Patents

Literature

63results about How to "Reduce work speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

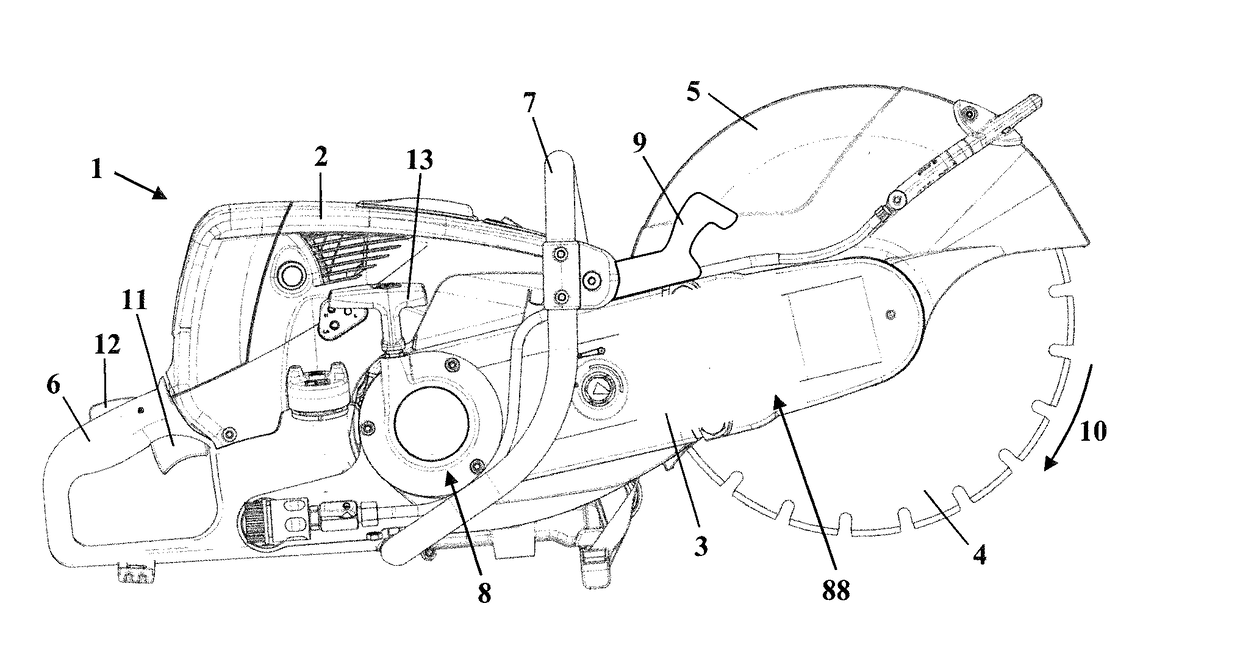

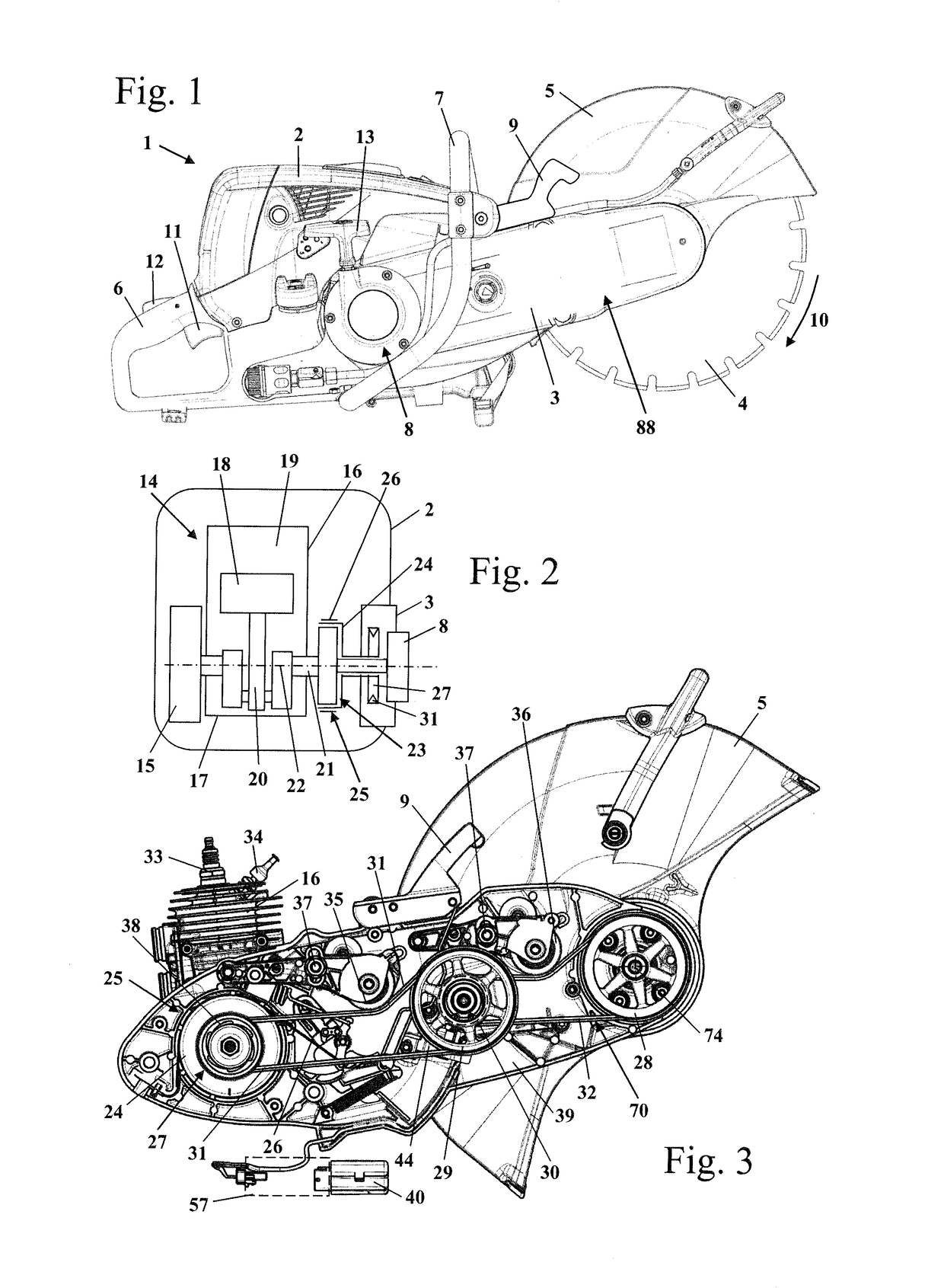

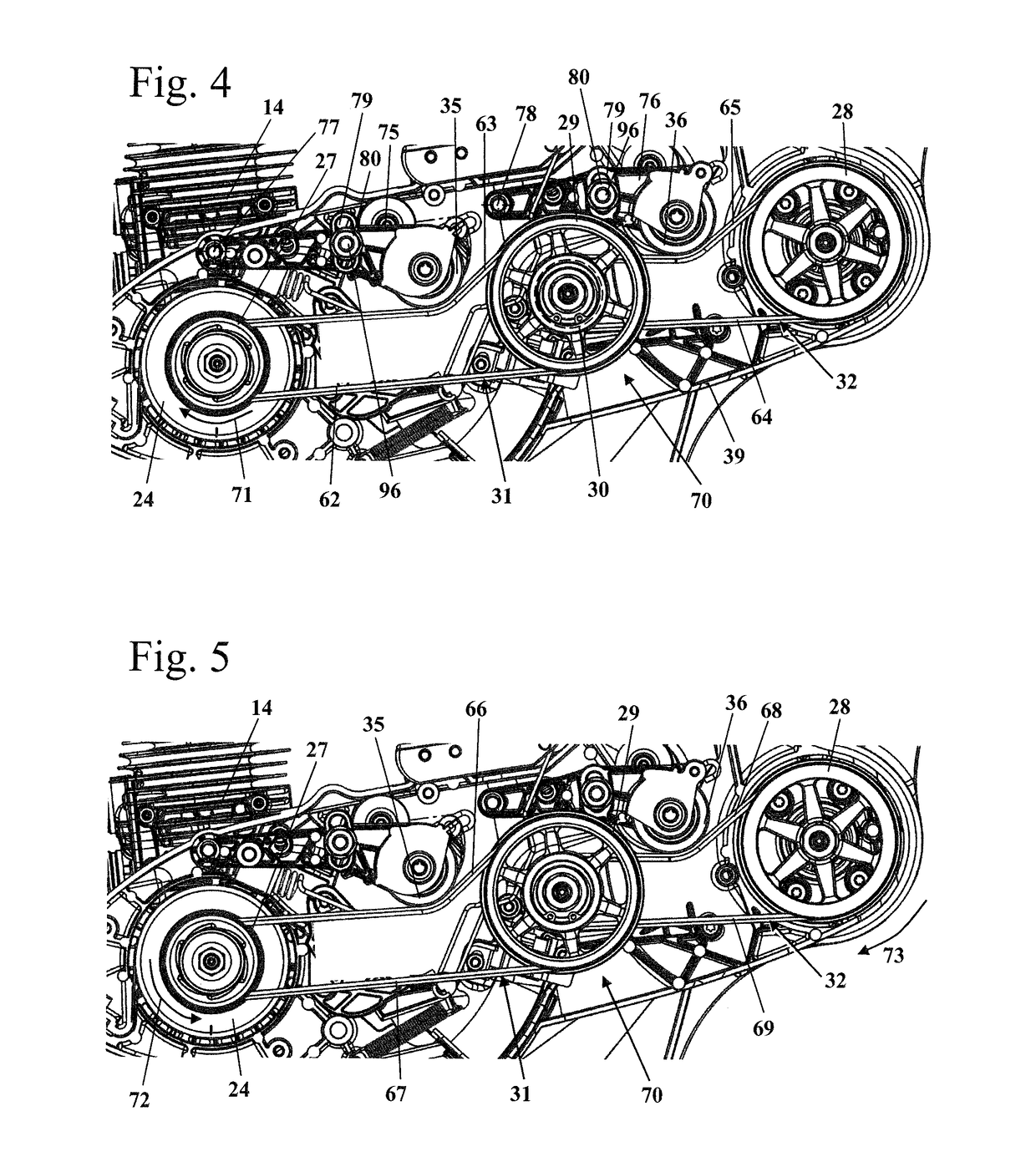

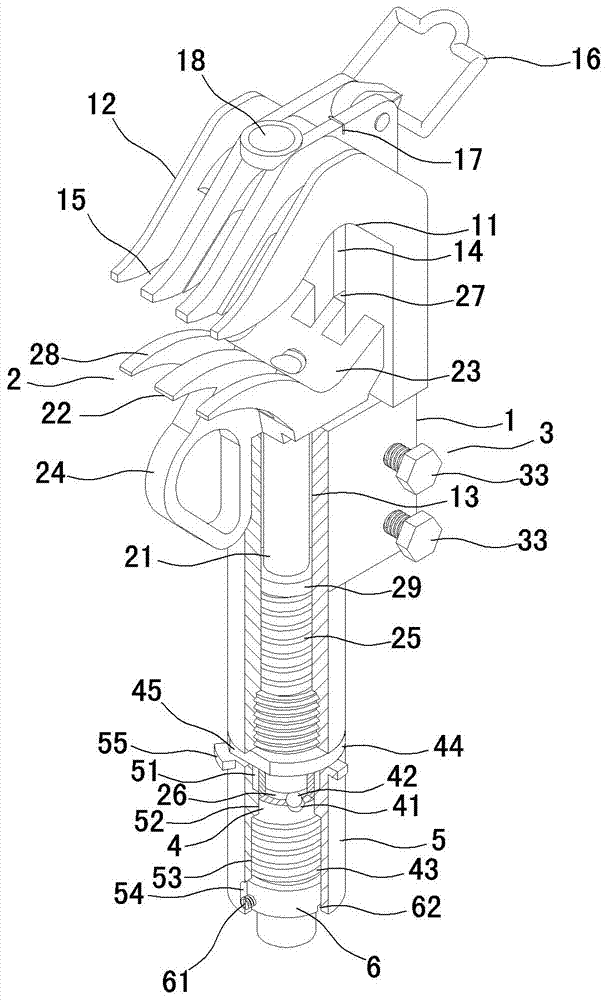

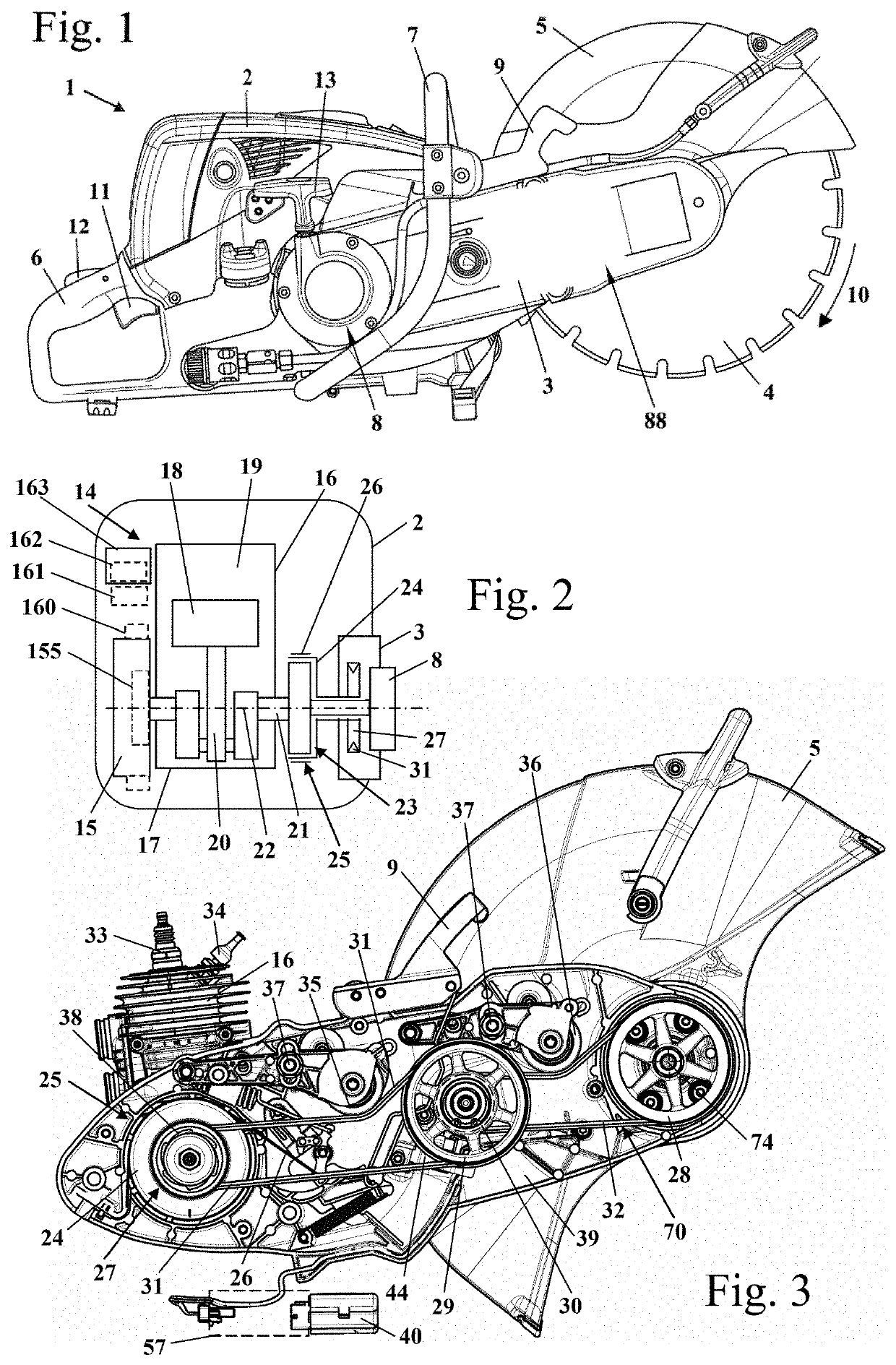

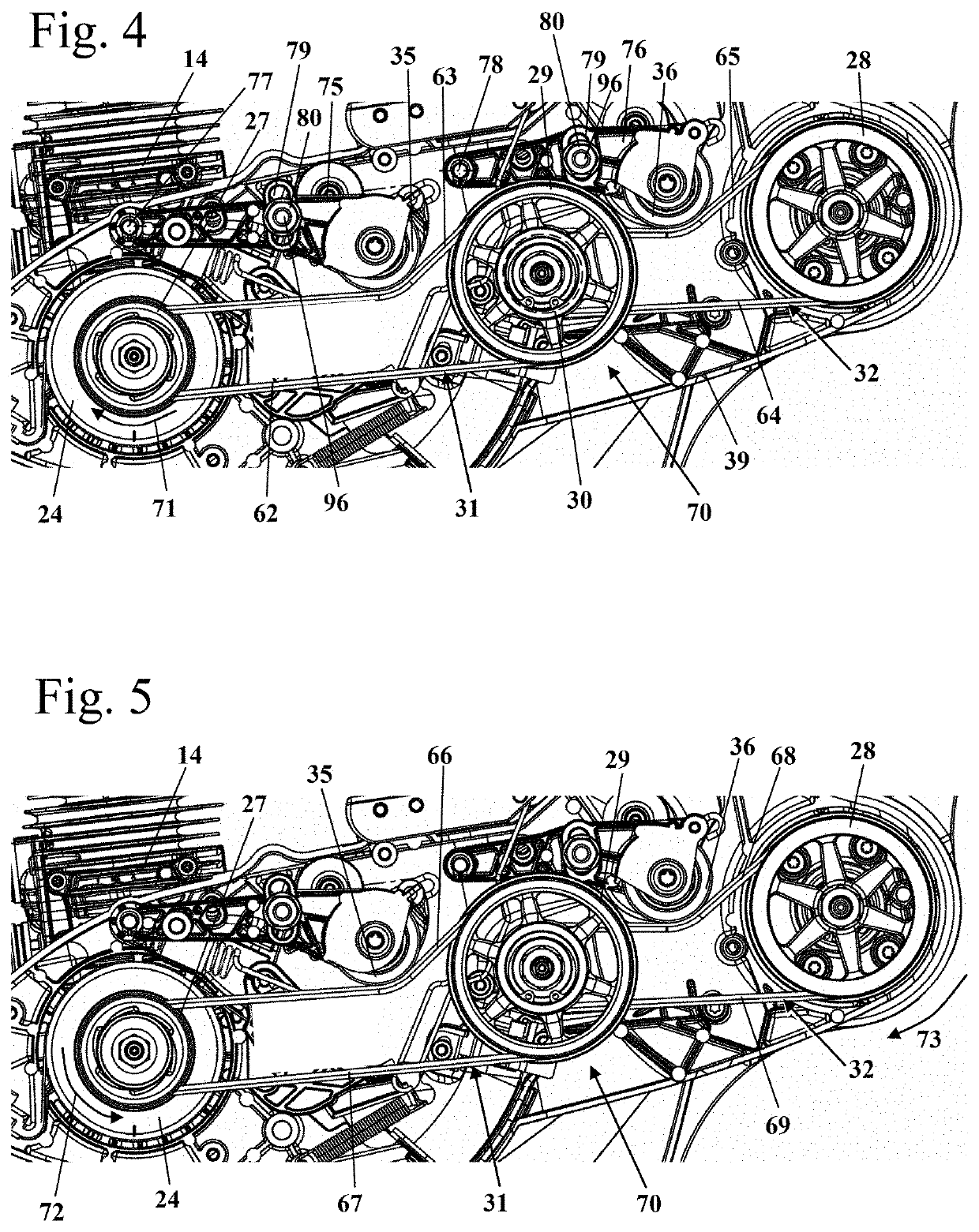

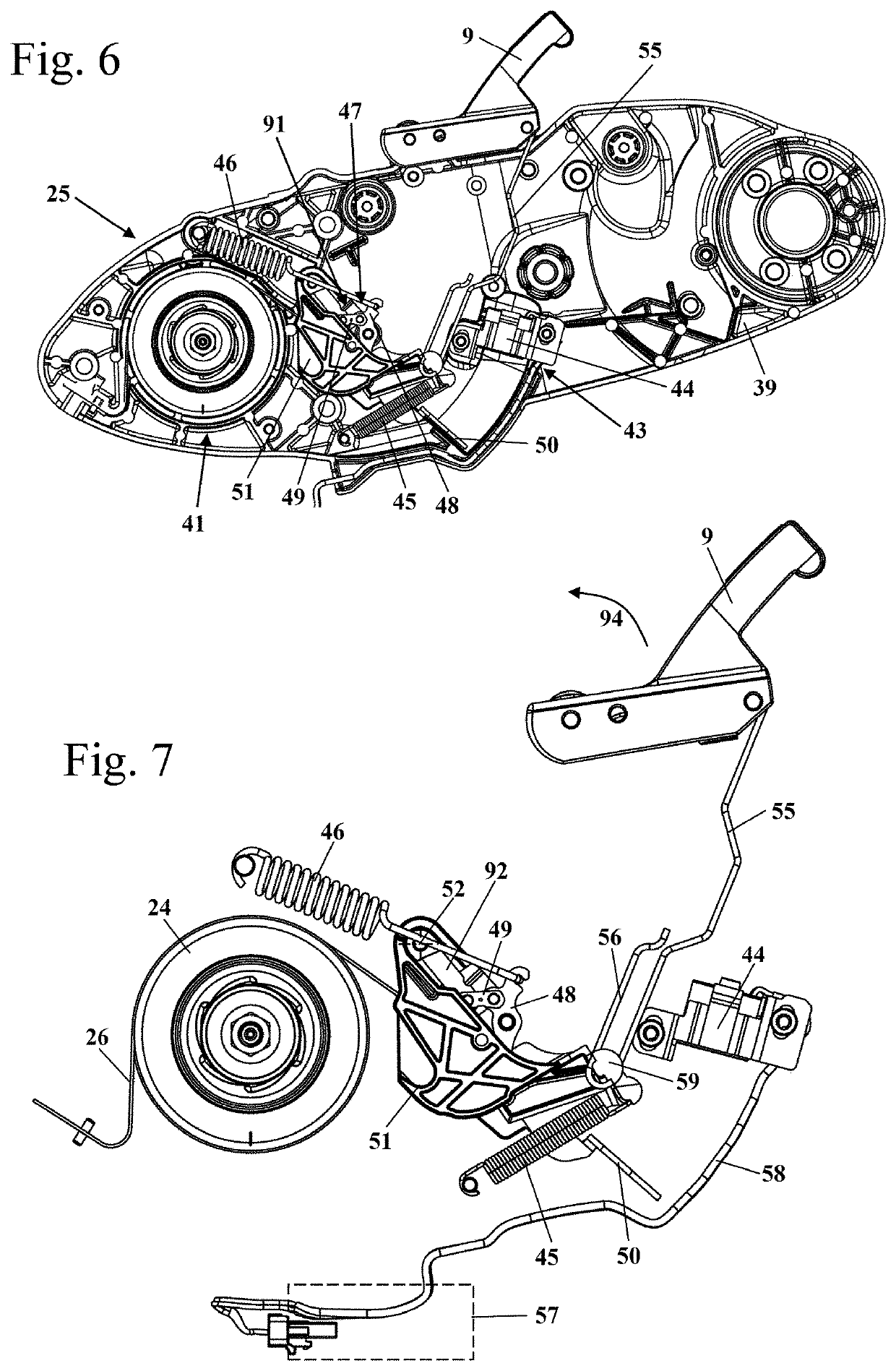

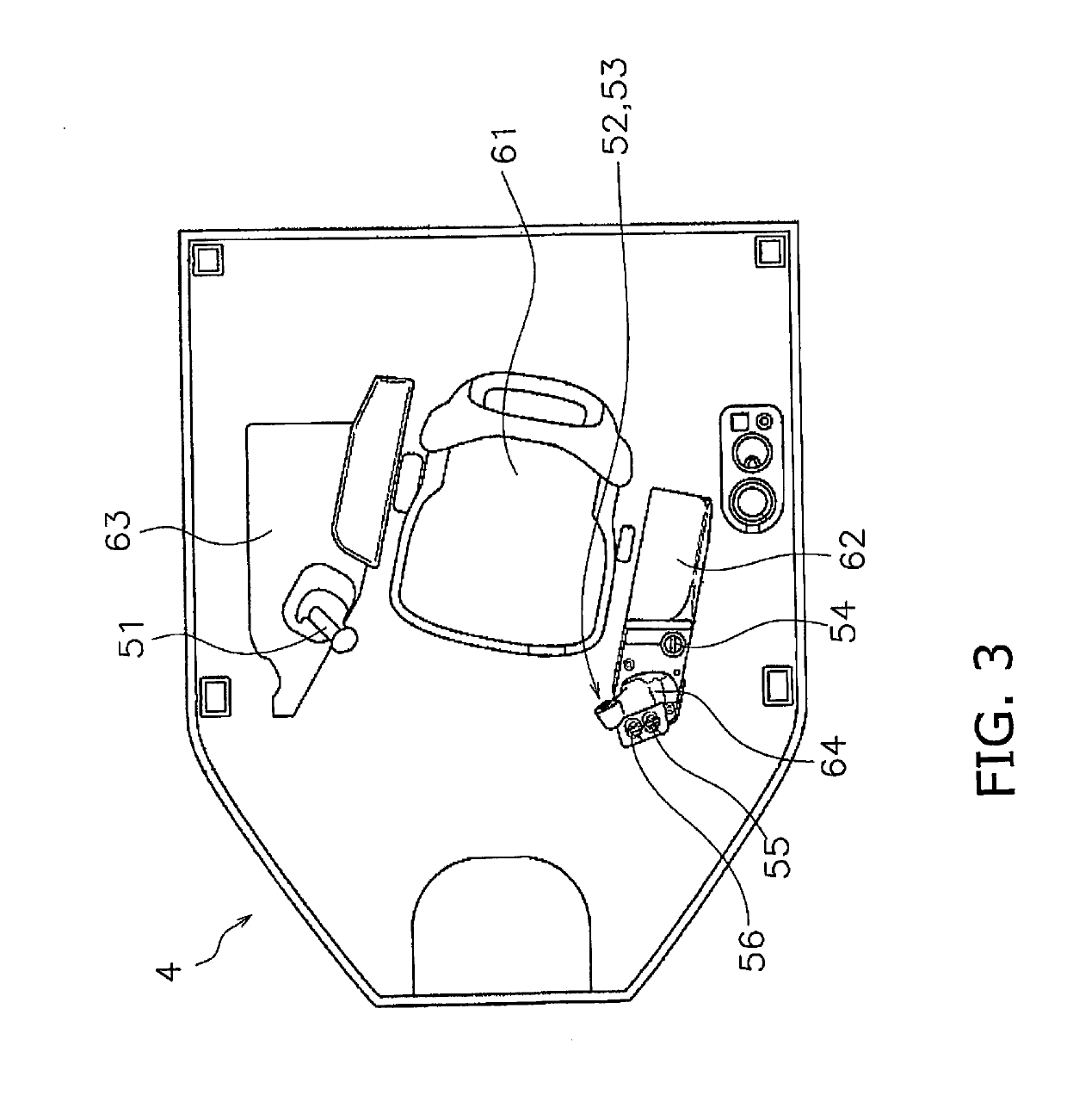

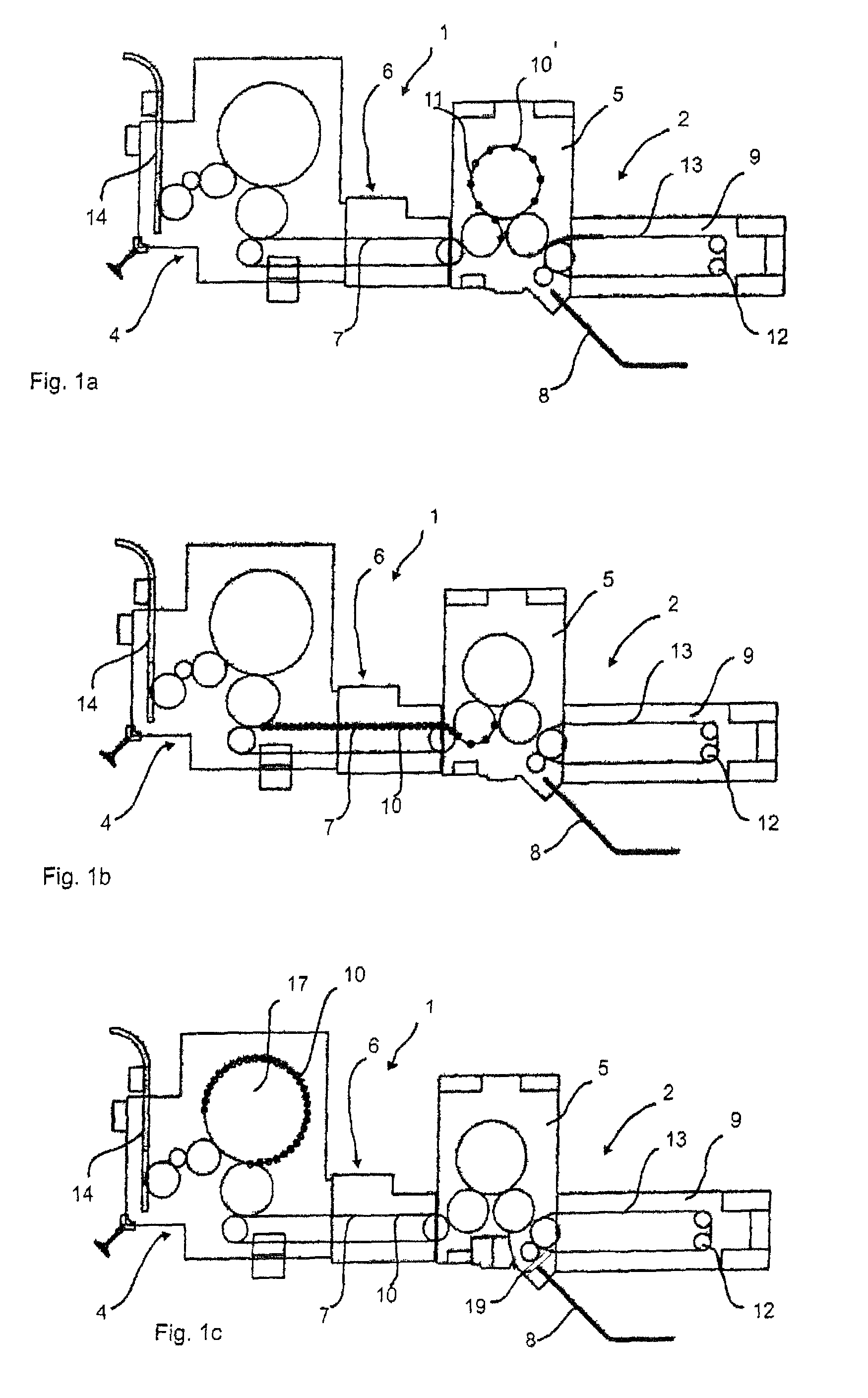

Handheld work apparatus

ActiveUS20170072482A1Reduce work speedReliable transmissionMetal sawing devicesMetal sawing accessoriesEngineeringDrive motor

Owner:ANDREAS STIHL AG & CO KG

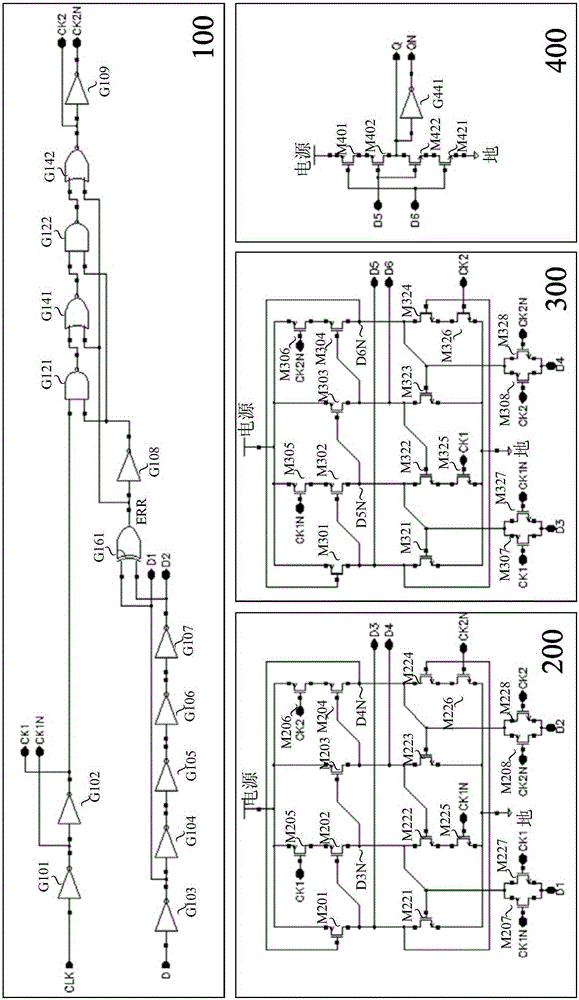

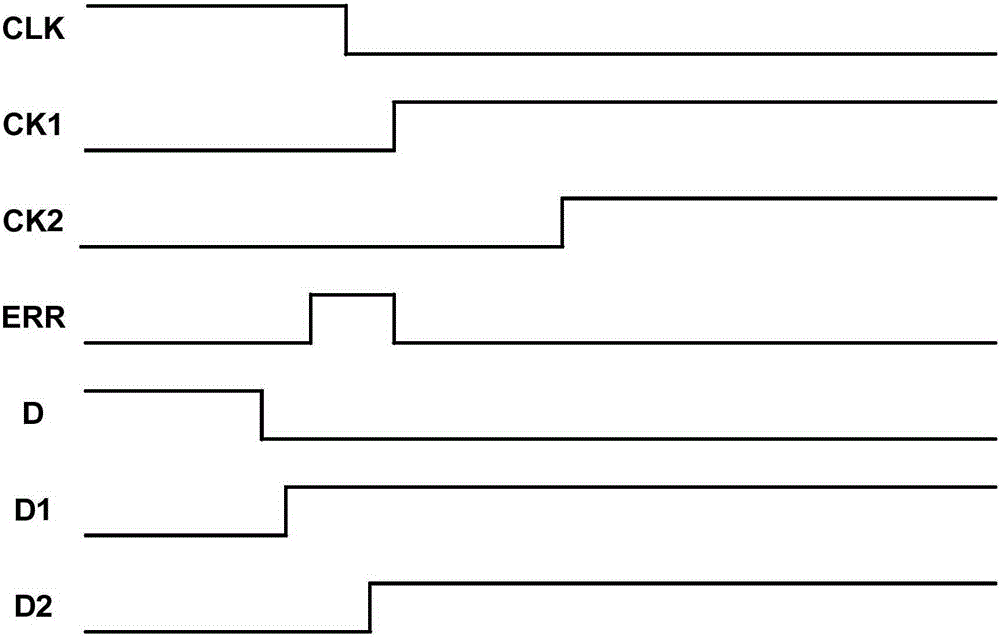

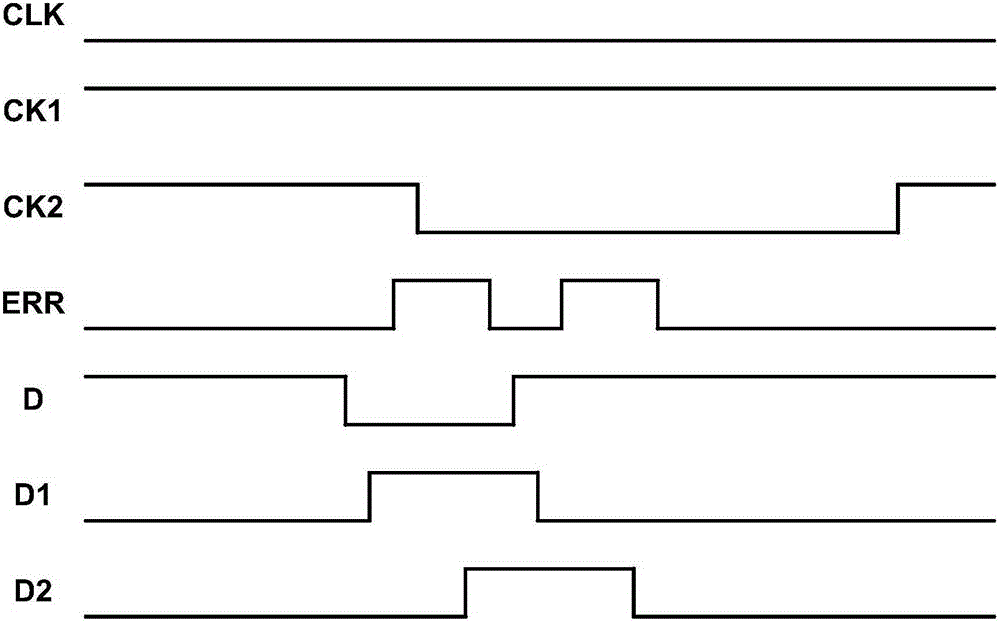

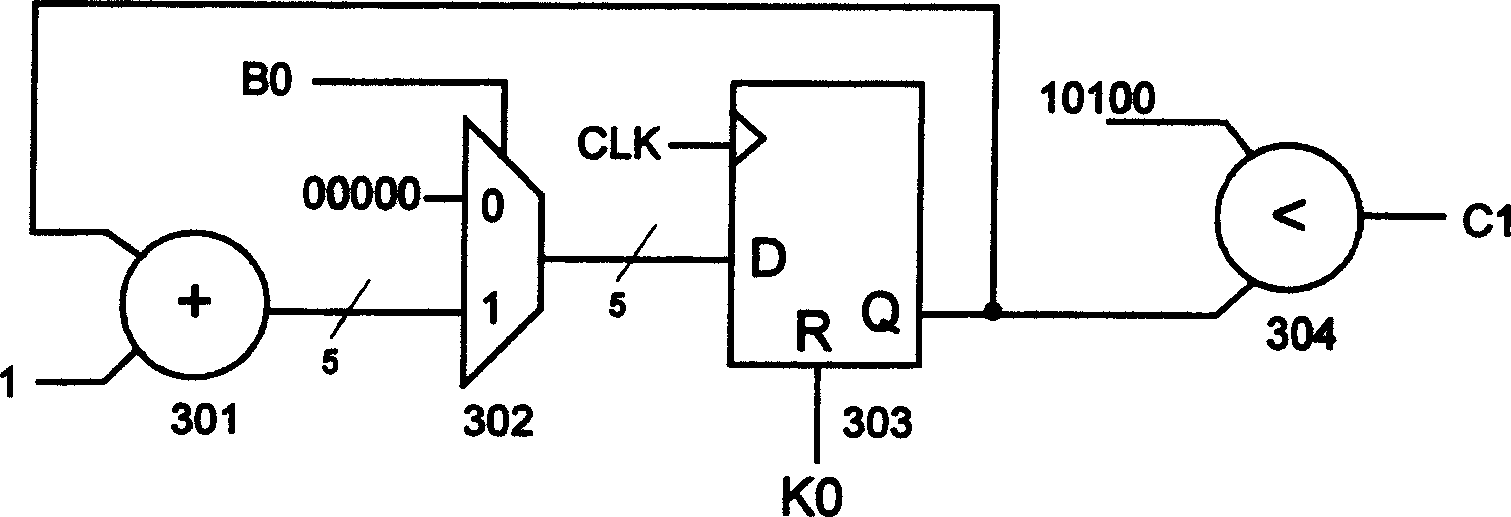

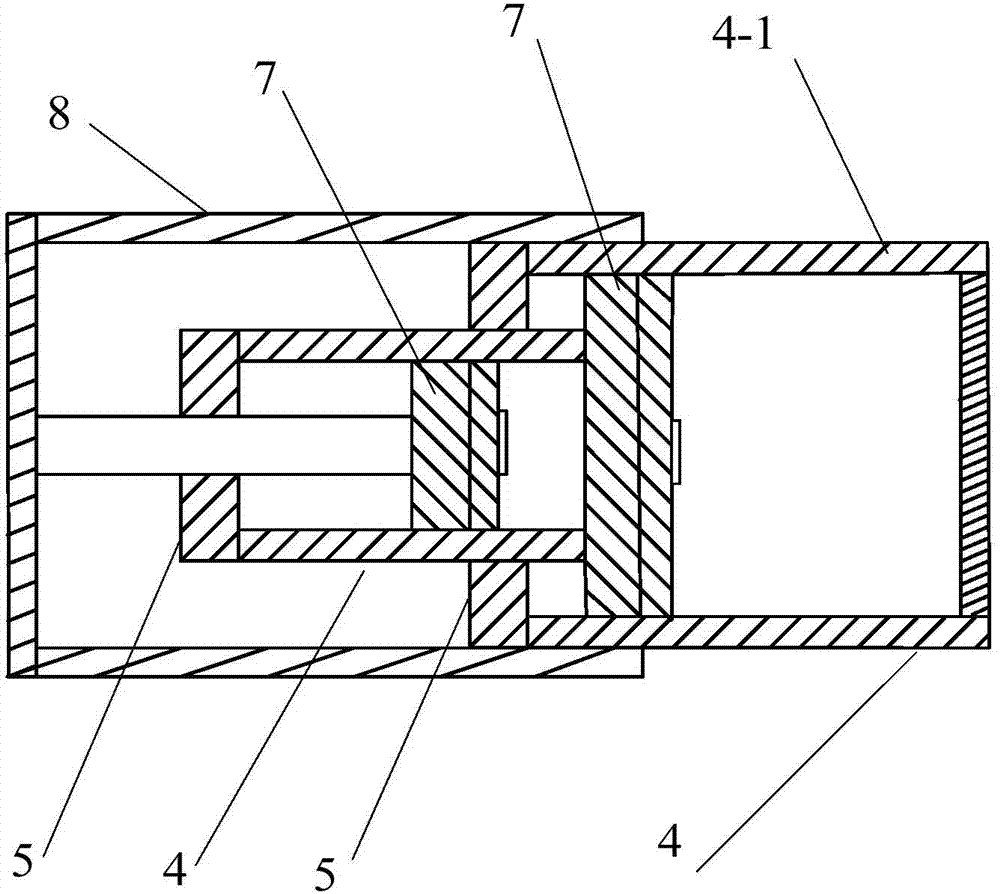

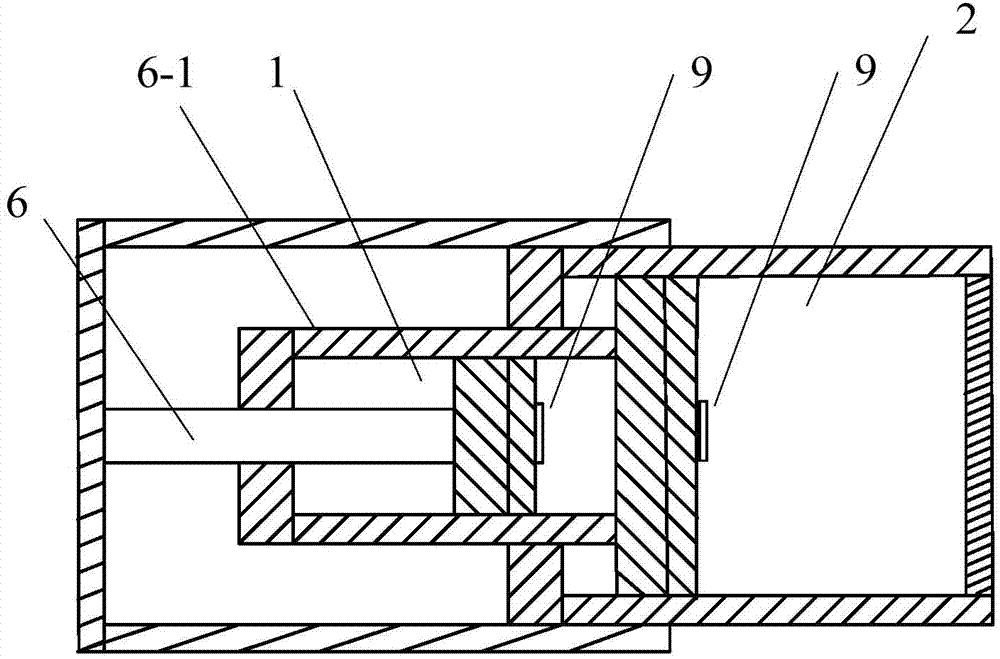

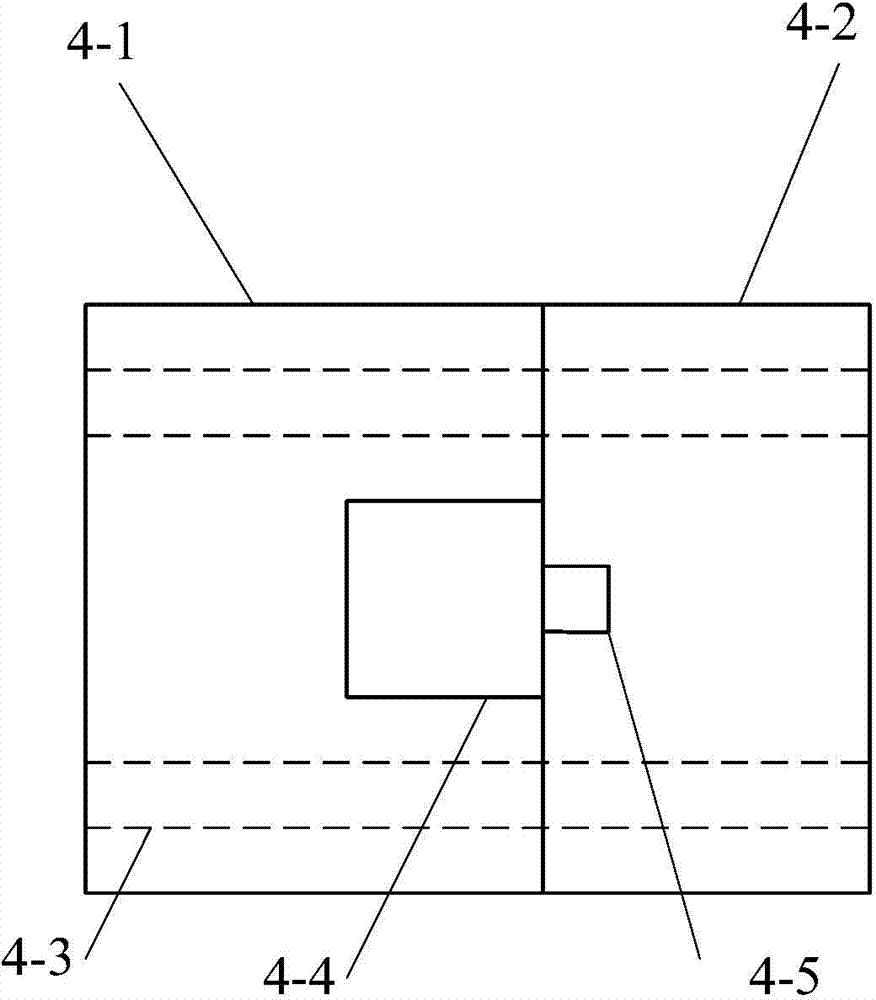

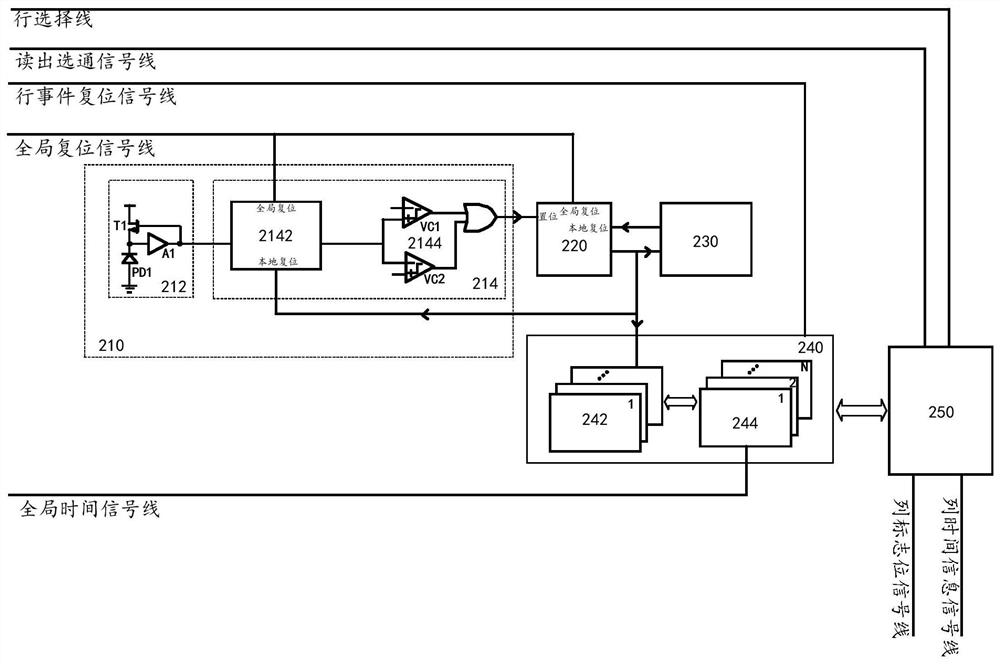

Single event transient (SET)-resistant reinforced register suitable for SRAM type FPGA for aerospace

A single event transient-resistant reinforced register suitable for an SRAM type FPGA for aerospace is disclosed. A register unit performs processing on a SET pulse by a novel delay unit to make the register have high SET capability. The reinforced register consists of four parts of an internal data and clock generation circuit, a master latch, a slave latch and an output buffer. The internal data and clock generation circuit uses an NAND gate and an NOR gate to form a delay chain for processing the SET pulse; and the master latch and the slave latch use a latch unit based on a DICE (Dual Interlocked storage CEll) structure. The reinforced register, by using inherent characteristics of a DICE unit, only uses one delay chain to shield the SET pulses in a clock terminal CLK and a data terminal D at the same time. Compared with a conventional SET reinforced register, the reinforced register provided by the present invention has fewer delay units, so that the overall area of the reinforced register is smaller than that of the conventional reinforced register.

Owner:BEIJING MXTRONICS CORP +1

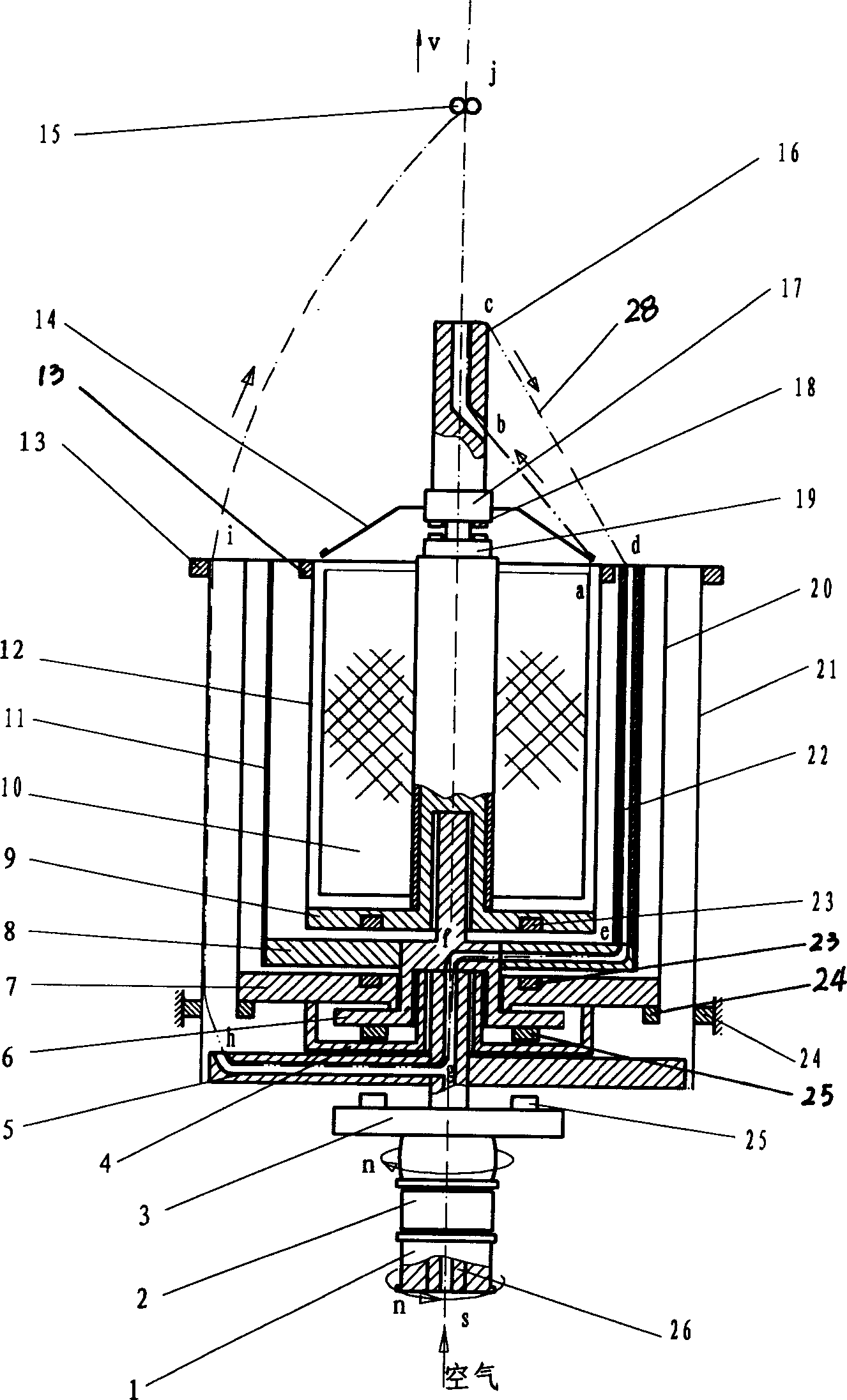

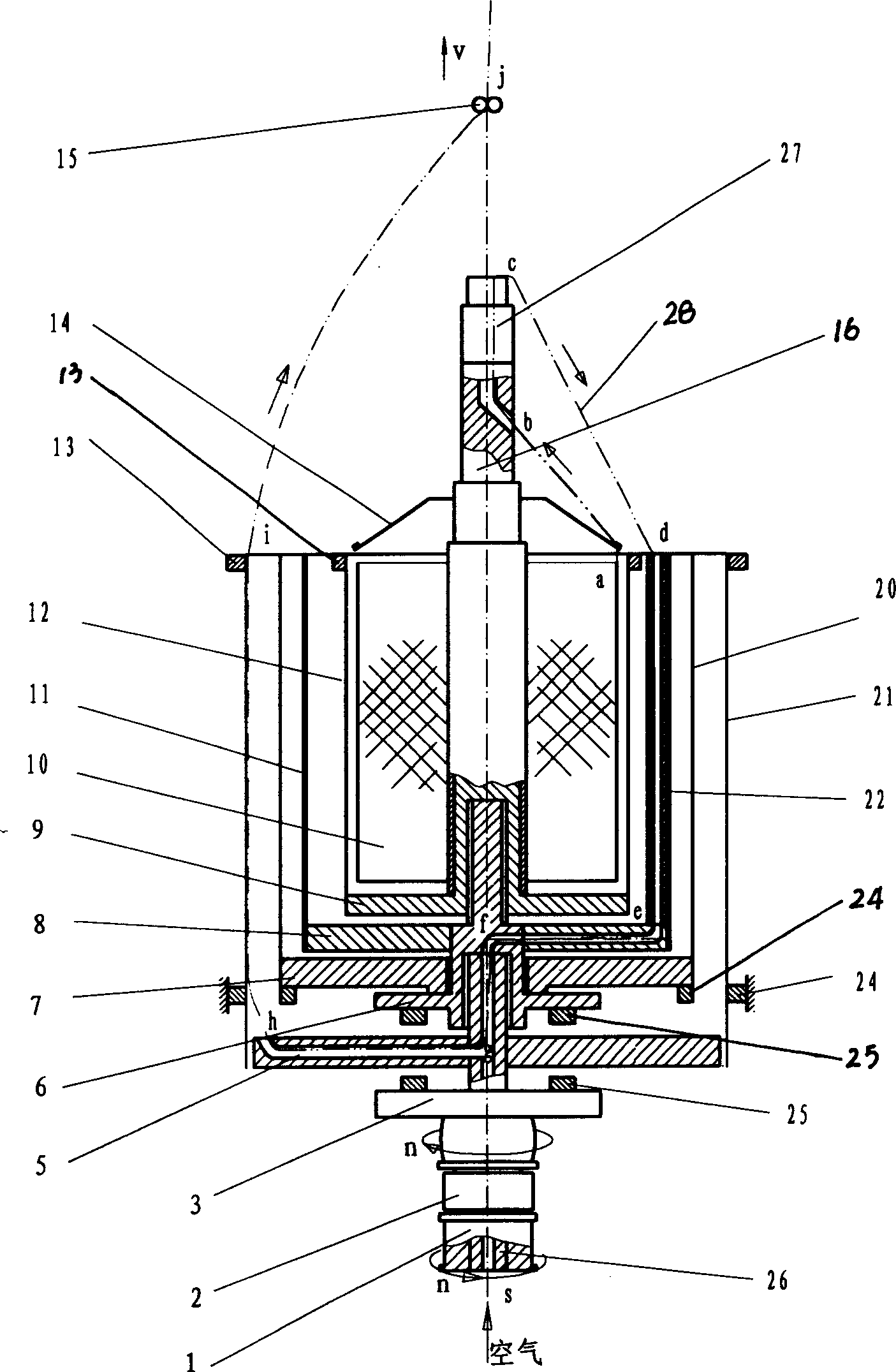

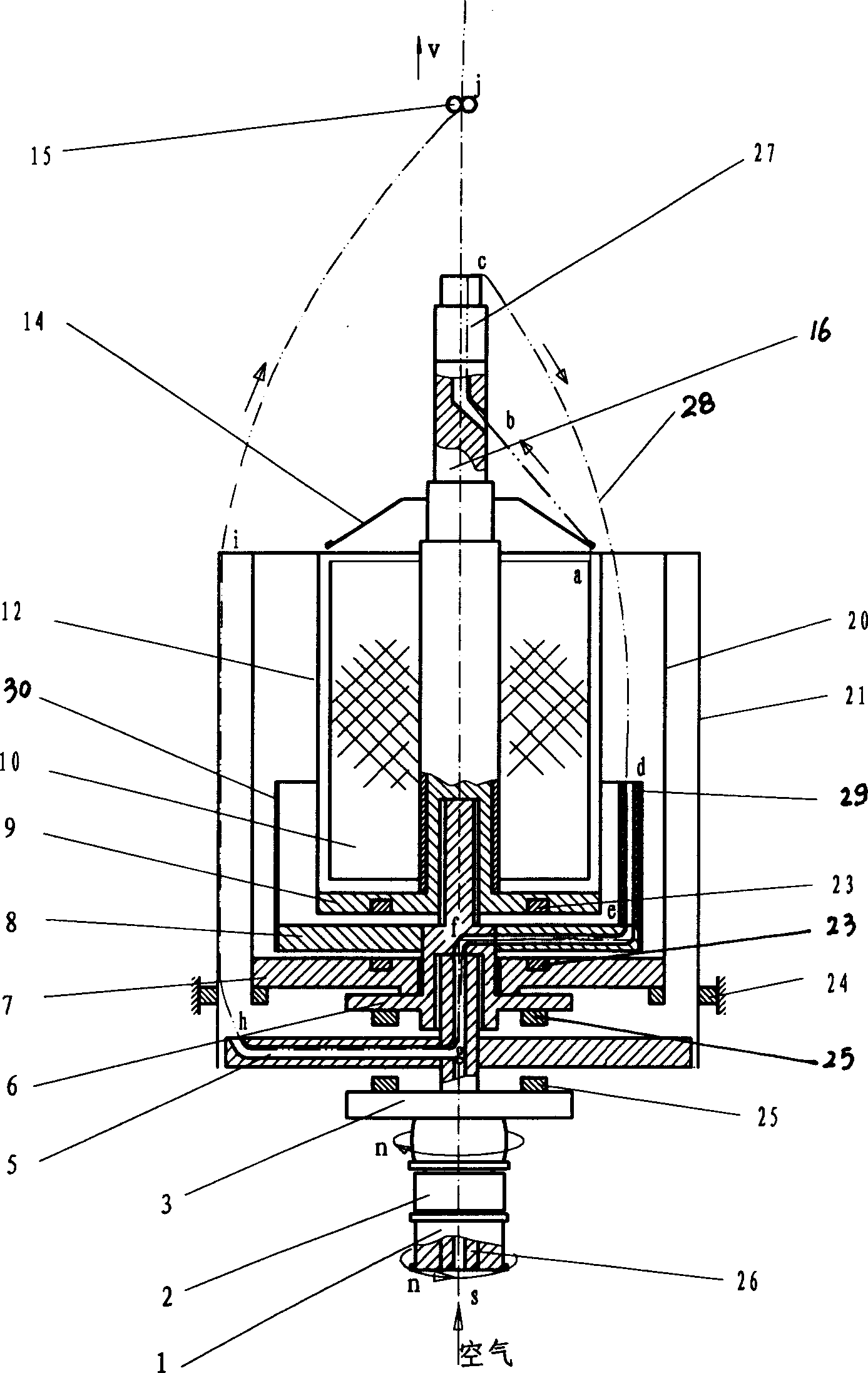

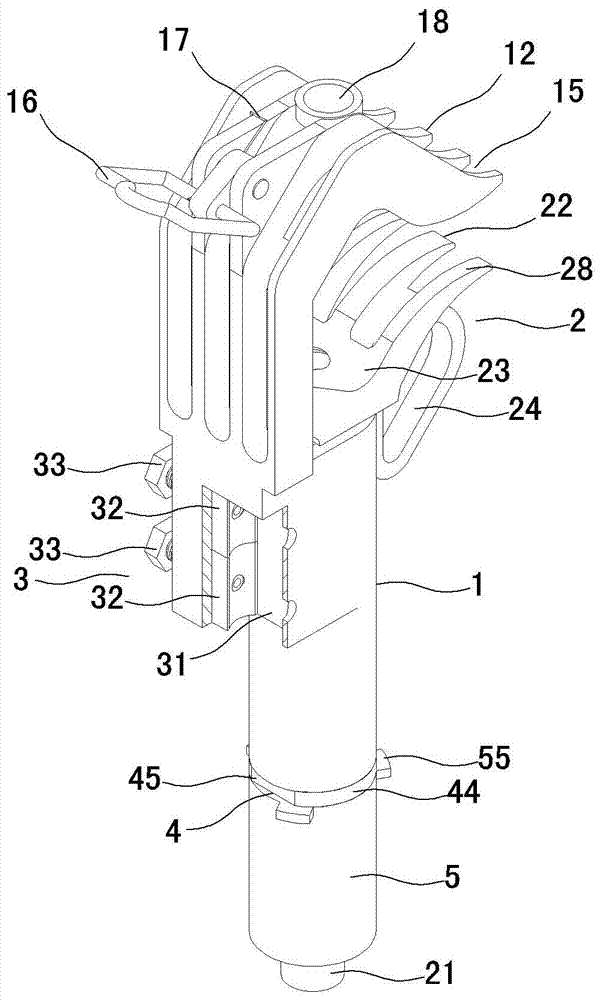

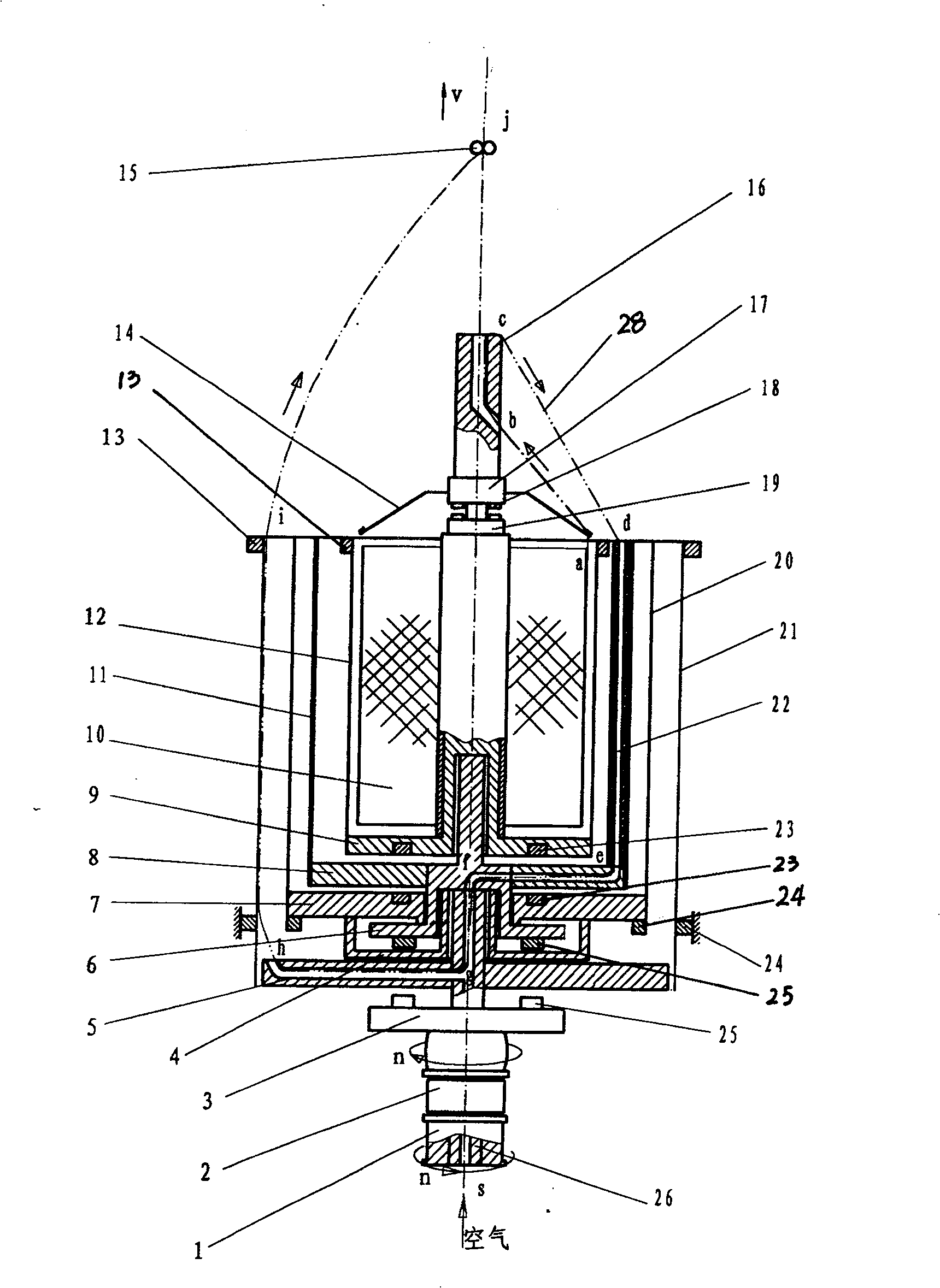

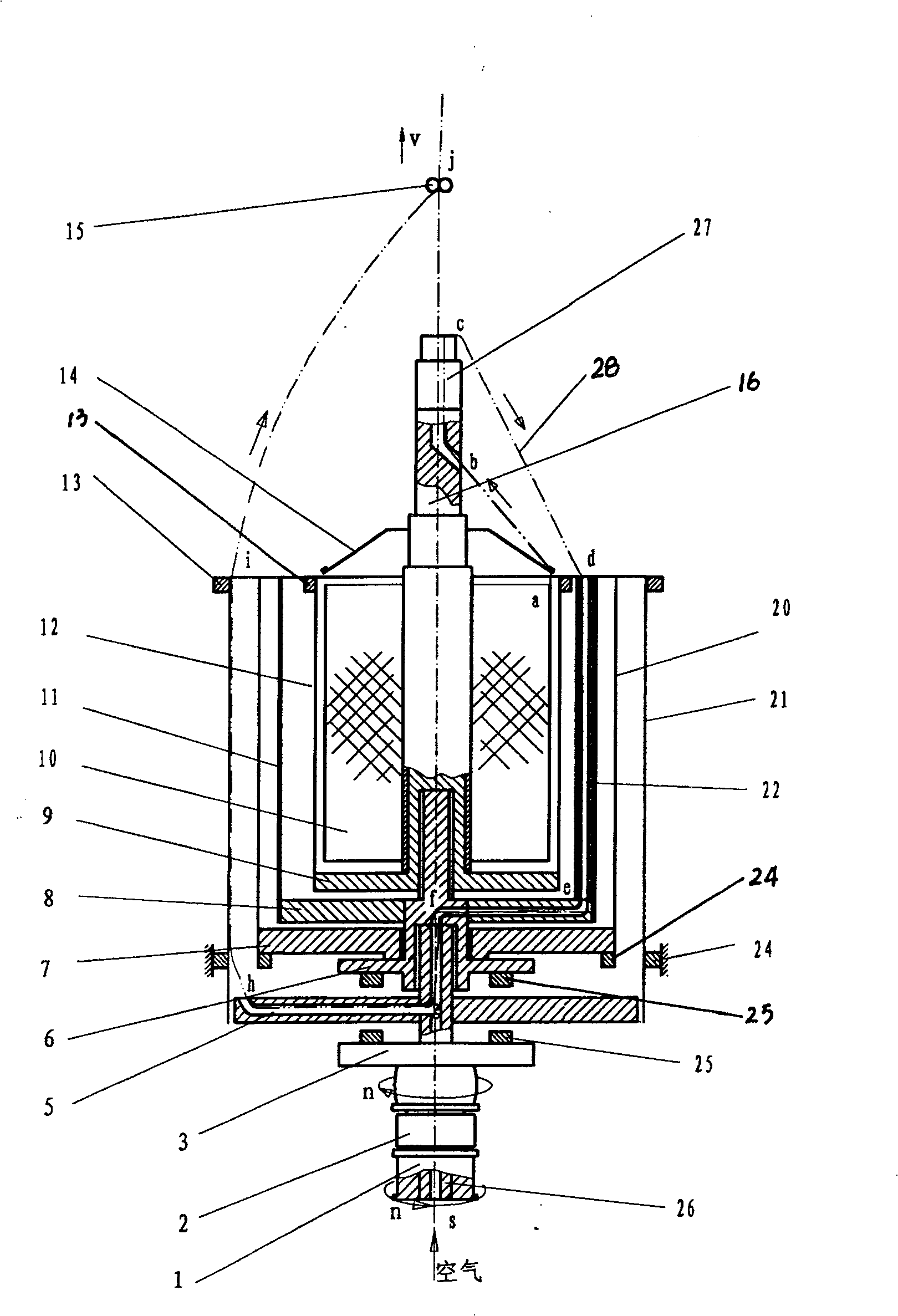

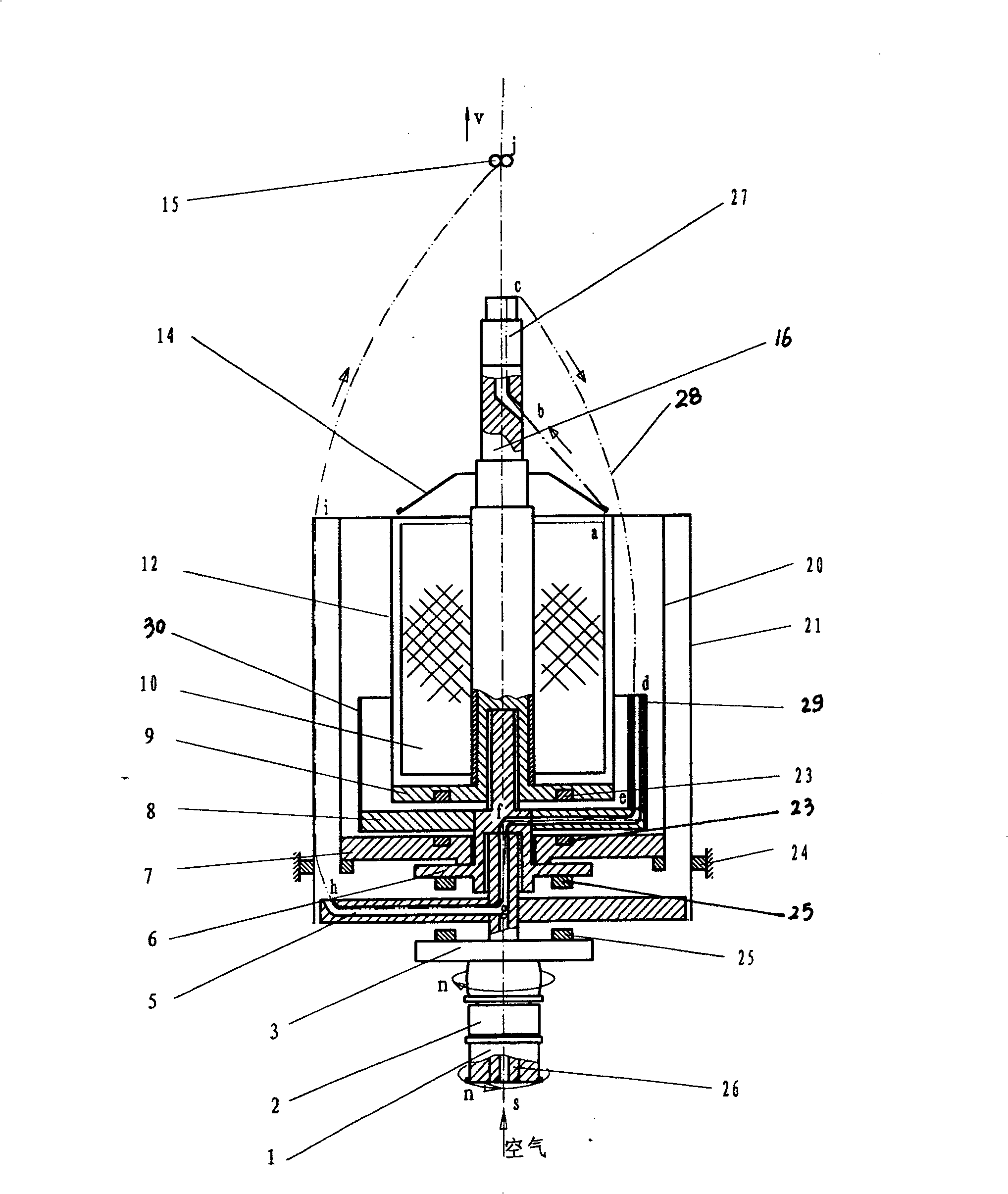

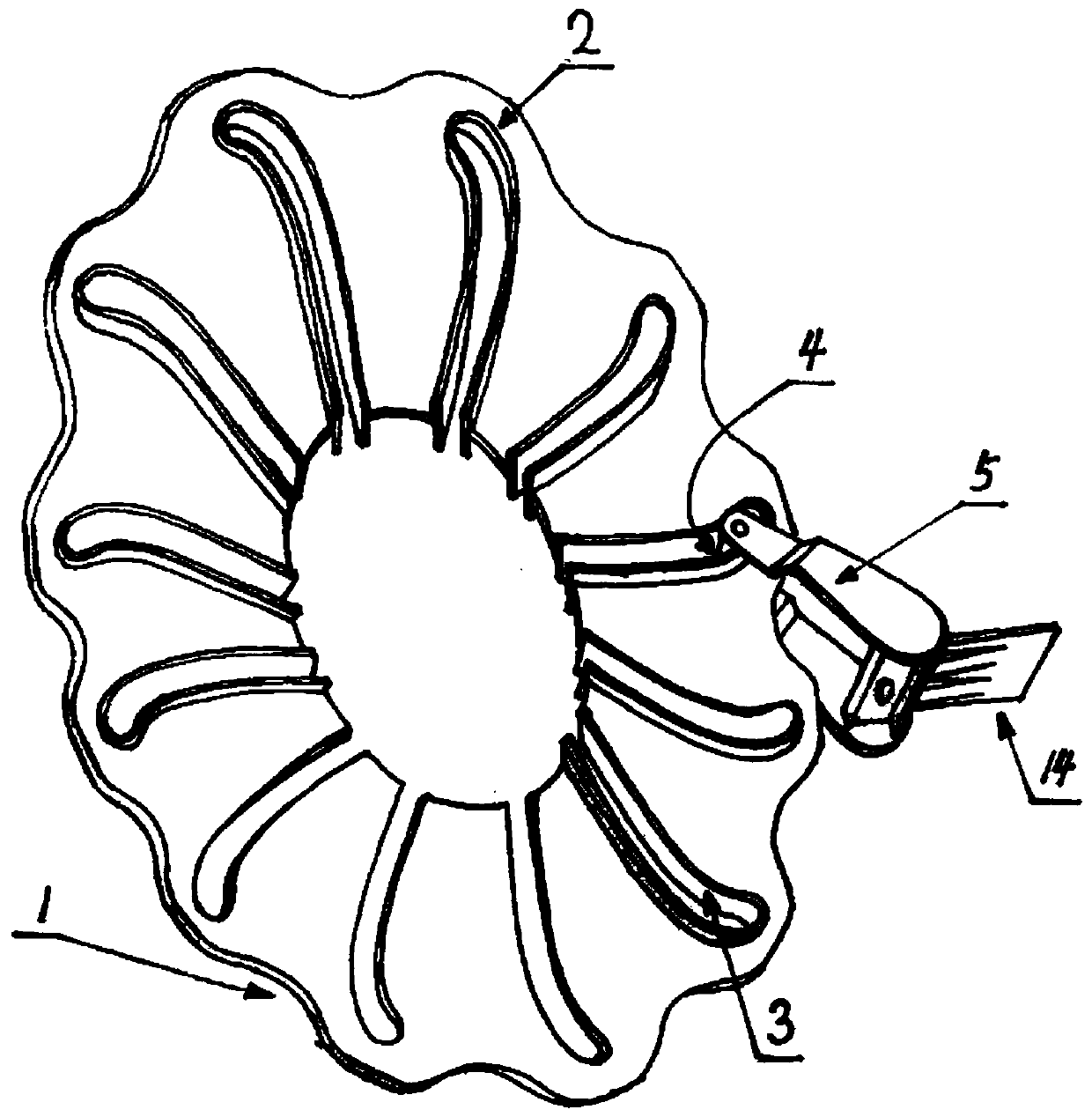

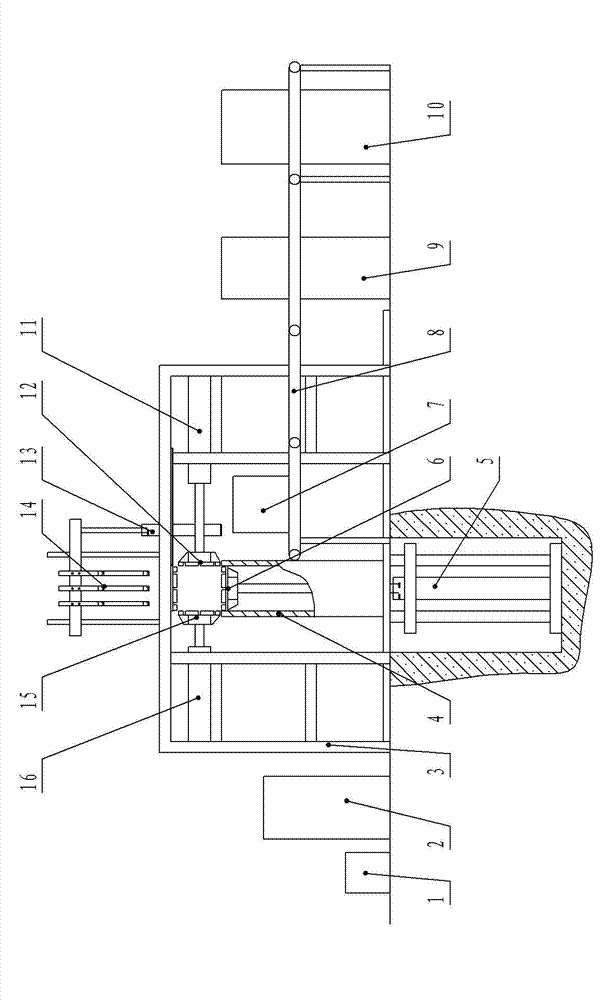

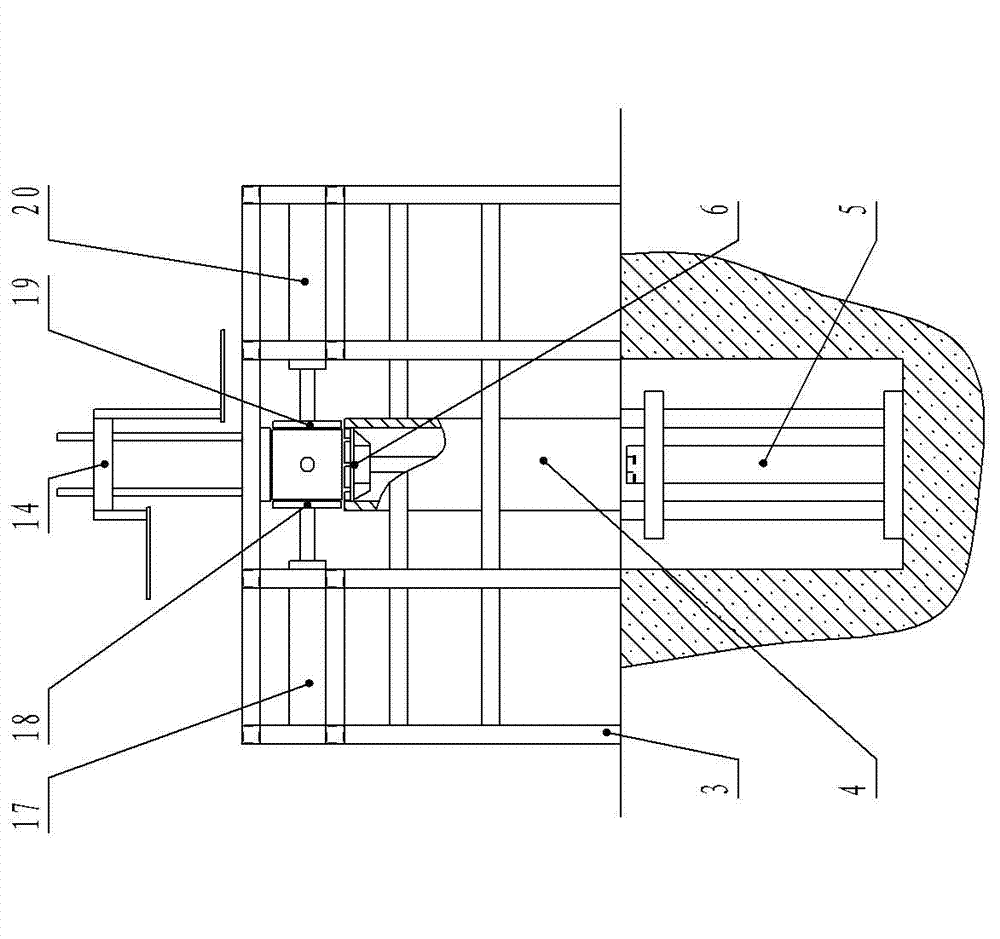

High power twister

The invention relates to a twisting device in the textile fiber twisting field. It is a high power twisting device, its character: it is composed of outer ingot device, inner ingot device, middle ingot device, package support mechanism, yarn retreating and guiding device and outer ingot cylinder mechanism, where the ingot rod of top rotary magnet base of the inner ingot device is supported on the top of the bottom ingot rod of the outer ingot device through the bearing, the static support base of the middle ingot device is supported on the ingot rod of top rotary magnet base through the bearing, the package support component of the package support mechanism on the top end of the ingot rod of top rotary magnet base through the bearing, the ingot-end cord rod and mouth are actively covered on the top end of the package support component, the outer ingot cylinder mechanism is outside the inner ingot device and the outer ingot cylinder is fixed with the frame. It has characters of rotation-rotation yarn feeding and 4 twisting rounds, simple structure, etc.

Owner:WUHAN TEXTILE UNIV

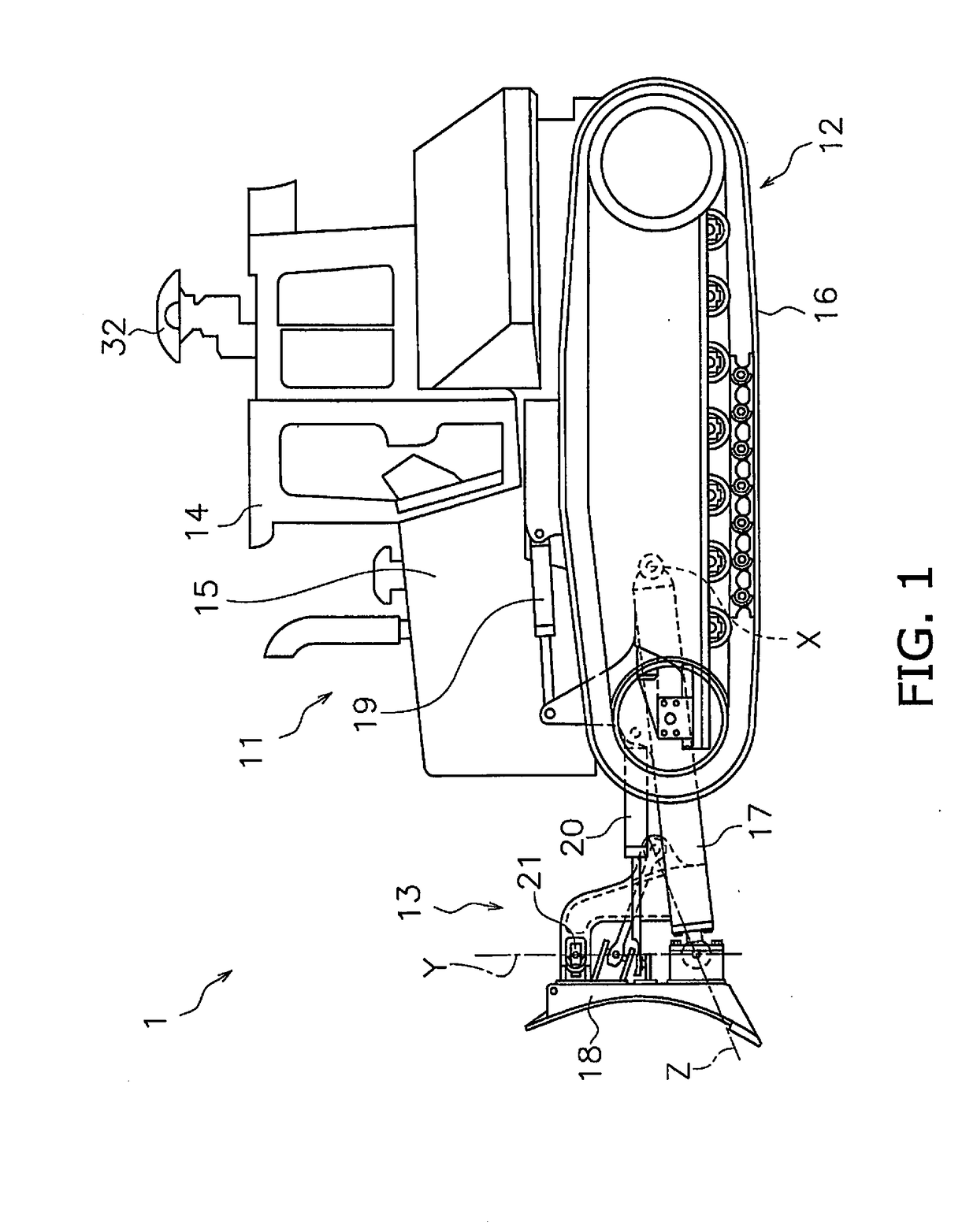

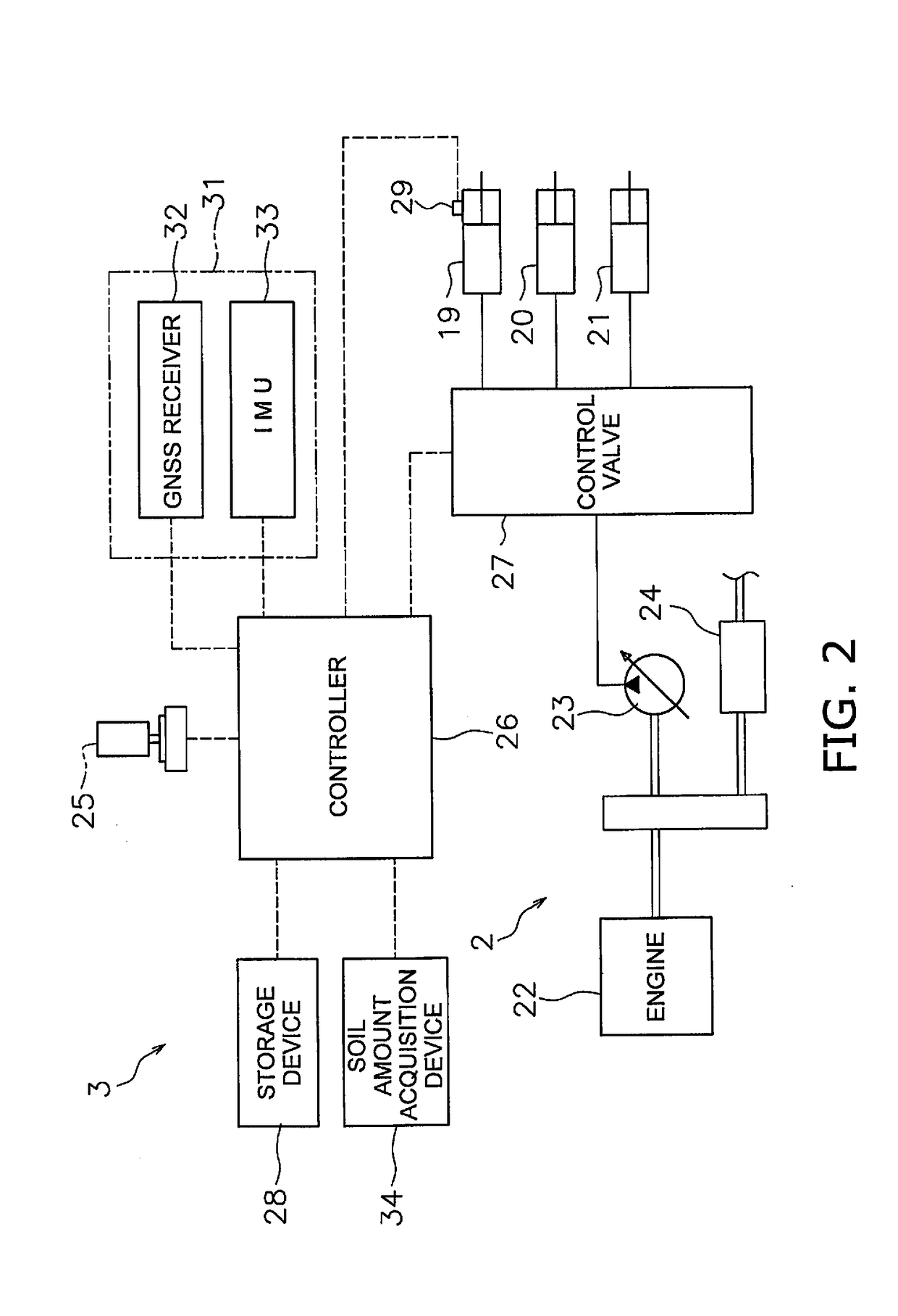

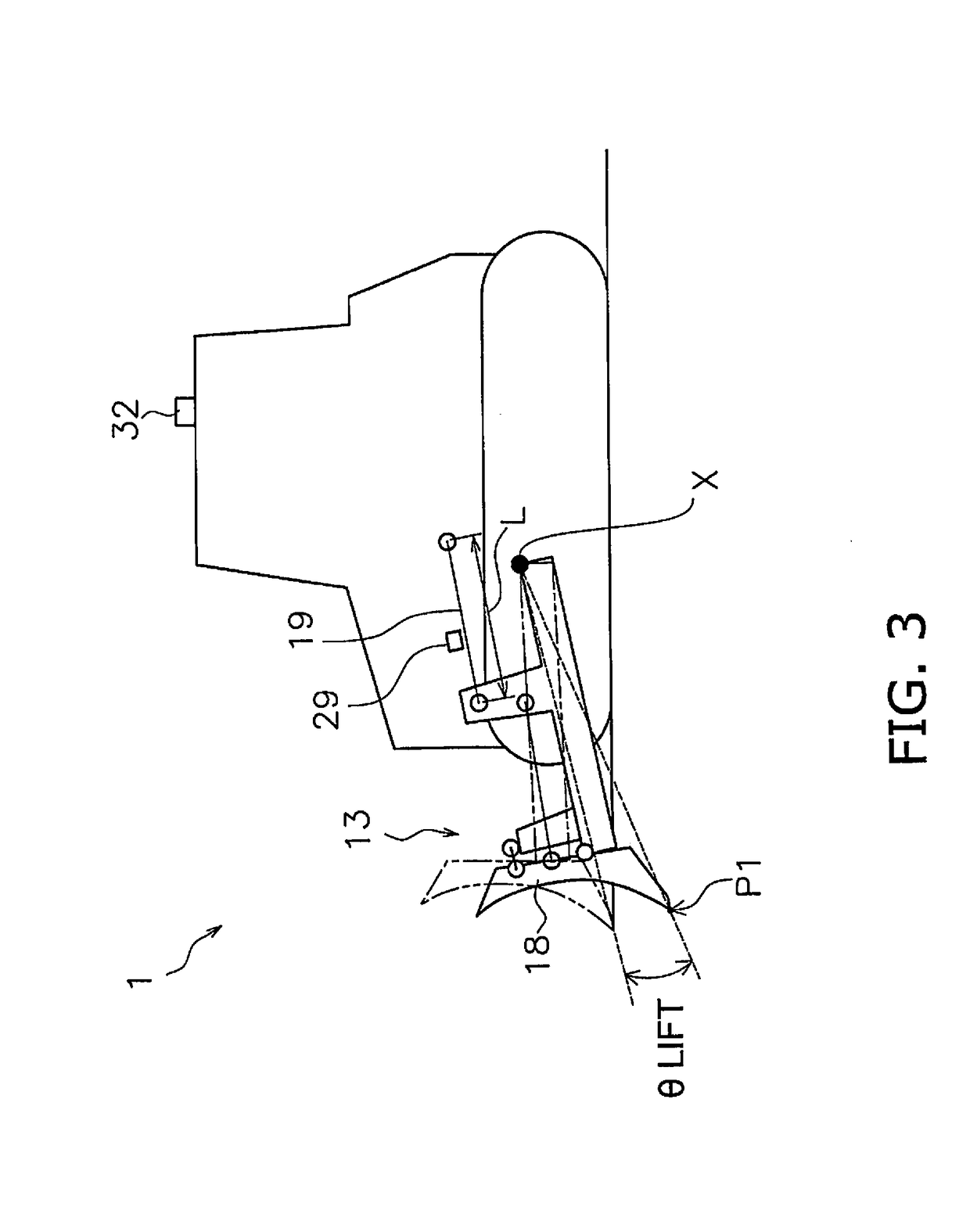

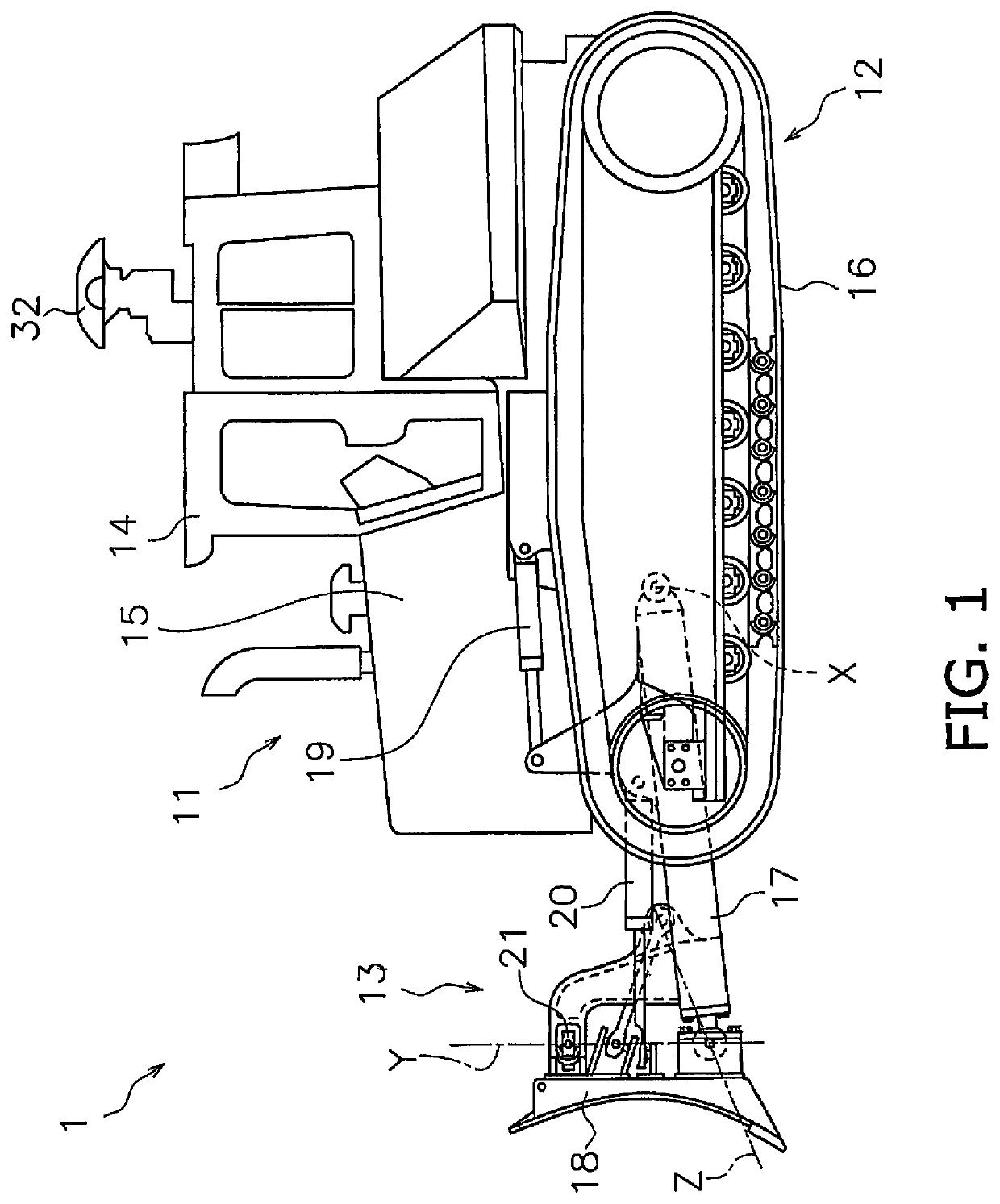

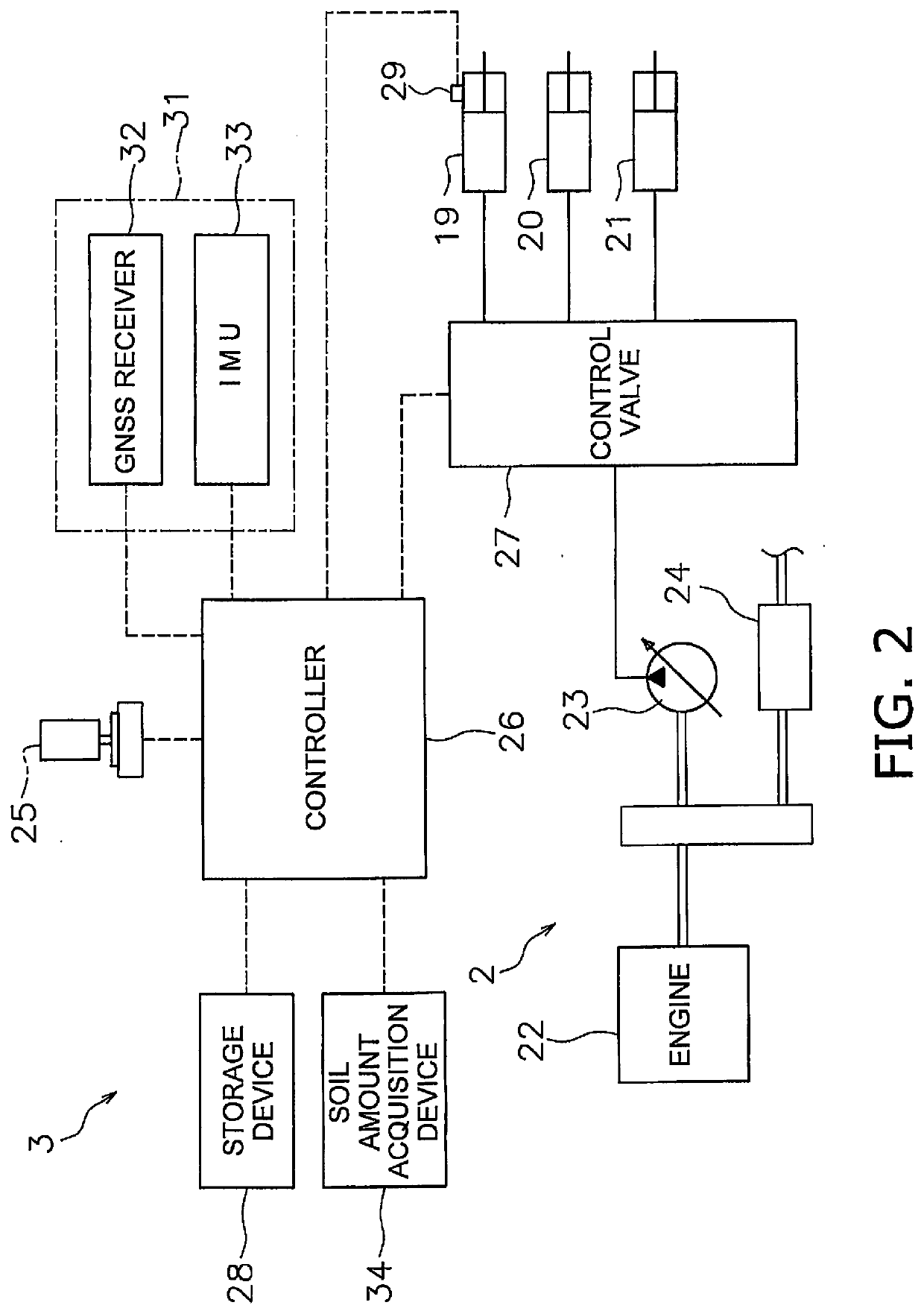

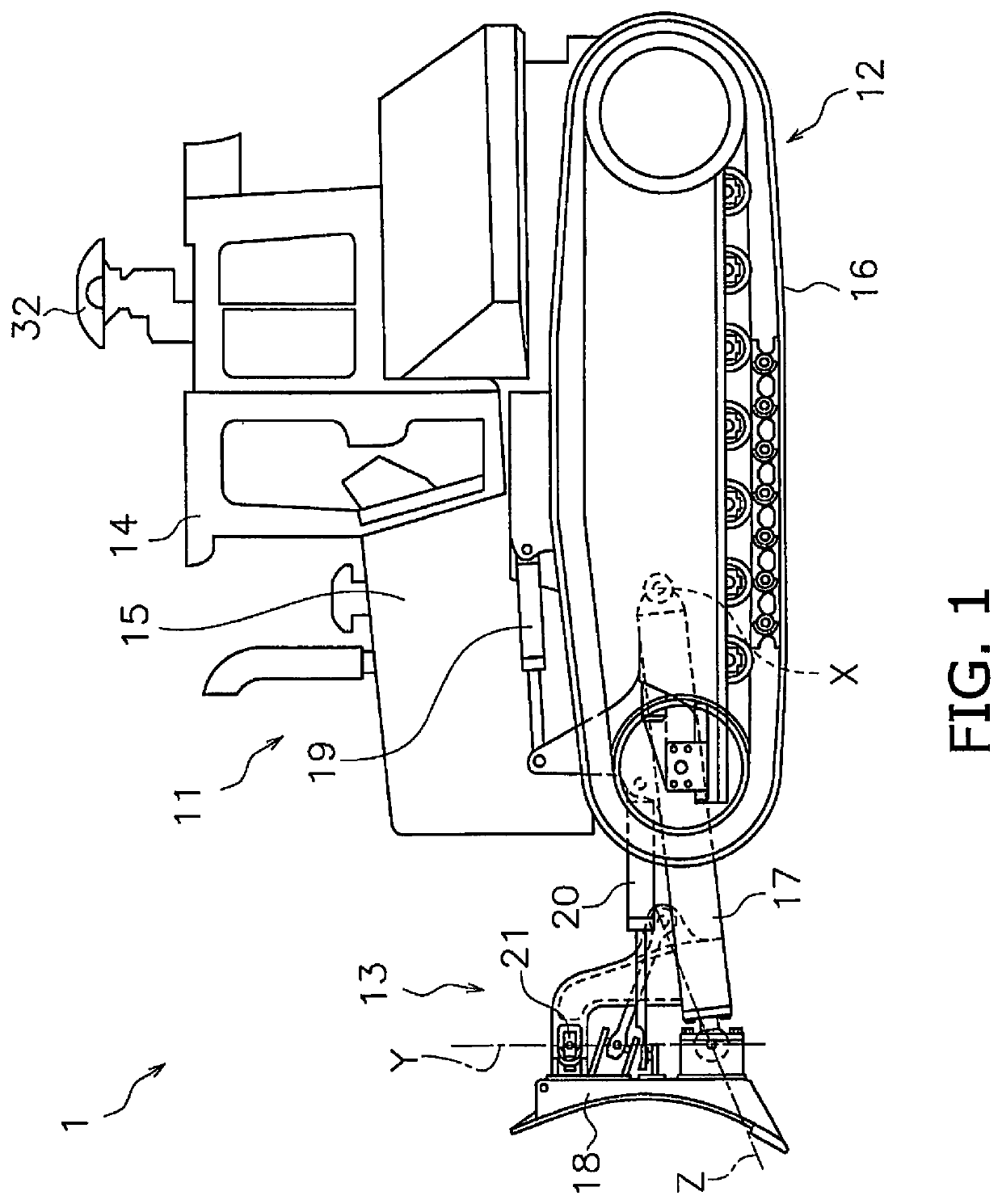

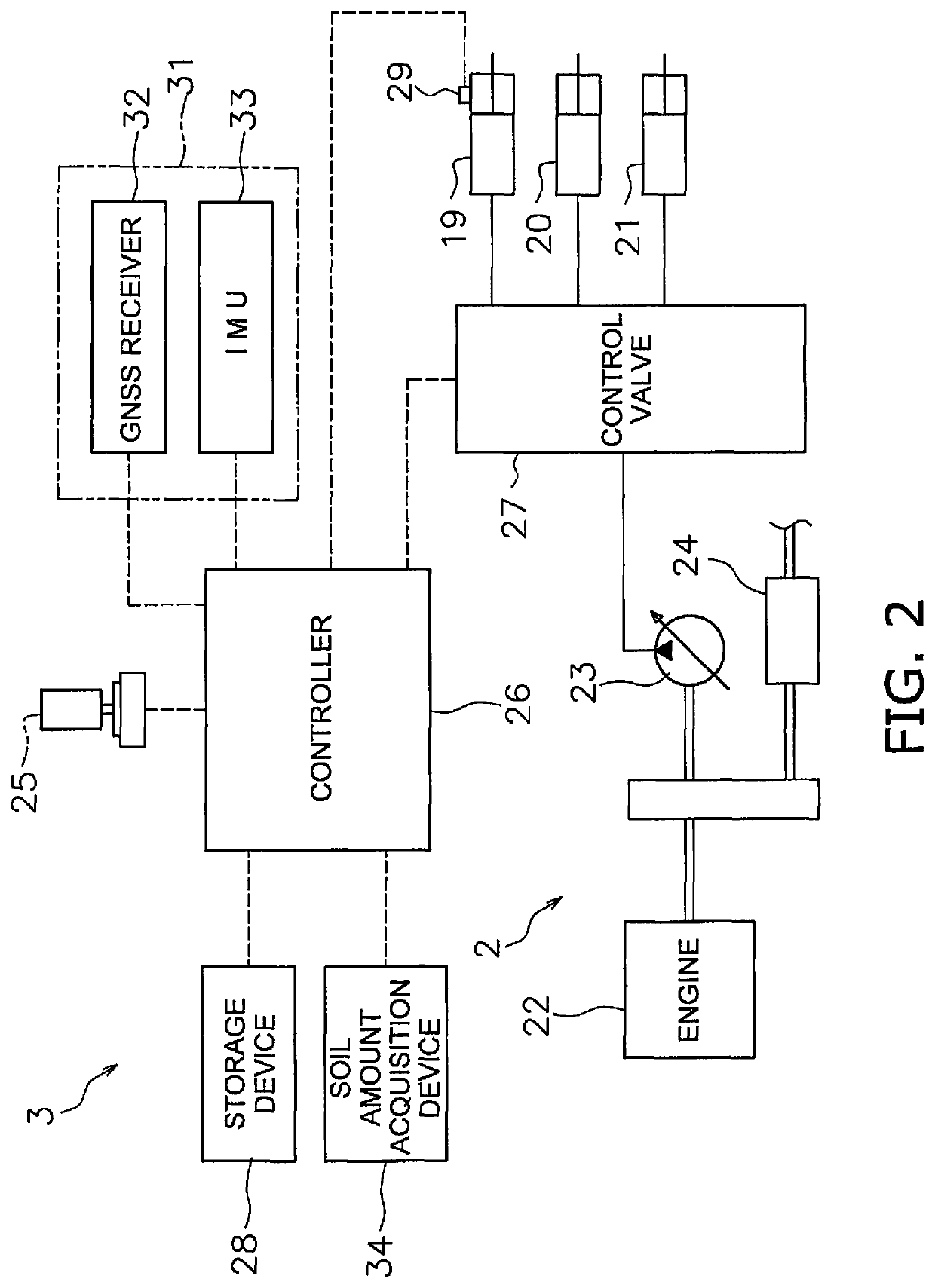

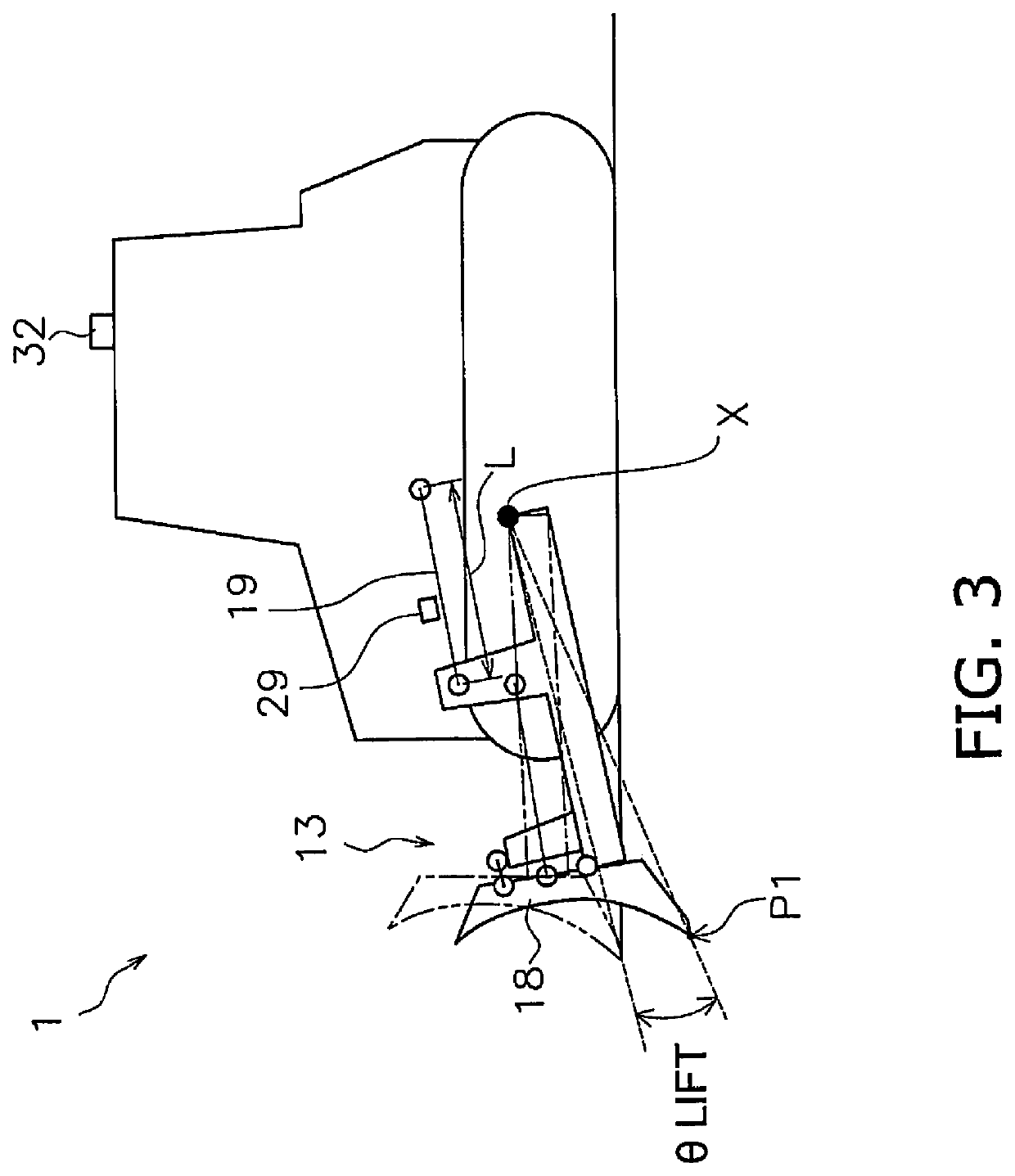

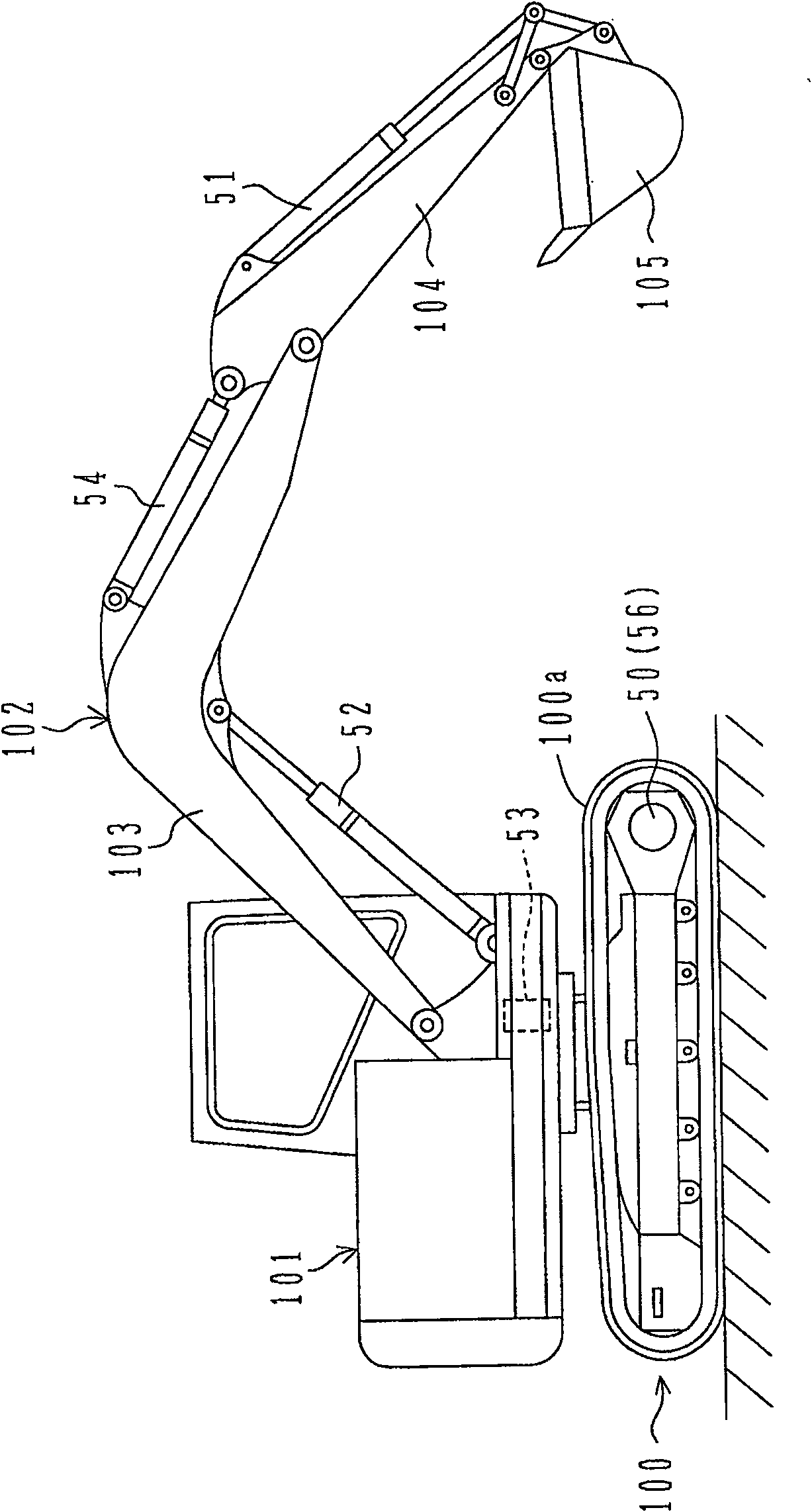

Control system for work vehicle, control method, and work vehicle

ActiveUS20190078297A1Promote densificationImprove the quality of the finishMechanical machines/dredgersVehicle position/course/altitude controlControl systemEngineering

A work vehicle control system includes an actual topography acquisition device, a storage device, and a controller. The actual topography acquisition device acquires actual topography information, which indicates an actual topography of a work target. The storage device stores design topography information, which indicates a final design topography that is a target topography of the work target. The controller acquires the actual topography information from the actual topography acquisition device. The controller acquires the design topography information from the storage device. The controller generates a command signal to move the work implement along a locus that is more gently sloped than the actual topography when the actual topography positioned below the final design topography is sloped.

Owner:KOMATSU LTD

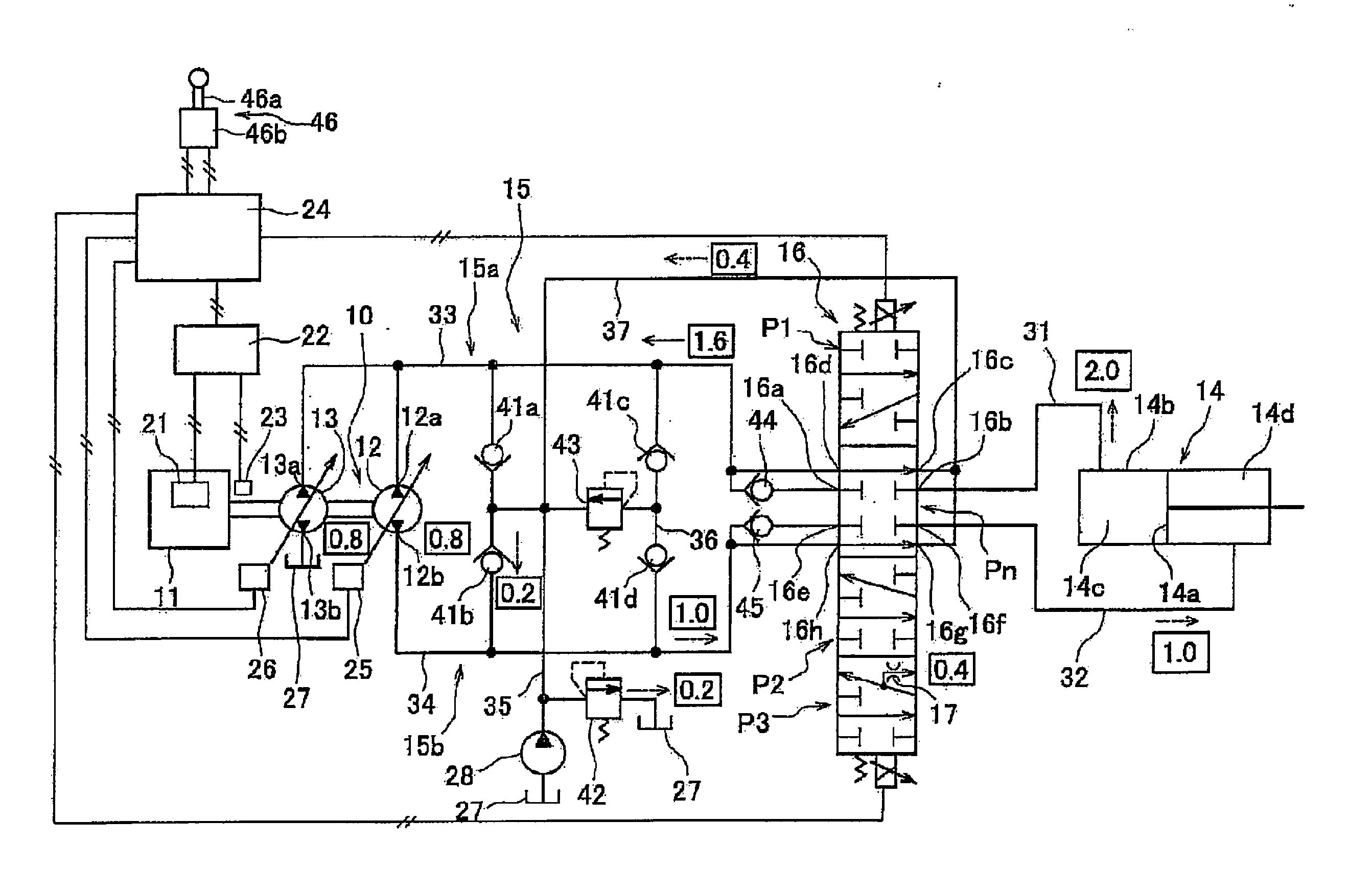

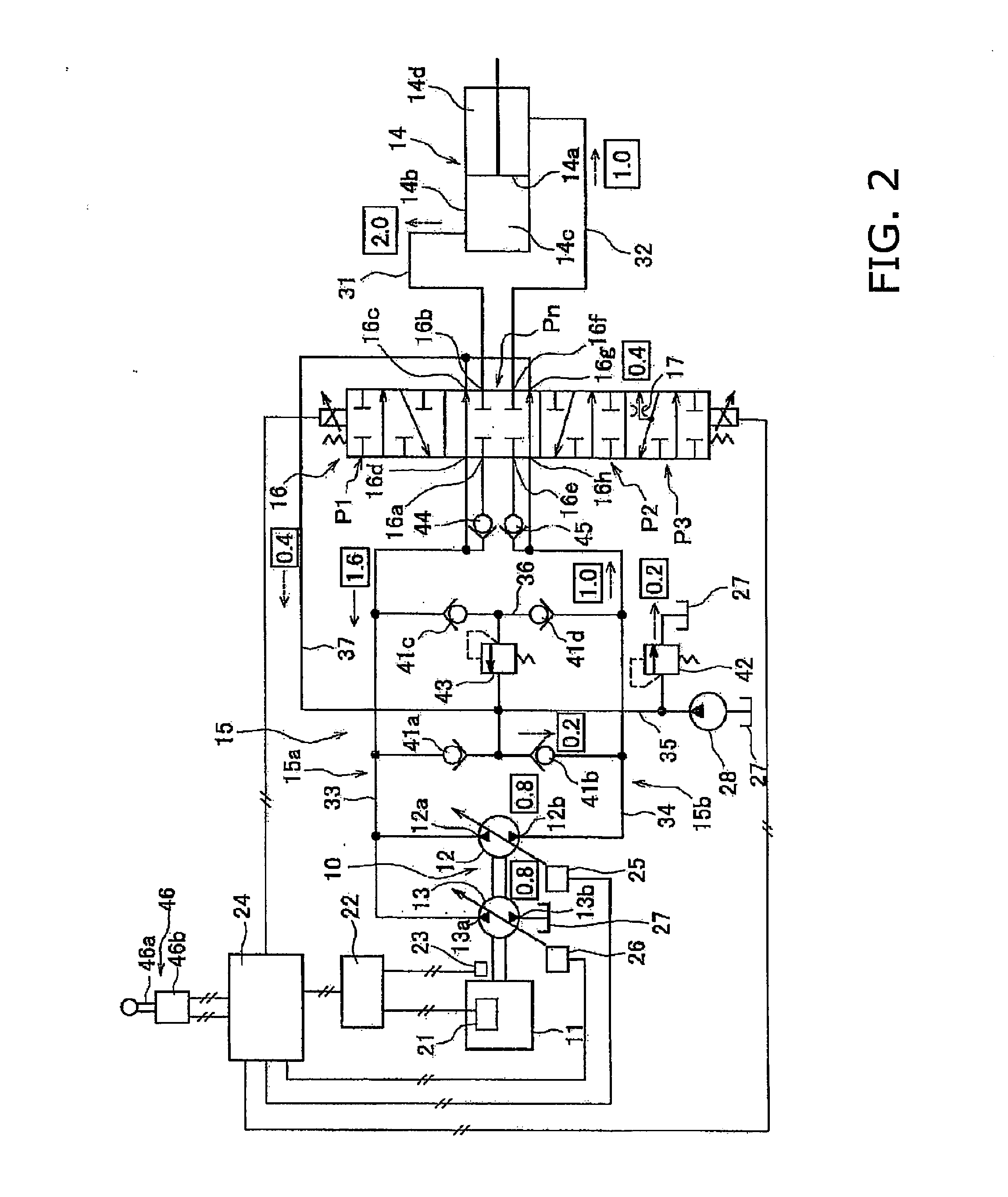

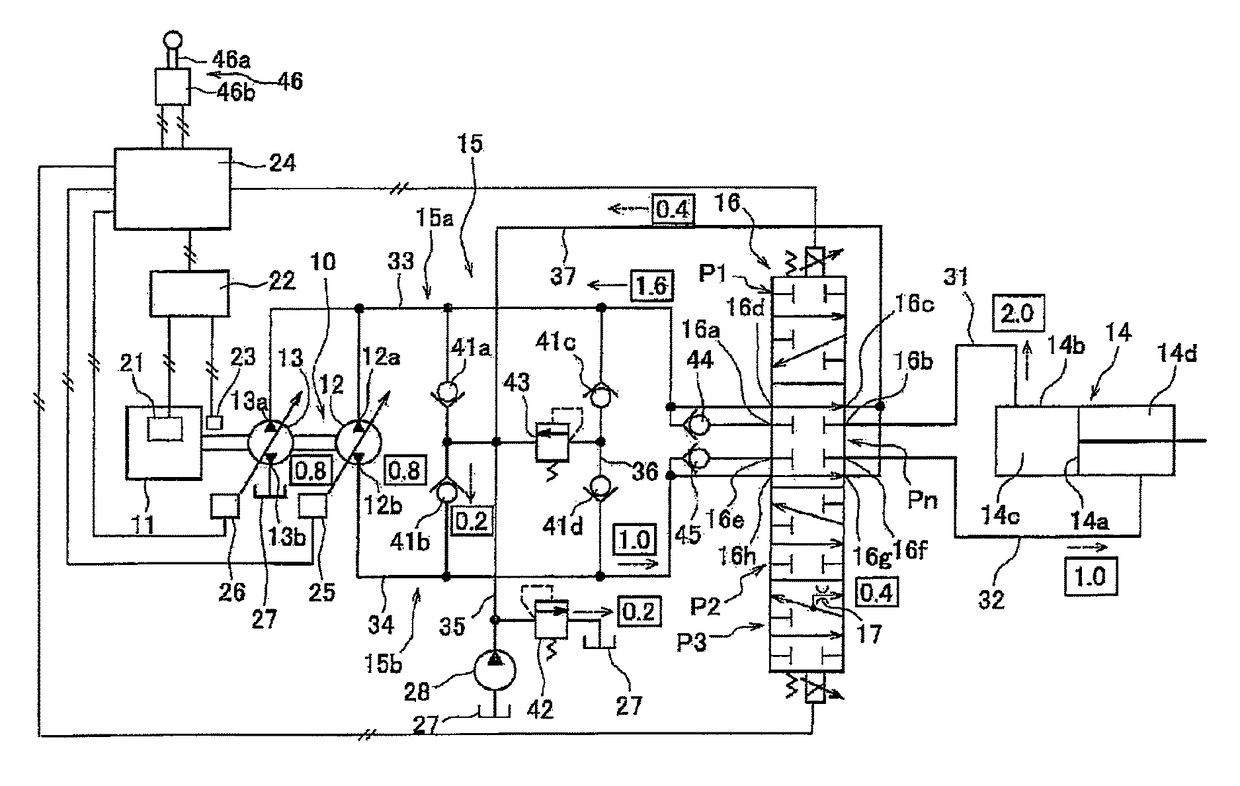

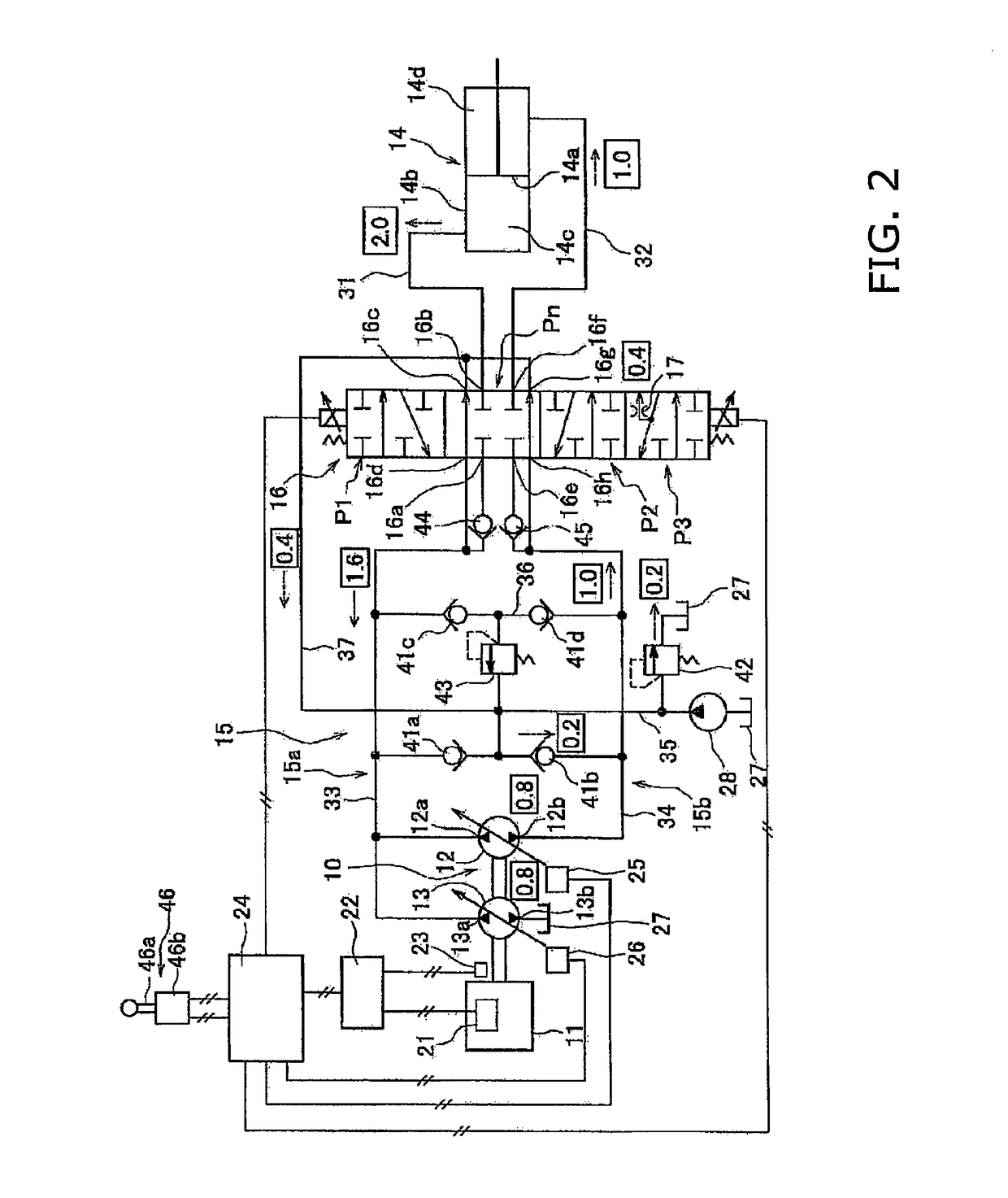

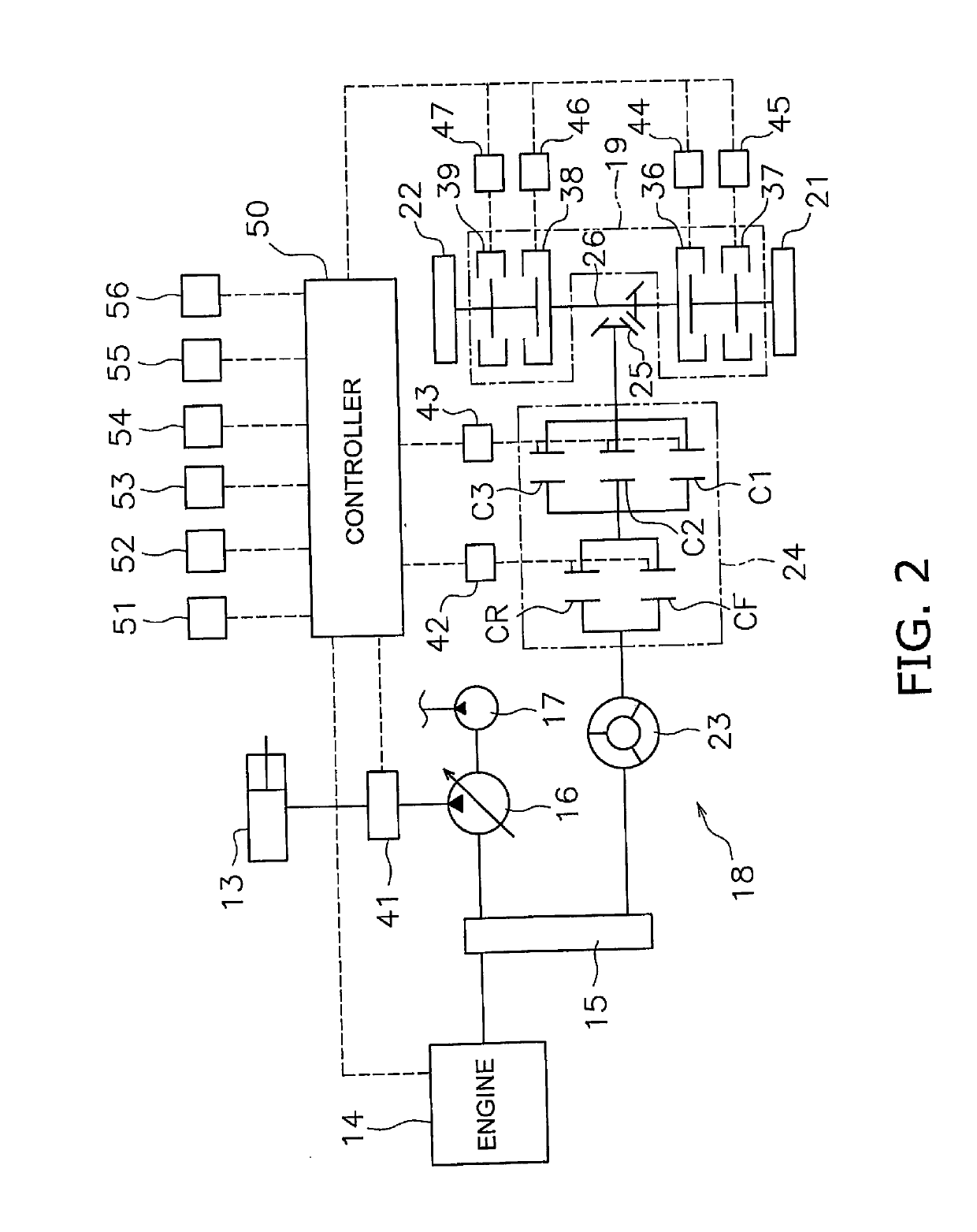

Hydraulic drive system

InactiveUS20150013320A1Improve work efficiencyReduce work speedFluid couplingsServomotor componentsHydraulic cylinderHydraulic pump

A hydraulic cylinder causes a work implement to be lowered due to the exhaust of hydraulic fluid from a first chamber and the supply of hydraulic fluid to a second chamber. A hydraulic fluid flowpath has a first flowpath and a second flowpath. The first flowpath connects a first pump port and the first chamber. The second flowpath connects a second pump port and the second chamber. The hydraulic fluid flowpath configures a closed circuit between a hydraulic pump and the hydraulic cylinder. A bleed-off flowpath branches off from the first flowpath. A portion of hydraulic fluid exhausted from the first chamber when lowering the work implement flows into the bleed-off flowpath.

Owner:KOMATSU LTD

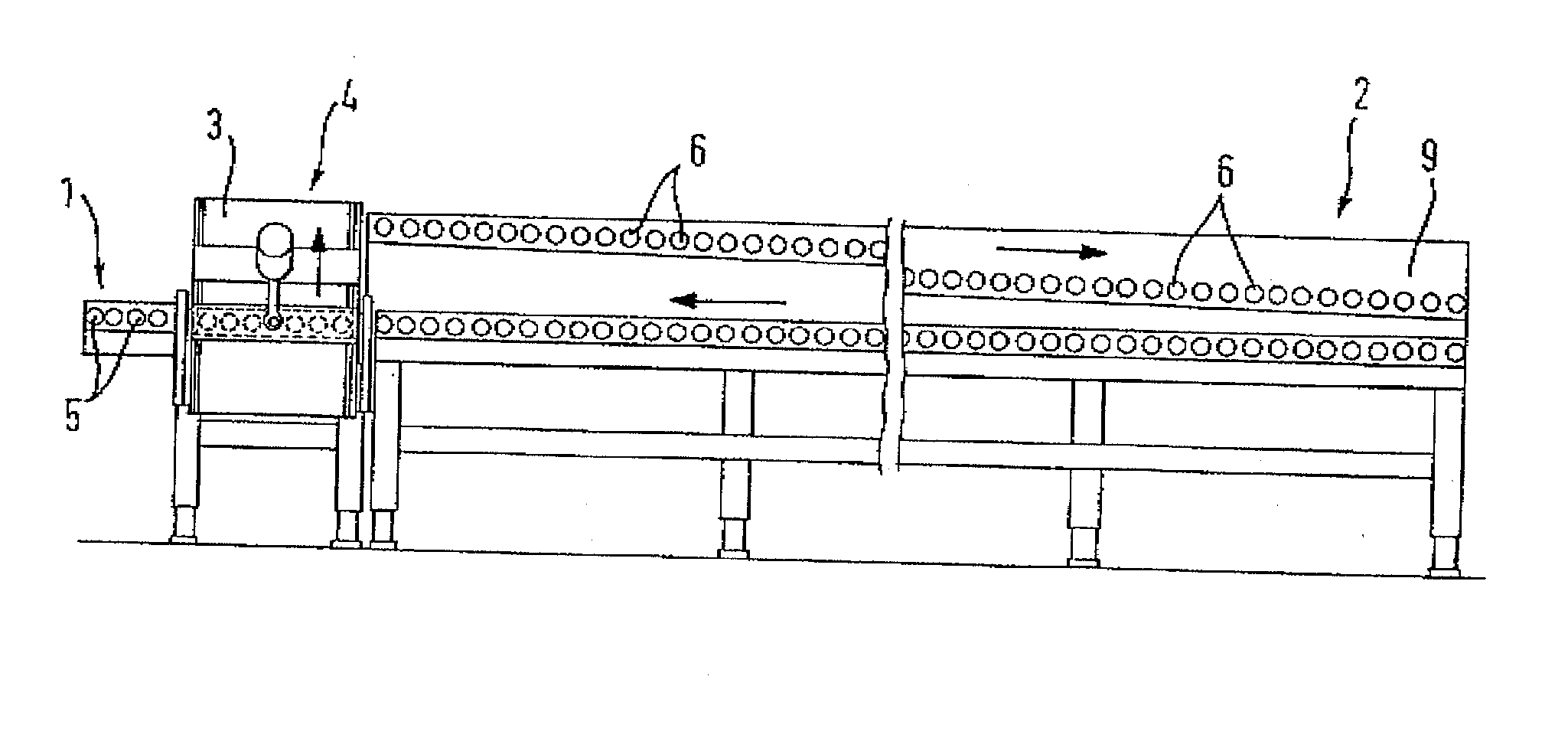

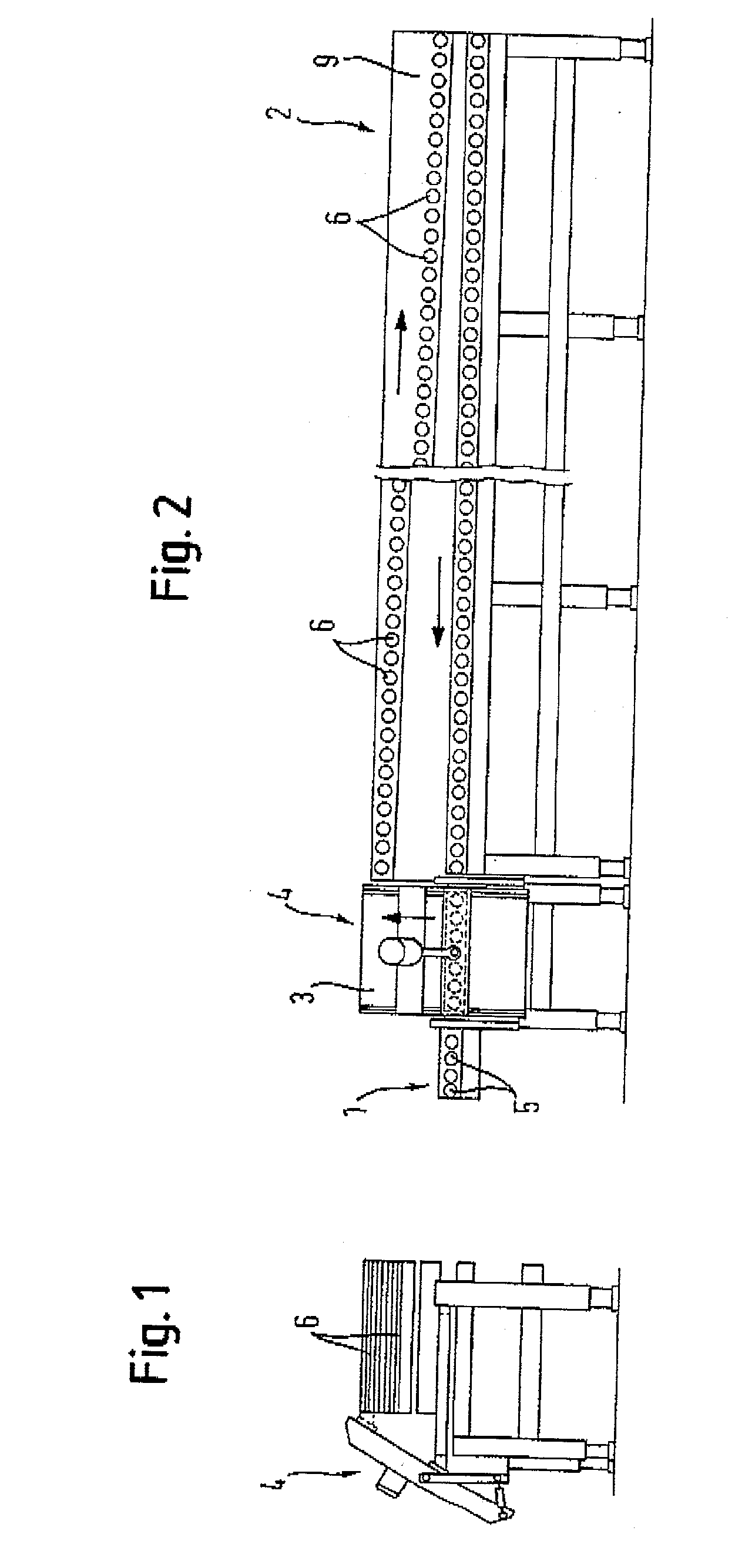

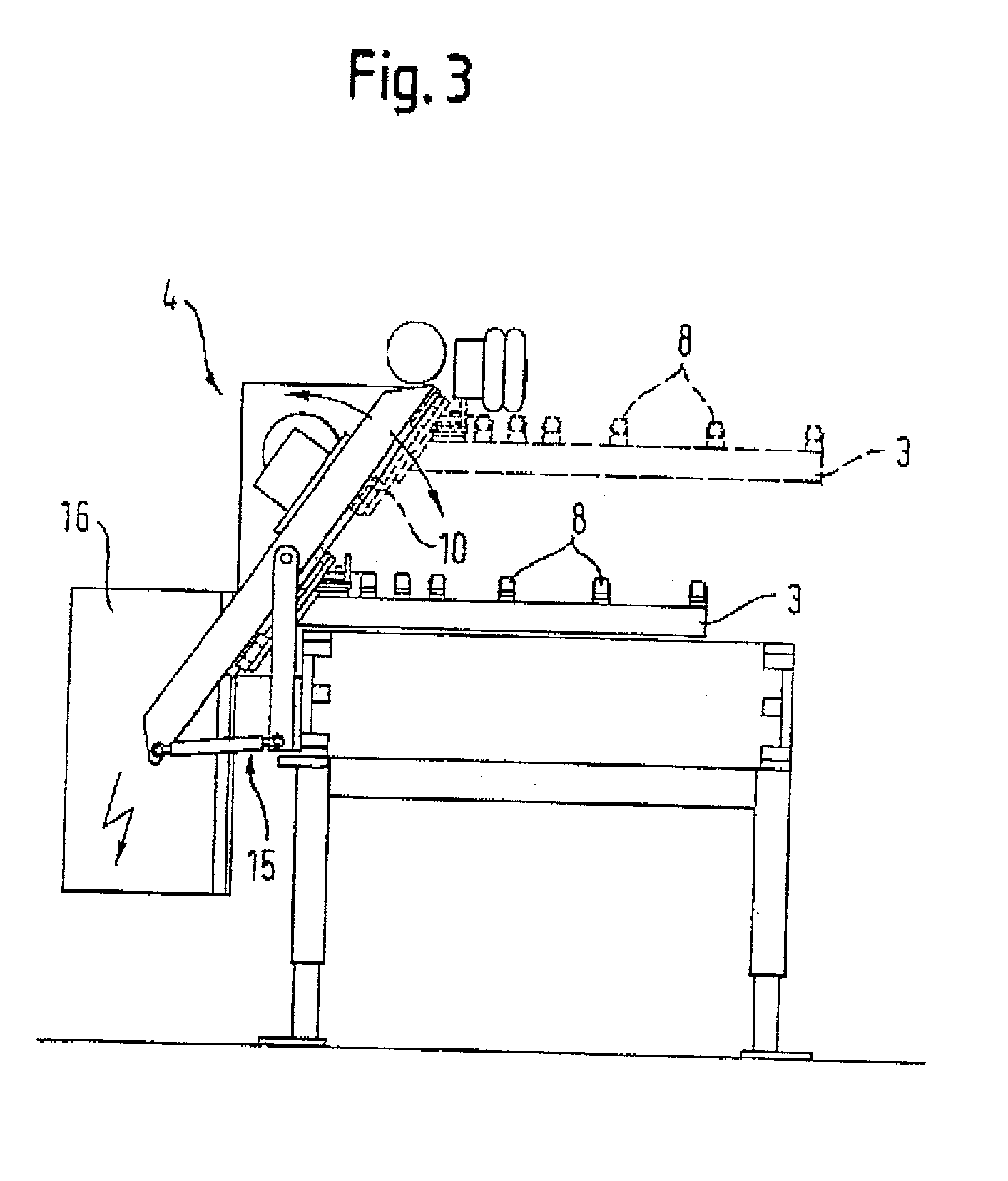

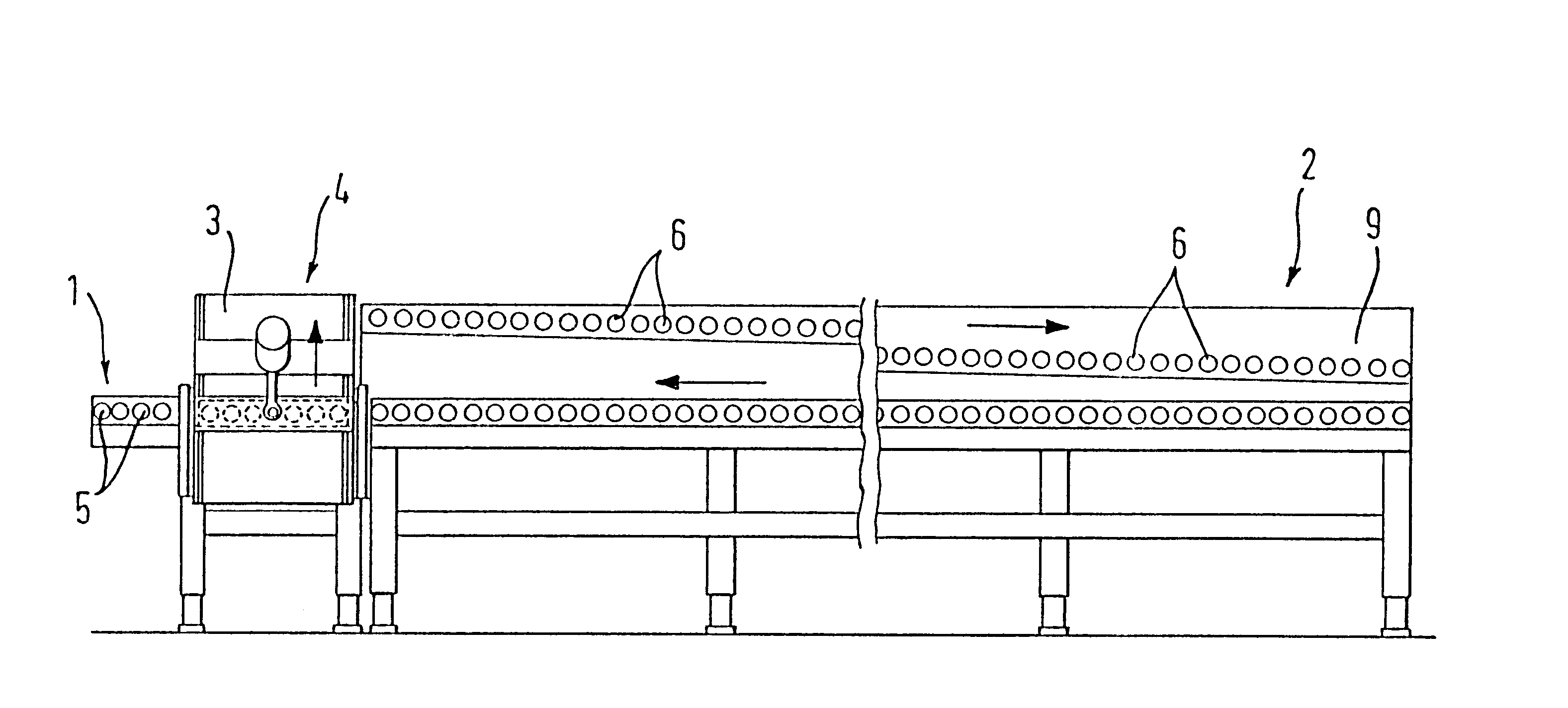

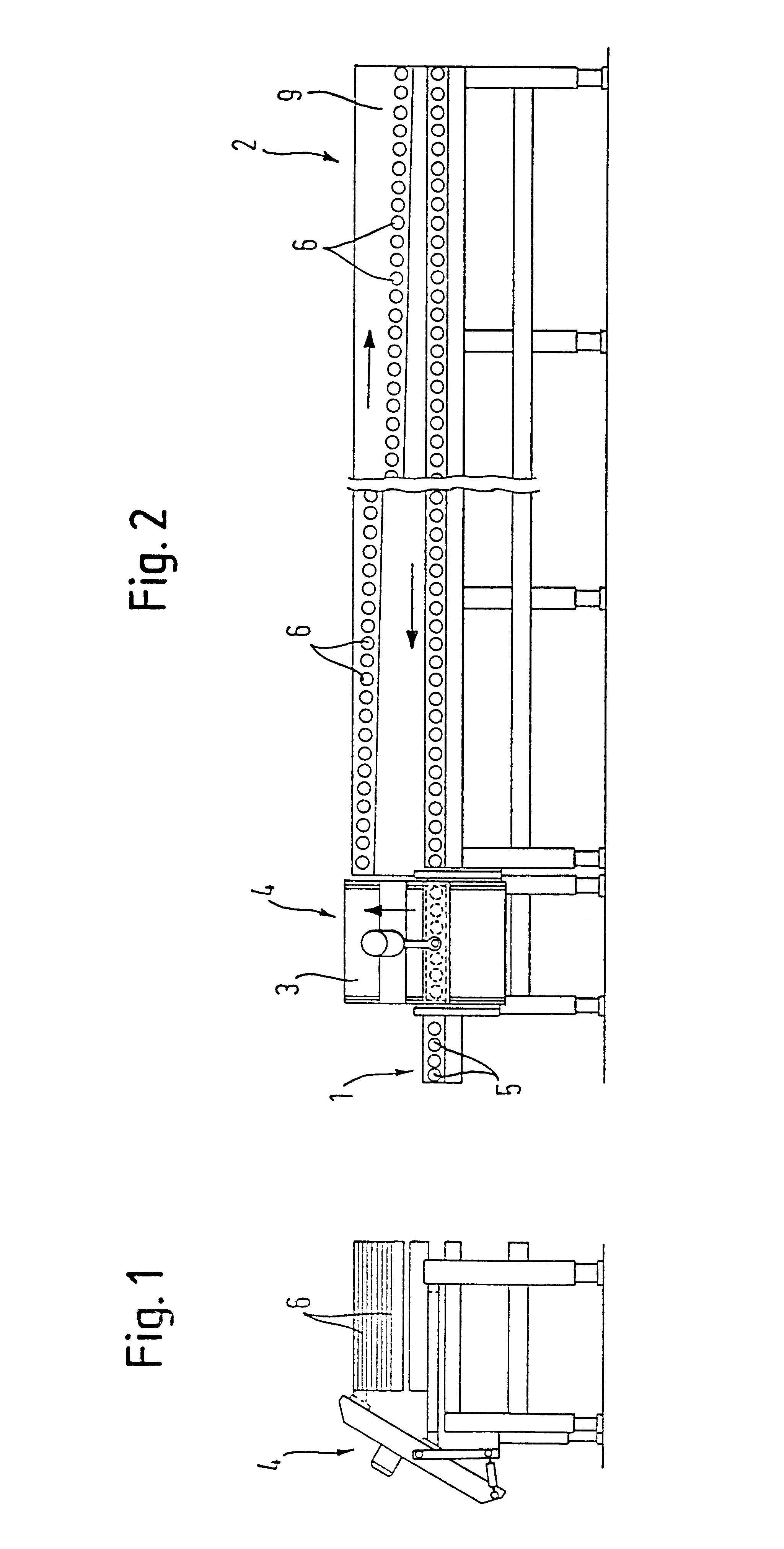

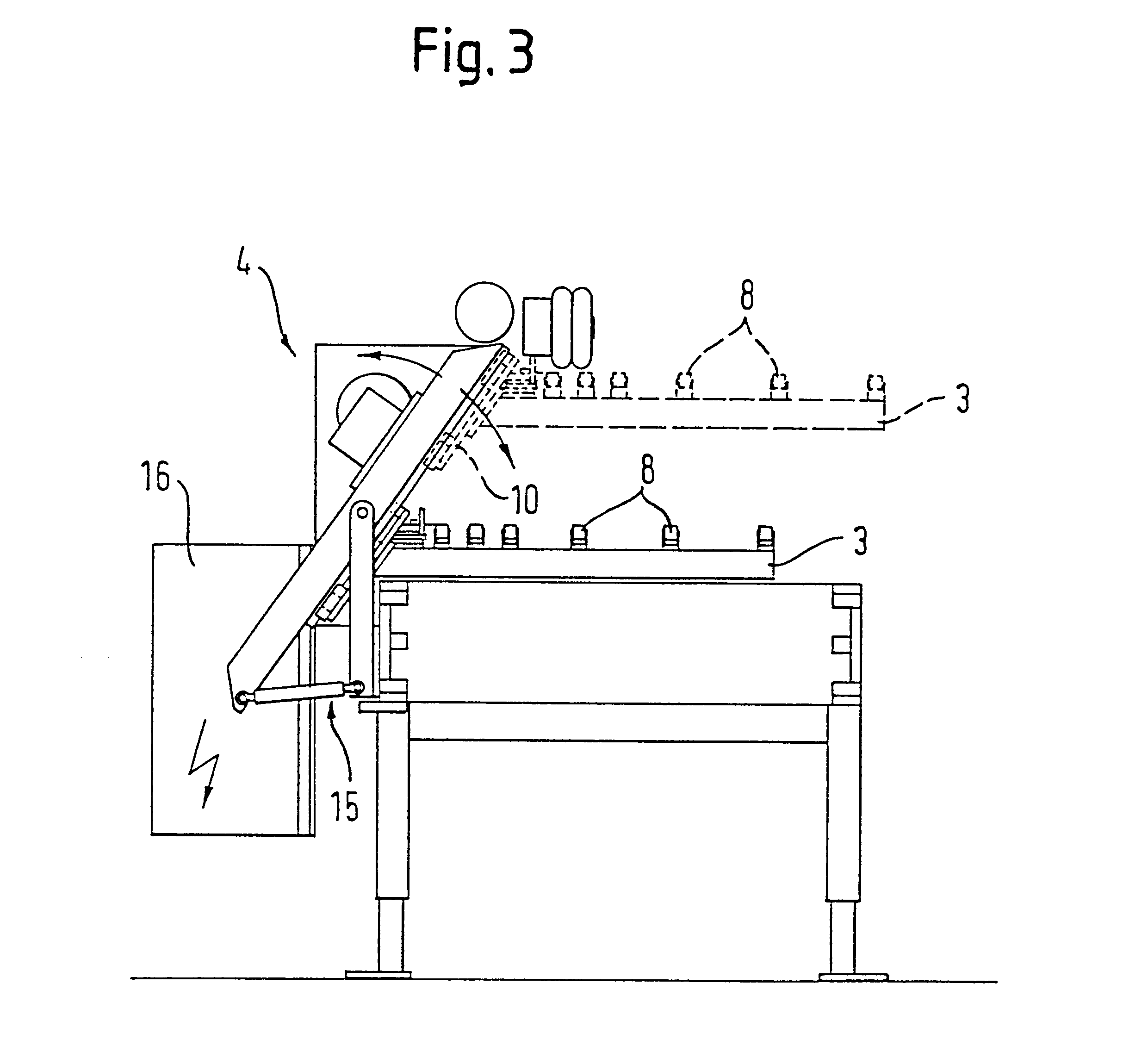

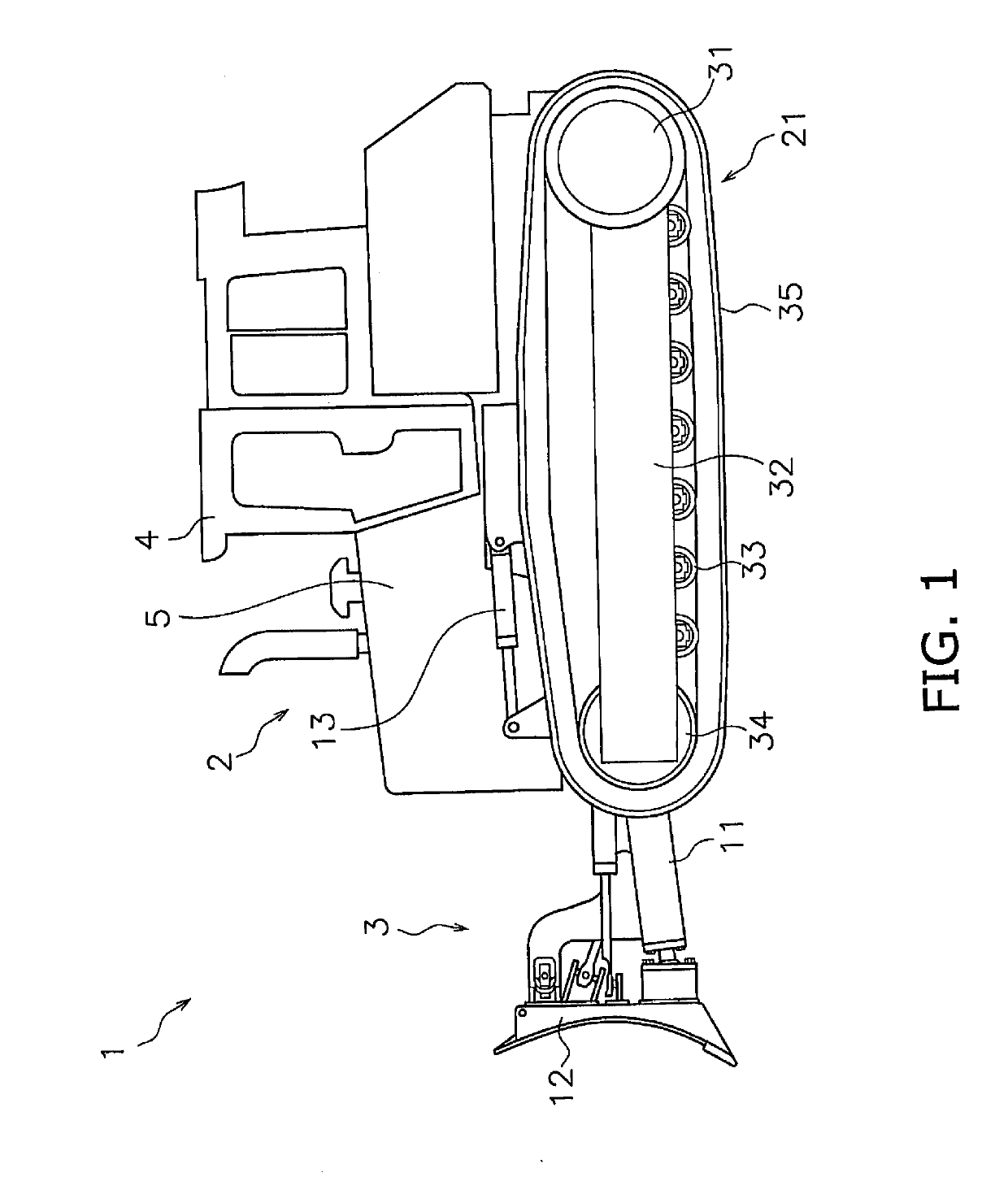

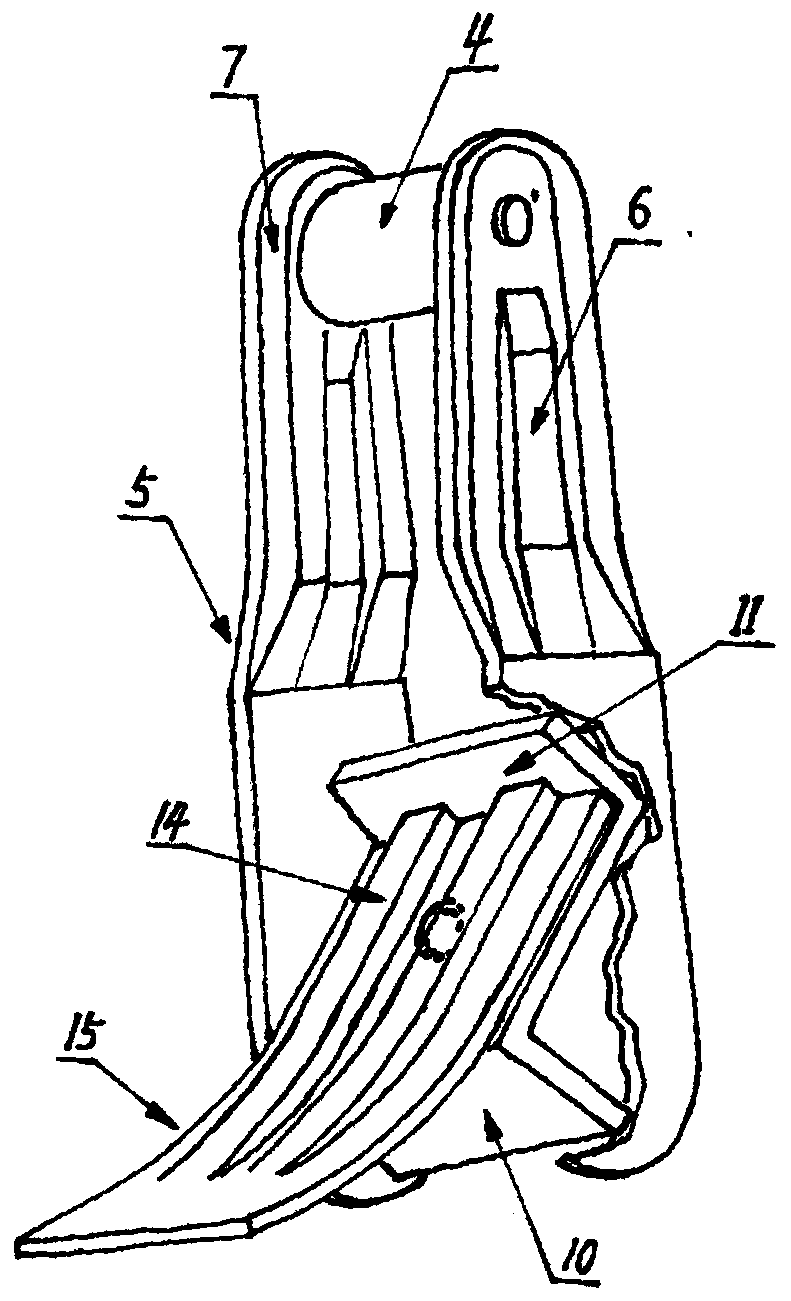

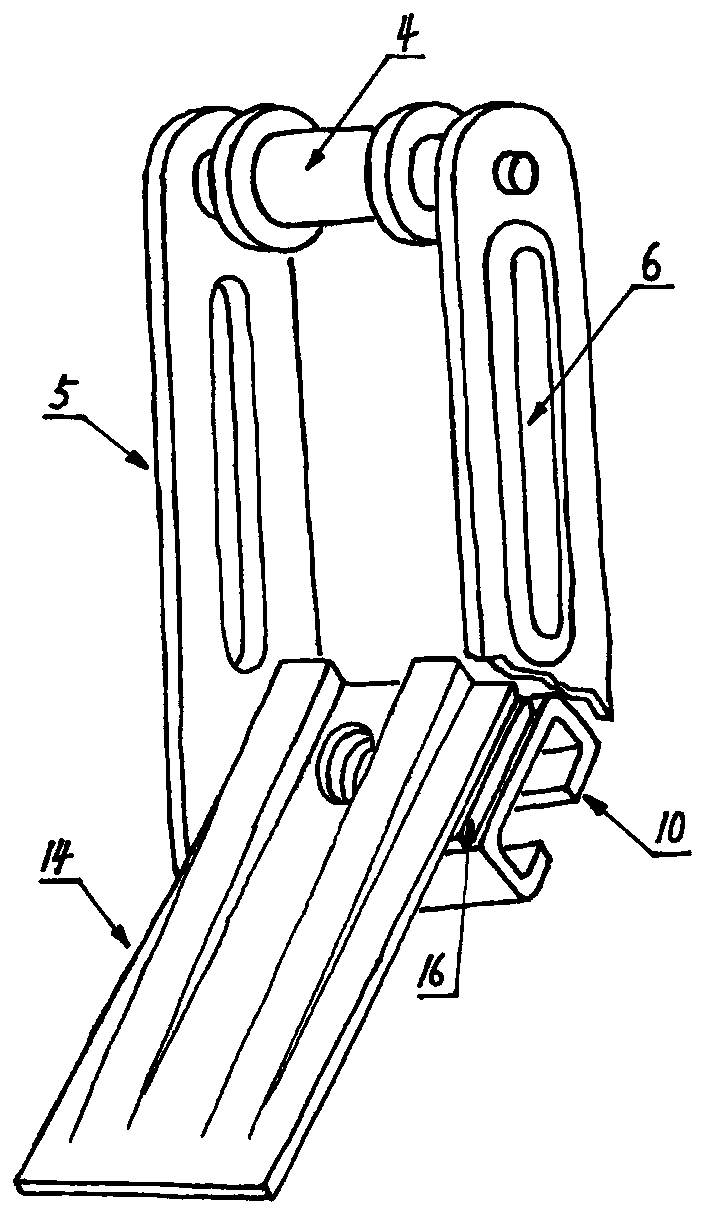

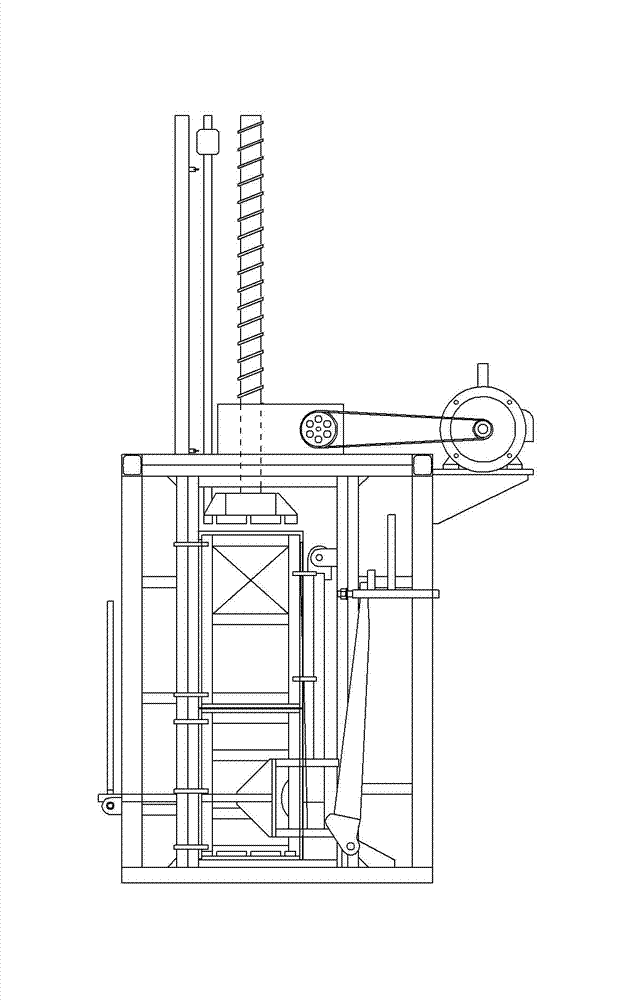

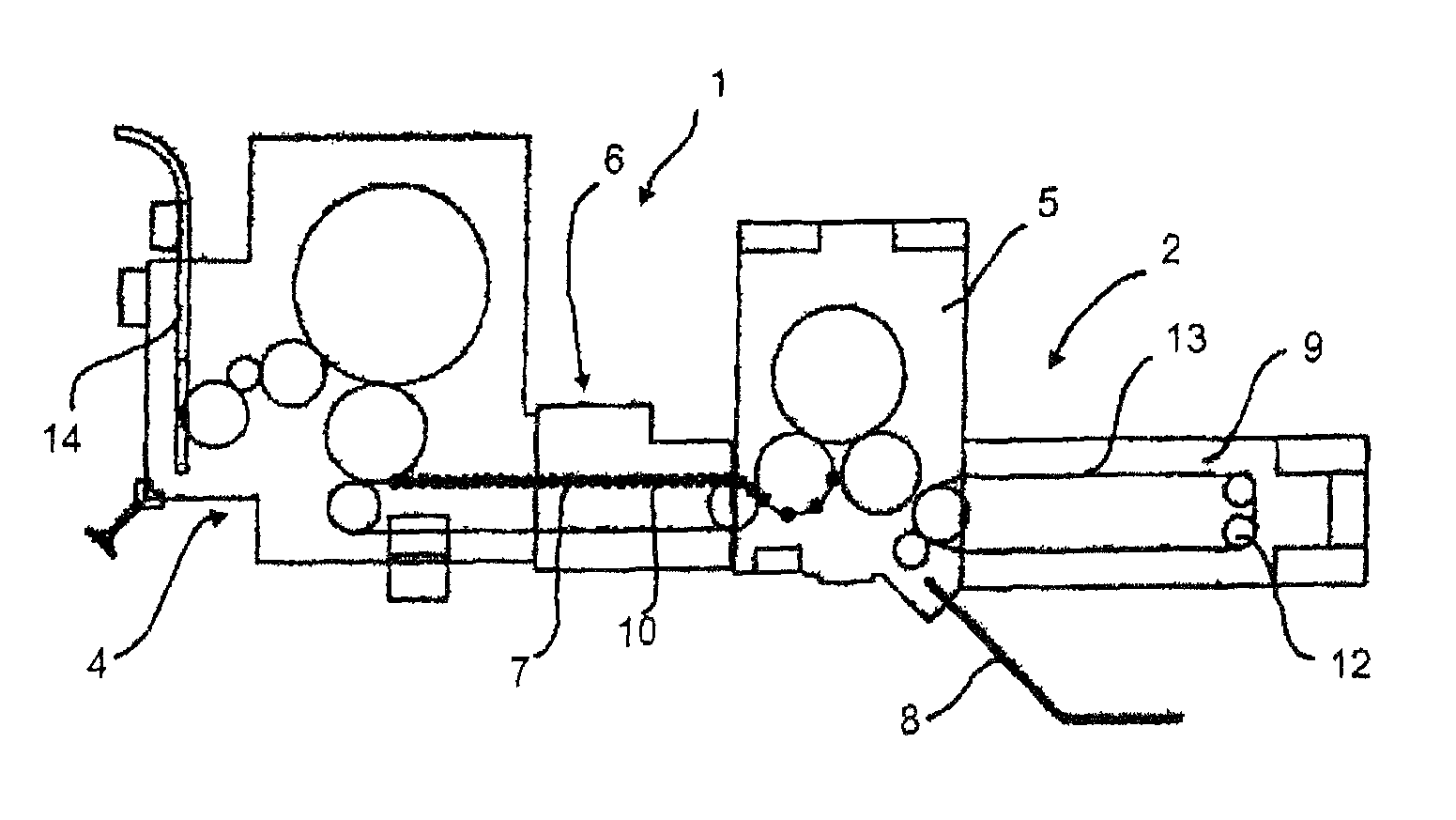

Crank drive for returning work pieces

InactiveUS20020195312A1Simple wayVelocity increasesGearingControl devices for conveyorsEngineeringReturn work

The invention relates to a mechanism for returning processed work pieces (7) from the output side to the loading side of a processing unit, which mechanism has a transfer mechanism (1) to transfer the work pieces (7) at the output side of the processing unit, a return mechanism (2) for transporting work pieces (7) delivered by the transfer mechanism (1) back to the loading side of the processing unit or to a further processing unit, and a lifting mechanism to lift the work pieces (7) to a return position located above the output position, whereby the lifting mechanism is located between the transfer mechanism (1) and the return mechanism (2) and has a lifting platform (3), with the lifting mechanism having a crank drive (4), by means of which the lifting platform (3) can be raised and lowered.

Owner:LIGMATECH AUTOMATIONSSYST

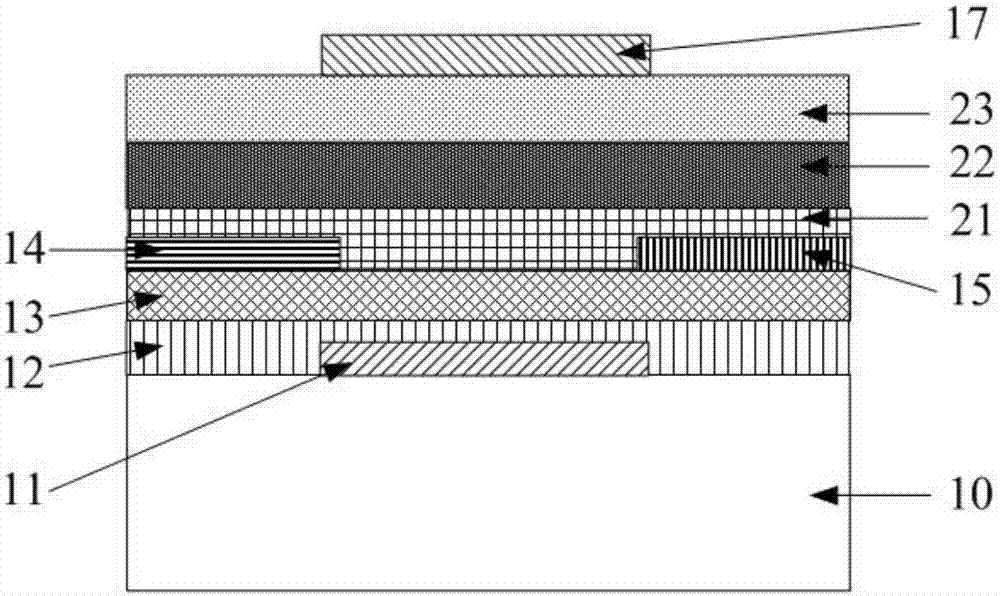

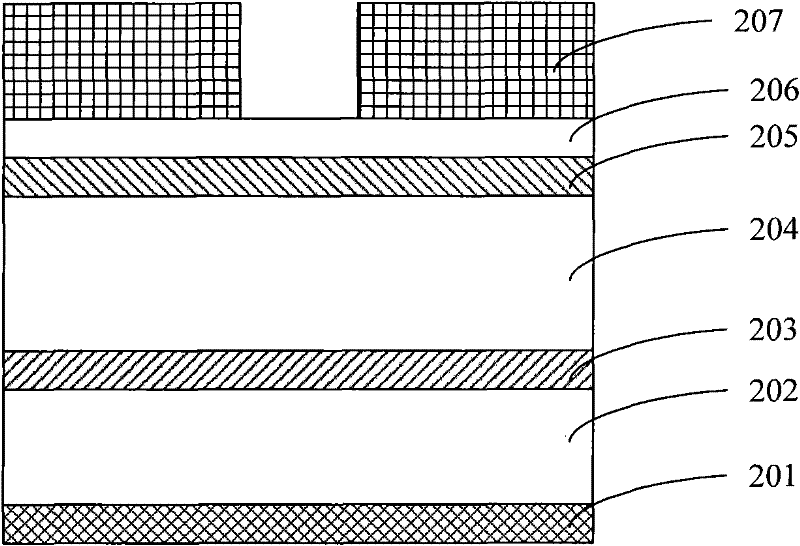

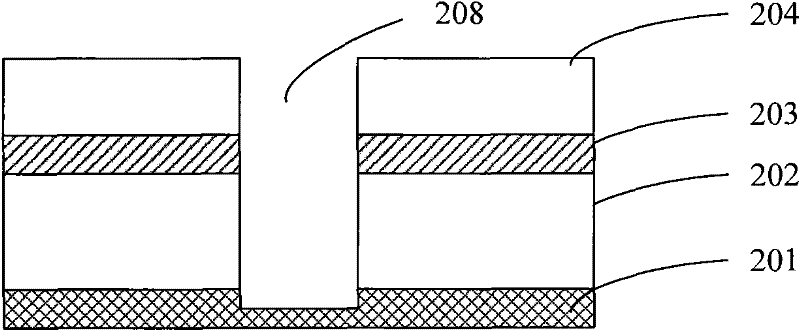

Application for taking thin film transistor with adjustable threshold voltage as nonvolatile memory

ActiveCN107301879AIncrease storage capacitySolve power consumptionTransistorDigital storageBottom gateEngineering

The invention discloses an application for taking a thin film transistor with adjustable threshold voltage as a nonvolatile memory. A top-gate memory is formed by the top gate, the barrier layer, the storage layer, the tunneling layer and the channel layer of the thin film transistor; and a bottom-gate TFT (Thin Film Transistor) is formed by the channel layer, the bottom gate oxidization layer and the bottom gate of the thin film transistor. The top-gate memory is operated to realize the ''Program / Erase'' operation of the nonvolatile memory, and the bottom-gate TFT is operated to realize the ''read'' operation of the nonvolatile memory. Through the separation of the ''Program / Erase, P / E'' operation and the ''read'' operation, a large memory window of the memory is realized, and the performance, including the reliability, the working speed and the like, of the memory can be improved.

Owner:SOUTHEAST UNIV

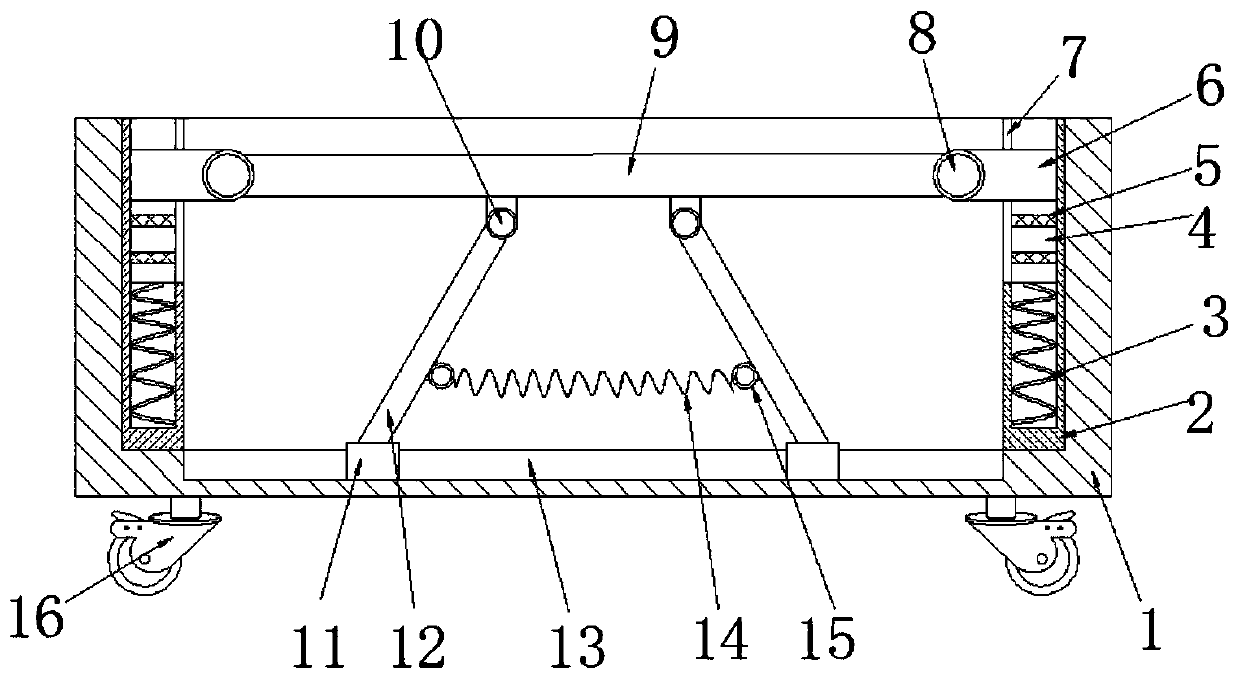

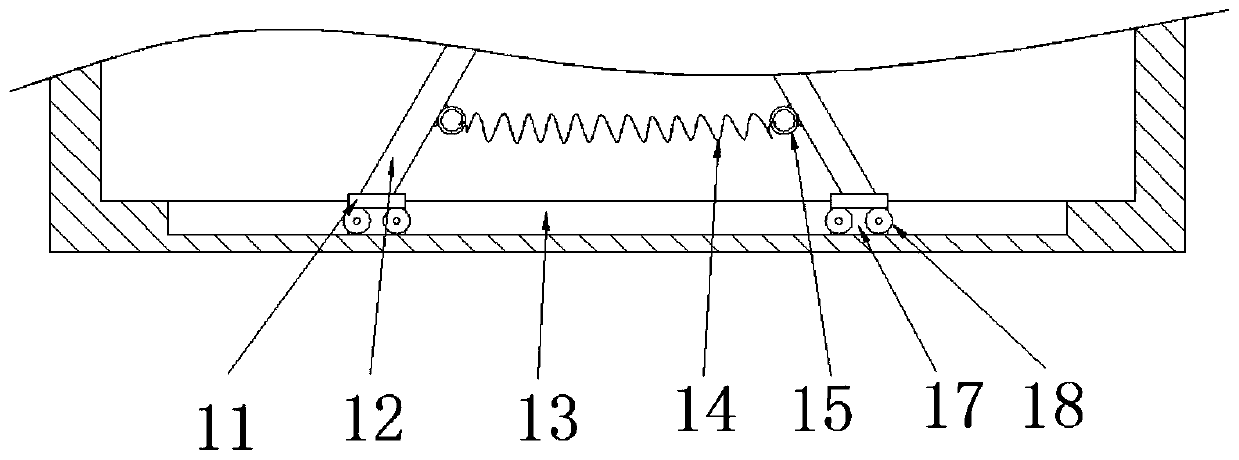

Damping machine base for mounting electromechanical equipment

InactiveCN110735885AReduce work speedImprove shock absorptionNon-rotating vibration suppressionStands/trestlesRubber ringMachine

The invention discloses a damping machine base for mounting electromechanical equipment. The damping machine base comprises a box body, sleeves are fixed to the four corners in the box body, supporting springs are fixed in the sleeves, movable openings are formed in the outer walls of one sides of the sleeves, piston are movably connected in the sleeves in an inserted mode, a plurality of annulargrooves are formed in the pistons, rubber rings attached to the inner walls of the sleeves are connected in the annular grooves in an embedded mode, sliding blocks in clamping fit with the movable openings are fixed t the top ends of the pistons, connecting lugs are fixed to one ends of the four sliding blocks, an object placing plate is fixedly arranged between every two connecting lugs, two shaft sleeves which are symmetrically distributed are fixed to the outer wall of the bottom of each object placing plate, supporting rods are rotatably connected in the shaft sleeves in an inserted mode,and a resetting mechanism is fixedly arranged between every two supporting rods. The damping machine base has the advantages that the installation work of the electromechanical equipment is facilitated, and in addition, the integral damping effect can be improved.

Owner:宝鸡市捷龙商贸有限公司

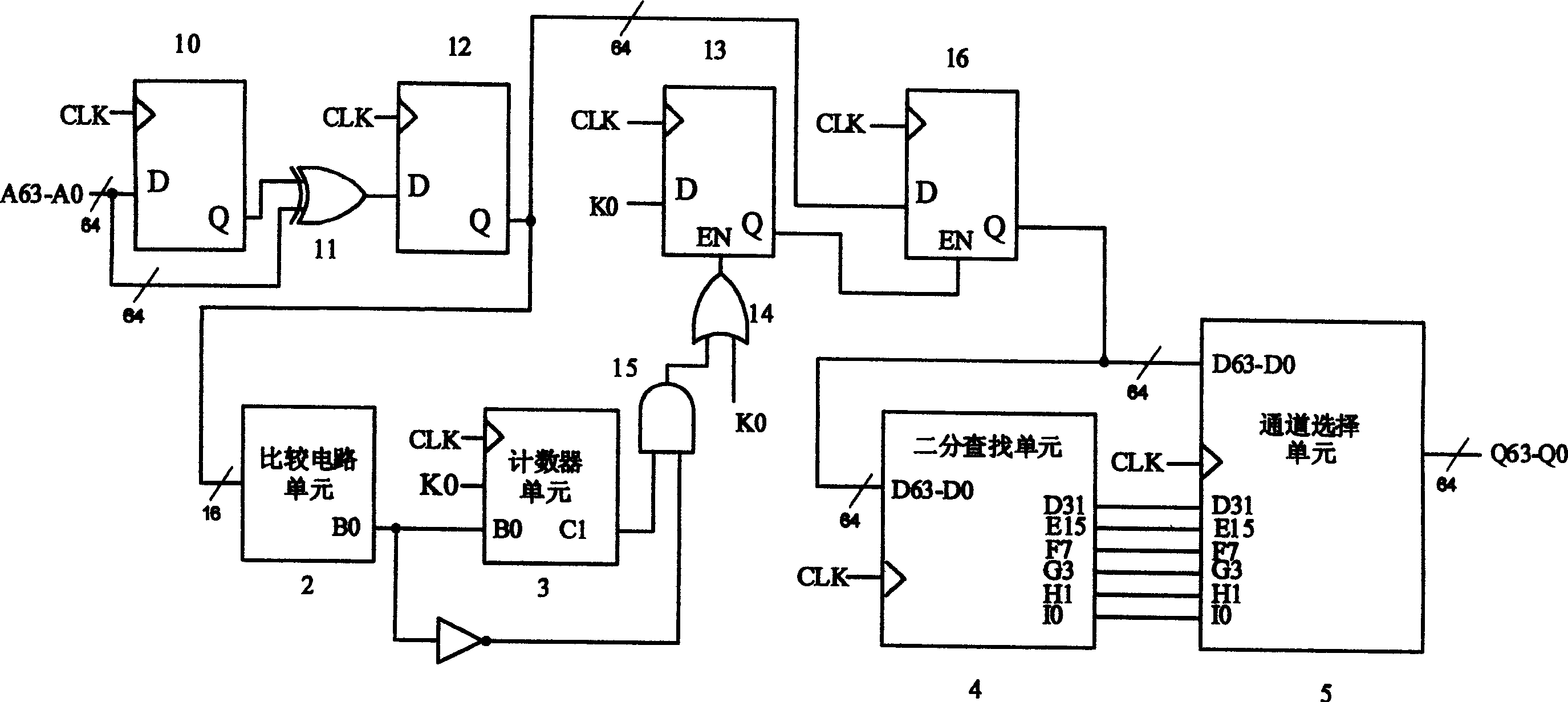

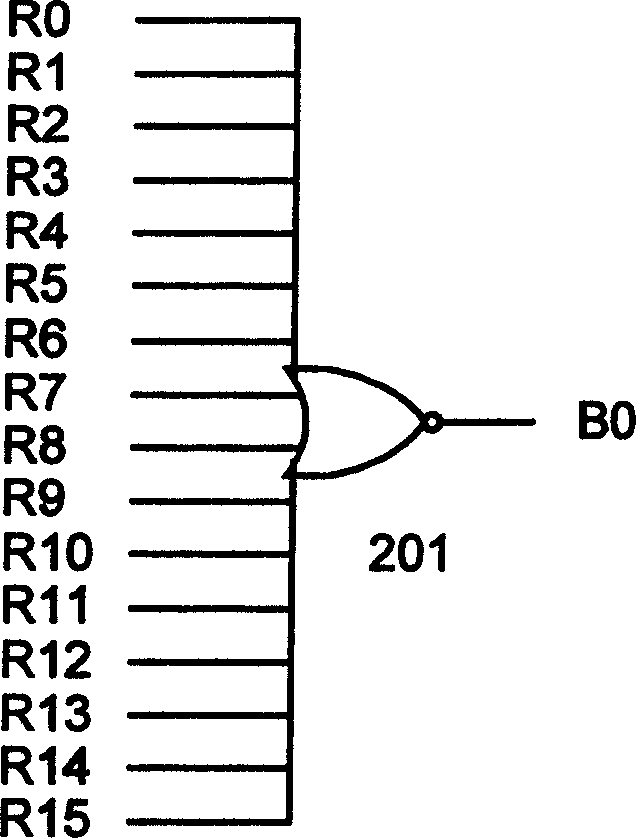

Parallel frame alignment circuit applied to optical synchronous digital transferring system

InactiveCN1564491AWork fasterSolve the speed problemTime-division multiplexElectromagnetic transmissionTransfer systemComparators circuits

The justification device includes main parts and connections as following: output end of first D trigger is connected to other end of exclusive-or gate. The output end of the exclusive-or gate is connected to input end of second D trigger. Output end of second D trigger is connected to input end of the fourth D trigger and comparator circuit unit respectively. Output end of the comparator circuit unit is connected to counter unit etc. Output end of the third D trigger is connected to 'EN' end of the fourth D trigger. Output end of the fourth D trigger is connected to binary search unit, and 'D63-DO0' of channel selection unit. Binary search unit is connected to channel selection unit through their relevant ends.

Owner:SOUTHEAST UNIV

Crank drive for returning work pieces

InactiveUS6607069B2Simple wayVelocity increasesGearingControl devices for conveyorsTransfer mechanismReturn work

The invention relates to a mechanism for returning processed work pieces (7) from the output side to the loading side of a processing unit, which mechanism has a transfer mechanism (1) to transfer the work pieces (7) at the output side of the processing unit, a return mechanism (2) for transporting work pieces (7) delivered by the transfer mechanism (1) back to the loading side of the processing unit or to a further processing unit, and a lifting mechanism to lift the work pieces (7) to a return position located above the output position, whereby the lifting mechanism is located between the transfer mechanism (1) and the return mechanism (2) and has a lifting platform (3), with the lifting mechanism having a crank drive (4), by means of which the lifting platform (3) can be raised and lowered.

Owner:LIGMATECH AUTOMATIONSSYST

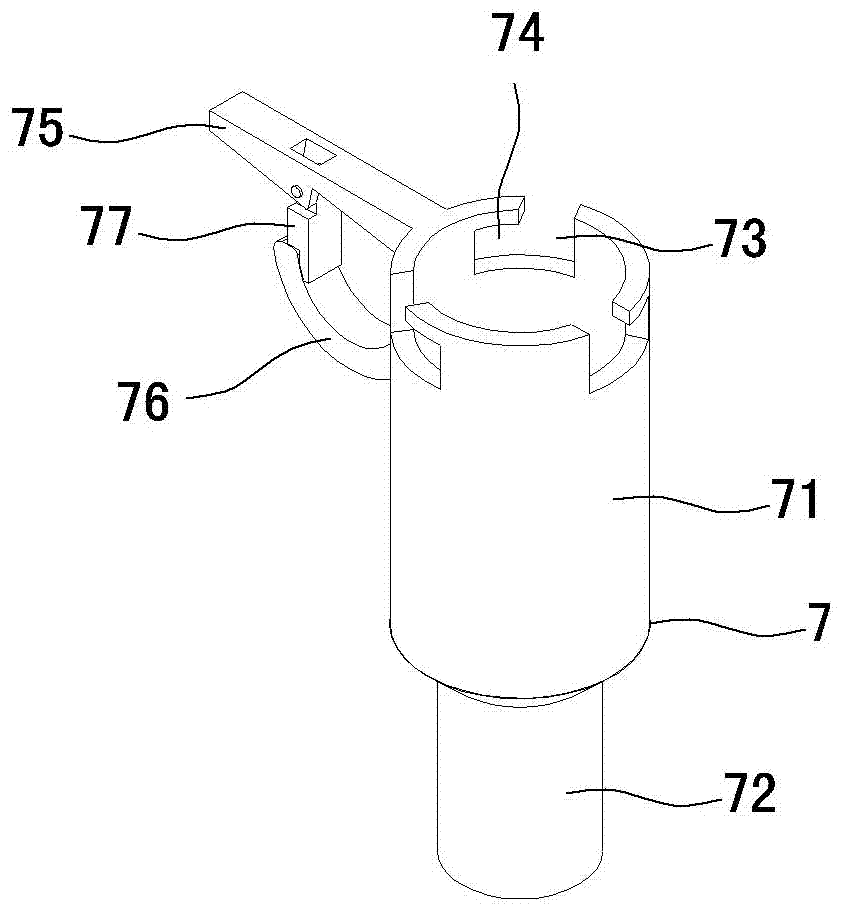

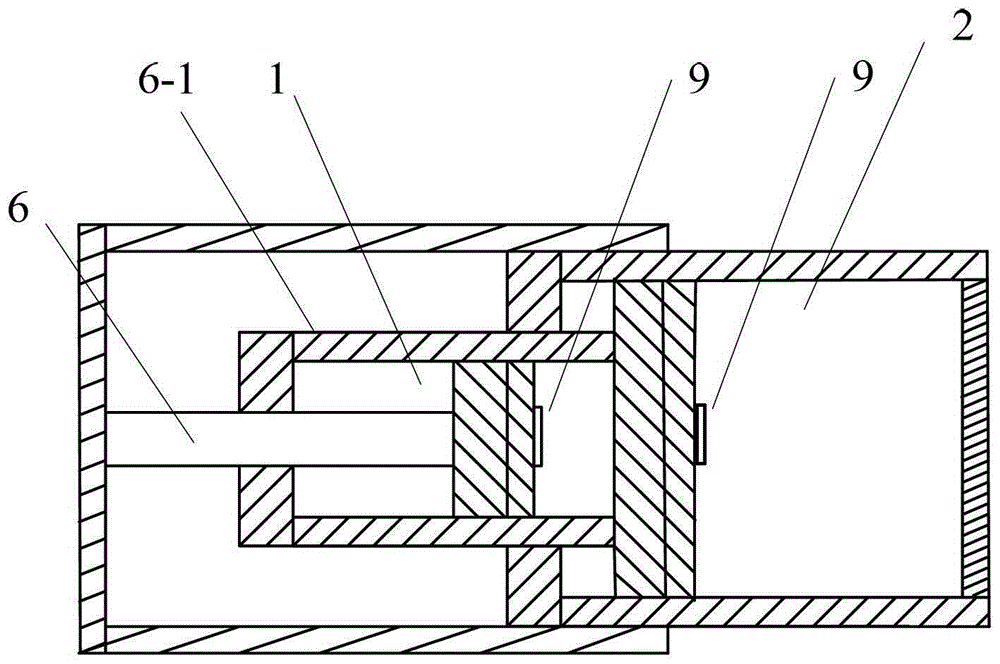

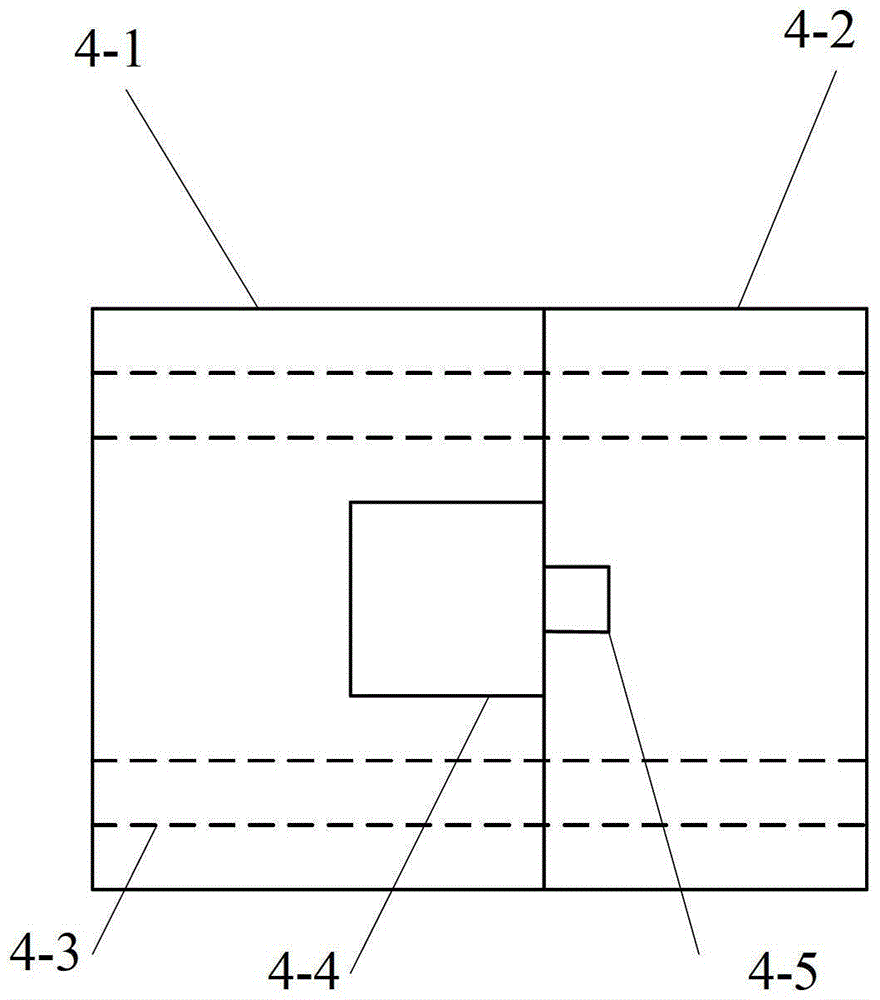

Rapid, reliable and safe grounding wire fixture

ActiveCN106877236AReliable contactQuick and easy to remove and hang the ground wireApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention relates to a rapid, reliable and safe grounding wire fixture. The rapid, reliable and safe grounding wire fixture comprises a fixed fixture (1) and a movable fixture (2), wherein a hook (12) is arranged at an upper part of the fixed fixture (1), a sliding rod (21) is arranged at a lower part of the movable fixture (2) and is arranged in a sliding hole of the fixed fixture, a movable fixture head (22) is arranged at an upper end of the sliding rod, a first press spring (25) is arranged in the sliding hole and sleeves the sliding rod, a connection sleeve (4) is arranged below the fixed fixture (1), a plurality of steel ball holes (41) are formed in a side wall of the connection sleeve, a steel ball (42) is arranged in each steel ball hole, an annular steel ball groove (26) is formed in an outer wall of the sliding rod, a control sleeve (5) is arranged below the fixed fixture, and a second press spring (43) is arranged in the control sleeve and sleeves the connection sleeve (4). By using the rapid, reliable and safe grounding wire fixture, reliable contact between the grounding wire fixture and an overhead wire can be ensured, the grounding wire is convenient and rapid to pick up and hang, the power failure maintenance time is favorably shortened, the operation speed is increased, and normal power supply is not affected.

Owner:刘义

A metal wiring etching method

ActiveCN102299097AReduced signal transmission speedReduce work speedSemiconductor/solid-state device manufacturingDielectricSilicon oxide

The invention provides a method for etching a metal connecting line. After depositing a first silicon oxide layer and a mask layer on a low dielectric coefficient interlayer dielectric in sequence, the method comprises the following steps: coating a first photoresist to form a first photoetching pattern for defining a through hole; forming a protective layer on the surface of the first photoetching pattern; coating a second photoresist on the protective layer to form a second photoetching pattern for defining a groove; etching to form the through hole and the groove by taking the first photoetching pattern and the second photoetching pattern as masks; ashing and removing mask layer residue after etching, and exposing the first silicon oxide layer. In the method for etching the metal connecting line provided by the invention, once etching is adopted to form the through hole and the groove in the low dielectric coefficient interlayer dielectric, thus reducing the rise of the dielectric coefficient k of the low dielectric coefficient interlayer dielectric caused by the attack of plasma on the low dielectric coefficient interlayer dielectric during the ashing process, and avoiding reducing the signal transmission speed of the semiconductor circuit and the working speed of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

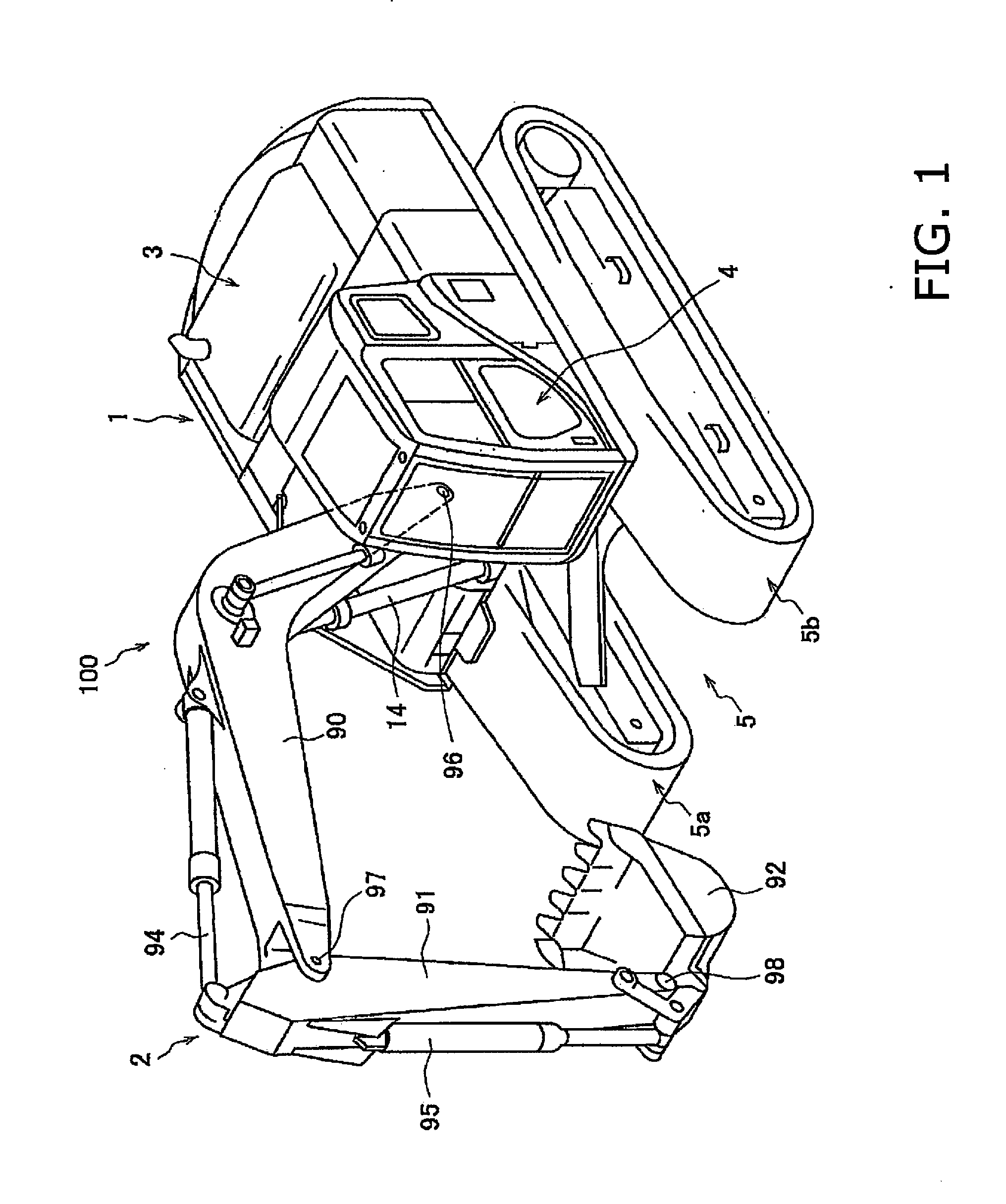

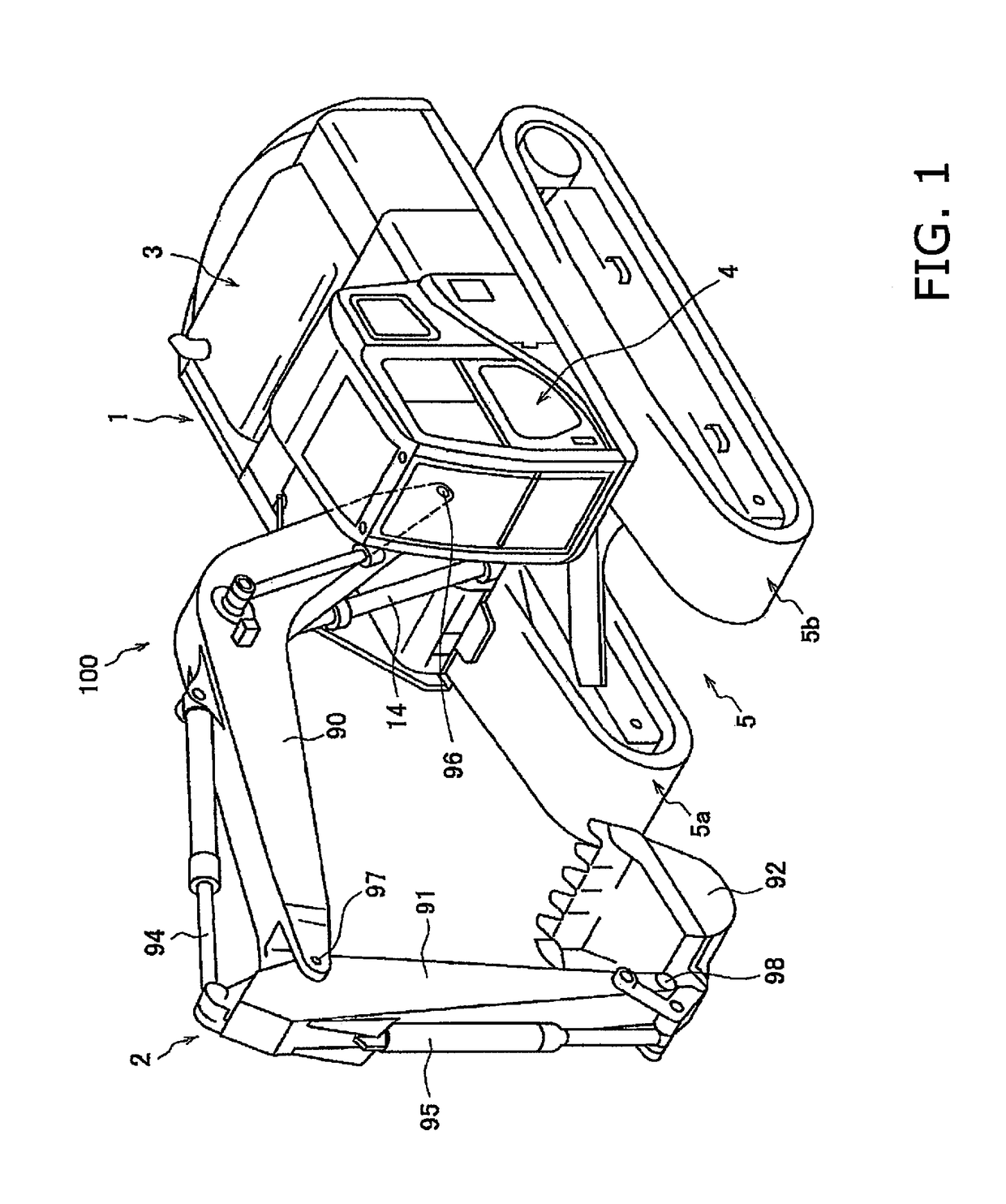

Control system for work vehicle, control method, and work vehicle

ActiveUS20200308809A1Promote densificationImprove the quality of the finishSoil-shifting machines/dredgersControl systemControl engineering

A work vehicle control system includes an actual topography acquisition device, a storage device, and a controller. The actual topography acquisition device acquires actual topography information, which indicates an actual topography of a work target. The storage device stores design topography information, which indicates a final design topography that is a target topography of the work target. The controller acquires the actual topography information from the actual topography acquisition device, and the design topography information from the storage device. The controller determines an intermediate design topography positioned above the actual topography and below the final design topography. The controller generates a command signal to move the work implement based on the intermediate design topography. The intermediate design topography includes a plurality of intermediate design surfaces divided in the traveling direction of the work vehicle. Inclination angles of at least two of the intermediate design surfaces differ from each other.

Owner:KOMATSU LTD

Hydraulic drive system

InactiveUS9695842B2Improve work efficiencyReduce work speedServomotor componentsServomotorsHydraulic cylinderHydraulic pump

A hydraulic cylinder causes a work implement to be lowered due to the exhaust of hydraulic fluid from a first chamber and the supply of hydraulic fluid to a second chamber. A hydraulic fluid flowpath has a first flowpath and a second flowpath. The first flowpath connects a first pump port and the first chamber. The second flowpath connects a second pump port and the second chamber. The hydraulic fluid flowpath configures a closed circuit between a hydraulic pump and the hydraulic cylinder. A bleed-off flowpath branches off from the first flowpath. A portion of hydraulic fluid exhausted from the first chamber when lowering the work implement flows into the bleed-off flowpath.

Owner:KOMATSU LTD

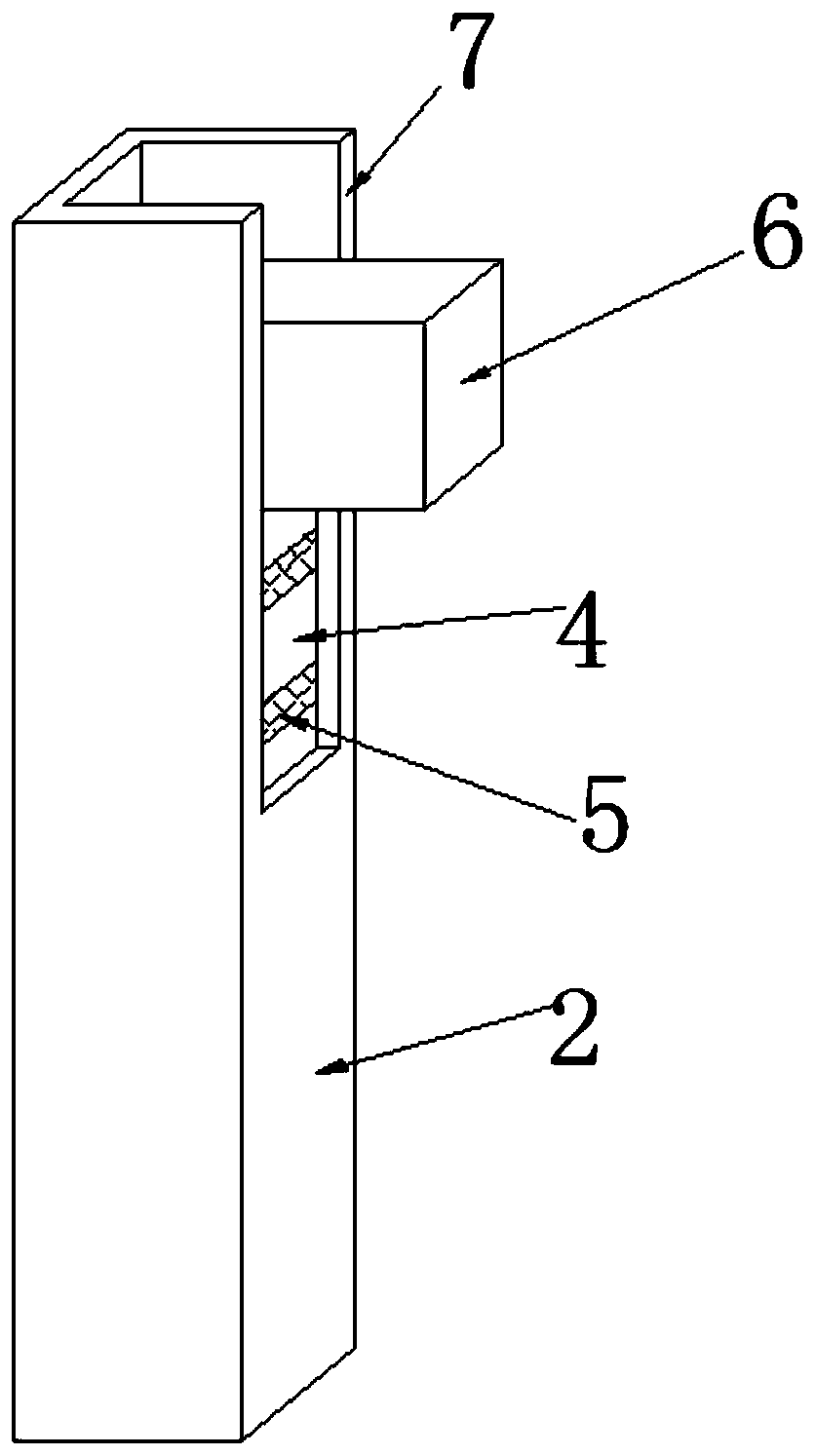

Handheld Work Apparatus

ActiveUS20200246957A1Low moment inertiaLarge braking forceMetal sawing devicesPortable power driven sawsControl engineeringHand held

A handheld work apparatus includes a work tool, a belt drive, a drive motor configured to drive the work tool via the belt drive, a brake unit configured to act on the belt drive, and a holding arrangement. The brake unit has a braking position and a released position and the holding arrangement is configured to hold the brake unit in the released position. The holding arrangement includes an electromagnet to which current is supplied during operation of the work apparatus.

Owner:ANDREAS STIHL AG & CO KG

Two-stage buffer

InactiveCN104747645AControl work speedReduce work speedSpringsSprings/dampers design characteristicsBody shapeEngineering

Owner:SUZHOU TANGSHI MACHINERY MFG

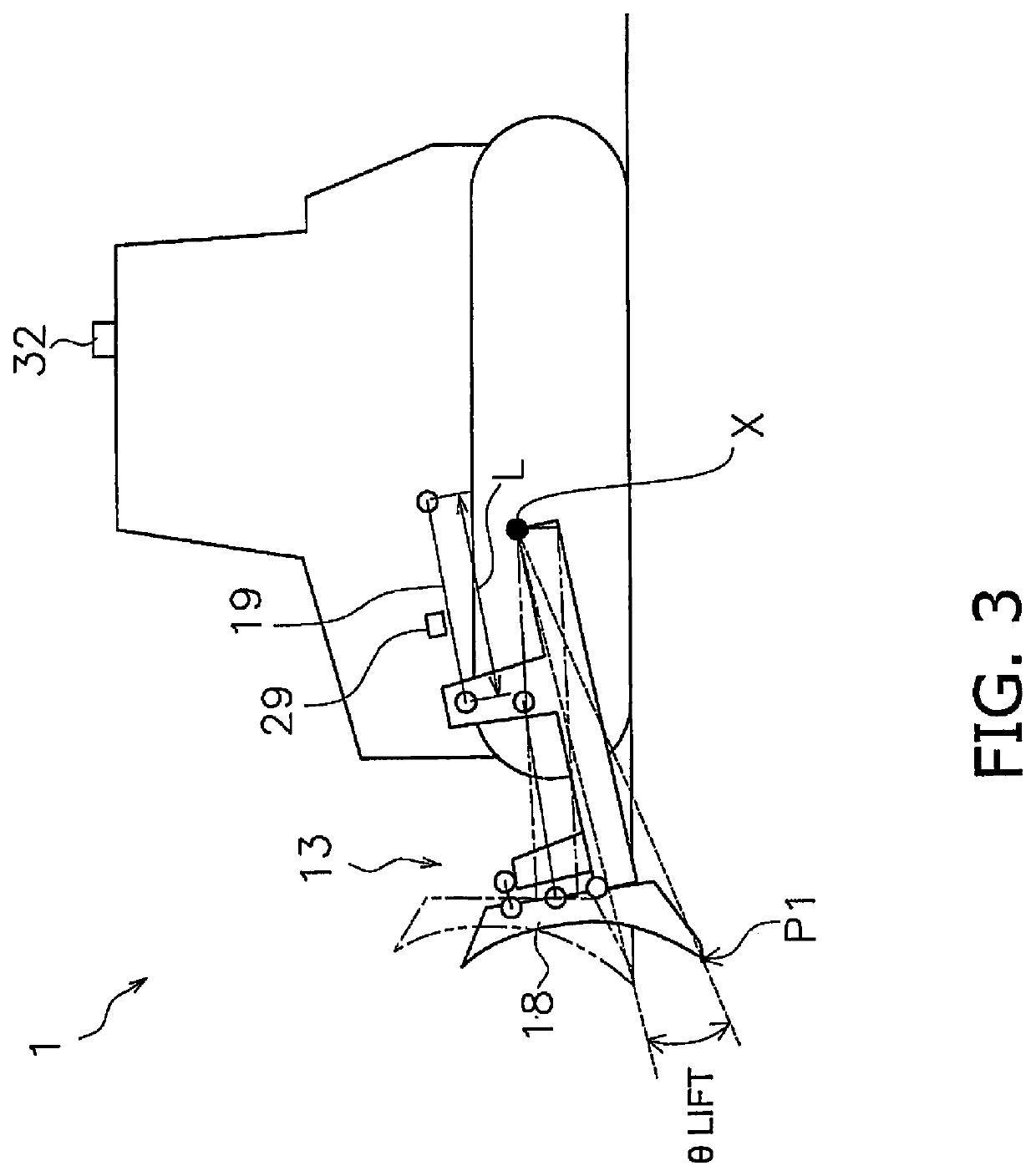

Work vehicle and control method for work vehicle

ActiveUS20190226178A1Easy to operateReduce speedMechanical machines/dredgersHand leversControl theory

Owner:KOMATSU LTD

High power twister

The invention relates to a twisting device in the textile fiber twisting field. It is a high power twisting device, its character: it is composed of outer ingot device, inner ingot device, middle ingot device, package support mechanism, yarn retreating and guiding device and outer ingot cylinder mechanism, where the ingot rod of top rotary magnet base of the inner ingot device is supported on the top of the bottom ingot rod of the outer ingot device through the bearing, the static support base of the middle ingot device is supported on the ingot rod of top rotary magnet base through the bearing, the package support component of the package support mechanism on the top end of the ingot rod of top rotary magnet base through the bearing, the ingot-end cord rod and mouth are actively covered on the top end of the package support component, the outer ingot cylinder mechanism is outside the inner ingot device and the outer ingot cylinder is fixed with the frame. It has characters of rotation-rotation yarn feeding and 4 twisting rounds, simple structure, etc.

Owner:WUHAN TEXTILE UNIV

Control system for work vehicle, control method, and work vehicle

ActiveUS10787789B2Avoid quality lossQuality of the work finishMechanical machines/dredgersVehicle position/course/altitude controlInformation controlControl system

A work vehicle control system includes an actual topography acquisition device, a storage device, and a controller. The actual topography acquisition device acquires actual topography information, which indicates an actual topography of a work target. The storage device stores design topography information, which indicates a final design topography that is a target topography of the work target. The controller acquires the actual topography information from the actual topography acquisition device. The controller acquires the design topography information from the storage device. The controller generates a command signal to move the work implement along a locus that is more gently sloped than the actual topography when the actual topography positioned below the final design topography is sloped.

Owner:KOMATSU LTD

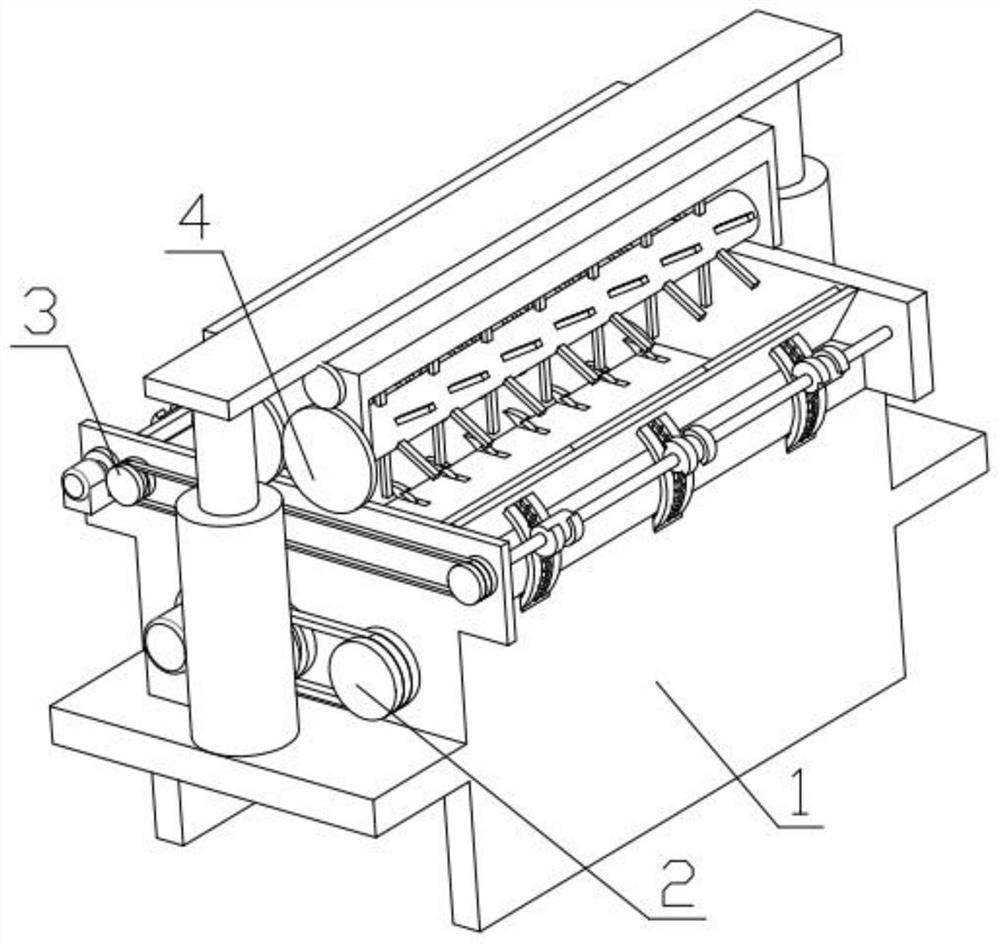

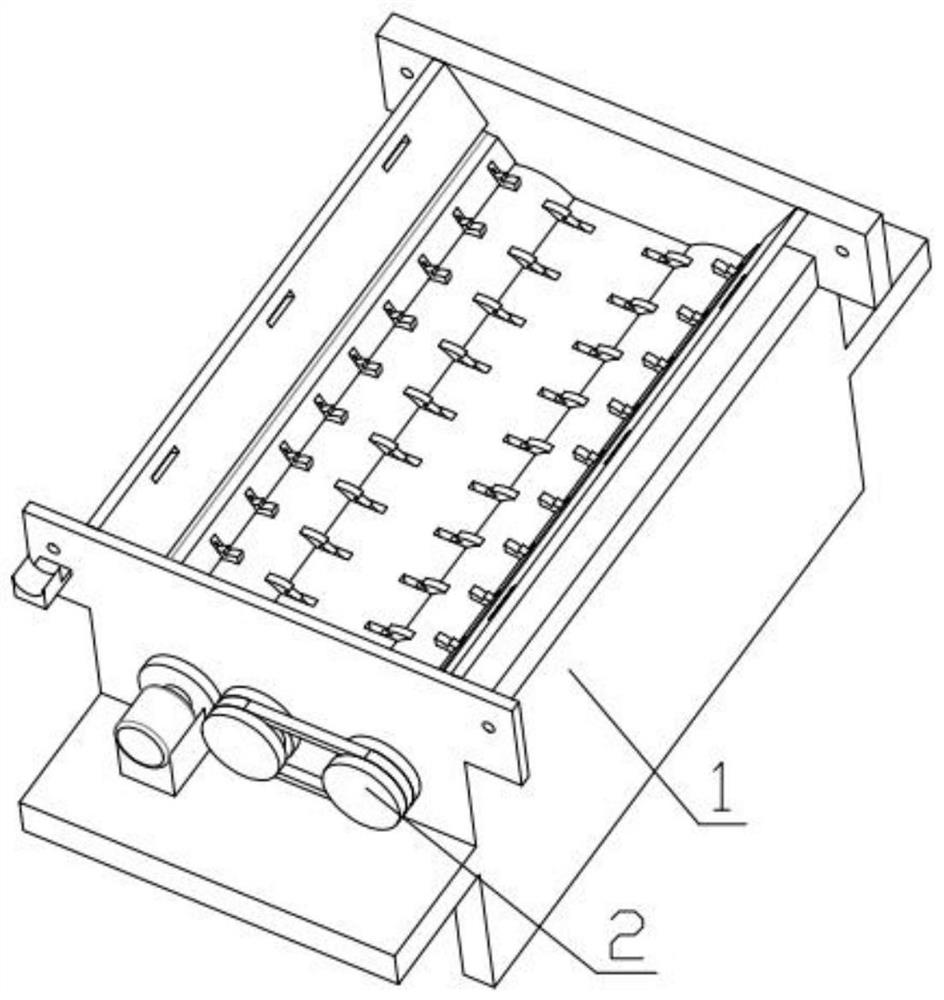

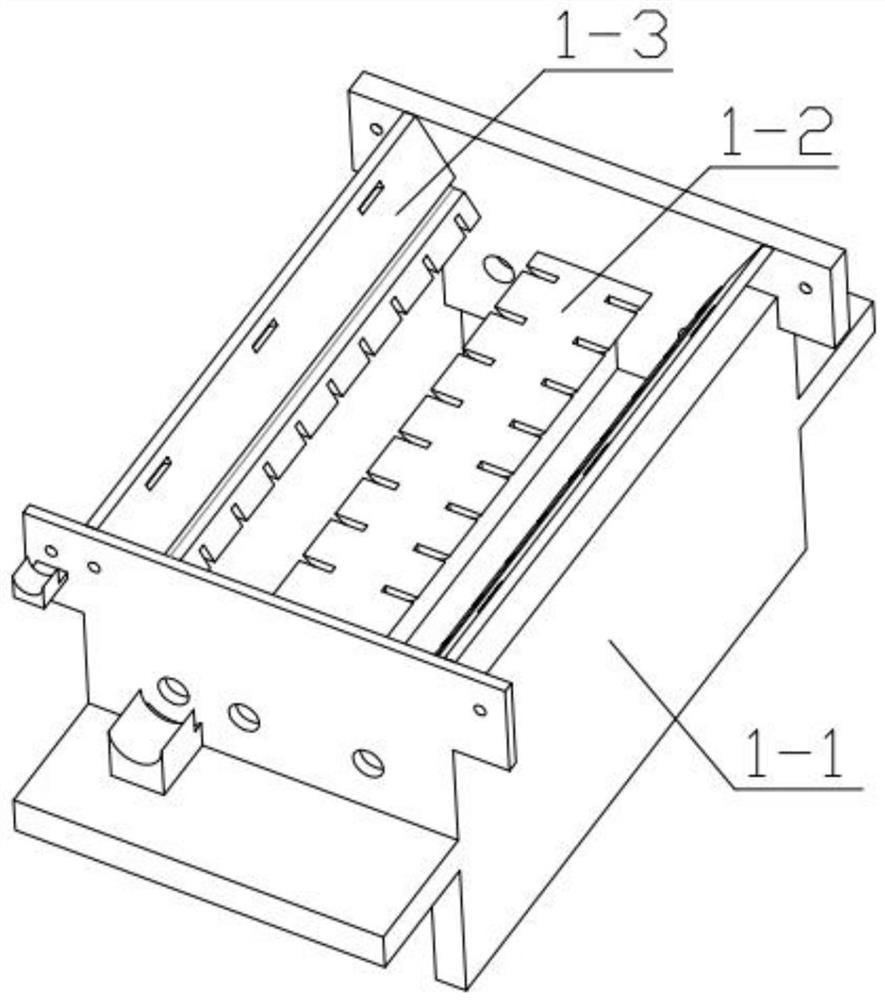

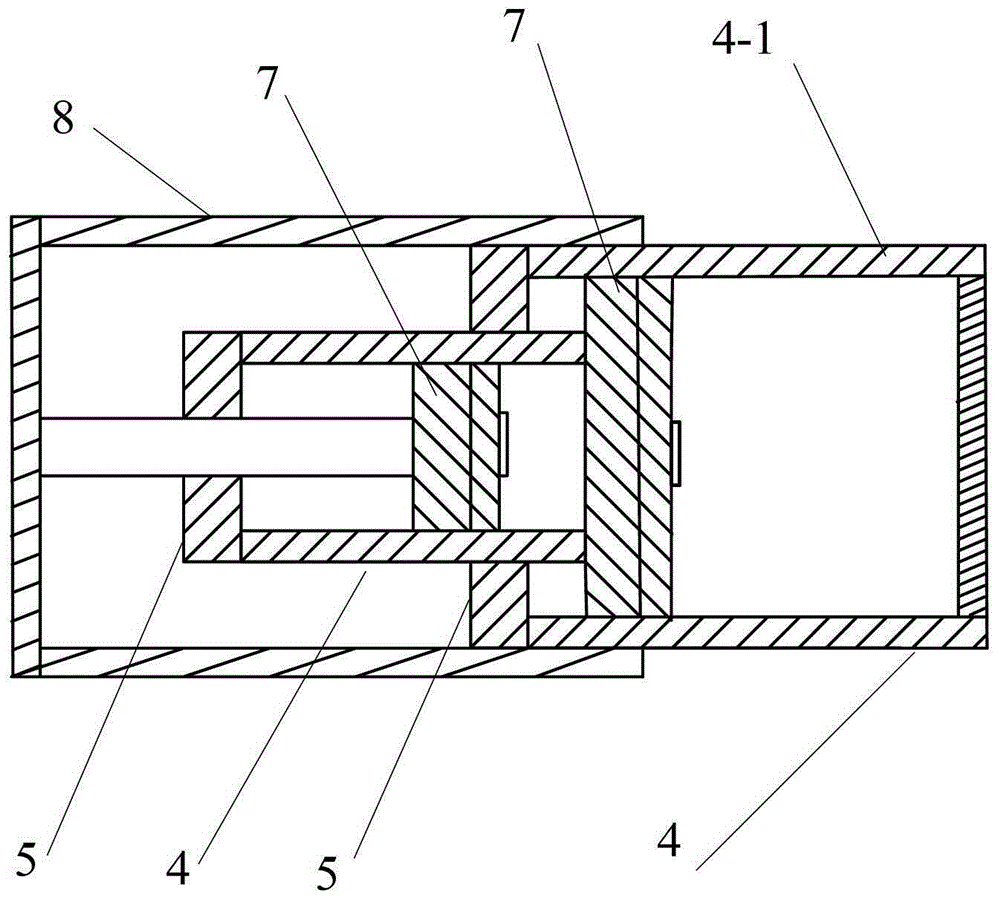

Rotating roller with high frequency impact and flexible removal

The invention belongs to the technical field of mechanical equipment manufacturing, and relates to a rotating roller with high frequency impact and flexible removal. A main structure of the rotating roller comprises a main shaft, wheel discs and impact devices, wherein the equally-spaced wheel discs sleeve the main shaft and follow the main shaft to rotate; long holes, each of which being of a through structure, are evenly distributed around the center of each wheel disc of a flake structure, each long hole is provided with a roller, the impact devices are connected with the wheel discs through the rollers, a main structure of each impact device comprises the rollers, two side beam plates with battens resisting stress of a flat or curved surface of a blade, a mounting seat, and impact blades; a buffer layer also can be added; the wheel discs drive the impact devices to rotate, the impact devices are thrown away under the action of centrifugal force, and when a hard obstacle is met andcannot be passed through, the rollers slide and roll toward the centers of the wheel discs in long hole wide table surfaces of the wheel discs. The main structure of the rotating roller is simple, thedesign concept is ingenious, the use is safe and convenient, the application environment is friendly, and the market prospect is wide.

Owner:张宇鹏

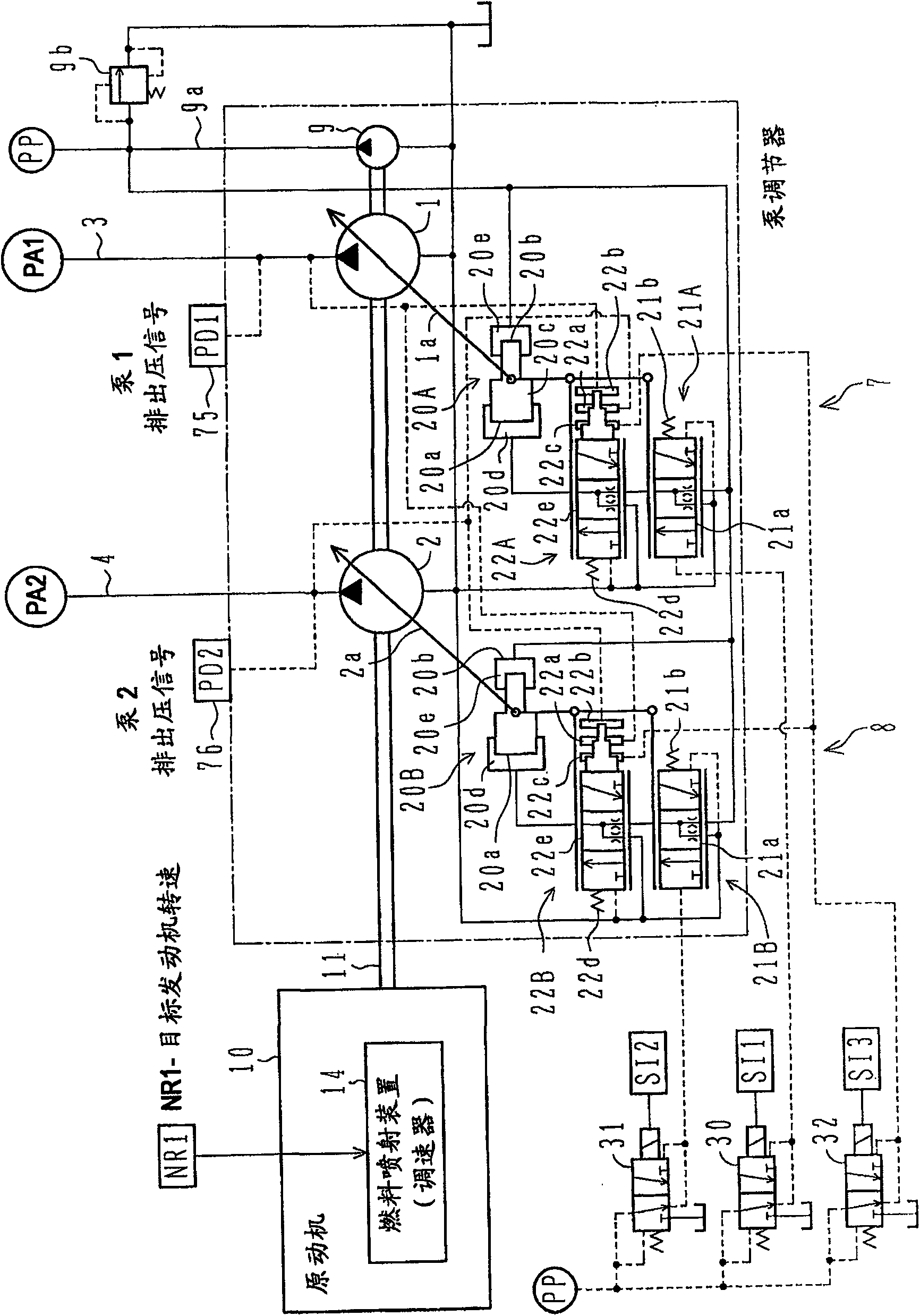

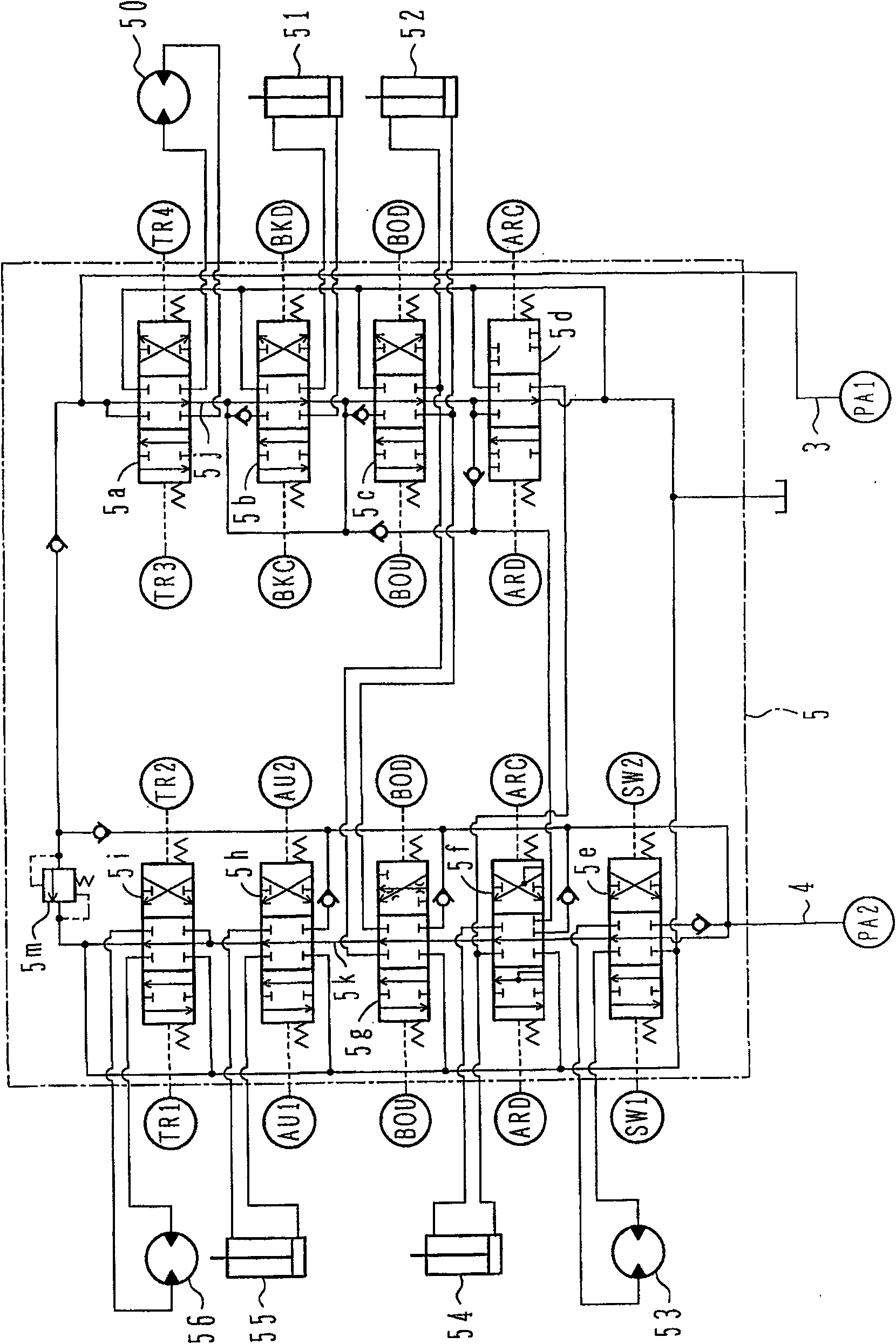

Controller for hydraulic construction machine

ActiveCN100554667CReduce speedReduce consumptionElectrical controlServomotorsEngineeringControl theory

The mode selection part (700e) is turned on when the mode selection instruction selects the economic mode, and outputs the engine speed correction value ΔN0 (ΔN1=ΔN0) calculated by the engine speed correction value calculation part (700d), and the subtraction part (700f) calculates the engine speed correction value ΔN0 from the rated value. Corrected engine speed ΔN1 is subtracted from target speed Nmax to obtain target engine speed NR2. A calculation unit (700d) calculates an engine rotation speed correction value ΔN0 corresponding to the pump discharge pressure average value Pm. In the memory table, the relationship between Pm and ΔN0 is set as follows: when Pm is below PA near the intermediate pressure, ΔN0 is 0, and when Pm is higher than PA, ΔN0 increases with the increase of Pm. Accordingly, through mode selection, the prime mover speed can be reduced to improve fuel consumption, and at the same time, in the necessary load area, the performance degradation caused by the reduction of pump discharge flow can be reduced, and the prime mover speed or pump discharge flow will not be discontinuous. Variety.

Owner:NIHON KENKI CO LTD

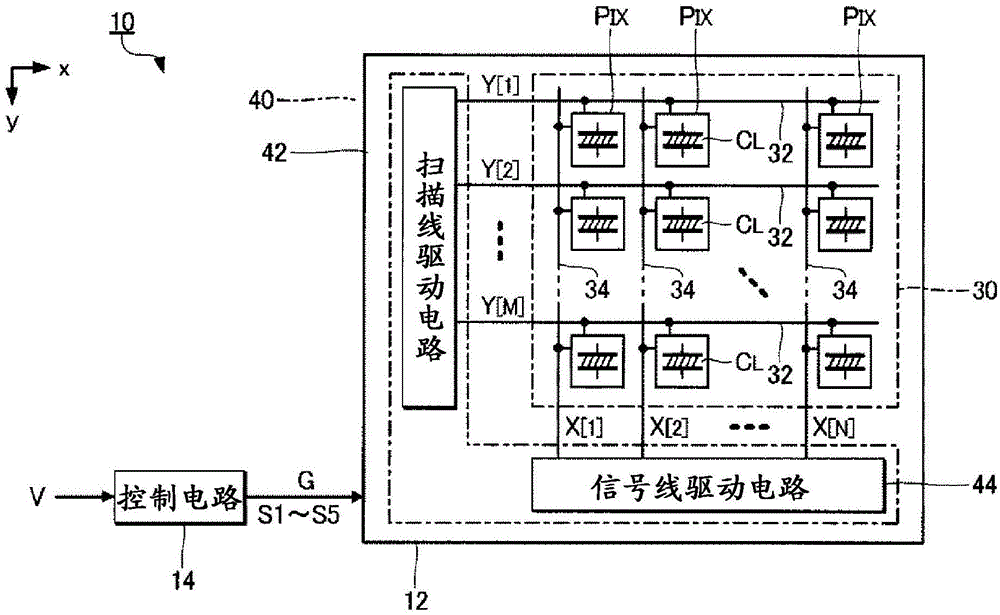

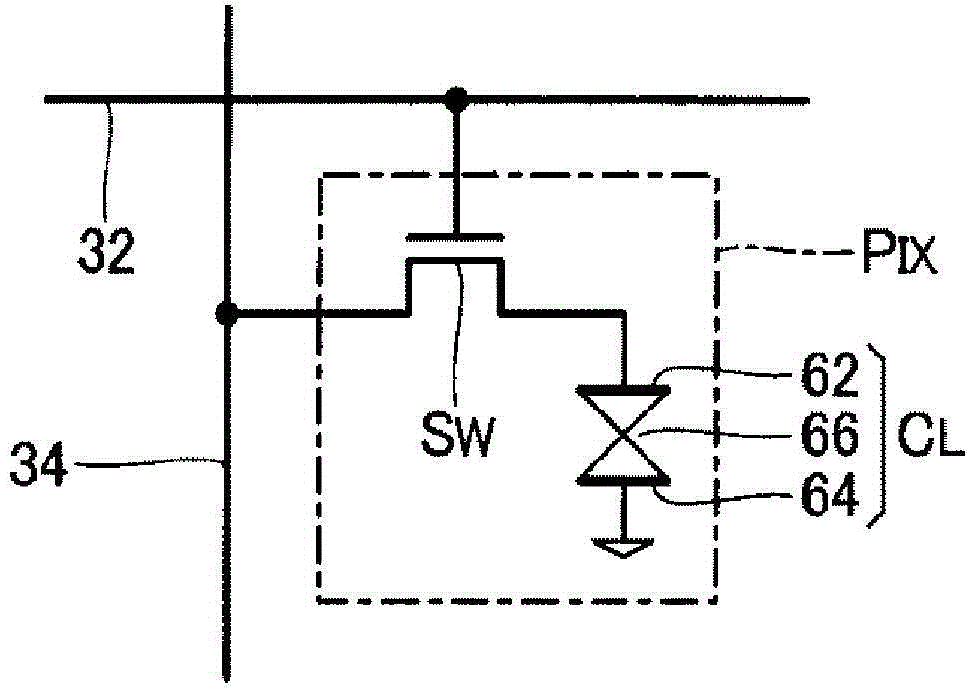

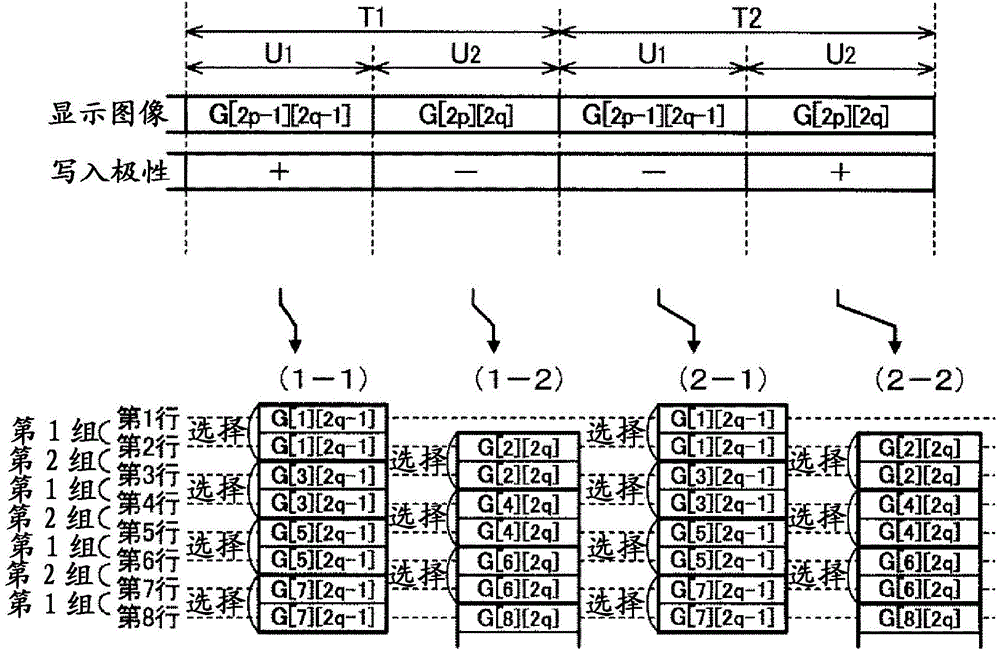

Display device and electronic apparatus

InactiveCN104885146ASlow down the working speedReduce circuit sizeStatic indicating devicesDisplay deviceEngineering

Provided is a display device capable of displaying a high resolution image while suppressing an increase in the size and cost of the display device. The display device comprises: two odd-row scanning lines sandwiching an even-row scanning line; two adjoining signal lines; a plurality of pixels provided for intersections between the scanning lines and the signal lines; a scanning line drive circuit for selecting a first group of scanning lines consisting of the even-row scanning line and one of the two odd-row scanning lines during a first unit period, and selecting a second group of scanning lines consisting of the even-row scanning line and the other of the two odd-row scanning lines during a second unit period; and a signal line drive circuit for supplying a first gradation potential to four pixels for the intersections between the first group of scanning lines and two signal lines during the first unit period, and supplying a second gradation potential to four pixels for the intersections between the second group of scanning lines and two signal lines during the second unit period.

Owner:SEIKO EPSON CORP

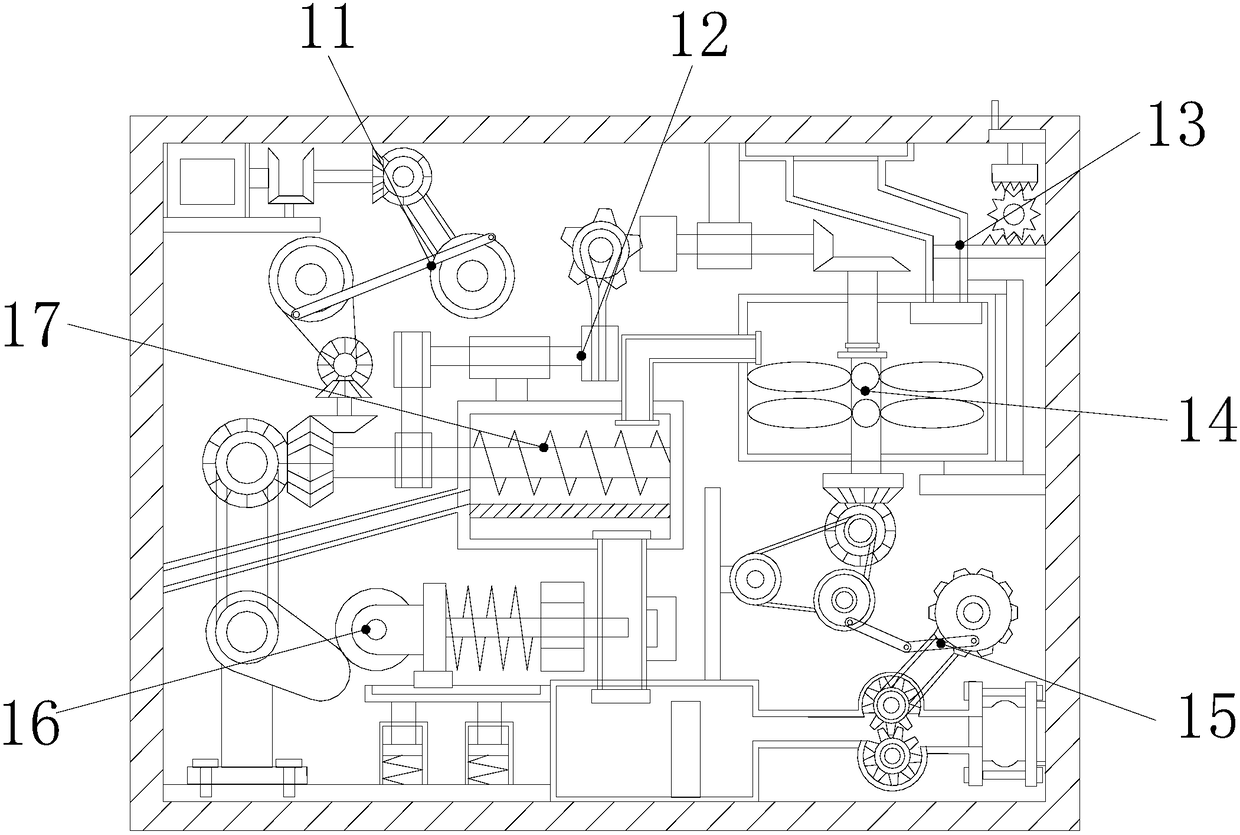

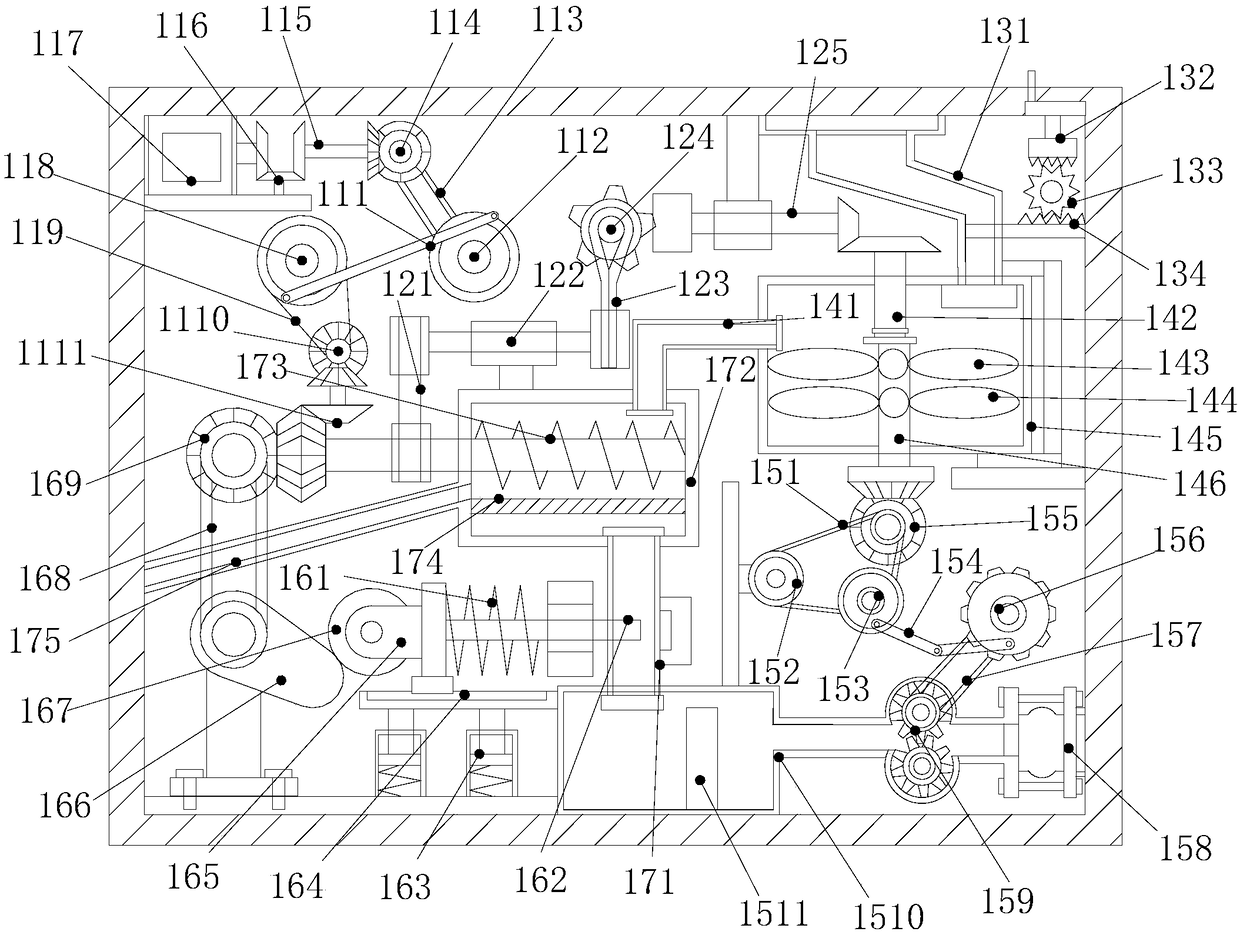

Tree section peeling device

ActiveCN113043409AReduce peeling forceImprove work efficiencyTree debarkingWood processingEngineering

The invention relates to a wood processing device, in particular to a tree section peeling device. The tree section peeling device comprises a device box body, a peeling mechanism, a wood section aligning mechanism and an auxiliary rolling mechanism, the peeling mechanism is fixedly installed on the device box body, the wood section aligning mechanism is fixedly installed on the device box body, and the auxiliary rolling mechanism is fixedly installed on the device box body. According to the tree section peeling device, in the peeling process, the placing positions of wood sections can be corrected, the peeling efficiency is improved, the peeling degree can be adjusted, adjustment can be conducted according to different tree types, when the number of the wood sections is too large, the wood sections can be assisted in rolling, and the working efficiency is improved.

Owner:泉州市池瑞科技有限公司

A working method of a temperature-protected two-stage buffer

ActiveCN103291805BControl work speedReduce work speedSpringsLiquid based dampersWorking temperatureMechanical engineering

Owner:苏州卫优知识产权运营有限公司

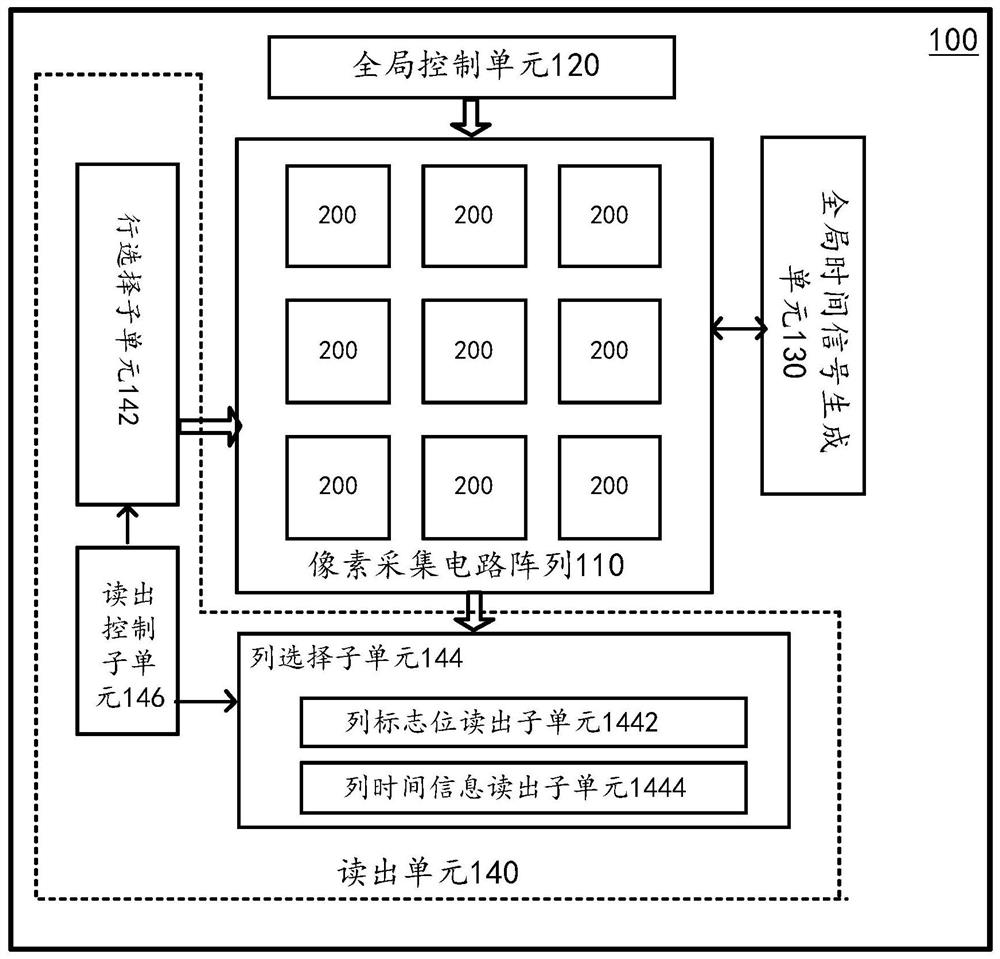

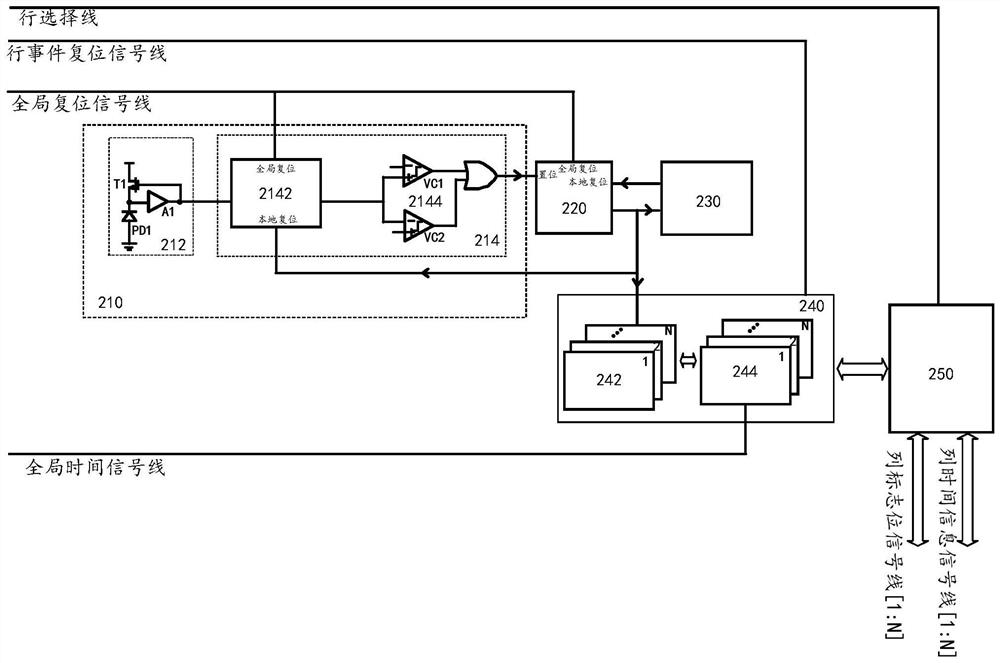

Pixel acquisition circuit and image sensor

ActiveCN113365004AReduce power consumptionReduce work speedTelevision system detailsColor television detailsComputer hardwareEngineering

The invention discloses a pixel acquisition circuit and an image sensor. The image sensor comprises: a pixel acquisition circuit array comprising a plurality of pixel acquisition circuits; a global control unit which is coupled with the pixel acquisition circuit array through a global reset signal line and is suitable for resetting the pixel acquisition circuit array when the image sensor is powered on; a global time signal generation unit which is coupled with the pixel acquisition circuit array through a global time signal line and is suitable for generating a global time signal representing time information; and a reading unit which is coupled with the pixel acquisition circuit array through a row selection line, a row event reset signal line, a column flag bit signal line and a column time signal line, and is suitable for reading event information of the event sequence generated by the pixel acquisition circuit array.

Owner:OMNIVISION SENSOR SOLUTION (SHANGHAI) CO LTD

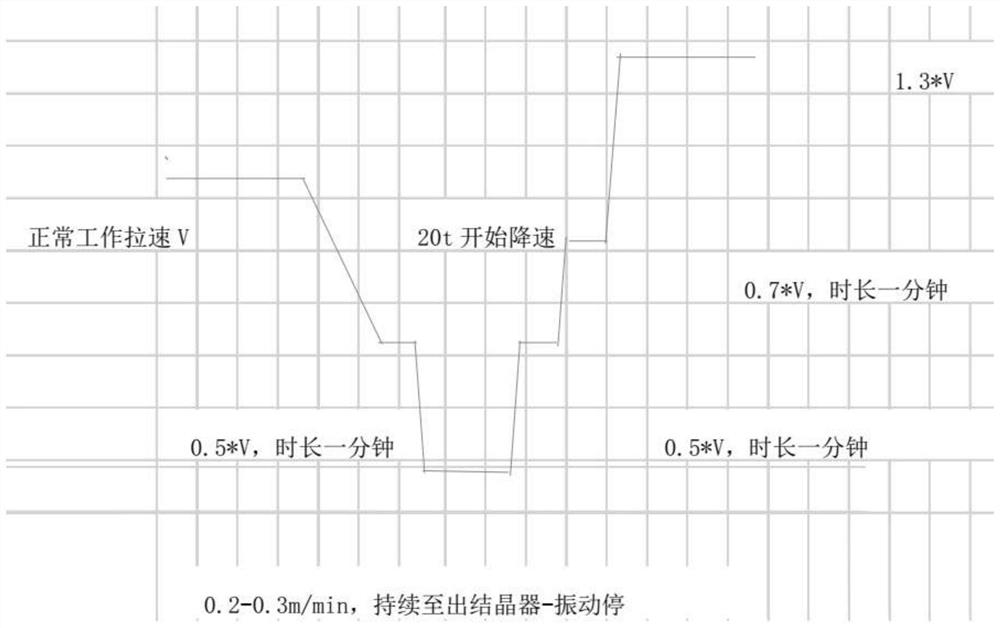

Process for safely and quickly ending continuous casting sheet billet

The invention discloses a process for safely and quickly ending a continuous casting sheet billet and relates to the technical field of steel production. The process comprises the following steps: S1, starting to gradually reduce the working pulling speed of a continuous casting machine when 20t of tundish remains; S2, before tundish pouring is finished, the working pulling speed of the continuous casting machine is reduced to 0.5 times of the normal working pulling speed; S3, after pouring of the tundish is finished, the working pulling speed of the continuous casting machine is reduced to 0.2-0.3 m / min according to the situation of the section of the sheet billet, and ending of the tail billet is started till the tail billet is discharged out of a crystallizer; S4, the pulling speed of the continuous casting machine is increased to 0.5 time of the normal working pulling speed for 1 min; S5, the pulling speed of the continuous casting machine is increased to 0.7 time of the normal working pulling speed for 1 min; and S6, the pulling speed of the continuous casting machine is increased to be larger than the normal working pulling speed till the tail billet comes out of a fan-shaped section, and the running out process is ended. The method effectively controls the tail billet steel overflowing when the continuous casting sheet billet is finished, shortens the running out process ending time, improves the productivity of the continuous casting machine, and reduces the safety risk of the running out process.

Owner:NANJING IRON & STEEL CO LTD

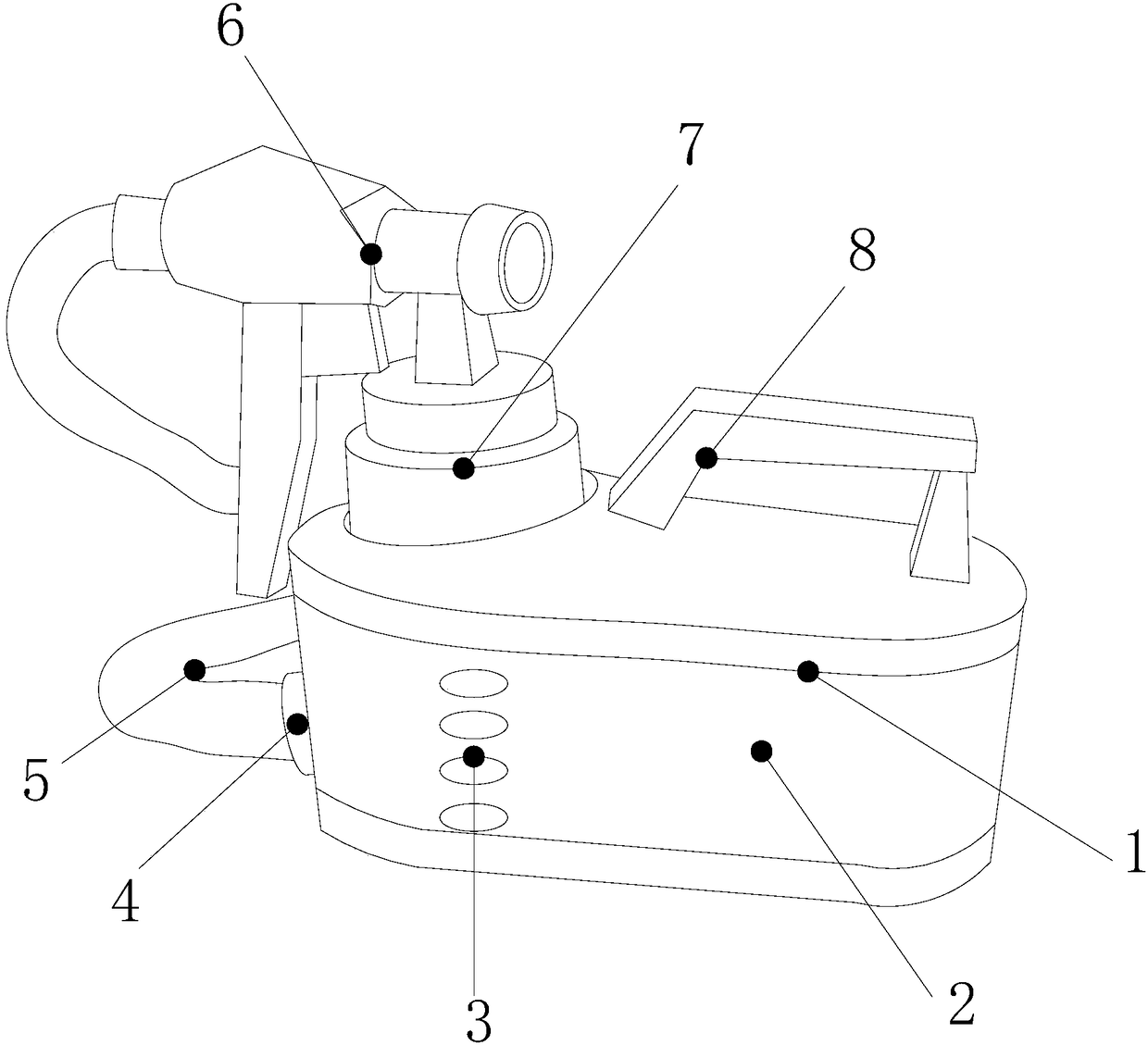

Efficient painting device for shipbuilding

InactiveCN108380415AImprove uniformityAvoid cloggingLiquid spraying apparatusPulp and paper industryTraffic volume

The invention discloses an efficient painting device for shipbuilding. The painting device structurally comprises a painting device, a machine body, heat dissipation ports, a connector, a connecting pipe, an injector head, a supporting frame and a lifting handle, wherein the painting device is arranged inside the machine body, the top of the right end of the machine body is welded to the bottom ofthe lifting handle, the heat dissipation ports are sequentially arranged on the front side of the left end of the machine body from top to bottom at equal intervals, the top of the left end of the machine body is perpendicularly connected to the bottom of the supporting frame, the right end of the connector is fixedly connected to the left end of the machine body, the bottom end of the connectingpipe is connected into the machine body through the connector, and the top end of the connecting pipe is fixedly connected to the left end of the injector head. The device has the advantages that paint can be stirred and filtered, the uniformity degree in the painting process can be improved, the injector head can be prevented from being blocked, meanwhile, the flow rate in the discharging process of the paint can be adjusted and controlled, meanwhile, the discharge amount of the paint is not too large, and therefore the situation that the interior of the device is vacuum can be avoided, andthe device can be more smooth in the spraying process.

Owner:李国珍

Cinnamon press-packing machine

The invention discloses a cinnamon press-packing machine and relates to the technical field of mechanical equipment manufacturing. The cinnamon press-packing machine comprises a machine frame, wherein hydraulic driving cylinders are respectively and correspondingly mounted on the machine frame in the front, back, left and right sides, and piston rods of the hydraulic driving cylinders are connected with pressing plates; a packing apparatus is mounted on top of the machine frame, and the packing apparatus is connected with a piston rod of a packing hydraulic driving cylinder fixedly mounted on the machine frame; a squeezing hydraulic driving cylinder is mounted at the bottom end of the machine frame which is over against the lower side of the packing apparatus, the piston rods of the hydraulic driving cylinders are connected with squeezing heads, and a feeding basket is arranged between the squeezing heads and the packing apparatus. The cinnamon press-packing machine can solve the problems that the cinnamon press-packing machine is high in maintenance cost, high in energy consumption and is low in production efficiency.

Owner:广西京桂香料有限公司

Plant for the production of warp-knitted goods and method for controlling a facility for producing warp-knitted goods

ActiveCN107400979AReduce consumptionSave energyProgramme controlWarp knittingTime rangeProcess engineering

The invention relates to a plant (1) for producing warp knit goods comprising at least one warp knitting machine (2, 3) and a production management device (4) having a parameter input device (5) for inputting product data. It would like to enable an economical operation of such a system. For this purpose, it is provided that the parameter input device (5) has means for inputting a time range, wherein the production management device (4) sets at least one operating parameter of the warp knitting machine (2, 3), taking into account the product data and the time range, so that the energy consumption is minimal.

Owner:KARL MAYER STOLL R&D GMBH

Bottle processing system

ActiveUS8251201B2Maintain working speedMaintain speedSynchronising machinesConveyorsEngineeringBottle

The invention relates to a device and a method of processing containers. Herein, a processing system is used in which all of the processing units for the containers are kinematically rigidly coupled to one another. According to the invention, a specified number of containers is supplied to the first processing unit of the system and the working speed of the system is reduced after the last container has left the first processing unit and before the specified number of the first containers has reached the second processing unit.

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com