Automatic coil bearer locating apparatus and method

A technology of positioning device and positioning method, which is applied in the directions of guiding/positioning/alignment devices, transportation and packaging, conveyor objects, etc., and can solve problems such as inaccurate position determination, affecting coil winding, and increasing equipment failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

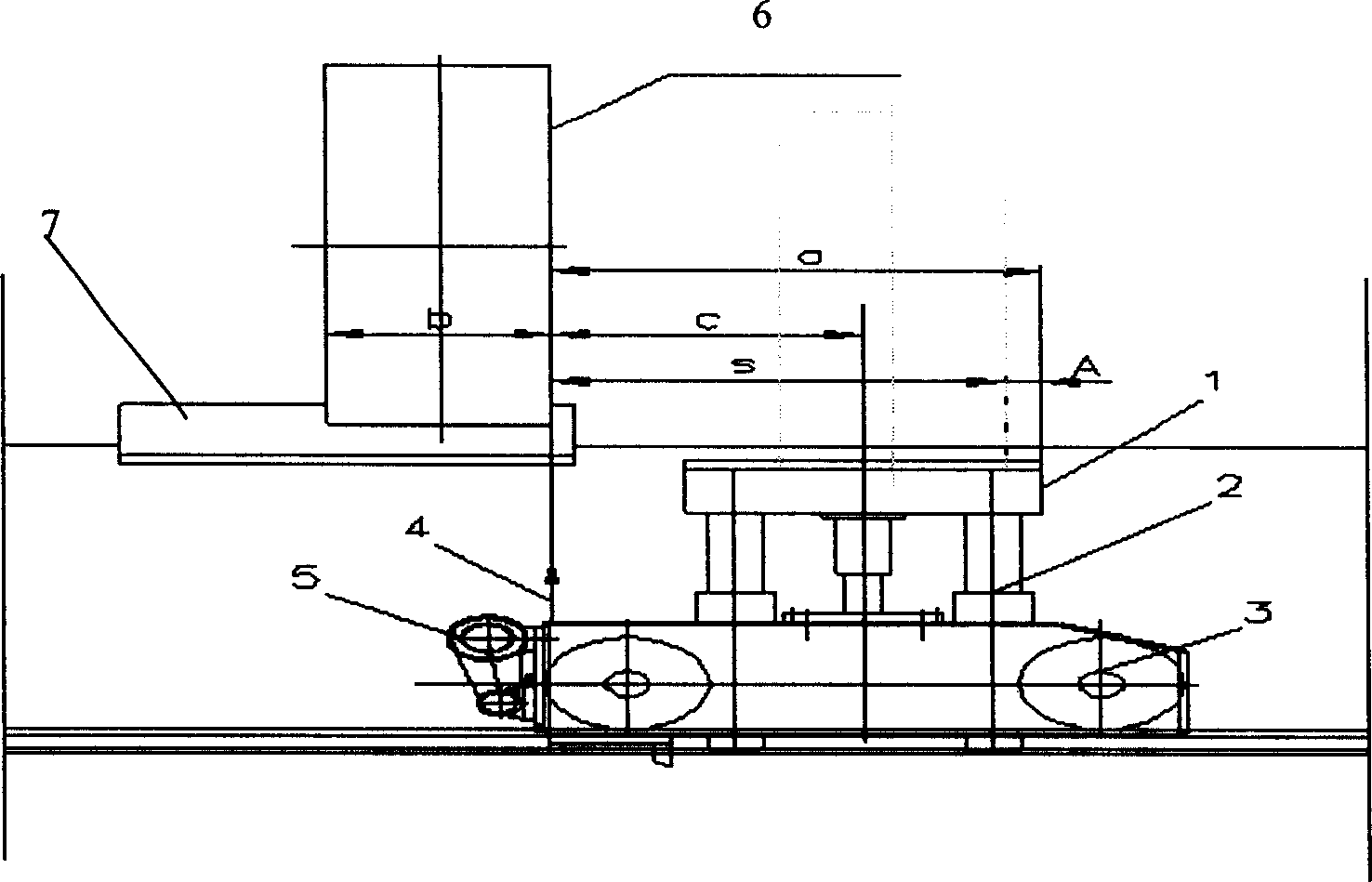

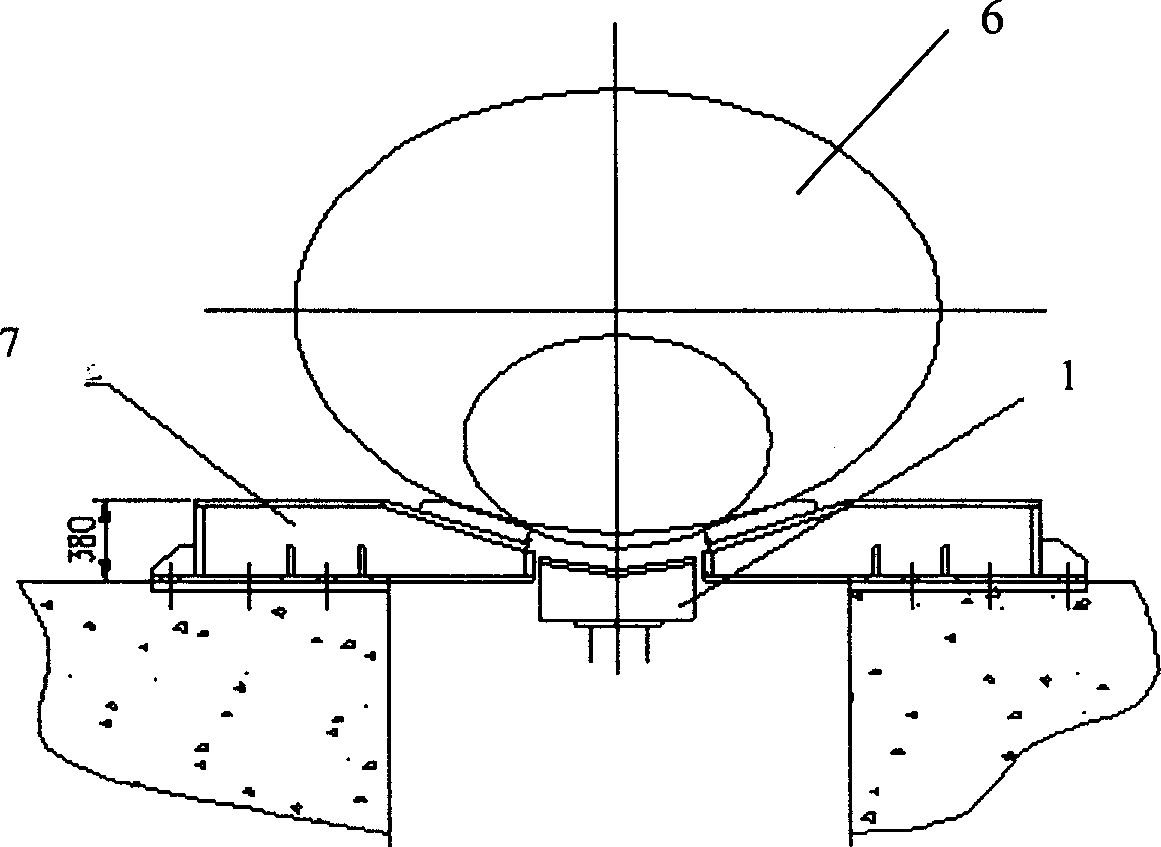

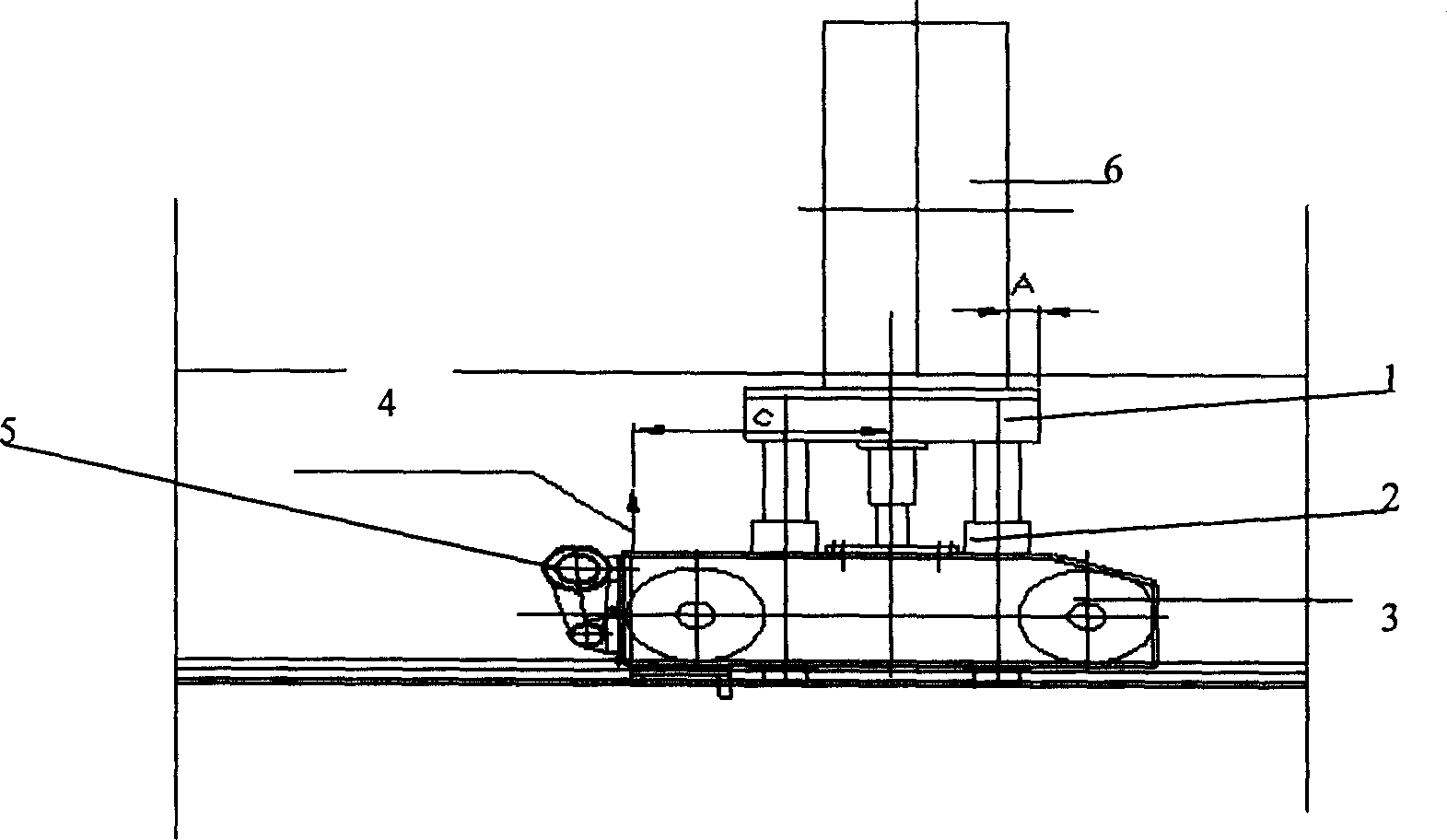

[0014] According to the drawings, the bracket 1 is made of steel structure processed by welding machine, the lifting mechanism 2 can use hydraulic cylinder or electric screw structure as power, and the running mechanism 3 is made of steel structure frame processed by welding machine, machined wheels and hydraulic pressure. A gear motor or a gear motor is used as the transmission device of the power mechanism, and a steel coil detection element 4 (reflective detection elements such as ultrasonic waves or photoelectric cells) is installed at the front end of the device. During operation, when the steel coil detection element 4 detects the front end of the steel coil on the fixed saddle, the relative position (distance e) between the steel coil front end and the bracket on the device is now determined, and the device continues to move forward , can also measure the coil width b and the position (distance e) of the steel coil center relative to the carrier, through relative stroke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com