Patents

Literature

82results about How to "Save refueling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

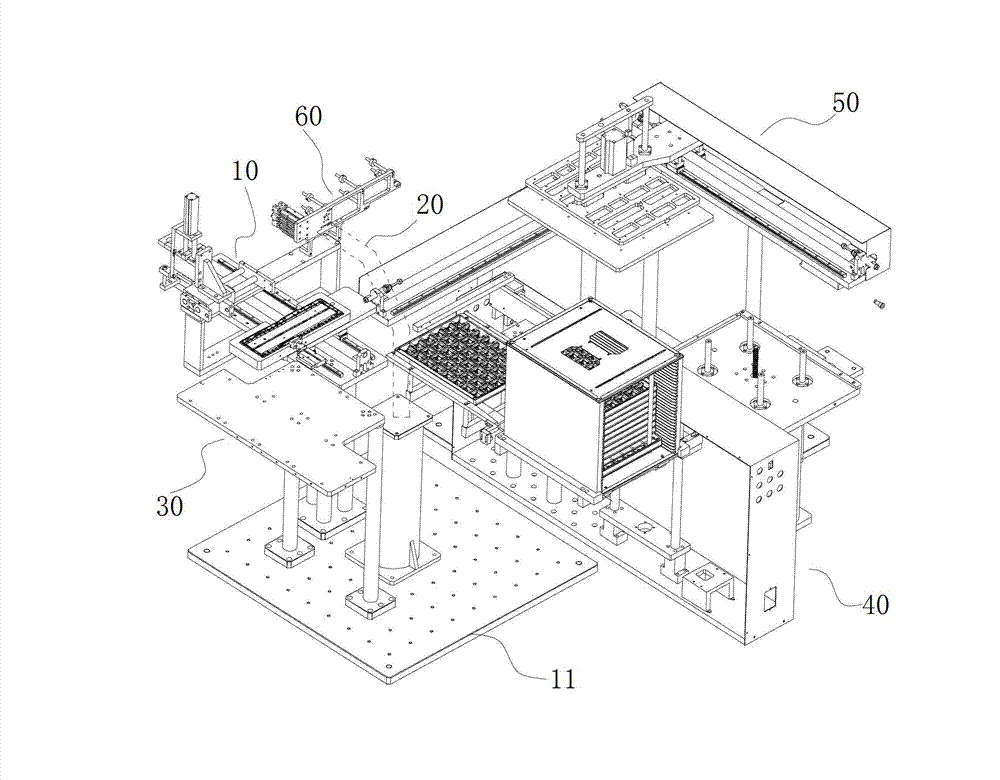

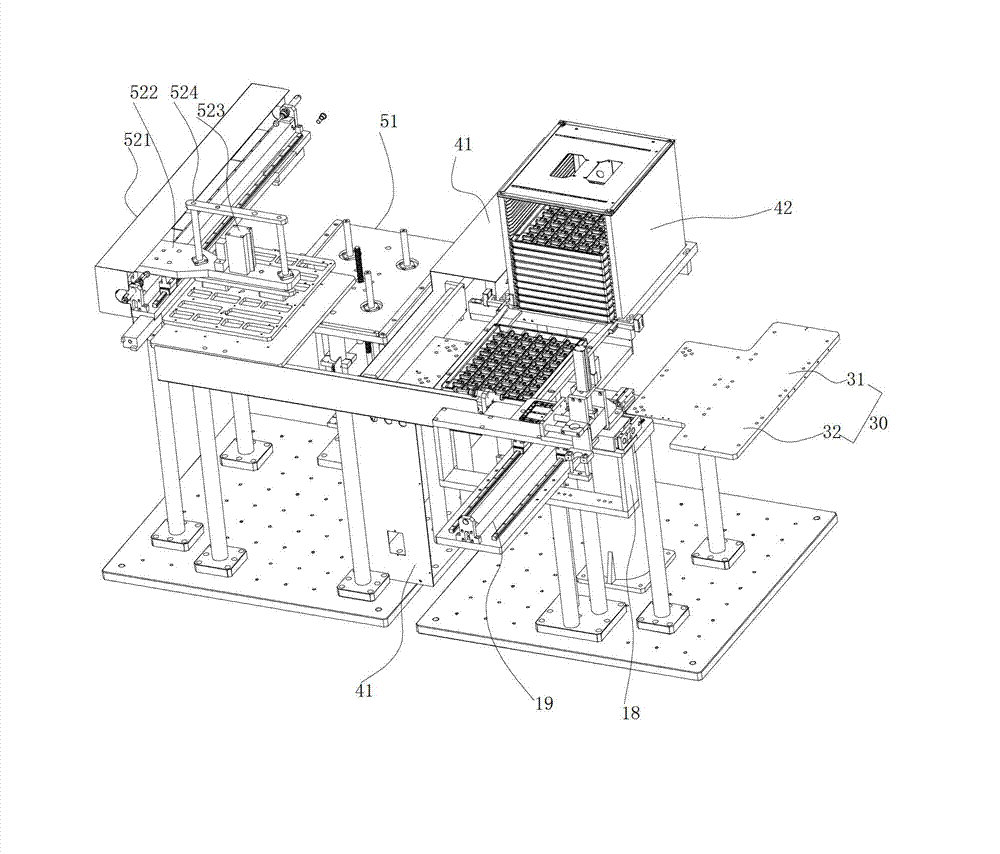

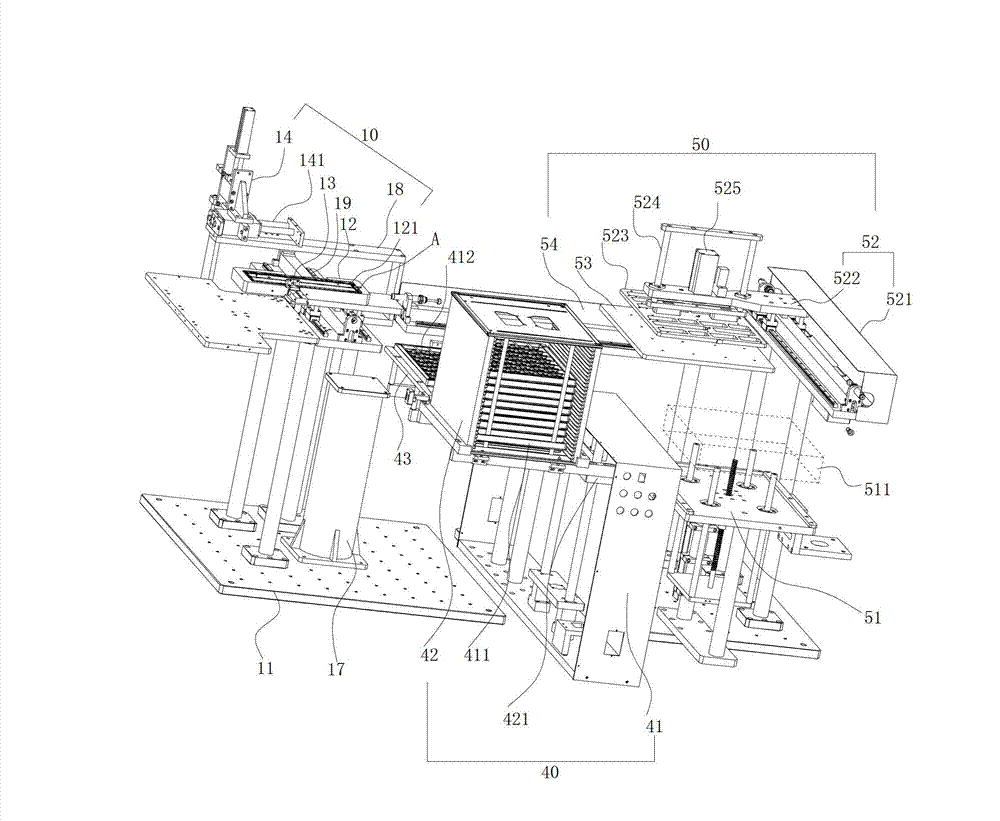

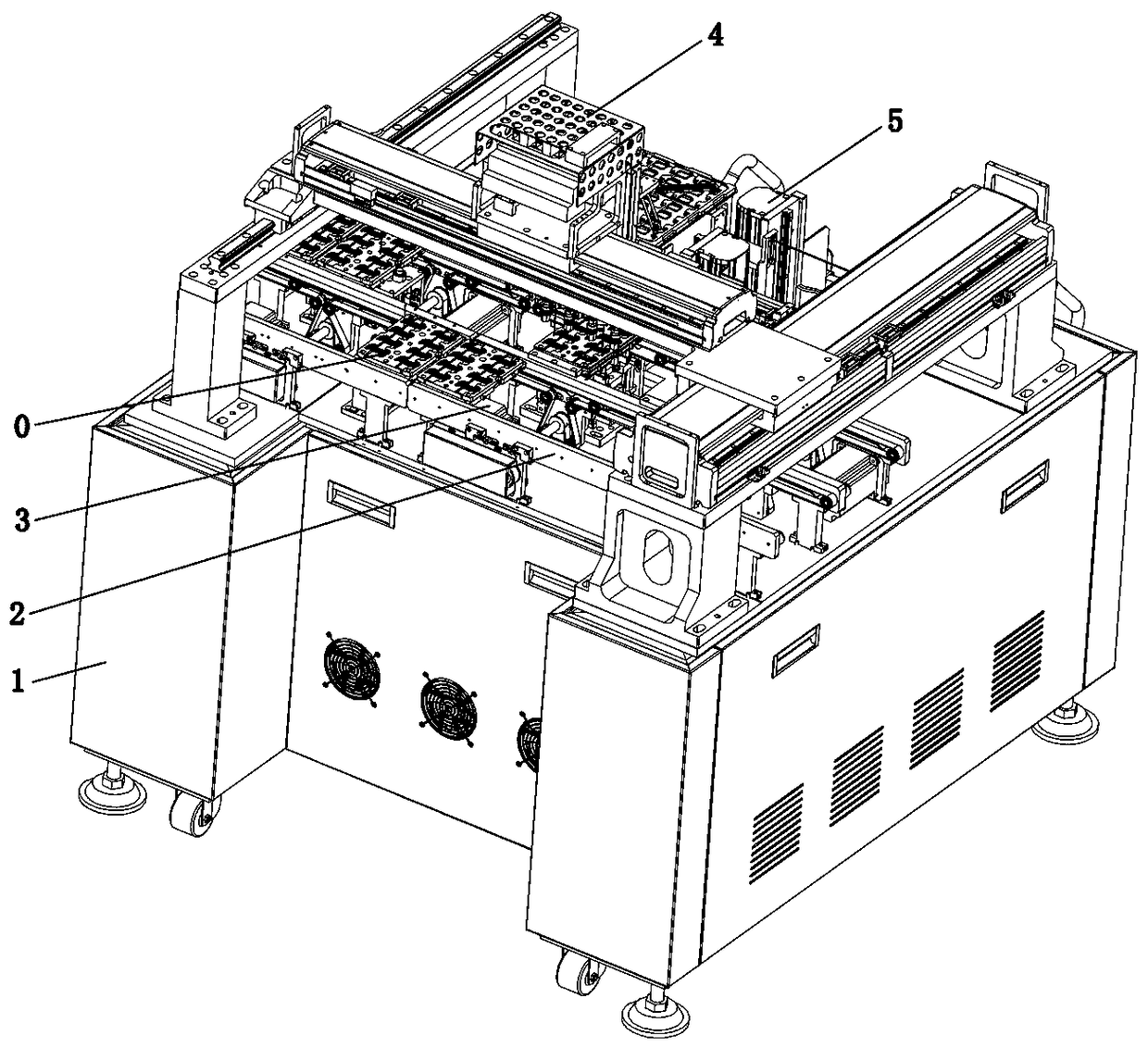

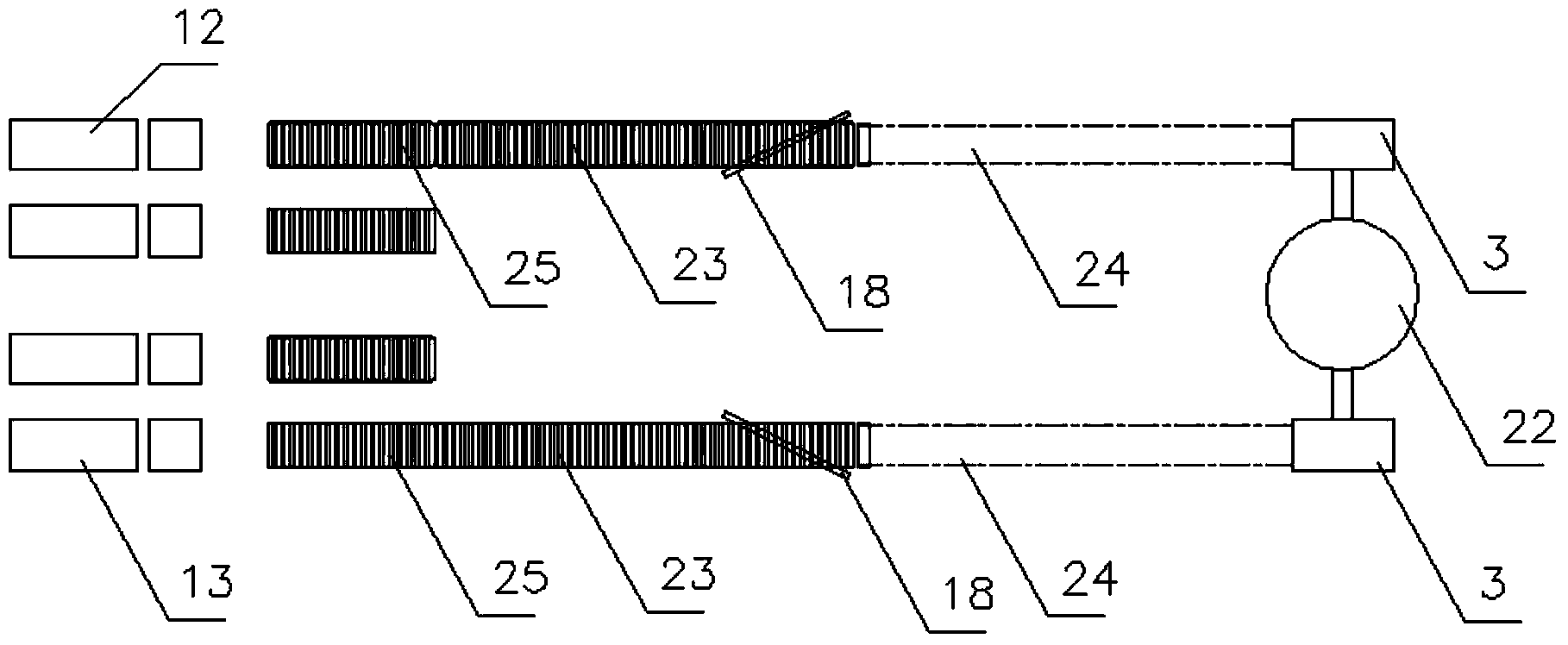

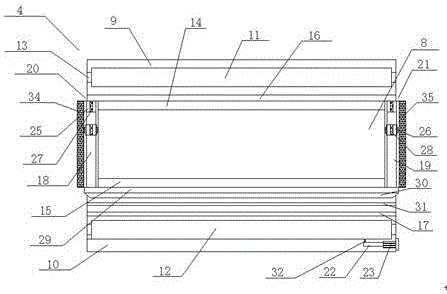

Feeding device of flexible printed circuit (FPC) board and keyboard base plate automated assembly system

InactiveCN103093988AIncrease productivityReduce in quantityElectric switchesAutomatic controlMechanical engineering

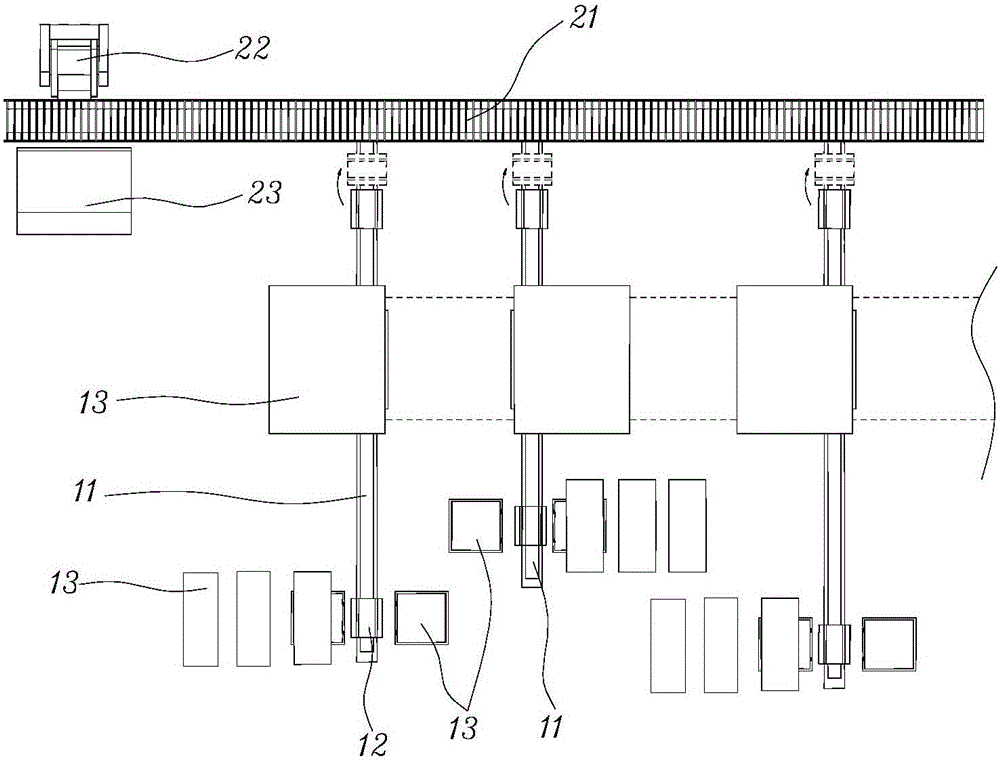

The invention discloses a feeding device of a flexible printed circuit (FPC) board and a keyboard base plate automated assembly system. The feeding device of the FPC board comprises a lifting material platform, a lengthways material moving mechanism and a material absorption frame which is connected with a sliding table, wherein a material box which is used for arranging the FPC board in a stack mode, the lengthways material moving mechanism comprises a lengthways slide and the sliding table which is in sliding connection with the slide, and the material absorption frame is arranged above the lifting material platform. By the adoption of the lifting material platform, the fact that the FPC board with multiple layers automatically feed the material to the position is achieved, only the whole box is needed to be changed, in the process of a robot continue assembling, the change of the material box of the FPC board has no need to be operated in a machine stopped state, reloading time is saved, and the production efficiency is improved. The keyboard under plate automated assembly system achieves assembling of each element by the adoption of the robot, the quantity of automatic control unit is reduced, and the floor area of the whole automated assembly system is benefitted to be reduced.

Owner:SHENZHEN RAPOO TECH

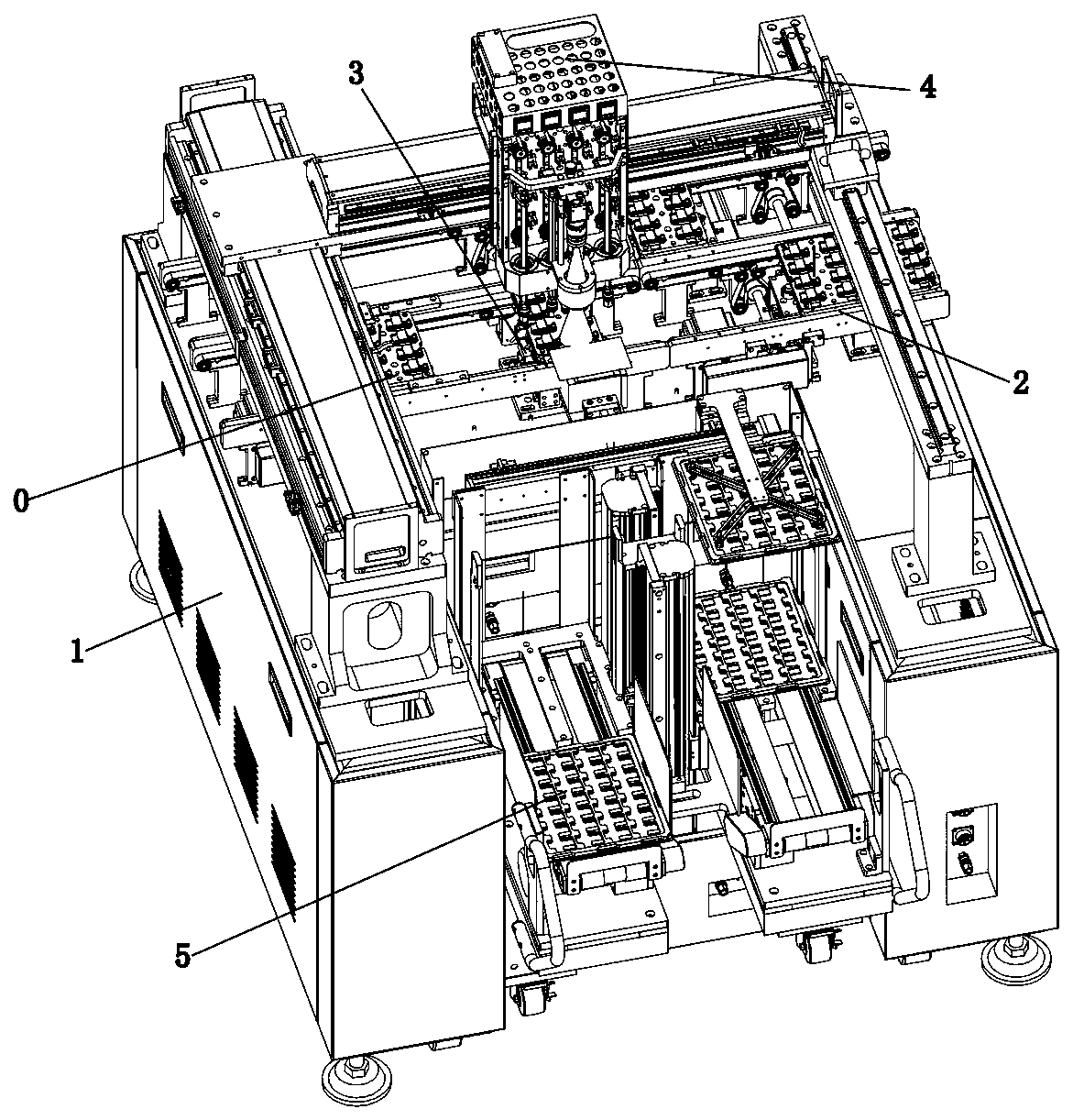

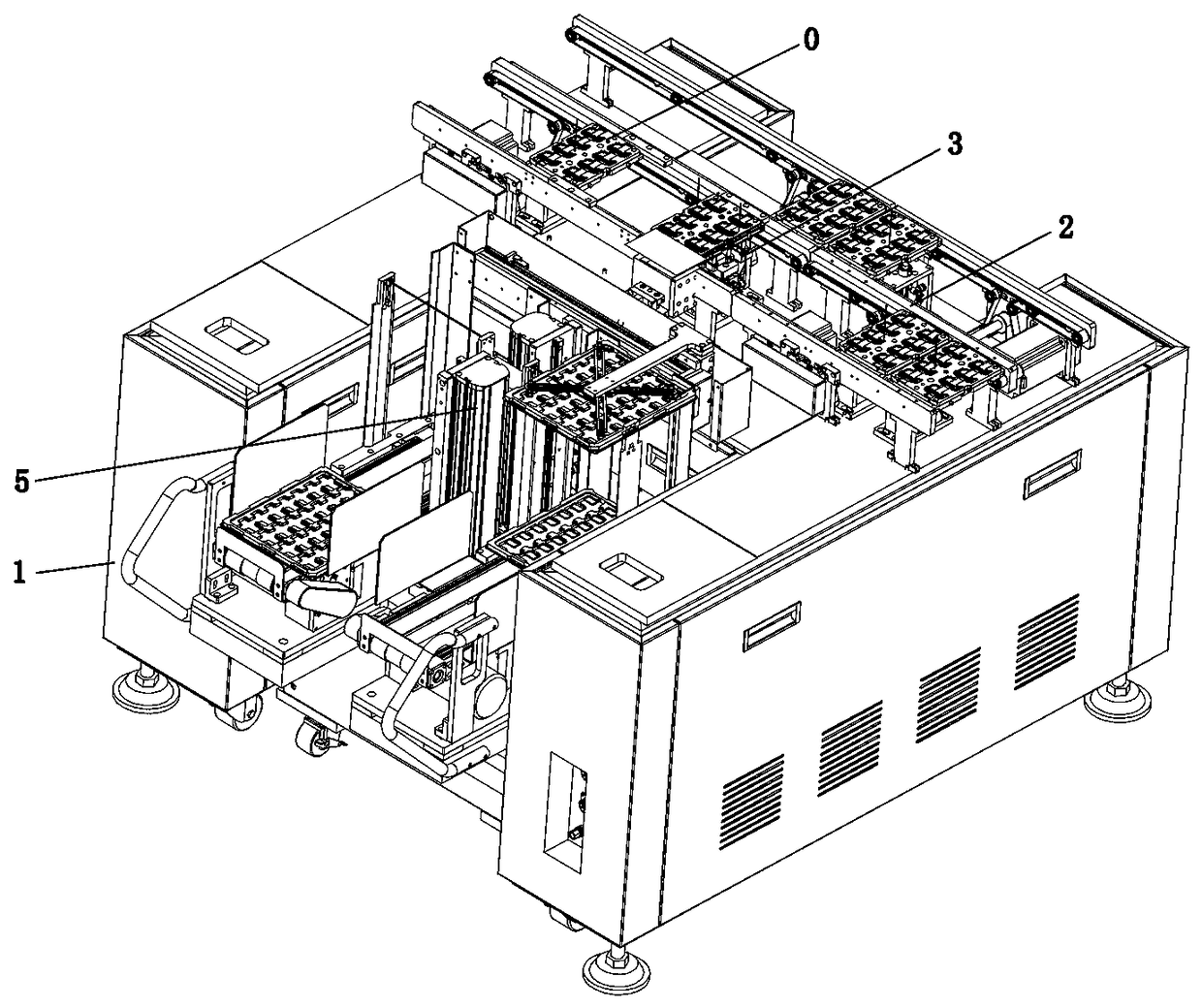

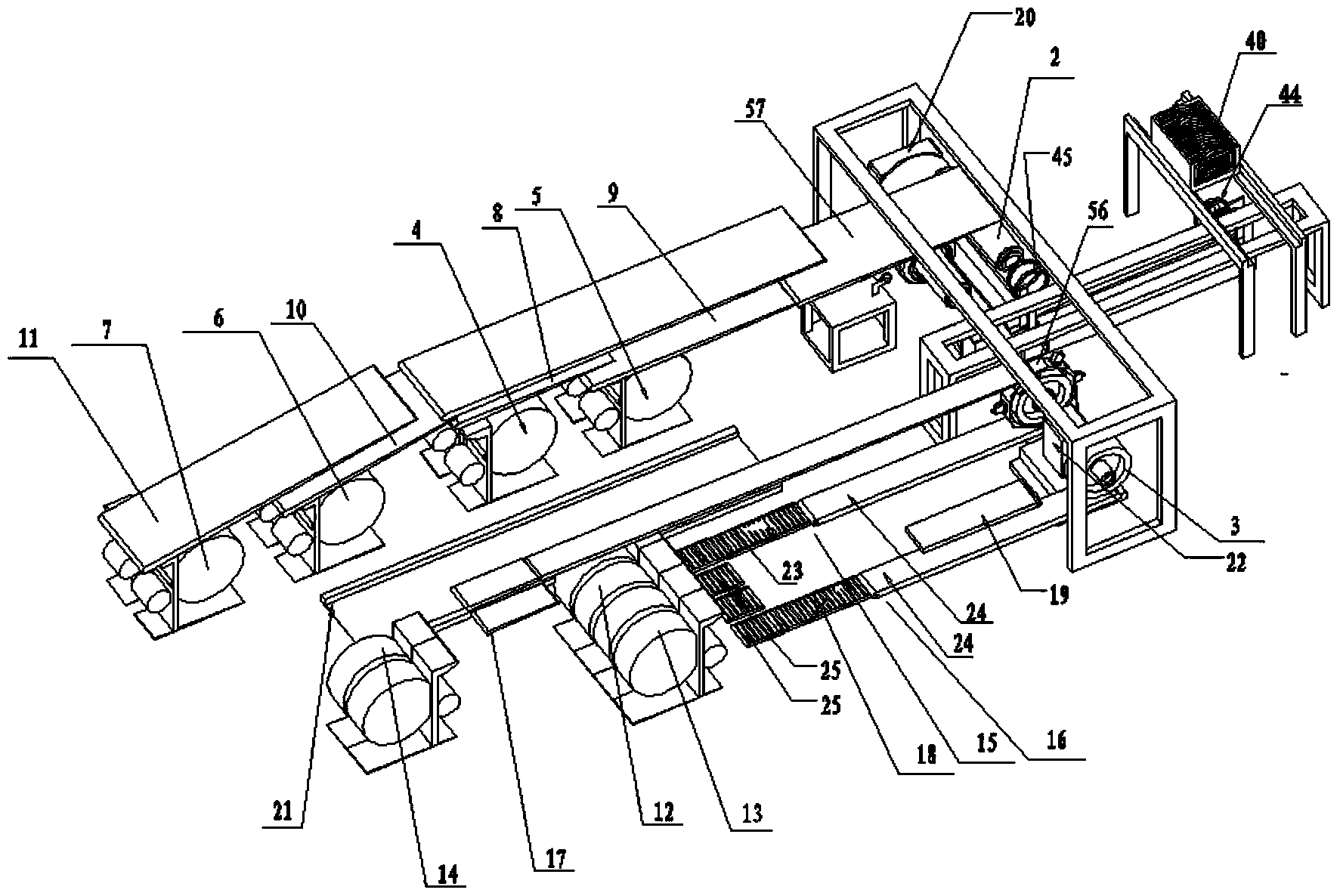

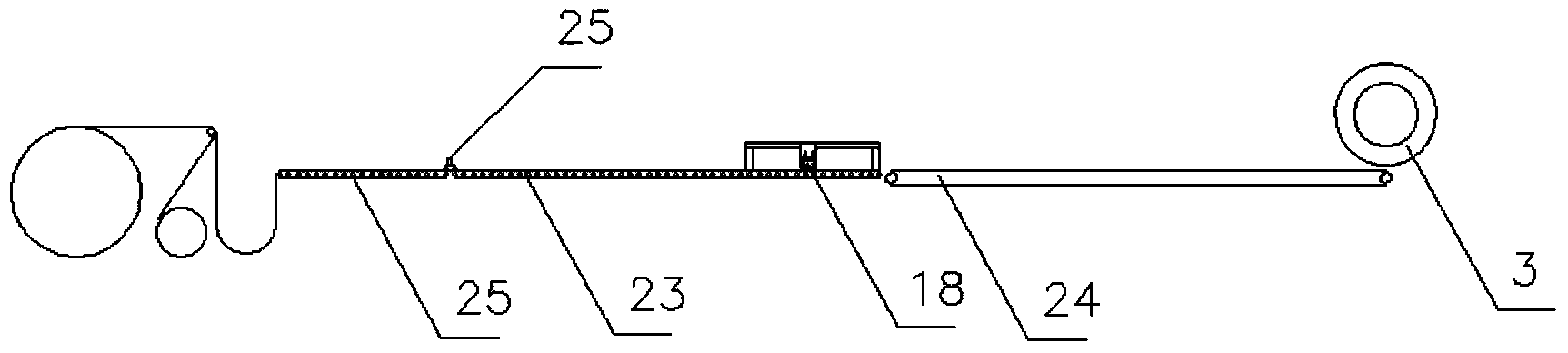

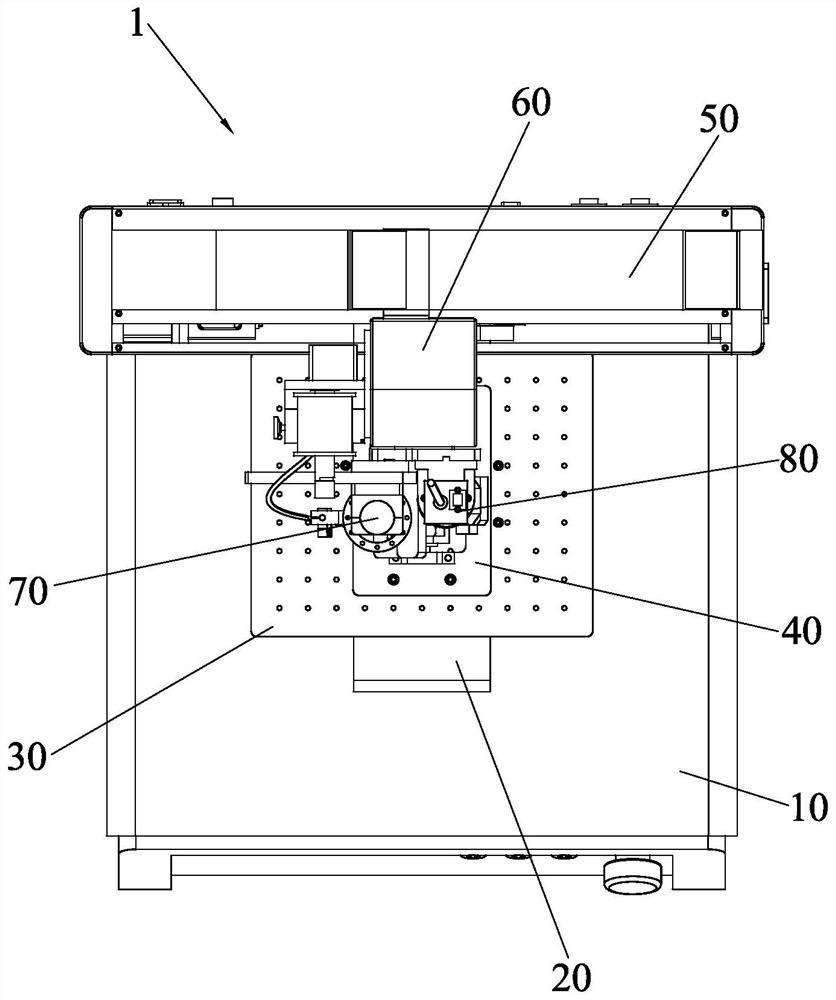

Automatic precise assembly machine

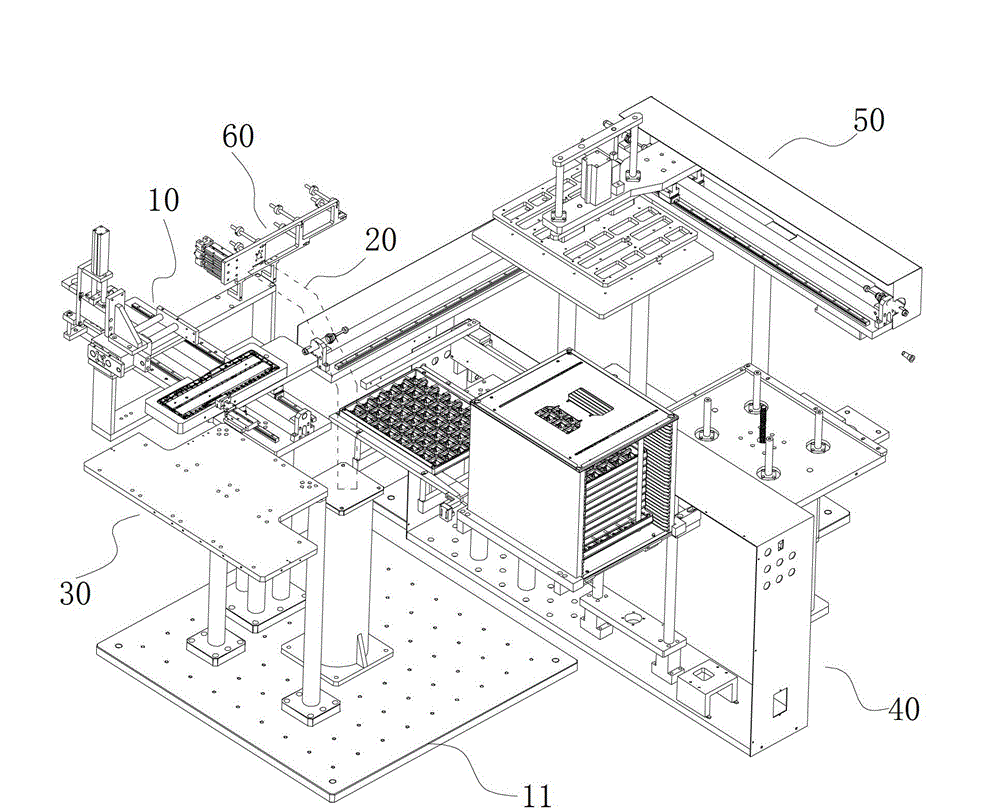

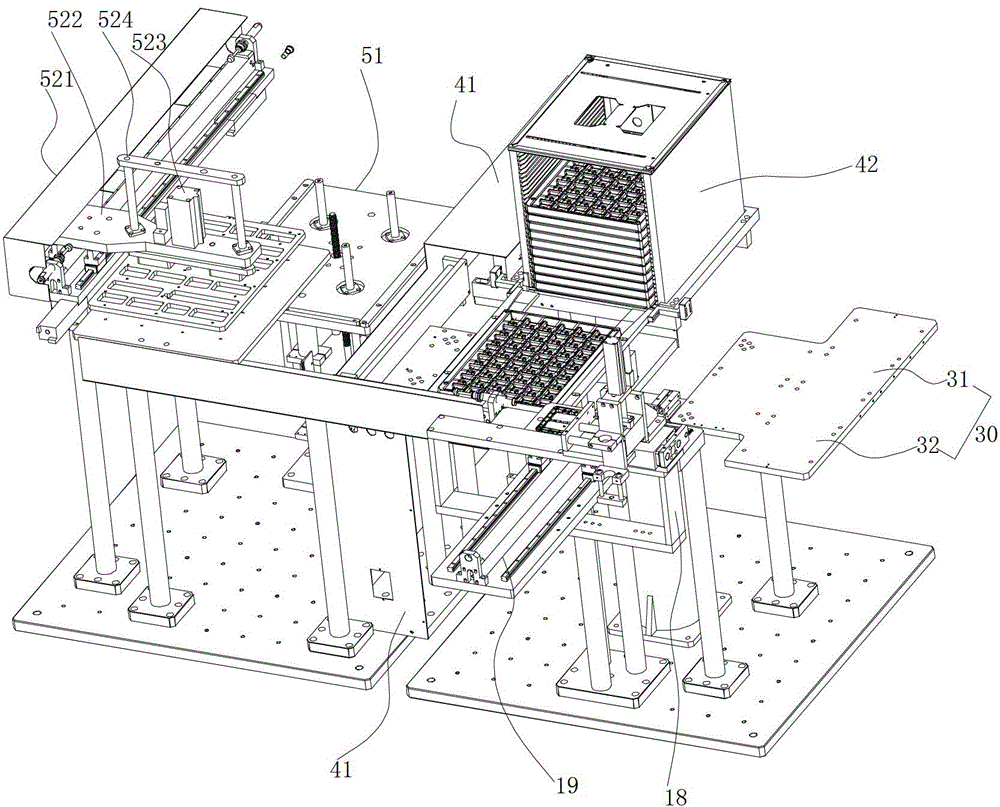

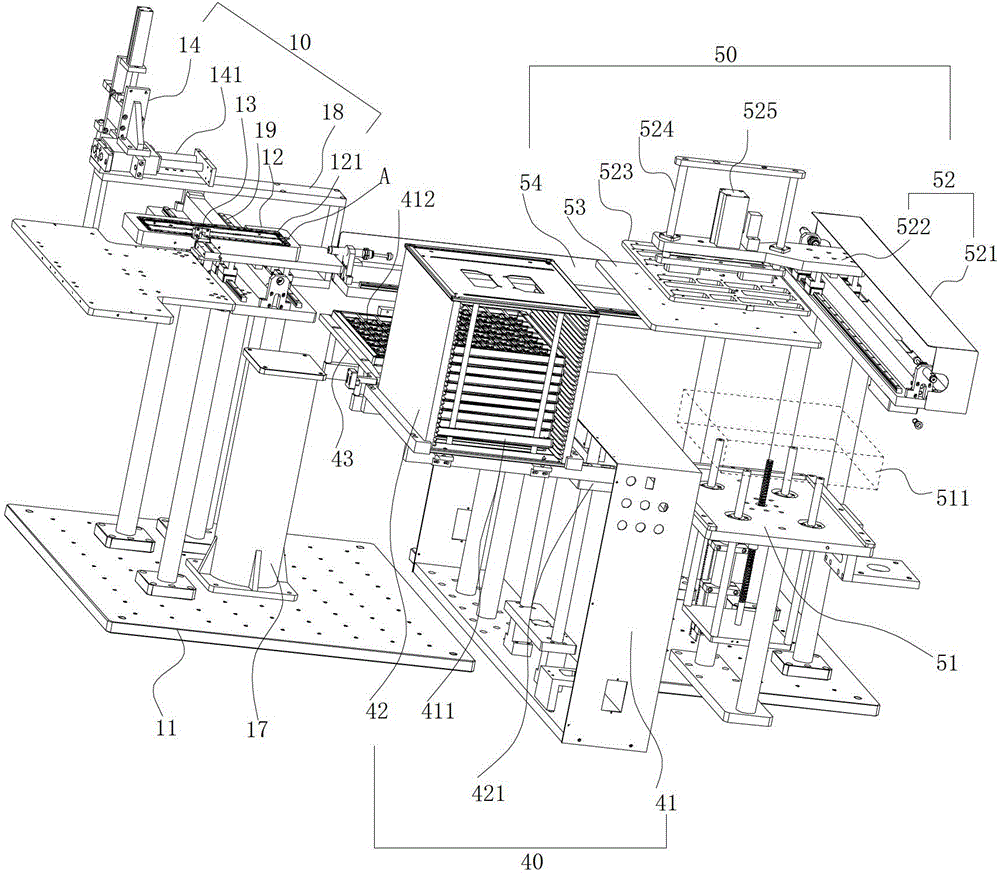

InactiveCN109317967AReduce the frequency of replacement and retransmissionAvoid position shiftAssembly machinesEngineeringGlass sheet

The invention discloses an automatic precise assembly machine. The automatic precise assembly machine comprises a conveying mechanism, a positioning and support mechanism, an assembly mechanism and aloading mechanism; the conveying mechanism is horizontally arranged on the frame; a synchronous belt is arranged on the inner side of the conveying mechanism; a tool for loading materials is placed onthe synchronous belt; at least two through grooves are formed in the tool; materials to be assembled are placed in the through grooves; and the assembly modules once absorb multiple materials from the loading mechanism, and assemble the materials to fittings in the through grooves of the tool. Through downward absorption fixation and flexible support of glass sheets, the displacement of the glasssheets in the assembly process is prevented, so that the assembly precision is guaranteed, the pressure crushing condition of the glass sheets is prevented, the loading and unloading time is shortened, the centralized unloading and loading of multiple products once are realized, the tray replacing and reloading time is shortened, and the overall production capacity is effectively improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

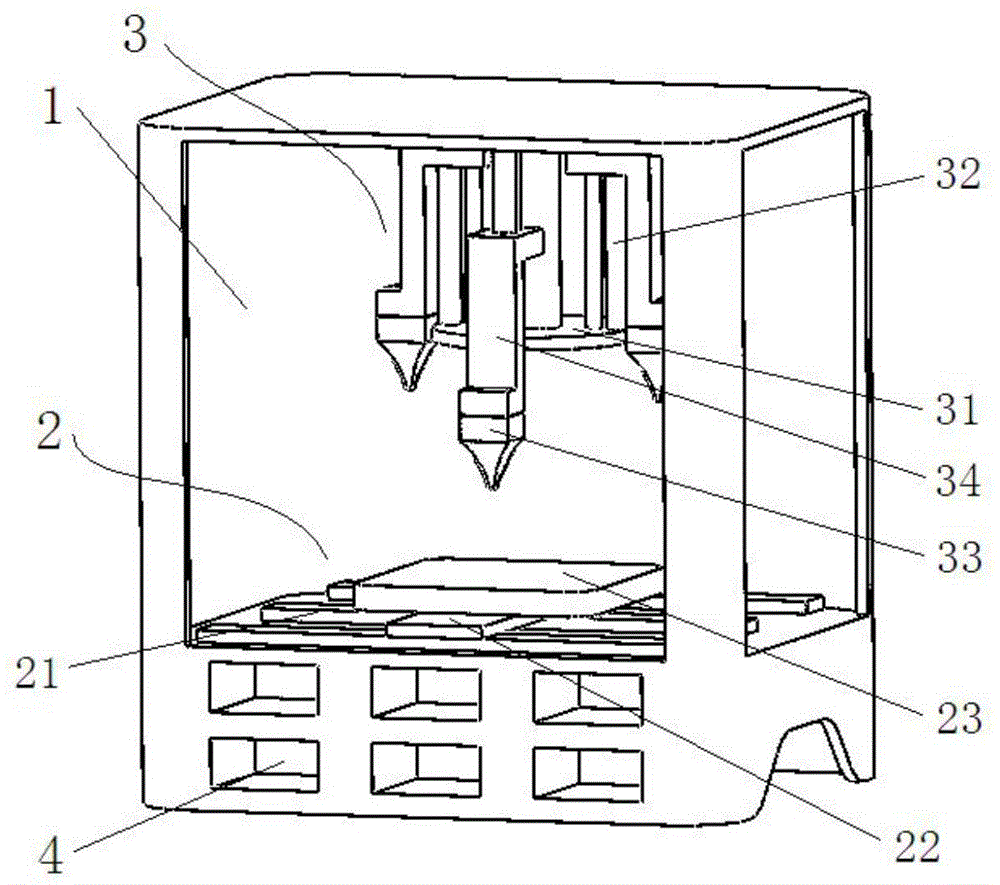

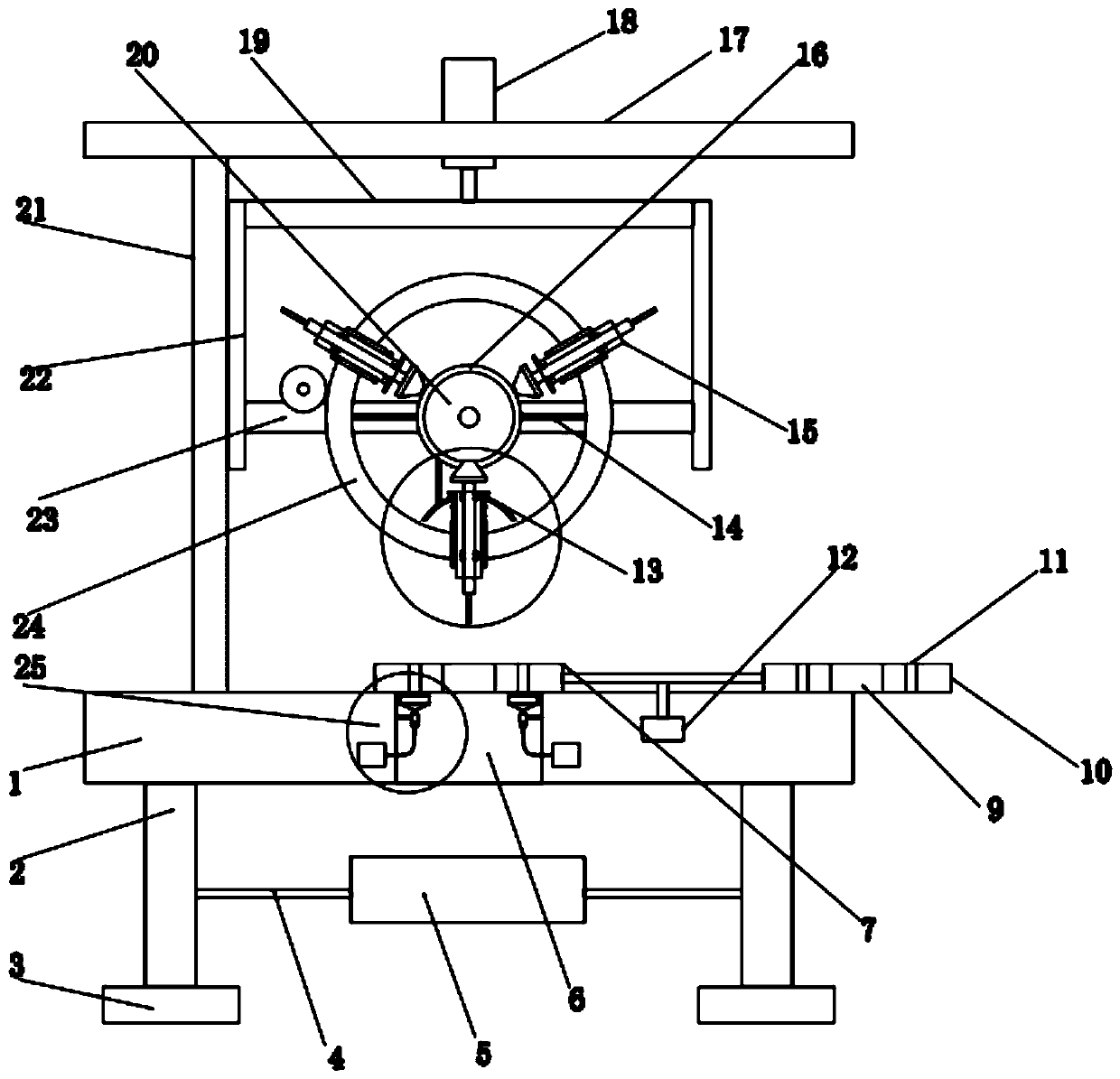

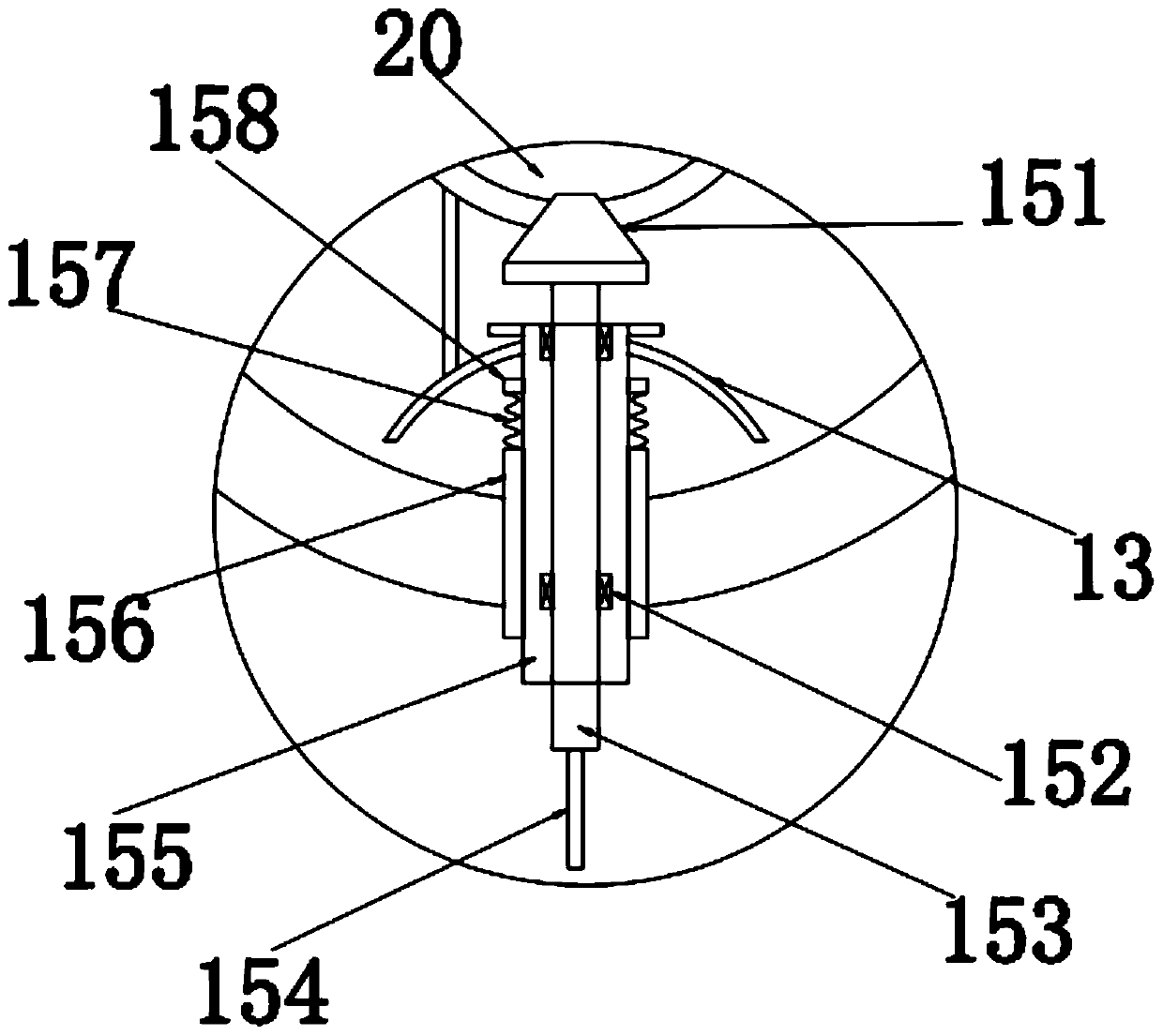

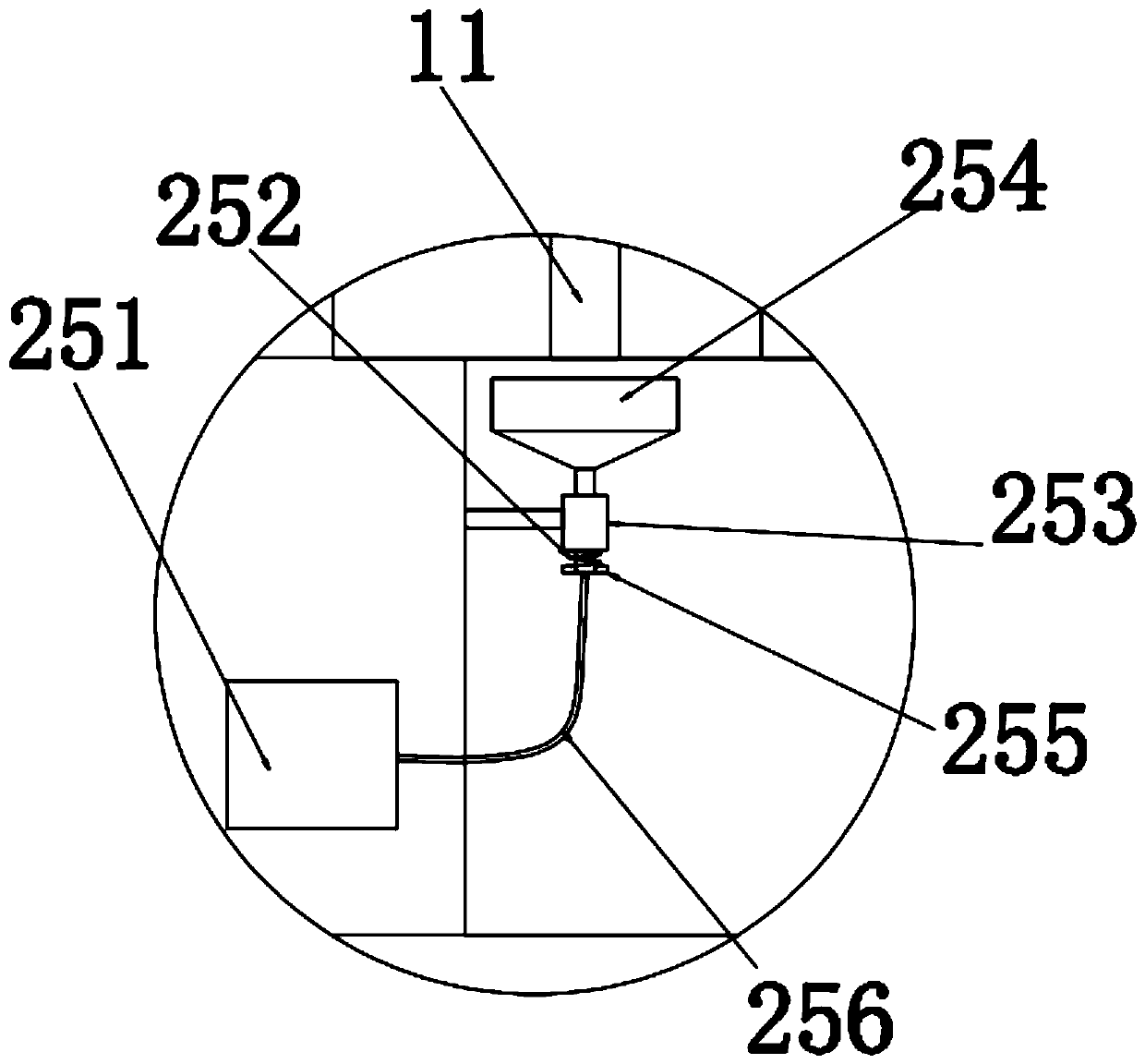

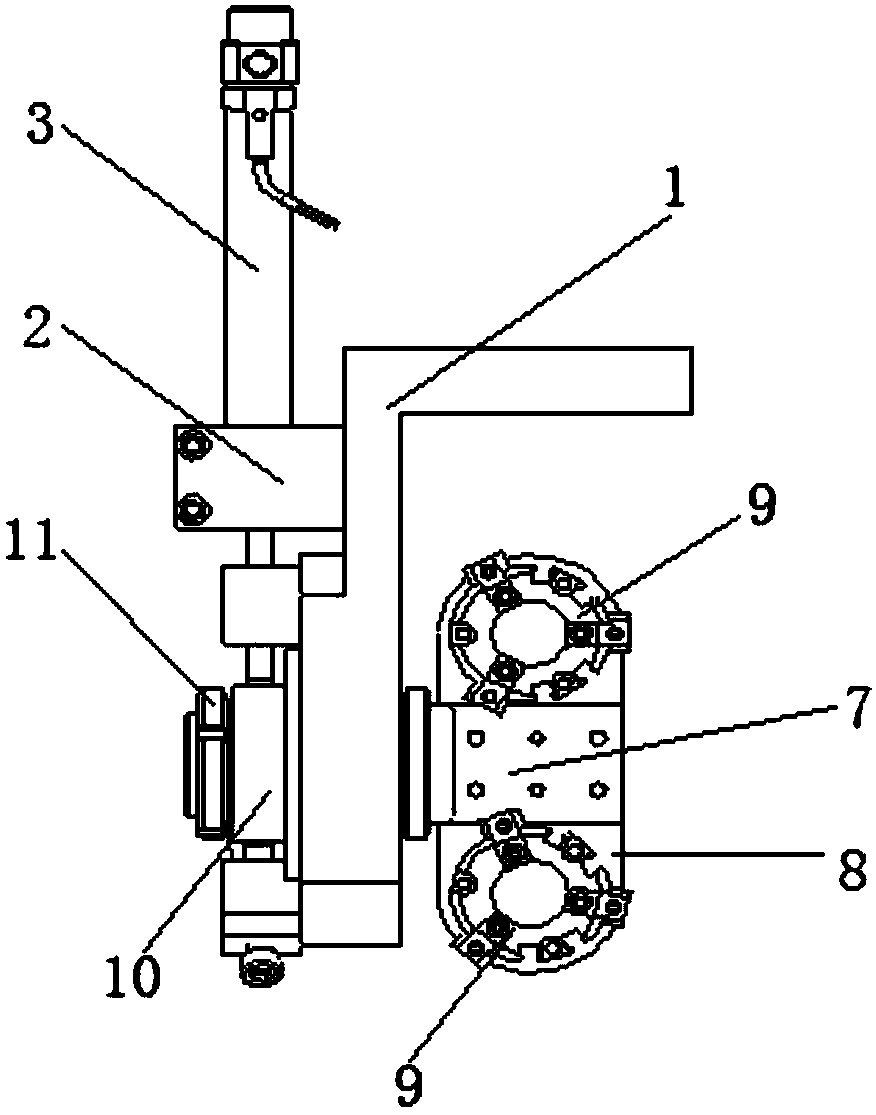

3D printing machine with multiple printing heads

The invention discloses a 3D printing machine with multiple printing heads. The 3D printing machine comprises a stander, a movable worktable which is used for storing a workpiece, a printing head mechanism for printing the workpiece, a plurality of material boxes for supplying printing materials to the printing heads, and a control system for controlling each components, wherein the movable worktable and the printing head mechanism are correspondently arranged in the stander; the printing head mechanism comprises a disc seat body which is arranged on the stander, and a plurality of lifting adjusting mechanisms which are uniformly distributed on the disc seat body, each lifting adjusting mechanism is provided with the printing head, and the disc seat body is driven by a motor to rotate; the printing heads correspond to the material boxes one by one. By adopting the 3D printing machine with the multiple printing heads, the different materials can be rapidly replaced, the material replacing time can be effectively shortened, and the operating efficiency can be improved; the reliability in action and the rapidness in reaction can be realized, the reliability is high, the overall structure is simple, and the application range is wide.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

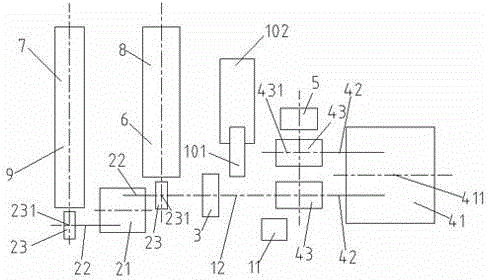

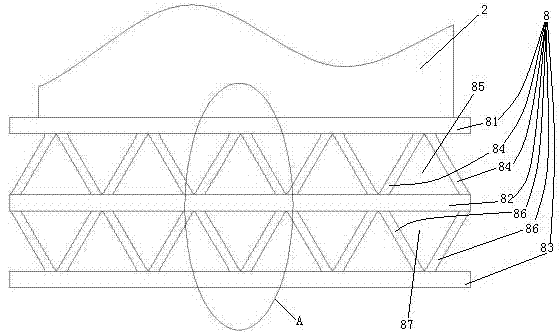

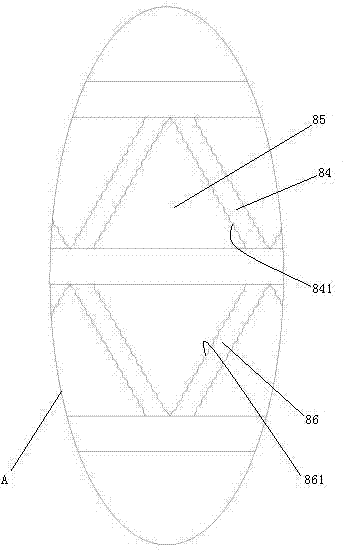

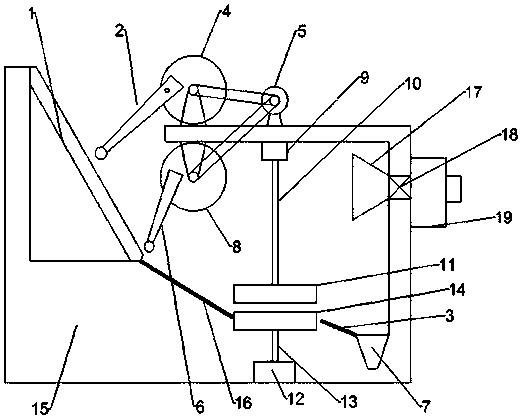

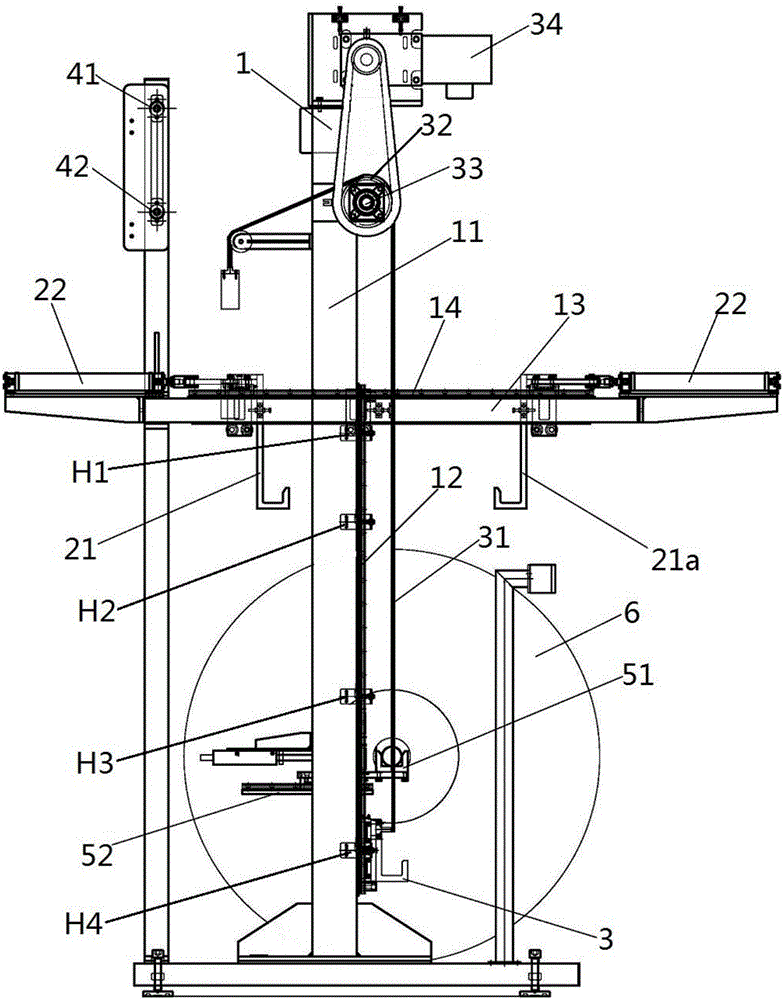

Two-section molding machine of passenger radial tire and molding method thereof

ActiveCN103331923AImprove work efficiencyWork time optimization balanceTyresMolding machineEngineering

The invention discloses a two-section molding machine of a passenger radial tire and a molding method thereof. The molding machine comprises a main machine and a feed frame, wherein the main machine comprises a base; a laminating device, a transfer ring and a calibrator are orderly arranged along the base; the laminating device comprises a laminating machine; two sets of belted layer drum mechanisms capable of rotating along the central line of the laminating machine are symmetrically arranged at the center of the laminating machine; the output shaft of each belted layer drum mechanism is provided with a belted layer drum; the calibrator comprises a main machine case; two sets of shaping drum mechanisms capable of rotating along the central line of the main machine case are symmetrically arranged at the center of the main machine case; the output shaft of each shaping drum mechanism is provided with a shaping drum. The molding machine adopts a dual-station structure layout on a laminating and calibrating system; layout of a feeding system is correspondingly arranged, so that the work time of each station is optimized to the maximal extent; the work efficiency of the two-section molding machine is obviously improved; meanwhile, the automatic degree of the equipment is improved; the labor intensity is reduced.

Owner:北京敬业机械设备有限公司

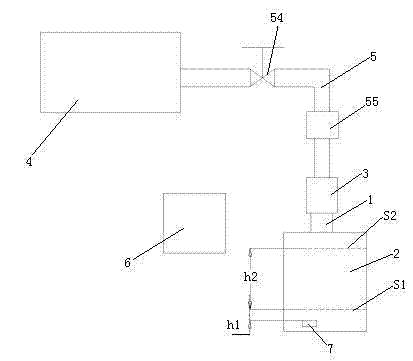

Lubrication device with automatic oil filling capacity

ActiveCN103807590ADoes not increase oil consumptionReduce in quantityLubricant transferMaintainance and safety accessoriesFuel tankLubrication

The invention relates to a lubrication device with automatic oil filling capacity. The lubrication device comprises a lubrication oil tank, a main oil tank and a control unit, wherein the main oil tank is located above the lubrication oil tank which is connected with the main oil tank through an oil pipe provided with an electrically operated valve, and the lubrication oil tank is provided with an oil sensor; and the control unit is used for switching on the electrically operated valve so as to enable lubricating oil in the main oil tank to flow into the lubrication oil tank under the action of gravity when the oil sensor detects that oil in the lubrication oil tank is less than the set minimum quantity and switching off the electrically operated valve when the oil in the lubrication oil tank reaches the set maximum quantity. The lubrication device with the automatic oil filling capacity can fill the lubrication oil tank automatically with the lubrication oil, so that the problem of time waste caused by the fact that the conventional lubrication device requires manual lubrication oil filling into the lubrication oil tank is solved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Novel high-efficient car radial tire molding device

The invention discloses a novel high-efficient car radial tire molding device. A composite member conveyor belt, a first cord fabric conveyor belt and a second cord fabric conveyor belt are respectively used for conveying a composite membrane, a first cord fabric and a second cord fabric to the surfaces of two tire body drums at the set position for winding, a steel ring can be arranged on the surface of the tire body drum at the set position in a sleeved manner through a steel ring clamping device, the tire body drums can be used for sequentially inflating and synchronously reversely packaging the materials, which wind the surfaces of the tire body drums, for molding a tire blank, a first belt bundle conveyor belt, a second belt bundle conveyor belt, a tire tread conveyor belt and a crowned belt strip winding device are used for conveying a first belt bundle, a second belt bundle, a tire tread and a crowned belt strip respectively to the surfaces of two belt bundle drums on a discharging end for winding, a product can be taken from the belt bundle drum through a tread transferring ring, the two tire body drums alternately arrive in the set position, and the two belt bundle drums can respectively arrive in the discharging end of the first belt bundle conveyor belt, the second belt bundle conveyor belt, the tire tread conveyor belt and the crowned belt strip winding device. Through the rotation of the two drums, the machining efficiency can be improved, and the production cost can be reduced.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

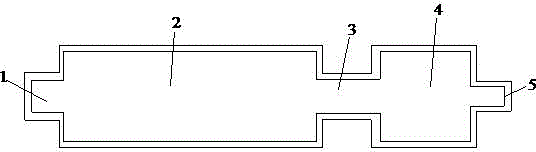

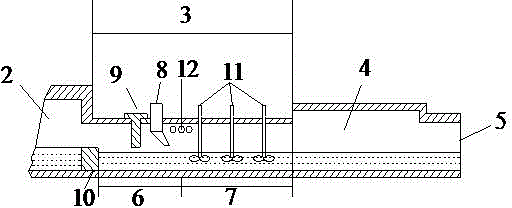

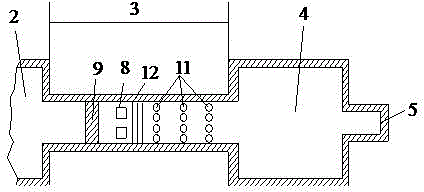

Melting furnace for producing float glass and colorant addition method

The invention relates to a melting furnace for producing float glass and a colorant addition method, belonging to the technical field of glass production. According to the invention, a neck (3) is used as a charging and mixing part; and coloring materials are added into molten glass via a charging channel (8) arranged at the charging area (6) of the neck. Since the melting furnace is filled with colorless basic molten glass, the operation of coloring is performed at the neck, thereby reducing displacement amount of the molten glass and effectively shortening changing time of the molten glass; and the method enables large-size melting furnaces to adapt to features of color glass demand market, and the features of the color glass demand market include demands for various varieties and little demand for a single variety.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

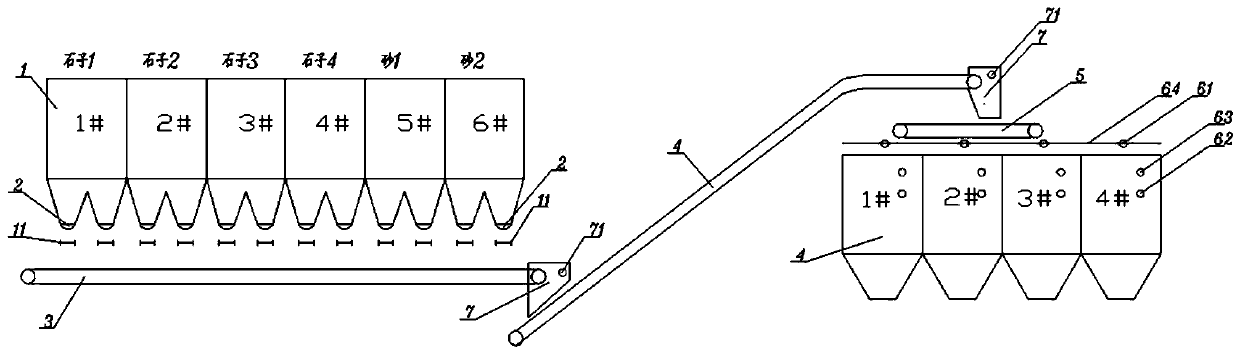

Stirring station aggregate feeding system and control method

PendingCN110394899AImprove reliabilityHigh degree of automationMixing operation control apparatusIngredients storageYardMaterial distribution

The invention discloses a stirring station aggregate feeding system. The stirring station aggregate feeding system comprises a storage yard provided with a plurality of stock bins, a flat belt, an inclined belt, a material distribution belt, and a stirring station provided with a plurality of stock bins, wherein the material distribution belt can rotate forwards and reversely so as to realize blanking at the two ends, a plurality of discharge arc doors are arranged in the storage yard stock bins, each discharge arc door is provided with a material flow detection device, and the flat belt, theinclined belt and the material distribution belt are sequentially connected through transition hoppers; material blockage detection devices are arranged on the transition hoppers, the material distribution belt is arranged on a rail, a position detection device is arranged on the rail, a material level detection device used for detecting the height of the material level in each stock bin and an over-limit inspection devices arranged at the height limit positions are arranged in each stock bin of the stirring station. According to the system, only full inspection signals are arranged, and no material null signals are arranged, so that the loading condition is met as long as material full signals are not detected, and the system can effectively improve the feeding reliability, the working efficiency and the automation level.

Owner:杭州江河机电装备工程有限公司 +1

Decking processing device capable of facilitating unloading

InactiveCN110860594AEasy to unloadQuick changeMetal-working feeding devicesPositioning devicesDrive shaftElectric machinery

The invention discloses a decking processing device capable of facilitating unloading. The device comprises a bed frame, a lifting rod, a first motor, a height adjusting groove, a first bolt and a second bolt, the fixing frame is arranged on the left side of the bed frame, an unwinding device is arranged in the fixing frame, rollers are arranged at the lower end of the unwinding device, the limiting rod penetrates through the fixing frame and is connected with the lower side of the unwinding device, a driving shaft and a driven shaft are arranged in the bed frame, the driving shaft is arrangedbelow the driven shaft, and pressing wheels are arranged on the outer side of the driving shaft and the outer side of the driven shaft. The decking processing device capable of facilitating unloadingis provided with a lifting table, a supporting table and a third motor, a second screw rod is arranged in a stand column on the outer side of the lifting table and is connected with the supporting table, the third motor drives the second screw rod to rotate through the cooperation of a transmission shaft and a worm, decking can be conveniently placed on the supporting table, meanwhile, the heightof the supporting table is adjusted, the uppermost decking and the lowermost end of an opening are located on the same horizontal plane, and unloading is facilitated.

Owner:江苏滨杰科技有限公司

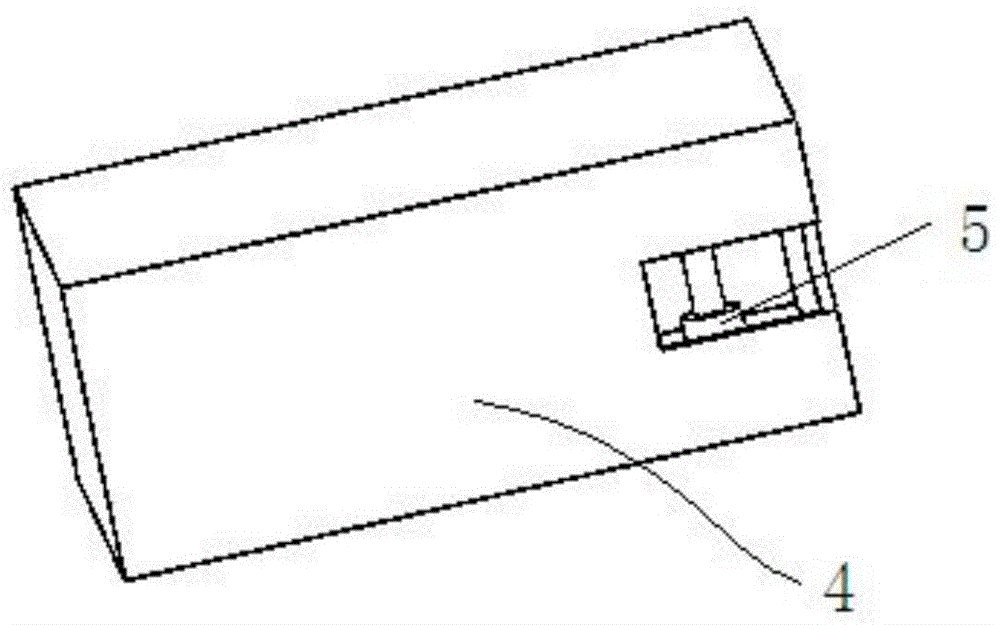

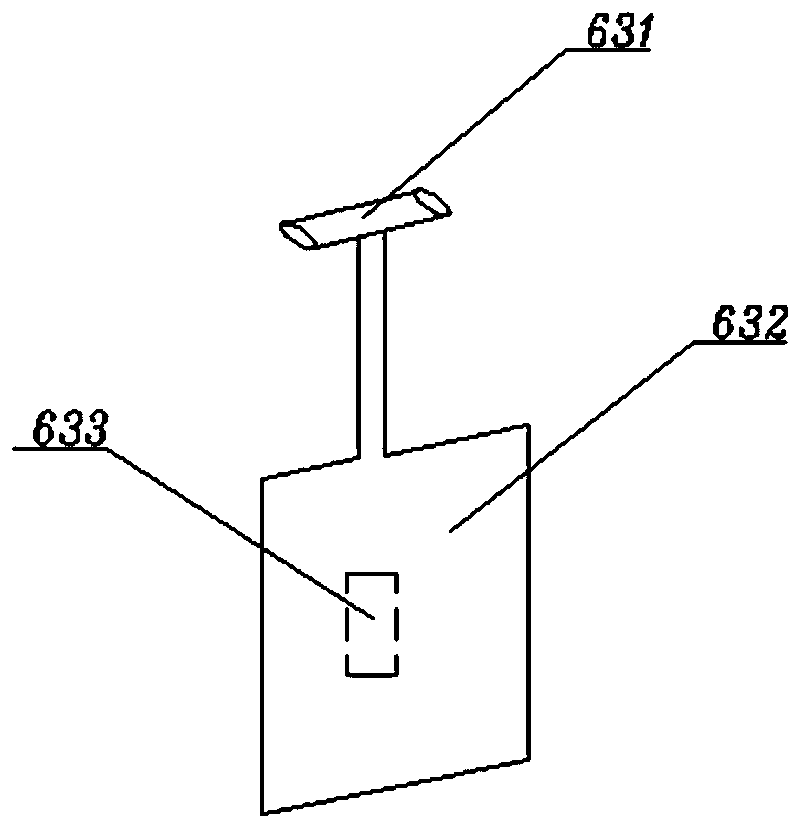

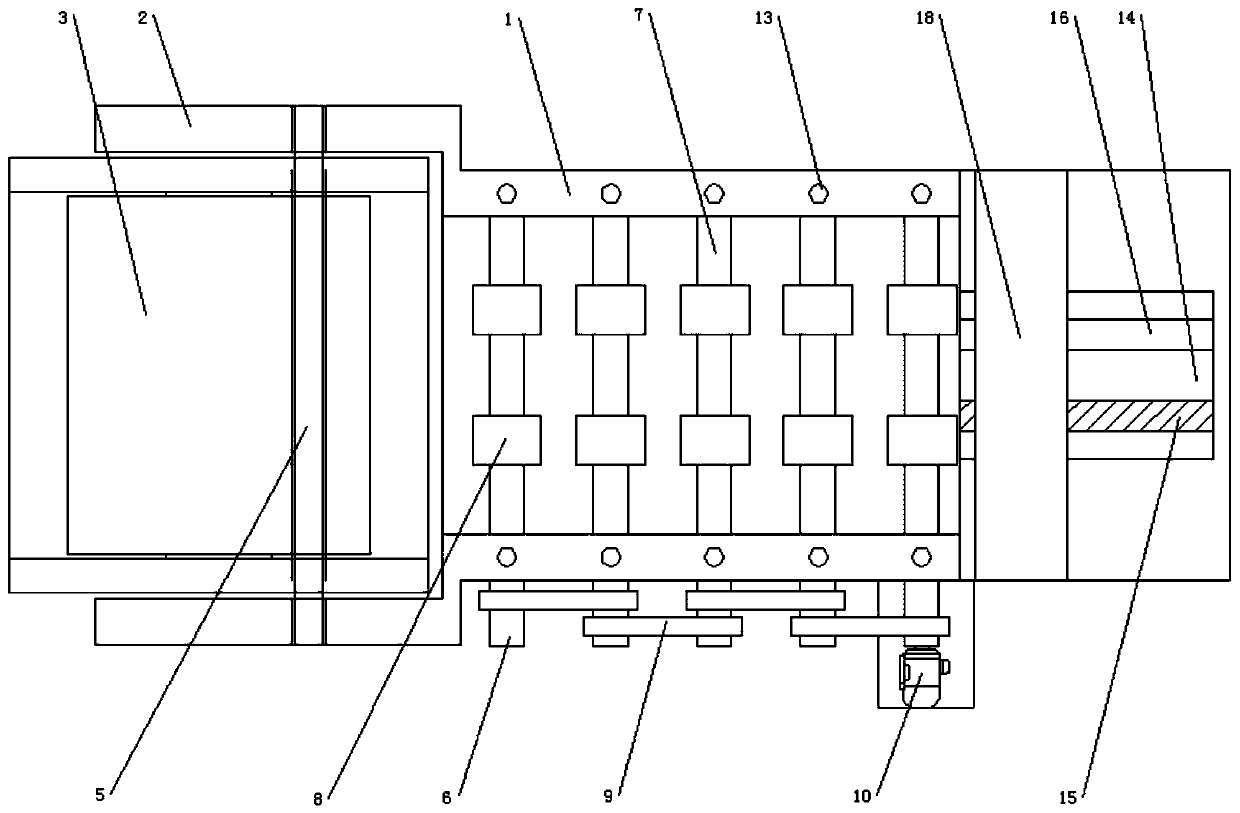

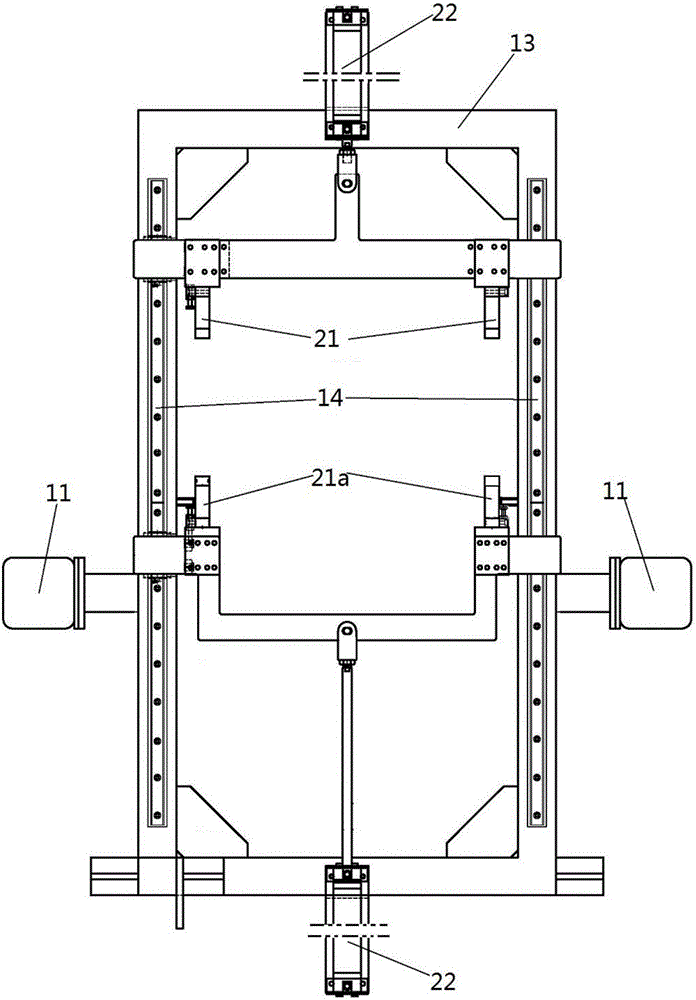

Pallet machine

InactiveCN105501996ASave refueling timeCompact structureDe-stacking articlesLoading/unloadingPalletEngineering

The invention discloses a pallet machine. Pallets are directly stacked inside a stack space and are not needed to be partitioned, clamping and blocking mechanisms are arranged at the two opposite sides of a frame, a parallel four-bar mechanism is adopted for each clamping and blocking mechanism, when the pallets are conveyed, the clamping and blocking mechanisms extend into the stack space for clamping the clamping grooves in the two opposite sides of the pallets, all the pallets in the stack space are clamped and positioned, and the pallet located at the lowermost position of the stack space is dropped to a transmission mechanism through a supporting mechanism and output from the bottom through the transmission mechanism. Therefore, the parallel four-bar mechanism is adopted for each clamping and blocking mechanism, so that the pallet machine has the advantages of being compact in structure, low in cost, stable in operation and large in bearing power.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

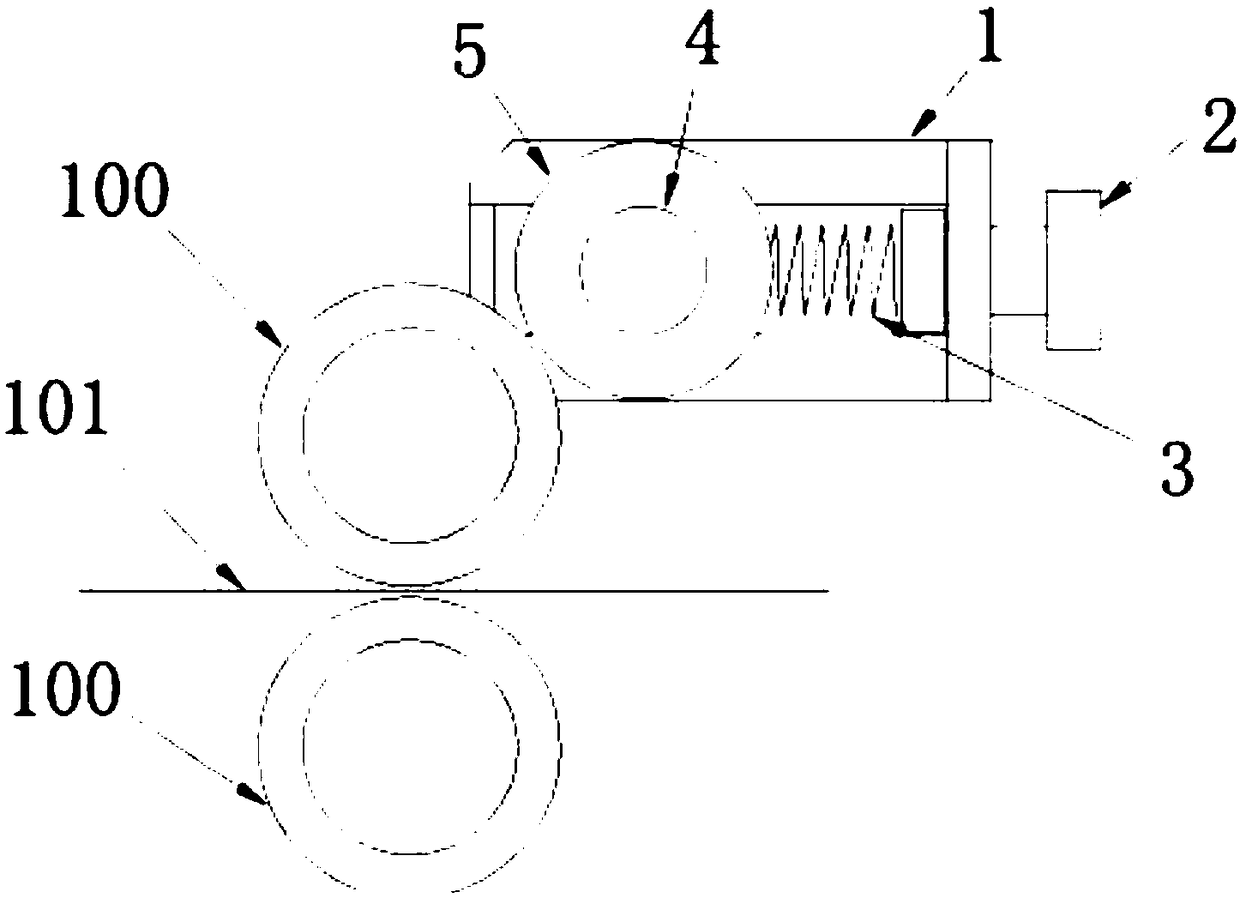

Dust removing device for rotary die cutting machine

InactiveCN108405488AEasily damagedFit tightlyCleaning processes and apparatusEngineeringMechanical engineering

The invention relates to the technical field of die cutting machines, particularly relates to rotary die cutting machines and specifically provides a dust removing device for a rotary die cutting machine. The dust removing device for the rotary die cutting machine comprises a pedestal, a regulating bolt, a telescopic component, an axis and a dust sticking roller; the pedestal is fixedly installedat one side of a rubber shaft; a telescopic component is installed inside the pedestal; the regulating bolt is in threaded connection with one side surface of the pedestal; the tail end of the regulating bolt extends into the pedestal and is connected with one end of the telescopic component; the other end of the telescopic component is connected with the axis; the axis can slide inside the pedestal under the driving of the telescopic component; and the dust sticking roller is rotationally arranged on the axis in a sleeving manner. The dust removing device provided by the invention can make the dust sticking roller and the rubber shaft closely cling to each other so as to take away dust and fragments which are adsorbed on the rubber shaft in a sticking way, realizes a better dust removal effect, runs stably, can also shorten the material replacement time, can prevent an incomplete adhesion effect caused by too small force, and can also prevent easy damage of the dust sticking roller due to too large force.

Owner:SHENZHEN CDL PRECISION TECH CO LTD

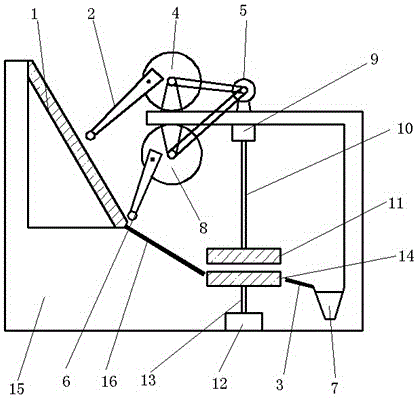

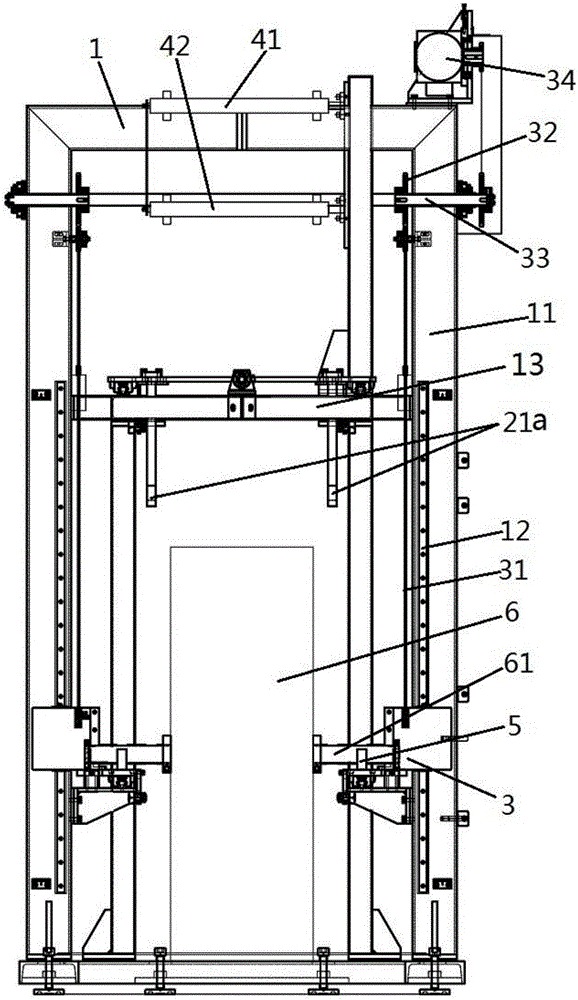

Dual-worktable position interchanging mechanism and leather cutting machine tool containing dual-worktable position interchanging mechanism

ActiveCN103451325ASimple structureImprove reliabilityLeather clicking/perforating/clickingEngineeringSteel frame

The invention relates to a dual-worktable position interchanging mechanism and a leather cutting machine tool containing the dual-worktable position interchanging mechanism, which aims to solve the problems that a great deal of working time is spent for picking up material after leather is paved and cut and the production efficiency is low since a worktable of an existing leather cutting machine does not have interchanging function. Lifting table short connecting rods are hinged to lifting table vertical plates; a lifting table of the lifting table short connecting rods walks up and down and rolls along a guide rail I; lifting table guide wheels of the lifting table short connecting rods roll between a guide groove and a guide rail II; the lower ends of the three lifting table short connecting rods are hinged to lifting table long connecting rods; expansion plates realize free motion in vertical direction through roller sleeve mechanisms. The dual-worktable position interchanging mechanism is fixed in a supporting steel frame; movable cross beams are arranged on longitudinal guide rails in a sliding manner; a vibration cutter assembly is fixed on the movable cross beams; a photographing projection equipment assembly is fixed at the top of a photographing projection equipment mounting rack. The dual-worktable position interchanging mechanism and the leather cutting machine tool are used for leather cutting.

Owner:哈尔滨同和光学精密机械有限公司

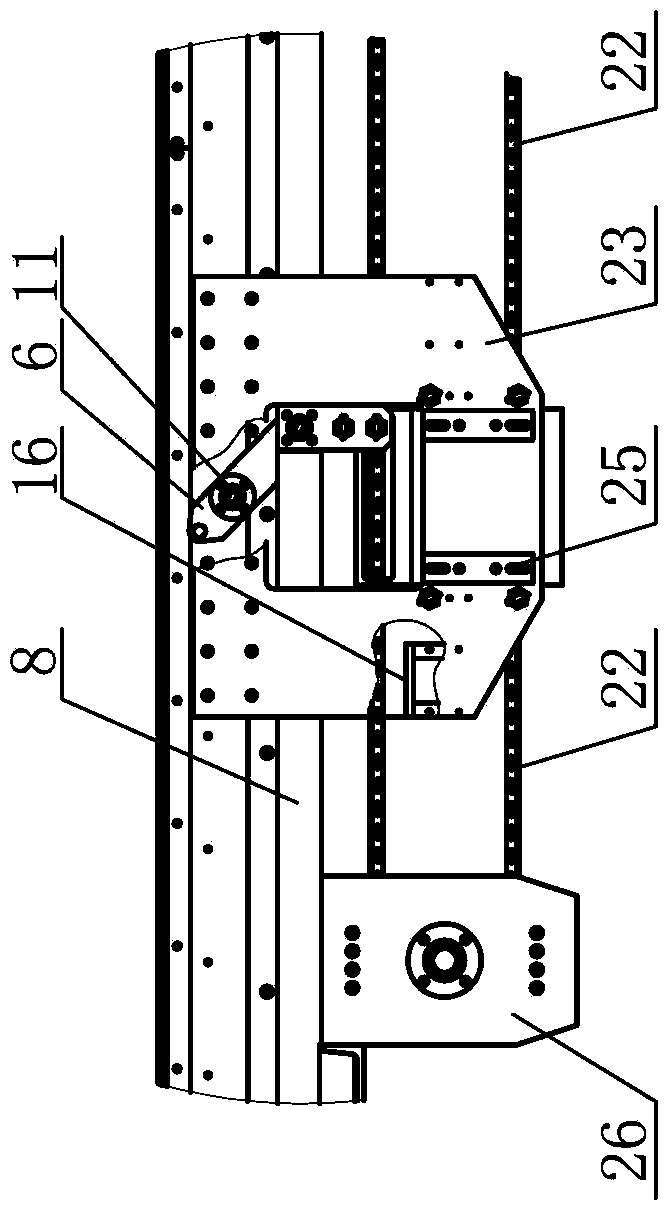

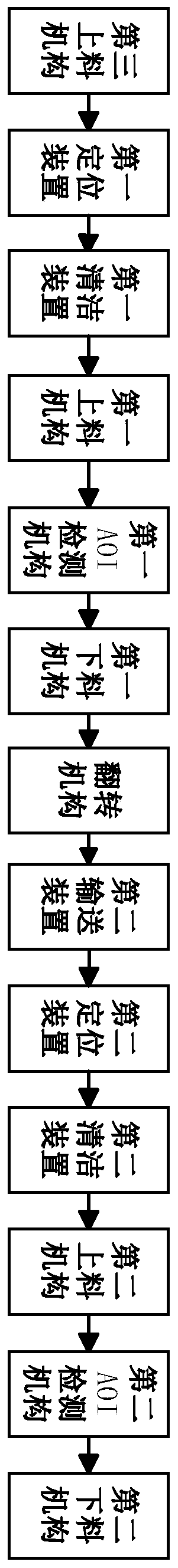

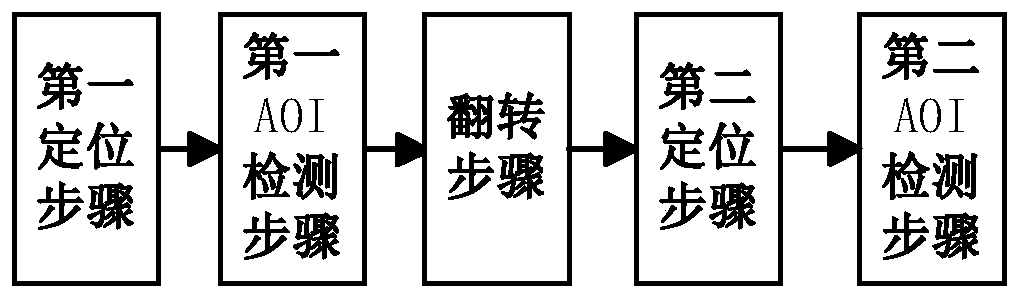

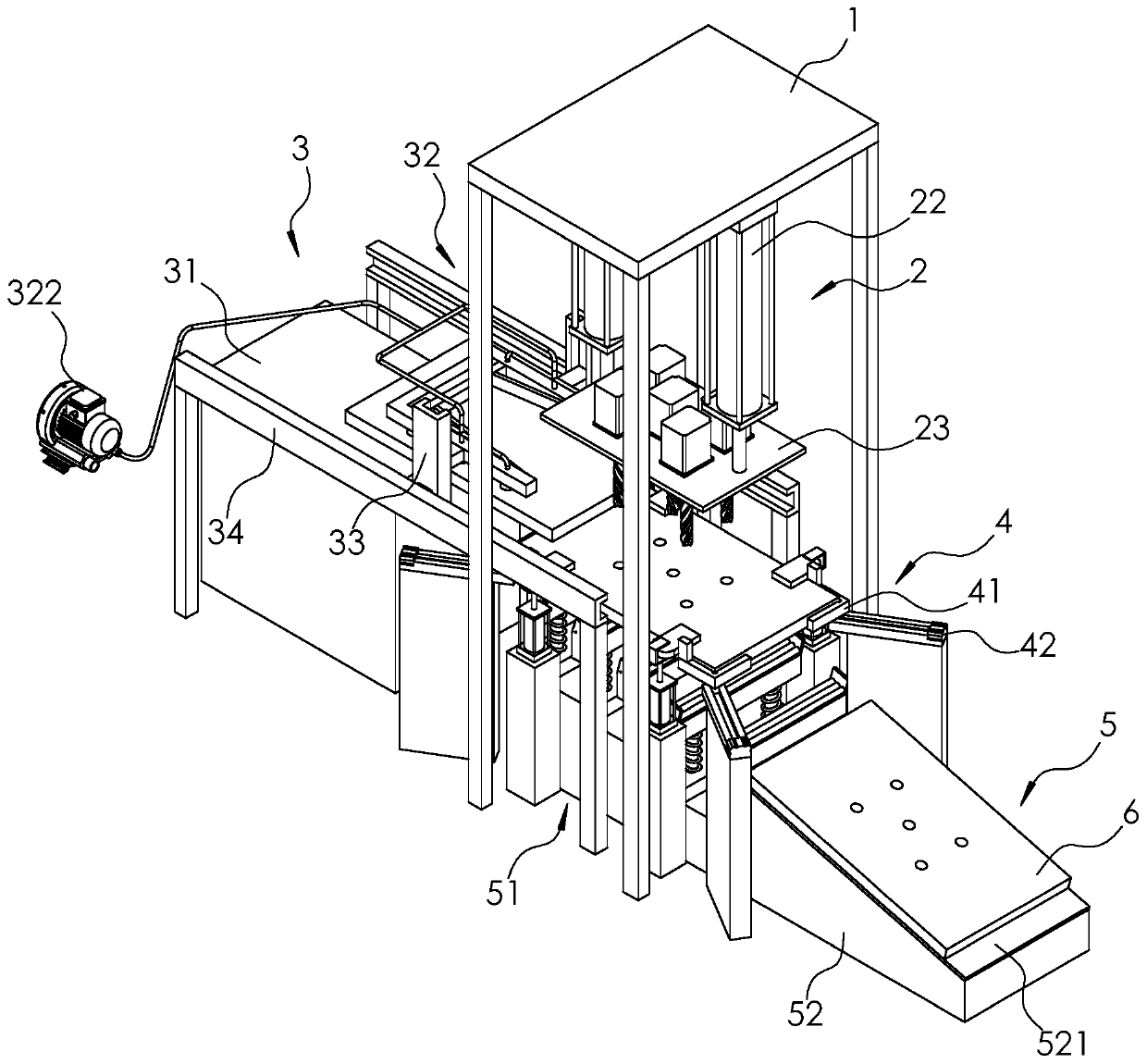

AOI detection method and system

InactiveCN110160959AImprove detection efficiencyOvercoming the technical problem of low detection efficiencyOptically investigating flaws/contaminationConveyor partsJob difficultiesAssembly line

The invention discloses an AOI detection method and system. The AOI detection system comprises a first positioning device, a first feed mechanism, a first AOI detection mechanism, a first blanking mechanism, an overturning mechanism, a second positioning device, a second feed mechanism, a second AOI detection mechanism and a second blanking mechanism which are arranged in order; the AOI detectionis performed on two surfaces of a circuit board in order, thereby realizing the assembly line AOI detection way; due to the work division, the job difficulty is simplified, the job degree of proficiency is easy to improve, and partial internal time is converted into external time, the AOI detection efficiency is effectively improved, and the maximum capacity is improved. The technical problem thatthe AOD detection efficiency is low in the prior art is overcome; and the AOI detection method effectively improves the AOI detection efficiency through the assembly line type AOI detection flow.

Owner:深圳明阳电路科技股份有限公司

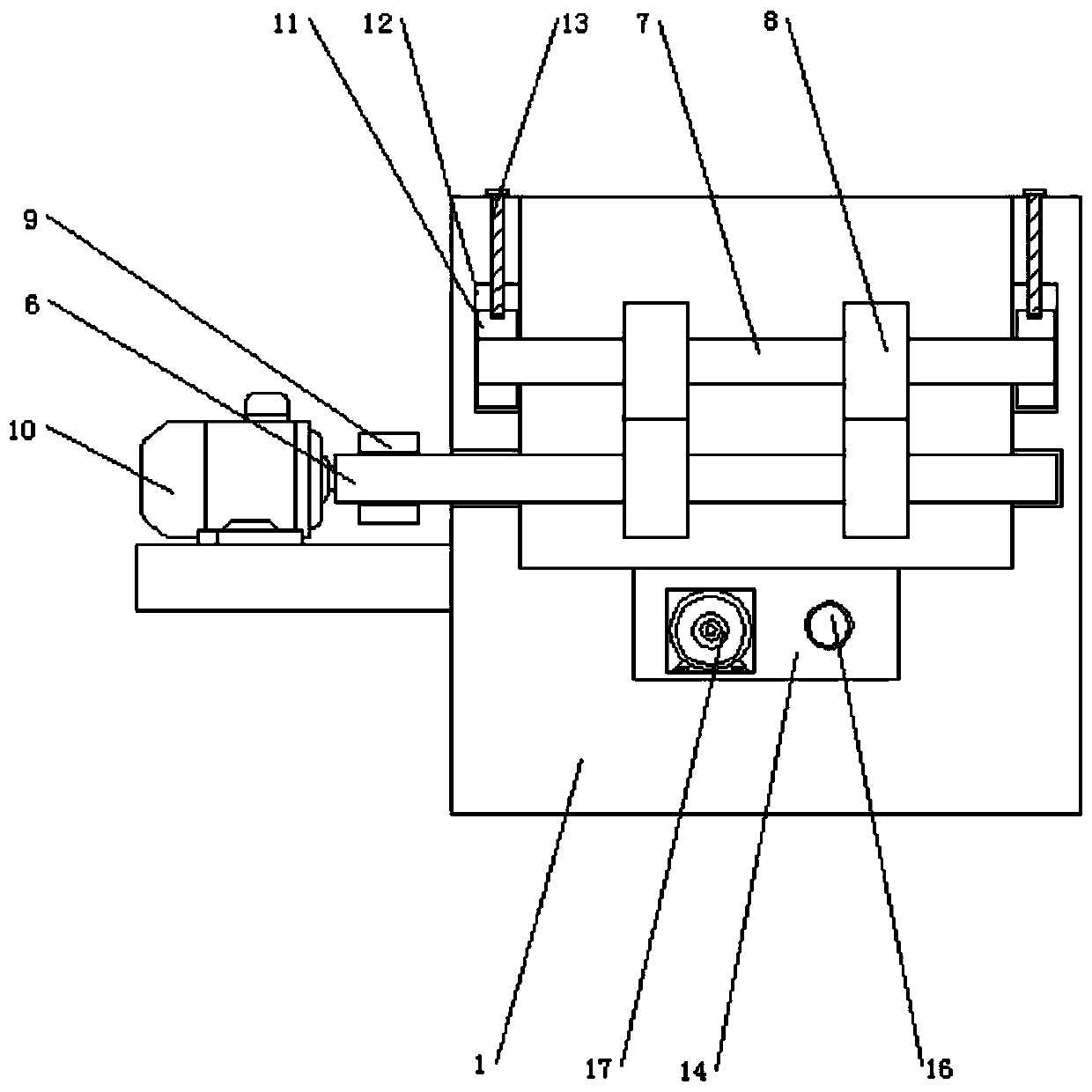

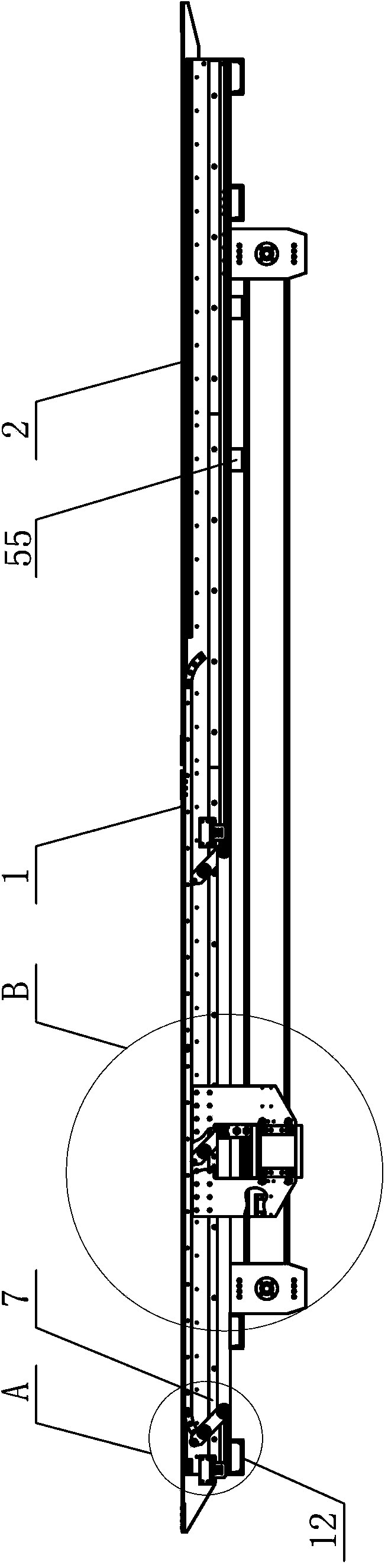

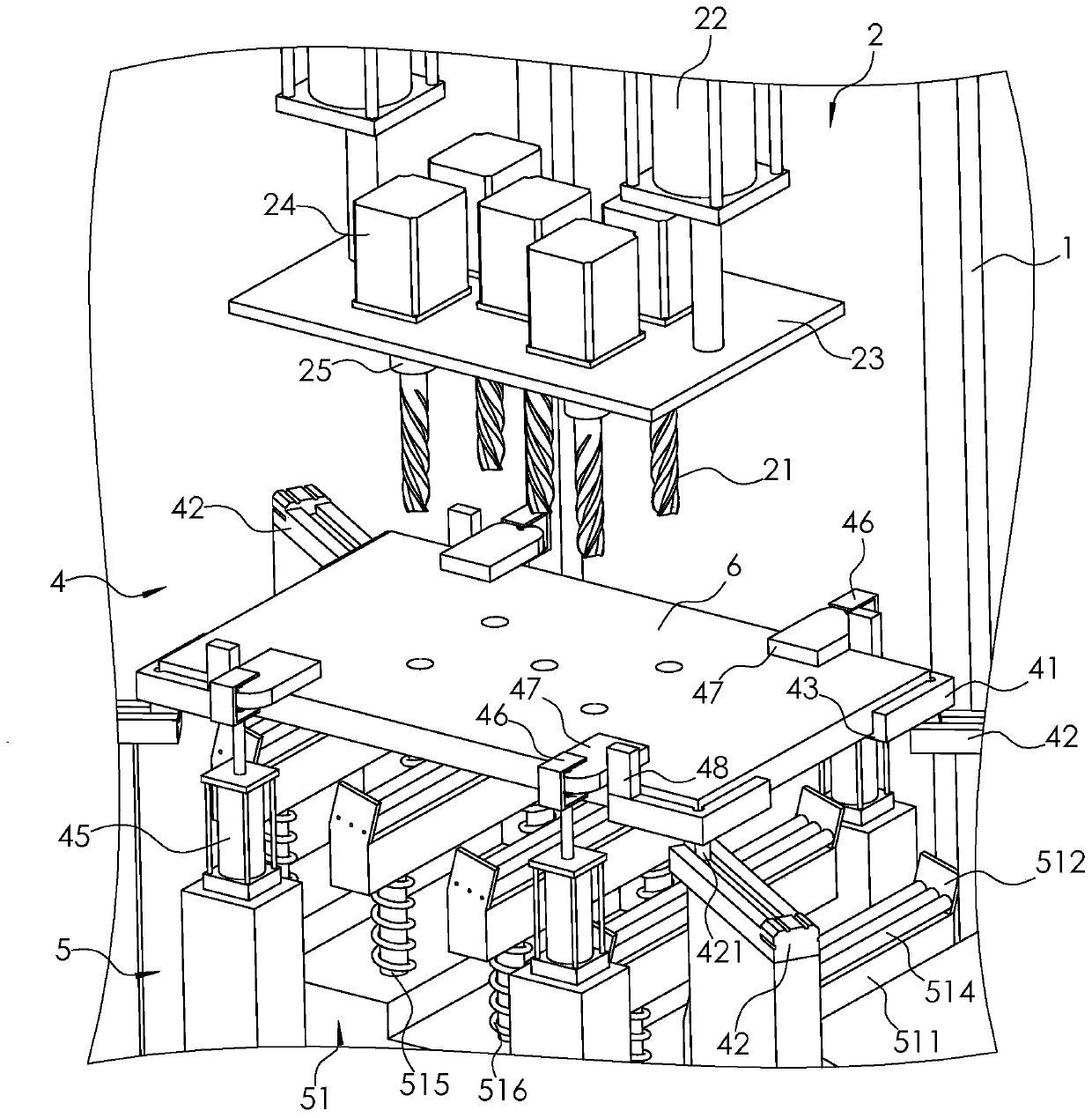

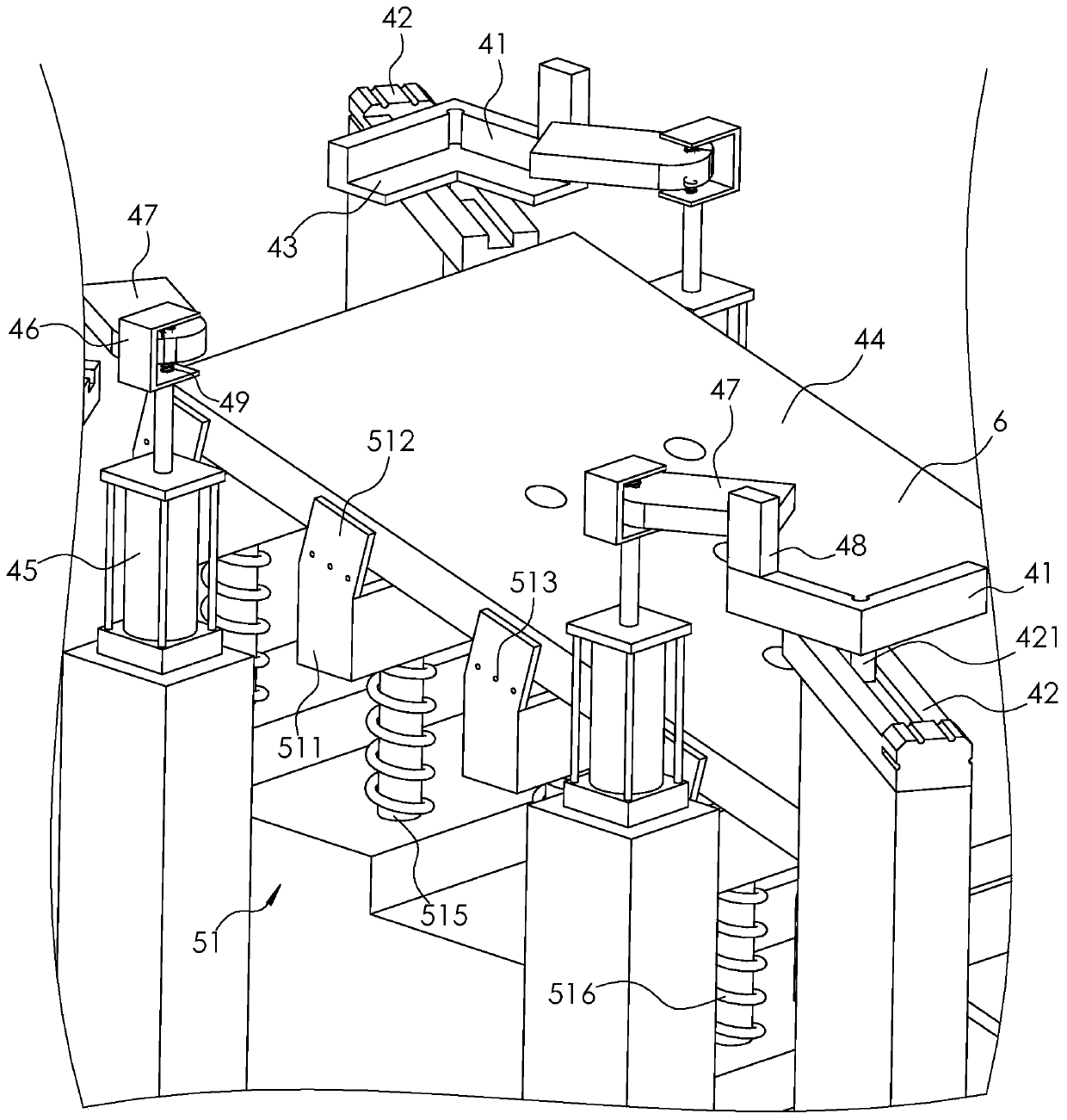

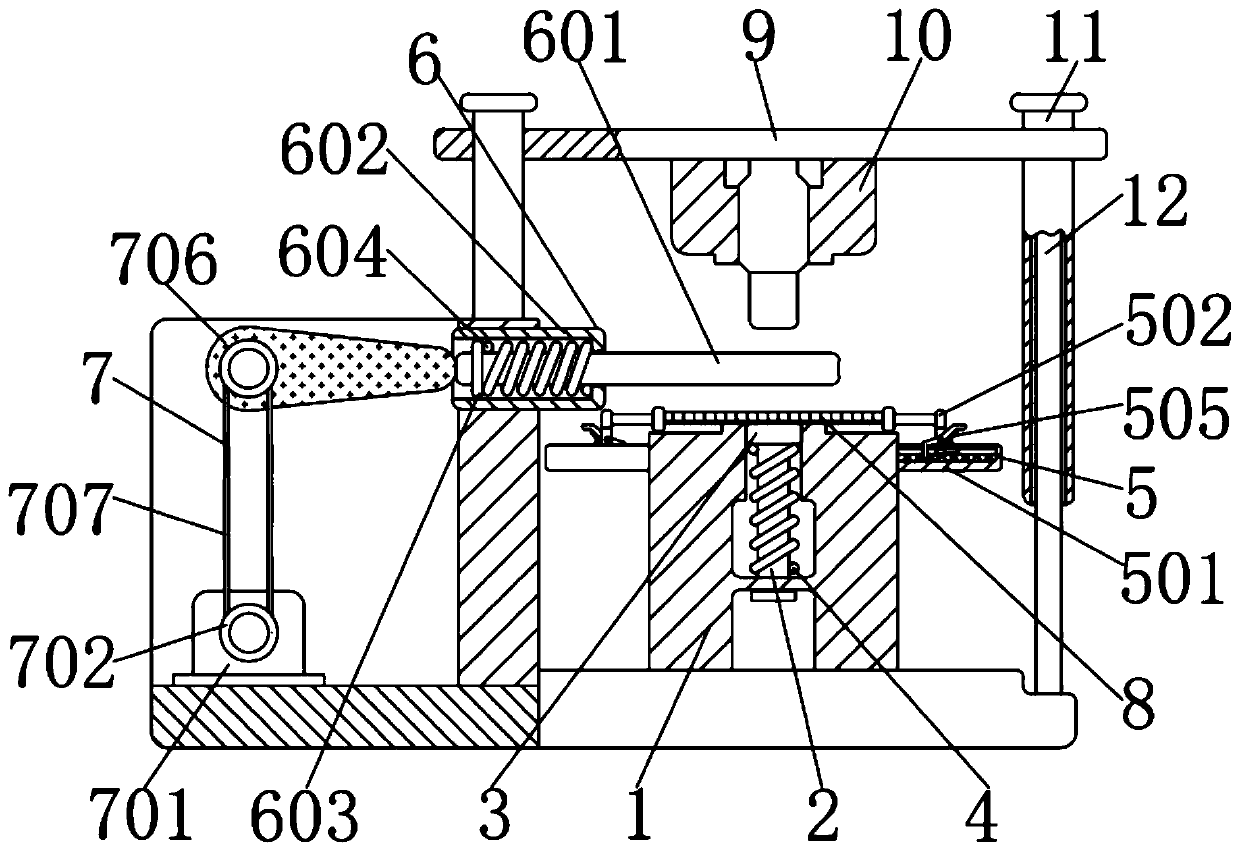

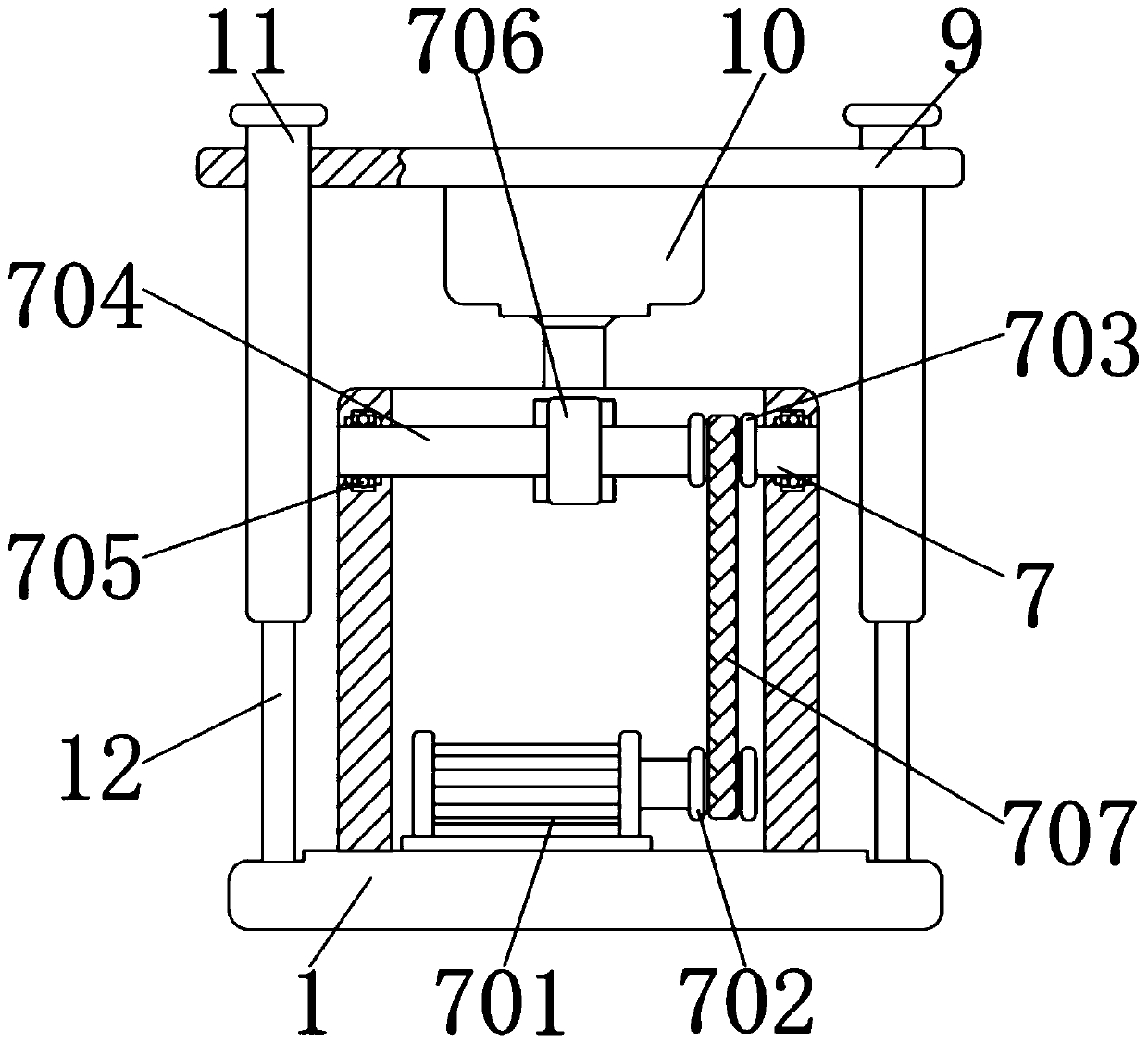

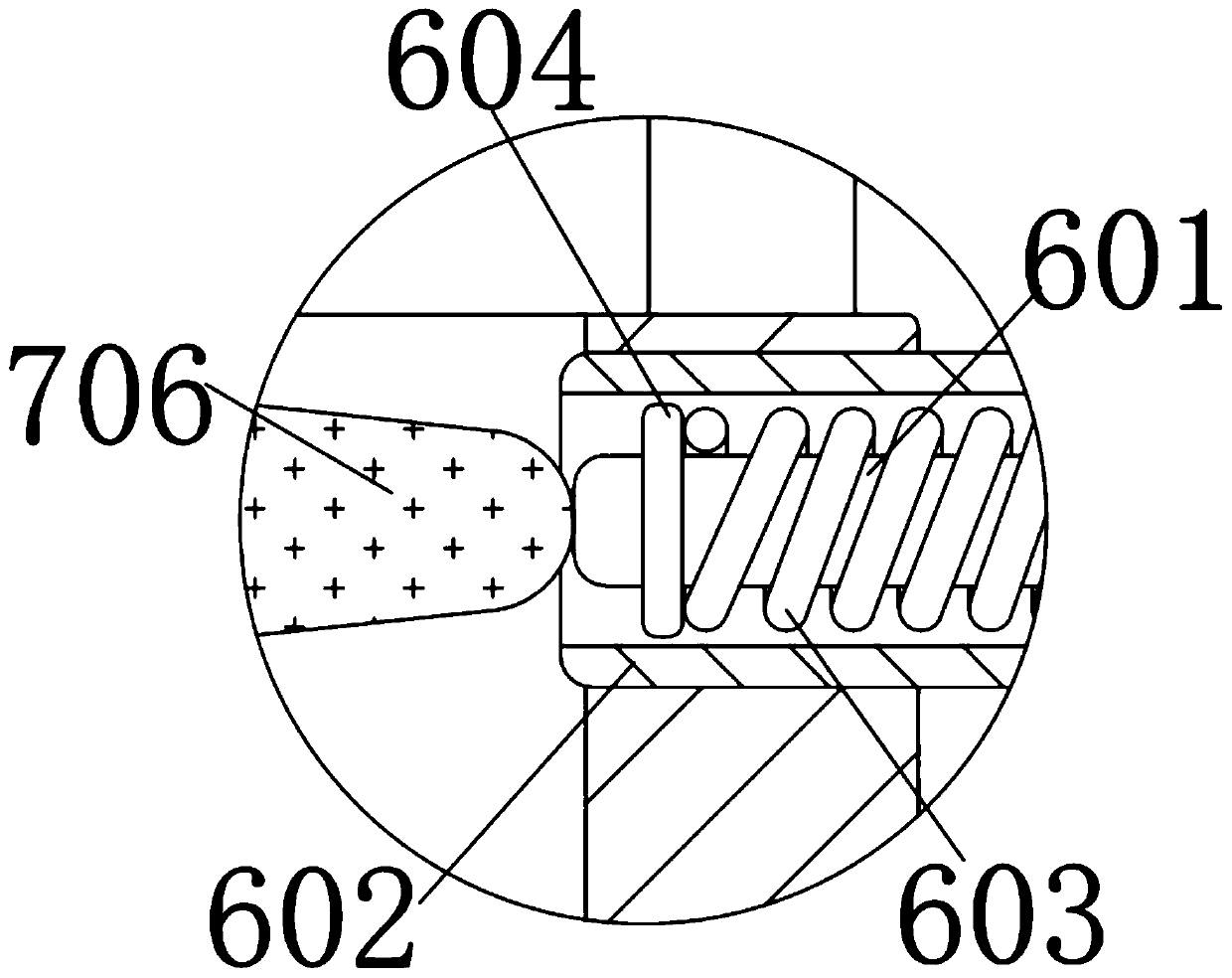

High-efficiency drilling machine

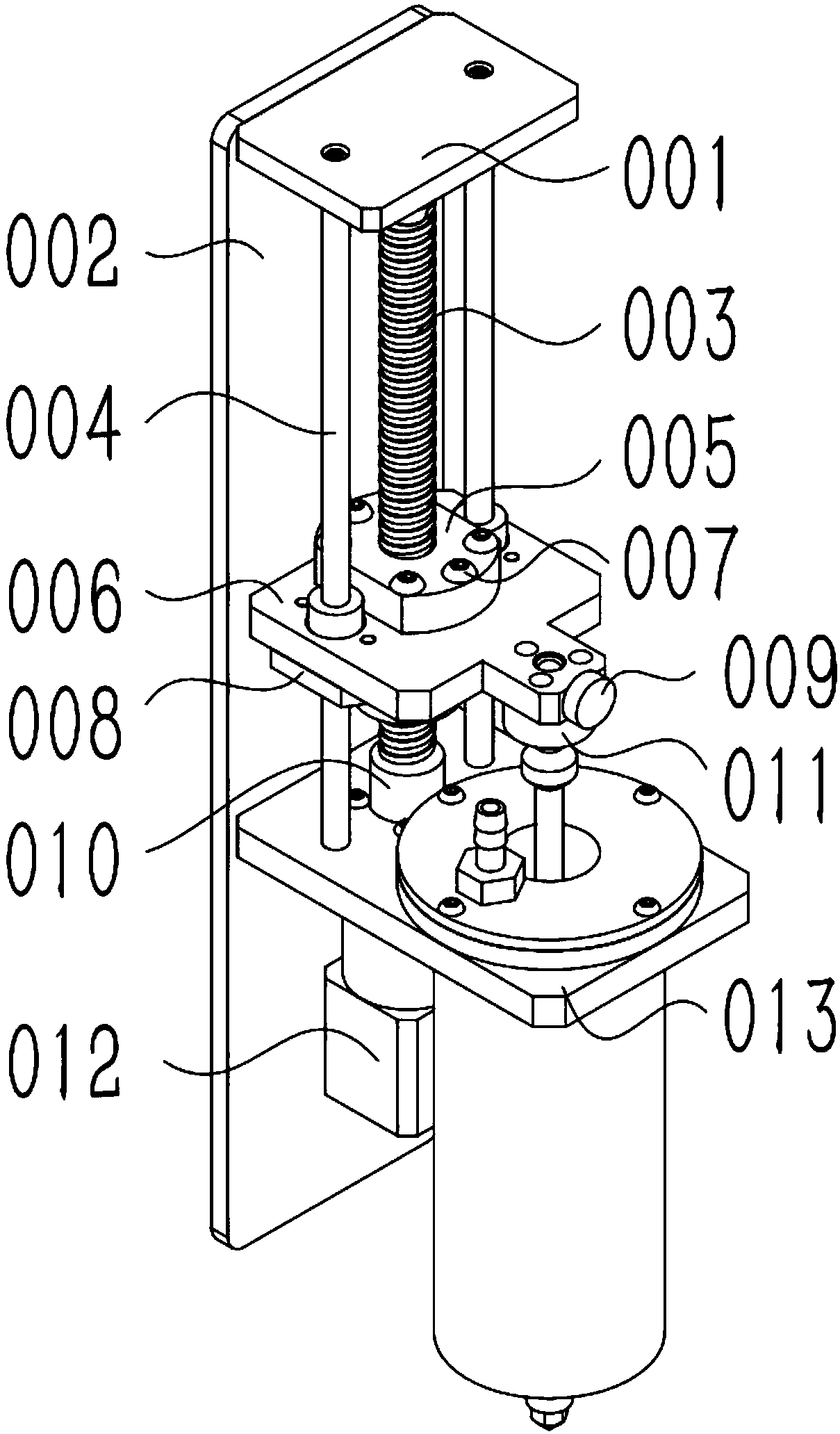

ActiveCN111203560AReduce the overall heightSave refueling timeWork clamping meansPositioning apparatusPhysicsSteel plates

The invention relates to a high-efficiency drilling machine. The high-efficiency drilling machine comprises a rack. A machining device, a material replacing device and a clamping device are arranged on the rack. The machining device comprises a plurality of drill bits, a plurality of rotary parts and a lifting assembly. The material replacing device comprises a standby material platform, a vacuumadsorption assembly, a vertical moving assembly and a horizontal moving assembly. The clamping device comprises four clamping plates and four driving assemblies. Supporting plates are fixed to the bottoms of the four clamping plates. When the driving assemblies drive the clamping plates to get away from the center of a steel plate, the four supporting plates define a falling cavity. A guide deviceis arranged below the falling cavity. When the high-efficiency drilling machine completes drilling of the steel plate, the driving assemblies drive the clamping plates to enable the steel plate to fall off from the falling cavity, the horizontal moving assembly and the vertical moving assembly drive and place a standby material onto the supporting plates gathering towards the center of the standby material, then the four clamping plates jointly clamp the standby material, and the whole material replacing process can be completed just within 10 s. The high-efficiency drilling machine substantially improves the machining efficiency of the steel plate.

Owner:杭州现代机械有限公司

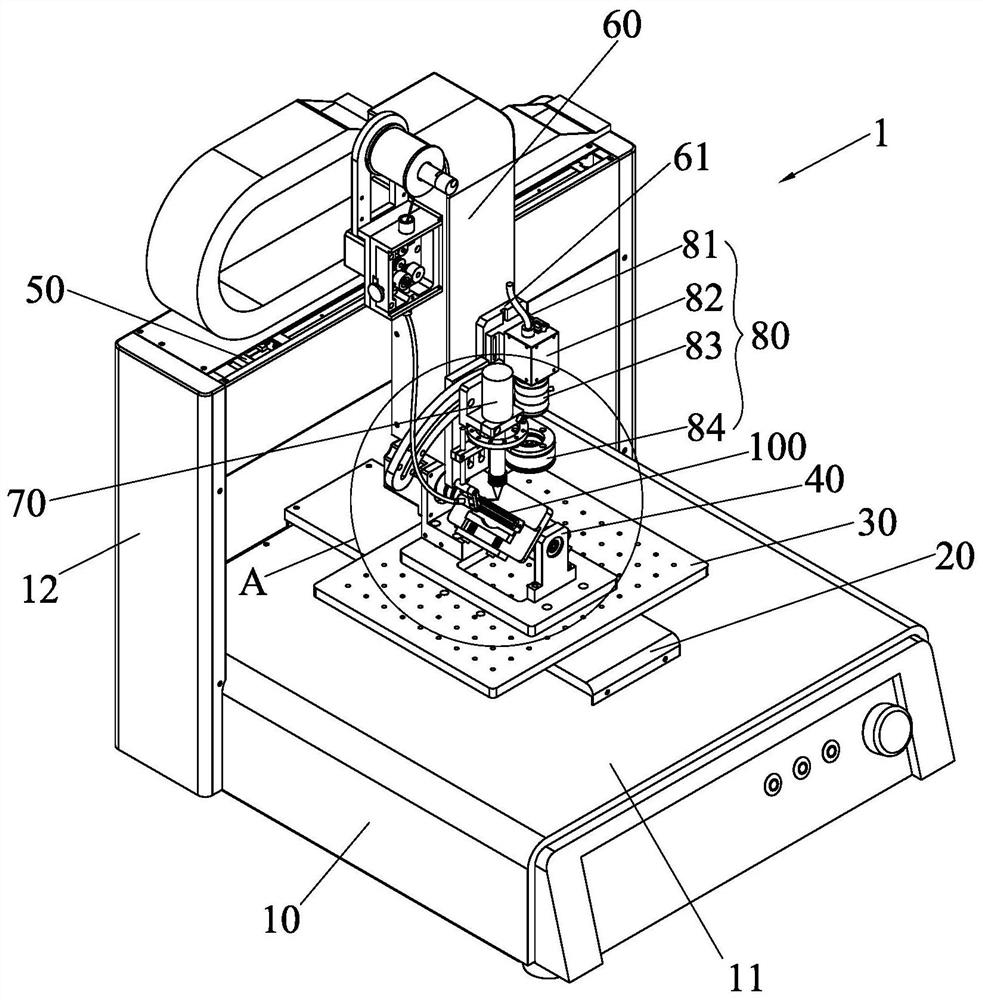

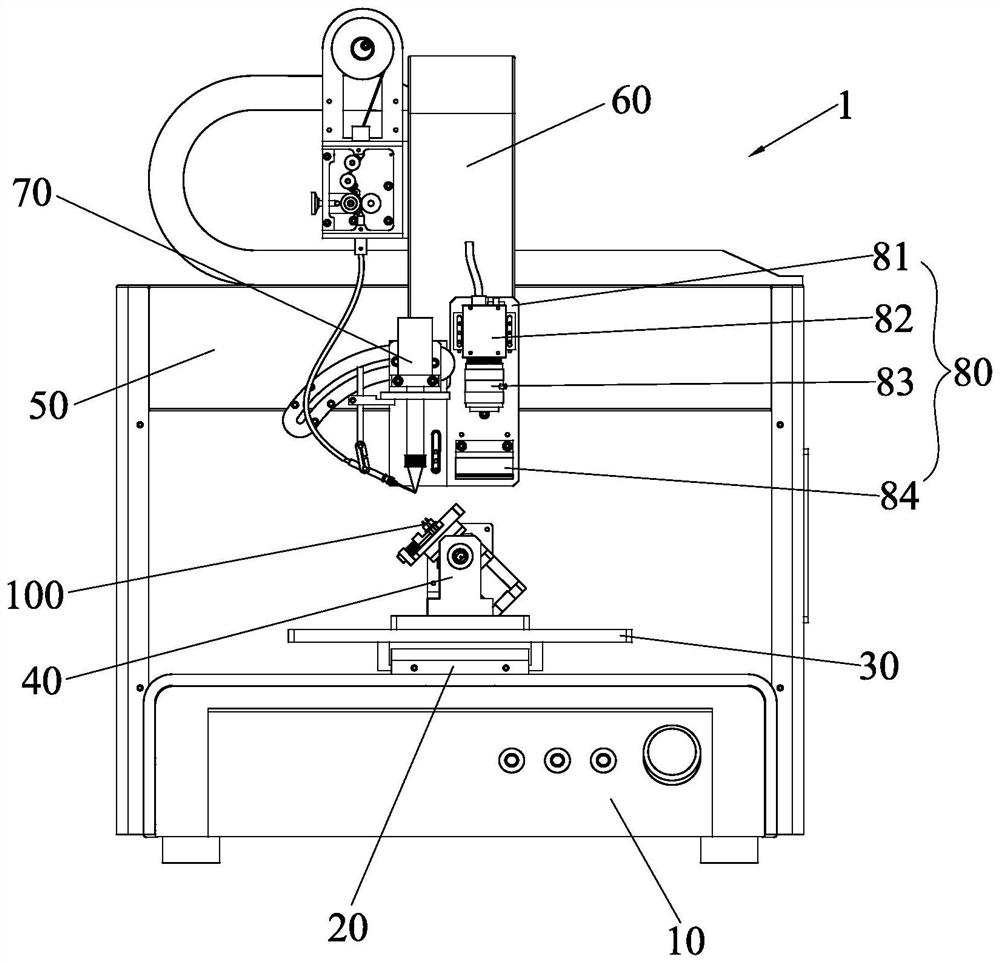

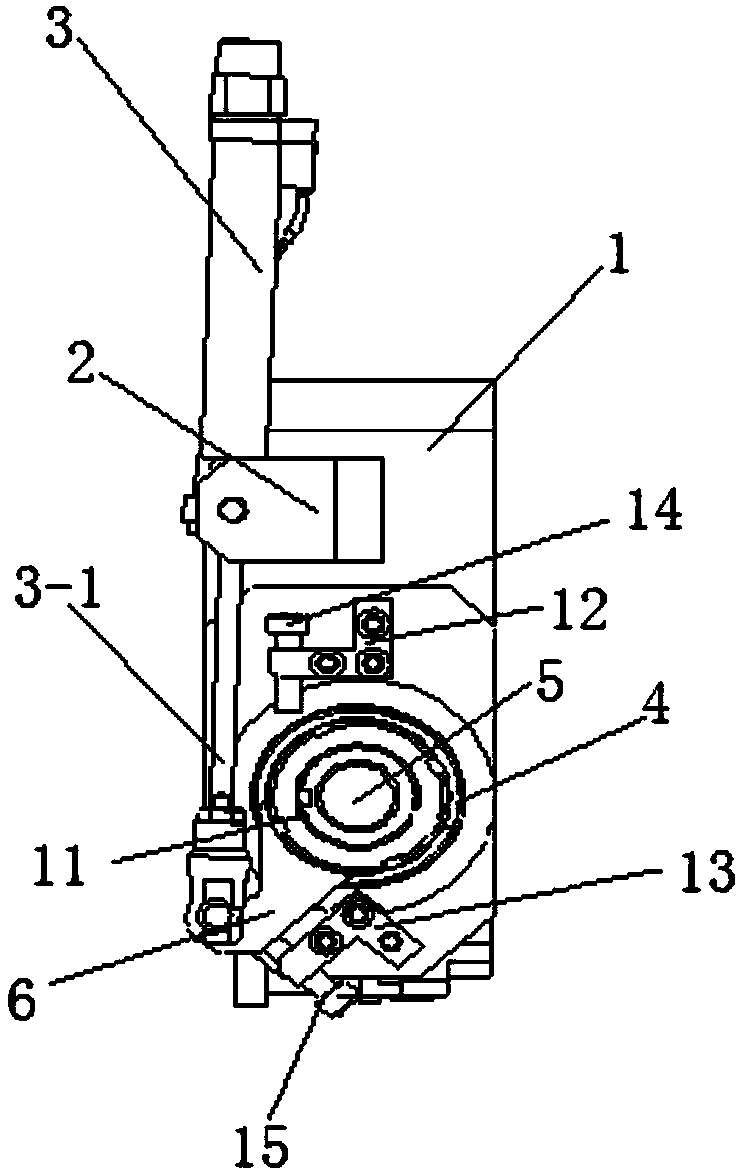

Table type soldering iron tin soldering equipment

PendingCN112170999AReduce use costReduce maintenance costsMetal working apparatusSolder feeding devicesEngineeringCamera module

The invention discloses table type soldering iron tin soldering equipment. The equipment comprises a machine box, a Y-axis linear module, a movable carrying table, a positioning and rotating mechanism, an X-axis linear module, a Z-axis linear module, a soldering iron tin soldering assembly and a camera module, the Y-axis linear module is arranged on a workbench of the machine box, the movable carrying table is arranged on the Y-axis linear module and can move forwards and backwards along with the Y-axis linear module, the positioning and rotating mechanism is arranged on the movable carrying table, the X-axis linear module is arranged above the workbench, the Z-axis linear module is arranged on the X-axis linear module, and the soldering iron soldering tin assembly and the camera module are arranged on the Z-axis linear module. A convenient table type structure is adopted, the equipment cost is low, and the placement position can be flexibly adjusted according to the layout of a plant;and a soldering iron soldering process is adopted, the process is mature, soldering iron use and maintenance cost is low, and tin soldering quality of products can be well guaranteed by replacing soldering iron according to the service life of the soldering iron.

Owner:厦门柔性电子研究院有限公司 +2

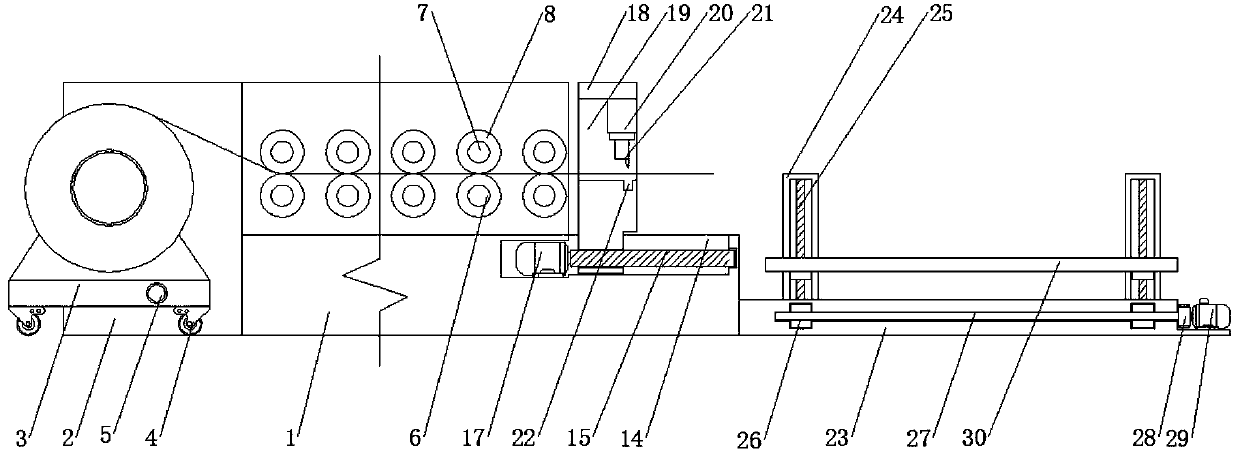

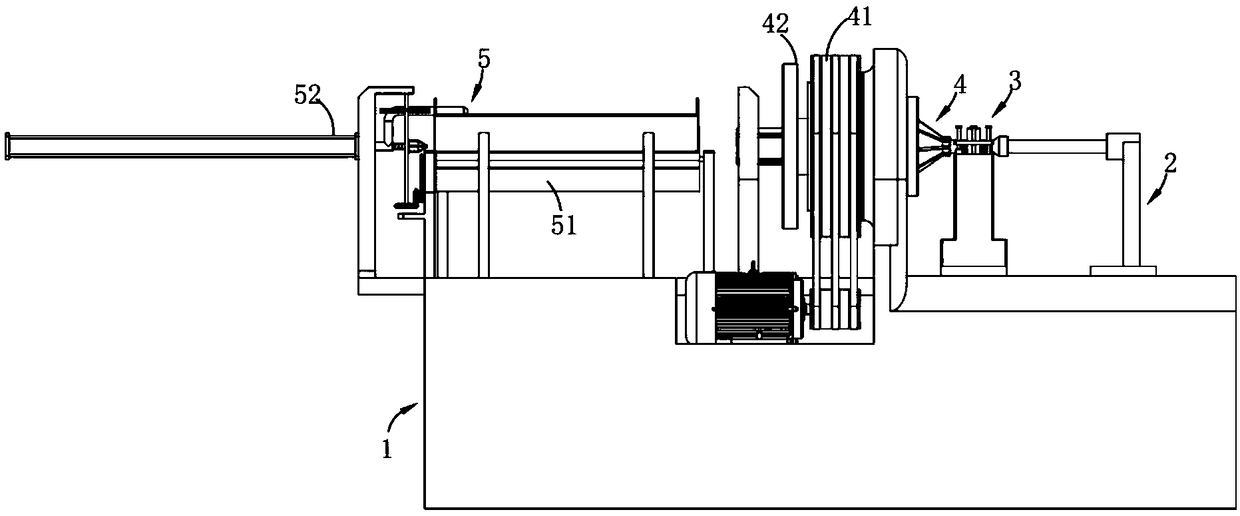

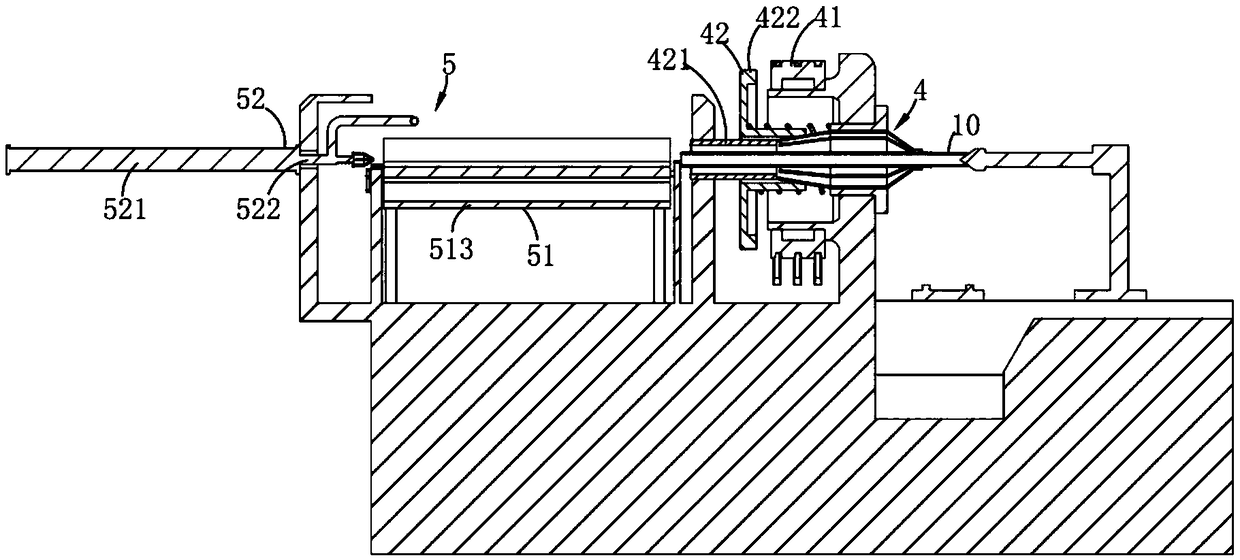

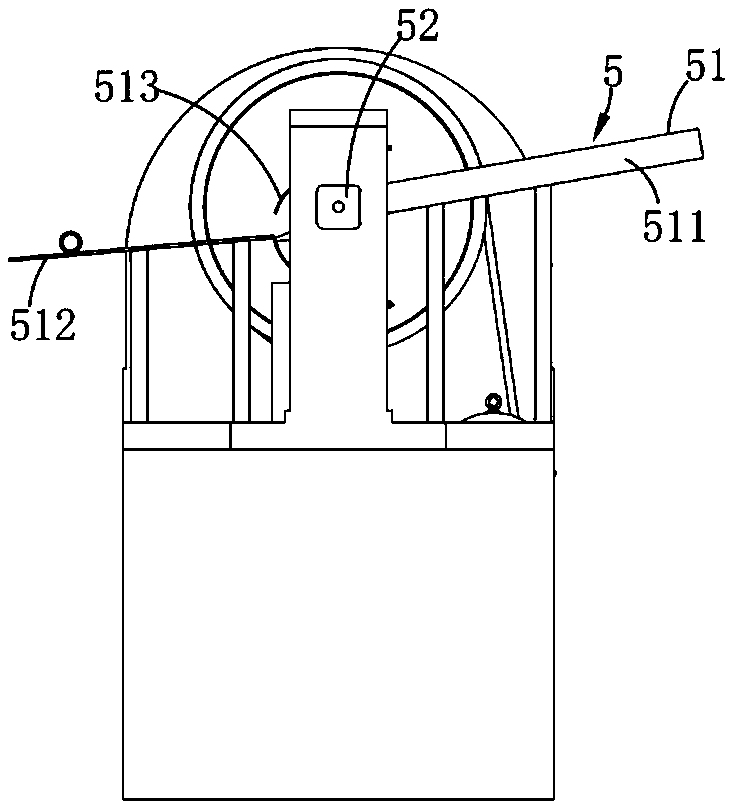

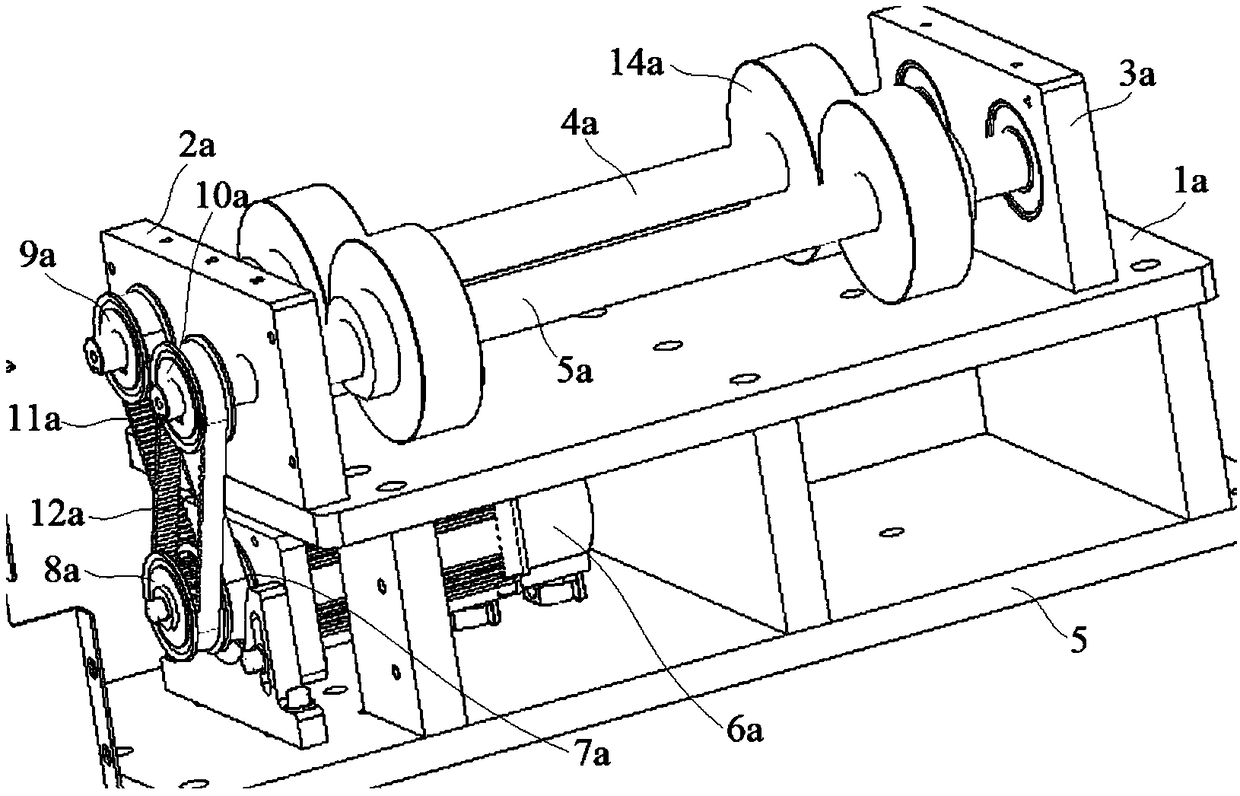

Automatic processing equipment for metal tubes

InactiveCN108838408AAchieve step upRapid positioningTailstocks/centresWorkpiecesAutomatic test equipmentReciprocating motion

The invention relates to the technical field of tube processing and production, in particular to automatic processing equipment for metal tubes. The automatic processing equipment comprises a lathe bed, a tip cone, a turning mechanism and a clamping mechanism, wherein the clamping mechanism comprises a power assembly, a clamping assembly comprises a jacket which is rotatably arranged in the powerassembly and a pretightening part which is used for extruding the jacket so as to press a workpiece located in the jacket, and the pretightening part makes intermittent contact with the power assemblyso as to synchronously drive the workpiece to rotate to be turned by the turning mechanism; a feed mechanism comprises a feed part which communicates with the jacket and a push assembly which is located on one end of the feed part so as to transfer the workpiece located in the feed part into the jacket in a reciprocating mode, and the pretightening part is driven to make intermittent contact withthe power assembly by the push assembly. In the process that a steel tube is directionally transferred by the push assembly, the workpiece is pressed by a fixture, and a jacking part makes contact with the power assembly, so that the workpiece rotates, and the technical problem of low turning production efficiency in the prior art is solved.

Owner:长兴新亚环保机械科技股份有限公司

Punching device for processing disposable food box mould

The invention discloses a punching device for processing a disposable food box mould. The punching device comprises a base and support legs arranged on the both sides of the lower end of the base, andthe lower end of each support leg is provided with a support block; a collection box is arranged between the right and left support legs, and the both sides of the collection box are connected with the support legs through locating rods fixedly; a top plate is arranged above the base, and the left lower side of the top plate is connected with the base through a support column fixedly; the base isprovided with a lower mould assembly used for placing a foot box to be machined, and the upper end of the top plate is provided with a lifting hydraulic cylinder; the output end of the lifting hydraulic cylinder is connected with an upper mould assembly corresponding to the lower mould assembly; and the upper mould assembly comprises a horizontal plate connected with the output end of the liftinghydraulic cylinder and arranged horizontally. The punching device is designed for overcoming the shortcomings of an existing device, and switching between drill bits can be achieved, thereby facilitating processing of different holes in a workpiece; the reloading time can be shortened, so that the processing efficiency of the device is improved; and the practicability is high.

Owner:福建榕丰塑胶有限公司

Clean-type two-jaw breaking grinding machine and control system thereof

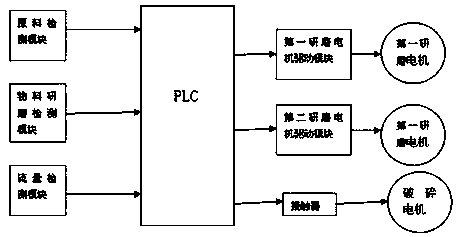

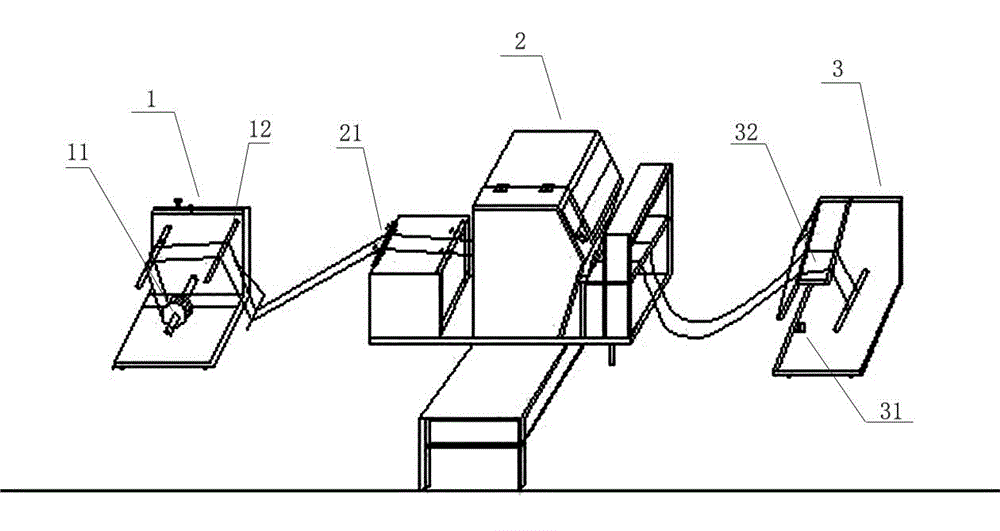

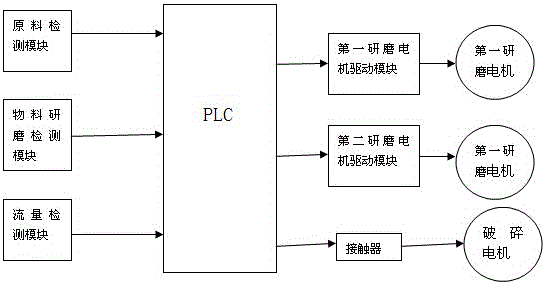

InactiveCN108325692AAchieve a brokenAchieve secondary crushingUsing liquid separation agentDirt cleaningMotor driveControl system

The invention discloses a clean-type two-jaw breaking grinding machine and a control system thereof. The clean-type two-jaw breaking grinding machine comprises a breaking stationary jaw, a first breaking movable jaw, a first breaking flywheel, a breaking motor, a second breaking movable jaw, a second breaking flywheel, a first grinding motor, a first grinding main shaft, a first grinding disc, a second grinding motor, a second grinding main shaft, a second grinding disc, a rack, a breaking discharge channel, a grinding discharge channel, a discharge hopper, a dust hopper, an air pump and a dust collecting box; and the control system consists of a raw material detection module, a material grinding detection module, a flow detection module, a PLC, a first grinding motor driving module, a second grinding motor driving module and a contactor. The clean-type two-jaw breaking grinding machine can achieve primary breaking, secondary breaking and grinding on a raw material, so that the degreeof size reduction of the raw material is raised, and the breaking time is shortened; and the air pump can be started during machining to suck dust, so that the cleaning property and safety are improved.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Full-automatic bar code printing and detecting equipment

InactiveCN102744980AOvercome spaceOvercome lengthTypewritersOther printing apparatusWinding machineEngineering

The invention discloses full-automatic bar code printing and detecting equipment. The full-automatic bar code printing and detecting equipment is characterized by comprising the following members of a feeding machine, a bar code printer and an automatic winding machine, wherein the feeding machine is provided with a material scroll and a plurality of pull rods; the wound printing material is assembled on the material scroll; feed paper bypasses from the upper parts or the lower parts of the pull rods to be flatted by stretching and the material scroll is connected with a driving device; and bar code detecting equipment is arranged on the bar code printer. The independent feeder is arranged on the full-automatic bar code printing and detecting equipment disclosed by the invention, so that the problem that the storage space of an integrated machine is limited is solved; and due to the arrangement of feeding drive, the condition that the drawing is difficultly realized by only using the winding machine due to over great and over weight of materials is avoided. Meanwhile, the bar code detecting equipment is arranged for further avoiding the conditions of double signs, sign leakage, sign error and the like; and the full-automatic bar code printing and detecting equipment has the advantages of long one-time printing length, fewer material connectors and low printing mistaken rate.

Owner:银河包装科技(昆山)有限公司

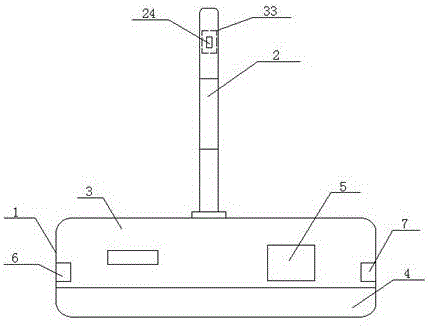

Automatic loading and unloading mop

ActiveCN106166052AAvoid pollutionAvoid damageCarpet cleanersFloor cleanersMechanical engineeringEngineering

The invention discloses an automatic loading and unloading mop. The mop comprises a mop head and a mop handle mutually connected. A power cavity is formed in the upper portion of the mop head and internally provided with a PLC, the lower portion of the mop head is provided with a cleaning cavity, a loading box and an unloading box are symmetrically installed on the front side and the rear side of the cleaning cavity respectively, the loading box and the unloading box are internally provided with a first coiling bar and a second coiling bar respectively, a first rolling shaft and a second rolling shaft are installed on the portion, between the loading box and the unloading box, of the cleaning cavity, the two sides of the cleaning box are provided with a sliding rail I and a sliding rail II respectively, and a sliding piece assembly I and a sliding piece assembly II are arranged on the sliding rail I and the sliding rail II respectively. Limited space of the mop head is reasonably used, and automatic replacement of wet wipes is achieved by means of additional arrangement of the loading box, the unloading box and a power device; compared with traditional manual wet wipe replacement, replacement time is greatly shortened; finger injuries caused by manual pressing and other phenomena are avoided, and cost is greatly reduced.

Owner:临沂高新物业管理有限公司

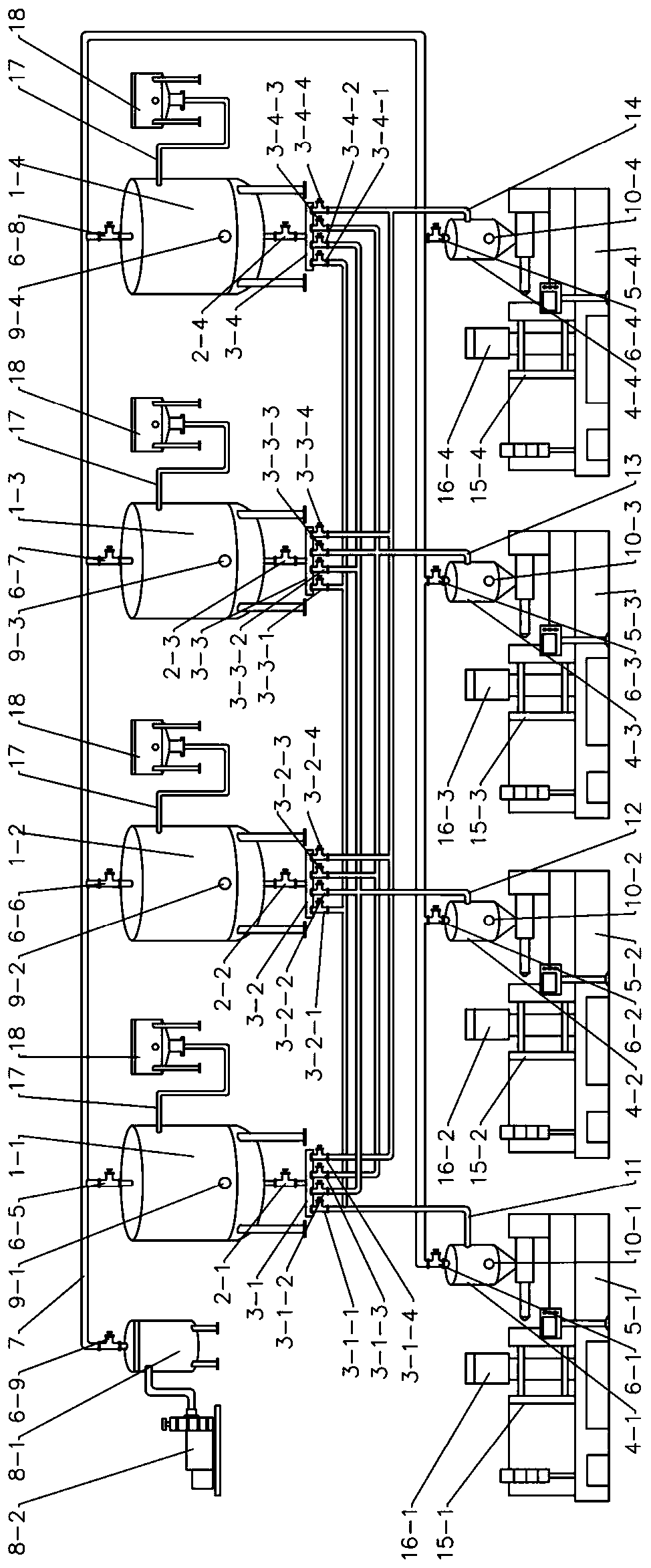

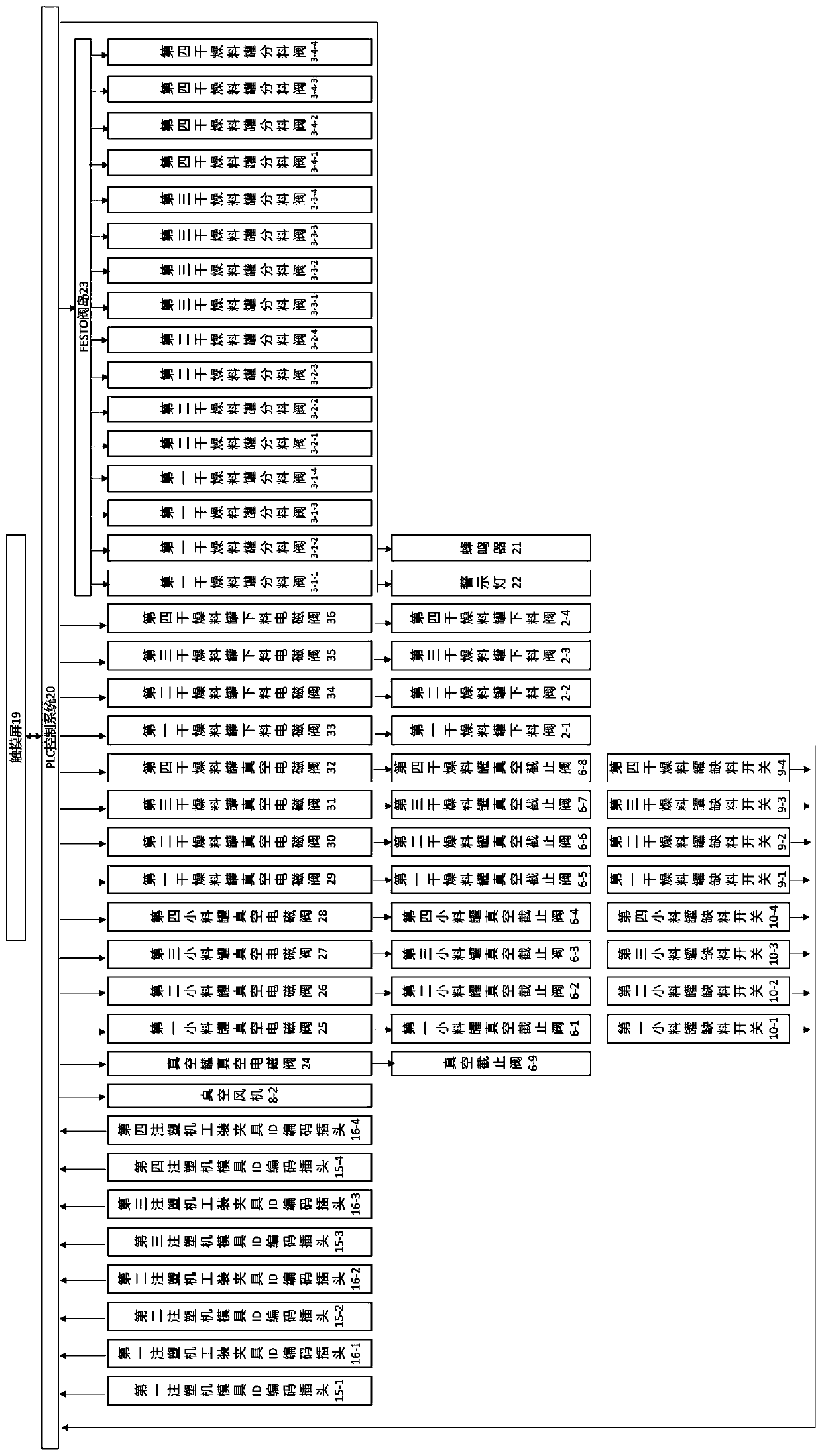

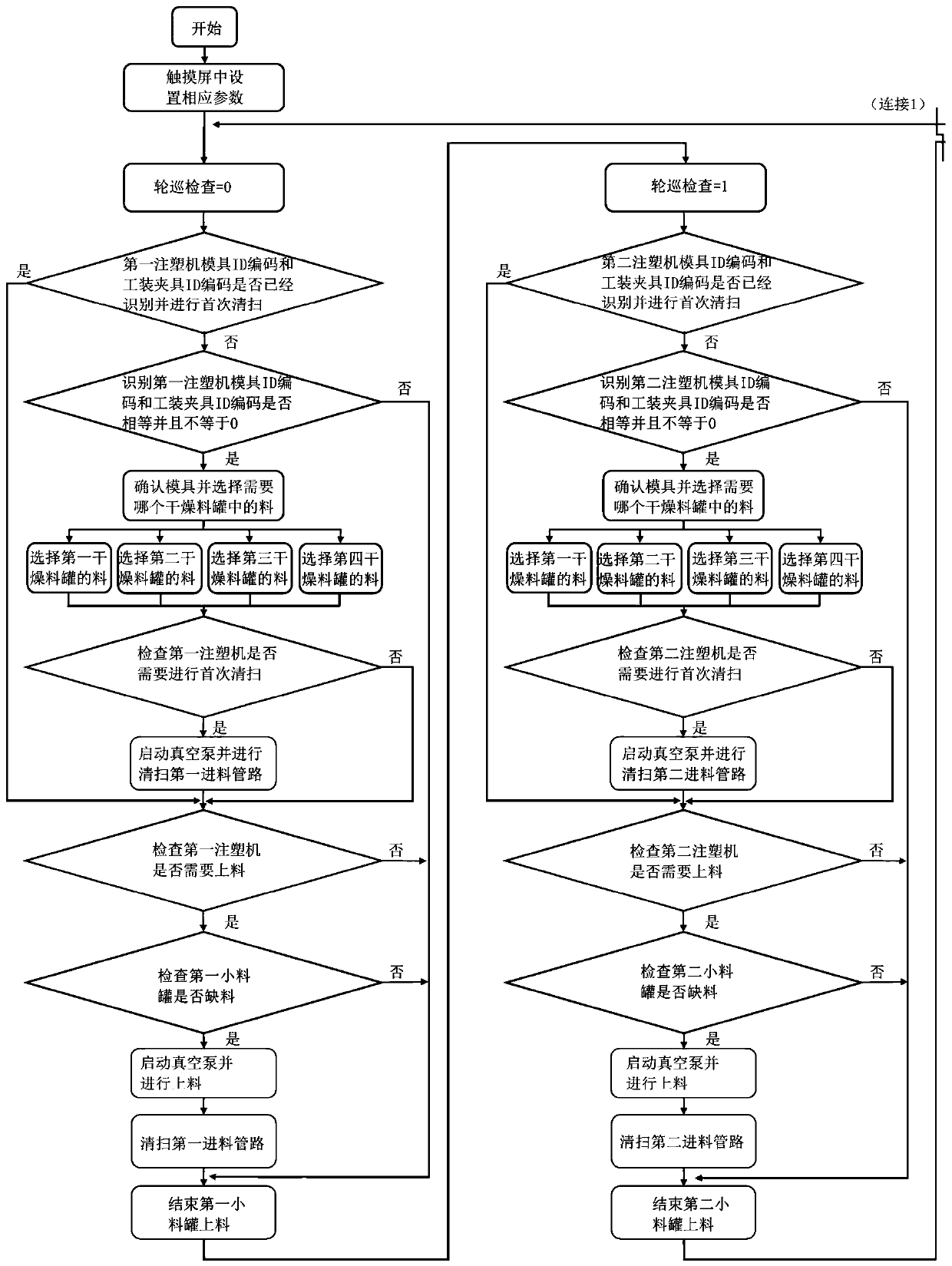

Automatic selection feeding system of injection molding machine for automotive interior trim parts and control system thereof

The invention discloses an automatic selection feeding system of an injection molding machine for automotive interior trim parts and a control system thereof. The automatic selection feeding system ofan injection molding machine for automotive interior trim parts and the control system thereof solve the problems that in the prior art, automatic selection of raw materials cannot be carried out, the material changing process is too long in time consumption and low in efficiency, material changing errors are prone to occurrence, then products are scrapped, and the yield and quality are affected.The automatic selection feeding system of the injection molding machine for the automotive interior trim parts and the control system thereof are characterized in that a plurality of drying materialtanks are connected with small material tanks of a plurality of injection molding machines through material distributing valves and feeding pipelines, a mold ID coding plug and a tool clamp ID codingplug are installed at the mold installation end of each injection molding machine, and a PLC control system checks whether the injection molding machines and the drying material tanks lack materials or not in a sequential inspection mode and conducts feeding. The automatic selection feeding system of the injection molding machine for the automotive interior trim parts and the control system thereof have the beneficial effects that flexibility of the feeding mode is achieved, automatic raw material selection is achieved, manual operation is reduced, generation of mistaken selection of the raw materials of the injection molding machines are effectively prevented, continuous production and monitoring functions are achieved, the product production efficiency and the product quality are improved, the feeding mode is flexible, energy is saved, the consumption is reduced, single-time material changing time is saved, and the production efficiency is high.

Owner:SHENYANG JINBEI YANFENG AUTOMOTIVE INTERIOR SYST CO LTD

Double-jaw crushing and grinding machine and control system thereof

InactiveCN106607114AAchieve a brokenAchieve secondary crushingCocoaGrain treatmentsMotor driveControl system

The invention discloses a double-jaw crushing and grinding machine and a control system thereof. The machine comprises a fixed crushing jaw, a first moving crushing jaw, a first crushing fly wheel, a crushing motor, a second moving crushing jaw, a second rushing fly wheel, a first grinding motor, a first grinding spindle, a first grinding disk, a second grinding motor, a second grinding spindle, a second grinding disk, a rack, a crushing discharging chute, a grinding discharging chute and a discharging hopper. The control system comprises a raw material detection module, a material grinding detection module, a flow detection module, a programmable logic controller (PLC), a first grinding motor driving module, a second grinding motor driving module and a contactor. With the machine, primary crushing, secondary crushing and grinding of raw materials can be realized, the crushing degree of the raw materials is increased, and the crushing time is shortened.

Owner:罗浩

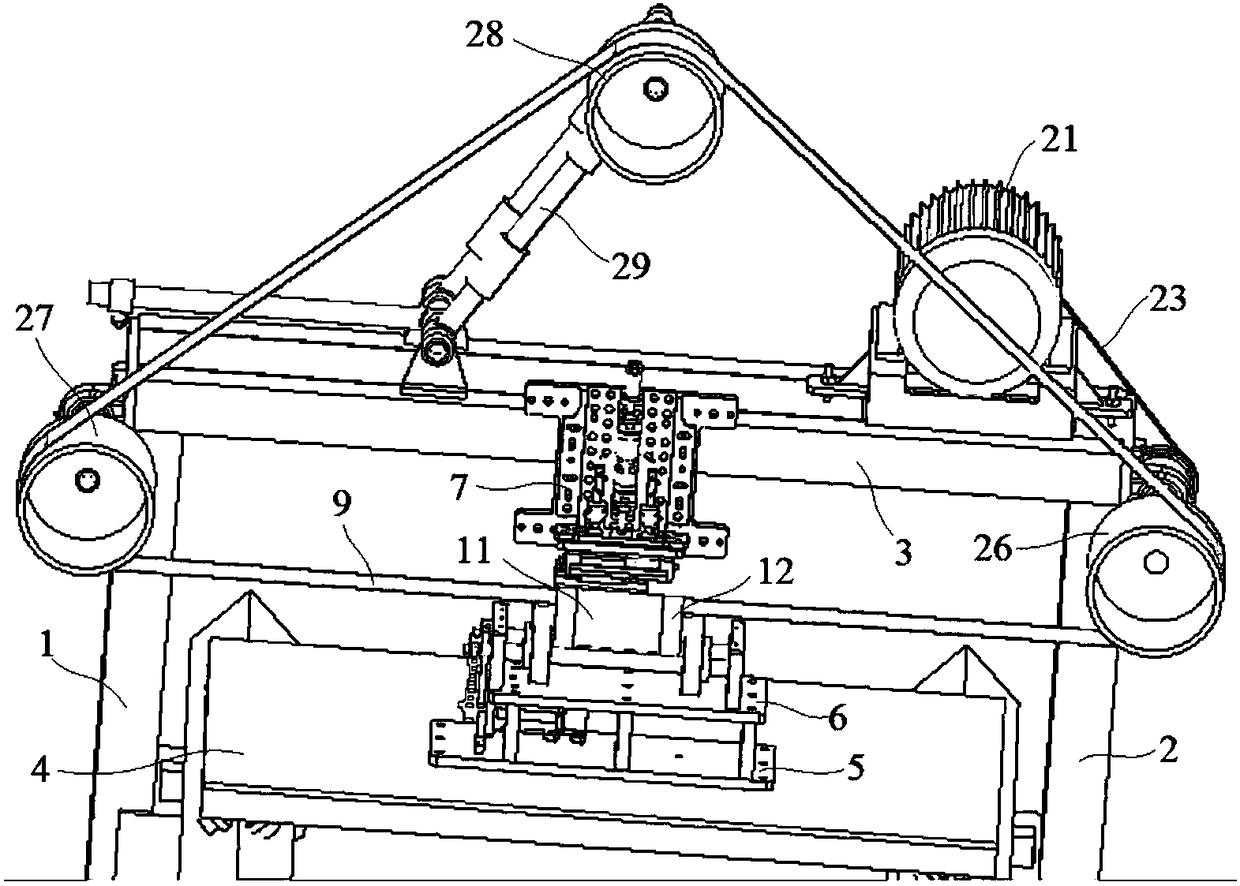

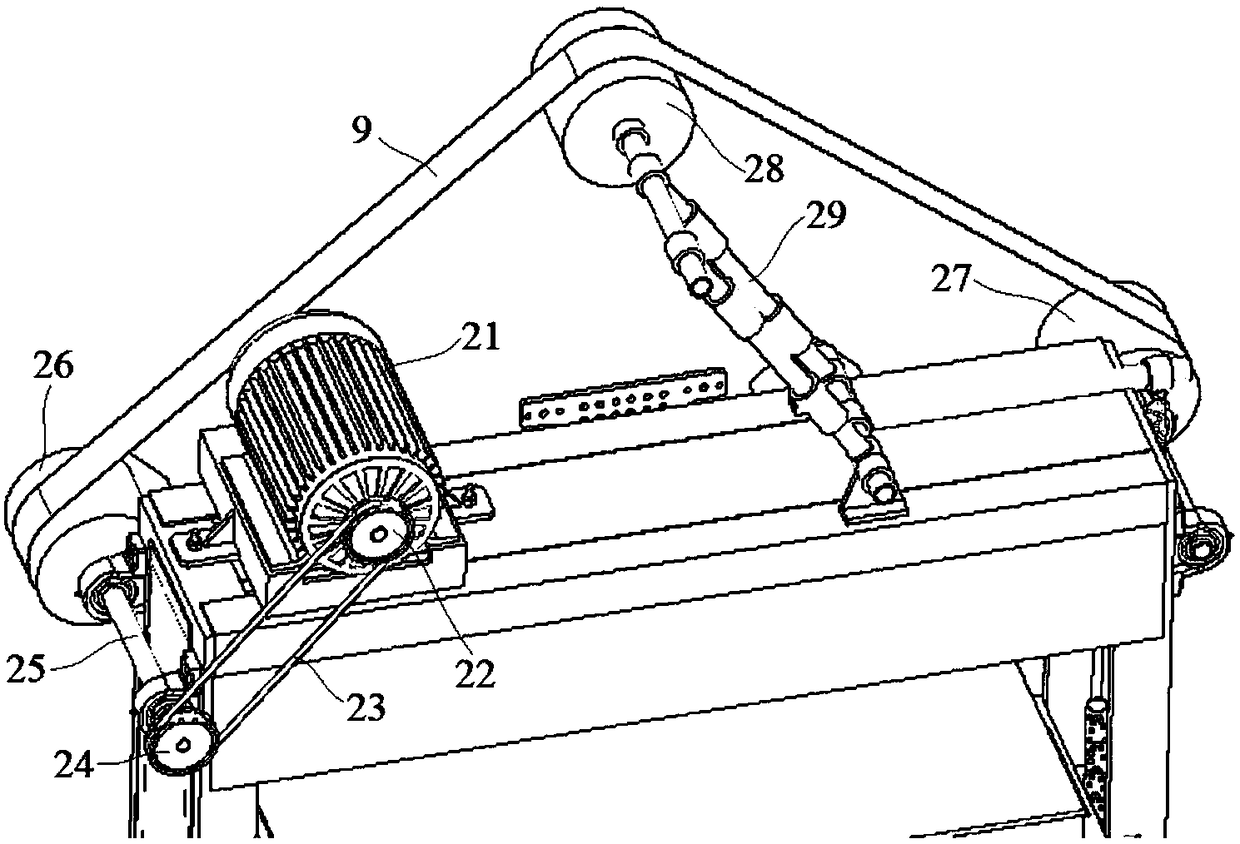

Automatic metal surface treatment device

ActiveCN108177061AAutomatic straight wire drawingGuaranteed drawing qualityGrinding drivesBelt grinding machinesDrive wheelPiston rod

The invention discloses an automatic metal surface treatment device which comprises a left vertical plate, a right vertical plate, a beam plate, a carrier plate, a base plate, a clamp base, a pressing-down mechanism and an abrasive belt. The left vertical plate and the right vertical plate are arranged in parallel. The beam plate is in bridging connection with the left vertical plate and the rightvertical plate. An output shaft of a motor is provided with a driving wheel, the driving wheel is in transmission connection with a driving auxiliary wheel through a belt, an air cylinder is vertically installed on the front surface of an installation plate, a piston rod of the air cylinder is fixedly connected with a pressing-down plate, a middle shaft is sleeved with a left fixing ring and a right fixing ring from the two ends of a supporting sleeve, the left fixing ring and the right fixing ring make close contact with the two end faces of the supporting sleeve correspondingly, and the supporting sleeve is sleeved with a circular pipe which is fixed through the left fixing ring and the right fixing ring. Straight wiredrawing operation of the metal surface can be automatically achieved,wiredrawing straightness, wire flow uniformity and wiredrawing efficiency are improved, the wiredrawing quality of the metal circular pipe is ensured, and the rate of finished products is improved.

Owner:苏州丰川电子科技有限公司

Punching die having function of fast positioning workpiece

InactiveCN110834053ASolve unqualifiedImprove practicalityShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a punching die having a function of fast positioning a workpiece. The punching die comprises a lower die seat, a vertical rod, a die demounting plate and a first compression spring. The vertical rod is connected in the lower die seat in a sleeved manner. The die demounting plate is fixedly connected to the top end of the vertical rod. The first compression spring is connected to the outer wall of the vertical rod in a sleeving manner. The upper end and the lower end of the first compression spring are attached to the die demounting plate and the lower die seat correspondingly. Positioning mechanisms are fixedly connected to the left end and the right end of the lower die seat. By means of the punching die having the function of fast positioning the workpiece, due tothe cooperative use of a torsion spring, a top seat, a rack groove plate and the like, the problem that when an existing punching is used, the workpiece is not accurately installed, and a punched product is not qualified is solved; and due to the cooperative use of a transverse rod, a second compression spring, a baffle and the like, the material change time is saved, and therefore the productionefficiency is improved, and operation is easy.

Owner:长兴鲁易模具有限公司

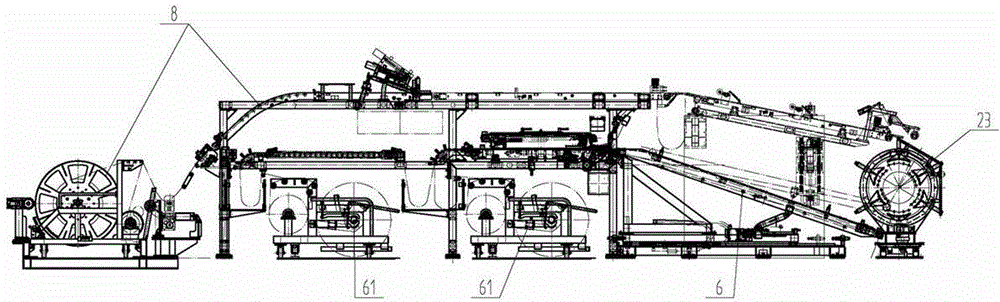

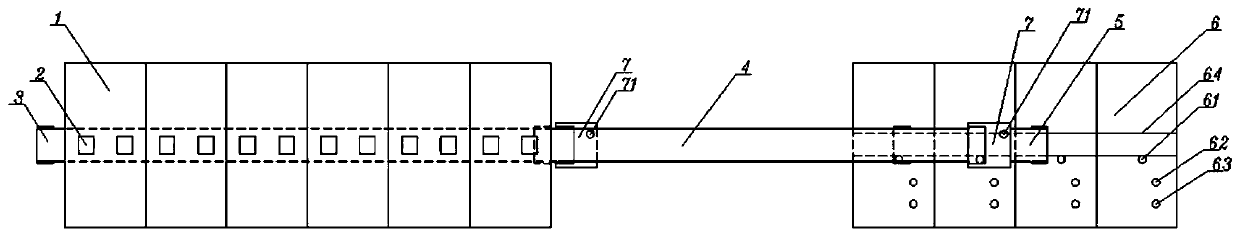

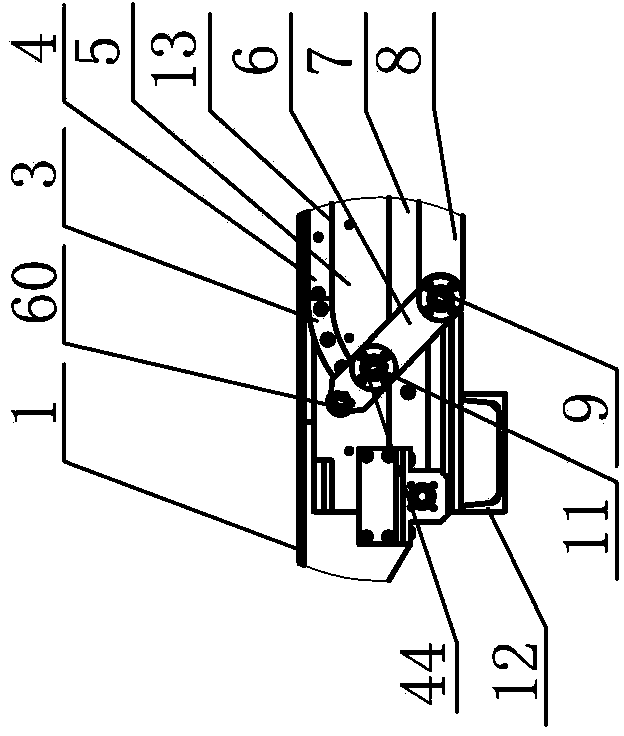

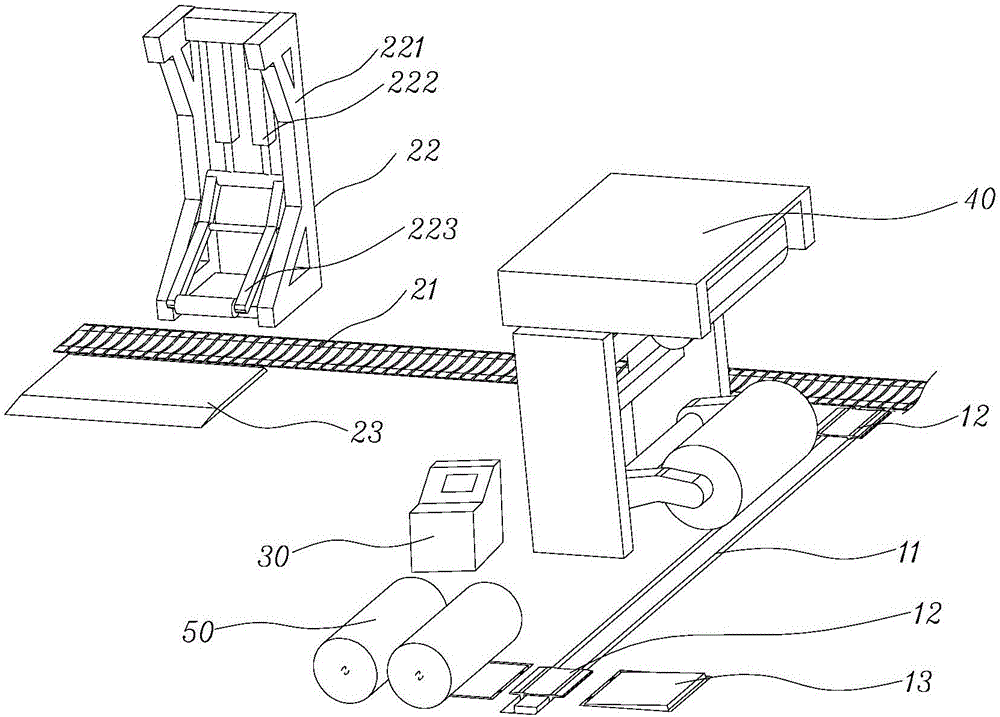

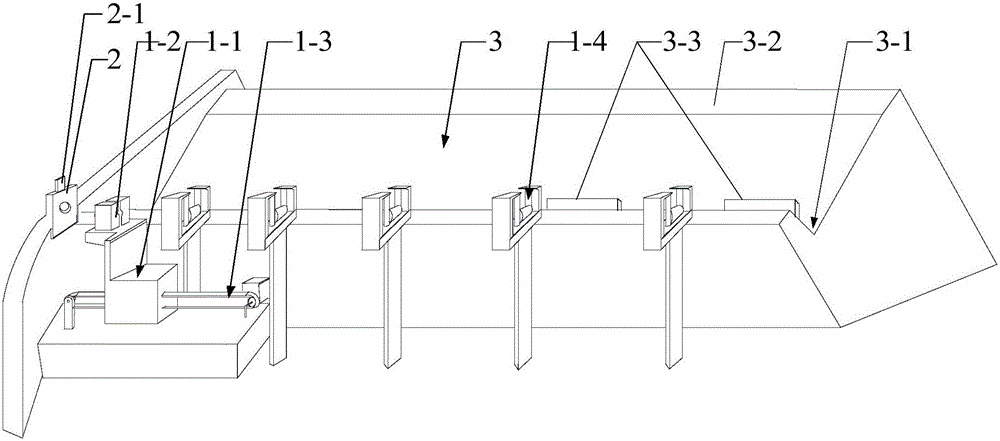

Material preparation, feeding and back-to-warehouse system for corrugated board production line

PendingCN106672605ASave refueling timeIncrease profitConveyor partsMechanical conveyorsMaterials preparationProduction line

The invention provides a material preparation, feeding and back-to-warehouse system for a corrugated board production line. The system is provided with material preparation tracks, a back-to-warehouse conveying belt and a controller, wherein the material preparation tracks are perpendicular to the back-to-warehouse conveying belt; and by means of the controller, material reloading can be achieved automatically at material reloading positions of corrugated paper processing machines for automatically conveying raw roll paper, and remaining materials which are unloaded are conveyed to the back-to-warehouse conveying belt through the material preparation tracks, so that automatic back-to-warehouse conveying is conducted. The process is controlled through the controller, no manpower needs to participate, and material preparation and reloading are completed automatically; meanwhile, when the system is arranged, the material preparation tracks which are different in length are adopted for conducting material preparation in a staggered manner, the utilization rate of a site can be increased, the materials can be prepared as many as possible, and production efficiency is further improved; and the material preparation, feeding and back-to-warehouse system is simple in structure, convenient to maintain and quite good in practicability.

Owner:佛山合信包装有限公司

Feeding device of flexible printed circuit (FPC) board and keyboard base plate automated assembly system

InactiveCN103093988BIncrease productivityReduce in quantityElectric switchesAutomatic controlMechanical engineering

The invention discloses a feeding device of a flexible printed circuit (FPC) board and a keyboard base plate automated assembly system. The feeding device of the FPC board comprises a lifting material platform, a lengthways material moving mechanism and a material absorption frame which is connected with a sliding table, wherein a material box which is used for arranging the FPC board in a stack mode, the lengthways material moving mechanism comprises a lengthways slide and the sliding table which is in sliding connection with the slide, and the material absorption frame is arranged above the lifting material platform. By the adoption of the lifting material platform, the fact that the FPC board with multiple layers automatically feed the material to the position is achieved, only the whole box is needed to be changed, in the process of a robot continue assembling, the change of the material box of the FPC board has no need to be operated in a machine stopped state, reloading time is saved, and the production efficiency is improved. The keyboard under plate automated assembly system achieves assembling of each element by the adoption of the robot, the quantity of automatic control unit is reduced, and the floor area of the whole automated assembly system is benefitted to be reduced.

Owner:SHENZHEN RAPOO TECH

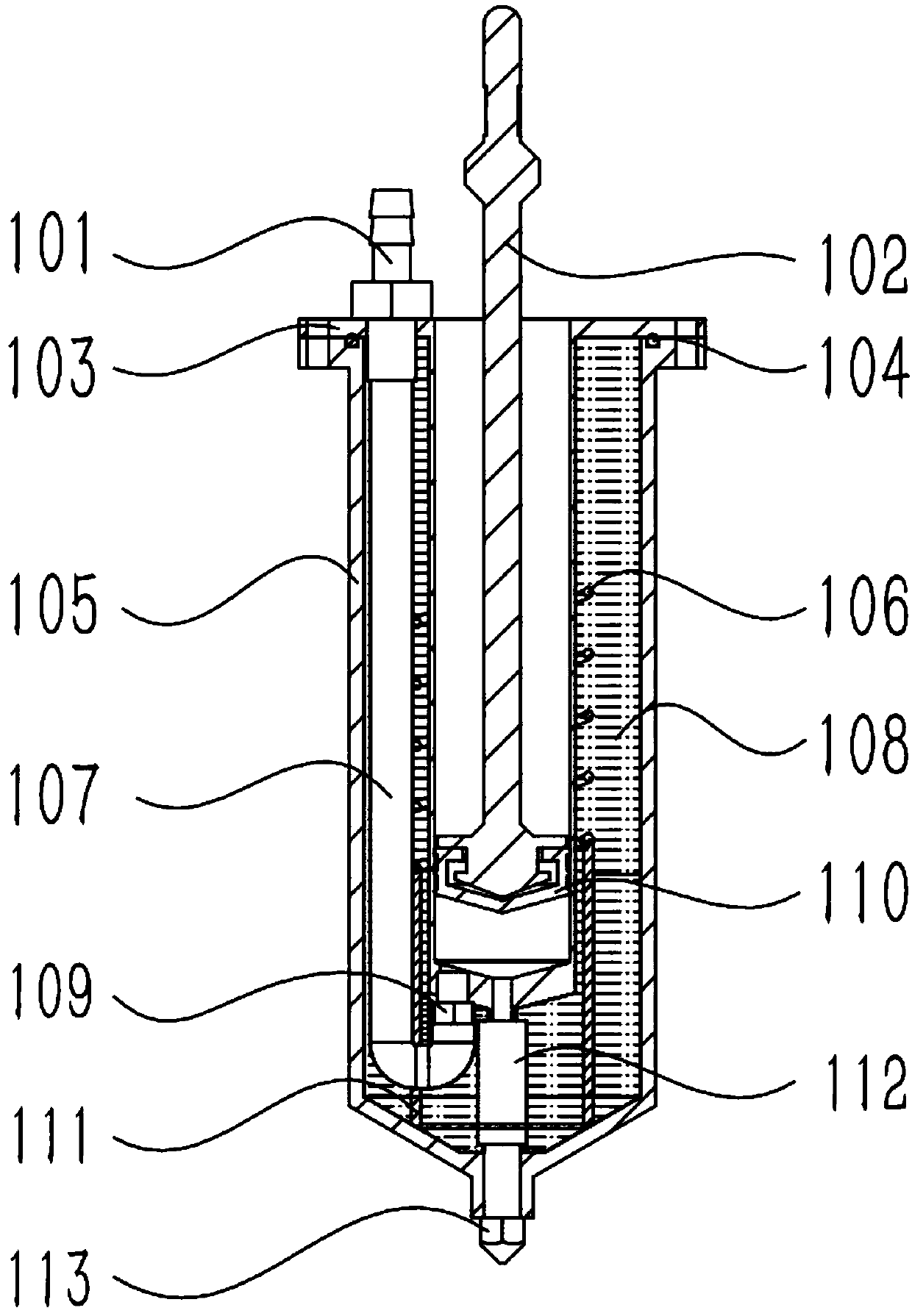

Half-fluid food 3D printer extrusion system

ActiveCN107752113APrecise temperature controlNot prone to cloggingFood shapingTemperature controlComputer printing

The invention relates to the technical field of 3D printing and in particular relates to a half-fluid food 3D printer extrusion system which comprises a power conveying module, a power conveying module, a pull type conveying module, a temperature control module, a screw rod fixing plate, a motor fixing base and an extrusion system back plate, wherein the upper end of the power conveying module isconnected with the screw rod fixing plate; the lower end of the power conveying module is connected with the motor fixing base; the screw rod fixing plate is fixedly connected with the upper end of the extrusion system back plate; the motor fixing base is fixedly connected with the lower end of the extrusion system back plate; the power conveying module is connected with the pull type conveying module; and the pull type conveying module is connected with the temperature control module. The invention provides the half-fluid food 3D printer extrusion system which is capable of feeding materialscontinuously, precise in temperature control and not liable to cause nozzle blocking phenomena.

Owner:深圳翱诺科技有限公司

Round steel cut-off equipment

The invention discloses round steel cut-off equipment which comprises a frame, a cut-off device, a feeding device, a loading device and a main control device, wherein the frame is fixed on the ground; the cut-off device is fixedly connected with the frame, and comprises a driving motor with flywheels; the flywheels are mechanically connected with a cutting part used for cutting off long round steel; the feeding device comprises feeding grooves fixedly formed in the frame, and also comprises a clamping component used for clamping the long round steel; the clamping component is connected with a conveying component; the conveying component is used for driving the clamping component to move back and forth in the length direction of the feeding grooves; the loading device is fixedly arranged on one side of the feeding device, and comprises a lifting component used for feeding to-be-treated long round steel in the feeding device; and the driving motor, the conveying component and the lifting component are all electrically connected with the main control device. The round steel cut-off equipment effectively solves the technical problems of low working efficiency, low precision, high labor cost and the like, which are caused by the fact that the round steel is cut off directly by manpower.

Owner:CHONGQING QILONG IND & TRADE CO LTD

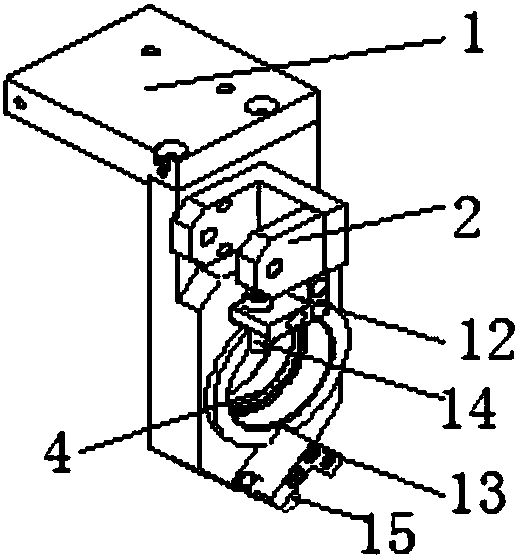

Gas claw overturning mechanism

The invention discloses a gas claw overturning mechanism. The gas claw overturning mechanism includes an inverted-L-shaped supporting frame. One side of a vertical frame body of the supporting frame is connected with an air cylinder through a supporting seat. A piston rod of the air cylinder is arranged downwards. The center of the vertical frame body of the supporting frame is provided with a through hole. The through hole is internally provided with a rotation shaft in a penetrating and sleeving mode. One end of the rotation shaft is provided with a swing arm. The swing arm is connected withthe piston rod of the air cylinder. The other end of the rotation shaft is provided with a connecting plate. The connecting plate is located on the other side of the vertical frame body of the supporting frame. The rotation shaft is connected with a gas claw fixing plate through the connecting plate. The gas claw fixing plate is provided with a gas claw. The gas claw overturning mechanism solvesthe problem that an existing mechanical arm is large in horizontal dimension and high in manufacturing cost.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

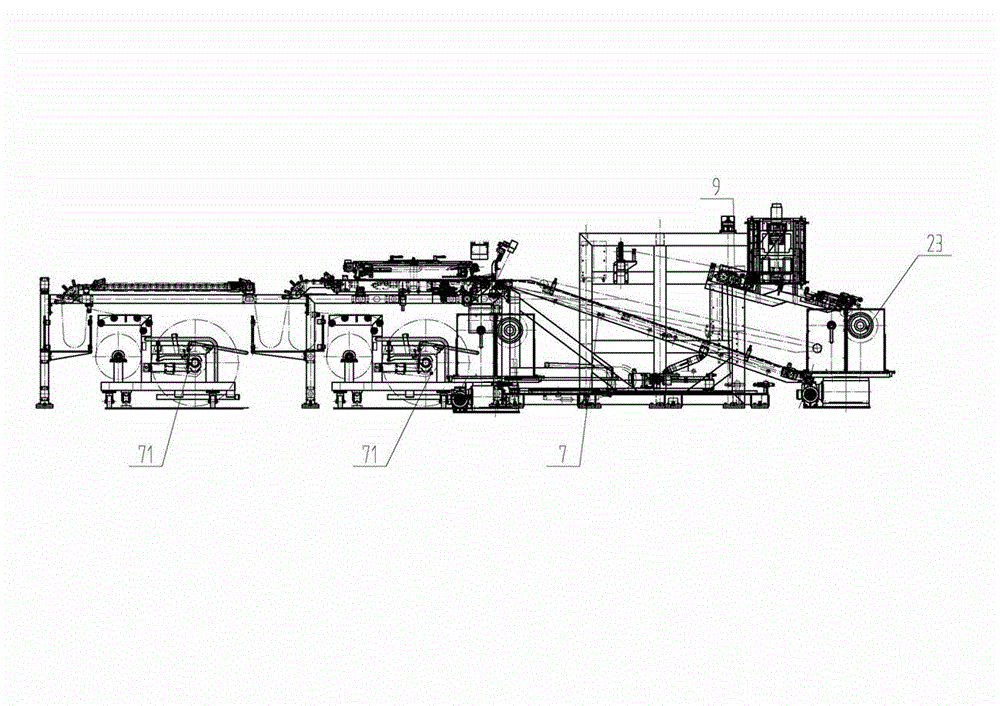

Paper pulp raw material emptying mechanism

ActiveCN106743861ASave refueling timeIncrease productivityFunction indicatorsWebs handlingPulp and paper industryRaw material

The invention discloses a paper pulp raw material emptying mechanism. The paper pulp raw material emptying mechanism comprises a rack, two feeding brackets, reloading lifting hooks and two feeding outlets, wherein the rack is provided with a vertically arranged supporting arm for bearing the weight; the two feeding brackets are arranged on the rack and are used for supporting paper pulp raw materials during production; the reloading lifting hooks are arranged on the rack and are used for conveying the paper pulp raw materials onto the feeding brackets when the paper pulp raw materials are changed; and the two feeding outlets are formed in the upper end of the rack, and the paper pulp raw materials placed on the two feeding brackets can be connected with production equipment in later working procedures through the two feeding outlets respectively. Compared with the prior art, the two feeding outlets are formed in the paper pulp raw material emptying mechanism disclosed by the invention, and the two feeding brackets are used for supporting the paper pulp raw materials for feeding respectively, so that two rolls of the paper pulp raw materials can be placed simultaneously during the production of the paper pulp raw material emptying mechanism, power-off change is not needed, the reloading time during long-time power-off for changing the paper pulp raw materials in the prior art is reduced, and the production efficiency is greatly improved.

Owner:ZUIKO (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com