Patents

Literature

43results about How to "Easy to control synchronously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

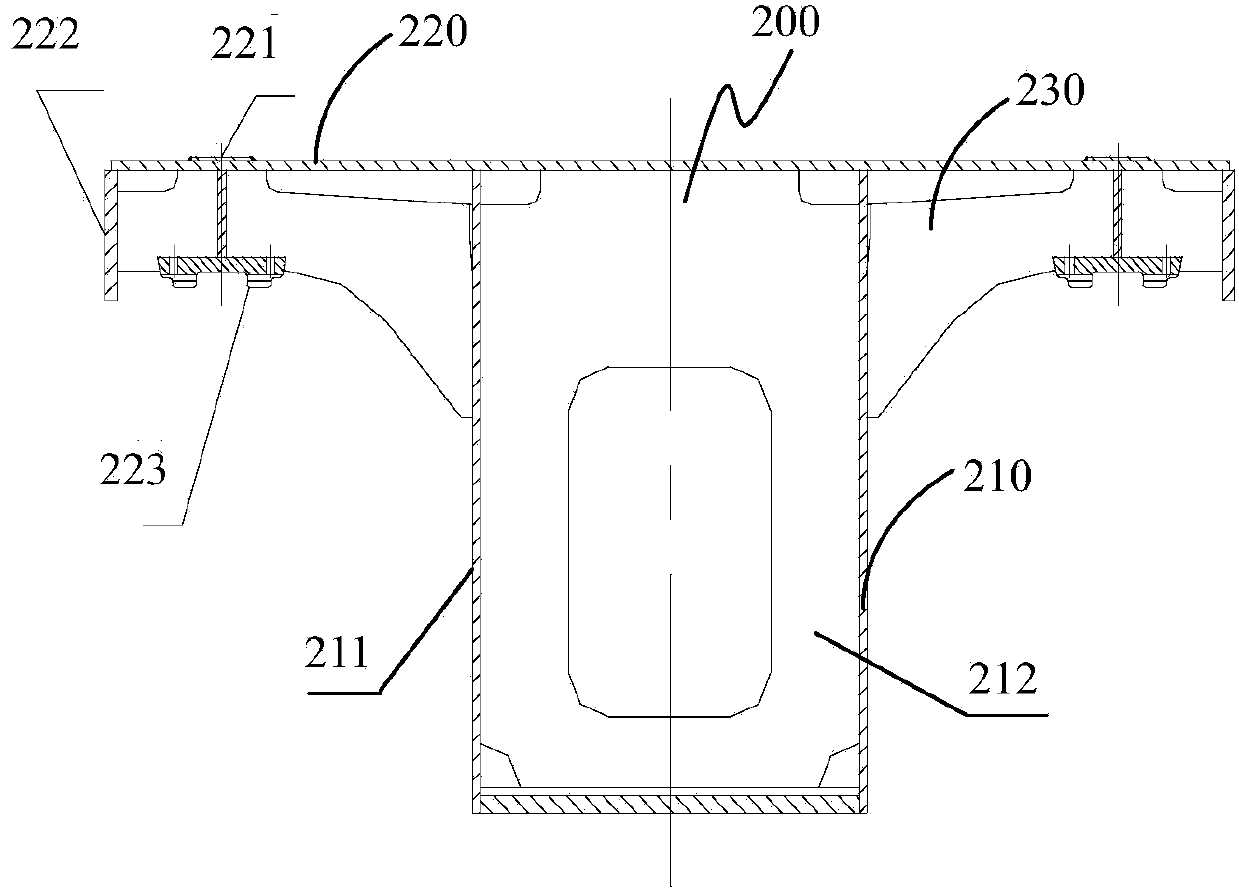

Can printing machine numerical-control system based on digital motion controller

ActiveCN103076766AEasy to make costEasy to control synchronouslyComputer controlSimulator controlProduction lineControl system

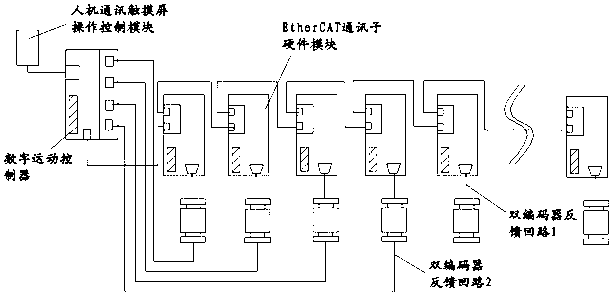

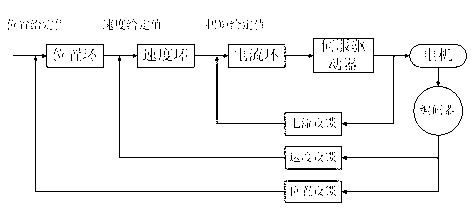

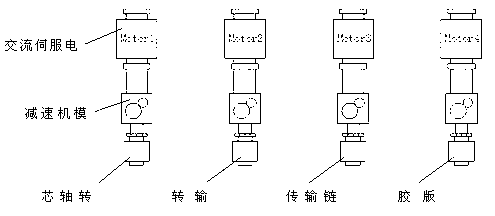

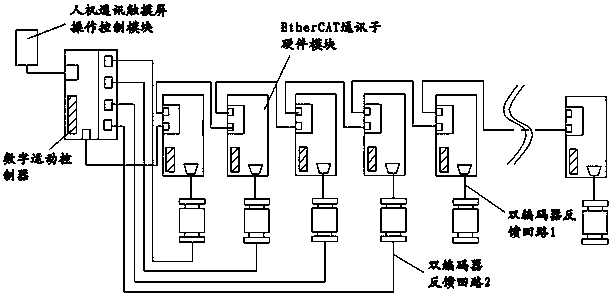

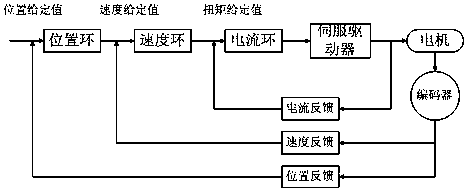

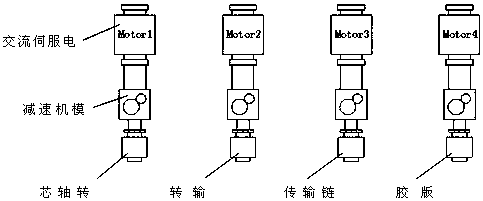

The invention relates to a can printing machine numerical-control system based on a digital motion controller, and the can printing machine numerical-control system comprises a human-machine communication touch screen operation control module based on a windows platform, a digital motion controller, a motion actuation module and a reducer module, wherein the human-machine communication touch screen operation control module based on the windows platform is connected with the digital motion controller through an Ethernet network cable, and the digital motion controller and an input / output (I / O) sub-board of the digital motion controller are directly connected with an I / O signal connection terminal of the motion actuation module, i.e. an alternative-current servo motor; the digital motion controller is connected with the motion actuation module i.e. the alternative-current servo motor through an Ethernet bus; and the digital motion controller is connected with four alternative-current servo motors to form a double-closed-loop motion control system. The system is simple in structure, each constitutional part is relatively independent, partial hardware can be directly purchased in the market to be used as the constitutional part, not only can the performance be comparable and the cost be reduced, but also simplicity in assembling, application and upgrading can be realized, and the tank printing machine numerical-control system can be mass popularized to a pop can printing production line and similar iron production lines.

Owner:FOSHAN DING ZHONG MACHINERY

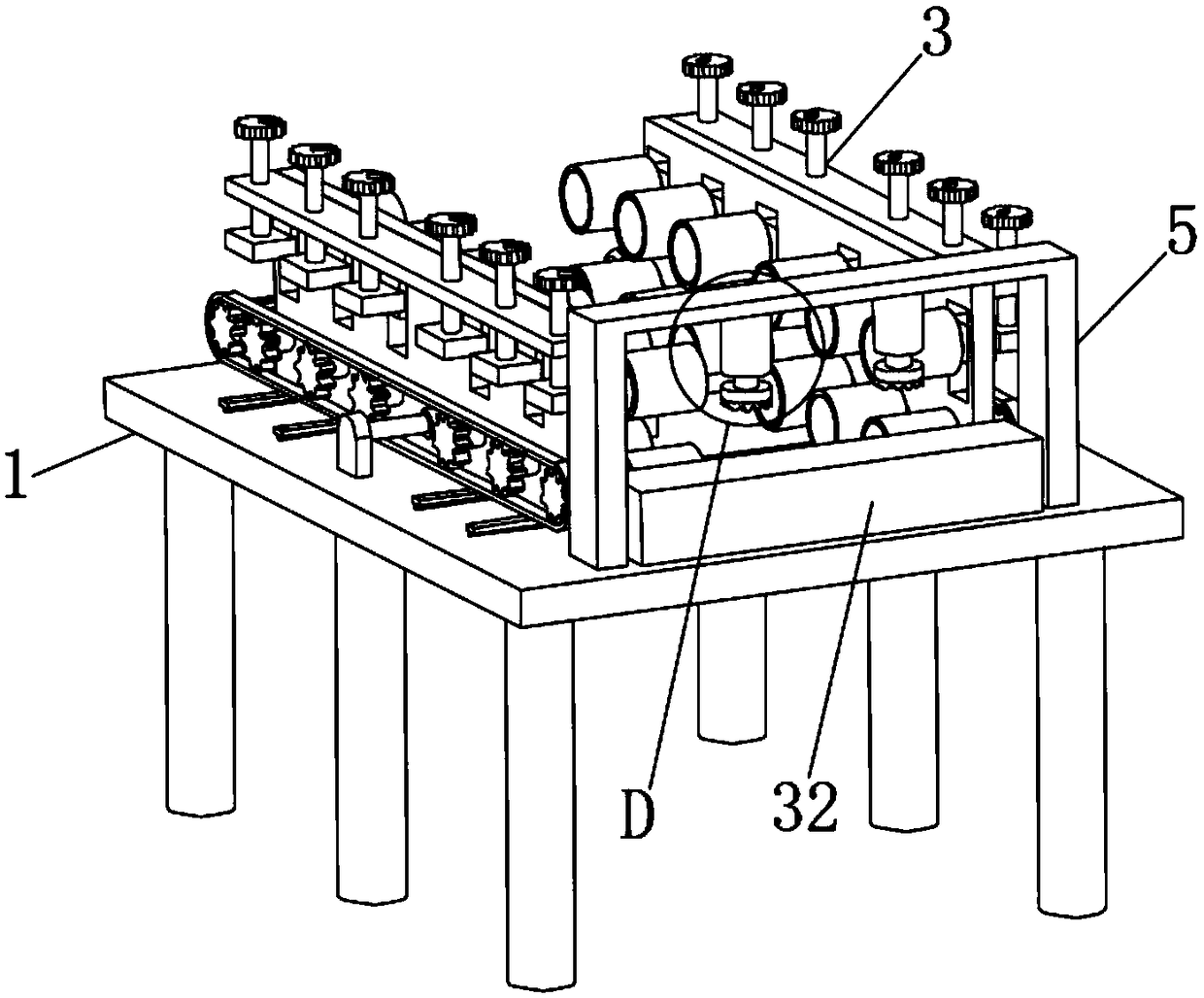

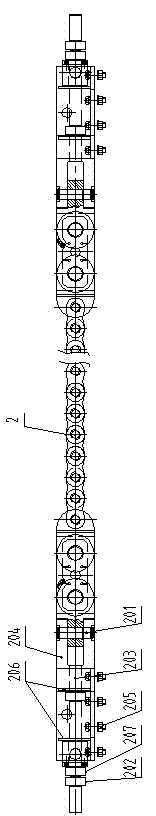

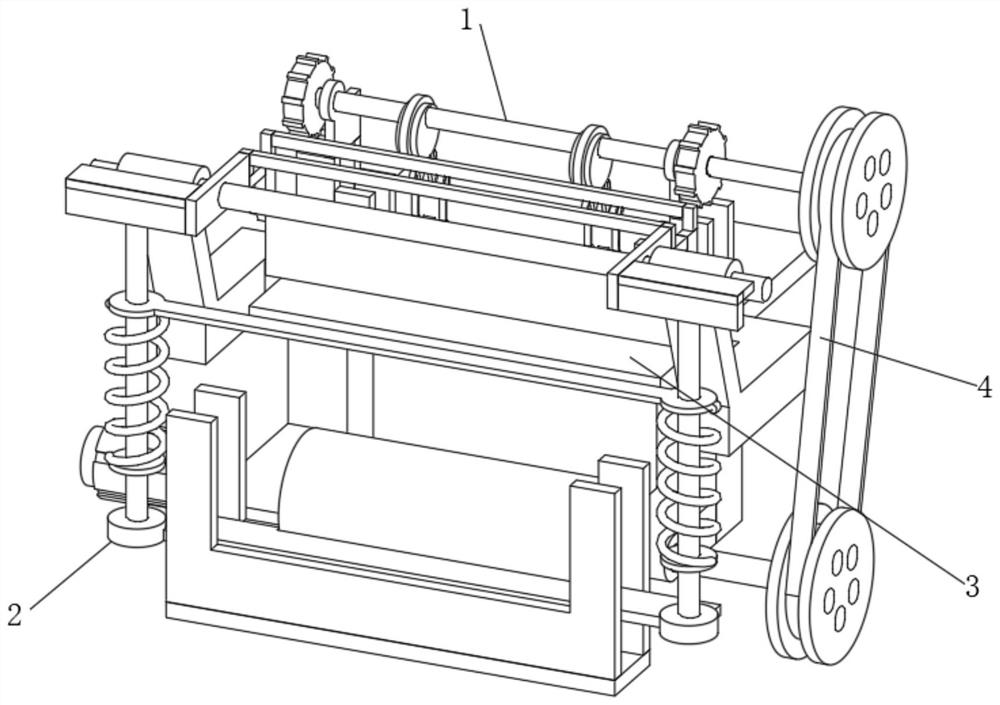

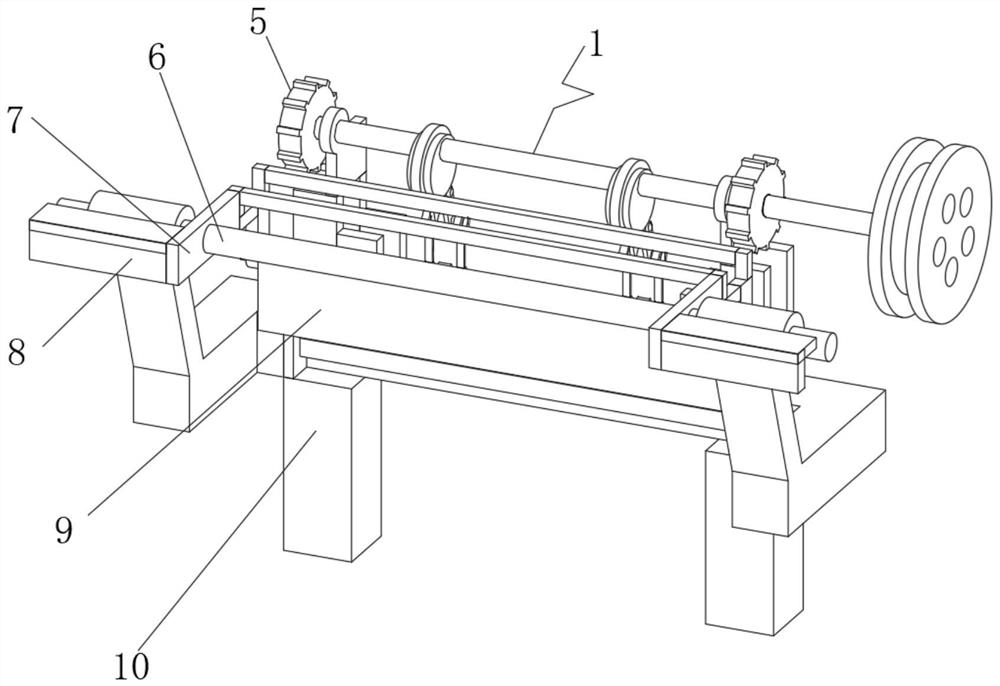

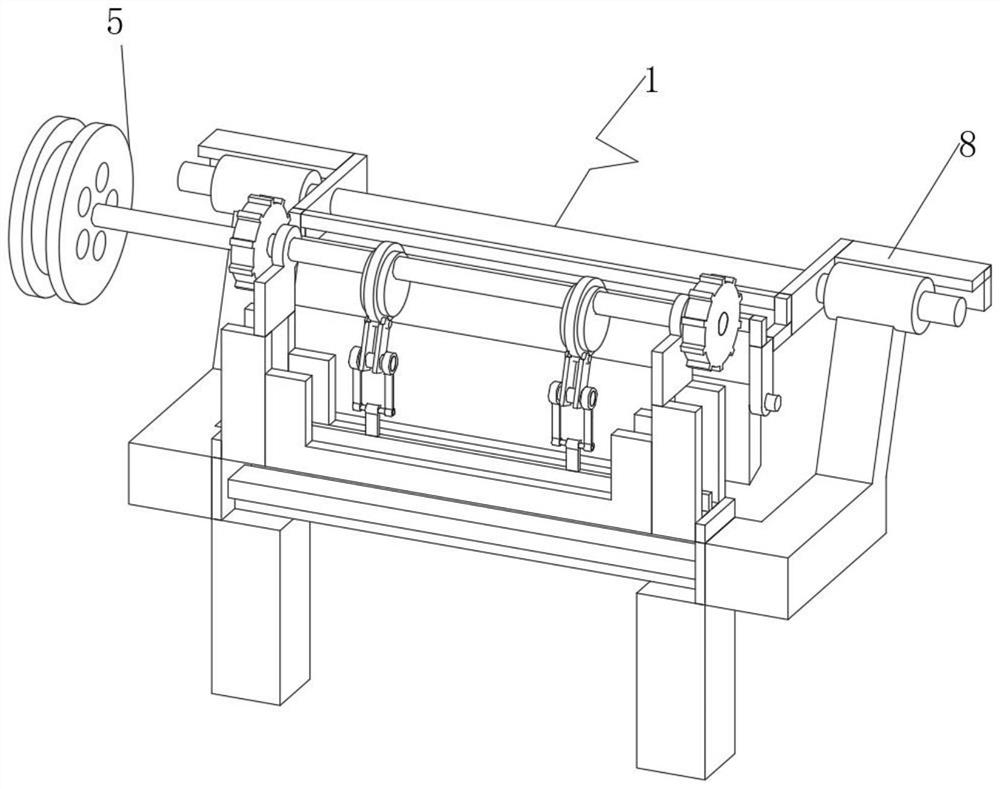

Feeding mechanism for sheet metal stamping based on Internet of Things

ActiveCN109482763AReduce usageImprove feeding efficiencyMetal-working feeding devicesMetal working apparatusProduction lineThe Internet

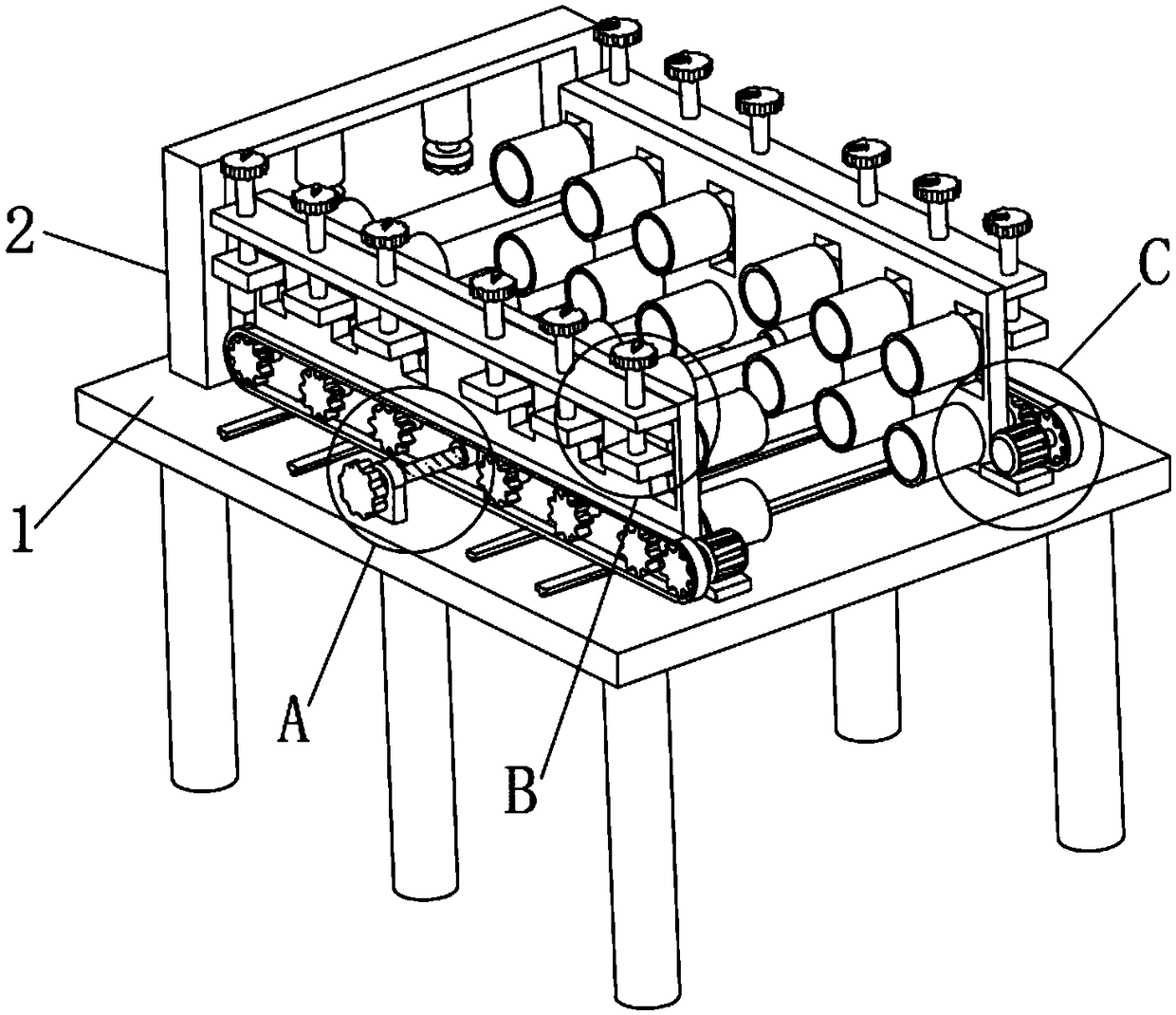

The invention discloses a feeding mechanism for sheet metal stamping based on Internet of Things. The feeding mechanism comprises a worktable and a feeding mechanism body. The feeding mechanism body includes two conveying devices, a width adjusting device and a fixing device. The two conveying devices are symmetrically distributed on the top of the worktable, wherein the conveying device comprisesa mounting plate, a driving roller, a passive gear, an executing device, a pressing roller and a thickness adjusting device; one end of the driving roller penetrates through the mounting plate to befixed to the passive gear, and the driving roller is rotatably connected with the mounting plate through a bearing; the passive gear is connected with the output end of the executing device; and the pressing roller is located above the driving roller, and one end of the pressing roller is connected with the output end of the thickness adjusting device. The feeding mechanism for sheet metal stamping can achieve a production line based on the Internet of Things, and is directly integrated into an intelligent manufacturing production line, and the integration and the reliability are high, so thatthe feeding efficiency of sheet metal is improved, and the mass production of the sheet metal is convenient.

Owner:XIAN SIYUAN UNIV

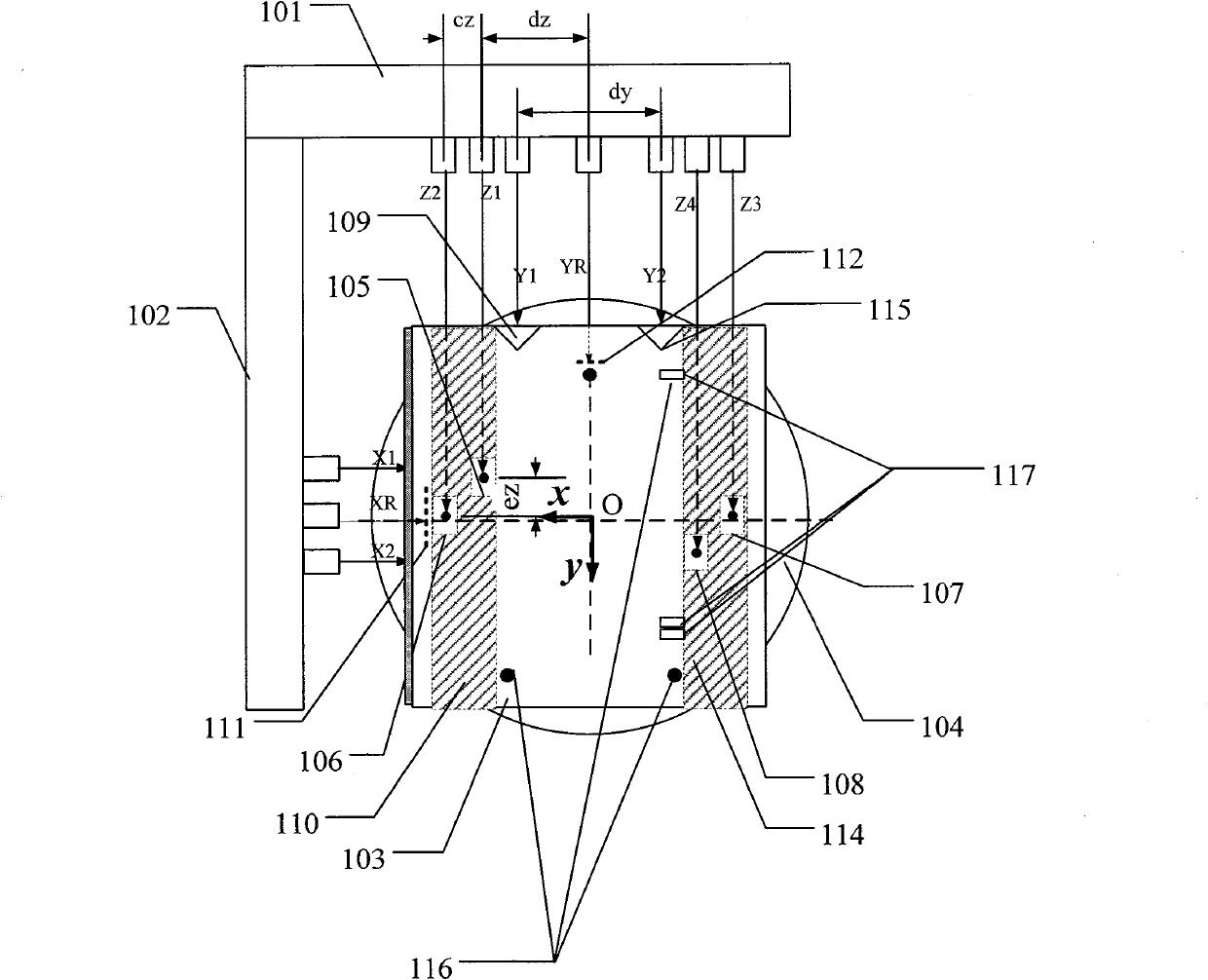

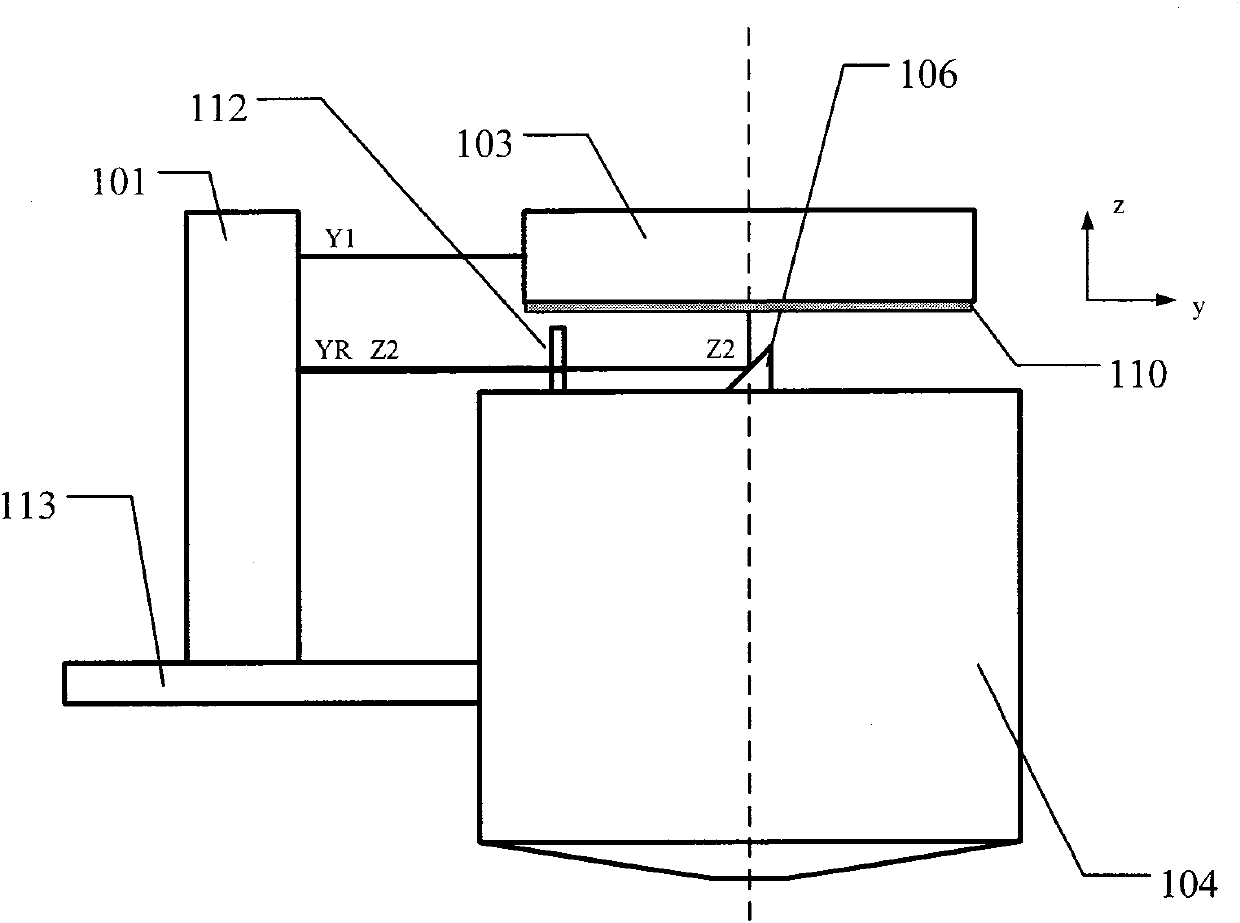

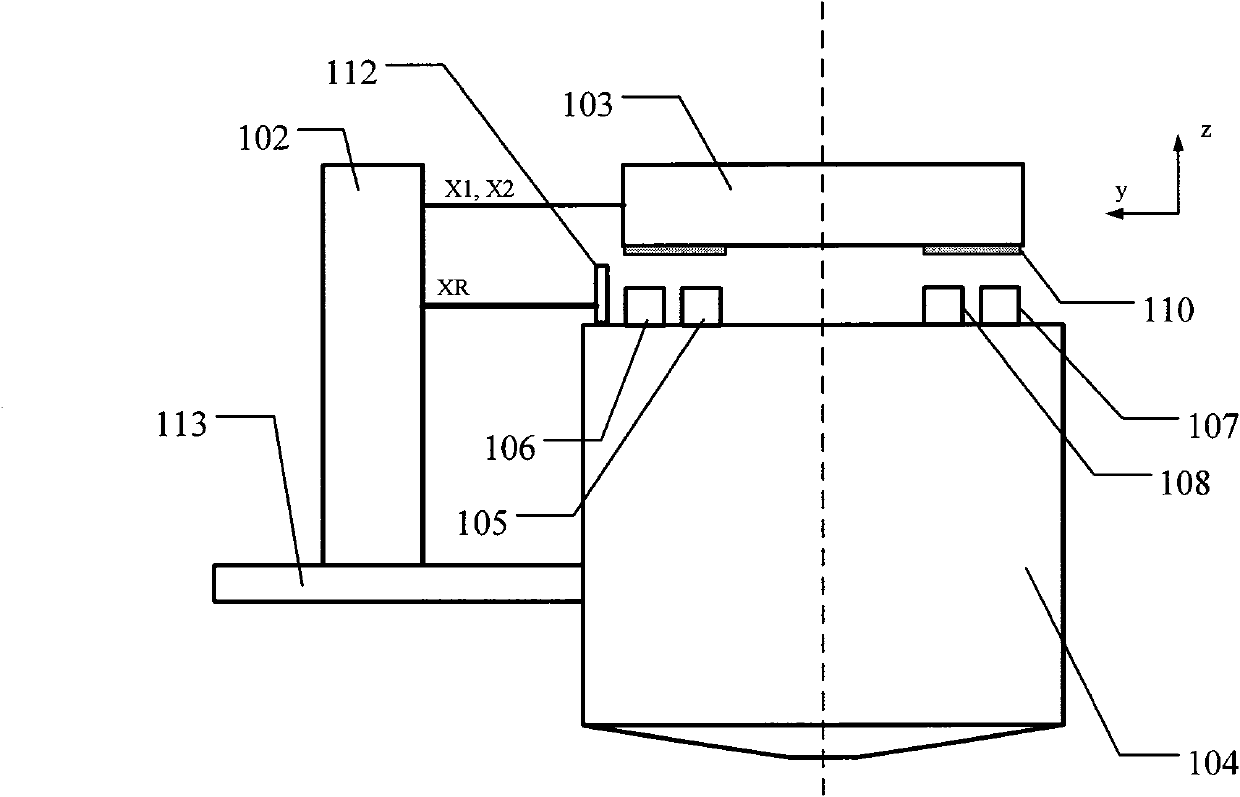

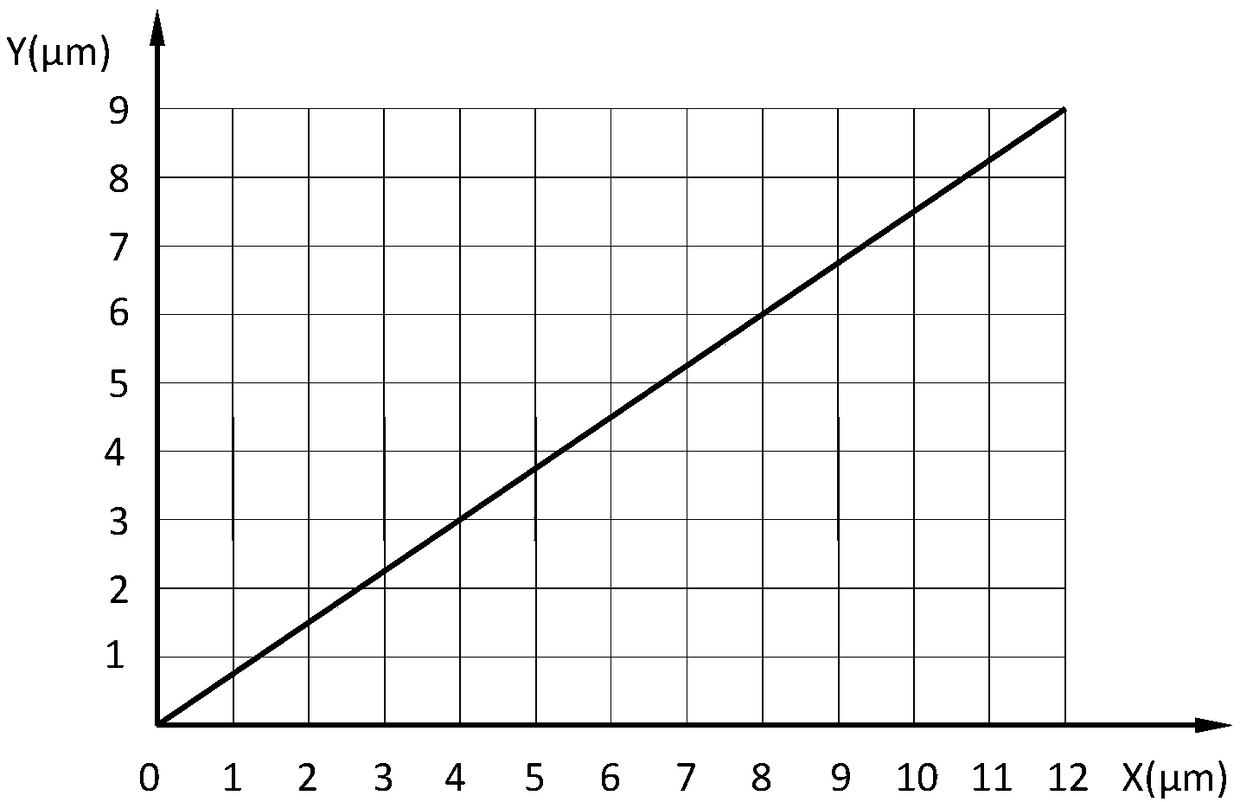

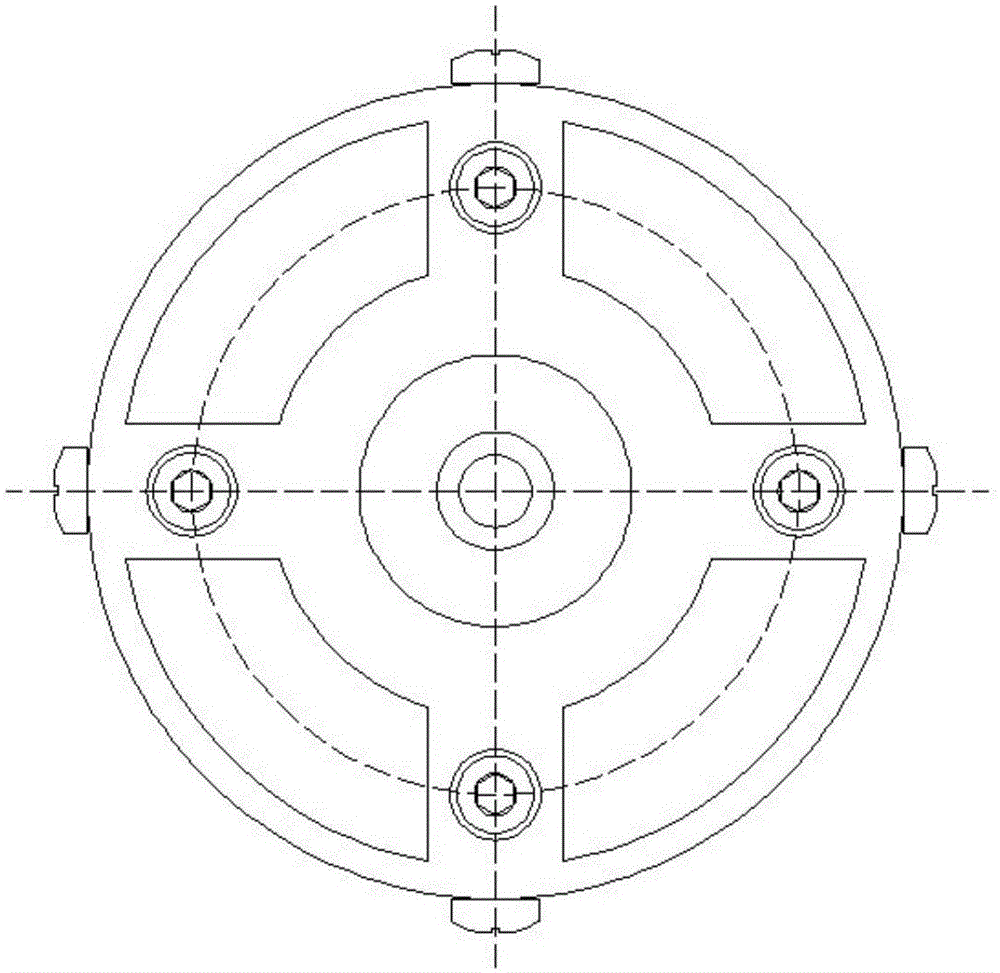

Measuring device and measuring method for position of reticle stage of scanning lithography

ActiveCN102087475AAccurate measurementEasy to control synchronouslyPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistRange of motion

A measuring device and a measuring method for the position of a reticle stage of a scanning lithography. Several laser interferometers are adopted in stead of capacitance sensors to allow the sensors in the horizontal and the vertical directions to be consistent, so the synchronous control of signals is convenient and the measuring range measured in the vertical direction is increased. In addition, interferometric light can be introduced from any horizontal direction by mounting a 45-degree reflector at the top of the objective, so measurements in the vertical direction can be carried out within a large moving range; and weight distribution of the interferometers measuring in every direction is introduced during the measurement of the inclination amount, so the measurement of the reticle stage position is more accurate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

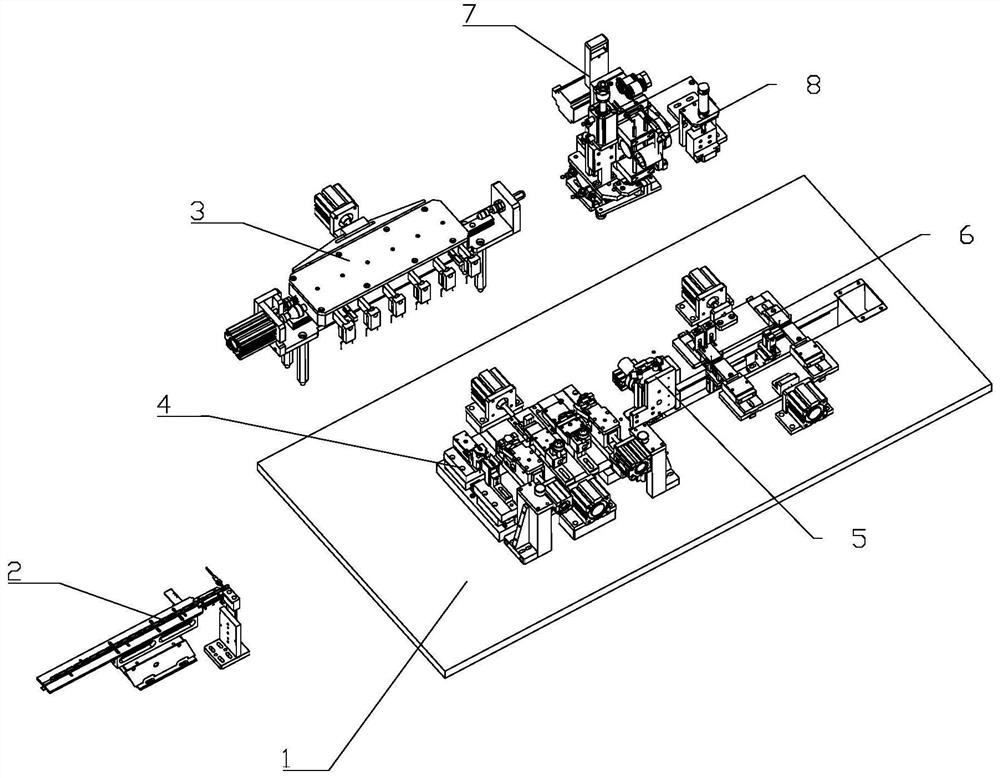

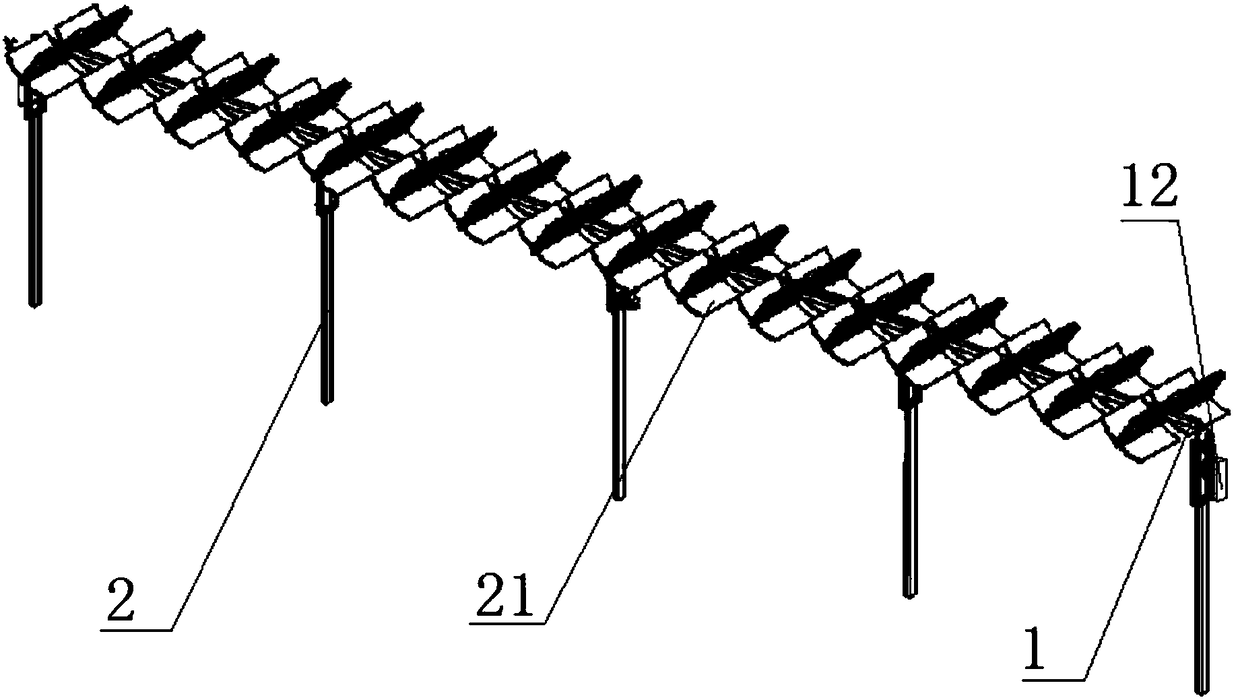

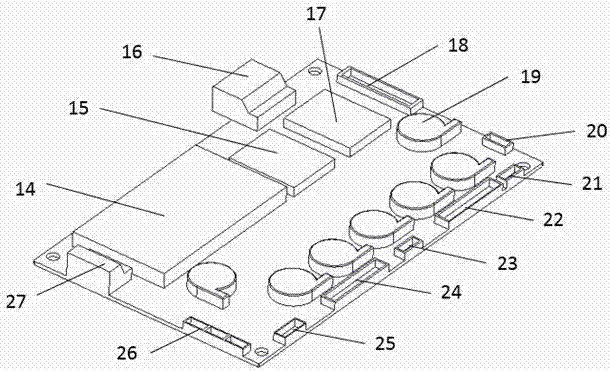

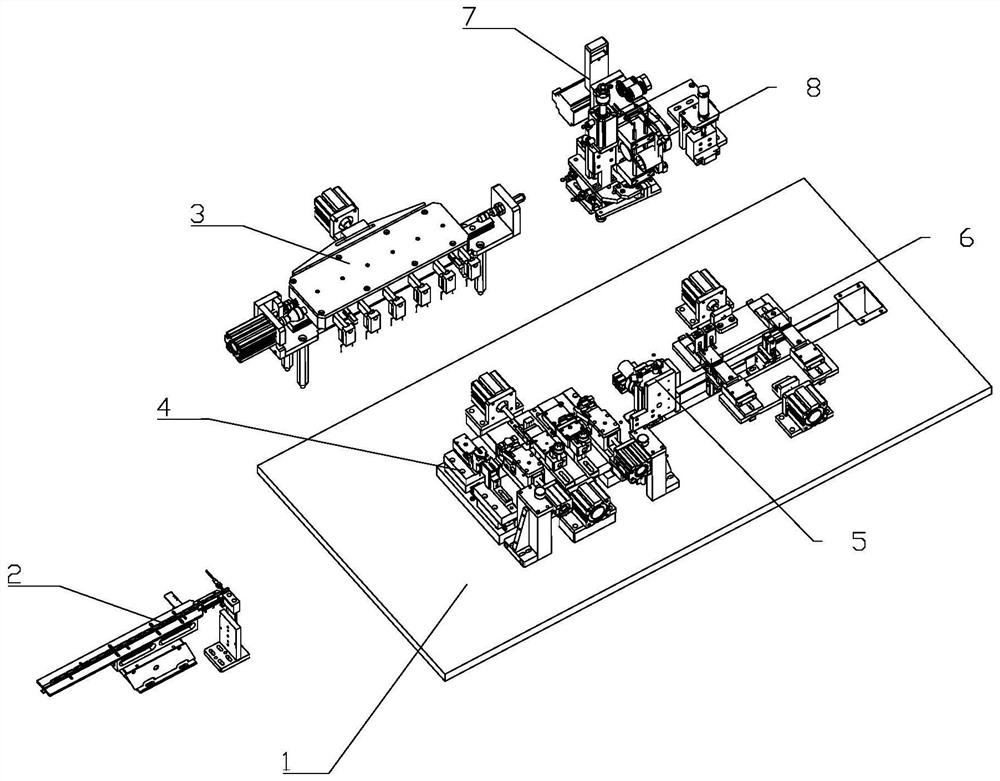

Thin-film capacitor and automatic production equipment and method thereof

InactiveCN111627706AHigh precisionRealize synchronous handlingThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention relates to the technical field of capacitor production. Automatic production equipment of a thin-film capacitor comprises a rack, and a feeding conveying device, a clamping and transferring device, a multifunctional forming device, a rotary material overturning device, an inverted conveying device, a pipe penetrating device and a pipe pressing device which are mounted on the rack, the feeding conveying device is connected with the clamping and transferring device, and the multifunctional forming device is located under the clamping and transferring device. The multifunctional forming device is connected with the inverted conveying device through the rotary material overturning device. The pipe penetrating device and the pipe pressing device are located over the inverted conveying device, the rack is further provided with a discharging barrel, and the discharging barrel is connected with the discharging side of the inverted conveying device. According to the invention, movement between film capacitor stations is efficient and positional accurate, the pins are flat and uniform in length, twice bending is completed by one action, and the forming and bending efficiency ishigh; the mobile capacitor is inverted to position a capacitor pin, so that pipe penetration is facilitated; and the heat shrink tube is integrally assembled, and the success rate of pipe penetrationis high.

Owner:温州源利智能科技有限公司

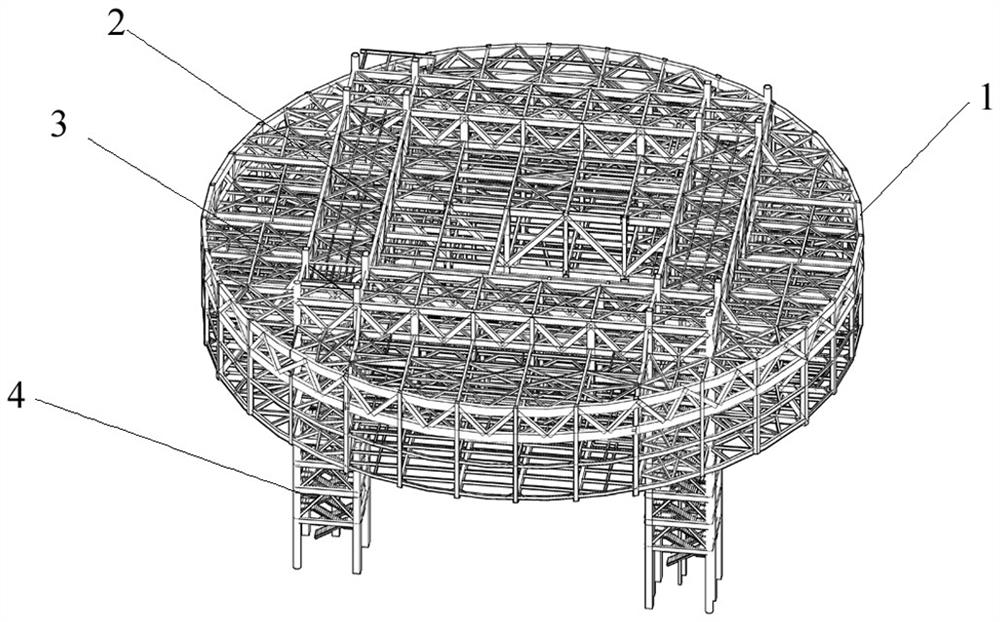

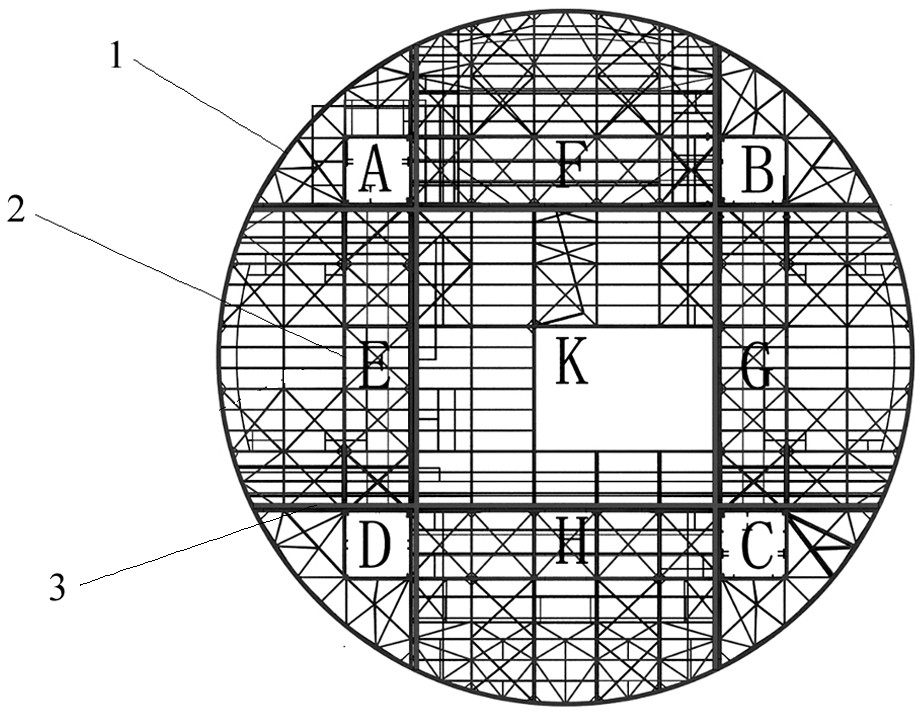

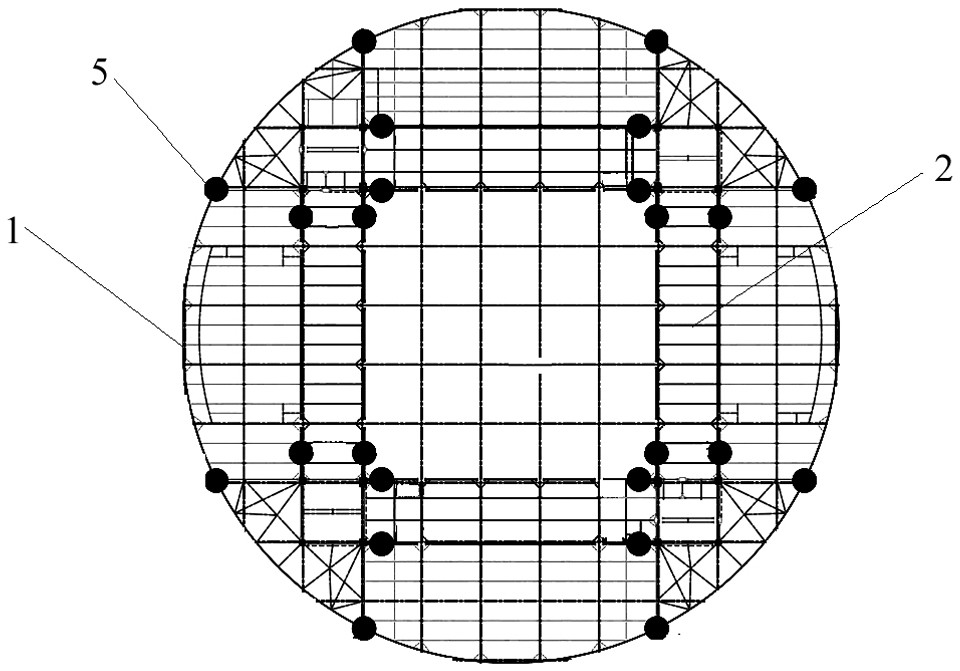

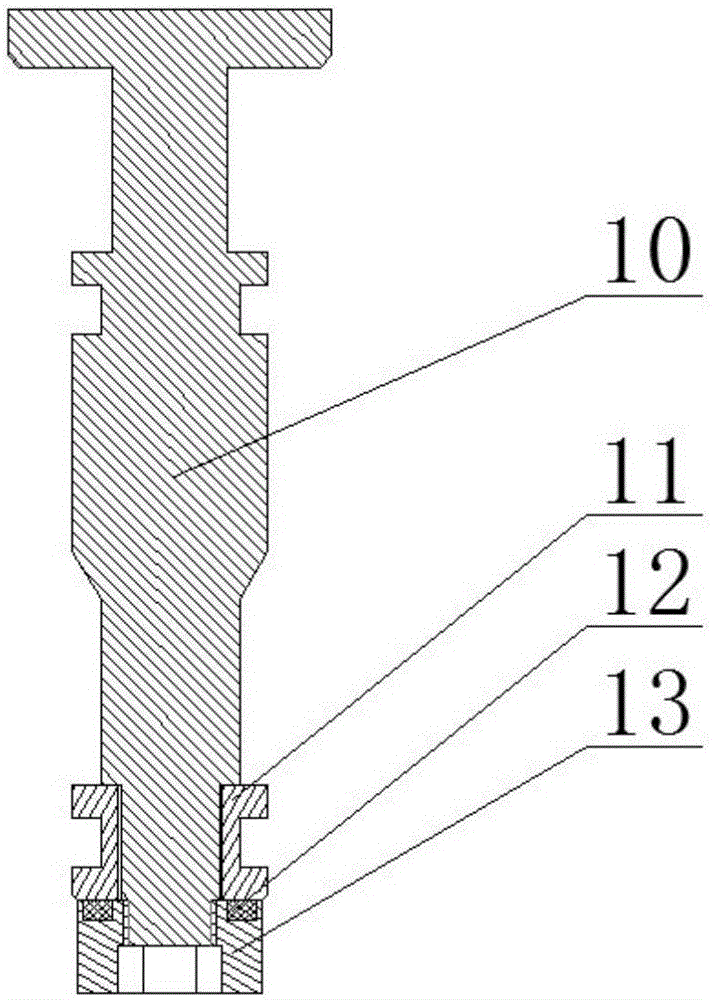

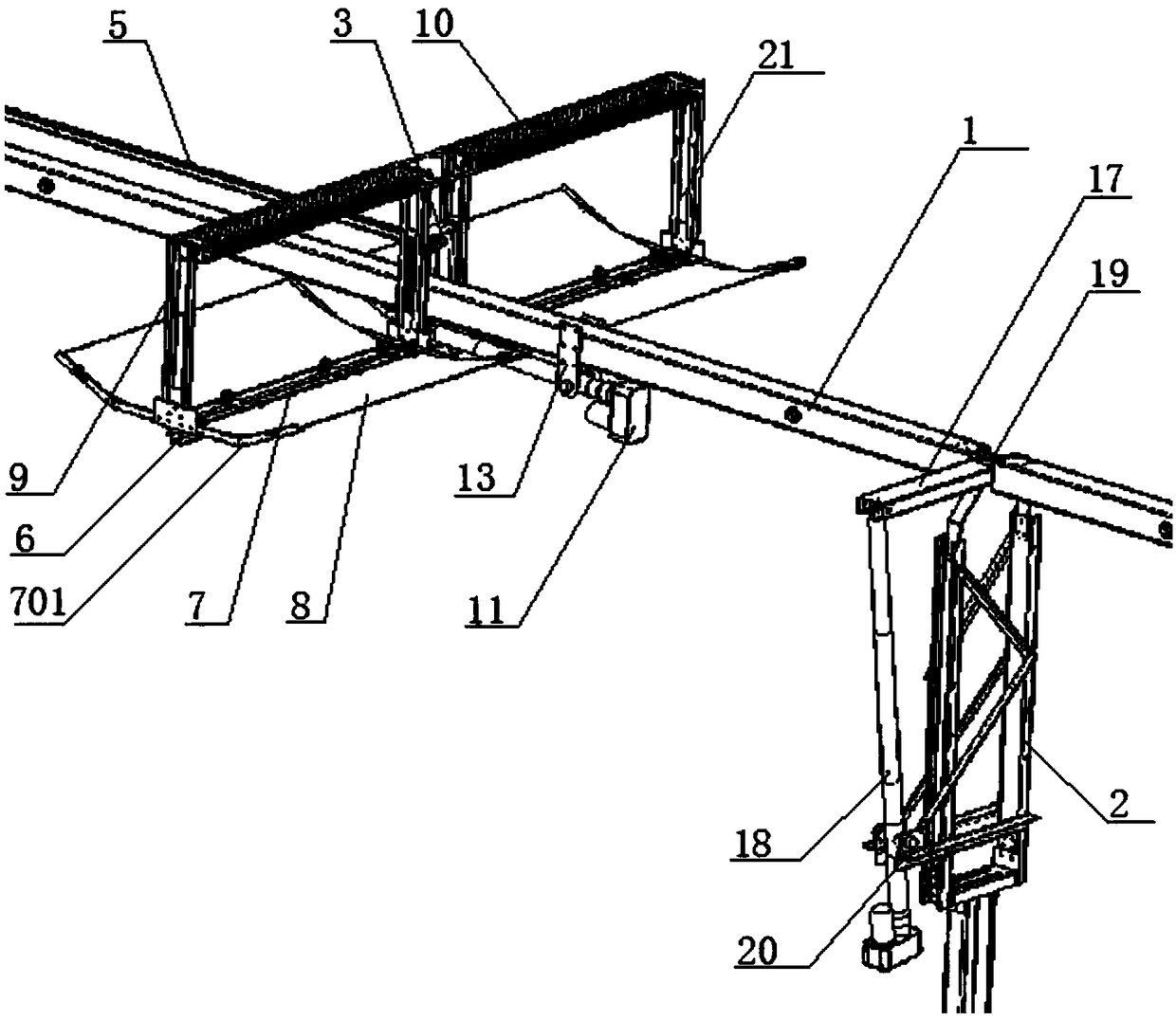

Construction method of complex space truss integral hoisting system

PendingCN113982280AEnsure the uniformity of forceGuaranteed installation accuracyDesign optimisation/simulationBuilding material handlingCoupling beamRing type

The invention discloses a construction method of a complex space truss integral hoisting system. The hoisting system comprises an external ring type truss, a main truss connected to the interior of the ring type truss, a coupling beam connected between the ring type truss and the main truss, truss columns connected to the joint of the main truss and the ring type truss, and hoisting frames arranged on the main truss and the ring type truss correspondingly. The overall lifting process of the space truss is simulated through three-dimensional software such as BIM software, and on-site lifting construction can be effectively guided; through pre-arching compensation and monitoring deformation control in the process, the stress uniformity and the mounting precision in the lifting process can be effectively guaranteed; the space truss is partitioned, so that unit splicing is facilitated, the mounting time can be guaranteed, and the mounting precision can also be guaranteed; through overall trial lifting and graded lifting, the installation space of lifting equipment is met, synchronous control during lifting is facilitated, and the in-place installation precision is guaranteed.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

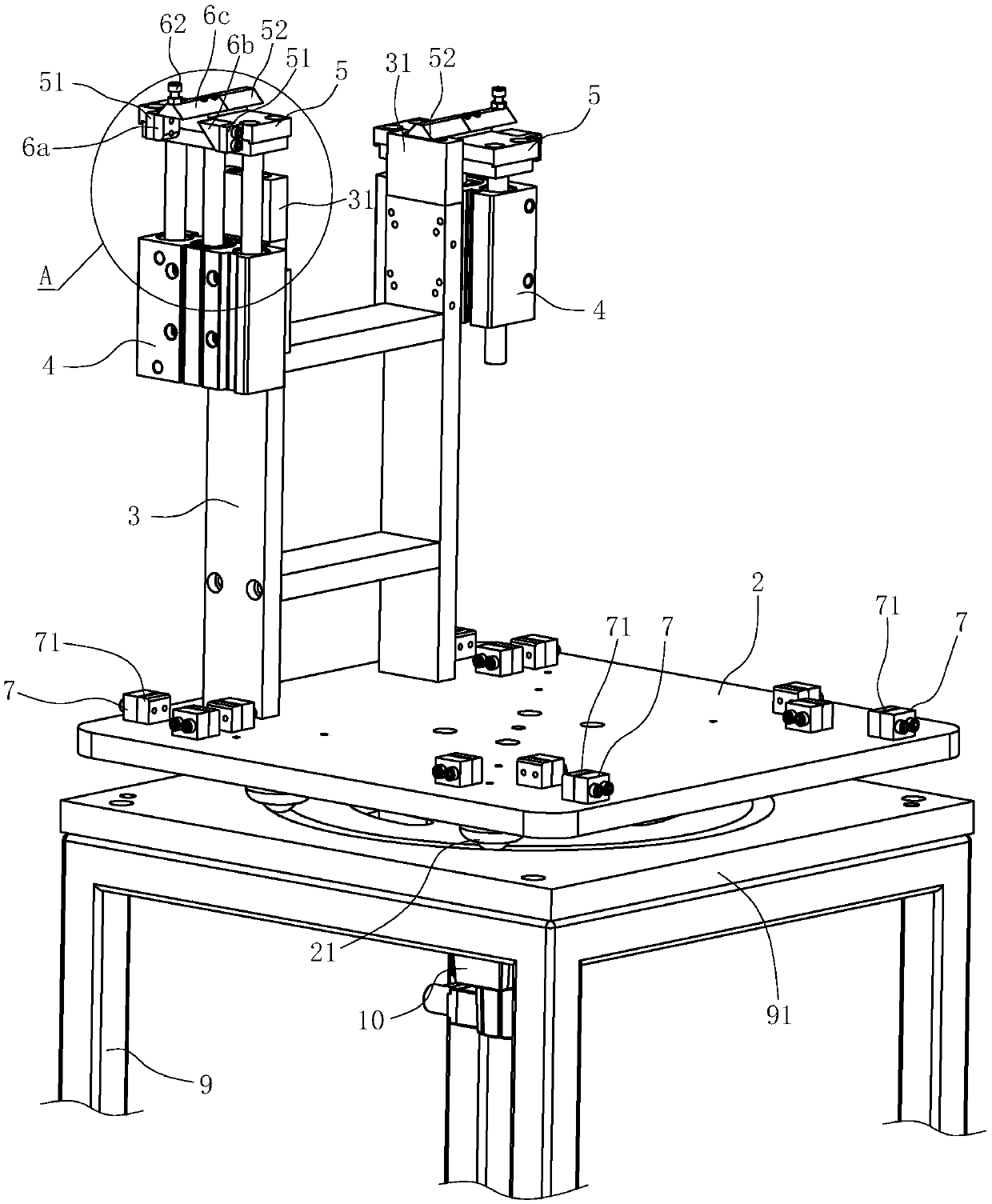

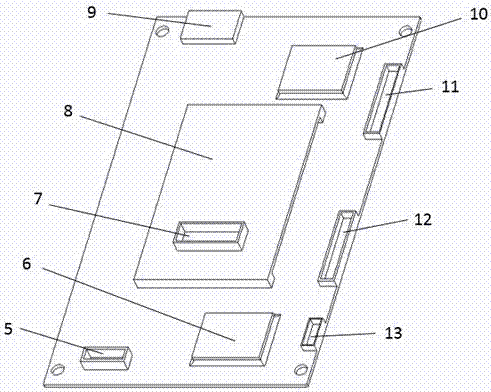

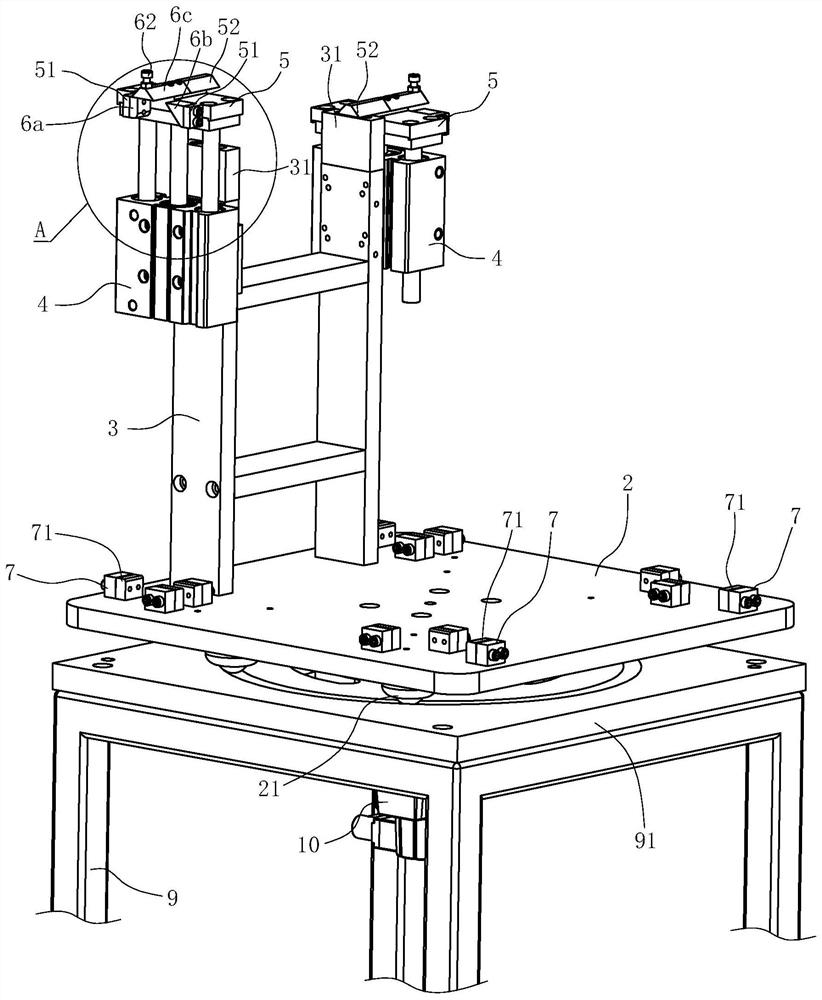

Stainless steel side plate welding clamp with weld gaps capable of being adjusted

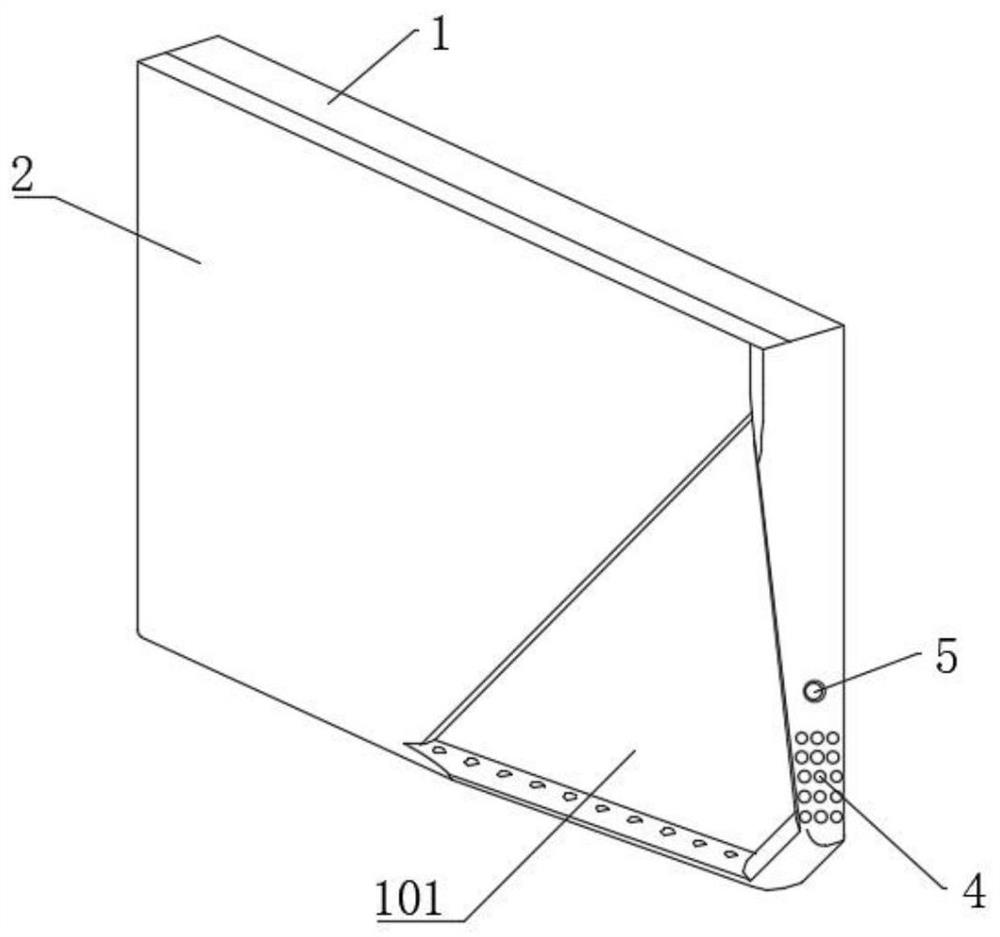

ActiveCN110614469AGuarantee welding qualityLess involvedWelding/cutting auxillary devicesAuxillary welding devicesSynchronous controlWeld seam

The invention relates to a stainless steel side plate welding clamp with weld gaps capable of being adjusted. The stainless steel side plate welding clamp comprises a platform, a mounting frame is fixed on the platform, the platform is at least provided with one clamping tool, the stainless steel side plate welding clamp is characterized in that the clamping tool comprises a positioning structurearranged on the platform and used for positioning the bottom of a vertical stainless steel side plate, a pressing air cylinder is fixed on the side wall of the mounting frame, a pressing plate is fixed on a piston rod of the pressing air cylinder, two mounting lugs which are arranged at an interval front and back are arranged on the outer side wall of the pressing plate, a first pressing block isfixed on one mounting lug, a second pressing block is fixed on the other mounting lug, a third pressing block is fixed on the top of the pressing plate, and the third pressing block is located betweenthe first pressing block and the second pressing block. The two weld gaps can be adjusted at the same time through one-time downward pressing of the pressing plate, the related parts are few, the structure is simpler, moreover, synchronous control is facilitated, and the operation steps are simplified.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

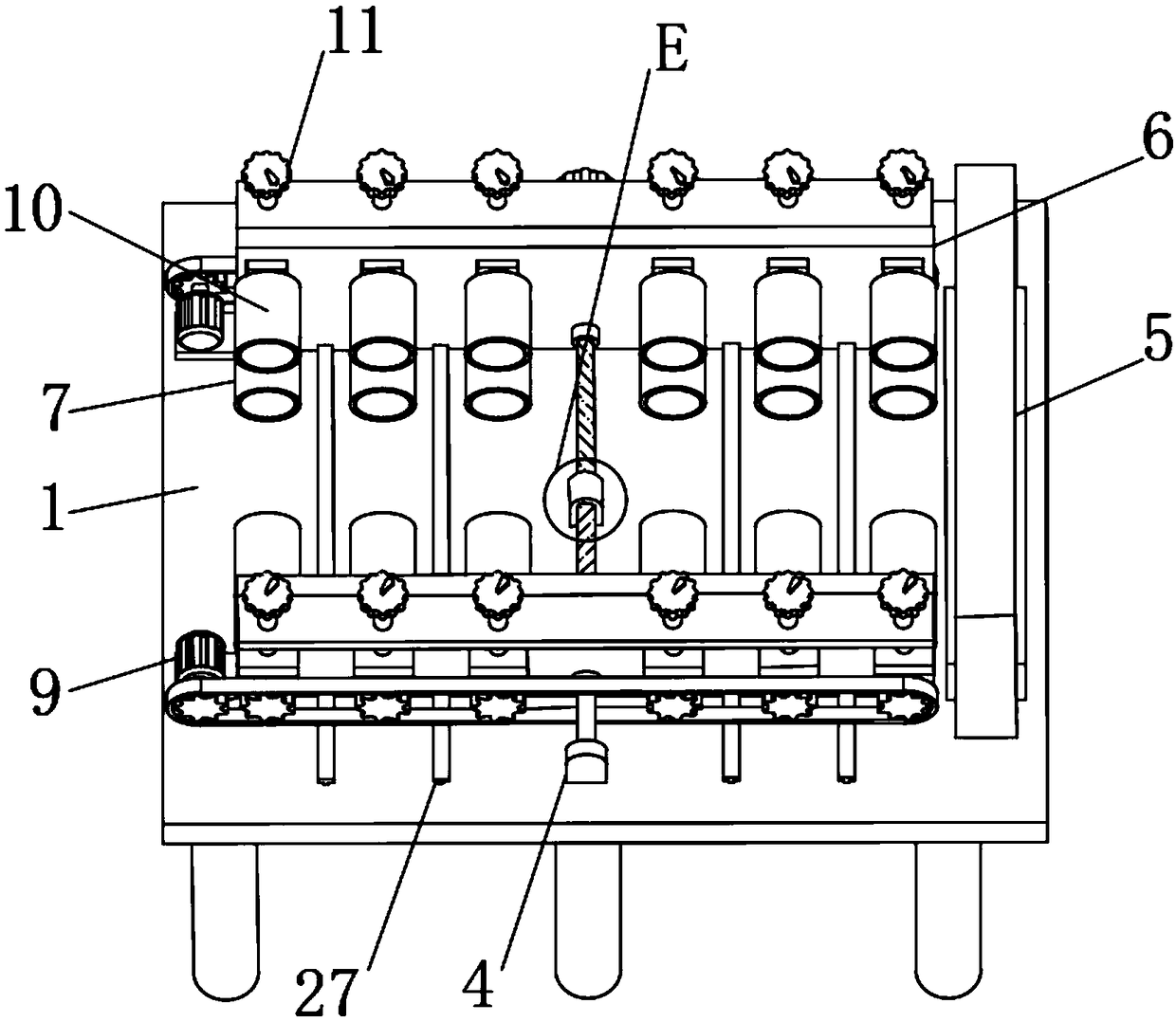

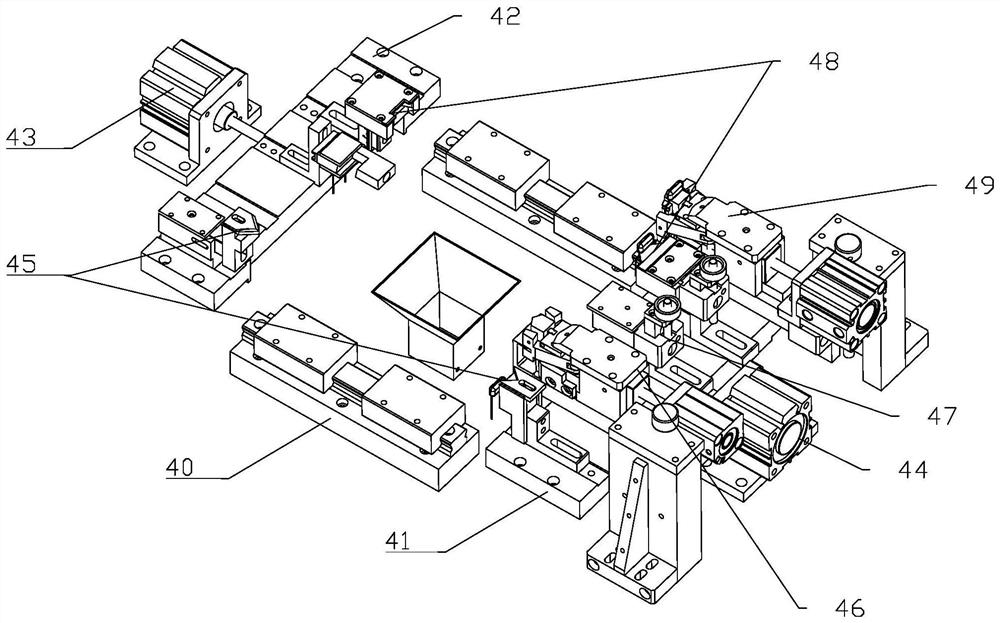

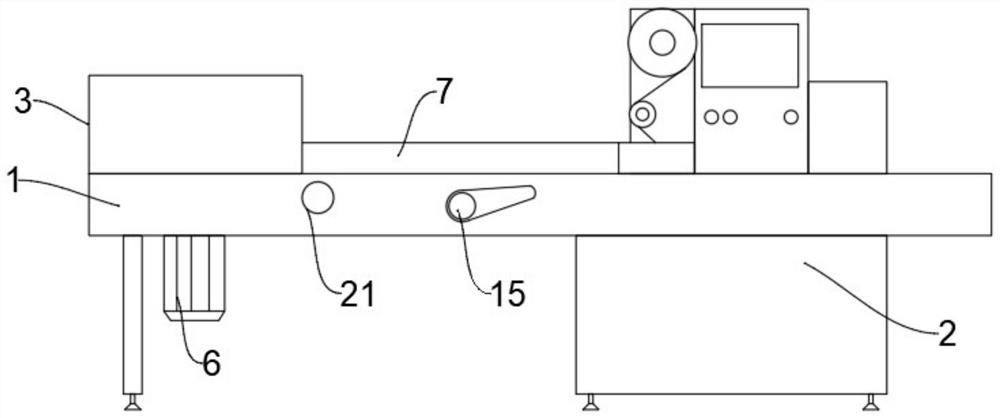

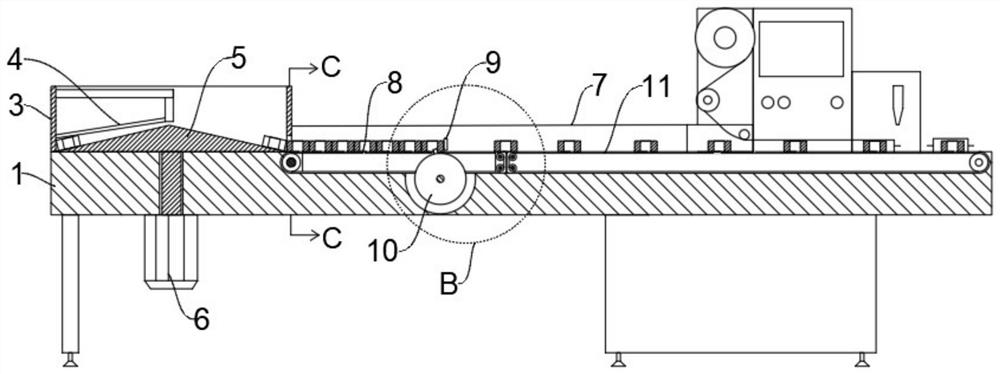

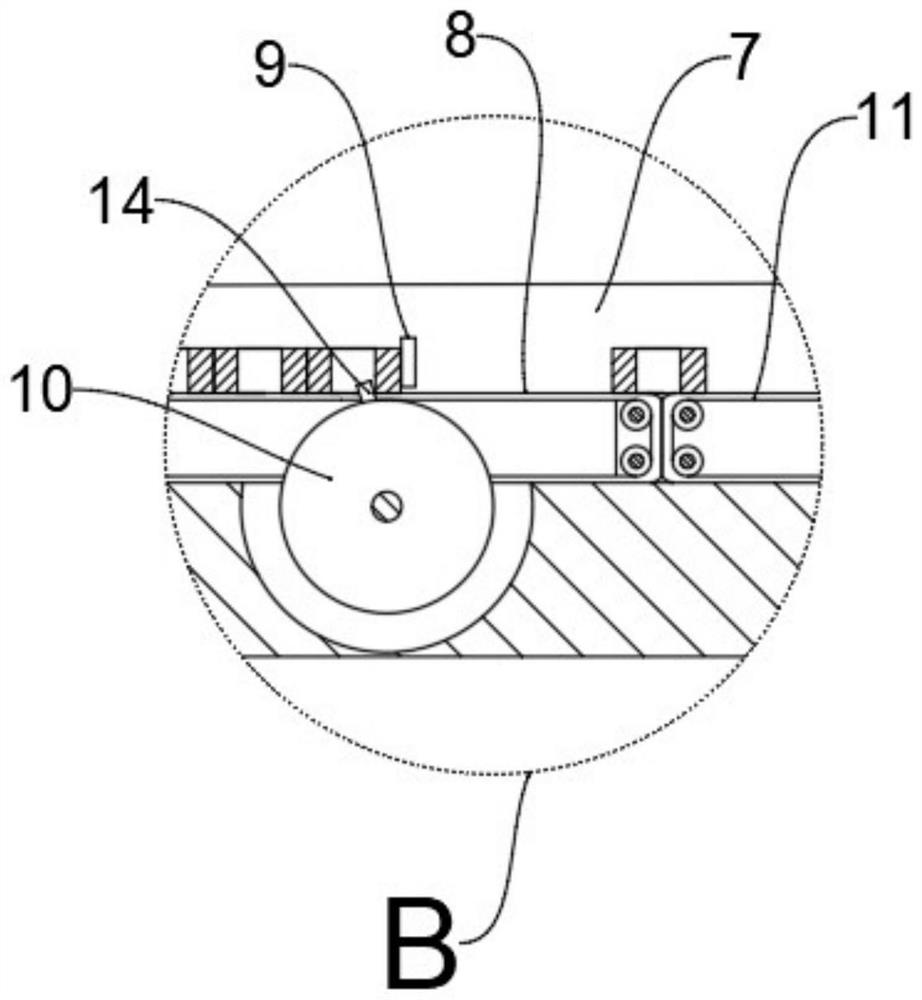

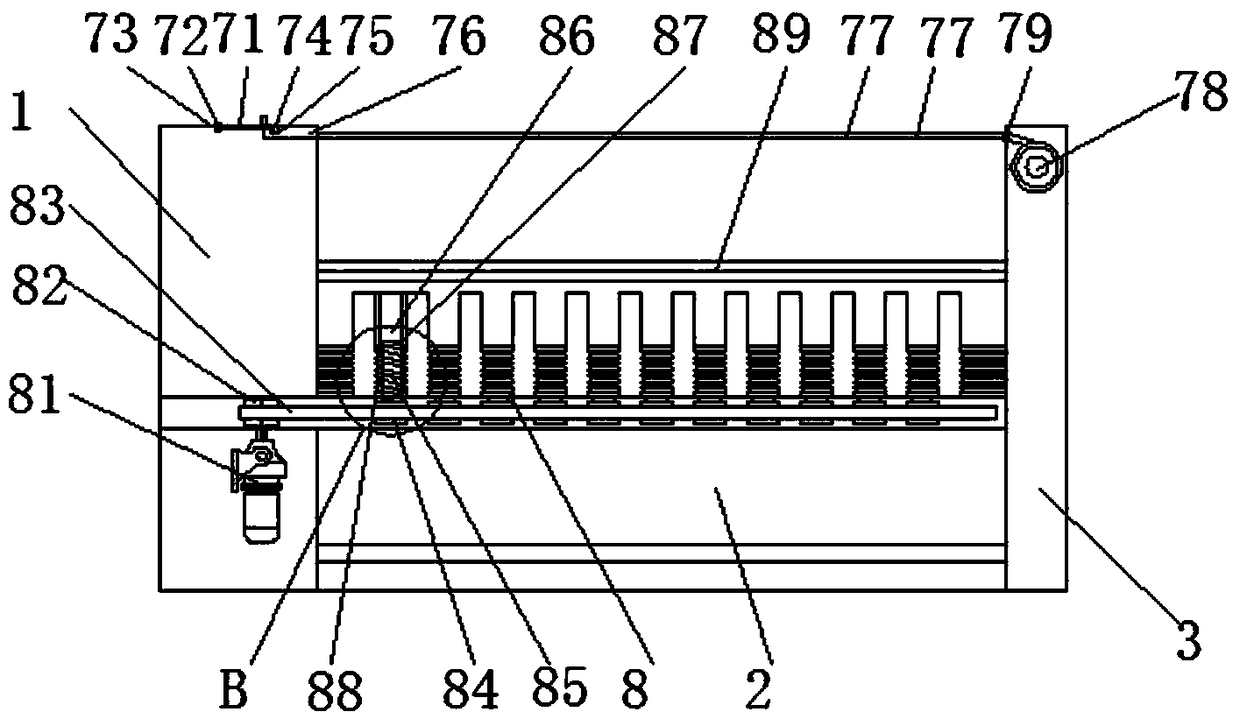

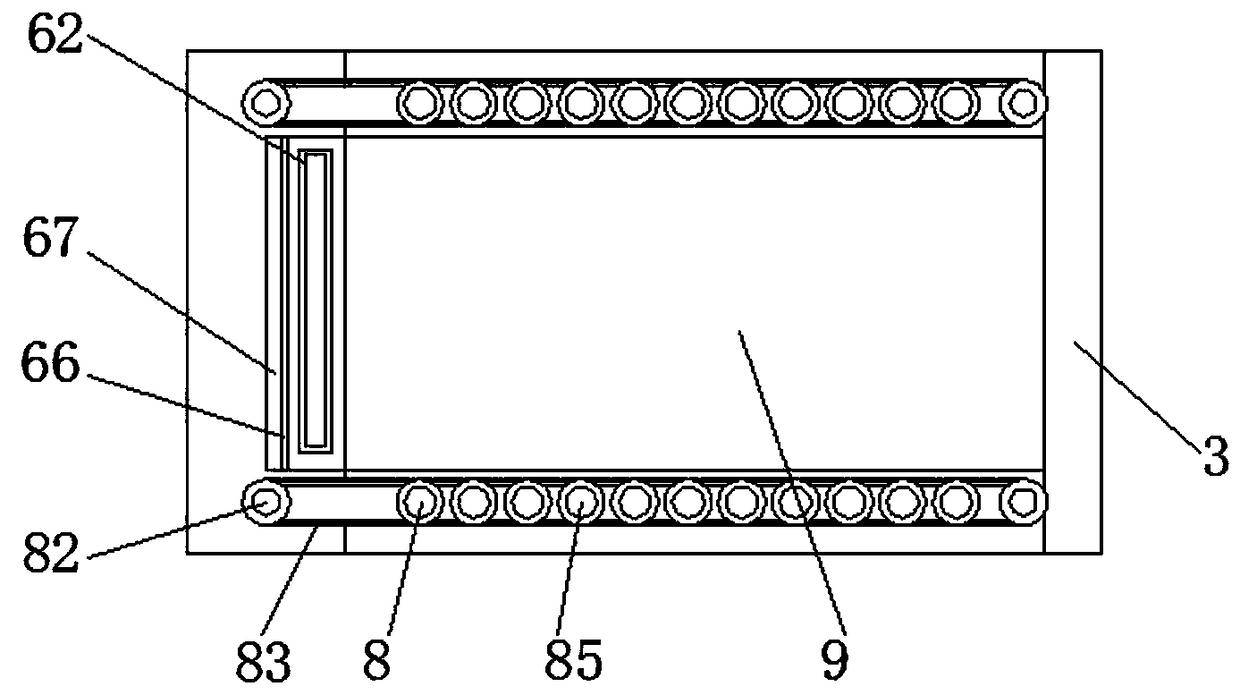

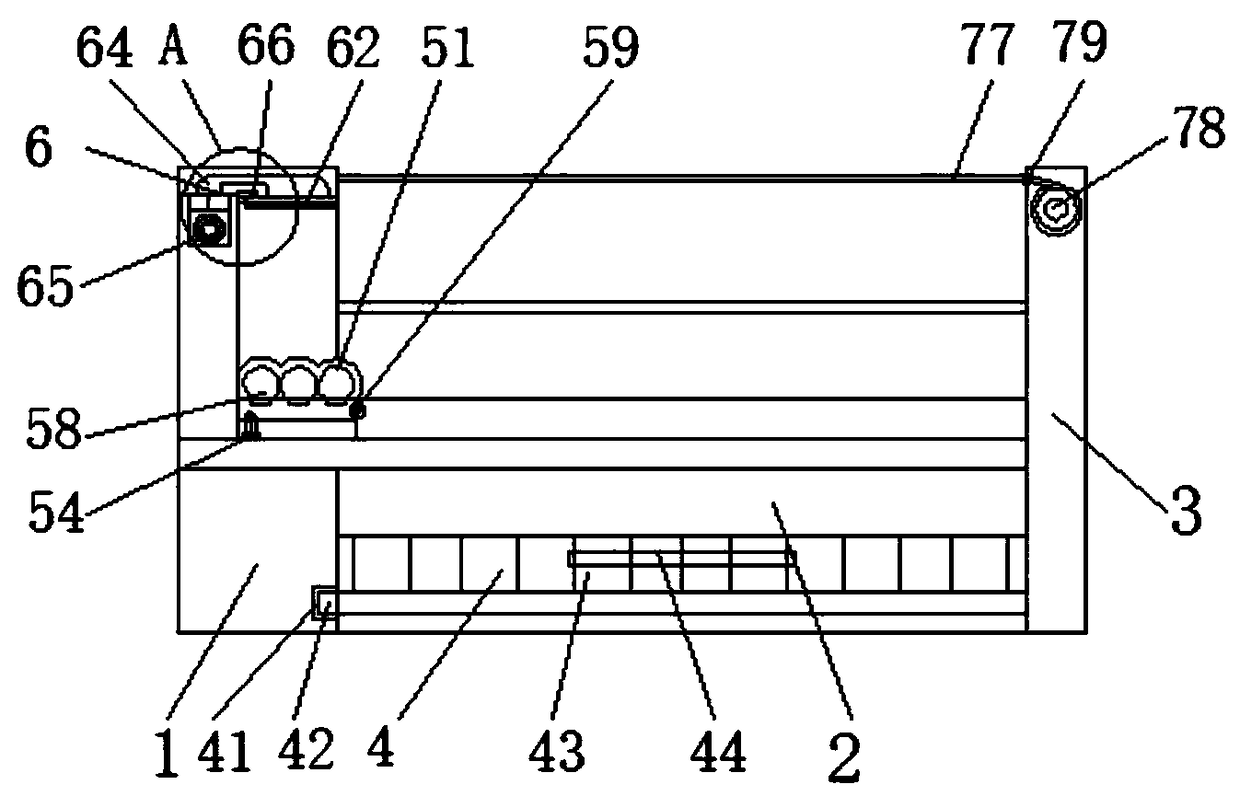

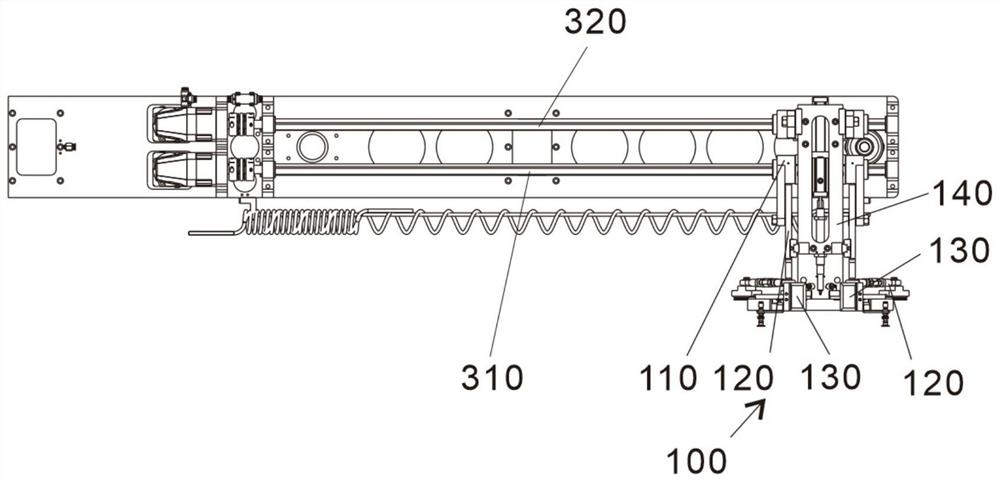

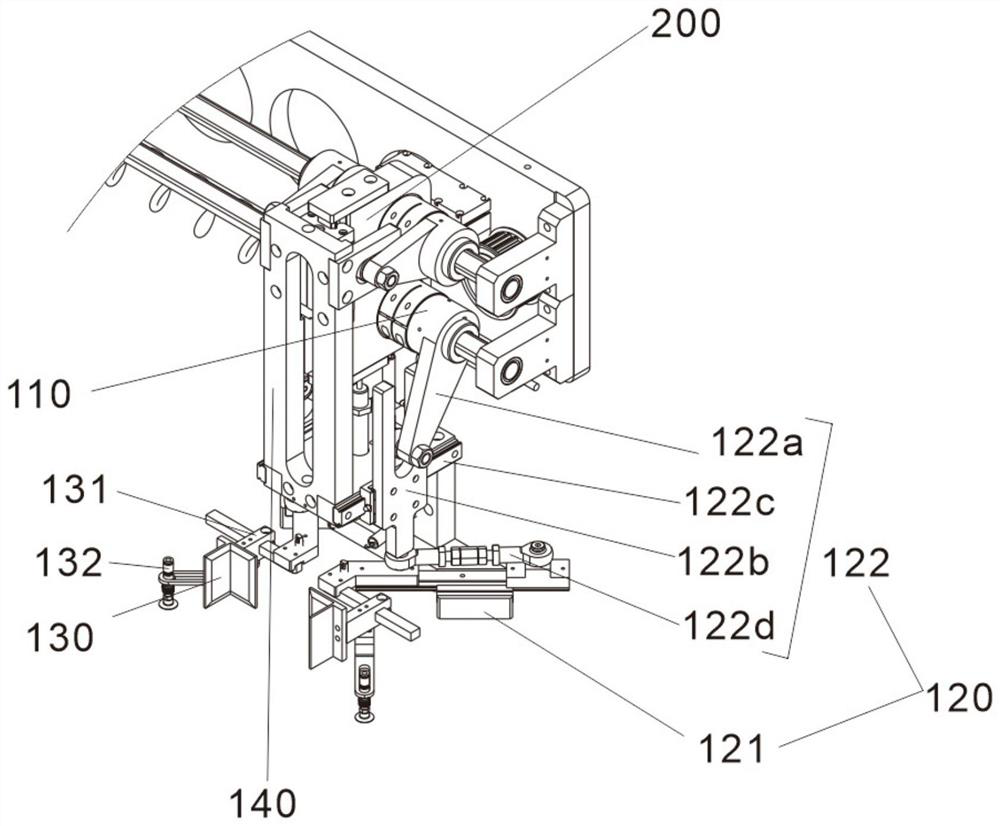

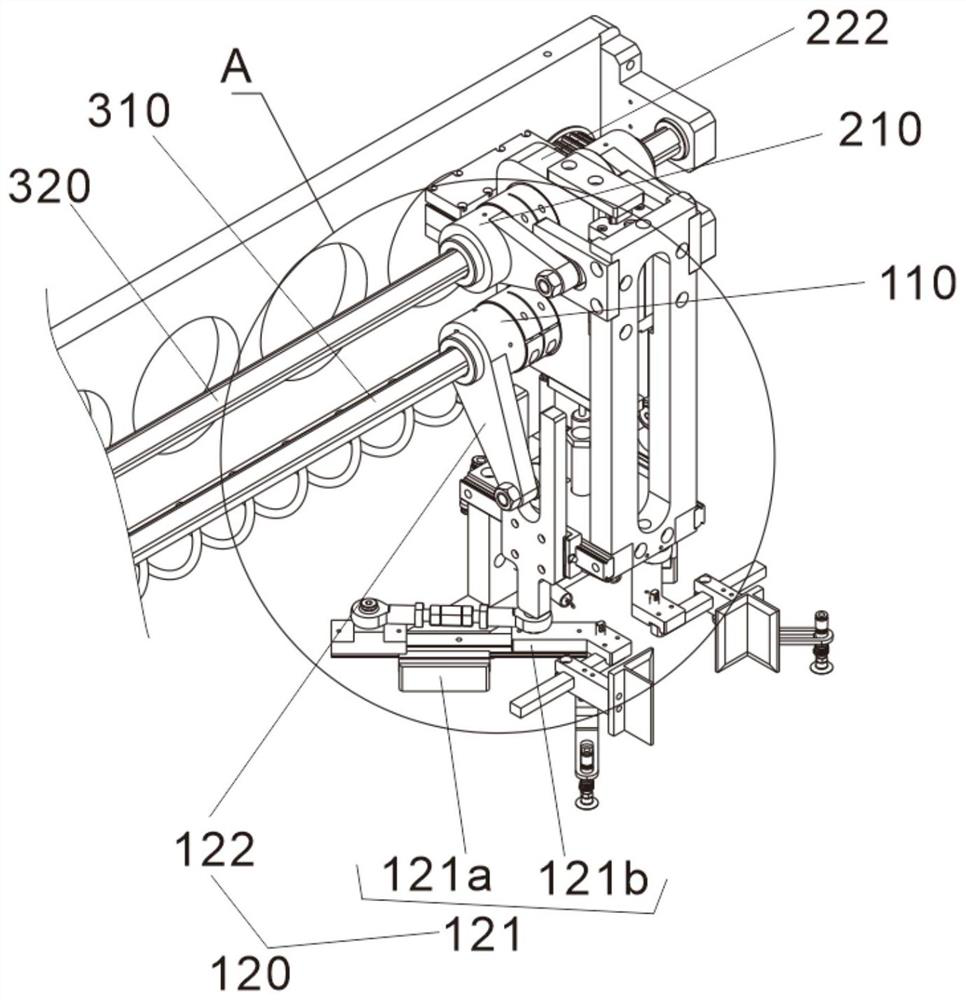

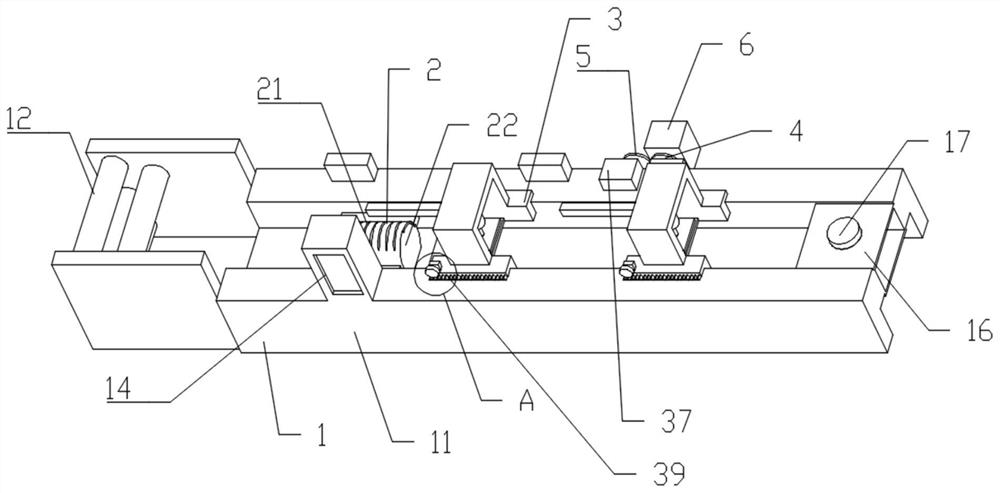

Bearing counting packaging machine

ActiveCN111731556AEasy to control synchronouslyEasy to achieve separationPackaging automatic controlPackaging machinesStructural engineeringIndustrial engineering

The invention relates to a bearing counting packaging machine. The bearing counting packaging machine comprises a rack, a placing mechanism, a pre-conveying device, a separating device and a packagingmachine body, the placing mechanism is fixed to one end of the upper surface of the rack, the packaging machine body is fixed to the other end of the upper surface of the rack, a discharging outlet of the placing mechanism directly faces one end of the pre-conveying device, and the other end of the pre-conveying device directly faces the feeding end of the packaging machine body. During using, aworker can directly place bearing parts into the placing mechanism, the bearing parts are preliminarily arranged under the action of internal components of the placing mechanism and then slide from the discharging outlet of the placing mechanism onto a pre-conveying belt of the pre-conveying device, the multiple bearing parts are linearly arranged on the pre-conveying belt, then the bearing partsare conveyed onto a feeding conveying belt of the packaging machine body at equal intervals through the separating device, the bearing parts are packaged at the next step, and the whole process can befully automated.

Owner:WUXI YUANTONG BEARING CO LTD

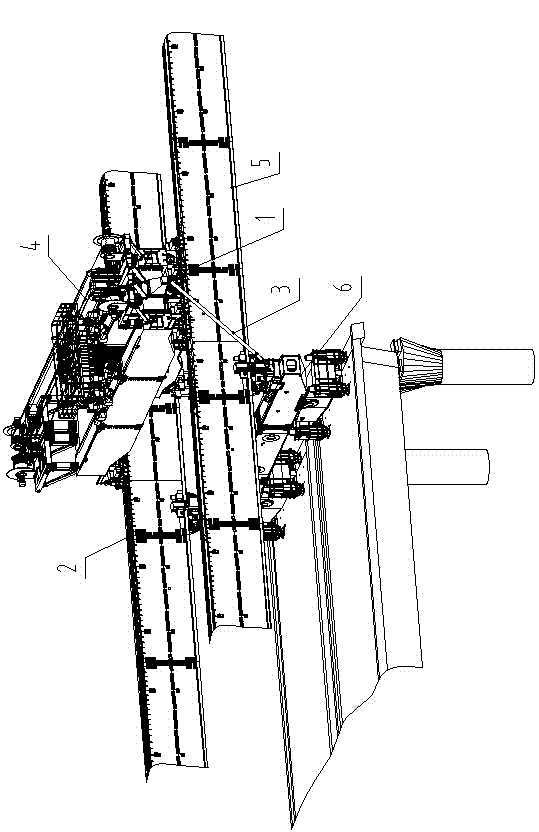

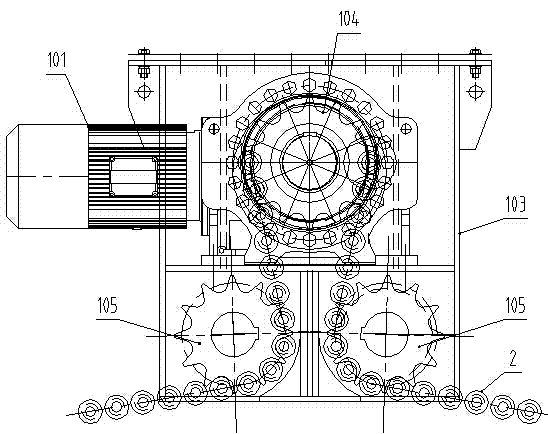

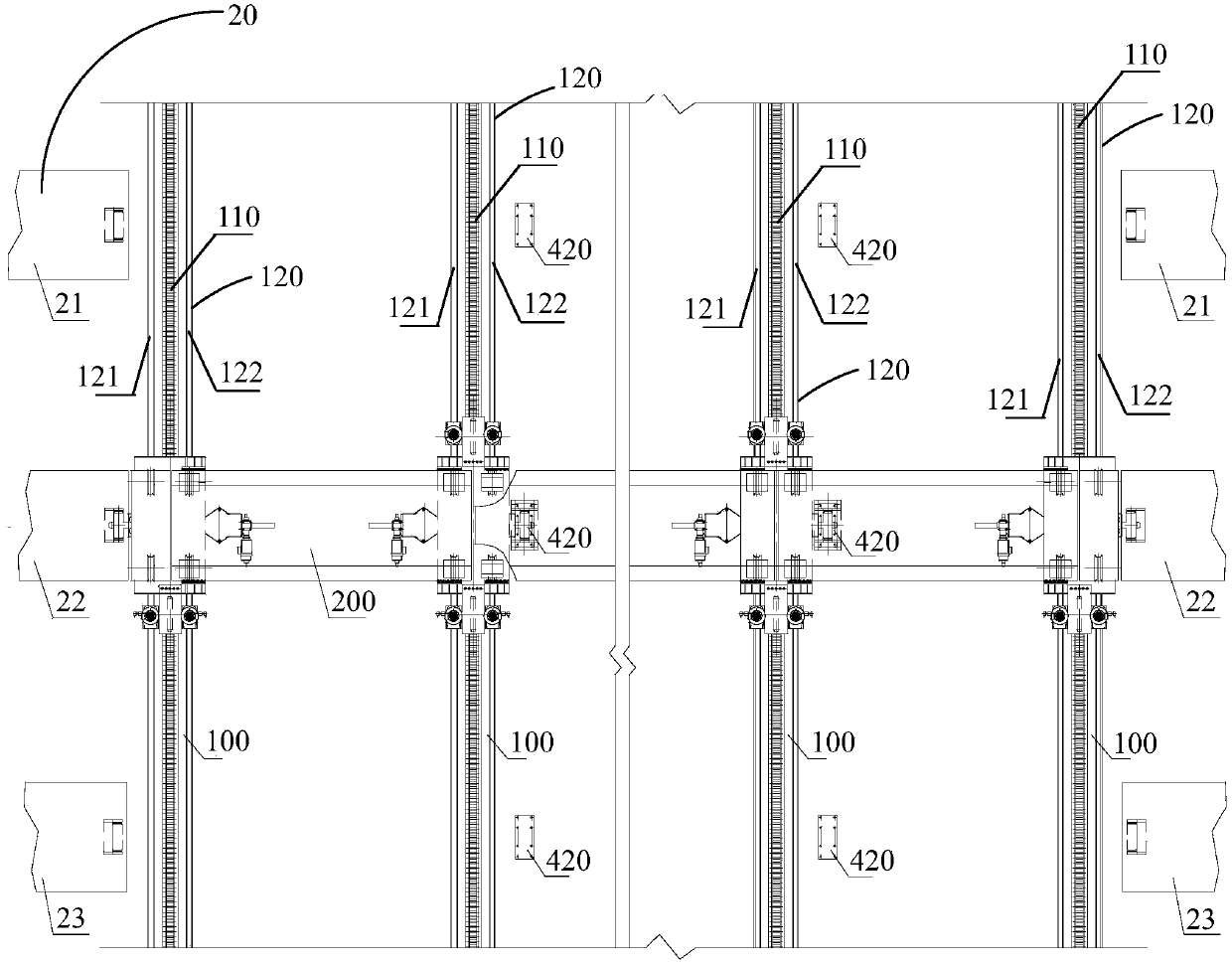

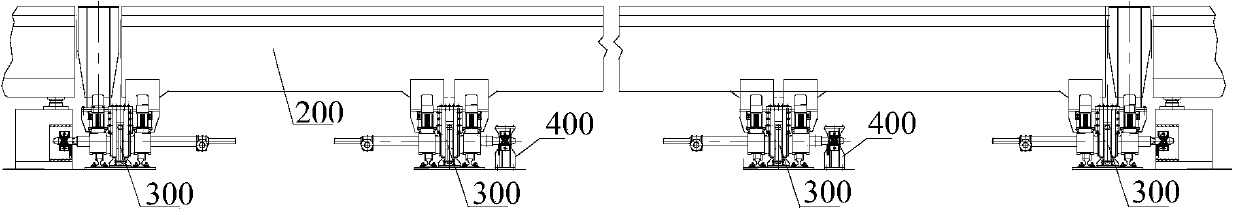

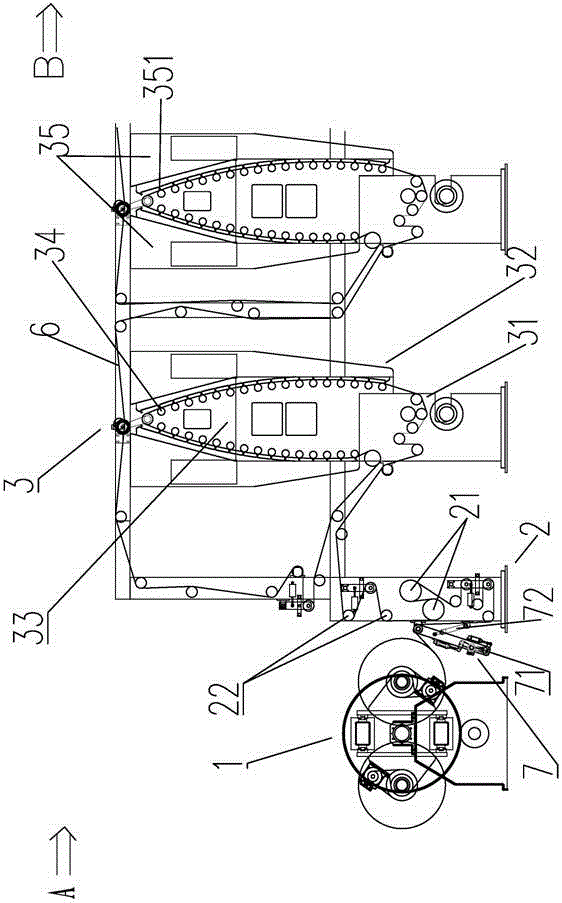

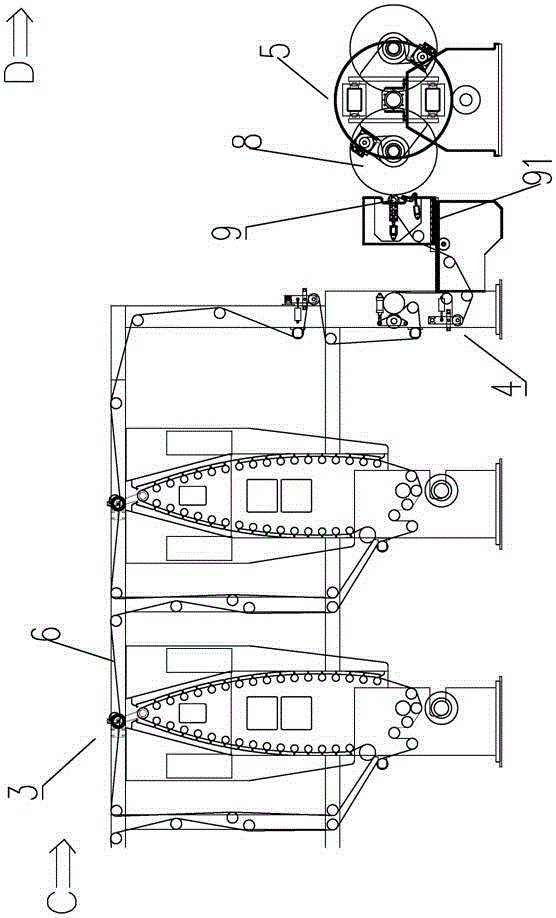

Multifunctional longitudinal movement driving device for bridge girder erection machine

ActiveCN104512802ASolve the slippery phenomenonAvoid security risksBridge erection/assemblyTravelling gearEngineeringBuilding construction

A multifunctional longitudinal movement driving device for a bridge girder erection machine comprises a driving module arranged on a crown block of the bridge girder erection machine, driving chains on main beams of the bridge girder erection machine and a support rod mechanism between the crown block of the bridge girder erection machine and a main landing leg. Longitudinal movement of the crown block of the bridge girder erection machine and via holes of the main beams can be achieved by one drive mechanism; the problems of insufficient driving power, operation skid, difficult mechanism layout and the like of the bridge girder erection machine during long-span, large-tonnage and heavy-grade bridge construction can be solved; and the device has the characteristics of safety, stability, low cost, compact mechanism layout and the like.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

Conveniently adjusted newborn nursing bed

The invention relates to a conveniently adjusted newborn nursing bed which comprises a first shell, a second shell, a third shell, a storage mechanism, a rotating mechanism, a ventilation mechanism, awinding mechanism and a lifting mechanism. The second shell is arranged on one side of the first shell, the third shell is arranged on the other side, far away from the first shell, of the second shell, the storage mechanism is arranged in the second shell, the rotating mechanism is arranged on one side, far away from the second shell, of the storage mechanism, the ventilation mechanism is arranged on one side, far away from the storage mechanism, of the rotating mechanism, the winding mechanism is arranged on one side, far away from the rotating mechanism, of the ventilation mechanism, and the lifting mechanism is arranged between the first shell and the third shell. The conveniently adjusted newborn nursing bed is provided with the ventilation mechanism, inner air in the bed can be circulated, air flow and illumination can be softer in the working process of the ventilation mechanism by the aid of a wind shielding plate and a light shielding plate below the ventilation mechanism, and the bed is more comfortably used.

Owner:陈小芹

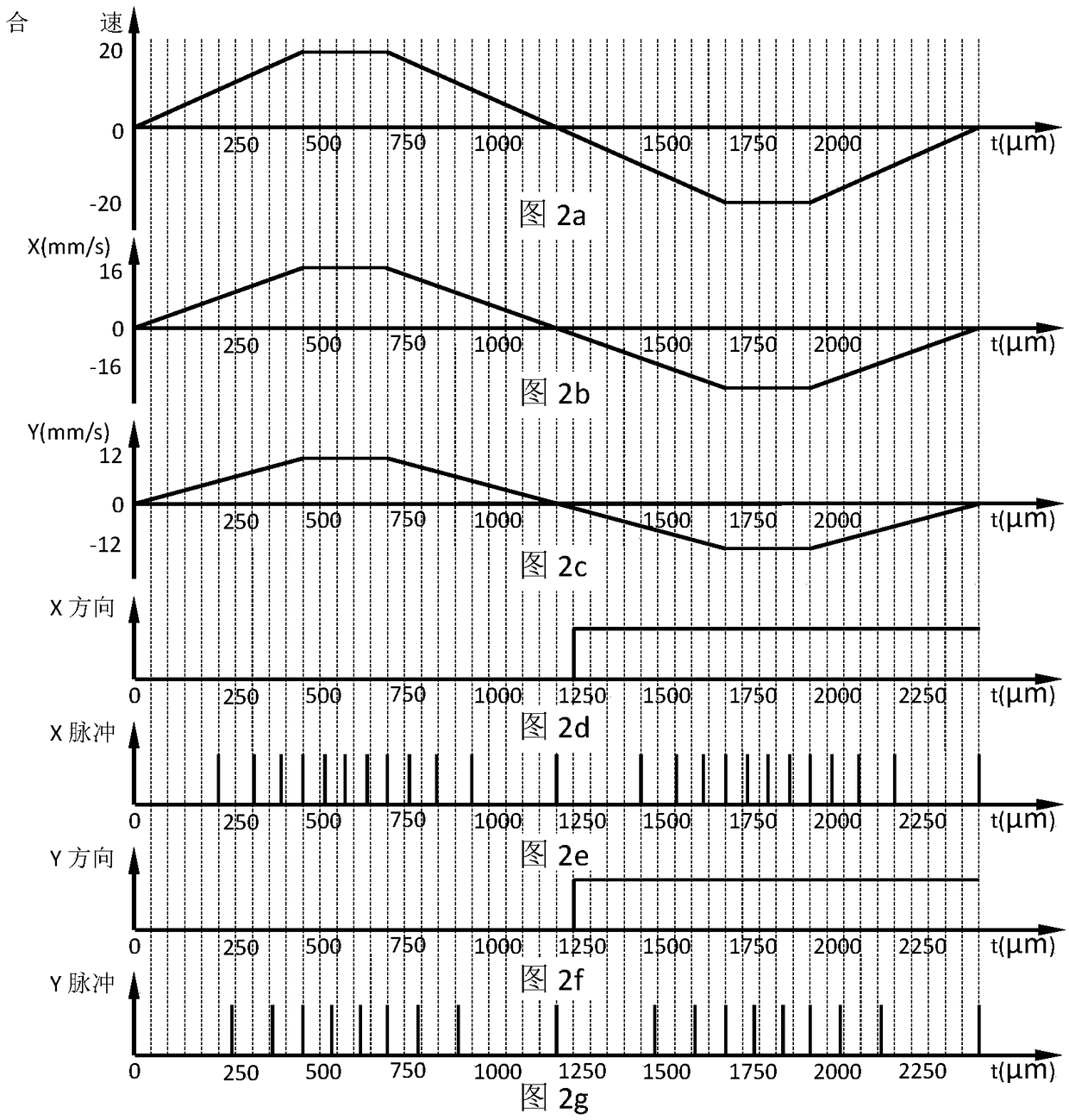

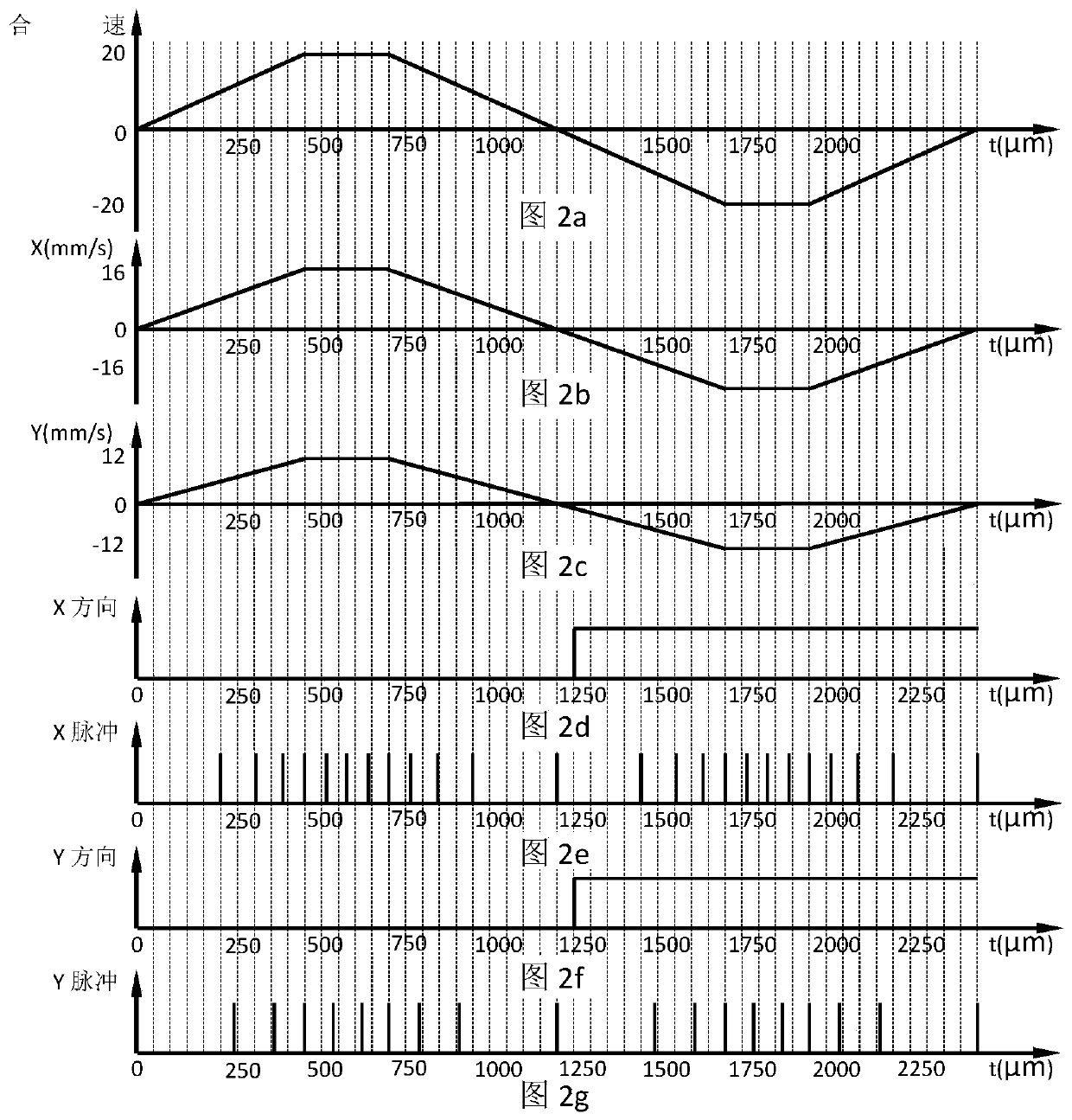

Control method for multi-axis synchronous movement with high speed and high precision based on double clock

ActiveCN109343473AHigh precisionEasy to control synchronouslyProgramme controlComputer controlNumerical controlData file

The invention discloses a control method for a multi-axis synchronous movement with a high speed and a high precision based on a double clock, and the final purpose is to output a pulse sequence and direction signals to a servo drive of each shaft. The method comprises steps of: determining an output time and a direction of a pulse through the calculation; determining a size clock period accordingto the maximum movement speed of each shaft and the input pulse range; converting the time and direction signals into pulse direction numbers, and storing the pulse direction data in a data file in the form of a two-dimensional array; reading and analyzing the pulse direction number of the two-dimensional array format in the data file by a numerical control device; uninterruptedly converting thepulse direction numbers of the two-dimensional array format into pulse and direction signals, by the switch and the timer, and the large-cycle clock is used as the synchronization signal; and inputting the signals to the servo drive, so that the trajectory movement is completed. According to the control method for the multi-axis synchronous movement with the high speed and the high precision basedon the double clock, the method realizes the control of the multi-axis synchronous movement with the high speed and the high precision through the calculation and hardware synchronous output method;improves the processing efficiency by the high speed; and improves the processing quality of the product with the high precision.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

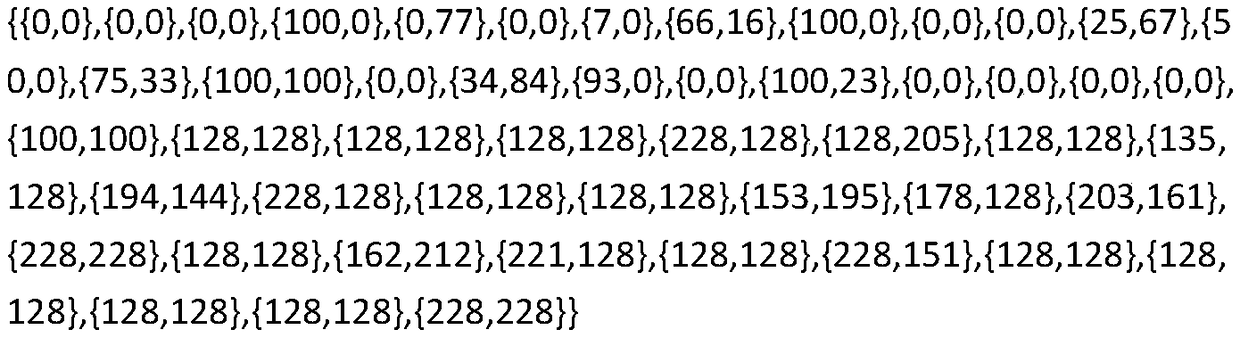

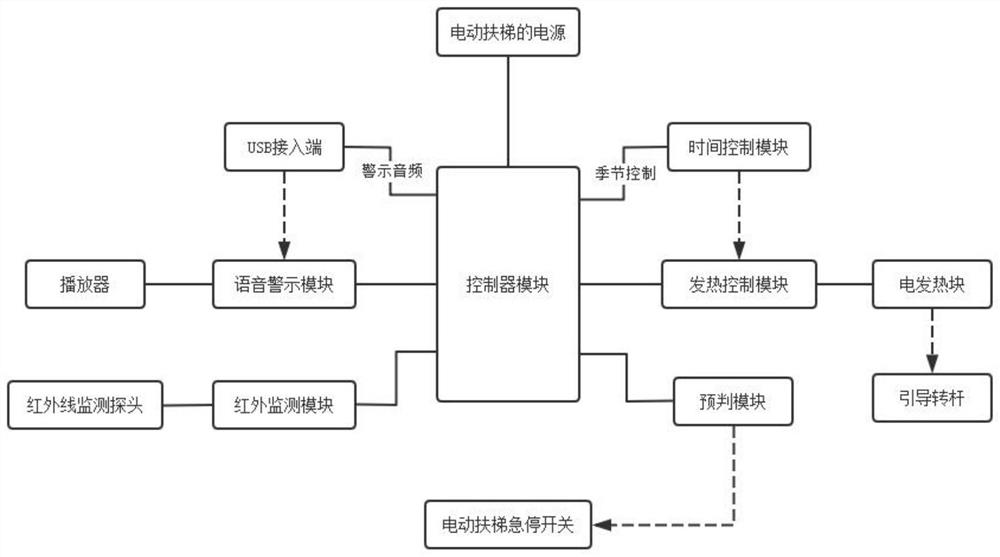

A system for controlling range hoods using cooker sensors

ActiveCN105864836BAccurate judgmentImprove reliabilityDomestic stoves or rangesLighting and heating apparatusInformation processingAutomatic control

The invention discloses a system for controlling a range hood by utilizing a cooker sensor. The system is characterized by comprising an information processing circuit, a heating sensing circuit, a pan temperature sensing circuit, a heating control circuit and a range hood control circuit, wherein the heating sensing circuit, the pan temperature sensing circuit, the heating control circuit and the range hood control circuit are connected with the information processing circuit, and the information processing circuit is used for controlling the heating control circuit and the range hood control circuit to operate according to feedback information of the heating sensing circuit, the pan temperature sensing circuit and the heating control circuit. According to the system, the pan temperature sensing circuit is arranged, so that a sensor for oil smoke does not need to be additionally arranged on the range hood, the judgment is accurate, the reliability is high, and the service life is long; the current cooking condition can be sensed, and the subsequent cooking condition can be automatically controlled, so that the variation trend of the oil smoke is indirectly sensed, intelligent control modes of a cooker and the range hood can be conveniently corrected in time, the condition that the air quantity changes before the oil smoke quantity changes is realized, and the intelligent control effect of the range hood is increased.

Owner:GUANGDONG MACRO GAS APPLIANCE

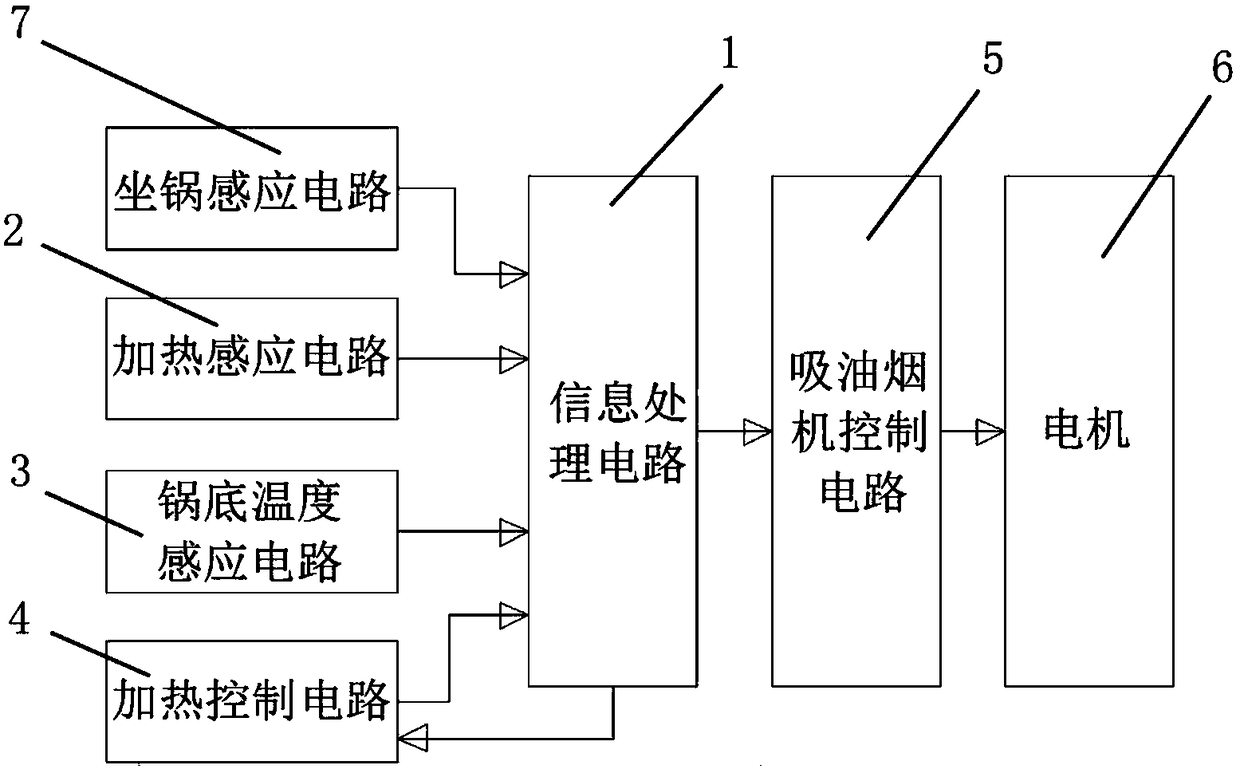

Voice-coil-motor-driven high-speed switch valve

ActiveCN105135028AAcceleration precise controlPrecise speed controlOperating means/releasing devices for valvesWater basedLow noise

The invention relates to a voice-coil-motor-driven high-speed switch valve. A voice coil motor is utilized to directly convert electric energy into rectilinear motion mechanical energy so as to drive the switch valve core to reciprocate without any intermediate switching mechanism. The voice-coil-motor-driven high-speed switch valve has the advantages of simple structure, no contact, no abrasion, low noise, high speed, high precision and the like. The valve core adopts a split balance-type cone valve structure, and thus, can be subjected to balanced stress in the high-speed switch valve opening / closing process, thereby enhancing the sealing reliability of the valve port, avoiding the leakage of the system, enhancing the pressure / flow control precision, avoiding the energy dissipation and having high pollution resistance. The high-speed switch valve has the characteristics of high response speed, high flow rate, small size, light weight and simple structure, is suitable for gas media and also suitable for system pipelines and the like using oil-base, water-base or any other working medium, is used for controlling the high-frequency opening / closing of the fluid medium, and has very important engineering application value.

Owner:BEIJING UNIV OF TECH

Magnetic levitation system traverse table

The invention discloses a magnetic levitation system traverse table. The magnetic levitation system traverse table is arranged among multiple railway track lines to switch a magnetic-levitation train borne by the magnetic levitation system traverse table among the railway track lines. The magnetic levitation system traverse table comprises multiple tracks and a movable beam, the tracks are arranged on a foundation in parallel, and each track comprises a pin tooth track. The movable beam crosses the tracks and is connected with each track through a driving piece, and each driving piece comprises a gear which is matched with the corresponding pin tooth track. The movable beam bears the magnetic-levitation train, and the gears drive the movable beam to move among the railway track lines when rolling along the pin tooth tracks. The magnetic levitation system traverse table is safe, reliable, high in precision and few in fault, and facilitates deformation control.

Owner:CHINA IPPR INT ENG

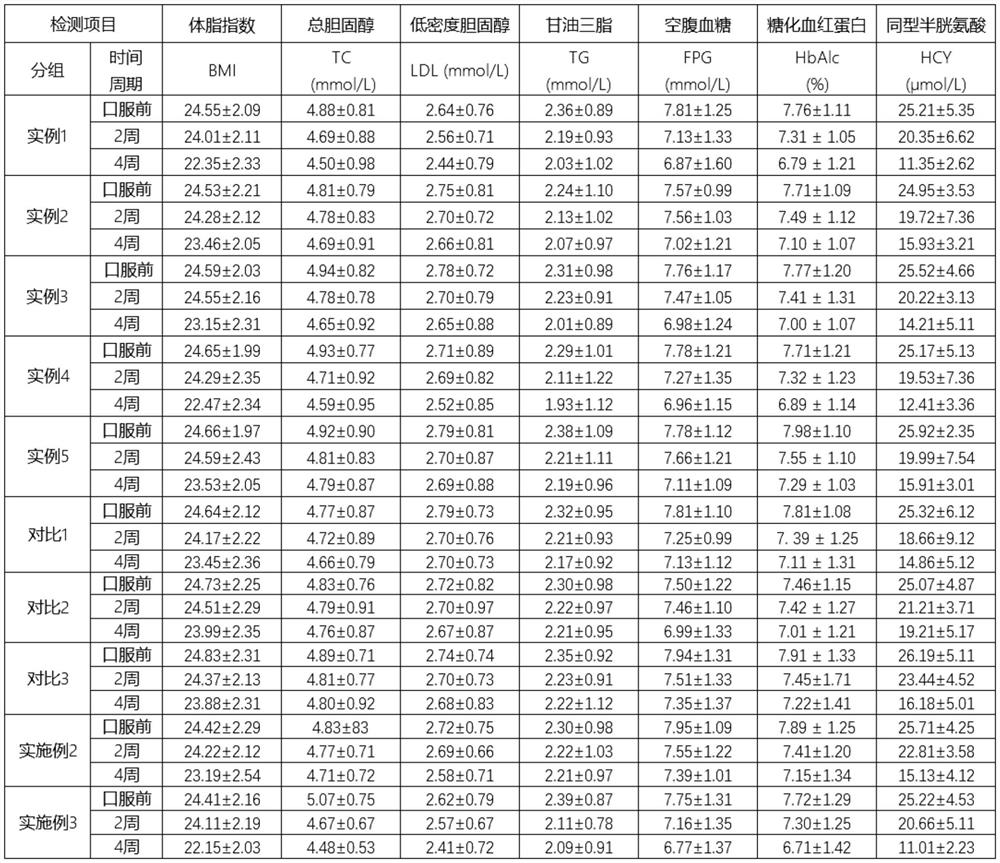

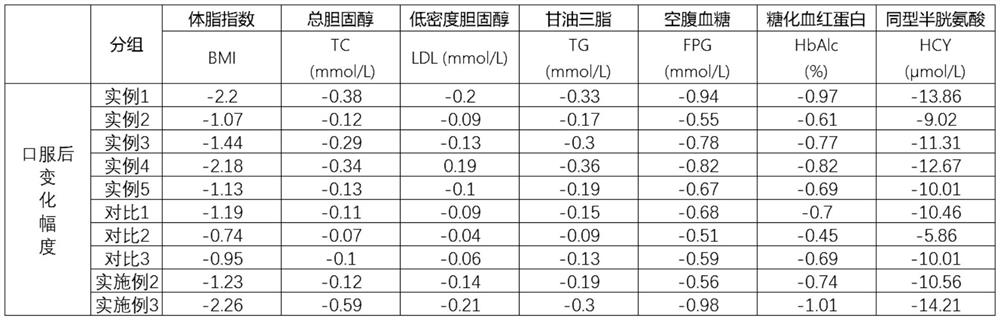

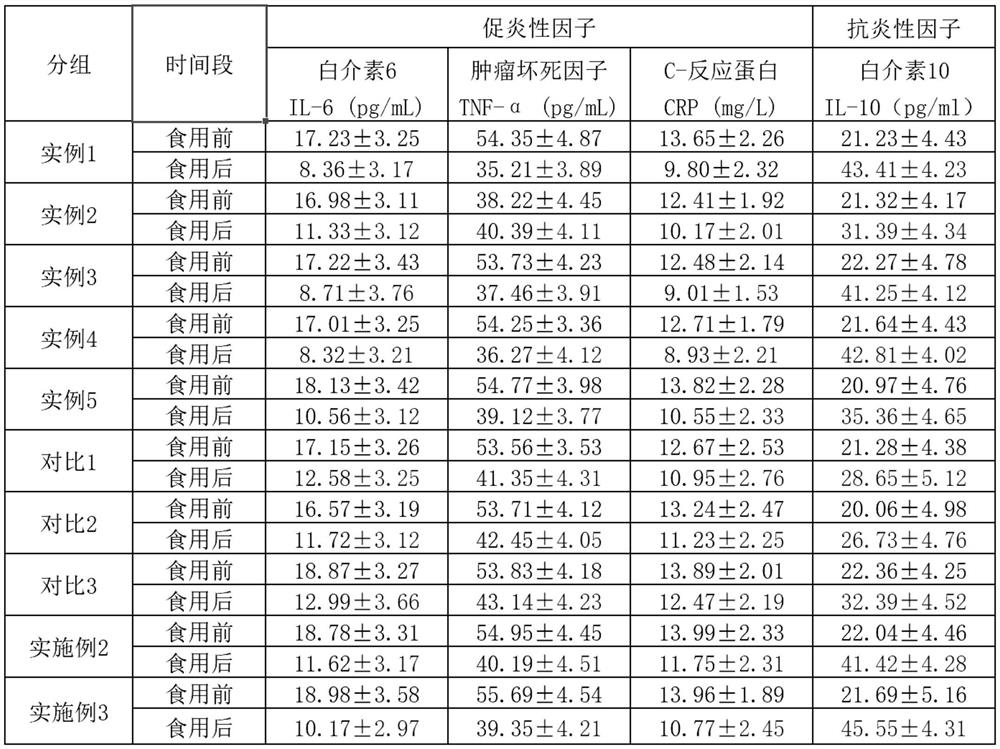

Composition, compound oil and application of composition and compound oil

InactiveCN112690453ALowering and inhibiting balanceMeet health needsEdible oils/fatsInflammatory factorsMedicine

The invention provides a composition, compound oil and an application of the composition and the compound oil. The composition comprises LA, ALA and CBD in a mass ratio of (7-9): (2-3): 1, The compound oil comprises hemp seed oil, krill oil and tetrahydrodiphenol in a mass ratio of (10-20): (1-6): 1. The composition and the compound oil effectively solve the problem that the effect of a substance for reducing the level of inflammatory factors disclosed in the prior art on improving human immune system imbalance and / or inflammatory physique is not very outstanding. The composition and the compound oil provided by the invention have the advantage of remarkably improving the human immune system imbalance and / or chronic inflammatory physique.

Owner:北京常春藤经贸有限责任公司

Box holding and transferring assembly and device and packaging box production equipment

PendingCN113085253ASimplify the assembly and commissioning processReduce in quantityBox making operationsPaper-makingHydraulic cylinderSynchronous control

The invention relates to the technical field of mechanical transferring devices, in particular to a box holding and transferring assembly and device and packaging box production equipment. The box holding and transferring assembly comprises a box holding mechanism, and the box holding mechanism comprises a first rotating part, at least two holding claw telescopic mechanisms and at least two holding claws; the holding claws are connected with the first rotating part through the holding claw telescopic mechanisms; and the first rotating part is connected with a power source and is driven by the power source to rotate, and the at least two holding claw telescopic mechanisms are connected with the first rotating part, so that the holding claws are driven by the first rotating part and the telescopic mechanisms to be close to or away from each other synchronously. By means of the box holding and transferring assembly, the first rotating part transmits power of the power source to drive the two holding claw telescopic mechanisms to synchronously act to drive the holding claws to be close to or away from each other. Compared with the prior art that each holding claw is provided with an independent air cylinder or hydraulic cylinder as the power source, the number of the power sources is reduced, the assembly and debugging process of the assembly is simplified, and synchronous control over actions of the holding claws is facilitated.

Owner:XUCHANG YUTO PRINTING & PACKING

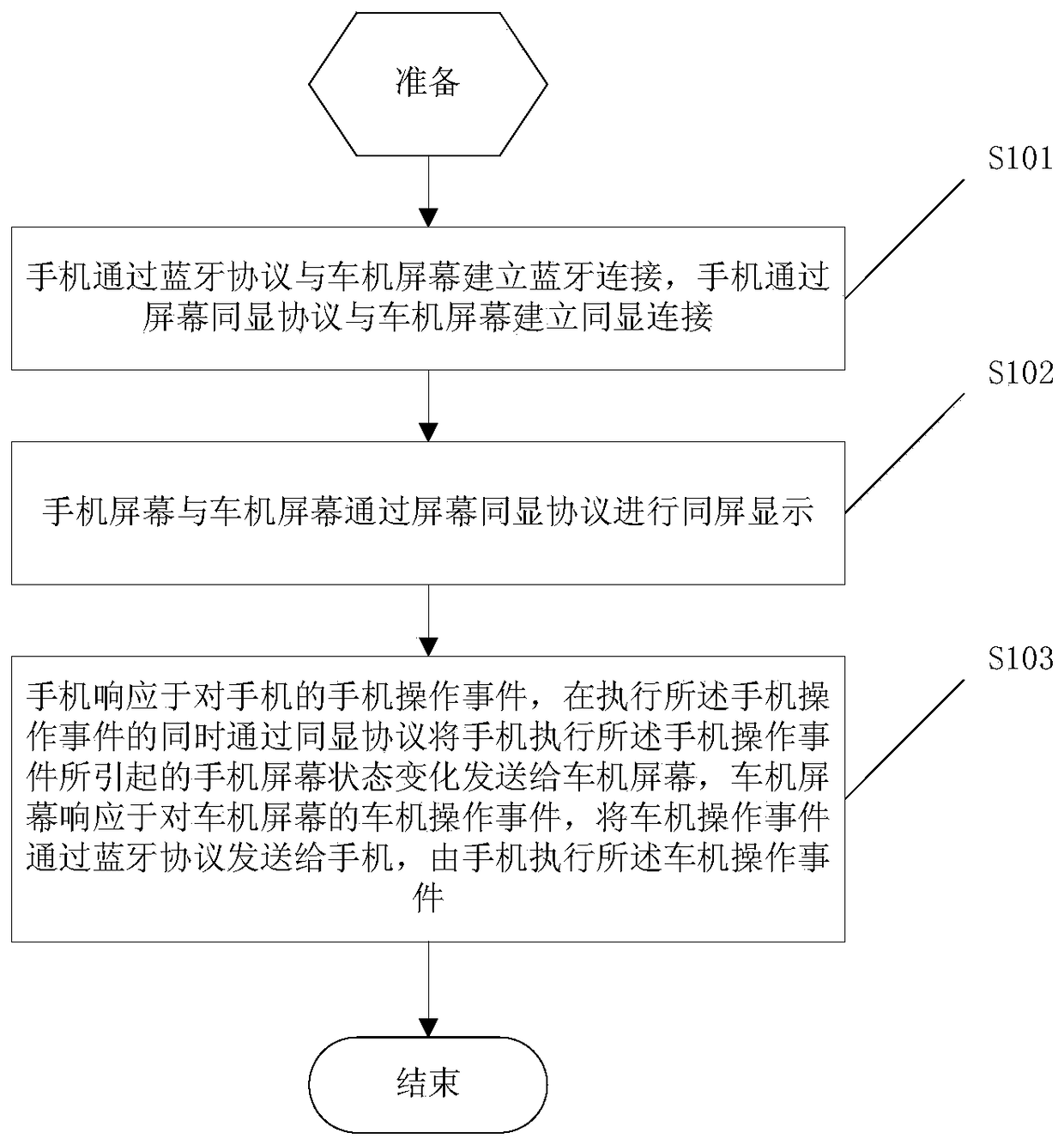

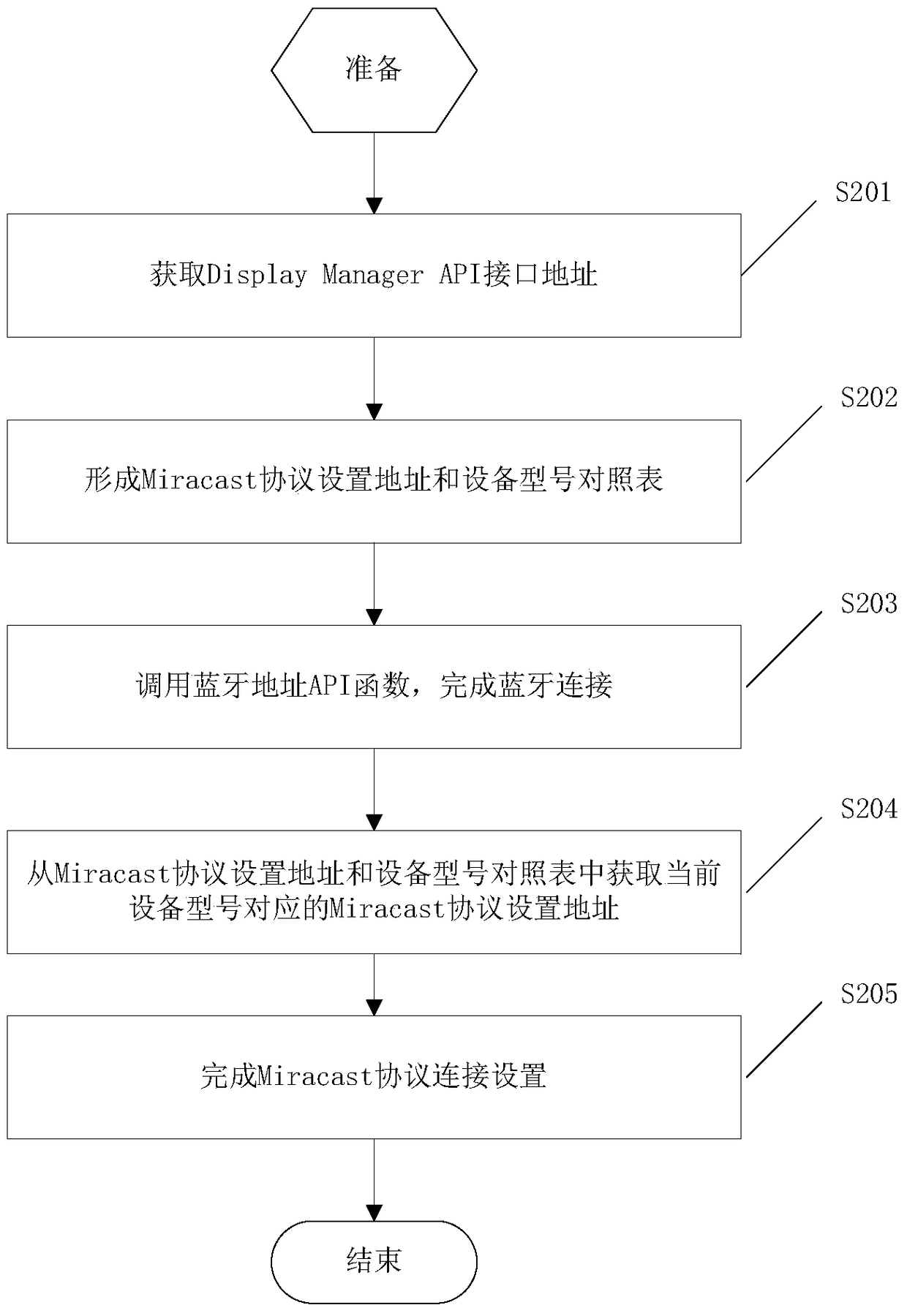

A connection control method and system for a car screen and a mobile phone

ActiveCN105117184BEasy to control synchronouslyEasy to controlSubstation equipmentShort range communication serviceComputer hardwareBluetooth

The invention discloses a connection control method and system between a mobile phone and a car screen. The method includes: establishing a Bluetooth connection between the mobile phone and the screen of the car through a Bluetooth protocol, establishing a co-display connection between the mobile phone and the screen of the car through a screen co-display protocol; The screen of the car is displayed on the same screen through the screen simultaneous display protocol; the mobile phone responds to the mobile phone operation event on the mobile phone, and at the same time performs the mobile phone operation event through the screen simultaneous display protocol to display the mobile phone screen caused by the mobile phone operation event The state change is sent to the car-machine screen, and the car-machine screen responds to the car-machine operation event on the car-machine screen, and sends the car-machine operation event to the mobile phone through the Bluetooth protocol, and the mobile phone executes the car-machine operation event. The invention enables the user to realize synchronous control while displaying on the same screen, and is convenient for the user to use the mobile phone to control the screen of the vehicle, or to control the mobile phone by using the screen of the vehicle.

Owner:DONGFENG MOTOR CO LTD

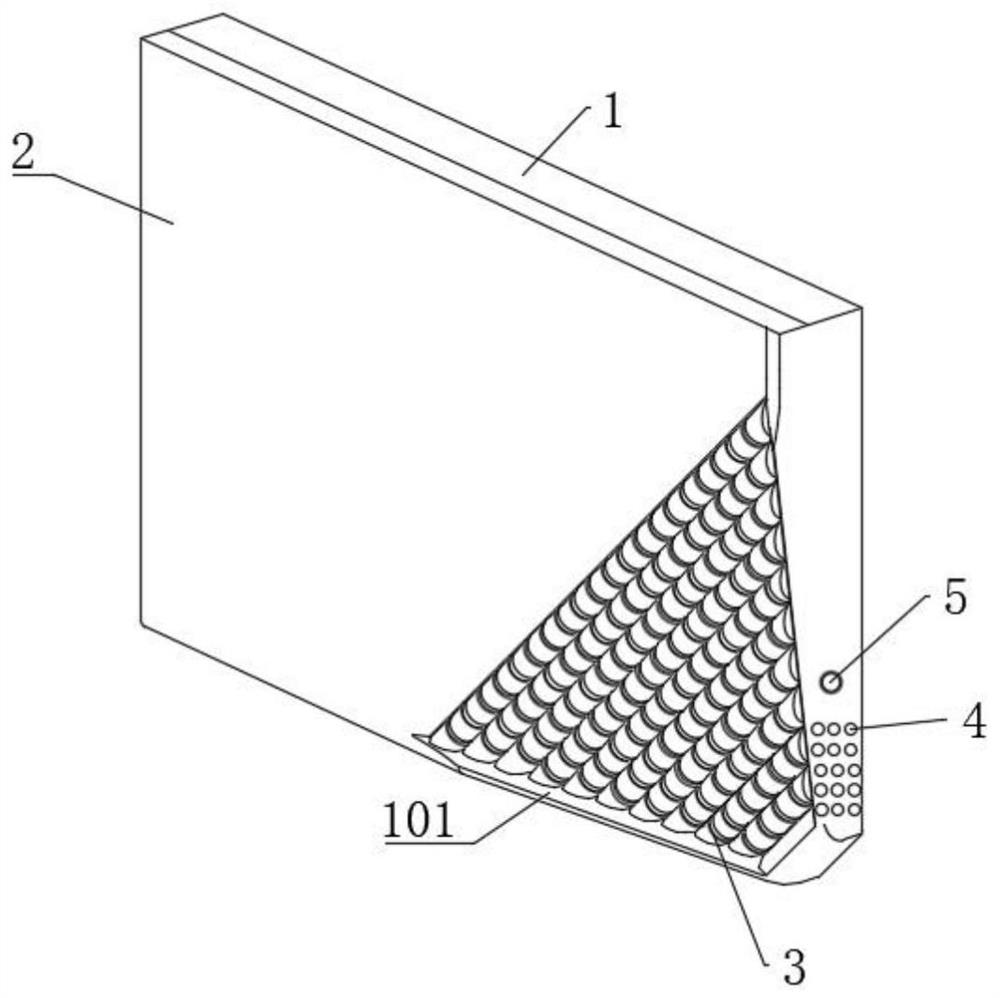

Self-guiding type escalator head-bump prevention protection plate

PendingCN112960528AImprove securityReduce noiseEscalatorsStructural engineeringMechanical engineering

The invention discloses a self-guiding type escalator head-bump prevention protection plate, and belongs to the field of escalators. The self-guiding type escalator head-bump prevention protection plate comprises a protection plate body, an inclined guiding surface is arranged at the front end of the protection plate body, a mounting groove is formed in the guiding surface, a guiding assembly is connected in the mounting groove, and comprises guiding rotating rods, the multiple guiding rotating rods matched with the mounting groove are rotationally connected in the mounting groove, guiding rotating rollers are fixedly connected to the outer ends of the guiding rotating rods, and a plurality of guiding lantern rings are arranged at the outer ends of the guiding rotating rollers in a sleeving mode. Through cooperation of the guiding surface and the guiding assembly, when a child keeps the head or the body out of an escalator, the direction of the head and the body of the child is guided, the direct collision force is effectively reduced, the child is protected, and the safety of the child taking the escalator is improved.

Owner:宋海豹

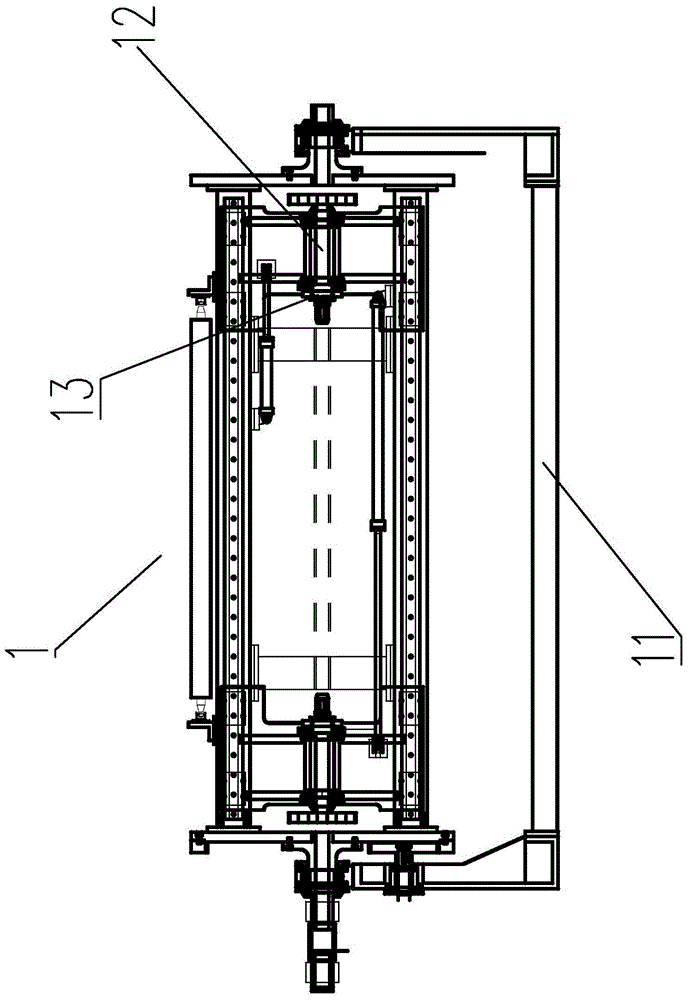

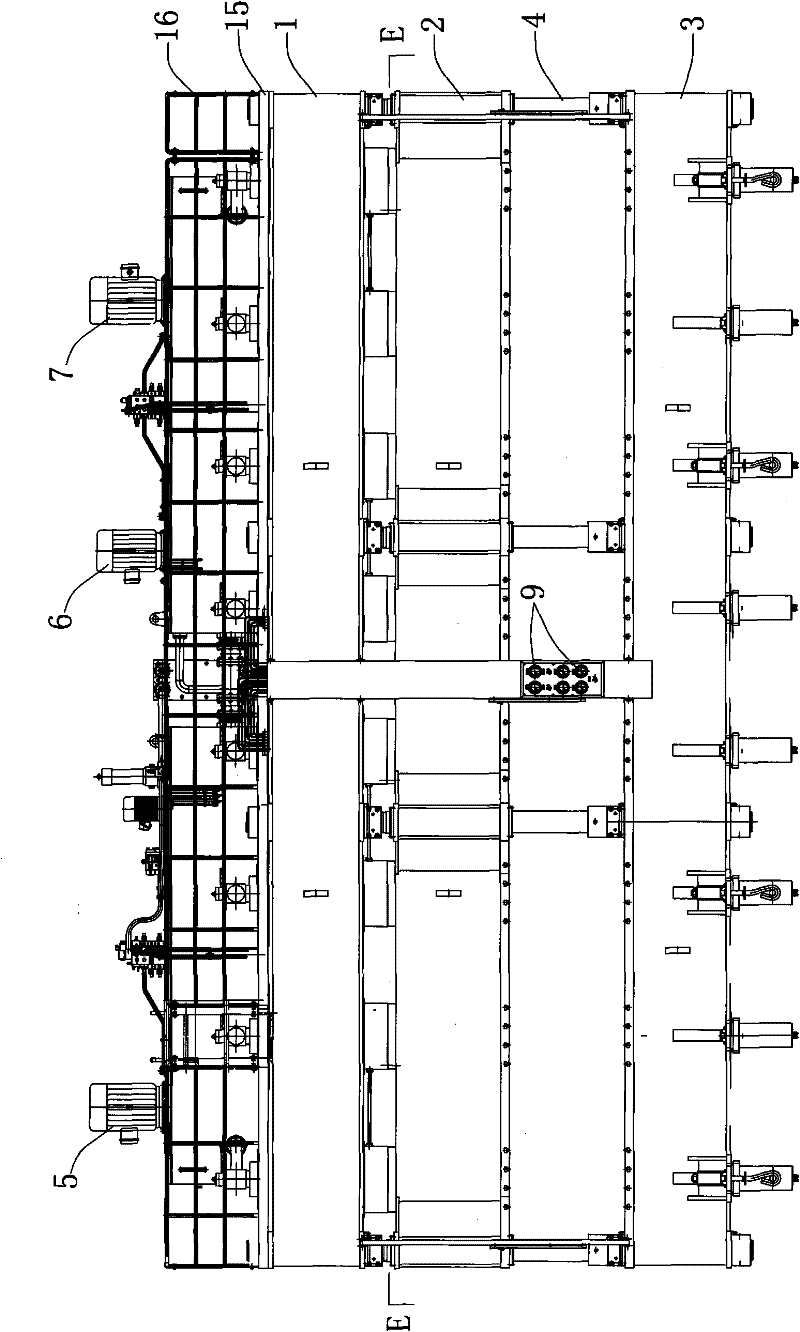

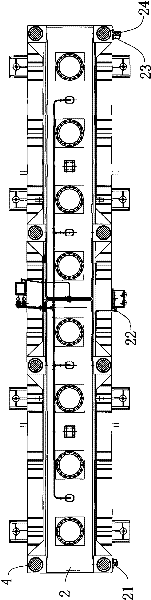

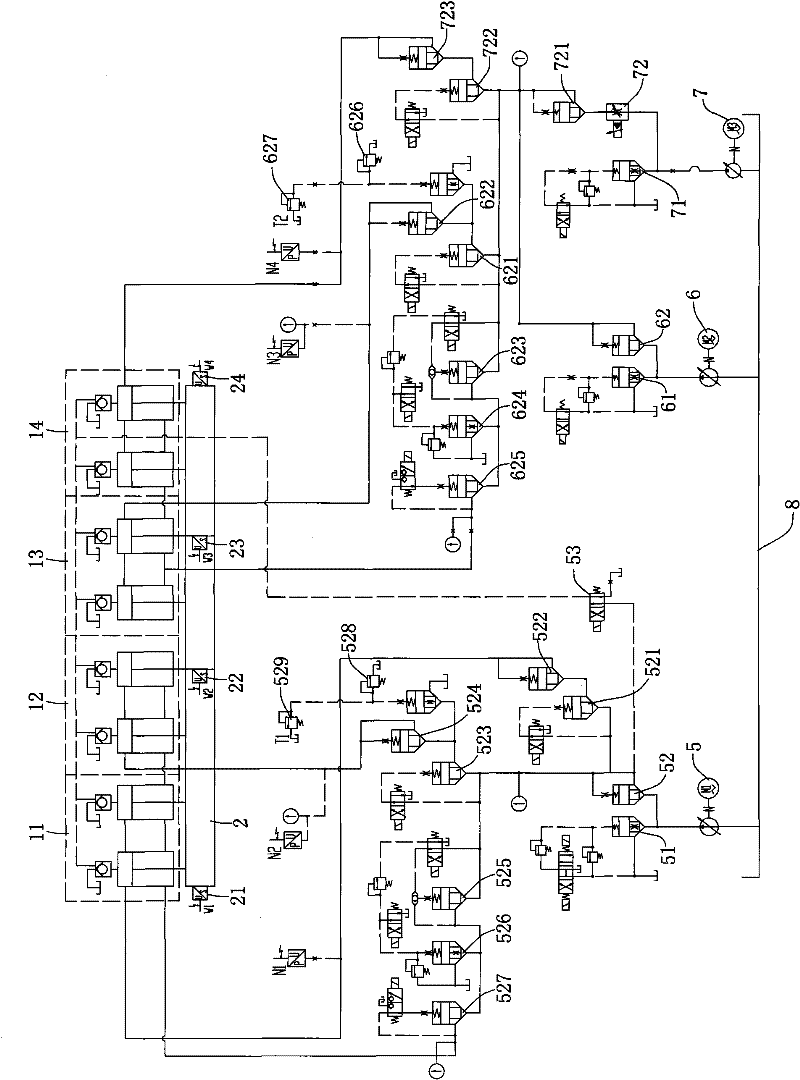

Full-digital numerical control hydraulic FRP pultrusion machine

The invention discloses a full-digital numerical control hydraulic FRP pultrusion machine which comprises a feeding assembly, a heating assembly, pull-out assemblies, a first gear, a second gear and a clamping motor. A plurality of wire rollers of the feeding assembly are rotationally connected with a material table, a bottom belt is rotationally arranged in a first through hole, and a forming die of the heating assembly is arranged on one side of the wire rollers. A heating coil is wrapped outside. The two pull-out assemblies are connected with the material table in a sliding mode, and two clamping oil cylinders are connected with the clamping motor through the first gear and the second gear. A raw material is placed on the wire rollers, the raw material is input into the forming die to enable the heating coil to melt the raw material for formation, the clamping oil cylinders drive a clamping table to move downwards to be matched with the bottom belt to clamp the sectional material, a traction table moves below a traction oil cylinder to pull out the sectional material, and the two pull-out assemblies are alternately matched to continuously pull out the sectional material. And the same clamping motor controls the two clamping tables to move, so that the two clamping tables are matched more conveniently.

Owner:南京海柯玛新材料科技有限公司

Heat transfer printing equipment and method thereof

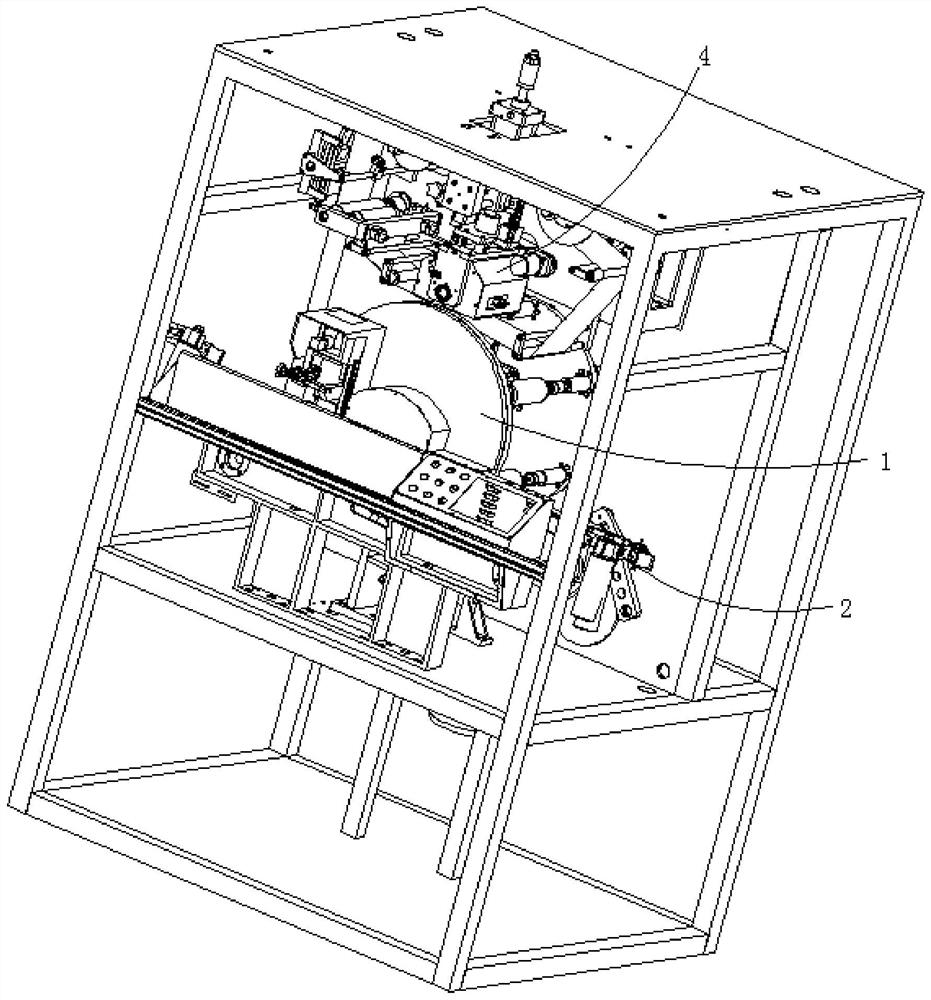

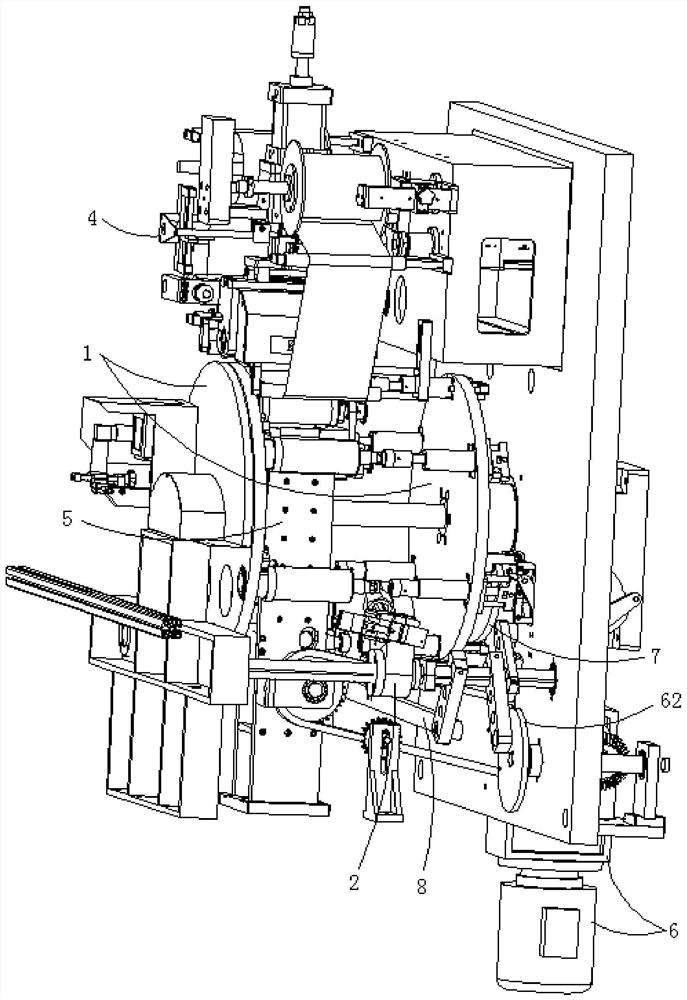

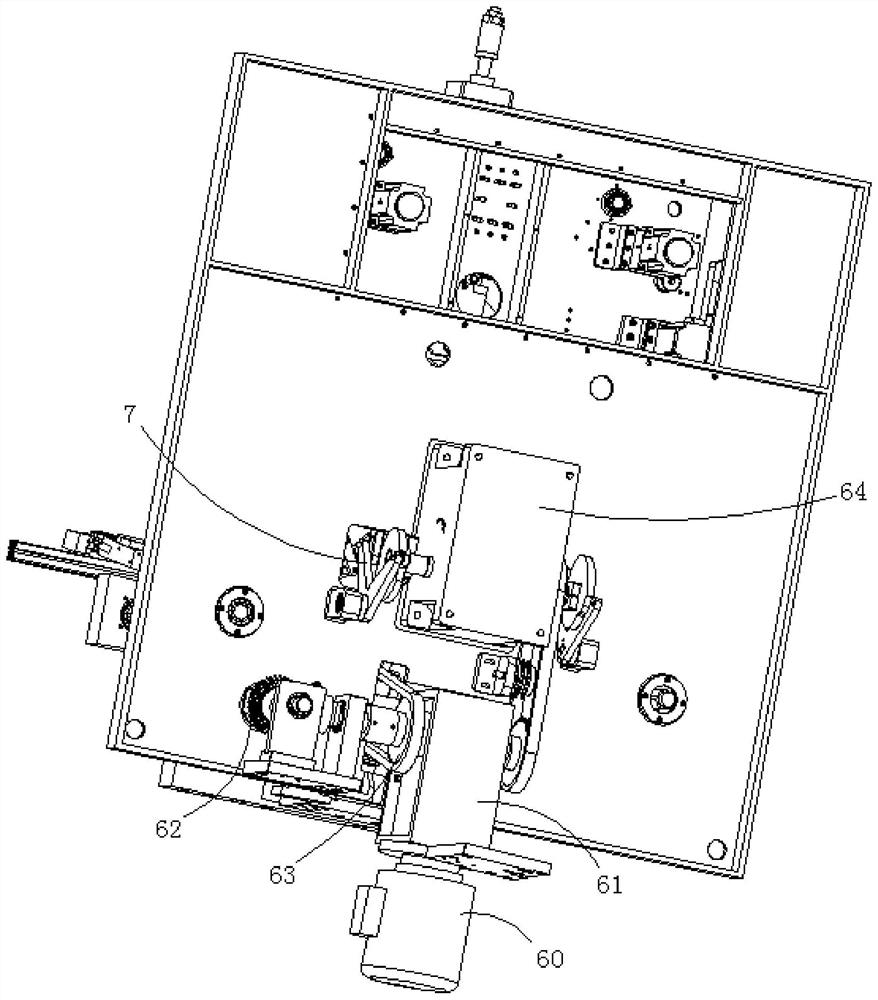

ActiveCN111716883ACompact and reasonable structureImprove processing efficiencyTransfer printingConveyor partsEngineeringDISC assembly

The invention relates to heat transfer printing equipment. The heat transfer printing equipment comprises a rotatable tool rotary disc assembly, and a plurality of workpiece clamping units are arranged on the tool rotary disc assembly around the rotating axis of the tool rotary disc assembly. One side of the tool rotary disc assembly is provided with a feeding assembly used for feeding workpiecesto the workpiece clamping units on the tool rotary disc assembly, and the other side of the tool rotary disc assembly is provided with a blanking assembly used for blanking the workpieces from the workpiece clamping units on the tool rotary disc assembly. A heat transfer printing assembly used for printing the workpieces on the tool rotary disc assembly is arranged above the tool rotary disc assembly. The heat transfer printing equipment further comprises a liftable supporting assembly for supporting the workpieces on the tool rotary disc assembly during printing, and a driving mechanism for driving the feeding assembly, the blanking assembly, the tool rotary disc assembly and the supporting assembly. The heat transfer printing equipment further comprises a first output unit for triggeringthe multiple workpiece clamping units at the lower end of the tool rotary disc assembly to loosen the workpieces. The structure is reasonable and compact, the machining efficiency is high, and synchronous control over feeding, blanking and heat transfer printing is extremely convenient.

Owner:深圳市鑫众塑料包装机械有限公司

Full-spectrum efficiently utilized low-magnification double-axis photovoltaic power generation device

InactiveCN108288951AImprove spotlight effectEasy to control synchronouslyPhotovoltaic supportsSolar heating energyElectric machineEngineering

The invention relates to a full-spectrum efficiently utilized low-magnification double-axis photovoltaic power generation device, wherein the main beam is arranged in the east-west direction, a plurality of groups of supports are movably connected to the bottom of the main beam, a bearing seat is arranged at the top ends of the supports, the bearing seat is rotationally connected with the main beam, a swing arm is installed on one side of the main beam, a south-north motor is movably connected to one of the plurality of groups of supports, the movable end of the south-north motor is movably connected with one end of the swing arm, a plurality of groups of low-magnification light gathering components are arranged on the main beam, a plurality of groups of low-magnification light gathering components are linked through a linkage rod, an east-west motor is movably connected below the main beam, and the movable end of the east-west motor is movably connected with the low-magnification light gathering components. The full-spectrum efficiently utilized low-magnification double-axis photovoltaic power generation device can synchronously adjust the east-west direction and the north-north direction of a plurality of groups of slot type light gathering plates, and the management work is facilitated.

Owner:安徽昂科丰光电科技有限公司

A Pneumatic Position Servo Controller Based on DSP

InactiveCN105650064BResolve mismatchHigh control precisionServometer circuitsFluid-pressure actuator componentsControl signalEngineering

Owner:ZHEJIANG UNIV

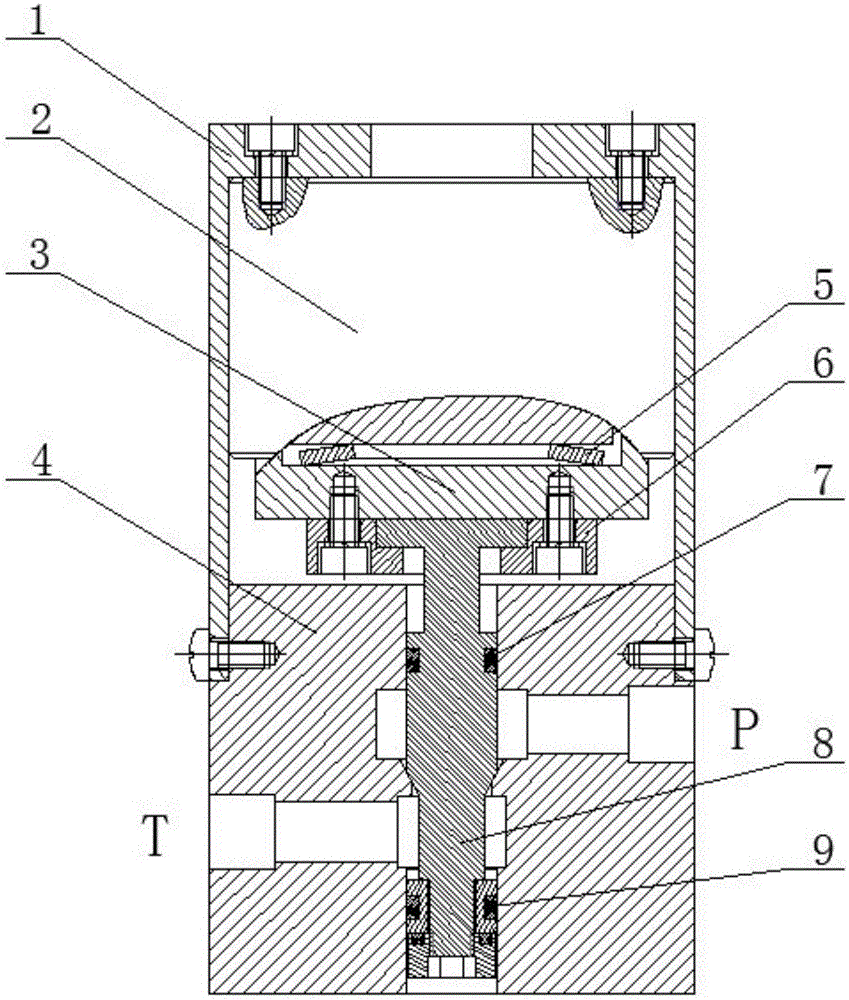

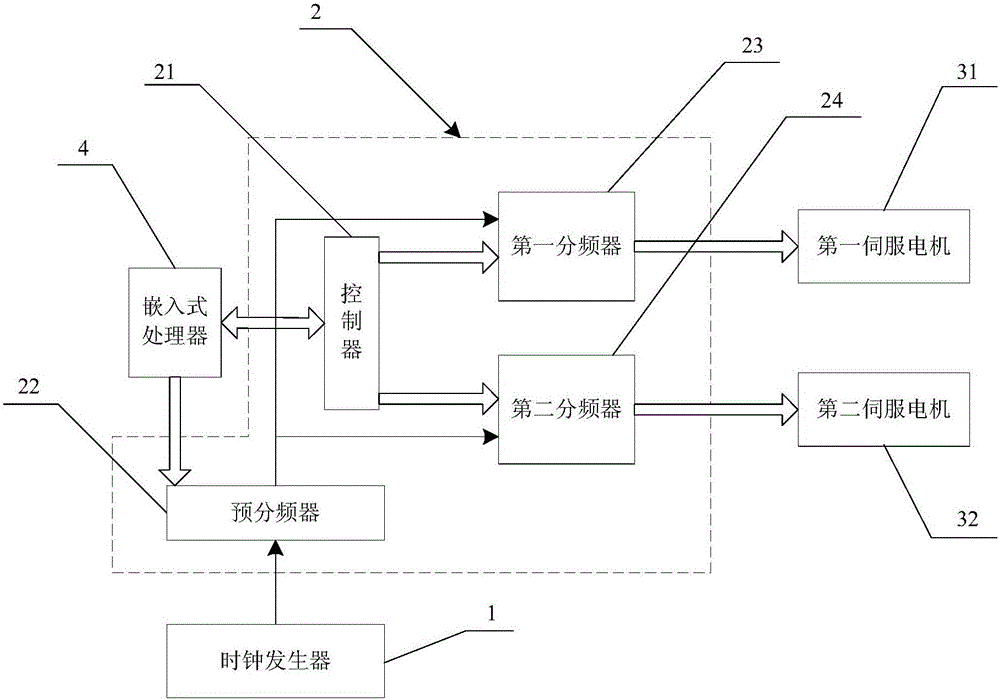

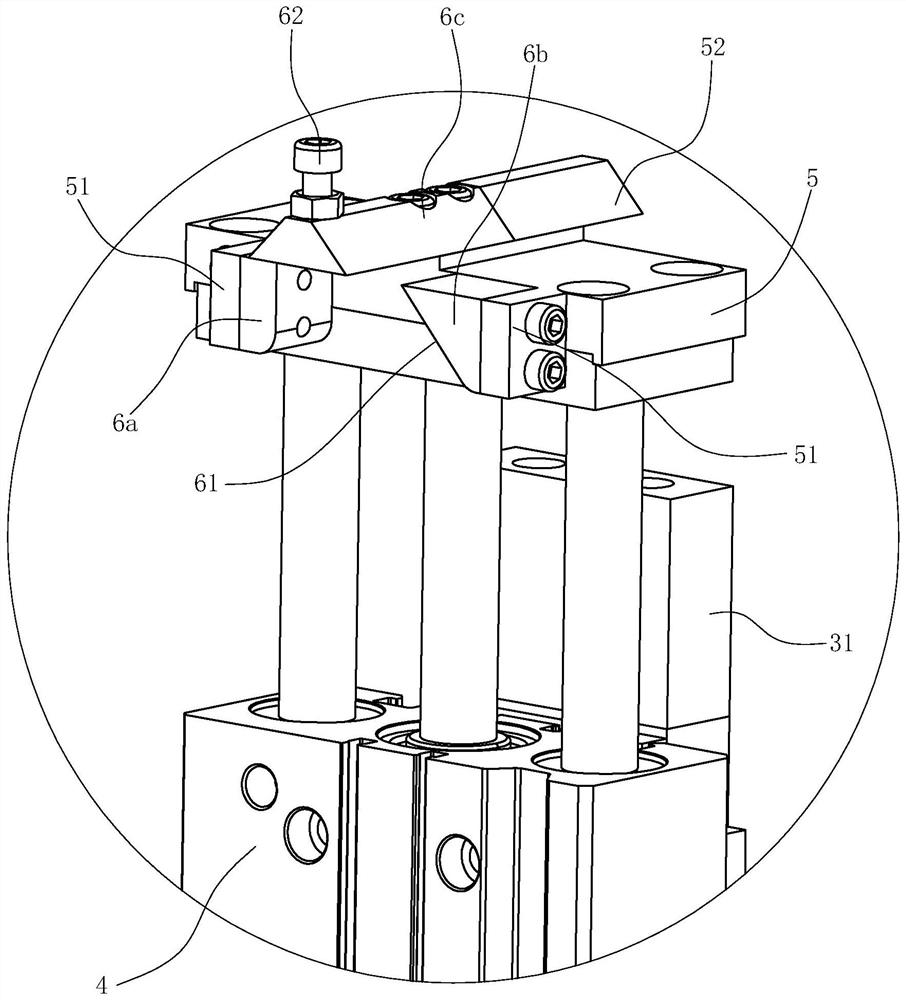

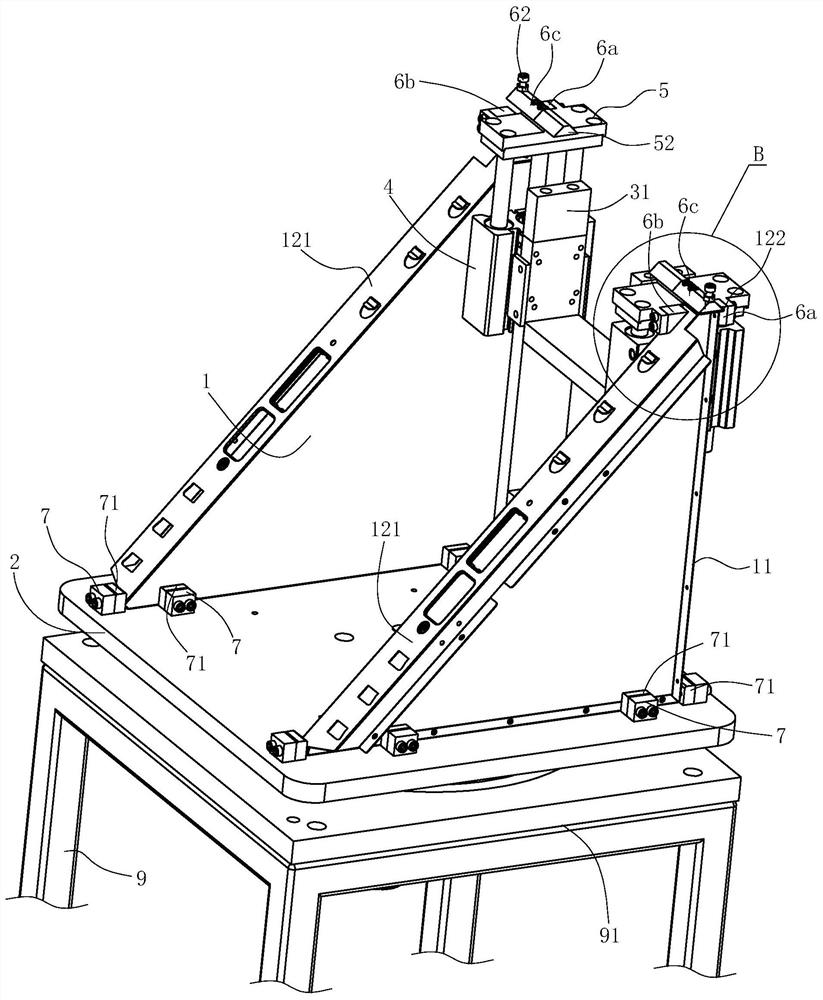

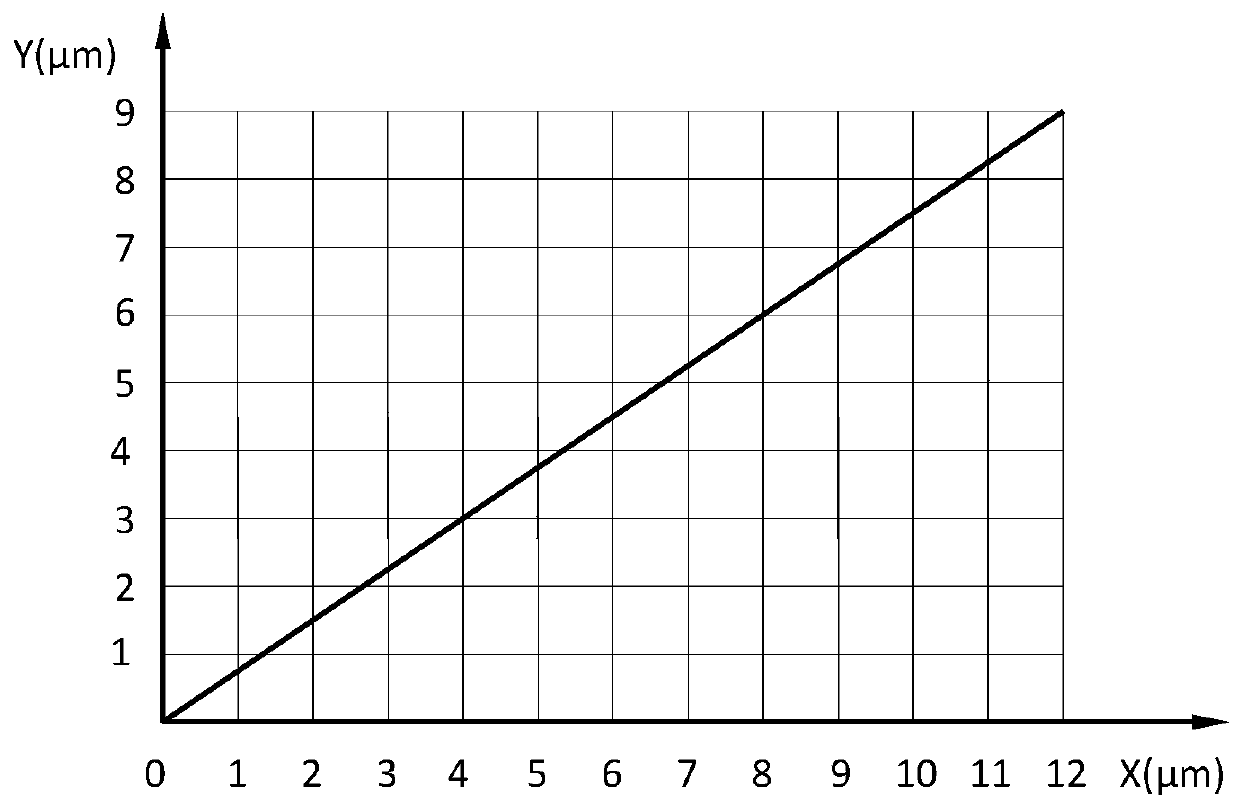

A servo or stepper motor control system and control method for realizing planar motion

InactiveCN103441711BEasy to control synchronouslyFast real-time controlDynamo-electric converter controlMultiple dynamo-electric motors speed regulationSynchronous controlMotor control

The invention discloses a control system and method of servo motors or stepper motors for achieving the plane motion. The control system of the servo motors or the stepper motors for achieving the plane motion comprises a clock generator, a PLD chip, a first servo motor or stepper motor and a second servo motor or stepper motor, wherein a controller, a prescaler, a first frequency divider and a second frequency divider are arranged in the PLD chip in a build-in mode, the output end of the clock generator is connected with the input end of the prescaler, the output end of the prescaler is connected with the input end of the first frequency divider and the input end of the second frequency divider, the controller has control over the frequency division number of the first frequency divider and the frequency division number of the second frequency divider, the output end of the first frequency divider is connected with the first servo motor or stepper motor, and the output end of the second frequency divider is connected with the second servo motor or stepper motor. The control system and method of the servo motors or the stepper motors for achieving the plane motion have the advantages that due to the fact that synchronous control over the two motors is achieved through the same clock signal, the resultant velocity of the plane motion produced by linkage of the two motors can be controlled, hardware resources are made full use of, and real-time control can be high in accuracy and high in speed.

Owner:NINGBO UNIV

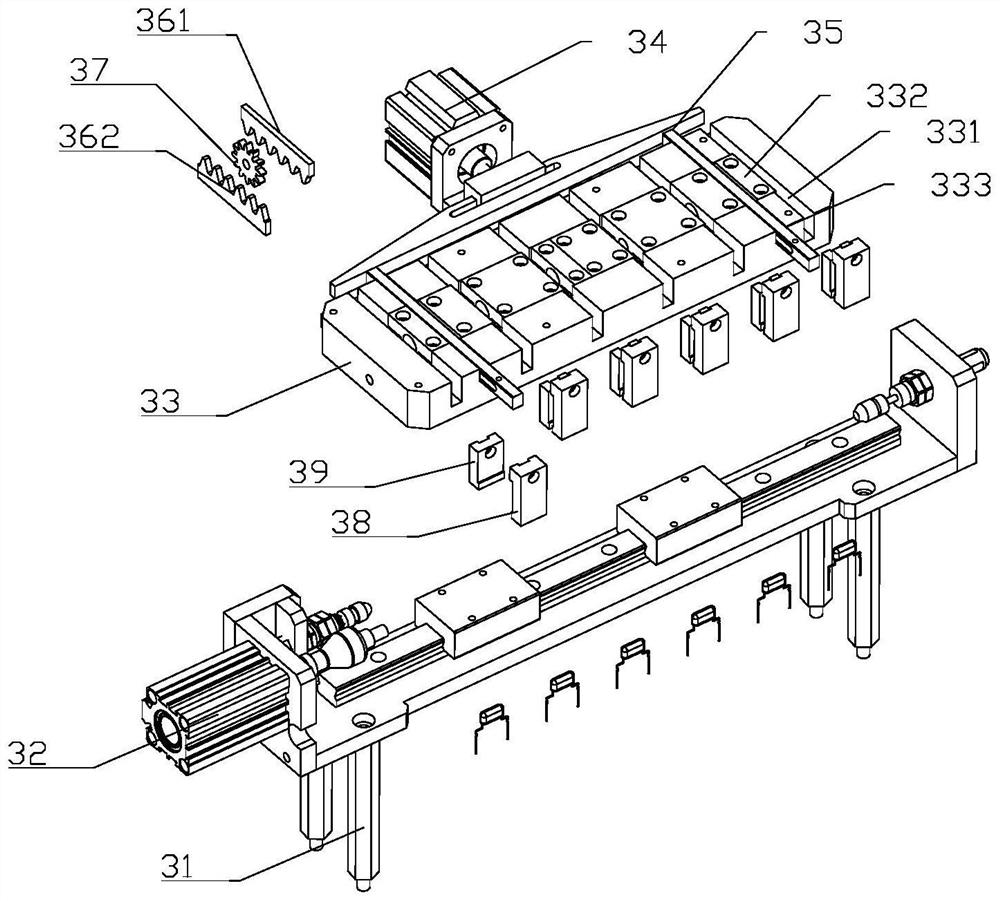

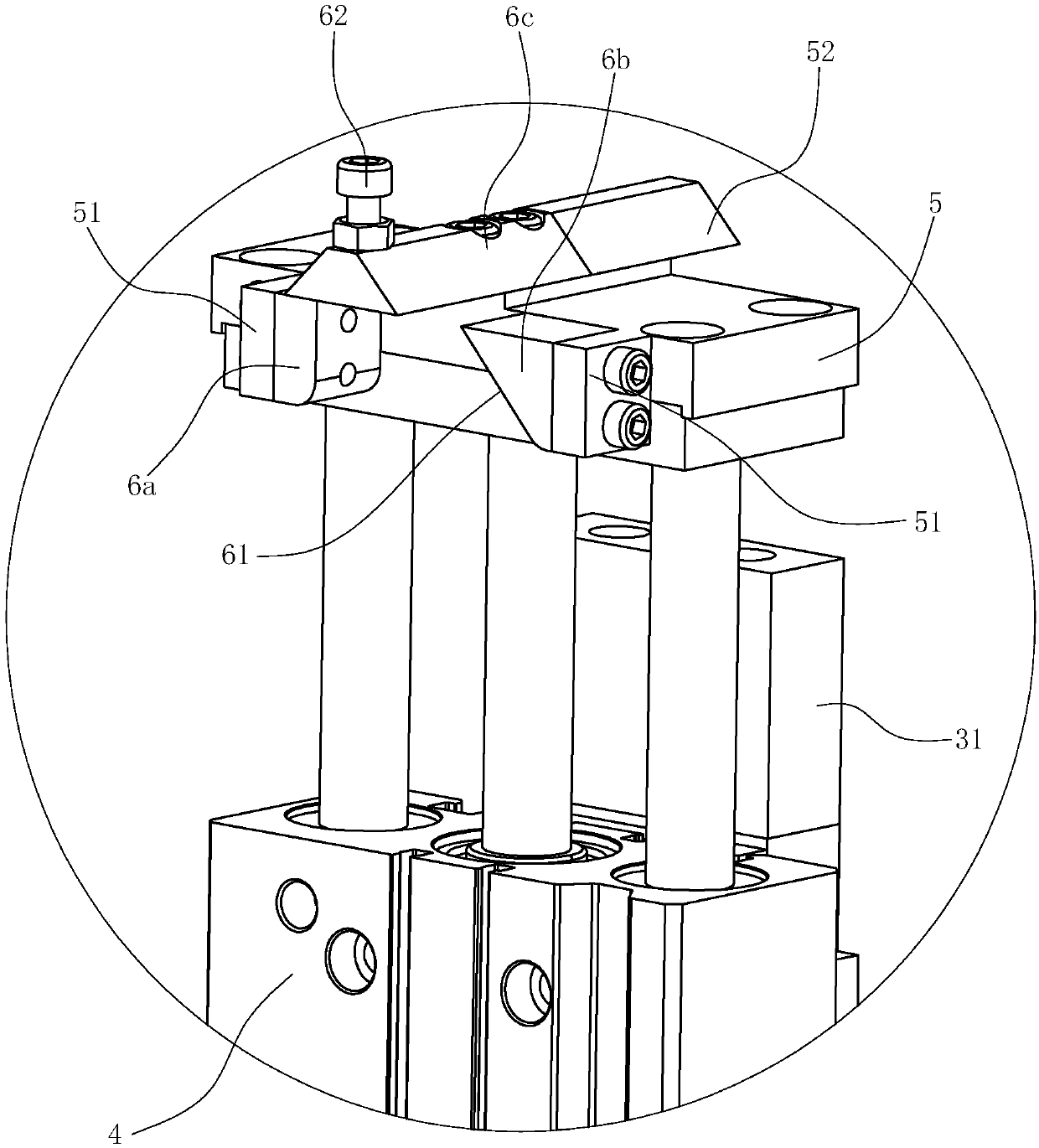

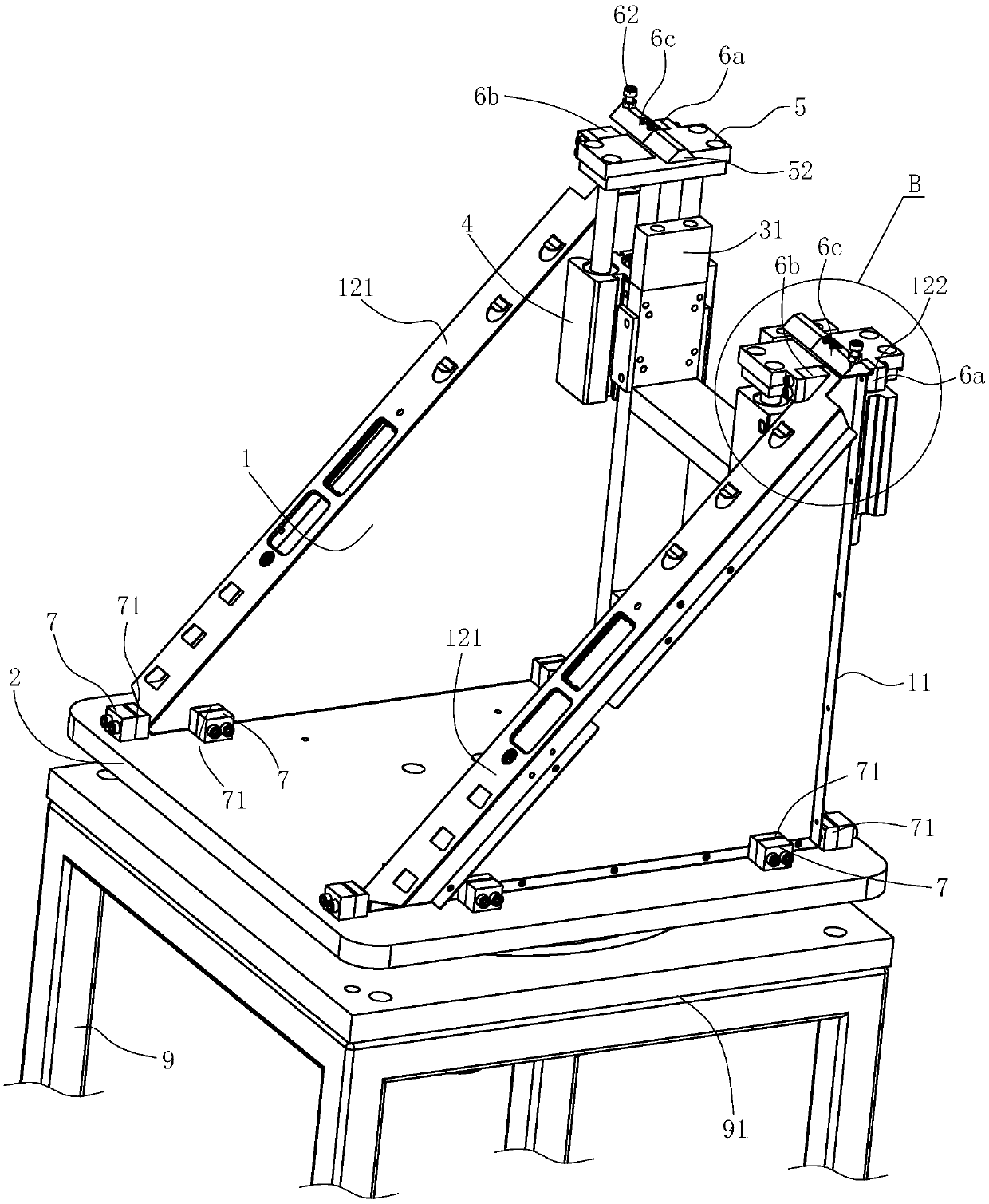

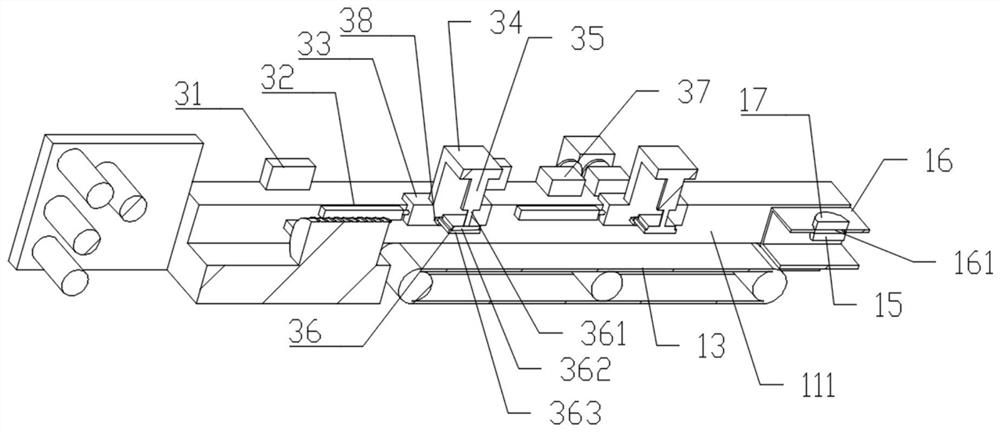

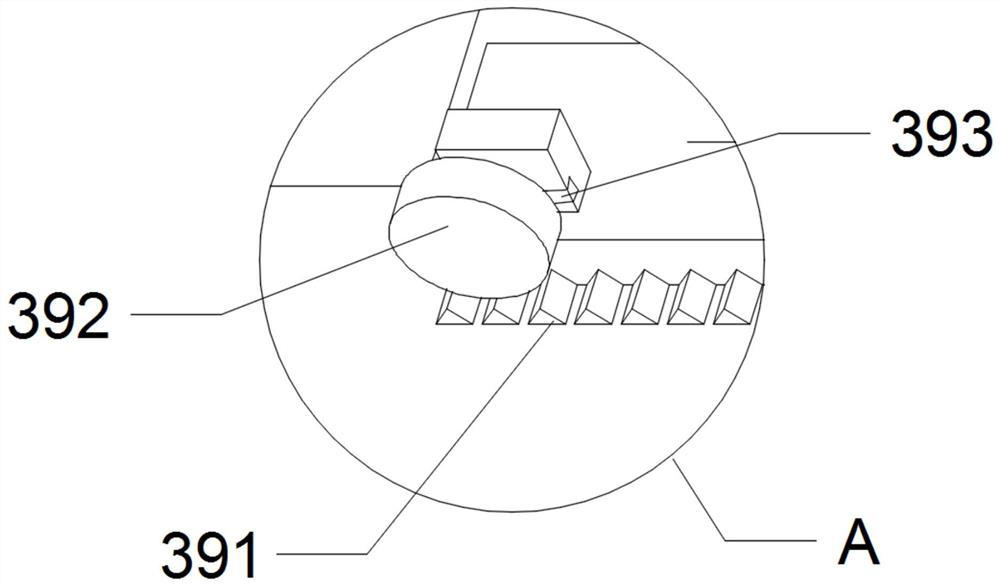

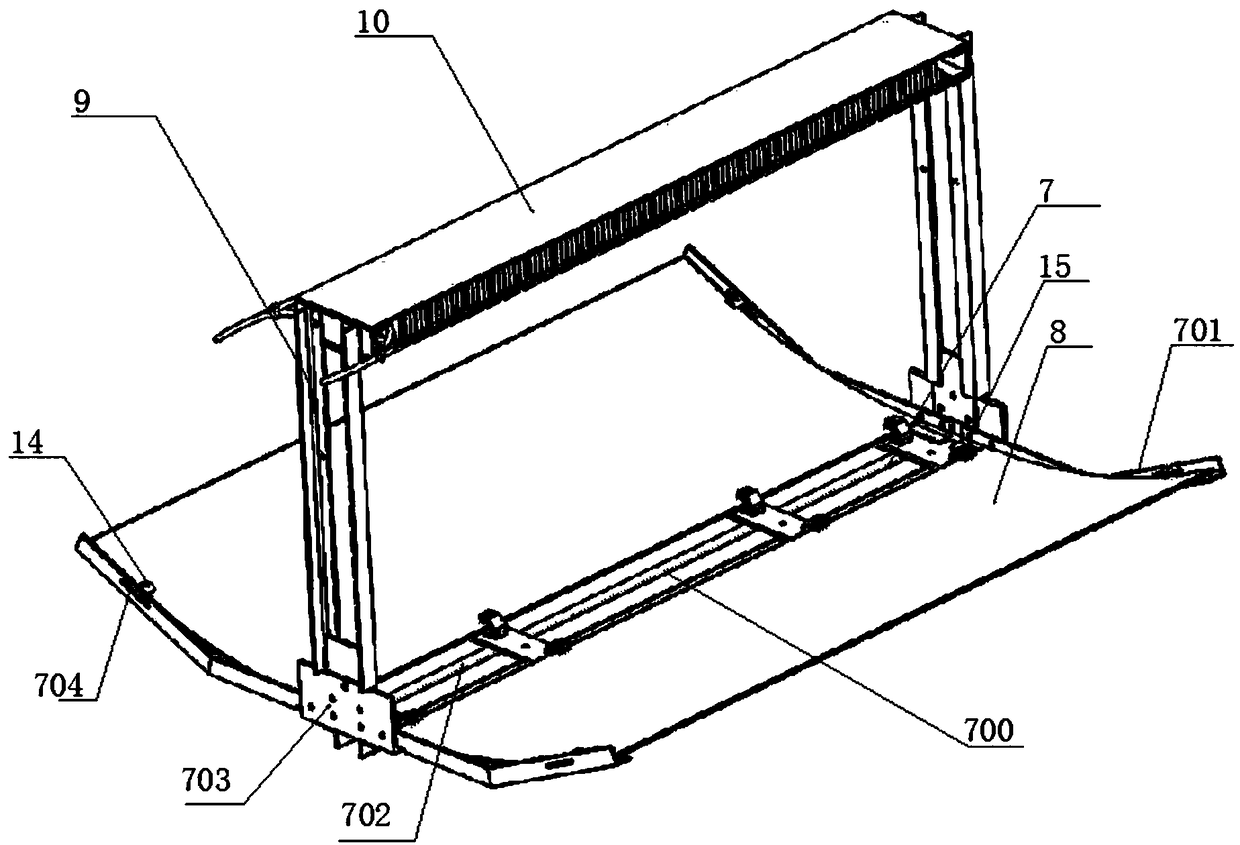

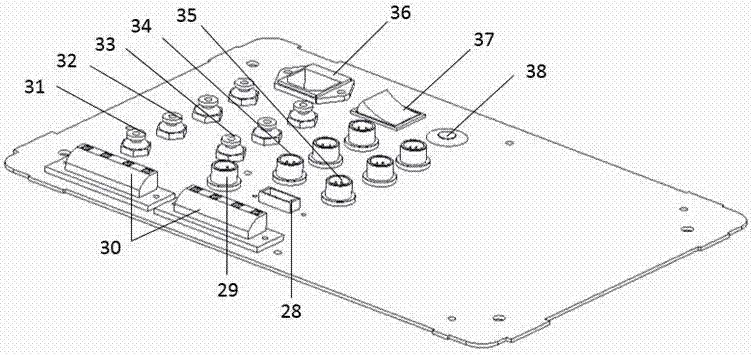

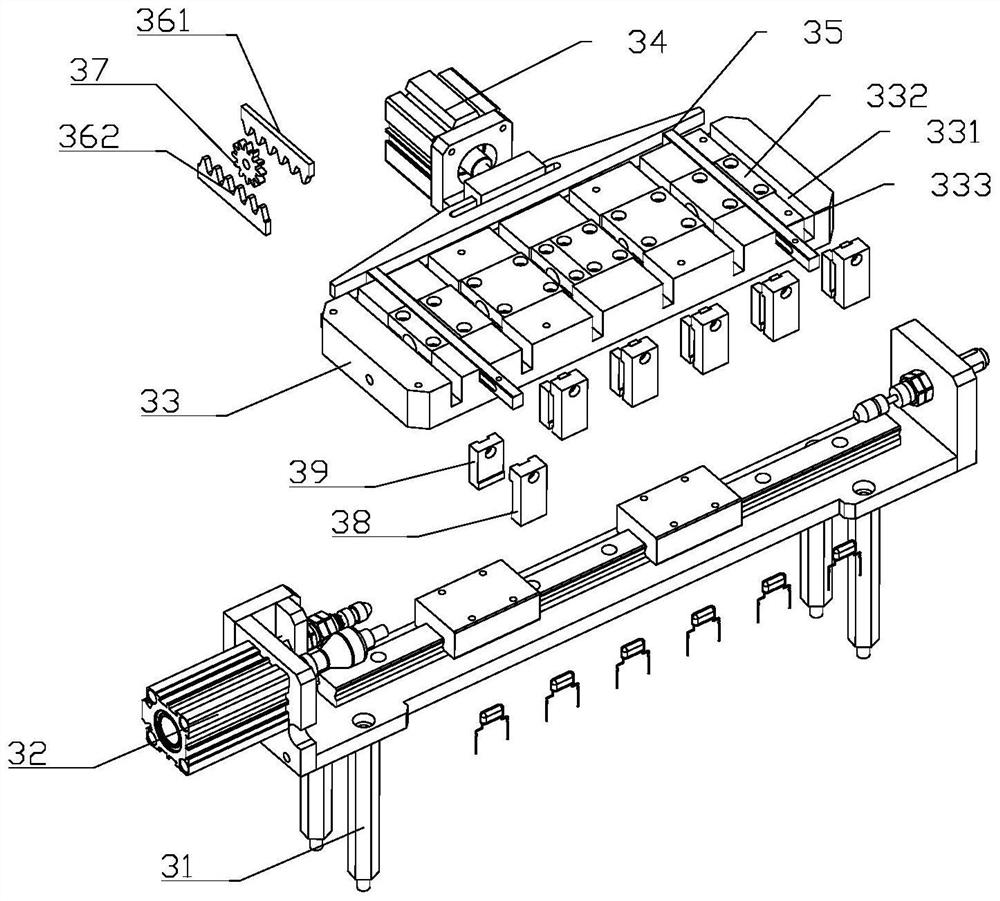

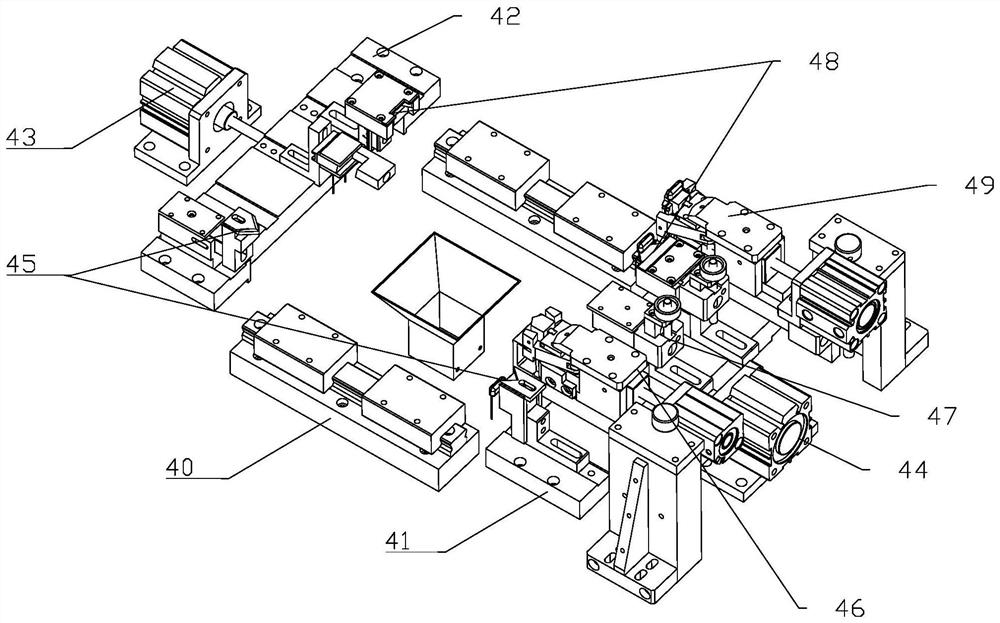

Multifunctional forming device for processing thin-film capacitor and pin processing method

InactiveCN111627701AHigh precisionRealize synchronous handlingThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention relates to the technical field of capacitor production. A multifunctional forming device for processing a thin-film capacitor comprises a base plate, a first sliding plate, a second sliding plate, a first sliding air cylinder, a second sliding air cylinder, a pin forking mechanism, a pin arranging mechanism, a cutting mechanism, a shaping mechanism and a bending mechanism. A slidingrail is arranged on the base plate, and the first sliding plate and the second sliding plate are connected to the sliding rail. The pin forking mechanism is in a split type, and two parts of the pin forking mechanism are arranged on the first sliding plate and the second sliding plate respectively; the cutting mechanism and the shaping mechanism are also in a split type; in the machining direction, the pin forking mechanism, the pin arranging mechanism, the cutting mechanism, the shaping mechanism and the bending mechanism are sequentially arranged at equal intervals; the multifunctional forming device has the advantages that the pins are flat and uniform in length, twice bending is completed in one time, and the forming and bending efficiency is high.

Owner:温州源利智能科技有限公司

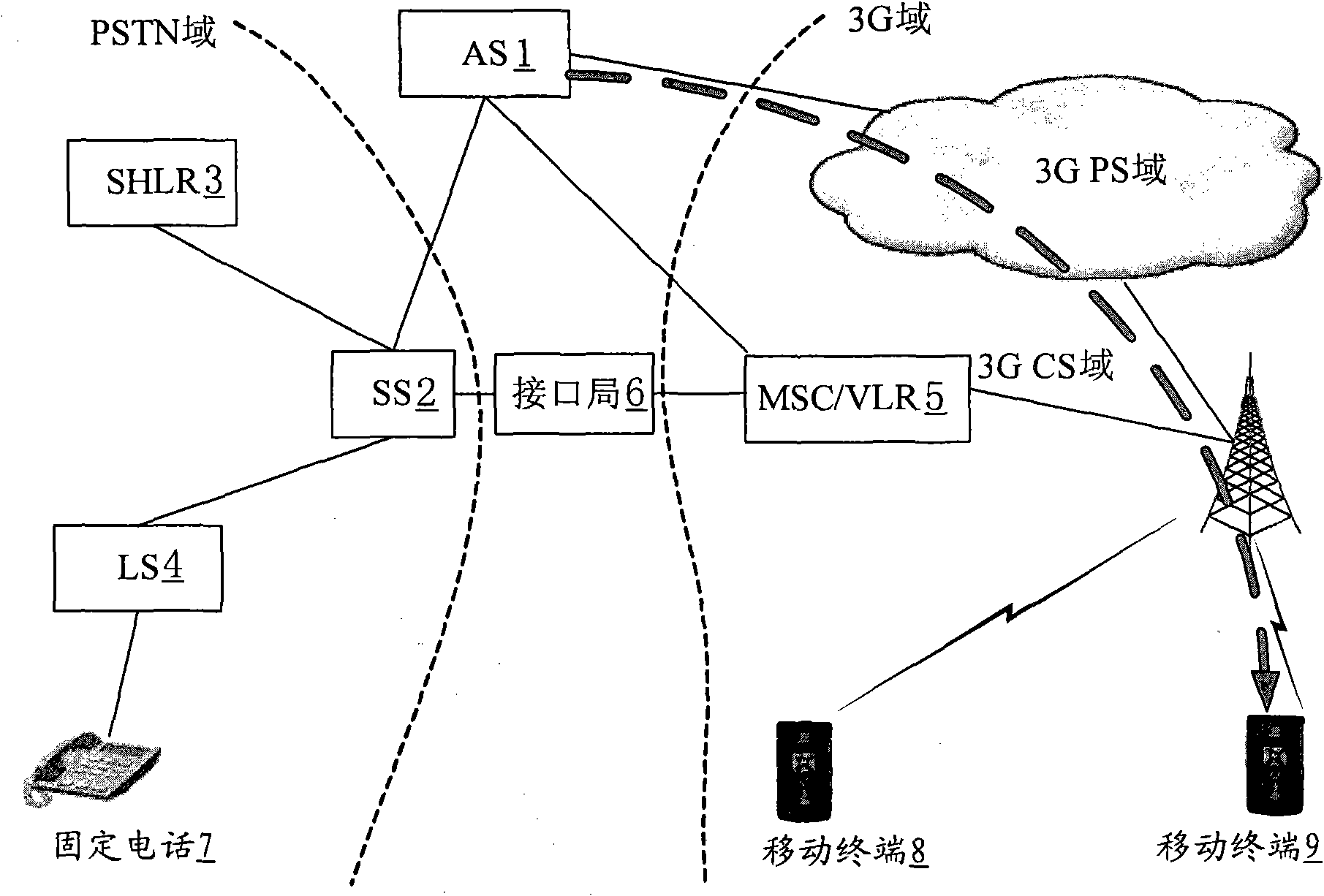

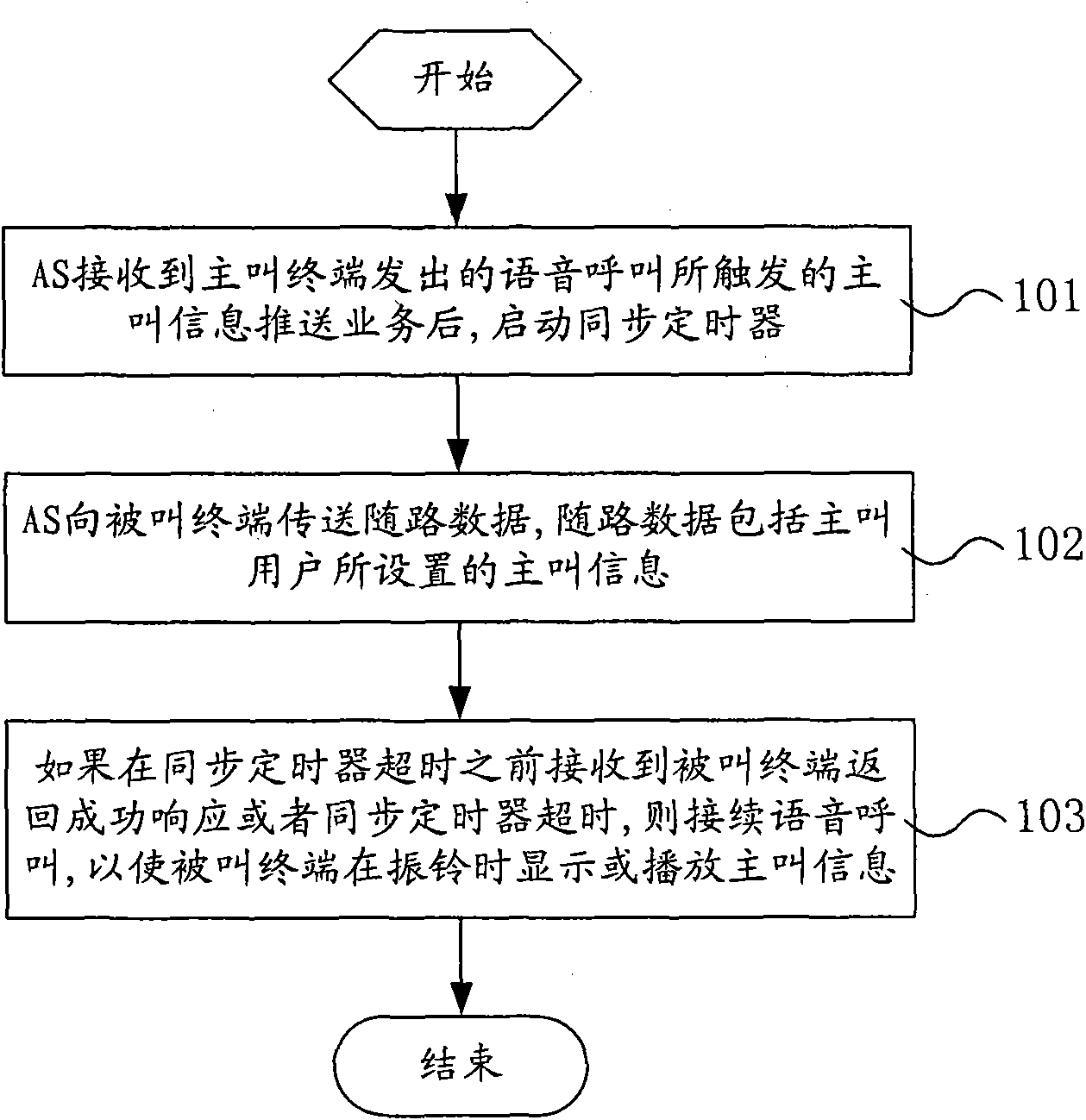

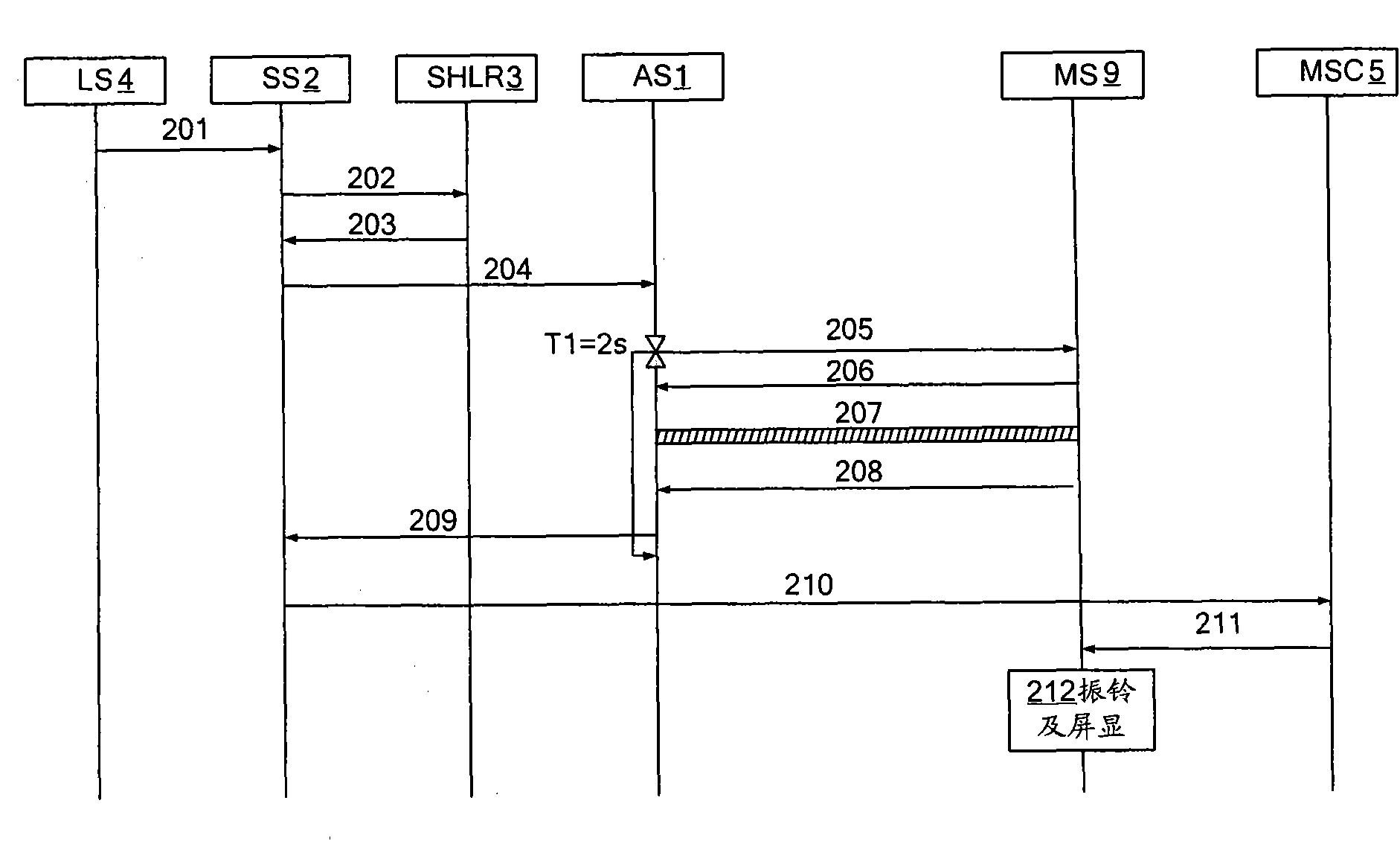

Method and system for pushing information in ringing process

ActiveCN102487491BEasy to control synchronouslyImprove business experienceSynchronisation arrangementMessaging/mailboxes/announcementsApplication serverService experience

The invention relates to a method for pushing information in a ringing process. The method comprises the following steps of: starting a synchronous timer by an AS (Application Server) after receiving calling information pushing service triggered by voice calling, and sending channel associated data to a called terminal; and if the synchronous timer receives response returned by the called terminal before over time or the synchronous timer is over time, connecting the voice calling so as to enable the called terminal to display the calling information when ringing. The invention further relates to a system for pushing the information in the ringing process. In the invention, during the voice calling process, the calling information is pushed to the called terminal by the AS through the channel associated data mode; and the called terminal can synchronously display the calling information in the ringing stage through the timer, so that the voice calling and the pushing information are excellently and synchronously controlled; the pushing and displaying performance of multimedia information in the ringing state of a mobile phone in the current mobile network can be filled or improved; and the service experience of users to 3G (The 3rd Generation) network is improved.

Owner:CHINA TELECOM CORP LTD

A Numerical Control System of Can Printing Machine Based on Digital Motion Controller

ActiveCN103076766BEasy to make costEasy to control synchronouslyComputer controlSimulator controlClosed loopMotion controller

A digital motion controller-based numerical control system for printing can machines, including: a Windows-based man-machine communication touch screen operation control module; a digital motion controller; a motion execution module; a reducer module; and a Windows-based man-machine communication touch screen operation The control module and the digital motion controller are connected through an Ethernet network cable, and the digital motion controller and its I / O sub-board are directly connected to the I / O signal connection terminal of the motion execution module, that is, the AC servo motor; the digital motion controller is connected to the motion controller through the Ethernet bus. The execution module is connected to the servo AC motor; the digital motion controller is connected to four AC servo motors to form a double closed-loop motion control system. The system structure of the present invention is simple, each component is relatively independent, part of the hardware can be directly purchased from commercially available products as components, not only the performance can be compared with it, the cost is reduced, but also the assembly, use and upgrade are extremely simple, and can be extended to pop cans in batches Printing production line and similar iron printing production line.

Owner:FOSHAN DING ZHONG MACHINERY

Stainless steel side plate welding jig with adjustable weld gap

ActiveCN110614469BGuarantee welding qualityLess involvedWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a stainless steel side plate welding clamp with weld gaps capable of being adjusted. The stainless steel side plate welding clamp comprises a platform, a mounting frame is fixed on the platform, the platform is at least provided with one clamping tool, the stainless steel side plate welding clamp is characterized in that the clamping tool comprises a positioning structurearranged on the platform and used for positioning the bottom of a vertical stainless steel side plate, a pressing air cylinder is fixed on the side wall of the mounting frame, a pressing plate is fixed on a piston rod of the pressing air cylinder, two mounting lugs which are arranged at an interval front and back are arranged on the outer side wall of the pressing plate, a first pressing block isfixed on one mounting lug, a second pressing block is fixed on the other mounting lug, a third pressing block is fixed on the top of the pressing plate, and the third pressing block is located betweenthe first pressing block and the second pressing block. The two weld gaps can be adjusted at the same time through one-time downward pressing of the pressing plate, the related parts are few, the structure is simpler, moreover, synchronous control is facilitated, and the operation steps are simplified.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A control method for high-speed and high-precision multi-axis synchronous motion based on dual clocks

ActiveCN109343473BHigh precisionEasy to control synchronouslyProgramme controlComputer controlComputer hardwareNumerical control

The invention discloses a control method for a multi-axis synchronous movement with a high speed and a high precision based on a double clock, and the final purpose is to output a pulse sequence and direction signals to a servo drive of each shaft. The method comprises steps of: determining an output time and a direction of a pulse through the calculation; determining a size clock period accordingto the maximum movement speed of each shaft and the input pulse range; converting the time and direction signals into pulse direction numbers, and storing the pulse direction data in a data file in the form of a two-dimensional array; reading and analyzing the pulse direction number of the two-dimensional array format in the data file by a numerical control device; uninterruptedly converting thepulse direction numbers of the two-dimensional array format into pulse and direction signals, by the switch and the timer, and the large-cycle clock is used as the synchronization signal; and inputting the signals to the servo drive, so that the trajectory movement is completed. According to the control method for the multi-axis synchronous movement with the high speed and the high precision basedon the double clock, the method realizes the control of the multi-axis synchronous movement with the high speed and the high precision through the calculation and hardware synchronous output method;improves the processing efficiency by the high speed; and improves the processing quality of the product with the high precision.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

A wide-format high-speed wood grain paper printing machine

The invention relates to a wide-width high-speed printing machine for woodgrained paper. The machine comprises an uncoiling unit, an uncoiling traction system, a plurality of printing units, a coiling traction mechanism and a coiling unit which are sequentially arranged based on the process; each printing unit comprises a printing body; a drying structure is arranged at a subsequent station of each printing body, comprising a bullet-shaped supporting frame, wherein the bullet-shaped supporting frame is composed of two arc-shaped surfaces; a plurality of positioning guide rollers for fixing paper tapes are arranged on the outer surfaces of the supporting frames; an air box which is in a shape matched with the arc shape of the outer surface of each supporting frame 33 is arranged at the outside of the outer surface of each supporting frame. According to the machine, a paper coil is supported by hydraulic propping and a variable width discharging and coiling mechanism is utilized for coiling and uncoiling; the width ranges from 1,210 to 2,150mm; compared with the traditional expansion shaft chuck, the machine has the advantages that the labor intensity in material replacement is reduced, the time of material replacement can be decreased, and the production can be performed at a high speed.

Owner:SOTECH SMARTER EQUIP CO LTD

Synchronous control system for longitudinal beam hydraulic machine

The invention discloses a synchronous control system for a longitudinal beam hydraulic machine. The synchronous control system comprises a machine body of the hydraulic machine, a beam, a worktable and a sliding block, wherein a plurality of groups of master cylinders connected with the sliding block are inserted into the beam; a power mechanism is arranged above the beam; the power mechanism comprises a variable oil pump motor assembly and a proportional servo oil pump motor assembly; the sliding block is a flexible beam; the variable oil pump motor assembly controls corresponding one or theplurality of groups of master cylinders according to the pressing lengths and the pressing positions of workpieces; the machine body is provided with a position detecting mechanism which induces displacement information of a plurality of positions on the sliding block corresponding to the worktable; and the proportional servo oil pump motor assembly provides compensation oil pressure for one or the plurality of groups of master cylinders corresponding to the position needing compensating power on the sliding block according to displacement signals of the plurality of positions on the sliding block. The improved system can set corresponding pressing ways according to different pressing lengths and pressing positions, ensures synchronous pressing and return trips of the sliding block, and improves the unbalance loading resistance of the hydraulic machine and the pressing quality of products.

Owner:HUZHOU MACHINE TOOL WORKS

Matching type square tube cutting die

InactiveCN114147279AEasy to fix instantlyEasy to cut offTube shearing machinesShearing machine accessoriesStructural engineeringKnife blades

The invention discloses a matching type square tube cut-off die which comprises a pressing device, a cut-off device is arranged at the bottom of the pressing device, the pressing device is connected with the cut-off device through a belt, and a square tube is slidably connected to the center of the pressing device and the center of the cut-off device. The pressing device comprises a lifting part, a center rod, a seesaw frame, a contact frame, a blade and a supporting bottom frame, the supporting bottom frame is arranged at the bottom of the inner end of the pressing device, the side end position of the supporting bottom frame is fixedly connected with the center rod, and the center position of the center rod is connected with the seesaw frame in a penetrating mode; one end of the seesaw frame is fixedly connected with the contact frame, the lifting component is arranged on the rear portion of the inner end of the pressing device, the blade is fixedly connected to the other side of the seesaw frame, and the cutting device comprises a supporting component, a vertical limiting frame and a driving component. According to the matching type square tube cutting die, the purpose of positioning and pressing the inner end is achieved through the arrangement of the pressing device.

Owner:胡江帆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com