End face tooth part connected power transmission device

A technology of power transmission device and face teeth, which is applied to vehicle components, transportation and packaging, wheel hubs, etc., and can solve problems such as abnormal starting noise, long splines, and assembly difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

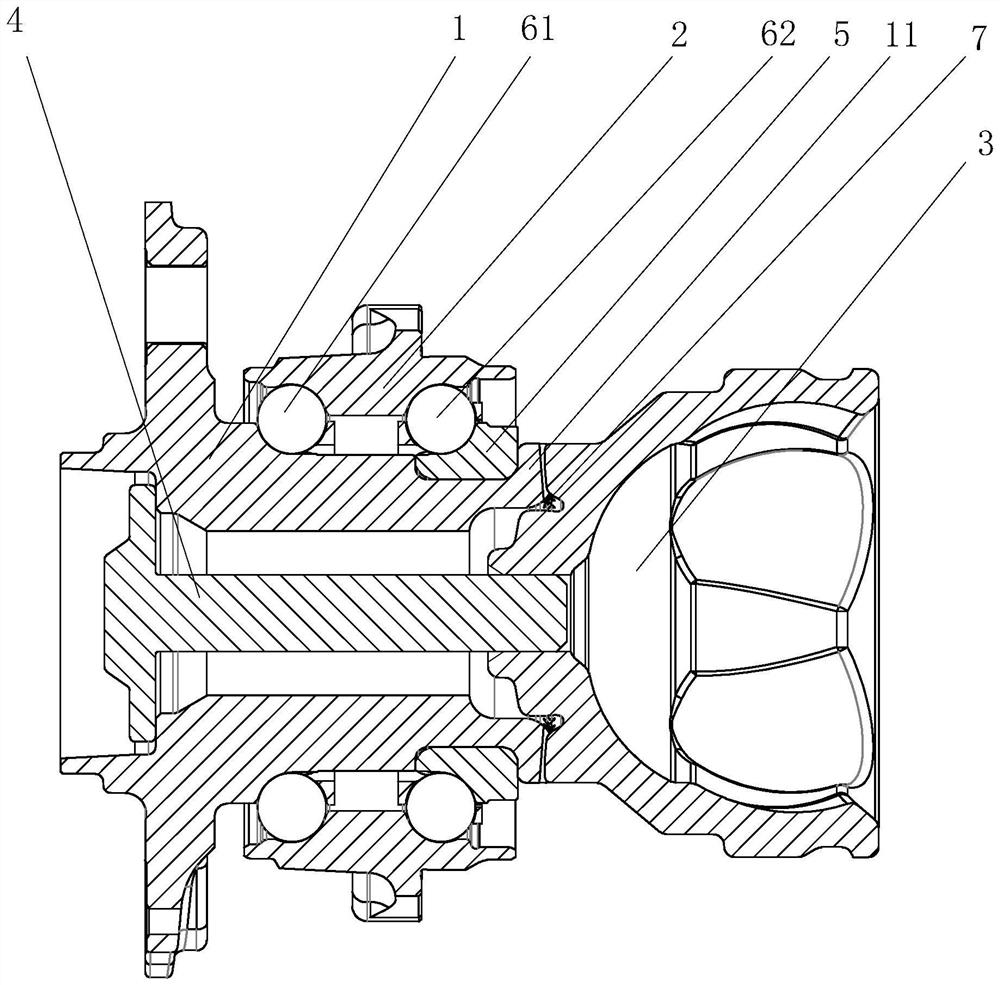

[0020] Embodiments of the power transmission device connected by end face teeth of the present invention are as follows figure 1 , Figure 5 , Image 6 and Figure 7 As shown: including outer ring 2, inner ring 1, universal joint 3 and locking bolt 4, a first raceway is set between the outer ring 2 and inner ring 1, and a first raceway is set in the first raceway Roller 61, the inner ring 1 is also equipped with an insert ring 5, a second raceway is formed between the insert ring 5 and the outer ring 2, and a second roller 62 is arranged in the second raceway, so The edge of the inner ring 1 corresponding to the position of the bezel 5 is provided with a curling flange abutting against the universal joint 3, and straight teeth are arranged along the circumferential direction on the abutting surfaces of the curling flange and the universal joint 3 respectively. 7. The universal joint 3 and the curling flange form the torque transmission between the inner ring 1 and the unive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com