Comprehensive treatment method of coking desulfurization waste liquid

A coking desulfurization waste liquid and comprehensive treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution, mixed components, and inability to sell. Achieve the effect of reducing production investment, simple processing technology and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

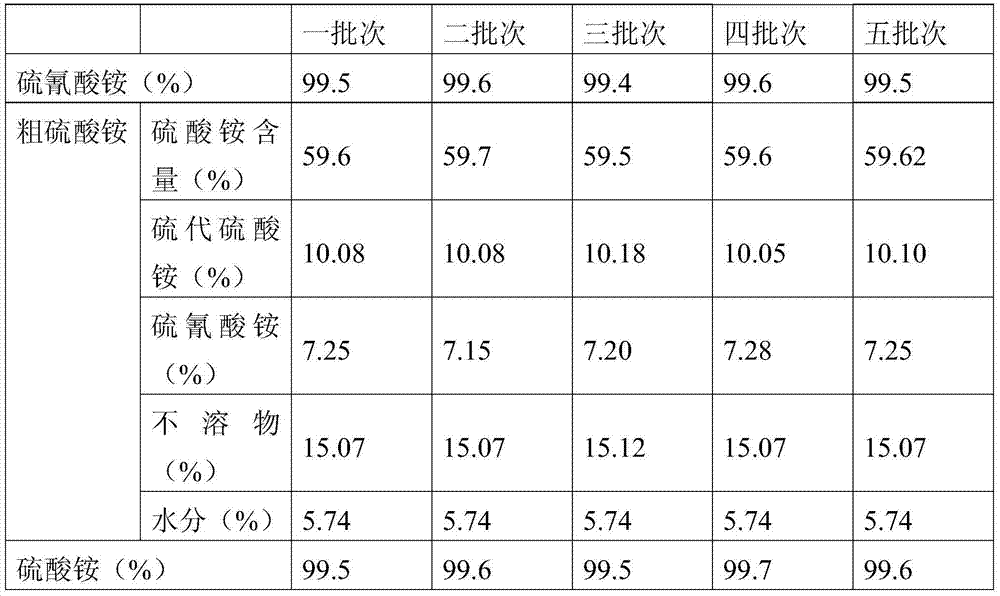

Examples

Embodiment

[0032] A comprehensive treatment method for coking desulfurization waste liquid, comprising the following steps:

[0033] (1) Desulfurization waste liquid is removed in the aeration tank, and activated carbon is added, and the amount of activated carbon added is 0.5-1.5kg / m 3 , to remove PDS, hydroquinone, dinuclear phthalocyanine cobalt sodium sulfonate and sulfur particle components in the desulfurization solution;

[0034] (2) feed hot blast in the aeration tank, the temperature of feeding hot blast is 60-75 degree, time is 3-5s, utilize the ammonium thiosulfate in the oxygen oxidation desulfurization waste liquid in the hot blast, form ammonium sulfate,

[0035] (3) Decolorization treatment for 12-16 hours, the treatment liquid is pumped to the plate and frame filter press for pressure filtration, and the filtrate is transported to the decolorization liquid storage tank for storage and preparation. The decolorization is to utilize the activated carbon adsorption that has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com