Process for safely and quickly ending continuous casting sheet billet

A slab and safety technology, which is applied in the field of continuous casting slab safe and fast finishing technology, can solve the problems of affecting the working efficiency of the continuous casting machine, increasing the production cost, and affecting the production safety, etc., so as to reduce the intensity of the secondary cooling water, The effect of slowing down the shrinkage speed and reducing the extrusion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

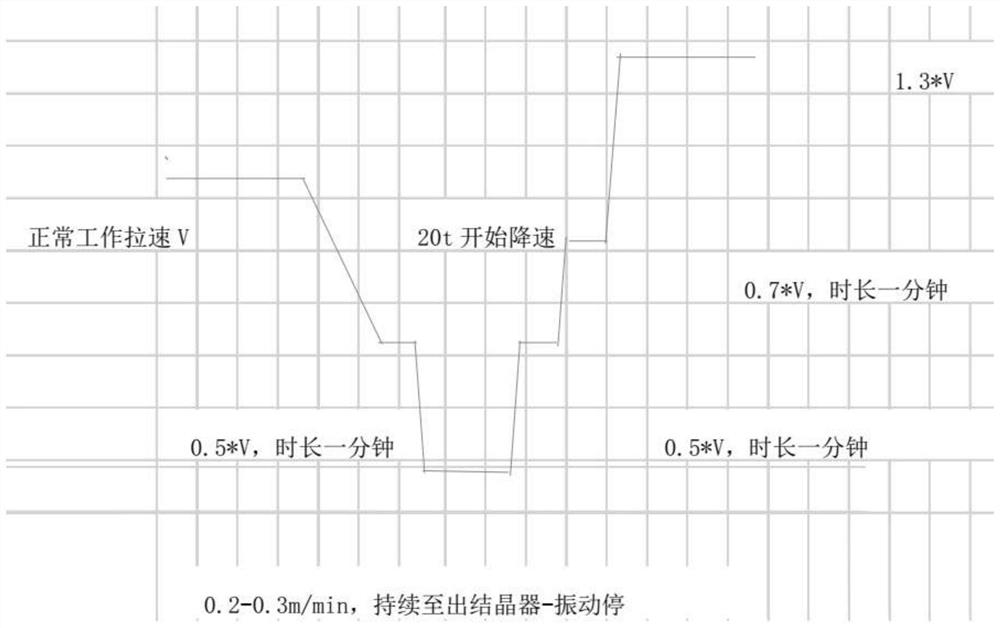

[0023] This embodiment provides a continuous casting slab safe and fast finishing process. The section of the continuous casting machine casting slab is 180*2500mm, and the normal casting speed is 1.2m / min, including the following steps:

[0024] S1. When the remaining tundish is 20t, gradually reduce the working speed of the continuous casting machine;

[0025] S2. Reduce the working casting speed of the continuous casting machine to 0.6m / min 1 minute before the end of the tundish pouring;

[0026] S3. After the casting of the tundish is finished, reduce the working casting speed of the continuous casting machine to 0.3m / min to start finishing the billet, and continue until the tail billet exits the mold;

[0027] S4, increase the casting speed of the continuous casting machine to 0.6m / min for 1min;

[0028] S5, increase the casting speed of the continuous casting machine to 0.85m / min for 1min;

[0029] S6. Increase the casting speed of the continuous casting machine to 1.8...

Embodiment 2

[0031] This embodiment provides a continuous casting slab safe and fast finishing process. The section of the continuous casting machine casting slab is 260*2570mm, and the normal casting speed is 0.85m / min, including the following steps:

[0032] S1. When the remaining tundish is 20t, gradually reduce the working speed of the continuous casting machine;

[0033] S2. Reduce the working casting speed of the continuous casting machine to 0.45m / min 1 minute before the end of the tundish pouring;

[0034] S3. After the tundish pouring is completed, reduce the casting speed of the continuous casting machine to 0.2m / min to start finishing the billet, and continue until the tail billet exits the mold;

[0035] S4, increase the casting speed of the continuous casting machine to 0.45m / min for 1min;

[0036] S5, increase the casting speed of the continuous casting machine to 0.6m / min for 1min;

[0037] S6. Increase the casting speed of the continuous casting machine to 1.25m / min accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com