Scroll compressor eccentricity regulating mechanism and scroll compressor

A scroll compressor and adjusting mechanism technology, applied in the field of compressors, can solve problems such as the inability of the eccentric bushing to adjust the eccentricity, the easy jamming of the eccentric bushing and the crankshaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

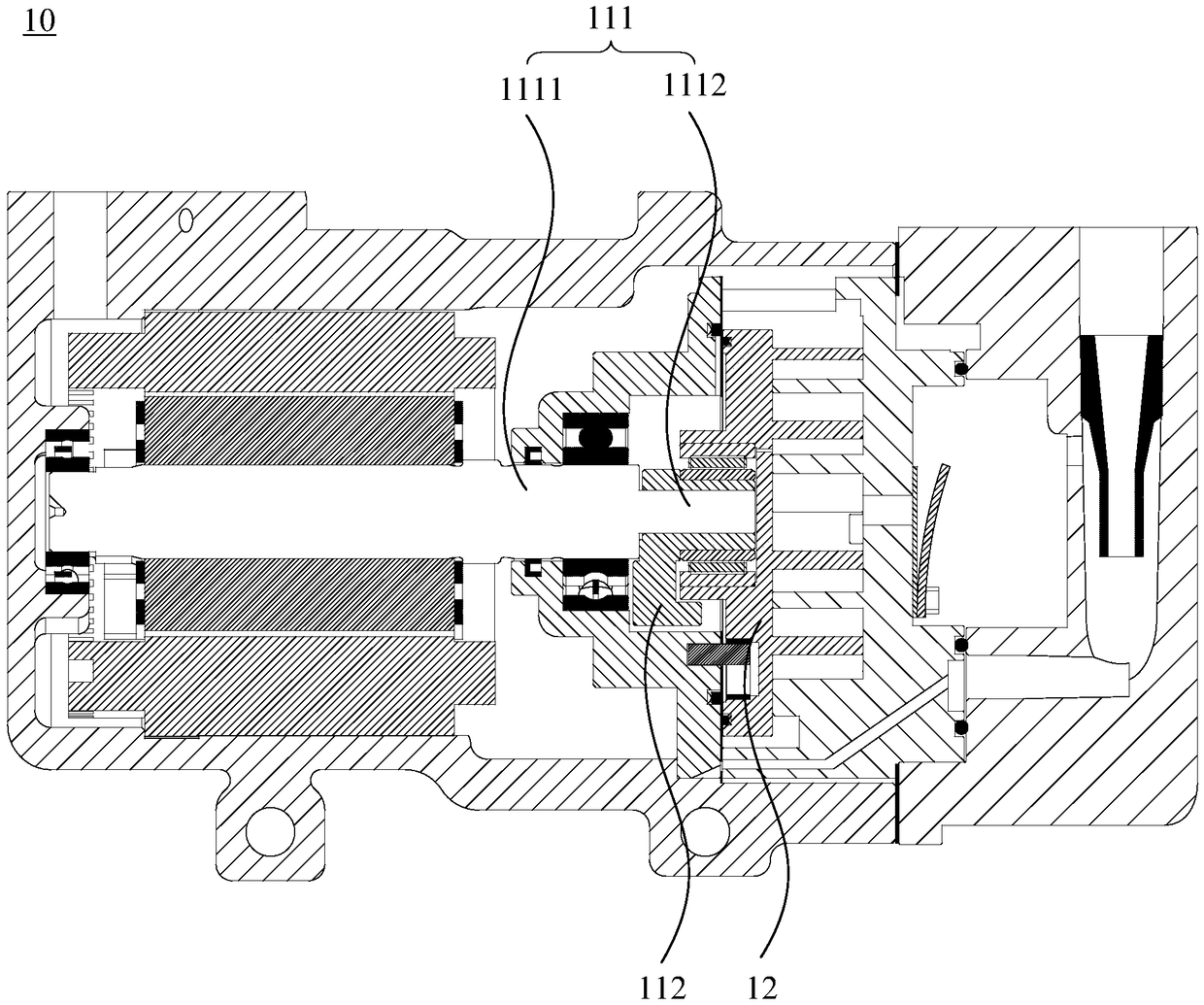

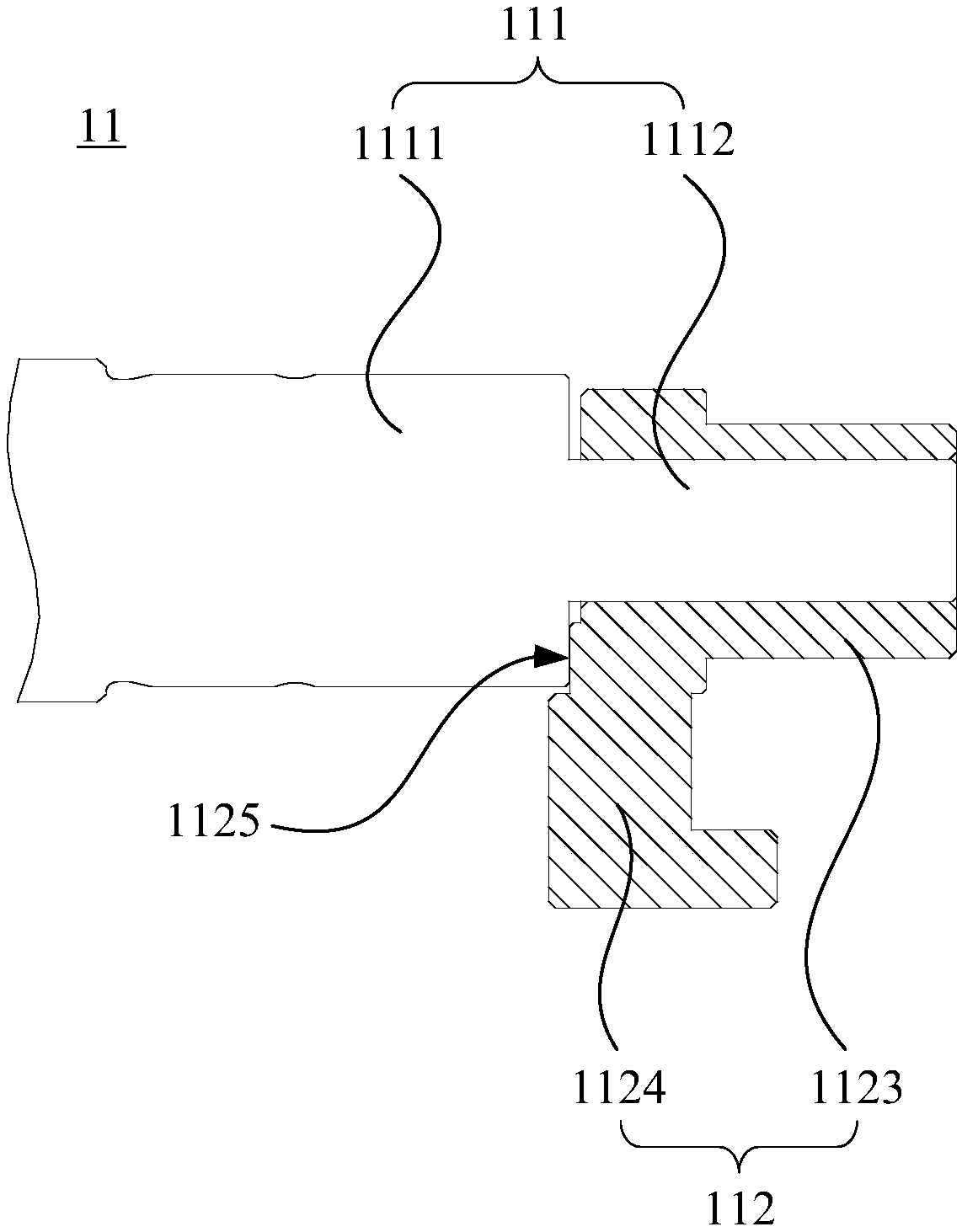

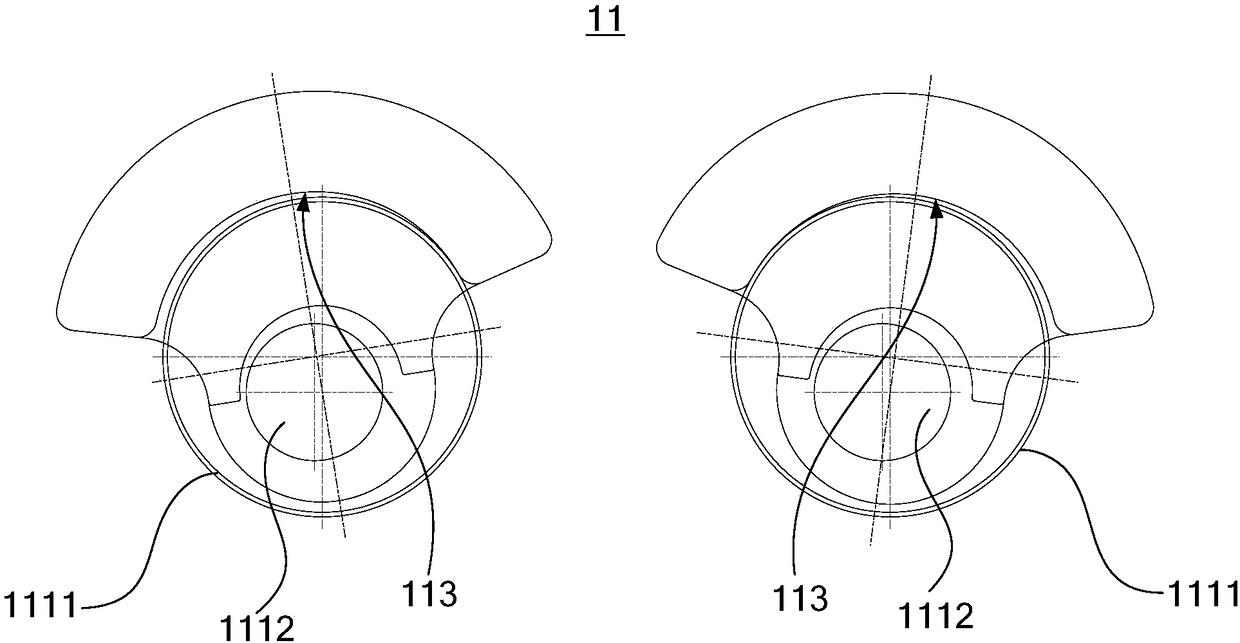

[0027] Such as Figure 1 to Figure 9 As shown, in one embodiment, a scroll compressor eccentricity adjustment mechanism 11 is provided, including a crankshaft 111 and an eccentric bushing 112 corresponding to the crankshaft 111, and the crankshaft 111 includes a main shaft that can correspond to the motor 1111, and an eccentric shaft 1112 eccentrically arranged relative to the main shaft 1111, the eccentric bushing 112 is sleeved on the eccentric shaft 1112, and is rotatably connected with the eccentric shaft 1112, as Figure 4 As shown, the surface of the eccentric bush 112 surrounding the side of the main shaft 1111 is the first abutment surface 113, and the first abutment surface 113 is provided with a first tangent plane 1131 at the limit position of the eccentricity angle. The side of the main shaft 1111 is provided with a second tangent plane 114 at the limit position of the eccentricity angle. The plane 114 fits.

[0028] The above solution provides a scroll compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com