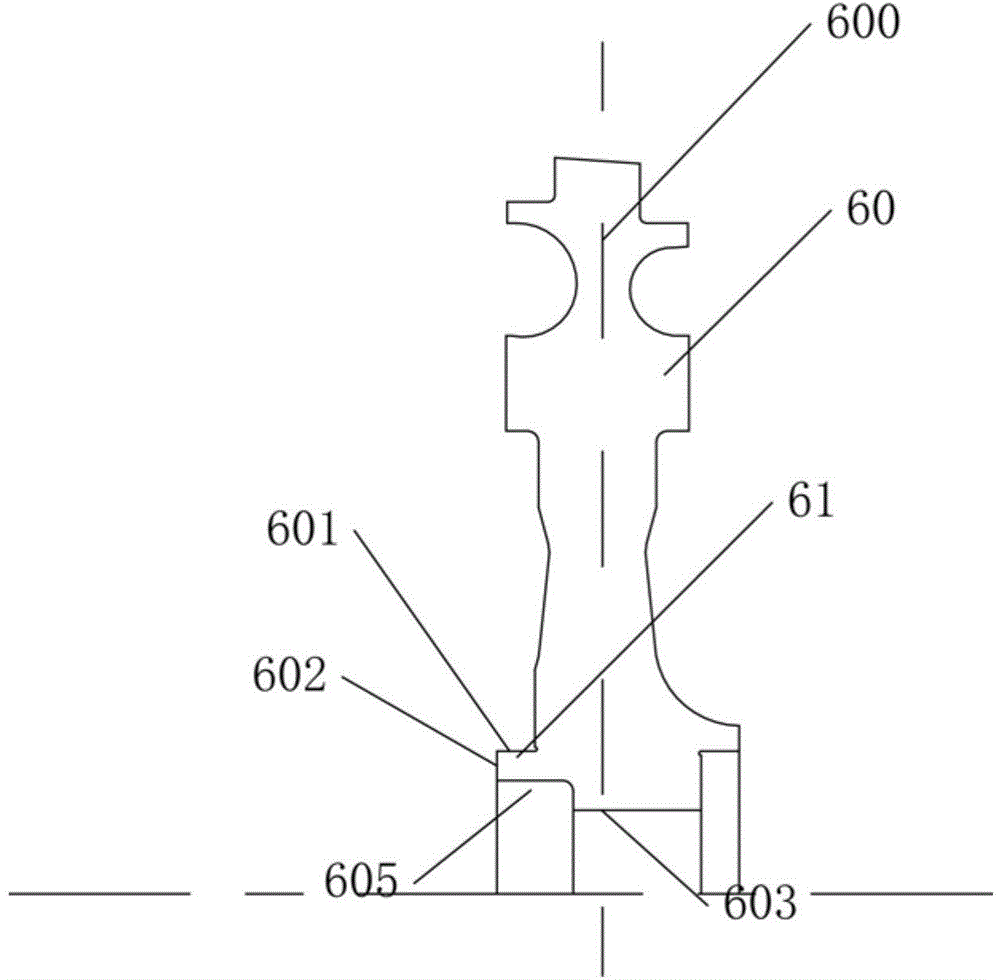

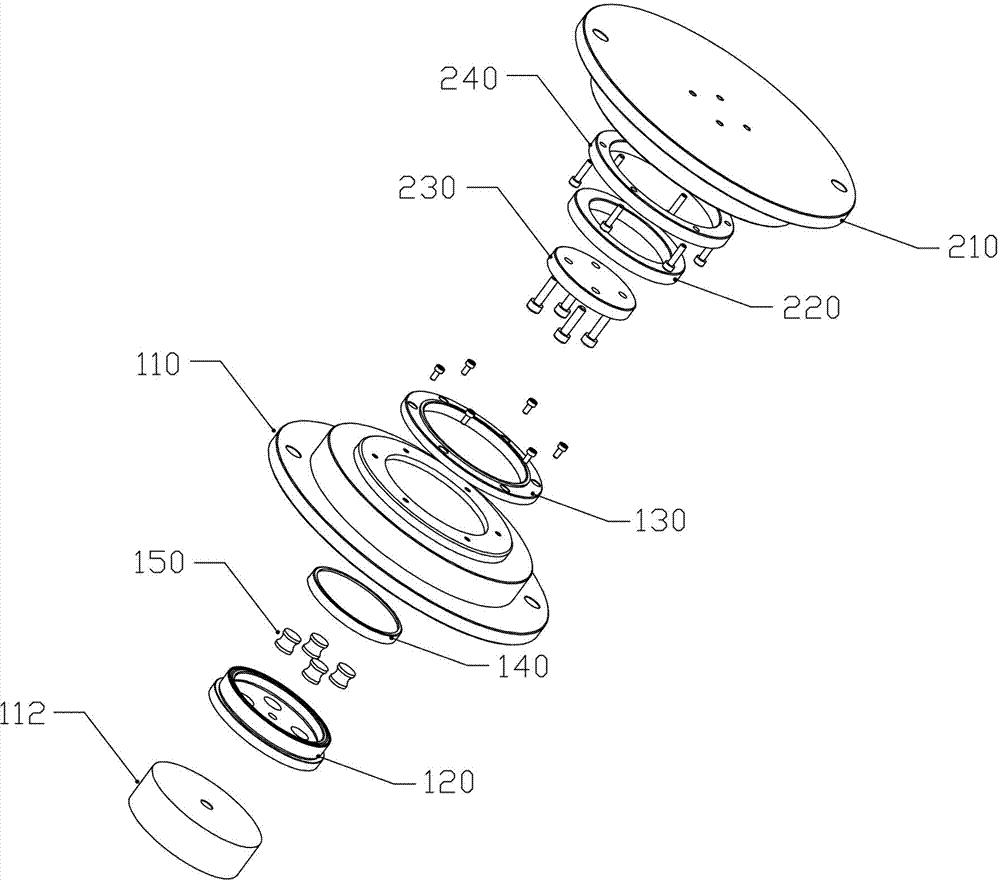

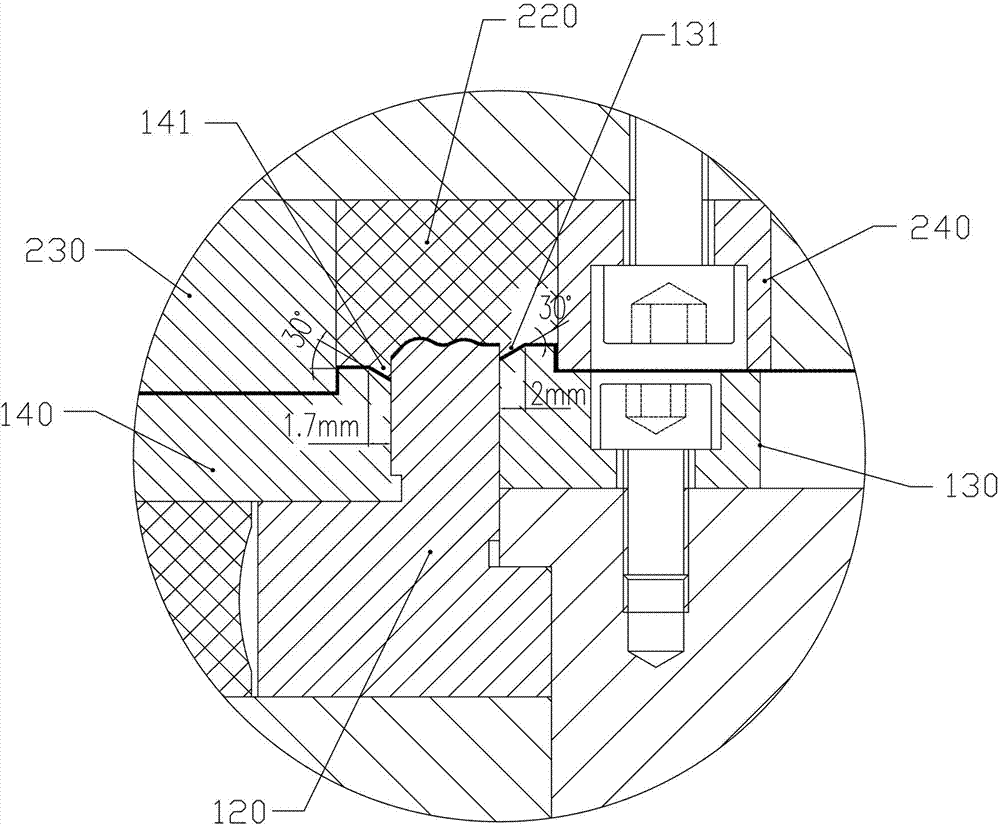

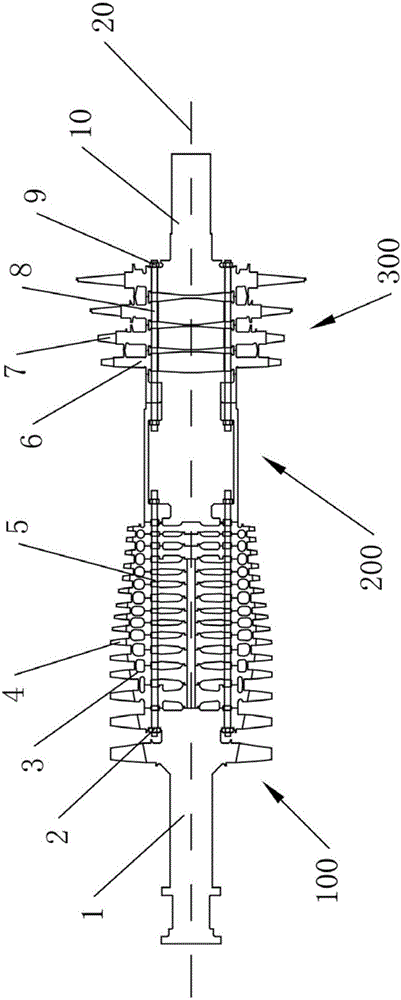

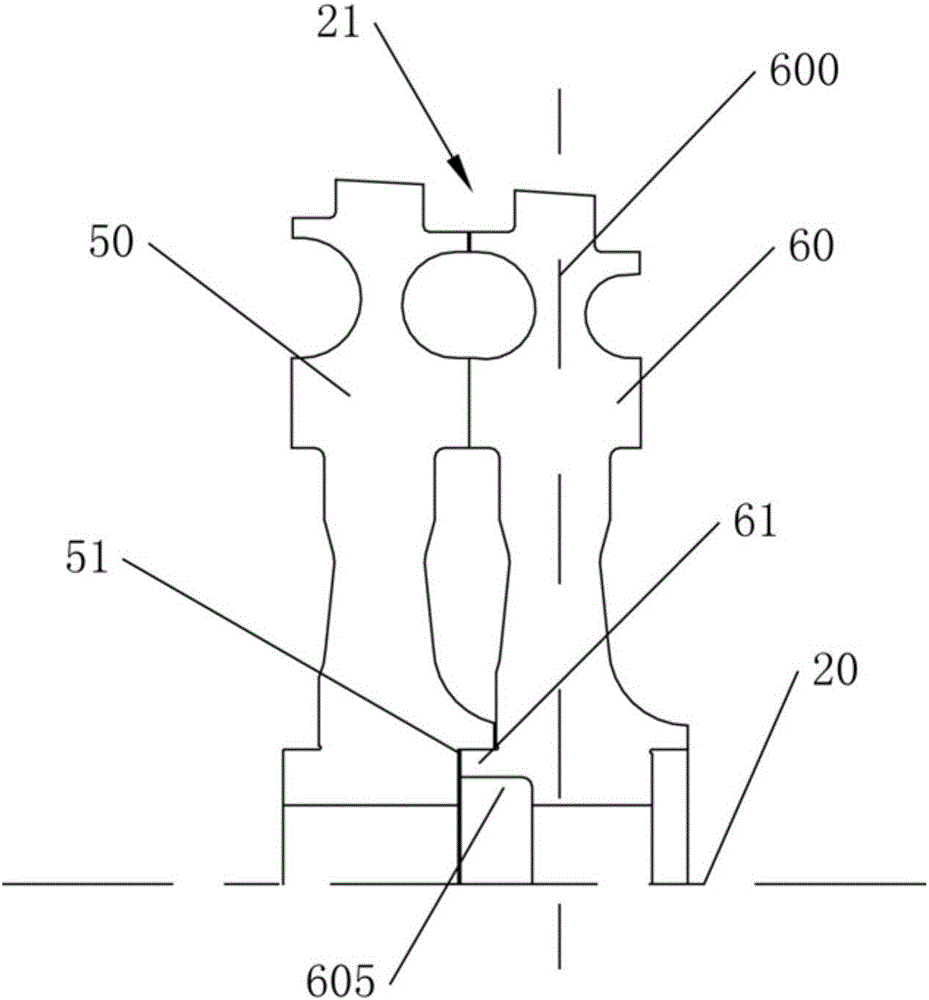

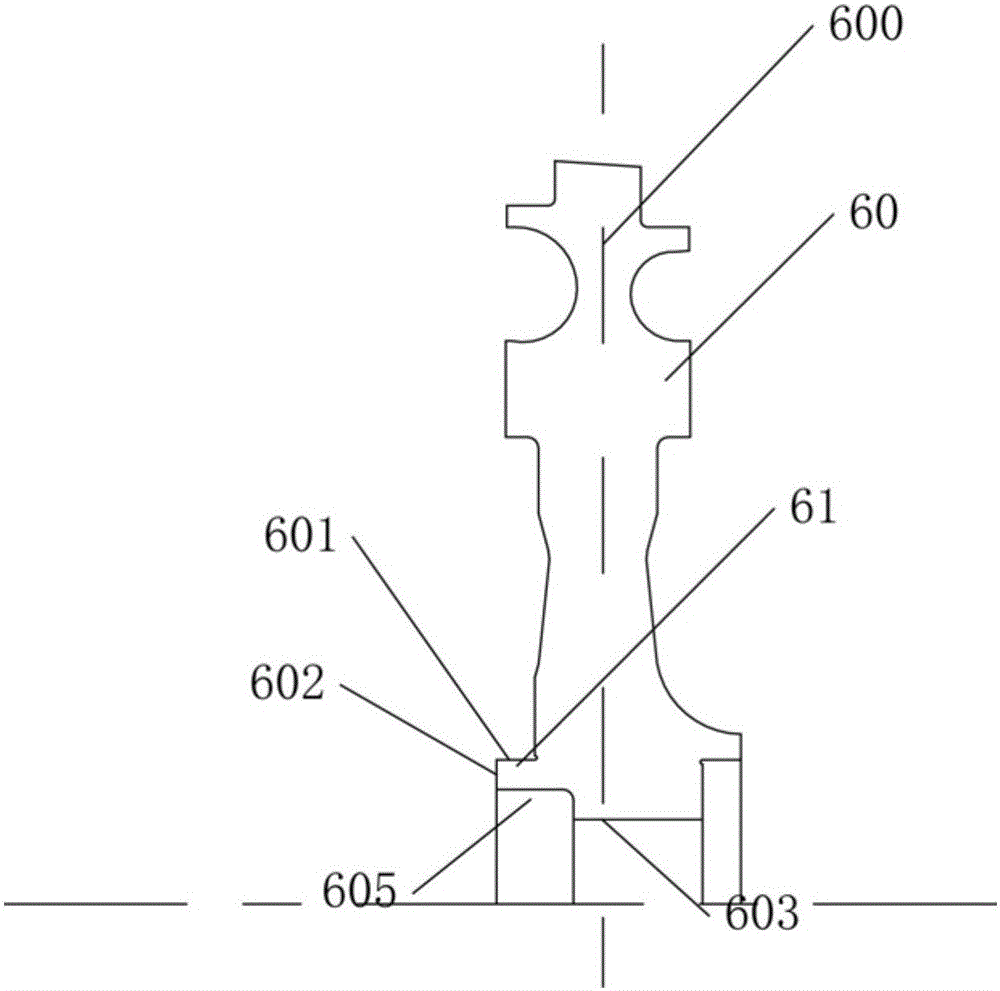

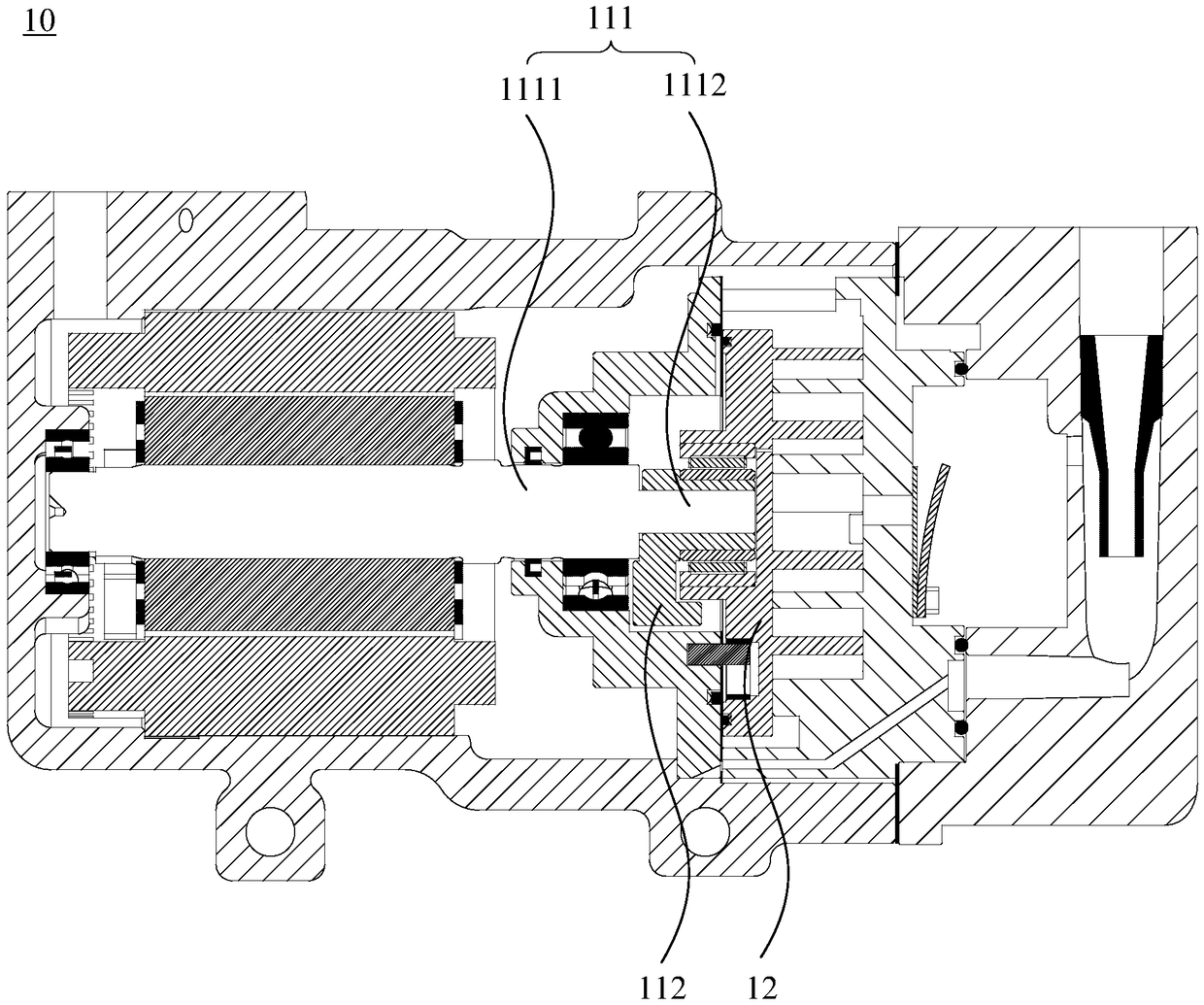

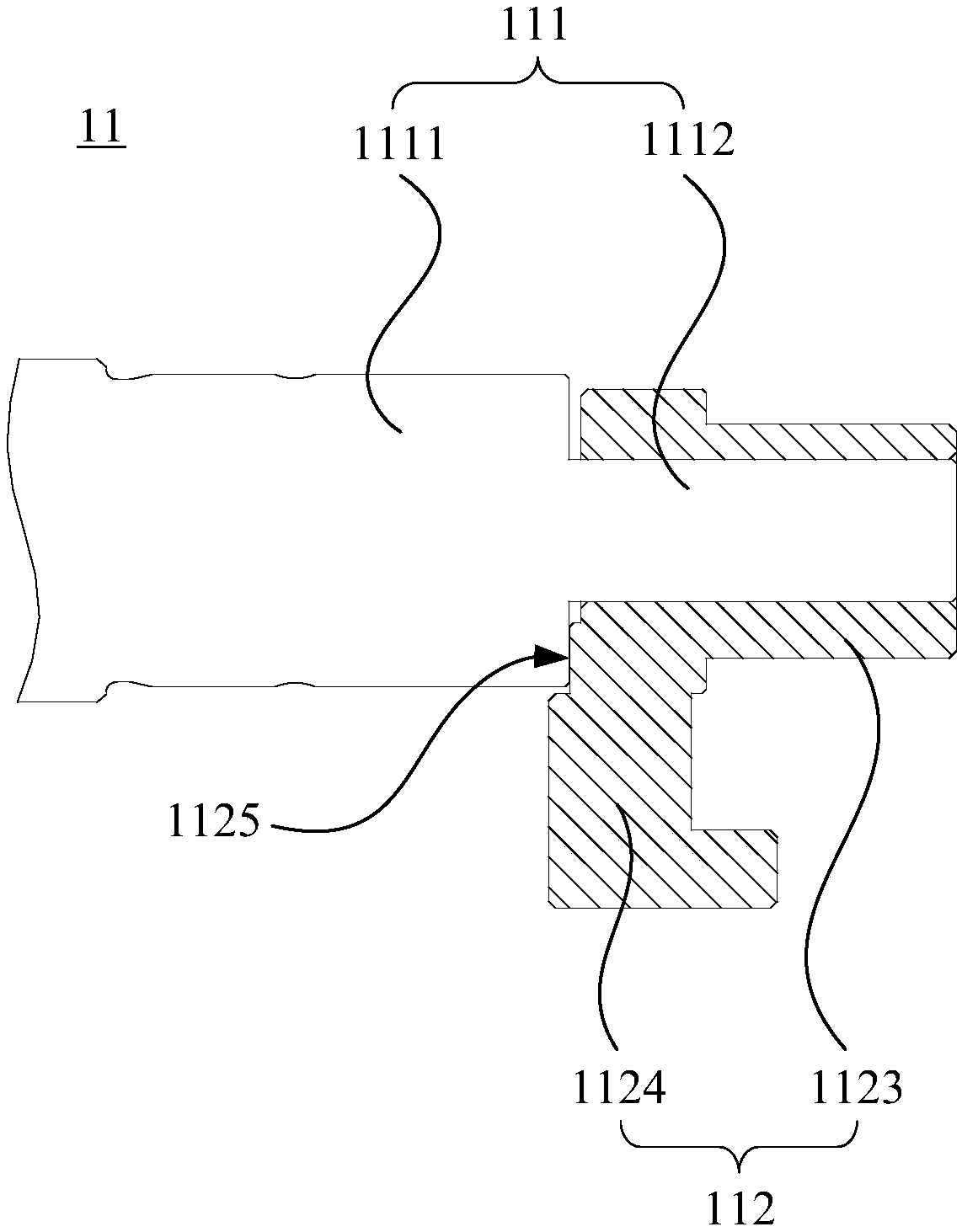

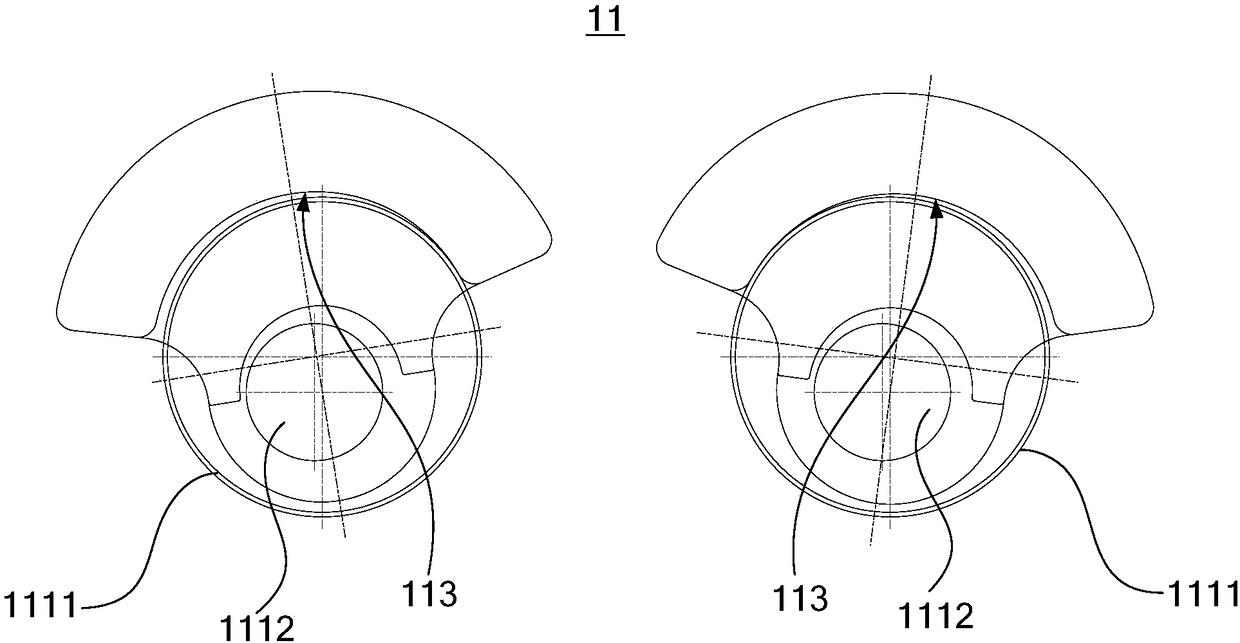

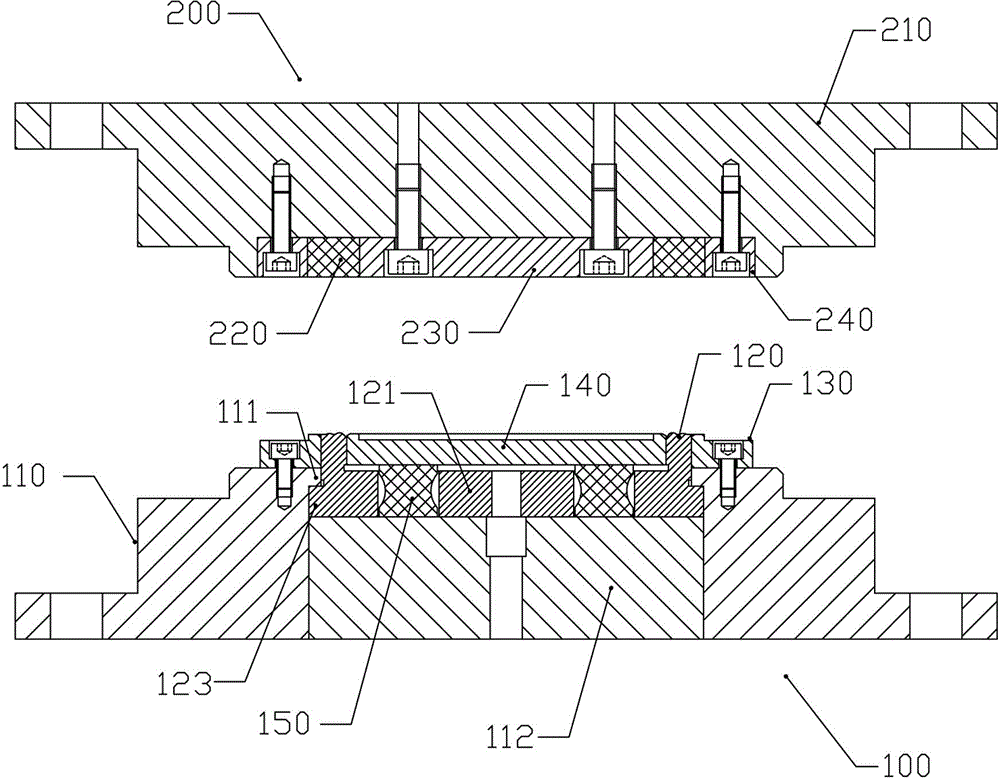

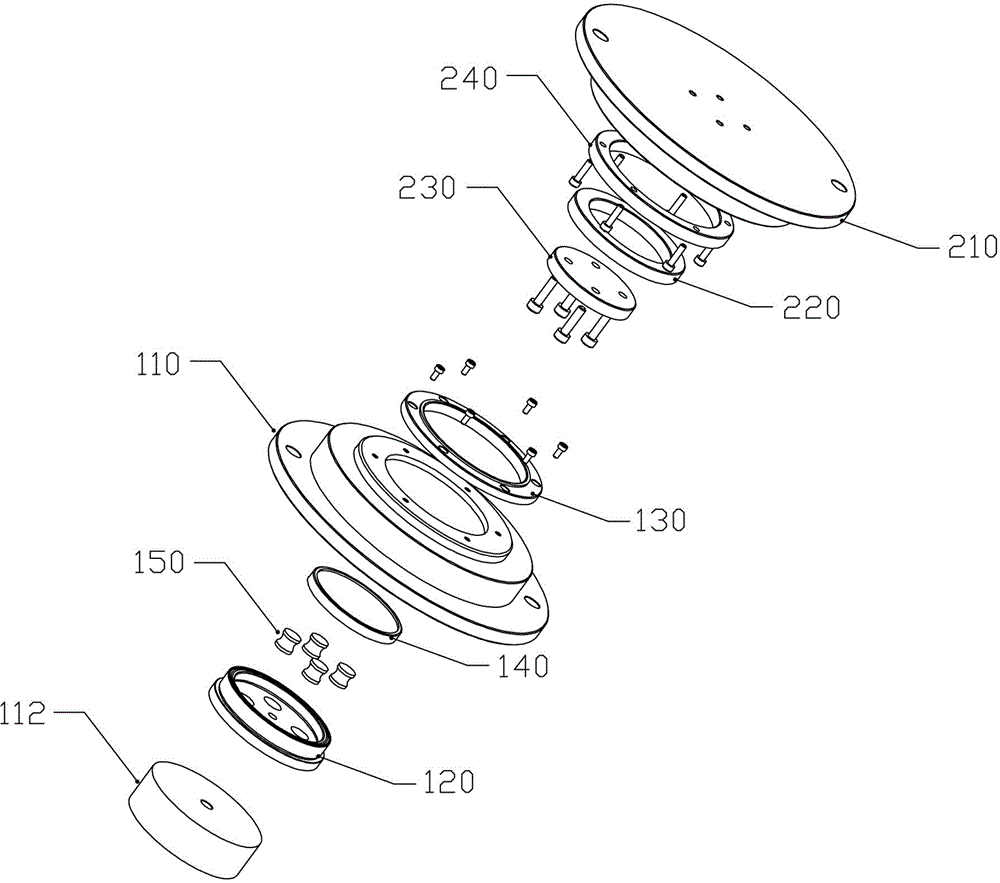

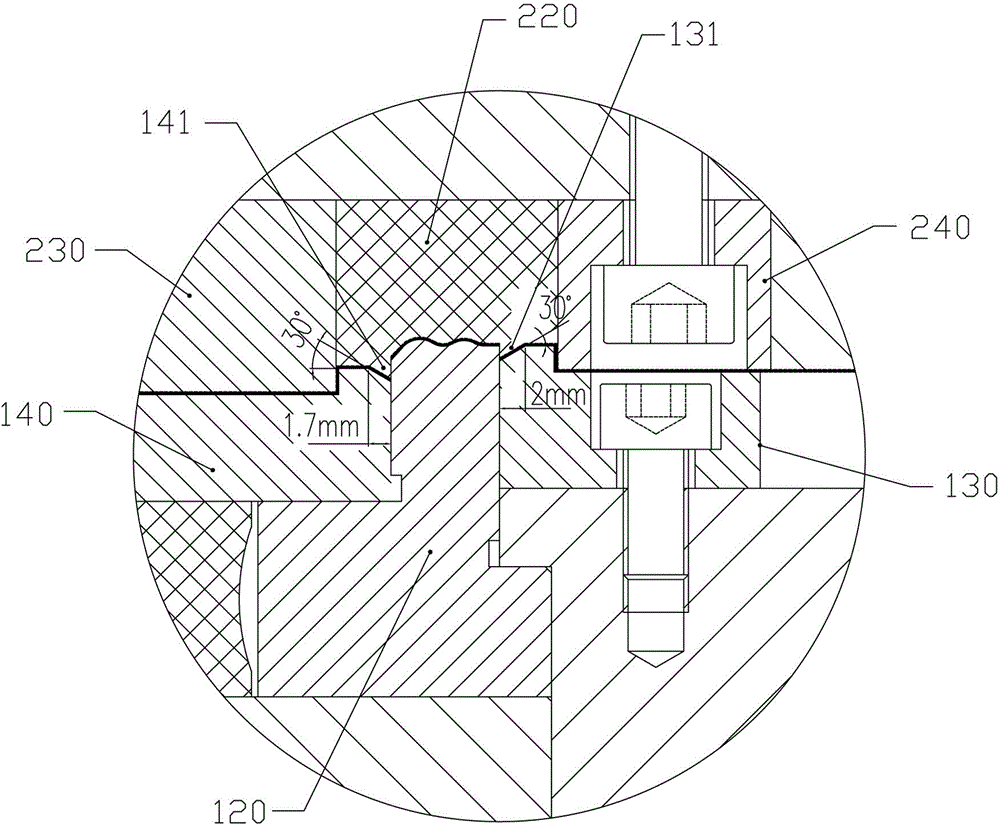

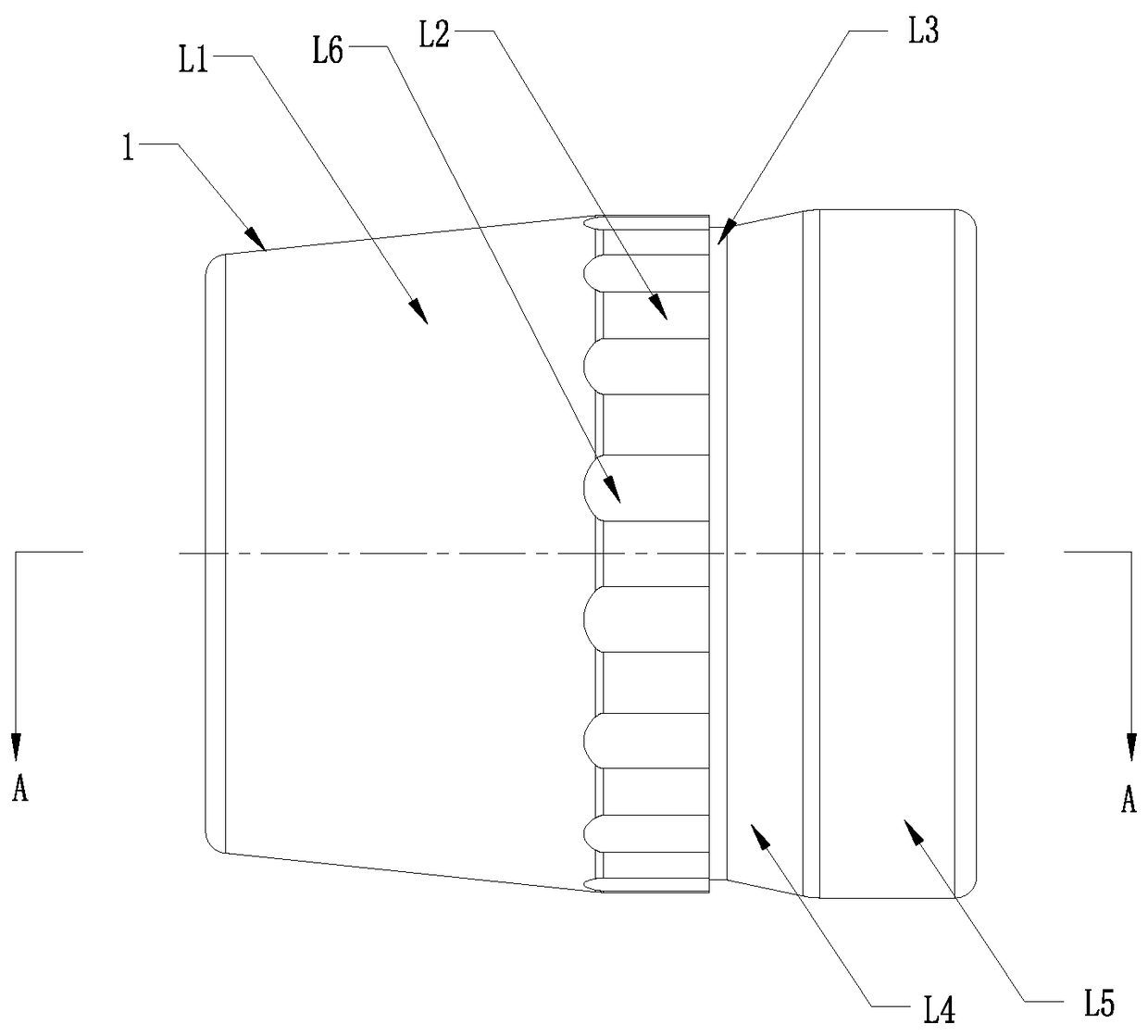

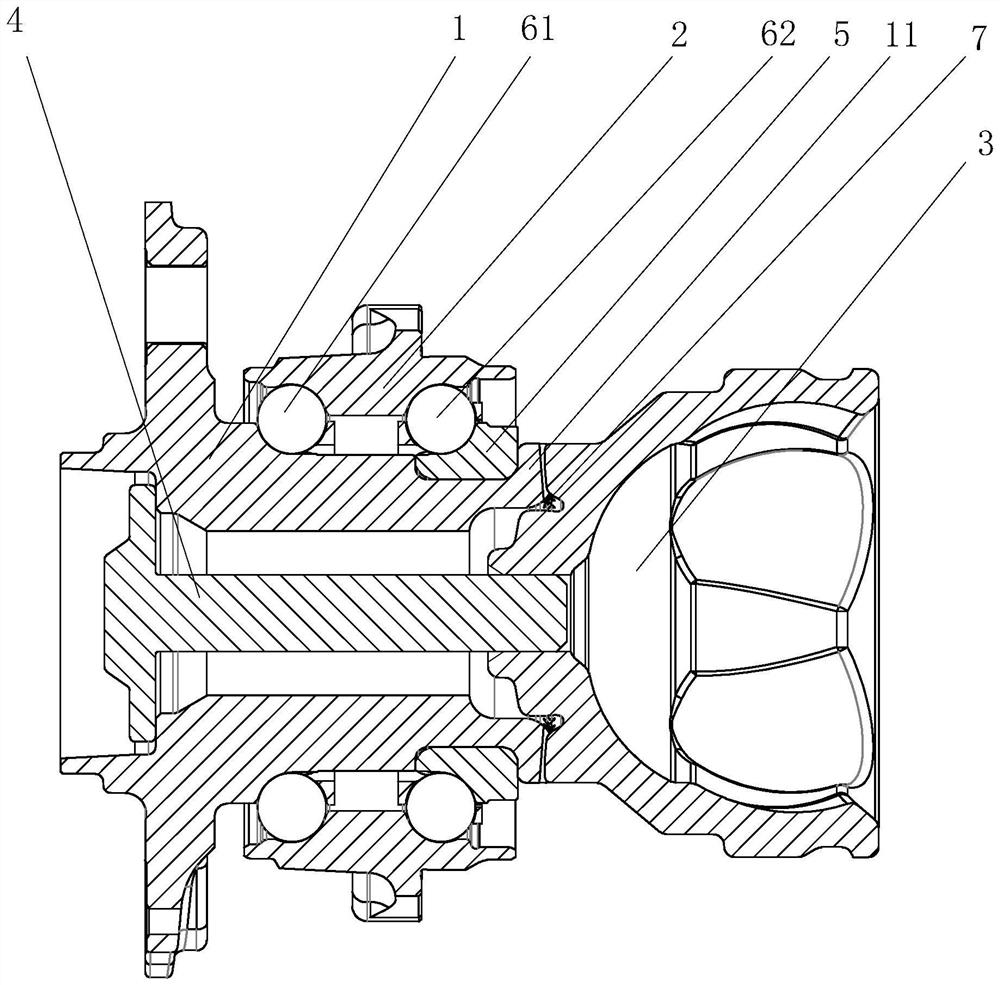

Wheel disc spigot locating structure of gas turbine rotor and gas turbine rotor

ActiveCN104533532AReduce extrusion stressEasy to assembleBlade accessoriesMachines/enginesGas turbinesTurbine rotor

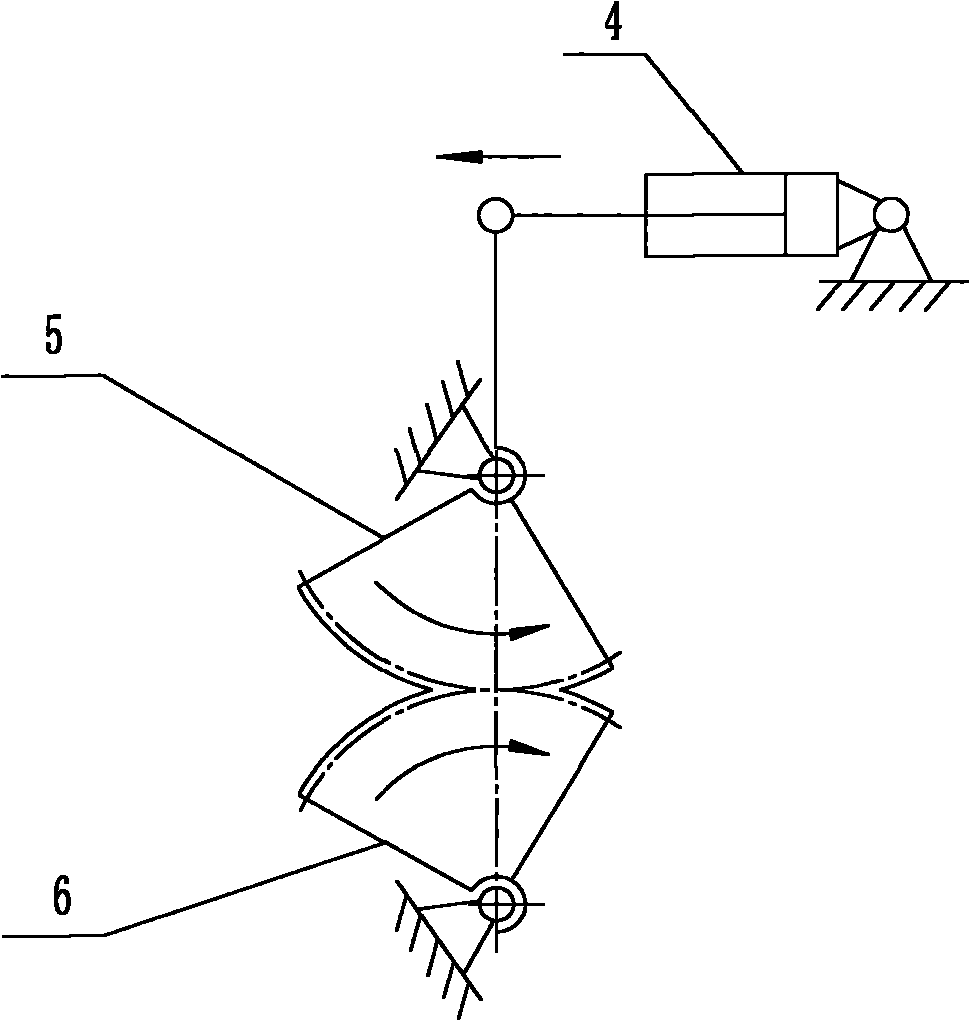

The invention relates to the field of gas turbine rotors and discloses a wheel disc spigot locating structure of the gas turbine rotor and the gas turbine rotor. Two wheel discs are axially overlapped, axial bumps are arranged at the opposite head faces of the two wheel discs, axial grooves are formed in the other head faces, and the outer diameters of the axial bumps are in interference fit with the inner diameters of the axial grooves; each axial bump is provided with an interference amount adjusting nick; the interference amount adjusting nick is a circular ring-shaped nick formed in the axial head face of the axial bump. By means of the wheel disc spigot locating structure, the wheel disc of the rotor can use a small interference magnitude when assembling, the device extrusion stress is reduced, the assembly is facilitated, the requirement on fixture is lowered, the rotor fits tightly under a working state, and the gas turbine rotor integrity is guaranteed.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

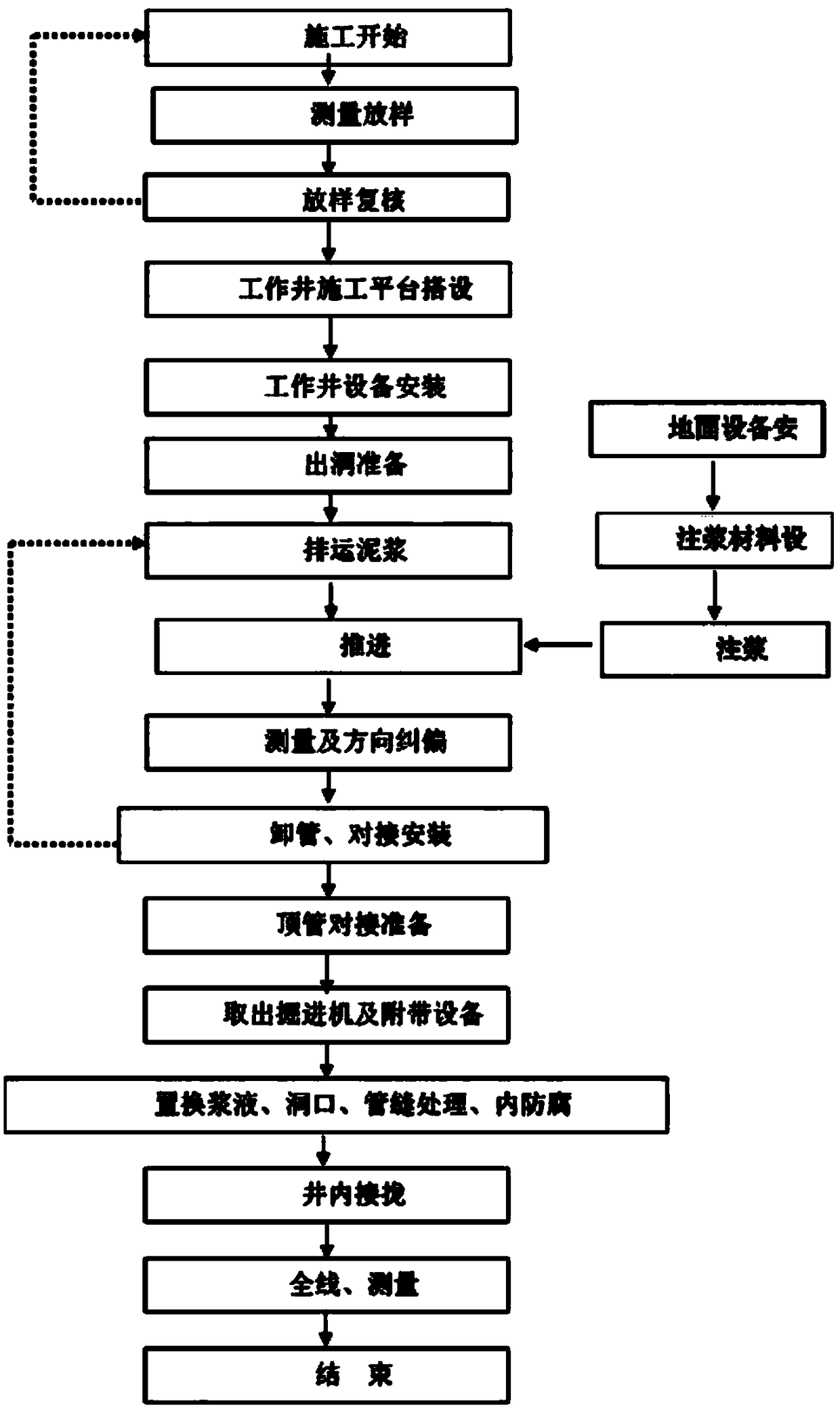

Pipe jacking construction method in complex terrain environment

InactiveCN109372532AReduce disturbanceReduce extrusion stressBuilding constructionsOrganic fertilisersTerrainEarth pressure balance

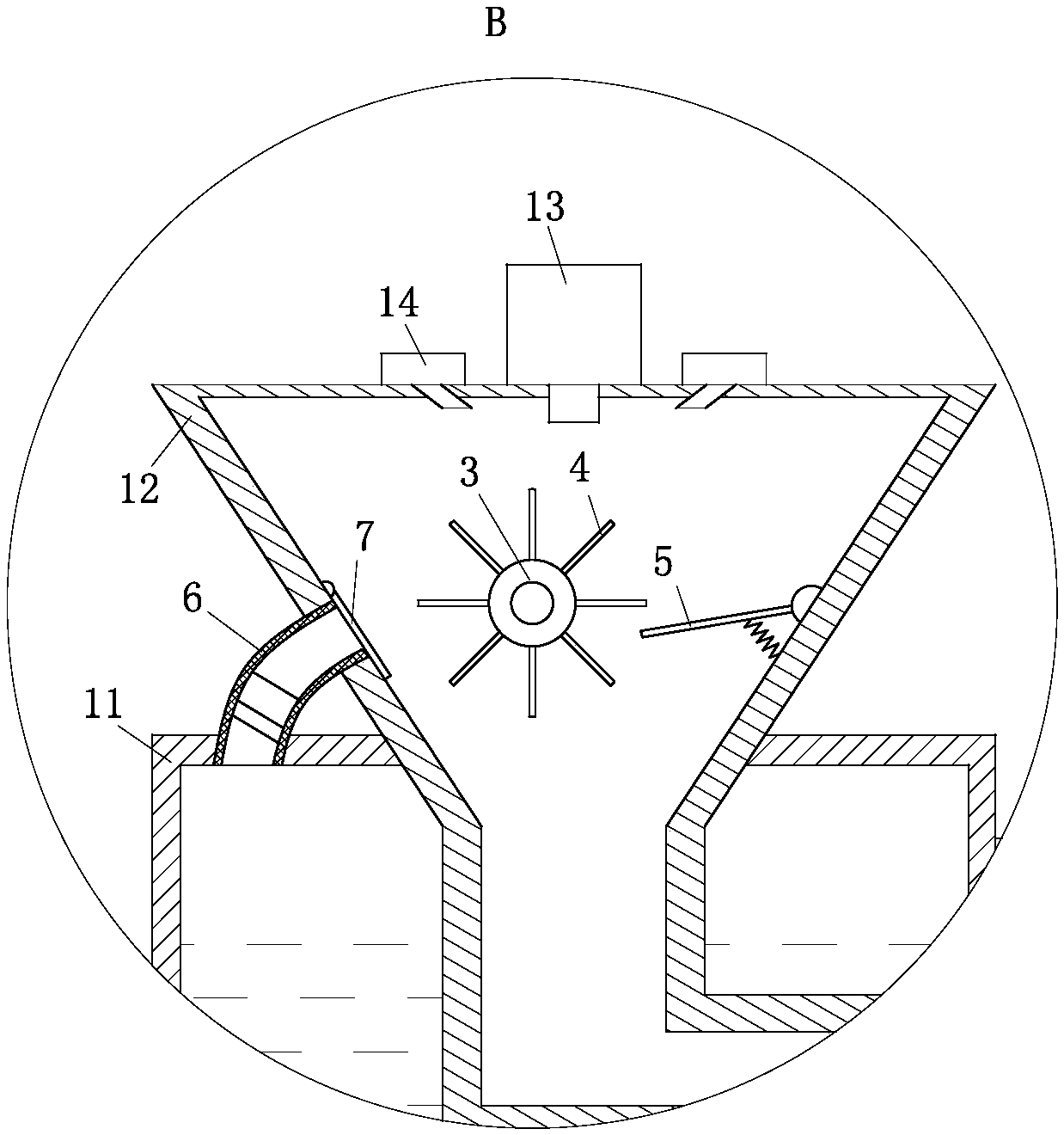

The invention discloses a pipe jacking construction method in a complex terrain environment. A panel type 3.5m large cutter head earth pressure balance pipe jacking heading machine is adopted; cut soil enters a muddy water cabin from gaps of a main cutting edge; soil in the muddy water cabin is broken into mud under the joint action of a stirring bar behind a cutter head and muddy water; and the water and earth pressure of excavation surfaces is balanced by controlling the mud and water pressure and the mud weight of the muddy water cabin, so that the excavation surfaces are always in a stablestate. As for sections with poor soil quality and a large buried depth of pipelines, or sections located in a prosperous region with buildings (structures) or traffic trunks above and strict restrictions on displacement and groundwater by surrounding environments, the large-diameter earth pressure balance pipe jacking method is easy and safety in construction, high in quality, low in investment and short in construction period, extrusion of surrounding pipelines and settlement of the ground are effectively controlled, and smooth operation of ground transportation is ensured while important underground pipelines are protected during construction.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

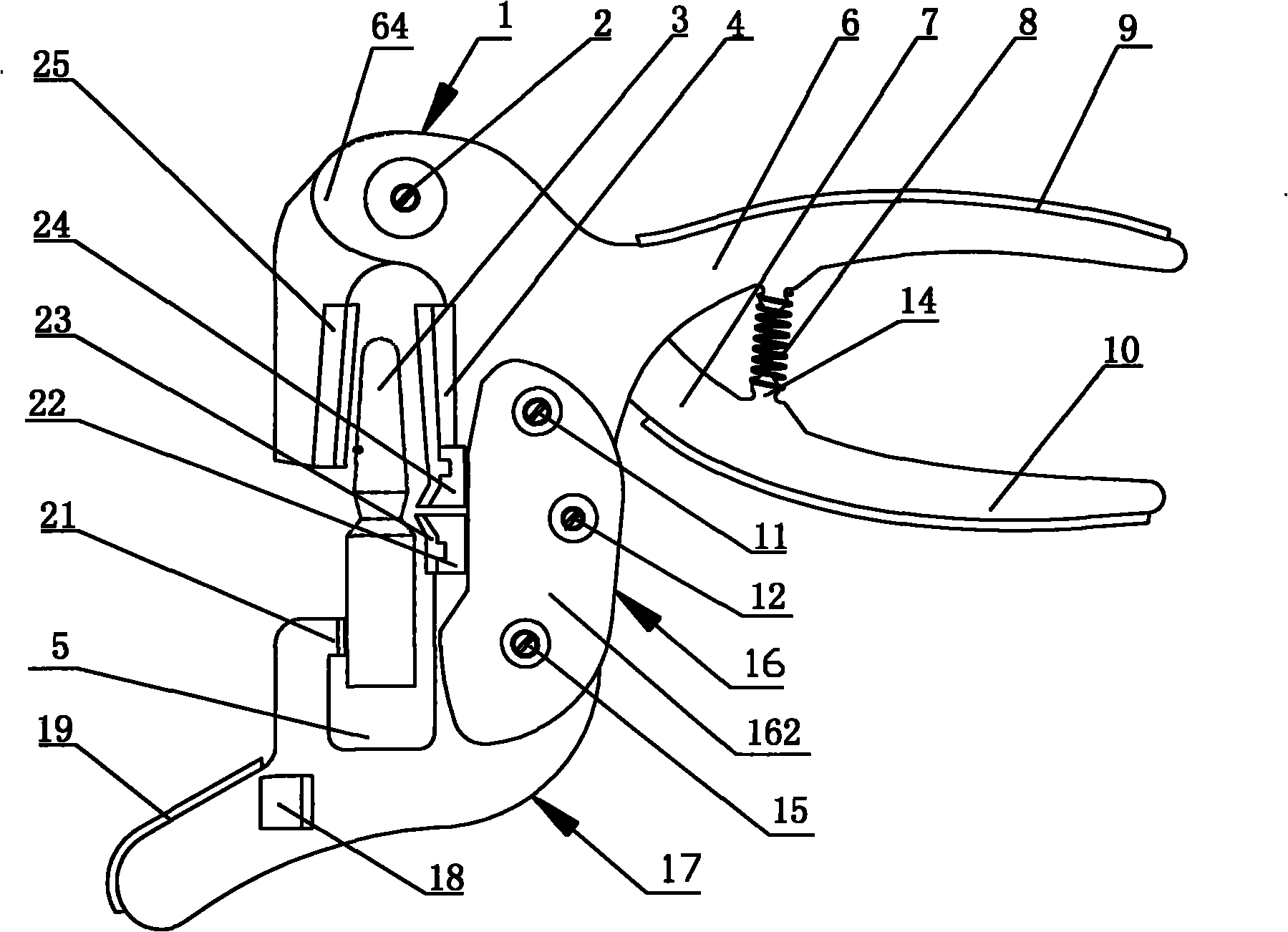

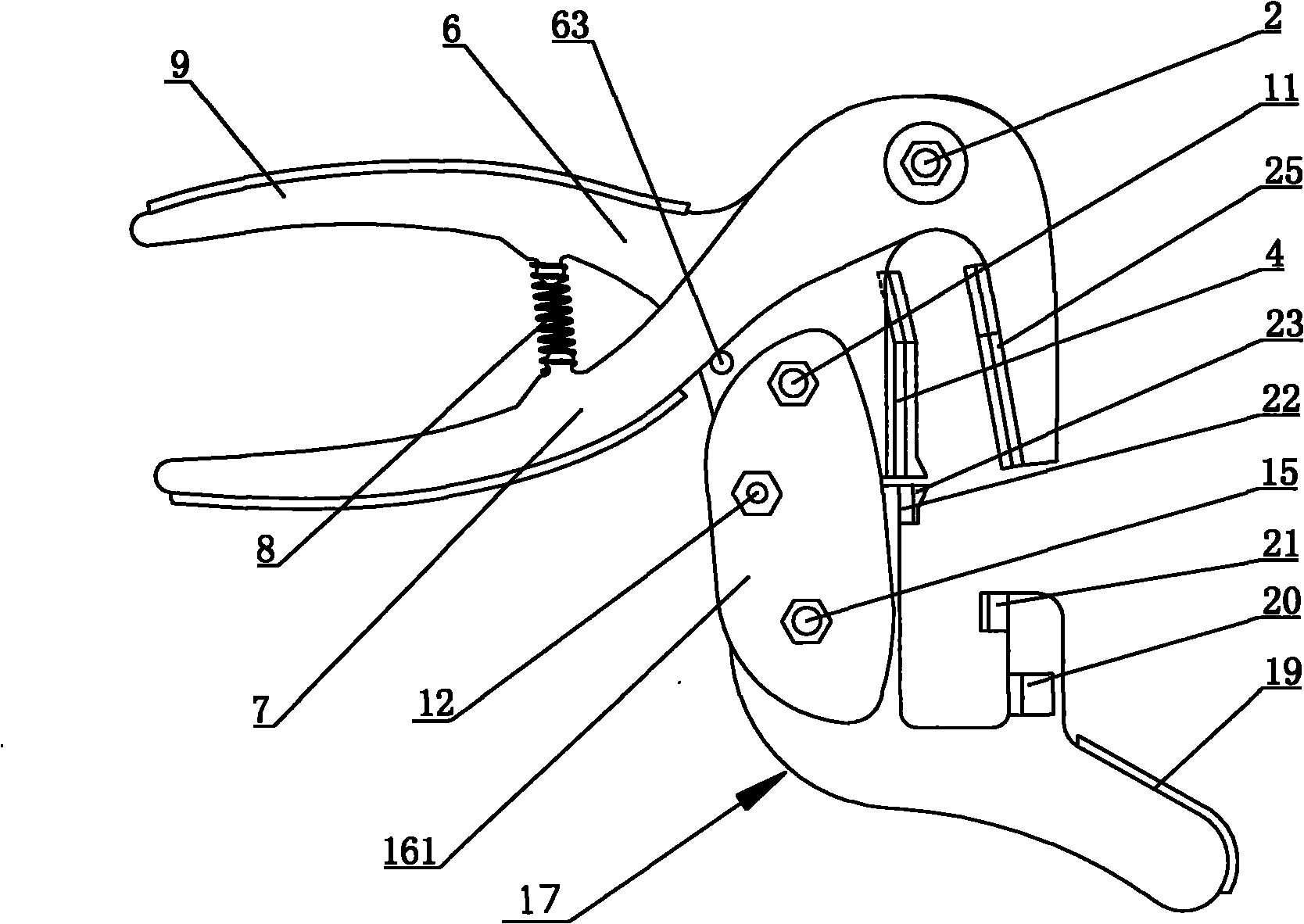

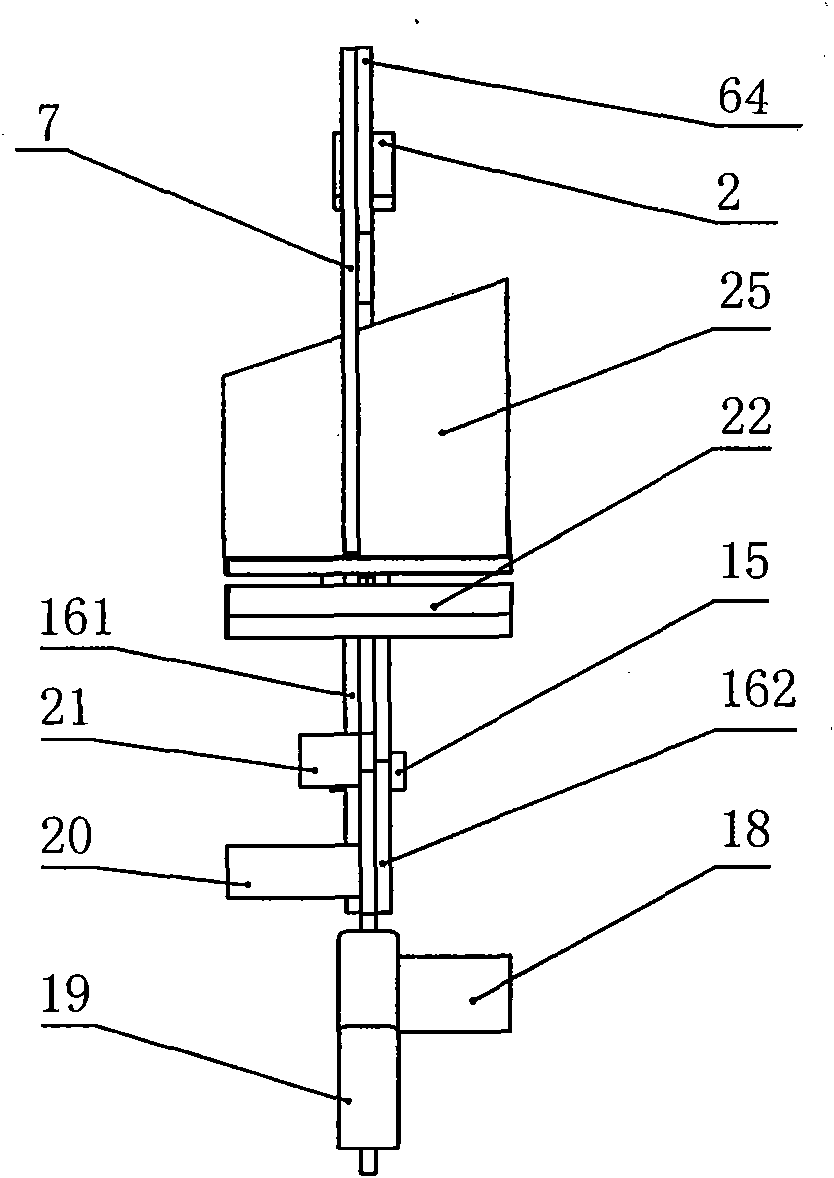

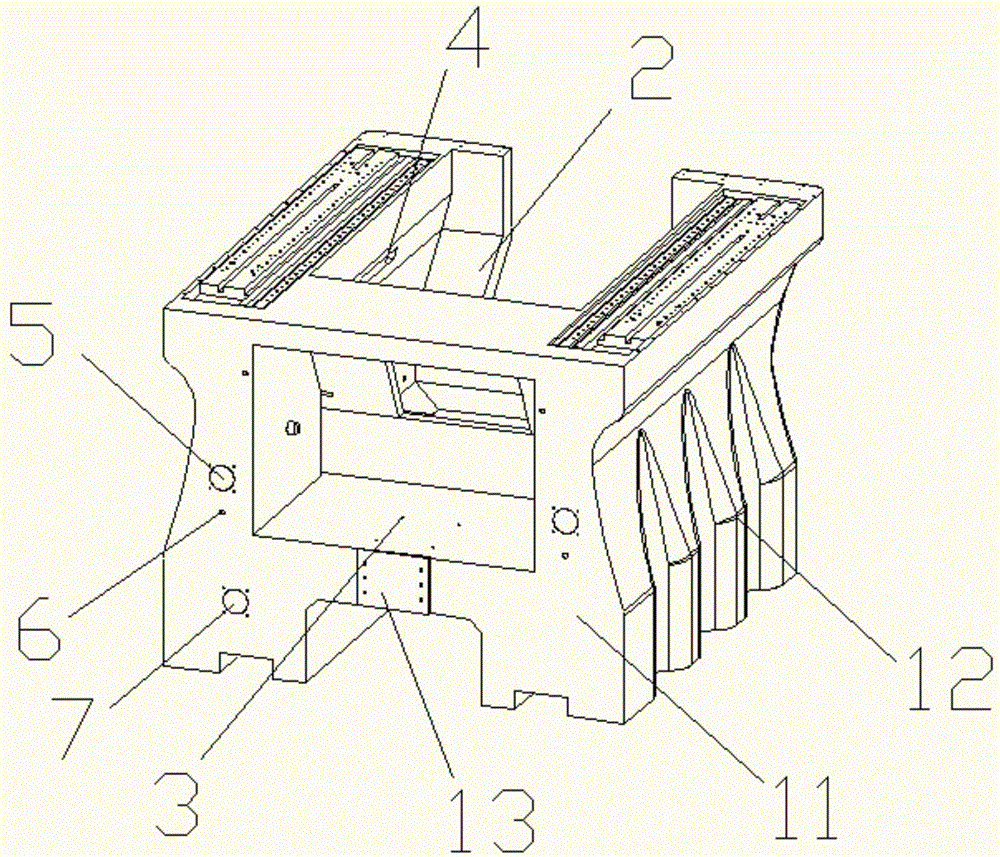

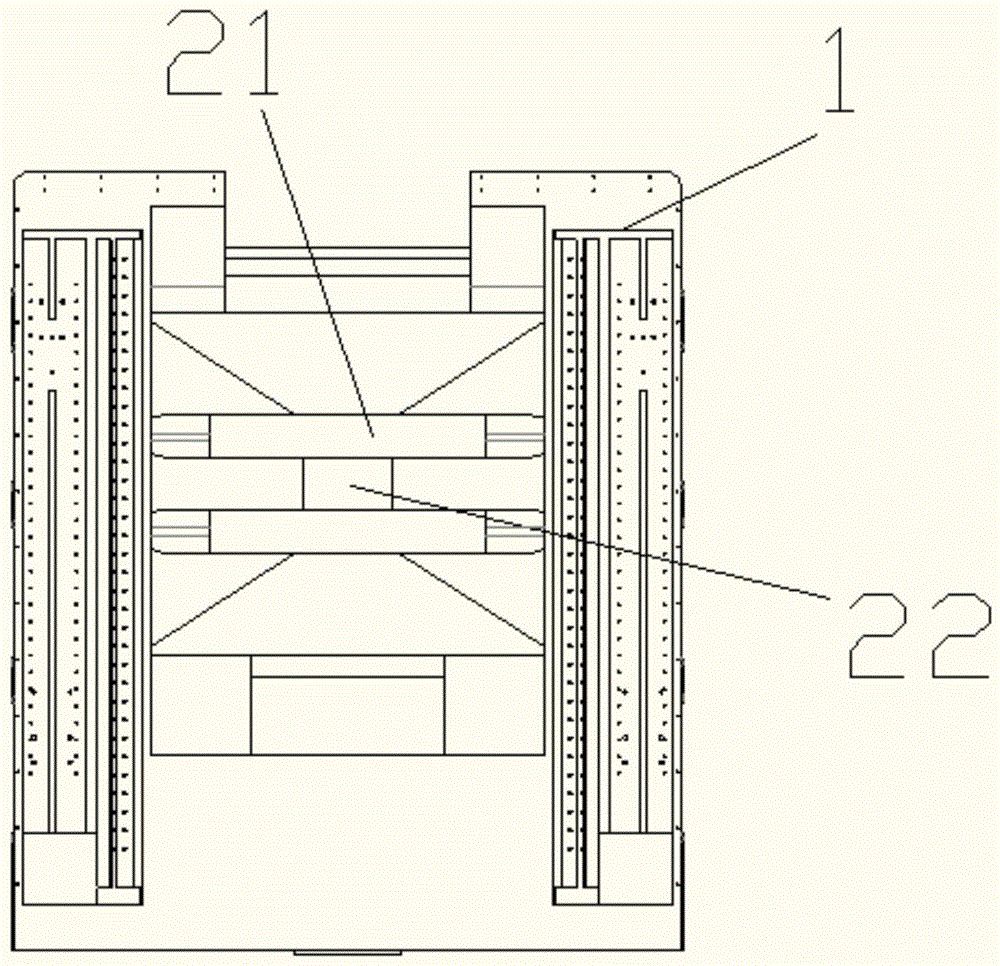

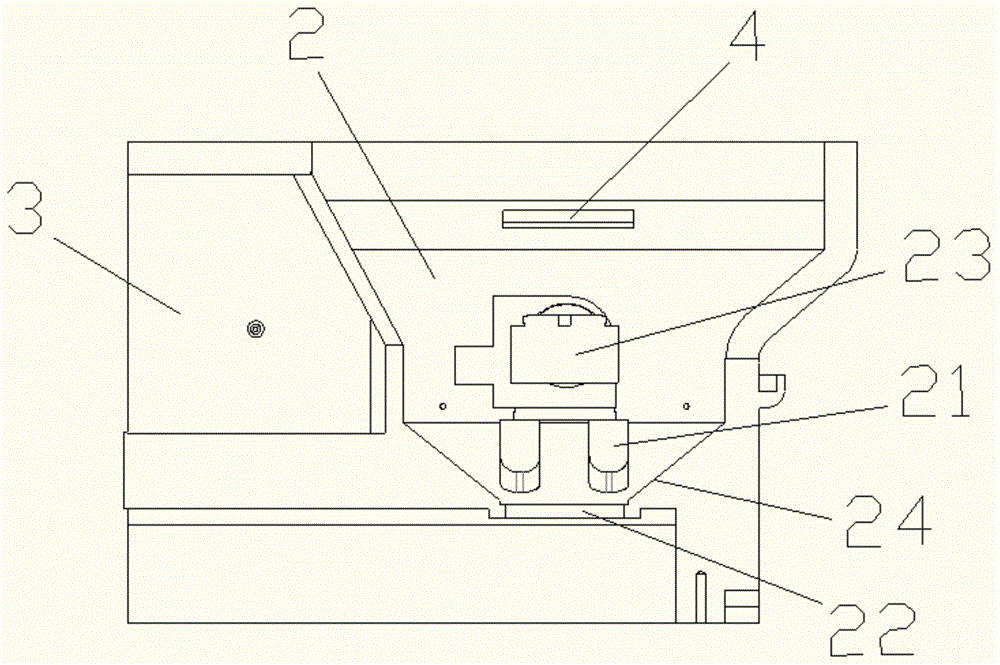

Ampoule splitter

InactiveCN101973505AHigh breaking forceGuaranteed against damageOpening closed containersBottle/container closureEngineeringBottle neck

The invention discloses an ampoule splitter which is a manual-operation type or full-automatic type ampoule splitter. The ampoule splitter comprises a bottle bubble clamp, a positioning frame and a bottle body frame and is characterized in that the upper part of the positioning frame is provided with the bottle bubble clamp used for clamping an ampoule bottle bubble and splitting the ampoule bottle bubble through a lever, and the bottle bubble clamp is formed by crosswise and movably connecting an upper clamp body and a lower clamp body through a clamp pin shaft. The lower part of the positioning frame is provided with the bottle body frame used for positioning and clamping the ampoule bottle body, and the bottle body frame comprise a connecting plate, a bottle neck lower force arm and a bottle body force arm. The positioning frame is formed by assembling the bottle bubble clamp and the bottle body frame together through double shafts in a linkage way, and the bottle bubble clamp is movably connected with the bottle body frame through the positioning frame. By using the ampoule splitter of the invention, fine glass fragments cannot be generated, the phenomena of hands injuring and medicinal liquid spilling are prevented, the table type or full-automatic type ampoule splitter can be used for splitting two or three ampoule bottles at the same time. The ampoule splitter has the advantages of convenient and rapid operation and meets the professional requirements of medical treatment.

Owner:向永川

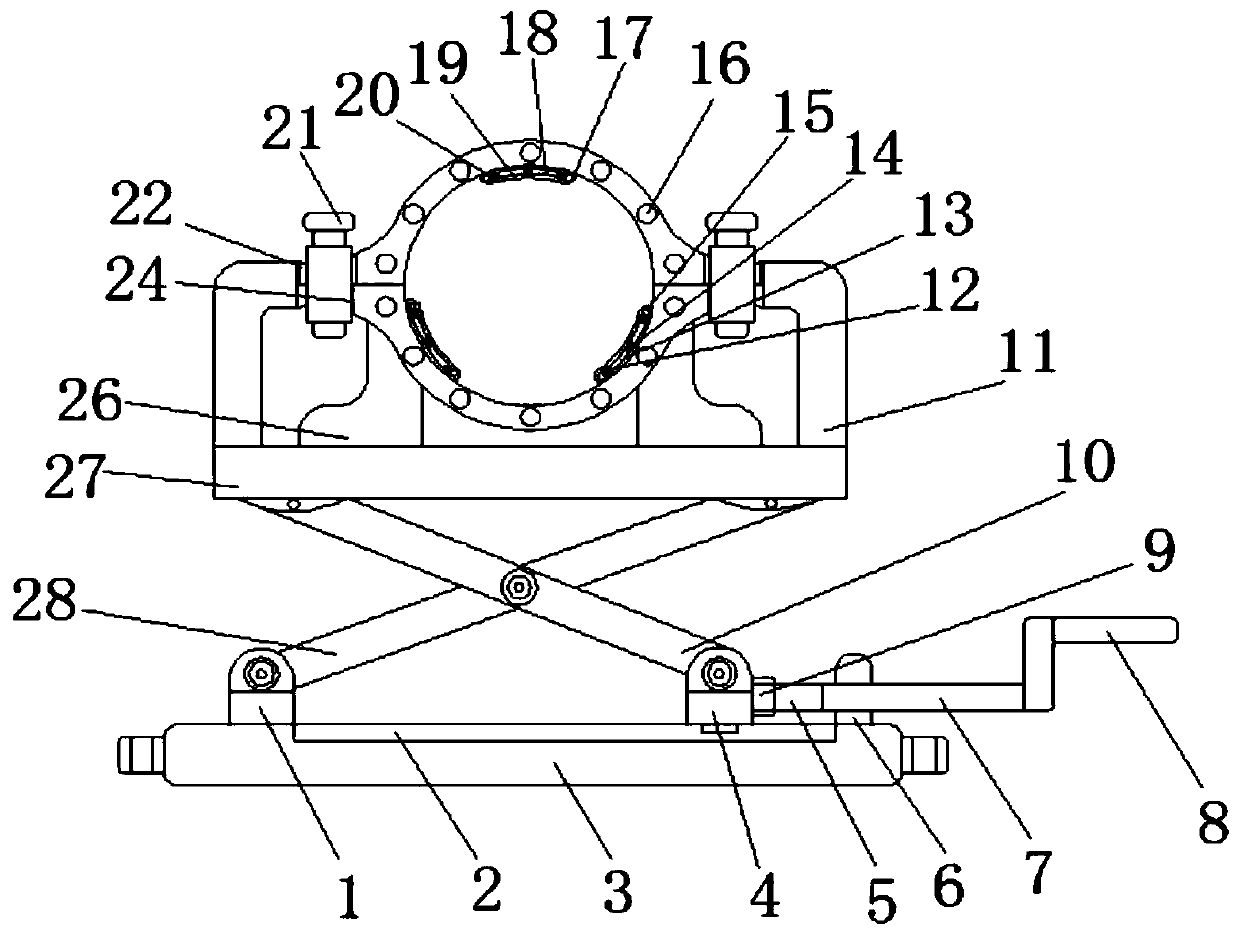

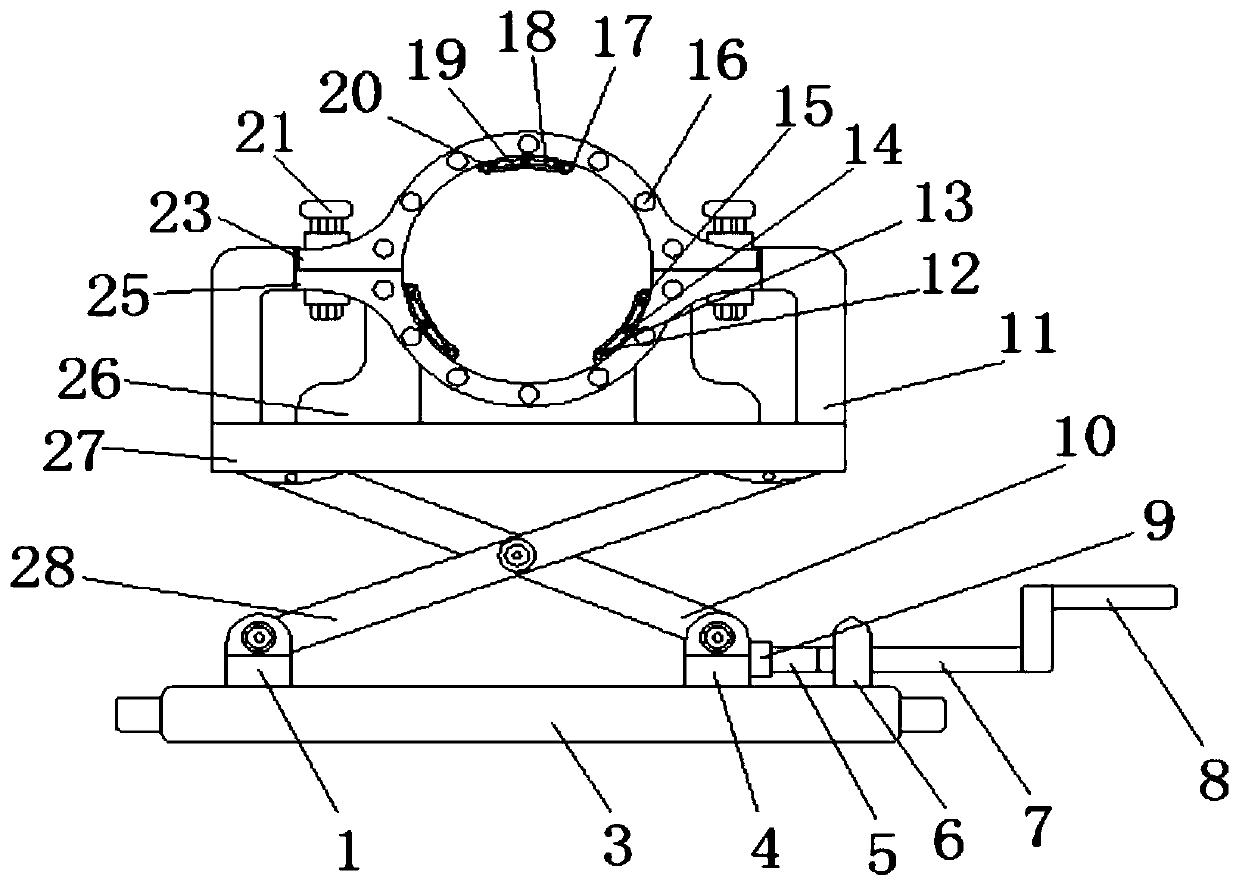

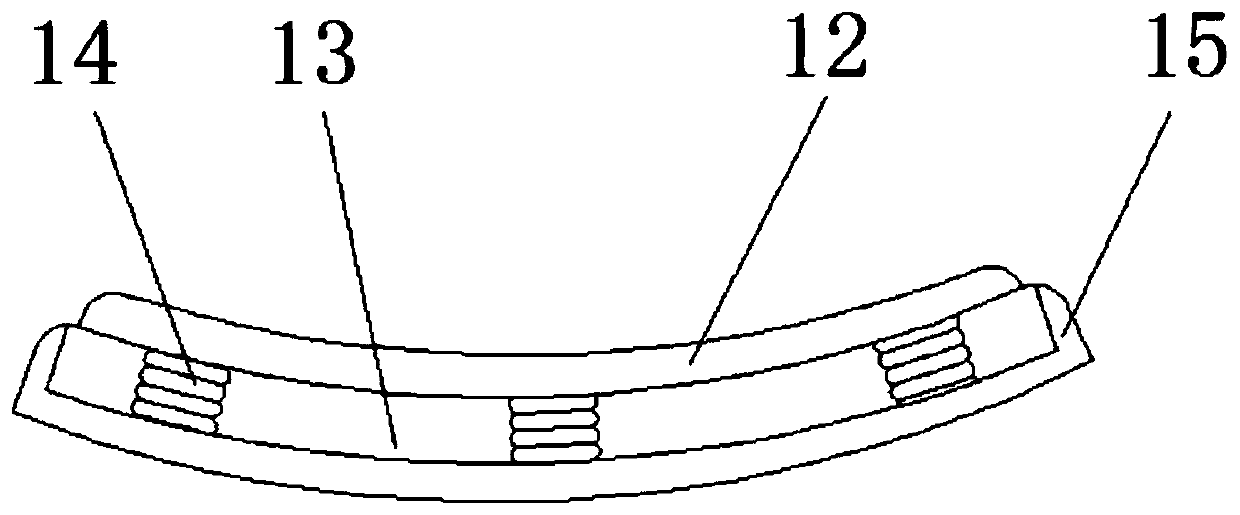

Crude oil pipeline conveying and fixing device

InactiveCN110260048AReduce wearExtended service lifePipe supportsPipe elementsButt jointThermal expansion

The invention belongs to the technical field of pipeline fixing equipment and particularly relates to a crude oil pipeline conveying and fixing device. A lifting mechanism composed of a first fixing block, a second fixing block, a first supporting rod and a second supporting rod is installed on the crude oil pipeline conveying and fixing device. The lifting mechanism is pushed to be lifted through a thread rod. The height of a connecting base can be adjusted, thus the height of fixing the pipeline can be adjusted, a worker can adjust the pipeline to the proper height, installation and butt joint of the pipeline are facilitated, adjustability of the device is high, the device can be popularized beneficially, the device is provided with a first elastic baffle, a first spring, a second elastic baffle and a second spring, by means of the elastic effect of the first spring and the second spring, when the crude oil pipeline generates thermal expansion, the crude oil pipeline has certain expanding space in the device, and extruding stress borne by the pipeline can be reduced.

Owner:NORTH HUAJIN CHEM IND CO LTD

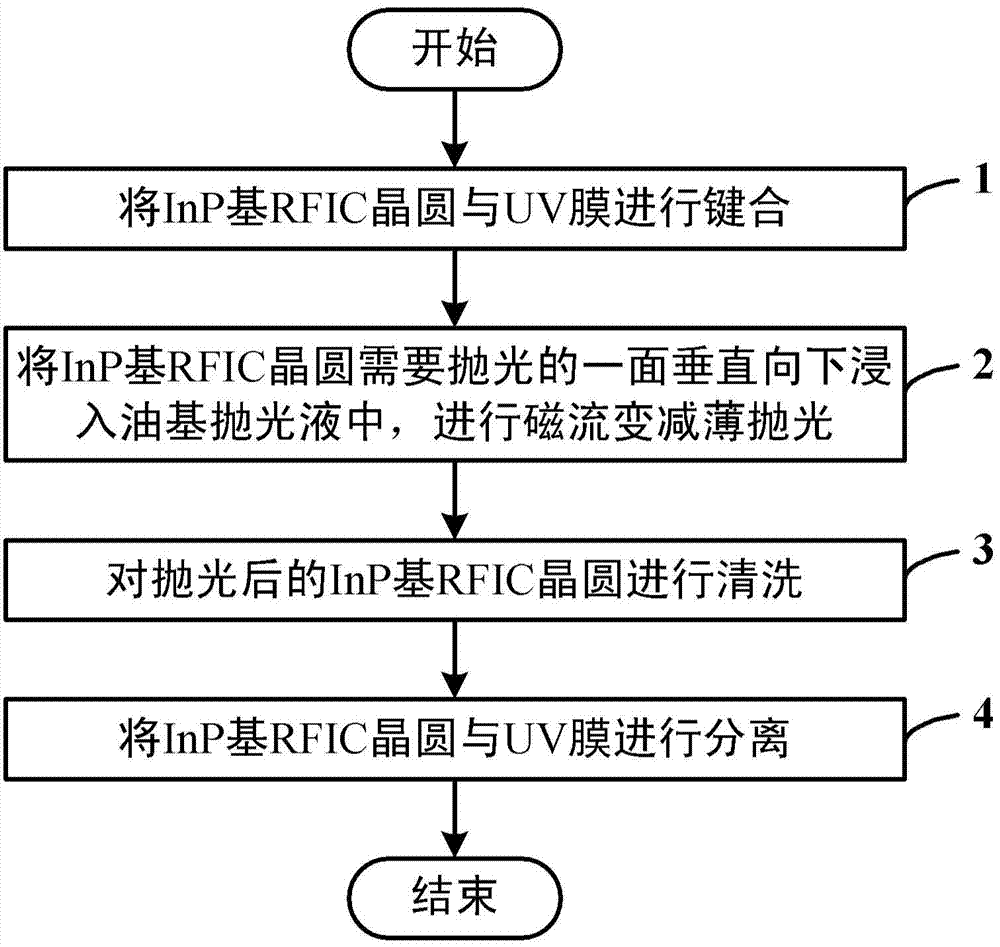

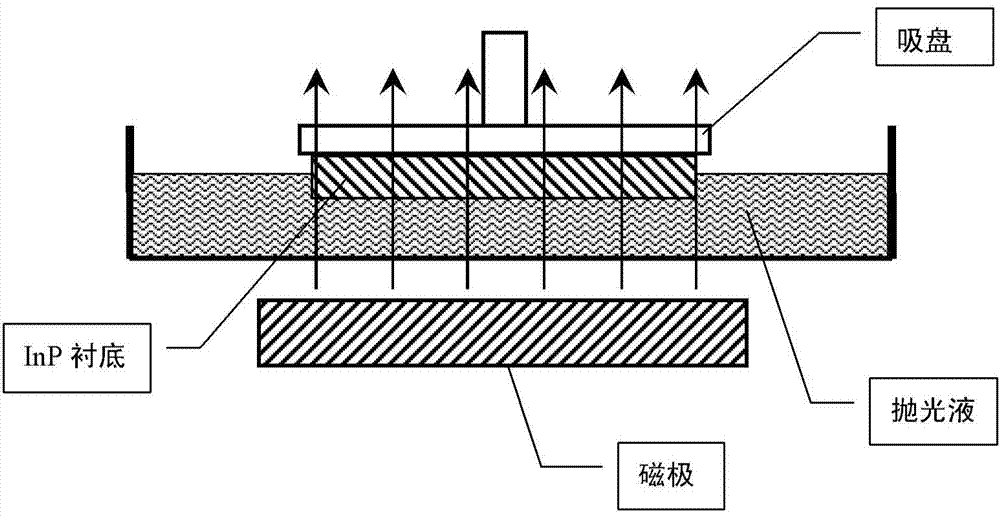

Method for conducting magneto-rheological thinning and polishing on InP-based RFIC wafer

The invention discloses a method for conducting magneto-rheological thinning and polishing on an InP-based RFIC wafer. The method comprises the InP-based RFIC wafer and a UV film bond with each other, wherein one surface, needing to be polished, of the InP-based RFIC wafer is vertically soaked in an oil-based polishing solution downwards, and magneto-rheological thinning and polishing are conducted; the polished InP-based RFIC wafer is cleaned; the InP-based RFIC wafer is separated from the UV film. By the magneto-rheological polishing method, extrusion stress on the InP-based RFIC wafer is reduced in a polishing process, and physical damage is greatly reduced. Under the action of a magnetic field, the polishing solution is high in fluid viscosity and good in elasticity, and is tightly attached to the InP-based RFIC wafer, machining precision distortion caused by deformation errors of a polishing disk in the conventional CMP process is avoided, and a very good polishing effect on the InP-based RFIC wafer is formed. The whole magneto-rheological process is stable, speed is high, controllability is good, multiplicity is high, and no dust pollution is caused. By means of polishing, the thickness of a substrate is 20 microns finally, and the surface Ra is less than 2nm.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

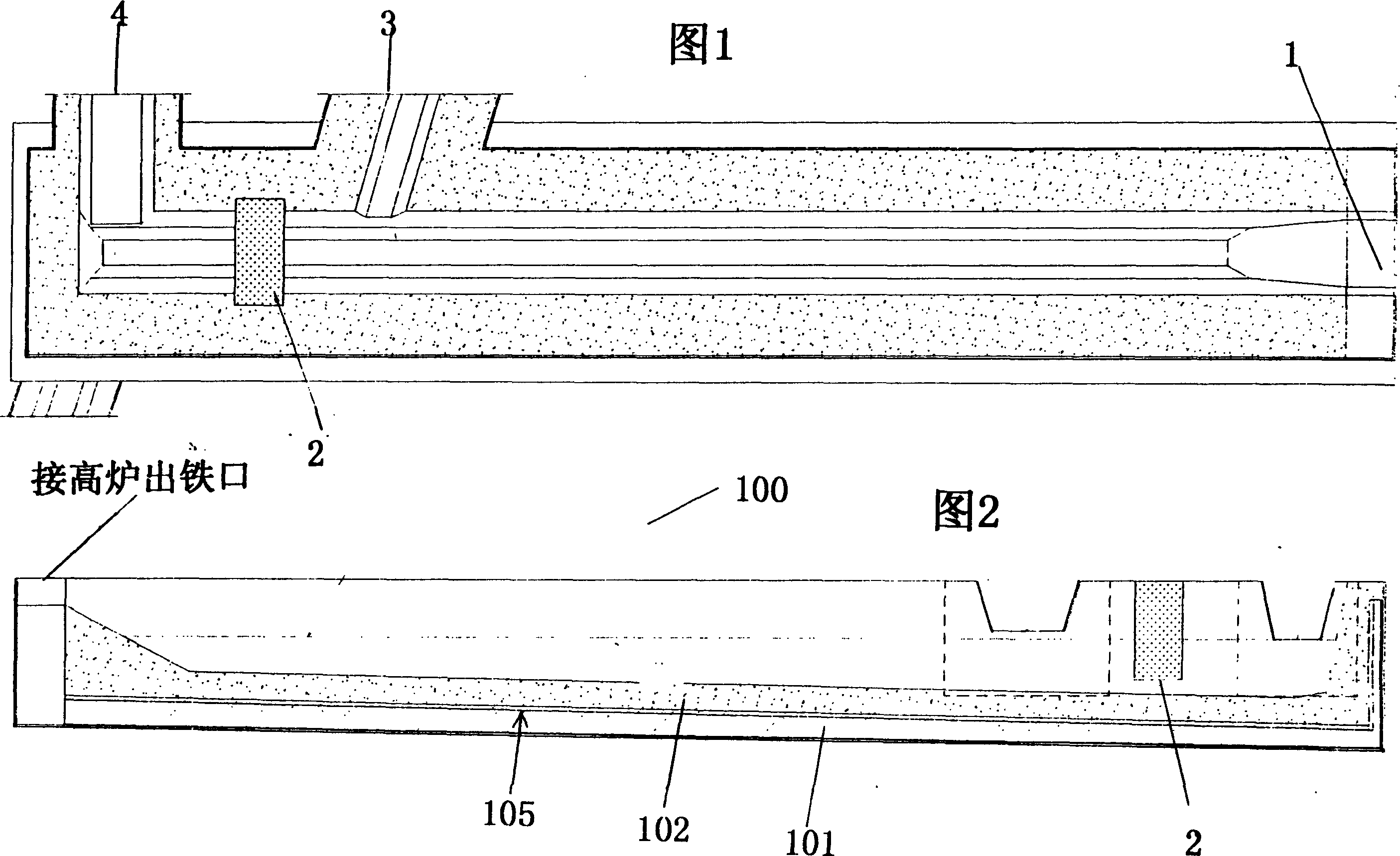

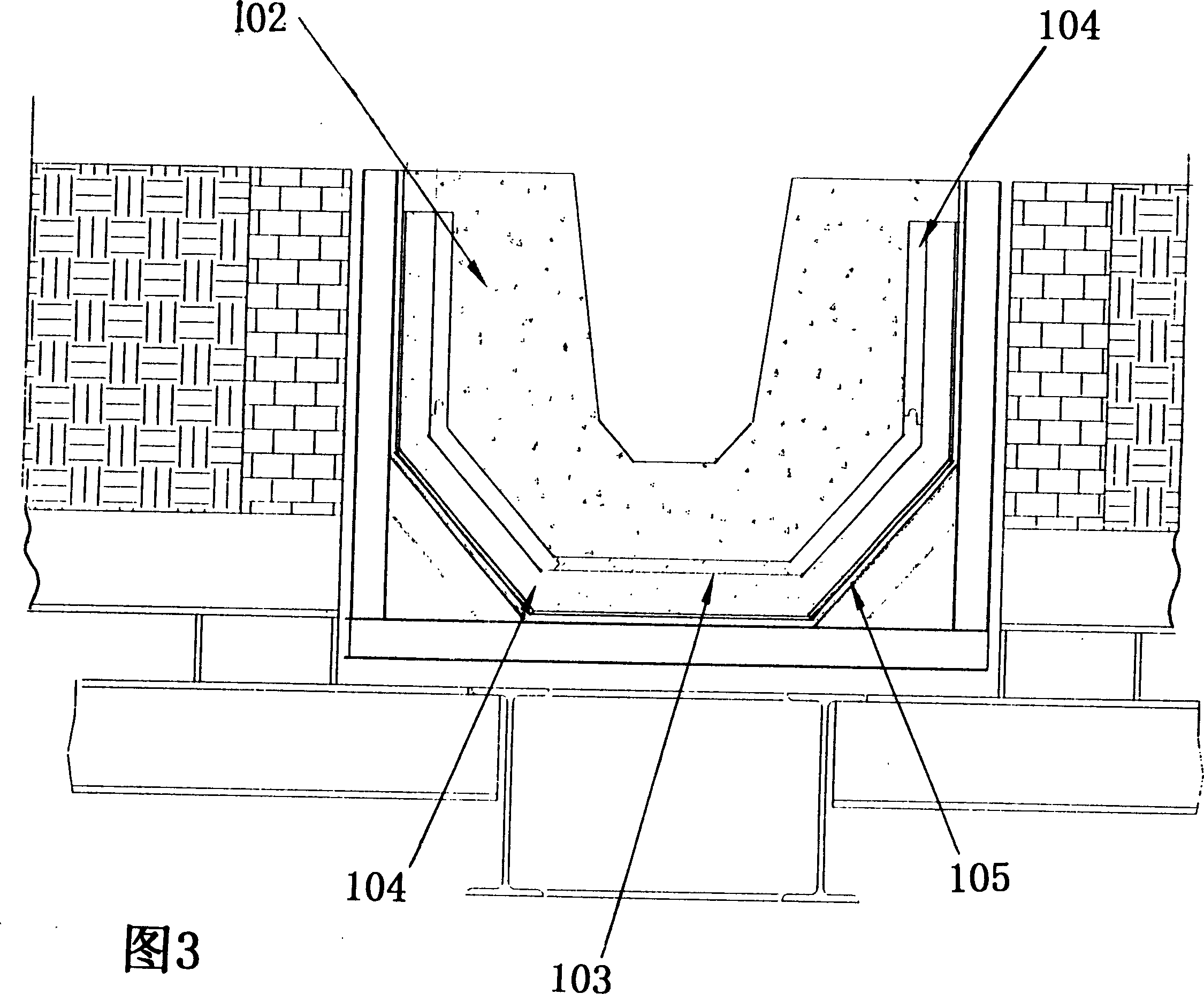

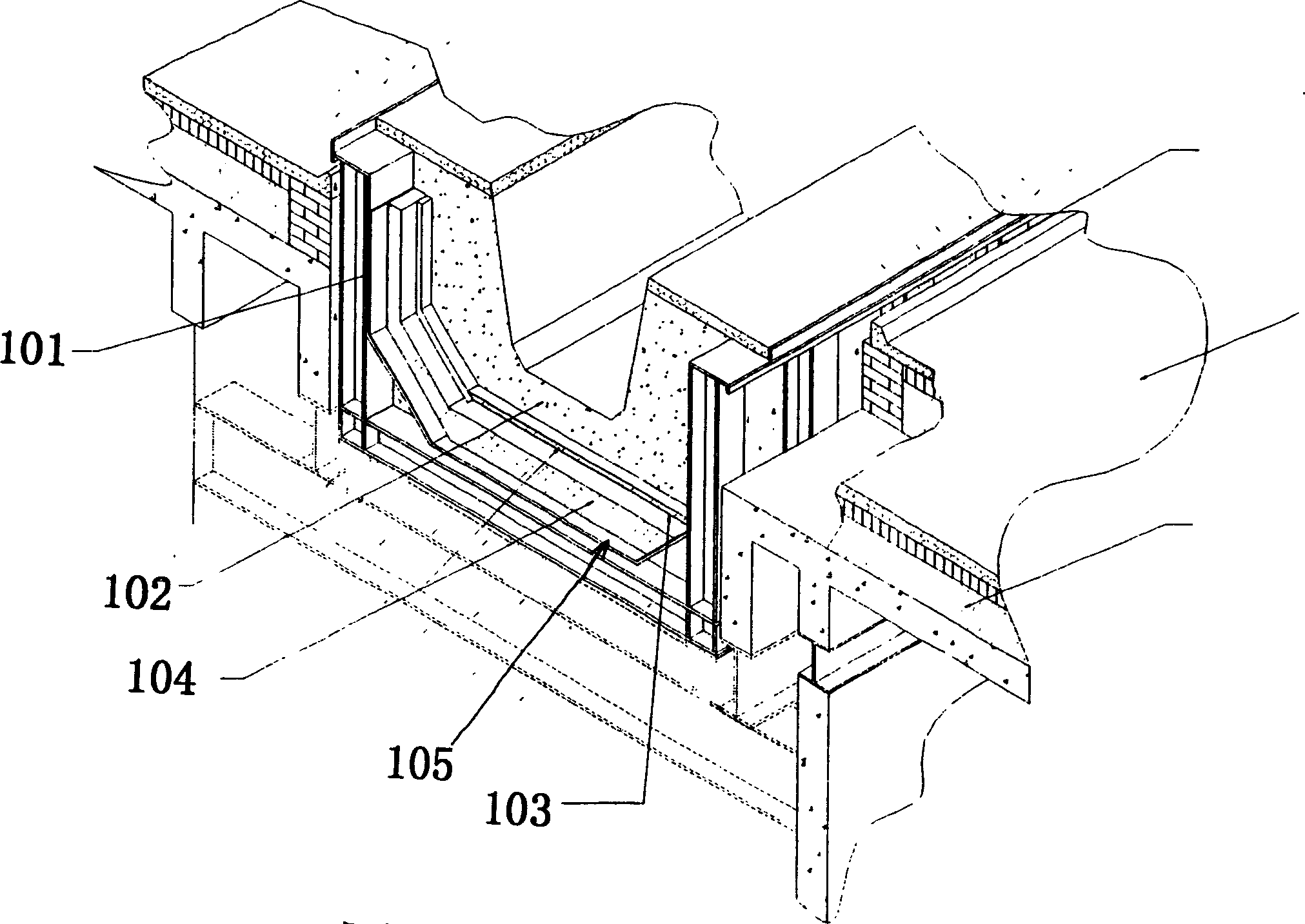

Floating main trough

A floating main-groove contains steel shell and operating layer cast material lying on the inboard of main-groove. Operating layer cast material is contacted with melted iron while steel shell is used to support the main-groove, and steel shell is separated from blast-furnace furnace wall, iron notch and slag hole, also there is a floating layer between steel shell and supporting ground. The main-groove steel shell can improve the safety, reliability and maintainability of main-groove and all its fireproof material backing, and can avoid many defects and problems appearing in traditional main-groove design.

Owner:ALLIED MINERAL PRODS TIANJIN

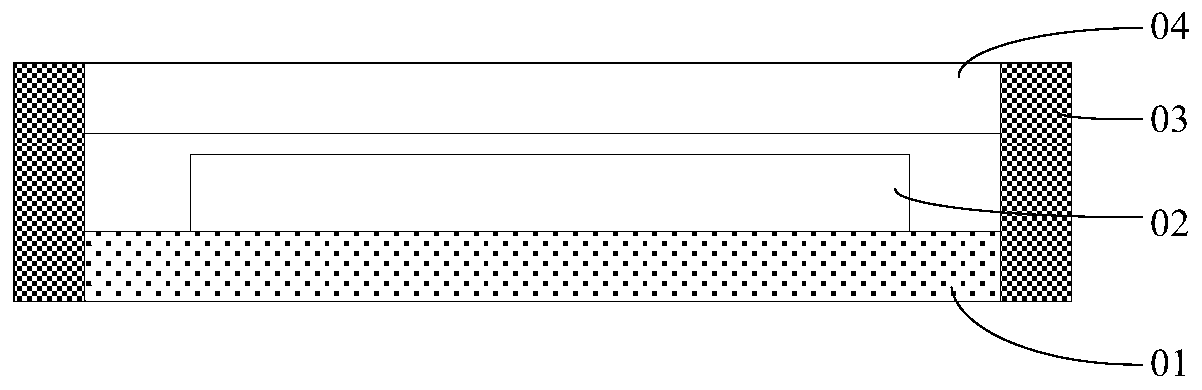

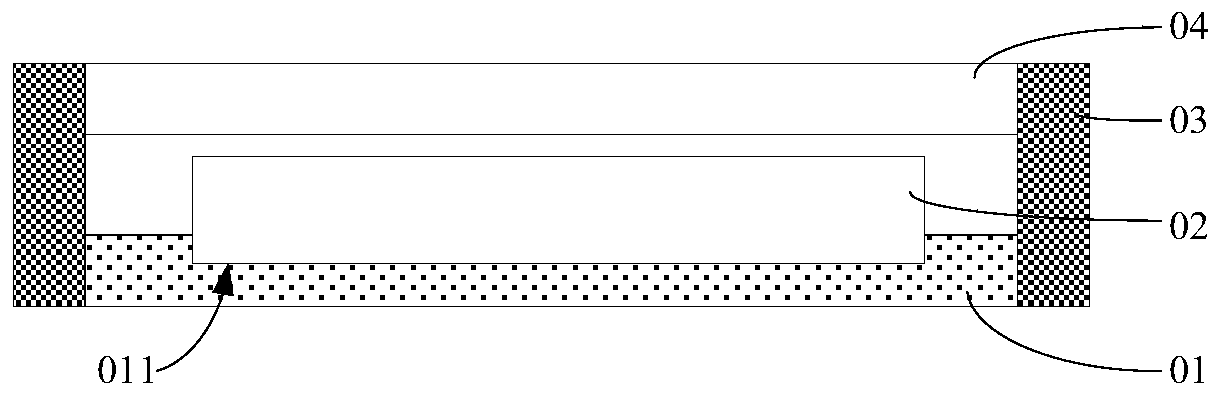

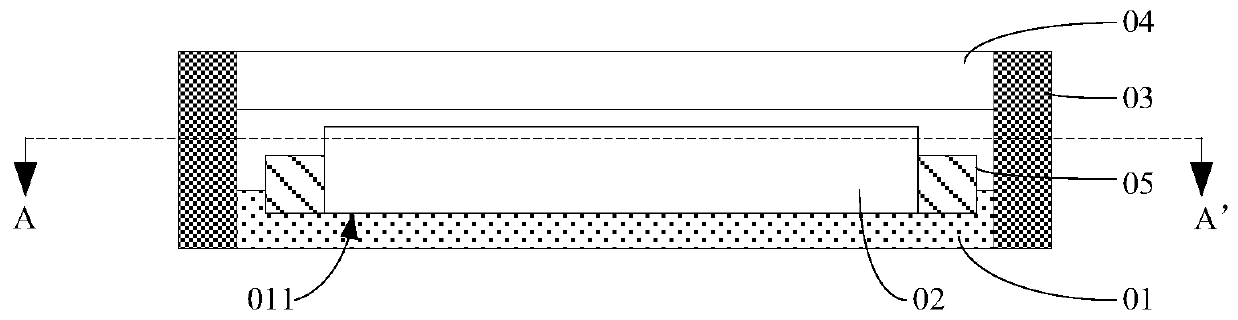

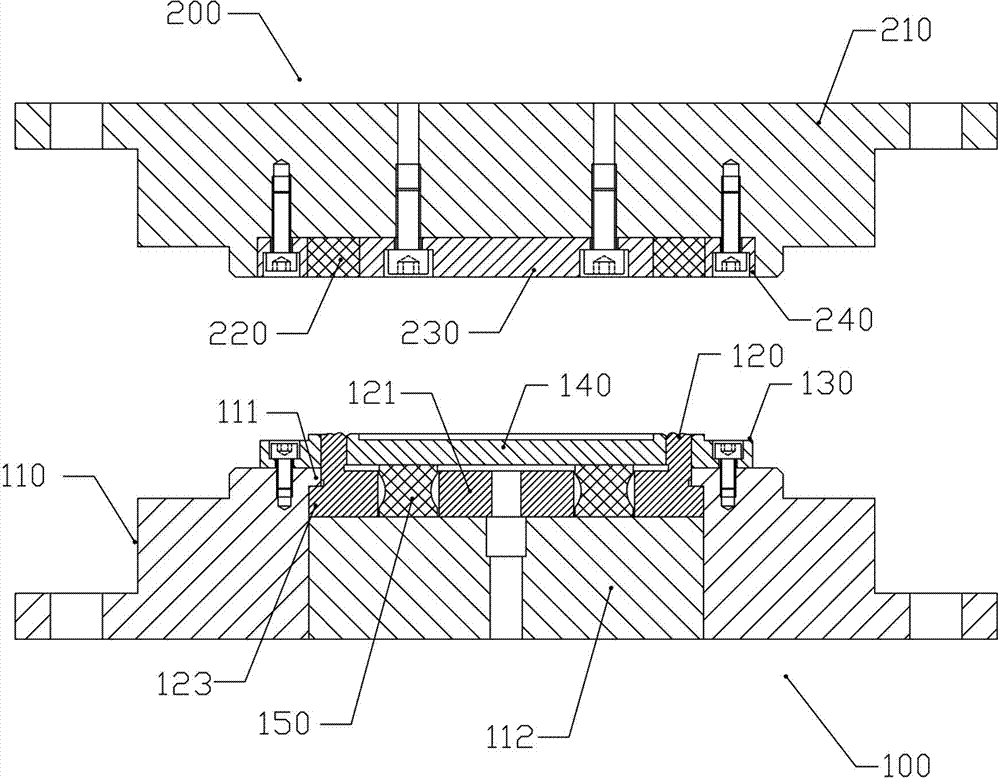

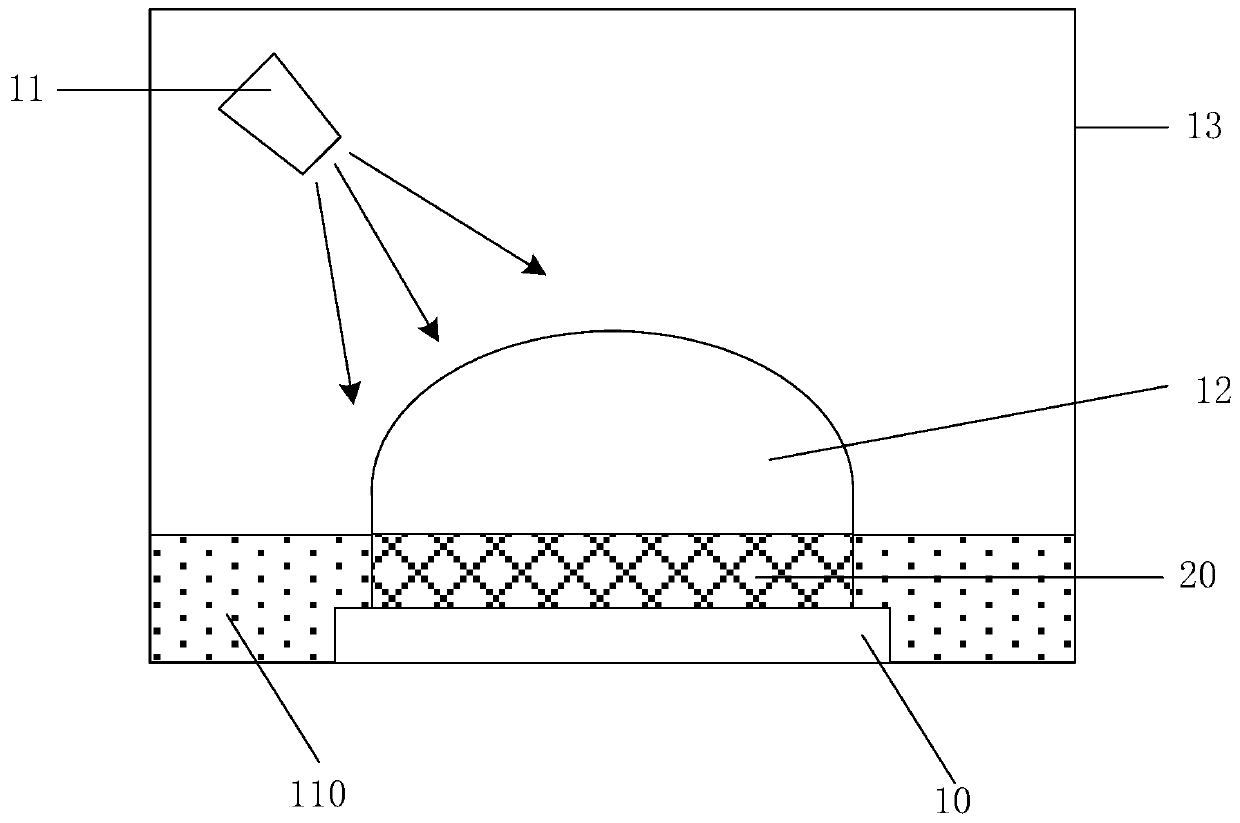

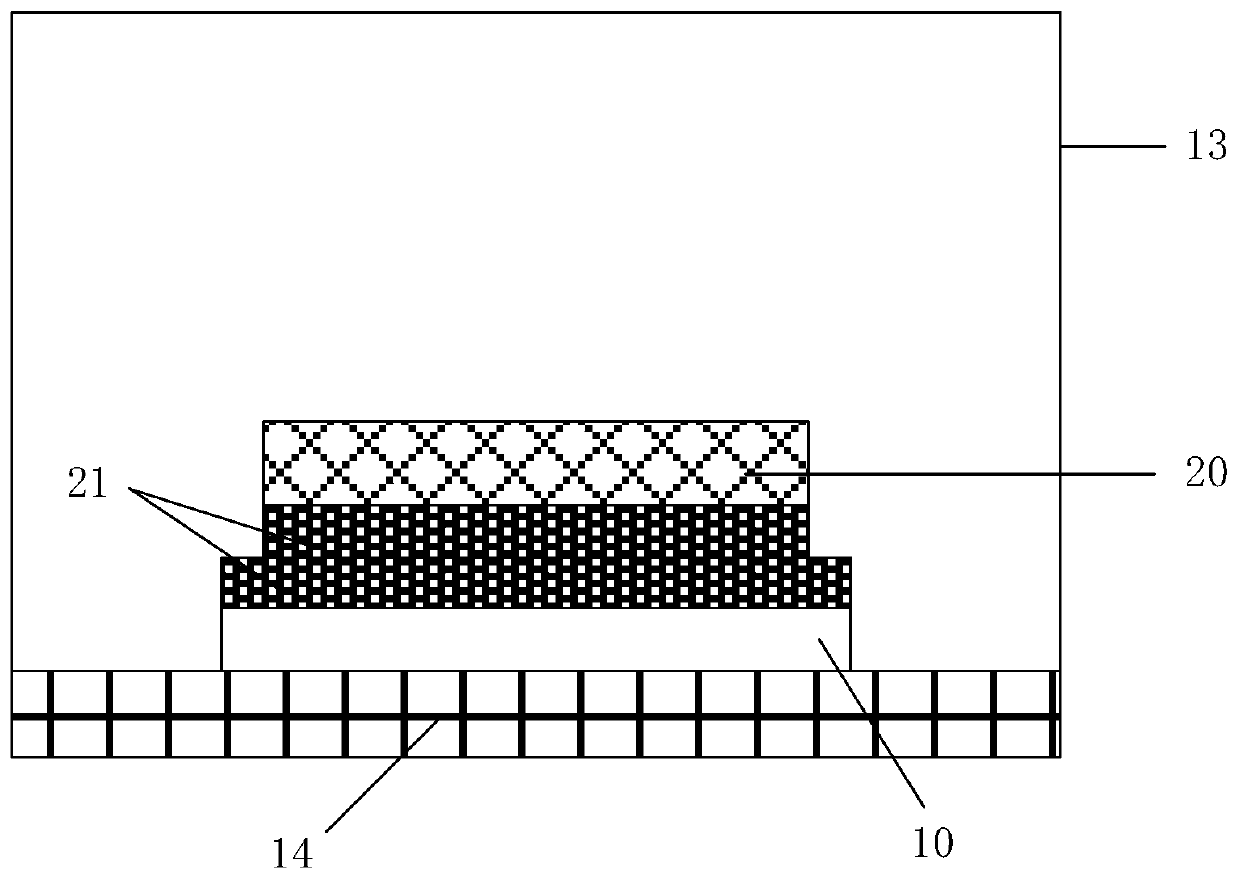

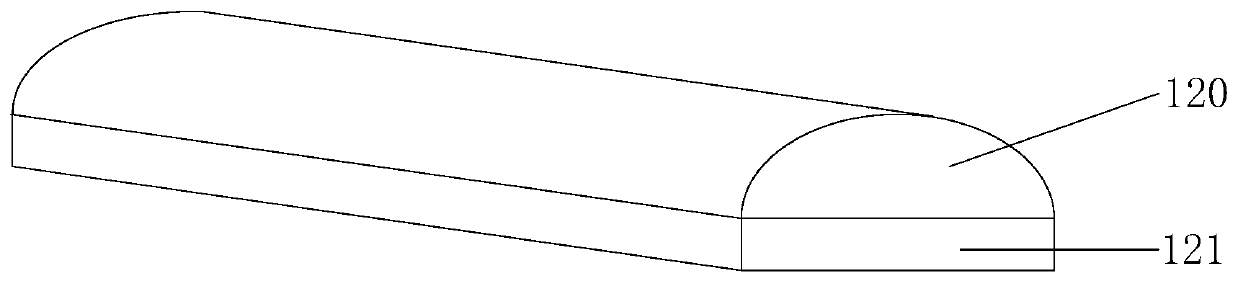

Chip package structure

PendingCN110137335AImprove stabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThermal deformationEngineering

The invention provides a chip package structure, the gap between a circuit substrate and a package plate is sealed by a sealing dam, and therefore, the package of a chip is achieved. Further, a recessis set in the circuit substrate to insert the chip into the recess, so the positions of the circuit substrates and the chips can be accurately determined, the bonding area between the chip and the circuit substrate is increased, and therefore, the stability of the chip package and the thermal conductivity between the chip and the circuit substrate is improved. A thermal conductive gasket is used,the heat dissipation of the chip is promoted, and the thermal deformation between the chip and the circuit substrate can be neutralized. When the chip is expanded due to heat, the contact area between the chip and the thermal conductive gasket is increased, the heat transfer amount is increased, the collision caused by the direct rigid contact of the chip with the circuit substrate is avoided, and the crushing stress borne by the chip is reduced.

Owner:JADE BIRD DISPLAY SHANGHAI LTD

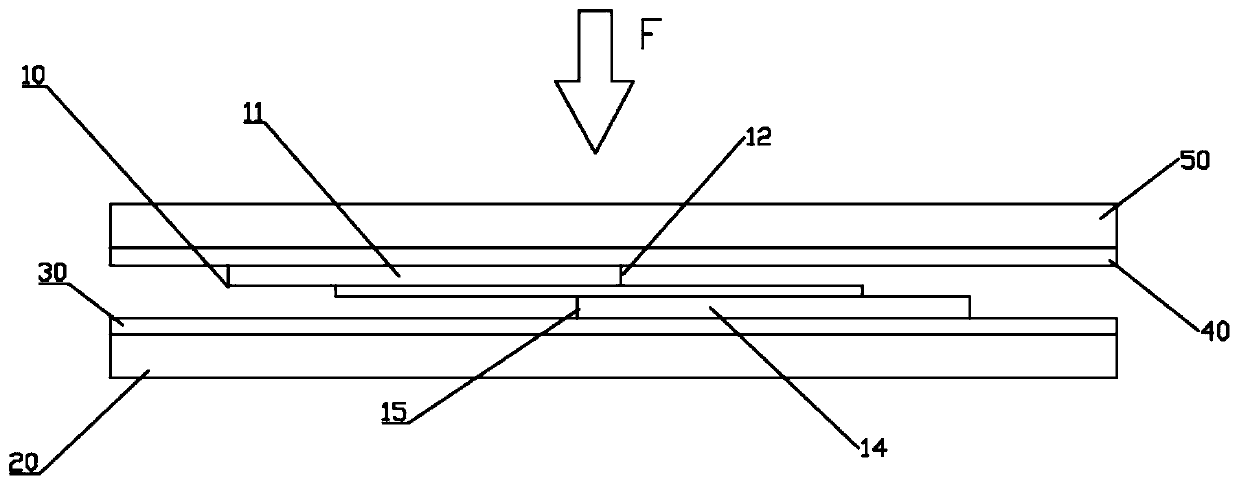

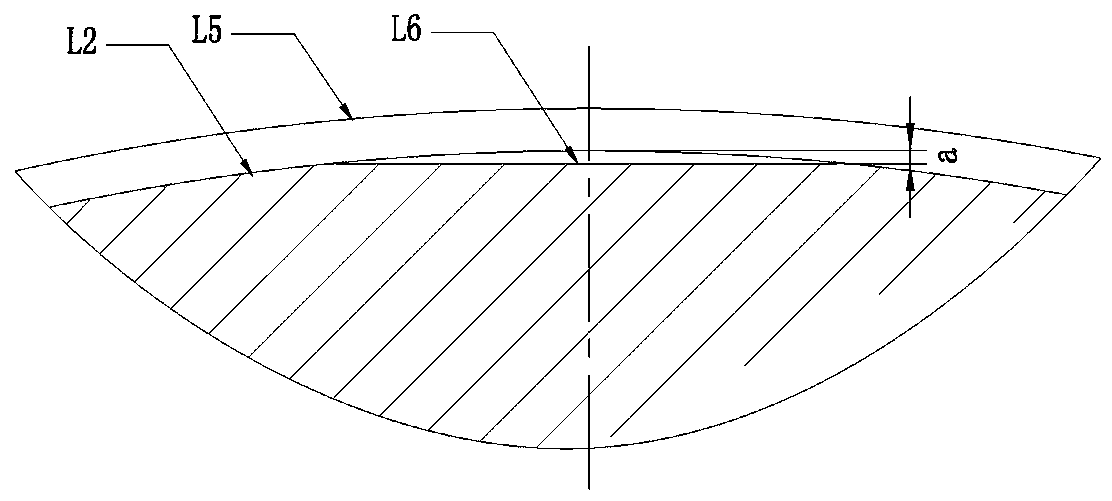

Wave plate falling device of welded metal corrugated pipe

The invention discloses a wave plate falling device of a welded metal corrugated pipe, which is mainly characterized in that a lower die assembly comprises a lower die base, a cutting die, an external pressure plate and an internal pressure plate. The upper end of the cutting die protrudes out of the top face of the lower die based and the top face of the cutting die is in a wave plate curve face. The external pressure plate is attached to the outer wall of the cutting die. The top face of the external pressure plate is aligned with the side face outside the cutting die and forms a first chamfered angle with the top end of the external pressure plate at the attached place of the cutting die. The internal pressure plate is placed in the cutting die, and the bottom face thereof leans against the lower die base through an elastic mandrill. The internal pressure plate is attached to the inner wall of the cutting die, and the to top face of the internal pressure plate is aligned with the highest point on the top face of the cutting die and forms a second chamfered angle with the top end of the internal pressure plate at the attached place of the cutting die. An upper die assembly comprises a rubber template fixed on the bottom face of the upper die base. The bottom face of the rubber template is planar. The rubber template flexibly squeezes, molds and cuts the wave plate, and the squeezing stress of the wave plate is small, so that the wave plate does not deform in case of stress recovery, and the molded wave plate is accurate in parameters and burr-free.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

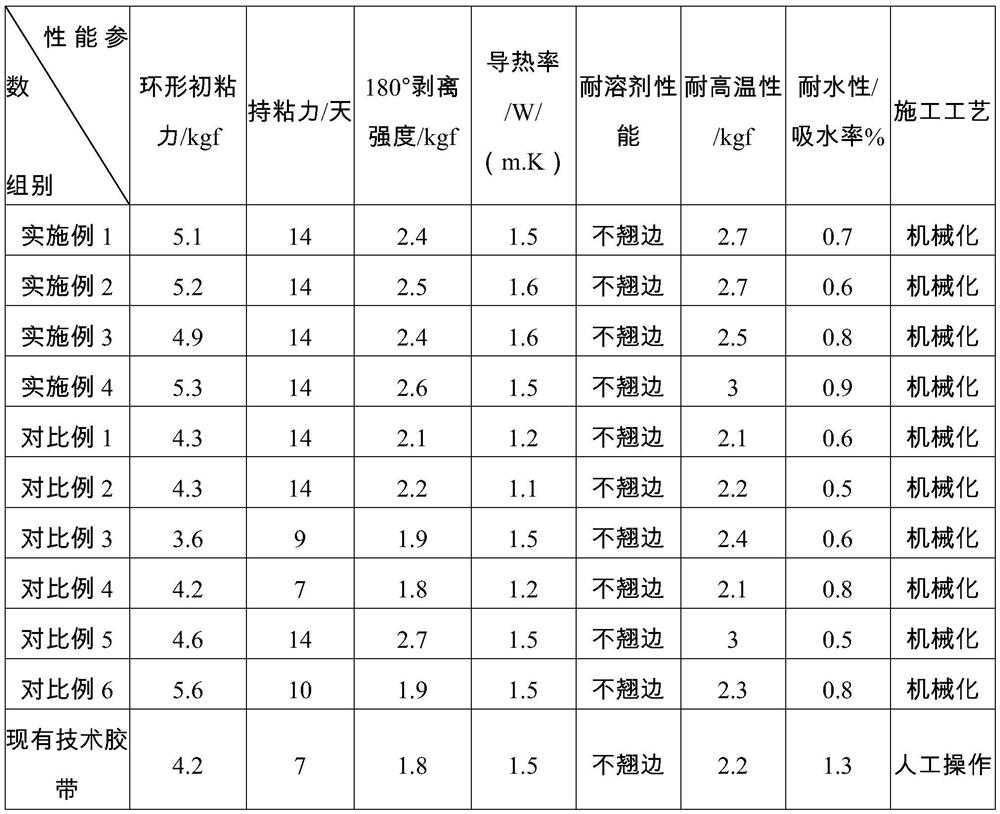

Ultraviolet curing heat-conducting adhesive tape, and preparation method and application thereof

ActiveCN113667429AGood adhesionImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceUltraviolet

The invention provides an ultraviolet curing heat-conducting adhesive tape, and a preparation method and application thereof. The ultraviolet curing heat-conducting adhesive tape is prepared from, by weight, 5 to 15 parts of light-cured resin, 5 to 10 parts of polyacrylate, 60 to 80 parts of a filler, 5 to 10 parts of an acrylate active monomer, 3 to 8 parts of a photoinitiator, 0.5 to 3 parts of a coupling agent and 0.3 to 1 part of a leveling agent. The invention also provides a preparation method of the heat-conducting adhesive tape. According to the heat-conducting adhesive tape, the manual laminating process of the heat-conducting adhesive tape can be omitted, automatic dispensing is achieved, and the production efficiency is improved.

Owner:矽时代材料科技股份有限公司

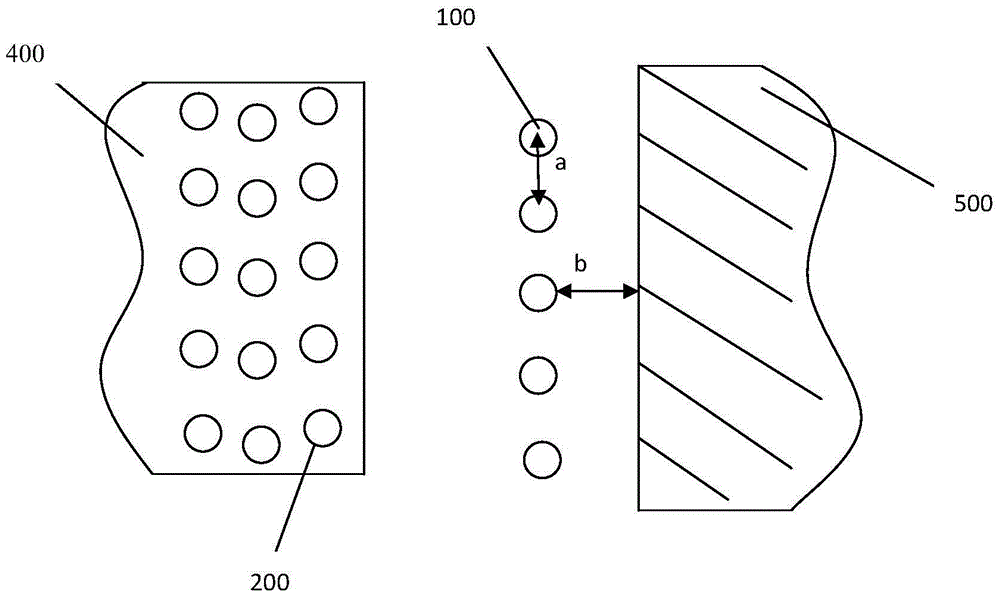

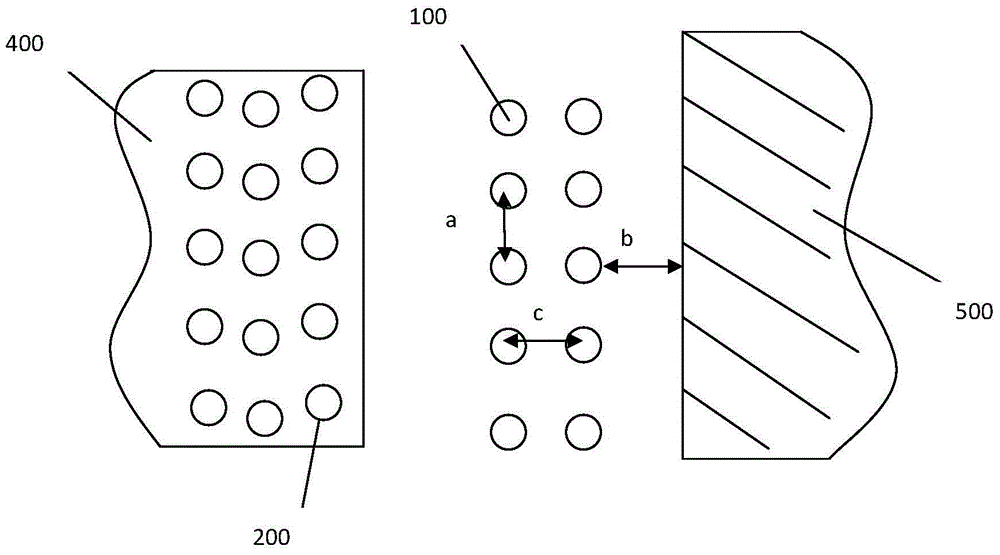

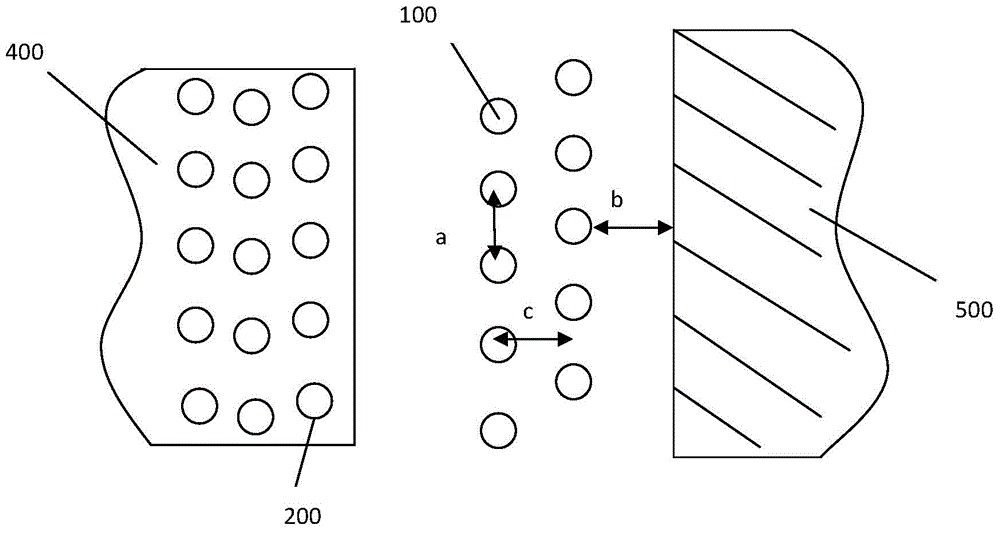

Structure and method for reducing extrusion stress of foundation

InactiveCN105064370AReduce extrusion stressHarm reductionExcavationsBulkheads/pilesPre stressEngineering

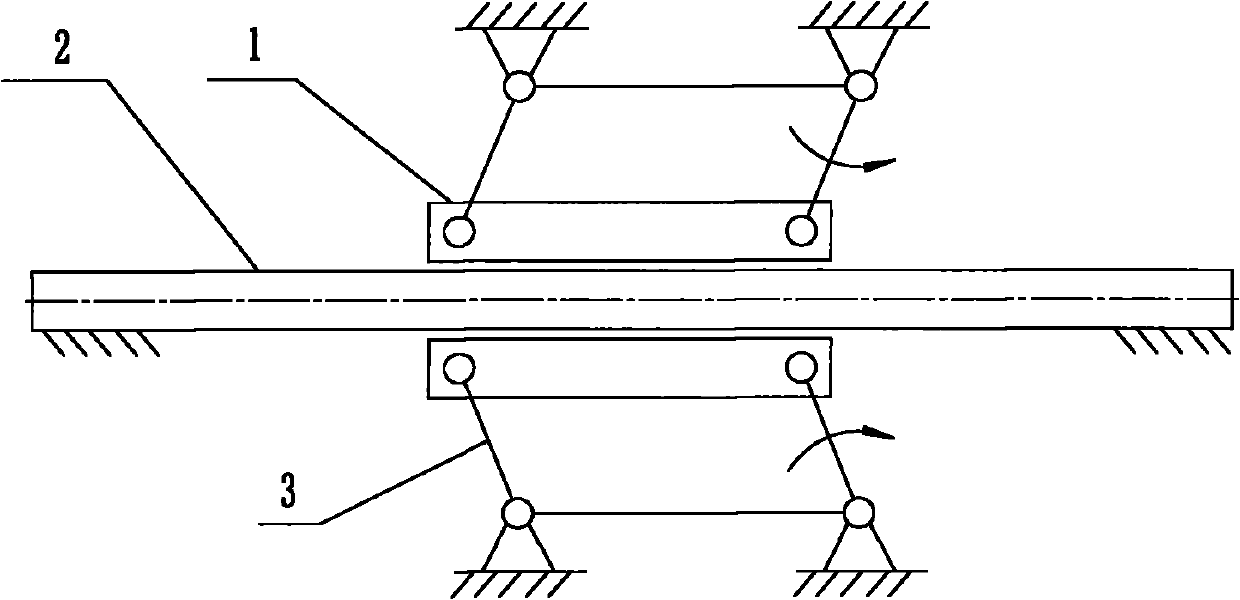

The invention relates to a structure for reducing extrusion stress of a foundation. The structure is used in construction of foundation pits close to buildings. The structure comprises prestressed pipe piles and further comprises one or more stress release holes. The stress release holes are located between the prestressed pipe piles of a foundation pit and a building. The invention further provides a method for reducing the extrusion stress of the foundation. The method comprises the steps that (1) the interval between the foundation pit and the building is measured; (2) the inserting piling position and depth of the prestressed pipe piles of the foundation pit are determined; (3) the stress release holes are formed between the pile bases of the prestressed pipe piles of the foundation pit and the building; and (4) the prestressed pipe piles are constructed at the bottom of the foundation pit. The structure and method for reducing the extrusion stress of the foundation can effectively release or eliminate stress and extrusion stress generated in the construction process of the prestressed pipe piles of the system, so that damage to the foundation of the surrounding building from stress is reduced, and the structure and method are especially suitable for construction of foundation pits close to buildings.

Owner:SINOHYDRO BUREAU 12 CO LTD

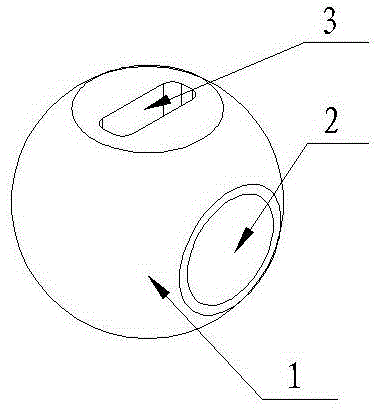

Ceramic ball core for ball valve

The invention discloses a ceramic ball core for a ball valve. The ceramic ball core comprises a ball core body, a ball core through hole and a valve stem hole, wherein the ratio a of the outer diameter of the ball core body to the diameter of the ball core through hole is more than or equal to 1.8. The ceramic ball core provided by the invention breaks through the conventional ratio concept of the outer diameter of the ball core body to the diameter of the ball core through hole, and has the characteristics of reliable sealing, light torque, high corrosion and wear resistance, long service life and high stability.

Owner:YANTAI KINGWAY SCI & TECH

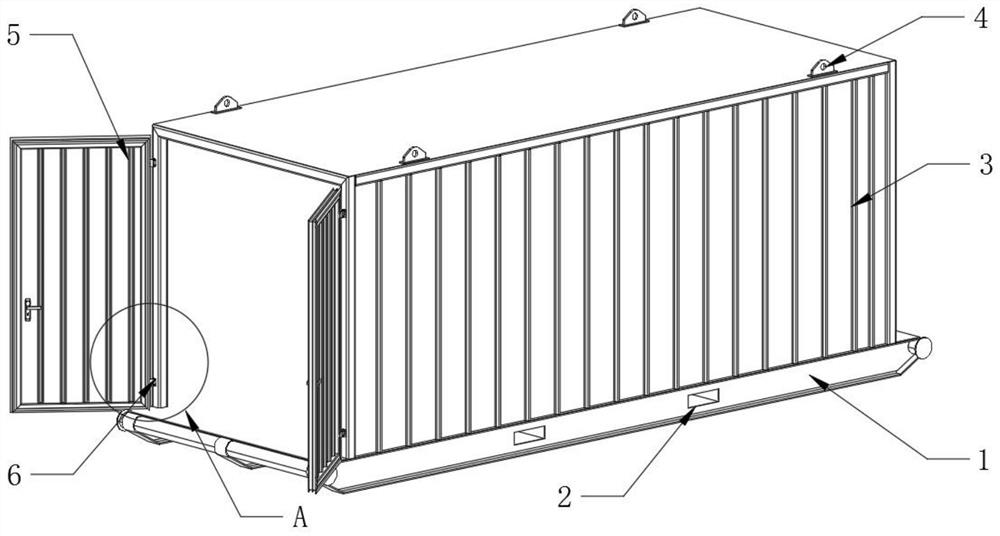

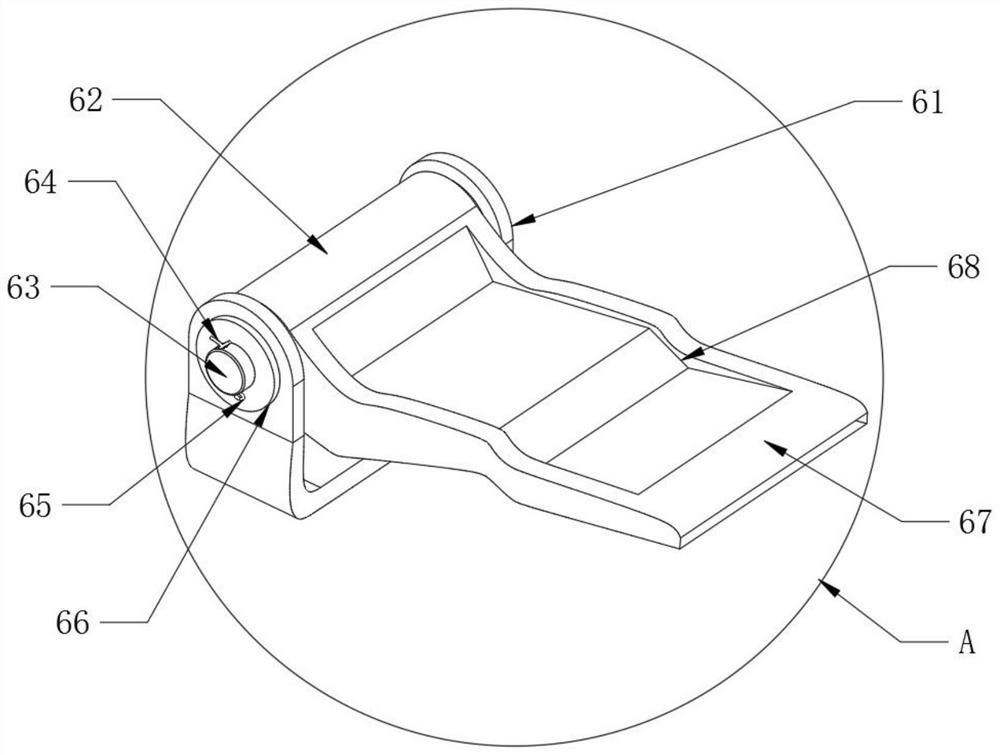

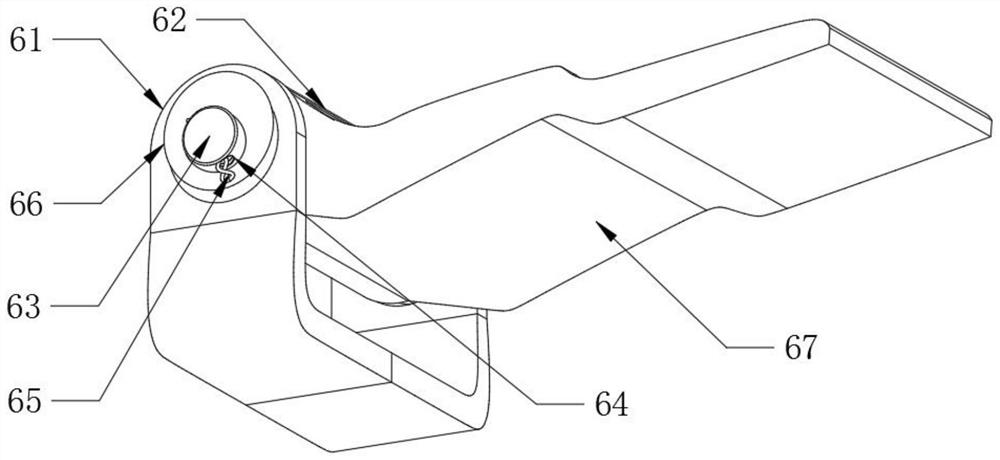

Hot-rolled profile steel door hinge device for container

The invention discloses a hot-rolled profile steel door hinge device for a container. The hot-rolled profile steel door hinge device comprises a base, slots, a container body, lifting lugs and a door plank. The device provided by the invention is improved on the structure of a hinge mechanism and has the following advantages: firstly, a uniform honeycomb-shaped connecting structure is arranged at a welding position, and the fastening degree of the connection between the base and the container body and the connection between a chain plate and the door plank can be improved by utilizing the characteristic that the hexagonal honeycomb-shaped structure is stable, so that the possibility that a welding part falls off is reduced under the condition of long-term rotation; secondly, due to the formation of a groove and the step-shaped characteristic of the groove, the dead weight of the chain plate can be reduced firstly, and the extrusion stress of the dead weight on a connecting part is reduced; thirdly, the rigidity of the chain plate is improved due to the formation of the groove; and in addition, the structural layers of the chain plate are increased due to the step-shaped transition of the groove, and stress transmission can be dispersed through inclined planes in steps, so that the purpose of improving the strength of the chain plate is achieved.

Owner:山东德坊新材料科技有限公司

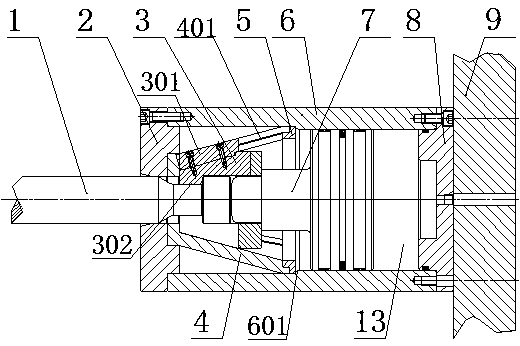

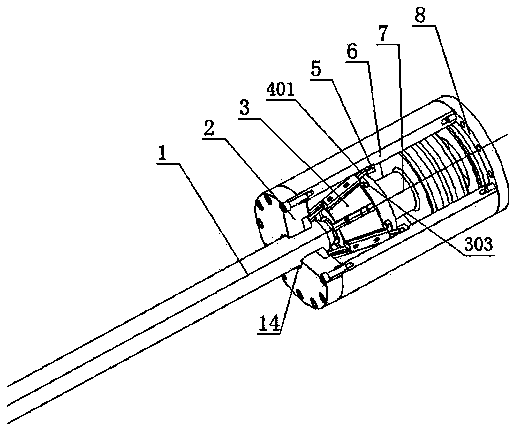

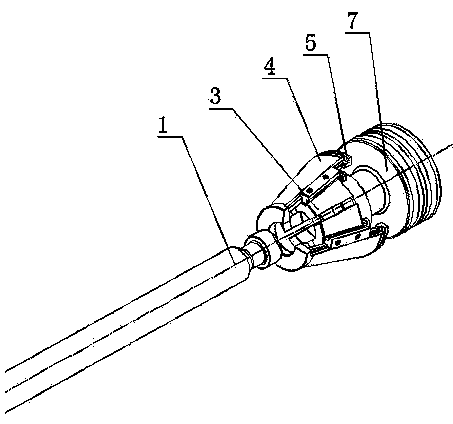

Self-locking locking mechanism

The invention provides a self-locking locking mechanism. The mechanism comprises a cylinder body, a front cover, a rear cover, a cone, a supporting ring and a piston, wherein the cylinder body is internally provided with a step; the cone and the supporting ring are arranged between the front end cover and the step in a pressing manner; the piston does reciprocating motion along a hydraulic containing cavity formed by the rear end cover and the step; a plurality of tapered slide ways are distributed on the periphery of the cone; a split clamping block is arranged on the tapered slide ways; the end part of the piston is movably connected with the split clamping block; and the front end cover is provided with a central hole communicated with the cone. The self-locking locking mechanism has the advantages that the locking effect is improved, and the service life and the valid period are prolonged. Continuous high-pressure oil does not need to be introduced into the locking mechanism, so that the energy consumption is reduced; and the split clamping block retracts to clamp a piston rod to realize self locking, and thus the self-locking locking mechanism is safe and reliable. After a die assembly and pressure keeping process is finished, pressure of a lock die cylinder is released, the clamping block is opened, and the piston rod withdraws from the locking mechanism so as to realize automatic unlocking, therefore, a sequence of unlocking and die opening is guaranteed after the pressure is released, and the self-locking locking mechanism is safe and reliable, is easy to operate and eliminates an oil chamber and a relative structure of the conventional locking mechanism. The self-locking locking mechanism has the advantages of small occupied space, simple structure, convenience for machining, small template width and high rigidity.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY +1

Manufacturing method for prolonging service life of KR stirrer

The invention discloses a manufacturing method for prolonging the service life of a KR stirrer, specifically comprising the steps of: selecting a steel core, removing impurities on the surface of the steel core, washing and cleaning the steel core, and airing; welding a group of riveting pieces with different heights ranging from 30mm to 80mm on the surface of the steel core; covering a refractory fiber material layer with the thickness of 0-50mm on the surface of the steel core, coating a castable layer with the thickness of 60-120mm on the refractory fiber material layer, and baking the entire device for 36-60h at the temperature of 80-100 DEG C; and continuously heating the baked device to ensure that the temperature reaches 320-350 DEG C, and maintaining the temperature for 8-16h. The method is simple and energy-saving, and the used materials are not molten at high temperature and can stop the heat from being transmitted to the steel core, therefore, not only is the expansion degree of the steel core alleviated, but also the extrusion stress generated due to the expansion of the steel core can be effectively buffered so that the quantity of the cracks generated after the KR stirrer is baked can be reduced to the minimum.

Owner:宜兴市瑞华工业炉科技有限公司

Gas turbine rotor disc seam positioning structure and gas turbine rotor

ActiveCN104533532BGuaranteed integrityQuality improvementBlade accessoriesMachines/enginesInterference fitEngineering

The invention relates to the field of gas turbine rotors and discloses a wheel disc spigot locating structure of the gas turbine rotor and the gas turbine rotor. Two wheel discs are axially overlapped, axial bumps are arranged at the opposite head faces of the two wheel discs, axial grooves are formed in the other head faces, and the outer diameters of the axial bumps are in interference fit with the inner diameters of the axial grooves; each axial bump is provided with an interference amount adjusting nick; the interference amount adjusting nick is a circular ring-shaped nick formed in the axial head face of the axial bump. By means of the wheel disc spigot locating structure, the wheel disc of the rotor can use a small interference magnitude when assembling, the device extrusion stress is reduced, the assembly is facilitated, the requirement on fixture is lowered, the rotor fits tightly under a working state, and the gas turbine rotor integrity is guaranteed.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

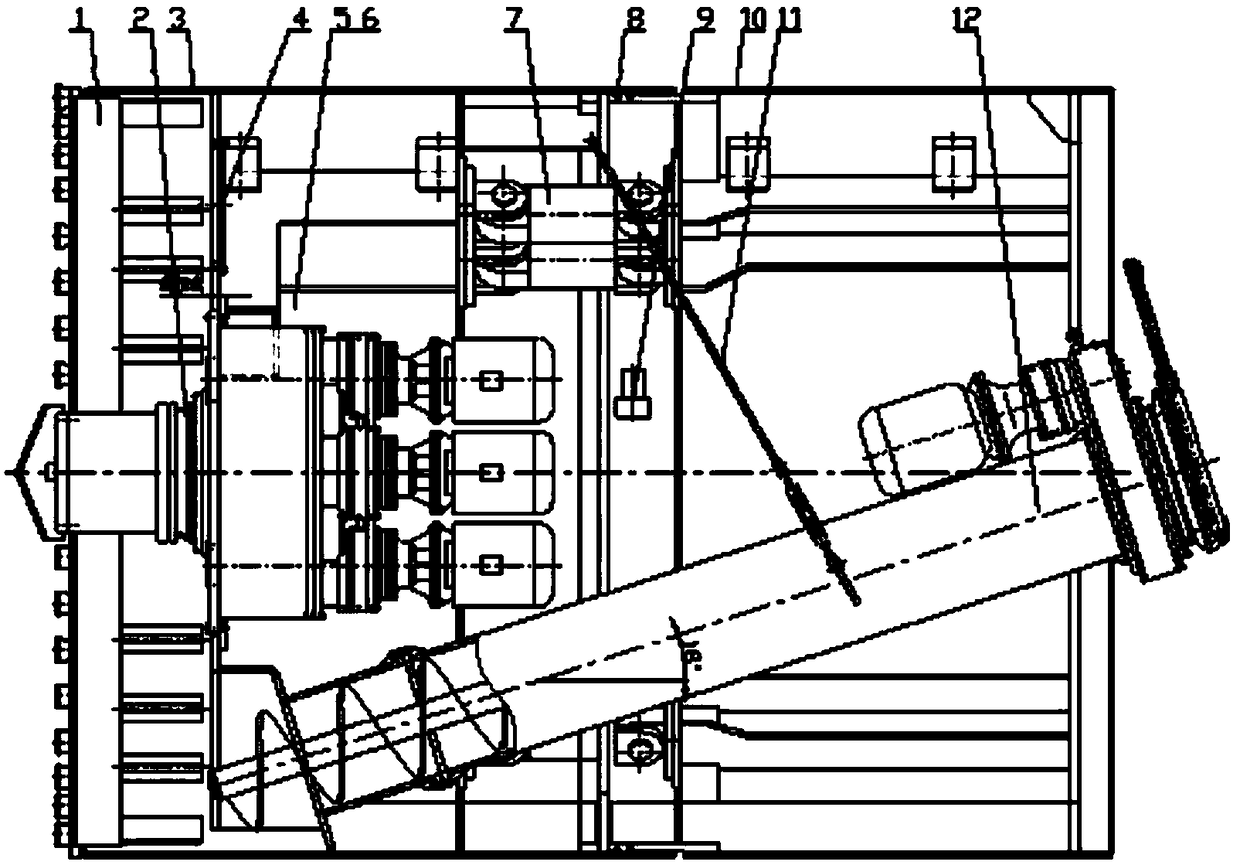

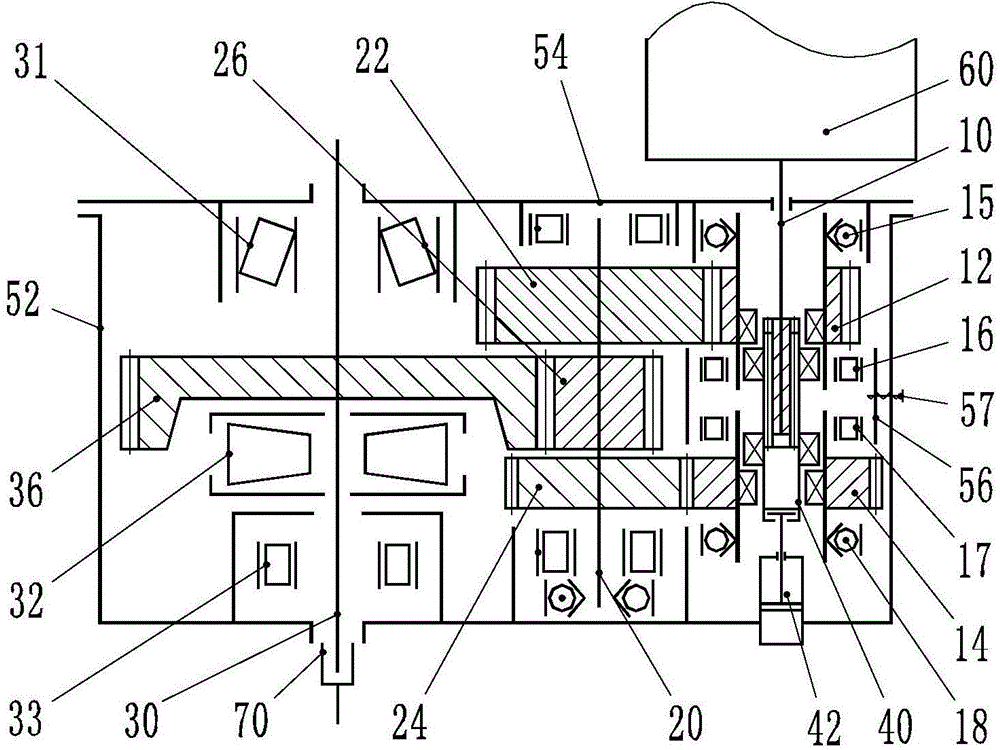

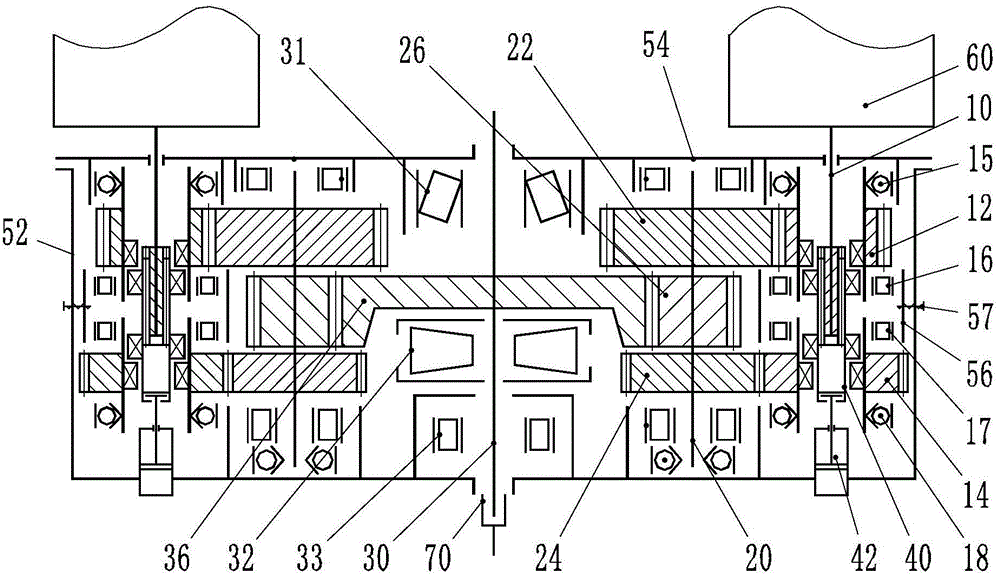

Two-gear gear speed reducing box used for top driving well drilling device

InactiveCN104595423AReduce contact stressReduce extrusion stressToothed gearingsTransmission elementsGear driveLow speed

The invention provides a two-gear gear speed reducing box used for a top driving well drilling device. The two-gear gear speed reducing box comprises a box body and mechanisms arranged in the box body, wherein each input mechanism comprises an input shaft and a grade-I low-speed gear driving gear and a grade-I high-speed gear driving gear which sleeve the periphery of the input shaft; each middle transmission mechanism comprises a middle shaft, and a grade-I low-speed gear driven gear, a grade-I high-speed gear driven gear and a grade-II driving gear which sleeve the middle shaft; an output mechanism comprises an output shaft and a grade-II driven gear which sleeves the output shaft; each speed changing mechanism comprises a sliding sleeve sleeving the input shaft; the sliding sleeves are mounted among the peripheries of the input shafts, and the inner walls of central holes of the grade-I low-speed gear driving gears and the grade-I high-speed gear driving gears respectively, slide along the input shafts, are matched with the inner walls of the central holes of the grade-I low-speed gear driving gears and the grade-I high-speed gear driving gears, and drive the grade-I low-speed gear driven gear pair and the grade-I high-speed gear driven gear pair to rotate. Compared with the prior art, the rotary speed output range can be improved by more than 2-3 times.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Screw bolt fixing mode wheel house installing structure

ActiveCN103625207AReduce extrusion stressImprove installation reliabilityWheel protectionEngineeringMechanical engineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

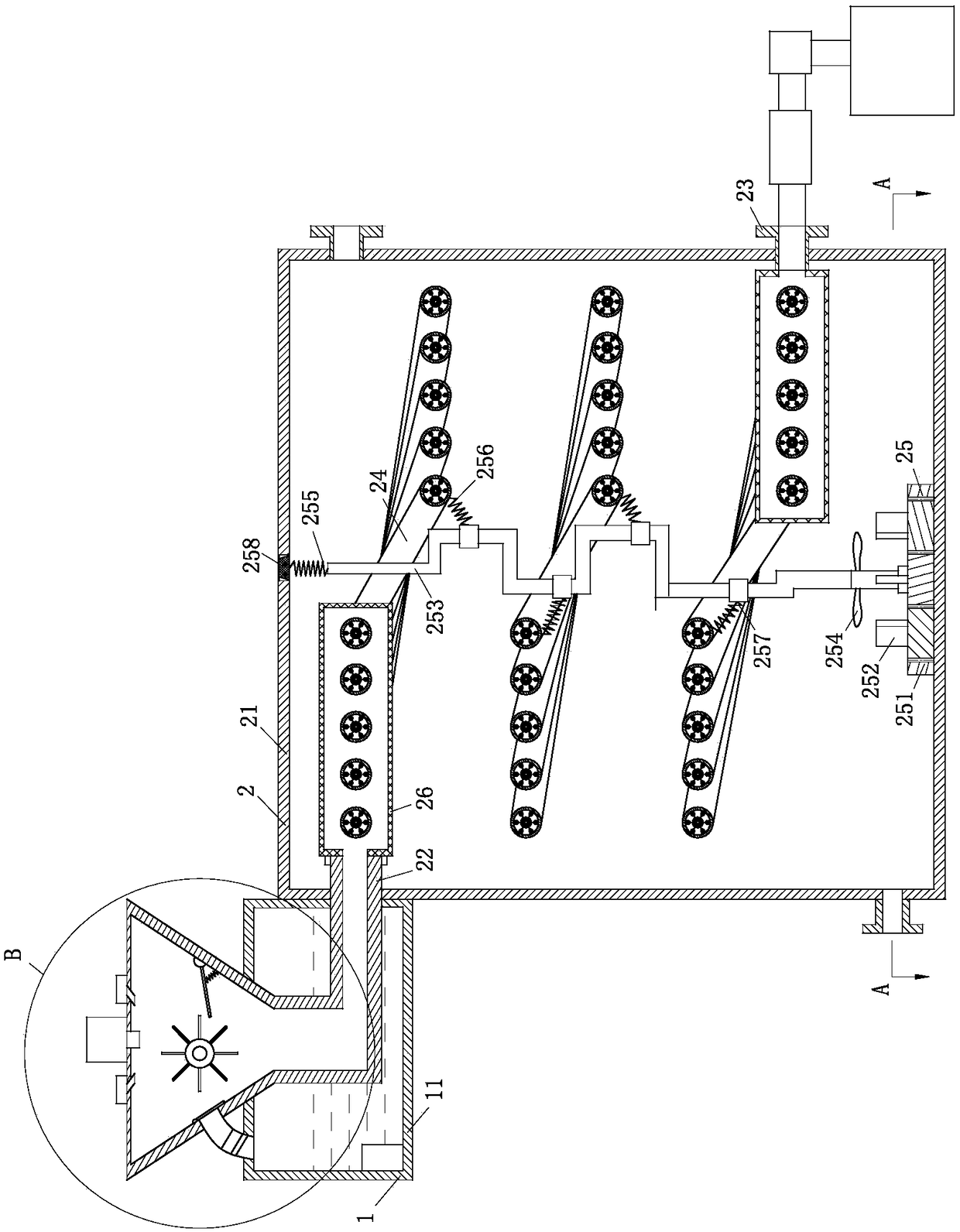

Edible oil dewaxing device

PendingCN109370774AAchieve cycleImprove the quality of dewaxingFatty-oils/fats refiningEdible oils/fatsGear systemEdible oil

The invention belongs to the technical field of dewaxing devices and particularlyspecifically relates to an edible oil dewaxing device. The edible oil dewaxing device comprises a mixing device, a crystallization device, a filtering device, an oil pump and an oil storage tank; the mixing device comprises a heating tank, a feeding hopper, a diatomite spraying pipe and oil spraying pipes; the feedinghopper is arranged in the heating tank; the diatomite spraying pipe is arranged at the upper end of the feeding hopper, and the oil spraying pipes are arranged on the two sides of the diatomite spraying pipe; the crystallization device comprises a crystallization box, an oil inlet, an oil outlet, a cold water inlet, a cold water outlet, spiral pipes and a stirring module; the oil inlet is connected with a flow-dividing hose, the oil outlet is connected with the flow-dividing hose, and the spiral pipes are connected to the flow-dividing hose; and the stirring module is arranged below the spiral pipe and comprises a planetary gear system, pushing plates and an S-shaped rotating shaft. According to the edible oil dewaxing device, the heating tank heats a mixture in the feeding hopper, so that mixing of edible oil and diatomite is accelerated, the dewaxing effect in subsequent work is improved, and the dewaxing quality of the edible oil is improved.

Owner:李晓垚

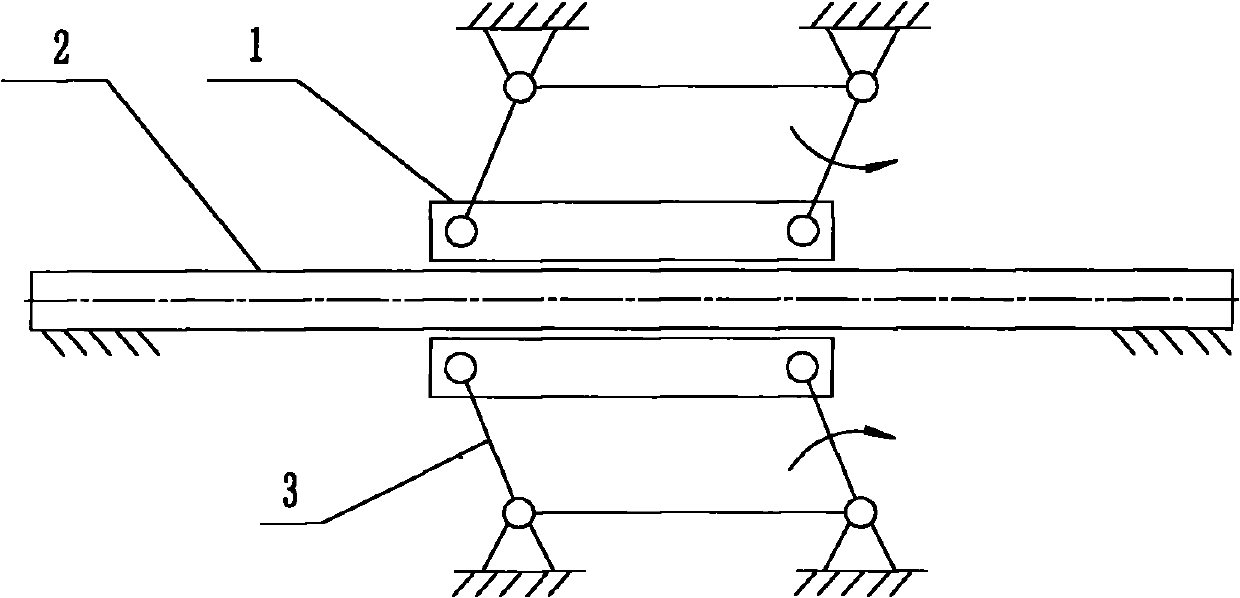

Locking device for corrugated board box covering machine

InactiveCN102001196AExtended service lifeImprove rigidityContainer making machineryCardboardPulp and paper industry

The invention provides a locking device for a corrugated board box covering machine. The locking device comprises a paper blocking board, a paper beating board and a frame and is characterized in that: a locking strip is fixed on the frame; two locking blocks which are symmetrically arranged relative to the locking strip are fixed on the paper blocking board; each locking block is connected with an oscillating mechanism which is arranged on the same side as that of the locking strip respectively; and two oscillating mechanisms drive the two locking blocks to extrude the locking strip for locking. The locking device has a simple and compact structure, can effectively lock a paper blocking mechanism, enhances the stability of a machine and prolongs the service life of the machine.

Owner:QINGDAO MEIGUANG MACHINERY

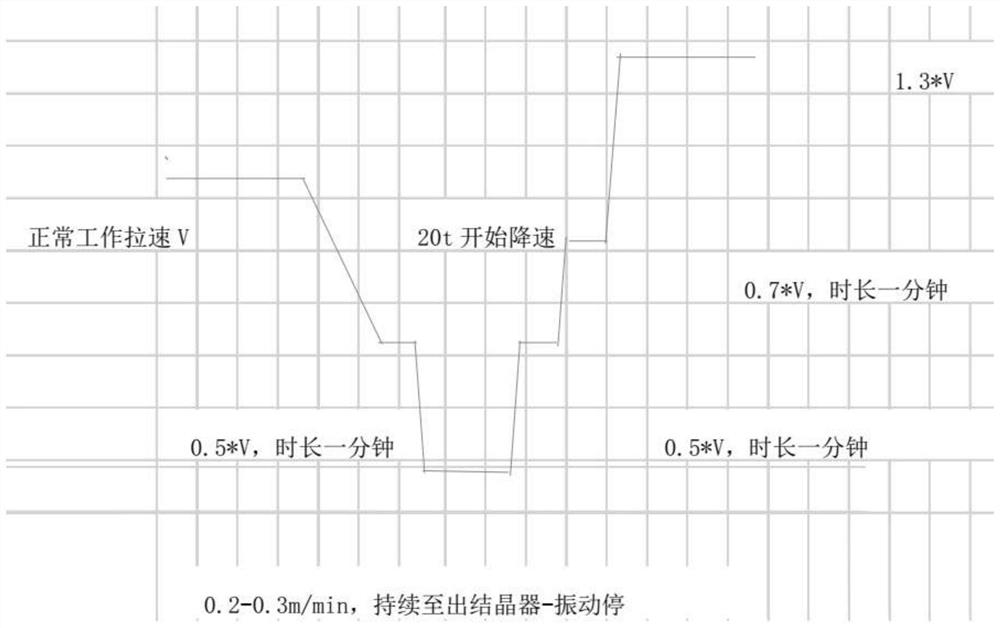

Process for safely and quickly ending continuous casting sheet billet

The invention discloses a process for safely and quickly ending a continuous casting sheet billet and relates to the technical field of steel production. The process comprises the following steps: S1, starting to gradually reduce the working pulling speed of a continuous casting machine when 20t of tundish remains; S2, before tundish pouring is finished, the working pulling speed of the continuous casting machine is reduced to 0.5 times of the normal working pulling speed; S3, after pouring of the tundish is finished, the working pulling speed of the continuous casting machine is reduced to 0.2-0.3 m / min according to the situation of the section of the sheet billet, and ending of the tail billet is started till the tail billet is discharged out of a crystallizer; S4, the pulling speed of the continuous casting machine is increased to 0.5 time of the normal working pulling speed for 1 min; S5, the pulling speed of the continuous casting machine is increased to 0.7 time of the normal working pulling speed for 1 min; and S6, the pulling speed of the continuous casting machine is increased to be larger than the normal working pulling speed till the tail billet comes out of a fan-shaped section, and the running out process is ended. The method effectively controls the tail billet steel overflowing when the continuous casting sheet billet is finished, shortens the running out process ending time, improves the productivity of the continuous casting machine, and reduces the safety risk of the running out process.

Owner:NANJING IRON & STEEL CO LTD

Scroll compressor eccentricity regulating mechanism and scroll compressor

PendingCN109162928AReduce extrusion stressAvoid Stuck SituationsRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention relates to a scroll compressor eccentricity regulating mechanism which comprises a crankshaft and an eccentric bushing correspondingly arranged with the crankshaft; the crankshaft comprises a main shaft capable of being corresponding to a motor and an eccentric shaft eccentrically arranged relative to the main shaft; the eccentric bushing is sheathed on the eccentric shaft and is rotationally connected with the eccentric shaft; the surface, enclosed on the side surface of the main shaft, on the eccentric bushing is a first abutting surface, the first abutting surface is providedwith a first tangent plane in an eccentricity angle limiting position, and the side surface of the main shaft is provided with a second tangent plane in an eccentricity angle limiting position; and when the eccentric bushing is rotated to the eccentricity angle limiting position relative to the main shaft, the first tangent plane is matched with the second tangent plane. In the eccentricity anglelimiting position, the crankshaft is in surface contact with the eccentric bushing, so that the situations of contact surface deformation caused by excessive extrusion stress and blockage are avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Processor base

InactiveCN107433457AImprove vibration resistanceImprove thermal stabilityLarge fixed membersHeat stabilityEngineering

The invention relates to a processor base applied to the field of equipment processing of numerically controlled machine tool industry. The processor base comprises a base body. A worktable placing tank and a magazine tool placing tank are arranged on the base body. The base body comprises two end surfaces and two side surfaces. A chip removal port communicating with the worktable placing tank is formed below the base body. Each of the side surfaces comprises a vertical portion located on the lower end and an inclined portion located on the upper end. The upper end of the inclined portion inclines toward the inner part of the base body and the side surface is wavy. The two side surfaces of the base body are arranged in a structure, one ends of which are closed. At the moment, the trapezoidal structure of the base is arranged, and the side surface is of the wavy shape, so that force dispersion in machine tool operation can be realized, the axial force and the radial force are reduced greatly, the internal stress and the extruding stress are reduced, and the unloading force is extremely enhanced. Meanwhile, the rigidity, the strength and the precision of the machine tool are improved by the processor base, the vibration resistance and the heat stability of the base are enhanced, and the stress of the base is relatively balanced.

Owner:张功煜

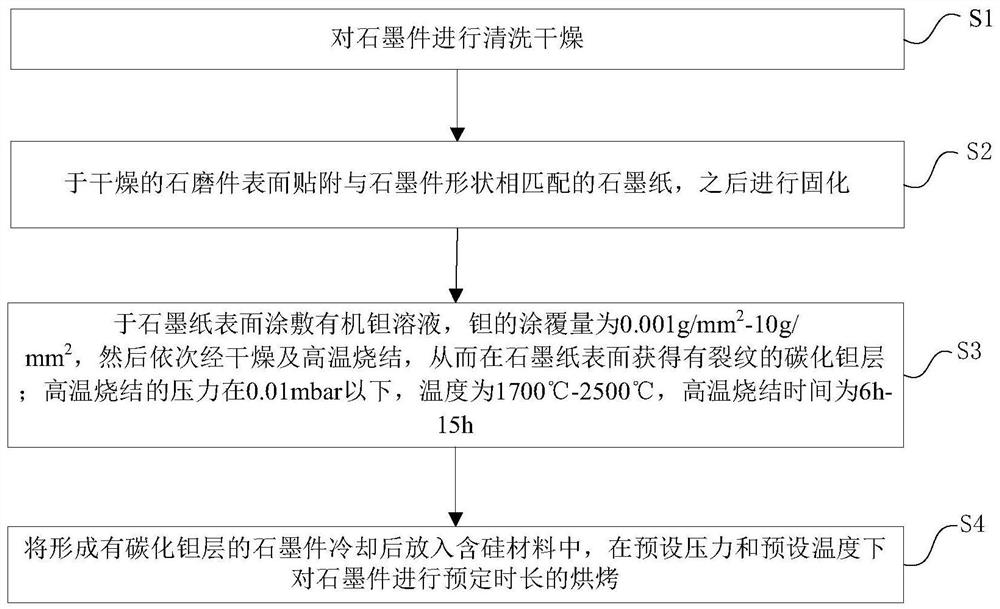

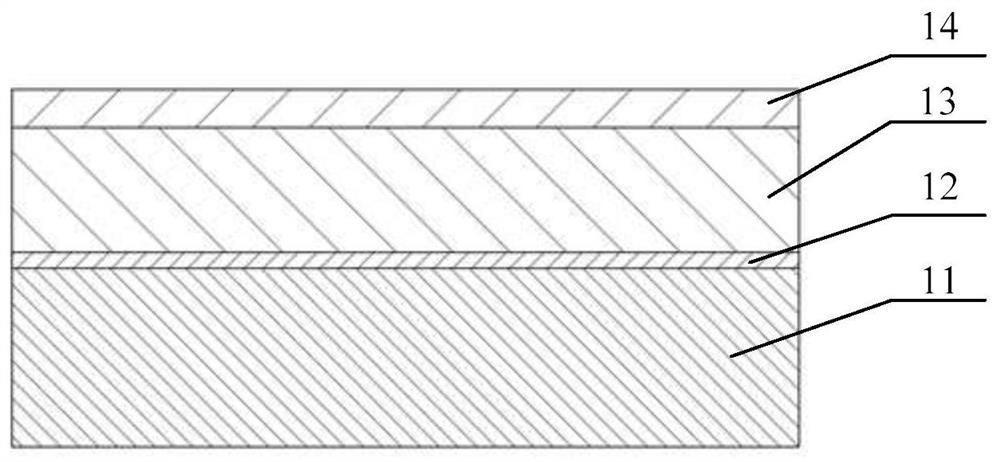

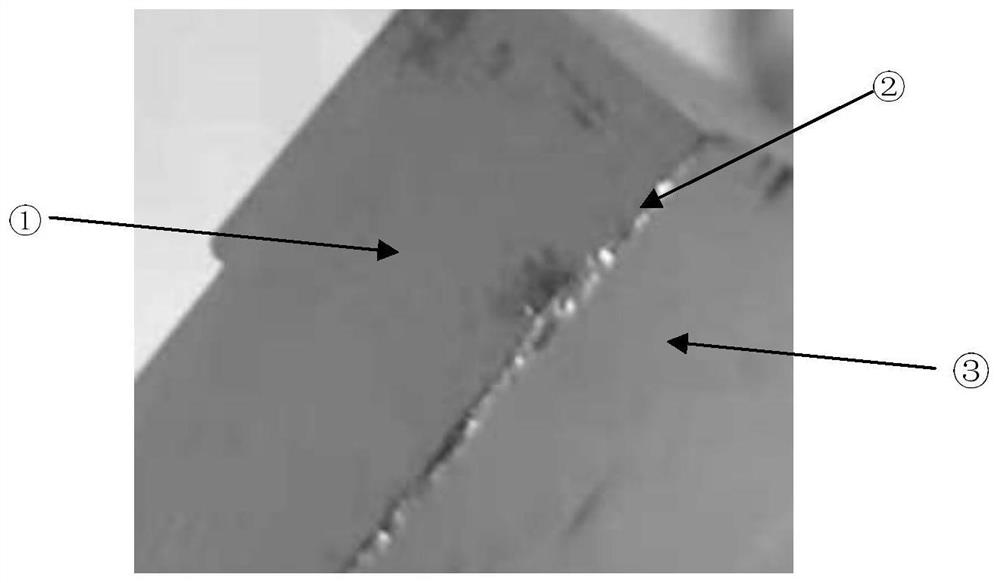

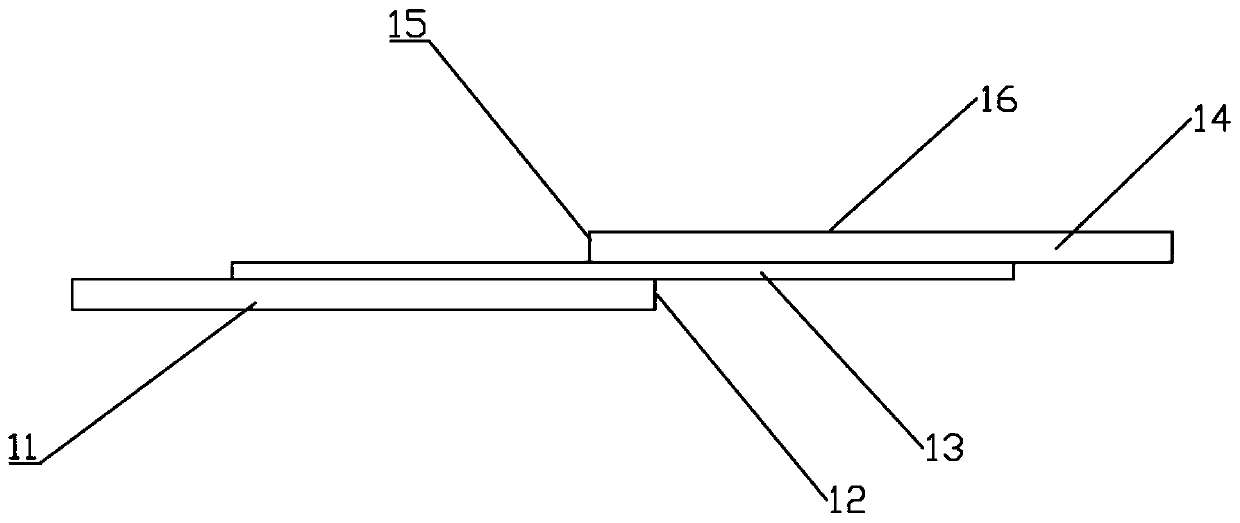

Graphite piece and processing method thereof, single crystal growth equipment

ActiveCN113185324BHigh mechanical strengthImprove growth qualityPolycrystalline material growthGraphiteCarbide siliconPhysical chemistry

The invention provides a graphite piece, its processing method, and single crystal growth equipment. The treatment method comprises steps: 1) cleaning and drying the graphite piece; 2) attaching graphite paper matching the shape of the graphite piece on the surface of the dried stone grinding piece, and then curing; 3) coating the organic tantalum solution on the surface of the graphite paper , the coating amount of tantalum is 0.001g / mm 2 -10g / mm 2 , and then sequentially dried and sintered at a high temperature to obtain a cracked tantalum carbide layer on the surface of the graphite paper; the pressure of the high-temperature sintering is below 0.01mbar, the temperature is 1700°C-2500°C, and the high-temperature sintering time is 6h-15h; 4) the The graphite piece formed with the tantalum carbide layer is cooled and put into the silicon-containing material, and the graphite piece is baked for a predetermined time under a preset pressure and a preset temperature. Compared with the prior art, the present invention can ensure that the surface of the prepared graphite parts is not corroded when applied in a thermal field environment, and the prepared graphite parts have considerable strength, which can provide a certain structural support.

Owner:CEC COMPOUND SEMICON CO LTD

Method for overlapping sliced battery slices

ActiveCN110137303AReduce distortionReduces the possibility of crackingFinal product manufacturePhotovoltaic energy generationEngineeringElectrical and Electronics engineering

The application discloses a method for overlapping sliced battery slices, comprising the step of successively stacking a solder strip and a second sliced battery slice on a first sliced battery slicesuch that the orthographic projection the first sliced battery slice and the orthographic projection of the second sliced battery slice on a plane where the solder strip is located have an overlappingarea, wherein the solder strip is located between the first sliced battery slice and the second sliced battery slice, the non-cut surface of the first sliced battery slice and the cut surface of thesecond sliced battery slice are located in the overlapping area, and the negative electrode of the first sliced battery slice and the negative electrode of the second sliced battery slice are facing upward. The method can reduce the possibility of deformation and cracking of the sliced battery slices during a lamination process, and reduce the cracking rate of the sliced battery slices.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Wave plate falling device of welded metal corrugated pipe

The invention discloses a wave plate falling device of a welded metal corrugated pipe, which is mainly characterized in that a lower die assembly comprises a lower die base, a cutting die, an external pressure plate and an internal pressure plate. The upper end of the cutting die protrudes out of the top face of the lower die based and the top face of the cutting die is in a wave plate curve face. The external pressure plate is attached to the outer wall of the cutting die. The top face of the external pressure plate is aligned with the side face outside the cutting die and forms a first chamfered angle with the top end of the external pressure plate at the attached place of the cutting die. The internal pressure plate is placed in the cutting die, and the bottom face thereof leans against the lower die base through an elastic mandrill. The internal pressure plate is attached to the inner wall of the cutting die, and the to top face of the internal pressure plate is aligned with the highest point on the top face of the cutting die and forms a second chamfered angle with the top end of the internal pressure plate at the attached place of the cutting die. An upper die assembly comprises a rubber template fixed on the bottom face of the upper die base. The bottom face of the rubber template is planar. The rubber template flexibly squeezes, molds and cuts the wave plate, and the squeezing stress of the wave plate is small, so that the wave plate does not deform in case of stress recovery, and the molded wave plate is accurate in parameters and burr-free.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

Polishing thinning device and polishing thinning method

InactiveCN111300260AReduce extrusion stressReduce machining damageSemiconductor/solid-state device manufacturingLapping machinesMachined surface

The invention provides a polishing thinning device and a polishing thinning method. The device comprises a tray, a spray head and a magnetic rotor. The tray is used for fixing a part to be machined, and the part to be machined comprises an InP-based wafer; the spray head is used for spraying polishing liquid to the surface to be machined of the part to be machined so as to polish the surface to bemachined; and the magnetic rotor is arranged on the surface to be machined of the part to be machined and used for mechanically grinding the surface to be machined through rotation and thinning the surface to be machined. Since the part to be processed such as the InP-based wafer does not rotate in the thinning process, the extrusion stress on the part to be machined such as the InP-based wafer in the polishing thinning process can be greatly reduced, and the machining damage to the part to be machined such as the InP-based wafer can be greatly reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

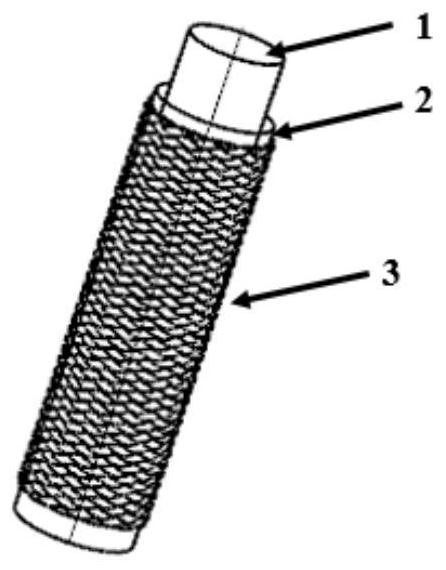

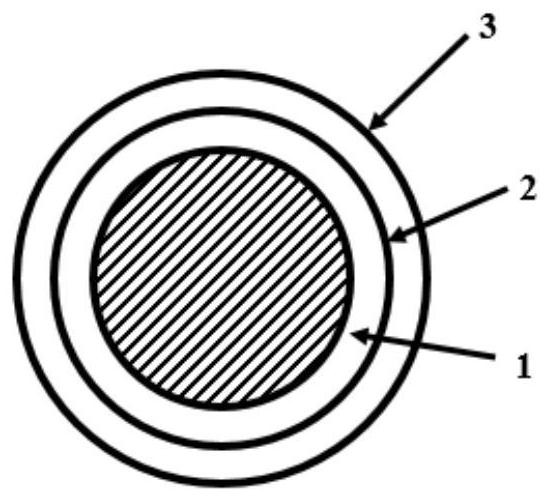

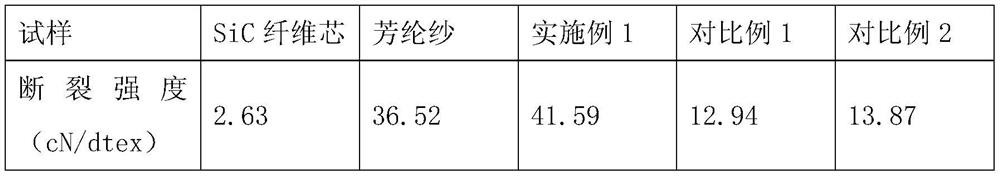

Preparation method and application of three-layer core-spun silicon carbide fiber wire

ActiveCN112125672BReduce frictionReduce extrusion stressFibre treatmentWeight reductionYarnCarbide silicon

The three-layer core-wrapped silicon carbide fiber wire of the present invention includes a SiC fiber core wire, the outer side of the SiC fiber core wire is a polytetrafluoroethylene intermediate layer, and the outermost layer is an aramid outer wrapping layer, which is suitable for a two-dimensional SiC fiber preform stitching to prepare two-dimensional SiC / SiC composites. The invention uses the characteristics of aramid yarn wear resistance and other characteristics as the outer wrapping layer, wraps the SiC fiber core wire with the polytetrafluoroethylene intermediate layer, and prepares the three-layer core-wrapped wire whose outer layer is closed and round and the core wire is not easily broken, thereby ensuring When the SiC fiber is used as a suture, it does not directly contact with the SiC fiber cloth when it penetrates into and out of the laminated SiC fiber cloth, which reduces the frictional force and extrusion stress on the SiC fiber suture and ensures the integrity of the SiC fiber suture after stitching. It has good stability and continuity, and solves the problem of easy thread breakage when using traditional carbon fiber as suture.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

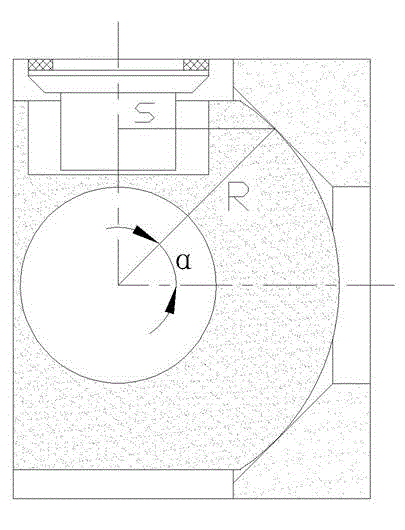

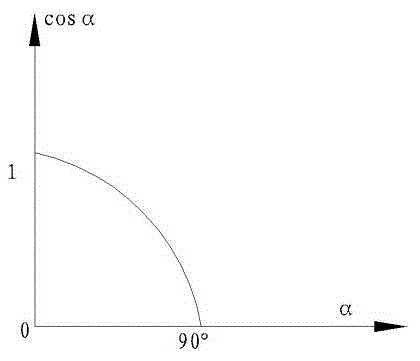

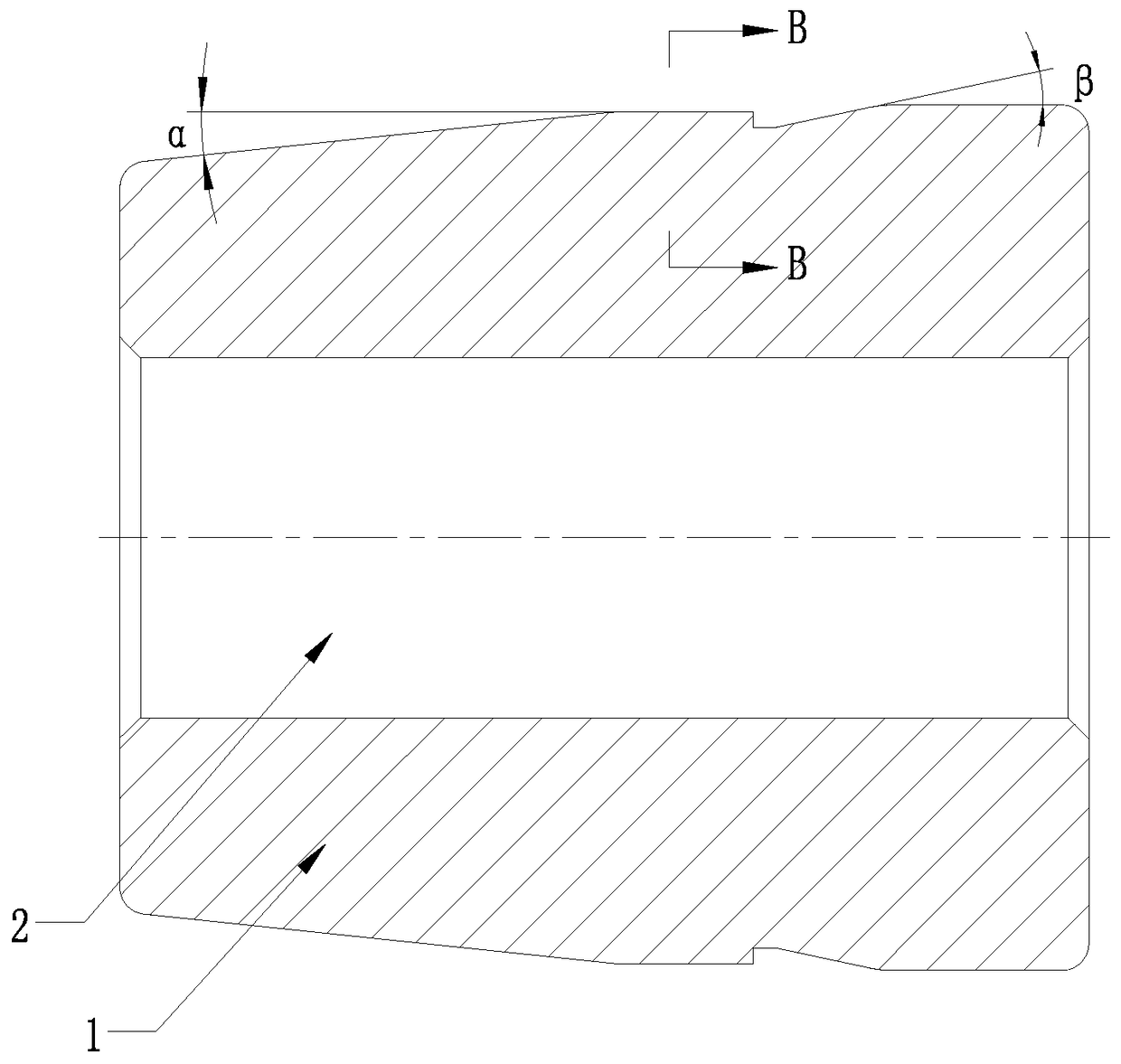

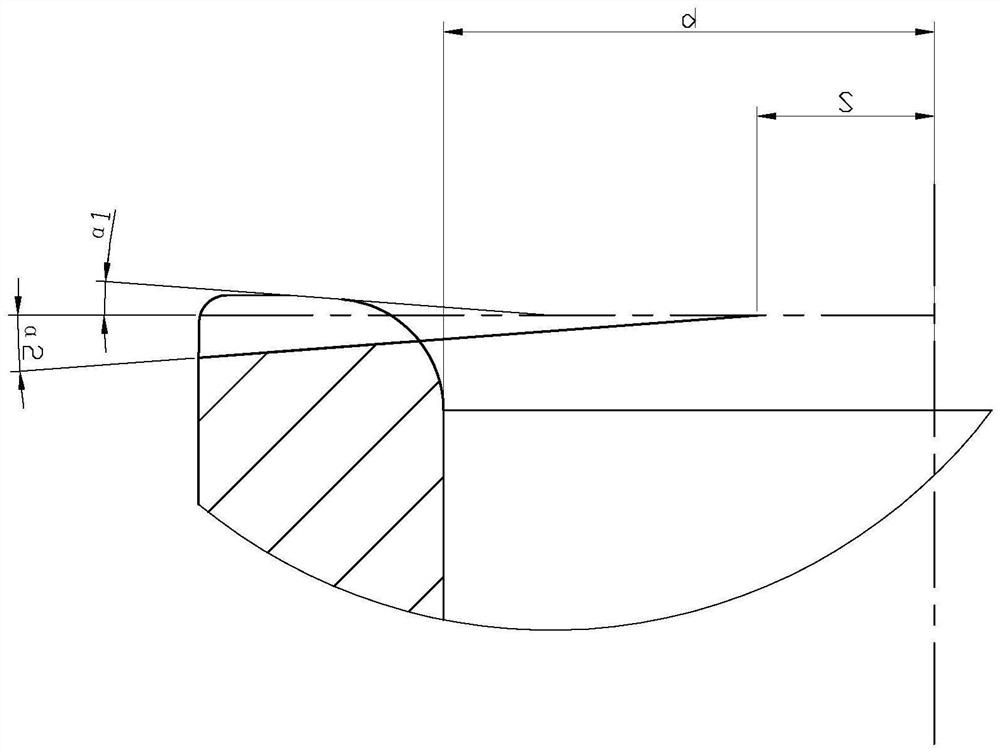

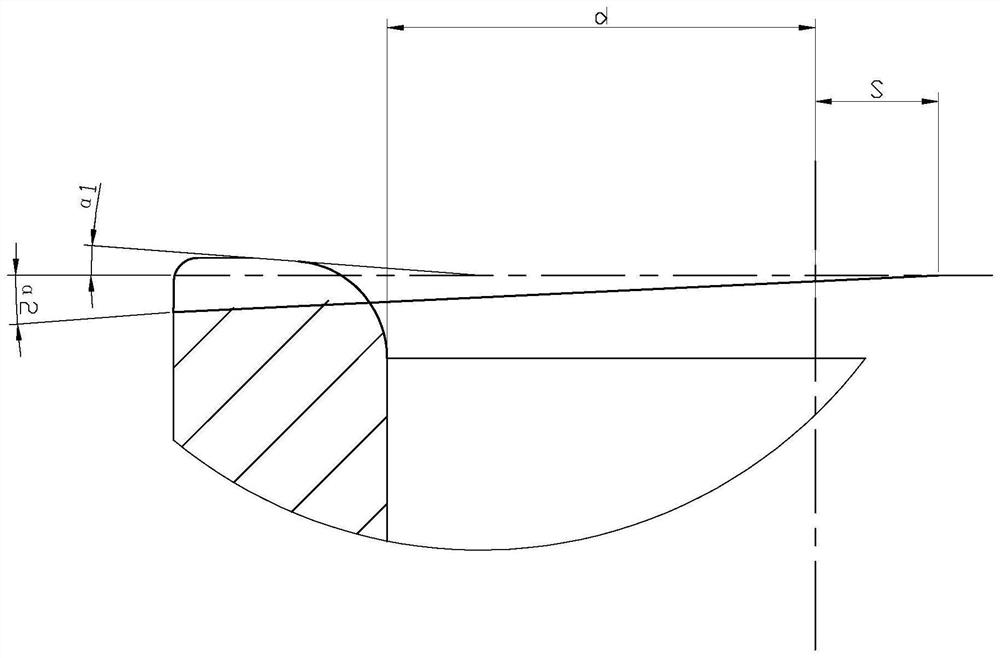

Cold-drawing inner mold for eliminating inner spiral ribbing of steel pipe

The invention relates to a cold-drawing inner mold for eliminating inner spiral ribbing of a steel pipe. The cold-drawing inner mold comprises an inner mold body; a first conical wall reduction section, a first cylindrical uniform-wall section, a transition section, a second conical wall reduction section and a second cylindrical uniform-wall section which are sequentially arranged in front and rear of the outer surface of the inner mold body; the conical angle alpha of the first conical wall reduction section is 2-10 degrees, the conical angle beta of the second conical wall reduction sectionis 8-15 degrees; the conical angle alpha of the first conical wall reduction section is smaller than the conical angle beta of the second conical wall reduction section; a plurality of planes are uniformly distributed on the circumference of the outer circle surface of the first cylindrical uniform-wall section in a milled mode; and the milling depth a of each plane is 0.1-0.5mm. The cold-drawinginner mold has the advantage that the inner spiral ribbing of the steel pipe can be eliminated.

Owner:江阴市洪腾机械有限公司

End face tooth part connected power transmission device

PendingCN114654939AImprove reliabilityFirmly connectedHubsWind energy generationUniversal jointTorque transmission

The invention discloses an end face tooth part connection power transmission device which comprises an outer ring, an inner ring, a universal joint and a locking bolt, a first roller path is arranged between the outer ring and the inner ring, a first roller is arranged in the first roller path, an embedded ring is further arranged on the inner ring in a matched mode, a second roller path is formed between the embedded ring and the outer ring, and a second roller path is arranged in the second roller path. A second roller is arranged in the second roller path, a hemming flange abutting against the universal joint is arranged at the position, corresponding to the embedded ring, of the edge of the inner ring, and straight teeth are distributed on the abutting face of the hemming flange and the universal joint in the circumferential direction. The universal joint and the hemming flange form torque transmission between the inner ring and the universal joint through mutual meshing of the straight teeth, the head portion of the locking bolt abuts against the side wall of the inner ring, and the rod portion of the locking bolt penetrates through an inner hole of the inner ring and then is in threaded fit with the universal joint. The power transmission device is compact in structure, lower in overall weight, high in installation precision and stable in power transmission.

Owner:C&U CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com