Sponge iron production technology by coal gasification

A technology of sponge iron and coal gasification, applied in the field of metallurgy, can solve the problems of reducing the degree of reduction of reduced gas, high investment, losses, etc., and achieve the effects of reducing the degree of reduction, saving investment, reducing investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

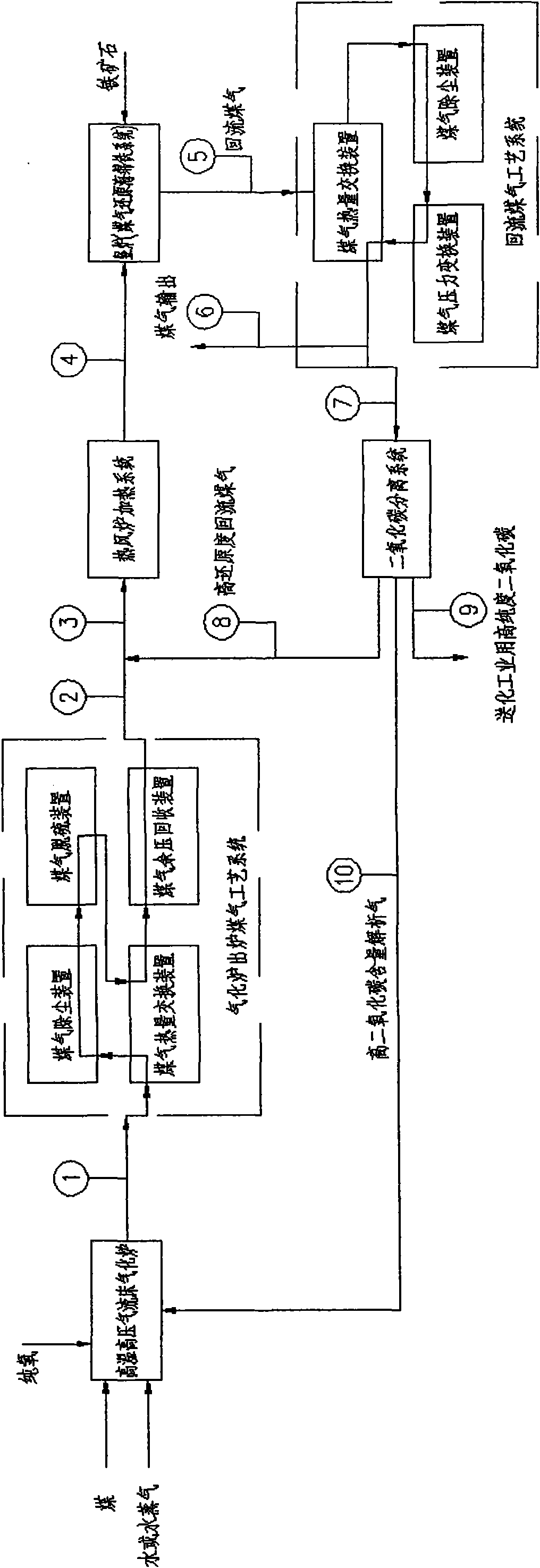

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0025] This process includes 6 sub-process systems: 1) High temperature and high pressure entrained bed gasifier; 2) Gasification process system for gasification furnace; 3) Hot blast stove heating system; 4) Shaft furnace (coal gas reduction sponge iron system); 5) Reflux Gas process system; 6) Carbon dioxide separation system.

[0026] 1) After the non-coking coal is ground by a coal mill, it is mixed with oxygen, water or water vapor and a part of the CO-enriched gas decomposed from the return gas of the shaft furnace. 2 The analytic gas (this part is rich in CO 2 The analytical gas can be zero) reacts in the high temperature and high pressure entrained bed gasifier to generate CO+H 2 ≥80%, N 2 Reducing coal gas with a content of less than 1%, a gasification pressure of 0.5-8.5MPa, and a gasification temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com