Method for comprehensive wastewater desalination and zero release in steel production

A technology that integrates waste water and steel, and is applied in the fields of metallurgical waste water treatment, general water supply conservation, chemical instruments and methods, etc. It can solve the problems of large sewage discharge and high new water consumption, and achieve low operating costs, long equipment life and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

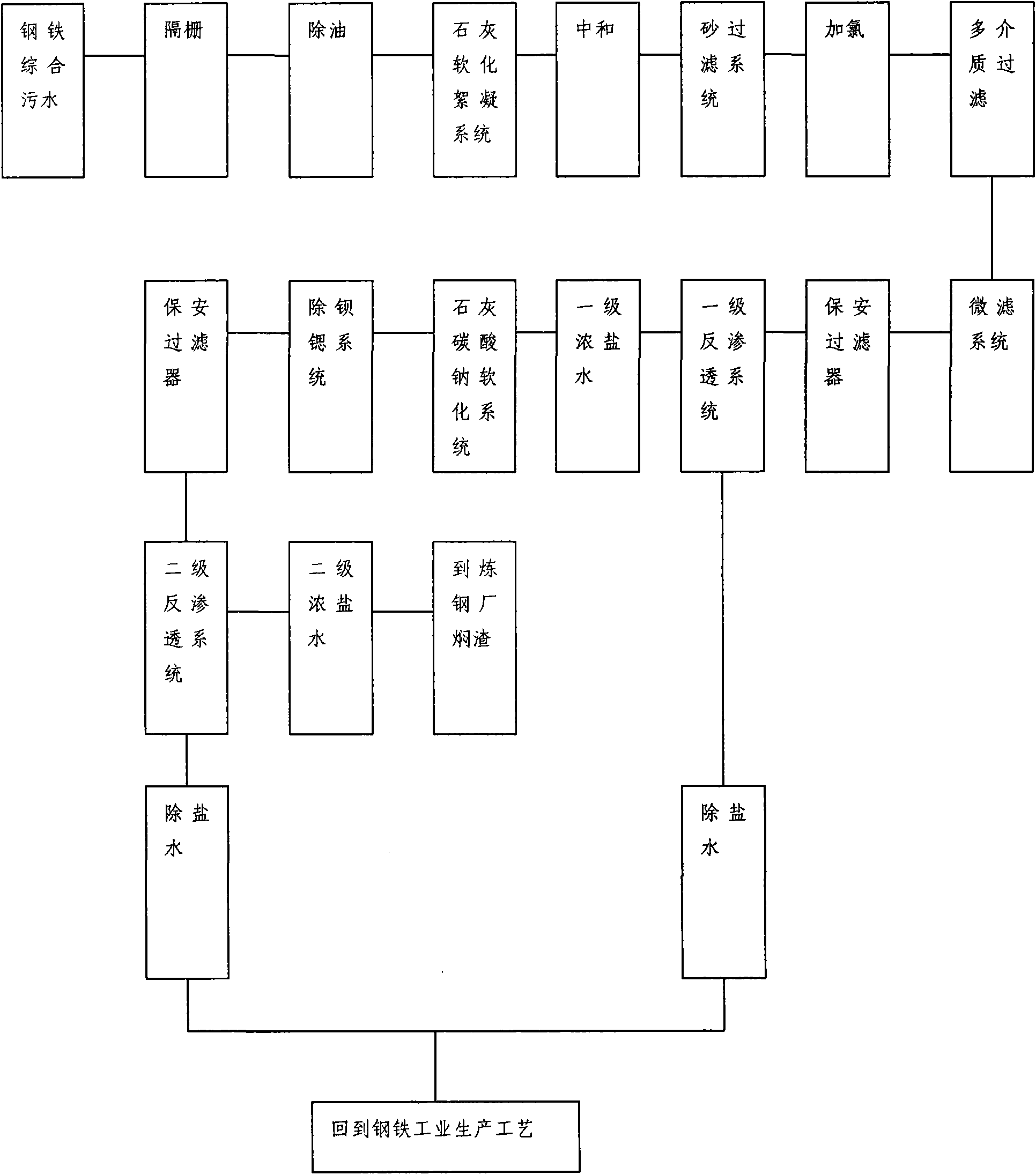

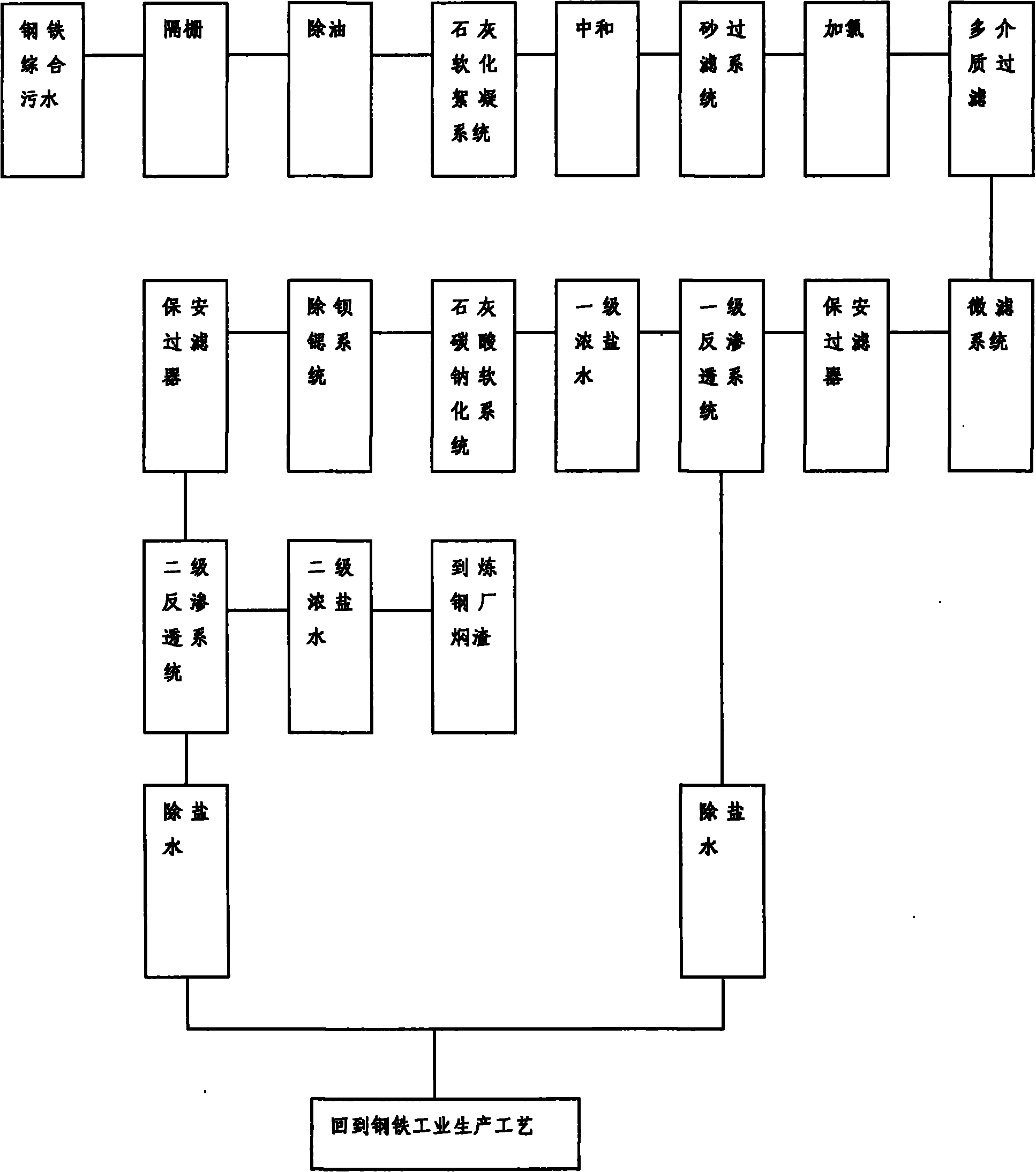

[0010] Attached below figure 1 Specific embodiments of the present invention will be described.

[0011] Such as figure 1 Shown: Iron and steel comprehensive wastewater passes through the grid, after degreasing, it goes through the lime softening flocculation sedimentation system, the supernatant water is neutralized, sand filtered, chlorinated, multi-media filtered, microfiltration system, security filter, primary reverse osmosis system, The first-stage reverse osmosis concentrated brine passes through the lime sodium carbonate softening system, security filter, second-stage reverse osmosis system, and second-stage reverse osmosis concentrated brine to the steelmaking plant for stewing slag, achieving zero discharge. The first-stage reverse osmosis desalted water and the second-stage reverse osmosis desalted water are sent back to the steel production process for use. The technical parameters in the process are as follows:

[0012] The wastewater passes through the grille ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com