Tree section peeling device

A technology for trees and wood segments, applied in the field of tree segment peeling devices, can solve problems such as reduced work efficiency, increased pits on the surface of wood segments, and inability to adjust rotors, and achieves the effects of reducing peeling force and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

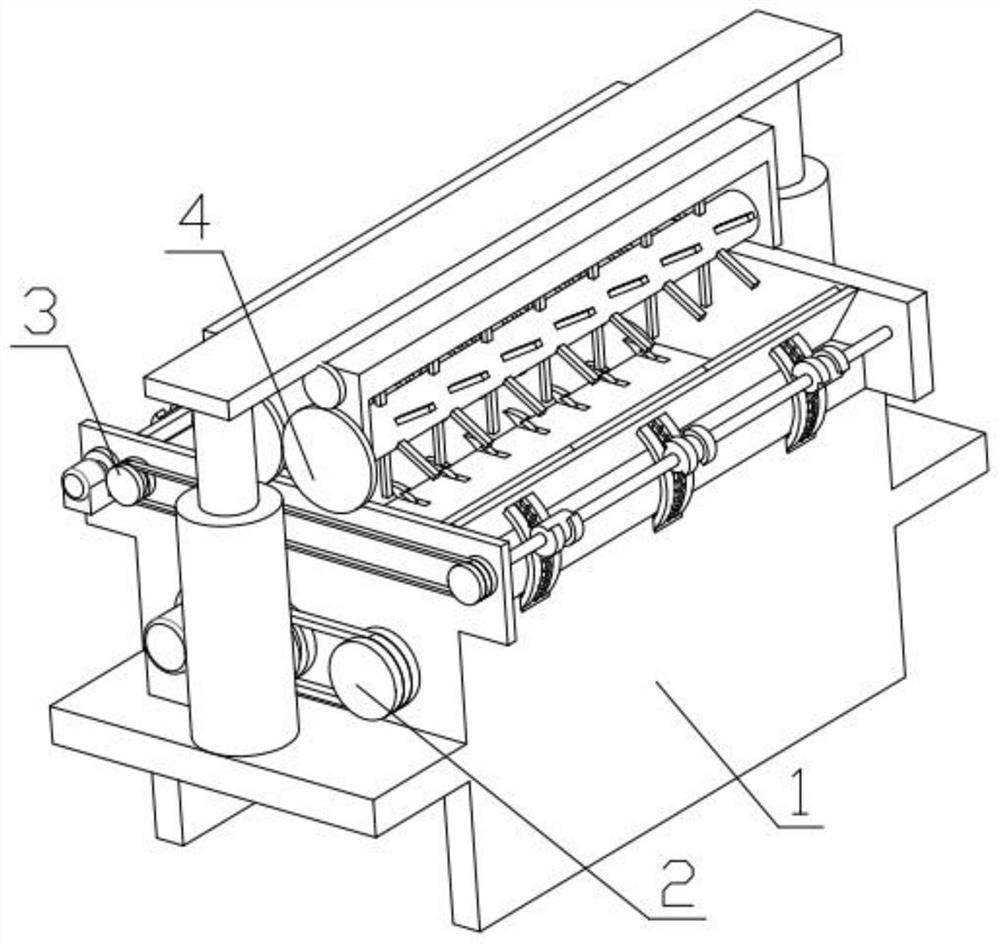

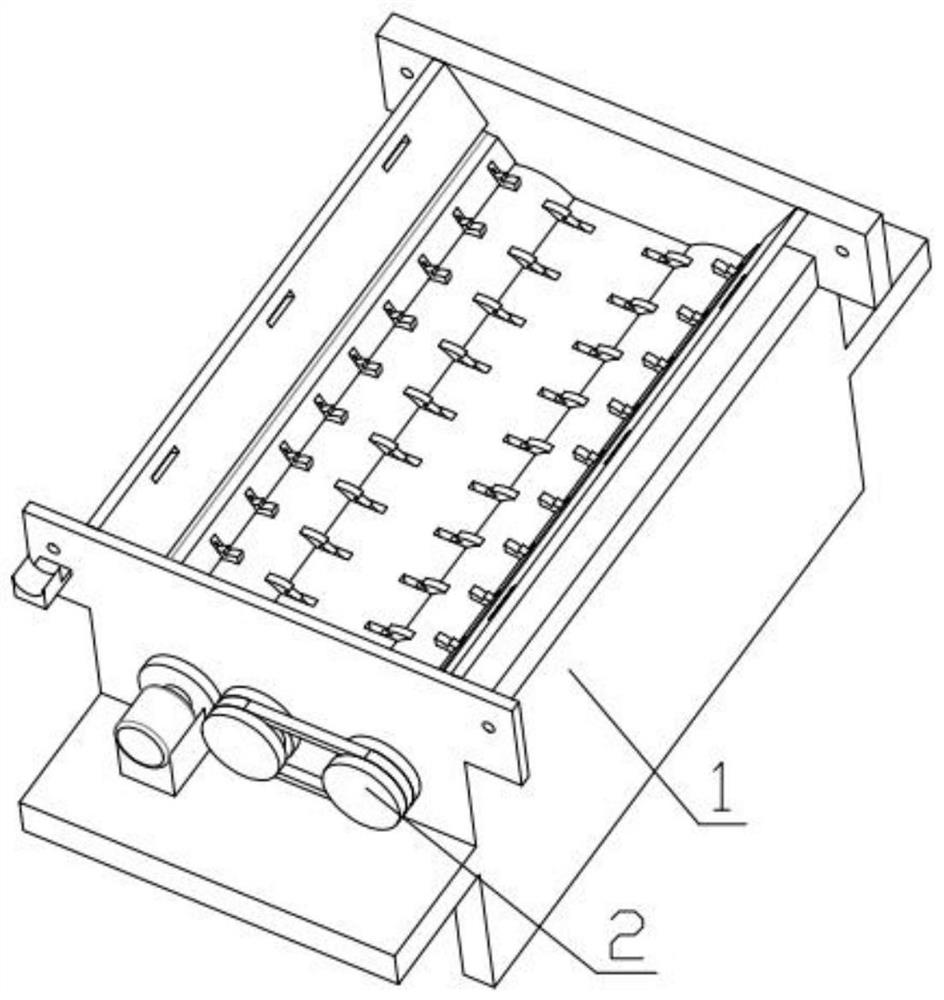

[0036] Combine below Figure 1-12 Description of this embodiment, a tree section peeling device, including a device box 1, a peeling mechanism 2, a wood section alignment mechanism 3 and an auxiliary rolling mechanism 4, the described stripping mechanism 2 is fixedly installed on the device box 1, and the wood section The alignment mechanism 3 is fixedly installed on the device box body 1 , and the auxiliary rolling mechanism 4 is fixedly installed on the device box body 1 .

specific Embodiment approach 2

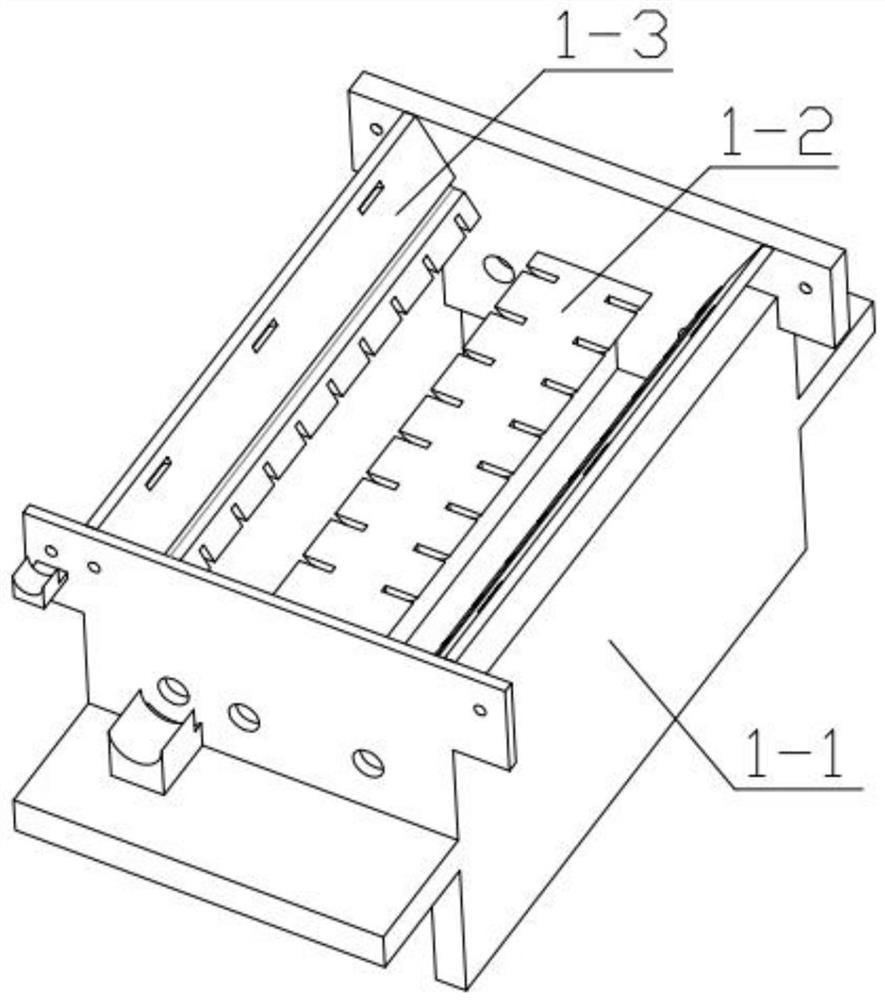

[0038] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the device box 1 includes a box body 1-1, a middle T-shaped plate 1-2, side baffles 1-3, the box body 1- 1 is fixedly installed with a middle T-shaped plate 1-2, and a side baffle 1-3 is fixedly installed on the box body 1-1;

[0039] The middle T-shaped plate 1-2 includes a T-shaped groove plate 1-2-1, a fixed horizontal plate 1-2-2, a limit column 1-2-3, an adjusting threaded rod 1-2-4, and a fixed horizontal plate 1 -2-2 is fixedly installed on the box body 1-1, and the limit post 1-2-3 is fixedly installed on the similar T-shaped slot plate 1-2-1, and the limit post 1-2-3 is slidably installed on the fixed horizontal In the through hole set on the plate 1-2-2, the adjusting threaded rod 1-2-4 is rotatably installed in the groove set on the T-shaped groove plate 1-2-1, and the adjusting threaded rod 1-2-4 is connected with the Fixed horizontal plate 1-2-2 t...

specific Embodiment approach 3

[0041] Combine below Figure 1-12 Illustrate this embodiment, this embodiment will further illustrate Embodiment 2, described peeling mechanism 2 comprises main motor 2-1, motor gear 2-2, first sprocket wheel 2-3, chain one 2-4, the first Two sprockets 2-5, one peeling shaft 2-6, two peeling shafts 2-7, the main motor 2-1 is fixedly installed on the box main body 1-1, and the output end of the main motor 2-1 is fixedly installed with motor gears 2-2, the motor gear 2-2 is fixedly connected with the peeling shaft one 2-6, the peeling shaft one 2-6 is rotatably installed in the groove provided on the box body 1-1, and the peeling shaft two 2-7 is rotatably installed in the In the groove provided on the casing main body 1-1, the peeling shaft two 2-7 is fixedly connected with the second sprocket wheel 2-5, and the second sprocket wheel 2-5 is meshed with the chain one 2-4, and the chain one 2- 4 Mesh with the first sprocket 2-3, the first sprocket 2-3 meshes with the motor gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com