High power twister

A technology of yarn guiding device and package, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of increased energy consumption, high yarn tension, and large moment of inertia, etc., and achieves easy manufacturing and installation, low yarn tension, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

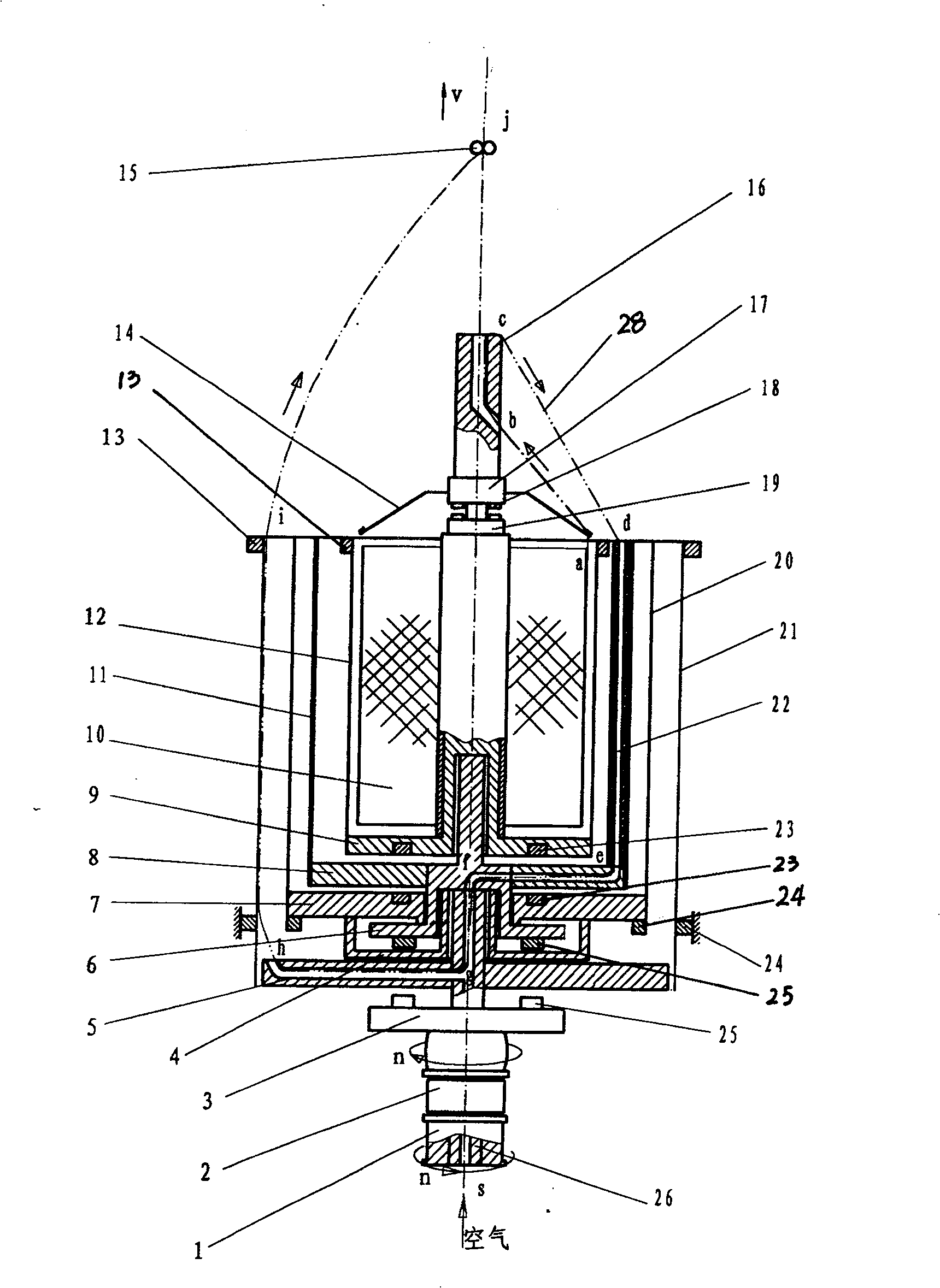

Embodiment 1

[0041] Such as figure 1 As shown, the high-power twisting device consists of a lower pulley 1, a support beam 2, an inner spindle drive plate 3, a static support sleeve 4, an outer spindle plate 5, an upper rotary magnet seat spindle rod 6, a static support seat 7, and an upper rotary Spindle disk 8, package support member 9, package 10, middle spindle cylinder 11, inner spindle cylinder 12, upper fixed magnet 13, yarn withdrawal frame 14, yarn guide hook 15, spindle end yarn guide rod and yarn guide nozzle 16, Upper tension ring 17, tension adjustment magnet 18, lower tension ring 19, middle spindle cylinder 20, outer spindle cylinder 21, yarn feeding guide 22, package fixed magnet 23, lower fixed magnet 24, driving magnet 25, and lower spindle rod 26 . It is divided into an outer spindle device, an intermediate spindle device, an inner spindle device, a supporting package mechanism, a yarn withdrawal guide device, and an outer spindle cylinder mechanism.

[0042] The outer...

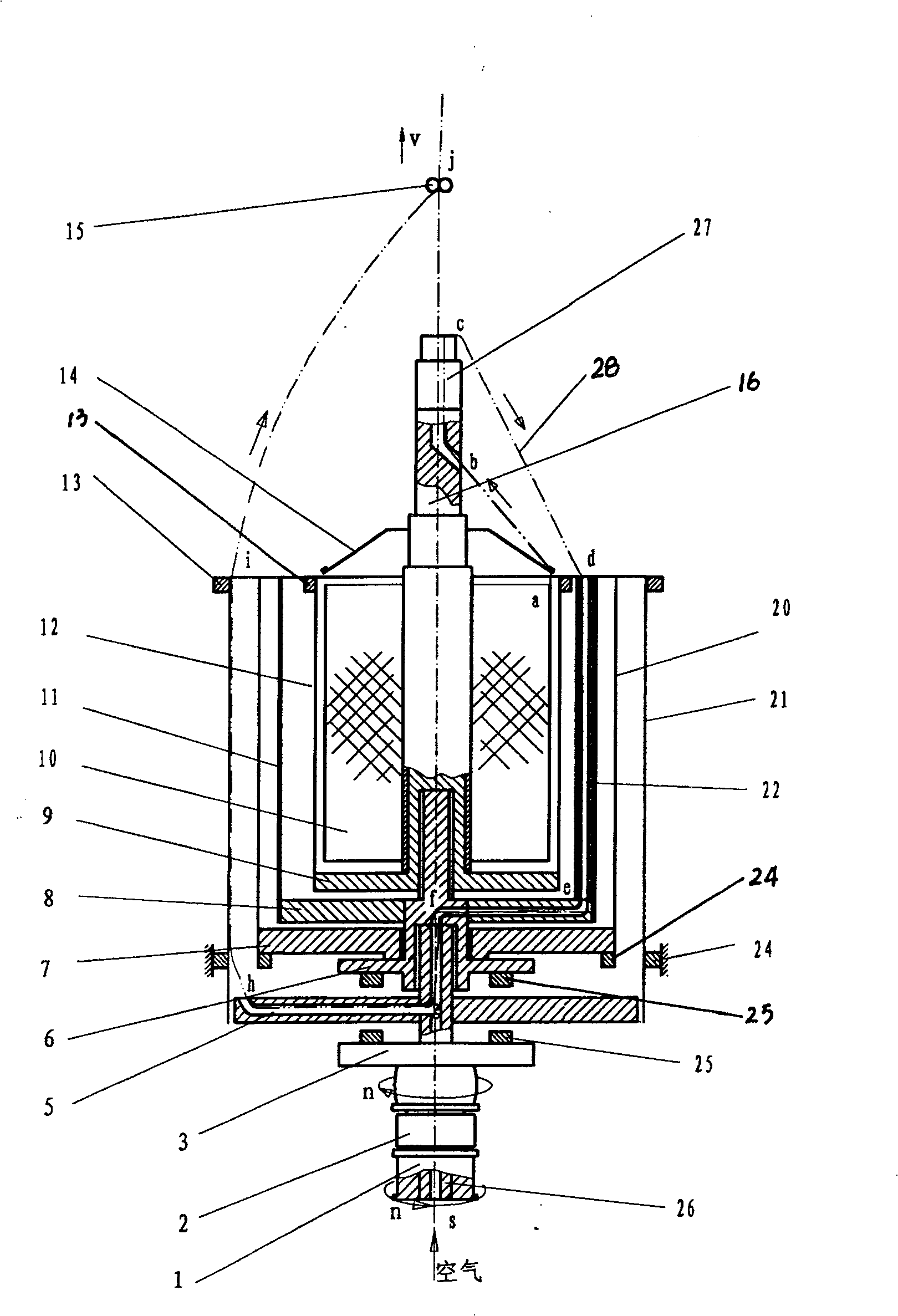

Embodiment 2

[0051] Such as figure 2 As shown, the high-power twisting device consists of a lower pulley 1, a support beam 2, an inner spindle drive disk 3, an outer spindle disk 5, an upper rotary magnet seat spindle rod 6, a static support seat 7, an upper rotary spindle disk 8, a coil Mounting support 9, package 10, intermediate spindle cylinder 11, inner spindle cylinder 12, upper fixed magnet 13, yarn withdrawal frame 14, yarn guide hook 15, spindle end yarn guide rod and yarn guide nozzle 16, intermediate spindle cylinder 20, The outer spindle cylinder 21, the yarn feeding guide 22, the lower fixed magnet 24, the drive magnet 25, the lower spindle rod 26, and the spring tensioner 27 are composed.

[0052] This embodiment is basically the same as Embodiment 1, except that: 1. This embodiment has no static support sleeve 4, and the upper rotary magnet seat spindle rod 6 is directly connected with the upper end of the lower spindle rod 26 by a bearing; 2. This embodiment For example, ...

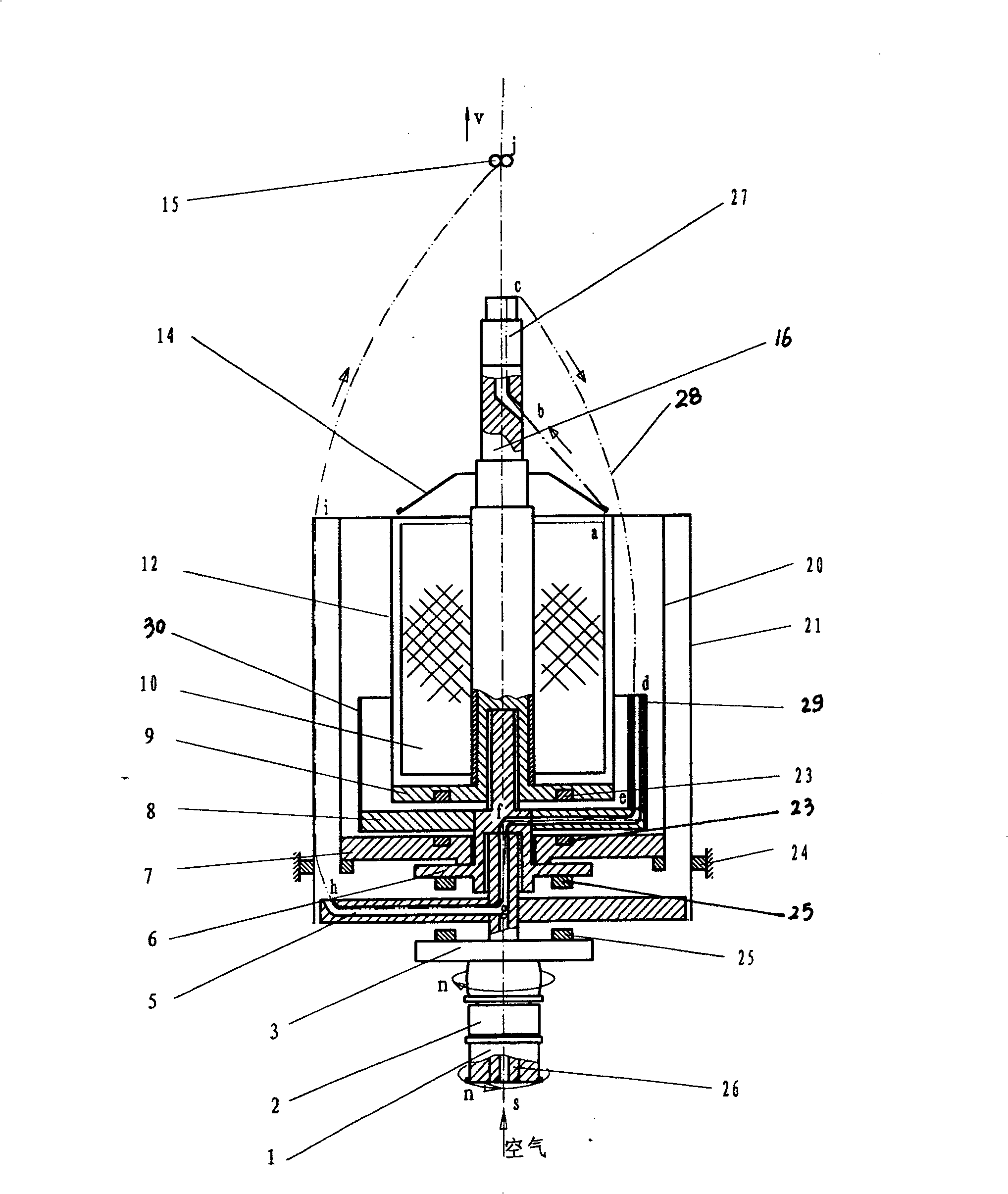

Embodiment 3

[0055] High-power twisting device, which consists of lower pulley 1, support beam 2, inner spindle drive disk 3, outer spindle disk 5, upper rotary magnet seat spindle rod 6, static support seat 7, upper rotary spindle disk 8, and coil support 9. Package 10, inner spindle cylinder 12, yarn return frame 14, yarn guide hook 15, spindle end yarn guide rod and yarn guide nozzle 16, intermediate spindle cylinder 20, outer spindle cylinder 21, yarn feeding guide tube 22, package fixation Composed of magnet 23, lower fixed magnet 24, driving magnet 25, lower spindle bar 26, spring tensioner 27, short yarn feed guide 29, and short intermediate cylinder 30,

[0056]This embodiment is basically the same as Embodiment 1, except that: 1. This embodiment has no static support sleeve 4, and the upper rotary magnet seat spindle rod 6 is directly connected with the upper end of the lower spindle rod 26 by a bearing; 2. Embodiment 1. The high intermediate spindle tube 11 and the yarn feed guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com