A wide-format high-speed wood grain paper printing machine

A wood-grain paper and printing press technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems that the color registration accuracy cannot meet the product requirements, the color registration accuracy cannot meet the requirements, and the products cannot be fully dried, etc. The effect of changing material time, ensuring tension, improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

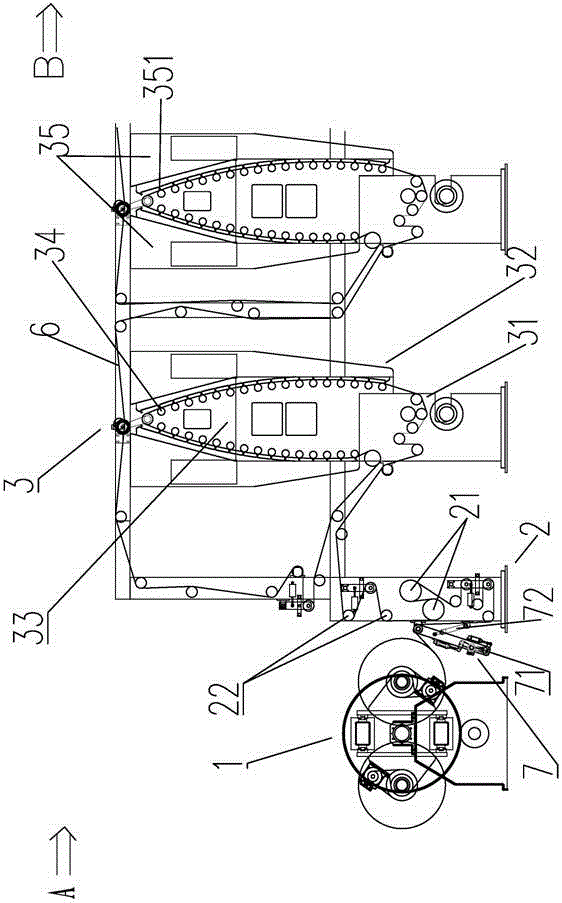

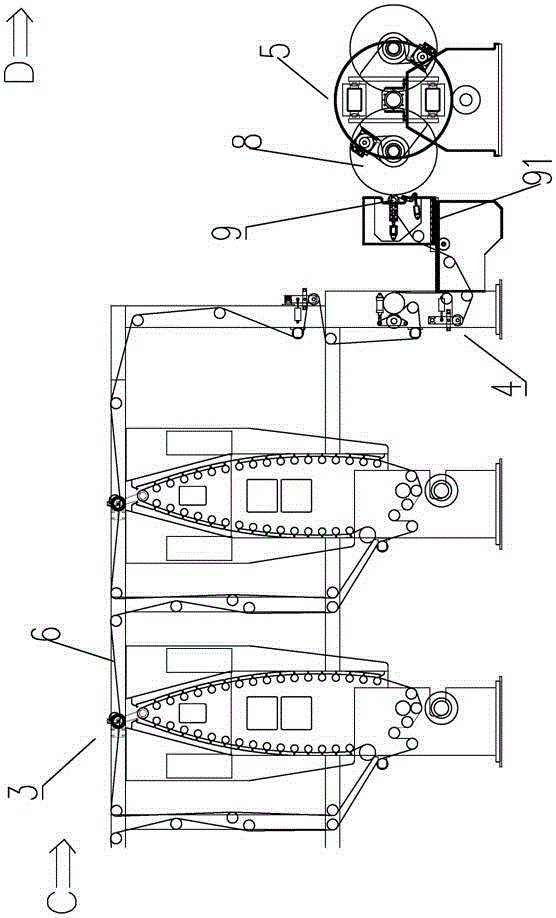

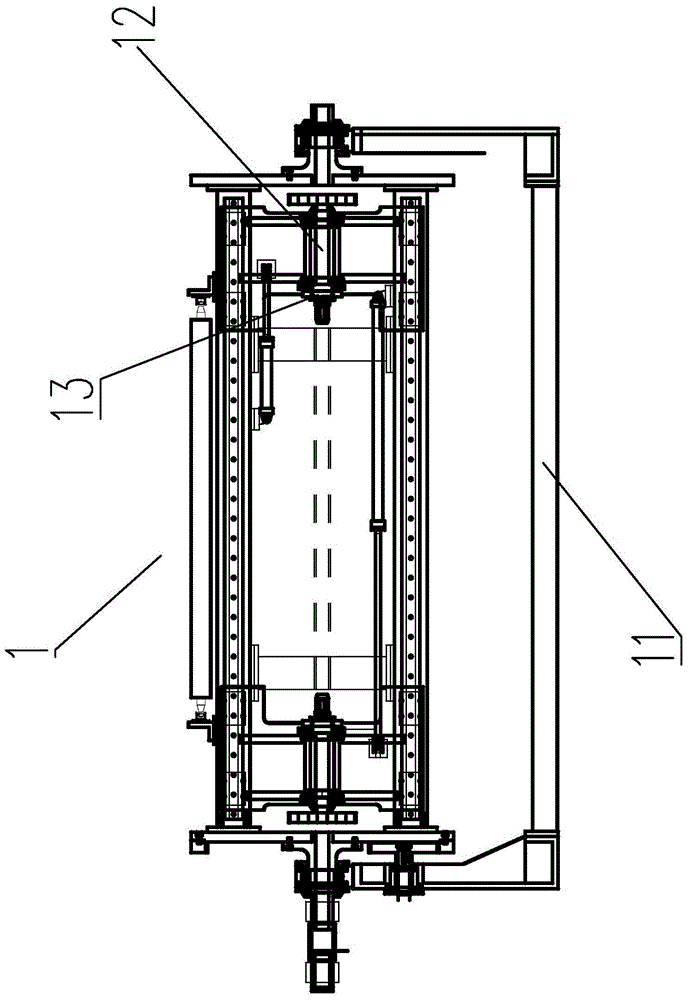

[0032] As shown in the figure, a wide-width high-speed wood grain paper printing machine includes an unwinding unit 1, an unwinding traction mechanism 2, and a plurality of printing units 3 arranged successively according to the flow process. The present invention has 4 printing units. The roll traction mechanism 4 and the winding unit 5, the printing unit 3 includes a printing main body 31, a drying structure 32 is arranged at the subsequent station of the printing main body 31, and the drying structure 32 is arranged above the printing main body 31, and the drying structure 32 comprises the support frame 33 of the bullet head shape that two arcuate surfaces are formed, and the outer surface of described support frame 33 is provided with the positioning guide roller 34 of a plurality of fixed paper strips 6, is provided outside the outer surface of described support frame 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com