Plant for the production of warp-knitted goods and method for controlling a facility for producing warp-knitted goods

A technology of warp knitted fabrics and equipment, which is applied in the field of equipment for manufacturing warp knitted fabrics, and can solve the problems of not being fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

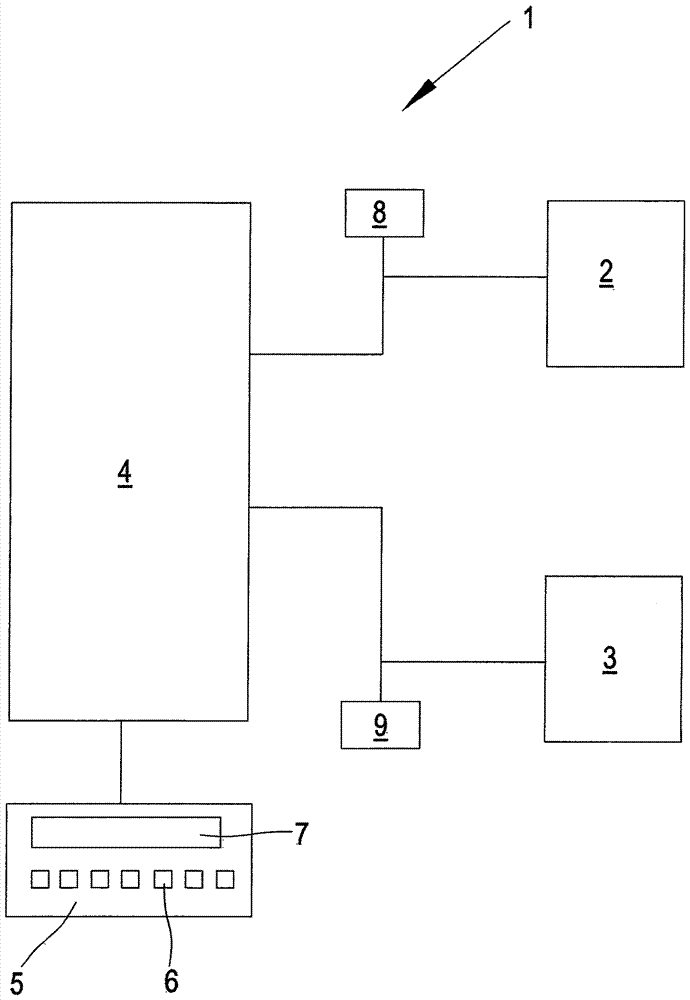

[0021] The installation 1 schematically shown in the drawing for the production of warp knitted fabrics has two warp knitting machines 2 , 3 which are connected to a common production management device 4 . The production management device 4 has a parameter input device 5 . The parameter input device 5 can also be a component of the production management device 4 . The parameter input device 5 has a plurality of keys 6 and a display 7 . The production management device 4 can also be arranged on one of the warp knitting machines 2 , 3 .

[0022] For example, product data can be entered via the parameter input device 5 , ie data defining, for example, the desired length of the warp knitted fabric to be produced. Furthermore, it is also possible with the parameter input device to input a time range available for the production of warp knitted fabrics.

[0023] The production management device 4 has a memory device 8 , 9 for each warp knitting machine 2 , 3 , in which operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com