Patents

Literature

755 results about "Iron production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

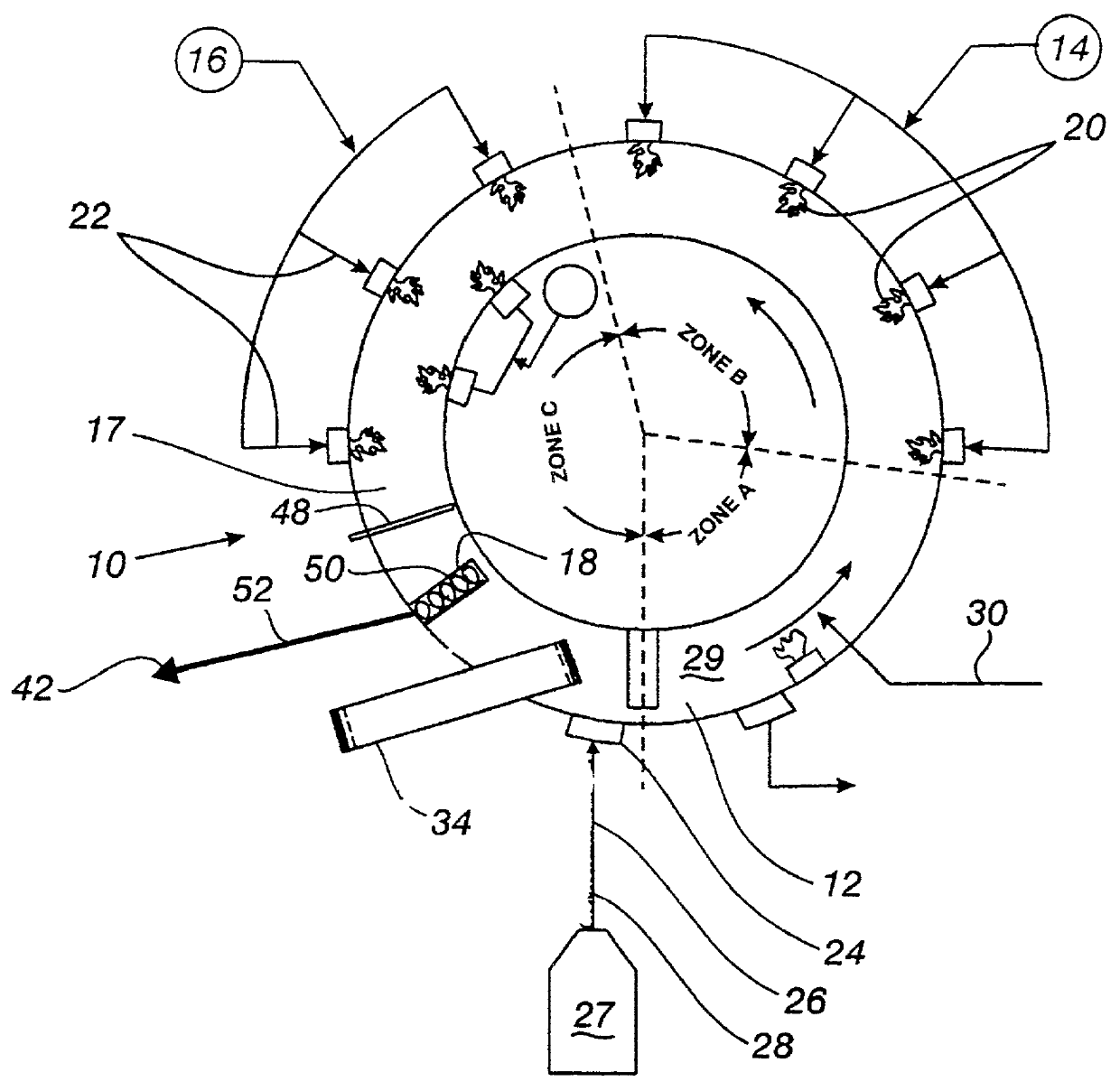

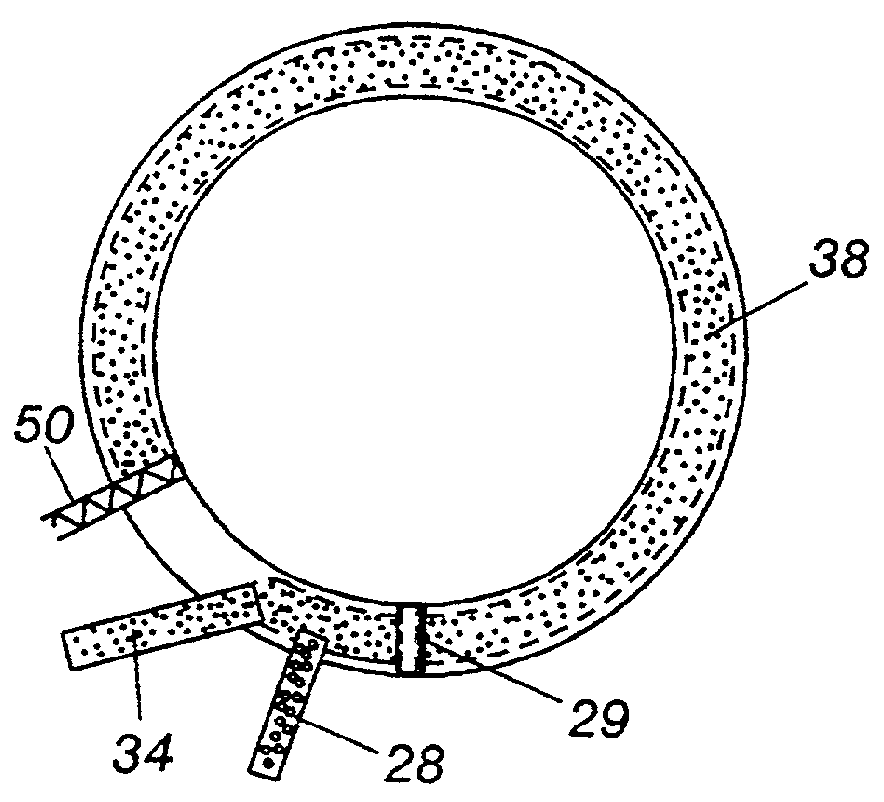

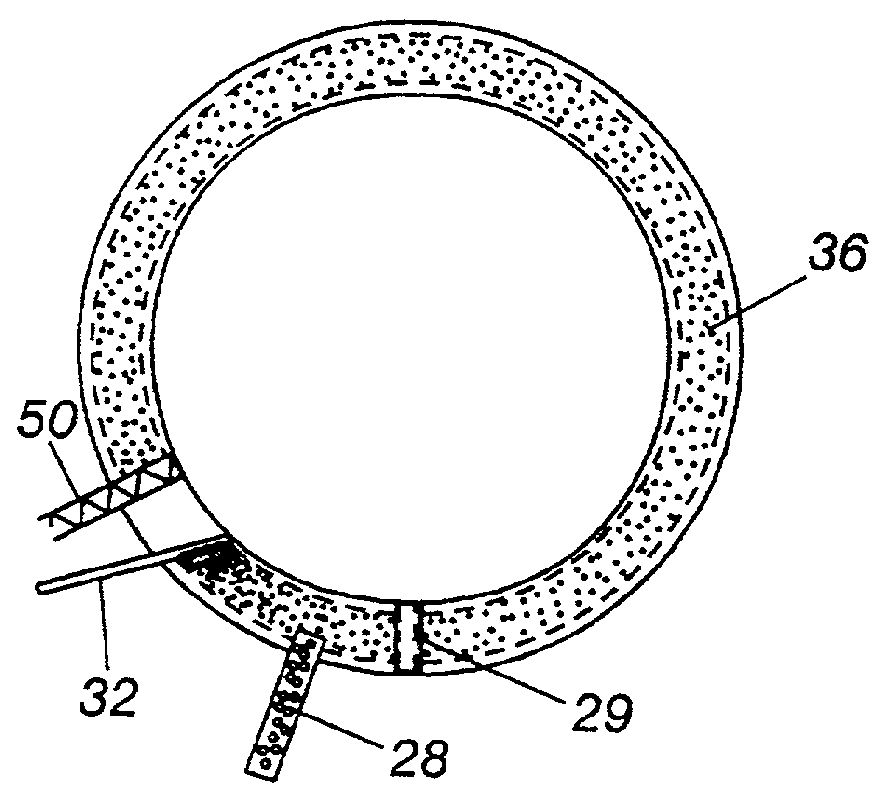

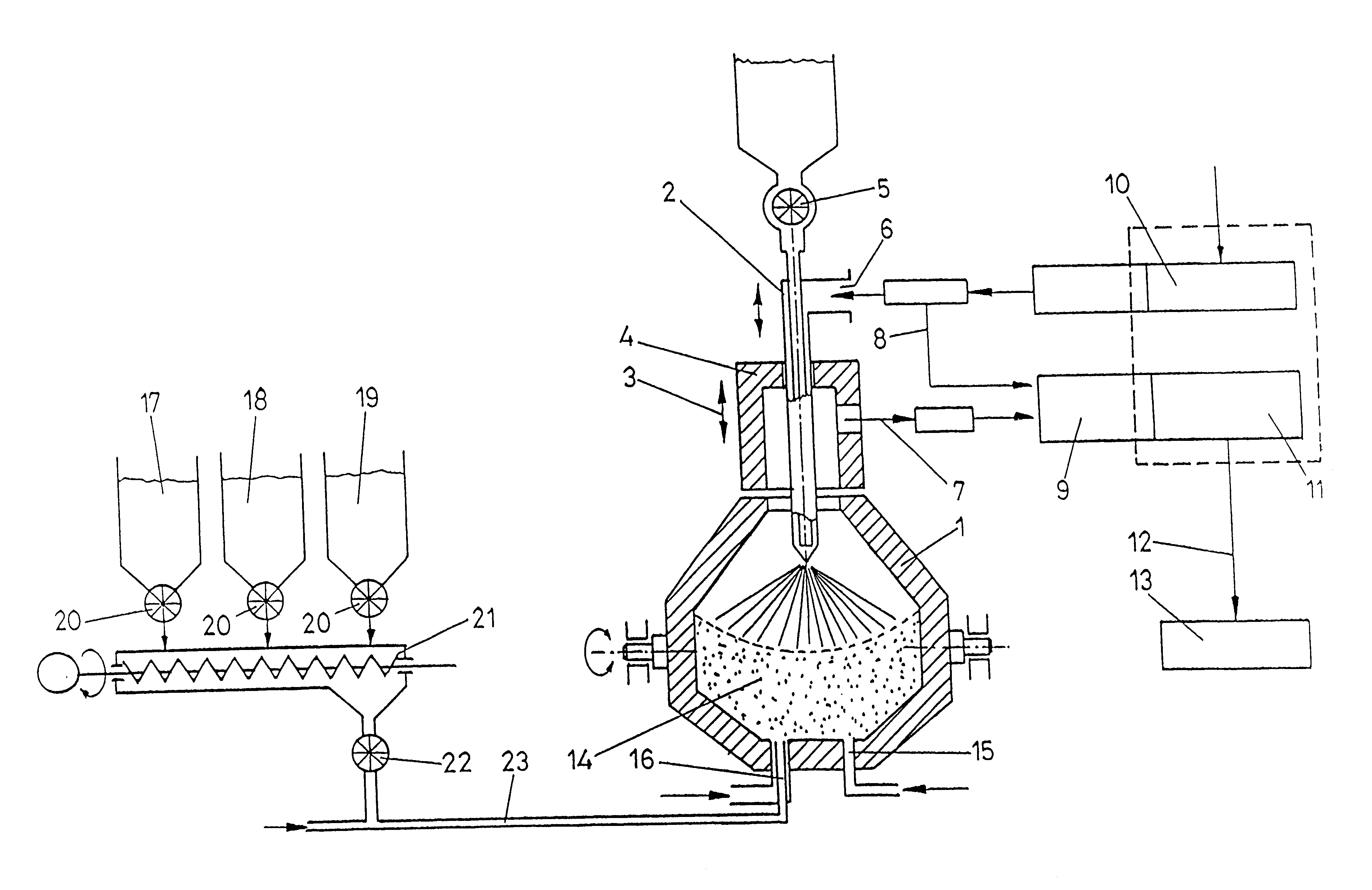

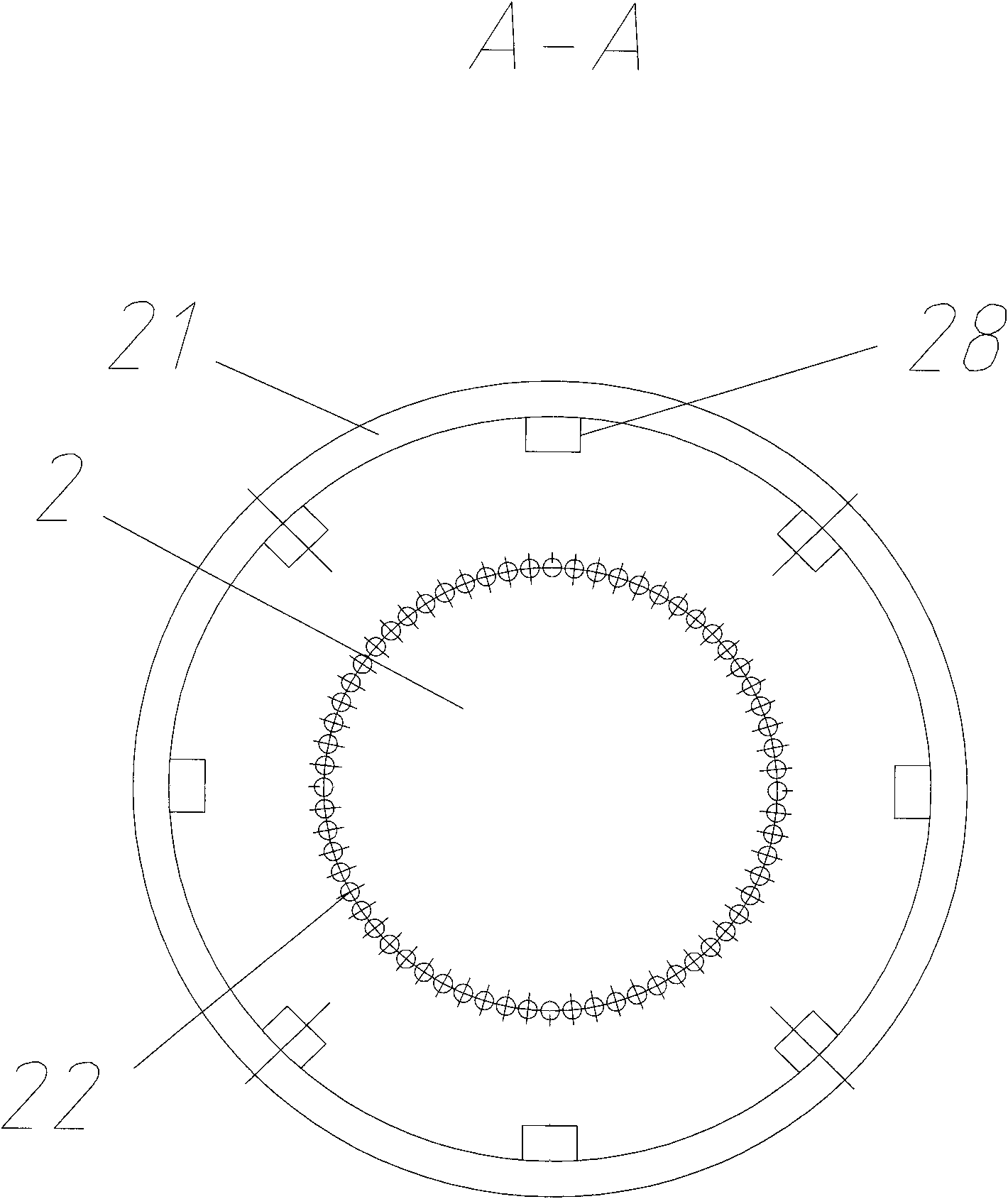

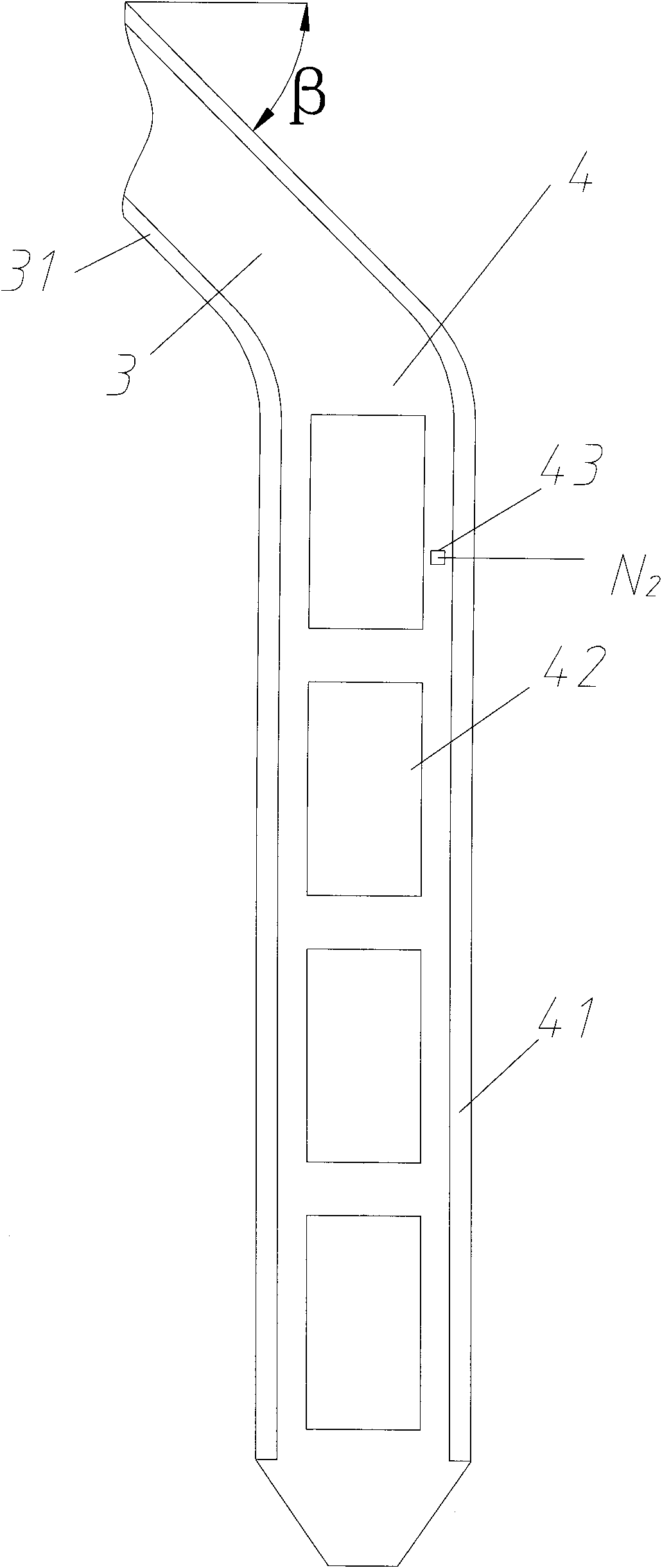

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

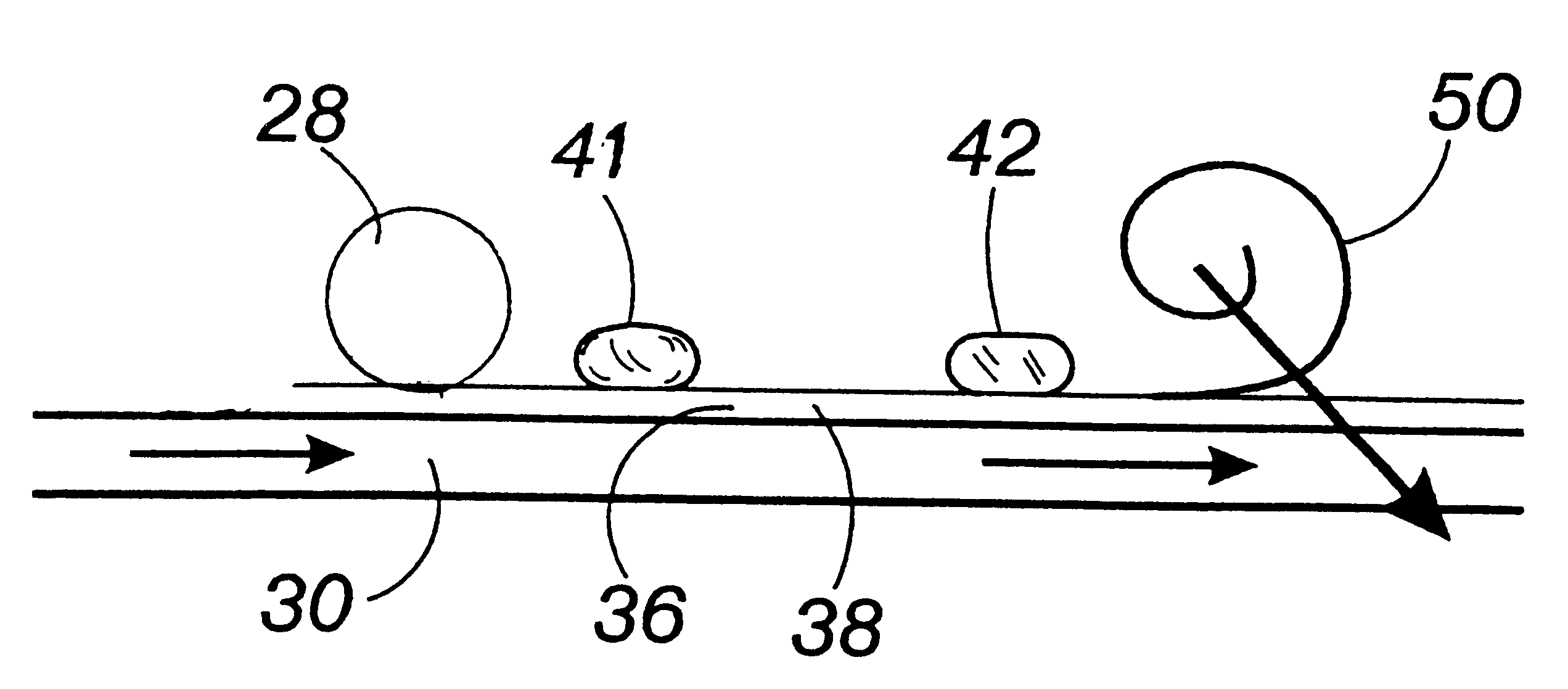

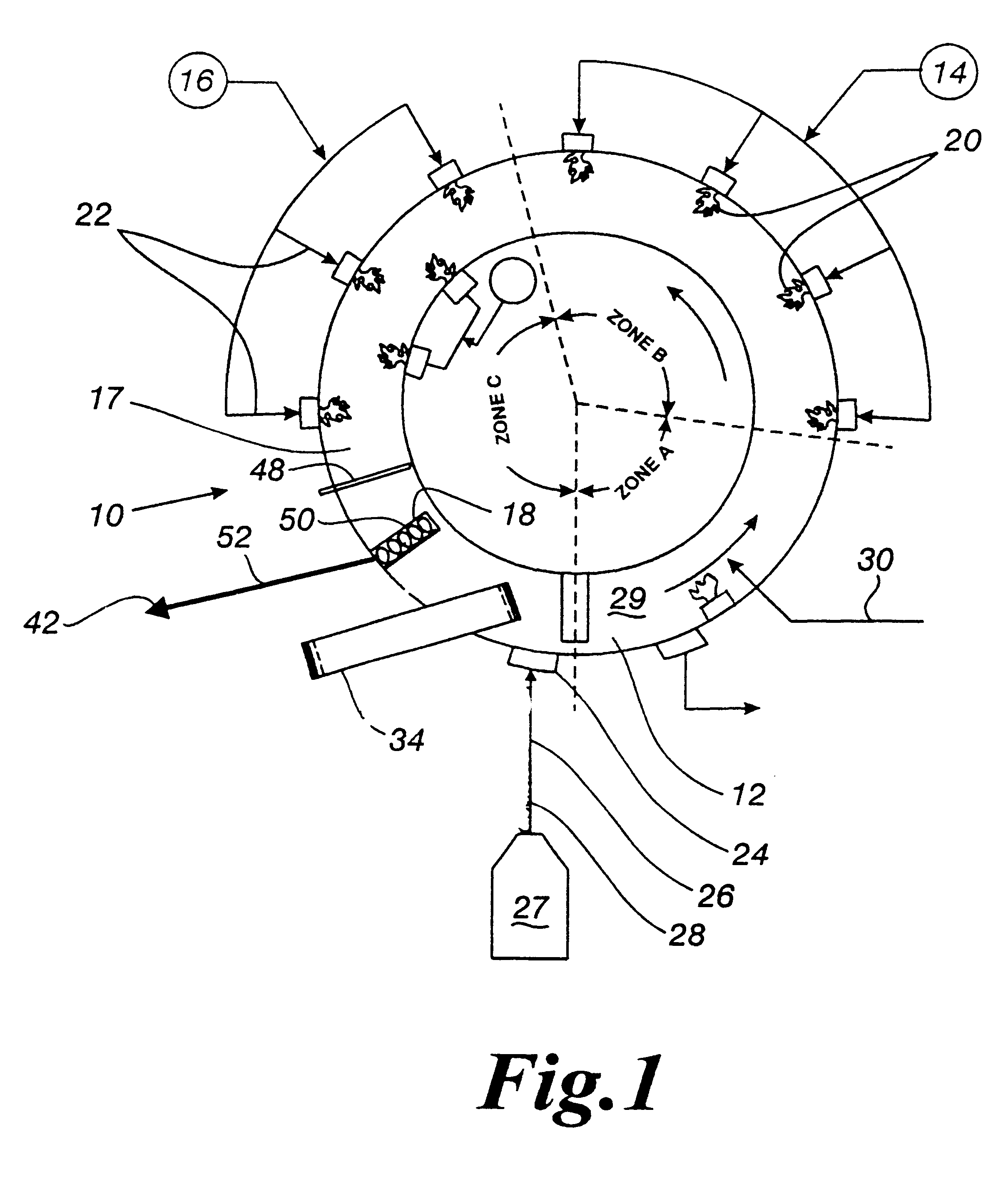

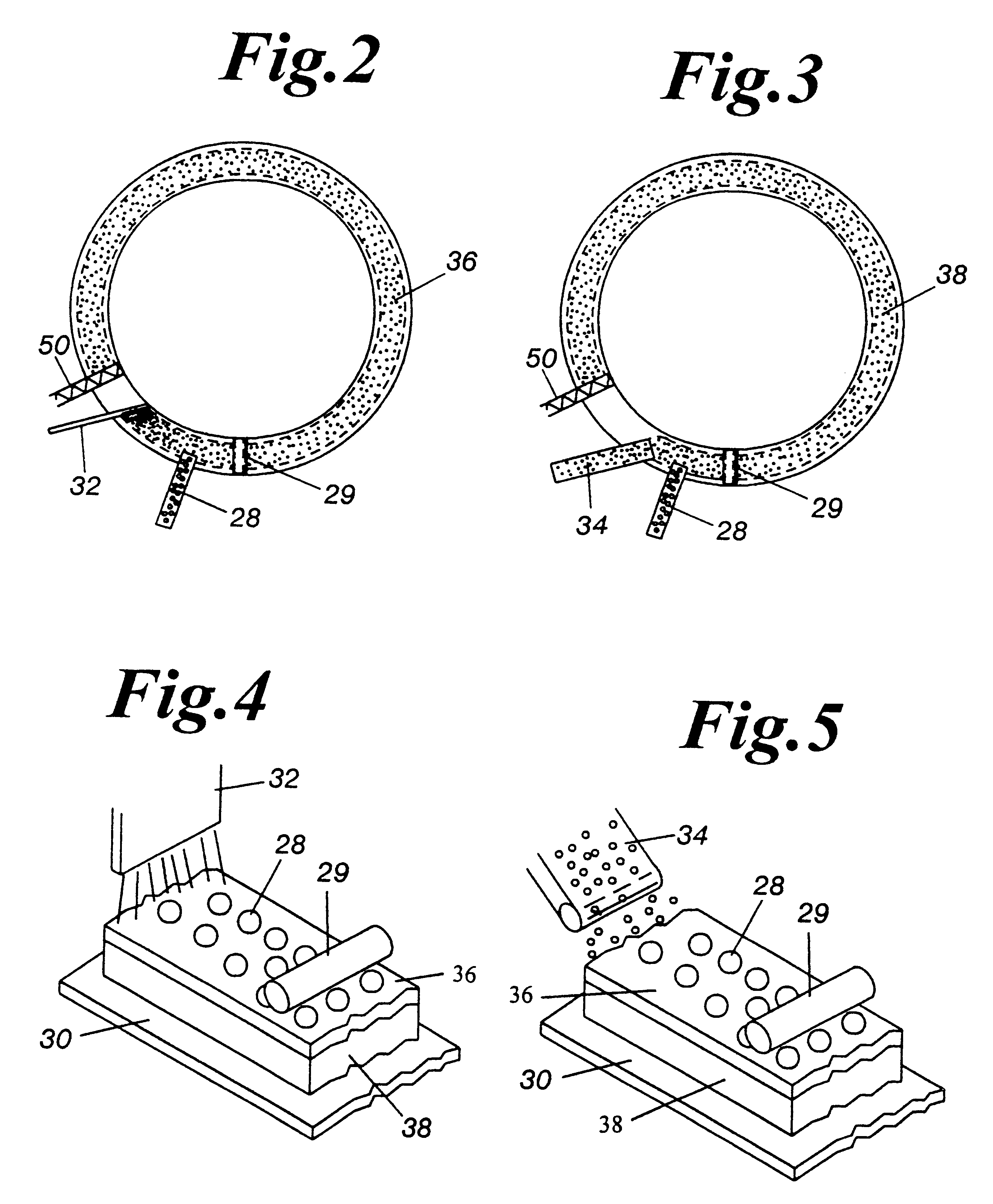

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

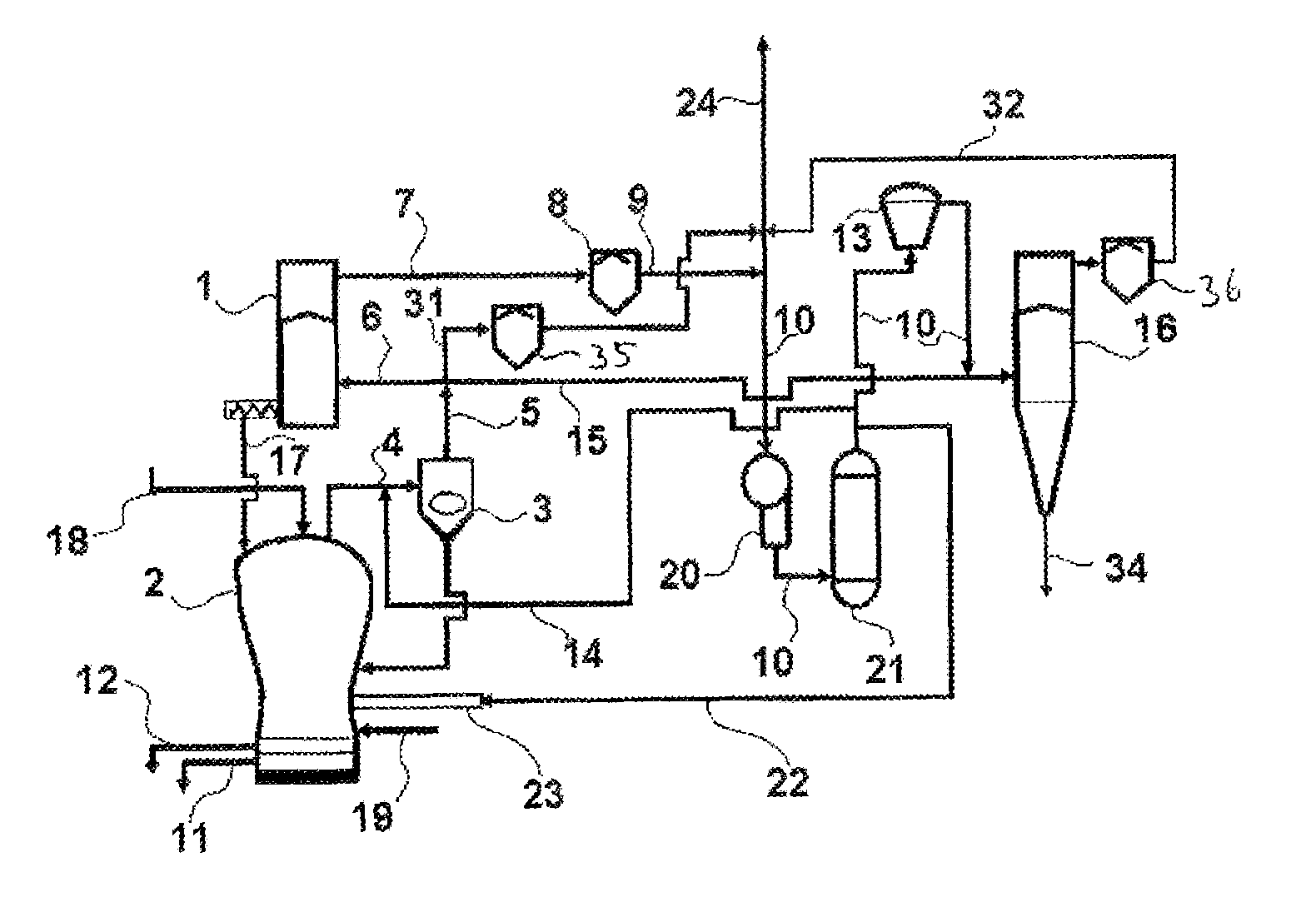

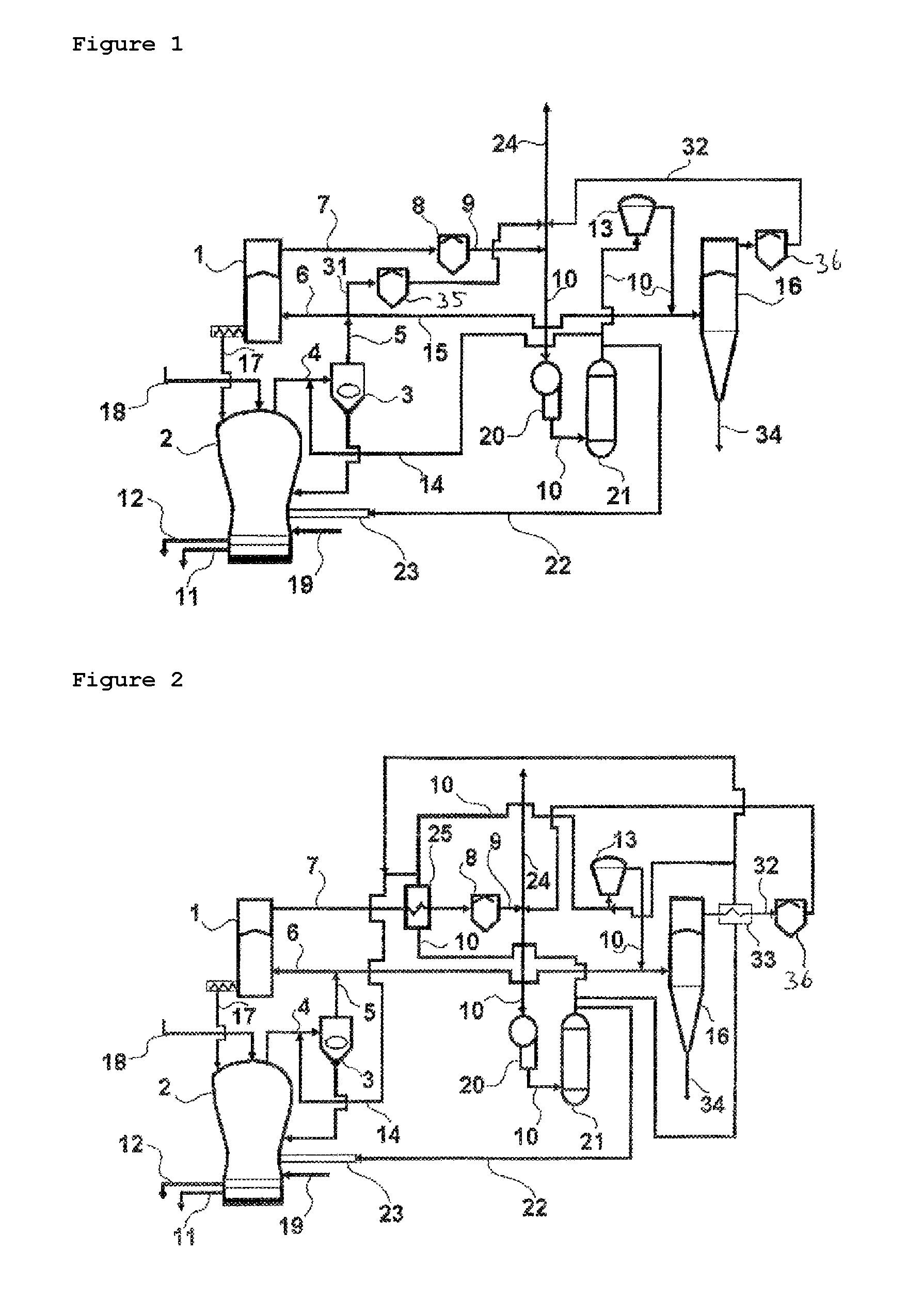

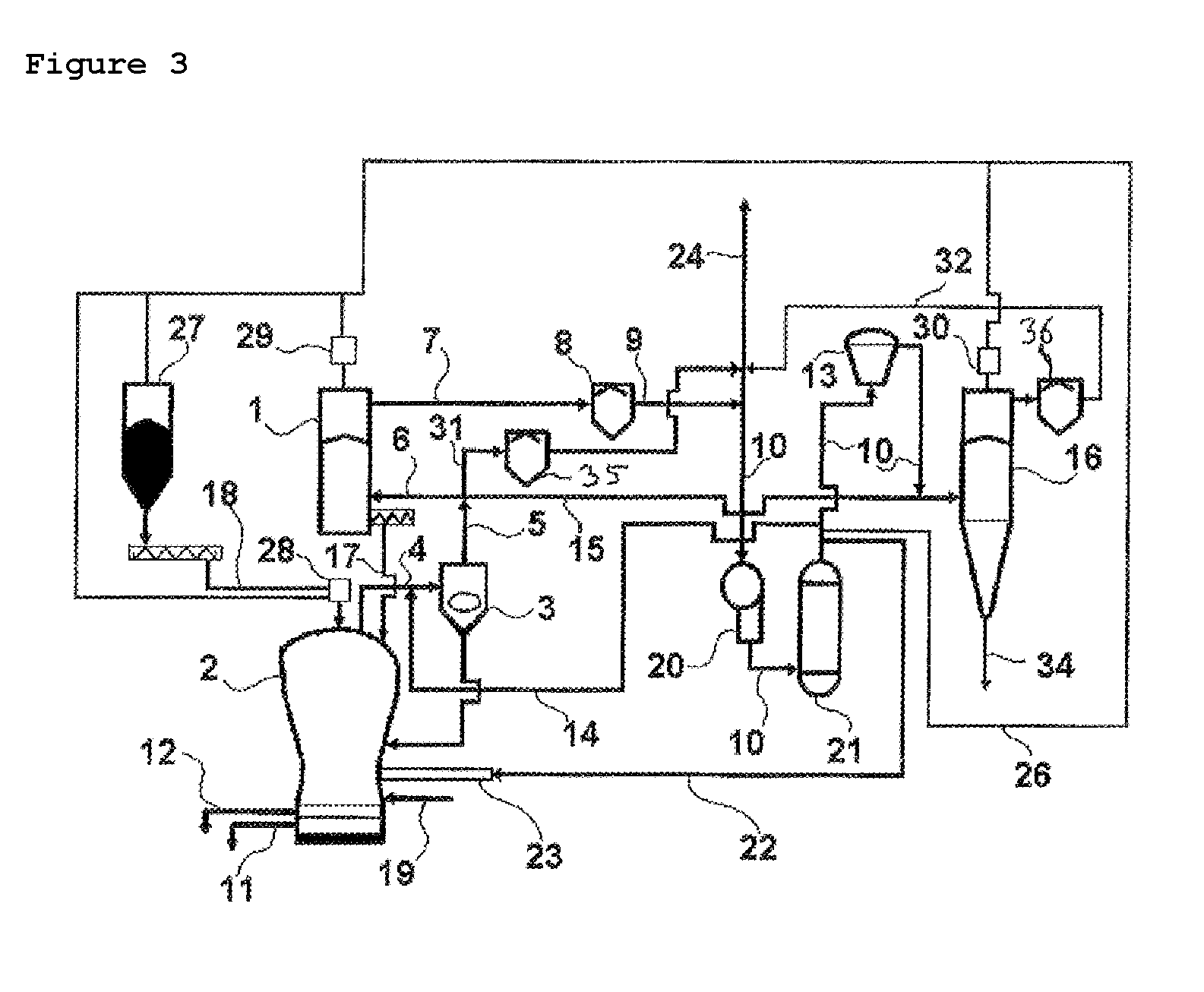

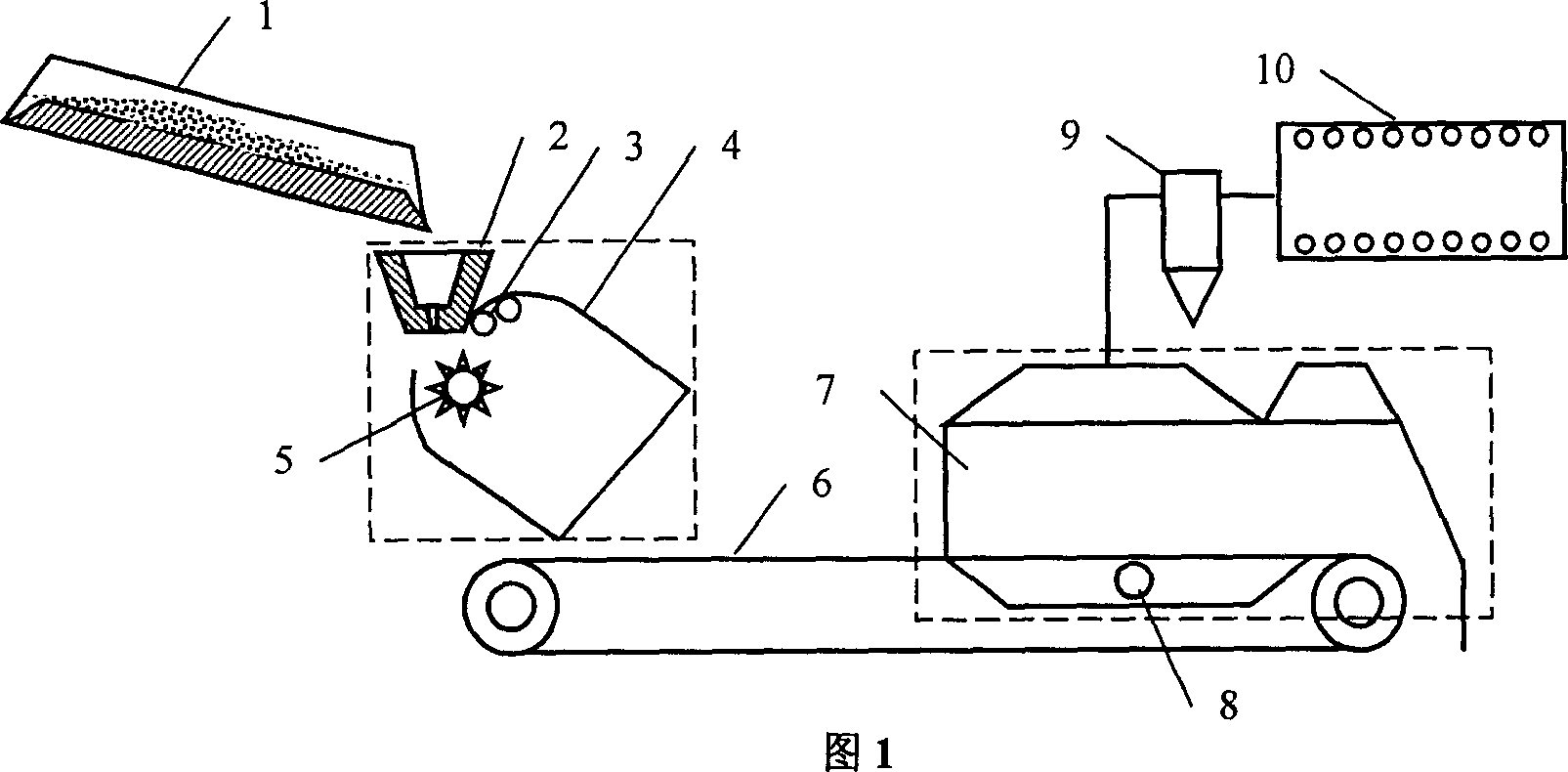

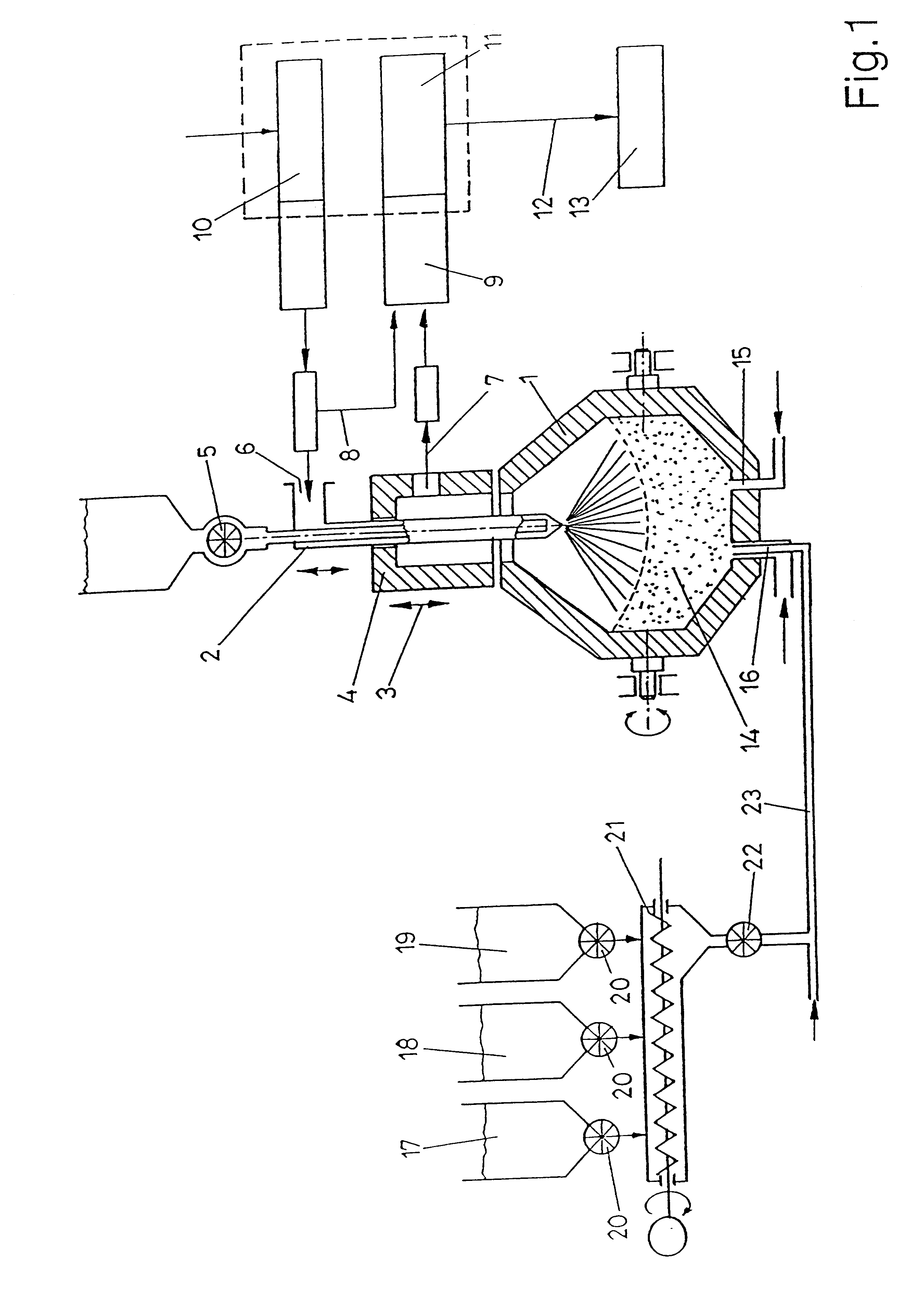

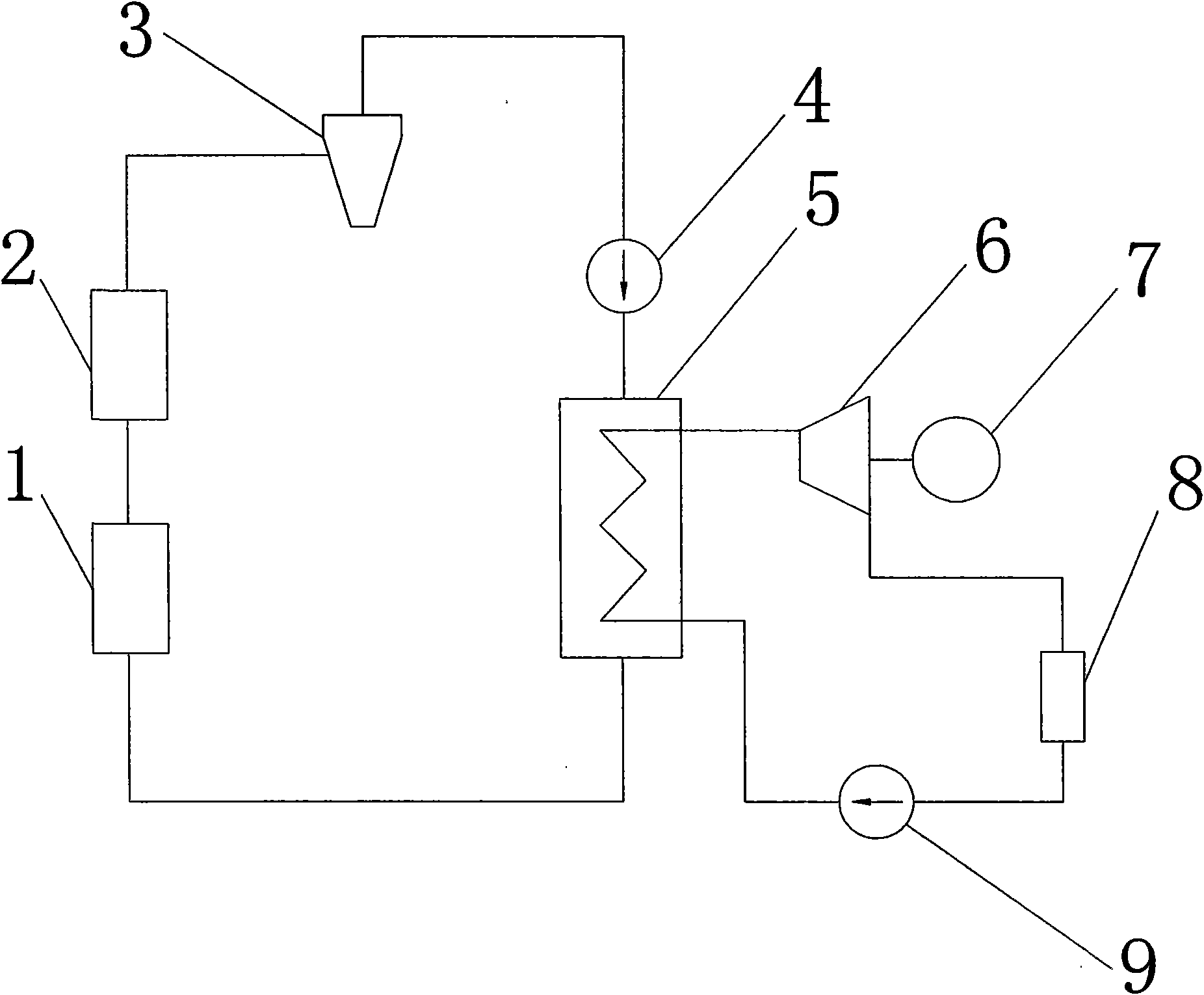

Method and system for energy-optimized and CO2 emission-optimized iron production

InactiveUS8419825B2Emission reductionIncrease profitBlast furnace detailsExhaust gas handlingProcess engineeringProduct gas

A process for energy- and emission-optimized iron production and an installation for carrying out the process. A first partial amount of a generator gas produced in a melter gasifier is used as a first reducing gas in a first reduction zone. A second partial amount is fed to at least one further reduction zone as a second reducing gas. In addition, after CO2 scrubbing, a partial amount of top gas removed from the first reduction zone is admixed with the generator gas after the latter leaves the melter gasifier, for cooling the generator gas.

Owner:PRIMETALS TECH AUSTRIA GMBH

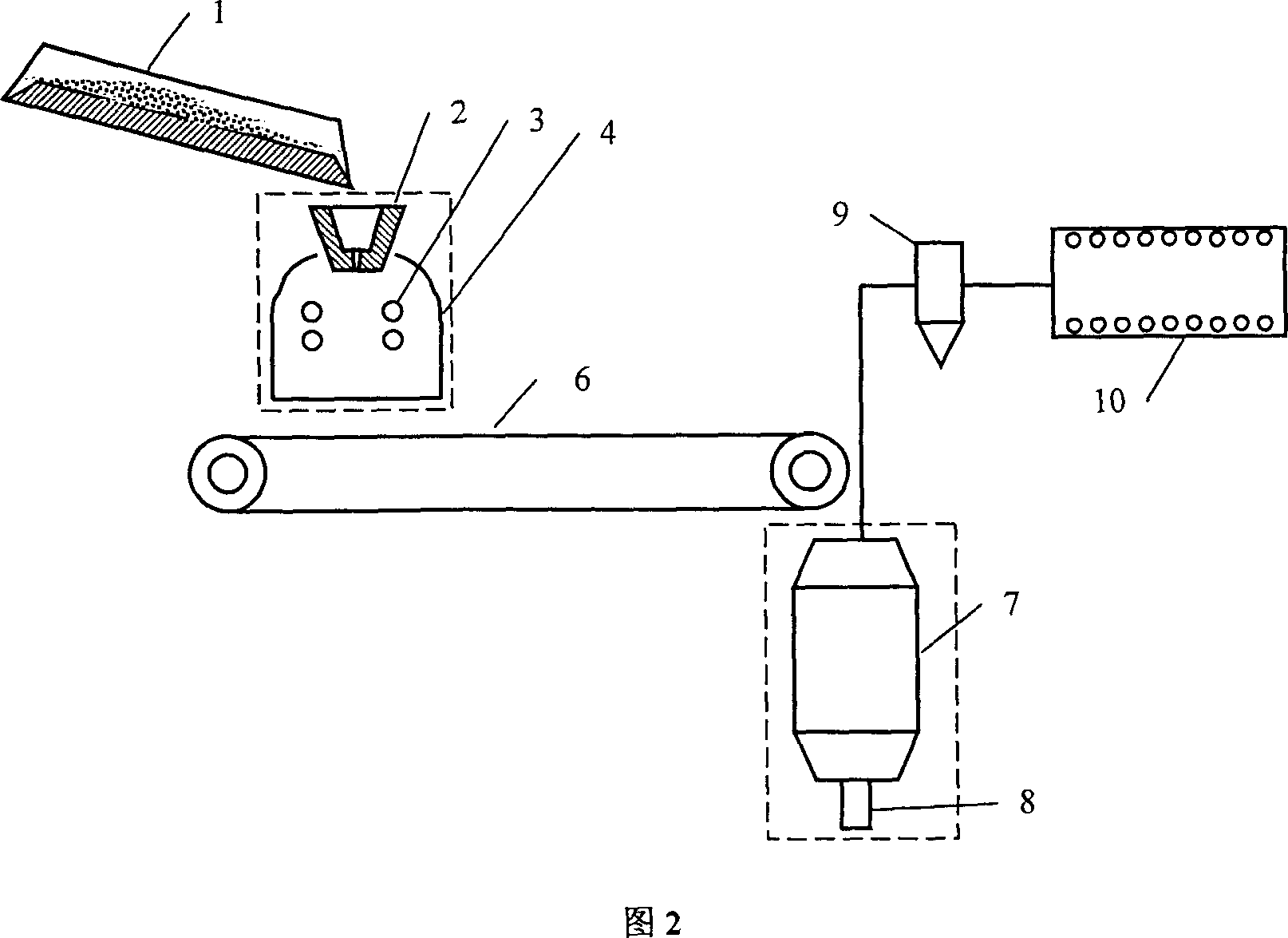

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

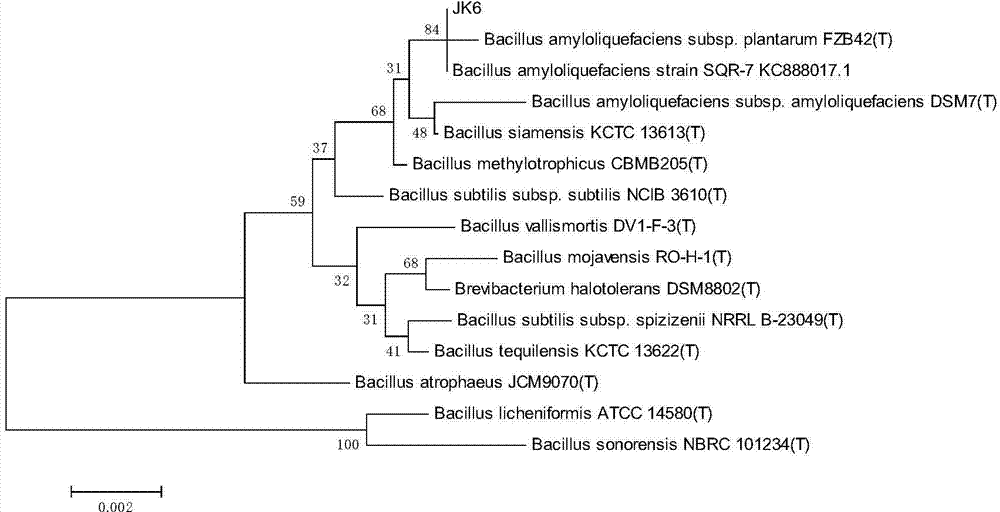

Bacillus amyloliquefaciens JK6 and biological fertilizer and application

The invention discloses bacillus amyloliquefaciens JK6 and biological fertilizer and application. The serial number of strain preservation is CGMCC No. 10658 and is stored in the China general microbiological culture collection center on March 23, 2015. The bacillus amyloliquefaciens JK6 is mainly used for biological prevention and control of pseudomonas solanacearum and is provided with an iron-production carrier, a biological membrane, protease, catalase, cellulose and IAA characteristics, multiple fungal pathogens of banana wilt pathogen, litchi anthrax germs, litchi frost phytophthora pathogens, rice blast fungus, cucumber wilt pathogen and the like, and growth of lettuce plants is obviously promoted; the K6 strain can be successfully planted, and disease preventing functional genes of yndj, srfAB, fend and ituC are expressed in soil; the strain is high in reproduction speed, simple in production technology, high in adverse resistance, easy to store and favorable for industrialized production, the biological fertilizer is prepared with the strain, soil-born diseases can be prevented and controlled, growth of the plants can be promoted, and application prospect is broad.

Owner:SOUTH CHINA AGRI UNIV

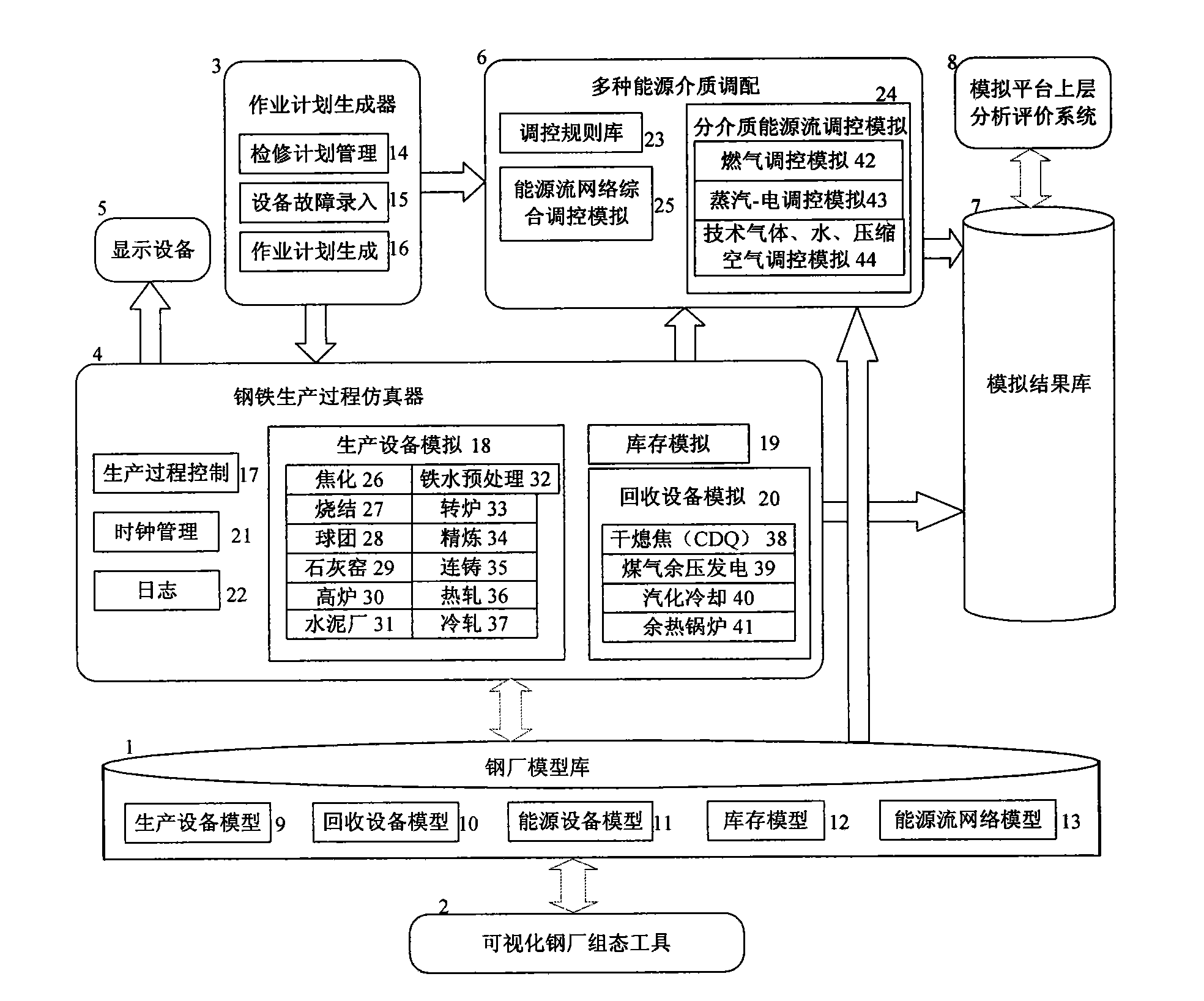

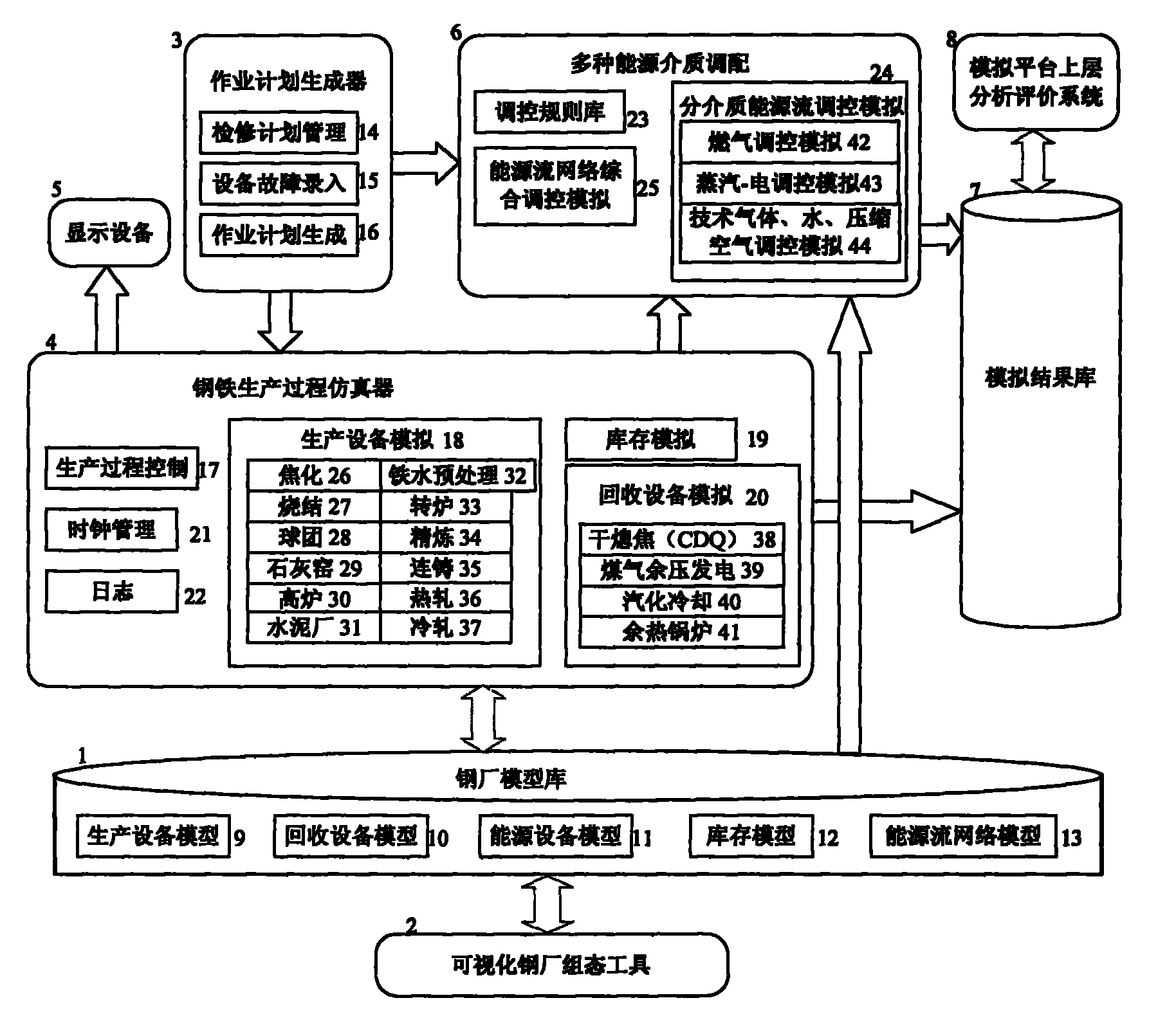

Computer-based iron and steel enterprise energy simulation platform

InactiveCN101980262AConsumption responseConvenient researchTechnology managementResourcesEvaluation systemSteel mill

The invention discloses a computer-based iron and steel enterprise energy simulation platform and belongs to the technical field of metallurgical energy simulation. The energy simulation platform comprises a steel mill model library, a visual steel mill configuration tool, an iron and steel production process simulator, display equipment, various energy medium mixers, a simulated result library and a simulation platform upper analysis and evaluation system, wherein the visual steel mill configuration tool is connected with the steel mill model library; the iron and steel production process simulator is connected with the steel mill model library and an operation plan generator, stimulates the production process and outputs results to the various energy medium mixers and the display equipment; and the simulated result library saves the simulated and regulated result and provides input for the simulation platform upper analysis and evaluation system. The computer-based iron and steel enterprise energy simulation platform has the advantages that: a transaction sign in an equipment model can analyze and evaluate the iron and steel enterprise energy situation under different conditions; a recovery plant independently constructs a model, and the research on a recovery scheme and efficiency is facilitated; and the tightly coupled energy medium forms three subsystems according to the correlation degree, and the solving is facilitated by a hierarchical coordination method.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND +1

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

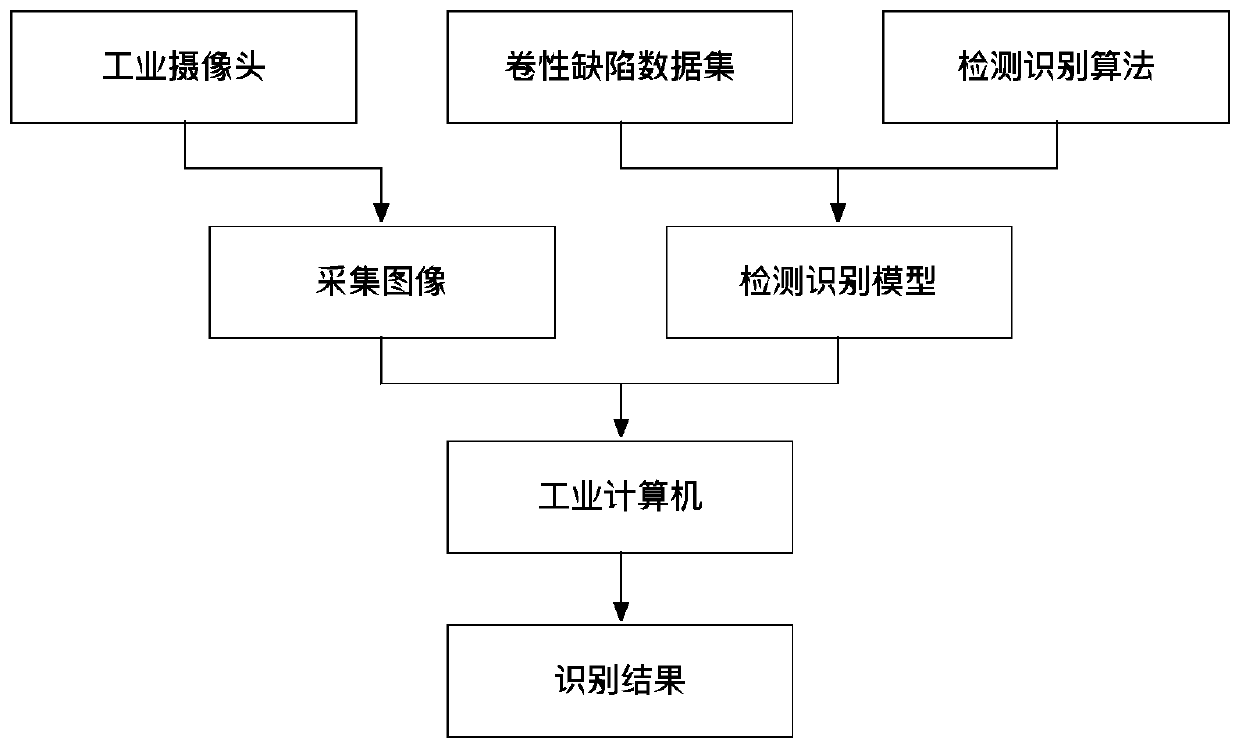

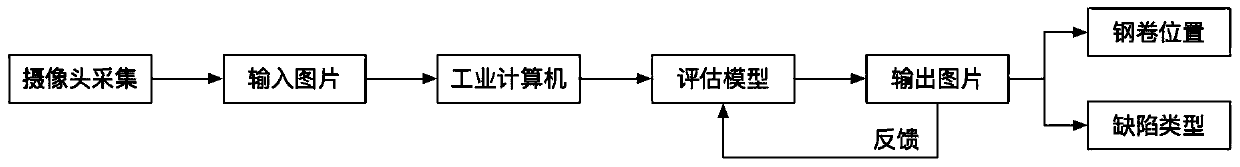

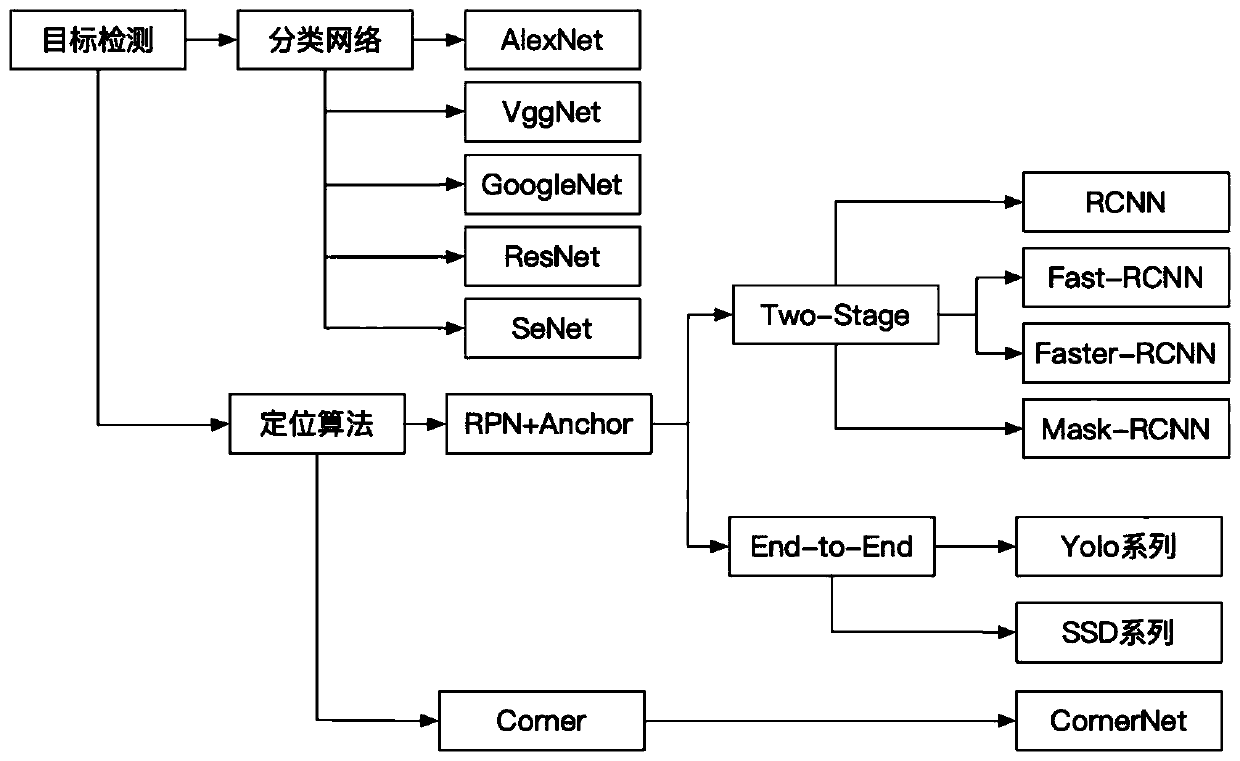

Steel coil shape defect detection and recognition method based on target detection

InactiveCN110197170AImprove automation performanceLow costData processing applicationsCharacter and pattern recognitionData setMaterials science

The invention belongs to the field of steel coil rolling, and relates to a steel coil shape defect detection and recognition method based on target detection. A large number of steel coil shape pictures are obtained from the site to construct a coil shape defect data set, and the task of detecting and identifying the coil shape defects of the steel coil is completed in the traditional steel production industry by utilizing the currently advanced Faster-RCNN target detection algorithm with high identification precision and high detection speed, and meanwhile, the Faster-RCNN is subjected to model compression by pruning, so that the model can meet the industrial embedded requirements. According to the method, a modern intelligent detection technology is utilized, and the method is applied toindustrial production detection of the steel coil.

Owner:UNIV OF SCI & TECH BEIJING

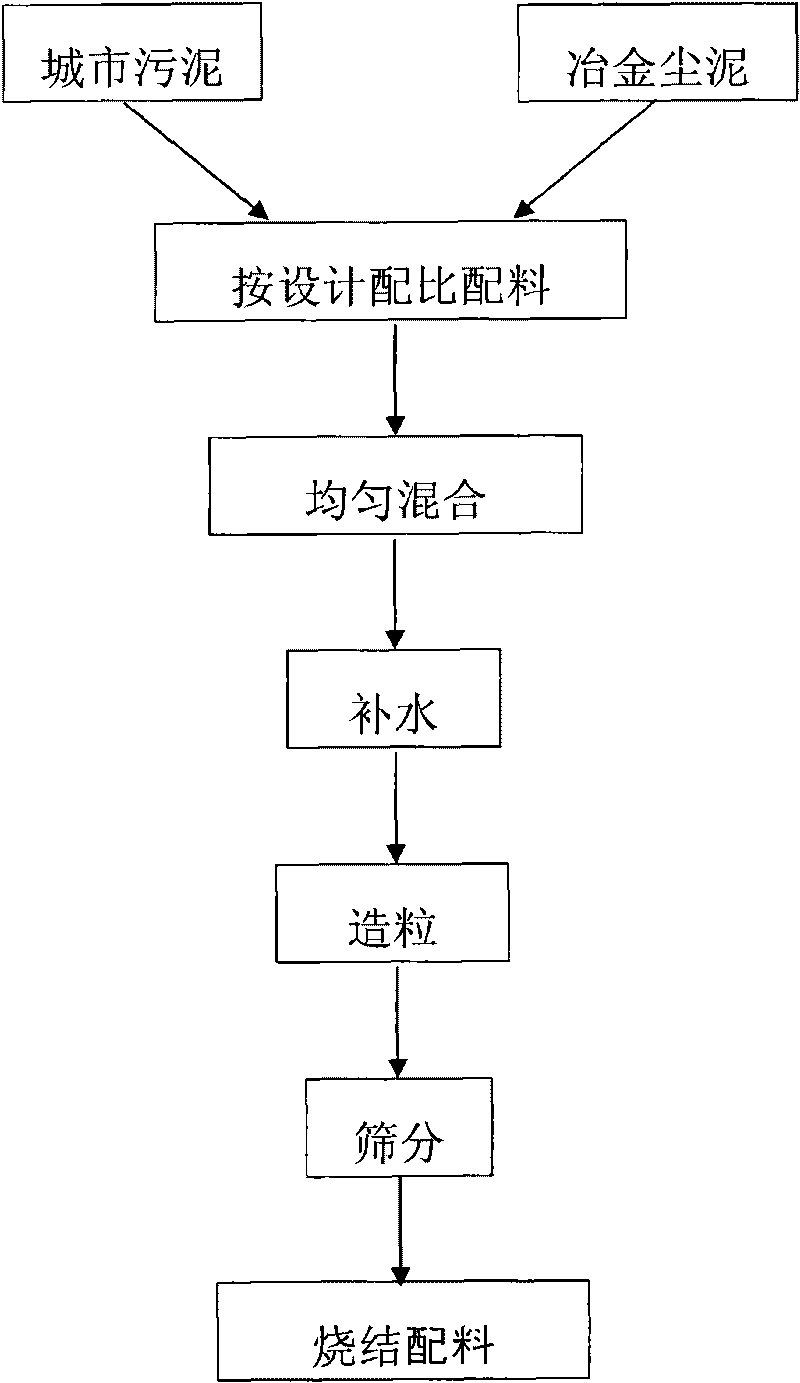

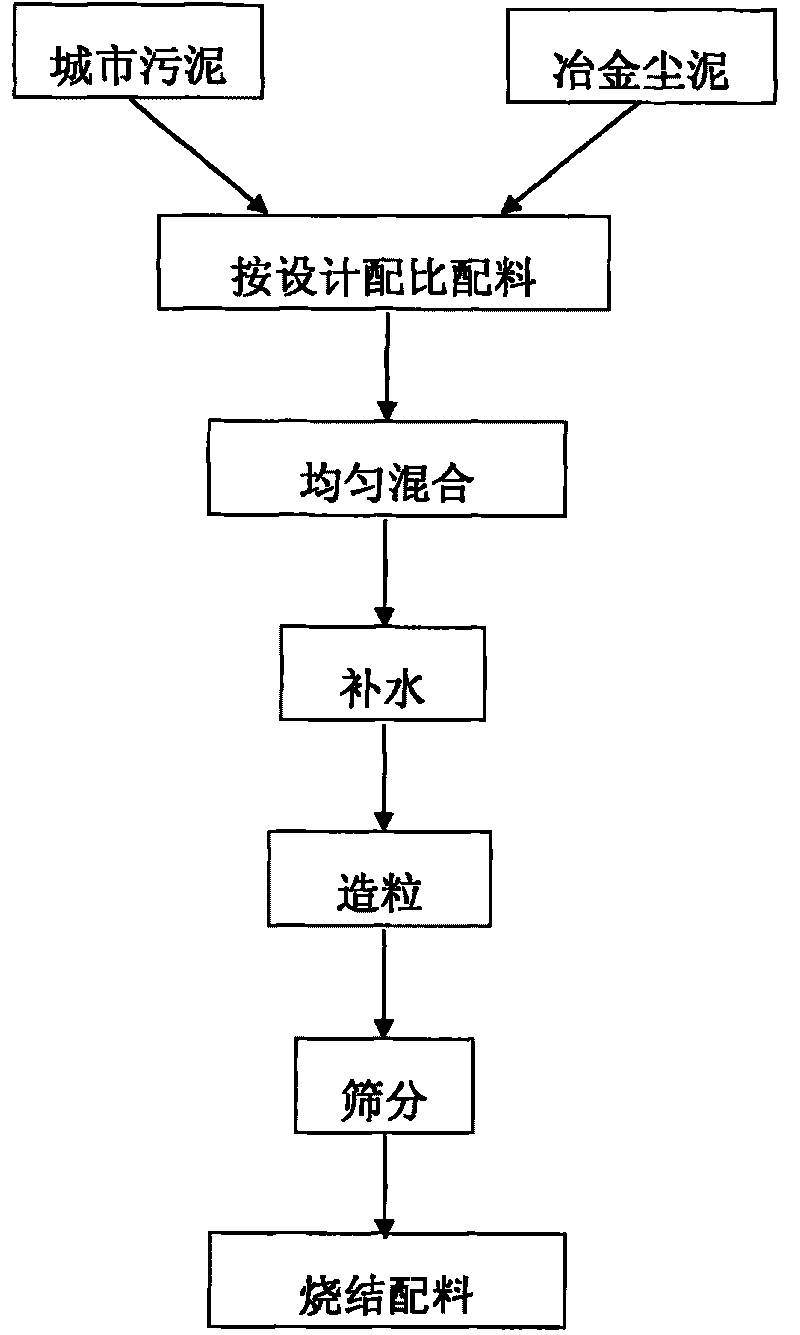

Method for preparing sintered mixture from municipal sludge and ferrous iron containing metallurgical dust

ActiveCN101717853ARealize unified utilizationEfficient recyclingProcess efficiency improvementSludgeNew energy

The invention relates to a method for preparing a sintered mixture from municipal sludge and iron containing metallurgical dust, which belongs to the technical field of resource recycling of the municipal sludge and the iron containing metallurgical dust. The method comprises the following steps of: preparing raw materials from 5-50 percent by weight of municipal sludge and 50-95 percent by weight of iron containing metallurgical dust, adding 0-20 percent by weight of water into the raw materials, then mixing and granulating to produce a sintered granular material, and using the sintered granular material as the mixture to be mixed into a sintering working procedure, wherein the proportion mixed into the sintering working procedure is 0.5-10 percent by weight of the total sintered raw materials quality. The method has the advantages that the processing flow of the municipal sludge is transferred to the mature sintering process flow of ferrous metallurgy, avoiding the problems of new energy consumption, secondary pollution and the like caused in traditional landfill and sintering processes of the municipal sludge, thereby recycling effective elements in the metallurgical dust and the municipal sludge in the steel production flow, improving sintering production process conditions to a certain degree and improving the sintering production efficiency.

Owner:SHOUGANG ENVIRONMENTAL IND +1

Microalloying third-generation car spring flat steel and preparing method thereof

The invention relates to a microalloying third-generation car spring flat steel and a preparing method thereof. The microalloying third-generation car spring flat steel comprises, by weight percentage, 0.48%-0.60% of C, 0.4%-0.8% of Si, 0.60%-1.00% of Mn, 0.80%-1.20% of Cr, 0.01%-0.05% of Nb, 0.0005%-0.003% of B, not larger than 0.025% of P, not larger than 0.025% of S, not larger than 0. 25% of Cu, not larger than 0.35% of Ni, not larger than 0.02% of Ti and the balance Fe. The preparing method includes the steps of blast furnace molten iron production, molten iron desulphurization, converter smelting, LF refining, RH vacuum treatment, square billet protection pouring, square billet heating, rolling, cooling bed slow cooling and fixed-size shearing. According to the microalloying third-generation car spring flat steel and the preparing method, niobium and boron microalloying and the silica content more suitable for the spring steel high elasticity ultra-low decarburization trend are adopted, the proper clean steel smelting process, rolling process and slow cooling control technology are adopted in a combined manner, and the high-end car spring flat steel having uniform texture, good hardenability, reasonably-matched comprehensive mechanicalness and good hardenability is developed.

Owner:东风汽车底盘系统有限公司

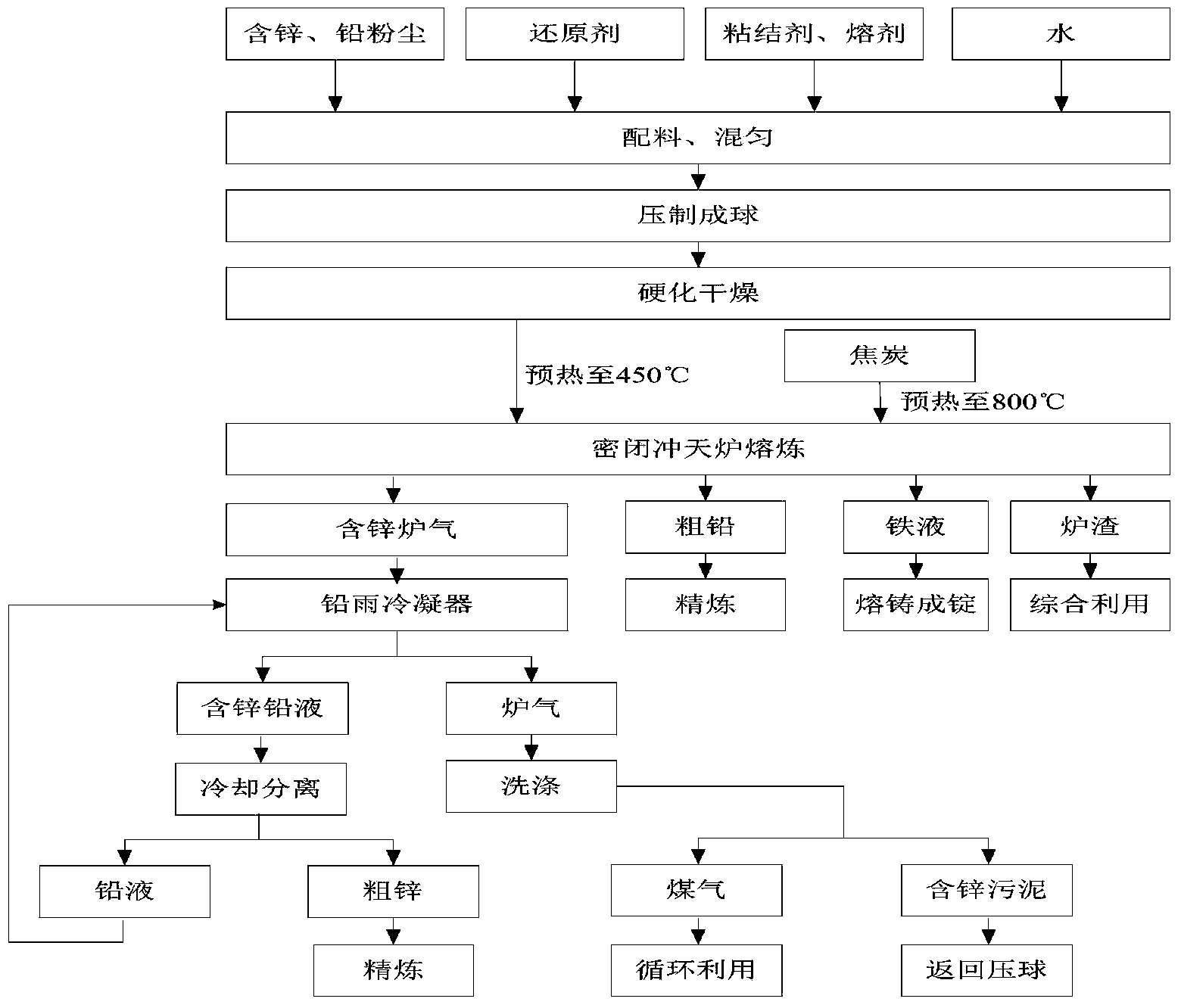

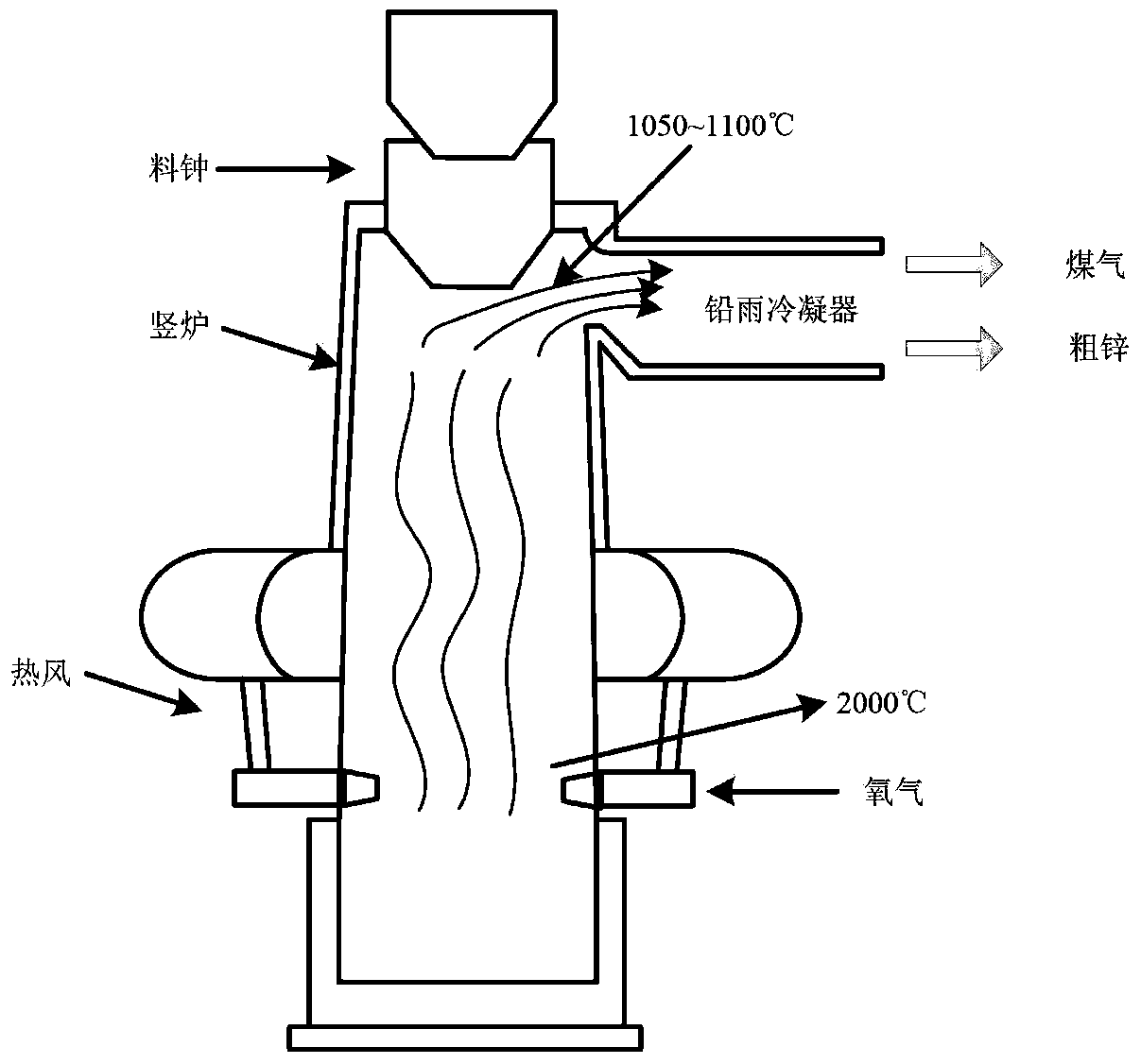

Method for processing dust containing zinc and lead in steel plant through closed cupola furnace

ActiveCN103468961AAdaptableIncrease production capacityProcess efficiency improvementSlagMixed materials

The invention discloses a method for processing the dust containing zinc and lead in a steel plant through a closed cupola furnace, and belongs to the field of steel production. The method is characterized in that the dust containing the zinc and the lead in the steel plant serves as the main raw material, certain quantities of a reducing agent, a binder, a fusing agent and water are added, and after fully mixing, the mixed materials are pressed by a ball pressing machine into balls; after being dried or maintained, the balls are conveyed into the closed cupola furnace to be smelted, and finally spelter, lead bullion and molten iron are obtained. The method has the advantages of being high in raw material adaptability, strong in production capability, high in processing efficiency and additional value of products and the like. The spelter, the lead bullion, the molten iron, gas, slag and the like can be directly obtained through the dust containing the zinc and the lead in the steel plant, the spelter and the lead bullion can be refined further, and the additional value of the products is improved. The molten iron is preprocessed and then is cast into ingots to be sold. After being processed, the slag can serve as building materials or cement or other production raw materials. The gas can serve as gas fuel to be used in the plant. The method is very obvious in economic benefits and environmental benefits.

Owner:UNIV OF SCI & TECH BEIJING

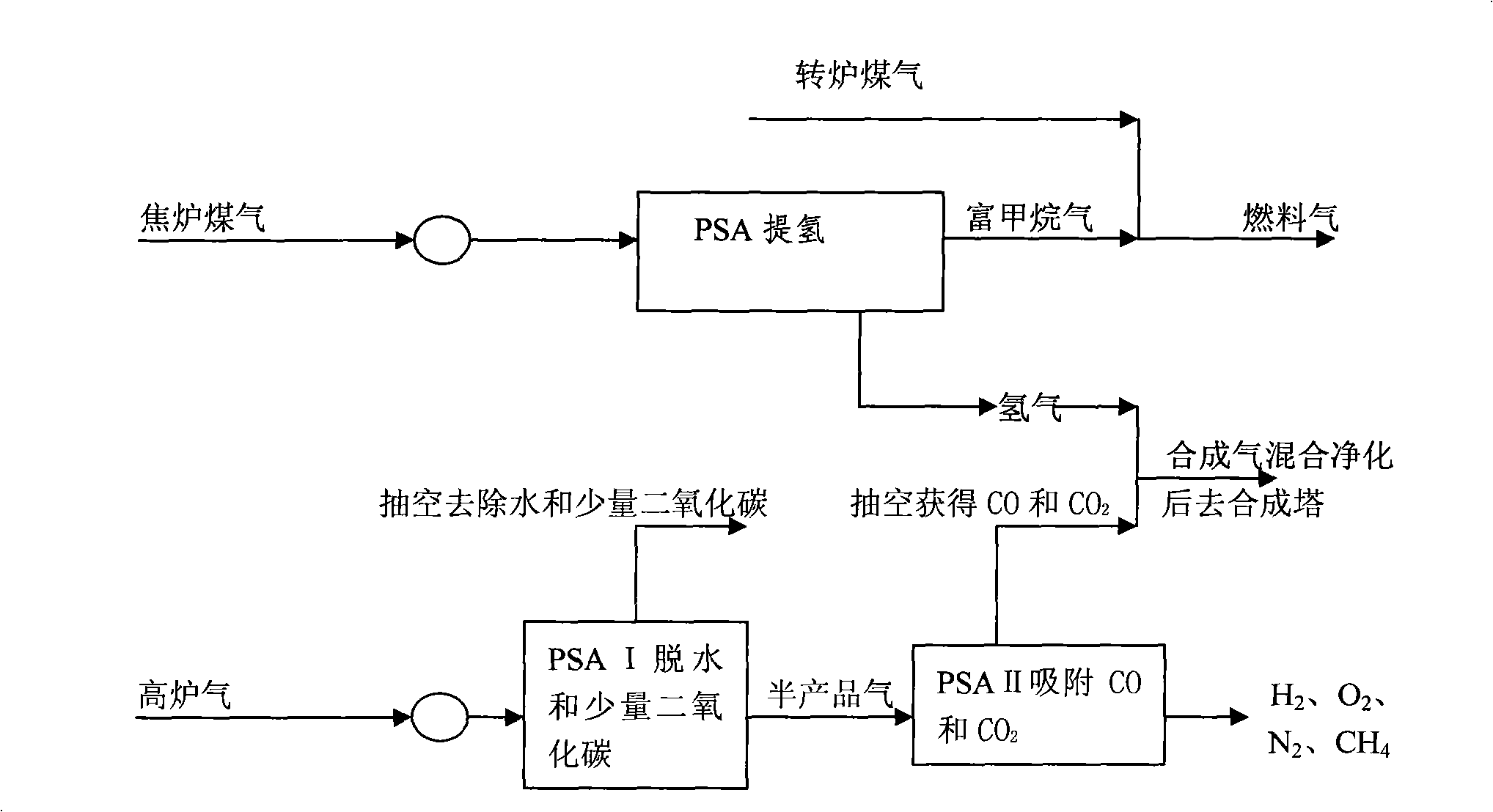

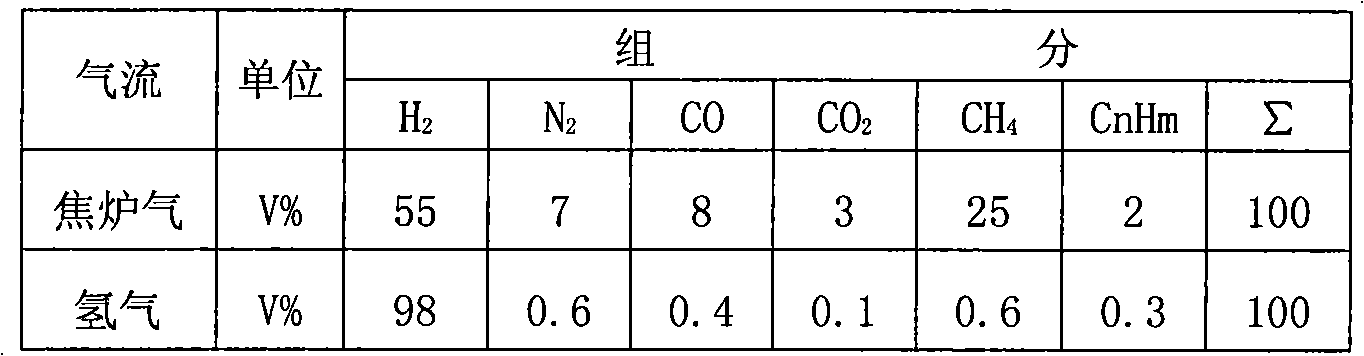

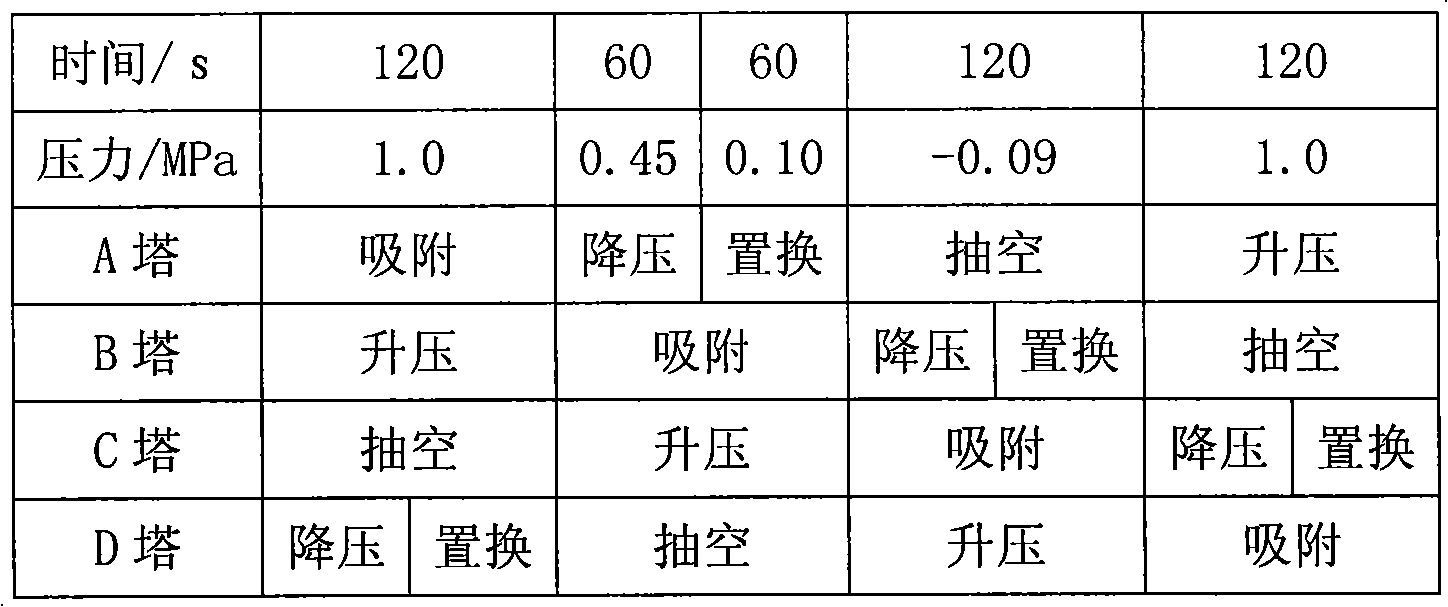

Method for preparing methanol synthesis gas with oven gas and blast furnace gas

InactiveCN101343580AEmission reductionReduce chemical reactionsGaseous fuelsChemical reactionSorbent

The invention discloses a preparation method for methanol synthetic gas through coke oven gas and blast furnace gas. The preparation method adopts coke oven gas as the raw material, and H2 is extracted through pressure swing adsorption; the blast furnace gas with high yield and relatively low calorific value is adopted as the raw material, an adsorbent which can adsorb CO and CO2 is utilized to simultaneously extract and reclaim the CO and the CO2 in the blast furnace gas, and then the H2, the CO and the CO2 are mixed and prepared into the methanol synthetic gas. The hydrogencarbon ratio f value of the methanol synthetic gas prepared according to the method is within the optimum range of 2.05 to 2.60, and the contents of nitrogen gas and other impure gases are suitable for the methanol production. The by-product gas generated during the steel production process is utilized to prepare the methanol synthetic gas, the useful components in the gas are utilized, the discharging of harmful substances into the environment is reduced, and not only the chemical reaction can not occur during the process, but also the carbon adding is not required, the technical process is short, the process is simple, and the cost is low, so the preparation method is one of the preferable methods for the preparation of methanol synthetic gas.

Owner:SICHUAN TIANYI SCI & TECH

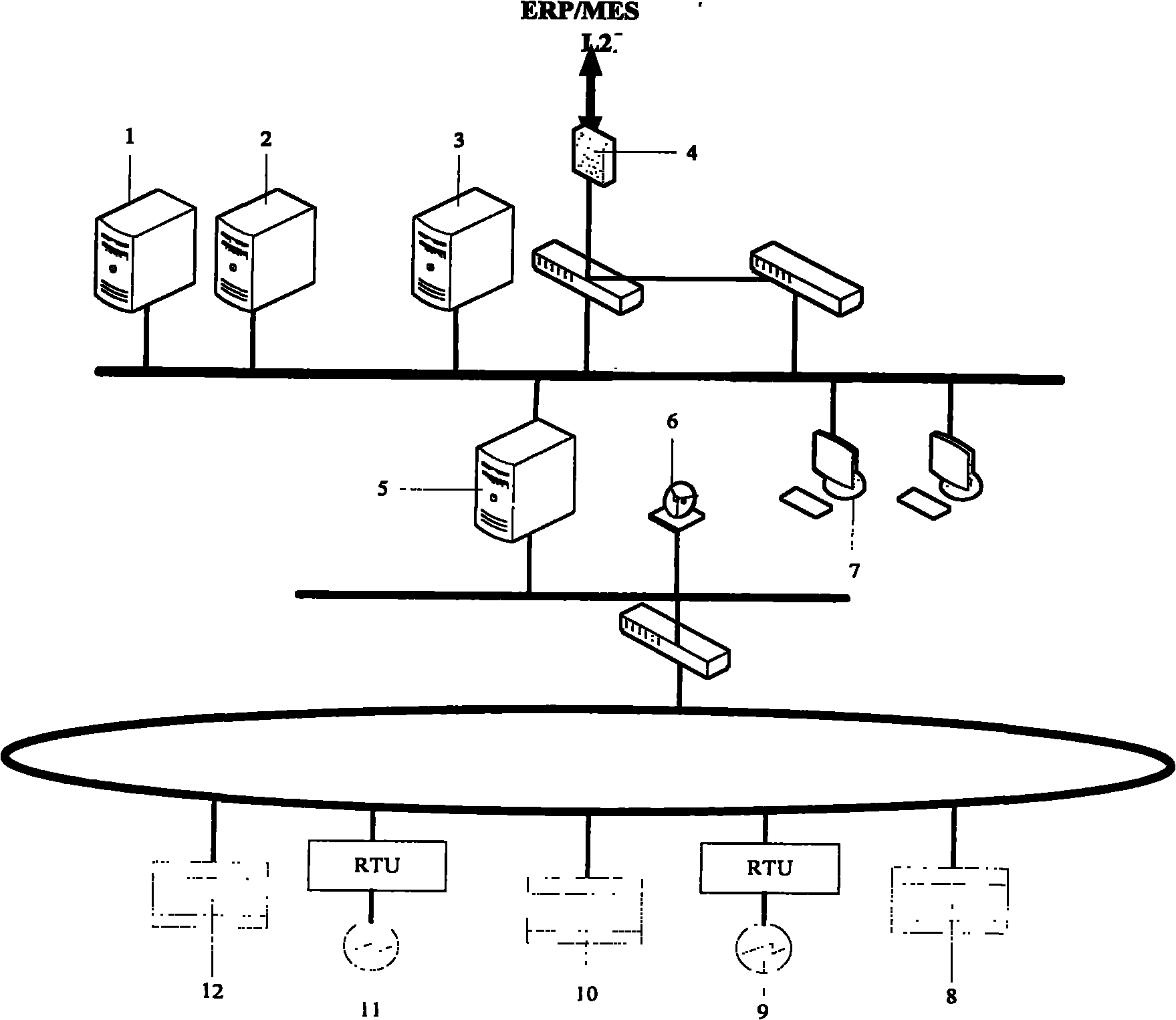

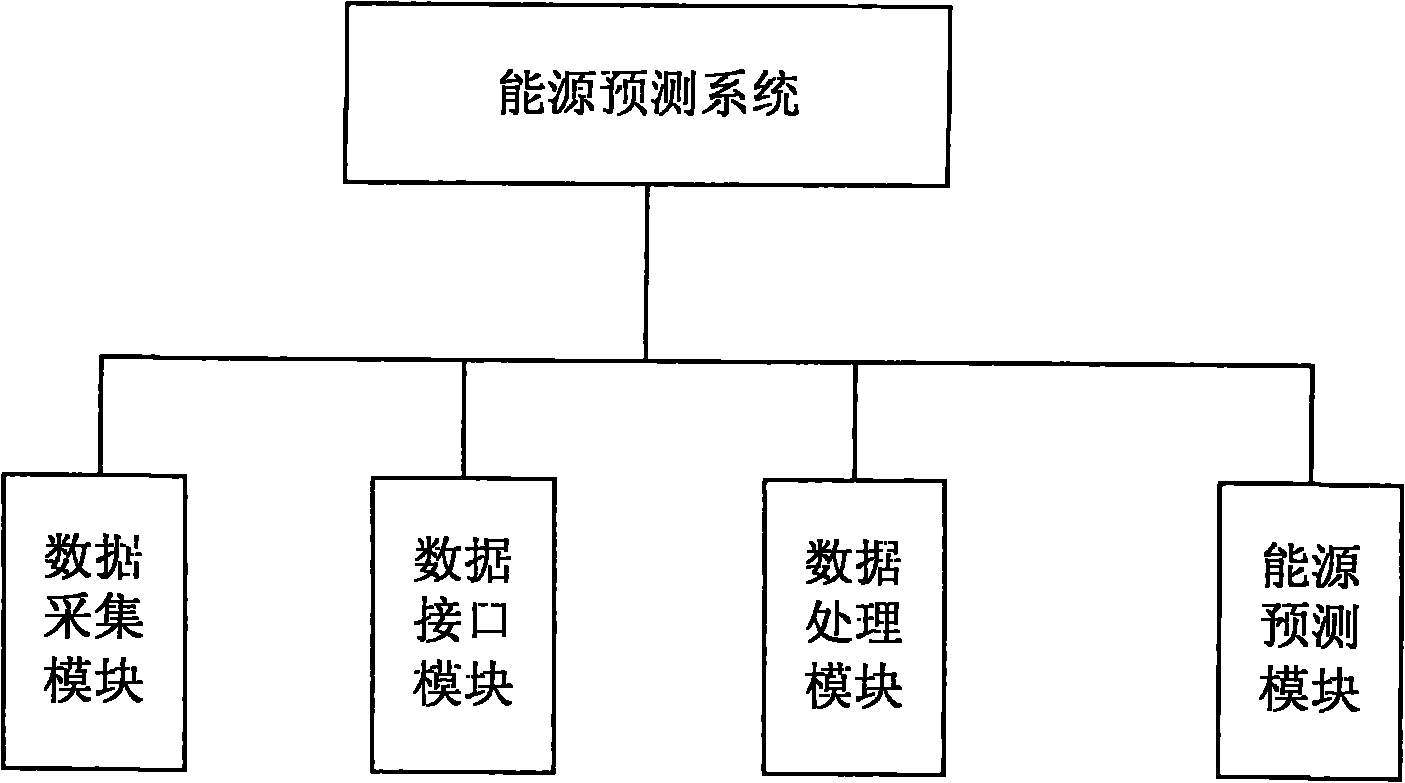

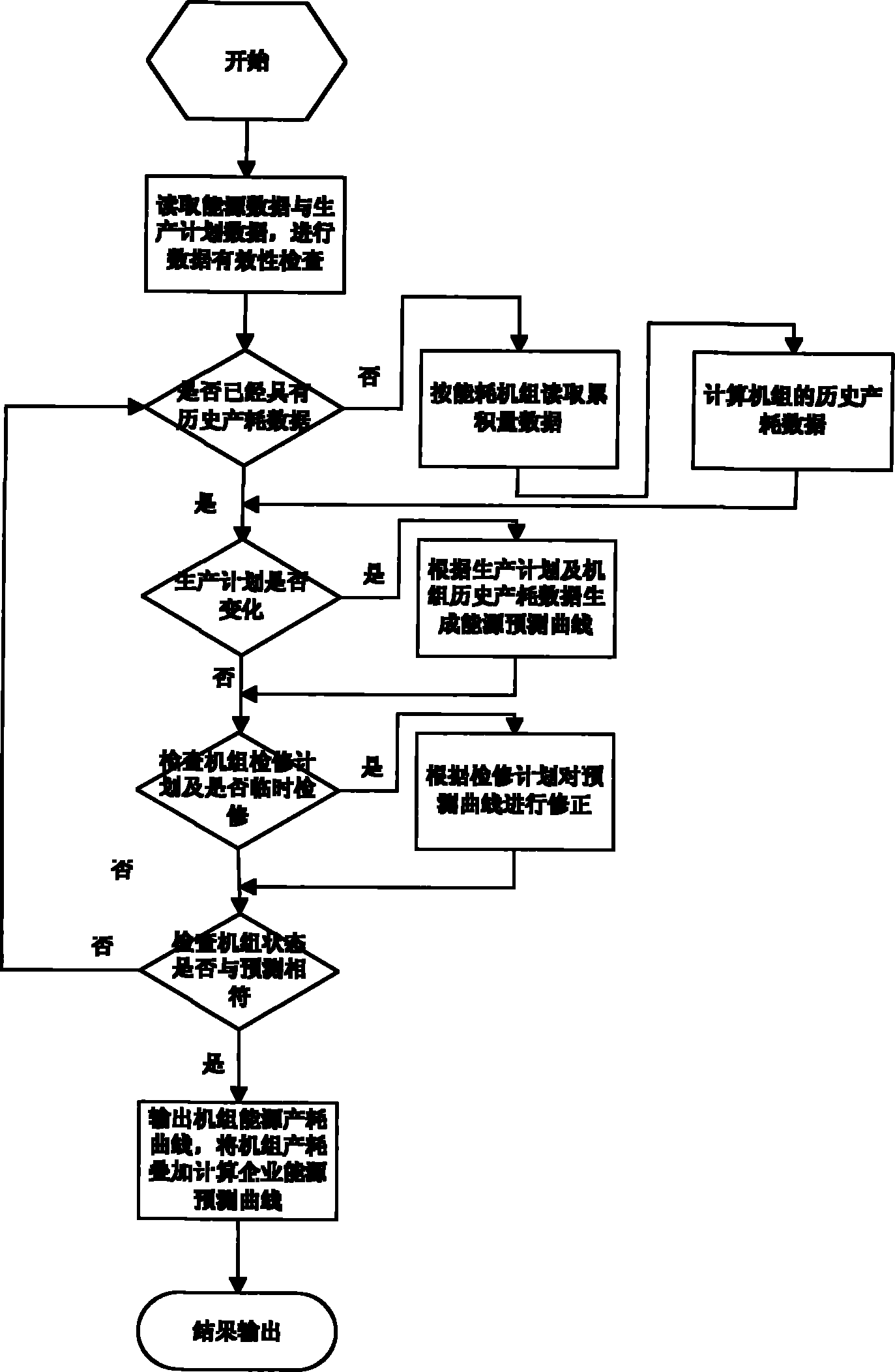

Steel production planning-based energy forecasting method

ActiveCN102156467AReduce wasteEnergy industryTechnology managementMeasuring instrumentPredictive methods

The invention provides steel production planning-based energy forecasting system and forecasting method. The forecasting system consists of a data acquisition network, an industrial ring network and a management network, wherein field real-time data of a measuring instrument and a programmable logic controller (PLC) is acquired through the data acquisition network, and output and consumption forecasting of an energy consumption unit in the future is realized by the energy forecasting module according to data of production plan, maintenance plan and equipment state acquired from enterprise resource planning (ERP) and manufacturing executive system (MES). The system can accurately forecast the energy output and consumption of a single unit or the whole enterprise according to the production plan, the maintenance plant and equipment state and other real time data, and provides basis for reasonable dispatching of energy of steel enterprises, thereby effectively reducing energy waste of the steel enterprises.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

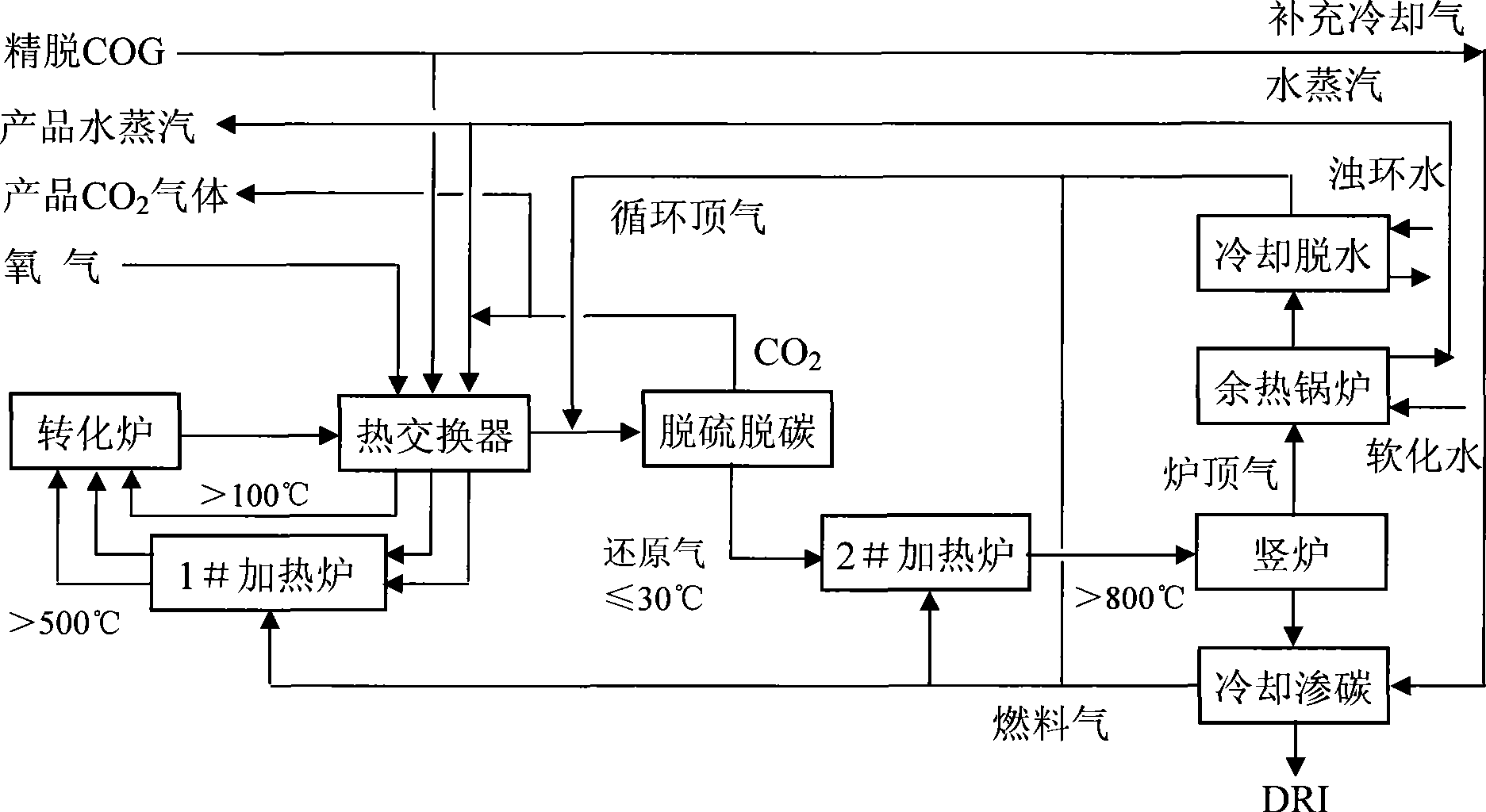

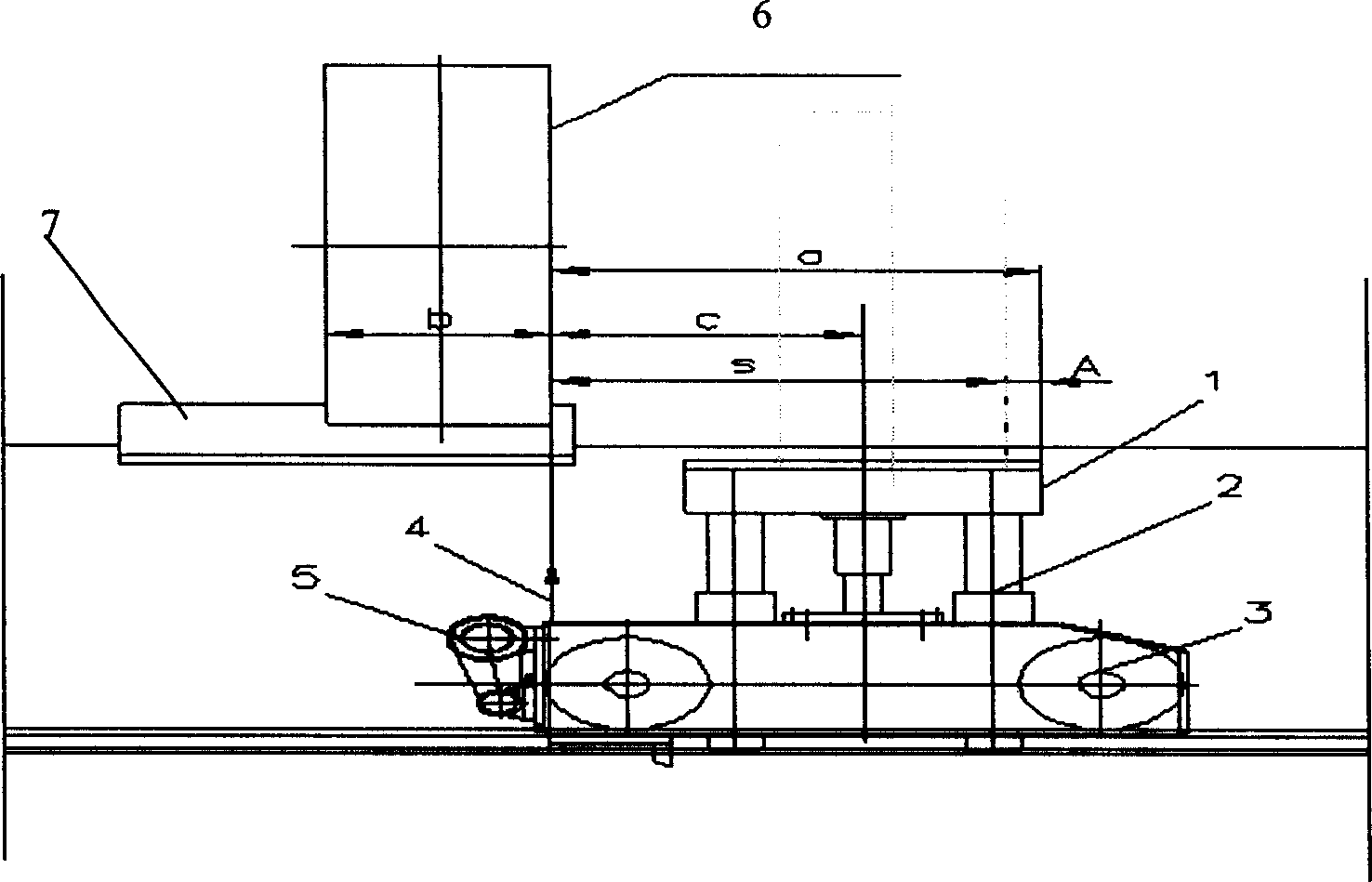

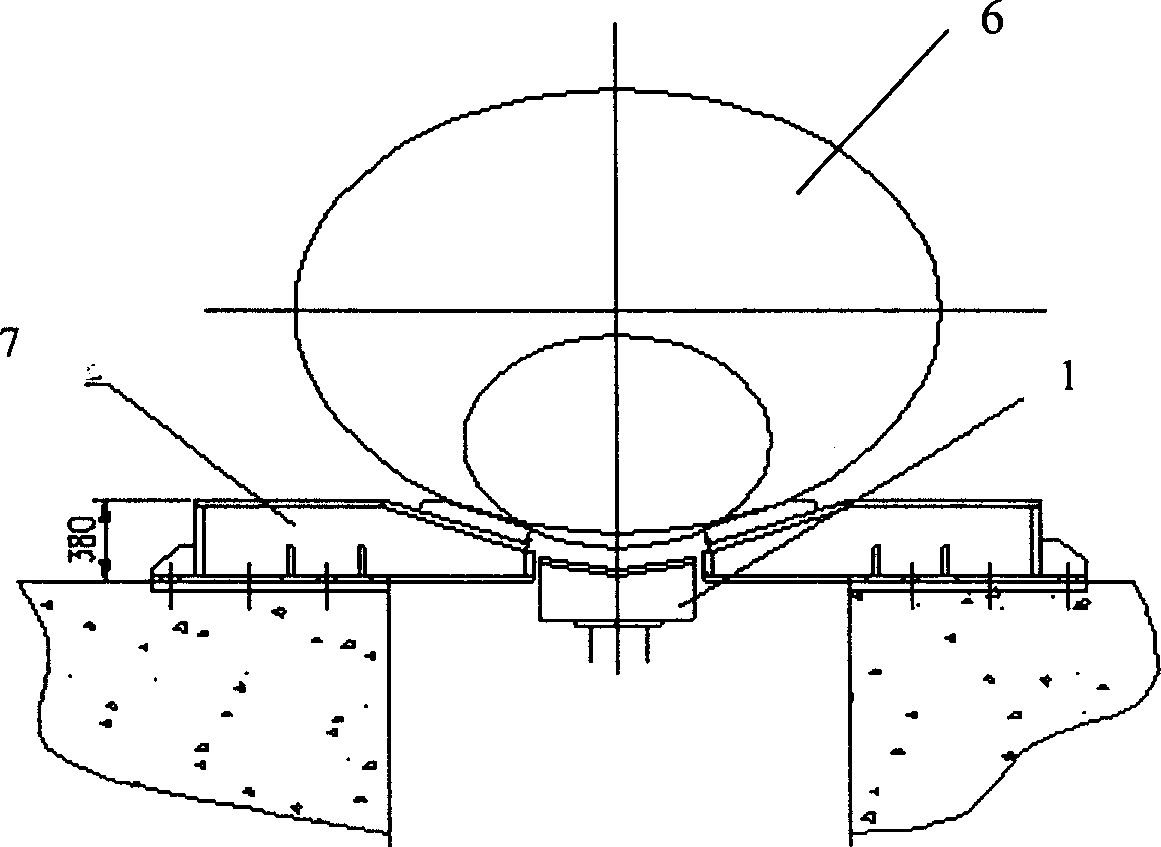

Conversion of coke oven gas carbon dioxide and gas-based shaft kiln directly reduced iron production method

ActiveCN101392192AMeeting Direct Reduction NeedsIncreased CO contentCombustible gas purificationComing outWater vapor

The invention discloses a method for conversing carbon oxide in coal oven gas and directly reducing Fe in a gas-based shaft furnace. The coal oven gas, to which initial purification treatment is carried out in a coking plant, is subjected to deep purification and desulfurization treatment and then is used as virgin gas, while oxygen, the carbon oxide and water vapour are used as a gas transforming agent and sent into a reformer for conversion, and reforming gas is used as reducing gas for directly reducing the Fe in the gas-based shaft furnace. Part of the gas that comes out from the top of the shaft furnace is used as fuel gas which is then used as fuel for a heating furnace; and part of the gas is used as process gas which returns to the shaft furnace as the reducing gas after being treated. The method solves a new gas source for the direction reduction in the gas-based shaft furnace and pertains to a new and highly efficient usage method of the coal oven gas. Compared with the current reforming gas from water vapour, the H2 / CO ratio of the reforming gas reduces from 4.6 of the reforming gas from the water vapour to 1.5 and is adjustable between 4.6 and 1.5.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

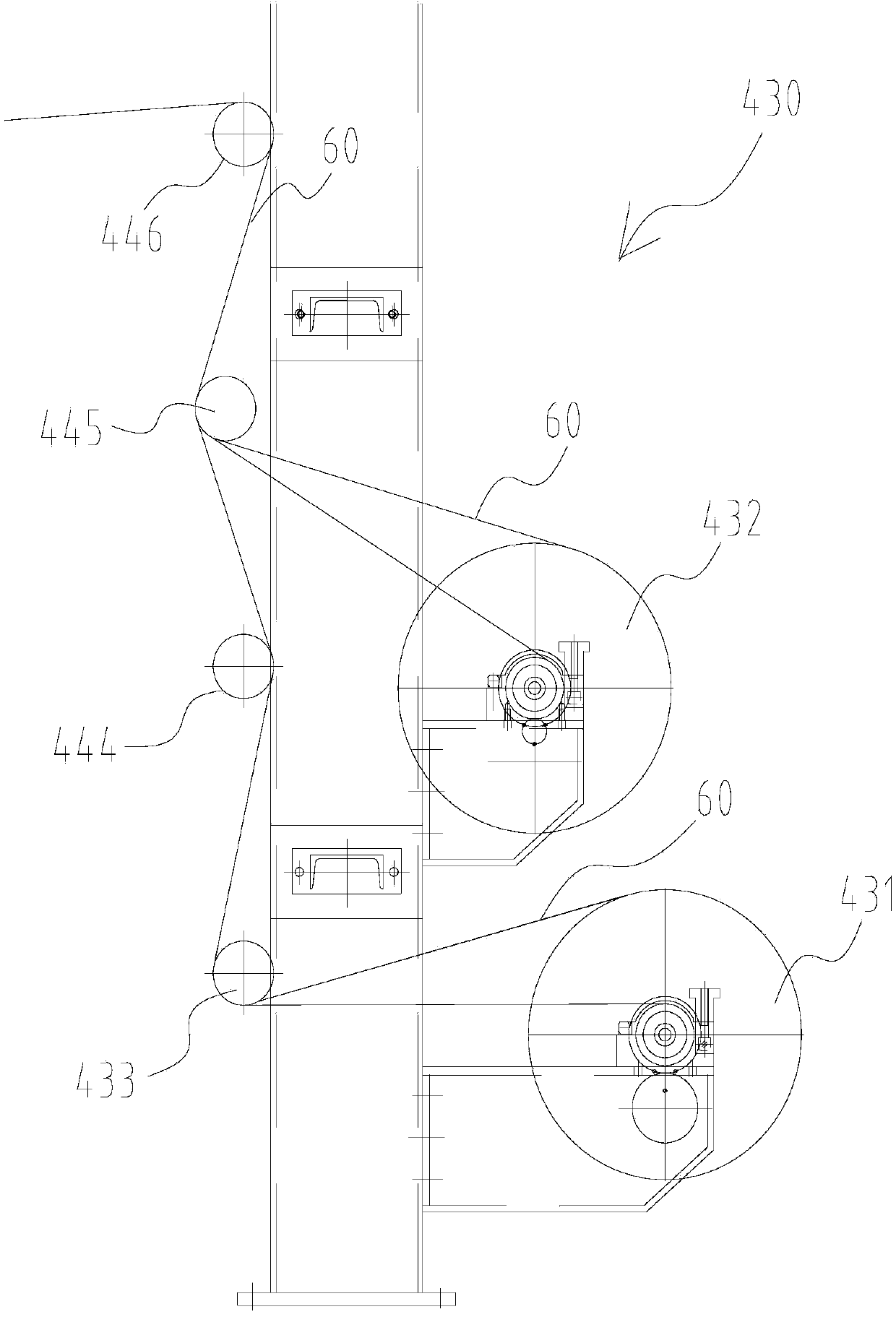

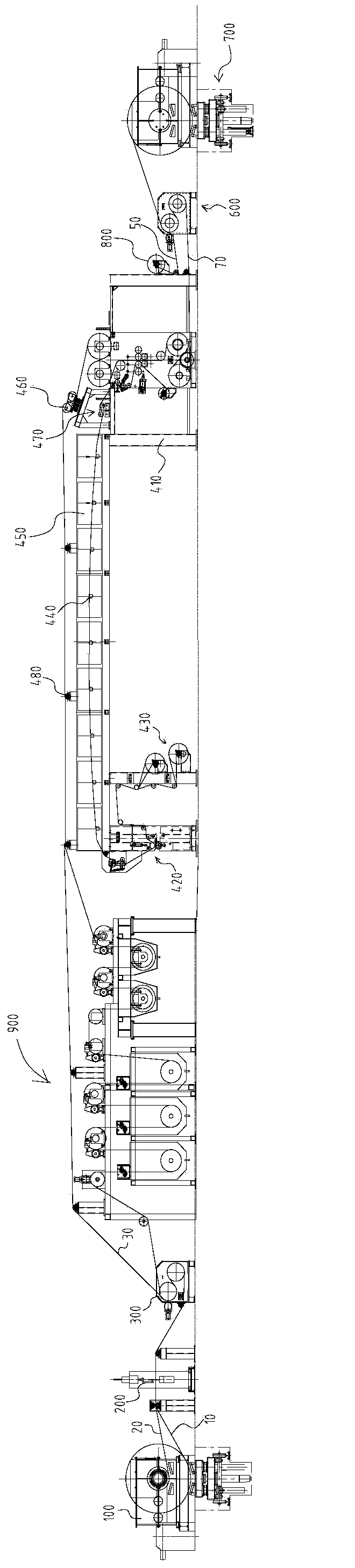

Multi-functional laminated iron production line

ActiveCN103640315AExcellent anti-rustImprove the decorative effectLamination ancillary operationsLaminationWinding machineProduction line

The invention discloses a multi-functional laminated iron production line. The multi-functional laminated steel production line comprises a cold rolled base plate unwinding device, a seam welder, two S turning roller sets, a first or / and second thin film release device, an iron sheet laminating device and a laminated iron winding machine, which are sequentially arranged in a conveying direction of metal base plates; the metal base plate from the seam welder enters the iron sheet laminating device after being tensioned and rectified, and a first thin film or / and second thin film is / are fed into an iron sheet laminating machine after rectification, so that the iron sheet laminating machine covers one surface or two surfaces of the metal base plate with the first thin film or / and the second thin film to form single-sided or double-sided laminated iron, the single-sided or double-sided laminated iron is fed into the other S turning roller set by the iron sheet laminating machine to be tensioned, and the tensioned single-sided laminated iron is wound by the laminated iron winding machine. The multi-functional laminated iron production line can produce both low-temperature bonded laminated iron and high-temperate melted laminated iron, is advanced iron laminating equipment capable of realizing efficient and continuous production, and can be well adaptive to the change of market requirement.

Owner:SUZHOU DONGHONGRUI PACKAGE TECH

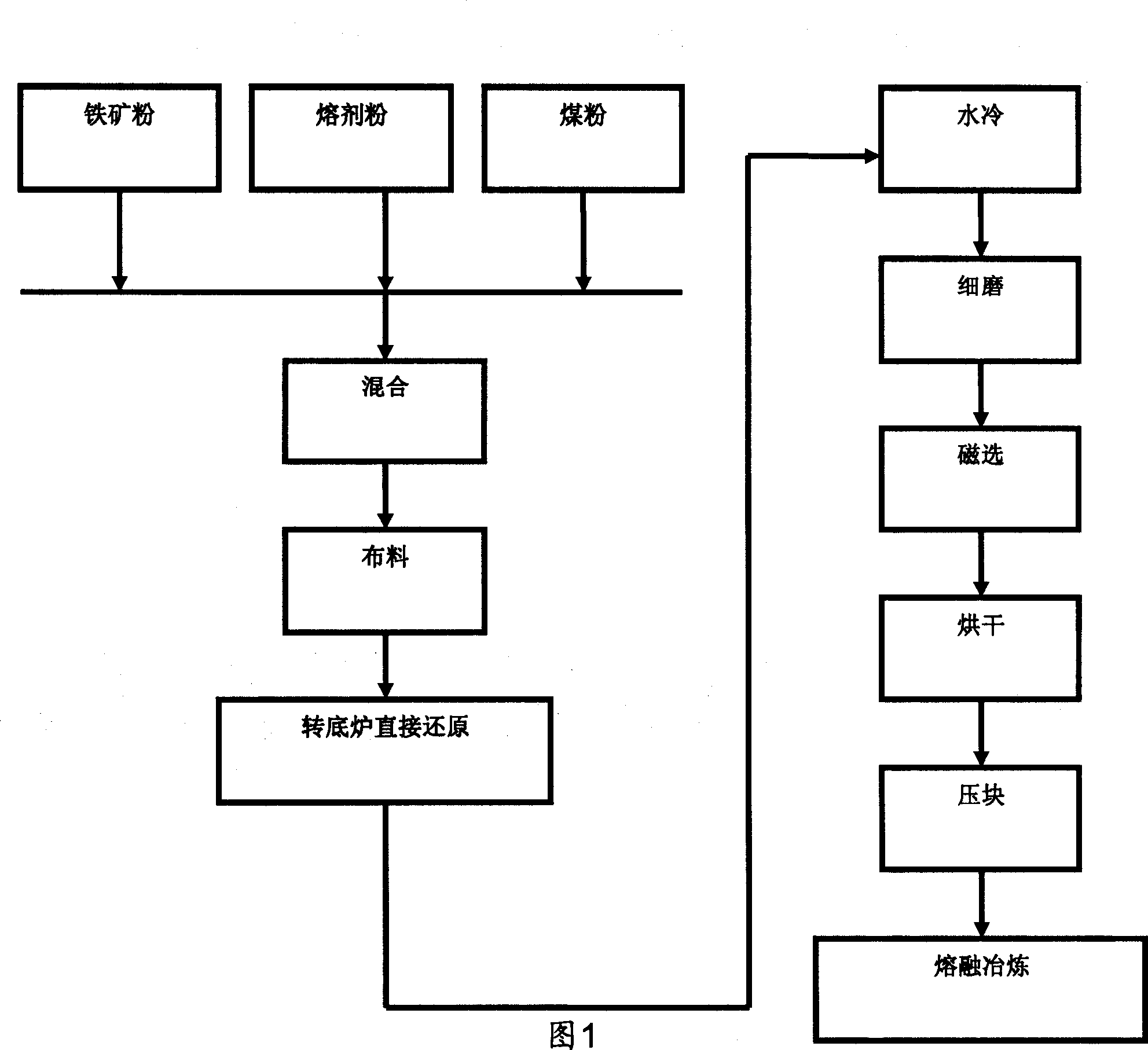

Ore coal, melting ironmaking method after direct reduction-flotation-agglomeration

The invention discloses a method for carrying out direct reduction, sorting, agglomeration, smelting and ironmaking on ore and coal. Firstly, certain amount of the ore, the coal and a solvent are mixed, are placed in a rotary hearth furnace and are heated to the temperature of between 1,100 and 1,350 DEG C, are kept at the temperature for 15 to 40 minutes and are directly reduced to obtain a reduced iron material with metallizing rate of between 80 and 92 percent; the reduced iron material at high temperature of between 800 and 1,100 DEG C is directly transported into water, is cooled and is subjected to fine grinding and sorting; and the iron material after the fine grinding and sorting is subjected to drying and agglomeration by high-temperature oxygen-lost exhaust gas and finally is transported into a submerged arc furnace or other smelting equipment for carrying out slag-iron separation and molten iron production. The method has a simple process, short flow and high efficiency, needs no coke and is suitable for low-grade ore and non-blast furnace ore which is difficult to be used by the prior blast furnaces, such as oolitic hematite, ultrafine particle hematite, limonite, siderite and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

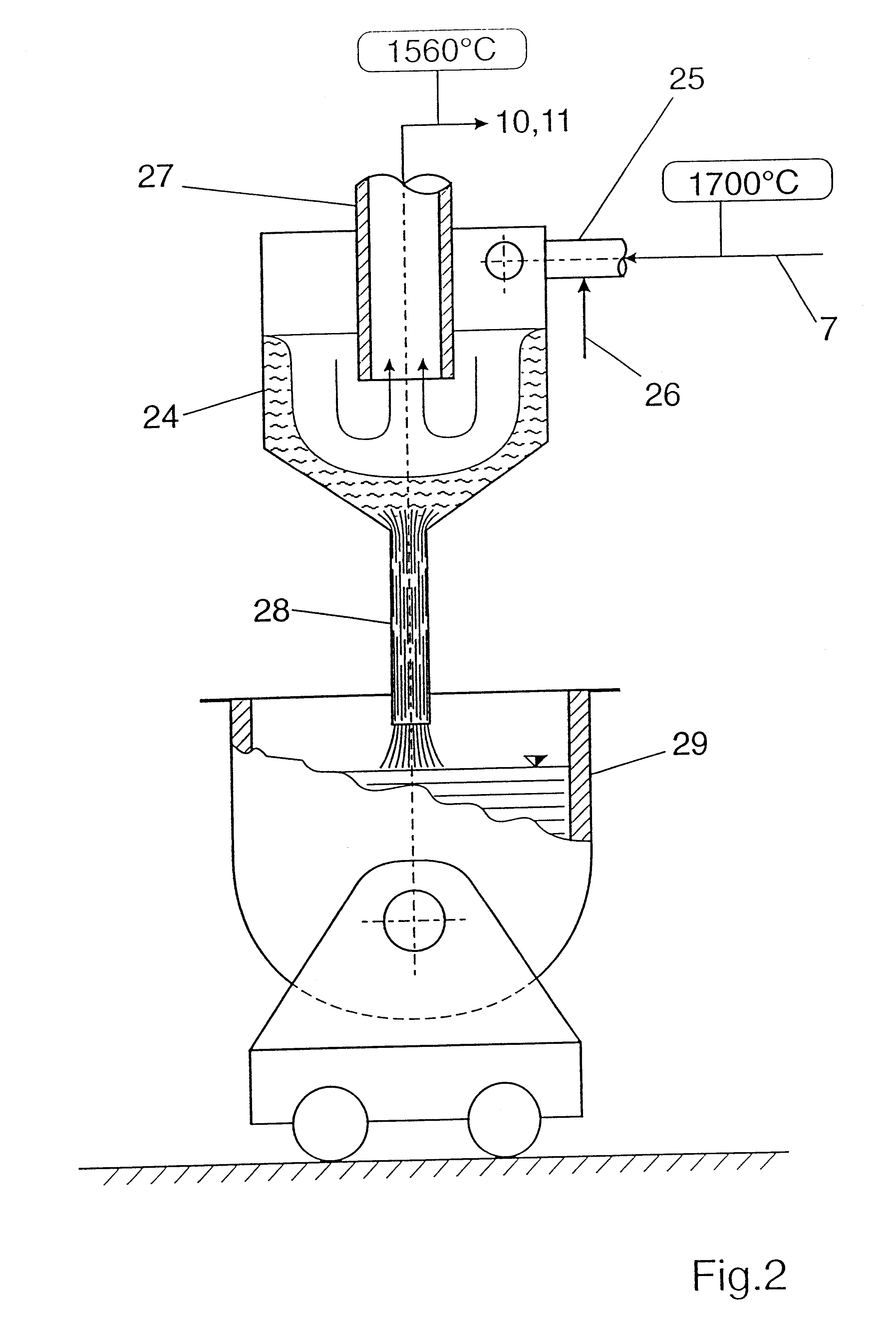

Process for working up steel slags and iron carriers for obtaining pig iron and environmentally safe slags

InactiveUS6332910B1Improve heat transfer performanceExtended service lifeManufacturing convertersProcess efficiency improvementAlkalinityNitrogen

In a process for working up steel slags and iron carriers such as, e.g., electric furnace slags, converter slags, fine ores, dusts from steel production, mill scales for obtaining pig iron and environmentally safe slags, the volume ratio of molten slag to iron bath is chosen to be larger than 0.5 to 1 and, preferably, 0.8:1 to 1.5:1 and the slags are supplemented with SiO2 carriers such as, e.g., foundry sands, metallurgical sands and / or fine ores so as to adjust a slag basicity (CaO / SiO2) of between 1.0 and 1.8 and, preferably, 1.2 and 1.8 at an Al2O3 content of between 10 and 25% by weight, based on the slag. In doing so, hot blast is top-blown and coal, optionally along with an inert gas and, in particular, nitrogen and, furthermore, optionally oxygen or hot air is blown through the iron bath.

Owner:HOLCIM

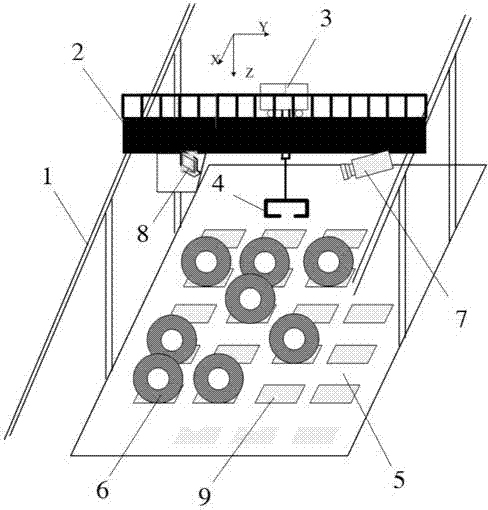

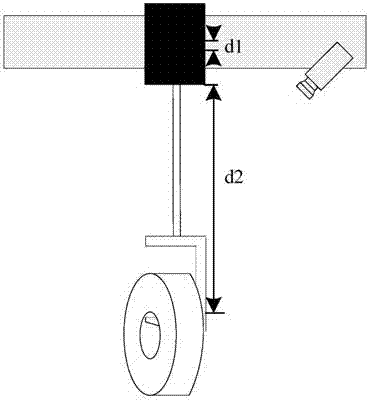

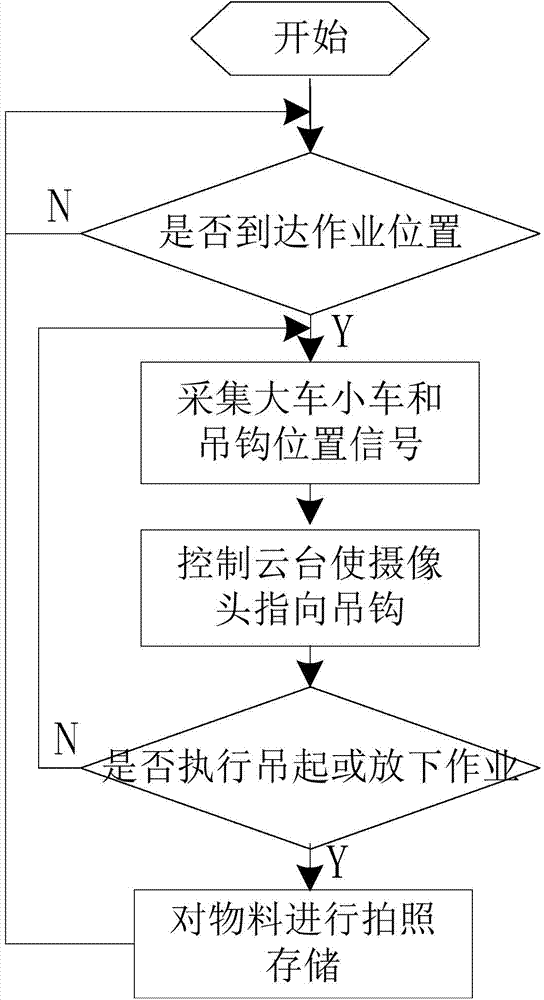

Automatic tracking device and automatic tracking method for production material storage and transportation operation images

ActiveCN104724606AImprove accuracyImprove securityLoad-engaging elementsAutomatic controlComputer vision

The invention discloses an automatic tracking device and an automatic tracking method for production material storage and transportation operation images. A computer is used for collecting and calculating space coordinate positions of a lifting hook of a crane and automatically controlling a camera to track the operational region of the lifting hook and displaying the operational images in real time. When the materials are hoisted or fall, the camera is automatically triggered to shoot the materials, and the images are stored. The device disclosed by the invention is not operated by operators and can be used for automatically monitoring the operational region, so that the accuracy and the safety in a steel production material storage and transportation process can be effectively improved.

Owner:SUZHOU YINGXING INFORMATION TECH

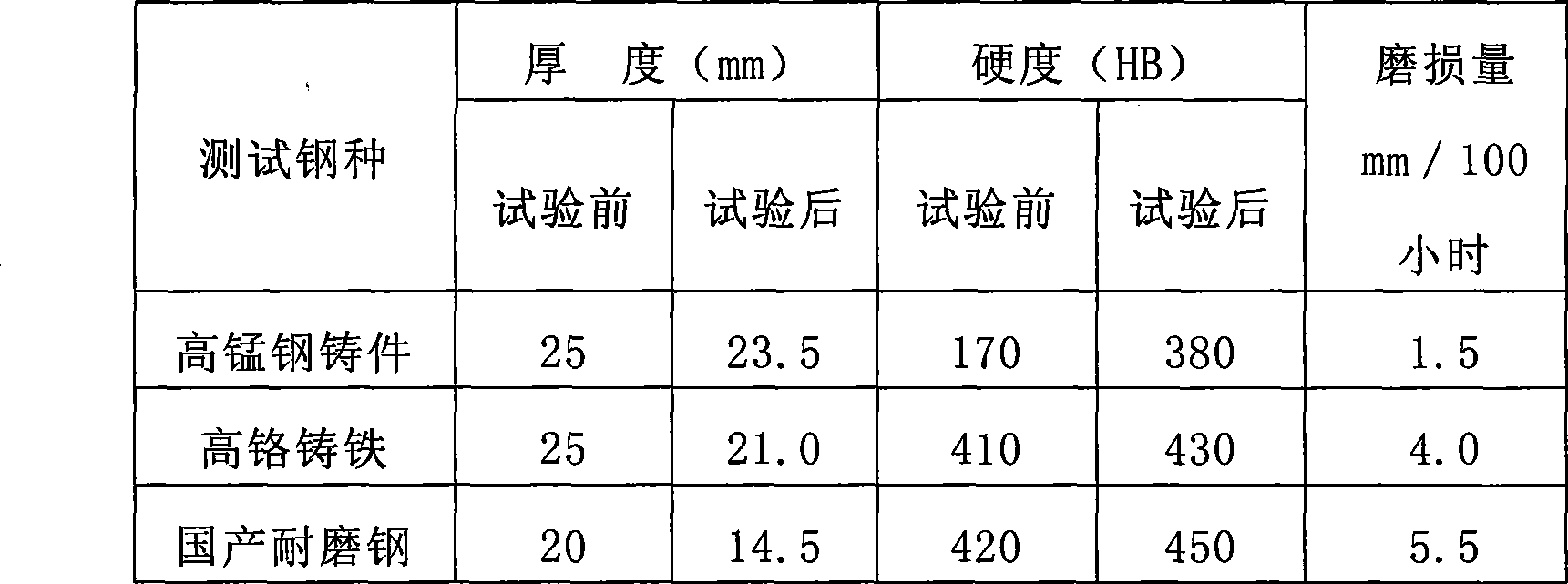

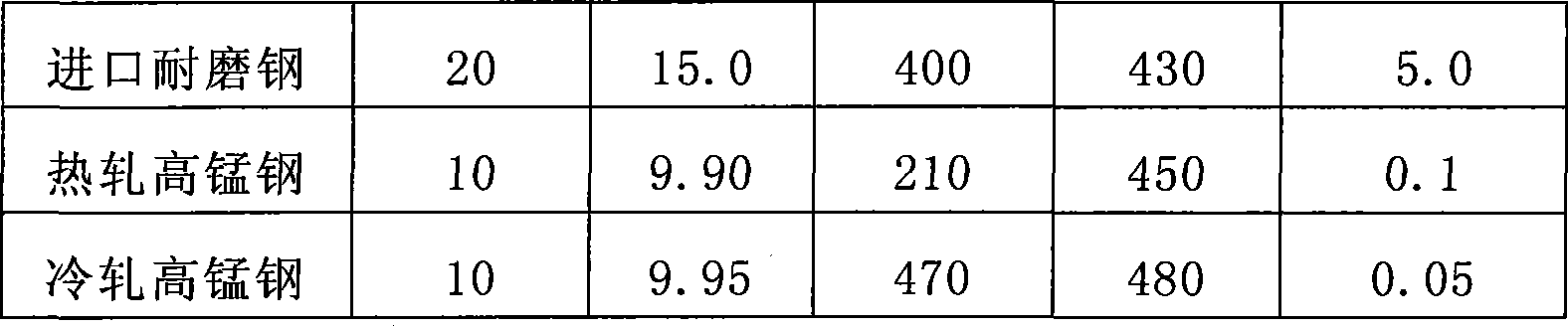

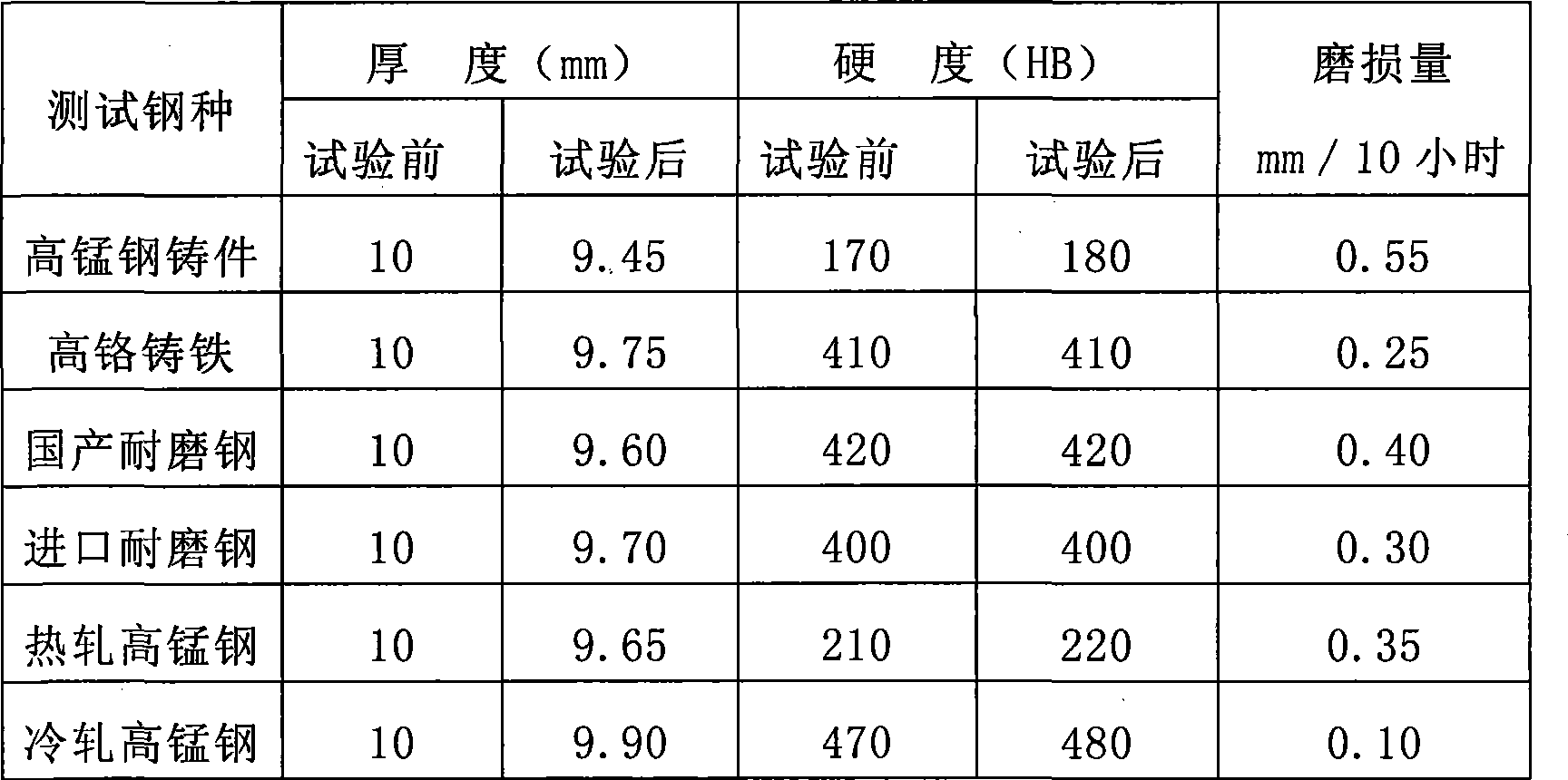

Method for producing high-manganses wear resistant steel plate and steel plate produced thereby

InactiveCN101423884ALess investment in productionImprove performanceFurnace typesHeat treatment furnacesSheet steelWear resistant

The invention relates to the technical field of steel production, in particular to a method for producing high-manganese wear-resistant steel plates, as well as a steel plate produced by the method. The invention discloses a method for producing high-manganese wear-resistant steel plates, which comprises the following steps of cold-rolling a hot-rolled high-manganese steel plate and obtaining a cold-rolled high-manganese steel plate. The production method has the advantages that the method is simple in steps, can fully utilize the prior equipment, reduce the production investment of enterprises, improves the properties of high-manganese steel and wear resistance, effectively increases the life span of the high-manganese steel, expands application range, and ensures that the high-manganese wear-resistant steel plates can completely replace high-manganese steel castings and high-chromium cast iron in environments of using plates. In addition, the production method reduces production pollution, protects environment, and saves resources and energy.

Owner:徐信

High-temperature synthesis gas sensible heat recovery device

ActiveCN101781586AIncreased thermal efficiency of gasificationGuaranteed uptimeChemical industryCombined combustion mitigationHigh pressureIntegrated gasification combined cycle

The invention relates to a high-temperature synthesis gas sensible heat recovery device which is characterized by comprising a radiation boiler, wherein the radiation boiler is connected with a convection boiler by a synthesis gas pipe. The invention recovers the sensible heat of the high-temperature synthesis gas from an entrained flow gasifier by using a radiation type steam generator, a gas quenching step and a convection type steam generator to generate medium-pressure or high-pressure steam, thereby increasing the thermal efficiency for the gasification of the entrained flow by more than10-15%. The device is concise and compact, has reliable operation and low investment, is a high-efficiency and energy-saving device, and can be widely used in the fields of integral gasification combination cycle power generation (IGCC), methanol and alkene production, coal-to-liquid, spongy iron production by the synthesis gas direct reduction iron-making method and the like.

Owner:SHANGHAI BOILER WORKS +2

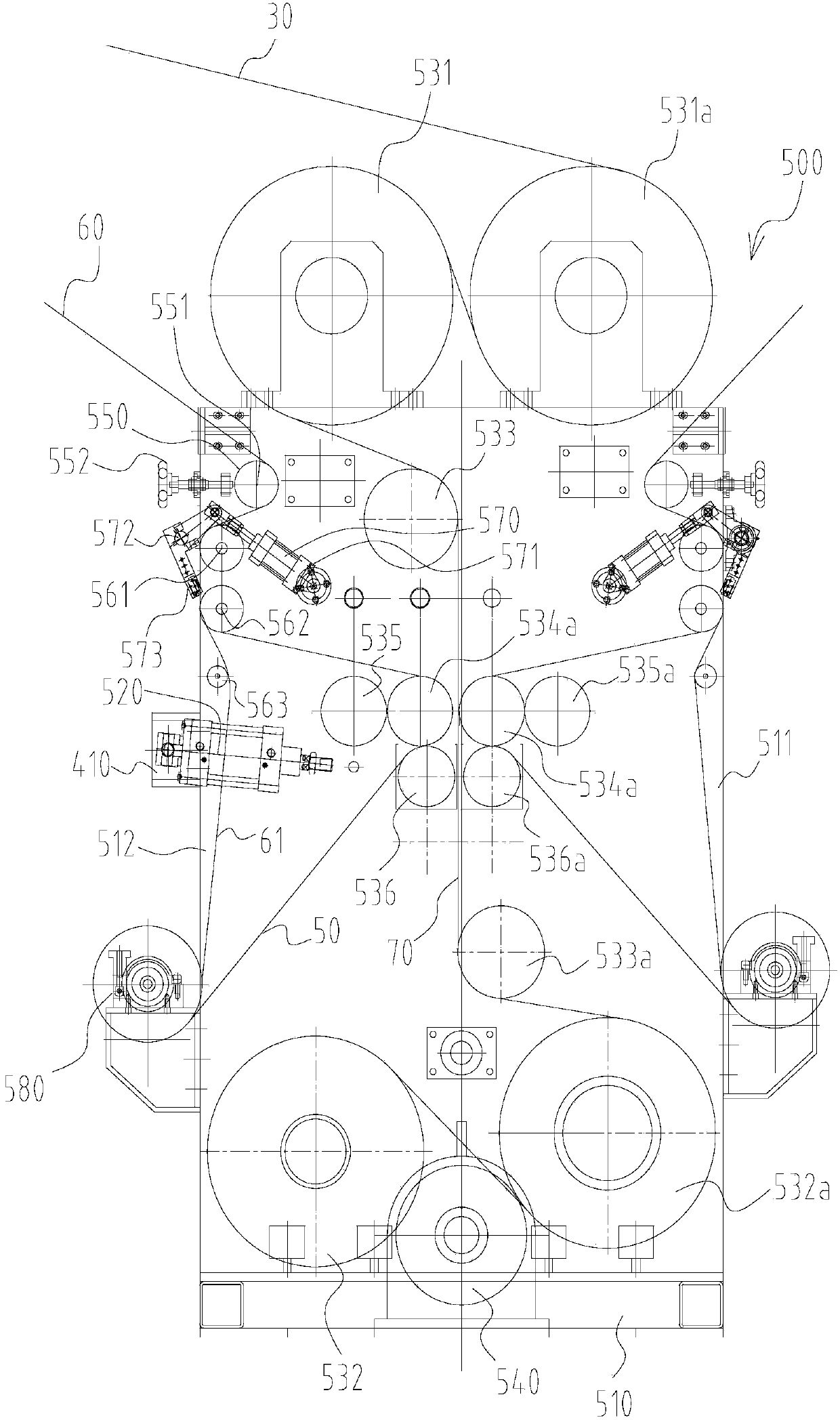

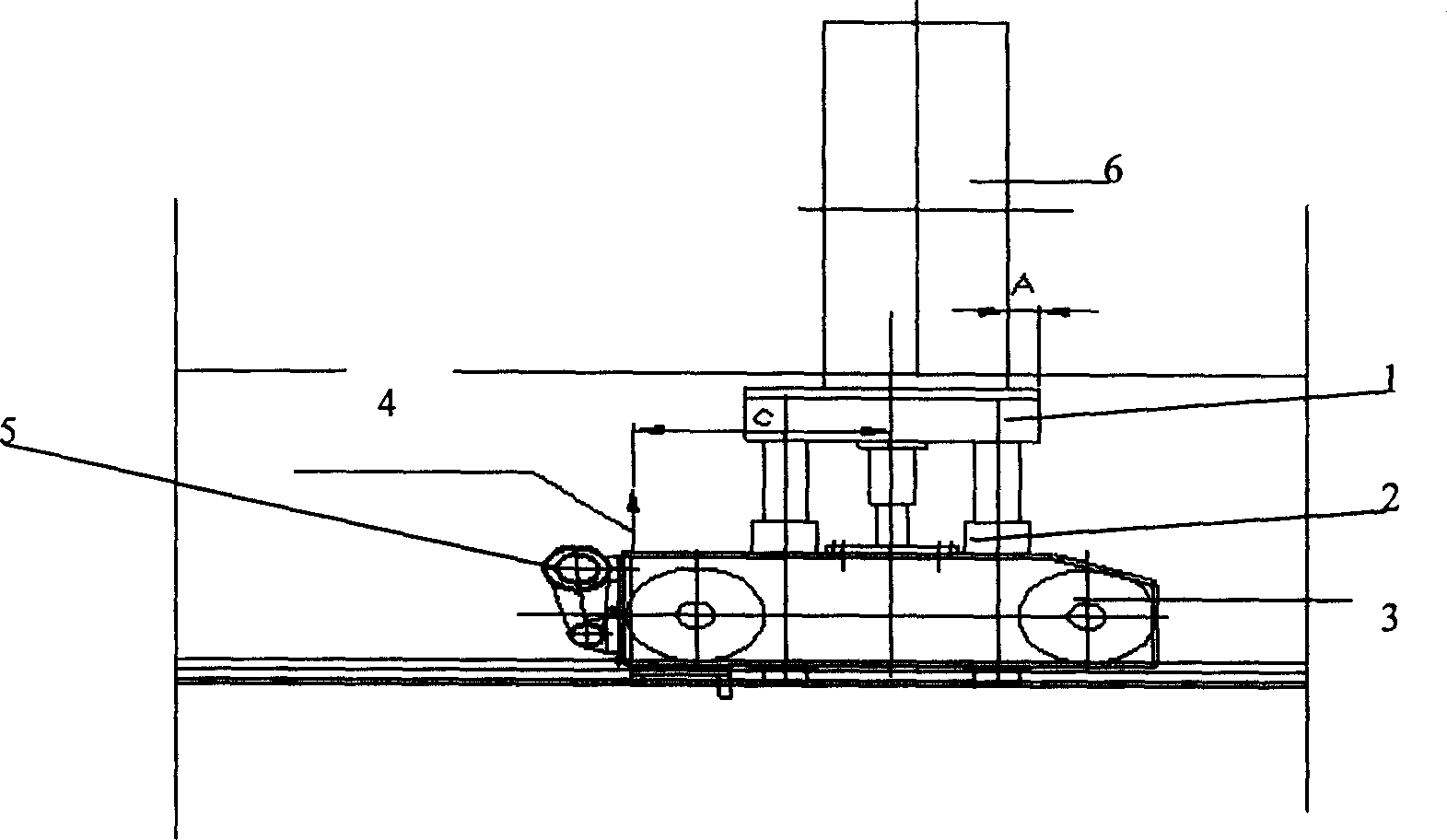

Automatic coil bearer locating apparatus and method

InactiveCN1857811APrecise deliveryAccurate parkingGuiding/positioning/aligning arrangementsConveyor partsBogieProduction line

The present invention relates to auxiliary iron and steel producing apparatus technology, and is especially automatic coil bearer locating apparatus and method for steel rolling production line and post-treatment line. The apparatus includes bearing seat, elevating mechanism, running mechanism, steel coil position detecting element, apparatus stroke detecting and locating control system. The present invention makes it possible to locate steel coil bogie or other conveying toll relatively to the coil accurately. The present invention is simple, smart and reliable.

Owner:BAOSTEEL ENG & TECH GRP

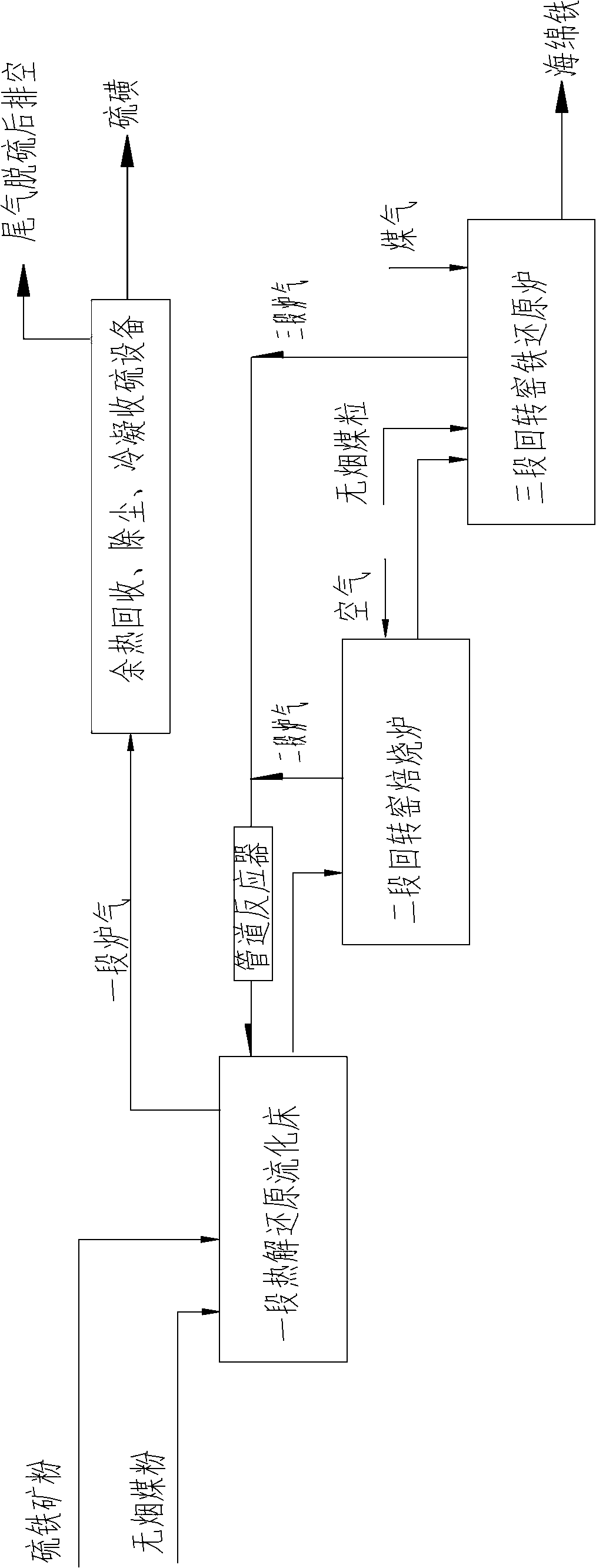

Method for producing sulfur by using pyrolysis-reducing united technique

ActiveCN103011090AIncrease profitIncrease concentrationEnergy inputSulfur preparation/purificationThermal energySlag

The invention discloses a method for producing sulfur and co-producing sponge iron by using a pyrolysis-reducing united technique, which comprises the following steps of: firstly carrying out first-step desulfurization-high temperature pyrolysis on sulfur-iron ores on a section of pyrolysis-reducing fluidized bed so as to generate sulfur steam and ferrous sulfide, wherein heat required by the pyrolysis process is mainly supplied by high-temperature flue gas from a pipe reactor and part of material combustion heat produced in the process; and 2, reducing iron oxide slag of a second-section furnace by using a coal-based rotary kiln direct reduction method, namely that on the basis of adopting a mature sponge iron production technology, fully using the high-order heat energy and high activity of the iron oxide slag discharged from the second-section furnace, therefore, effects of remarkably saving energy and reducing consumption as well as improving the production efficiency are achieved. The method is remarkable in energy saving effect, high in comprehensive utilization of mineral resources, environmental-friendly, and especially applicable to the large-scale development and utilization of sulfur-iron resources in sulfur resource-rich areas and the comprehensive utilization of high-sulfur fault coals; and meanwhile, the method also provides a new way for the comprehensive and efficient utilization of associated sulfur resources in the non-ferrous smelting industry.

Owner:新疆中驰恒谊环保科技有限公司

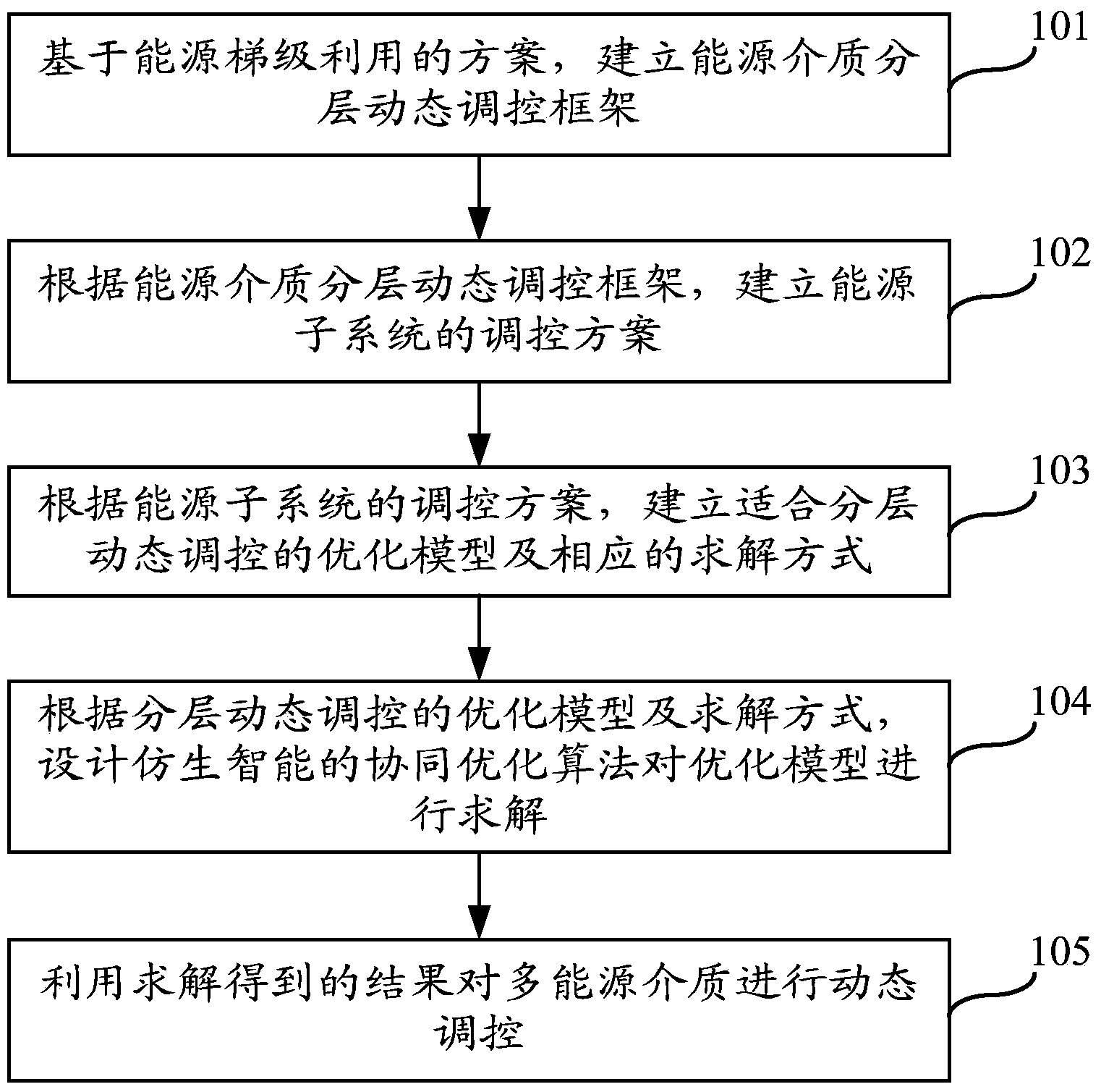

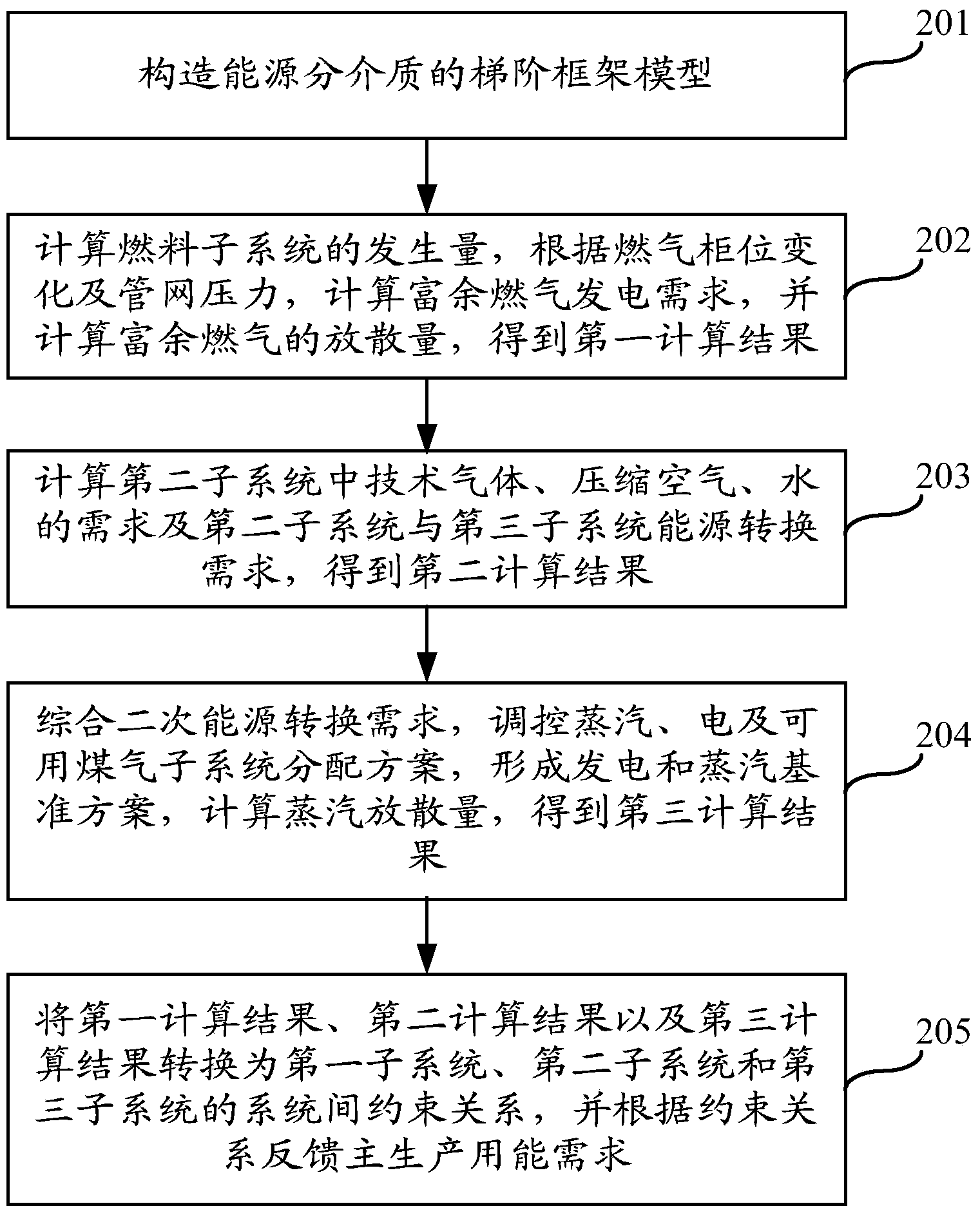

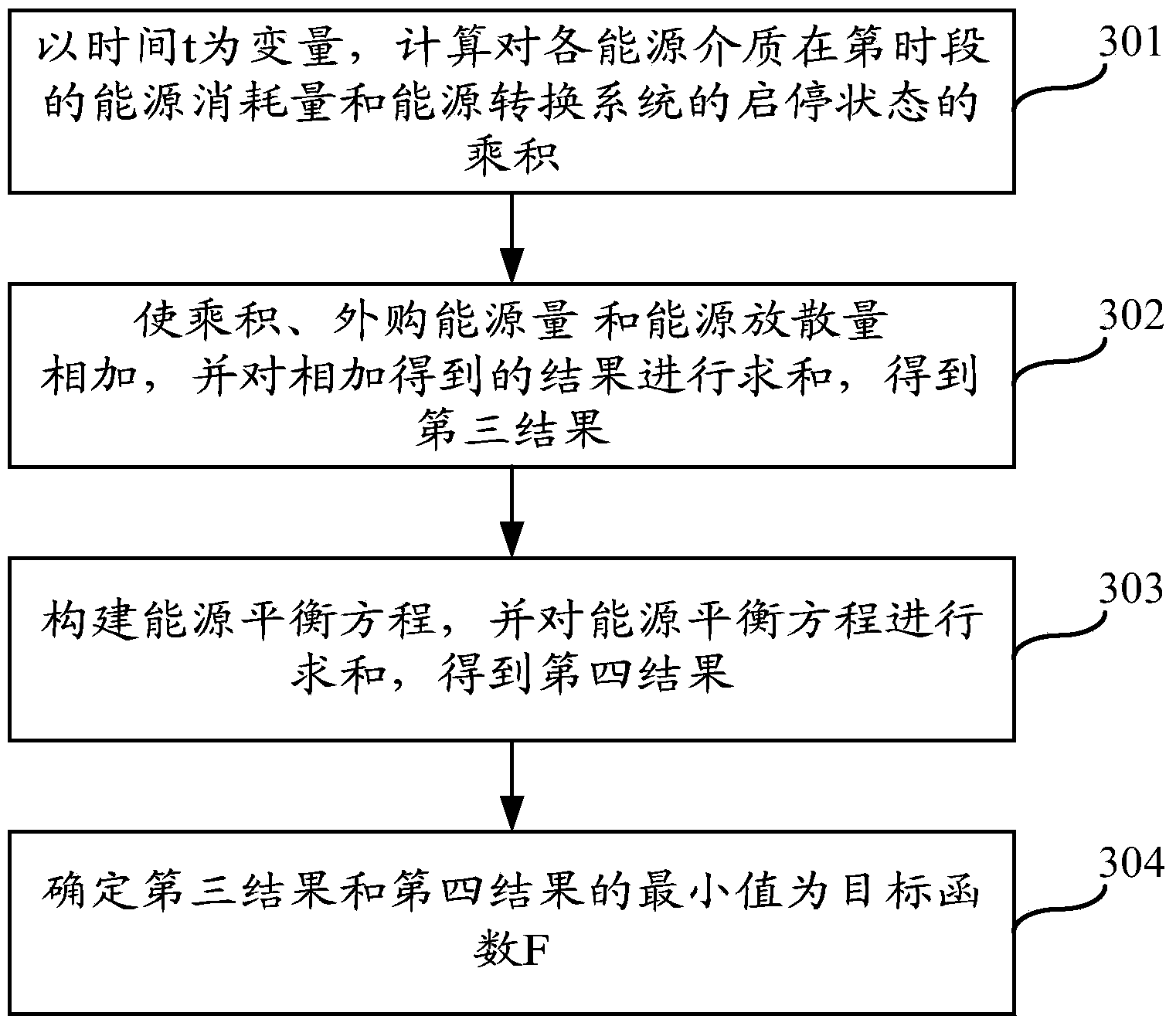

Layered dynamic regulation method for multiple energy media

The invention provides a layered dynamic regulation method for multiple energy media. The method comprises the steps that on the basis of an energy gradient utilization scheme, an energy medium layered dynamic regulation frame is built; according to the energy medium layered dynamic regulation frame, a regulation scheme of an energy subsystem is built; according to the regulation scheme of the energy subsystem, an optimization model and a corresponding solution mode which are suitable for layered dynamic regulation are built; according to the optimization model and the solution mode of layered dynamic regulation, a collaborative optimization algorithm of bionic intelligence is designed to solve the optimization model; dynamic regulation is carried out on multiple energy media according to the result obtained through solution. According to the layered dynamic regulation method for multiple energy media, a regulation strategy suitable for layered step collaborative optimization of multiple energy media is built, multi-cycle multi-target dynamic collaborative optimization of energy regulation is achieved, the optimization model is built, a differential evolution algorithm with a self-learning mechanism is designed to solve the optimization model, collaborative optimized dispatching of multiple energy media in a complex environment for steel production is achieved, and the method is good in comprehensive economical efficiency and effectiveness.

Owner:徐雪松

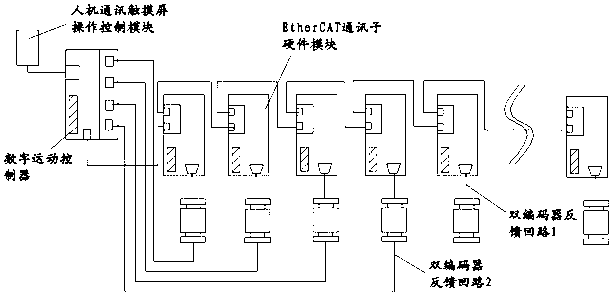

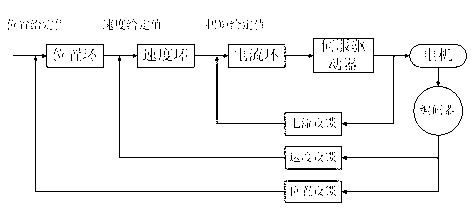

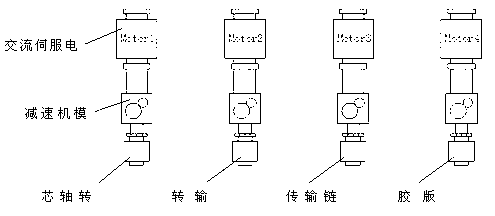

Can printing machine numerical-control system based on digital motion controller

ActiveCN103076766AEasy to make costEasy to control synchronouslyComputer controlSimulator controlProduction lineControl system

The invention relates to a can printing machine numerical-control system based on a digital motion controller, and the can printing machine numerical-control system comprises a human-machine communication touch screen operation control module based on a windows platform, a digital motion controller, a motion actuation module and a reducer module, wherein the human-machine communication touch screen operation control module based on the windows platform is connected with the digital motion controller through an Ethernet network cable, and the digital motion controller and an input / output (I / O) sub-board of the digital motion controller are directly connected with an I / O signal connection terminal of the motion actuation module, i.e. an alternative-current servo motor; the digital motion controller is connected with the motion actuation module i.e. the alternative-current servo motor through an Ethernet bus; and the digital motion controller is connected with four alternative-current servo motors to form a double-closed-loop motion control system. The system is simple in structure, each constitutional part is relatively independent, partial hardware can be directly purchased in the market to be used as the constitutional part, not only can the performance be comparable and the cost be reduced, but also simplicity in assembling, application and upgrading can be realized, and the tank printing machine numerical-control system can be mass popularized to a pop can printing production line and similar iron production lines.

Owner:FOSHAN DING ZHONG MACHINERY

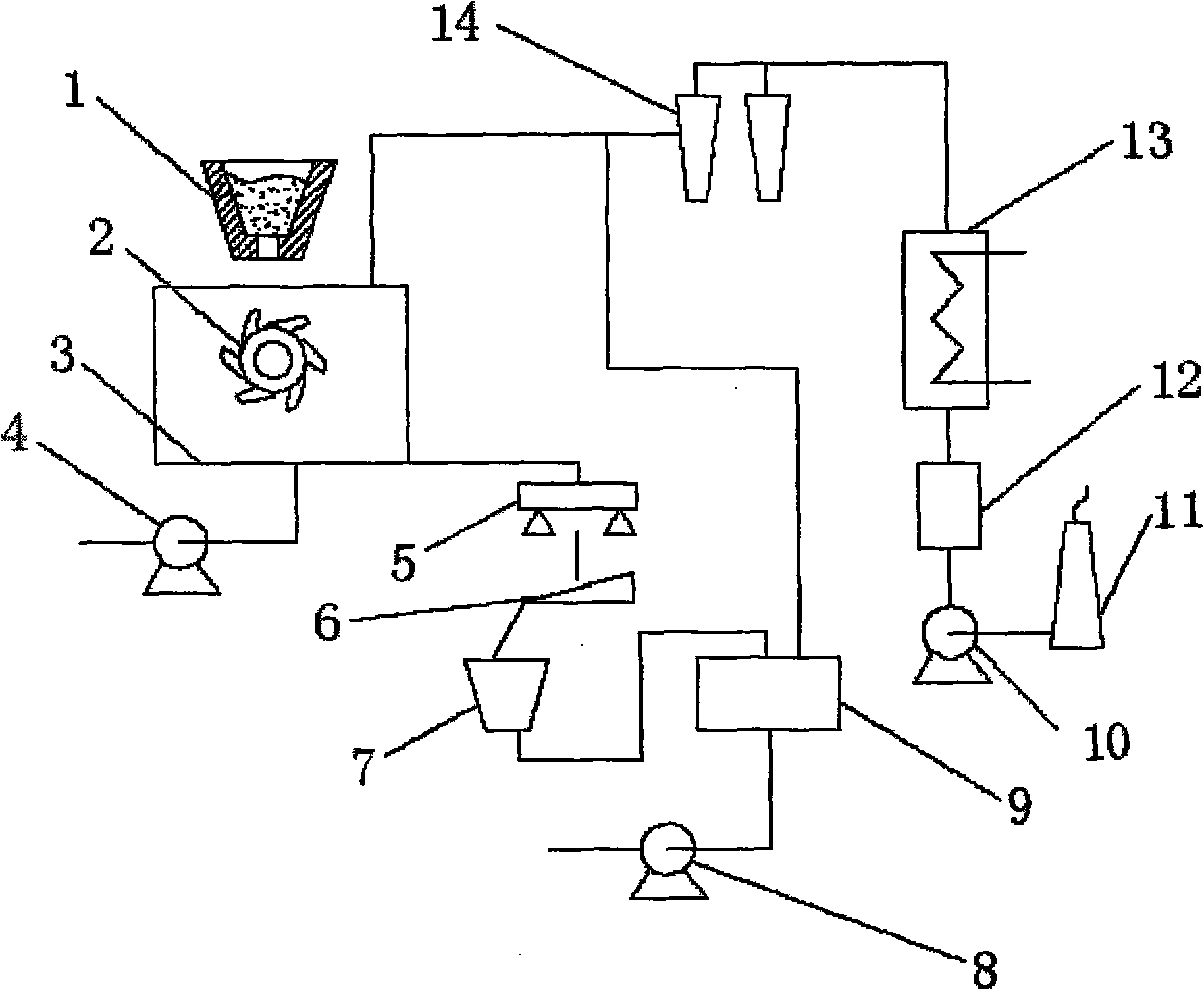

Recovery method of steel slag residual heat and system thereof

ActiveCN101551199AReduce consumptionEliminate pollutionProcess efficiency improvementWaste heat treatmentRecovery methodFluidized bed

The invention discloses a recovery method of steel slag residual heat and system thereof. The system is composed of a steel slag flow distributor, a water-cooling granulation wheel, a first fluidized bed, a weigher, a vibration sieve, a hot slag particles bunker, a second fluidized bed, a dedusting device, a blower and a residual heat boiler in sequence. The method is that, pouring high-temperature liquid slag into the steel slag flow distributor, the steel slag flown out of the steel slag flow distributor falling onto the water-cooling granulation wheel and being crushed and throwing out to fall into the first fluidized bed for exchanging heat with air, hot slag particles discharged from the first fluidized bed is stored in the hot slag particles bunker after going through the weigher and the vibration sieve, and discharging when the temperature is cooled to 350 DEG by a heat exchanger of the second fluidized bed. High-temperature air discharged from the first fluidized bed and the second fluidized bed enters the residual heat boiler for exchanging heat after dedusting. The invention can reduce energy consumption in steel production, graining effect of the steel slag is good, which is benefit for following degradation of free CaO and magnetic separation of wasted steel.

Owner:HANGZHOU BOILER GRP CO LTD

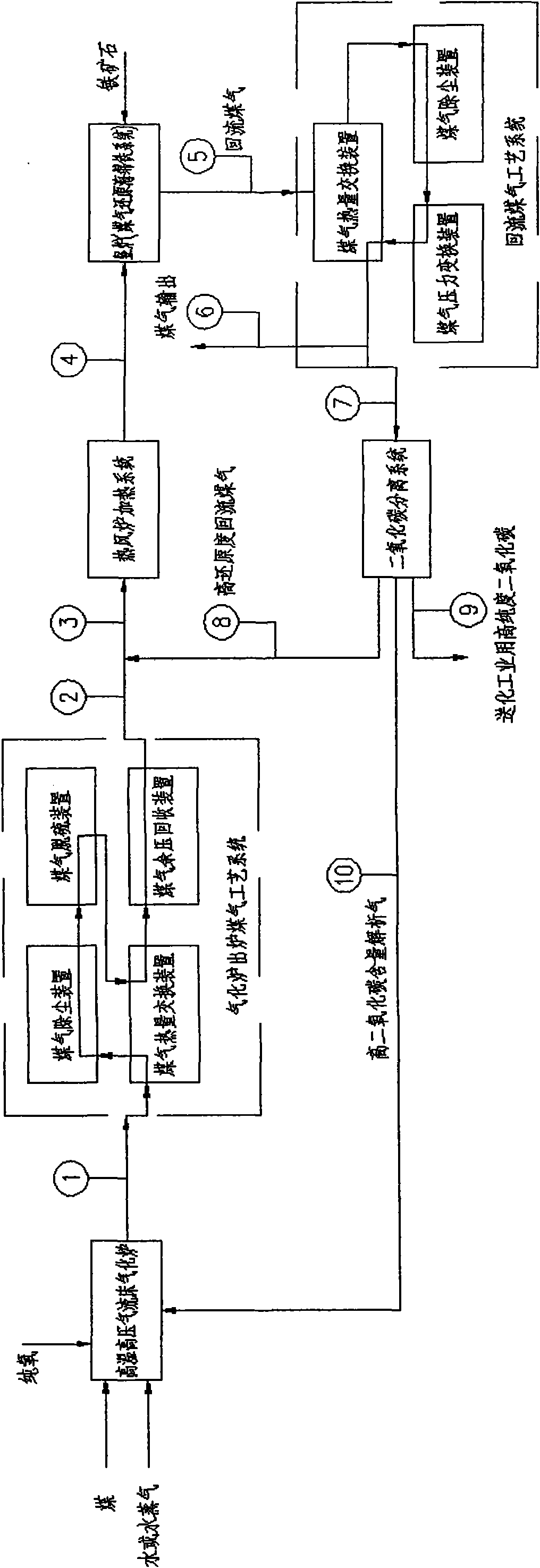

Sponge iron production technology by coal gasification

ActiveCN101643809AReduce consumptionReduce investmentProcess efficiency improvementShaft furnaceProcess systemsWater vapor

The invention belongs to the metallurgy technical field and discloses a sponge iron production technology by coal gasification. The invention is characterized in that: coal and oxygen, water or steamreact in a high temperature high pressure entrained flow gasifier to generate reducing coal gas rich in CO+H2, the reducing coal gas is subject to dust removal, desulfuration and pressure and heat transformation by a gasifier discharge coal gas process system and then mixed with decarburization gas rich in CO+H2 after shaft furnace top gas passes through a return coal gas process system and a carbon dioxide separation system, and then the mixed gas is heated to the temperature range required by the shaft furnace and then fed into the shaft furnace to reduce iron ore, so as to produce sponge iron. The invention reduces high temperature high pressure entrained flow gasifier cost; the shaft furnace top gas circulating reflux is fully utilized to reduce coal use consumed in sponge iron production, and cost is saved; and CO2 is collected and recycled.

Owner:CISDI ENG CO LTD

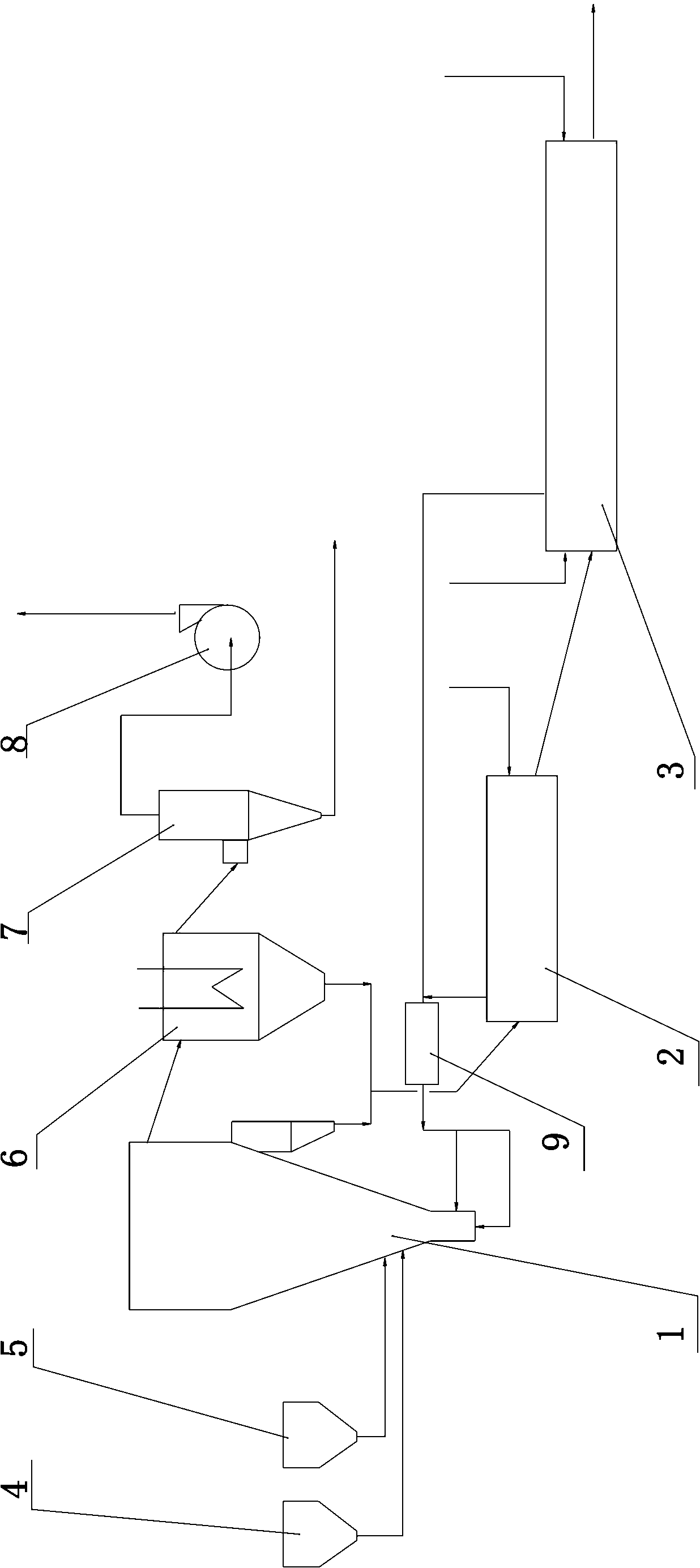

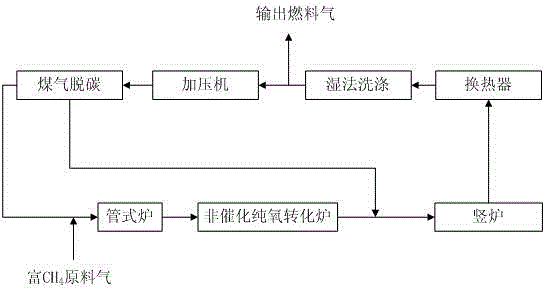

Direct reduction process for sponge iron production implemented by using non-catalytic conversion of CH4

ActiveCN103146866ALower the preheat temperatureLess investmentShaft furnaceGas emission reductionDust controlShaft furnace

The invention discloses a direct reduction process for sponge iron production implemented by using the non-catalytic conversion of CH4, and the direct reduction process comprises the following steps: feeding a feed gas rich in CH4 and subjected to purification and pressure regulation and a stock gas output by a shaft furnace and subjected to cooling, dust removal, pressurization and decarburization into a tube furnace together and preheating; feeding the preheated coal gas into a non-catalytic pure oxygen reforming furnace, performing combustion reaction and heating on the preheated coal gas and oxygen in the non-catalytic pure oxygen reforming furnace, and performing non-catalytic conversion on the CH4 so as to generate CO+H2; after the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace and the stock gas discharged at the front end and subjected to cooling, dust removal, pressurization and decarburization are mixed and cooled, feeding the mixed gas into the shaft furnace and reducing iron ores, thereby producing sponge irons; and after the stock gas discharged from the shaft furnace is subjected to cooling, dust removal, pressurization and decarburization, feeding part of the stock gas and the supplementary feed gas rich in CH4 into the tube furnace and the non-catalytic pure oxygen reforming furnace together, wherein the other part of the stock gas is used as the cold-doped coal gas of the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace. Because the preheating temperature is low, no carbon precipitation occurs, and no strict limitation on the H2S content of the feed gas rich in CH4 exits, so that the bonding of the sponge irons can be prevented.

Owner:CISDI ENG CO LTD

Recovery method of blast furnace slag water residual heat and method thereof

ActiveCN101550461AEnsure safetyGuaranteed lifeIncreasing energy efficiencyWaste heat treatmentRecovery methodSlag

The invention discloses a recovery method of blast furnace slag water residual heat and method thereof. The recovery system of resudual heat includes a blast furnace slag system, a sedimentation tank, a hydrocyclone separator, a water pump, a heat exchanger, a steam turbine, a refrigerant condenser, a refrigerant pump. The recovery method is that applying bicirculating low temperature hot water generation system to recovery residual heat and penerating power. The specific process is: guiding the blast furnace slag water into the heat exchanger after preprocessing of impurity precipitation and transmitting heat to low boiling refrigerant; the low boiling refrigerant absorbing heat in the heat exchanger and entering the steam turbine for expansion of doing work; the refrigerant after doing wirk changing into low-pressure superheated steam, the low-pressure superheated steam entering the concenser to releast heat and changing into liquid refrigerant of low-temperature and low-pressure, then being sent to the heat exchanger by the refrigerant pump for absorbing heat, becoming the superheated steam again to push the steam turbine to do work. The invention can recovery residual heat of the blast furnace slag water and generate power, and reduce energy consumption in steel production; and reduce temperature of blast furnace slag water which is benefit to improve quality of blast furnace water slag and reduce discharge of sulphide in slag washing process.

Owner:HANGZHOU BOILER GRP CO LTD

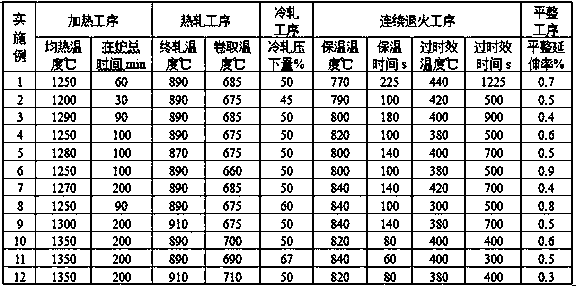

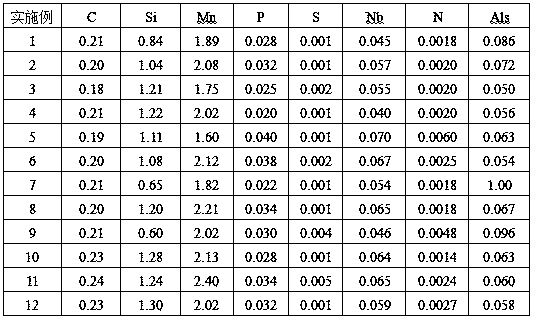

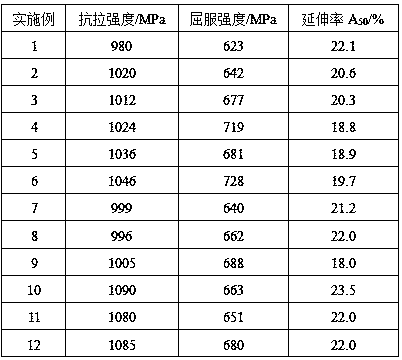

980MPa-grade automobile cold-rolled high-strength Q&P steel and production method thereof

The invention discloses 980MPa-grade automobile cold-rolled high-strength Q&P steel and a production method thereof, and belongs to the technical field of steel production. The Q&P steel comprises thefollowing components, by weight percentage: 0.18-0.24% of C, 0.60-1.30% of Si, 1.60-2.40% of Mn, 0.02-0.04% of P, less than or equal to 0.005% of S, 0.040-0.070% of Nb, less than or equal to 0.0060%of N, 0.50-1.0% of Als and the balance of Fe and inevitable impurities. The production method comprises the steps of carrying out steel-making, carrying out heating, carrying out hot rolling, carryingout cold rolling, carrying out continuous annealing and carrying out leveling, wherein the holding temperature of a soaking zone in the continuous annealing process is 770-840 DEG C, and the holdingtemperature of an overaging zone is 300-440 DEG C. The obtained Q&P steel has the advantages that the mechanical property is excellent, the yield strength is greater than or equal to 550MPa, the tensile strength is greater than or equal to 980MPa, the elongation percentage is greater than or equal to 18%, and the cold forming property is good.

Owner:TANGSHAN IRON & STEEL GROUP +1

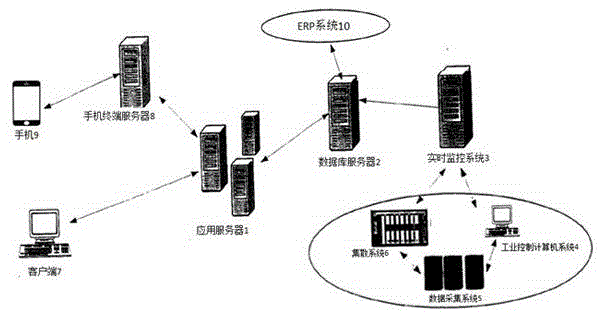

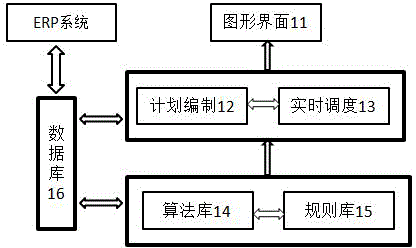

Iron and steel enterprise production scheduling management system and production scheduling management method

InactiveCN104835012AEliminate biasSolve the problem that the front and back processes are difficult to coordinateResourcesManufacturing computing systemsApplication serverDatabase server

The invention provides an iron and steel enterprise production scheduling management system and a production scheduling management method, which is applied to plan formulation and real-time scheduling in the production process of iron and steel enterprises. The iron and steel enterprise production scheduling management system comprises a database server, an application server, a client and a real-time monitoring system. The production scheduling management method comprises plan formation, dynamic monitoring and real-time scheduling. The advantages lie in that production plan automatic formation and real-time scheduling are integrated, a problem that front and back working procedures are difficult to be coordinated in dynamic scheduling is solved, and the system and the method are applicable to iron and steel production enterprises with a characteristic of fixed flow.

Owner:HUNAN STEERING SCI & TECH DEV

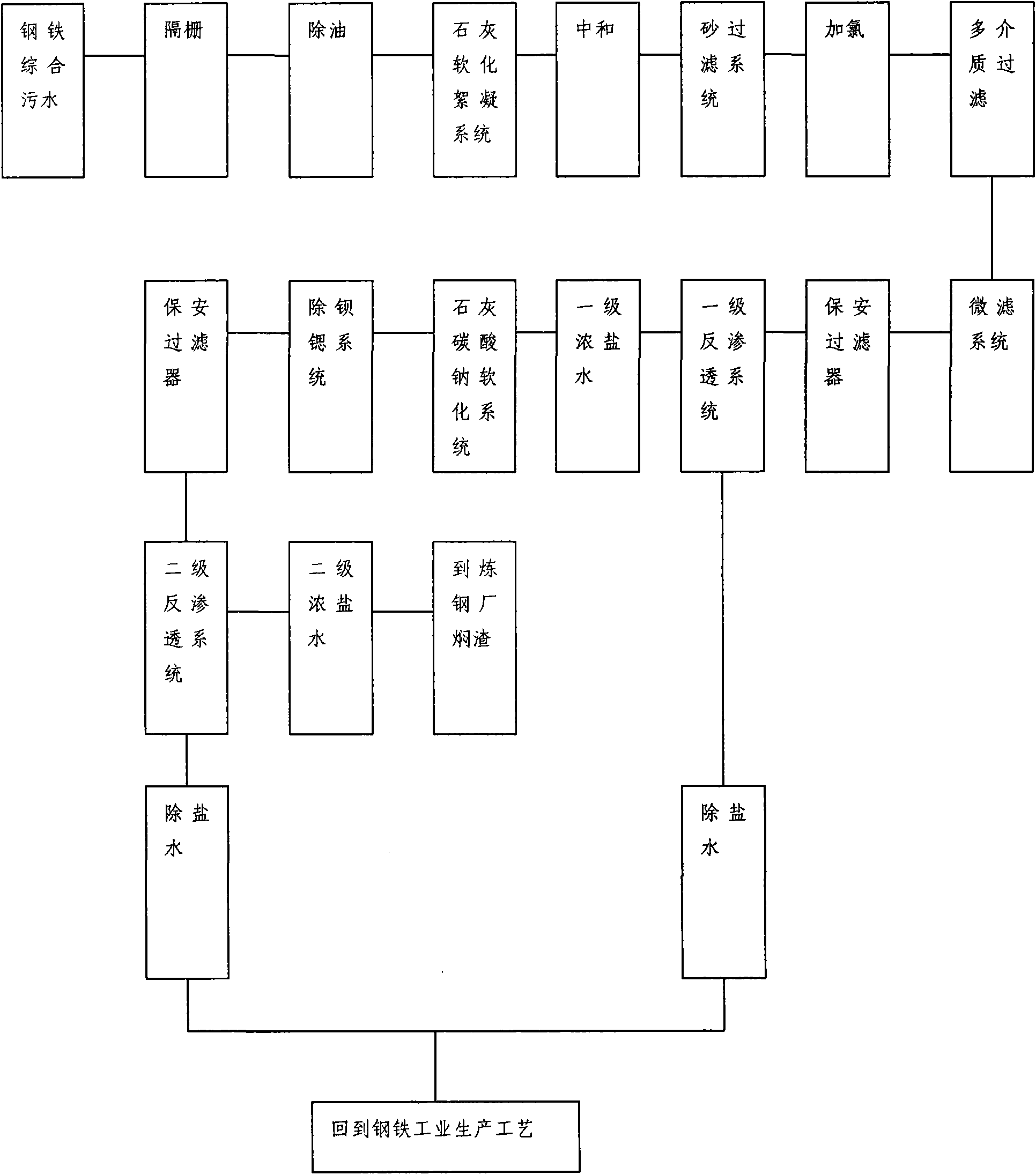

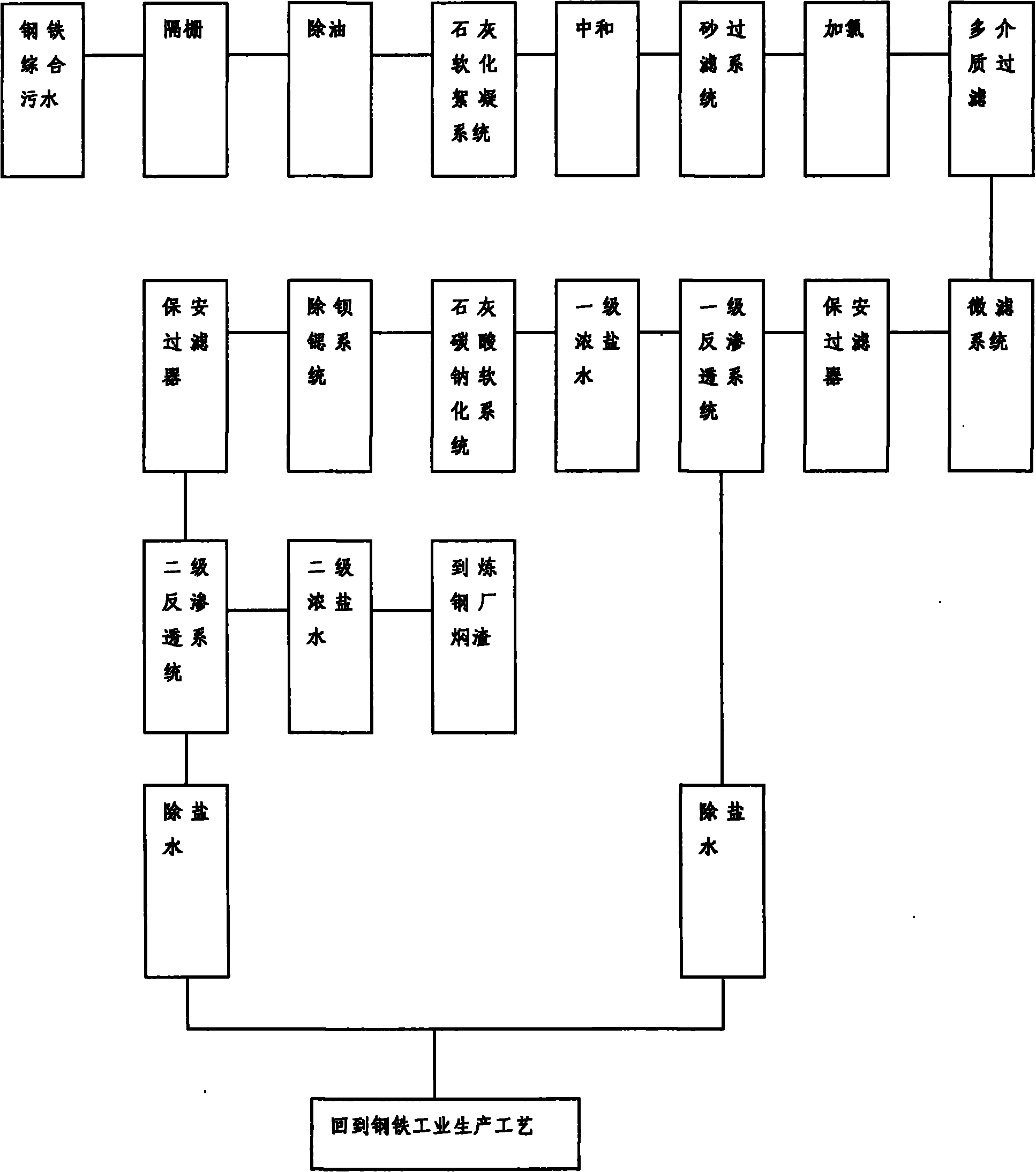

Method for comprehensive wastewater desalination and zero release in steel production

ActiveCN102030437AAvoid easy cloggingTo achieve the goal of zero pollutionGeneral water supply conservationWaste water treatment from metallurgical processSteelmakingFlocculation

The invention discloses a method for comprehensive wastewater desalination and zero release in steel production, belonging to the technical field of wastewater desalination and zero release. The method comprises the following steps of: introducing wastewater to a regulating pond through a fence, wherein the regulating pond is provided with a deoiling device; deoiling the wastewater; then introducing the wastewater into a lime softening flocculation precipitation system; enabling a supernatant to be subjected to neutralization, sand filtration, chlorination, multi-medium filtration and then introducing into a micro-filtration system, a cartridge filter and a primary reverse osmosis system; introducing primary reverse osmosis strong brine to a lime sodium carbonate softening system, the cartridge filter and a secondary reverse osmosis system; introducing secondary reverse osmosis strong brine for steelmaking and slag stewing so as to achieve zero release; and returning primary reverse osmosis demineralized water and secondary reverse osmosis demineralized water to the steel production process for application. The method has the advantages that a film is not blocked easily and the service life of equipment is long because the micro-filtration system, the primary reverse osmosis system, the resin softening system, the cartridge filter and the secondary reverse osmosis system are utilized. The primary reverse osmosis strong brine is introduced to the lime sodium carbonate softening system, the cartridge filter and the secondary reverse osmosis system; and the secondary reverse osmosis strong brine is introduced for steelmaking and slag stewing so as to achieve zero release of the wastewater.

Owner:BEIJING SHOUGANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com