Ultraviolet curing heat-conducting adhesive tape, and preparation method and application thereof

A UV-light and light-curing resin technology, which is applied in the direction of adhesives, amide/imide polymer adhesives, film/sheet adhesives, etc., can solve problems such as capacity limitations and reduce the impact of thermal conductivity , Improve the effect of reducing expenditure and saving manual lamination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

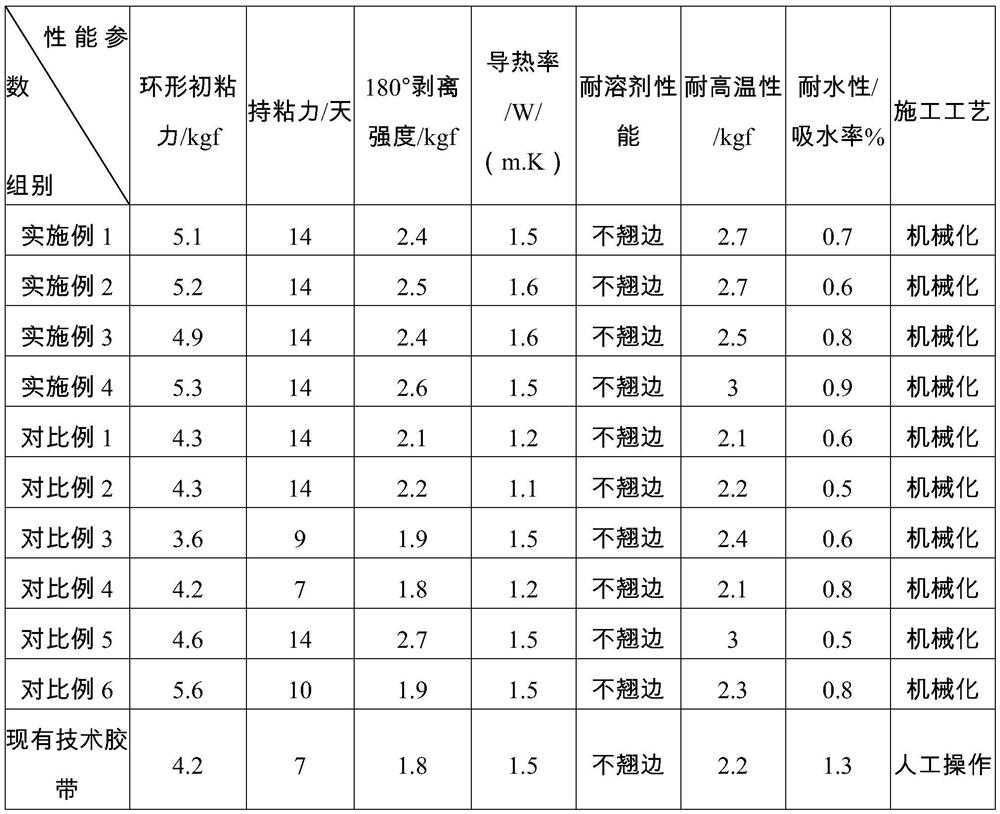

Examples

Embodiment 1

[0030] This embodiment provides a UV-curable thermally conductive tape, the UV-curable adhesive includes the following components in parts by weight: 5 parts of photocurable resin, 10 parts of polyacrylate, 70 parts of filler, 8 parts of acrylate active monomer, 5 parts of photoinitiator, 1 part of coupling agent, 1 part of leveling agent.

[0031] Wherein, the photocurable resin is 5 parts of self-synthesized urethane acrylate; 10 parts of the polyacrylate; the filler is: 40 parts of aluminum oxide (3000 mesh), 30 parts of aluminum hydroxide (600 mesh); The acrylate reactive monomer is made up of the following components by weight: 3 parts of isobornyl acrylate, 5 parts of isooctyl acrylate; the leveling agent is 1 part of acrylate leveling agent; the coupling agent is 1 part of KH550 coupling agent; The photoinitiator is made up of the following components by weight: 1 part of 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone and 4 parts of 1-hydroxy-cyc...

Embodiment 2

[0043] This embodiment provides a UV curable thermally conductive adhesive tape, which includes the following components in parts by weight: 10 parts of photocurable resin, 5 parts of polyacrylate, 75 parts of filler, 5 parts of acrylate active monomer part, 3.5 parts of photoinitiator, 1 part of coupling agent, and 0.5 part of leveling agent.

[0044] Wherein, the photocurable resin is 10 parts of self-synthesized urethane acrylate; 5 parts of the polyacrylate; the filler is: 60 parts of alumina (3000 mesh), 15 parts of hexagonal boron nitride (3 microns); The acrylate reactive monomer is composed of the following components by weight: 1 part of isobornyl acrylate, 2.5 parts of lauryl acrylate, 1.5 parts of N,N-dimethylacrylamide; the leveling agent is modified acrylic acid 0.5 part of ester leveling agent; the coupling agent is 1 part of KH792 coupling agent; the photoinitiator is composed of the following components by weight: 1.5 parts of benzoin dimethyl ketal and 2 parts...

Embodiment 3

[0047] This embodiment provides a UV-curable thermally conductive adhesive tape, which includes the following components in parts by weight: 15 parts of photocurable resin, 8 parts of polyacrylate, 60 parts of filler, and 10 parts of acrylate active monomer. parts, 4.7 parts of photoinitiator, 2 parts of coupling agent, and 0.3 parts of leveling agent.

[0048] Wherein, the photocurable resin is 15 parts of self-synthesized urethane acrylate; 8 parts of the polyacrylate; the filler is: 55 parts of aluminum hydroxide (600 mesh), 5 parts of silicon carbide (1200 mesh); The acrylate active monomer is composed of the following components by weight: 2 parts of hydroxyethyl acrylate, 6 parts of butyl acrylate, 2 parts of trimethylolpropane trimethacrylate; the leveling agent is silicone fluid 0.3 parts of leveling agent; the coupling agent is 2 parts of KH570 coupling agent; the photoinitiator is made up of the following components by weight: 2-hydroxyl-2-methyl-1-phenyl-1-acetone 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com