A servo or stepper motor control system and control method for realizing planar motion

A technology of stepping motor and planar motion, which is applied in the direction of motor generator control, control system, multiple motor speed adjustment, etc. It can solve the problems of speed limitation, high speed and high precision at the same time, and achieve fast speed and convenience Synchronous control, the effect of solving trajectory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

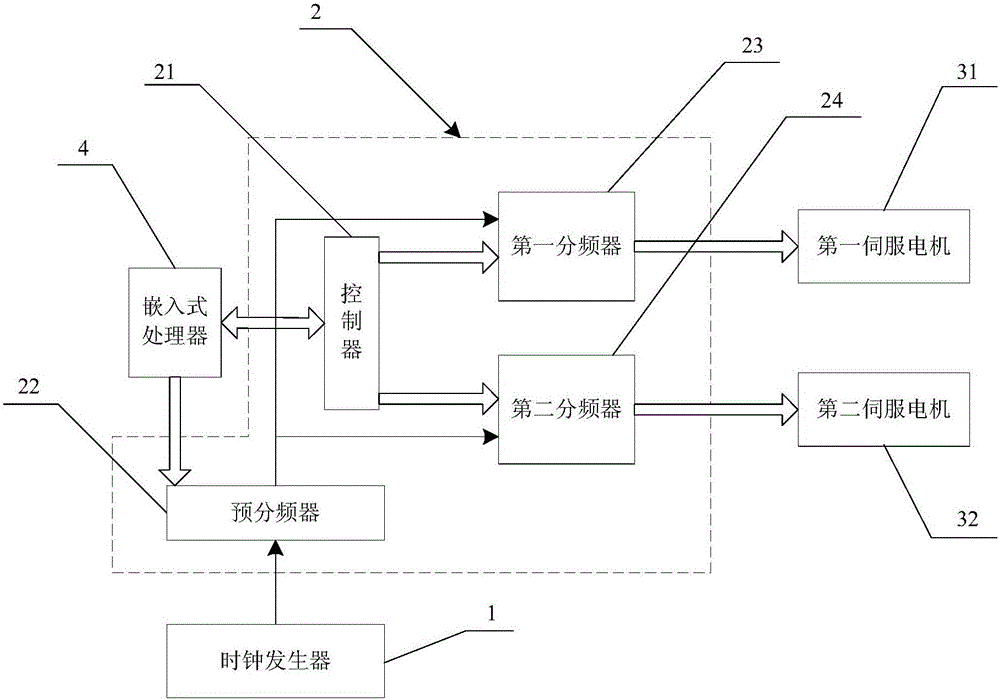

[0022] A kind of servo or stepper motor control system that this embodiment proposes realizes planar motion, such as figure 1 As shown, it includes a clock generator 1, a PLD (ProgrammableLogicDevice, programmable logic device) chip 2, a first servo or stepper motor 31, a second servo or stepper motor 32, and a conventional embedded processor 4, the PLD chip 2 Built-in controller 21, prescaler 22 for speed control, first frequency divider 23 and second frequency divider 24 for trajectory control, embedded processor 4 and controller 21 and prescaler respectively The frequency converter 22 is connected, and the embedded processor 4 outputs the parameters (such as the slope of the straight line, etc.) to realize the linear plane motion or the parameters (such as the radius of the arc) to the controller 21, and the embedded processing Device 4 controls the frequency division number of prescaler 22, and the signal output end of clock generator 1 is connected with the signal input e...

Embodiment 2

[0026] A kind of servo or stepper motor control method for realizing planar motion proposed in this embodiment is based on the servo or stepper motor control system proposed in Embodiment 1, which includes the following steps:

[0027] ①The clock signal is generated by the clock generator 1, and the clock signal is transmitted to the prescaler 22 built in the PLD chip 2, and the received clock signal is divided by the prescaler 22 to obtain the prescaler The pulse signal, and then the prescaler 22 transmits the prescaled pulse signal to the first frequency divider 23 and the second frequency divider 24 built in the PLD chip 2 .

[0028] 2. The first frequency divider 23 and the second frequency divider 24 respectively carry out frequency division processing to the pulse signals received respectively to obtain the pulse signal after frequency division again, wherein the frequency division number of the first frequency divider 23 and The frequency division number of the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com