Method for conducting magneto-rheological thinning and polishing on InP-based RFIC wafer

A thinning polishing and magnetorheological technology, applied in the field of InP RFIC preparation, can solve problems such as physical damage of InP substrate extrusion stress, and achieve the effects of avoiding distortion of machining accuracy, good elasticity and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

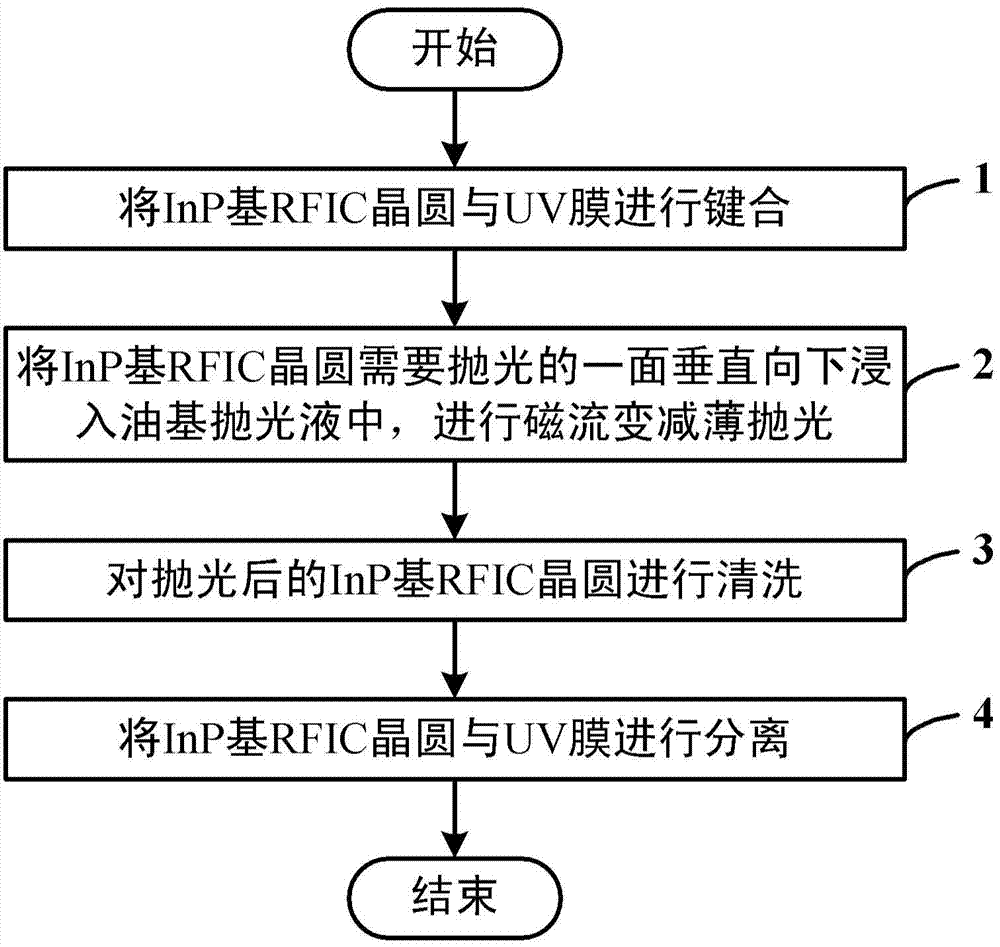

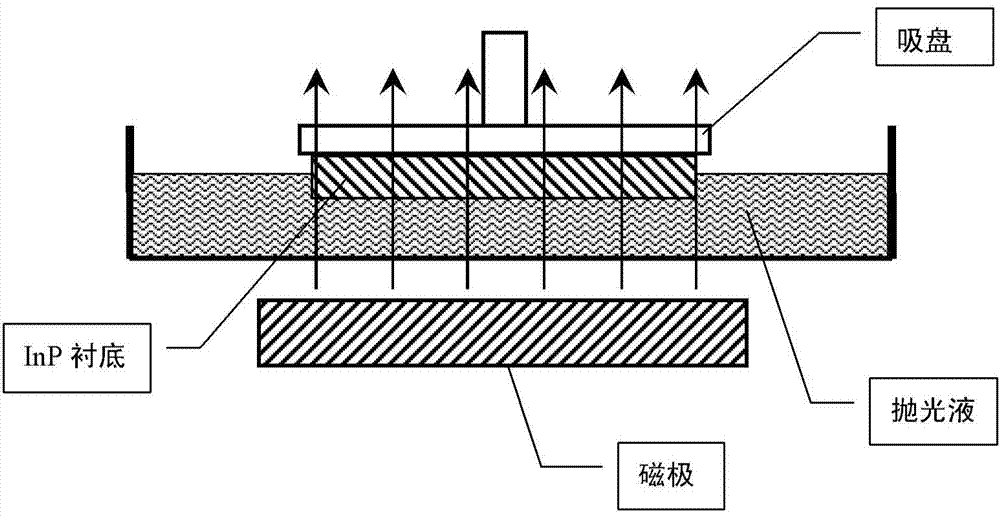

[0021] Such as figure 1 as shown, figure 1 It is a flow chart of a method for performing magnetorheological thinning and polishing on an InP-based RFIC wafer according to an embodiment of the present invention, and the method includes the following steps:

[0022] Step 1: Bond the InP-based RFIC wafer with the UV film:

[0023] In this step, the InP-based RFIC wafer to be thinned is placed on the UV adhesive film, placed on a hot plate, and the temperature of the hot plate is 60°C, at 2×10 -2 Under mabr vacuum, apply a pressure of 0.6 bar to the InP-based RFIC wafer for bonding, and the bonding time is 20 minutes.

[0024] Step 2: Dip the side of the InP-based RFIC wafer to be polished vertically downward into the oil-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com