Wave plate falling device of welded metal corrugated pipe

A technology for welding metal and blanking devices, which is applied in the field of corrugated plate blanking devices, can solve problems such as poor stress and fatigue resistance of bellows, difficulty in forming original corrugated plate blanking, and affecting welding and sealing effects, etc., to achieve Quick and easy mold calibration, low requirements on mold precision, and small extrusion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

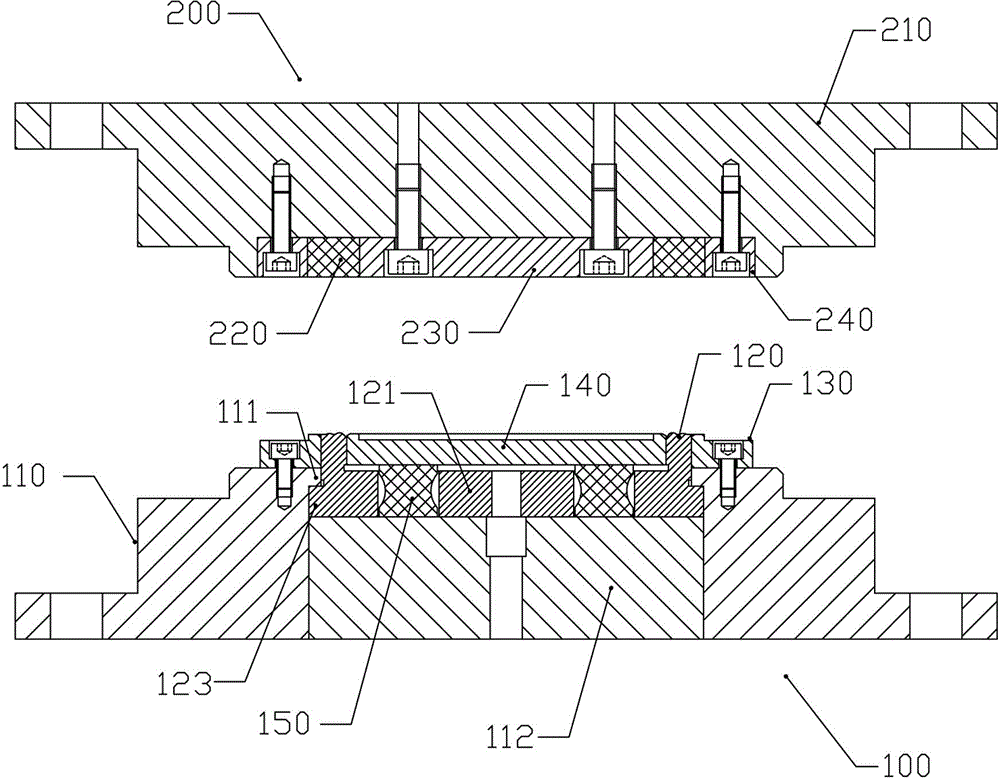

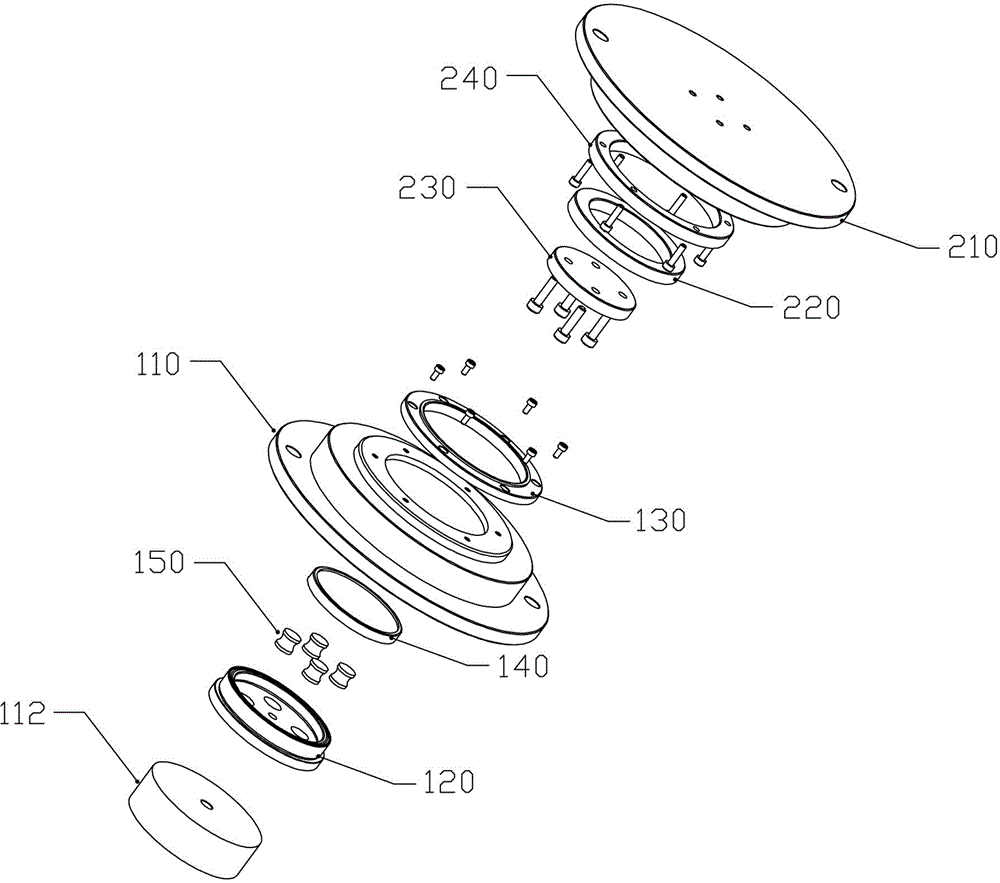

[0018] refer to figure 1 and figure 2 , a corrugated plate blanking device for welding metal bellows, comprising a lower mold assembly 100 and an upper mold assembly 200 .

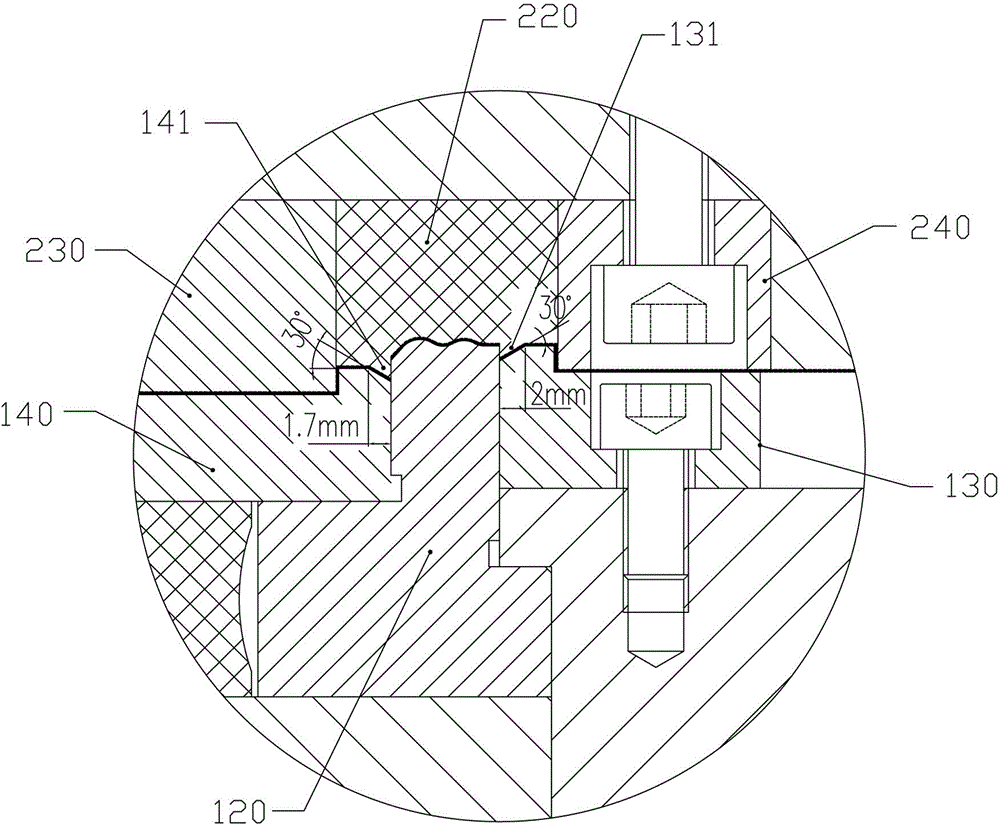

[0019] refer to Figure 3 to Figure 5 , the lower mold assembly 100 includes a lower mold base 110 with a sinkhole on the top surface, an annular knife mold 120 installed in the sinkhole, an outer binder 130 with a hollow circle and a circular inner binder 140, wherein The outer binder 130 is preferably ring-shaped, the upper end of the knife die 120 protrudes from the top surface of the lower mold base 110, and the top surface of the knife mold 120 is a corrugated curved surface, and the outer binder 130 is fixed on the lower mold base 110 by screws. Above, the inner wall of the outer binder 130 is attached to the outer wall of the die 120 , and the top surface of the outer binder 130 is flush with the outer top surface of the die 120 , and the outer binder of the joint with the die 120 The top of 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com