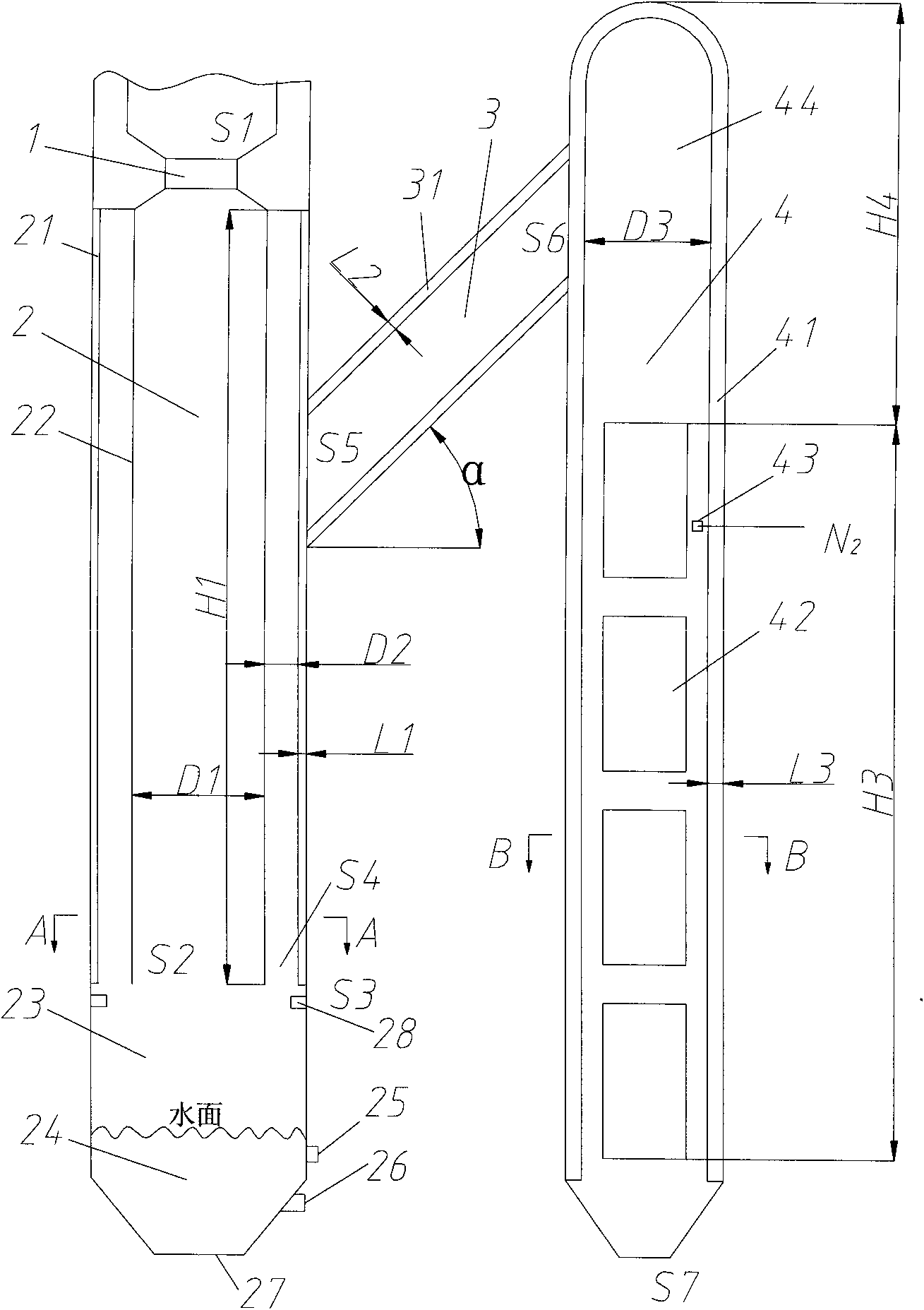

High-temperature synthesis gas sensible heat recovery device

A technology of sensible heat recovery and synthesis gas, which is applied in the directions of joint combustion mitigation, production of combustible gas, and climate sustainability. The device is simple and compact, the investment is low, and the operation is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

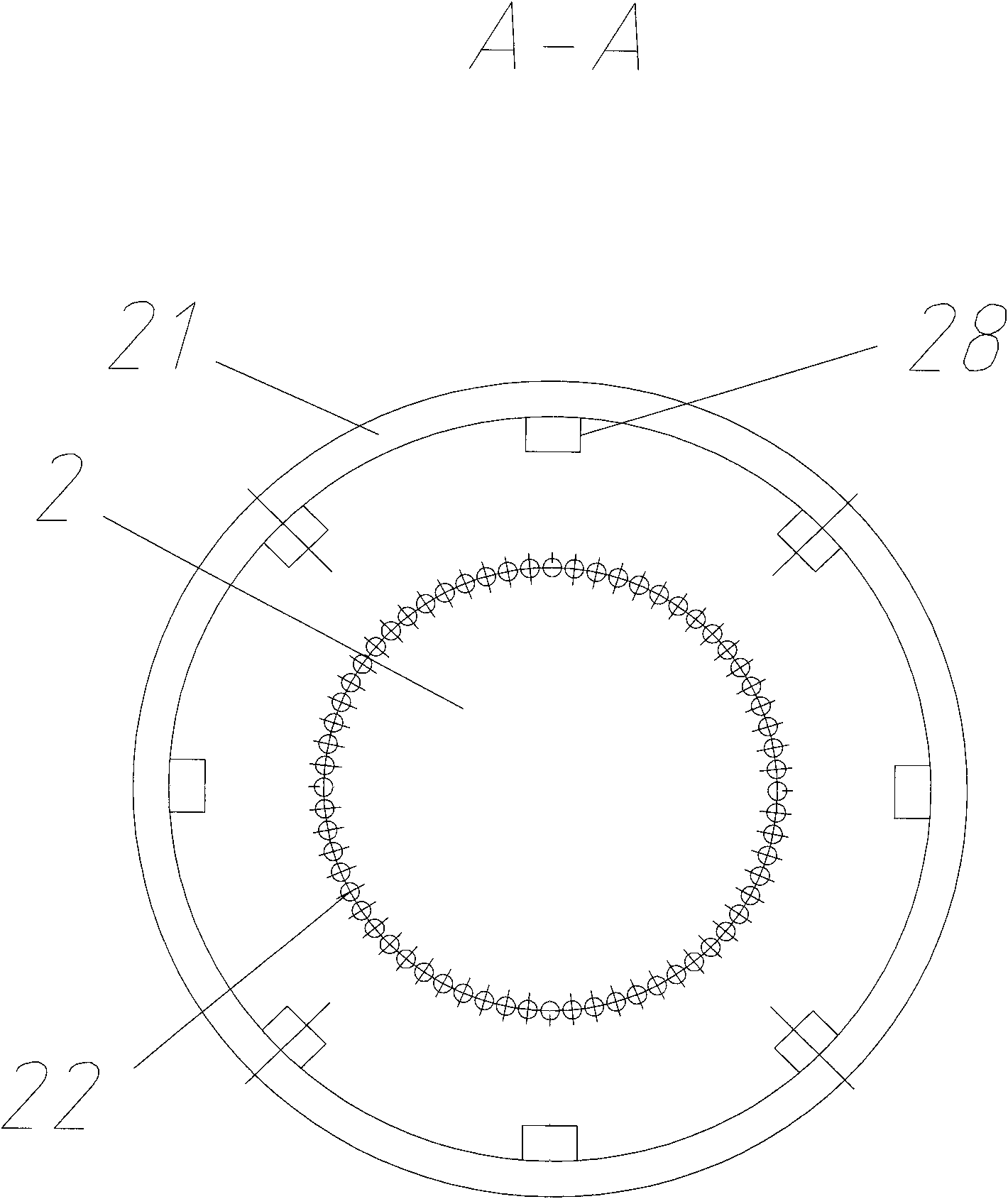

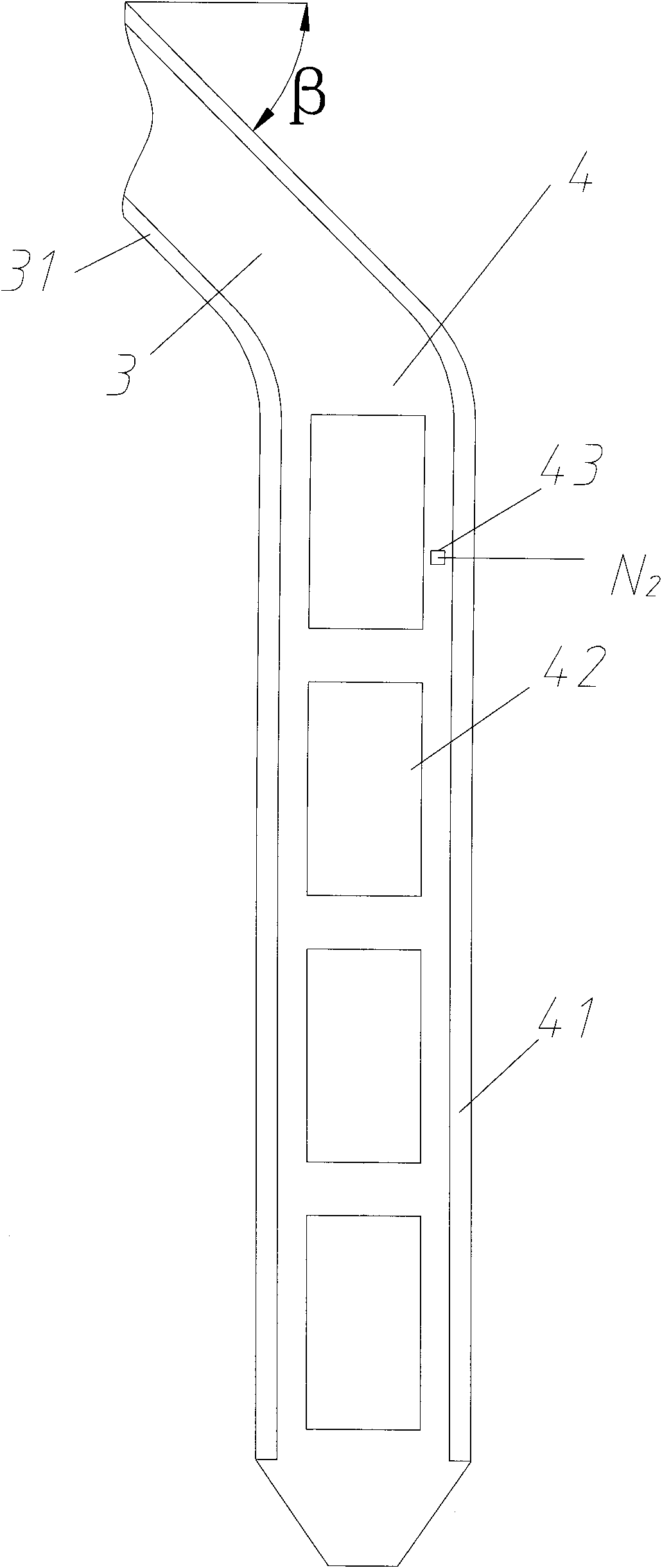

Image

Examples

Embodiment

[0044] A pulverized coal fed entrained gasifier with a daily processing capacity of 2,000 tons of coal, the operating pressure is 4.0 MPa, and the operating temperature is 1,500°C. The characteristic data of the coal used are:

[0045] Industrial Analysis:

[0046] Received base moisture Mar 14% (wt);

[0047] Received base volatile Var 36.49% (wt)

[0048] Received base ash Aar 12% (wt)

[0049] Elemental analysis:

[0050] Received base carbon Car 61.45% (wt)

[0051] Received base hydrogen Har 3.61% (wt)

[0052] Received base oxygen Oar 7.80% (wt)

[0053] Received base nitrogen Nar 0.71% (wt)

[0054] Received base total sulfur St, ar 0.43% (wt)

[0055] Calorific value:

[0056] Received base low calorific value Qnet, ar 23420kJ / kg

[0057] Ash melting point:

[0058] Flow temperature FT 1350°C

[0059] The process data of the syngas outlet of the gasifier and the sensible heat recovery device of the high-temperature syngas are shown in Table 1:

[0060] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com