Self-locking locking mechanism

A locking mechanism, self-locking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

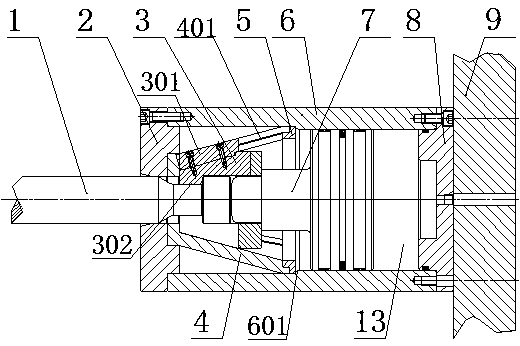

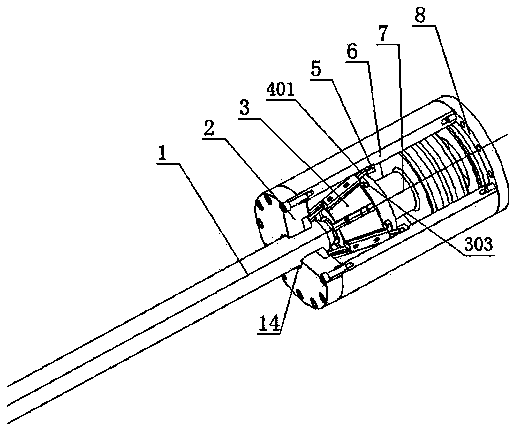

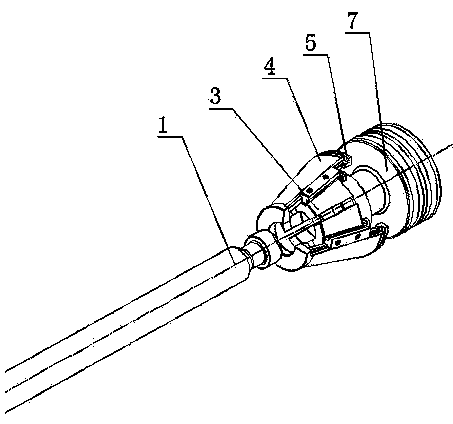

[0023] As shown in the figure, the self-locking locking mechanism includes a cylinder body 6 with a step 601 inside, which is connected to the front and rear end covers 2 and 8 by screws, and is sequentially press-fitted on the cone between the front end cover 2 and the step 601. Body 4, support ring 5, and piston 7 that reciprocates along the hydraulic chamber 13 formed between the rear end cover 8 and the step 601. A plurality of conical slides 401 extending along the direction of the generatrix are evenly distributed on the peripheral surface of the cone 4, and the conical slides 401 are respectively provided with separate parts that reciprocate along them and close into a ring toward the axis of the cone 4. Block 3, the cross-section of the tapered slideway 401 of the cone 4 is T-shaped (also Y-shaped), and the split block 3 is provided with a T-shaped slide block 301 corresponding to the tapered slideway 401. The inner surface of the body block 3 is provided with a limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com