Method for producing high-manganses wear resistant steel plate and steel plate produced thereby

A production method and technology of wear-resistant steel plates, which are applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of urgent changes in high manganese steel production technology, low production efficiency, and energy waste, so as to reduce production pollution and protect Environment, the effect of reducing production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Production of cold-rolled high manganese steel plate

[0029] Heat the steel slab after rough rolling, grinding and finishing to 1200°C (furnace temperature) for hot rolling, the initial rolling temperature is 1100°C (steel temperature), and the final rolling temperature is not lower than 900°C (steel temperature), to obtain Hot rolled high manganese steel plate. After the steel plate is trimmed and solid-solution heat treated, it is made into a steel plate with a width ≥ 500mm, a length ≥ 1000mm, and a thickness of 6-40mm. Then it is cold-rolled at a compression ratio of 15%-50% to a thickness of 1-30mm to obtain a cold-rolled high manganese steel plate.

Embodiment 2

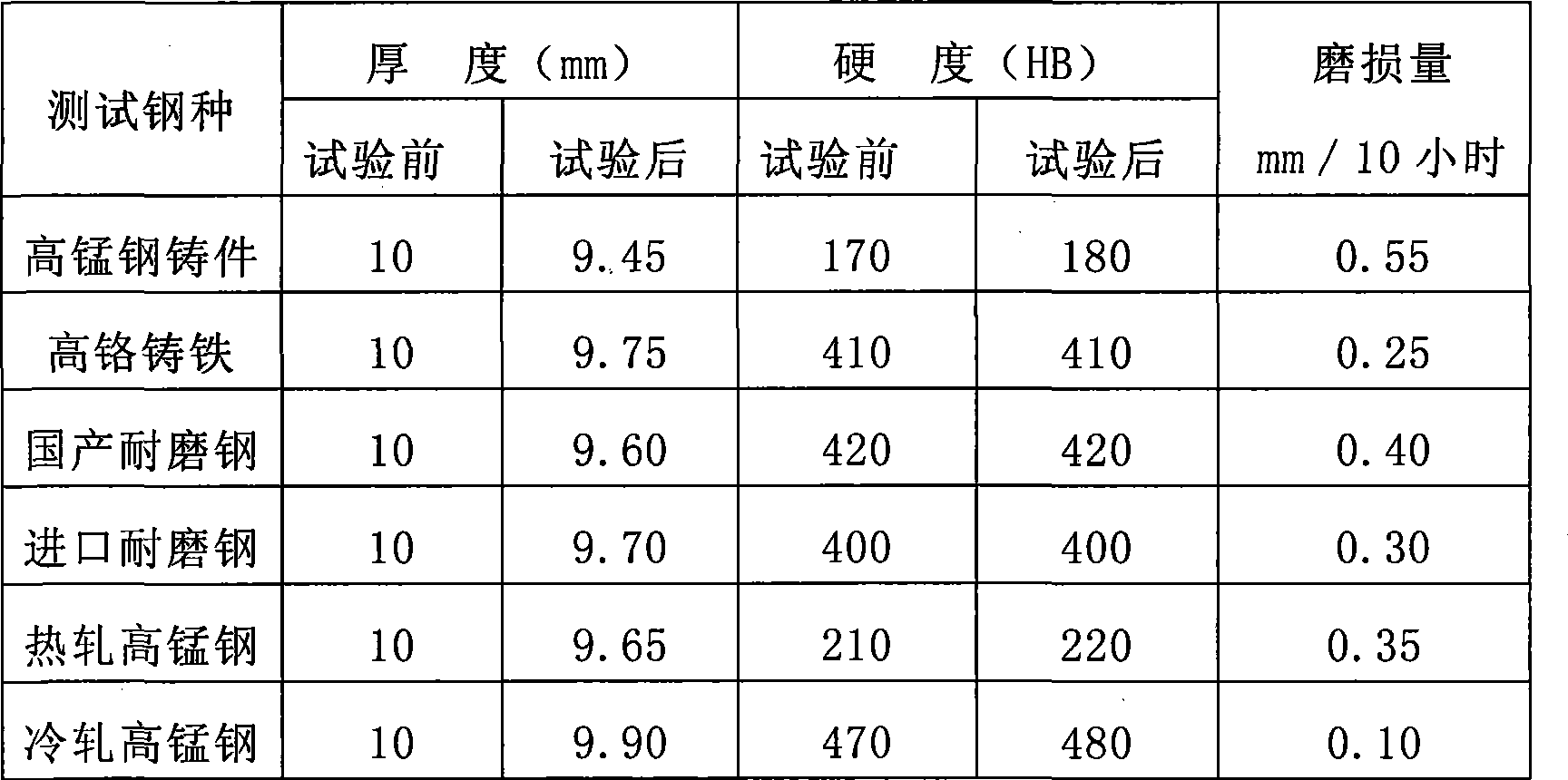

[0031] Embodiment 2: mechanical performance detection

[0032] According to the known technical standards in this technical field, the actual performance is measured, and the results are compared in Table 2 (taking the thickness of 10mm as an example):

[0033] Table 2 Performance comparison

[0034] High manganese

[0035] It can be seen from the measured performance data that the strength performance of the high manganese wear-resistant steel plate prepared by the method of the present invention is obviously improved, but the elongation is reduced. As the most important hardness index of wear-resistant materials, it has been effectively improved.

Embodiment 3

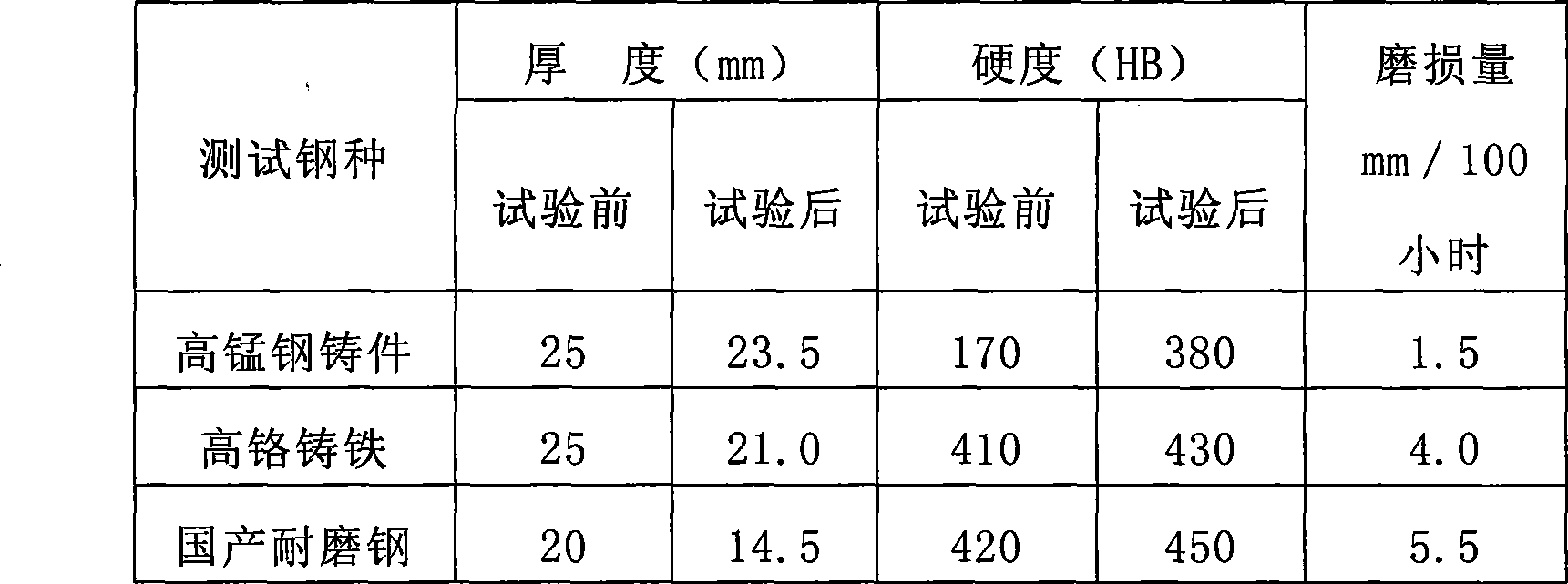

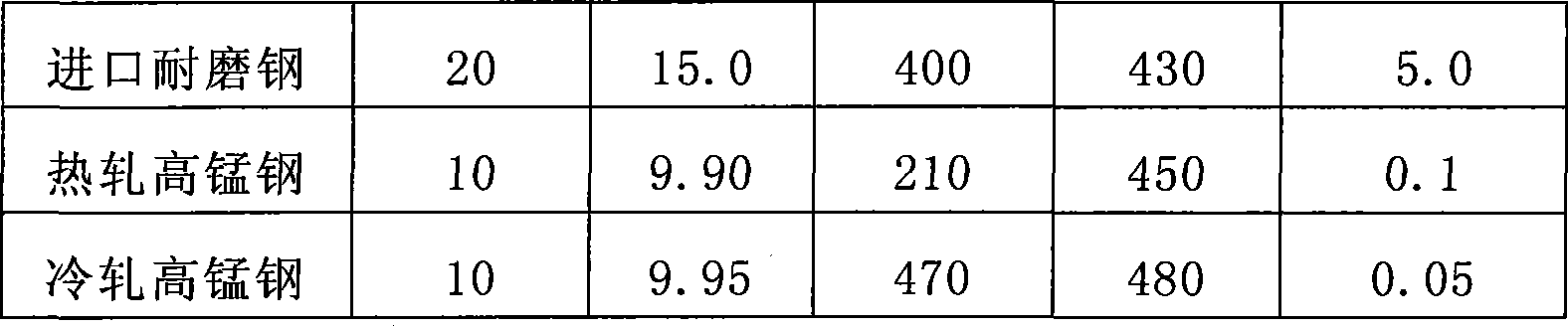

[0036] Example 3: Comparative test of anti-strong impact and high pressure wear performance

[0037] Take high manganese steel castings (containing 13% Mn), high chromium cast iron (containing 20% Cr), domestic NM420 wear-resistant steel plates, imported tough up to 400 steel plates, hot-rolled high-manganese steel plates, cold-rolled high-manganese steel plates. The width is 500mm×500mm, and the thickness is different (due to the limitation of the material source, the thickness cannot be unified, and the thickness tolerance standard is GB709). Ten test points are selected for each steel plate, and then put into the shot blasting chamber of the shot blasting machine with a greater impact The parts most likely to be damaged by steel shots are hit. The test conditions are: the distance between the steel plate and the projectile head is 700mm, and the projectile is a steel wire cut shot with a diameter of 1.5mm; direct impact; the projectile speed is 75m / s; the angle between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com