Stirring station aggregate feeding system and control method

A mixing plant and aggregate technology, applied in chemical instruments and methods, mixing operation control, mixing operation control devices, etc., can solve the problems of lack of material, easy to appear full warehouse, affecting blanking, etc., to reduce manual operation and improve work. Efficiency, the effect of reducing the refill time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

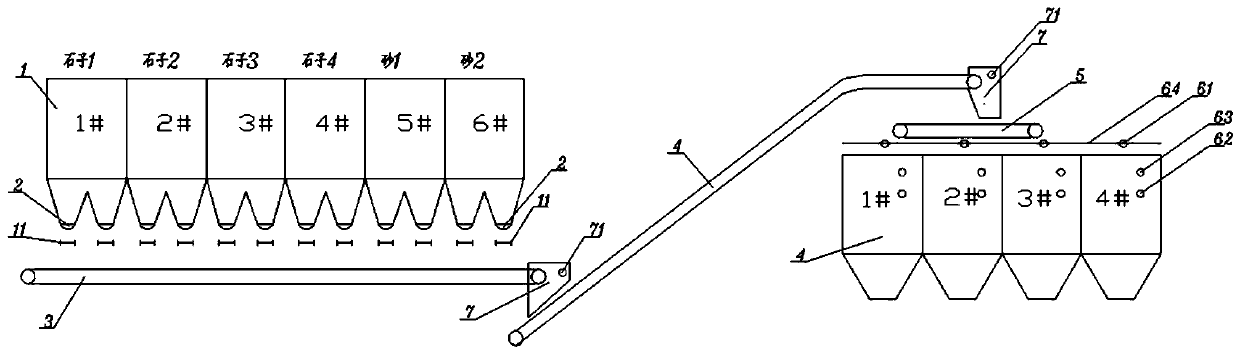

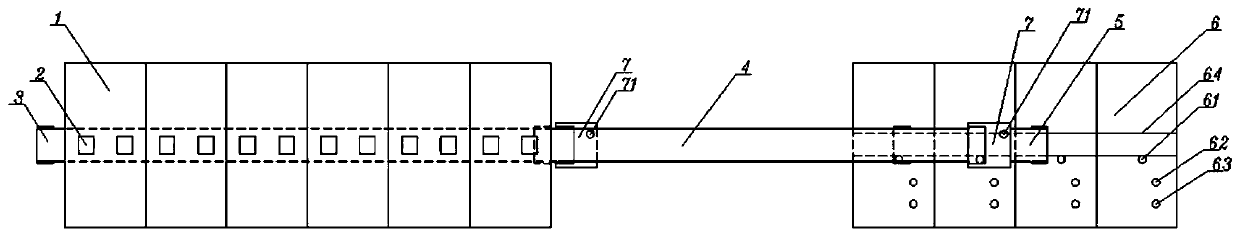

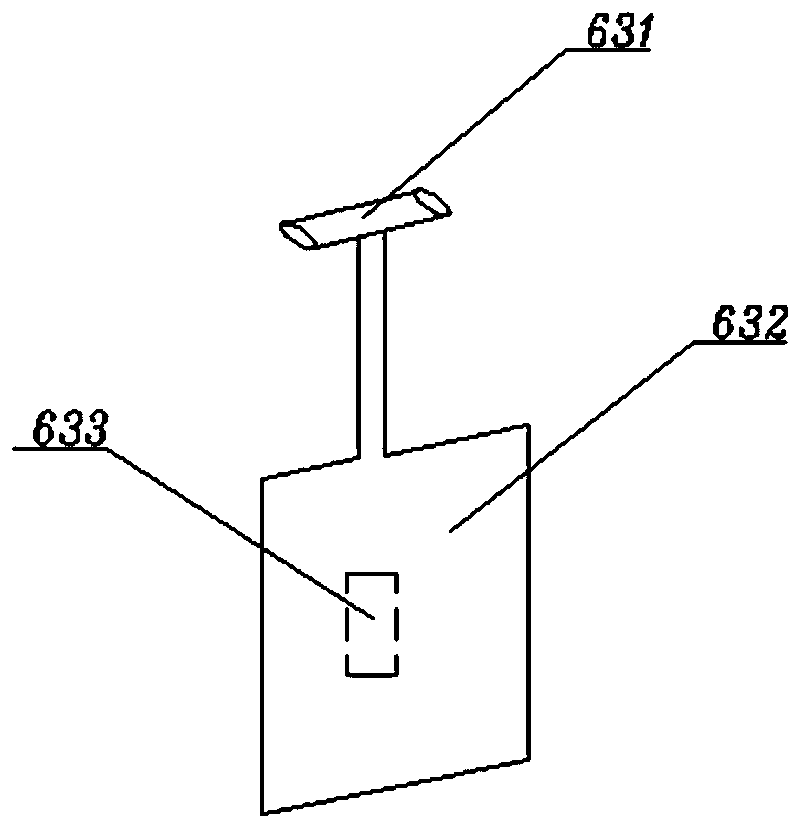

[0026] In order to solve the problems existing in the aggregate bin feeding system of the concrete mixing plant, the present invention proposes a new type of aggregate bin feeding system and control method. The system includes a stockyard with multiple bins, a flat belt , oblique belt, fabric belt, and a mixing station with multiple silos; the bottom of each silo in the storage yard is equipped with multiple discharge arc doors, and the flat belt is located under each storage silo and on the top of the mixing station. There is a track connecting the silos of each mixing station. The fabric belt is set on the track and can move along the track. The lower end of the inclined belt is connected to the flat belt through a transition hopper, and its higher end is connected to the fabric belt through another transition hopper. The fabric belt can be rotated forward and revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com